Patents

Literature

1384 results about "Die cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Die cutting is the general process of using a die to shear webs of low-strength materials, such as rubber, fiber, foil, cloth, paper, corrugated fiberboard, chipboard, paperboard, plastics, pressure-sensitive adhesive tapes, foam, and sheet metal. In the metalworking and leather industries, the process is known as clicking and the machine may be referred to as a clicking machine. When a dinking die or dinking machine is used, the process is known as dinking. Commonly produced items using this process include gaskets, labels, tokens, corrugated boxes, and envelopes.

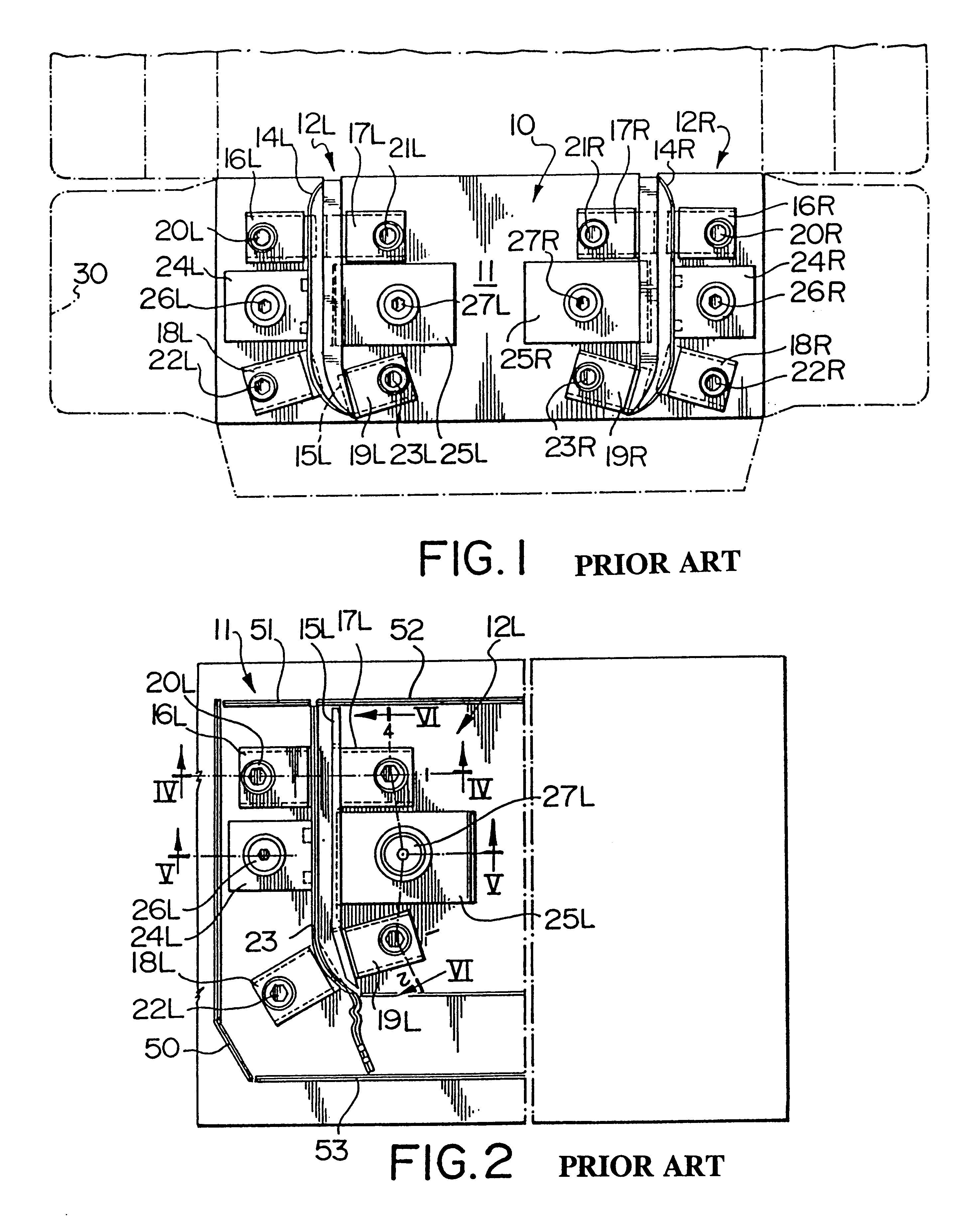

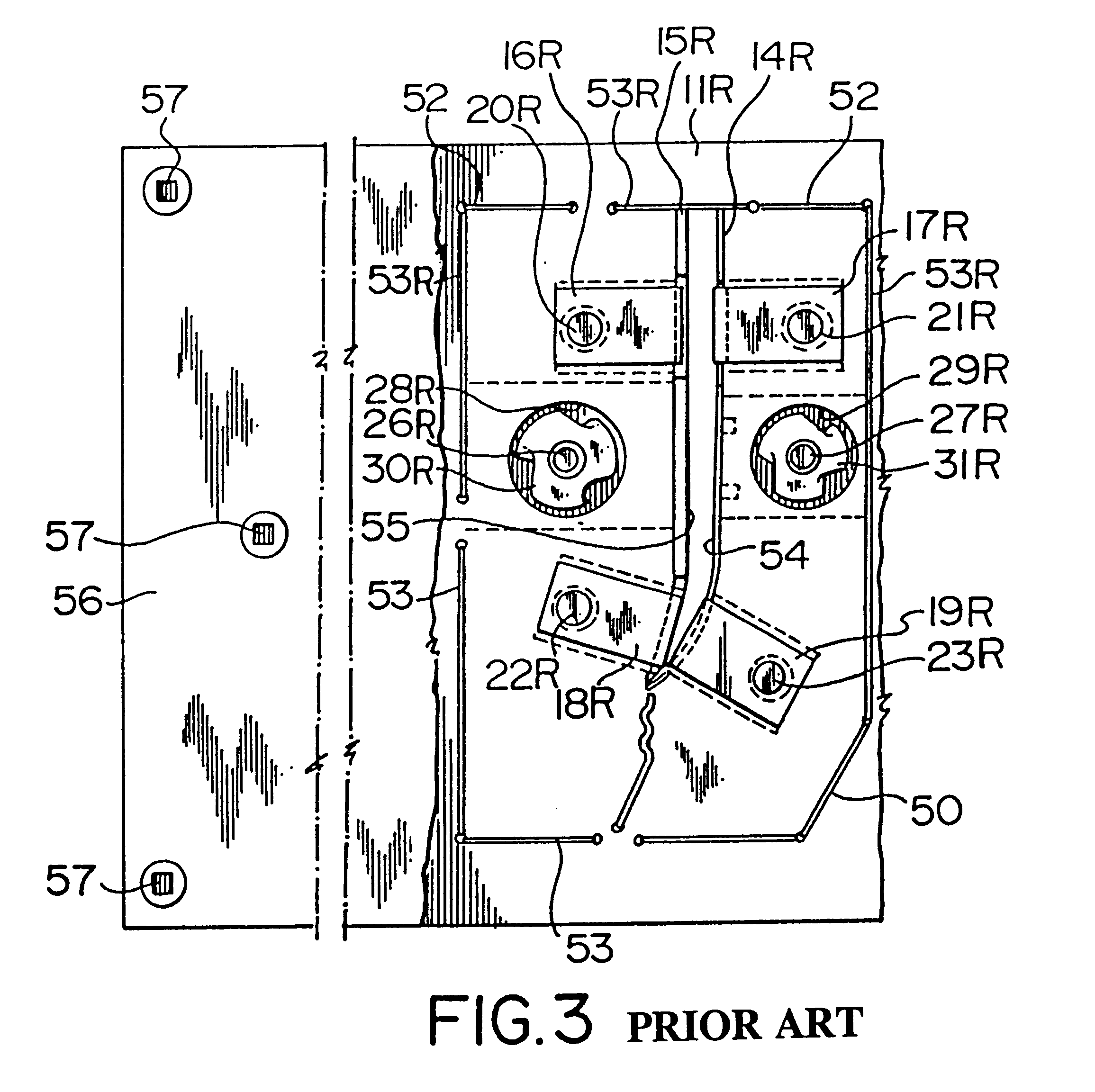

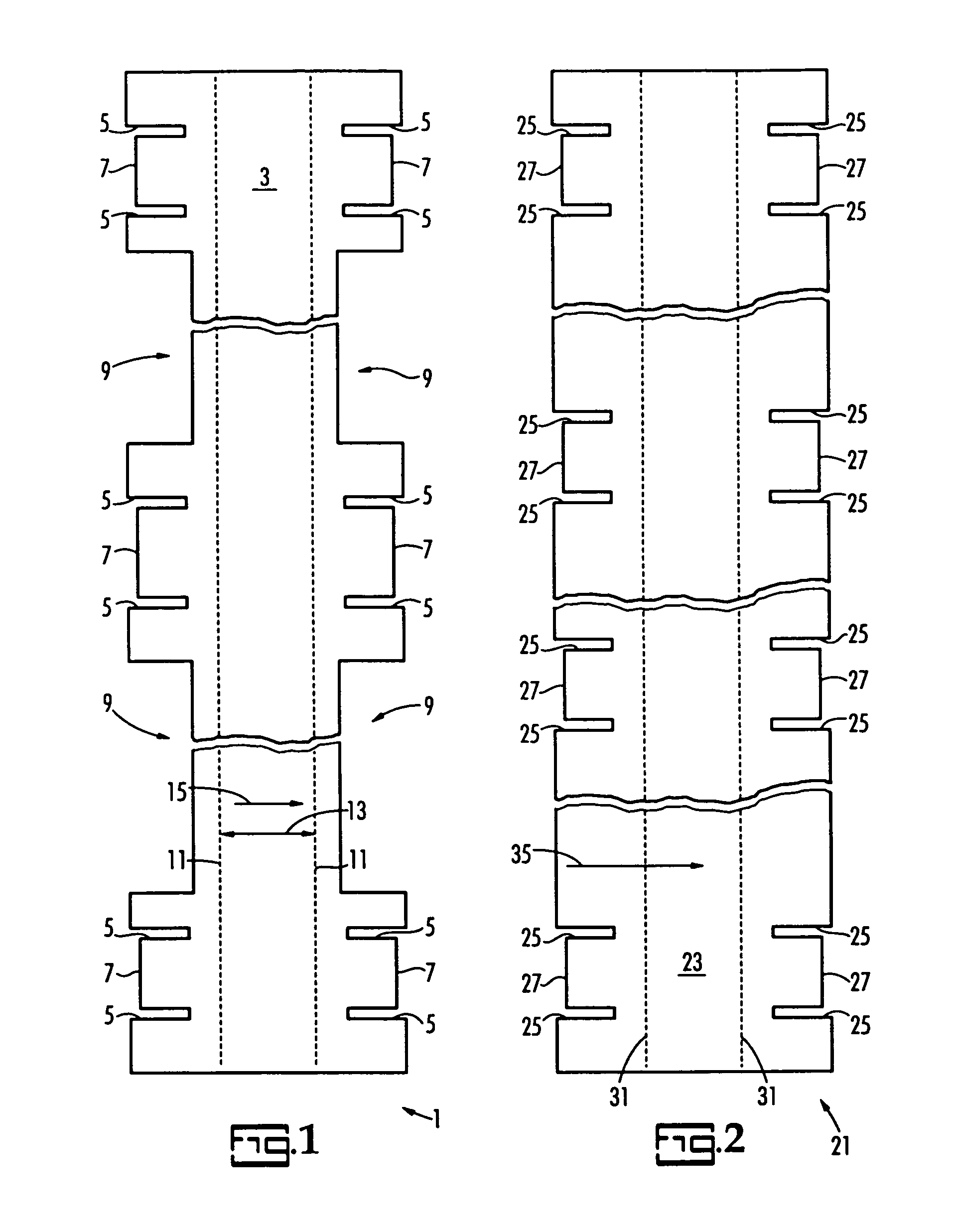

Cutting, scoring and perforating die set and method

InactiveUS6203482B1Accurate startMechanical working/deformationBox making operationsCartonPaperboard

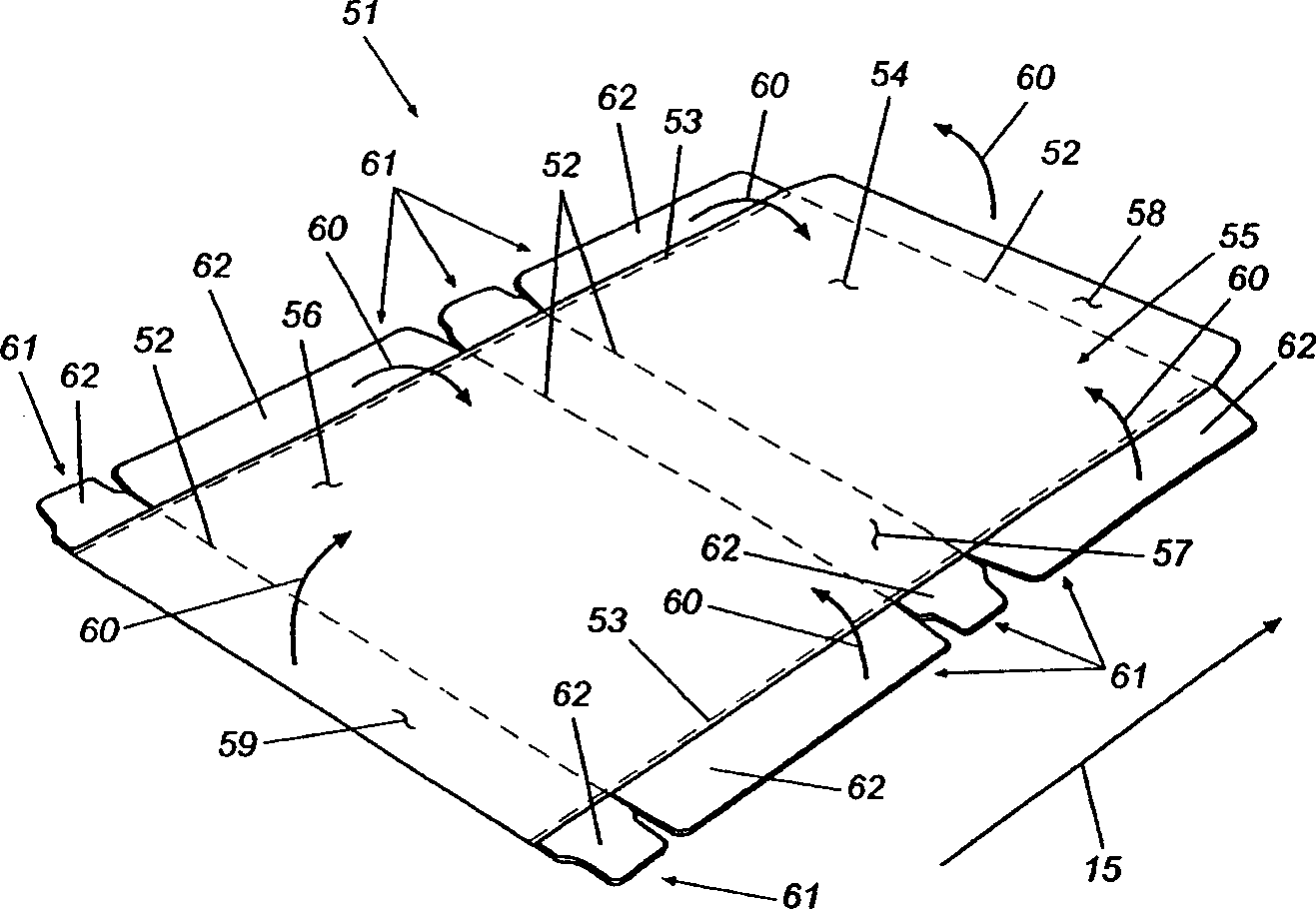

An apparatus for substantially-simultaneously die cutting cardboard sheets for forming folded cardboard cartons and an openable and closable tab. The improvement resides in a die set comprising a plurality of cutting knives projecting from a base, the cutting knives being fixed into a preselected pattern of grooves within the base. The die set may further include at least one transversely-spaced-apart pair of a die blade and a perforating knife mounted in the base, in which either or both of the die blade or the perforating knife is "jackably mounted" for selective manual raising or lowering. The die set may alternatively further include at least one transversely-spaced-apart pair of a die blade and an anvil mounted in the base, in which either or both of the die blade or the anvil is "jackably mounted" for selective manual raising or lowering. In either case, the base is secured to a back-up plate. Either die set is used in a double platen die cutting apparatus in which the die set is mounted on the upper platen and in which the lower platen is movable towards the upper platen. The perforating knife may still further alternatively be mounted on the lower platen. In all cases, the die blade and the perforating knife converge to a common focal or starting point when the platens are urged towards one another with the cardboard therebetween, to provide for a common starting point for the operable and closable tab.

Owner:SANDFORD PETER NMI

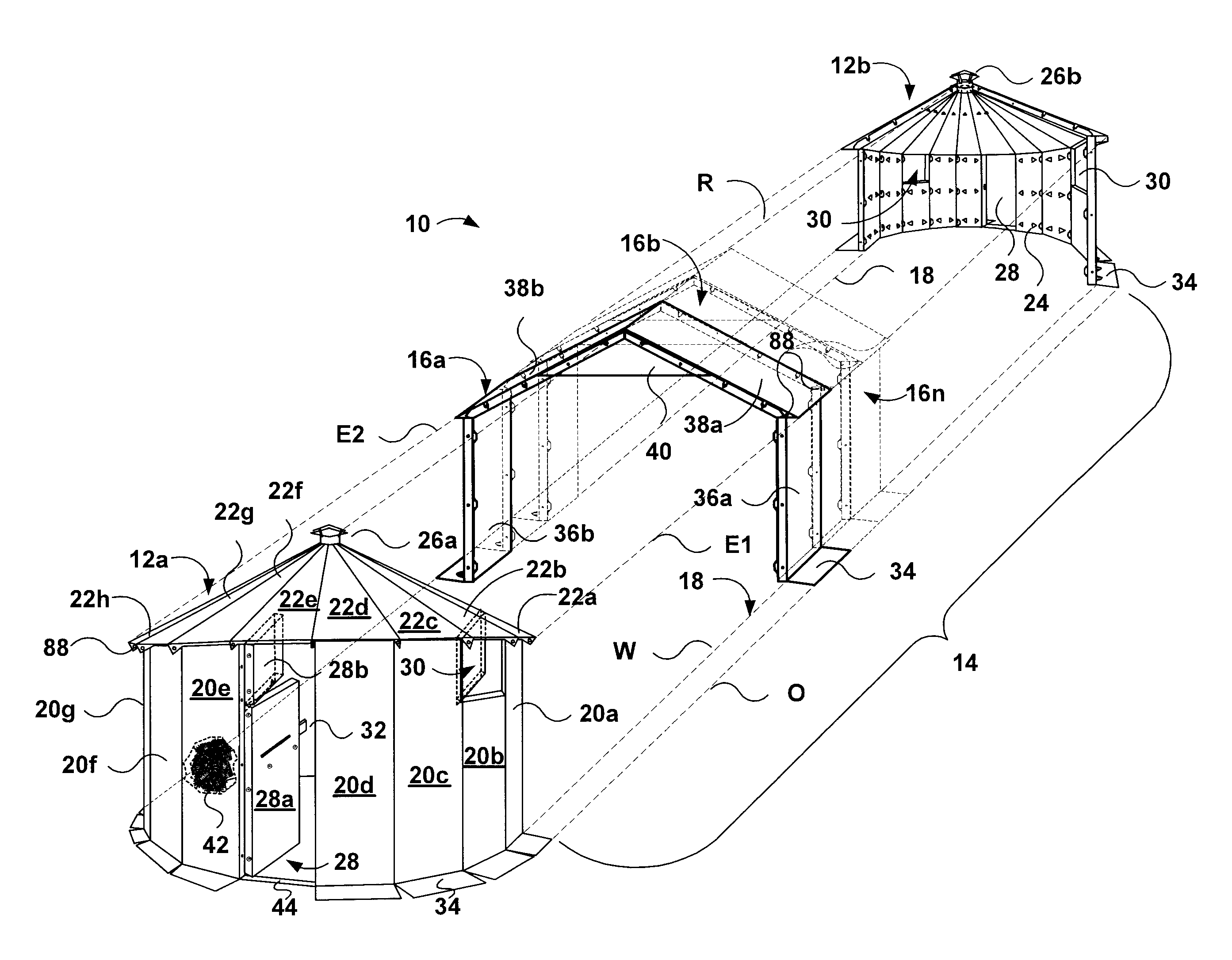

Segmented, elongated, expandable, 4-season, double-walled, low-cost, rigid extruded plastic panel structures

InactiveUS8381454B1Easy to die cutImprove structural stabilityTents/canopiesHospitalsDouble wallRigid wall

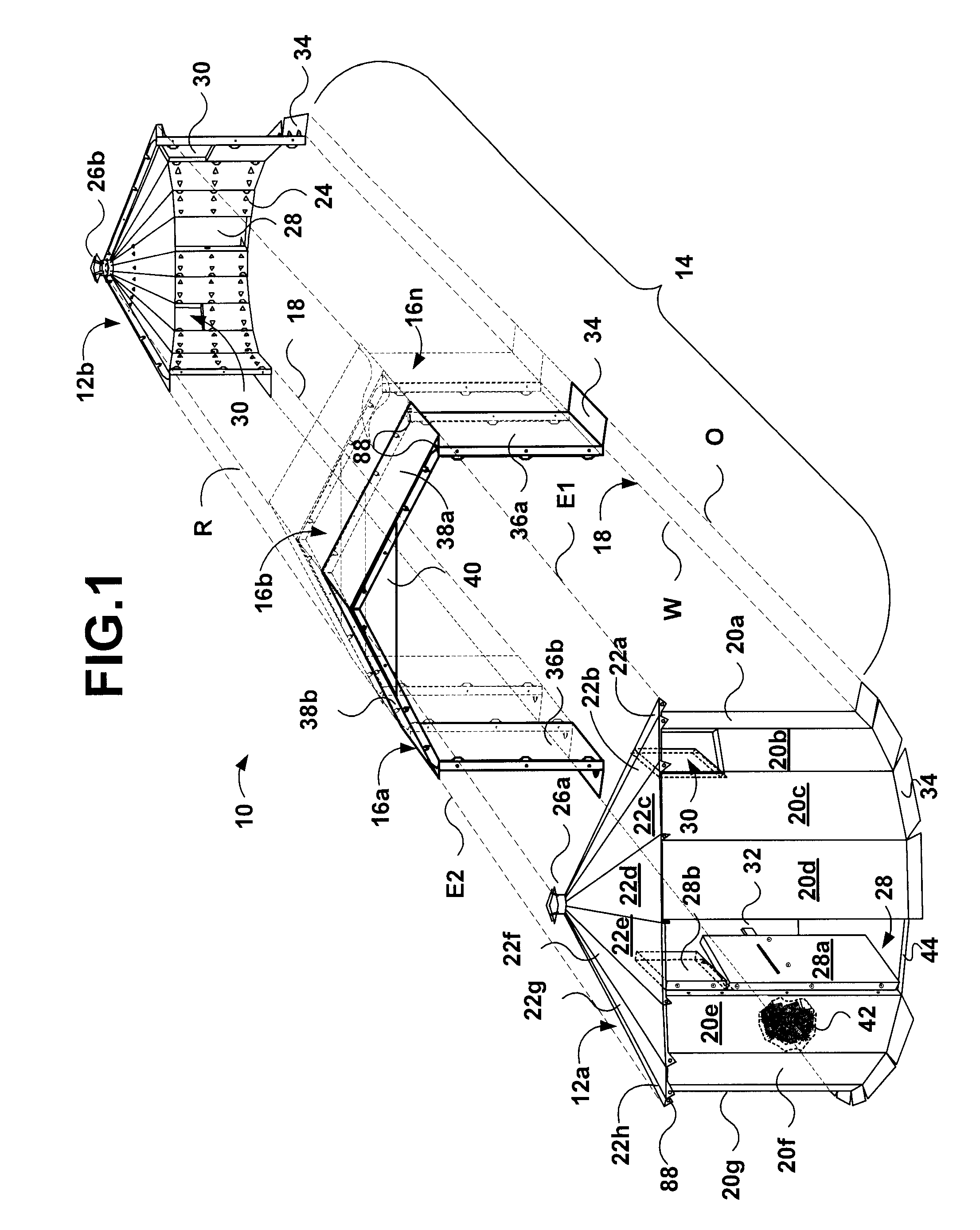

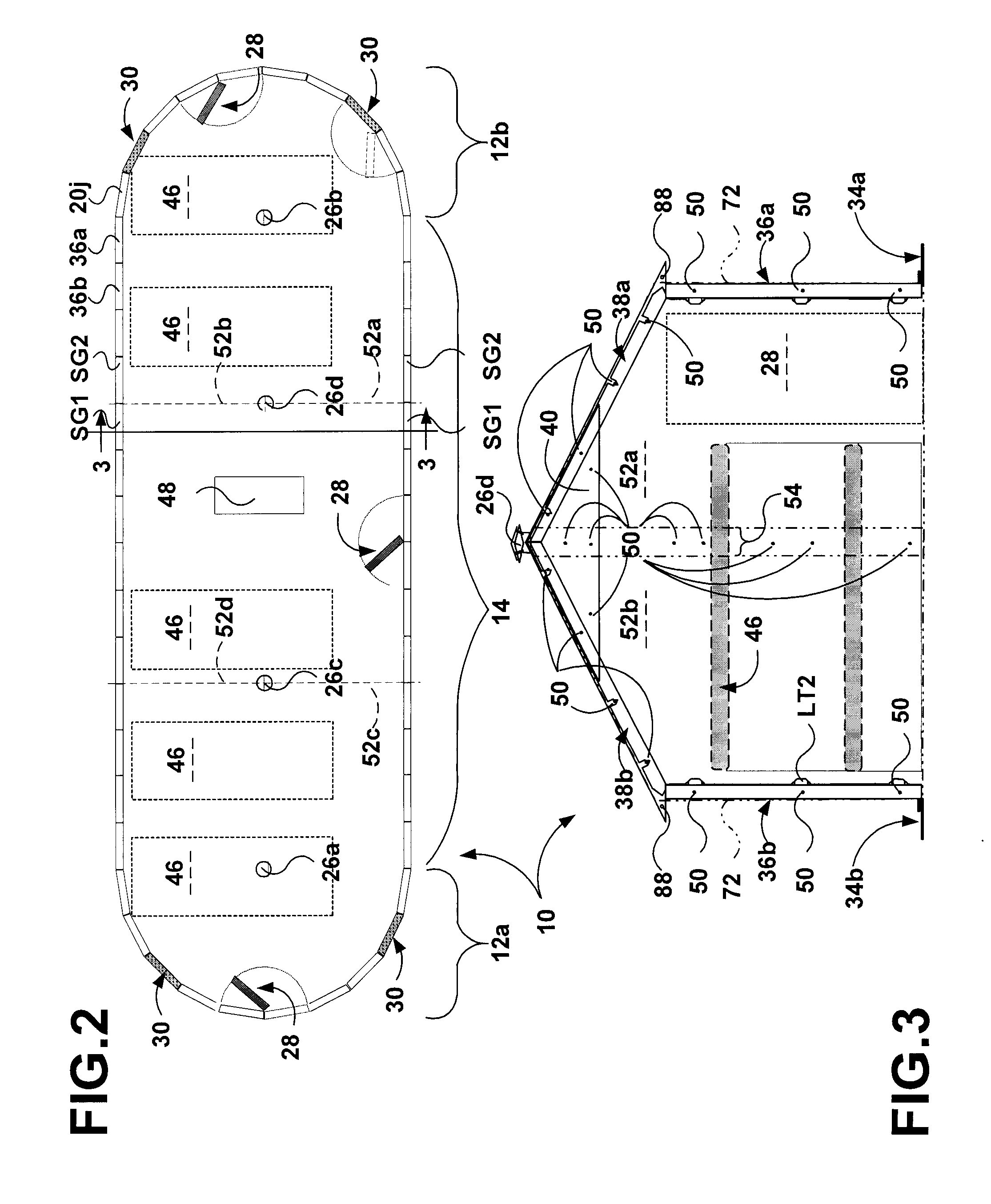

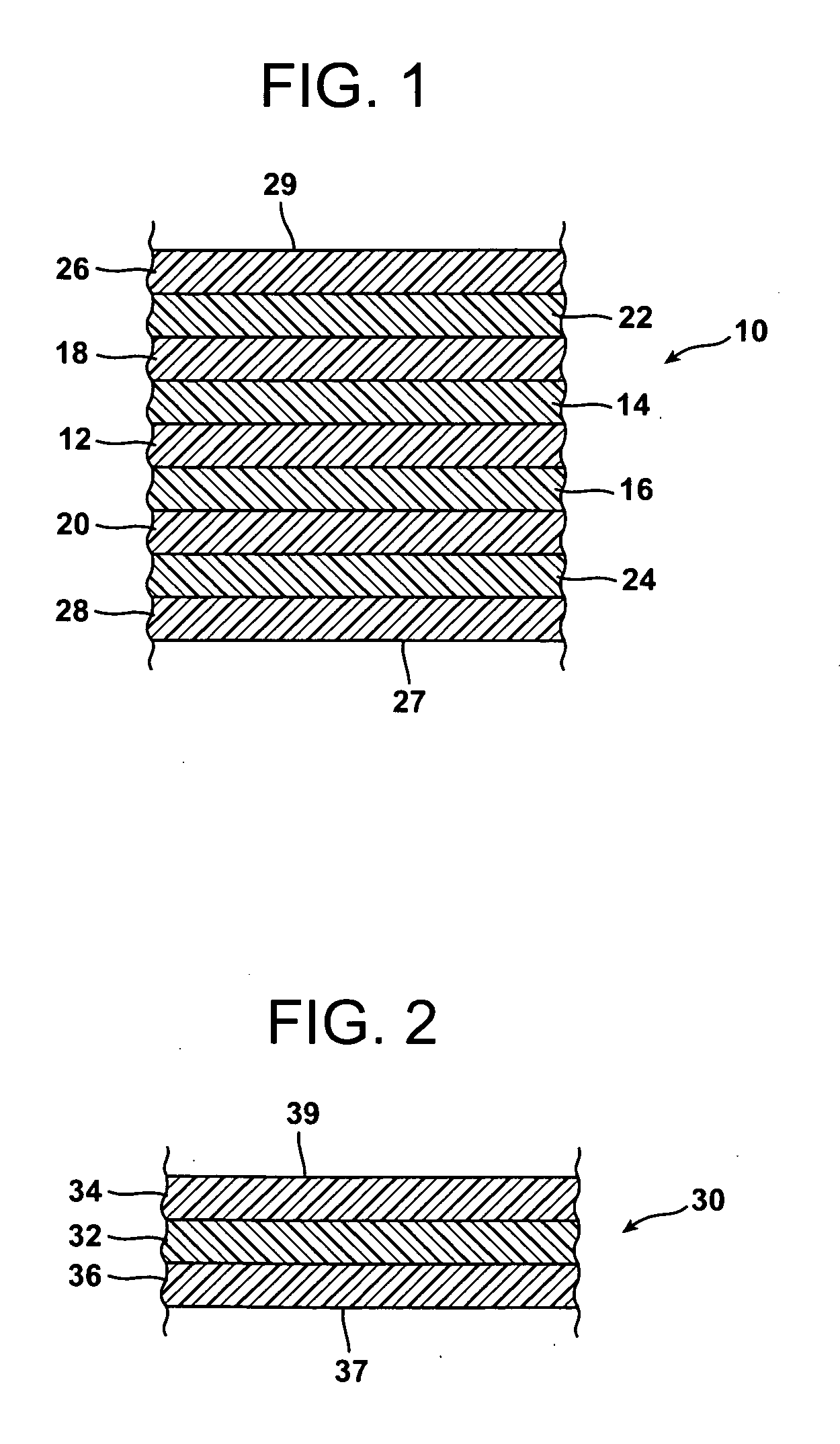

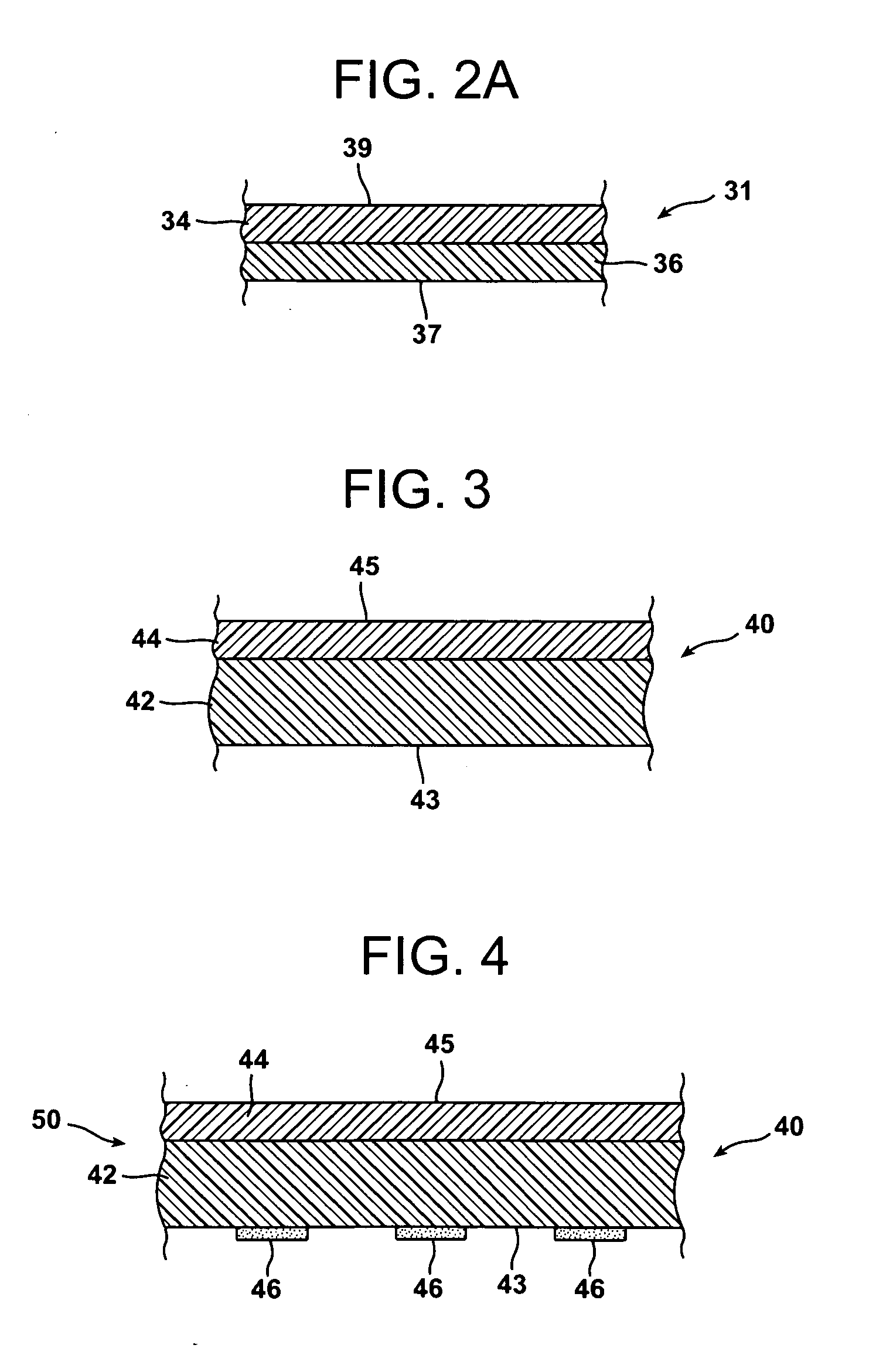

Low-cost, semi-permanent rigid-wall modular longhouse-type, peaked-roof structures, stadium-shaped (in plan view), made of light-weight, water-proof cellular extruded plastic sheet material die cut into blanks that are easily portable, quickly field erectable and dismountable by unskilled workers for a wide variety of uses. Two semi-circular end portions are spaced apart and joined by multiple segments of straight wall and roof modules, the length depending only on the number of intermediate segments. Blanks are easily folded on site into double-walled, bolt-together, modular wall and roof panels. Only four basic panel configurations are needed to form all structural elements. Multiple modular structures may be grouped to form larger compound structures with individual ones assigned to individual persons or dedicated work space usages: disaster shelters, sleeping, gathering, storage, hygiene, medical treatment, schooling, entertainment, goods manufacture, cooking, eating, herding, etc. Double-wall modules provide inter-stitial space for cold-weather insulation and passive ventilation in hot environments.

