Patents

Literature

51 results about "Form liner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

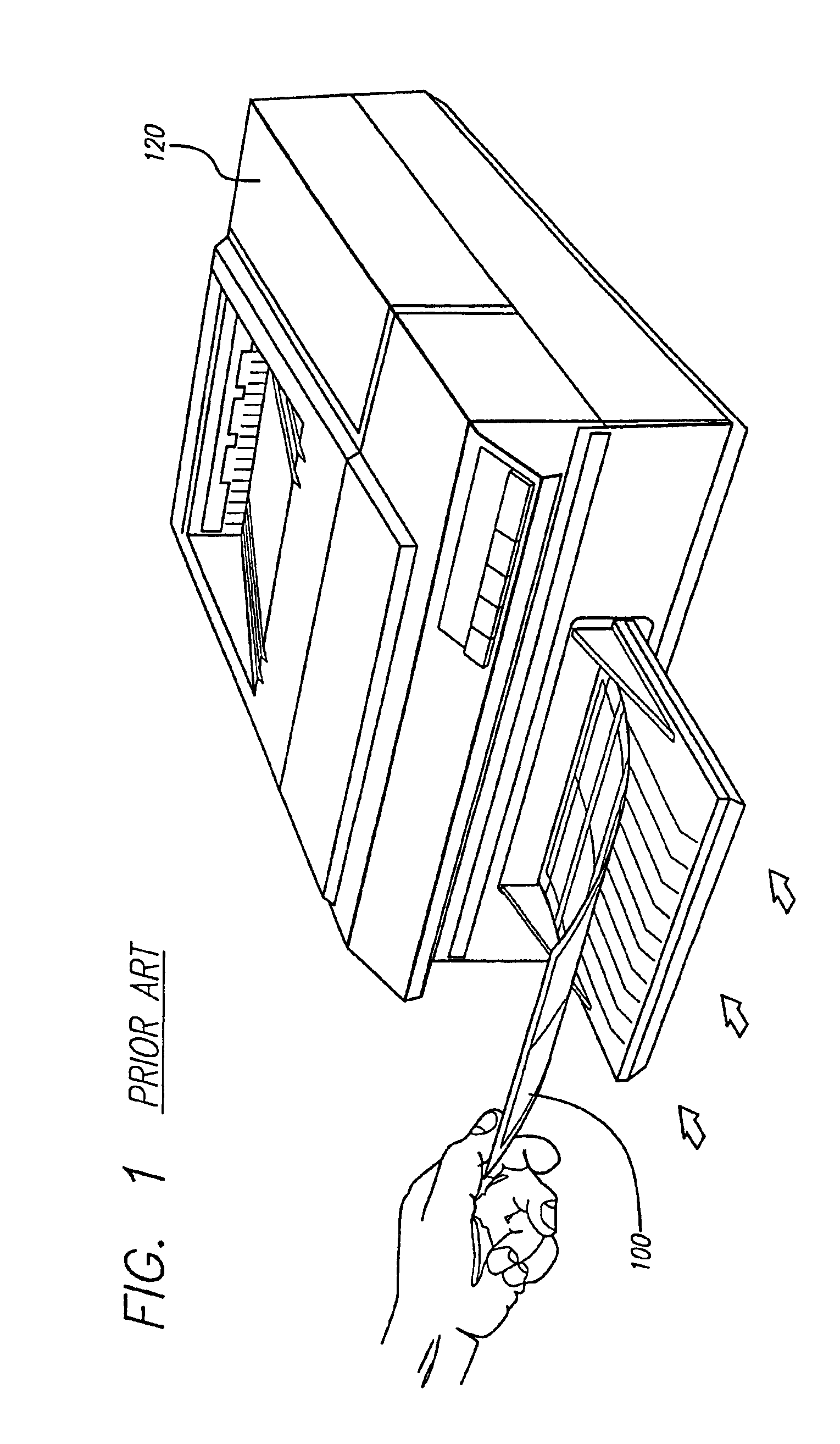

Form liners are the liners used in the preparation of designs on concrete walls. The use of form liners often results in more attractive walls for highways, neighborhoods, beaches and parks. Form liners come in many different shapes and designs, and can produce a variety of different results on concrete.

Methods of forming different finfet devices having different fin heights and an integrated circuit product containing such devices

One illustrative method disclosed herein includes forming a plurality of trenches in a plurality of active regions of a substrate that defines at least a first plurality of fins and a second plurality of fins for first and second FinFET devices, respectively, forming liner materials adjacent to the first and second plurality of fins, wherein the liner materials adjacent the first fins and the second fins have a different thickness. The method also includes removing insulating material to expose portions of the liner materials, performing an etching process to remove portions of the liner materials so as to expose at least one fin in the first plurality of fins to a first height and at least one of the second plurality of fins to a second height that is different from the first height.

Owner:GLOBALFOUNDRIES US INC

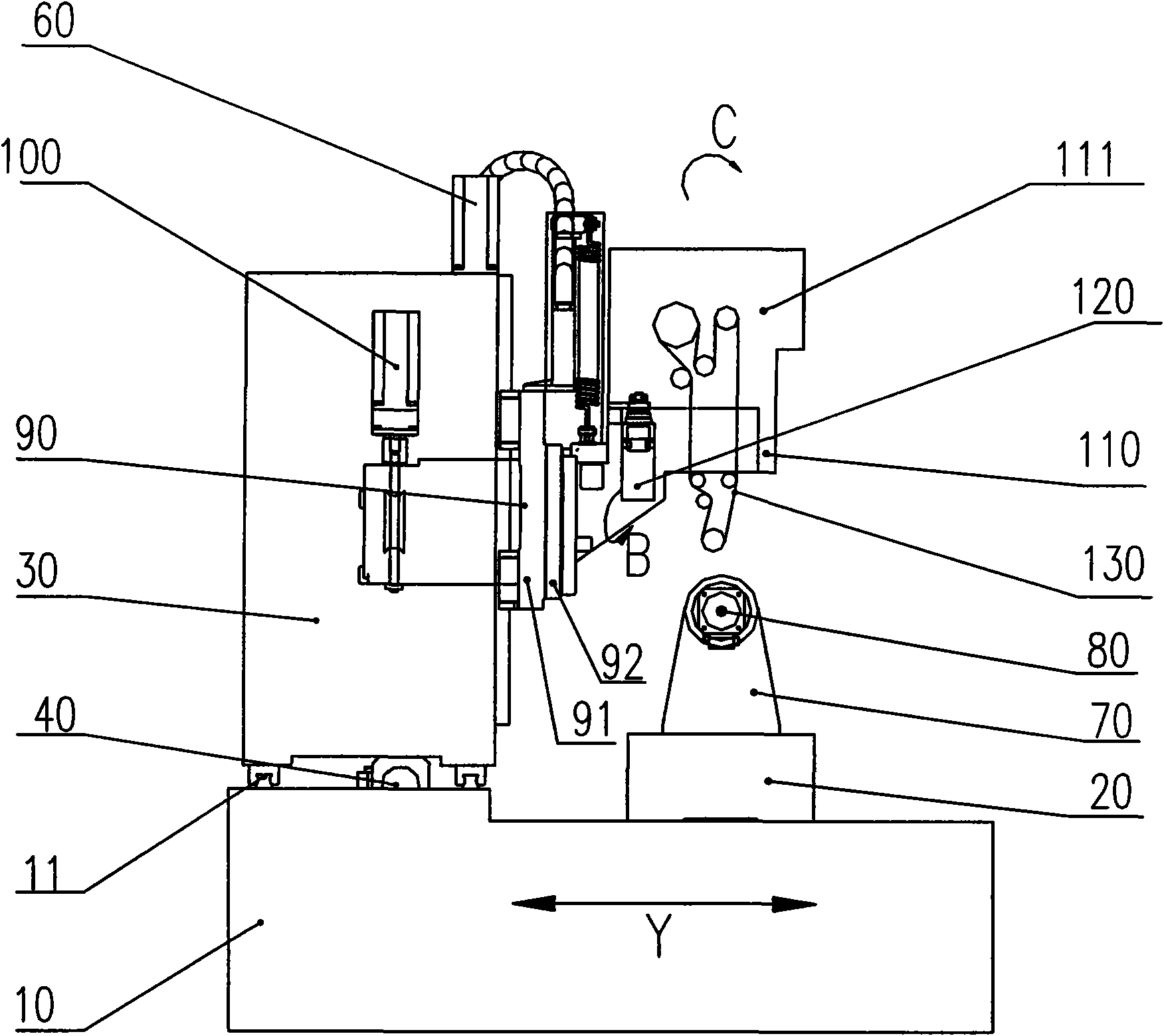

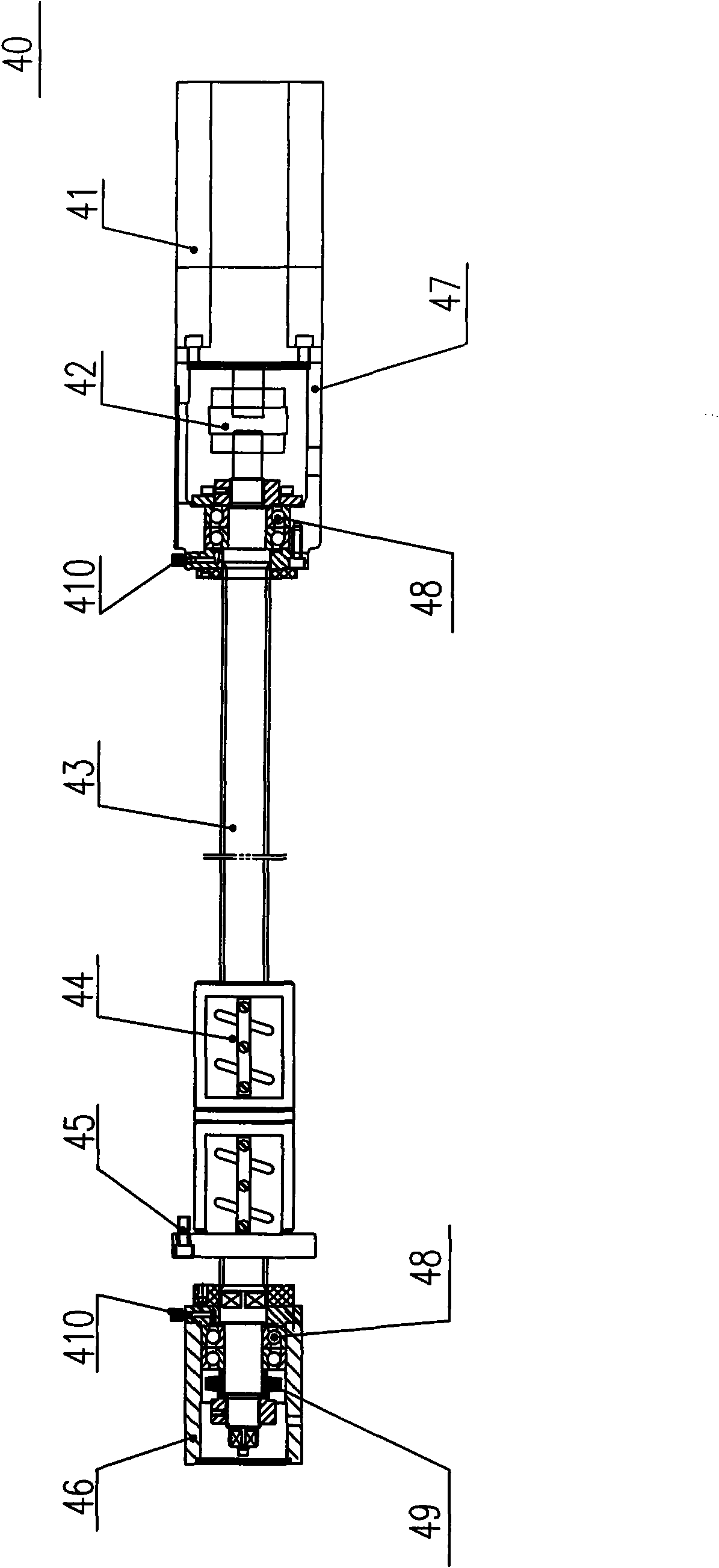

Numerical control abrasive belt grinding machine with six-axis linkage

ActiveCN101559574AImprove processing efficiencyHigh dimensional accuracyGrinding carriagesBelt grinding machinesMachine controlForm liner

The invention discloses a numerical control abrasive belt grinding machine with six-axis linkage. An upright post component and a worktable are arranged on the grinding machine body in a sliding way, and the relative sliding between the two of the upright post component and the worktable and the grinding machine body respectively forms liner motion of X-axis direction and Y-axis direction; an A-axis component is arranged above the worktable and used for clamping a workpiece to rotate around the axial line thereof so as to form rotary motion of the A-axis; a cantilever on the upright post component is provided with a grinding seat which is connected with the upright post component through a box body in a sliding way so as to form liner motion of Z-axis direction; a turntable is arranged on the box body in a rotating way, and the relative rotation between the turntable and the box body forms rotary motion of B-axis direction; an abrasive belt machine is arranged inside the grinding seat, and the relative rotation between the abrasive belt machine and the grinding seat forms swivel motion of C-axis direction; and the grinding machine controls the motion of each axis direction by a numerical control system. The numerical control abrasive belt grinding machine can greatly enhance grinding efficiency, and can effectively improve the grinding precision and surface quality of the workpiece.

