Full-automatic bar code printing and detecting equipment

A detection equipment, barcode printing technology, applied in printing devices, printing, typewriters, etc., can solve the problems of limited length, many joints, difficult traction, etc., to save the time of changing materials, avoid repeated codes, and increase the effect of length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific implementation methods.

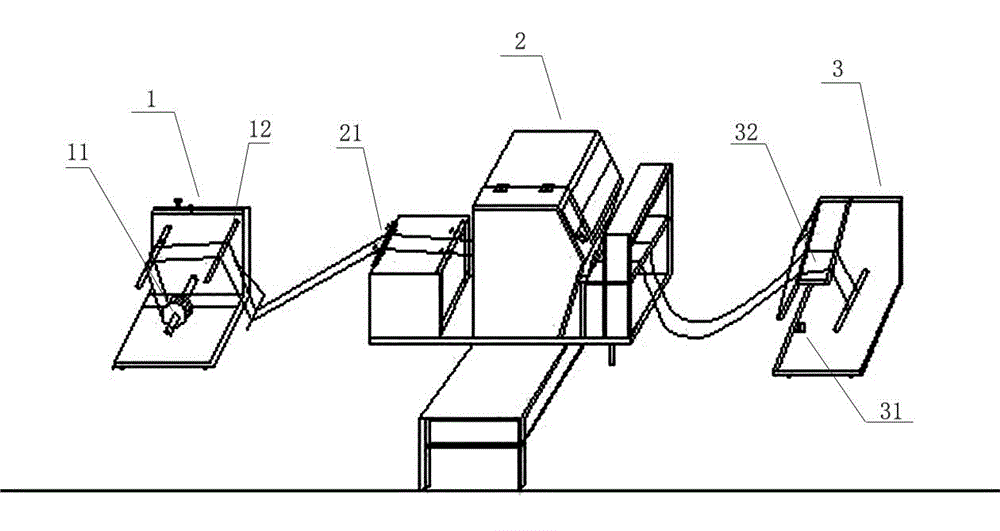

[0022] Such as figure 1 As shown, a fully automatic barcode printing detection equipment includes the following components:

[0023] 1) Feeder 1.

[0024] The feeder 1 is provided with a material reel 11 and a plurality of pull rods 12. The printed materials in rolls are assembled on the material reel 11, and the material paper is bypassed from the top of the pull rod 12, so that the material paper is flat, and the material reel 11 Connect to the drive unit.

[0025] 2) Barcode printer 2.

[0026] Described barcode printer 2 is provided with barcode detection equipment at discharge port, and described barcode detection equipment comprises a barcode scanner, and described barcode scanner is connected with computer, scans information and detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com