Owner:INNOVATION LAW GROUP

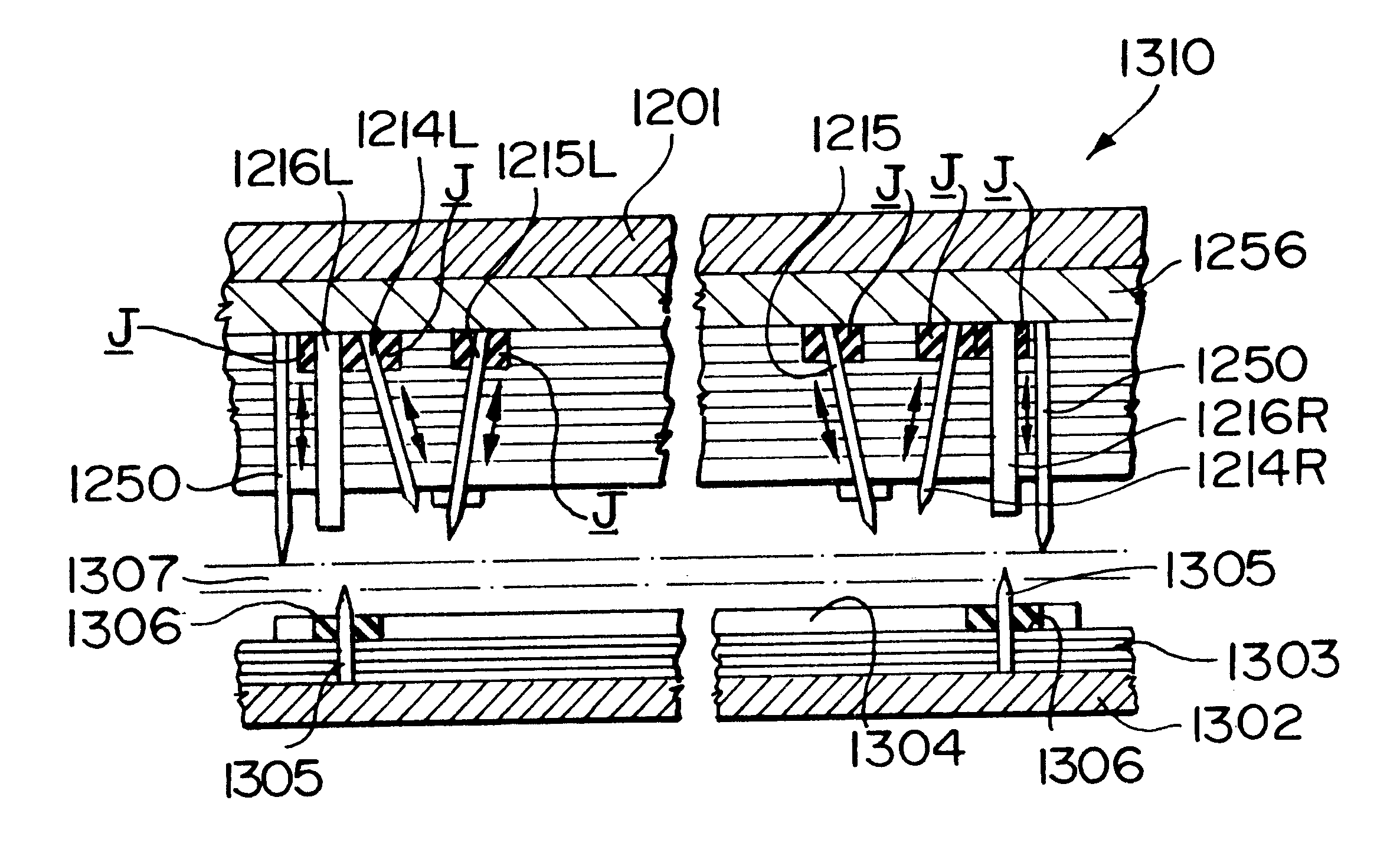

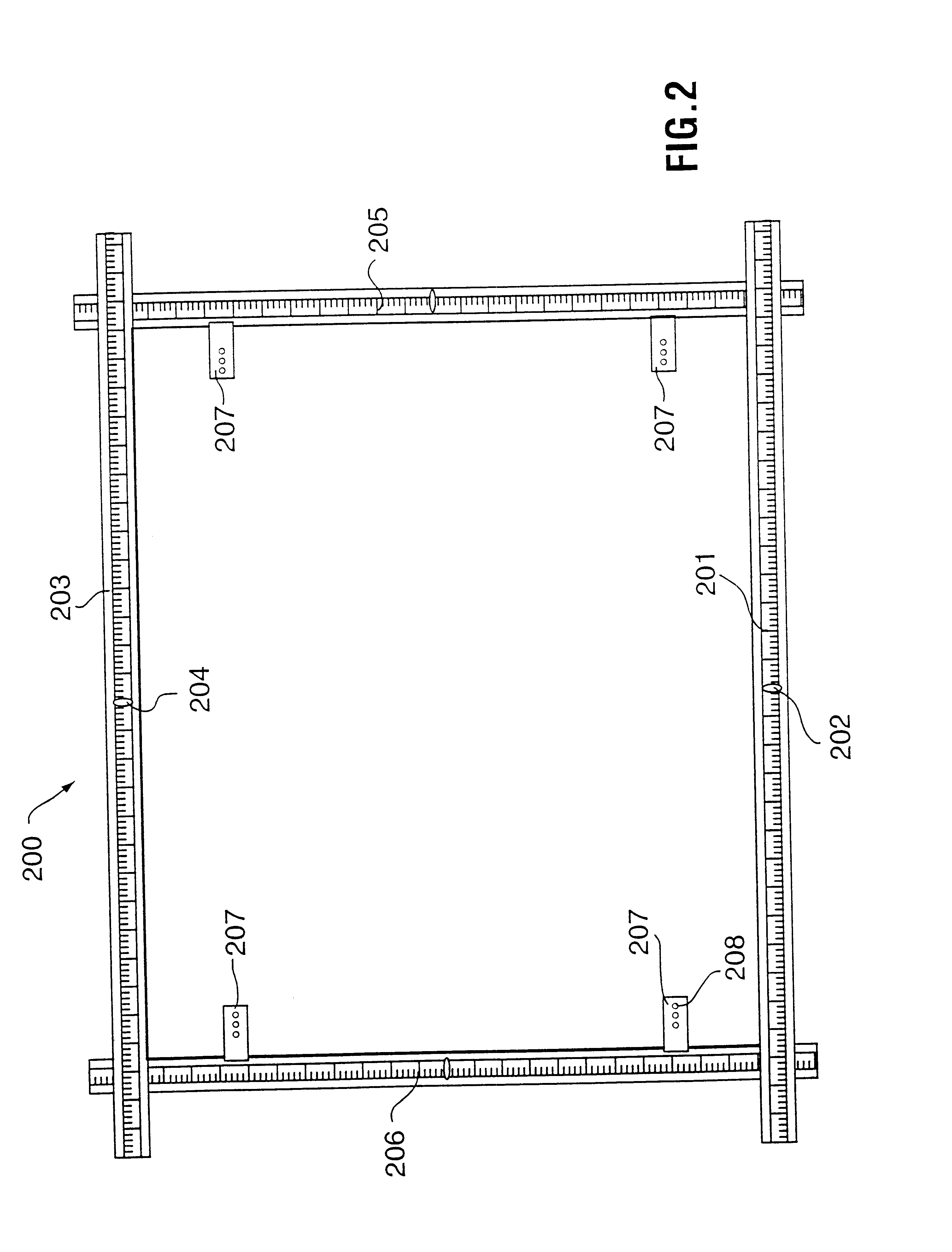

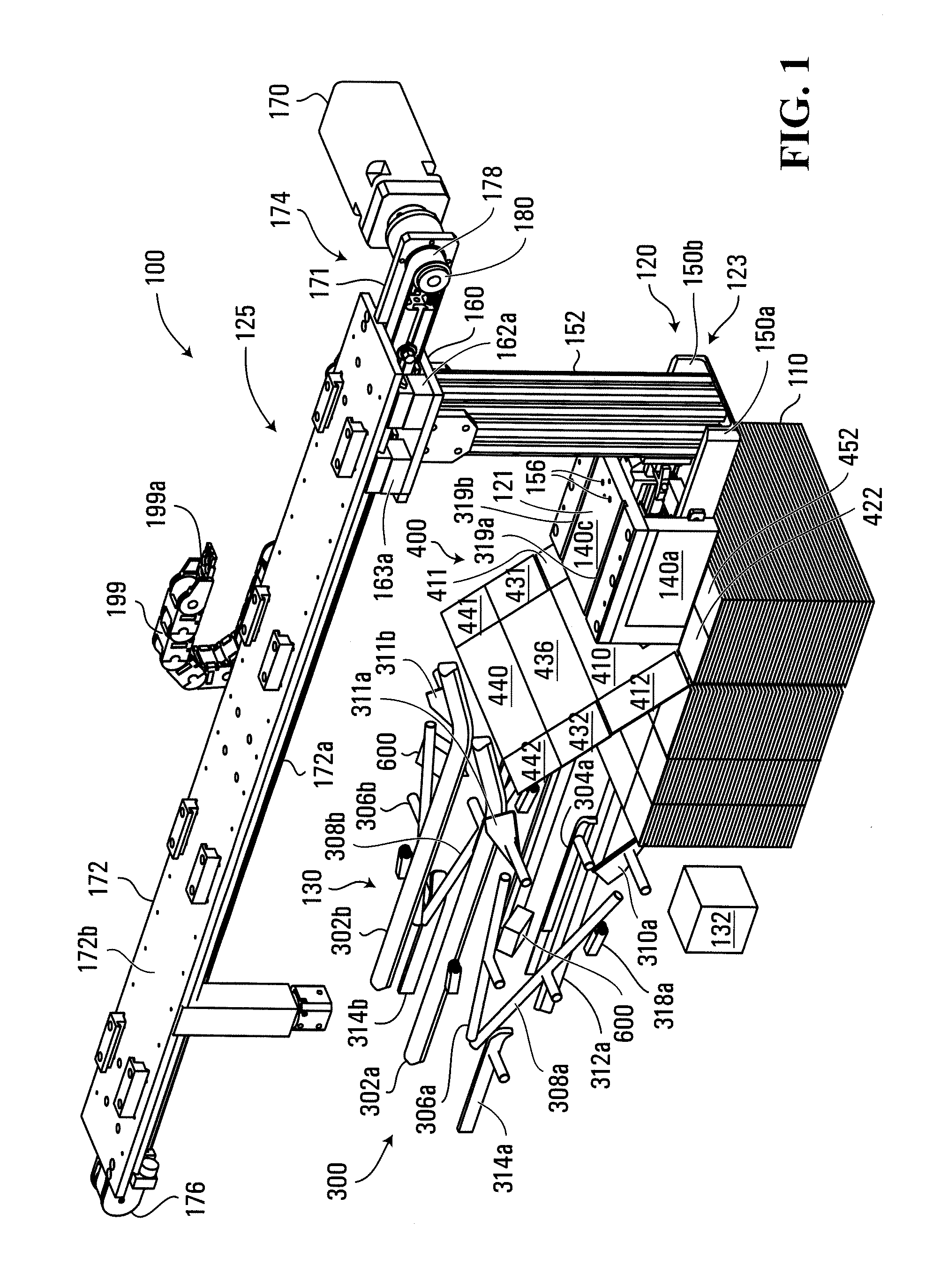

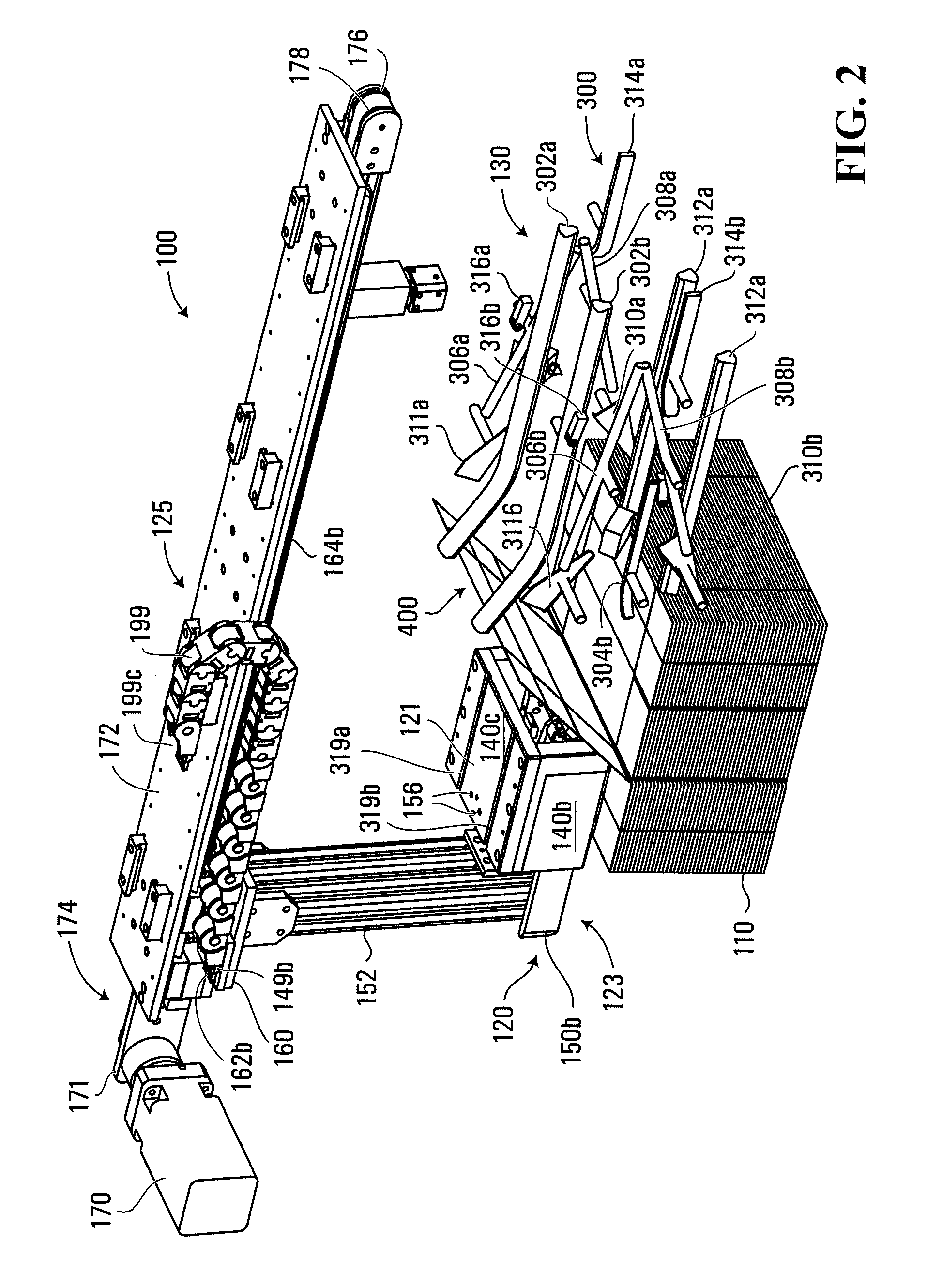

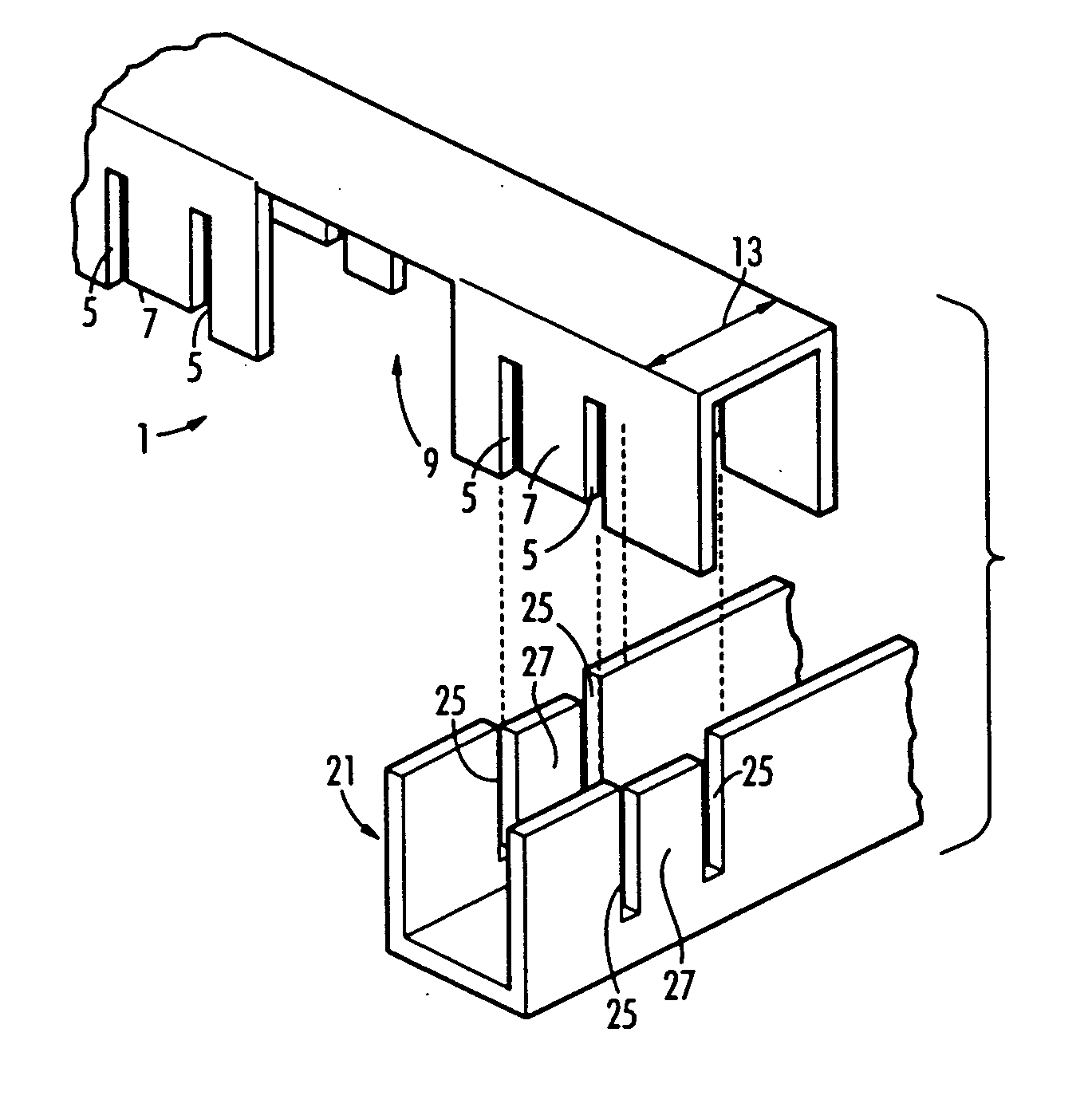

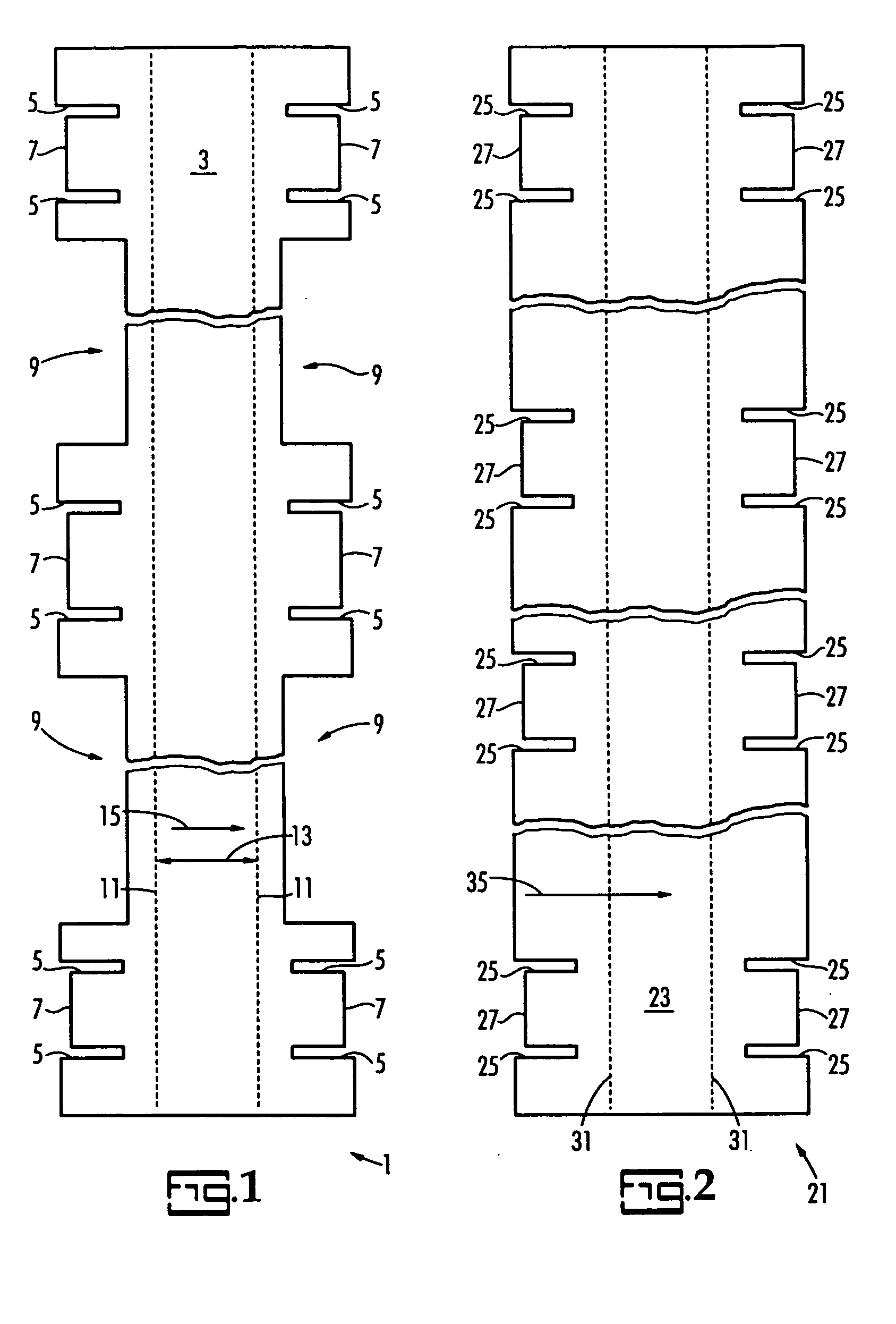

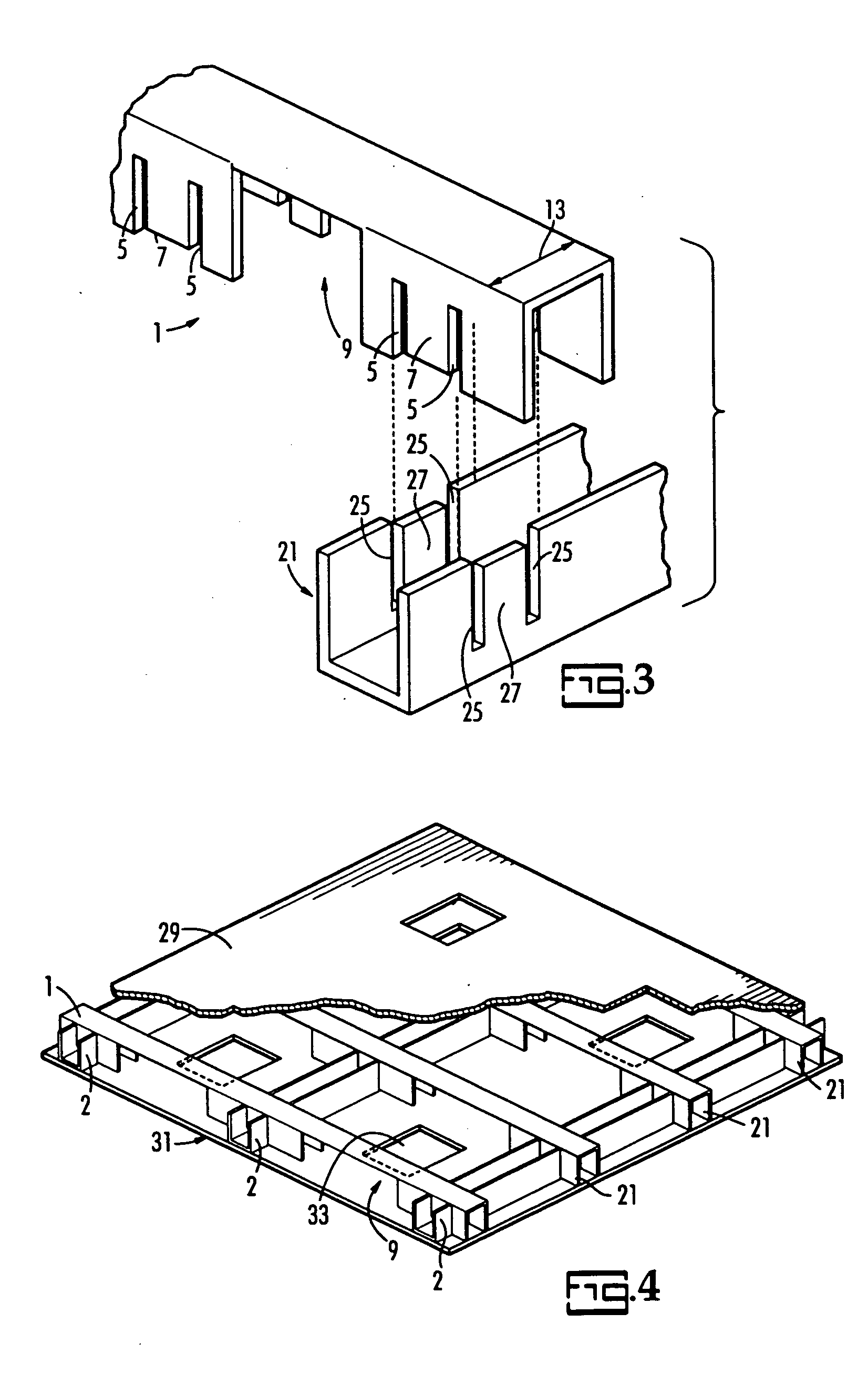

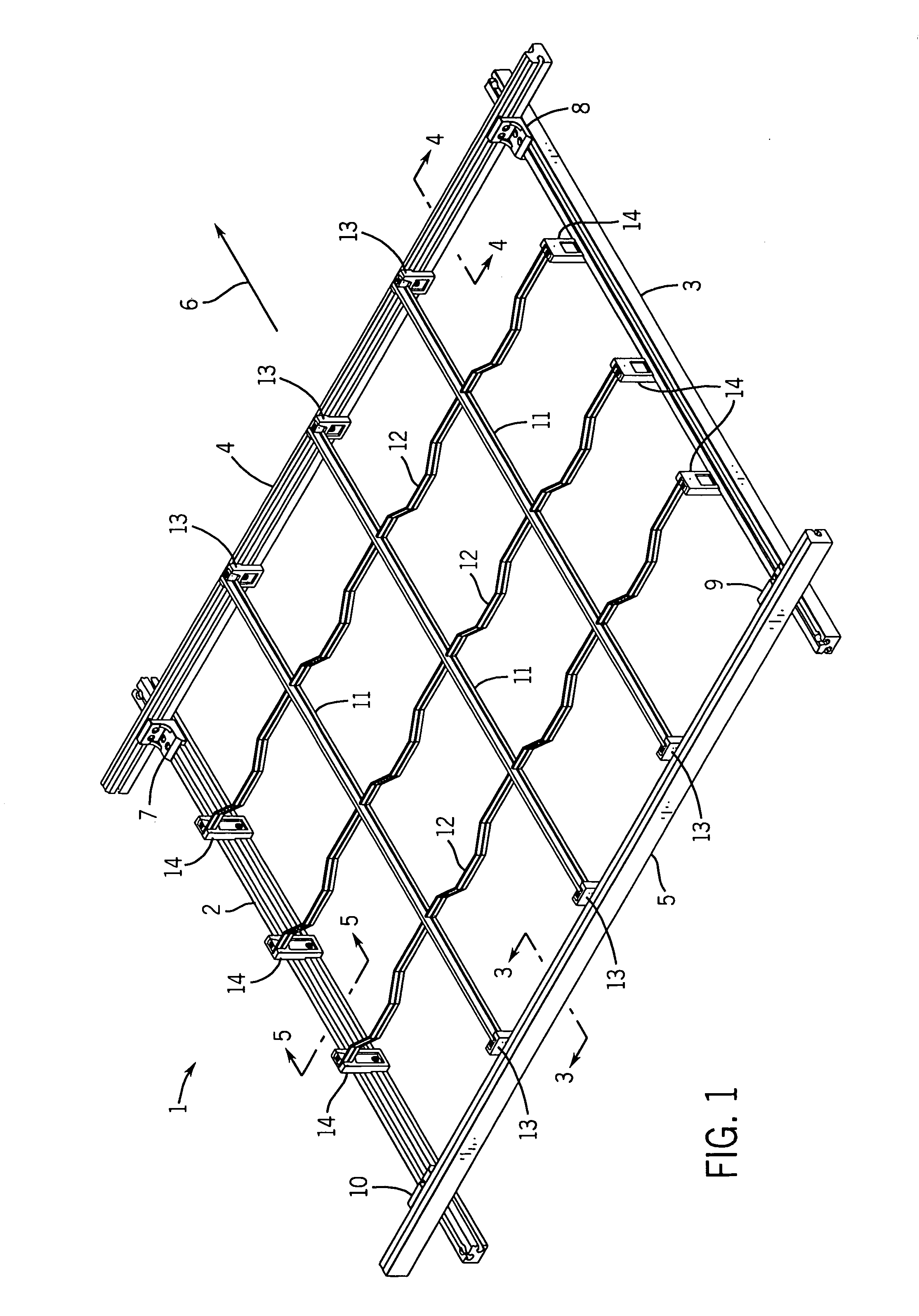

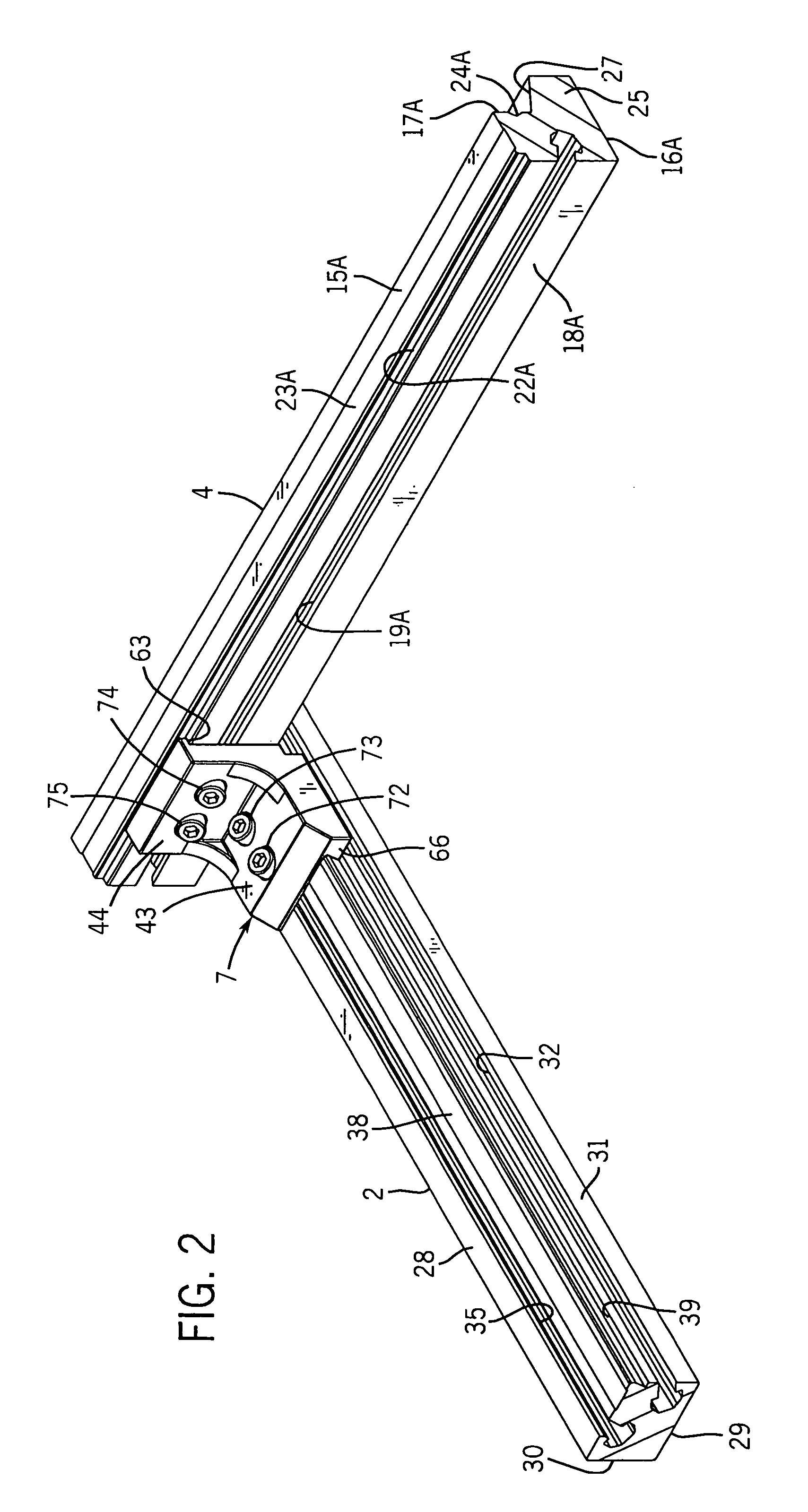

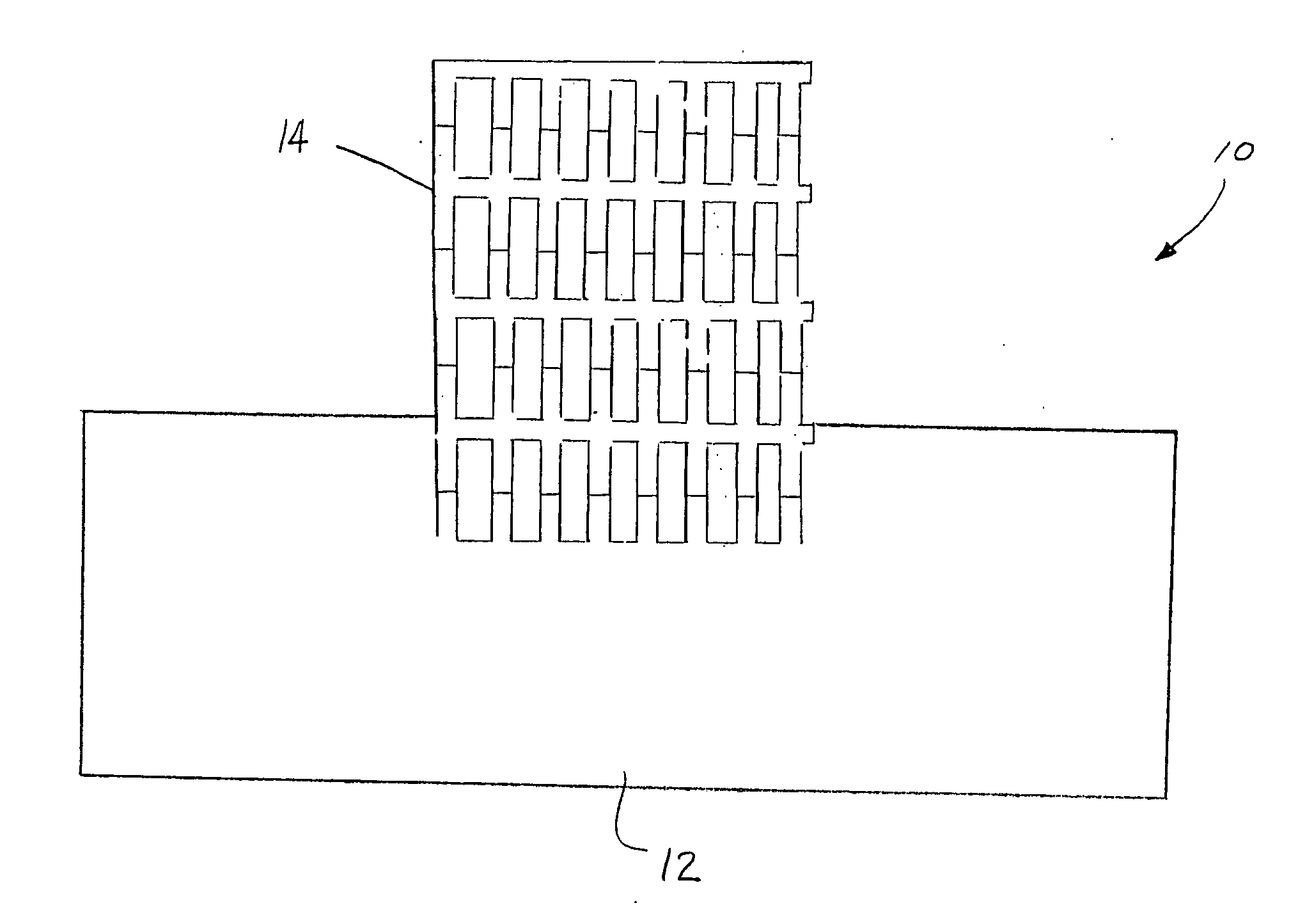

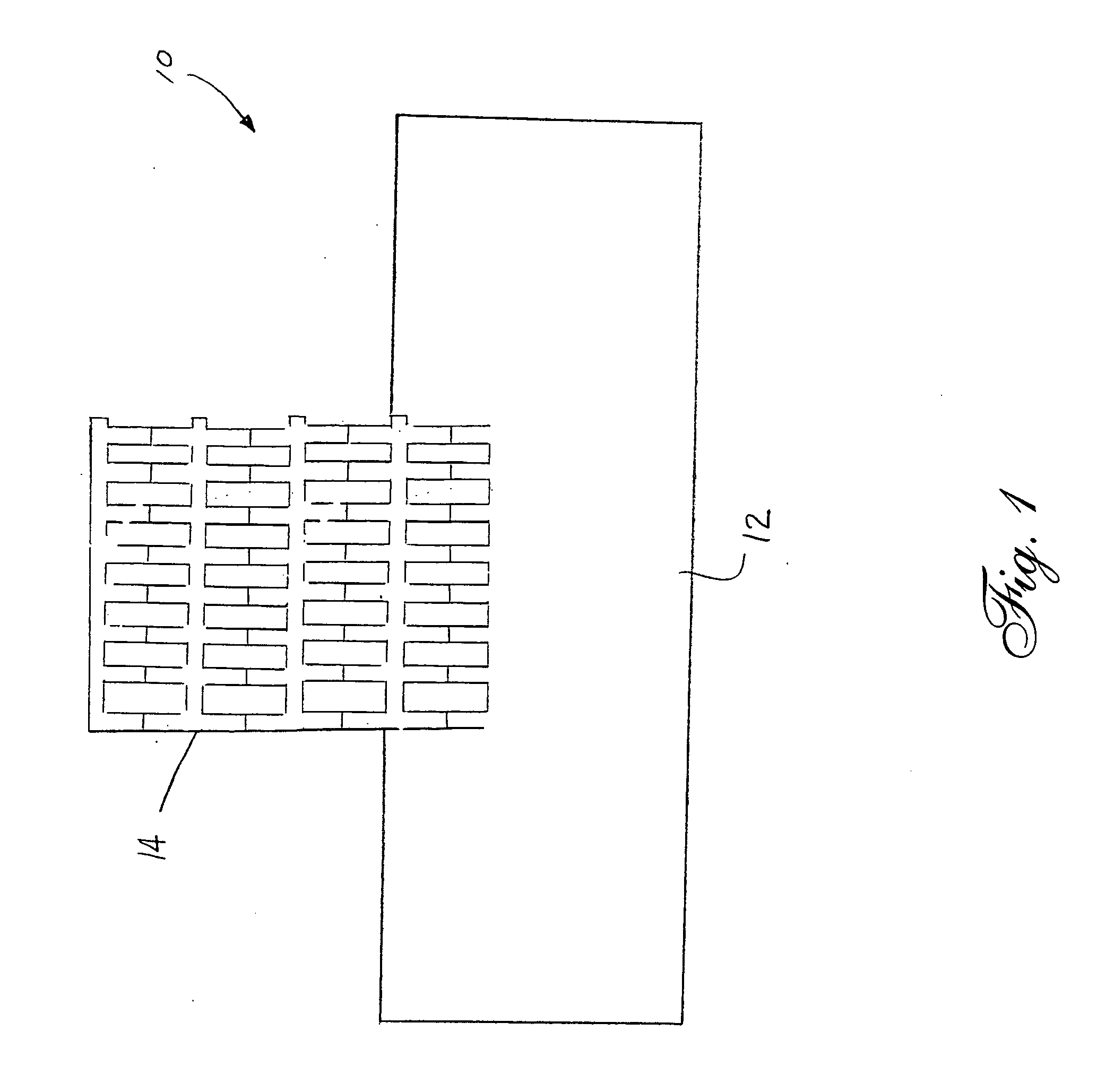

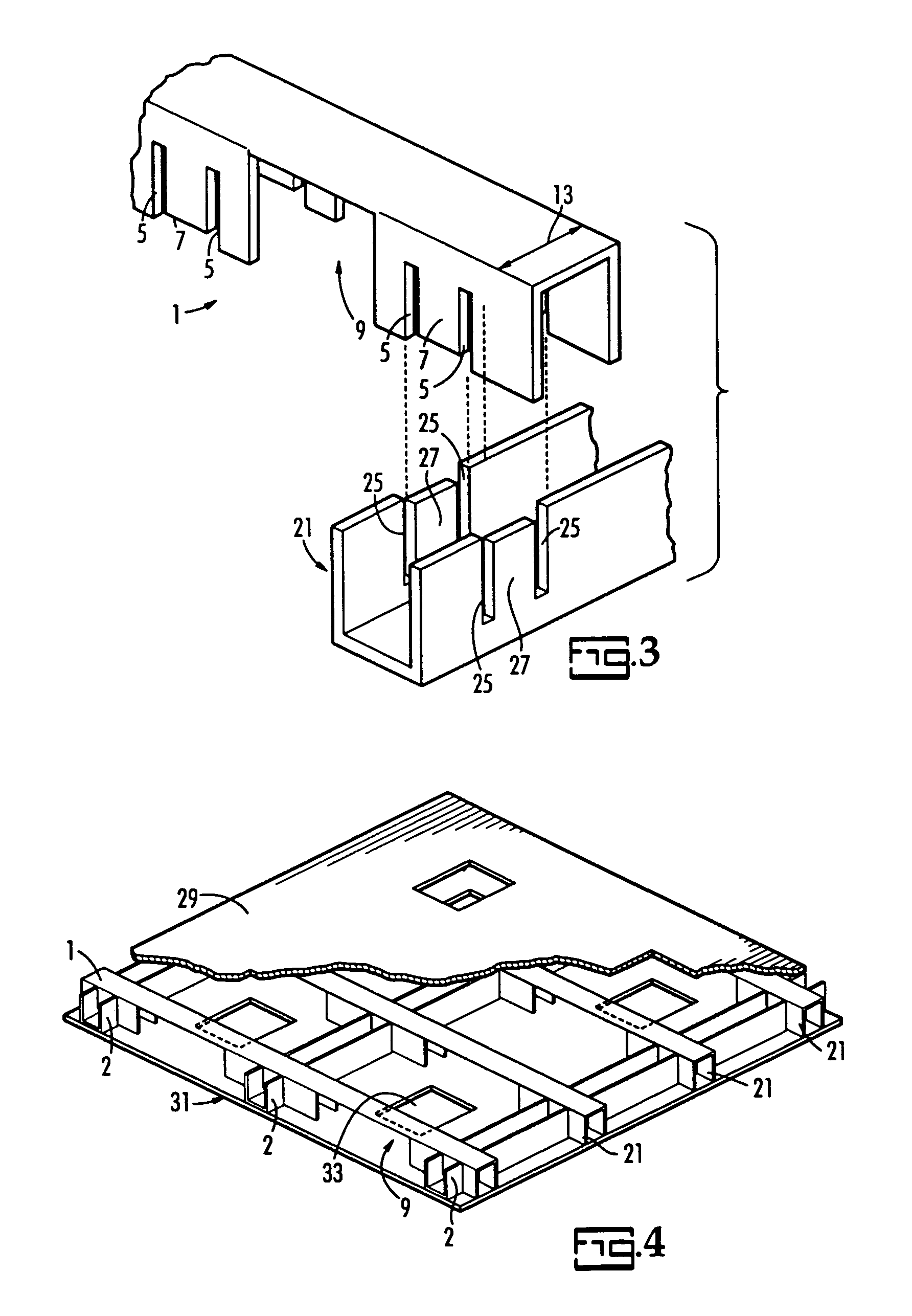

Jogger member, system and method for mounting jogger members and female and male blanking dies provided therewith