Owner:北京胜为弘技数控装备有限公司

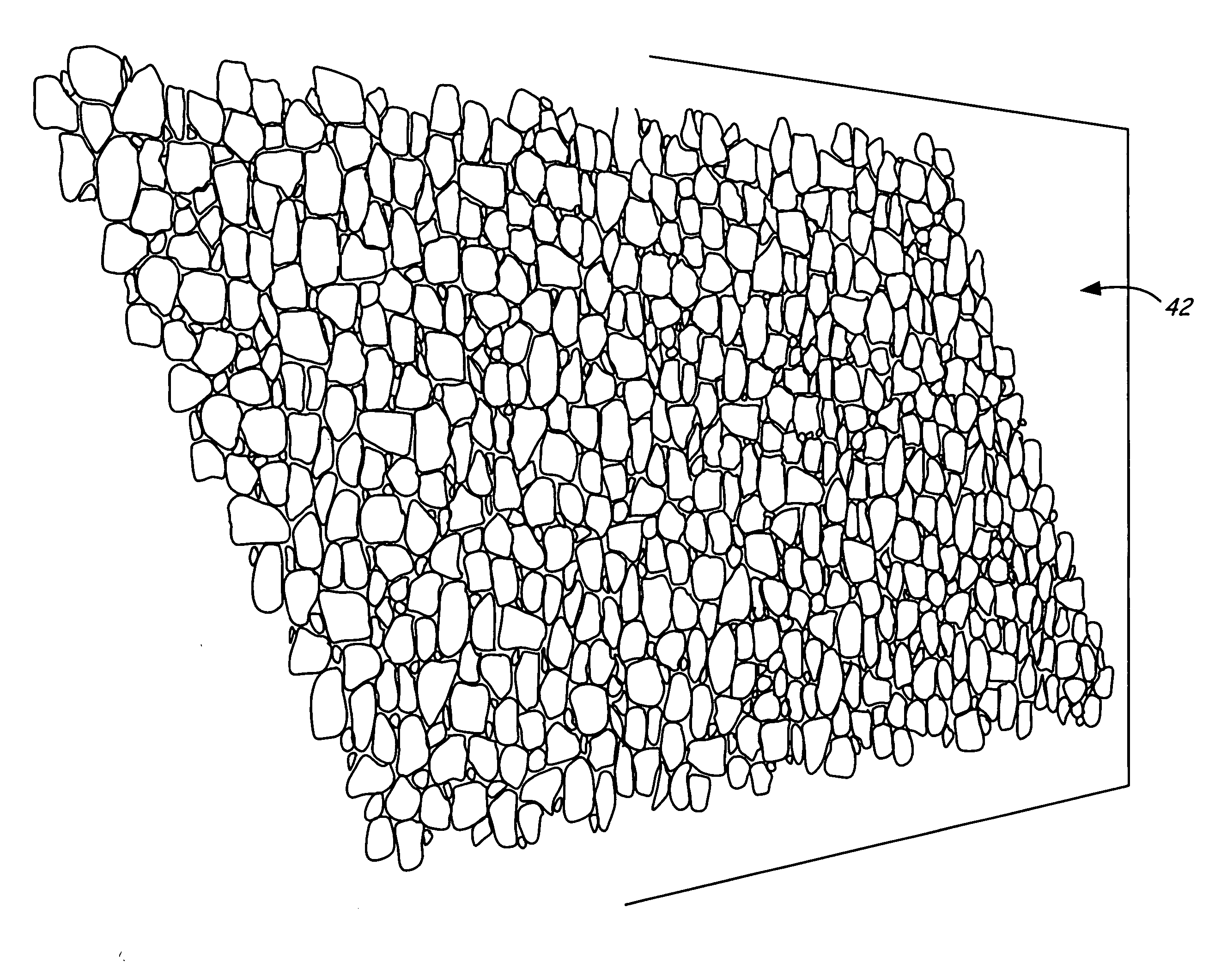

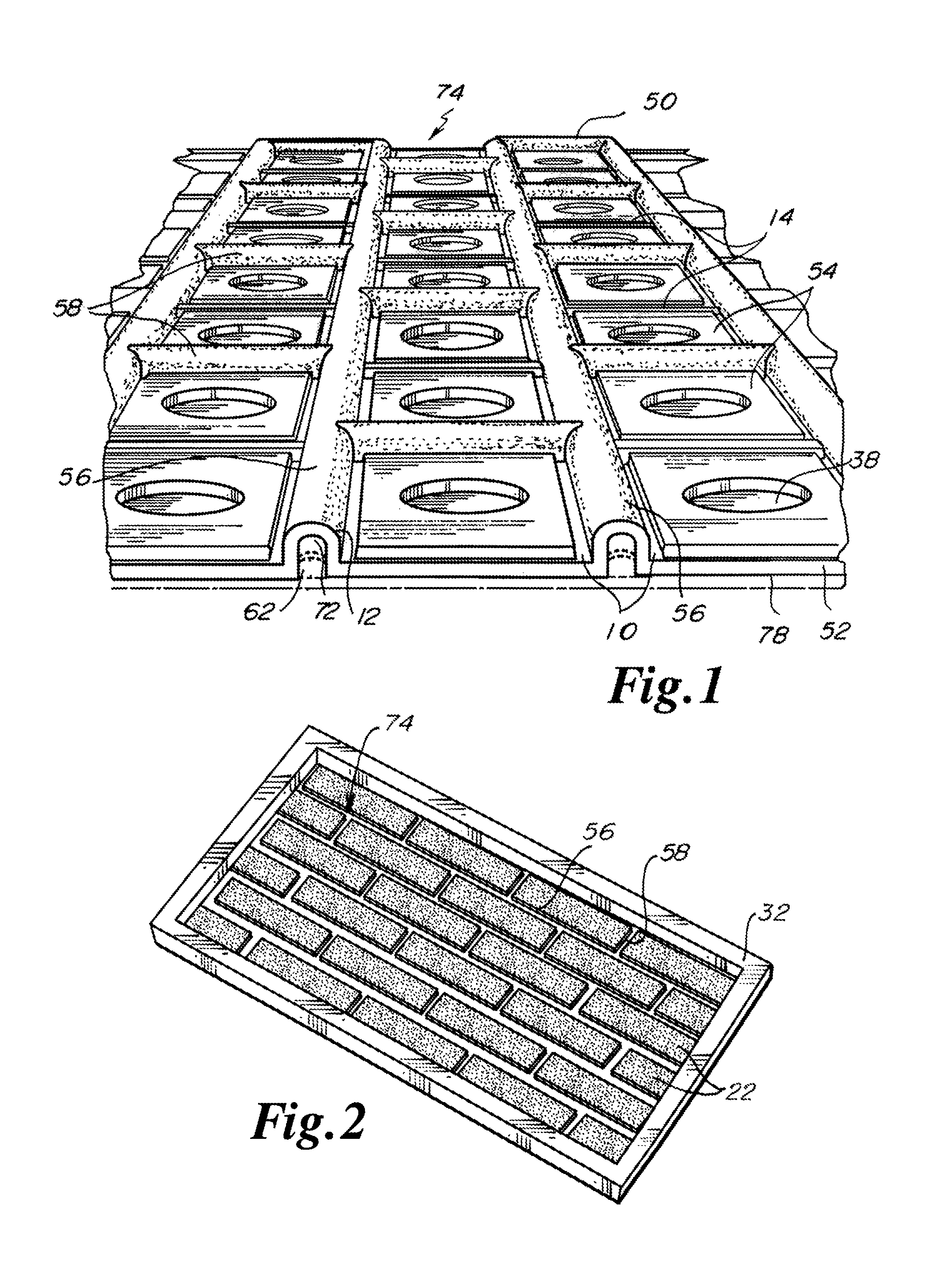

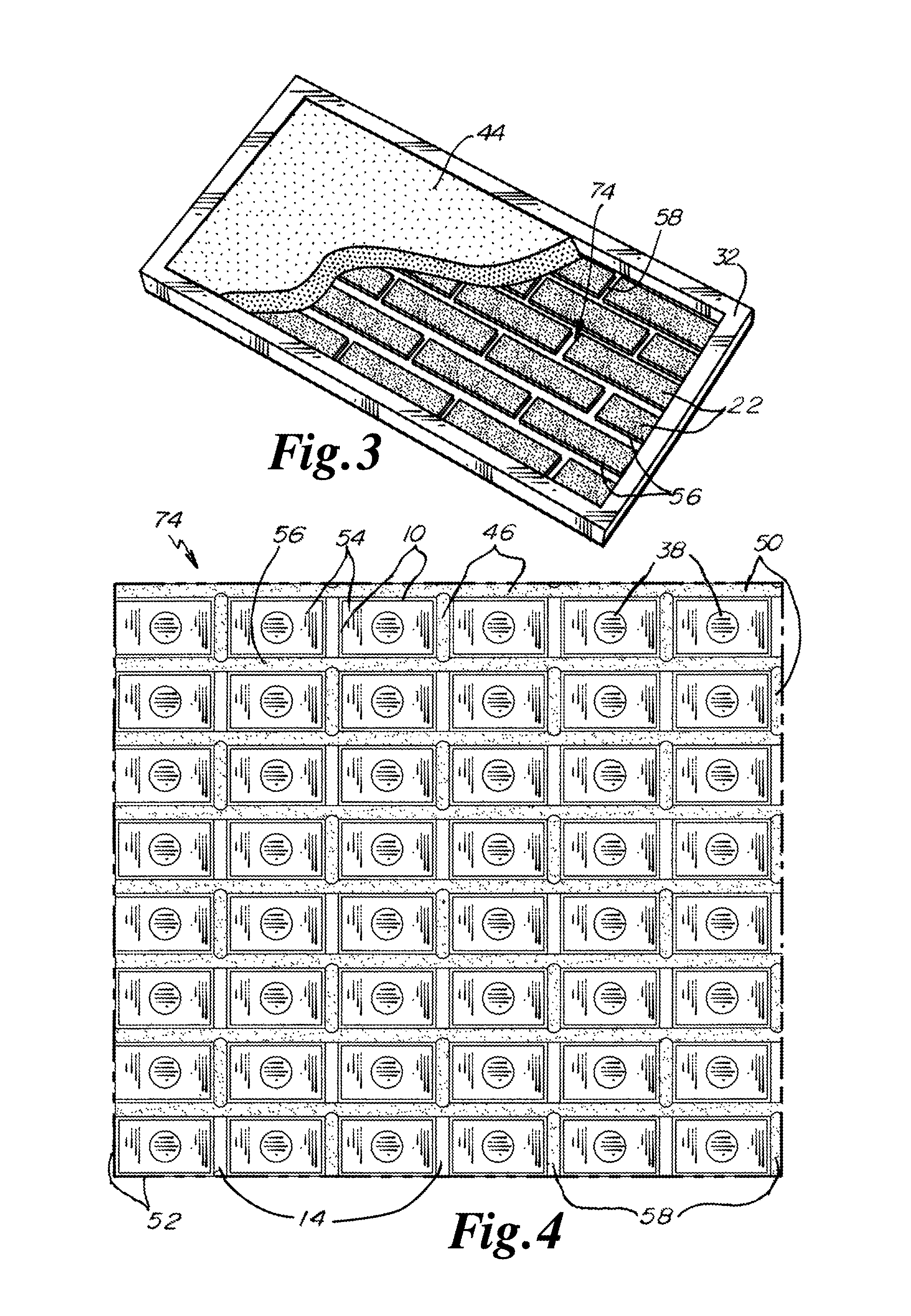

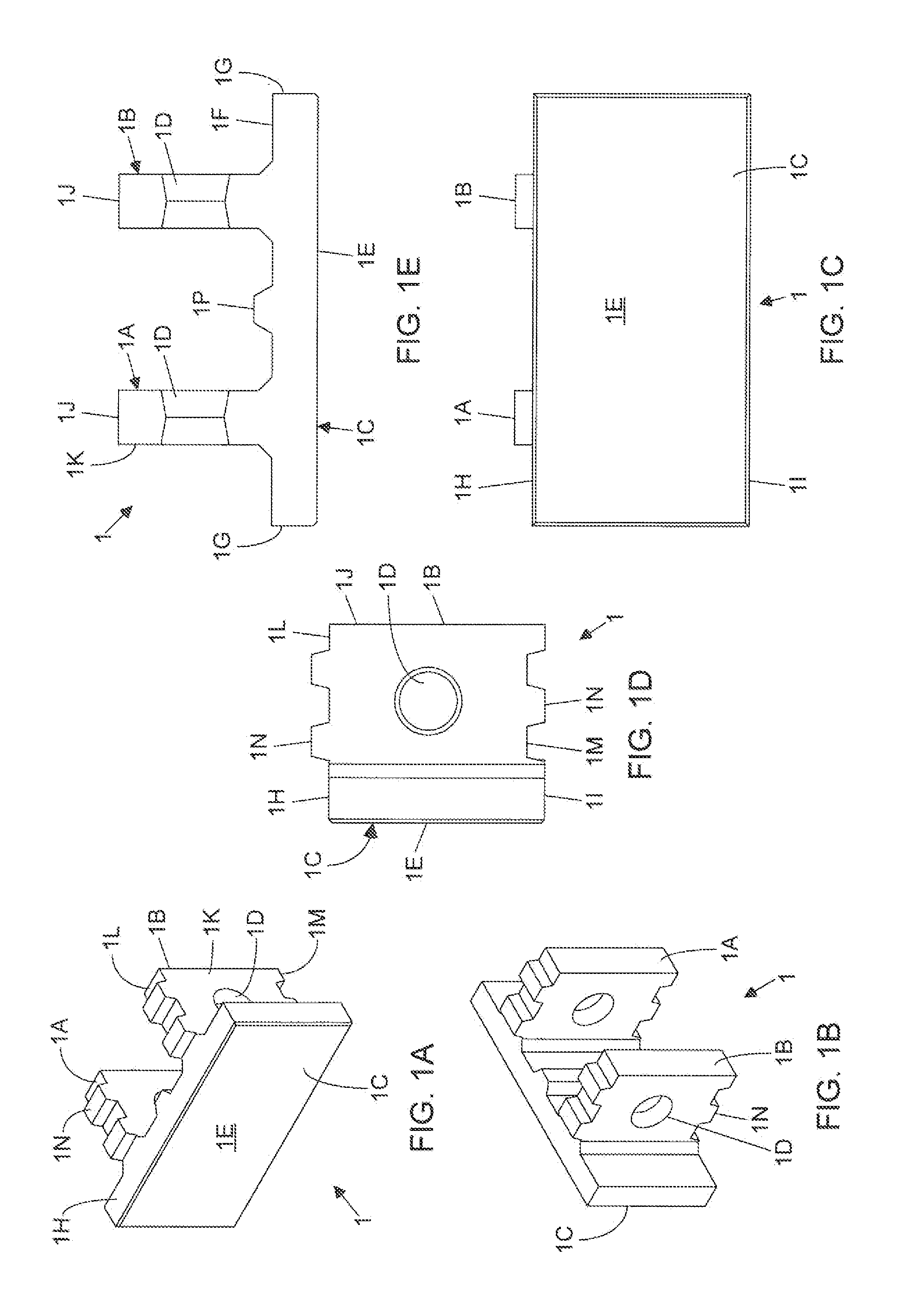

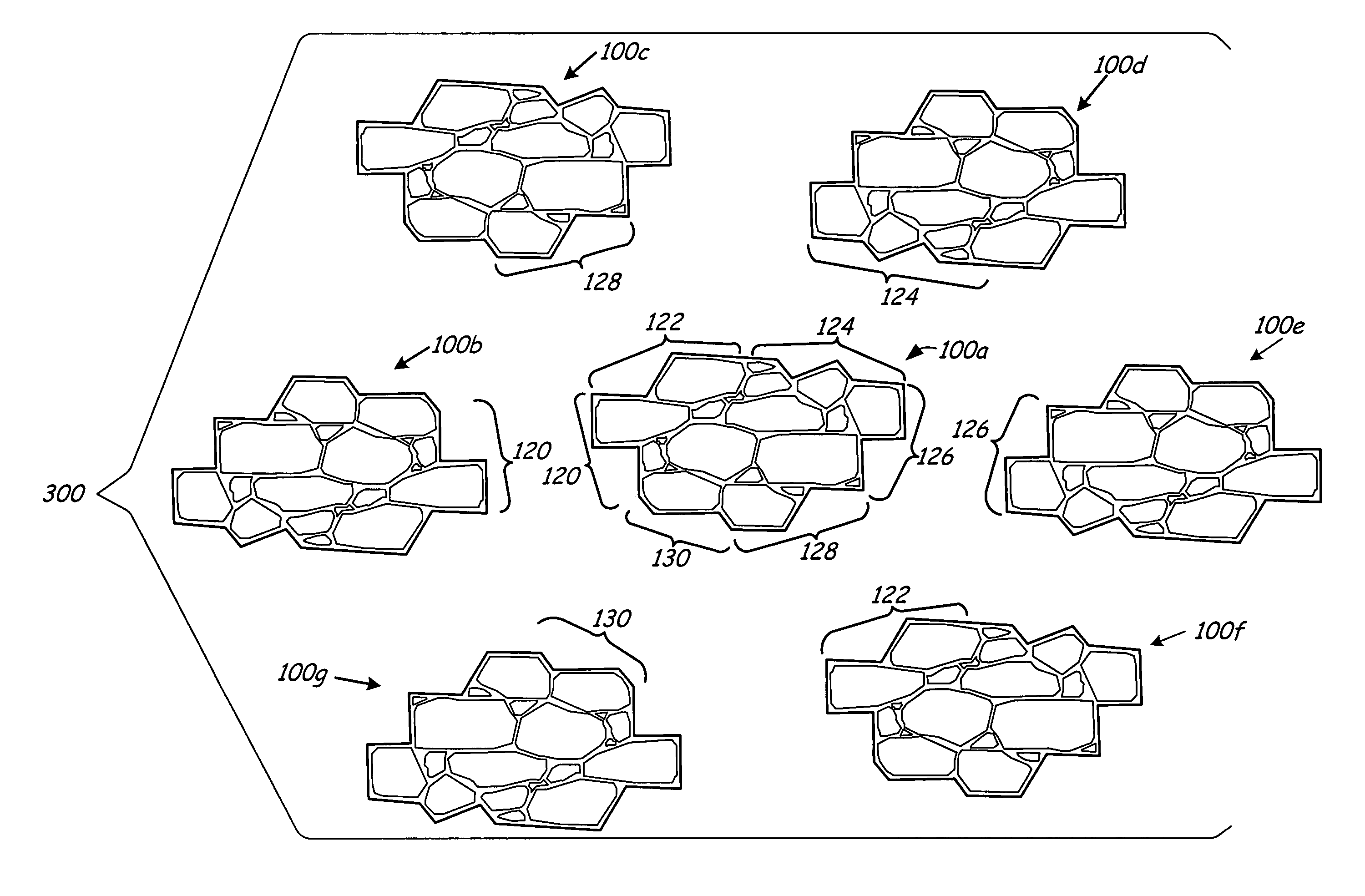

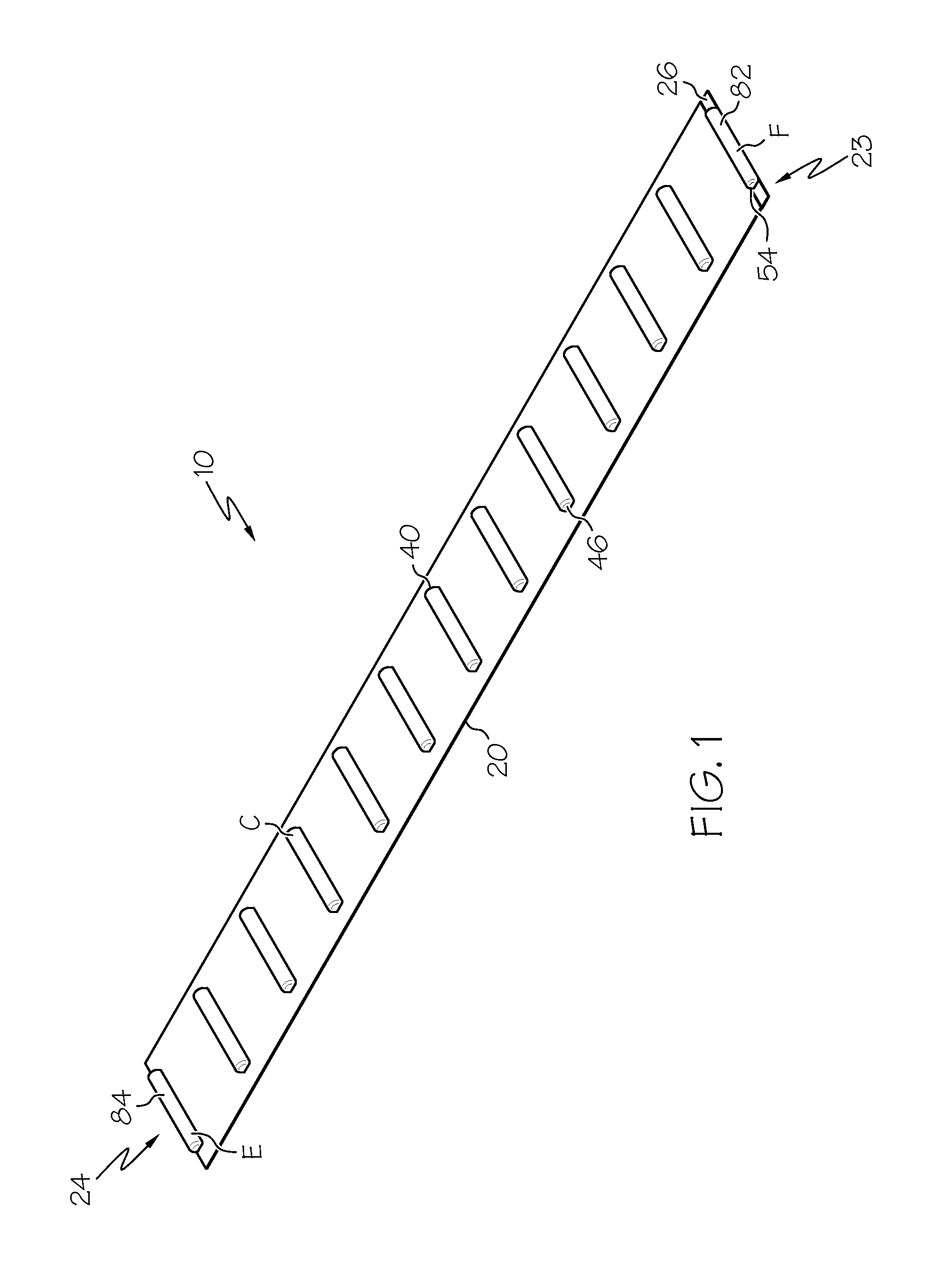

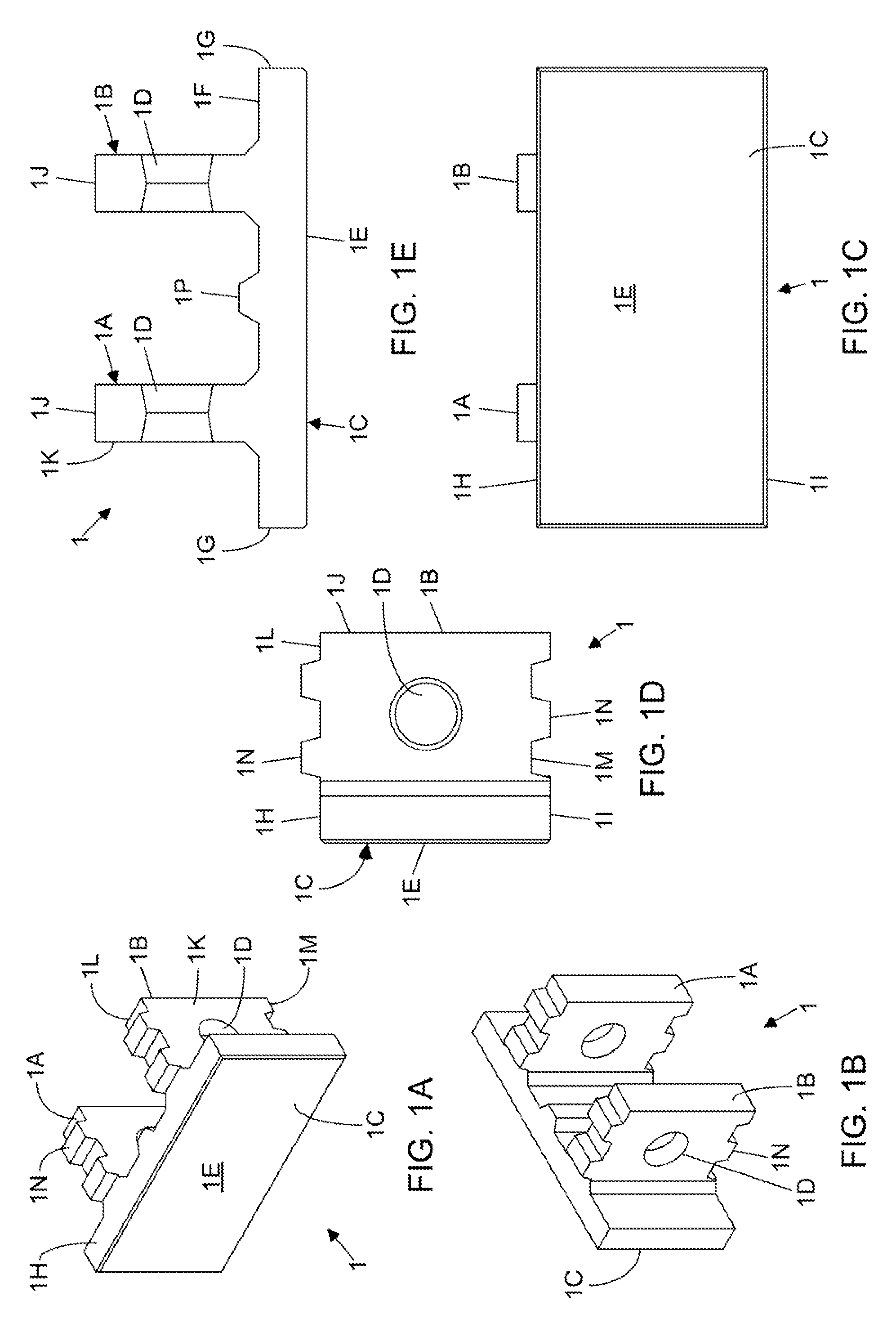

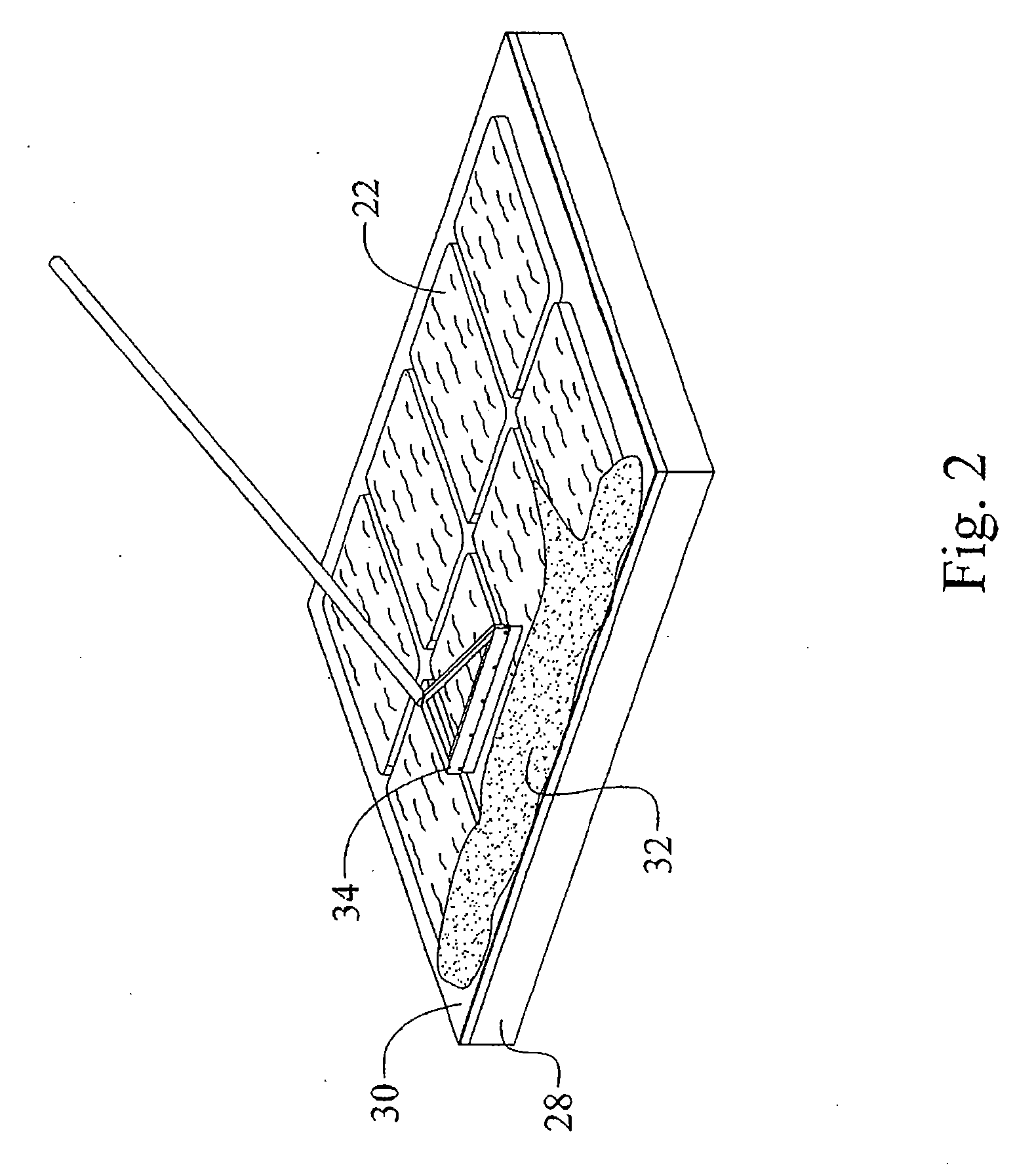

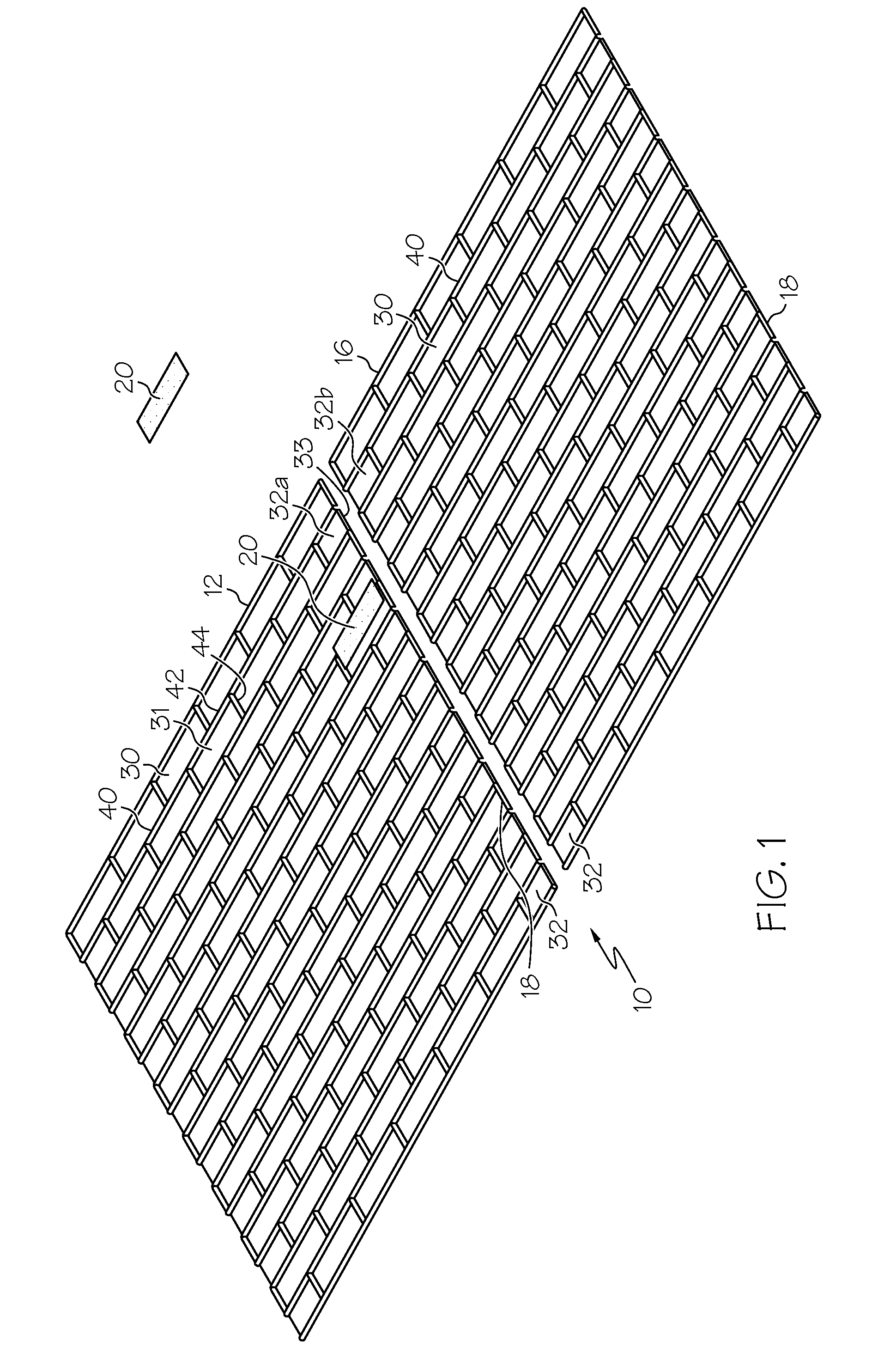

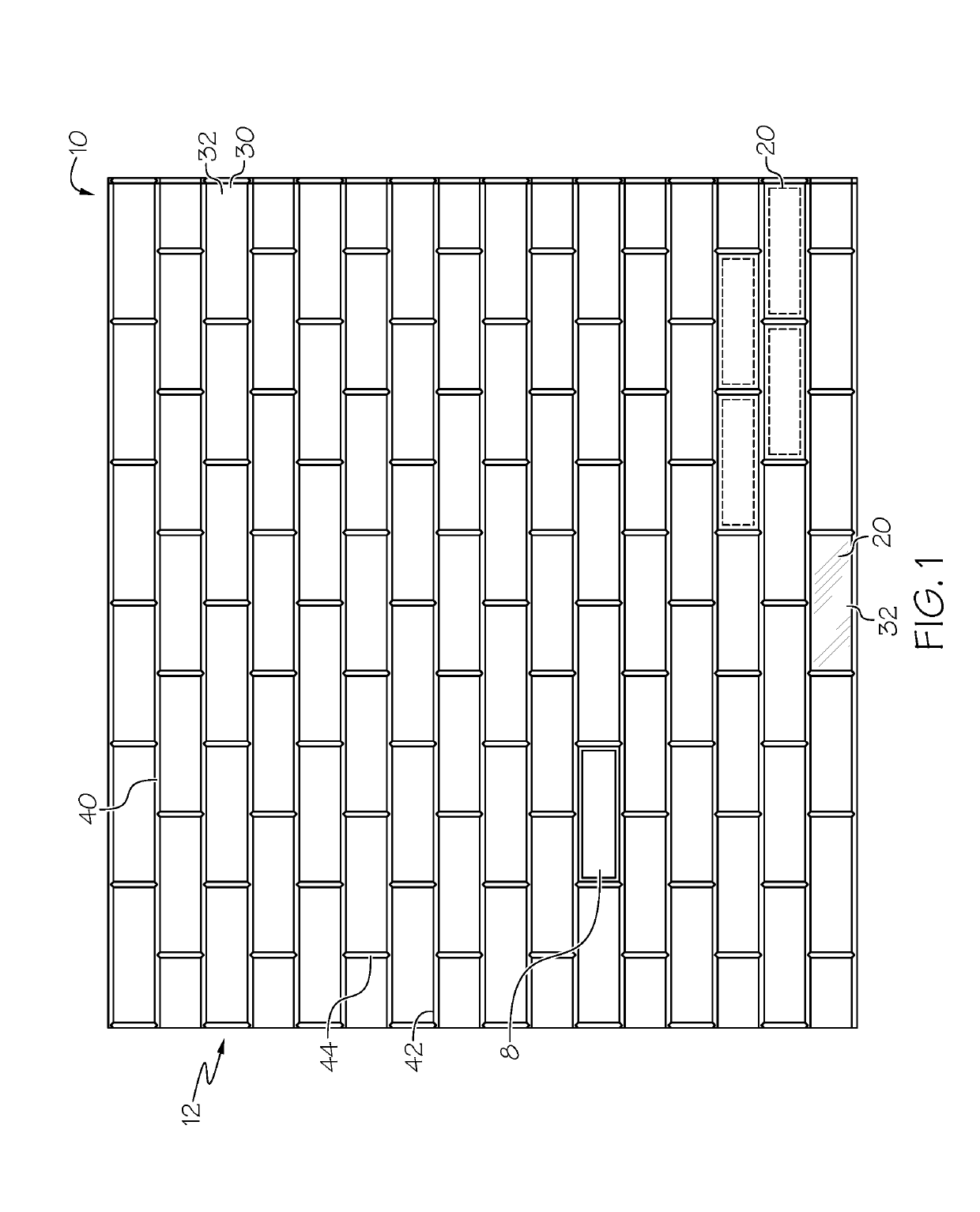

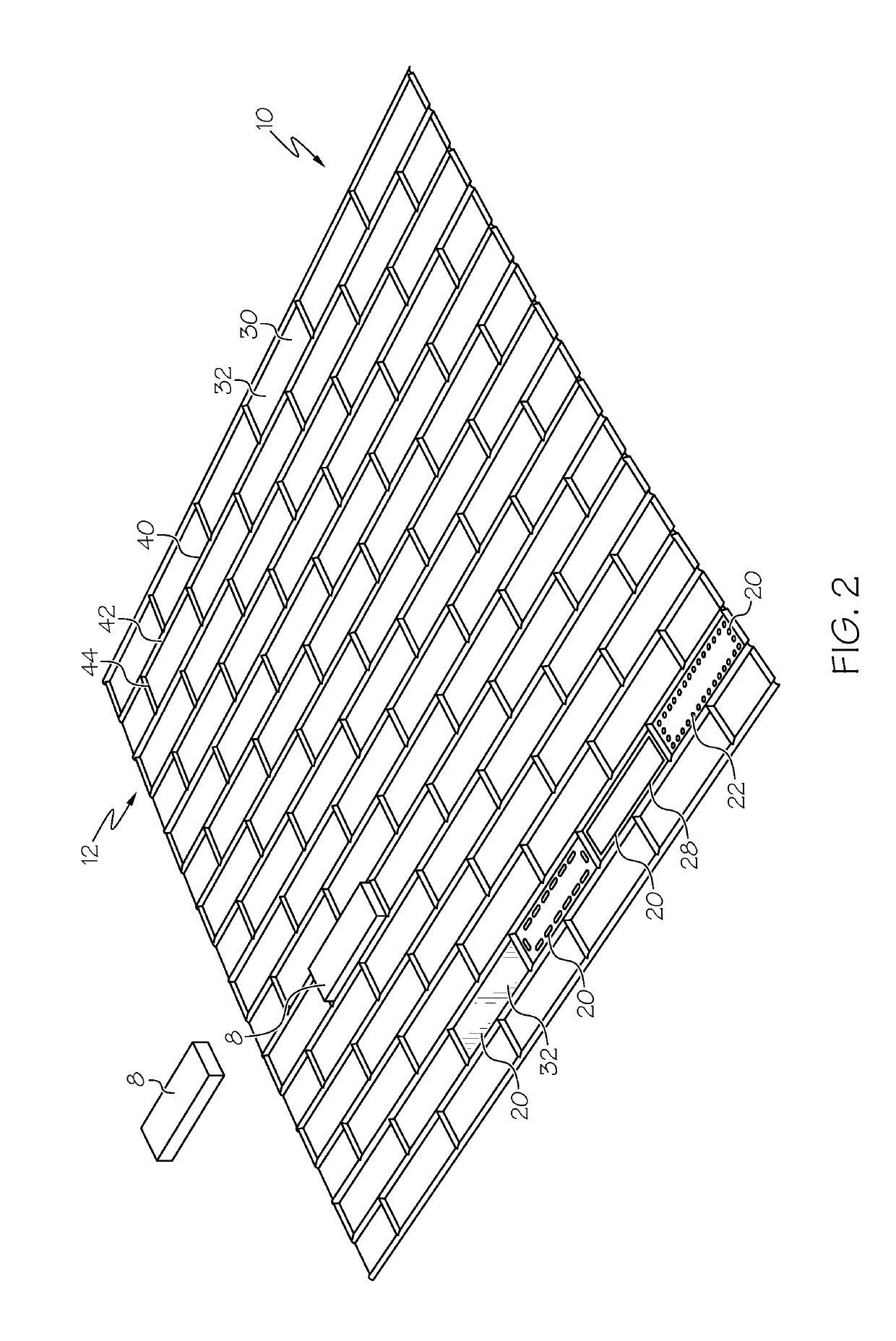

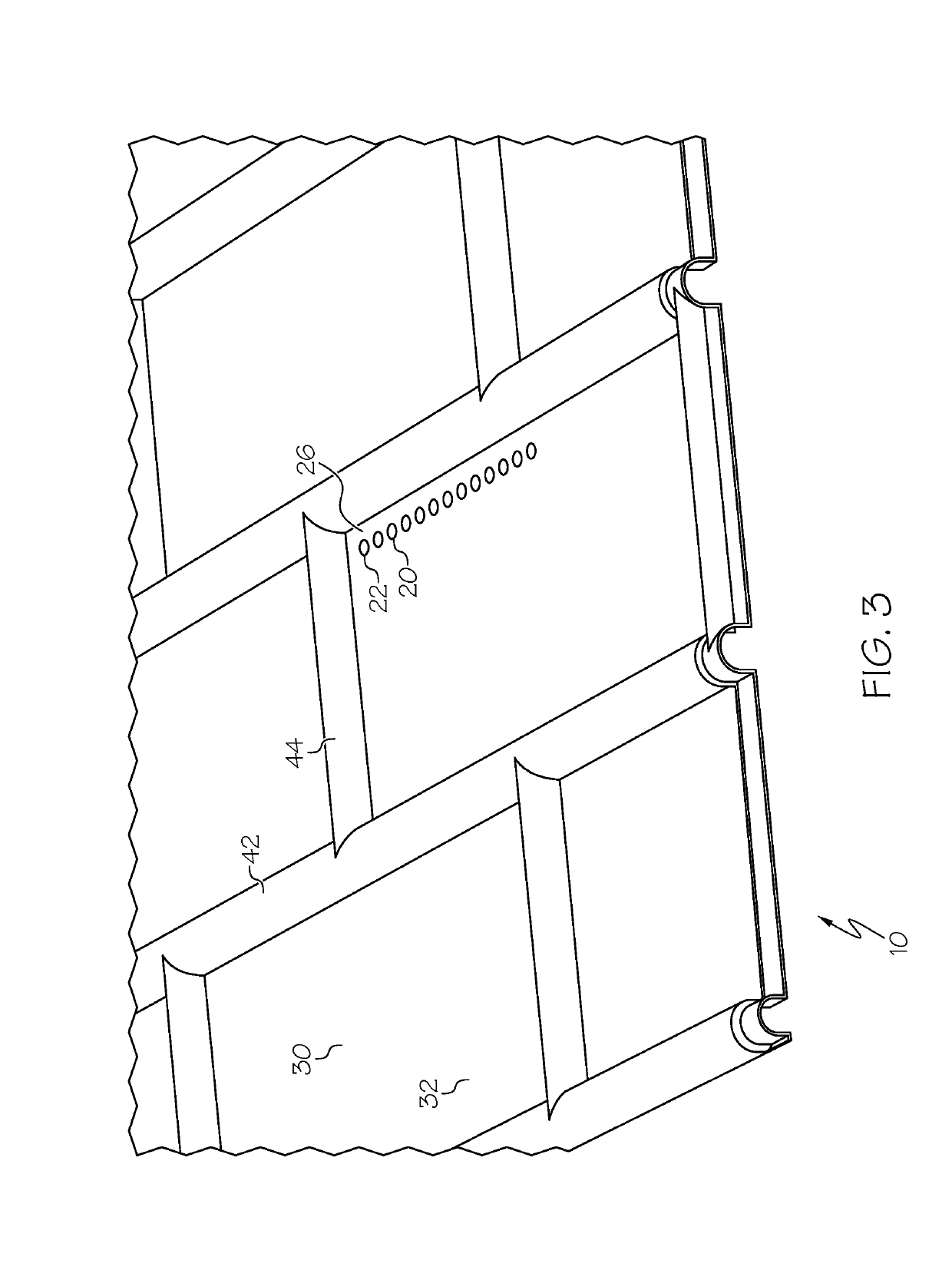

Form liner for creating a realistic stone wall pattern

The form liner of the present invention simulates a natural stone wall having a random pattern. The form liner comprises an outer edge and a surface that is contoured to resemble a plurality of stones held together by an adhesive substance. The outer edge of the form liner has six connection regions made up of multiple linear segments. No two adjacent connection regions are connected at a ninety degree angle and no linear segment of the fifth connection region lies along the same linear path as any linear segment of the sixth connection region.

