Dust removing device for rotary die cutting machine

The technology of a dust removal device and a die-cutting machine is applied in the direction of cleaning methods and utensils, chemical instruments and methods, etc., which can solve the problems of die-cut product pollution, high cost, dirty products and foreign matter defects, and achieve the reduction of refueling time, Stable operation and good dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

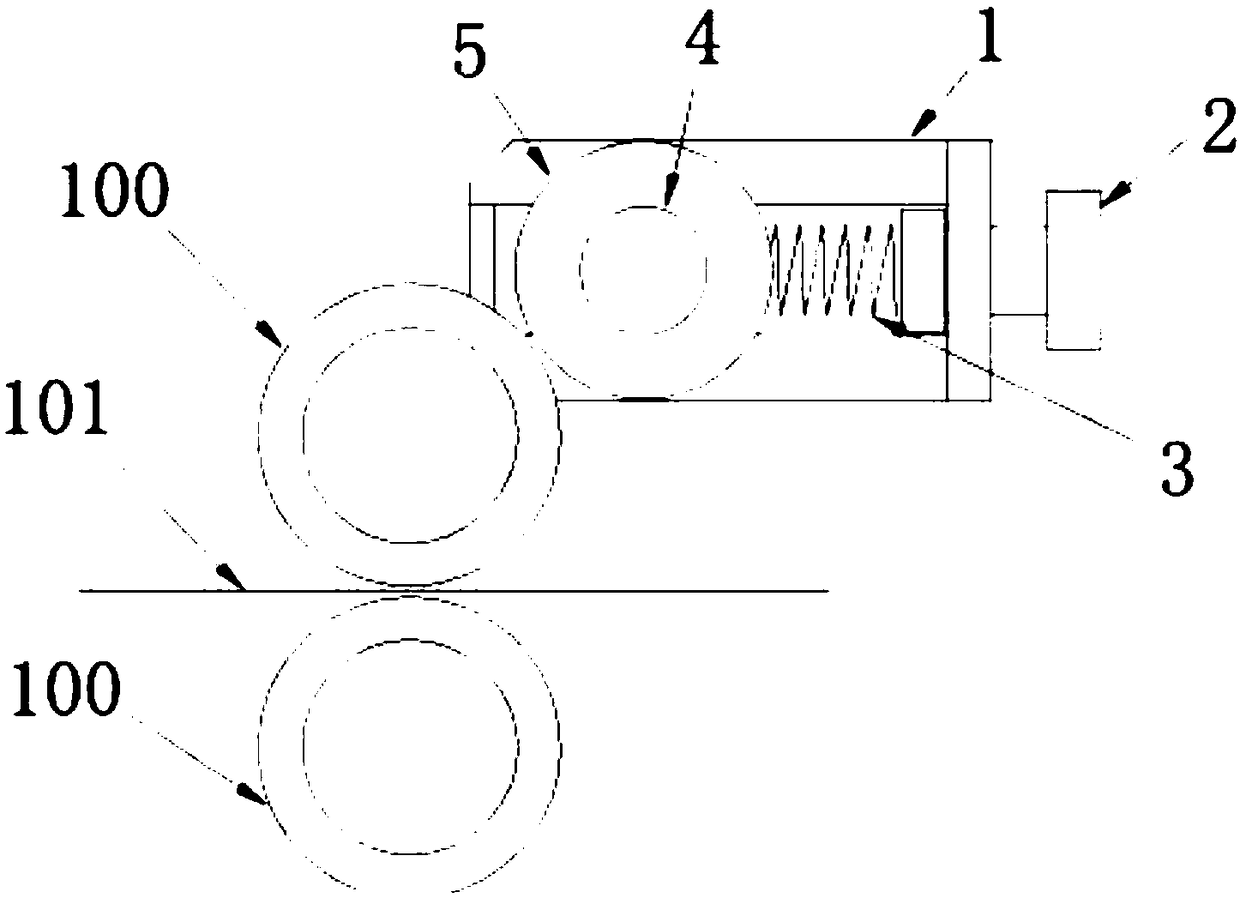

[0021] The dust removal device of the rotary die cutting machine includes a base 1, an adjusting bolt 2, a telescopic assembly 3, an axis 4 and a sticky roller 5, the diameter of the axis 4 is 20mm, and the outer diameter of the sticky roller 5 is 40mm , the diameter of the rubber shaft 100 is 100mm, the bonding force between the sticky roller 5 and the rubber shaft 100 is 40N, and the dust removal device of the rotary die cutting machine operates stably.

Embodiment 2

[0023] The dust removal device of the rotary die-cutting machine includes a base 1, an adjusting bolt 2, a telescopic assembly 3, an axis 4 and a sticky roller 5, the diameter of the axis 4 is 30mm, and the outer diameter of the sticky roller 5 is 50mm , the diameter of the rubber shaft 100 is 80mm, the bonding force between the dust-sticking roller 5 and the rubber shaft 100 is 30N, the material of the dust-sticking roller 5 is PET and the surface is coated with acrylic glue, the rotary mold The cutting dust removal device operates stably.

Embodiment 3

[0025] The dust removal device of the rotary die cutting machine includes a base 1, an adjusting bolt 2, a telescopic assembly 3, an axis 4 and a sticky roller 5, the diameter of the axis 4 is 40mm, and the outer diameter of the sticky roller 5 is 60mm , the diameter of the rubber shaft 100 is 90mm, the bonding force between the sticky roller 5 and the rubber shaft 100 is 40N, and the dust removal device of the rotary die cutting machine operates stably.

[0026] By producing the dust removal device of the rotary die cutting machine obtained in Examples 1 to 3, the dust and debris adsorbed on the rubber shaft can be better sticked away, the dust removal effect is better and the operation is stable, and it can also reduce The refueling time meets the requirements of reducing product pollution and reducing defects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com