InactiveUS6477930B1Precise positioningProvide supportPaper-makingBox making operationsAnimal scienceCarton

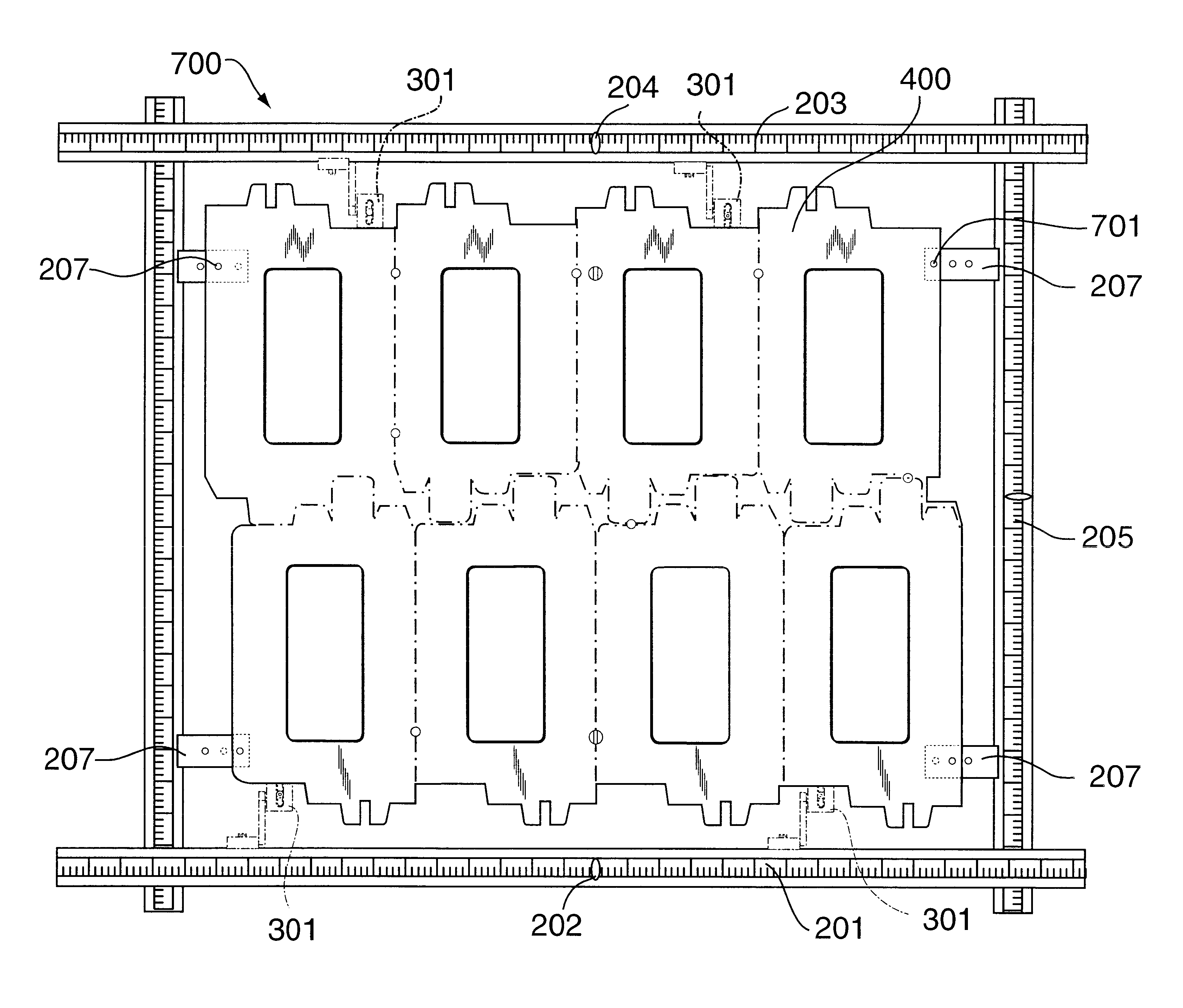

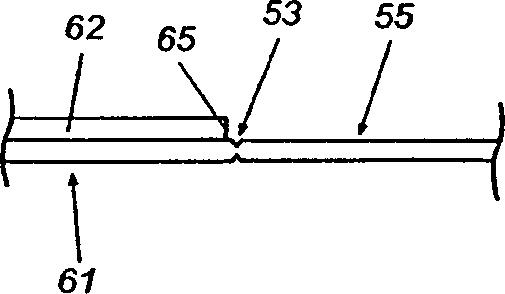

A female blanking die for a die cutting machine for die cutting and / or blanking a carton blank, as well as a male blanking die / female blanking die combination, and methods of producing them, and elements constituting essential integers thereof, are all provided herein. The male blanking die / female blanking die combination includes a specifically-configured male stripping die. Such male stripping die includes a template having a particularly-specified perimeter, the template including a plurality of foam plastic pads which are removably secured to the undersurface of the template, the template being accurately secured at a predetermined position to the underface of a movable upper plate of the blanking station of the die cutting machine. The male blanking die / female blanking die combination also includes a specifically-configured female blanking die. Such female stripping die includes a rectangular framework and a plurality of grid support members, each grid support member having a slot across its upper face, the grid support members being selectively disposed along the internal perimeter of the rectangular framework. A grid is provided comprising a plurality of intersecting rails, the pattern of the intersecting rails having a predefined shape. The grid is disposed within the slots atop the grid support members. A plurality of jogger members are provided which are selectively disposed along the internal perimeter of the rectangular framework, each jogging member having a particularly-recited structure. The plurality of jogger members are oriented along the internal perimeter of the rectangular framework in a particularly-recited way. The female blanking die is accurately secured at a predetermined position atop a lower fixed plate of the blanking station of the die cutting machine. The male blanking die and the female blanking die are accurately aligned to cooperate to press and separate the carton blanks from a web holding them together, and to force the separated cartons through aligned openings in the female blanking die.

Owner:SANDFORD PETER E

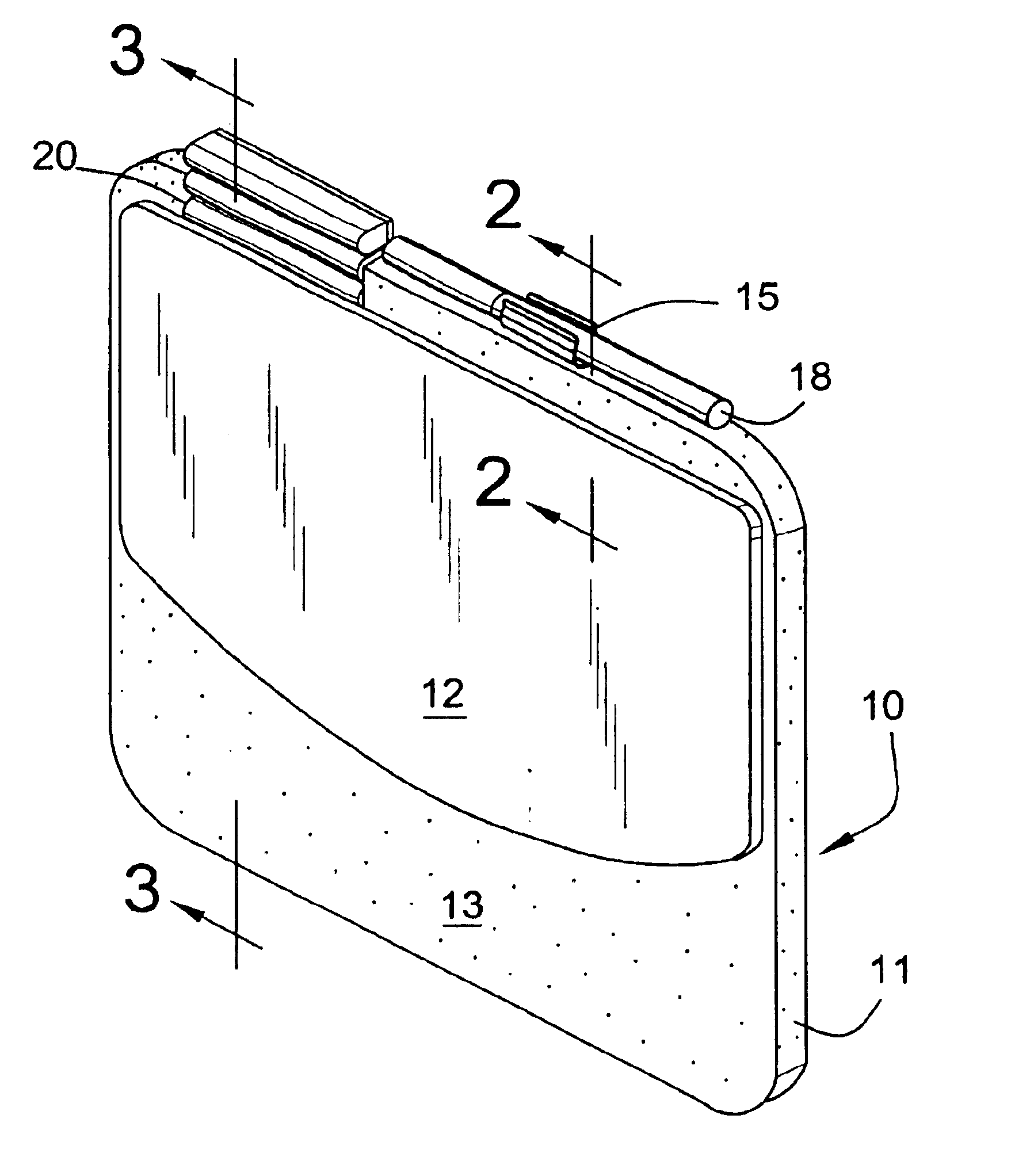

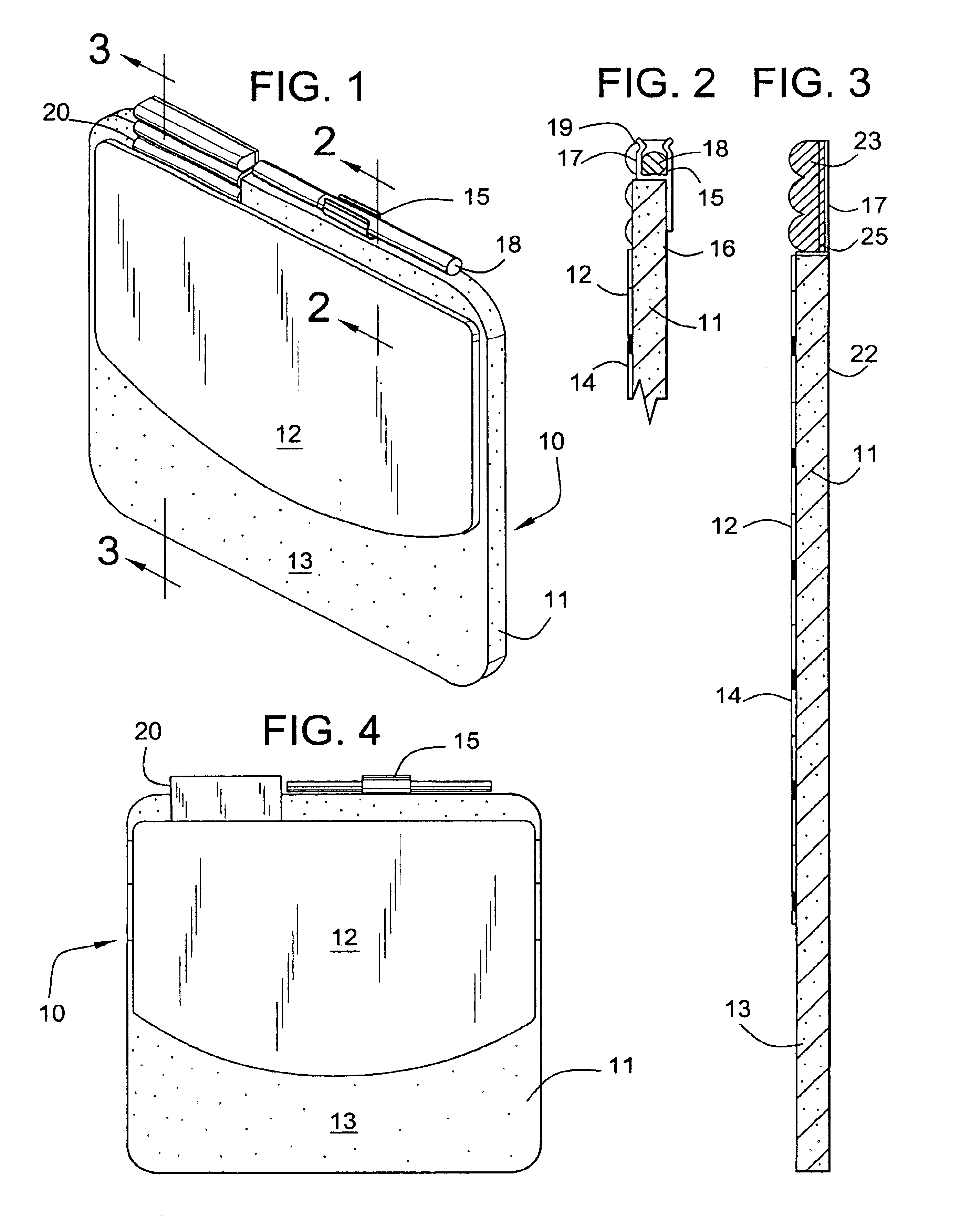

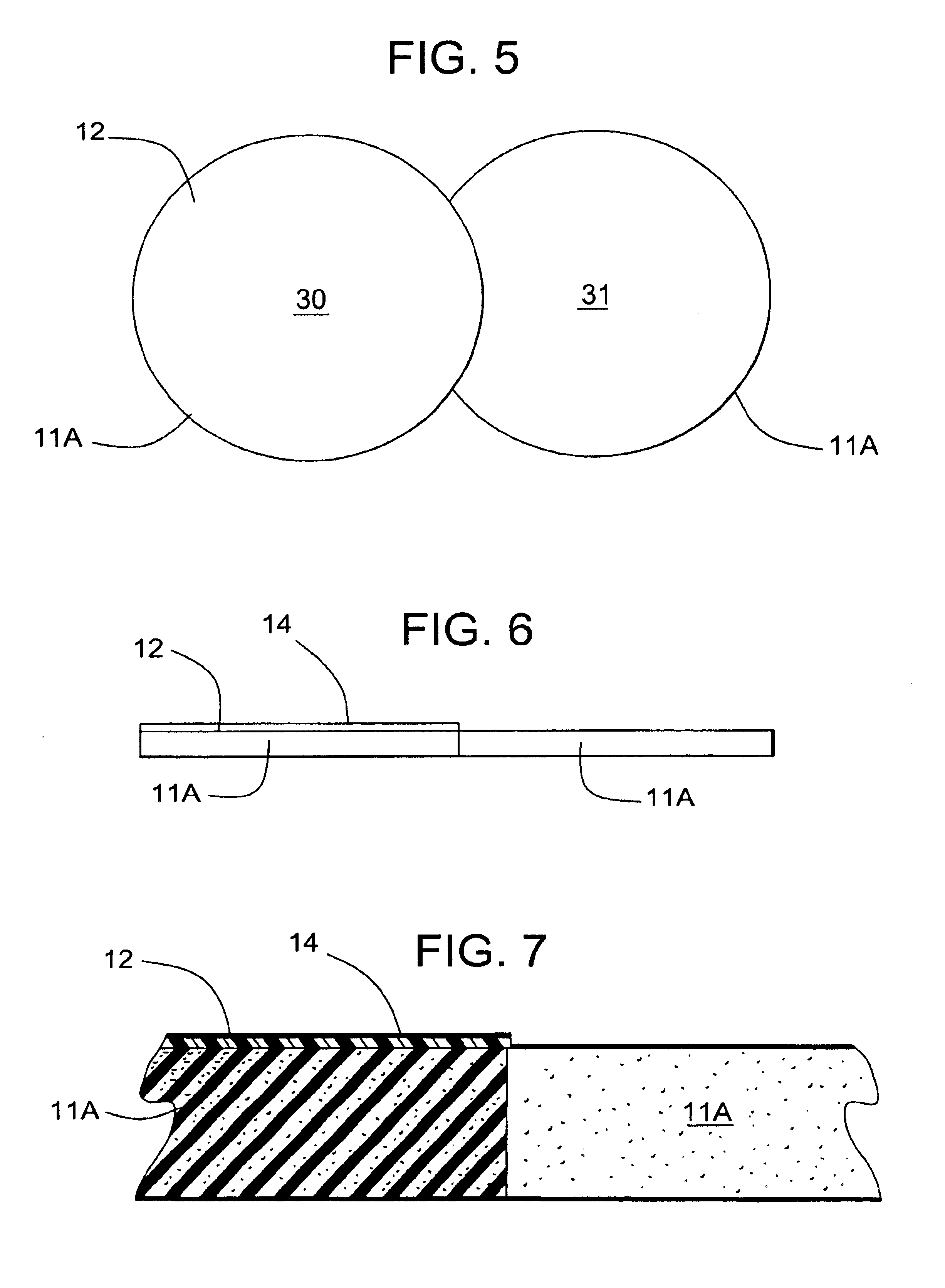

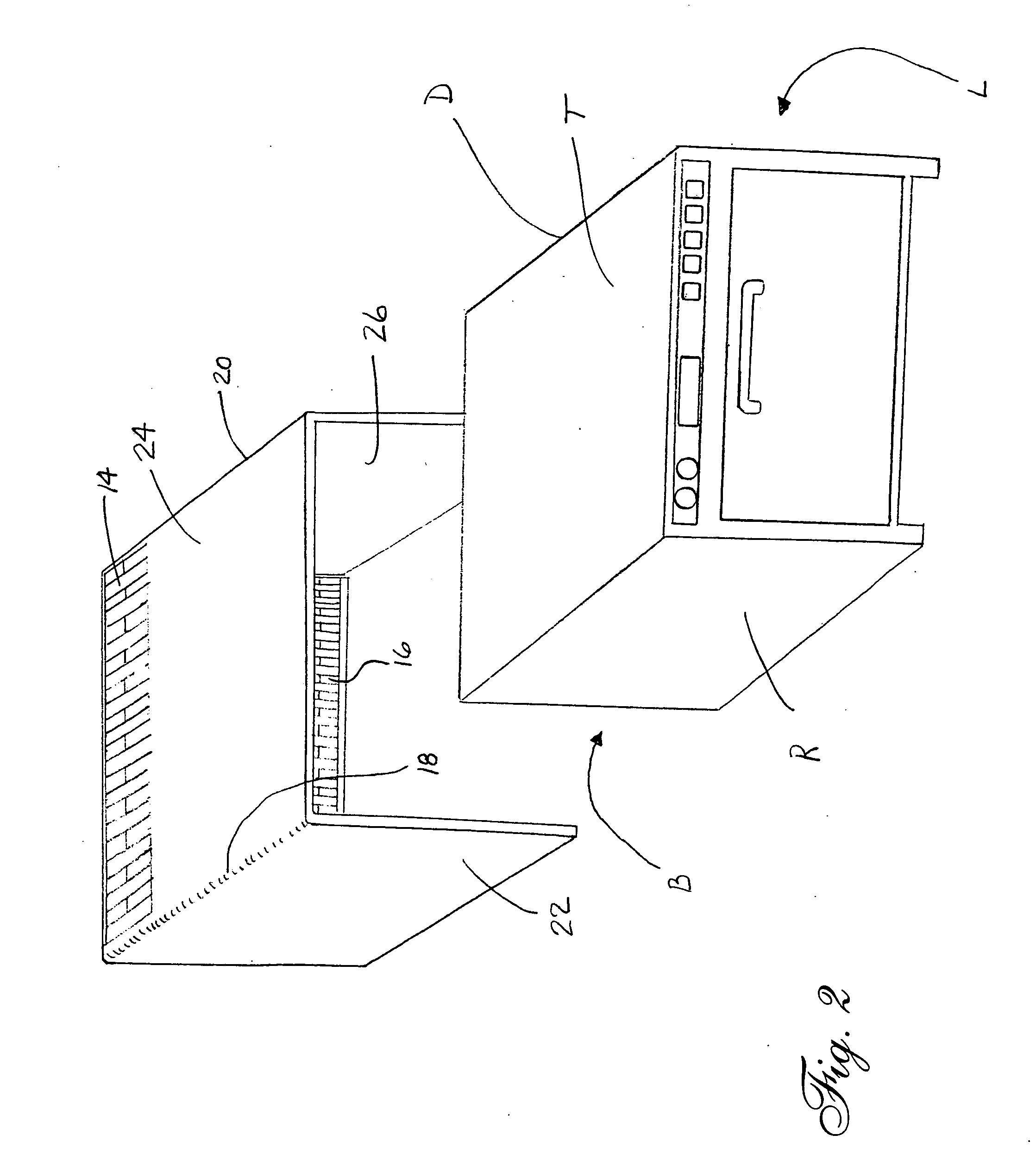

Tackable and markable dry erase board assembly

Tackable and markable dry erase display boards which have no frame and which may be die cut from moldable foam material capable of receiving and holding mounting pins and substantially closing after a pin is withdrawn. Such boards are light weight and can be mounted on substantially any desired surface without hardware or tools, and can be fabricated in substantially any desired color. The boards may have convenient means for holding accessories such as an eraser or marking implement.

Owner:GEN BINDING

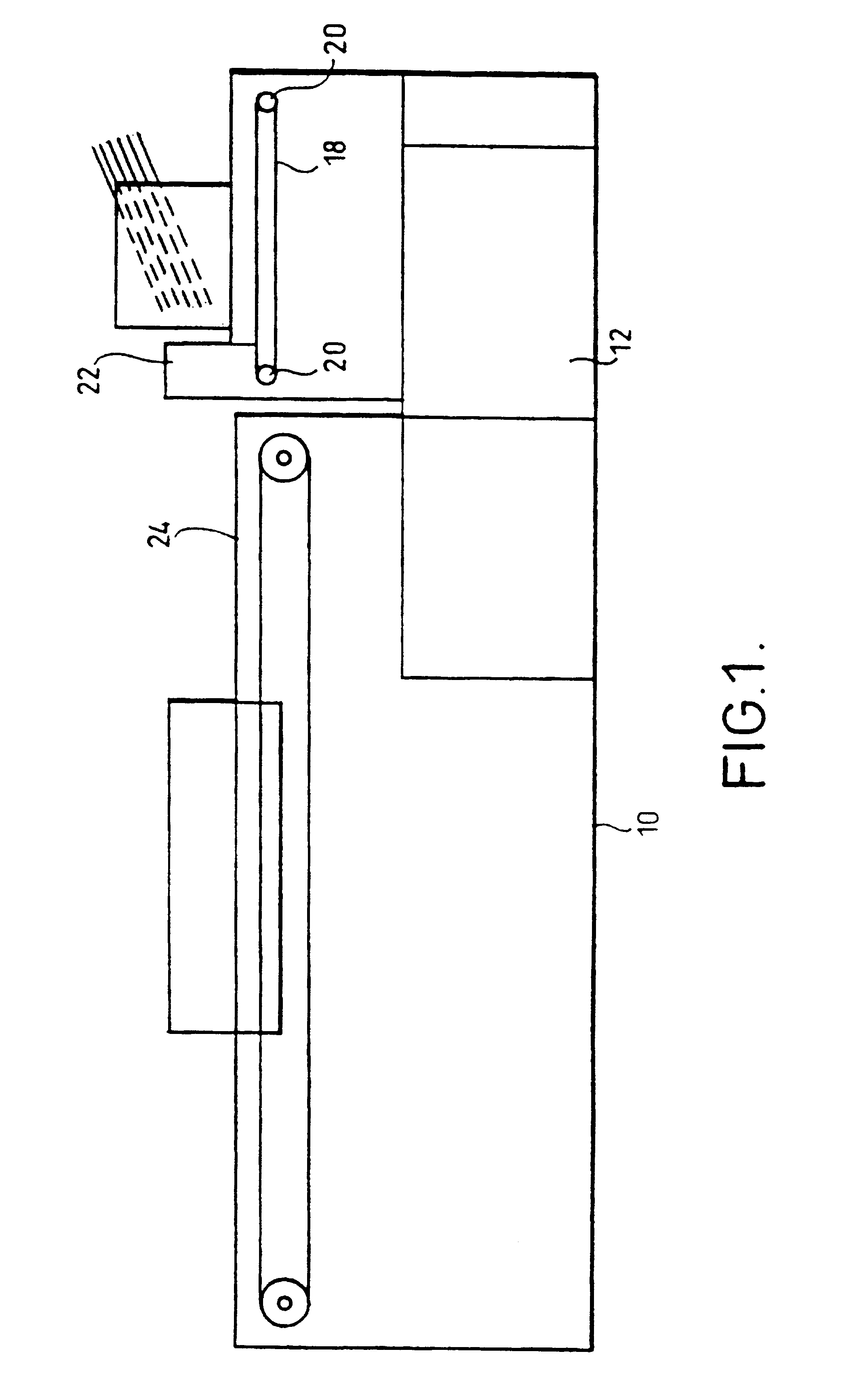

Paperboard cartons with laminated reinforcing ribbons and method of making same

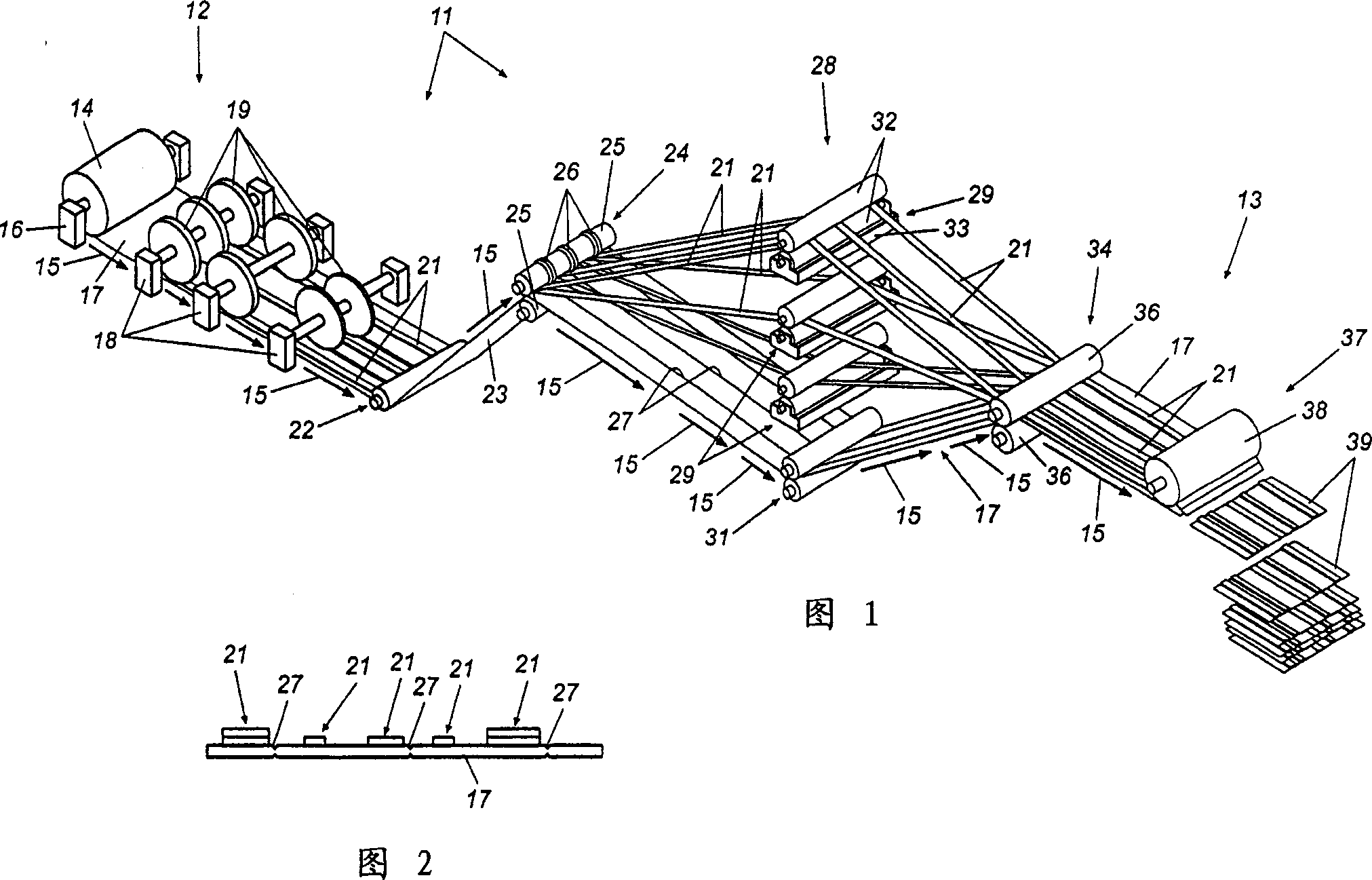

A method of making a reinforced carton includes the steps of advancing a carton blank along a path, and progressively laminating at least one strip of reinforcing material to the advancing carton blank. The strip of reinforcing material, which may also be paperboard, has a width less than the width of the paperboard blank and is applied with adhesive at selected locations across the width of the paperboard blank. The paperboard blank and laminated strips of reinforcing material are cut into pieces of predetermined size; the piece is then die cut and creased with fold lines to form the carton blank. Next, the carton blank is formed into a carton for articles, and the laminated reinforcing material is reinforced in selected portions of the carton. Multiple strips of reinforcing material and multiple layers of the strips may be laminated at selected locations on the carton blank to provide reinforcement in more than one portion of the carton.

Owner:RIVERWOOD INT CORP

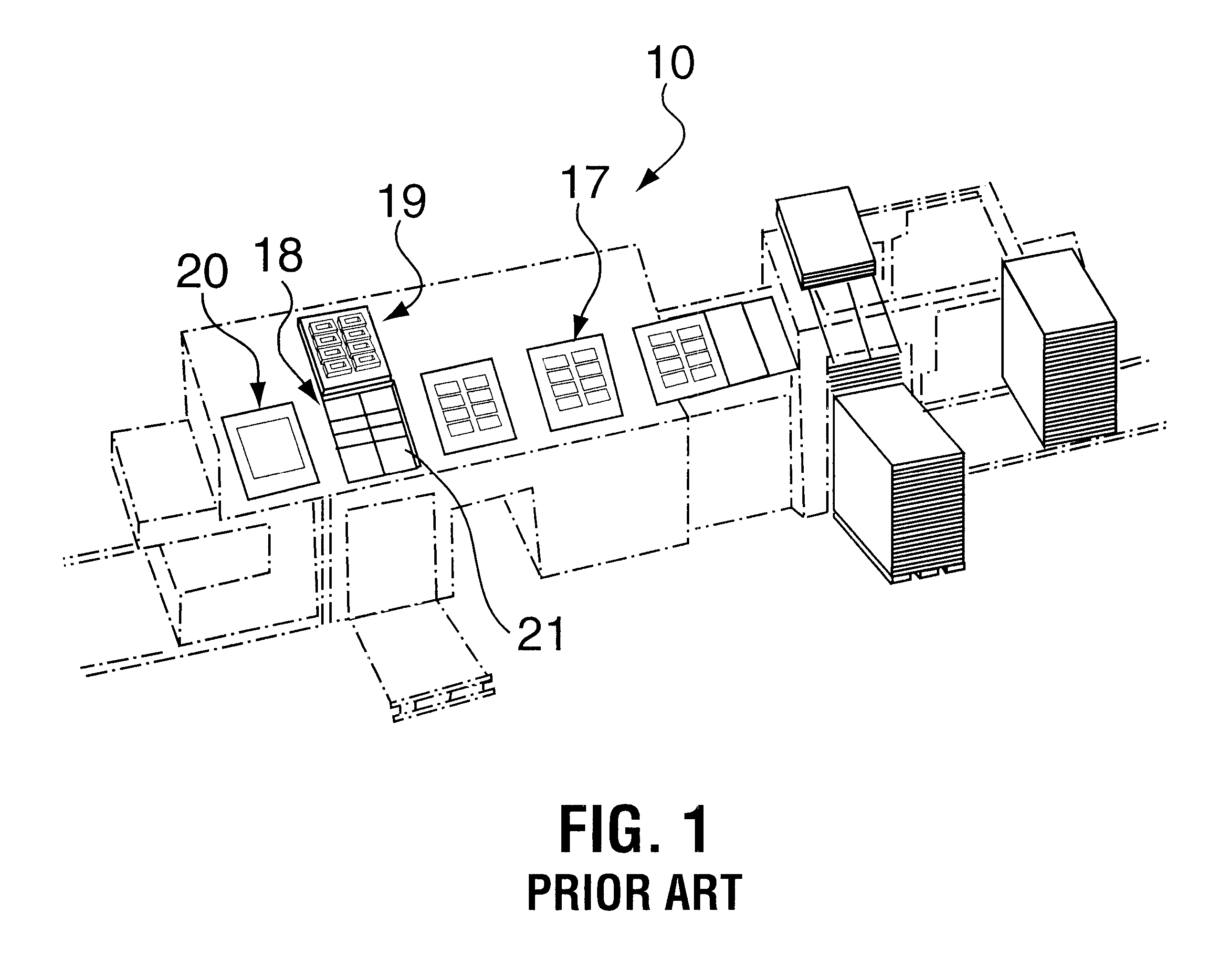

Method and apparatus for forming containers with corrugated material

ActiveUS20100263333A1Reduce manufacturing costEquivalent and good strengthMechanical working/deformationBoxes/cartons making machineryEngineeringCorrugated fiberboard

A case is disclosed that is made from a corrugated material and has a generally flat transversely extending base panel and first and second transversely extending, generally parallel, side wall panels upstanding from, and being oriented generally orthogonal to, the base panel. First and third end wall panels meet at a first vertically extending seam extending upwards from one end of the base panel and second and fourth end wall panels meet at a second vertically extending seam extending upwards from an opposite end of the base panel. A blank for forming such a case is also disclosed. A method comprises forming a sheet of corrugated fiberboard; operating a die cutting apparatus to form a generally flat case blank from the sheet of corrugated fiberboard at a first location; transporting the flat case blank to a second location; operating a case forming apparatus at the second location to fold the case blank to form the case; after the case has been formed by the case forming apparatus, operating a loading apparatus to load at least one item into the case; and sealing opposed top panels.