Owner:NASVIK PAUL C

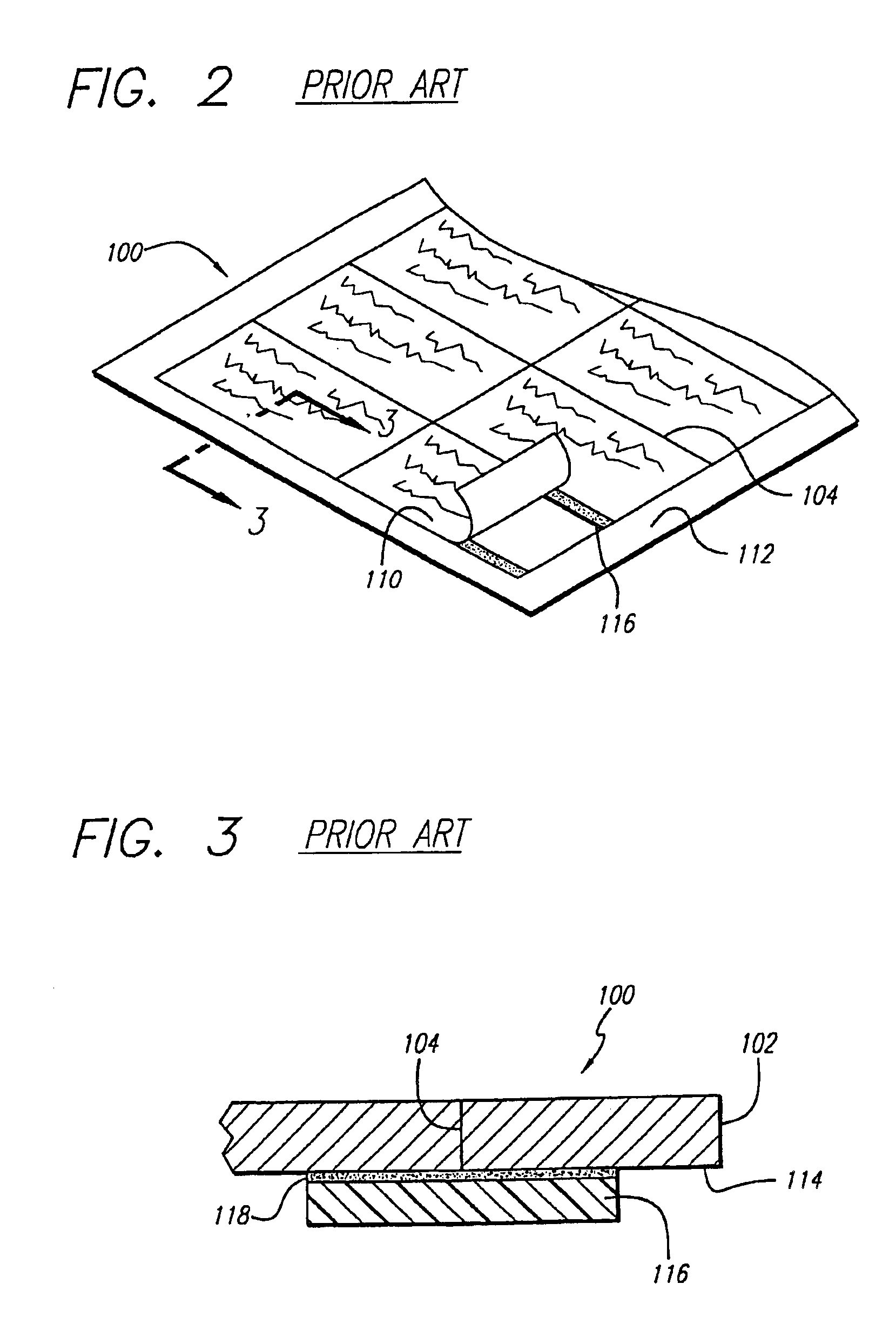

Method of forming sheets of printable media

InactiveUS6890397B1Reduce the amount requiredEffectively fed into printerOther printing matterLamination ancillary operationsLow-density polyethyleneEngineering

A low density polyethylene film layer is extrusion coated on densified bleached kraft paper liner to form a film-coated liner sheet. A facestock sheet is adhered with a layer of hot melt adhesive to the film layer to form a laminate sheet web, which is rolled on a roll. The facestock sheet, the film layer and the adhesive layer together define a laminate feedstock. The roll is transported to and loaded on a press with the liner side up. One (or both) edge(s) of the web is (are) crushed with a calendering die to form thin lead-in edge(s). The web is die cut on the bottom face, up through the laminate facestock, but not through the paper liner, to form the perimeters of a grid of blank business cards or other printable media, with a waste paper frame of the laminate facestock encircling the grid. The web is then die cut from the top through the paper liner and to but not through the laminate facestock, to form liner strips covering the back face of the laminate facestock. According to one preferred embodiment of the invention, alternate ones of the strips are then pulled off of the laminate facestock web. A final production step is to sheet the web to form the desired sheet width (or length) of the laminated sheet construction. The individual laminated business card sheets can be stacked into the infeed tray of an ink jet printer for example, and the sheets individually and automatically fed lead-in edge first into the printer and a printing operation performed on each of the printable media, to form a sheet of printed media. The remaining strips on the back of the laminate facestock cover the lateral cut lines in the laminate facestock and thereby hold the facestock together as it is fed into and passed through the printer. The user then individually peels the printed media off of the strips and out from the waste paper frame. Thereby printed business cards (or other printed media), each with its entire perimeter defined by clean die cuts, are formed. Instead of calendering both edges of the web and thus the sheet, one end can be calendered and a strip of the laminate facestock can be stripped off of the liner sheet from the other end. The remaining thin liner sheet strip at the other end forms a thin infeed edge for feeding into a horizontal feed, ink jet printer.

Owner:CCL LABEL INC

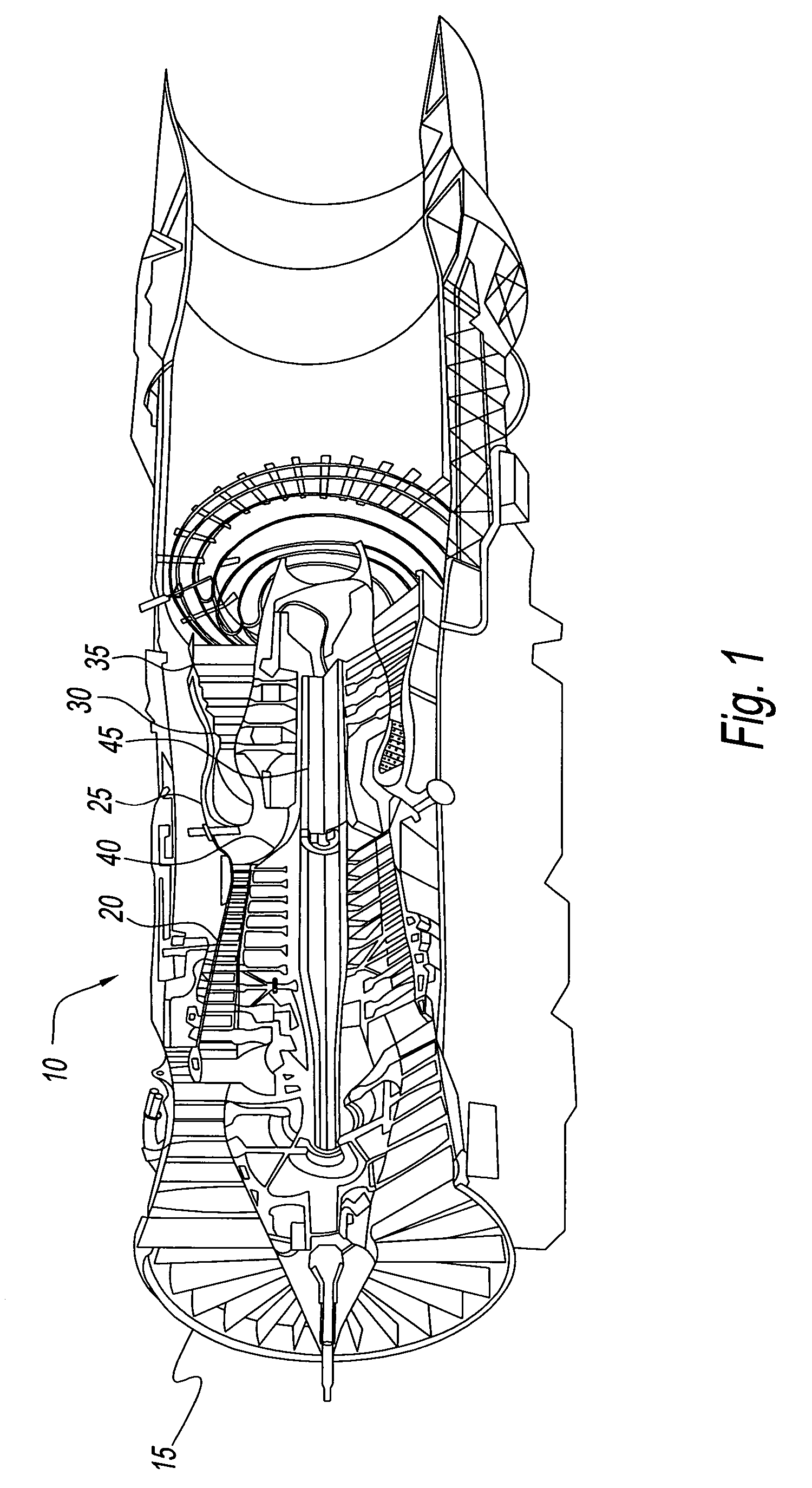

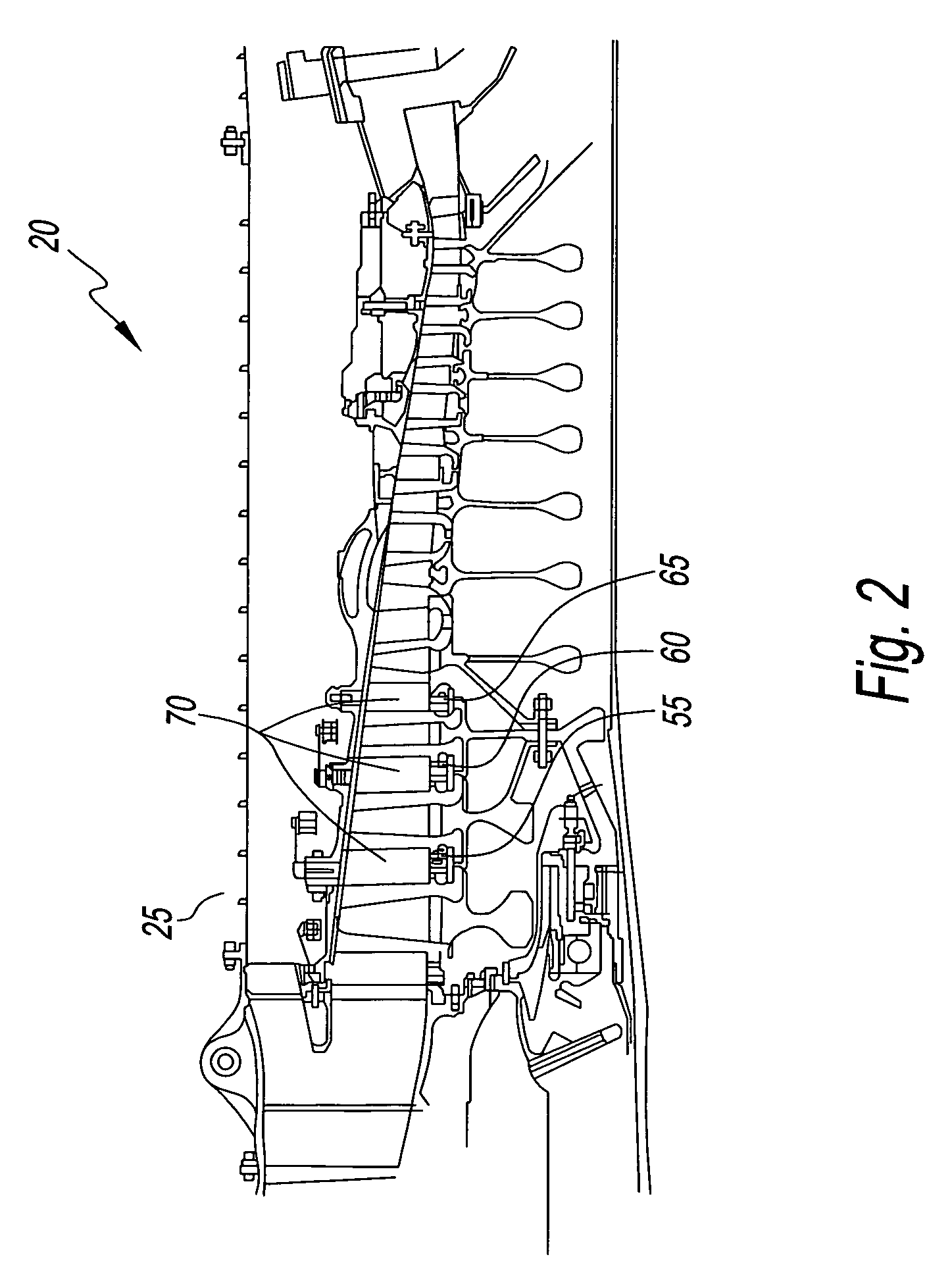

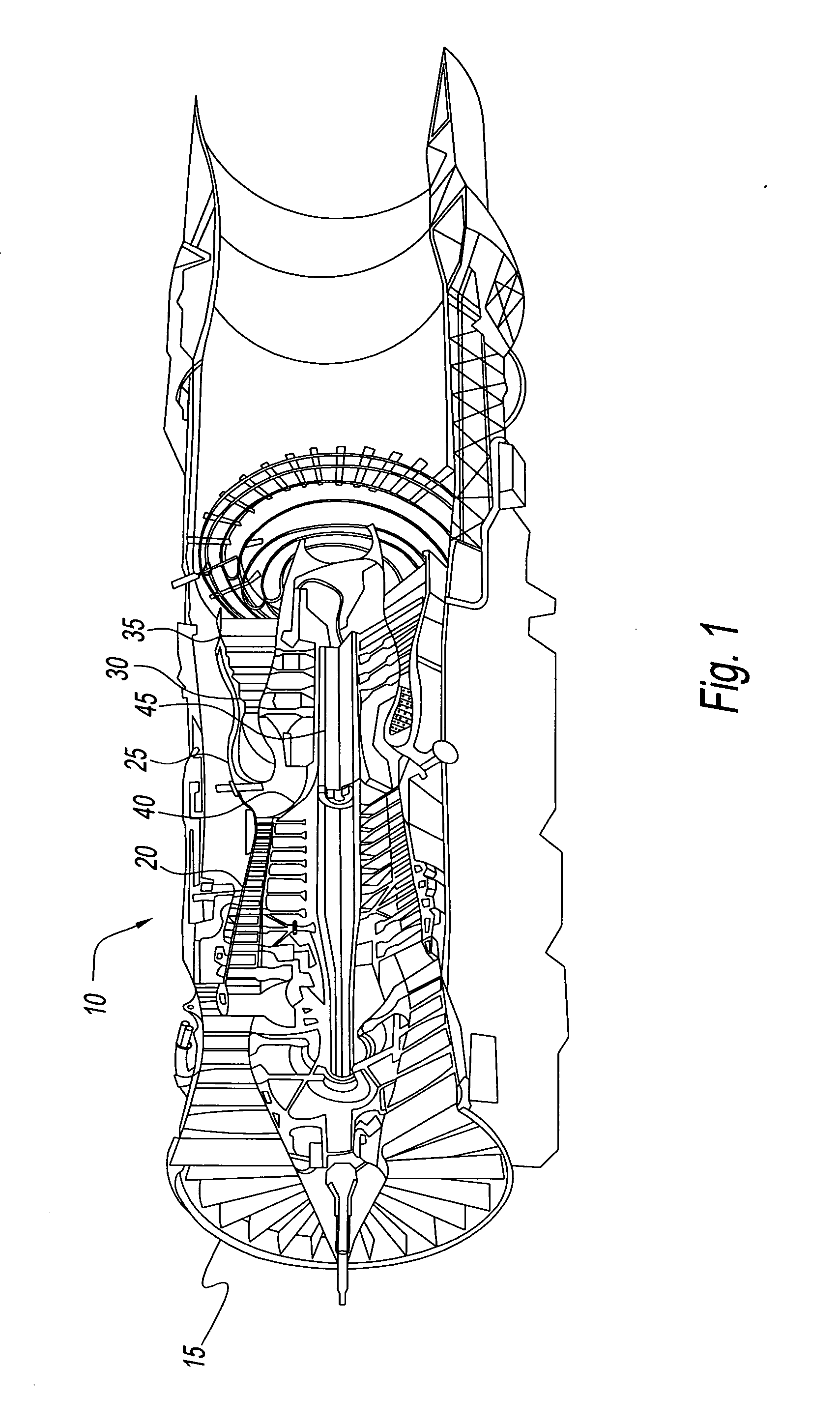

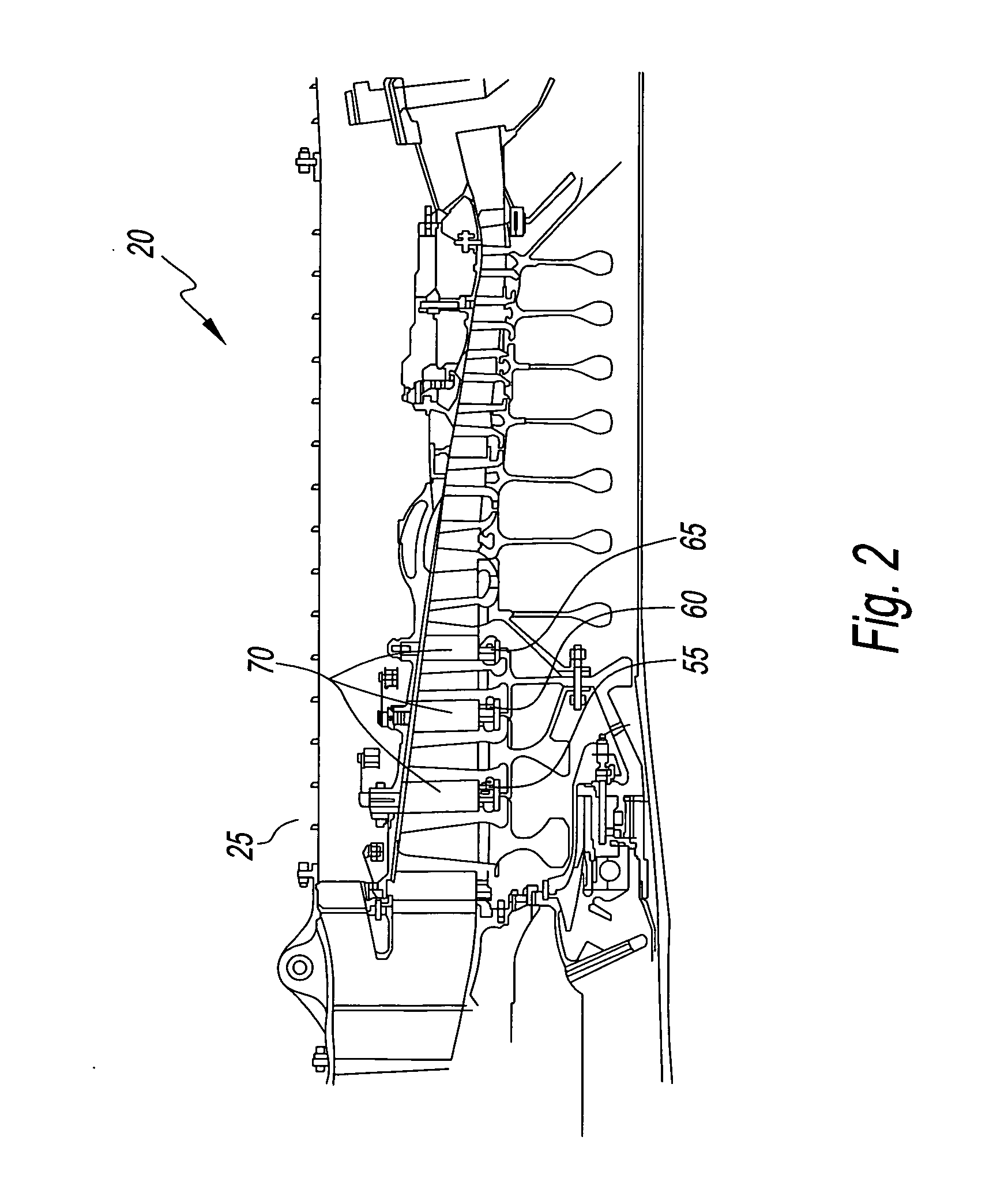

Sacrificial inner shroud liners for gas turbine engines

A split shroud system for a gas turbine engine having a pair of annular-shaped shrouds that each have an inner pocket; to form a pair of inner pockets. Each of the pair of pockets having liner parts that form a circle. Liner parts of one of the pair of pockets facing liner parts of the other of the pair of pockets to form liner part pairs. One of each of said of pair of liner parts has a mutual abutting surface that forms a plurality of slots for accepting a plurality of vane inner trunnions.

Owner:RTX CORP

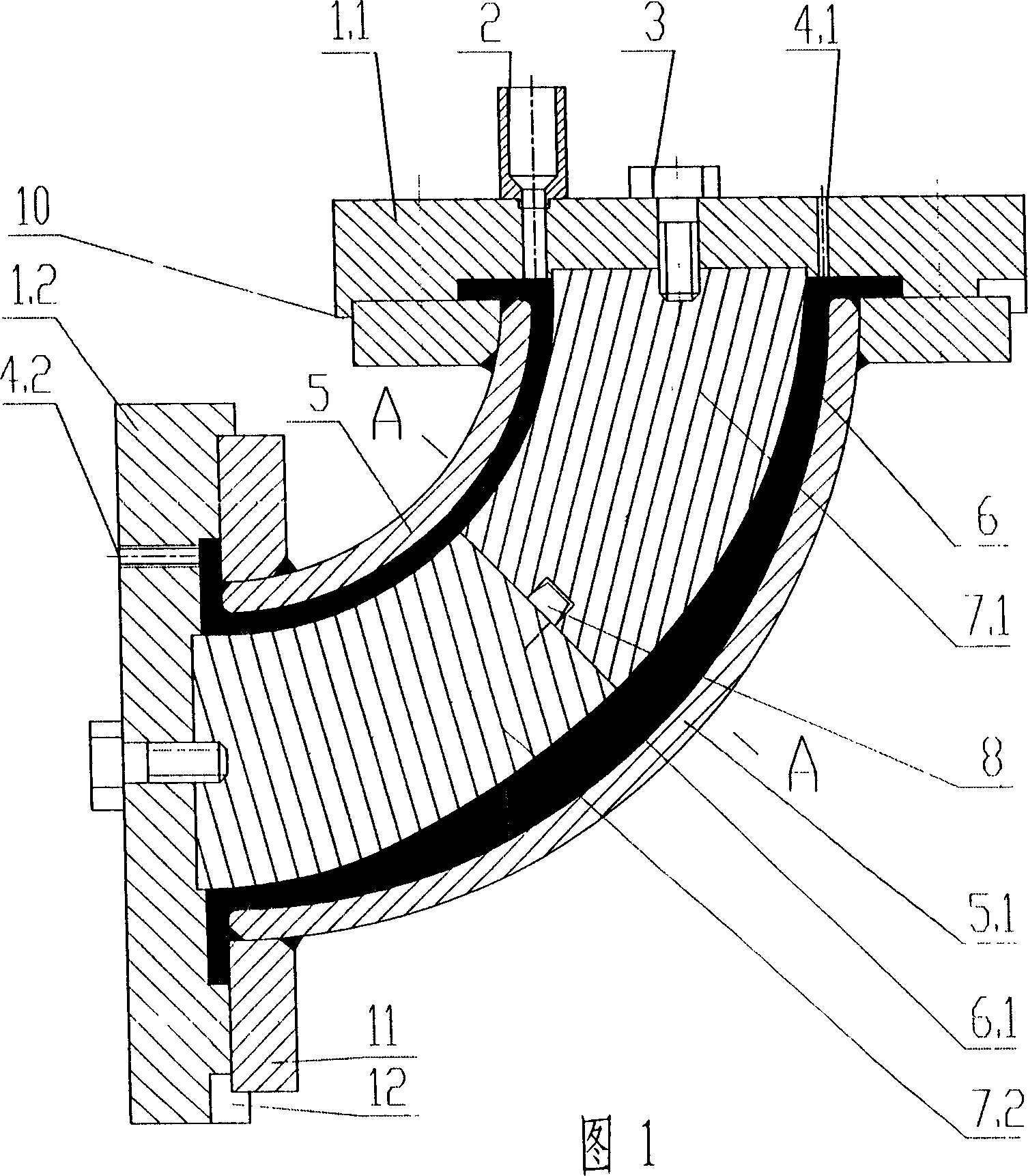

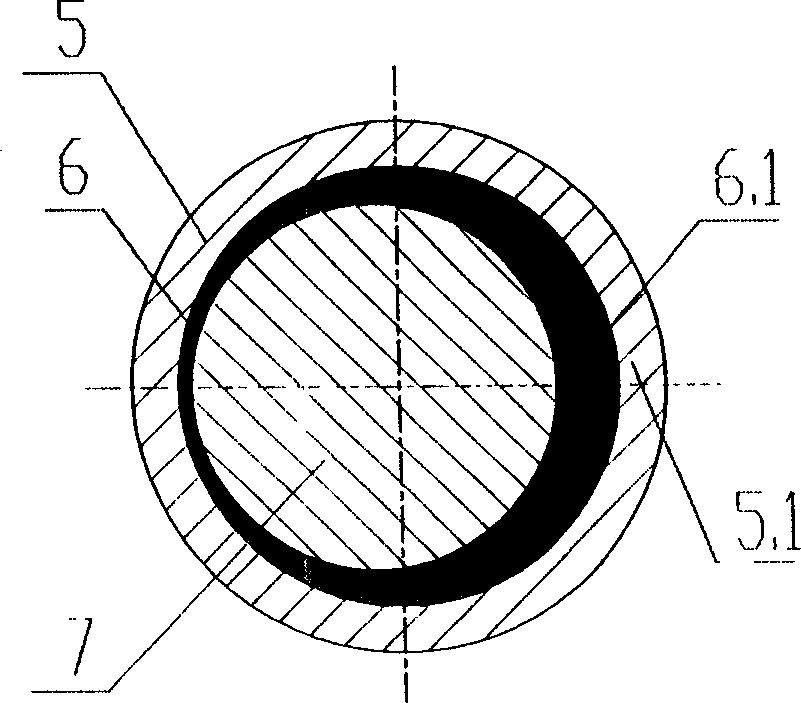

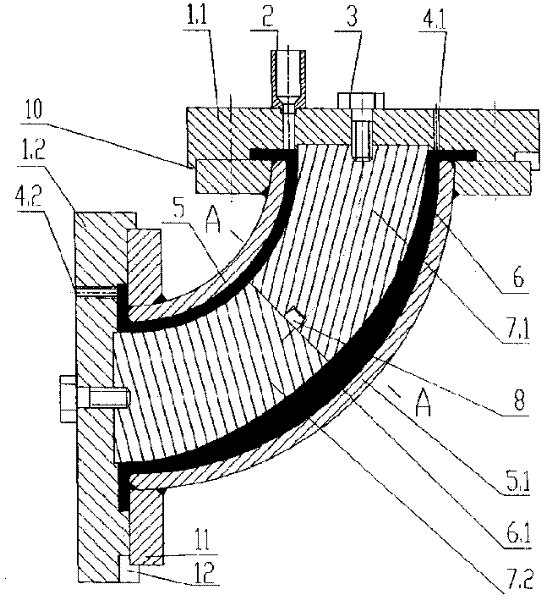

Channel elbow with wearable liner and lining method thereof

InactiveCN1415888AExtended service lifeImprove wear resistancePipe protection against damage/wearSiphonsForm linerWear resistant

This invention relates to a wear-resistant liner pipeline elbow and forming method which can prolong it life time characterizing in thickening inside of pipeline elbow bow part of wear-resistant liner to turn thinner and thinner steadily towards the two sides and fixing noncircle axial combined core and enabling to increase the bow part inside gap steadily in the bend inside hole to form liner layer in gaps of unequal width faces between inside of liner elbow and the core mode formed by filling or pressing especially by urethane rubber to pour the liner to increase the wear resistance of the easiest worn out part of the elbow.

Owner:宜兴市宙斯泵业有限公司

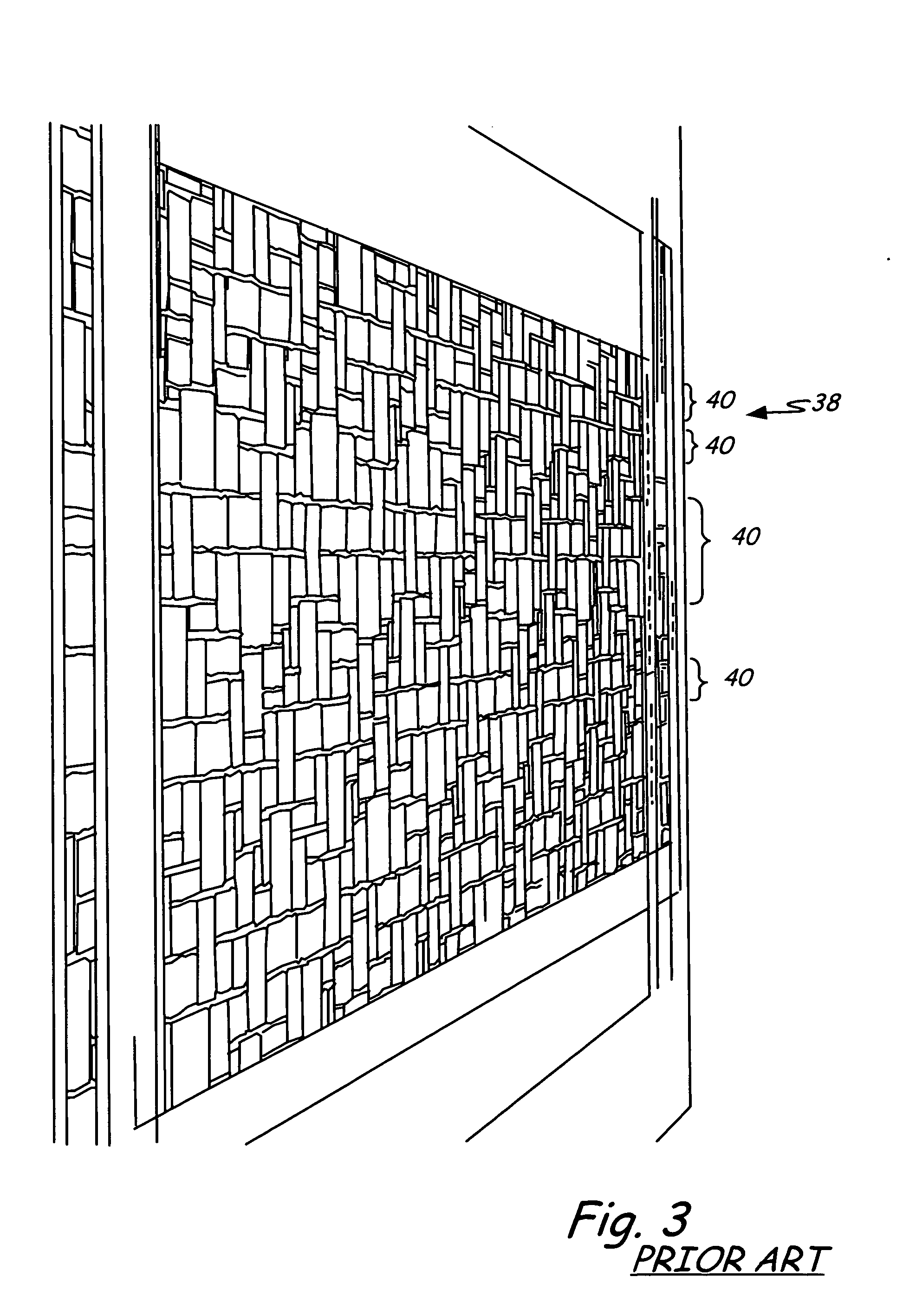

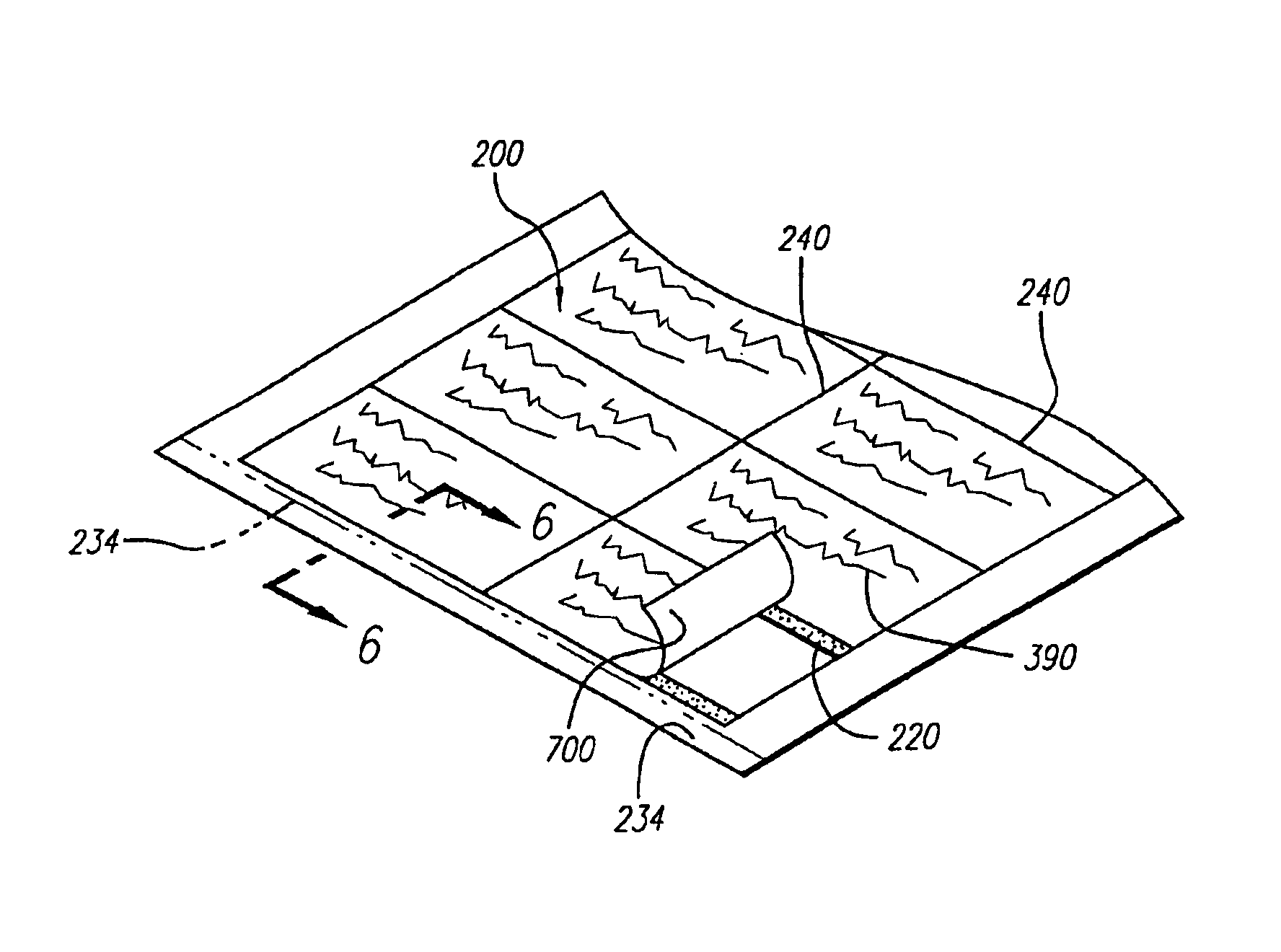

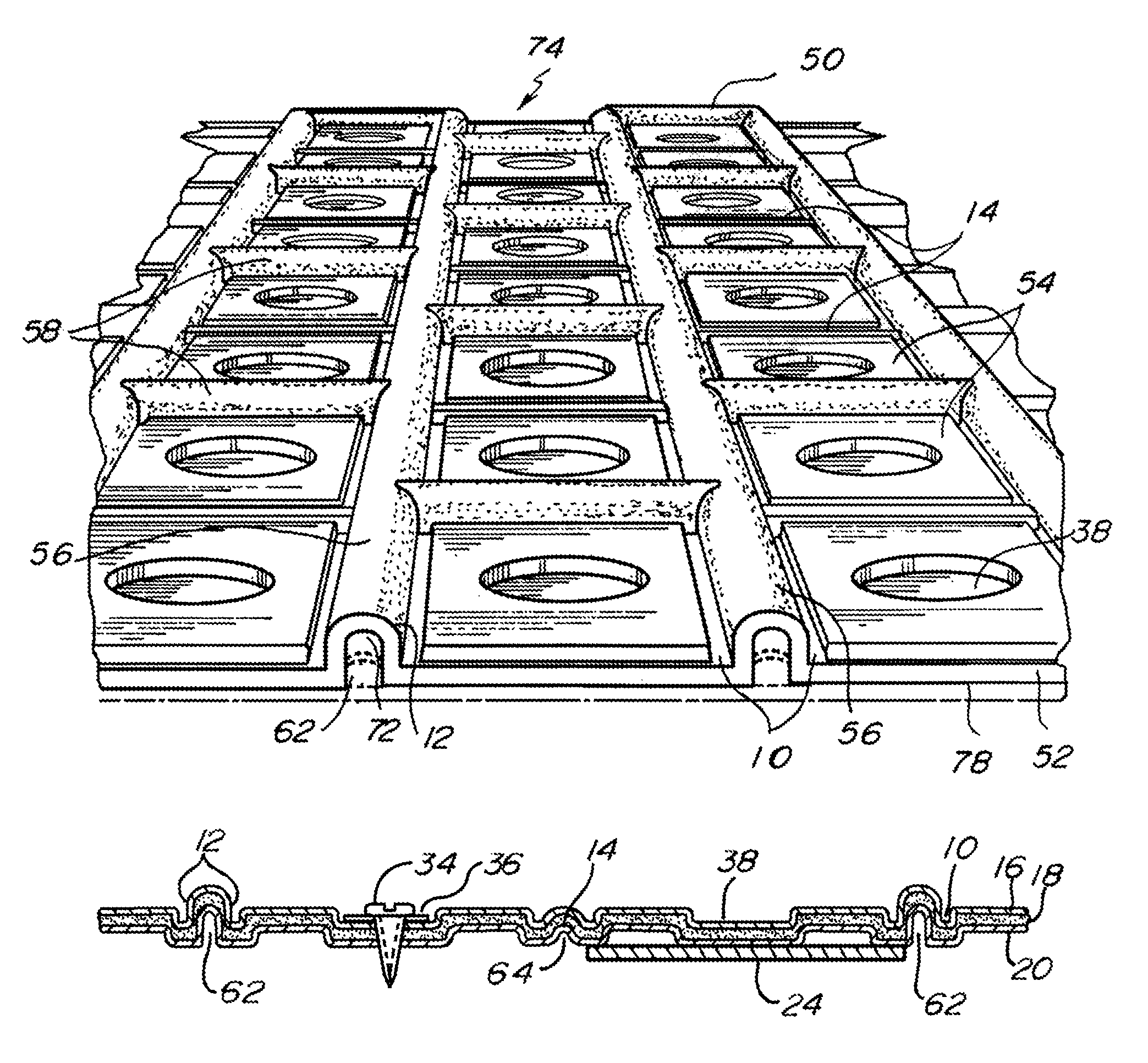

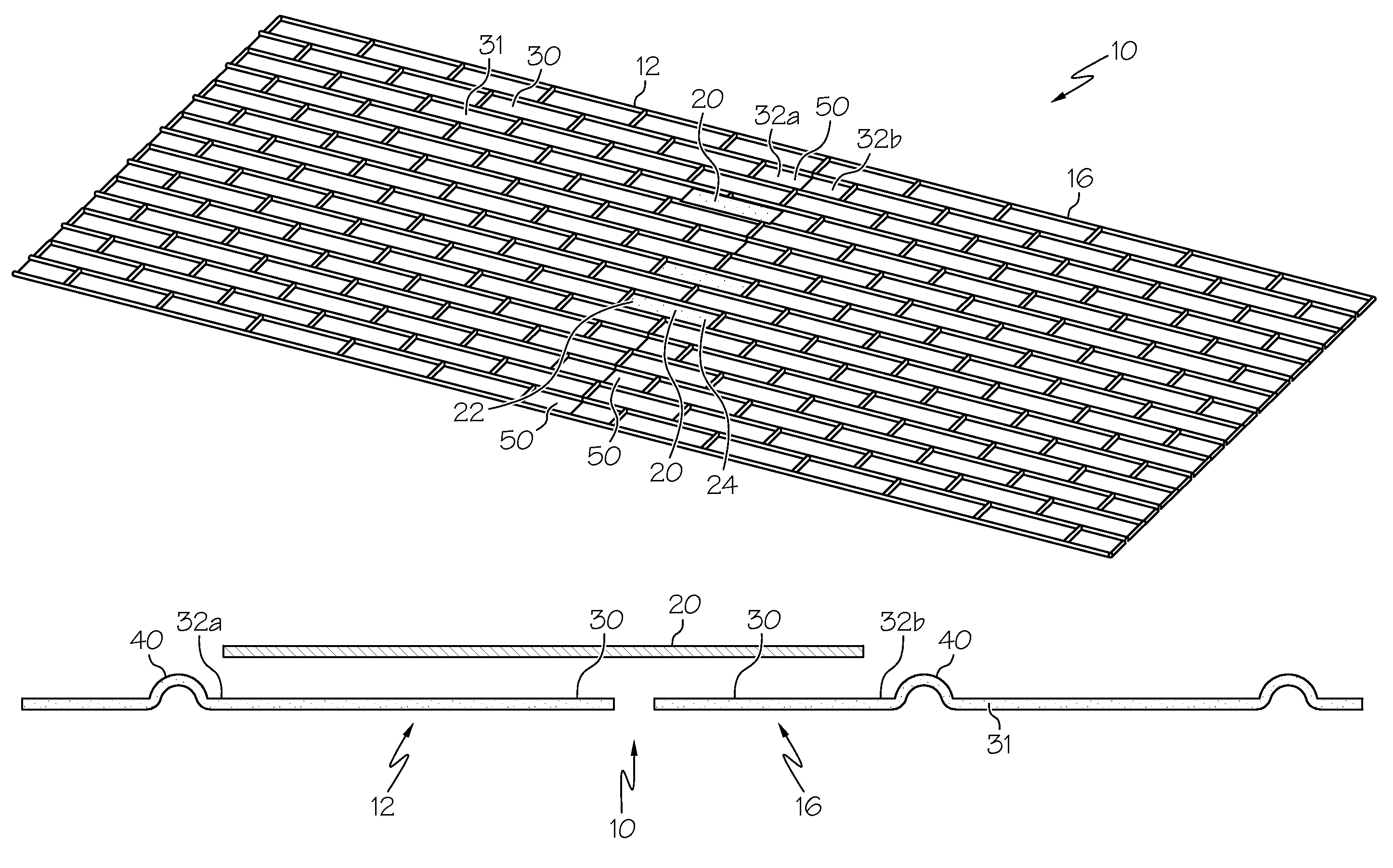

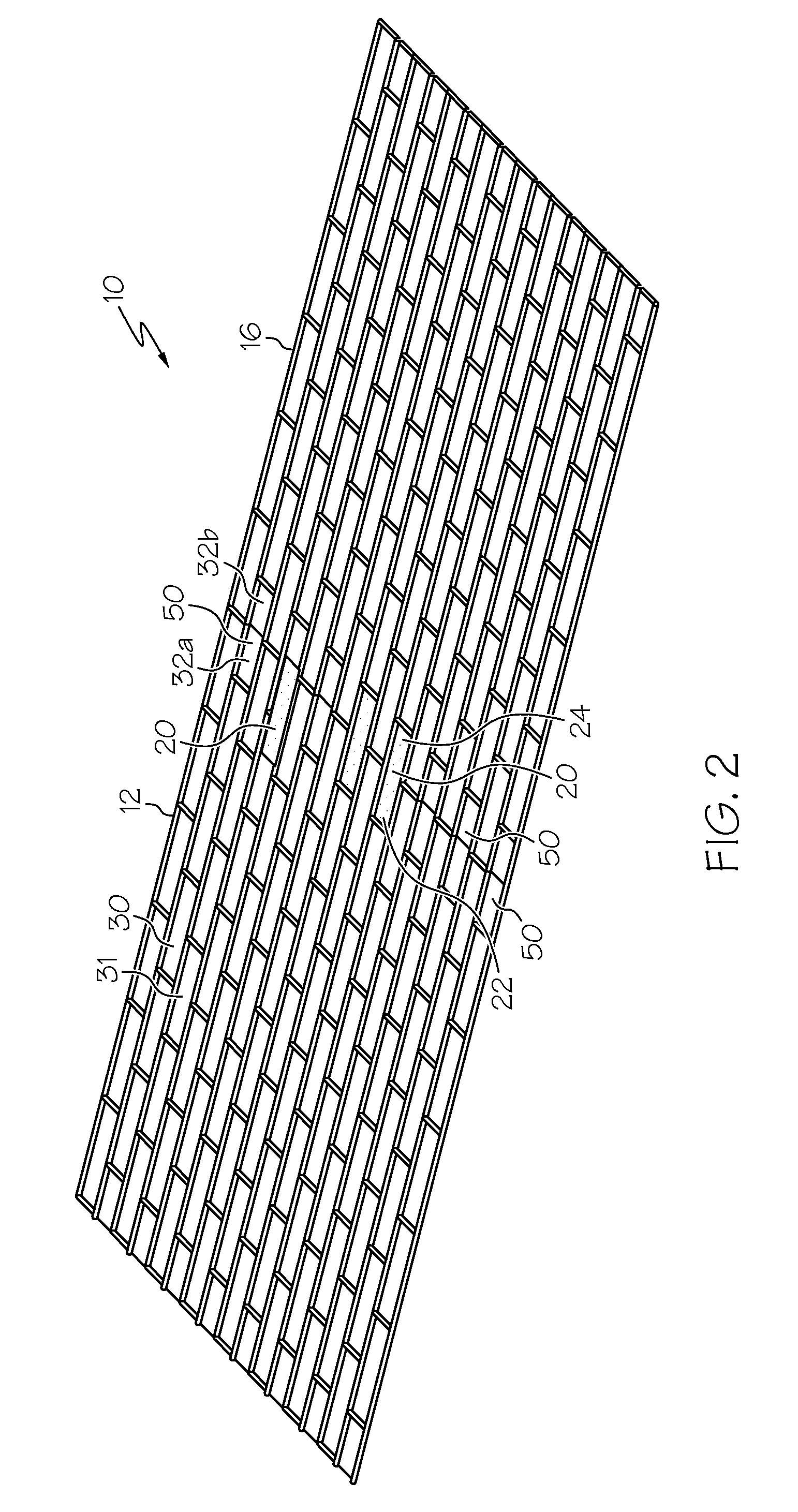

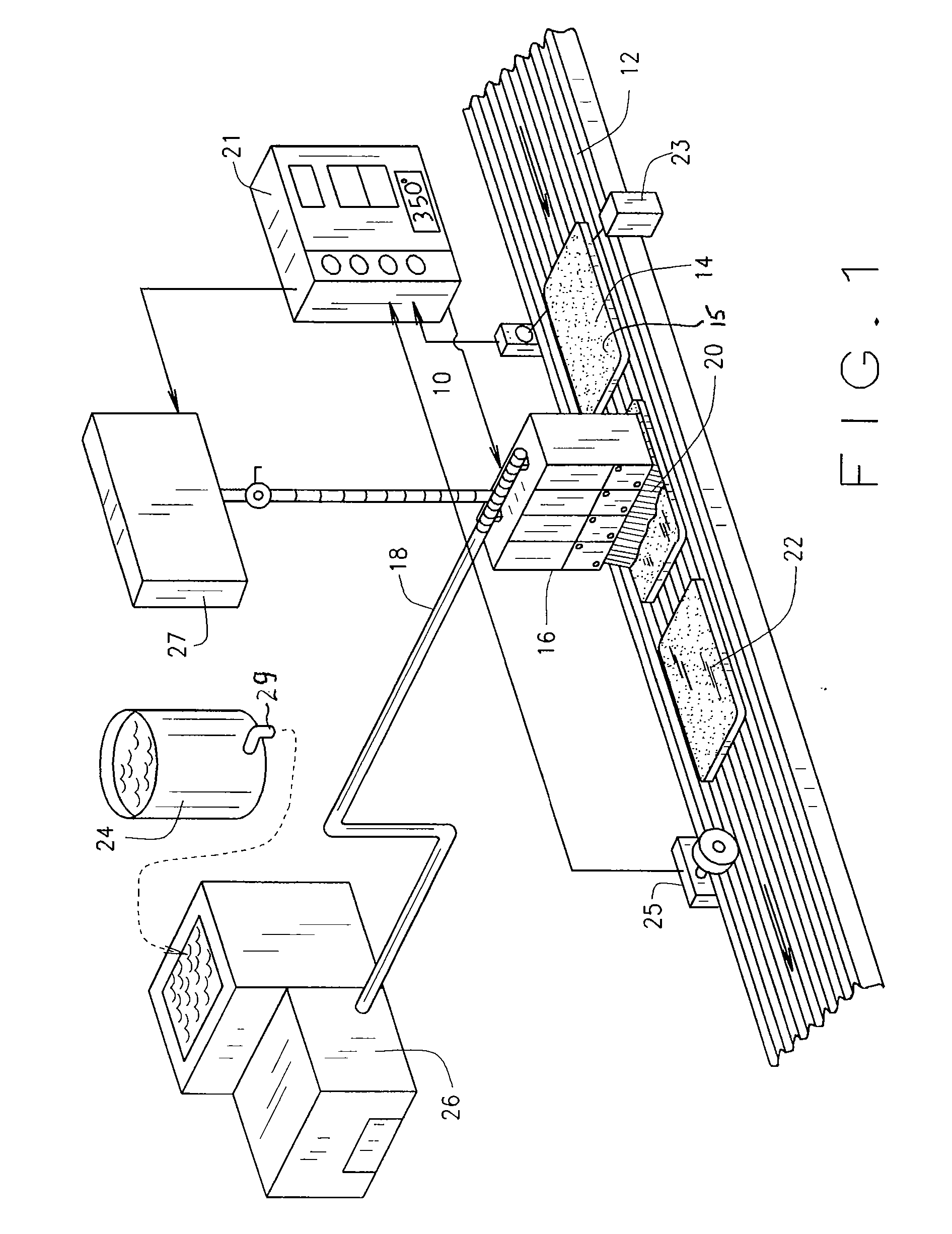

Thermoplastic liner for casting textures and objects into poured wall

A re-useable liner that can be used to make textures as well as secure and seal objects within a form for a poured wall. The liner and the method of making the liner by thermoforming layers which comprises a polyolefin foam sheet, a thermoplastic elastomer, and a polyolefin plastic sheet into a form liner that can imprint various shapes and textures into a poured wall or can be thermoformed into a liner which includes a plurality of joints which can secure objects in a form for a poured wall. The joints between the objects can be formed to be semicircular or flat and also with a variety of textures. The invention includes, a cavity between layers in the joint to allow maximum flexibility of oversized objects, an expansion / contraction absorption device, a channel along the bottom of the grout joint that allows the material layers to stretch, a built in mechanism to attach the apparatus to metal forms using magnetic sheets, an adhesive layer on the edges in order to make the liner larger by joining together one liner to another using an adhesive on the sides and the variable horizontal and vertical joint widths within the liner to make the wall panel look natural.