Owner:LANGEN H J PAUL

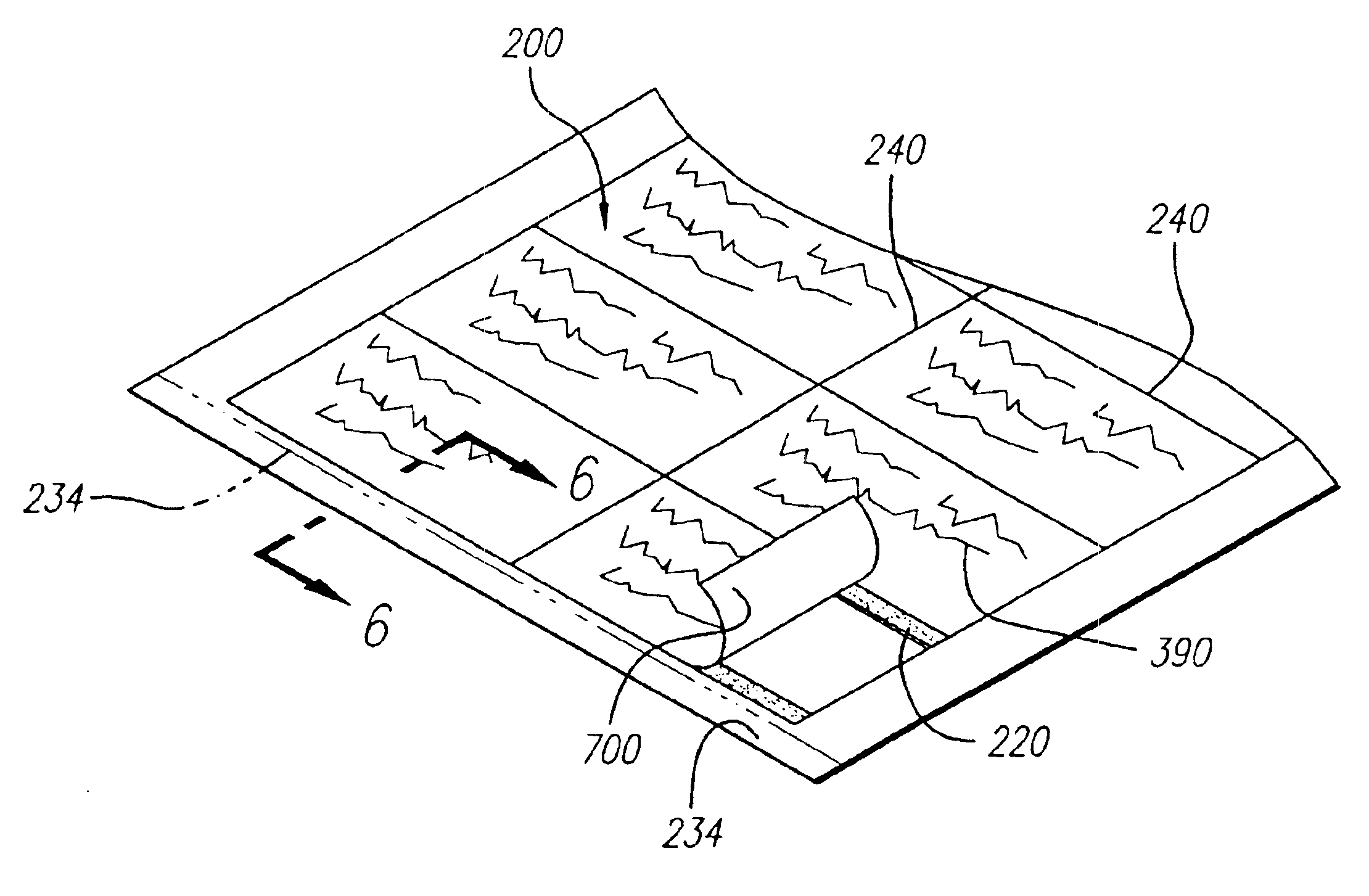

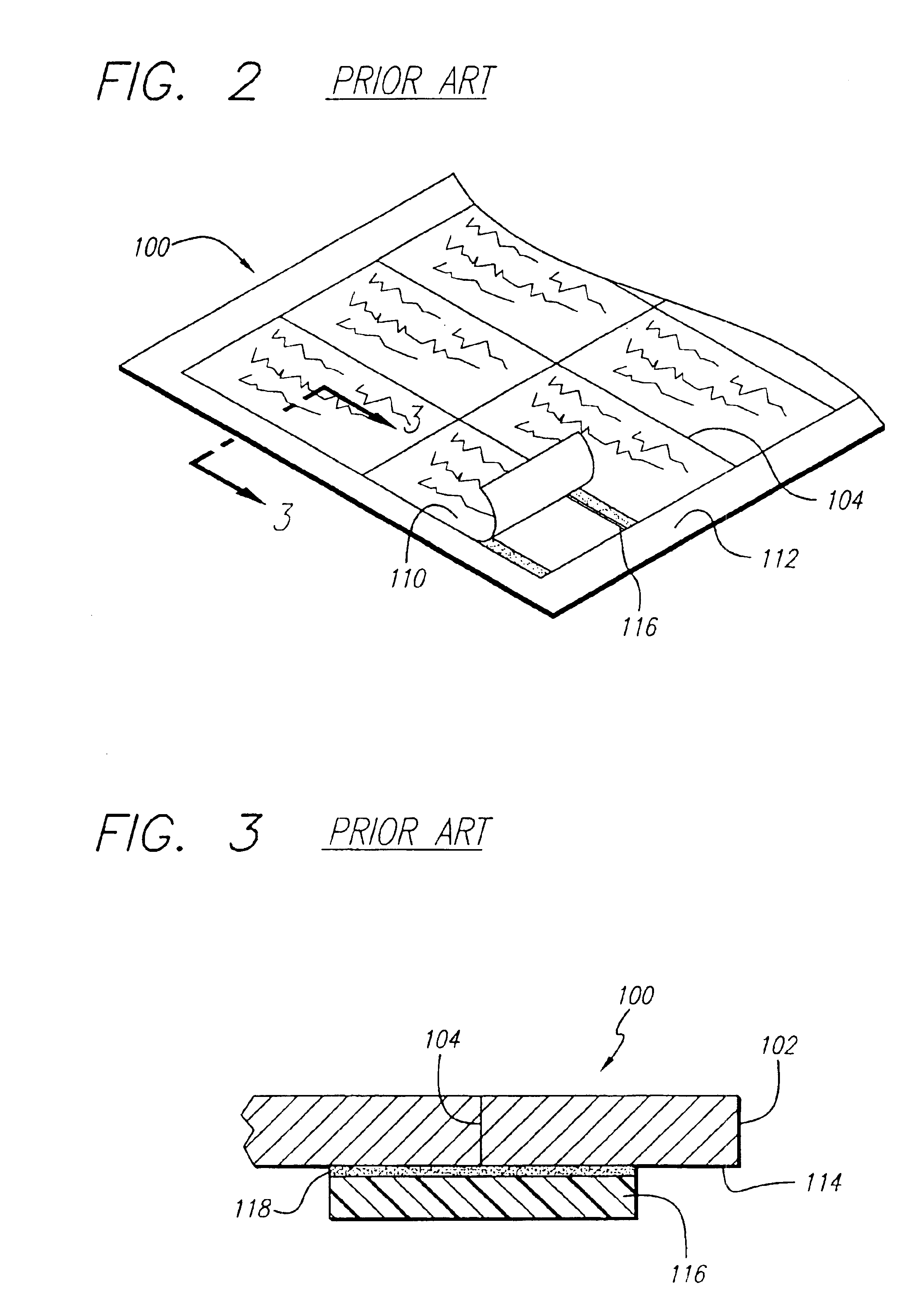

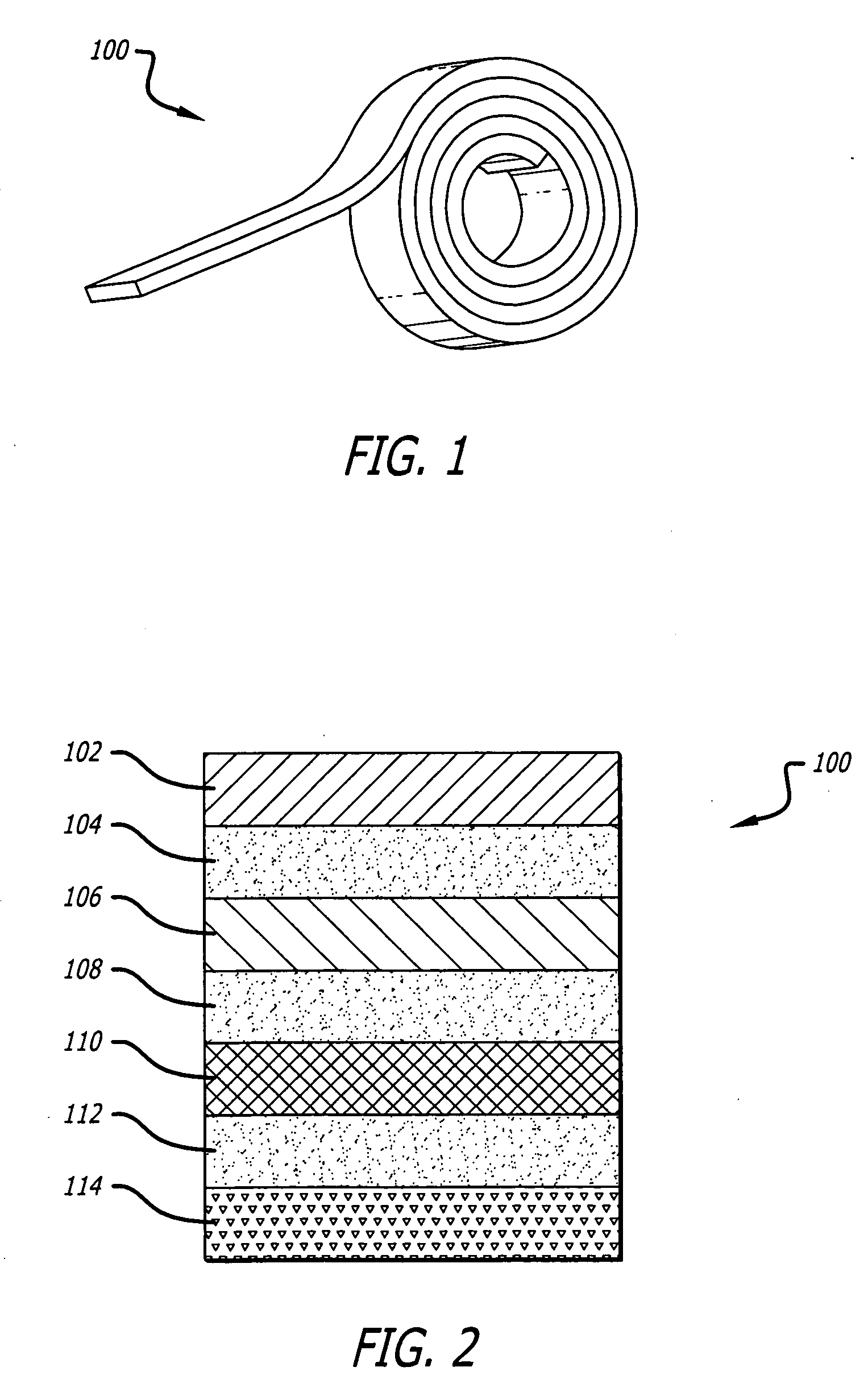

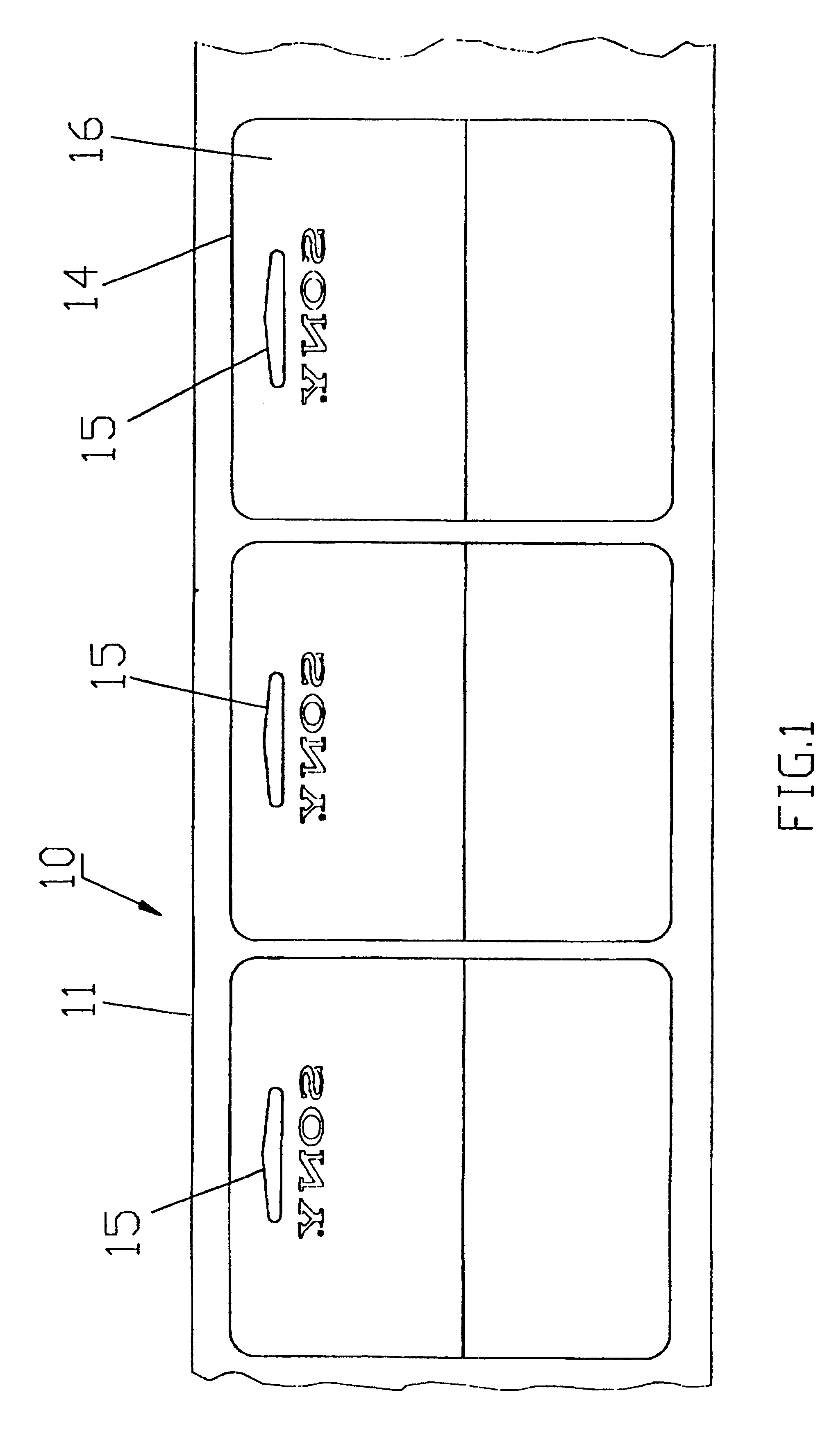

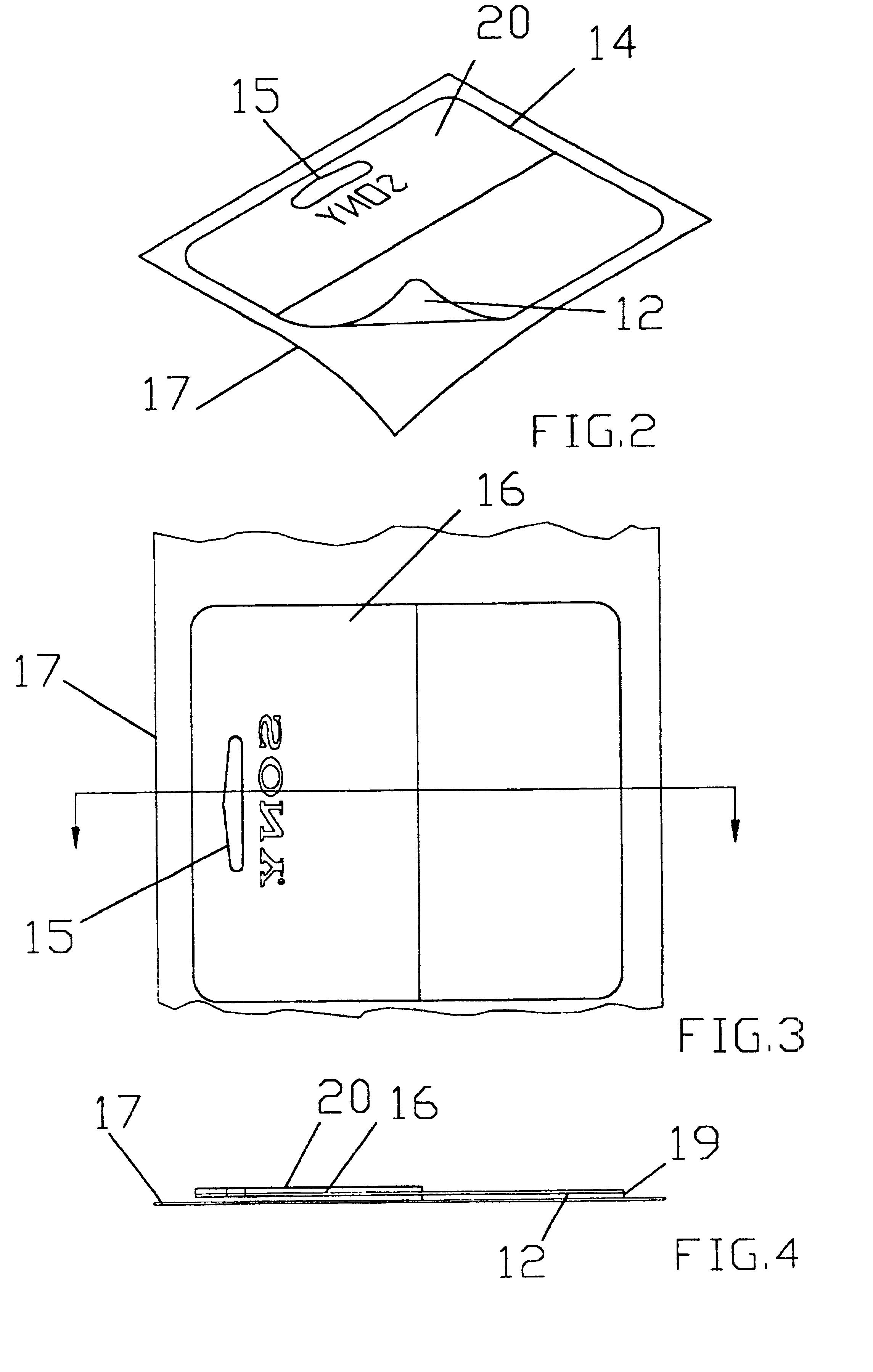

Method of forming printable media

InactiveUS6837955B1Less puckeringFeel moreOther printing matterLamination ancillary operationsCard stockBusiness card

Ultraremovable adhesive is applied to a paper sheet to form therewith a liner sheet and the liner sheet is laminated to a cardstock sheet to form a laminate cardstock. The cardstock sheet is then die cut therethrough, but not through the liner sheet, to form cardstock cut lines that define at least in part perimeters of business cards (or other printable media). The outer face of the liner sheet is then die cut therethrough, but not through the cardstock sheet, to form liner sheet strips on a back side of the cardstock sheet. Some of the strips define cover strips covering some of the cardstock cut lines, and others of the strips define waste strips. The waste strips are then matrix removed from the back of the cardstock sheet. The resulting business card sheet construction is then fed through a printer or copier by the user and the desired indicia printed on the front sides of the business cards, while the cover strips hold the cards together as a unit sheet construction. After this printing operation, the printed cards are easily peeled off of the cover strips, ready for use. By designing the sheet construction to form in the printed media with different sizes and shapes and by including optional scored fold lines, and / or additional flexibility cut lines or flexibility perforation lines, media aside from business cards, such as post cards and greeting cards, can be constructed and used pursuant to this invention.

Owner:CCL LABEL INC

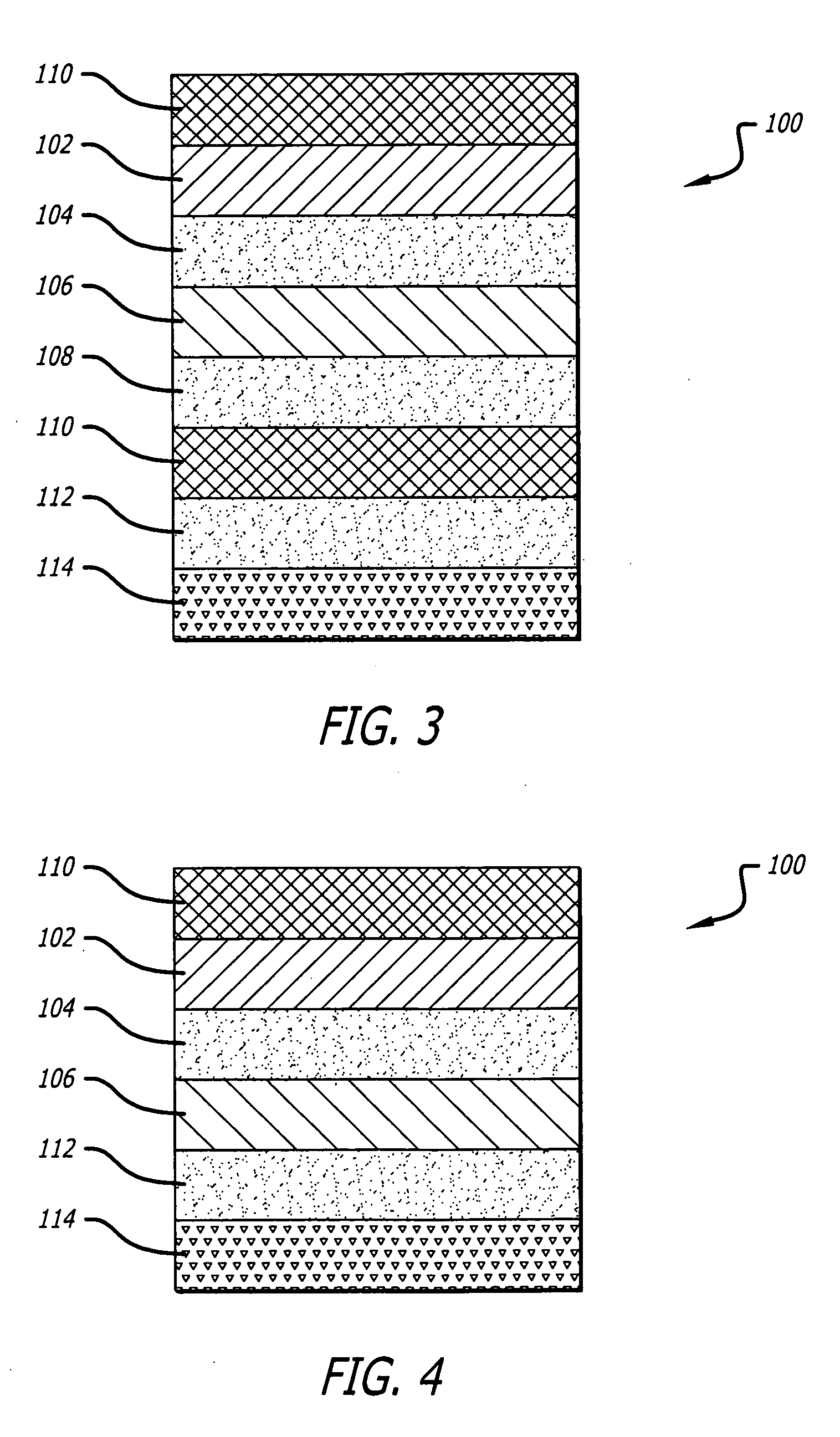

Apparatus and Process for Cutting Adhesive Labels

InactiveUS20110132522A1Avoid attenuationStampsLamination ancillary operationsMechanical engineeringPressure sensitive

A method and apparatus are provided for die cutting label stock comprising a facestock, an adhesive and optionally a liner to form labels where a liner of the linered pressure sensitive adhesive label stock may be a thin or ultrathin liner.

Owner:AVERY DENNISON CORP

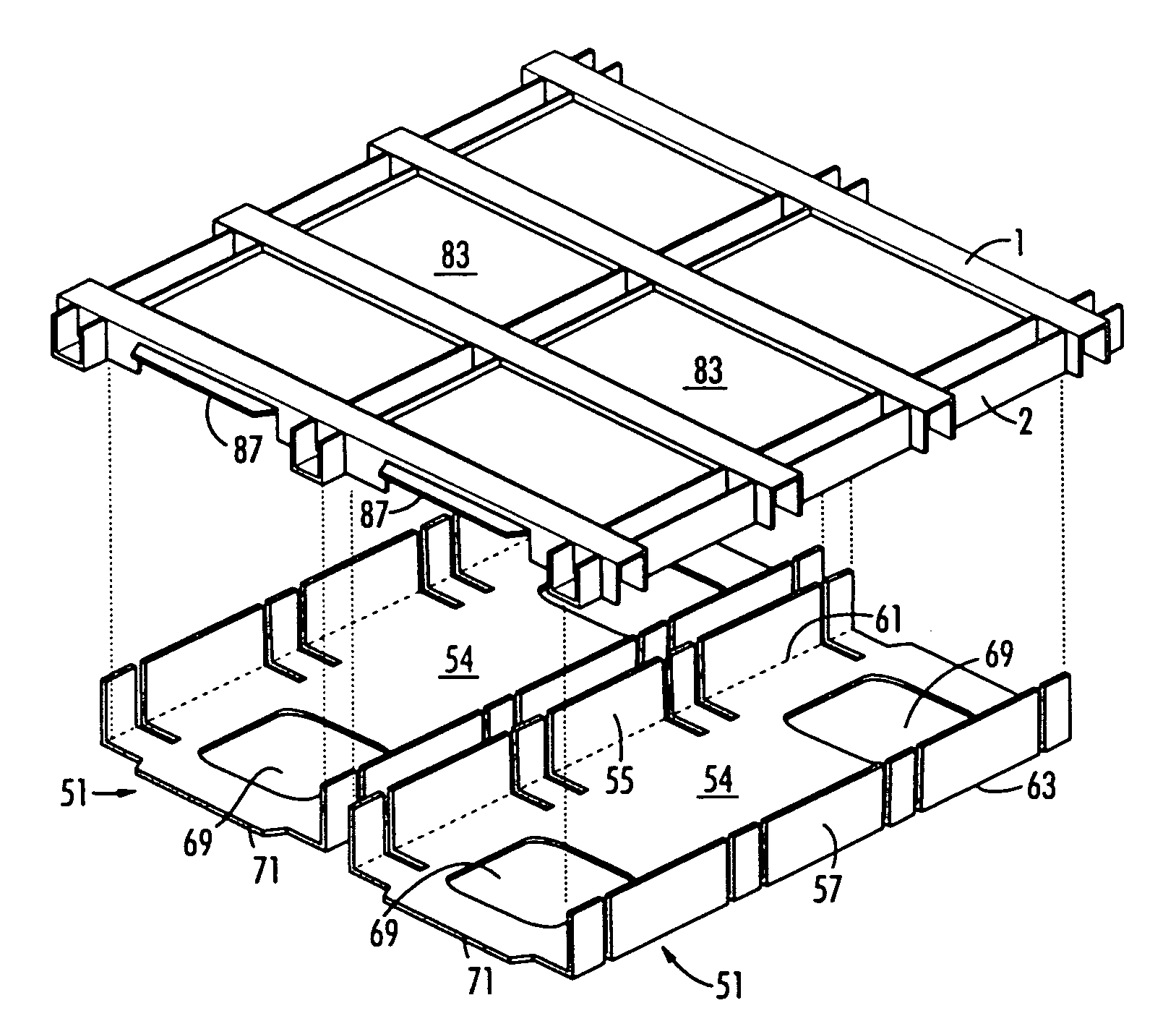

Corrugated pallet

InactiveUS20050247240A1Improve carrying capacityHigh stackingsContainer decorationsLevel indicationsAdhesiveEngineering

A shipping pallet compatible with fork-lifts and pallet-trucks is made from stamped or die cut flat corrugated board. Stringer and cross-braces form an interlocking grid work to which a top and bottom flat sheet are attached by an adhesive. The pallet may be recycled as paper and not returned to the sender. Additional reinforcement structures may be added for heavier loads.

Owner:NELSON DUANE

Method of Manufacturing and Operating an Antenna Arrangement for a Communication Device

InactiveUS20110304520A1Simple and complexSimple and complex antenna designSimultaneous aerial operationsAntenna supports/mountingsTelecommunicationsCommunication device

Thin, flexible antenna arrangements for use in communication devices, such as mobile communications devices, and methods of making and using the antenna arrangements are provided. The methods used to make the antenna arrangements are print-based and provide a simplified procedure, with a reduced number of process steps, the use of fewer materials and the production of less material waste than conventional methods based on etching and die cutting.

Owner:ILLINOIS TOOL WORKS INC

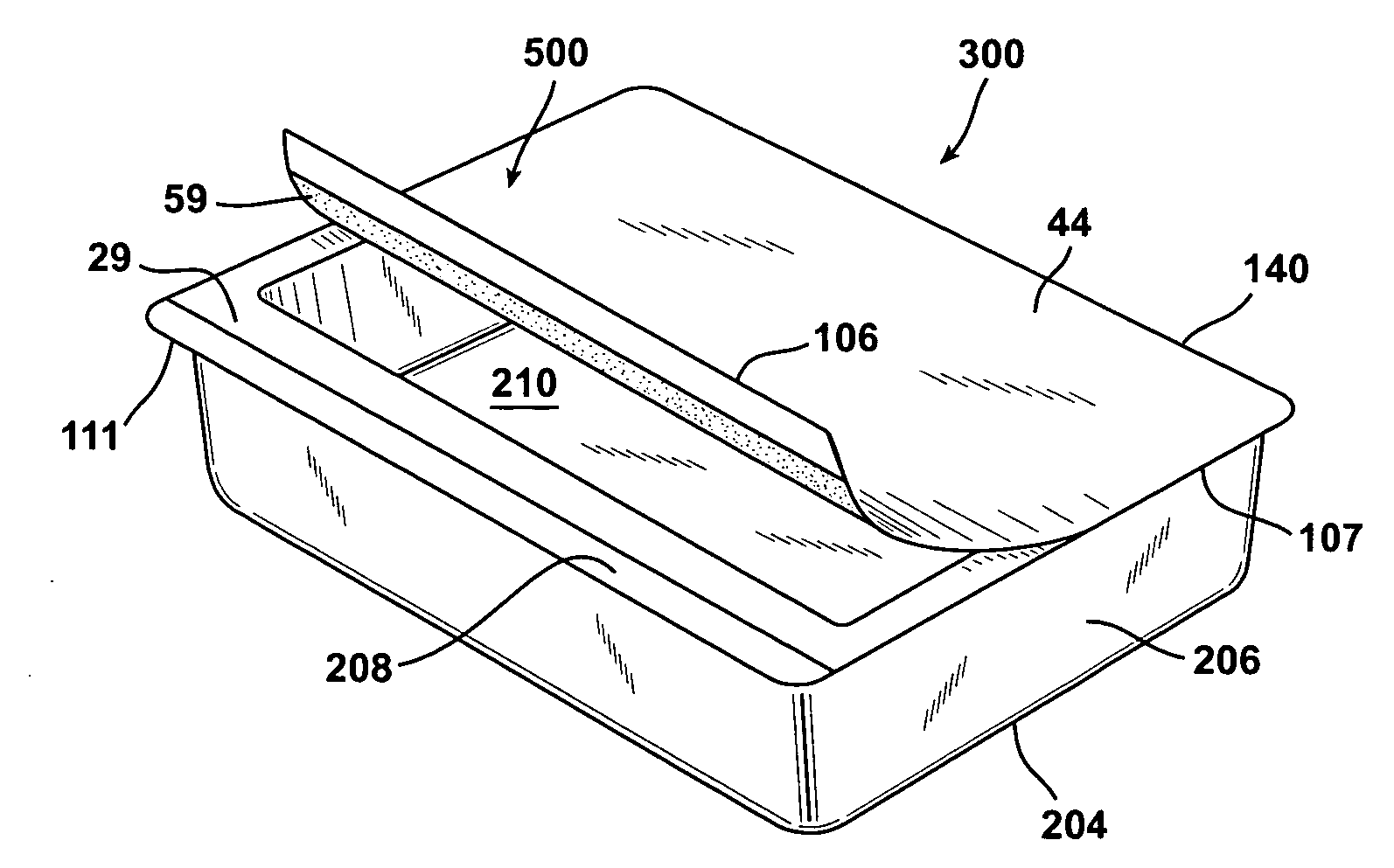

Laminated lidstock and package made therefrom

A laminated lidstock includes a substrate film, a support web; a pressure sensitive adhesive disposed between the substrate and support webs, and covering the substrate film and support web; a product die cut disposed in the substrate film; and an array of opening die cuts disposed in the substrate film; wherein at least one of substrate film and the support web comprises an oxygen barrier, and wherein at least one of the substrate film and the support web carries a registration device. A method of making the lidstock, and a package, are also disclosed.