Owner:ADVANCED FORMLINERS

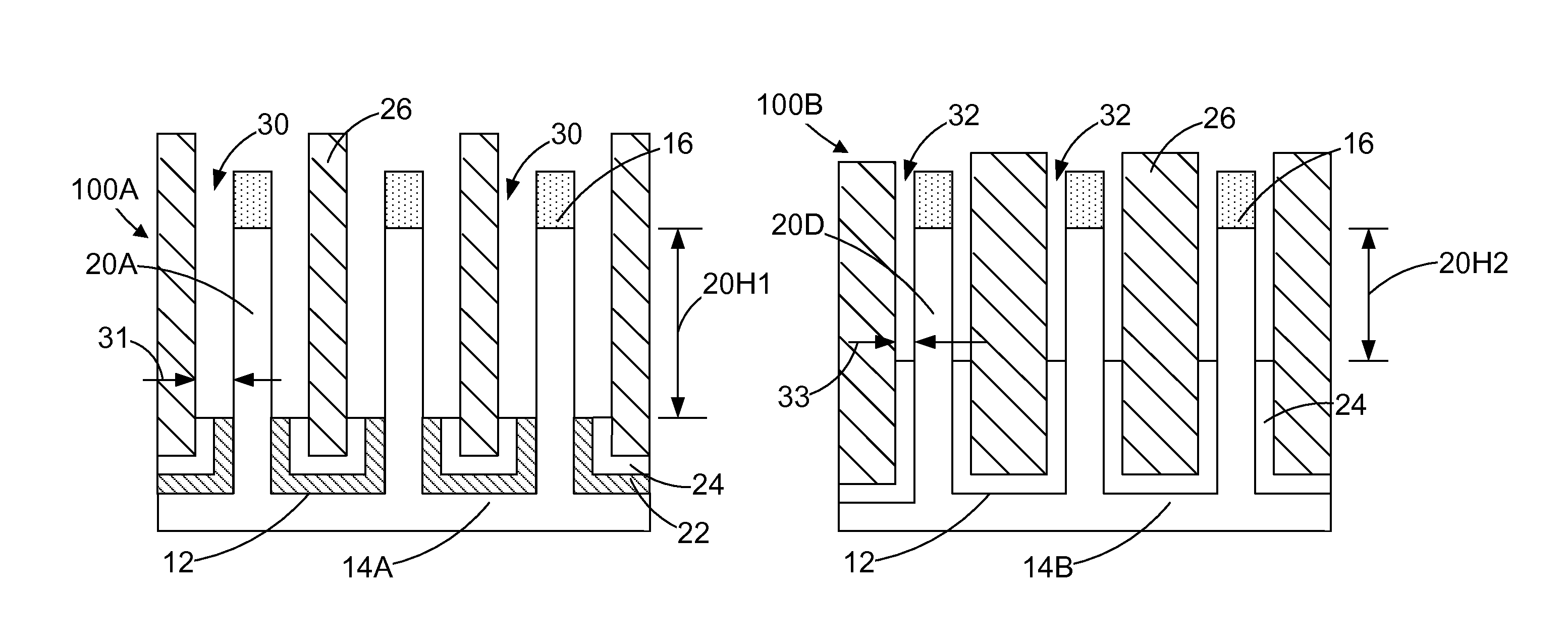

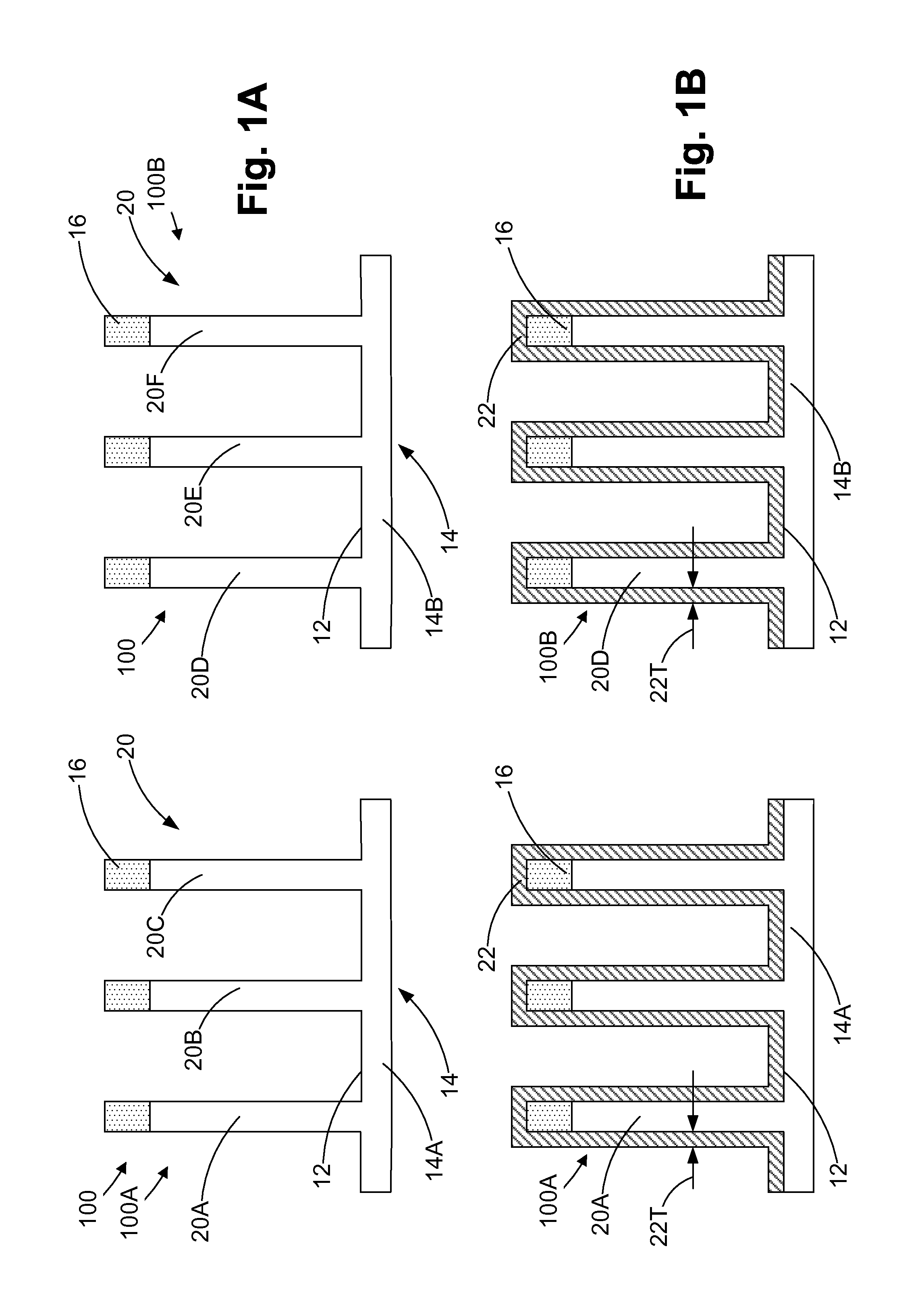

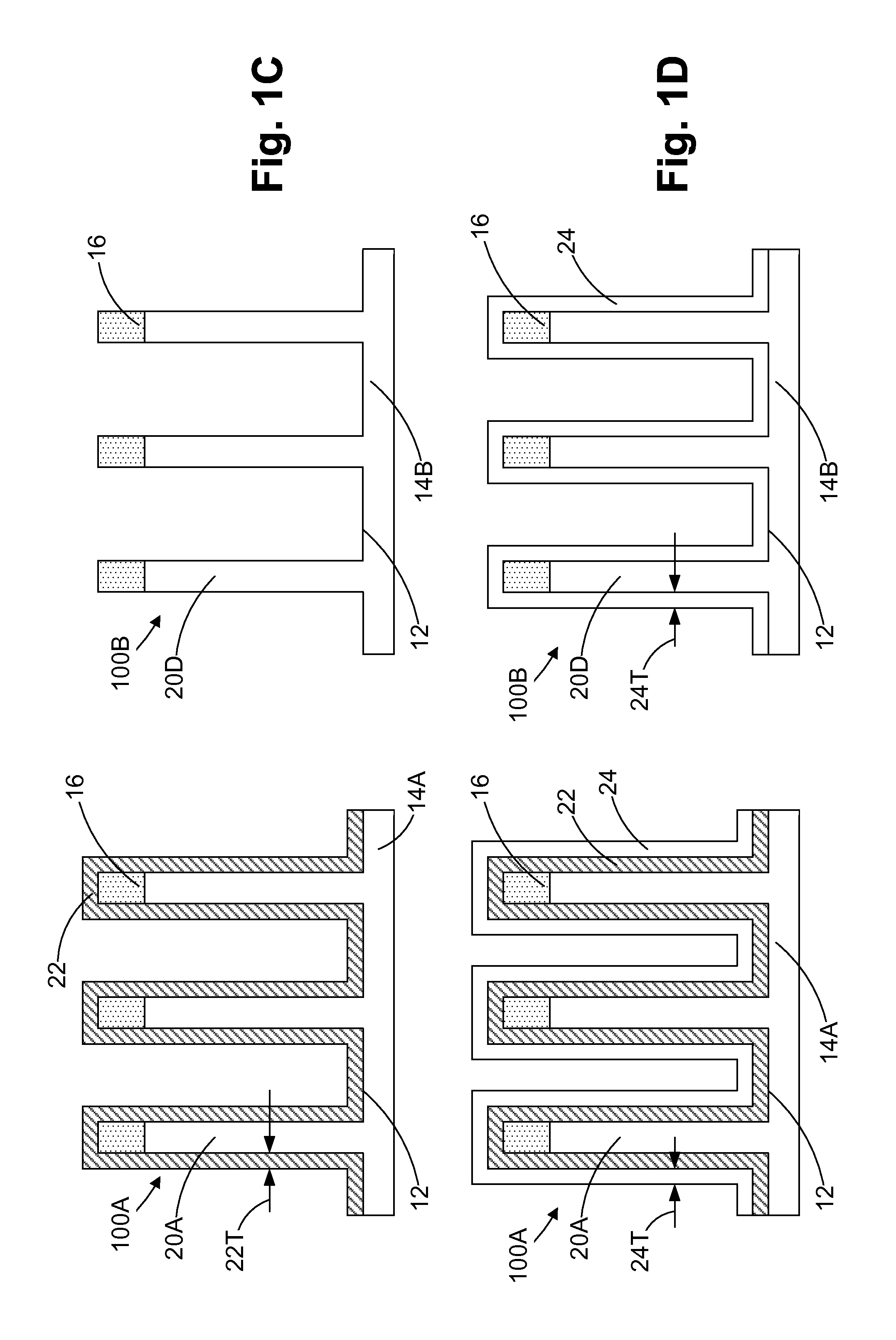

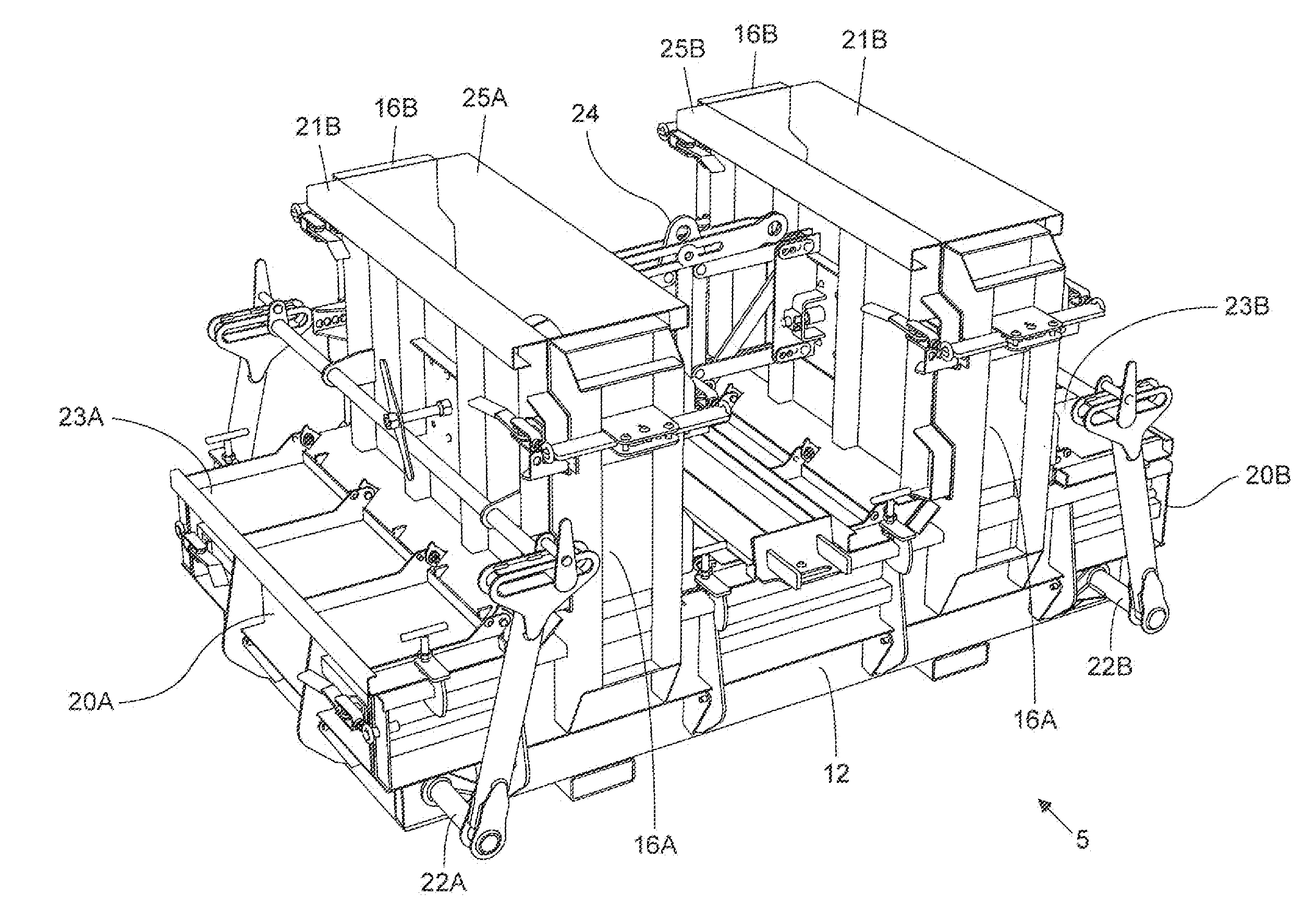

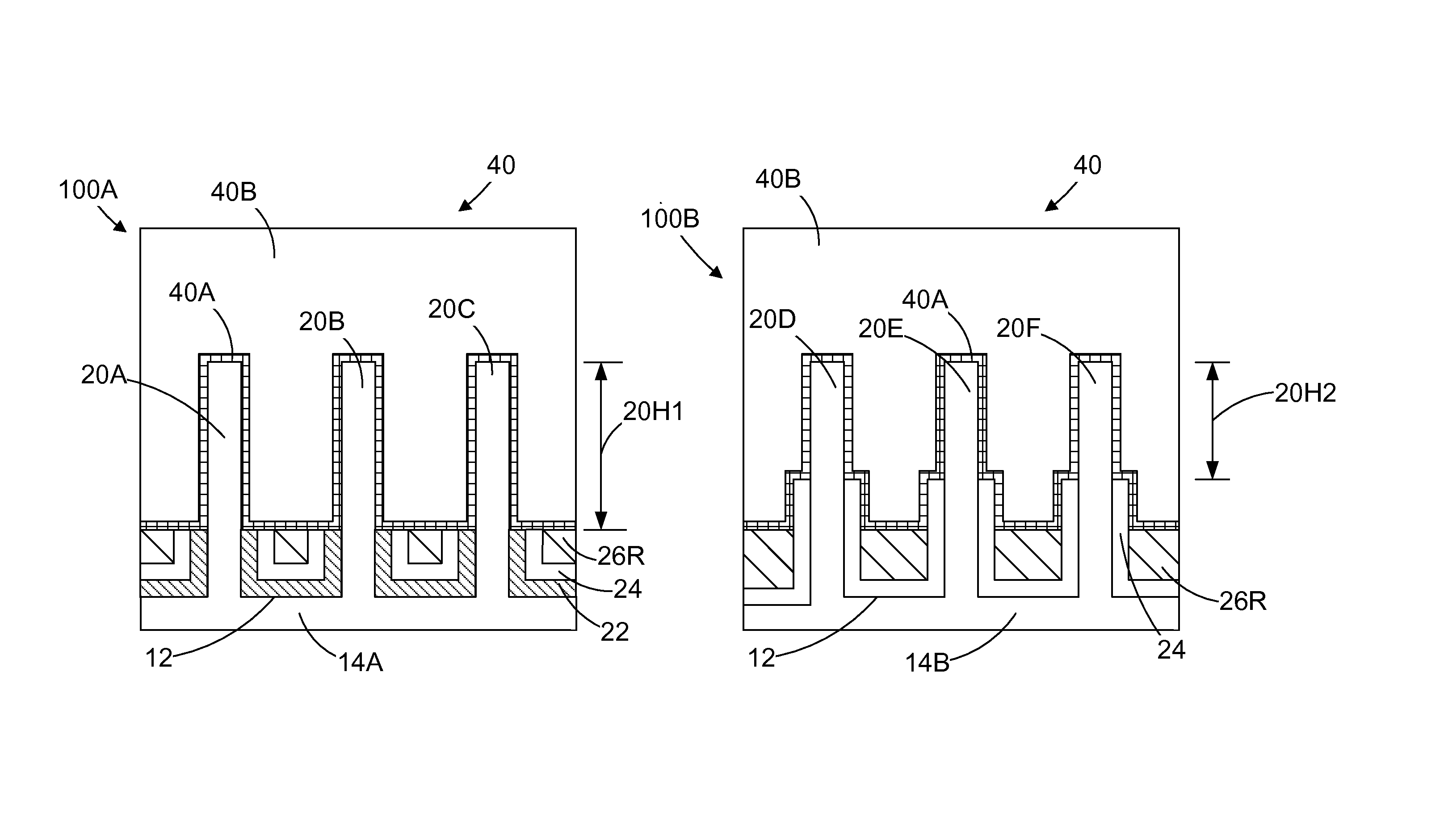

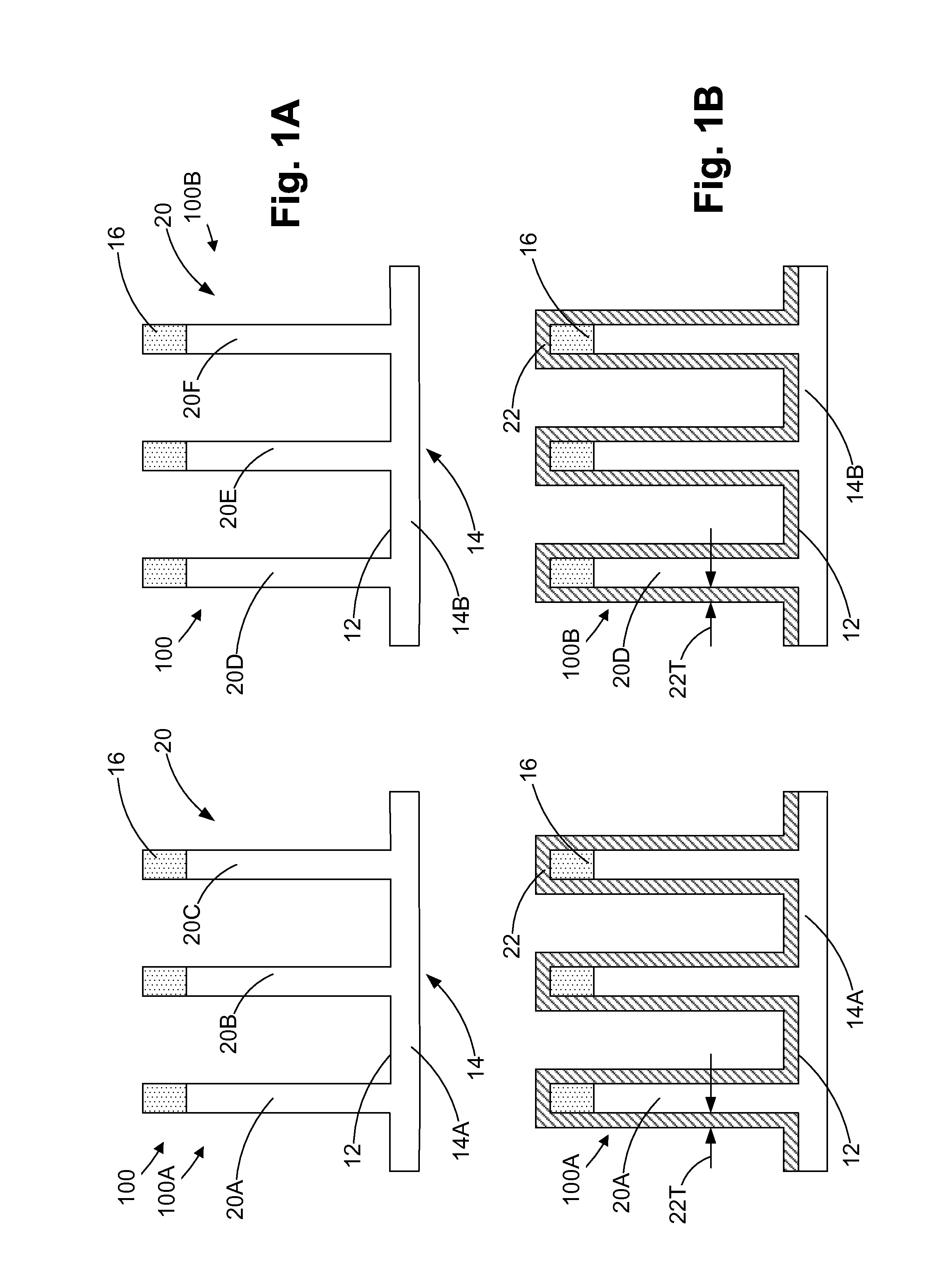

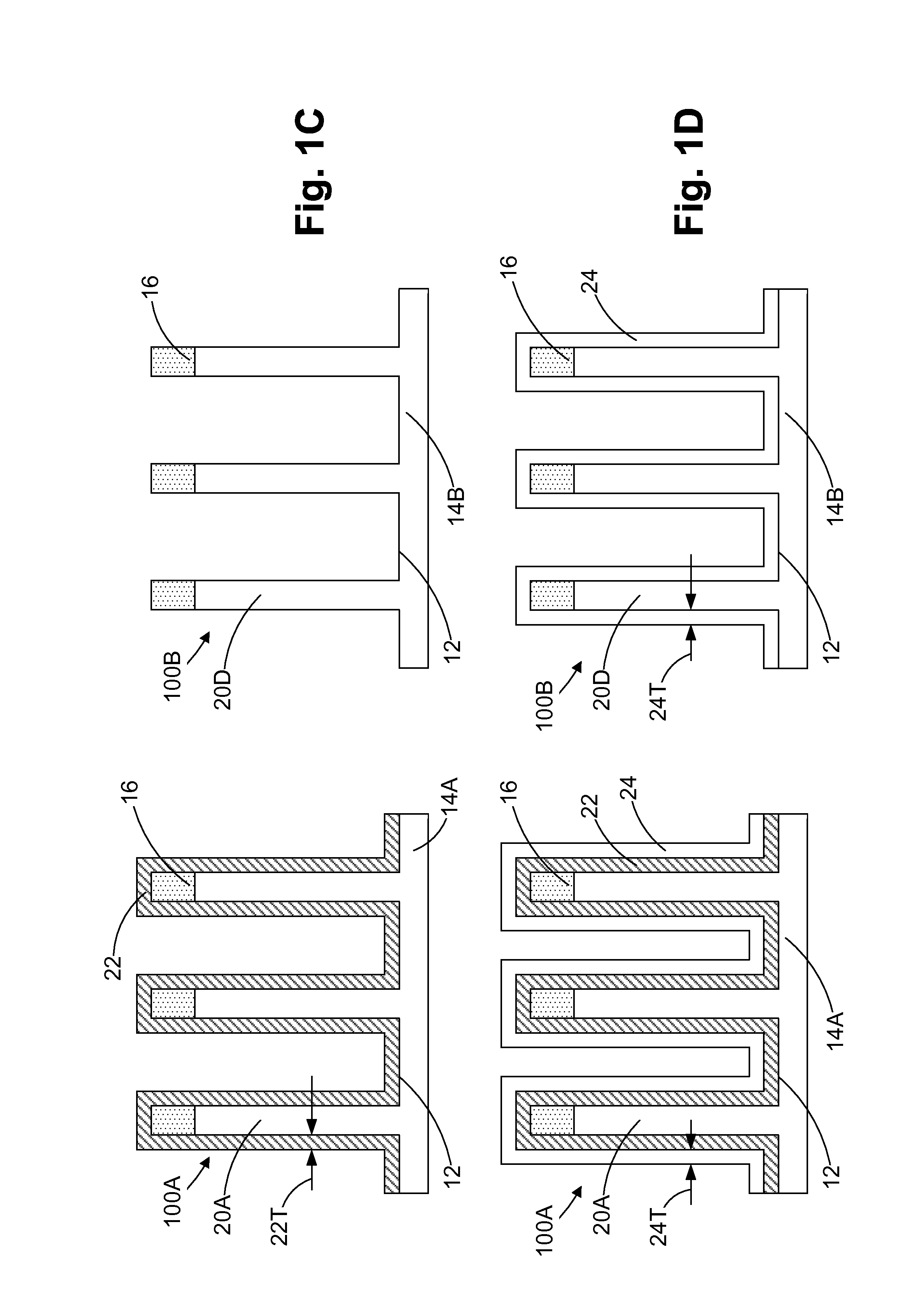

Methods of forming bulk FinFET devices by performing a recessing process on liner materials to define different fin heights and FinFET devices with such recessed liner materials

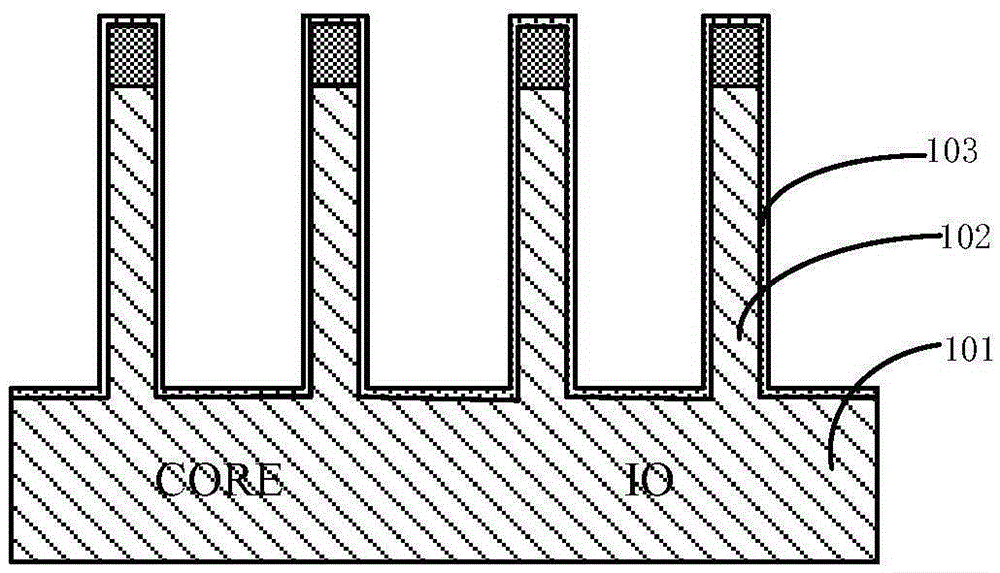

ActiveUS8835262B2Solid-state devicesSemiconductor/solid-state device manufacturingForm linerEngineering

One method includes performing an etching process through a patterned mask layer to form trenches in a substrate that defines first and second fins, forming liner material adjacent the first fin to a first thickness, forming liner material adjacent the second fin to a second thickness different from the first thickness, forming insulating material in the trenches adjacent the liner materials and above the mask layer, performing a process operation to remove portions of the layer of insulating material and to expose portions of the liner materials, performing another etching process to remove portions of the liner materials and the mask layer to expose the first fin to a first height and the second fin to a second height different from the first height, performing another etching process to define a reduced-thickness layer of insulating material, and forming a gate structure around a portion of the first and second fin.