Owner:CRYOVAC INC

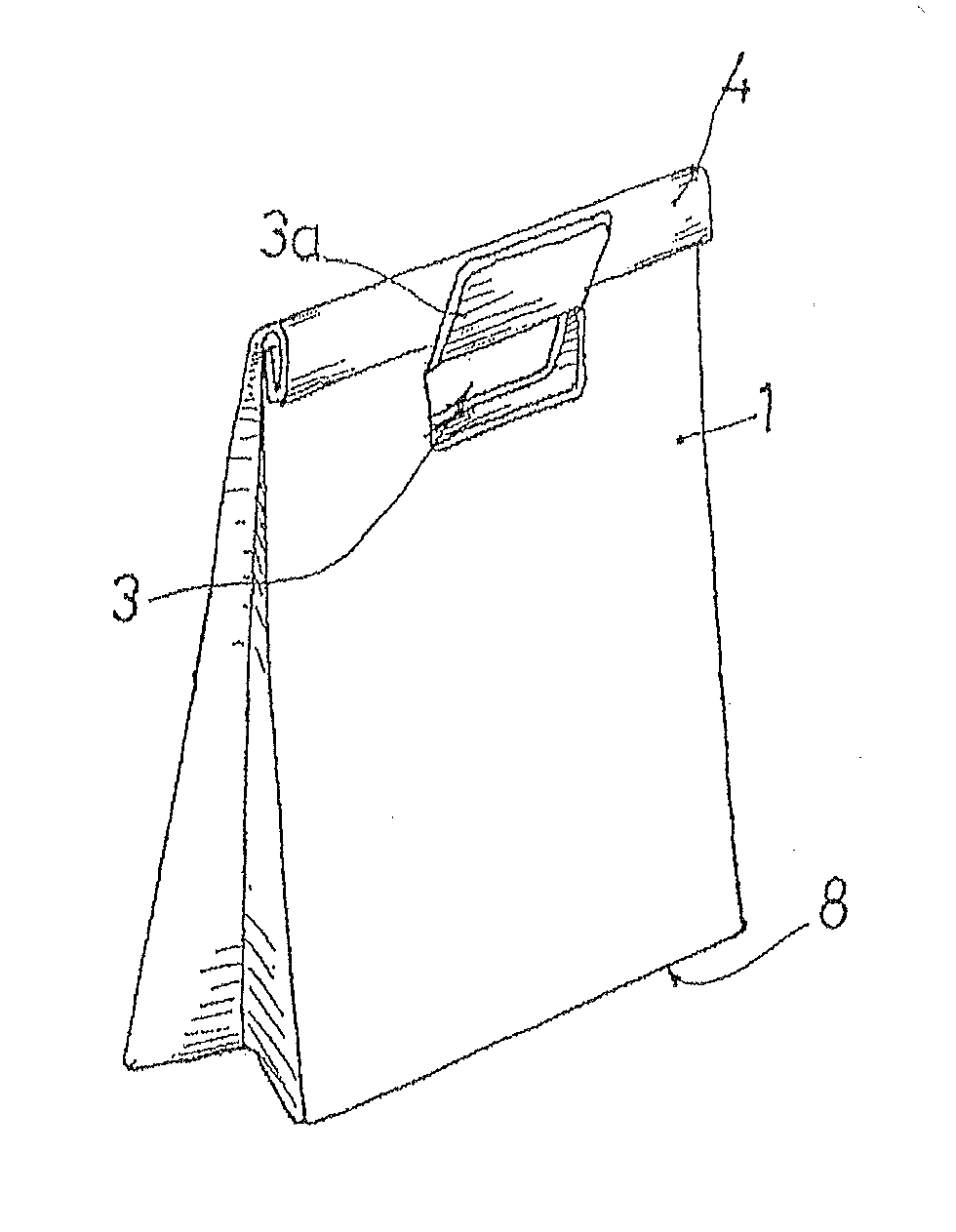

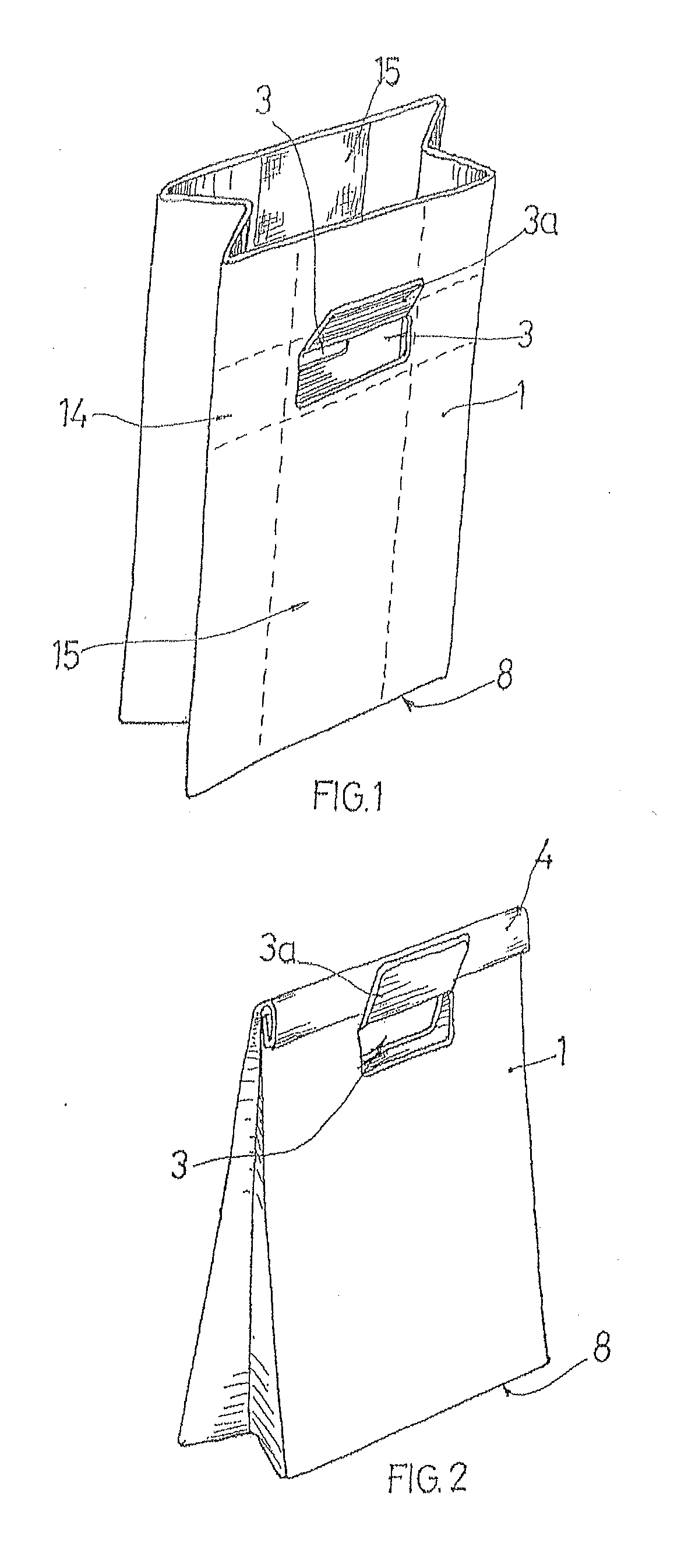

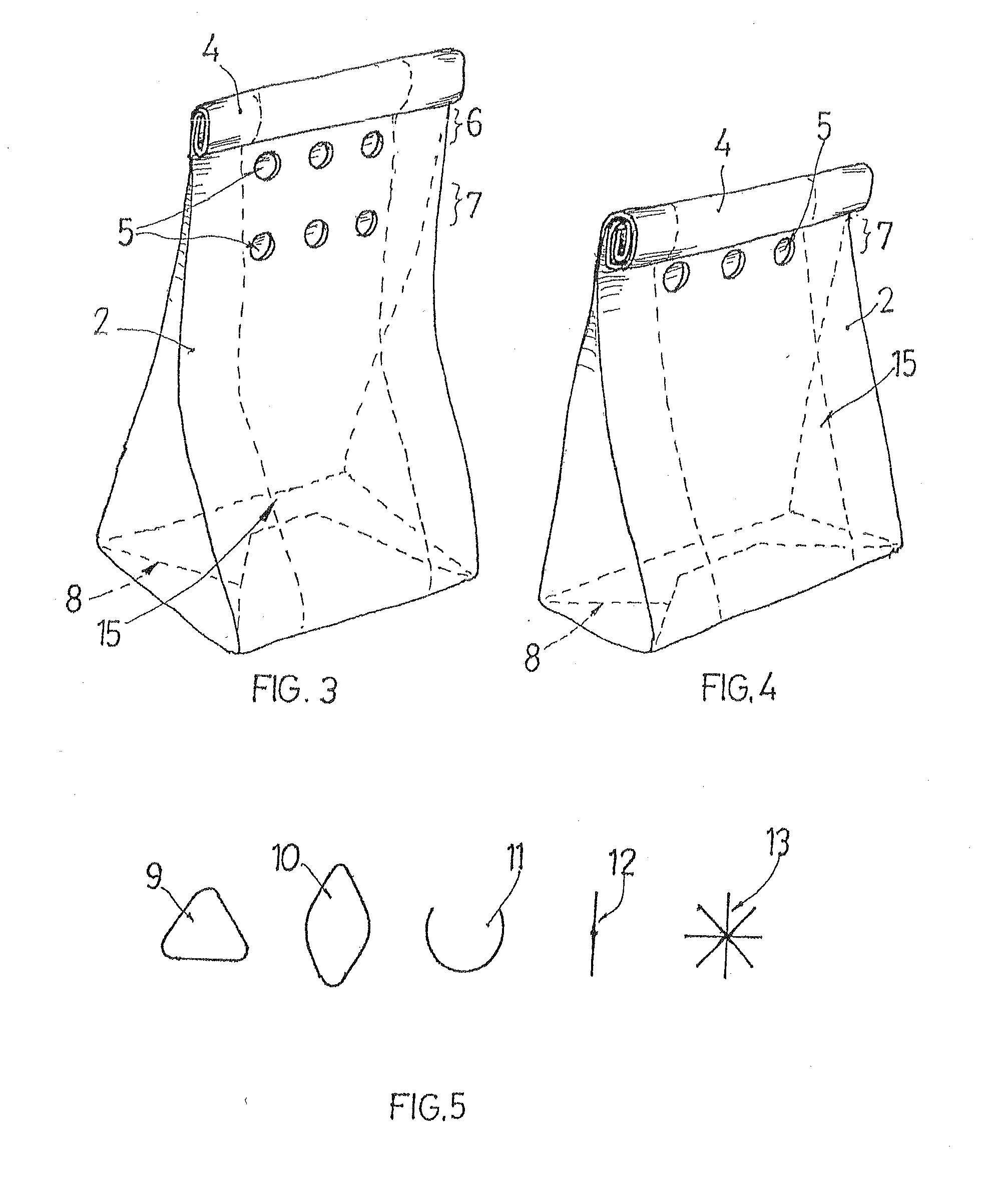

Paper bag with integrated handle

On the top part of the pleated-style bag (1) or “American”-style bag (2), without pleat, and near its open edge, it has some die cut drill holes with a rectangular (3) or circular (5) shape, located at a sufficient distance from the top edge to allow performing some folds (4) to close the bag (1) or (2), being said die cut drill holes (3) or (5) located just below said folds (4), defining the height, from the folds (4) to the base (8) of the bag, for its usable capacity. In the “American”-style bag (2) there is a second area (7) of die cut drill holes, which allows performing more folds (4) when closing the bag (2). It optionally has two reinforcements made of paper, fabric or cotton mesh, attached to the inner sides and in the area of the die cut drill holes, which can have a rectangular shape (3) with its flap (3a), and a circular (5), triangular (9), ovoid (10), semi-circular (11) slanted (12) or multi-slanted (13) shape.

Owner:TEIXIDO VIDAL JOSEP +1

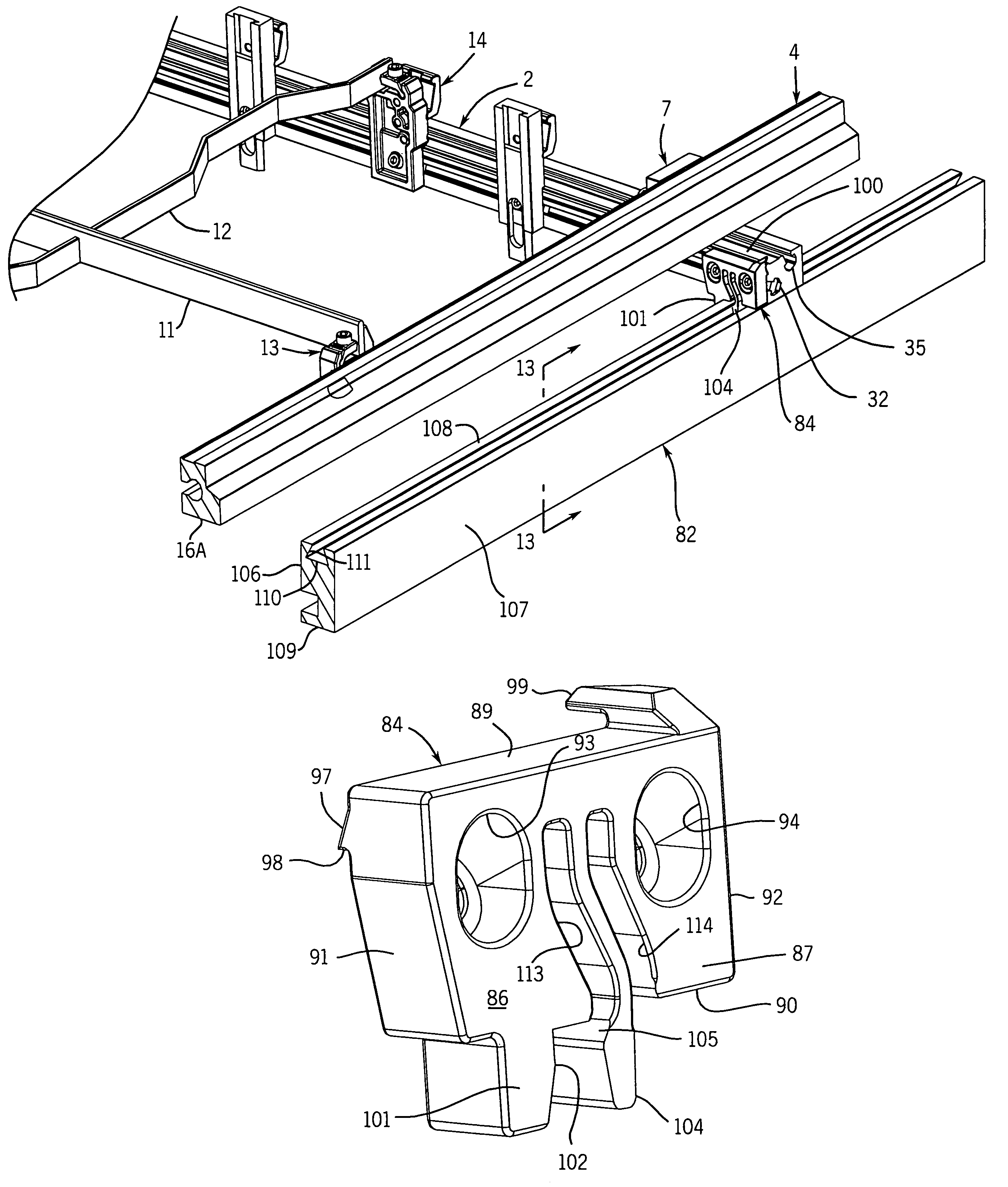

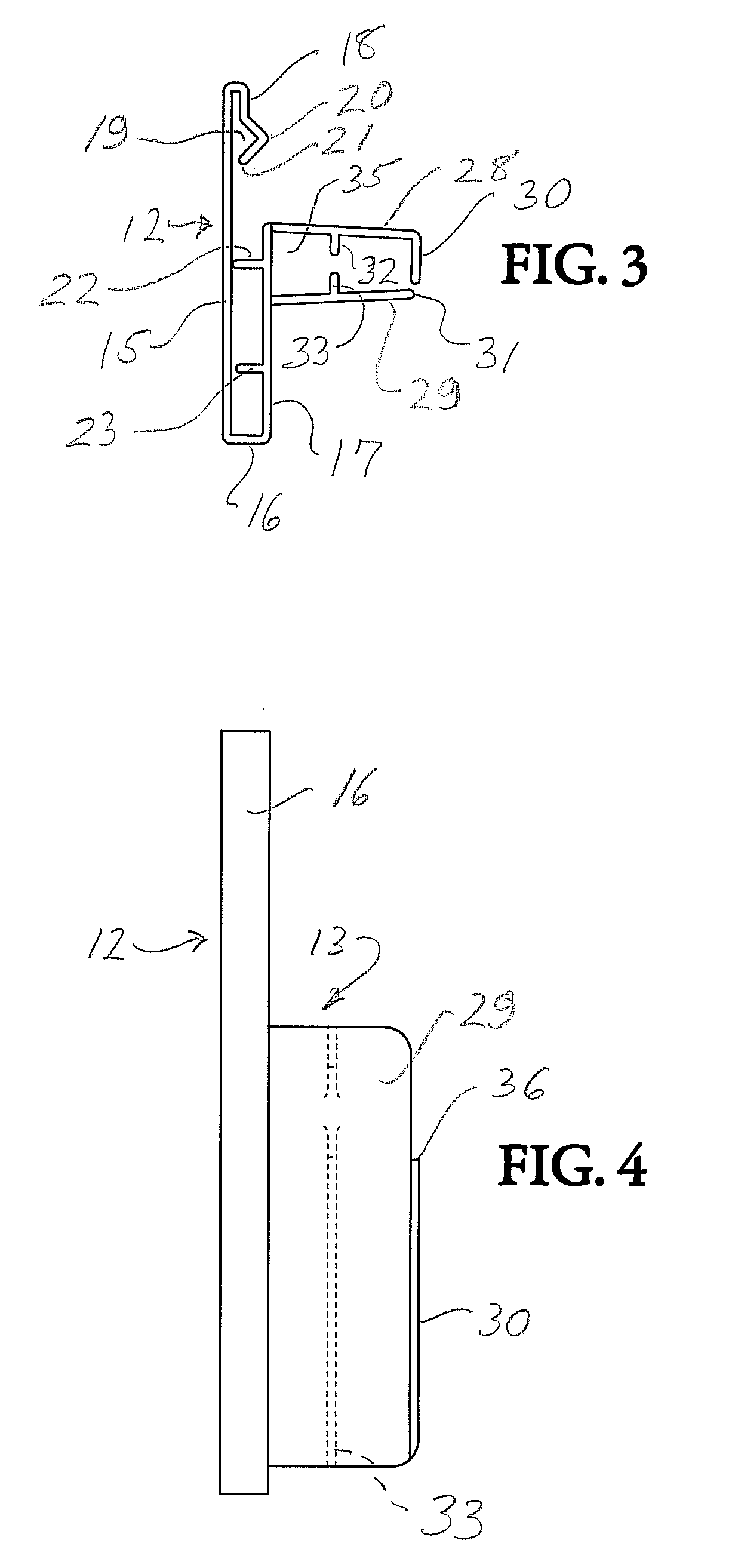

Locator bracket for the lower frame assembly of a blanking tool

InactiveUS6997364B2Easy to assemblePrecise positioningMetal working apparatusArticle deliveryDetentCarton

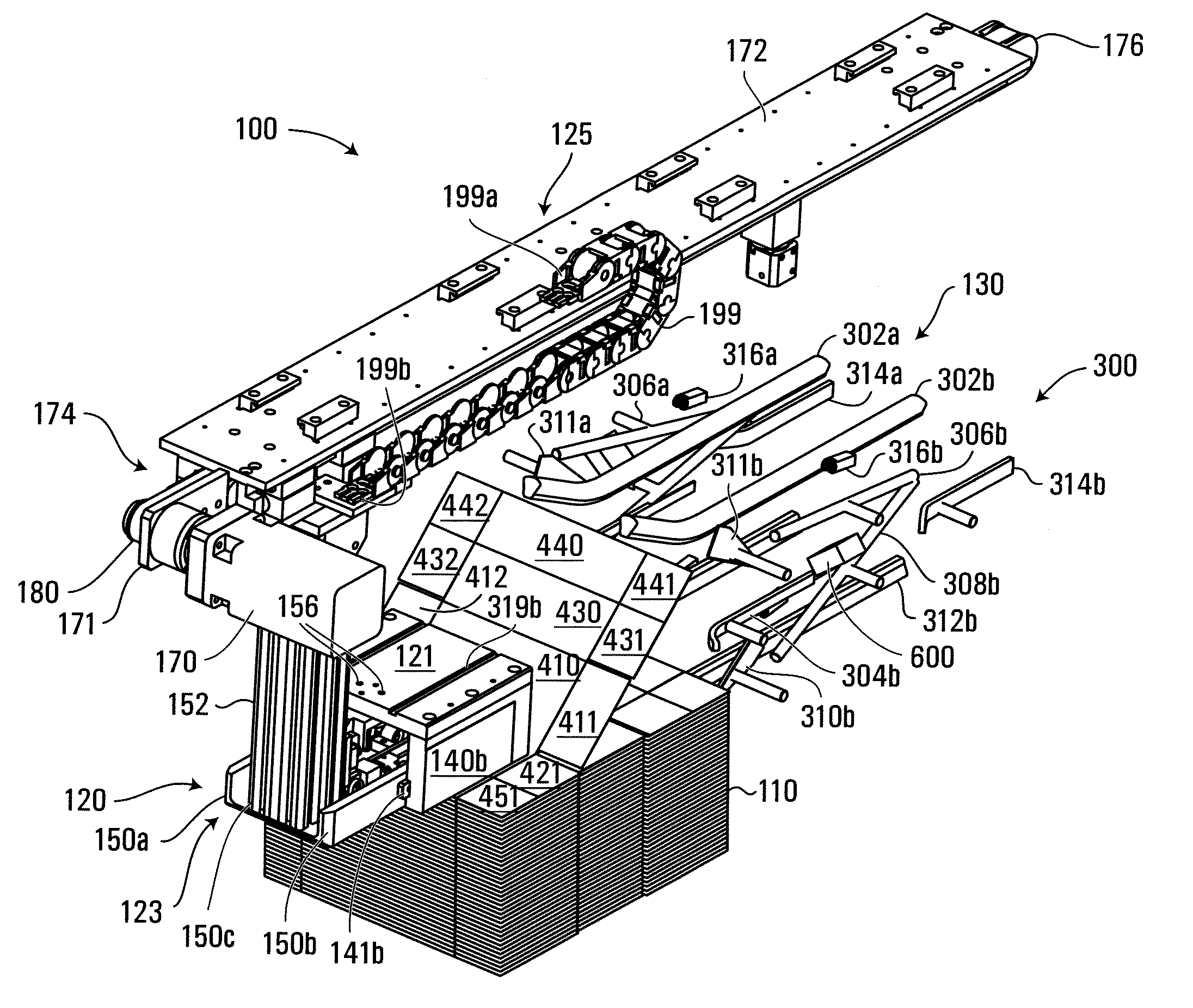

A bracket for properly locating a lower blanking tool with respect to a pull-out frame during a blanking operation in a carton die cutting machine. The bracket is mounted on the inner side of a side rail for the lower blanking tool and includes a projecting spring member releasably engageable within a groove formed in the top side of a corresponding cross rail of the pull-out frame. The bracket also includes a projecting datum member engageable with the inner side of the pull-out frame's cross rail to aid in positioning the lower blanking tool on the pull-out frame.

Owner:BLANKING SYST

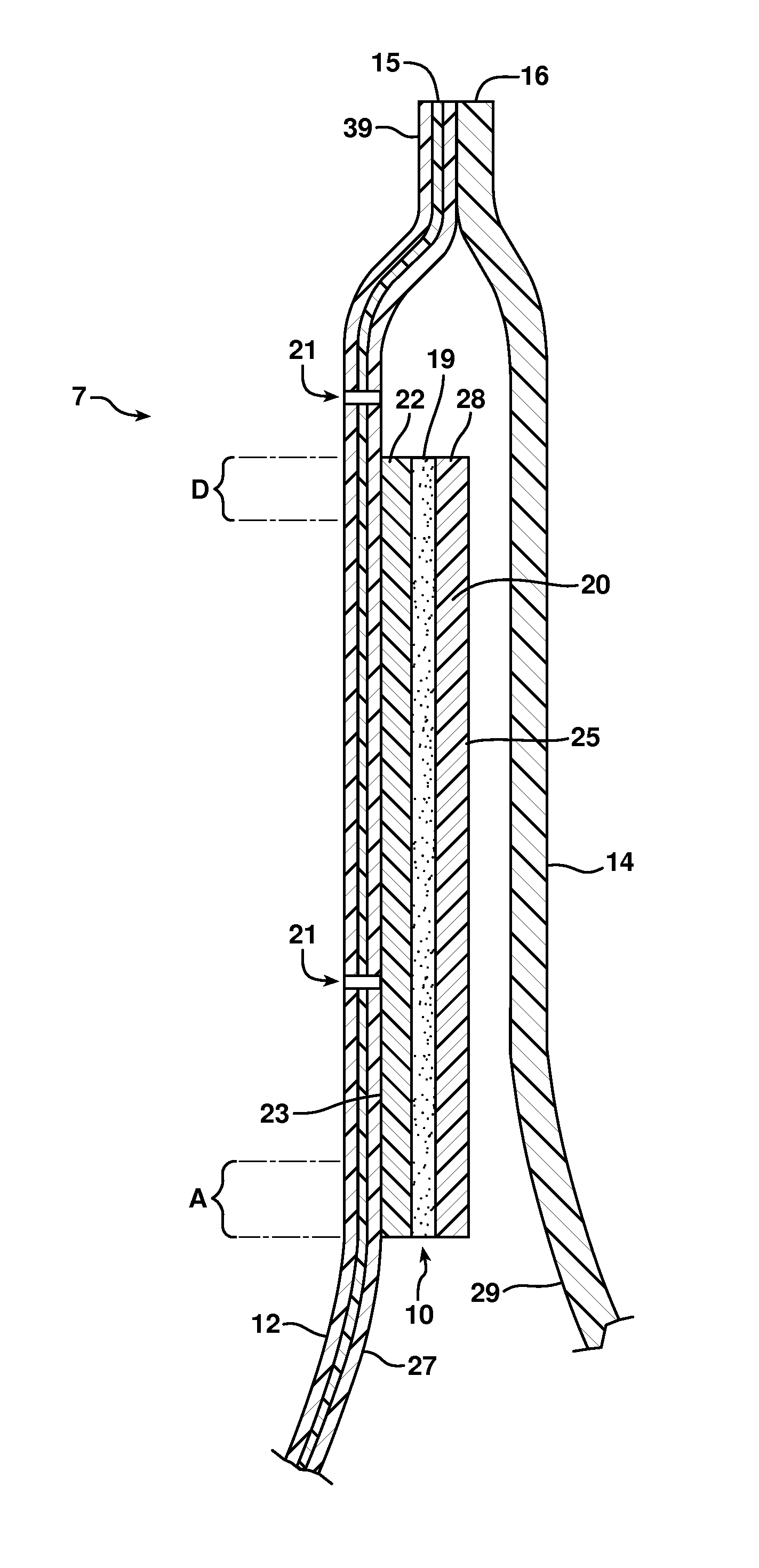

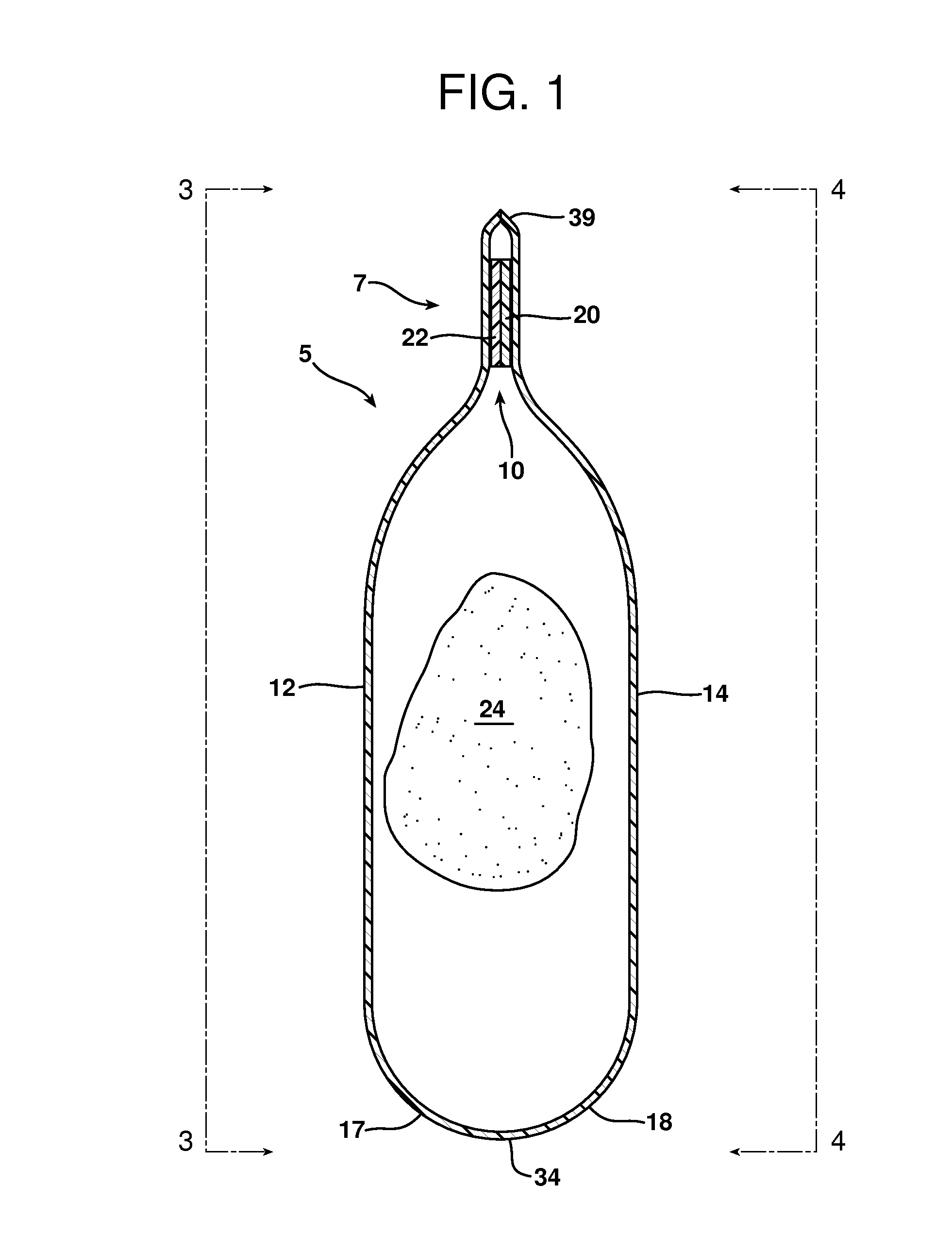

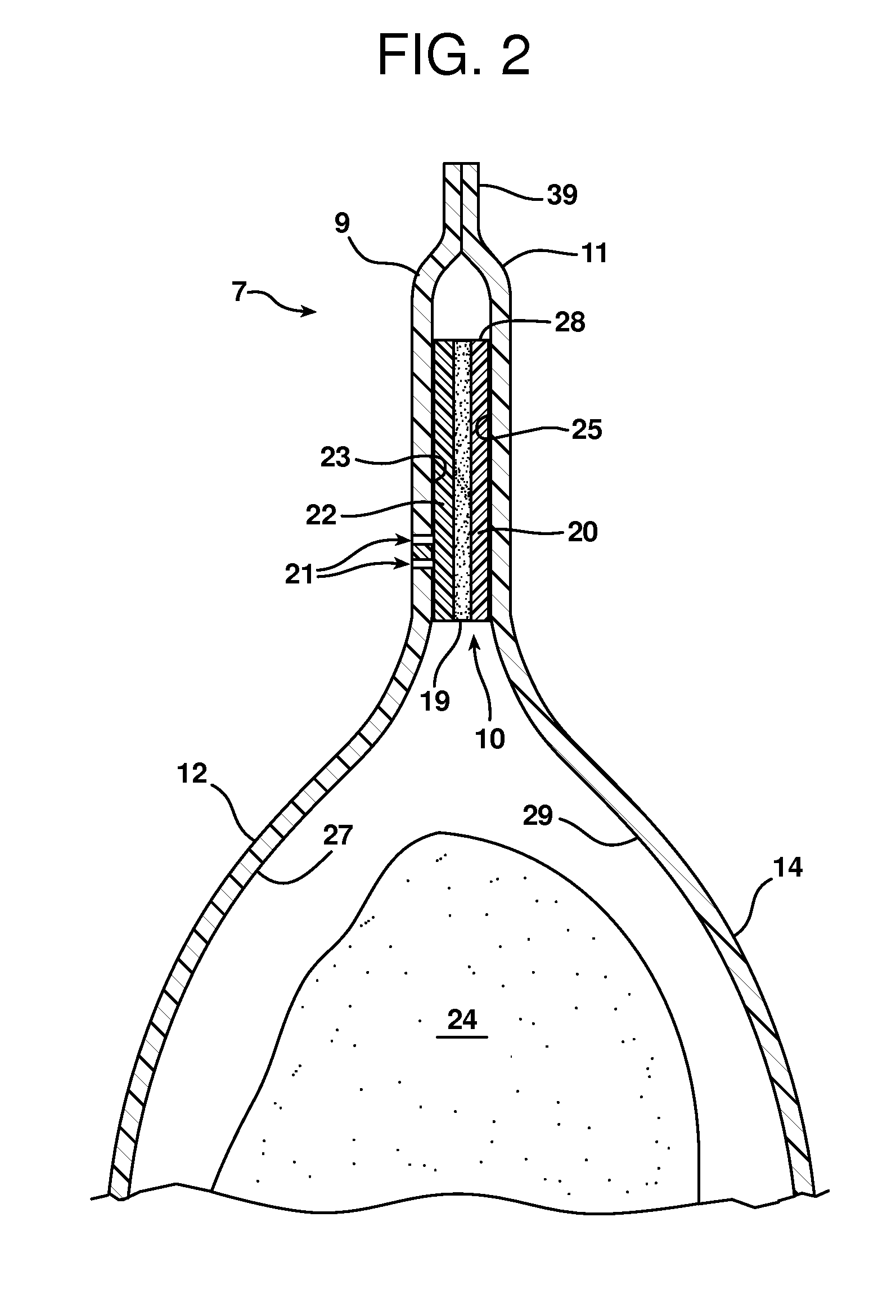

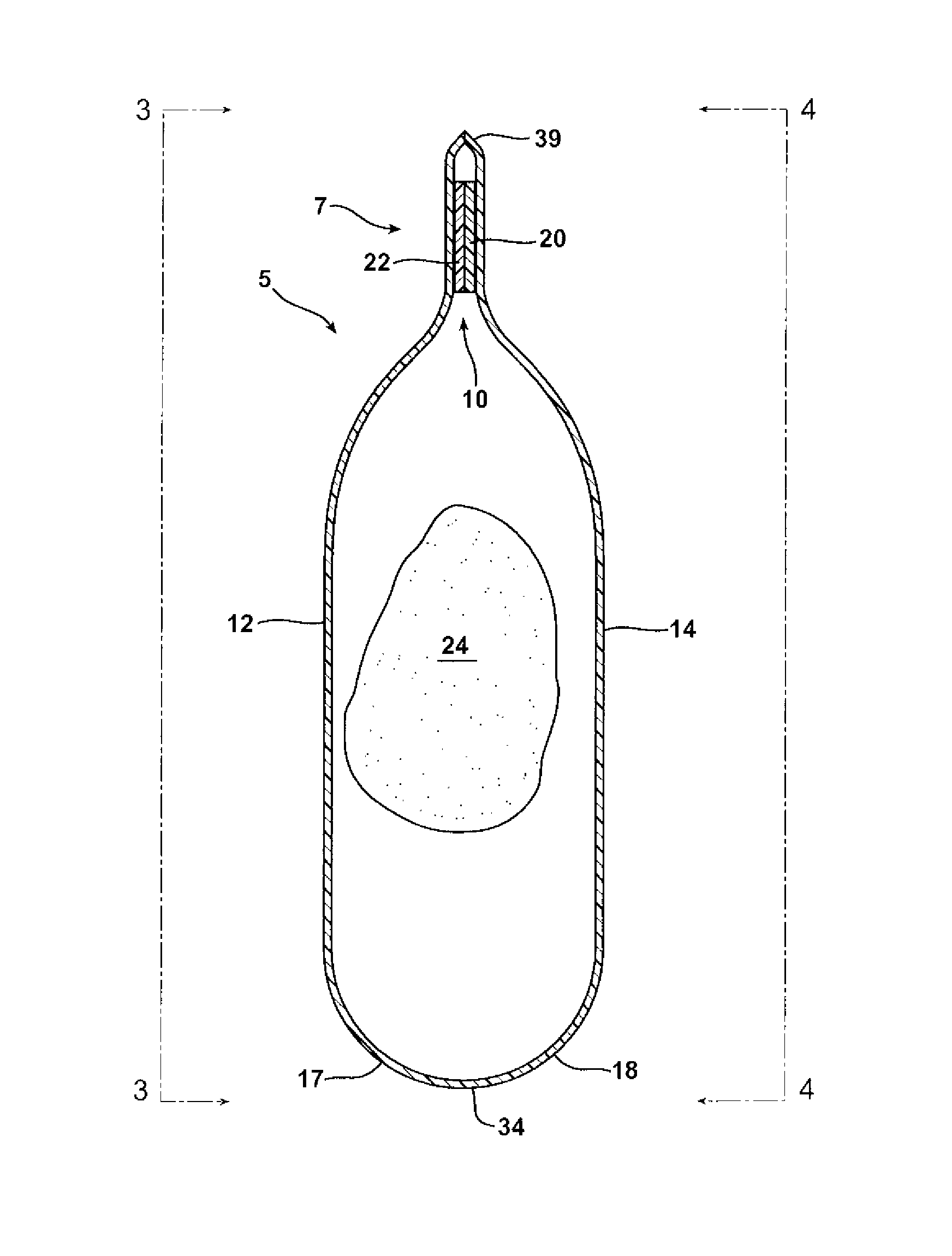

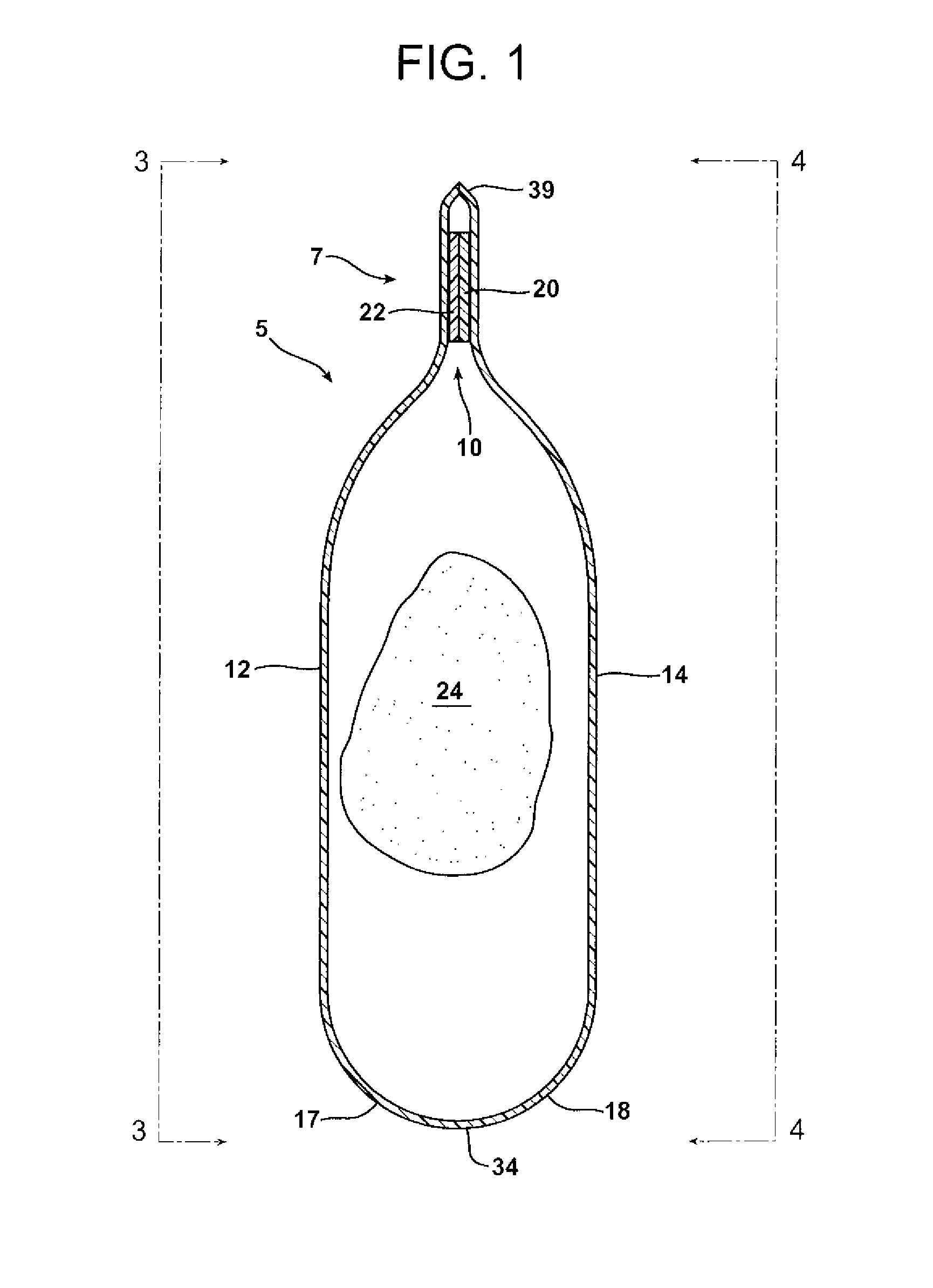

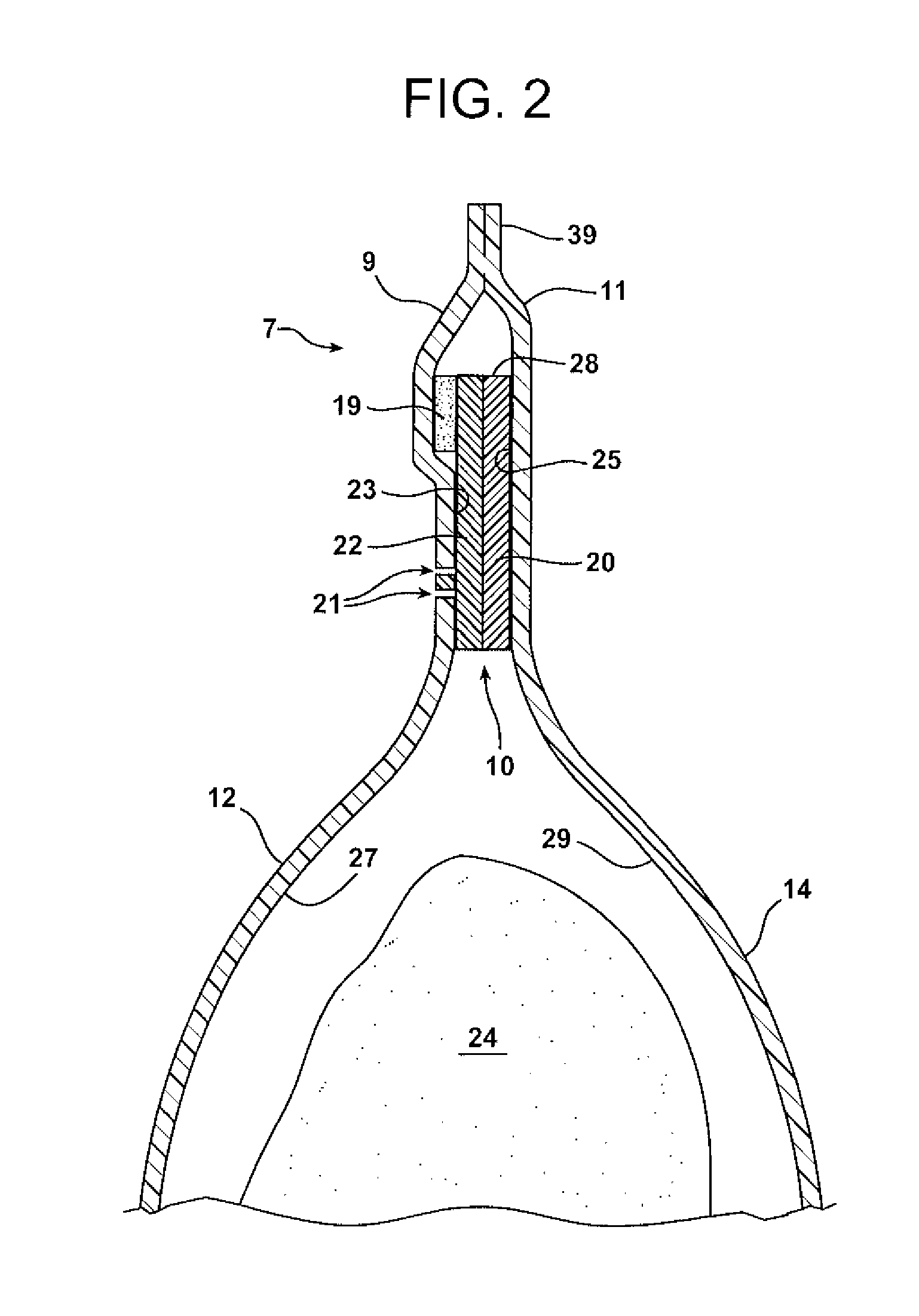

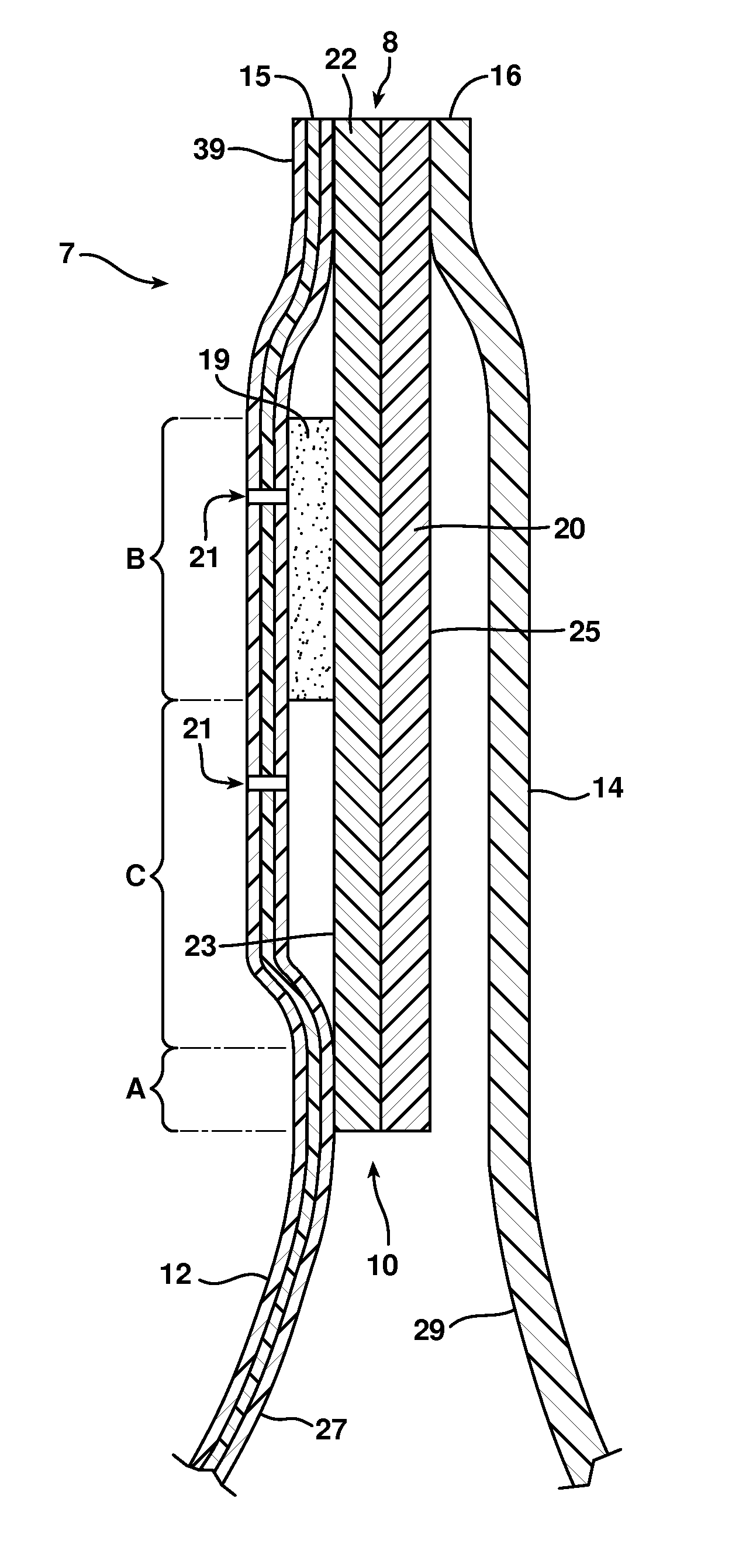

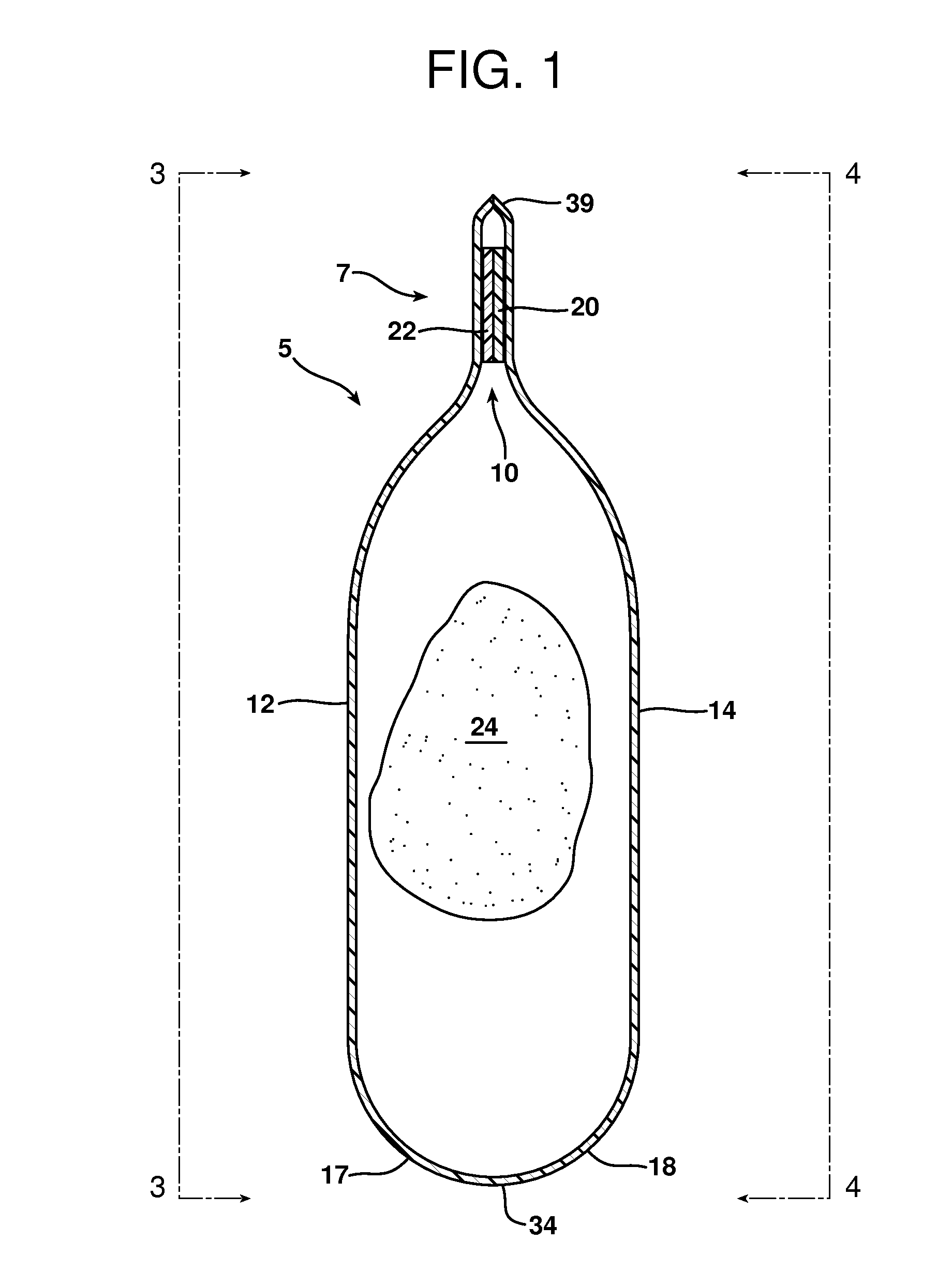

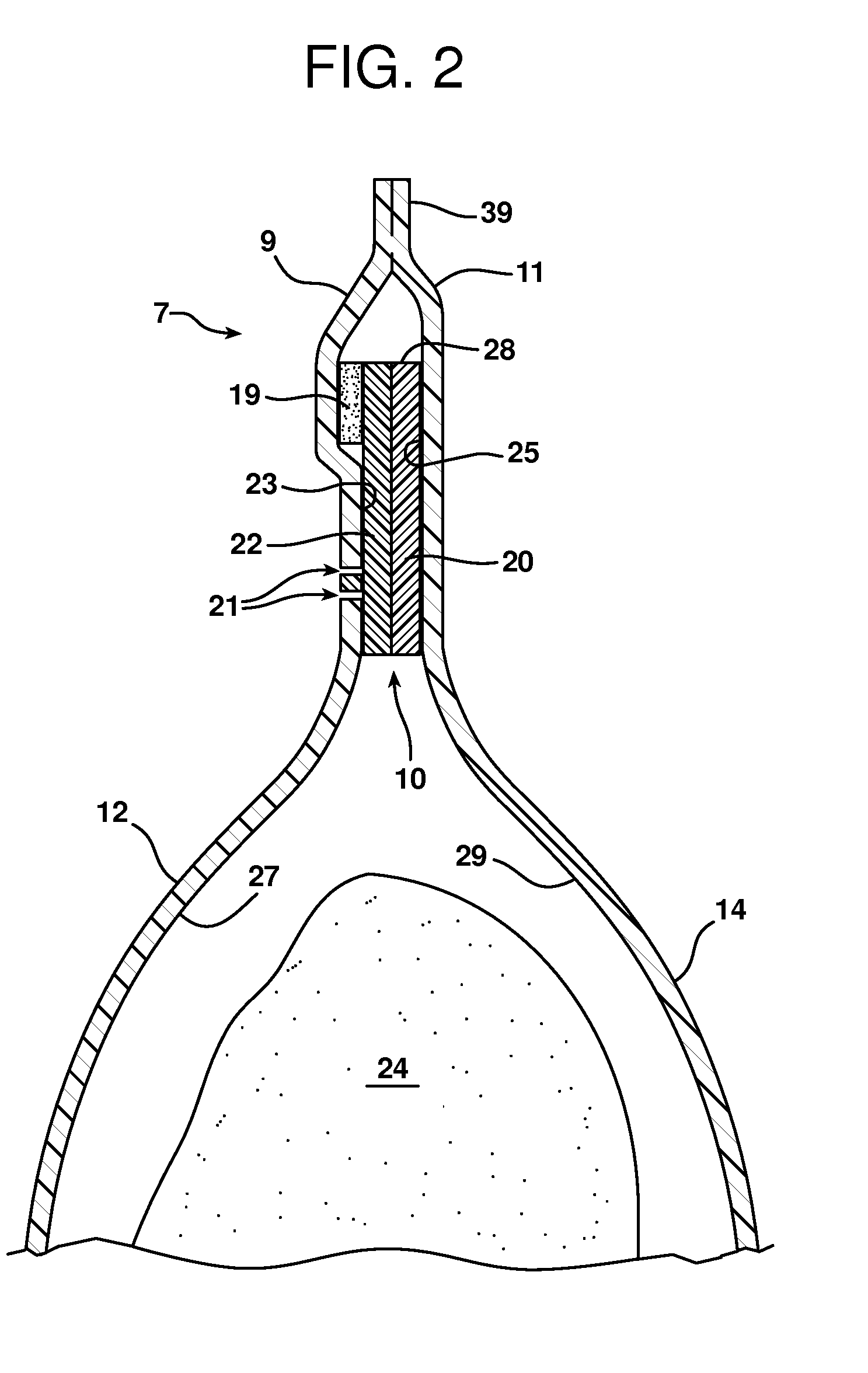

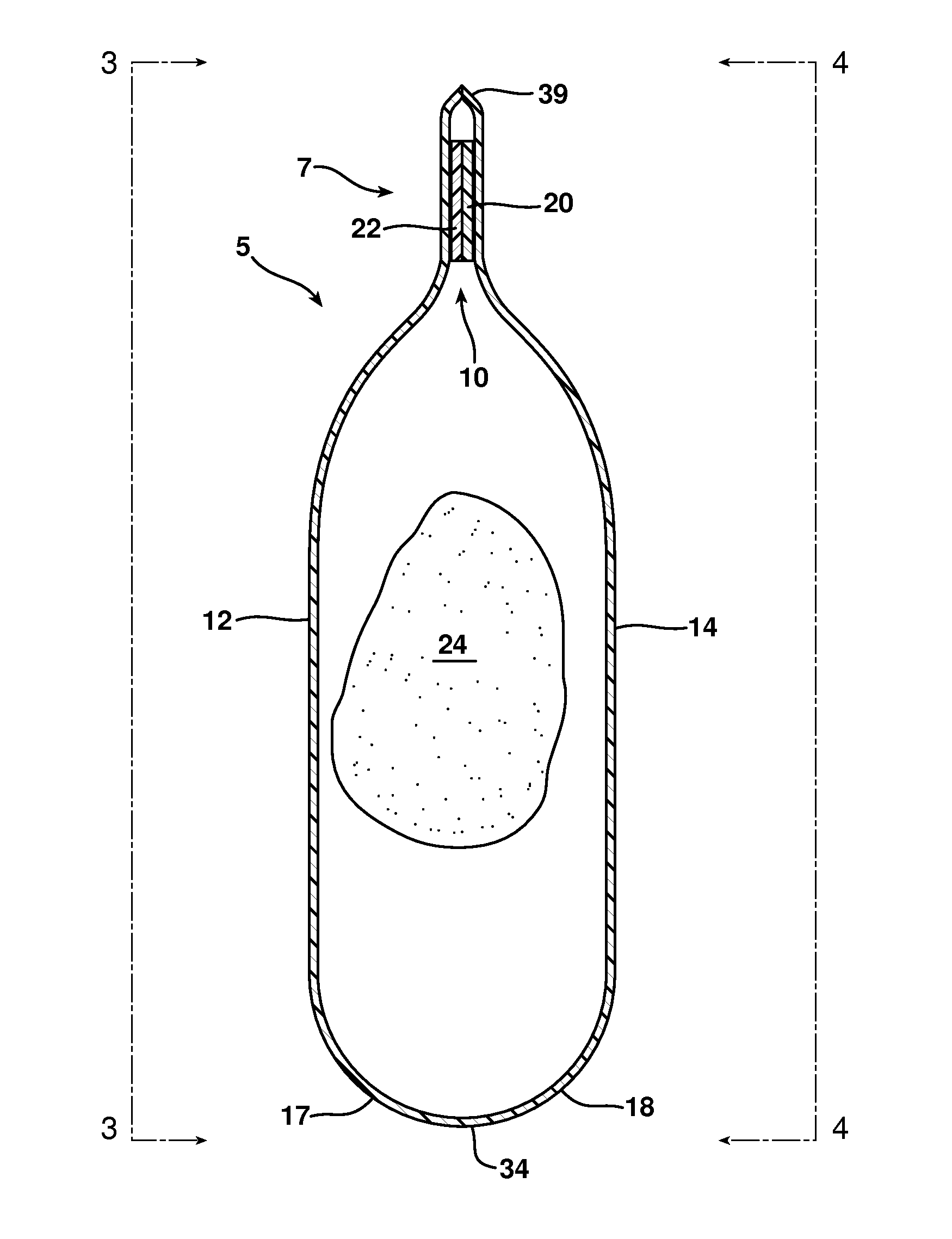

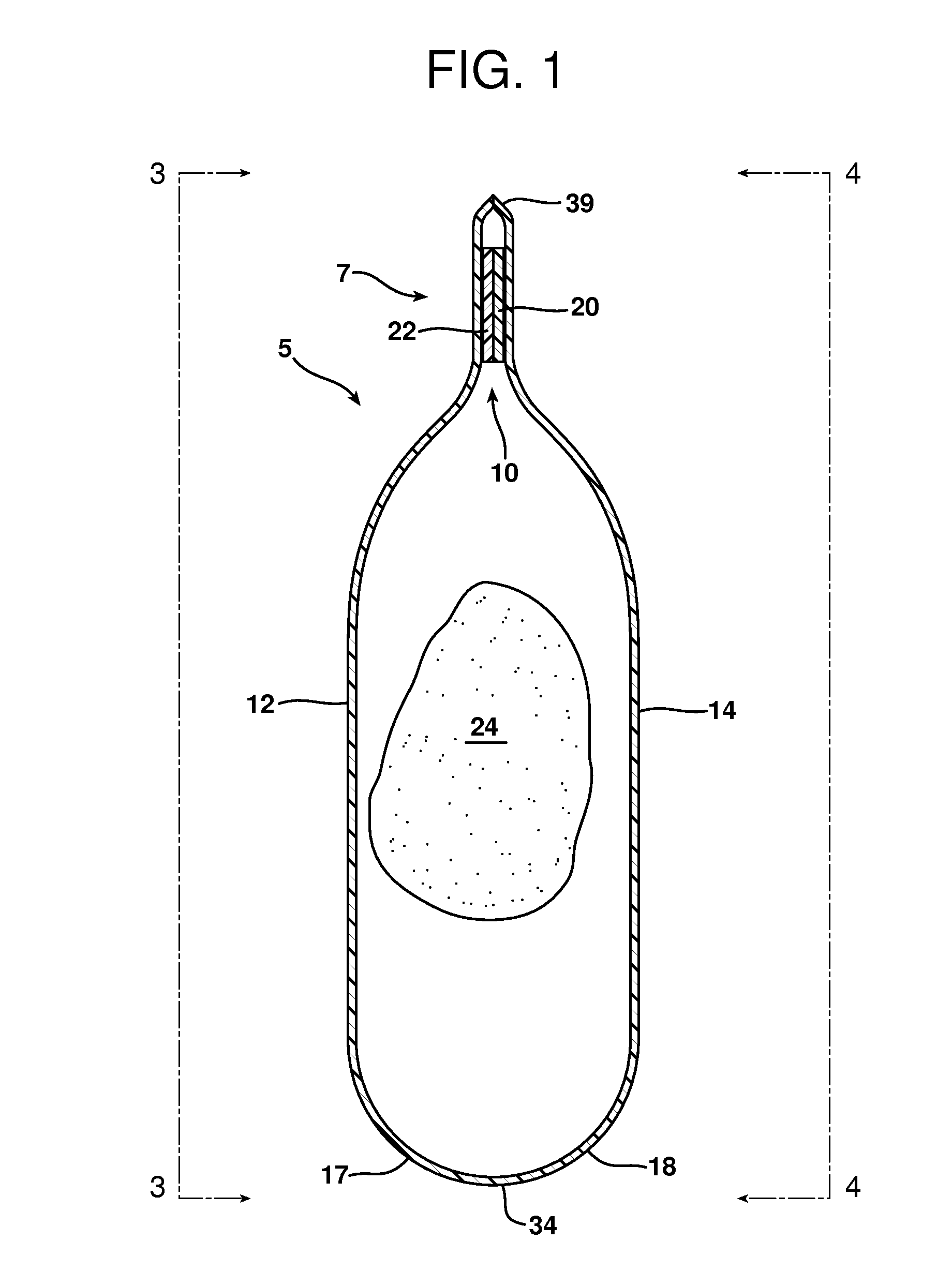

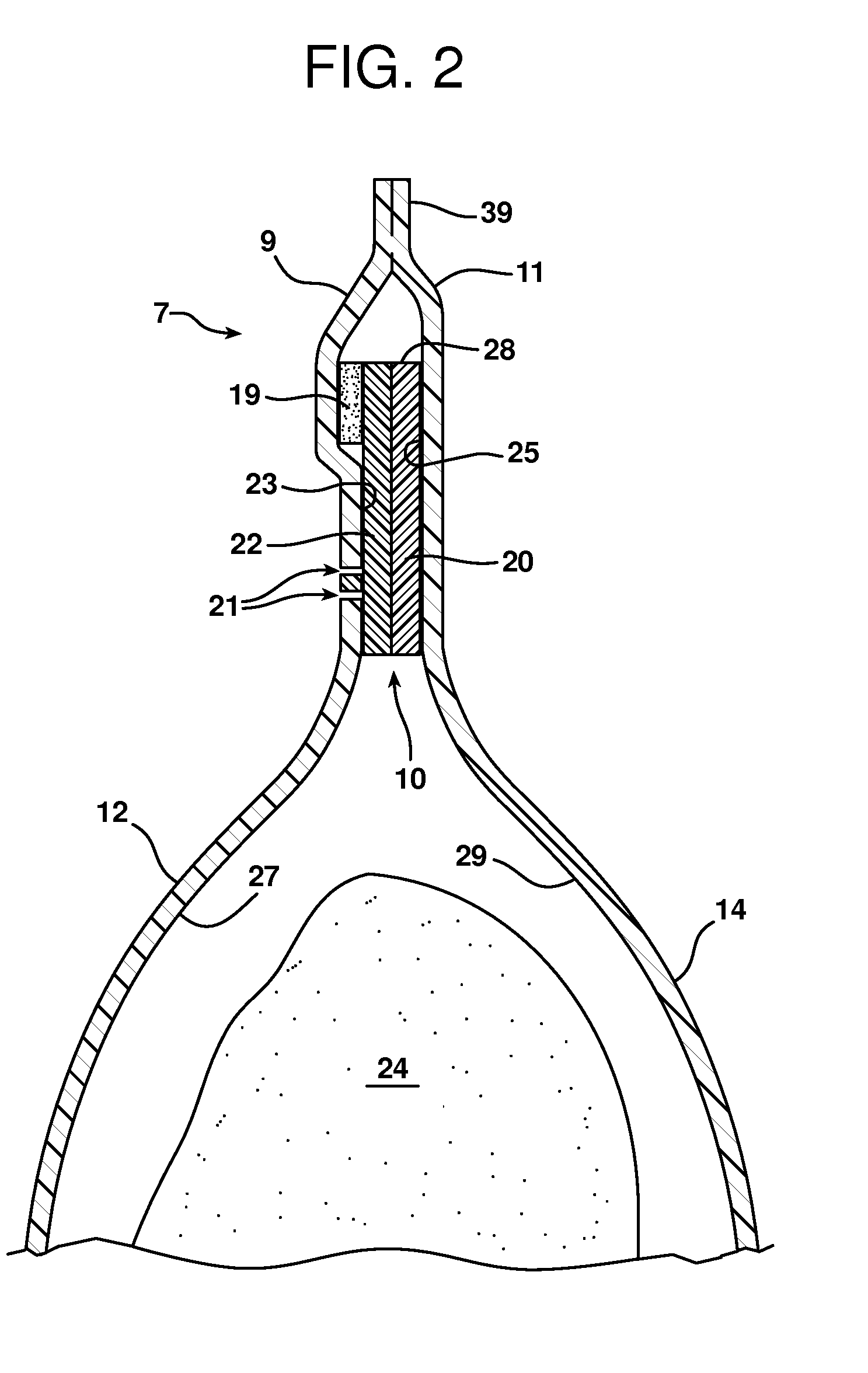

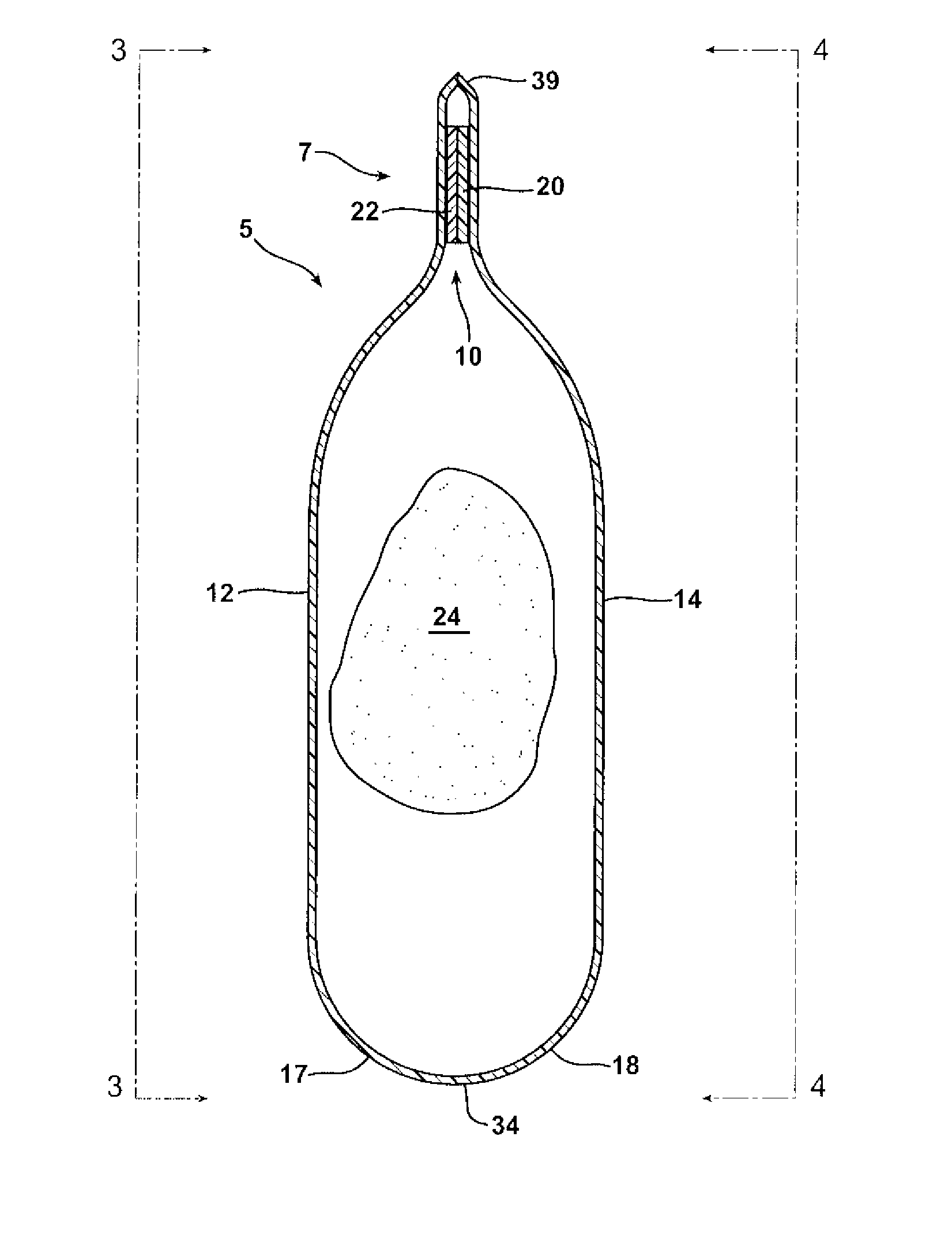

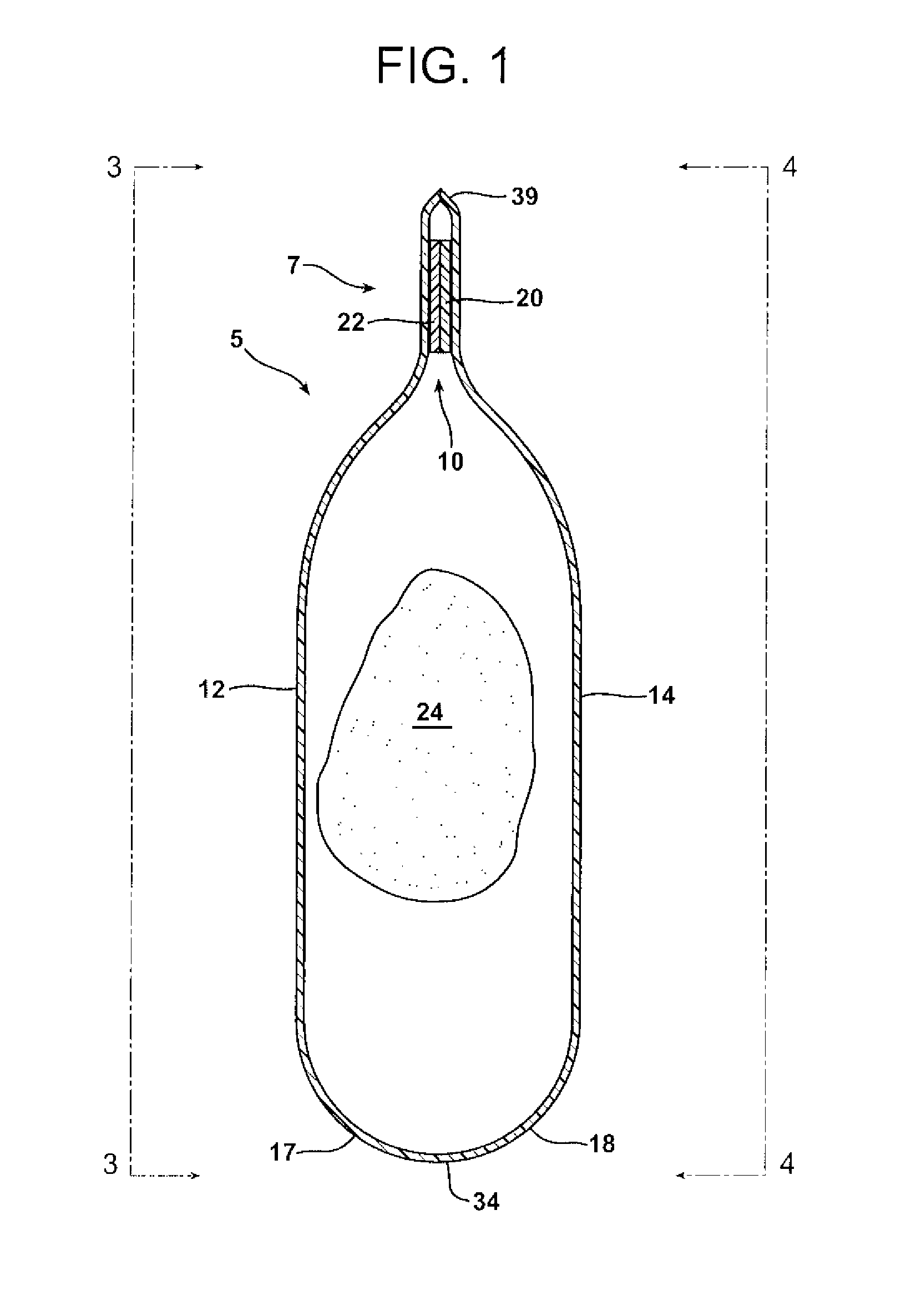

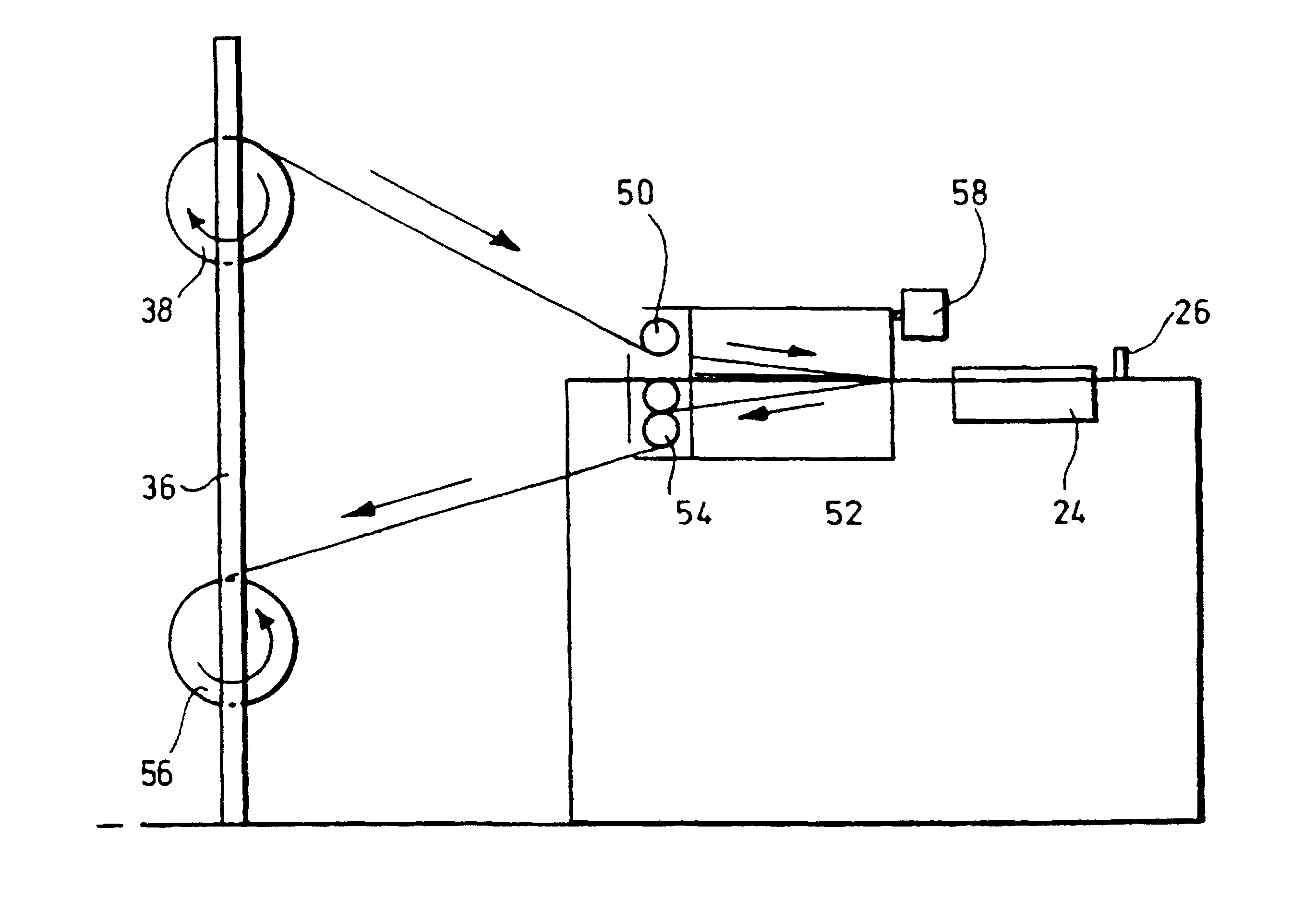

Easy Open and Reclosable Package with Discrete Strip and Die-Cut Web

An easy-open and reclosable package includes a pouch including a discrete strip, between first and second side panels, including a sealing segment, a backing segment, and an intermediate layer including a pressure sensitive adhesive; a first portion of the strip anchored to the first panel at a first location, and a second portion of the strip anchored to the first panel at a second location; a die cut in the first panel defining a die cut segment, so arranged that when the package is opened, the sealing segment is partially removed from the discrete strip, the intermediate layer comprising a pressure sensitive adhesive is partially exposed, and the package can be reclosed by adhering at least one of the first and second panels to the adhesive; and a product in the pouch.