Owner:AURIGA INNOVATIONS INC

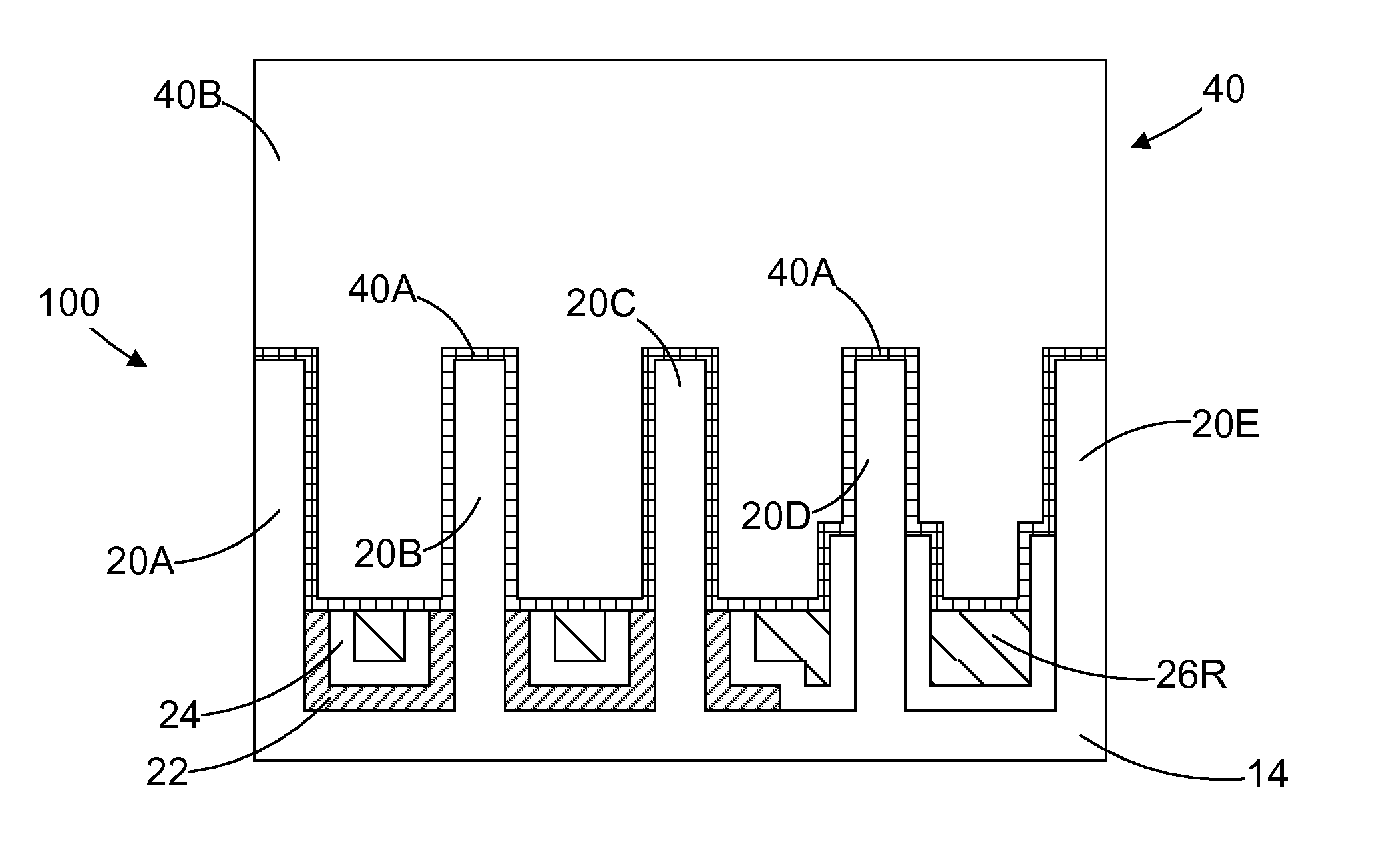

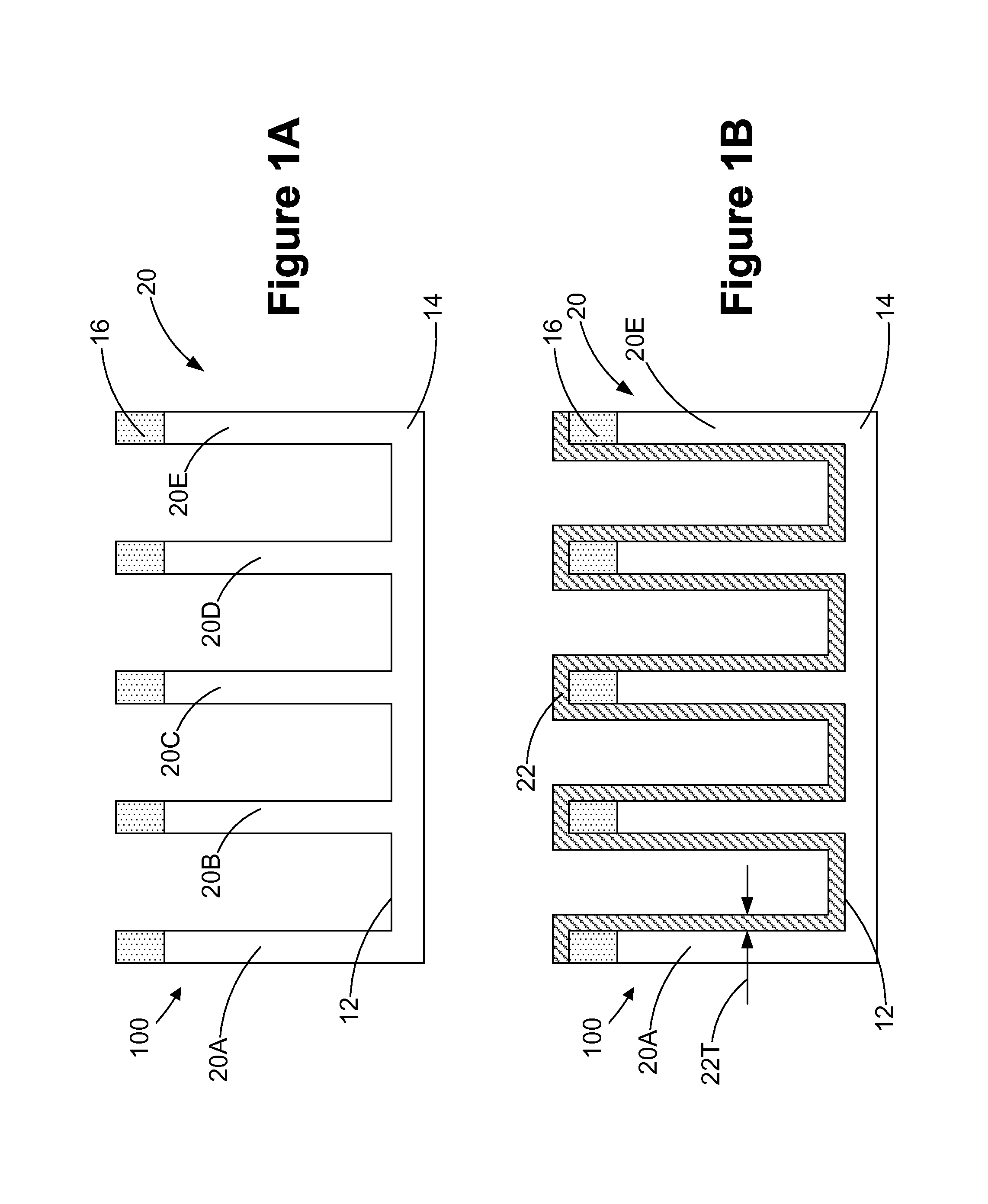

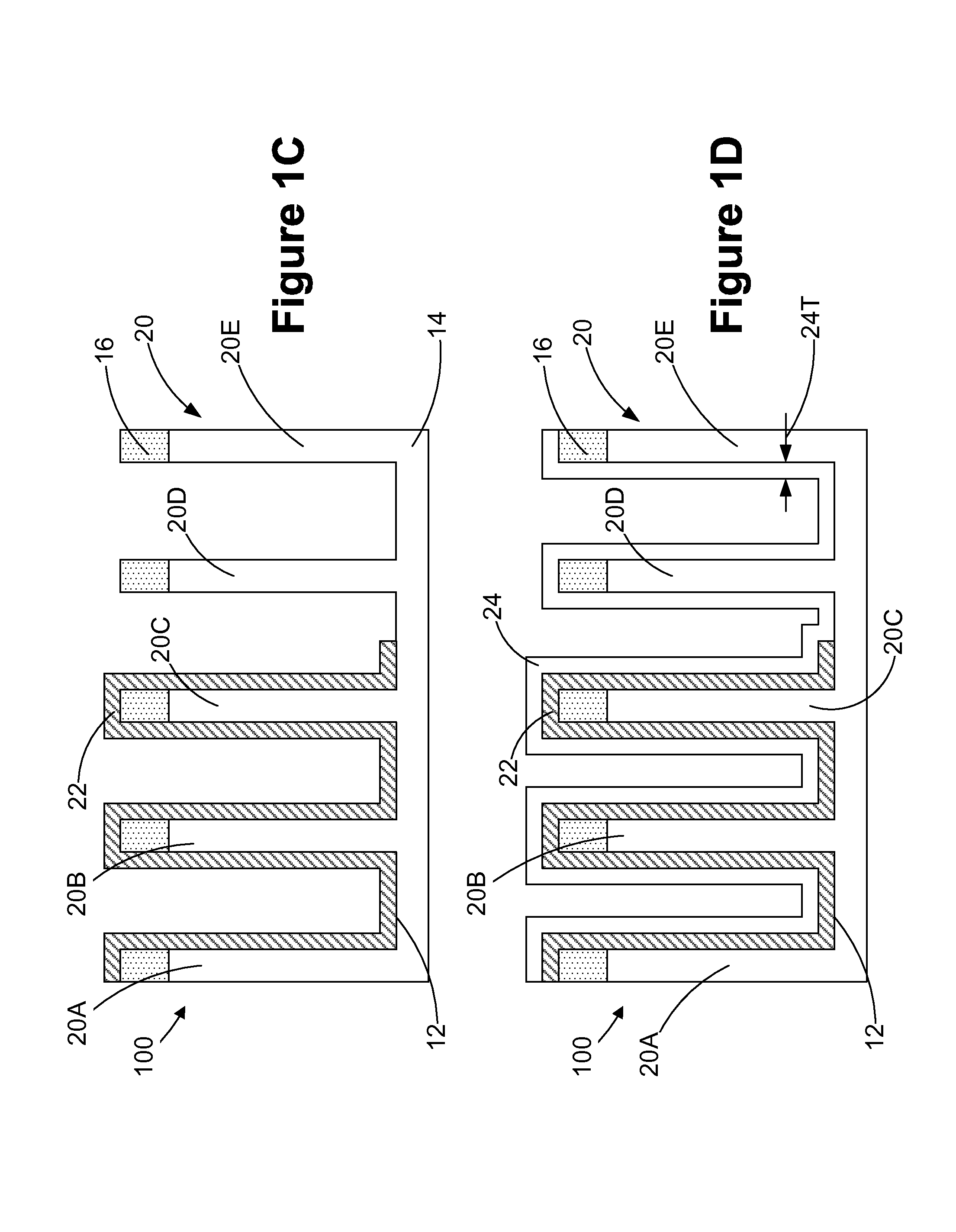

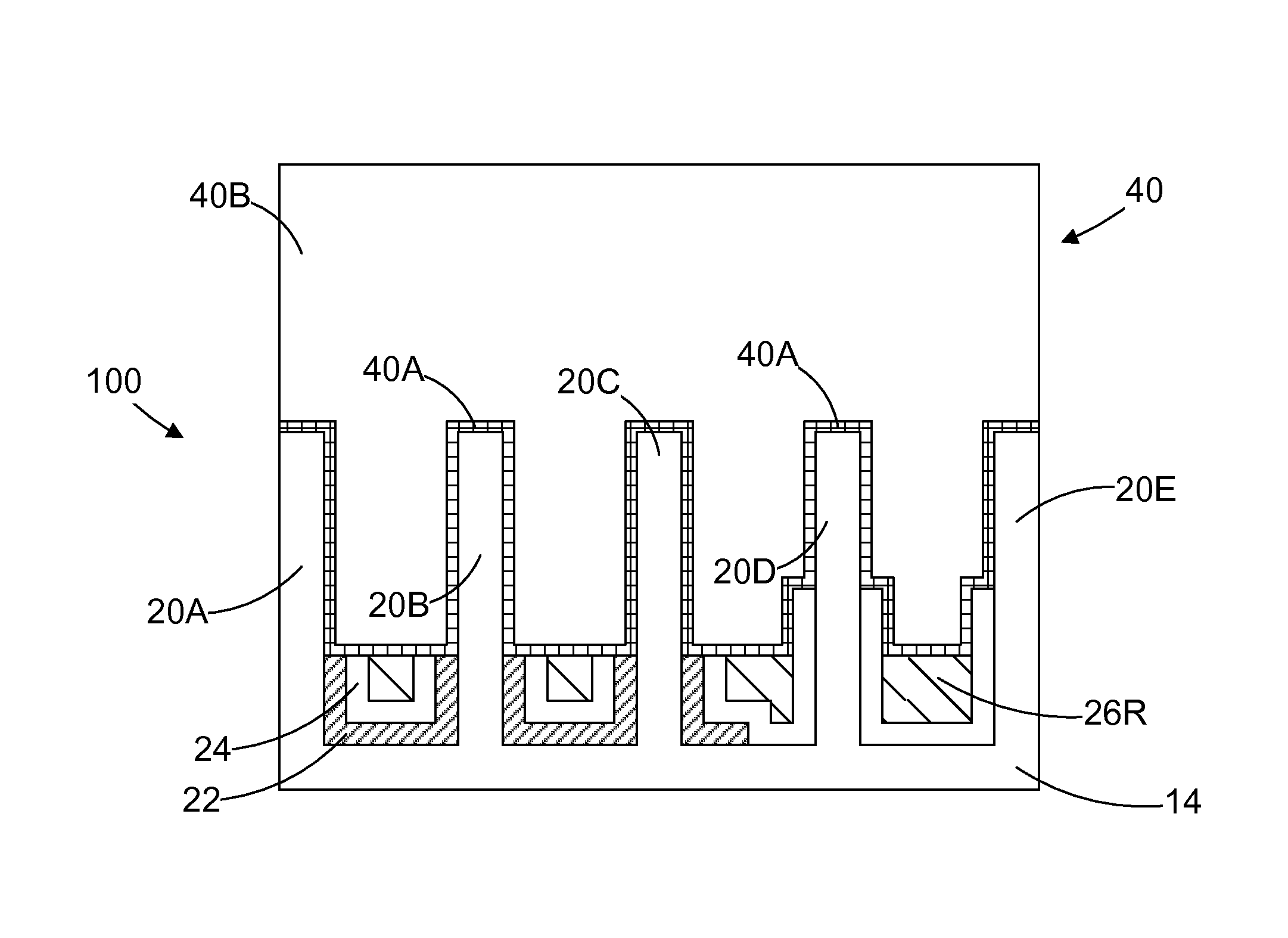

Methods of forming bulk finfet devices by performing a recessing process on liner materials to define different fin heights and finfet devices with such recessed liner materials

ActiveUS20140191324A1Well formedSolid-state devicesSemiconductor/solid-state device manufacturingForm linerEngineering

One method includes performing an etching process through a patterned mask layer to form trenches in a substrate that defines first and second fins, forming liner material adjacent the first fin to a first thickness, forming liner material adjacent the second fin to a second thickness different from the first thickness, forming insulating material in the trenches adjacent the liner materials and above the mask layer, performing a process operation to remove portions of the layer of insulating material and to expose portions of the liner materials, performing another etching process to remove portions of the liner materials and the mask layer to expose the first fin to a first height and the second fin to a second height different from the first height, performing another etching process to define a reduced-thickness layer of insulating material, and forming a gate structure around a portion of the first and second fin.

Owner:AURIGA INNOVATIONS INC

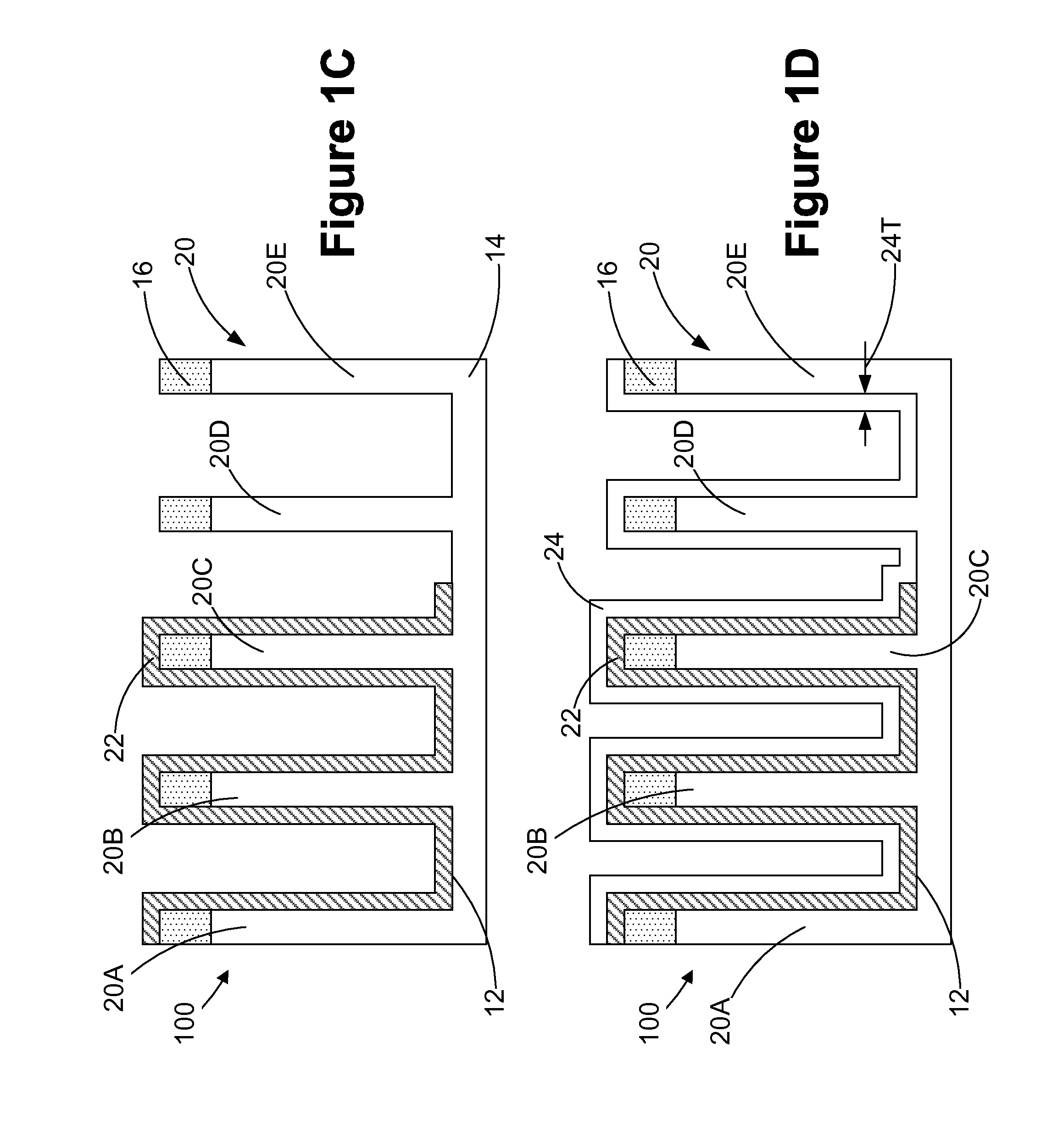

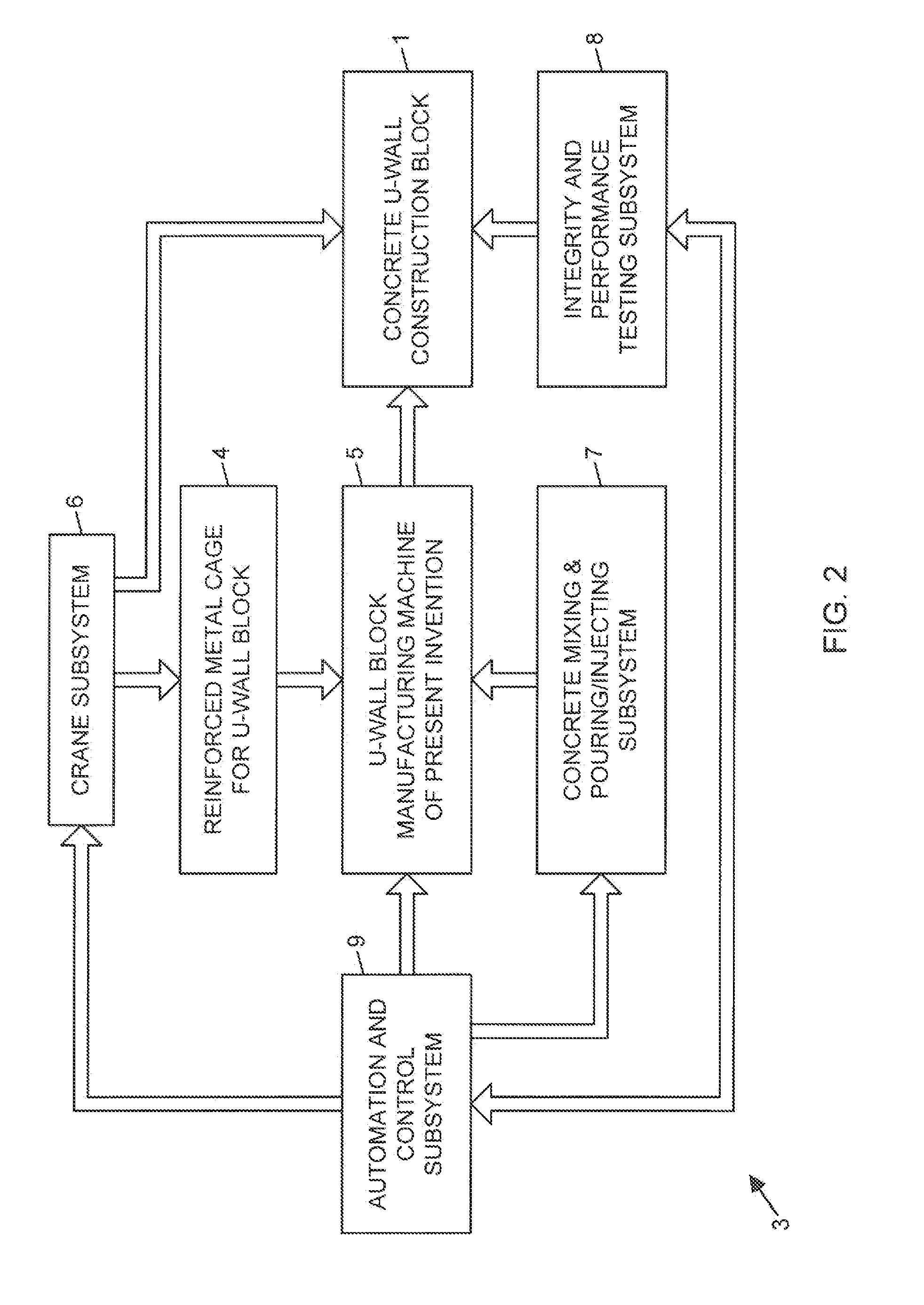

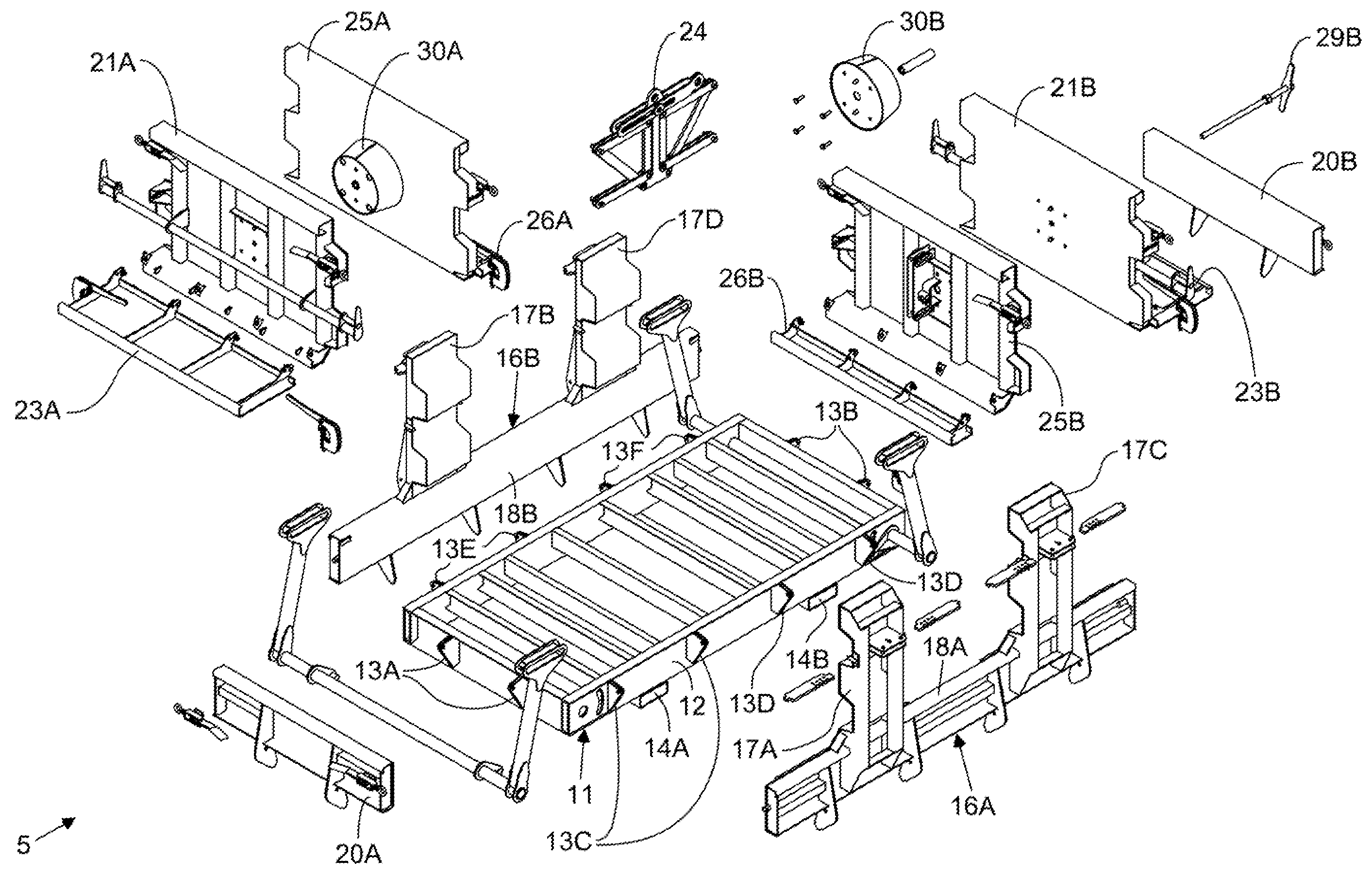

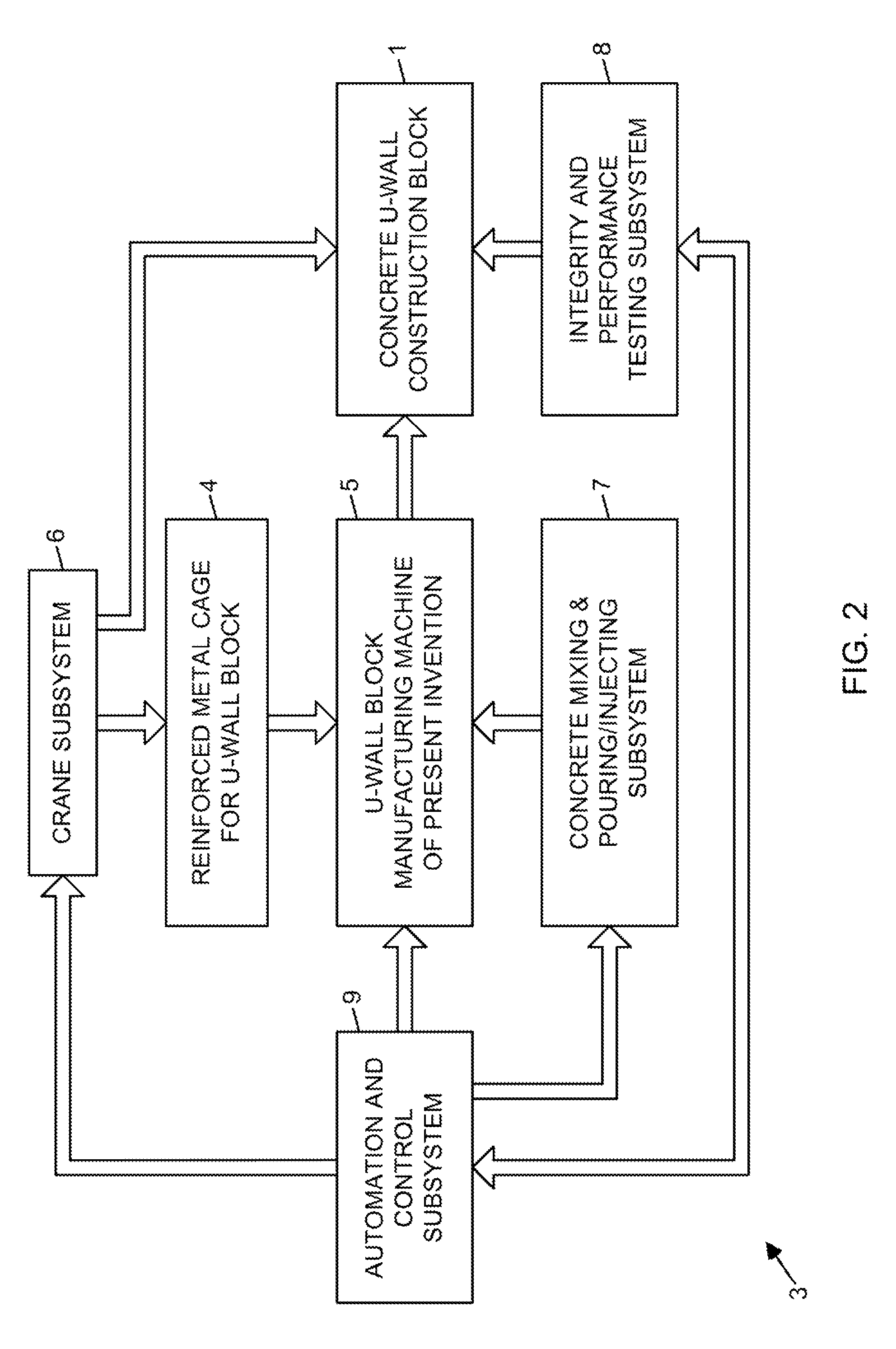

Method of and machine for manufacturing concrete u-wall type construction elements and method of operating the same

ActiveUS20120175814A1Avoid shortcoming and drawbackAvoiding shortcoming and drawbackDischarging arrangementMouldsShell moldingSupport surface

A machine for and method of manufacturing concrete U-wall construction blocks, each having a front wall portion and a pair of stem portions extending from said front wall portion. The method involves providing a system of molding jacket panels, including a core molding assembly having a pair of inside stem jacket panels that are adjustably supportable in a substantially parallel manner during a molding process, and arranged is such a manner that the front wall portion is molded in downwardly facing direction toward a horizontal support surface and completely enclosed in one or more molding jacket panels. Before block molding operations, the thickness of the front wall portion of the U-wall construction block is set by determining the thickness of a front wall surface liner and installing the front wall surface forming liner within the system of molding jacket panels. Also, thickness of the stem portions of the U-wall construction block is set by determining the proper distance between the pair of said inside stem jacket panels supported in a parallel manner during the block molding process. Thereafter, concrete is poured or injected through pour openings provided in the molding jacket apparatus to form the front wall portion and stem portions of the concrete U-wall block.

Owner:STABLE CONCRETE STRUCTURES +1

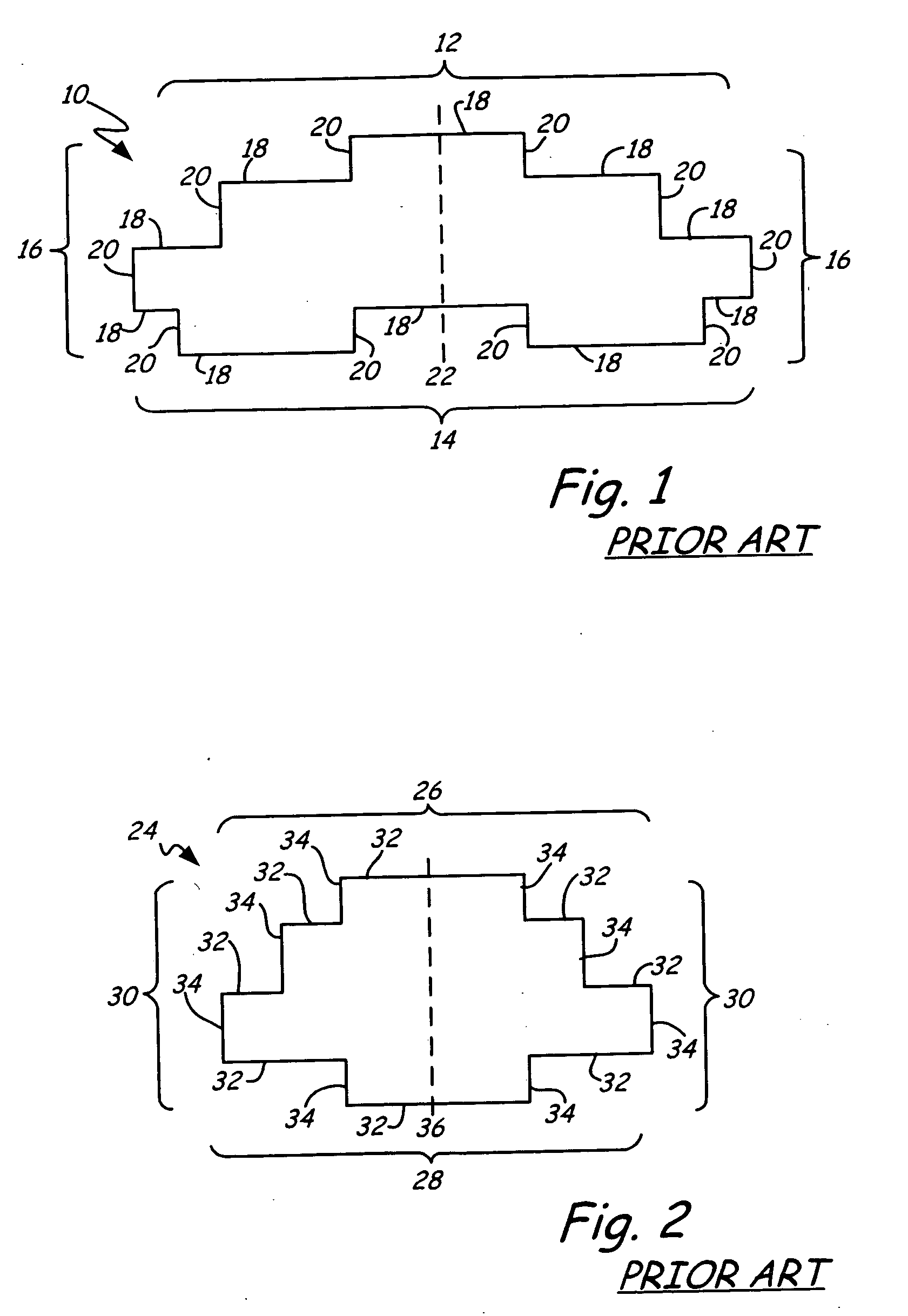

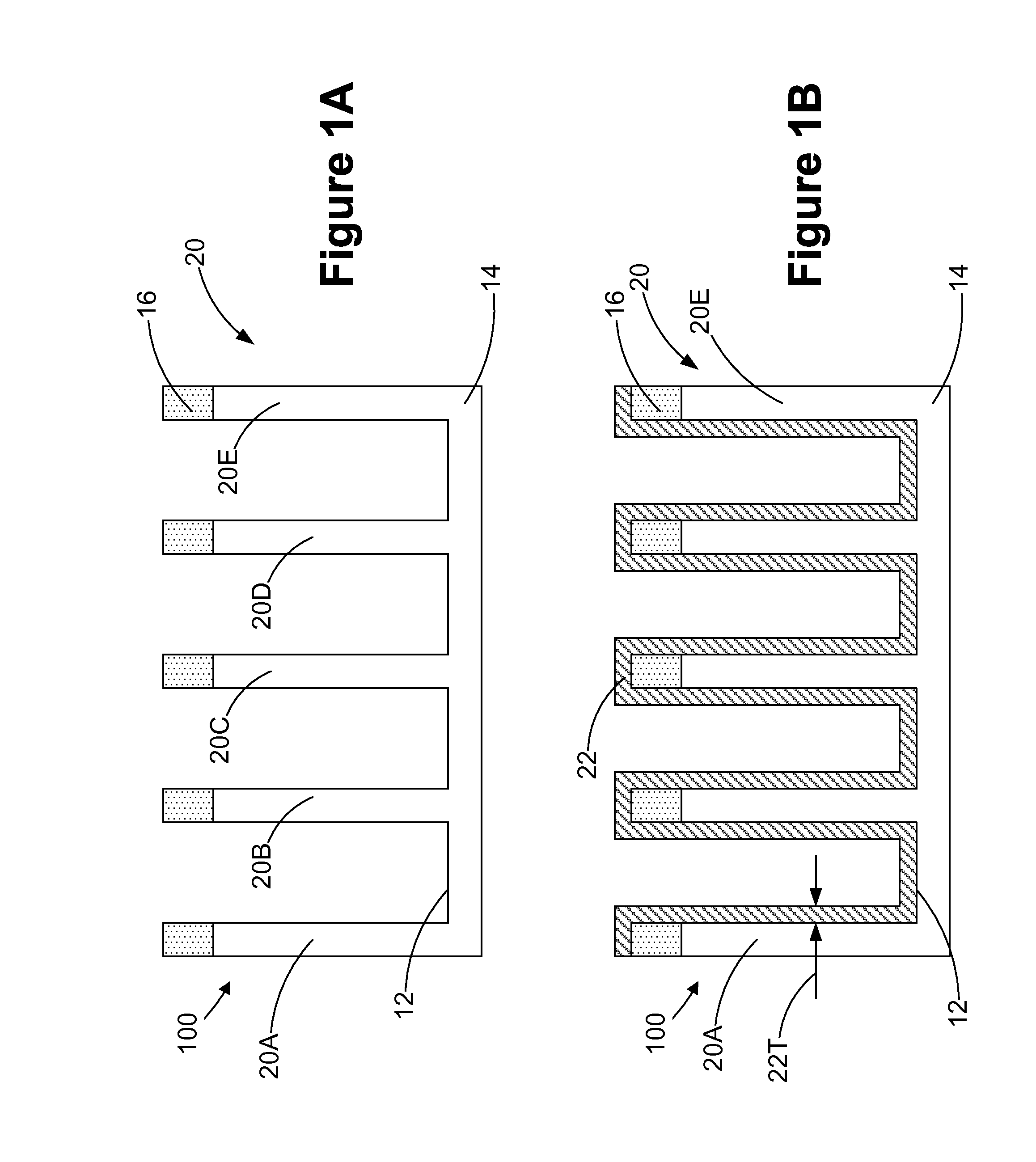

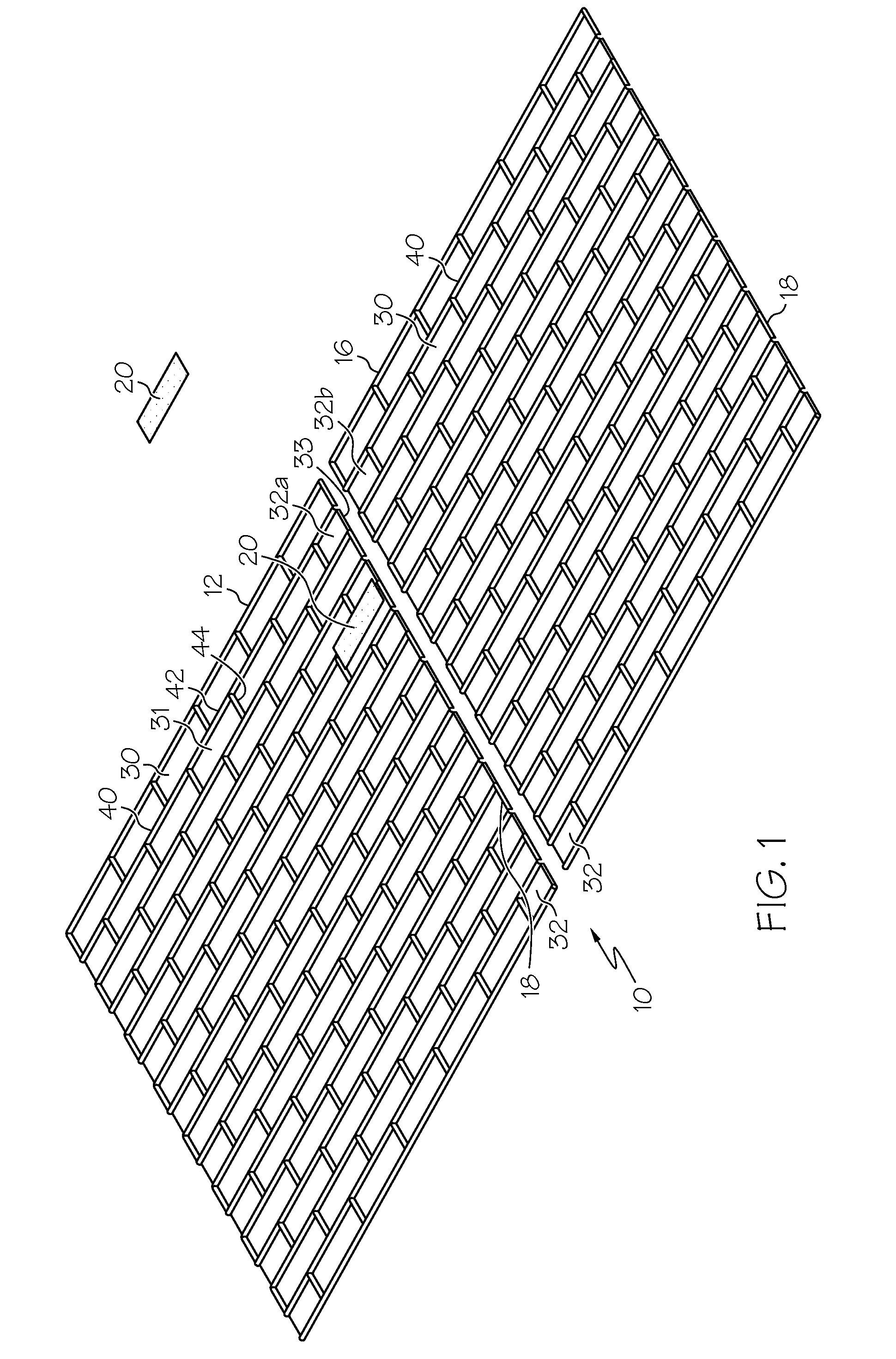

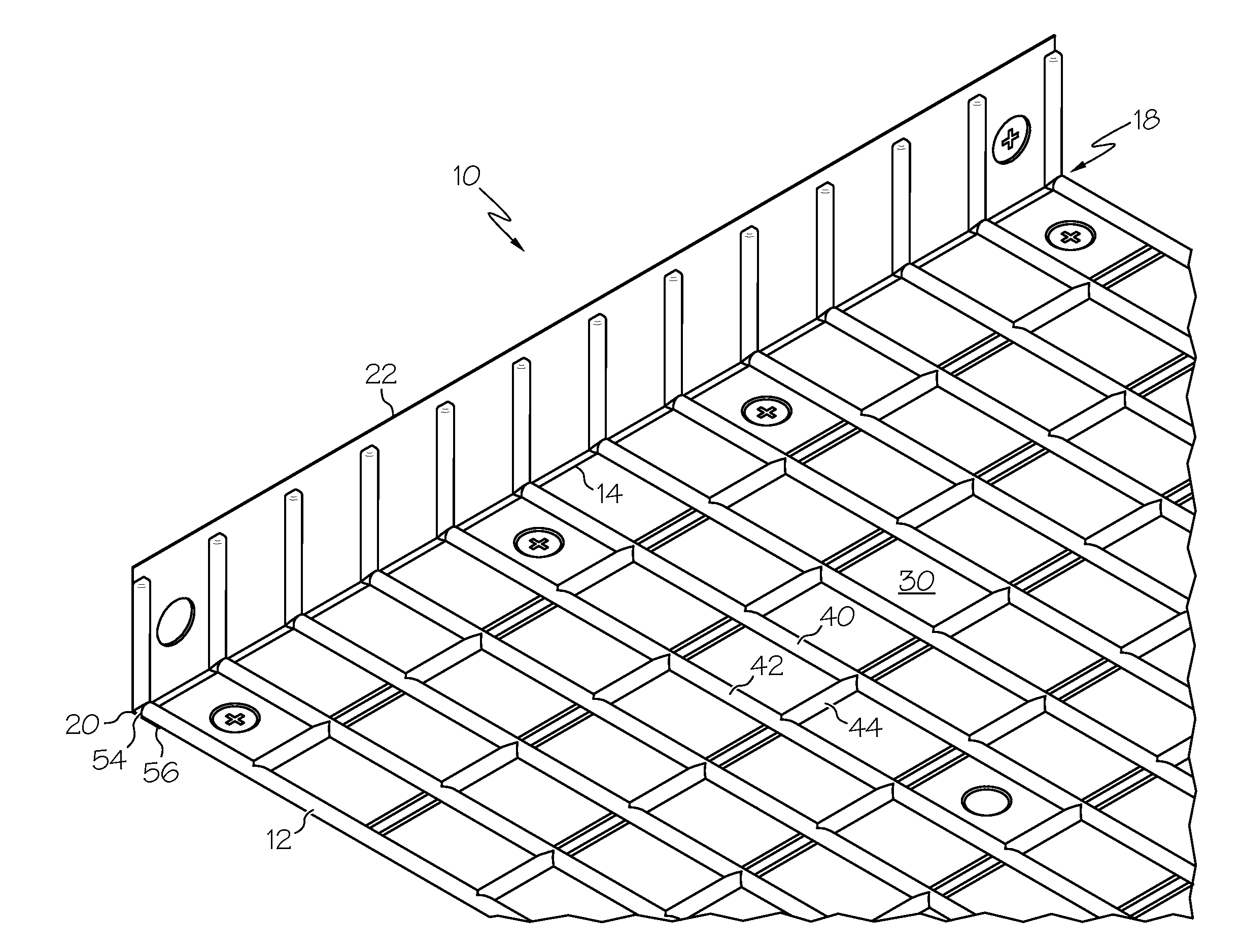

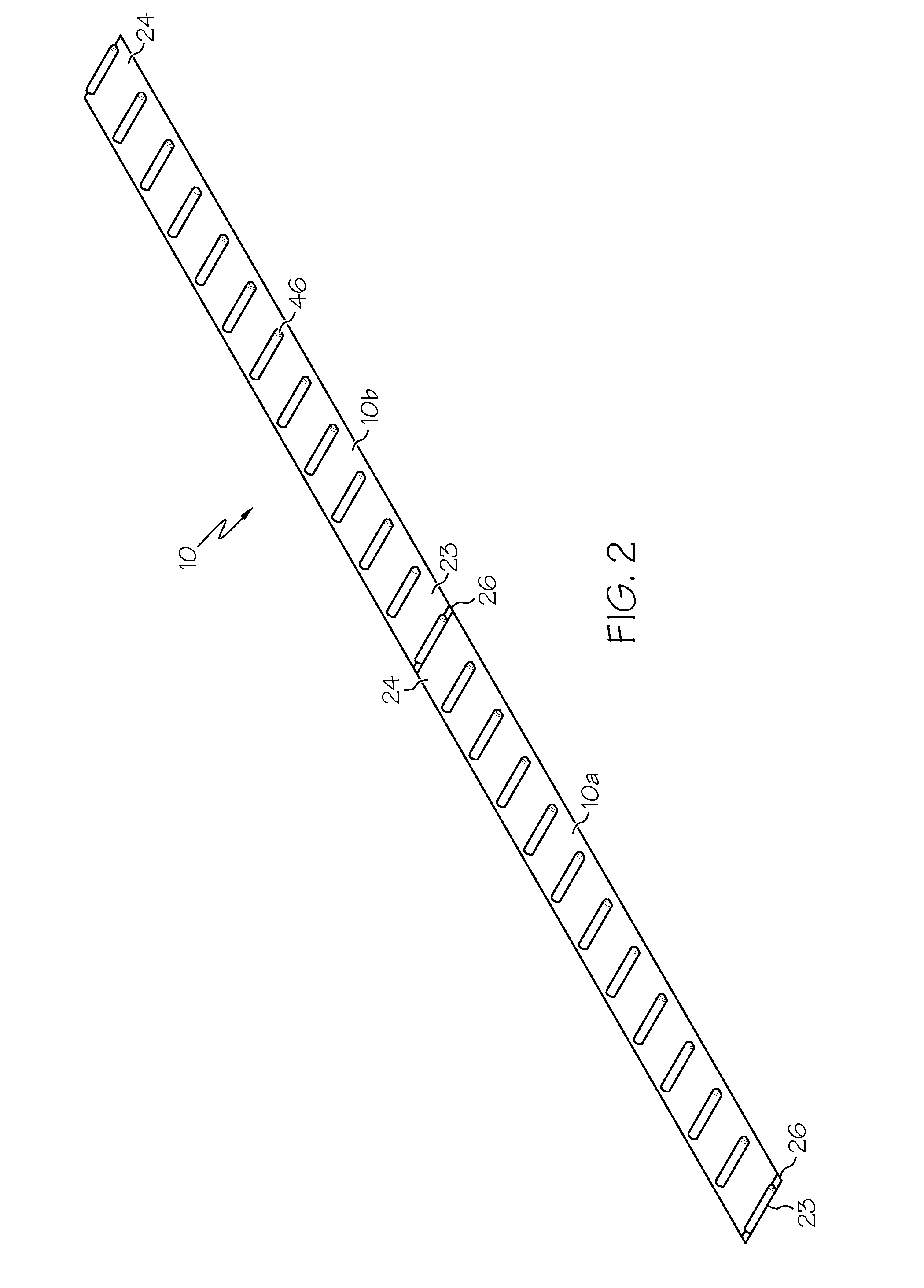

Form liner with connection regions having a plurality of linear segments for creating a realistic stone wall pattern

Owner:NASVIK PAUL C

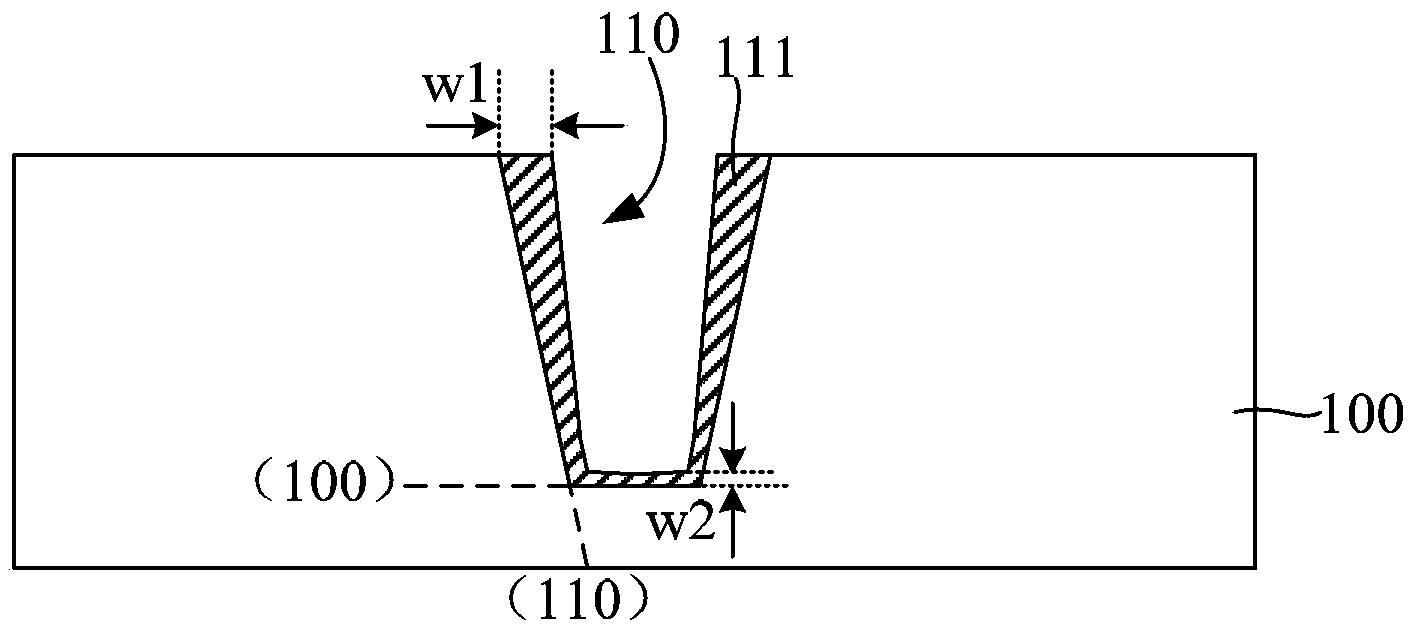

Method for manufacturing high-voltage semiconductor device

ActiveCN102569159AImprove performanceReduce stressSemiconductor/solid-state device manufacturingGate dielectricForm liner

The embodiment discloses a method for manufacturing a high-voltage semiconductor device, which comprises the steps as follows: a substrate is provided, an etching barrier layer material on an STI shallow trench corner is partially removed in the horizontal direction; a body layer material on the STI shallow trench corner is removed to enable the sharp corner of the STI shallow trench to become round and smooth; an STI shallow trench isolation region, and a well region and a drift region of the high-voltage semiconductor device are formed; and a gate dielectric layer is formed on the substrate surface including the STI shallow trench isolation region as well as the well region and the drift region of the high-voltage semiconductor device. According to the embodiment of the invention, the body layer material on the STI shallow trench corner is removed to enable the sharp corner of the STI shallow trench to become round and smooth, and the stress on the STI shallow trench corner is reduced, so that a follow-up formed liner oxidation layer is distributed more evenly on the STI shallow trench corner, furthermore the phenomenon of thin gate dielectric layer on the STI shallow trench isolation region corner is improved, and the performance of the device is remarkably improved.