Owner:CRYOVAC INC

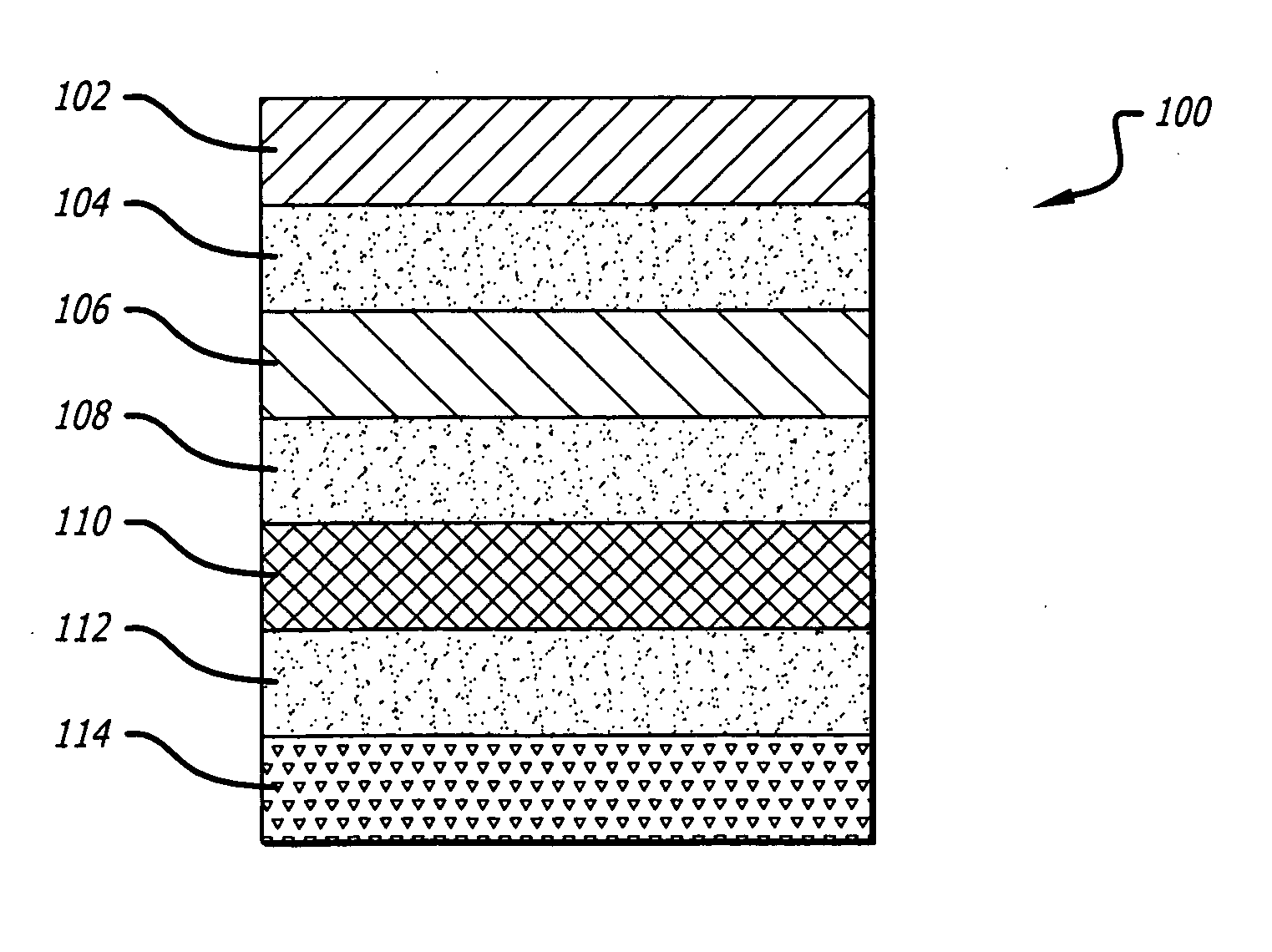

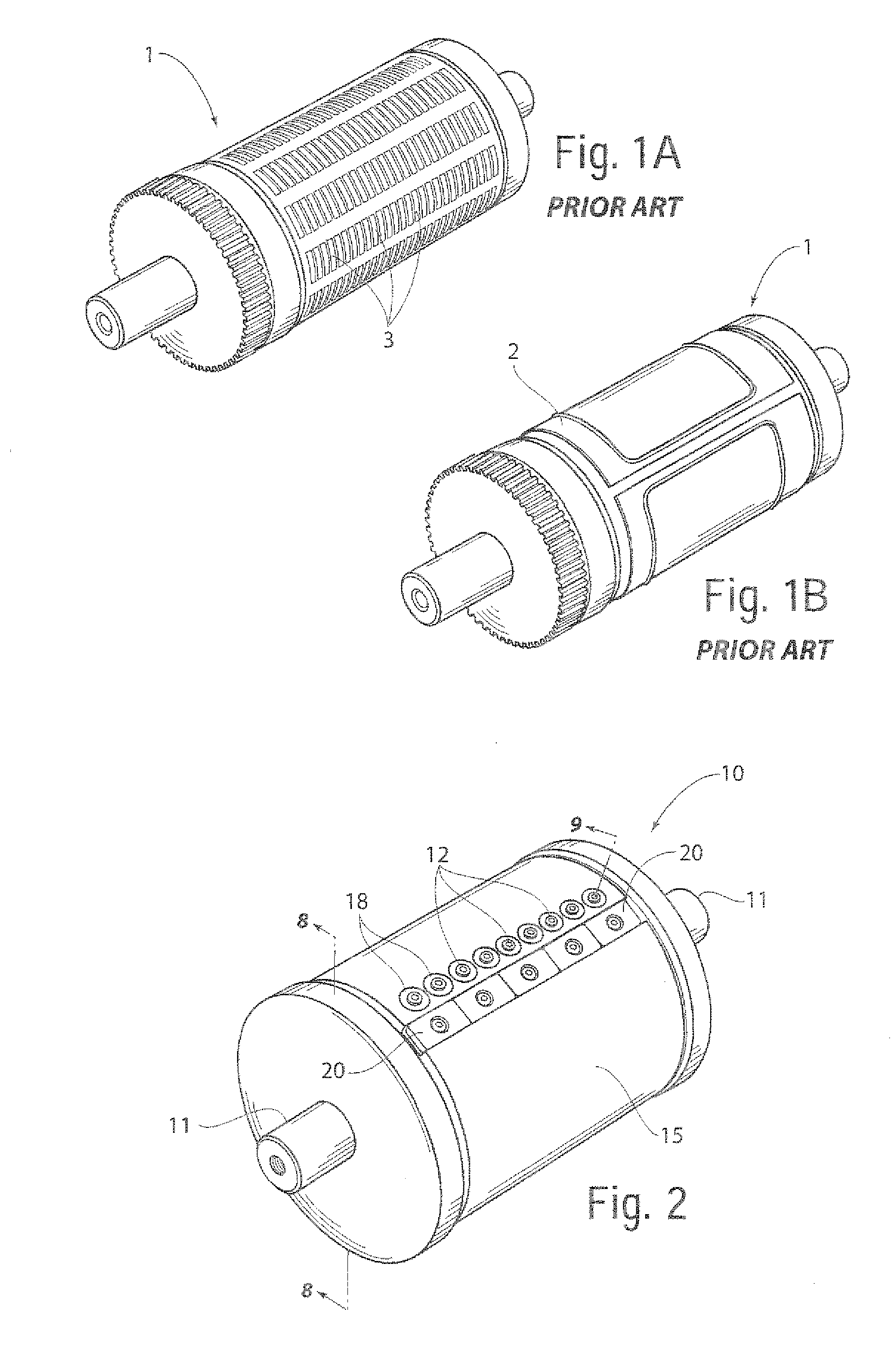

Novel enhanced high temperature tapes for high velocity Oxy fuel processes

InactiveUS20070110942A1Increase resistanceHigh strengthFilm/foil adhesivesAdhesive articlesMetal foilAdhesion strength

A finished high velocity oxy fuel (HVOF) tape used with, for example, during known HVOF processing imparts high temperature silicone pressure sensitive adhesives that provide enhanced adhesion strength to provide a firm adhesion to its own backing and unexpectedly leave no residue upon removal from metals. The novel enhanced tapes are made up of coated or uncoated, woven or non-woven glass cloth and ceramic based fabric laminated to at least one side of a metal-foil using a silicone based laminating adhesive, which is then laminated with another layer of a pre-selected combination of the same materials and coated with a high temperature silicone pressure sensitive adhesive and wound to itself to make a self wound tape or covered adhesive assembly with a release liner to make a laminated sheet for die cut samples, among other things. Applications including military and commercial aircraft, automobiles and metal finishing usages leverage of on the unique and inherent benefits of the novel enhanced tapes of the instant teachings.

Owner:SCAPA NORTH AMERICA

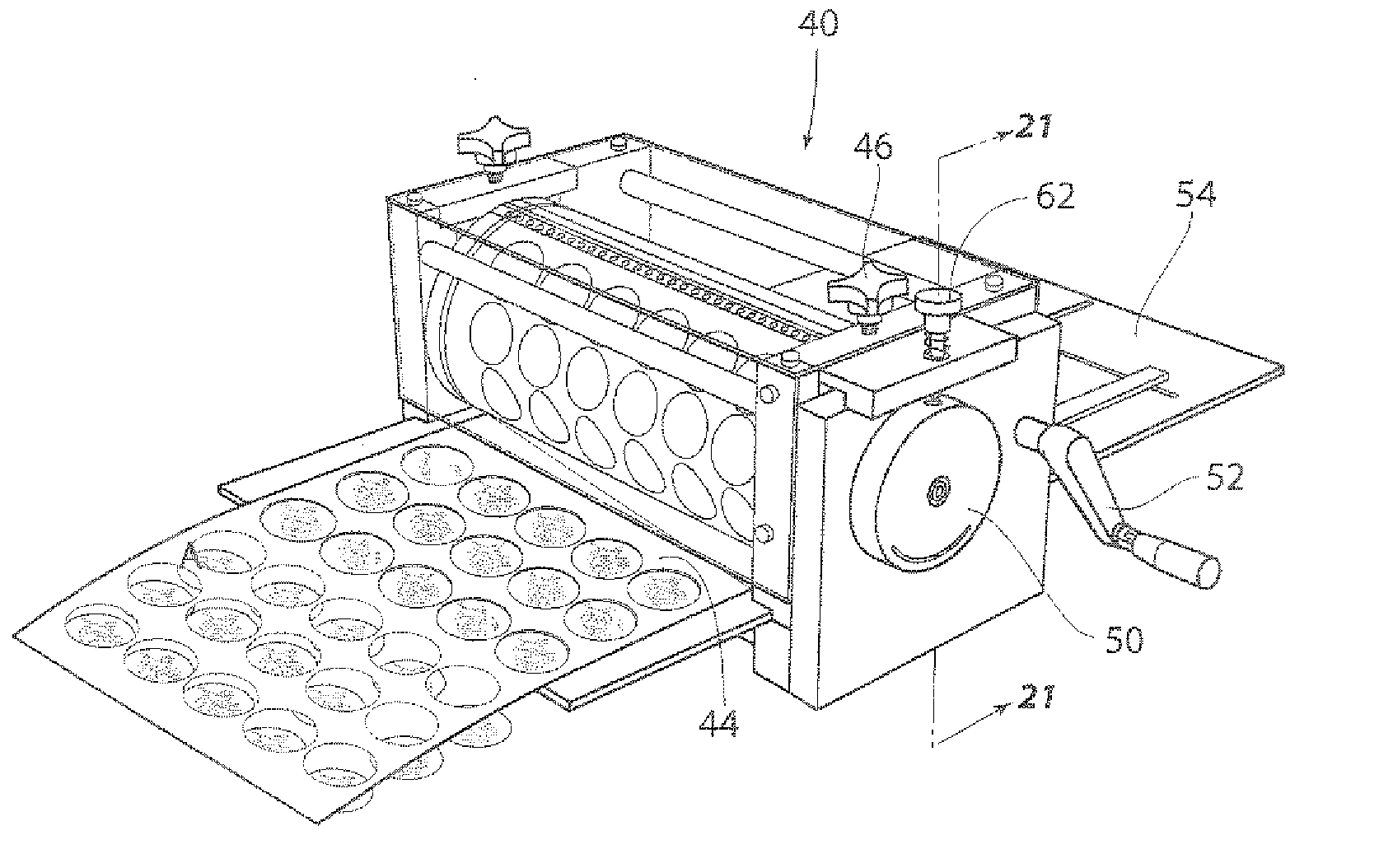

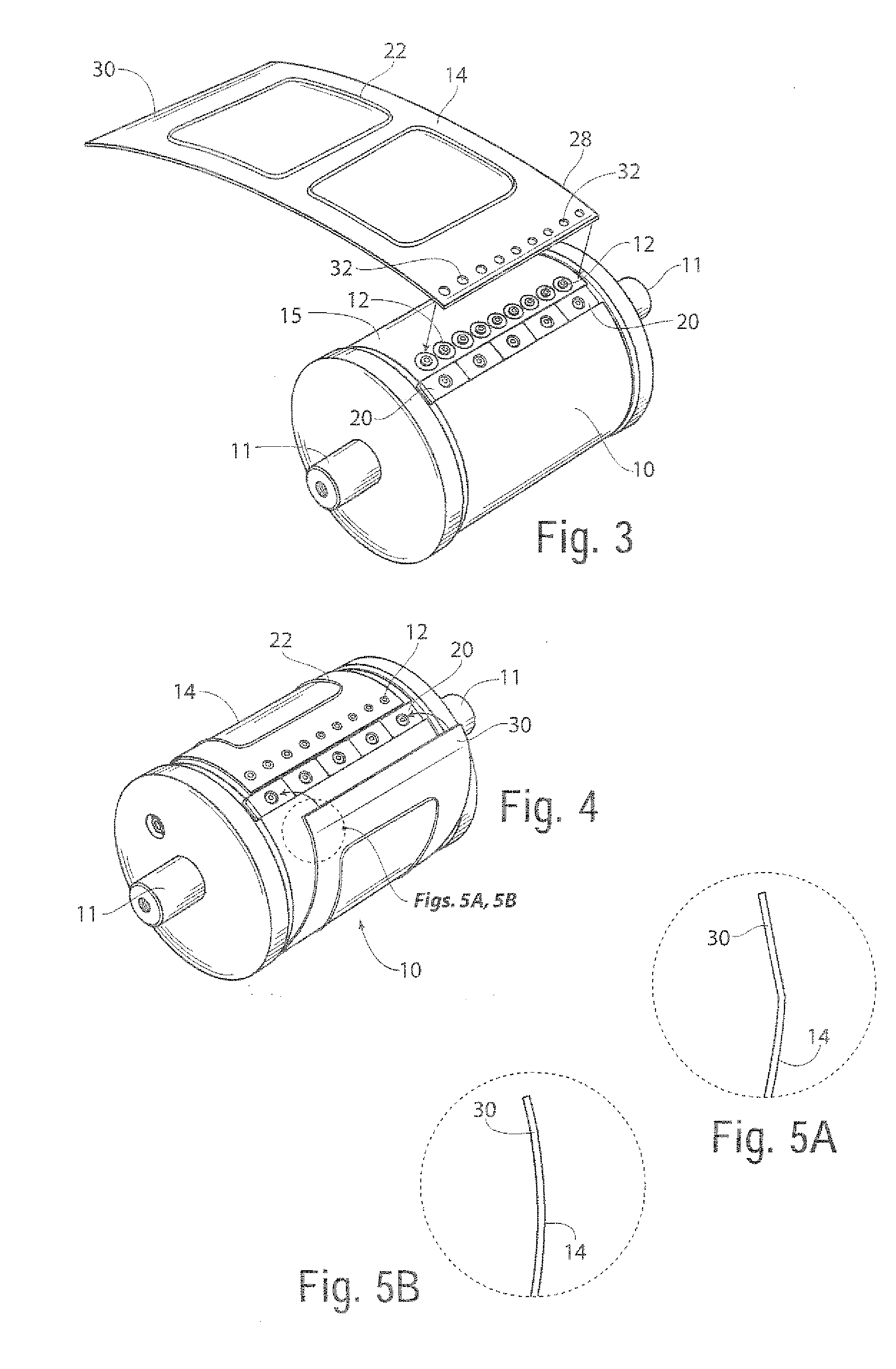

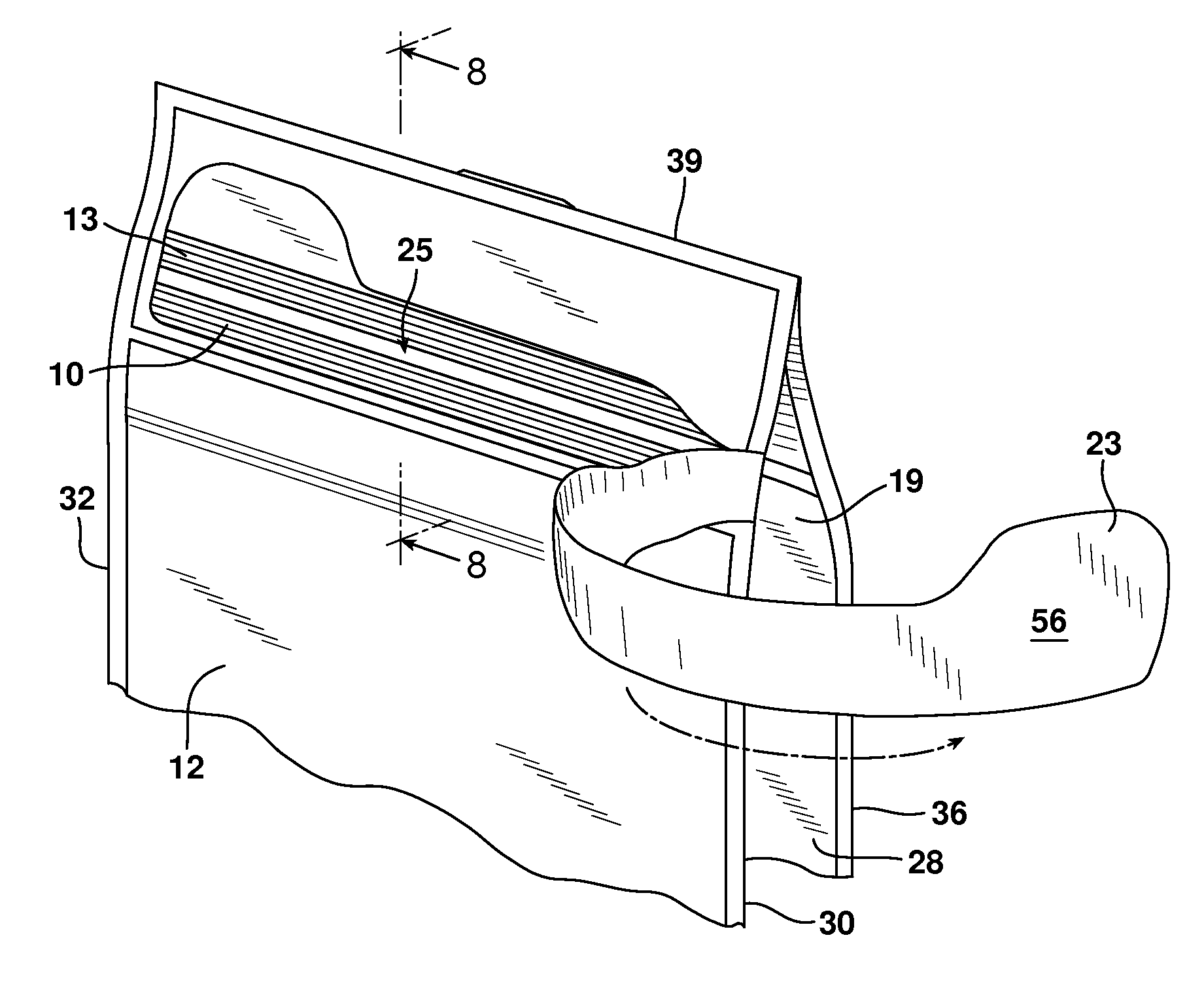

Flexible die retaining system and method

InactiveUS20140260851A1For accurate cuttingStock shearing machinesMetal working apparatusEngineeringDie cutting

A method and apparatus for producing shaped articles from a web material is disclosed. The apparatus generally includes a rotary cylinder adapted to receive a flexible cutting die, and an anvil roller operating in cooperating rotational movement with the rotary cylinder. The cylinder includes attachment mechanisms that are adapted to be received by apertures in the flexible cutting die to thereby secure the cutting die to the cylinder. The apparatus die cuts web material into predetermined shapes.

Owner:BEAUDRY WALLACE J

Easy Open and Reclosable Gusseted Package with Die-Cut Web and Reclosure Mechanism

An easy-open / reclosable gusseted package includes a reclosure mechanism including a first and second interlocking strip; a die cut in a first panel and in a first and optionally a second gusset. The die cut defines a die cut segment spaced from the first and second ends of the package that can be displaced to open the package and access a contained product between the interlocking strips, the interlocking surfaces being at least partially exposed. The package can be reclosed, after removing the die cut segment, by engaging the interlocking surface of a second portion of the first interlocking strip with itself in the first gusset, and optionally a third portion of the first interlocking strip with itself in the second gusset, folding the package, and engaging the interlocking surface of the second interlocking strip with the interlocking surface of the first portion of the first interlocking strip.

Owner:CRYOVAC ILLC

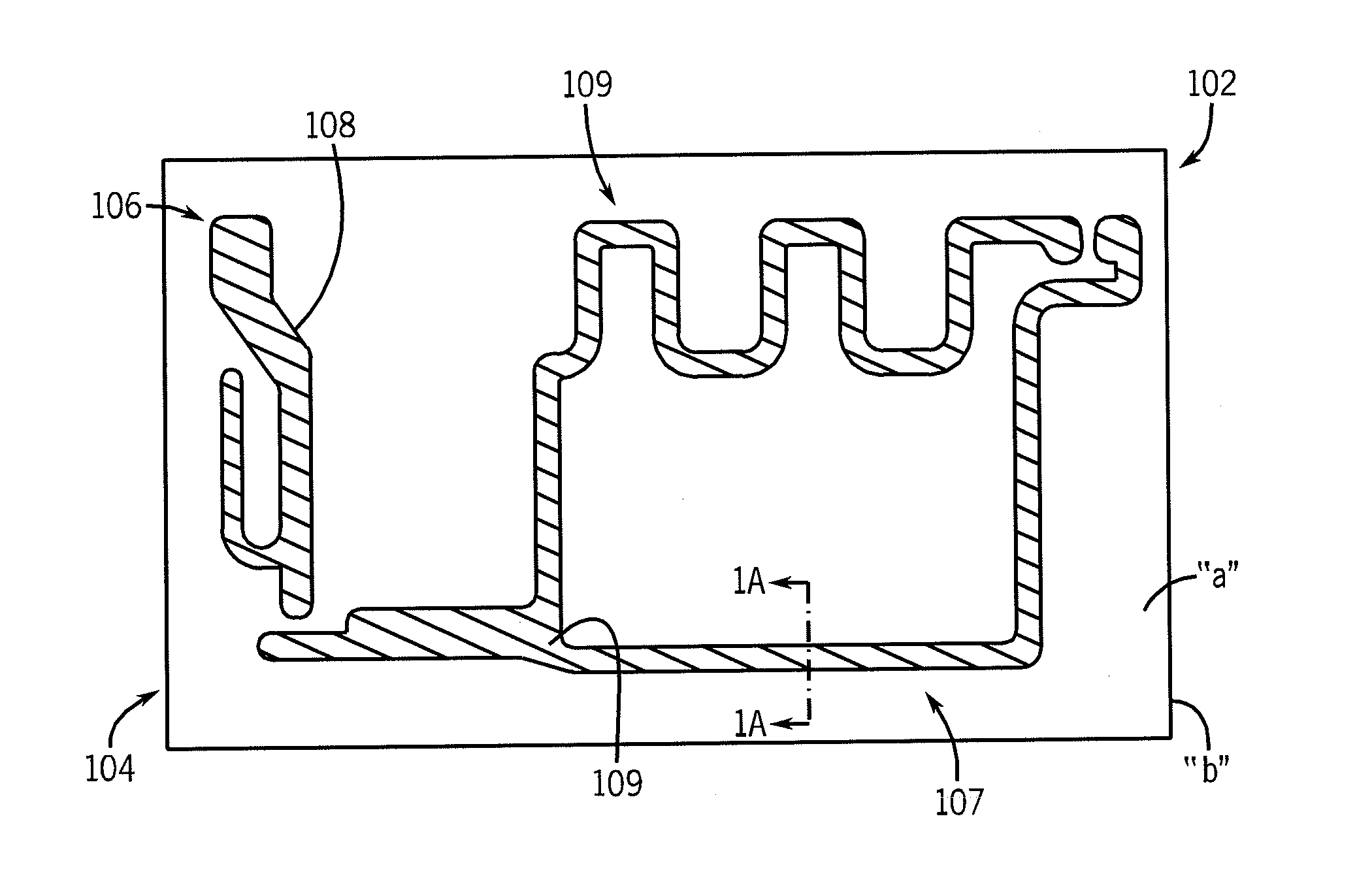

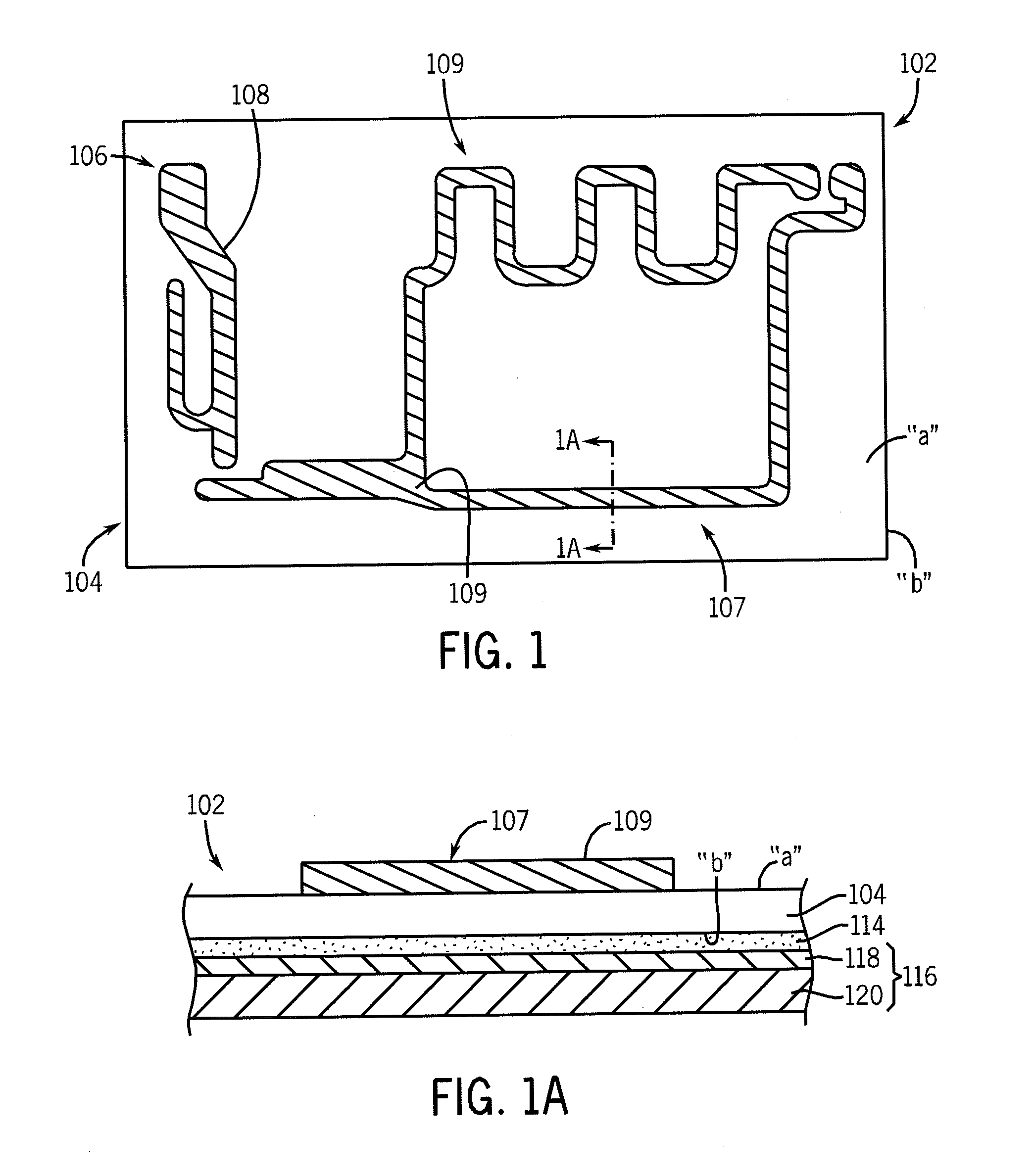

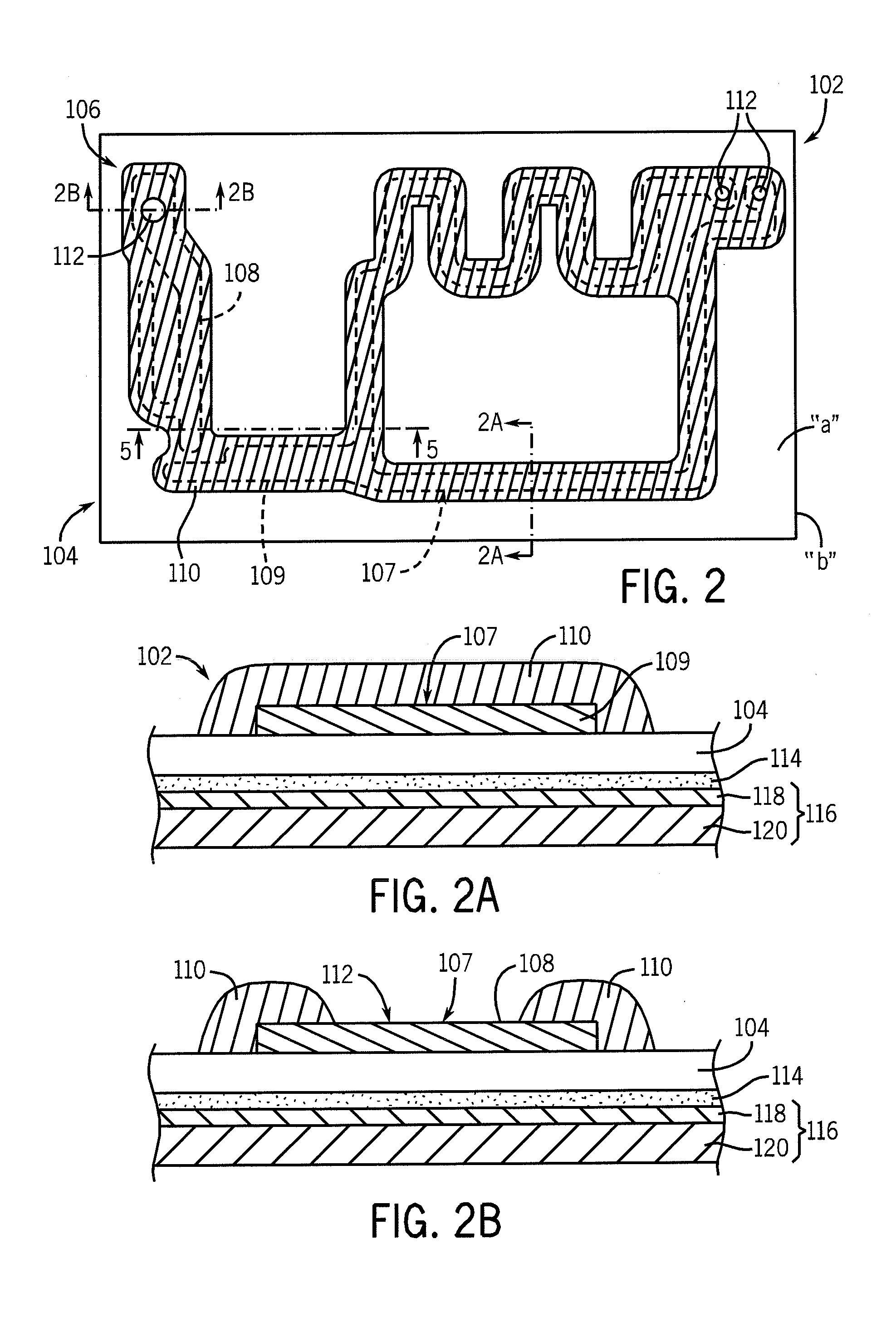

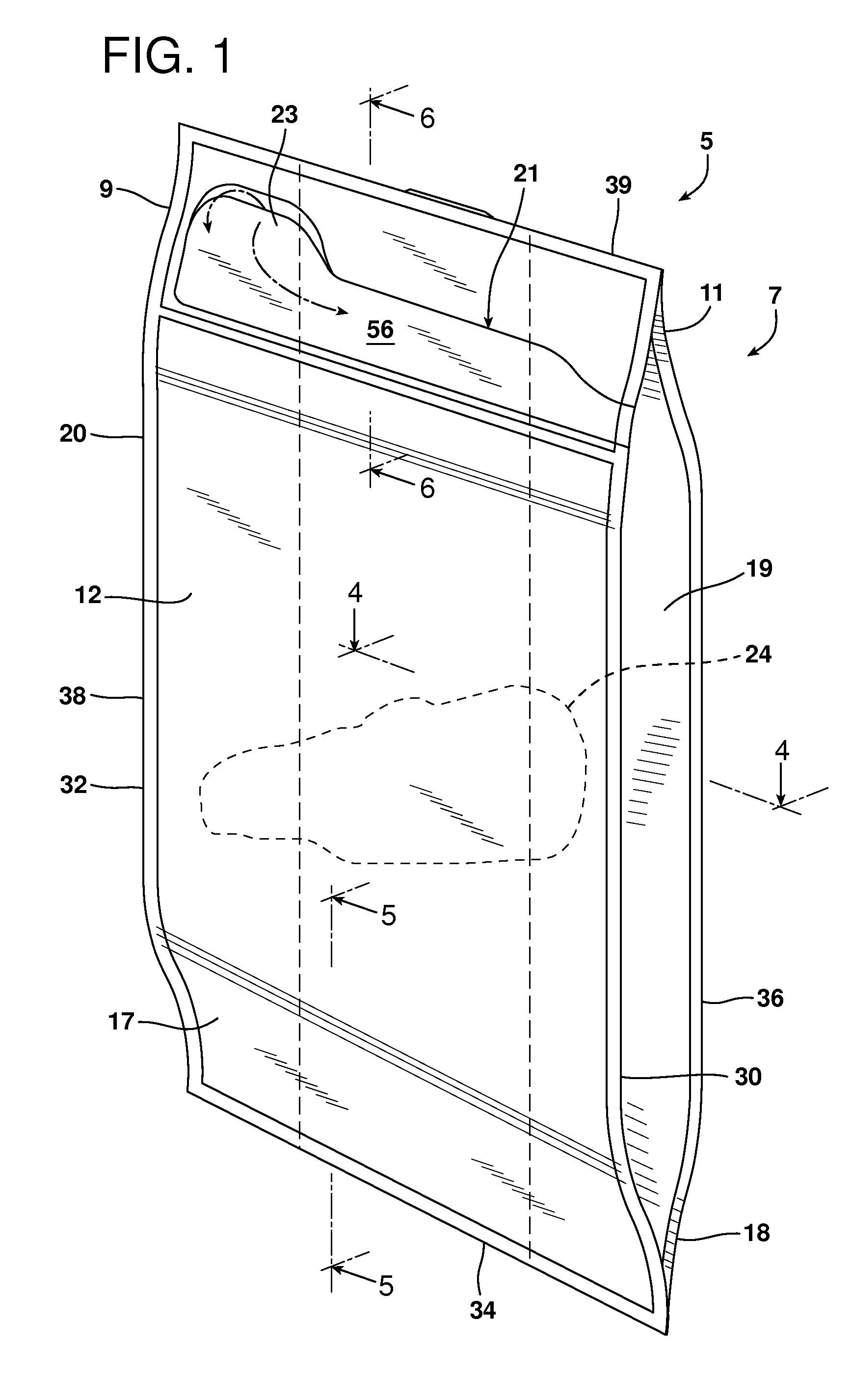

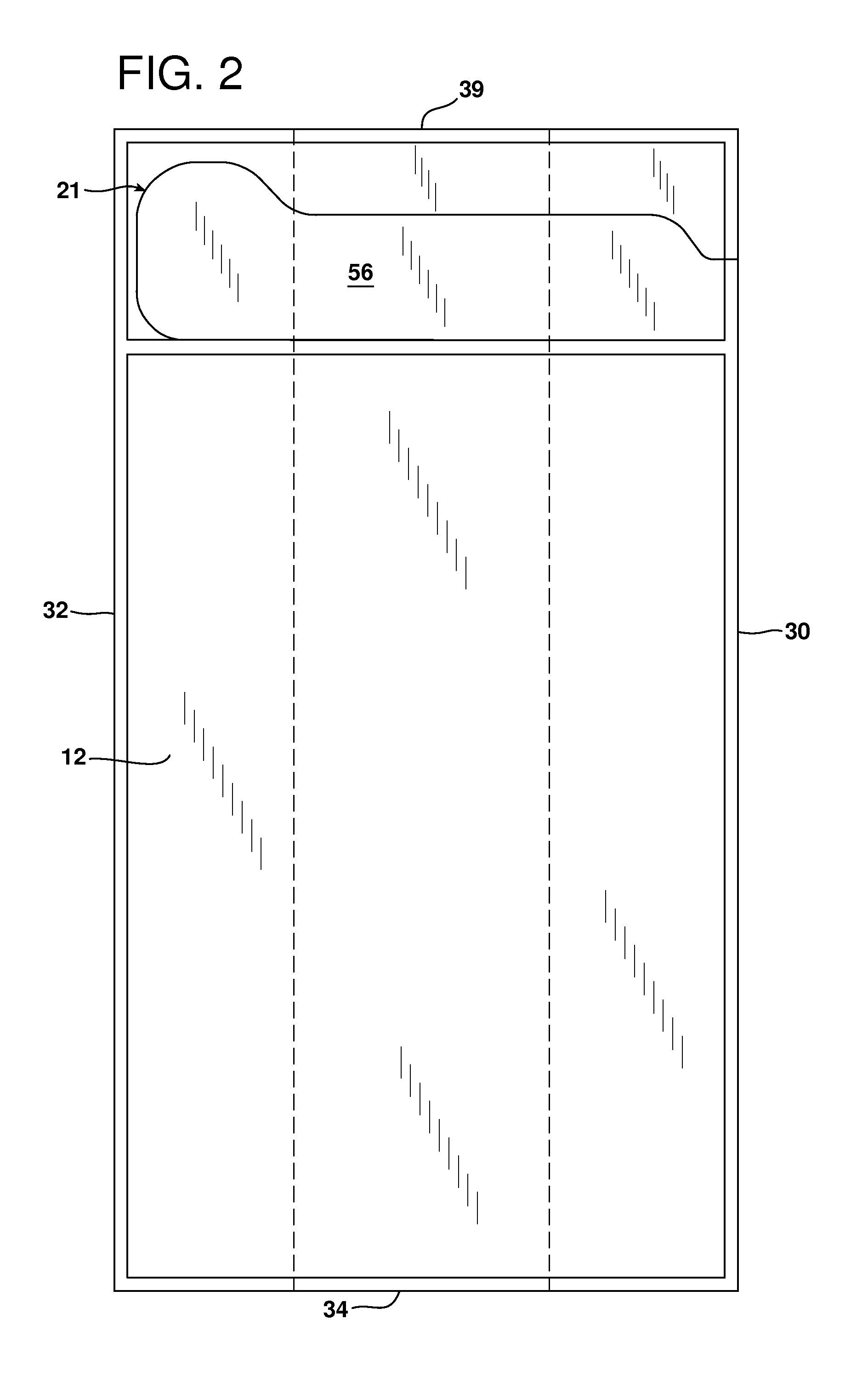

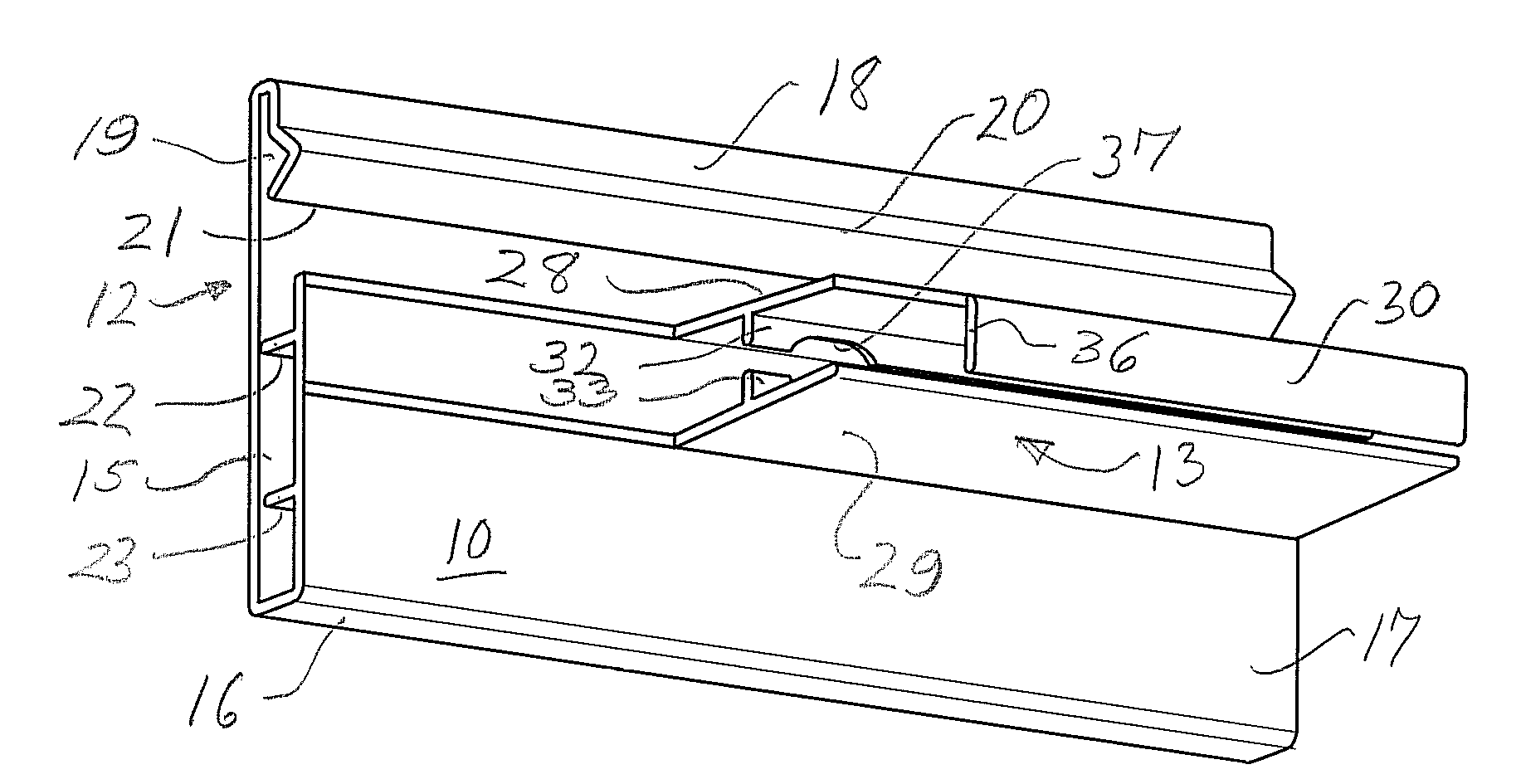

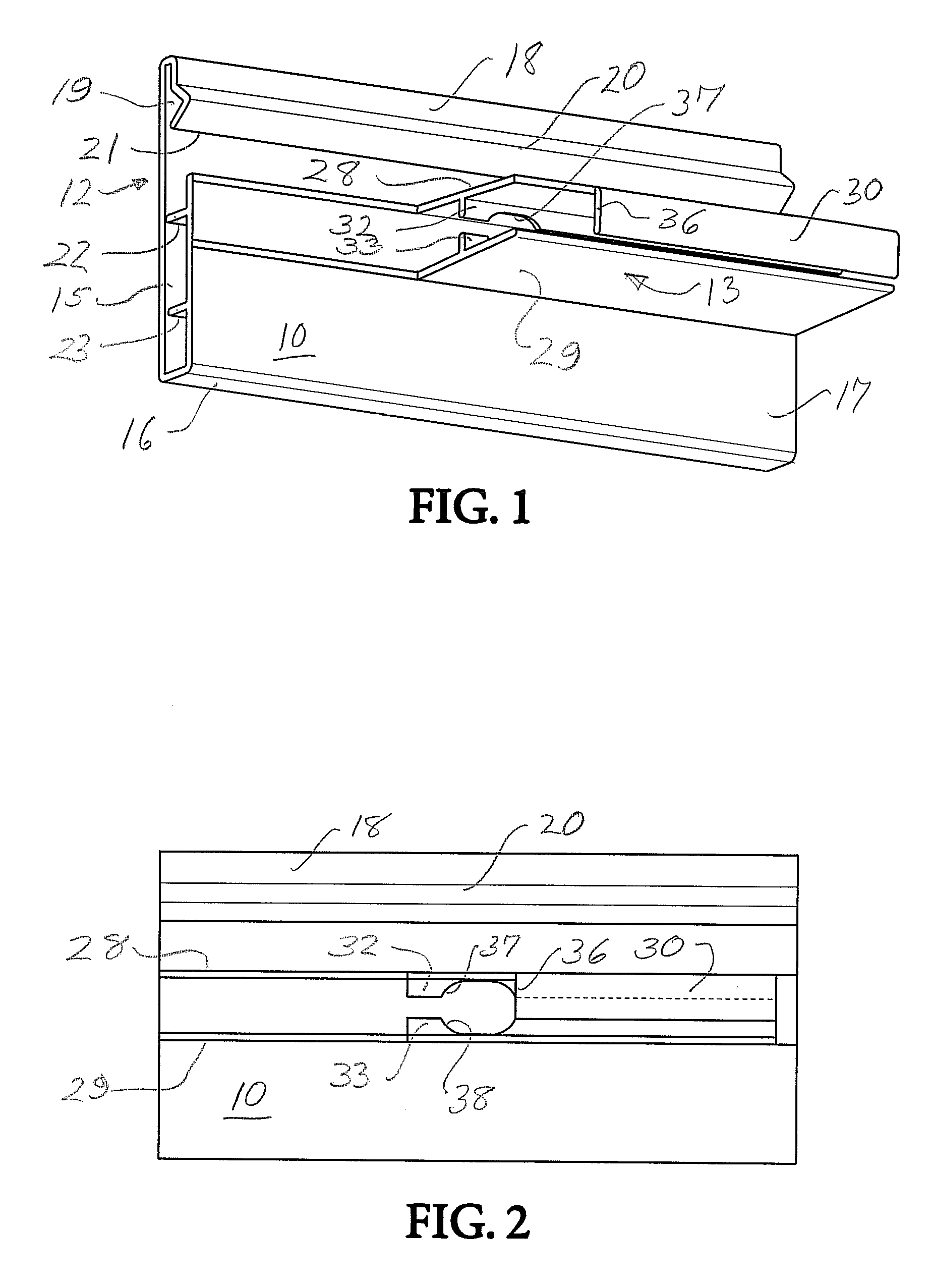

Label holder for merchandise display hooks and method of making same

InactiveUS20080307687A1Low costCenter positioning is accurateStampsMetal rolling stand detailsWire rodEngineering

A label holder for displaying information labels at the front of merchandise display hooks, and method for making the label holder. The label holder is of inexpensive continuously extruded construction, which is inexpensively processed after extrusion to eliminate the typical shortcomings of conventional extruded label holders. The extruded body form is cut to usable length and subjected to a plurality of die cutting operations on the back or mounting portion of the label holder, to form positioning and retention features. The label holder is thus provided with many if not most of the beneficial features of specially molded label holders, without incurring the greater expense involved in the molding process. The label holder is designed to accommodate mounting on label holders of several wire sizes commonly found in use in merchandise displays.

Owner:TRION IND

Easy Open and Reclosable Package with Die-cut Web and Discrete Tape Anchored to Second Side Panel

An easy-open and reclosable package includes a pouch including a discrete tape including a base strip between first and second side panels; at least a first portion of the first surface of the strip coated with a pressure sensitive adhesive and adhered by the adhesive to the inner surface of the first panel at a first location, and the second surface of the strip anchored to the inner surface of the second side panel; a die cut in the first panel, defining a primary die cut segment so arranged that when the package is opened, it can be reclosed by adhering the adhesive to the first panel; and a product in the pouch. A secondary die cut segment can be disposed between the primary die cut segment and an end of the package. This secondary die cut can be at least partially underlain by the adhesive.

Owner:CRYOVAC ILLC

Easy open and reclosable package with discrete tape and die-cut web

Owner:CRYOVAC ILLC

Easy Open and Reclosable Package with Discrete Tape and Die-cut Web

An easy-open and reclosable package includes a pouch including a discrete tape including a base strip between first and second side panels; at least a first portion of the first surface of the strip coated with a pressure sensitive adhesive and adhered by the adhesive to the inner surface of the first panel at a first location, and a second portion of the first surface of the strip anchored to the inner surface of the first panel at a second location; a die cut in the first panel, the die cut defining a die cut segment, the die cut segment so arranged that when the package is opened, it can be reclosed by adhering at least one of the first and second panels to the adhesive; and a product in the pouch.

Owner:CRYOVAC ILLC

Two-sided conductive fabric adhesive tape and production technology thereof

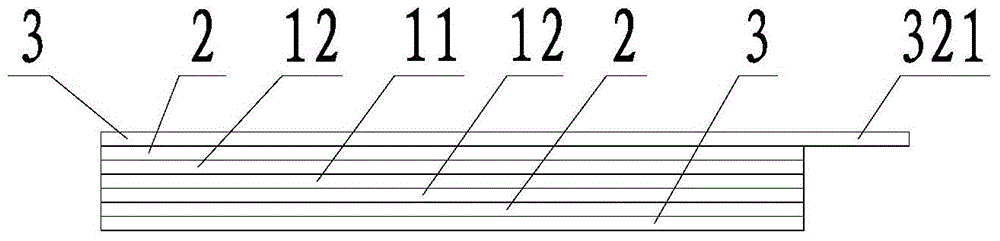

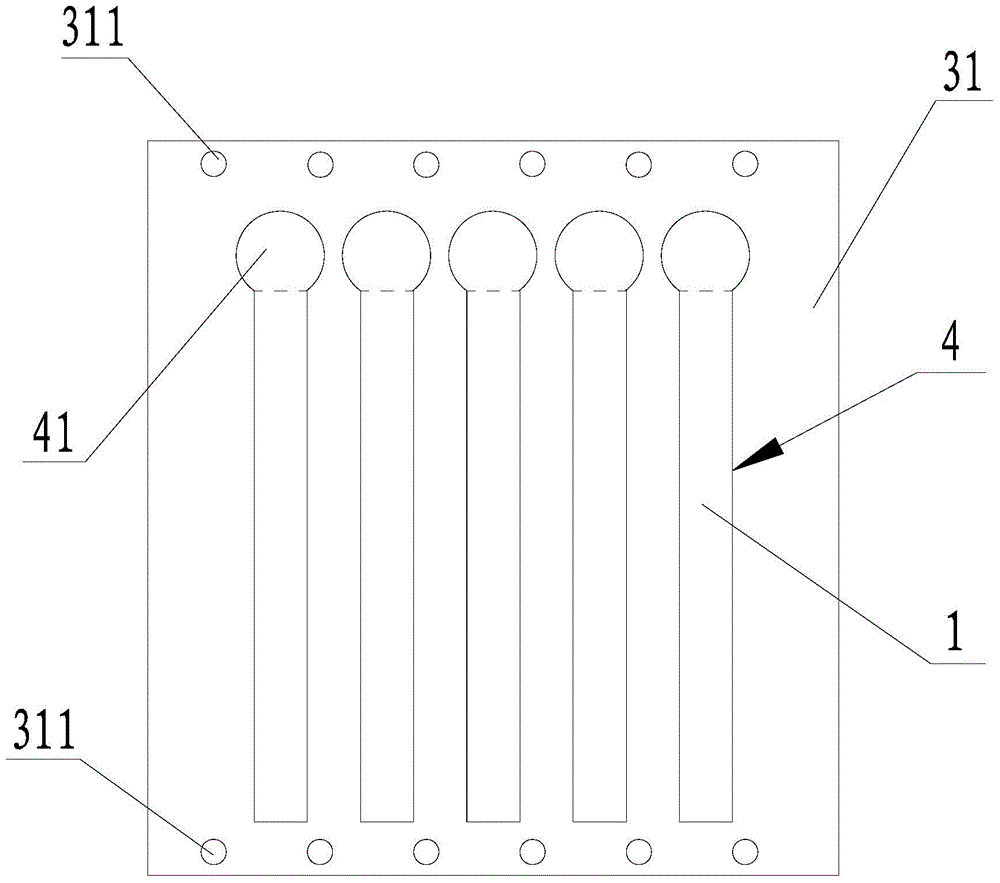

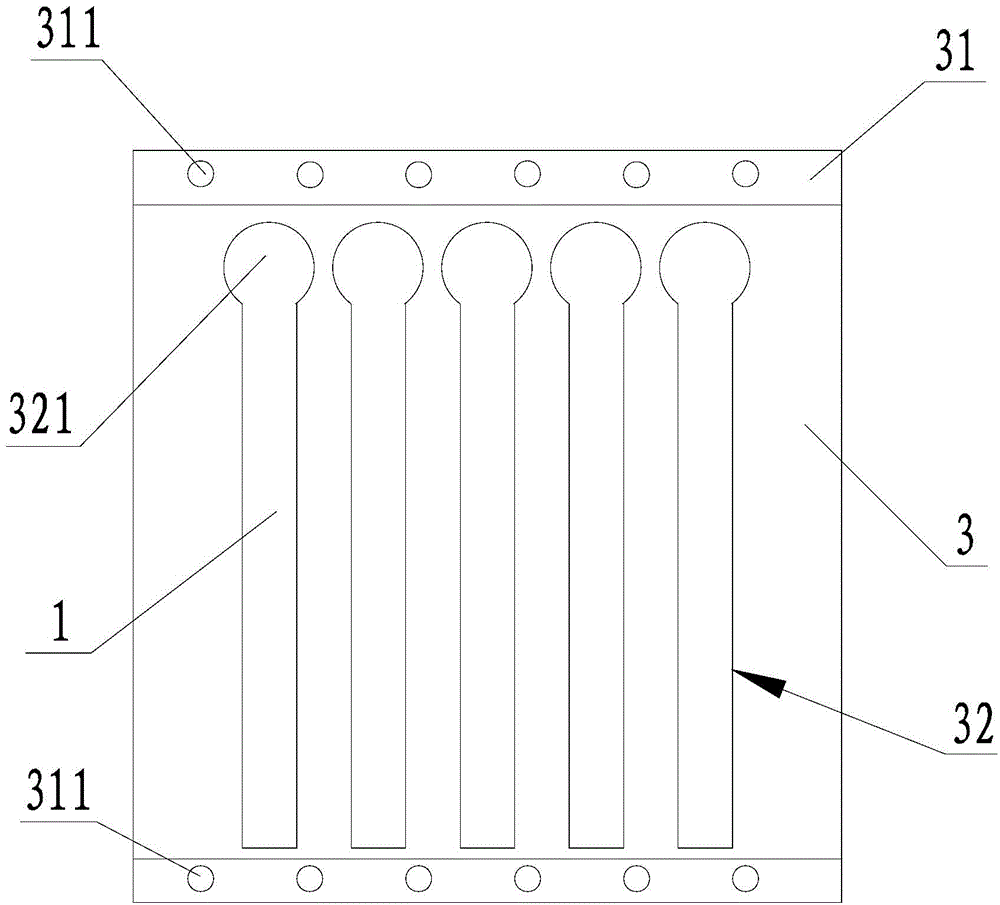

InactiveCN104087195AFacilitate strippingRealize automatic waste dischargeFilm/foil adhesivesAdhesive beltIsolation layer

The invention discloses a two-sided conductive fabric adhesive tape which comprises a conductive fabric layer, adhesive layers attached to two side surfaces of the conductive fabric layer, and isolation layers attached to two side surfaces of the conductive fabric layer through the adhesive layers, wherein the isolation layer on at least one side surface extends outwards along the length direction or width direction of the conductive fabric layer to form a handle part for lifting, and the conductive fabric layer comprises a shield base layer and metal layers plated on two side surfaces of the shield base layer. As the handle is arranged on the isolation layer on one side surface of the two-sided conductive fabric adhesive tape, the isolation layer can be conveniently peeled off from the conductive fabric adhesive tape. The invention also discloses a production technology of the two-sided conductive fabric adhesive tape. By adopting the production technology, automatic waste discharge is realized; in punching, die cutting is carried out twice on two side surfaces of the conductive fabric adhesive tape, so that broken filaments are reduced, and the overall productivity is improved.

Owner:隆扬电子(昆山)股份有限公司

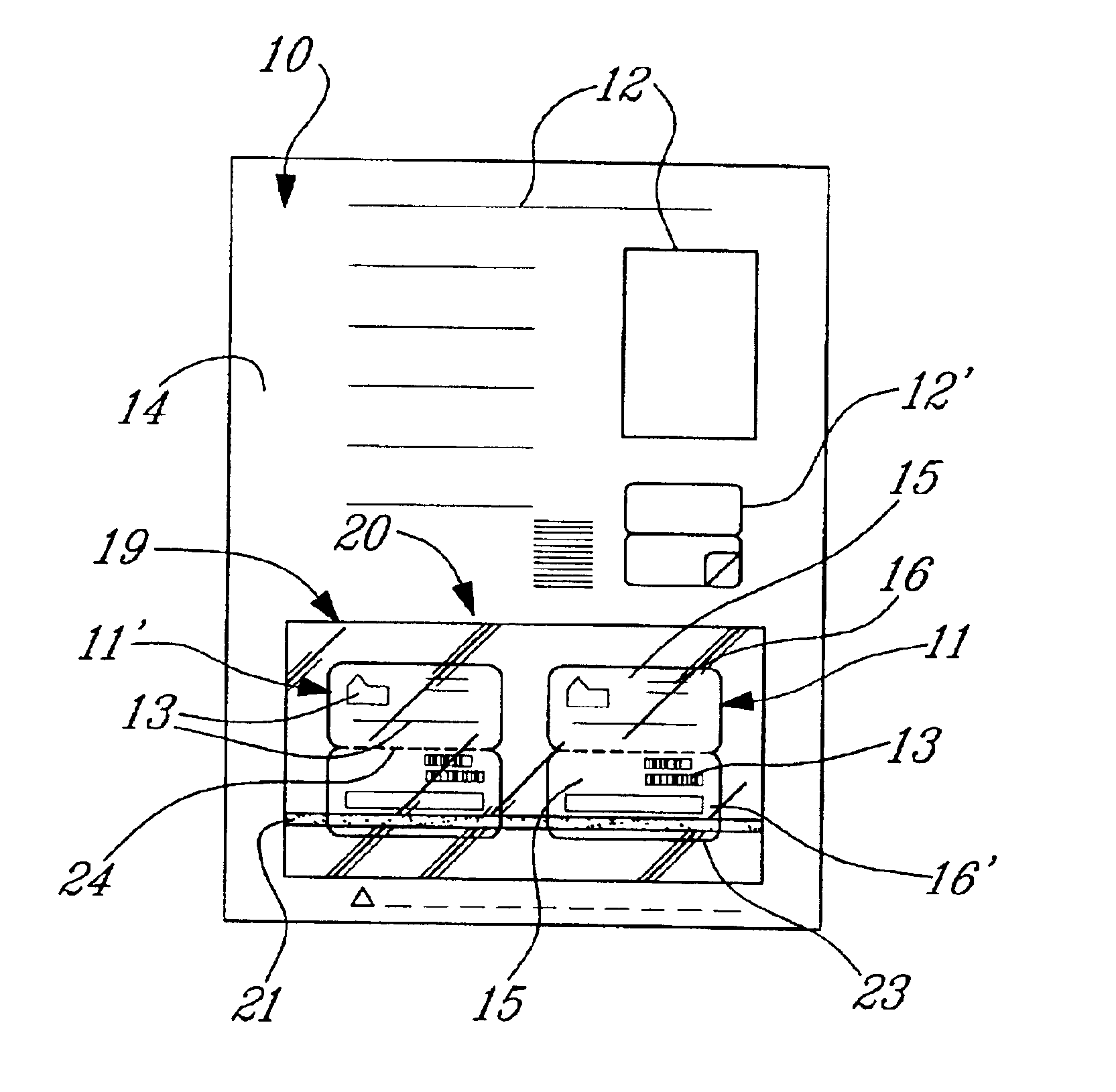

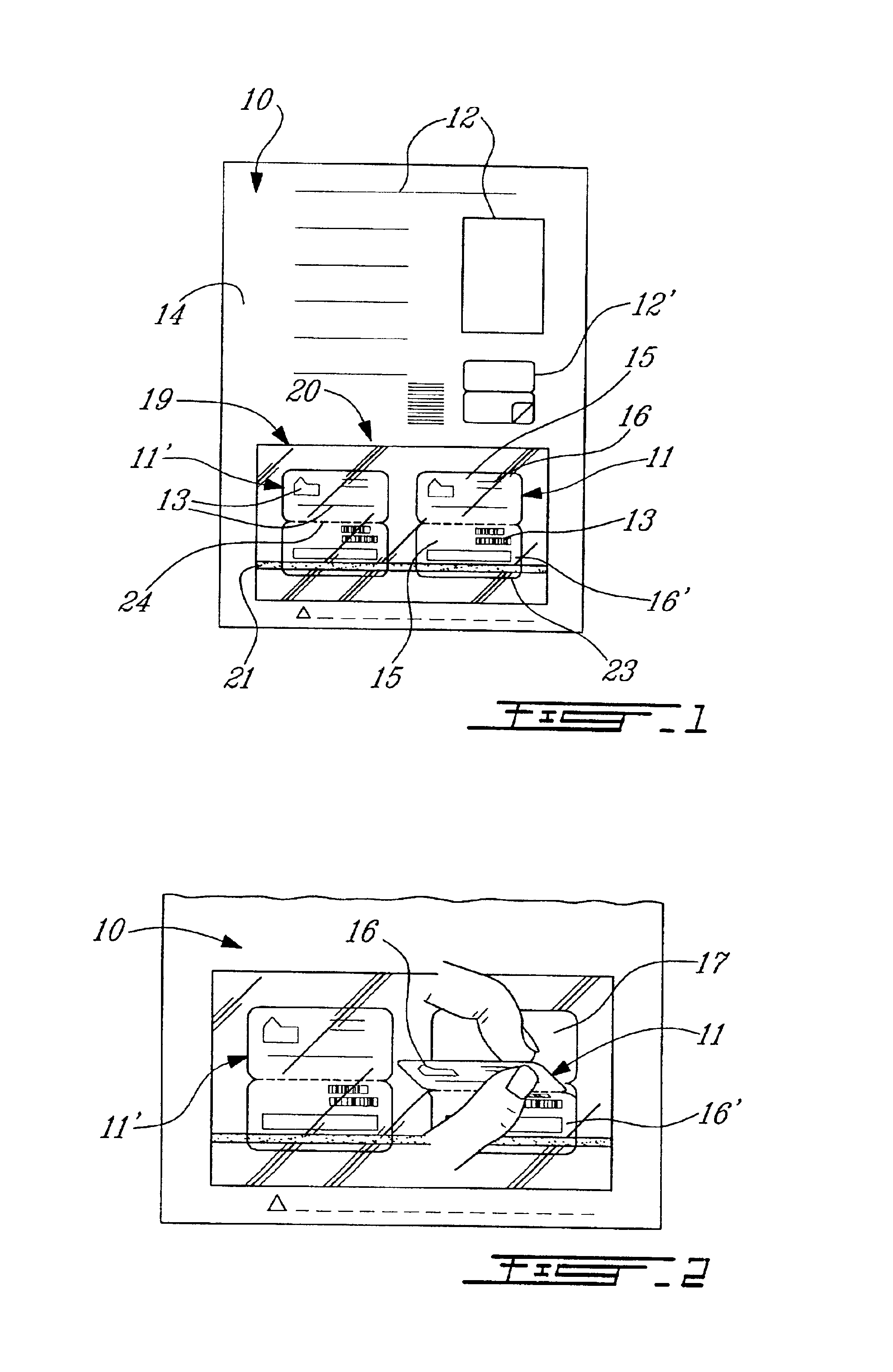

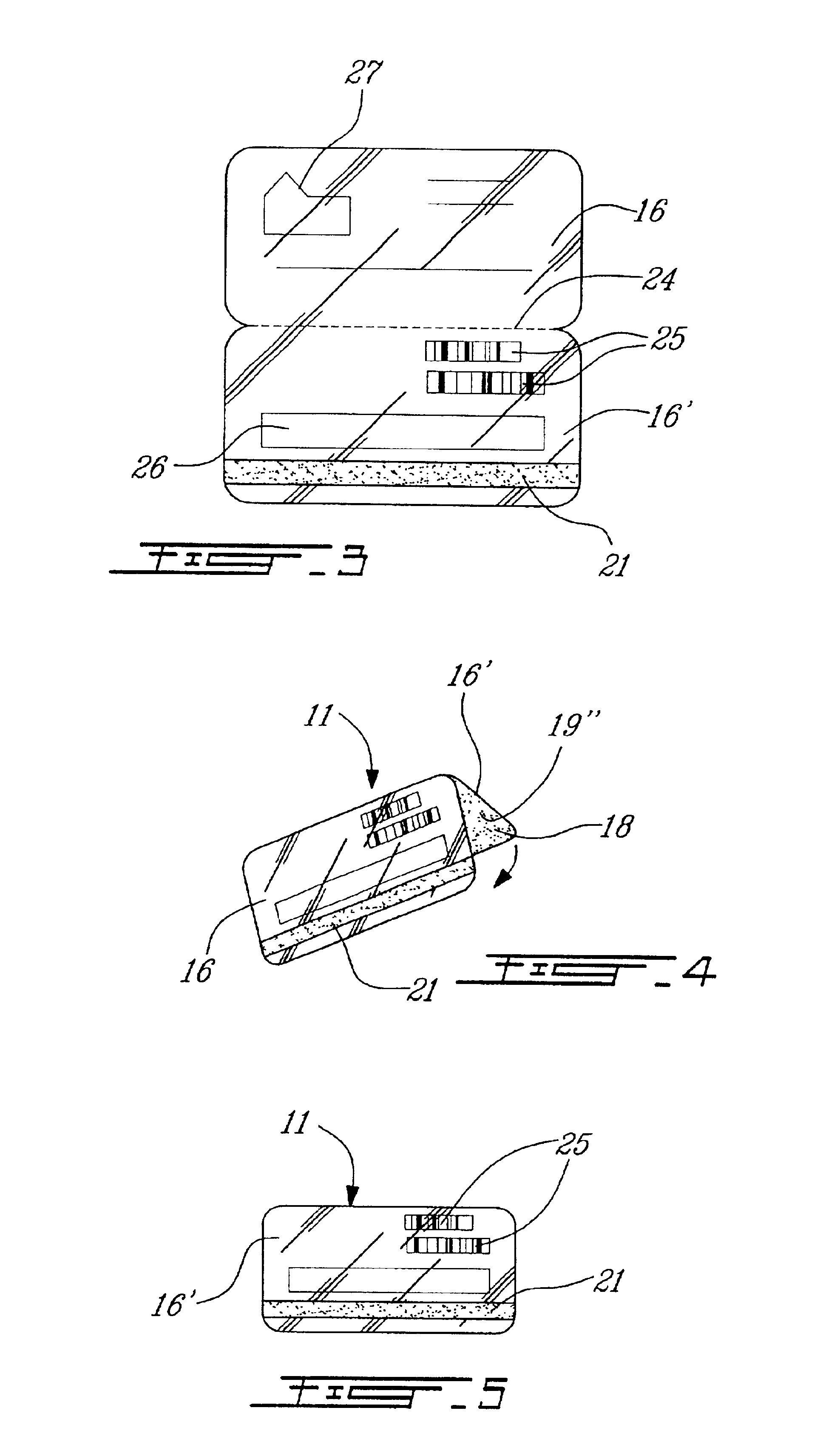

Integrated plasticized card in a paper carrier and method of manufacture

A carrier sheet with an integrated card and preferably, but not exclusively, a magnetic strip card is described. The sheet contains printed information which is in part card information printed at a predetermined location on a front face of a carrier sheet in a card region thereof and oriented to be disposed on an outer surface of the front and a rear card panel of the card to be formed. The siliconized liner patch, containing a pressure-sensitive adhesive, is laminated on the back surface of the carrier sheet and disposed to extend over the card region. A face patch of clear poly material containing a magnetic strip is immovably secured over the card region on the front face of the paper carrier sheet. A die cut delineates card contour panels and a straight fold line separates the panel whereby they may be folded together when detached from the carrier sheet with the pressure-sensitive adhesive of the liner being transferred to the rear surface of the panels so that the panels can be folded together with their rear surface stuck together. The method of manufacture and a method of use is also described herein.

Owner:RELIZON CANADA

Die cut insulation blanket and method for producing same

InactiveUS20070042156A1Reduce materialSignificant material savingPaper/cardboard articlesCellulosic plastic layered productsStructural engineeringHoneycomb like

A blanket is provided including a first panel of material having a honeycombed portion that is expanded to form a second, projecting panel from the first panel material. The invention also includes a method of reducing the material needed to construct a multipanel structure. The method includes the steps of providing a first panel of material; honeycombing a portion of that first panel and expanding the honeycombed portion of the first panel to form a second panel projecting from the first panel. Advantageously, the second panel is formed from material of the first panel and no additional material is required.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Corrugated pallet

InactiveUS7000549B2Improve carrying capacityHigh stackingsContainer decorationsLevel indicationsAdhesiveEngineering

A shipping pallet compatible with fork-lifts and pallet-trucks is made from stamped or die cut flat corrugated board. Stringer and cross-braces from an interlocking grid work to which a top and bottom flat sheet are attached by an adhesive. The pallet may be recycled as paper and not returned to the sender. Additional reinforcement structures may be added for heavier loads.

Owner:NELSON DUANE

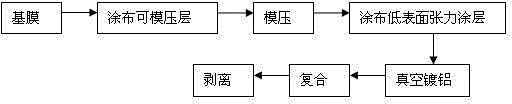

Production technology for laser hollow-out aluminized paper

InactiveCN104532668AReduce usagePrevent volatilizationDecorative surface effectsCoatingsInformation layerMetallic aluminum

The invention relates to a production technology for laser hollow-out aluminized paper. The technology comprises: coating a base membrane containing a laser information layer with a low-surface-tension coating containing picture and text, performing vacuum aluminizing, depositing a metal aluminium layer on the place without being coated with the low-surface-tension coating, then combining with paper, and peeling, so as to obtain the aluminized paper containing the laser information and hollow-out picture and text. The production technology is simple, high in production efficiency and low in cost, and the production process is relatively beneficial for environment protection. The picture and text on the laser hollow-out aluminized paper produced by the technology is capable of replacing a part of picture and text needing printing at a later period, and the laser hollow-out aluminized paper can be used as an exquisite packaging material after being subjected to simple bar code printing, gold stamping and die cutting. The technology helps to substantially reduce usage of printing ink, avoid evaporation of a large amount of organic solvents, reduce volatile organic compound residual quantity of printed matters, and enable the packaging material to be relatively environment-friendly and safe and enhanced in anti-fake property.

Owner:YANTAI BOYUAN TECH MATERIALS

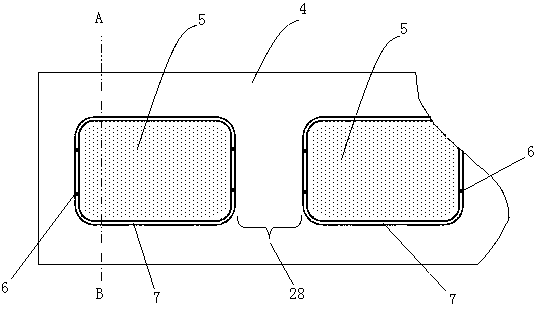

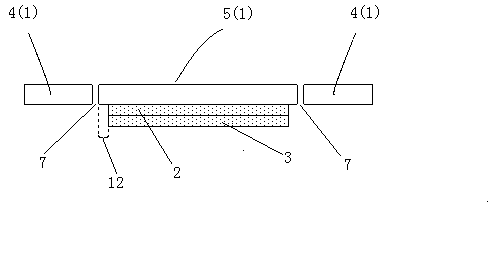

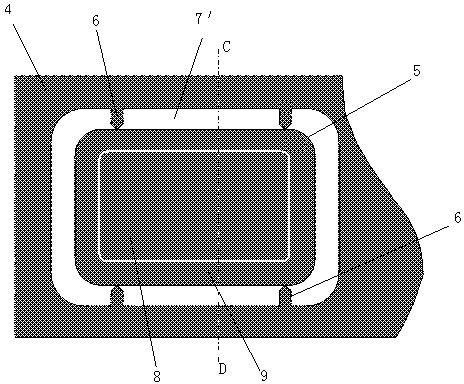

No-body-paper label as well as process method and label roll thereof

InactiveCN103268731AReduce thicknessSave materialStampsIdentification meansProcess engineeringSingle label

The invention provides a no-body-paper label as well as a process method and a label roll thereof. A baseband layer is subjected to die cutting and cut into a waste material unit and a plurality of lined-up single label units, and the waste material unit and each label unit are respectively connected by multiple sections of reserved or adhered connecting lines to form an entangled structure. The method comprises the following steps that the label is firstly pressed and pasted on a pasted object by a thermoprinting machine or a thermal transfer printer or a heat sealing machine; then, the waste material unit is pulled; the connecting lines are broken or stripped; and the label units are separated from the waste material unit so as to finish the label pasting working procedure. According to the invention, material waste can be reduced, and cost is reduced. According to the invention, the automatic label pasting speed can be improved by the traditional general equipment, and the limitation of a rectangular label can be broken through.

Owner:KHAINAN YAYUAN ANTI TSOUNTERFEIT TECH RES INST

Easy Open and Reclosable Package with Die-Cut Web, and Discrete Strip Anchored to Second Side Panel

An easy-open and reclosable package includes a pouch including a discrete strip, between first and second side panels; including a sealing segment, a backing segment, and an intermediate layer including a pressure sensitive adhesive, the first surface of the strip anchored to the inner surface of the first panel at a first location, and the second surface of the strip anchored to the inner surface of the second side panel at a first location; a die cut in the first panel, defining a primary die cut segment so arranged that when the package is opened, it can be reclosed by adhering the adhesive to the first side panel; and a product in the pouch. A secondary die cut segment can be disposed between the primary die cut segment and an end of the package. This secondary die cut can be at least partially underlain by the adhesive.

Owner:CRYOVAC INC

Product display hanger and process

A clear / printed hang tag, a hanging system for suspending a package of products from a single wire hanger and / or a double wire hanger, automatic labeling of product packaging on a billboard, and the process for making hang tags. The hang tag has an opening for receiving a single or a double wire hanger cut near the top of a billboard region containing printed matter. The hang tag is made from a continuous web of polyester film with a process including, printing graphics on the back side of the upper portion using reverse image flexographic printing, coating the printed image with a UV cured, opaque ink coating, a lower portion of the front side with a clear, pressure sensitive adhesive, combining and adhering the continuous web of polyester film to a release liner, die cutting the hang tag shape and the hanger opening, stripping the waste material from the liner, and rewinding the combined hang tags and liner on a reel for shipment to a customer. The package consists of at least two bundled products forming a compact package, wrapped and sealed in a clear, oriented polypropelene shrink wrap film, and the adhering region is pressed against the topmost product and adhered thereto by the adhesive.

Owner:WISCONSIN LABEL CORP CORP

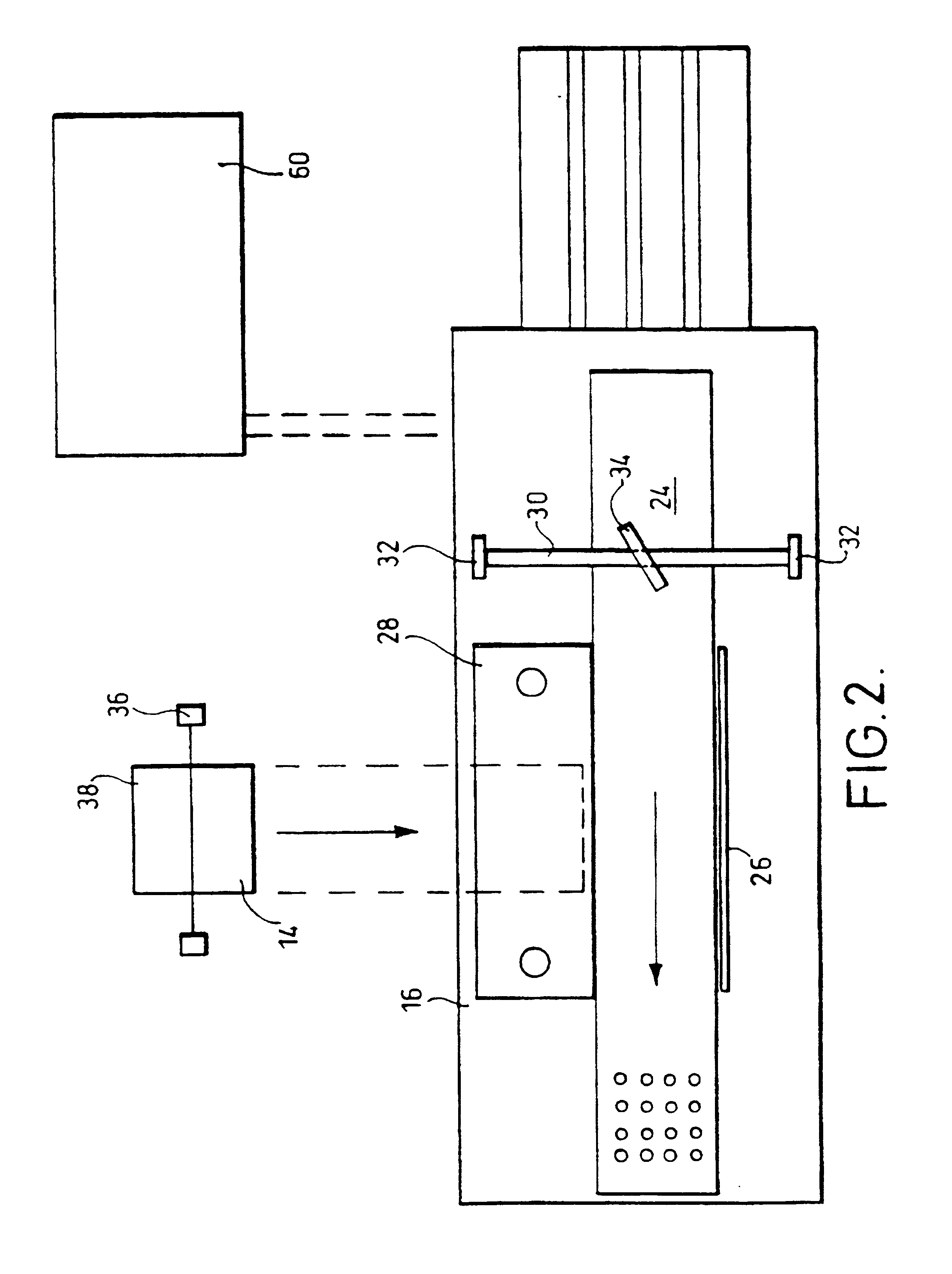

Apparatus for mounting a cutting strip

This invention provides an apparatus for attaching a cutting strip to a carton blank. The apparatus includes a first member for conveying carton blanks past a second member, and the second member is arranged to cut a cuffing strip from a supply of cuffing strip material and deposit the cutting strip upon a carton blank. The first member may be a conveyor belt fitted with a suction member, and the second member may be upper and lower dies that are movable relative to one another and a member that can feed a supply of cutting strip material between the dies. Initial downward movement of the upper die cuts a cutting strip from the supply of cutting strip material and the cutting strip is retained on the upper die. Further downward movement of the upper die brings the cutting strip into contact with a carton blank. The apparatus may also include an alignment member to ensure that the carton blanks are properly positioned relative to the second member when the cutting strips are attached.

Owner:CARTON EDGE SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com