Owner:CSMC TECH FAB2 CO LTD

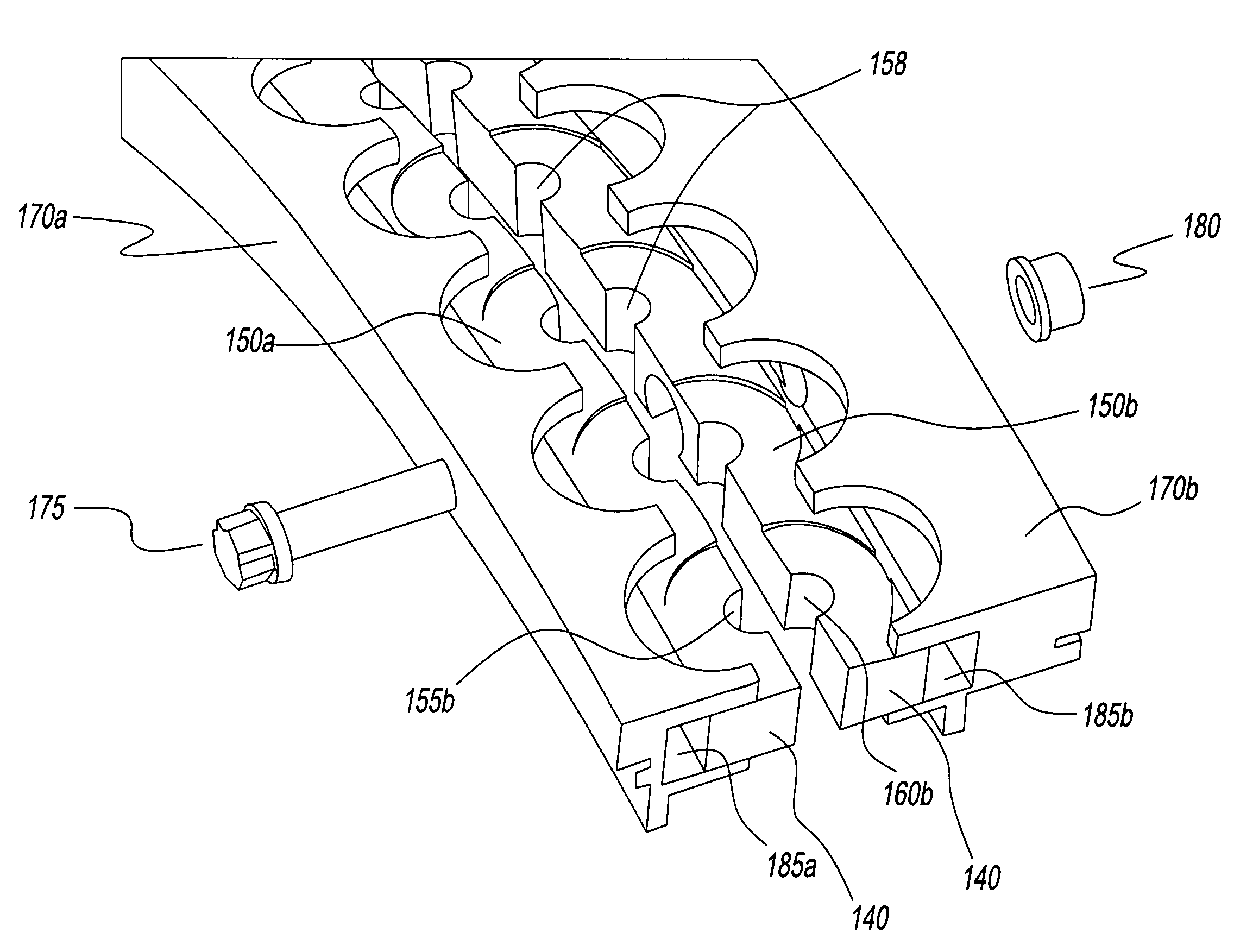

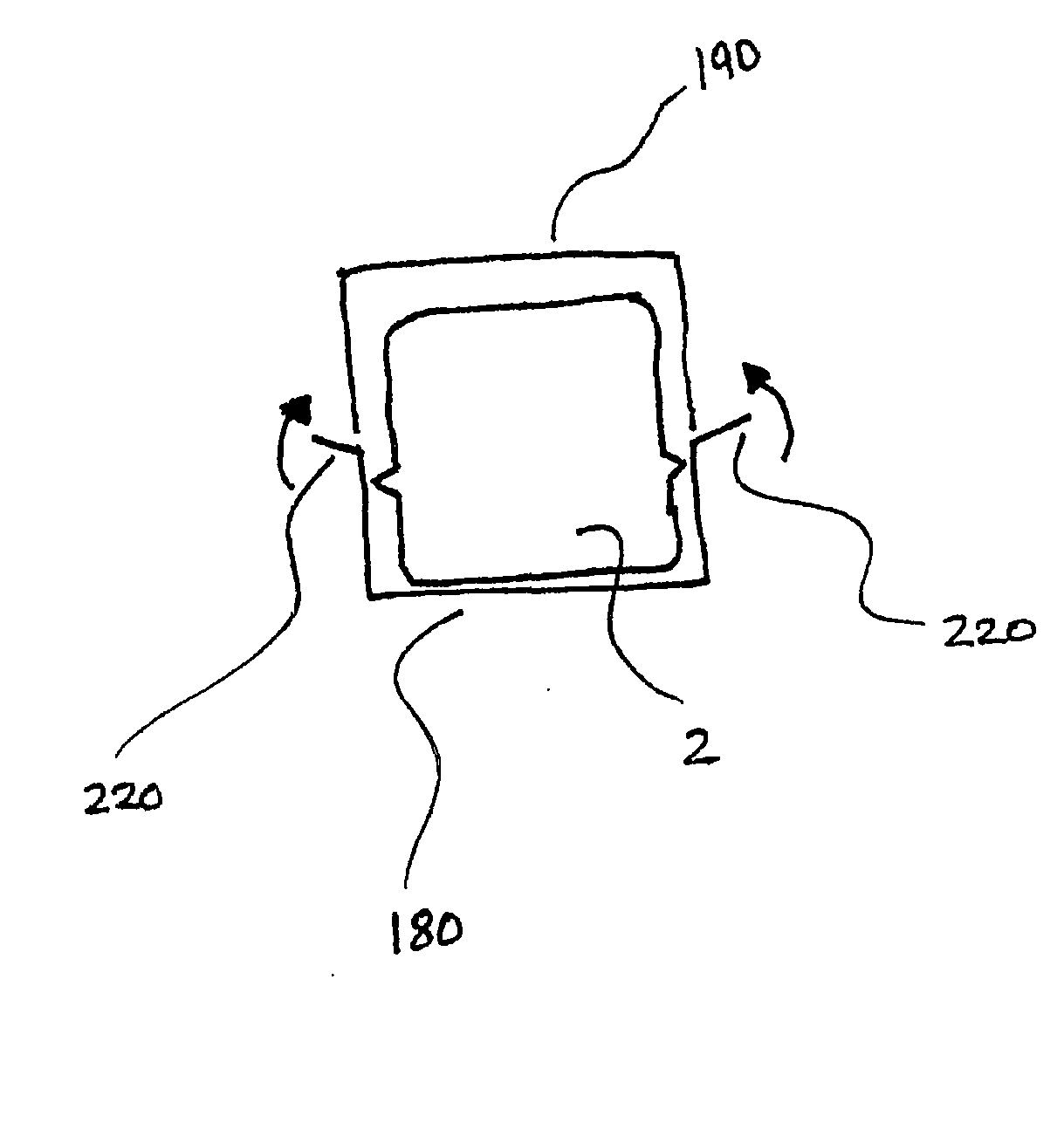

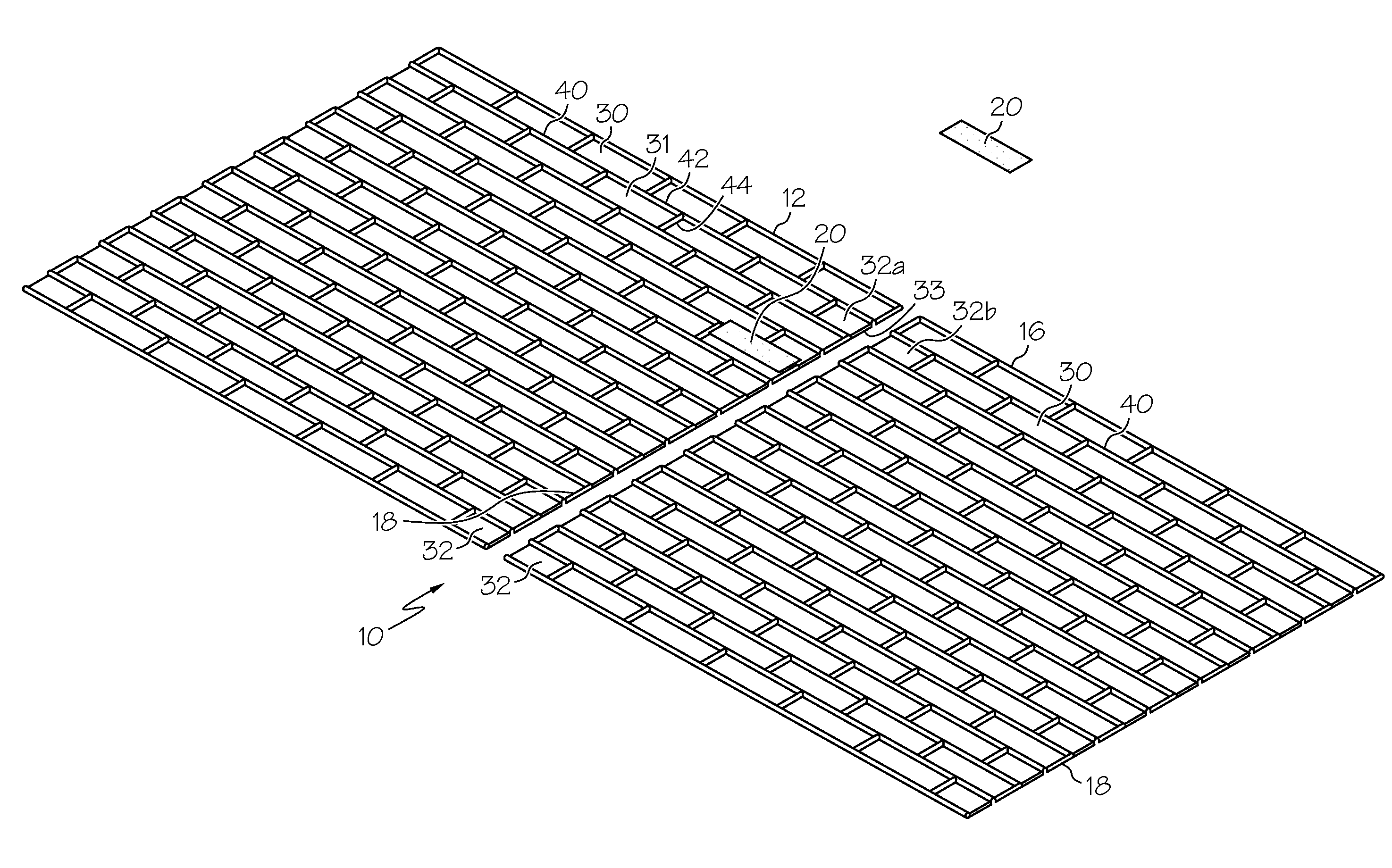

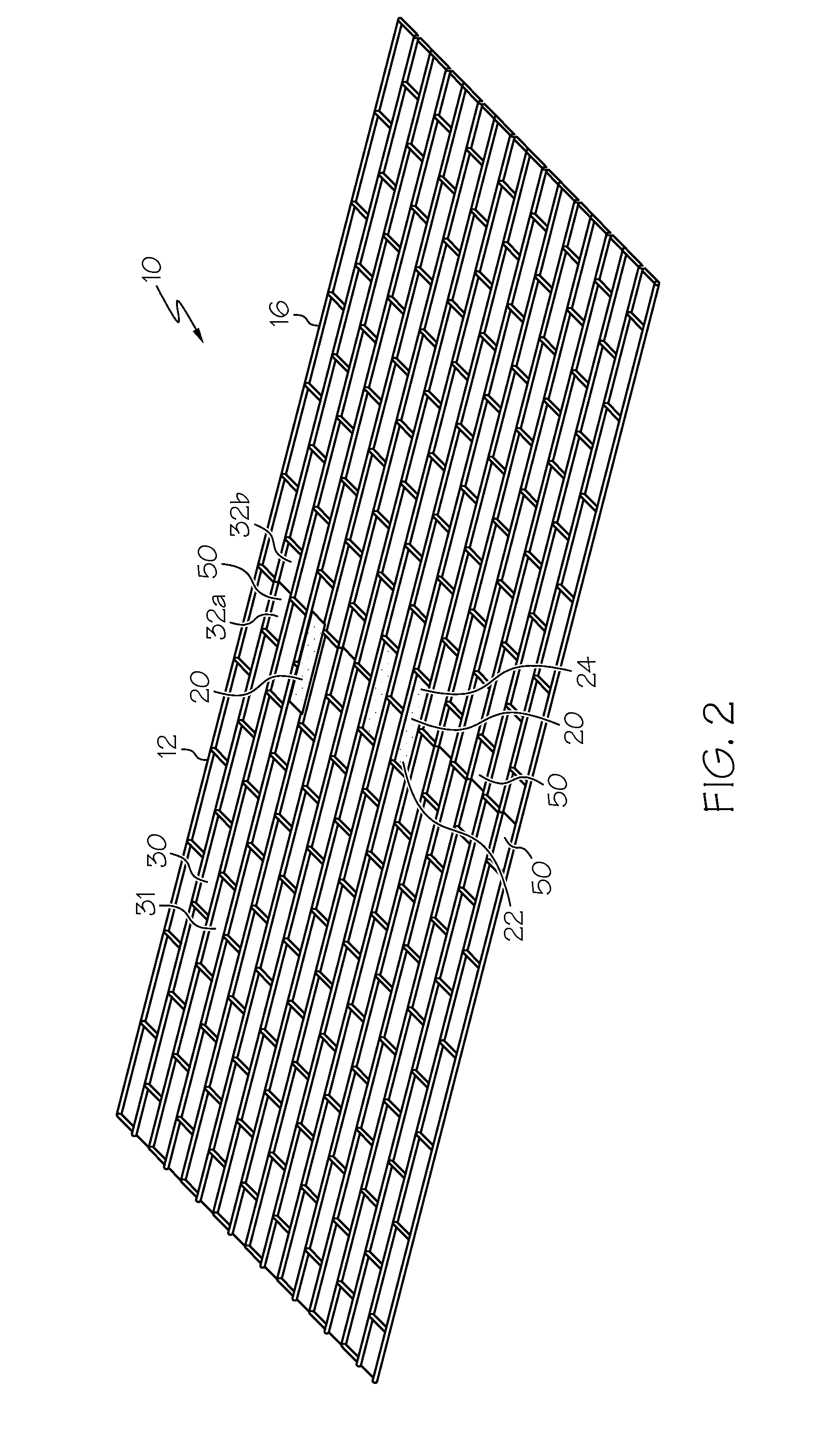

Bridge member spanning formliner joint

A form liner system comprises a first form liner, a second form liner and a bridge member. Each form liner comprises a plurality of raised portions defining a plurality of cells and at least one partial cell. The form liners are arranged such that the partial cells form a collective cell. The bridge member can be oriented in said collective cell, wherein a first portion of the bridge member is oriented in the first liner partial cell and a second portion of the bridge member is oriented in the second liner partial cell.

Owner:ADVANCED FORMLINERS

Sacrificial inner shroud liners for gas turbine engines

A split shroud system for a gas turbine engine having a pair of annular-shaped shrouds that each have an inner pocket; to form a pair of inner pockets. Each of the pair of pockets having liner parts that form a circle. Liner parts of one of the pair of pockets facing liner parts of the other of the pair of pockets to form liner part pairs. One of each of said of pair of liner parts has a mutual abutting surface that forms a plurality of slots for accepting a plurality of vane inner trunnions.

Owner:RAYTHEON TECH CORP

Formliner Layout Member

In some embodiments, a form liner system comprises a form liner sheet comprising a plurality of raised rows at a predetermined spacing, and a layout member comprising a base portion and a plurality of raised portions. The raised portions are constructed and arranged to nest with said raised rows.

Owner:ADVANCED FORMLINERS

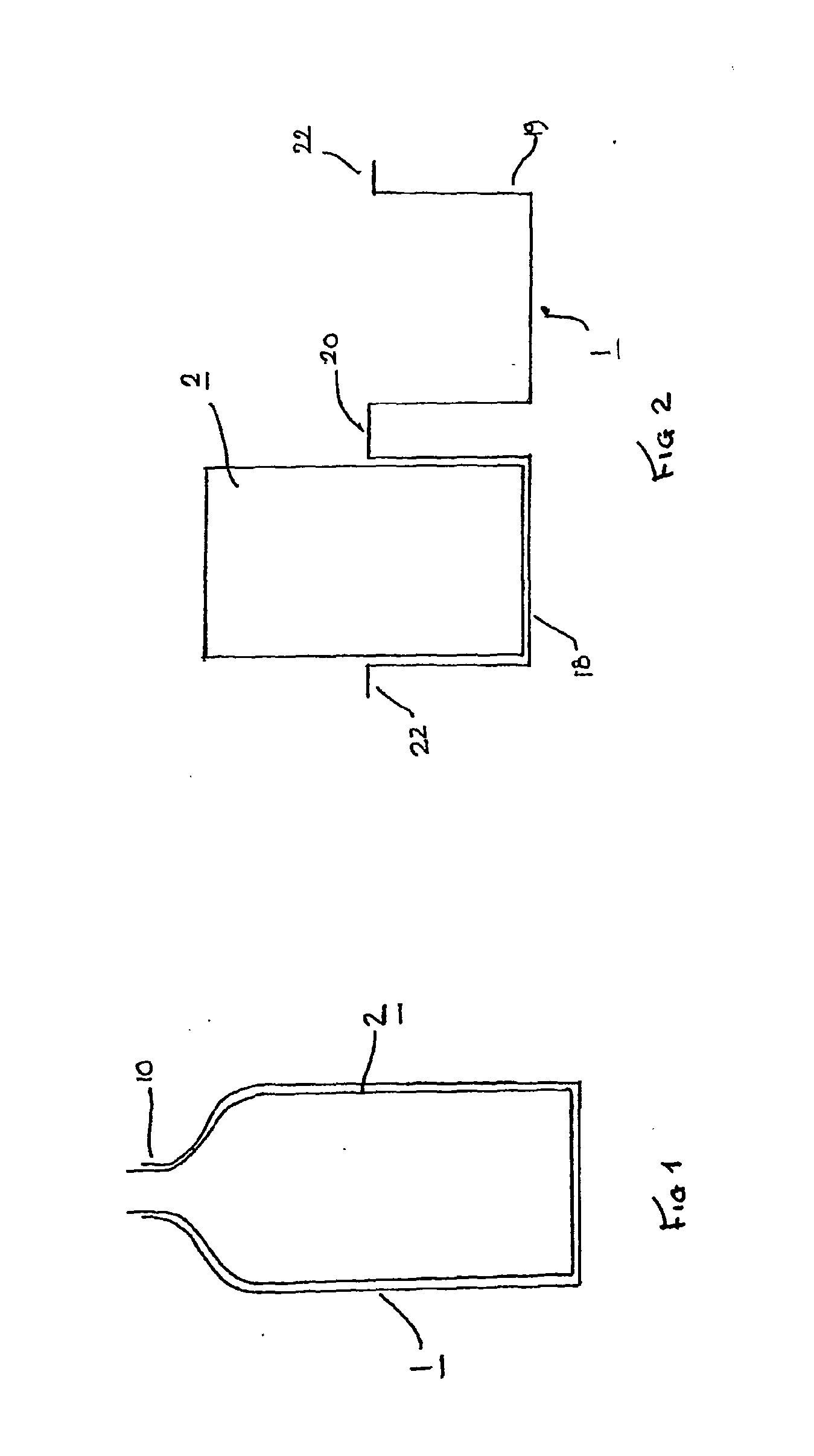

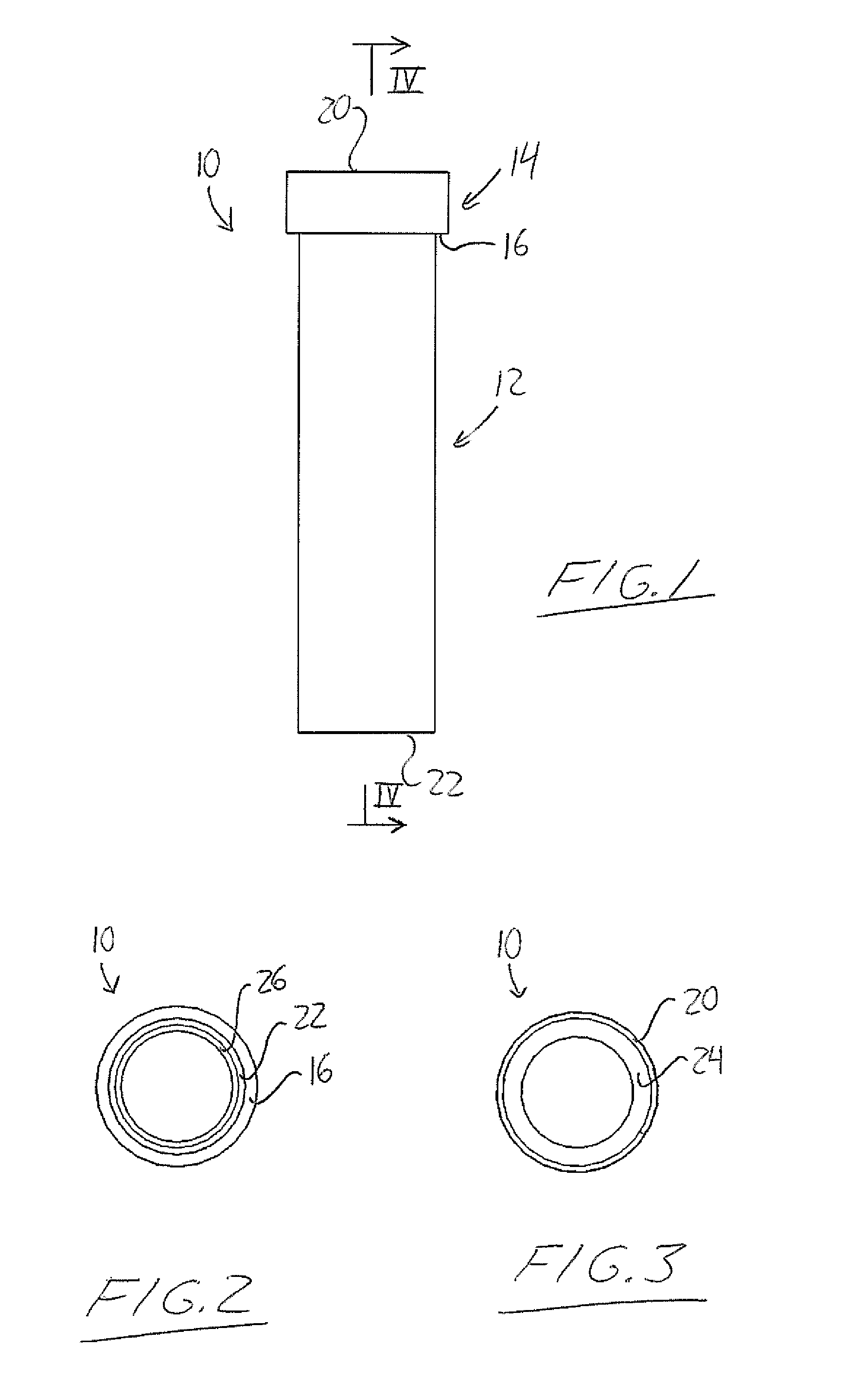

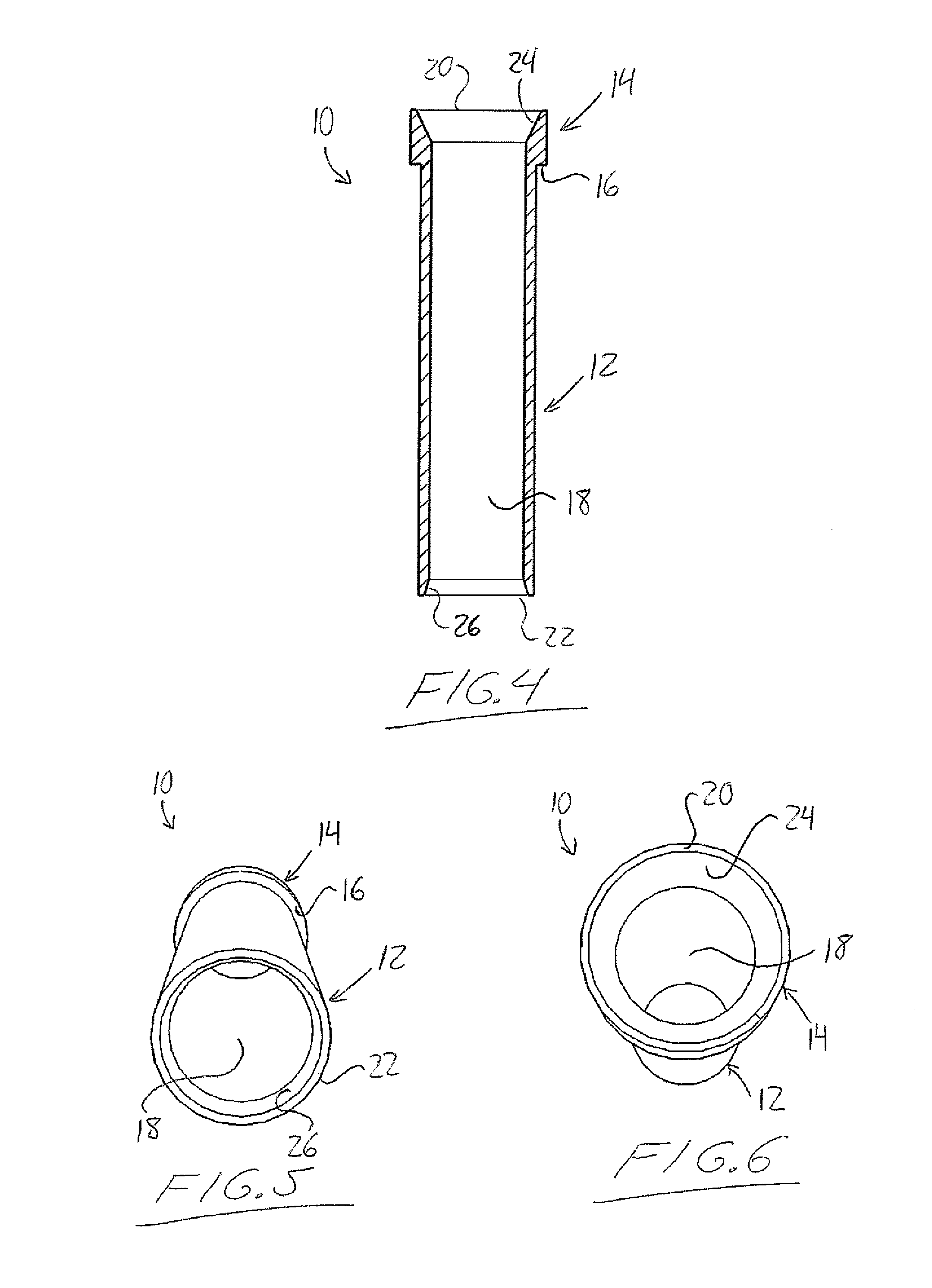

Container

InactiveUS20130206755A1Easy to holdEasily manipulatedLarge containersLinings/internal coatingsForm linerEngineering

Container and method of forming a container comprising an inner liner and an outer shell by providing an open shell that is closeable to provide the outer shell, vacuum forming the liner with a shape conforming generally to at least a portion of the inner volume of the shell from at least one film, positioning the formed liner in the open shell and closing the shell.

Owner:GREENBOTTLE

Methods of forming different FinFET devices having different fin heights and an integrated circuit product containing such devices

One illustrative method disclosed herein includes forming a plurality of trenches in a plurality of active regions of a substrate that defines at least a first plurality of fins and a second plurality of fins for first and second FinFET devices, respectively, forming liner materials adjacent to the first and second plurality of fins, wherein the liner materials adjacent the first fins and the second fins have a different thickness. The method also includes removing insulating material to expose portions of the liner materials, performing an etching process to remove portions of the liner materials so as to expose at least one fin in the first plurality of fins to a first height and at least one of the second plurality of fins to a second height that is different from the first height.

Owner:GLOBALFOUNDRIES US INC

Machine for manufacturing concrete U-wall type construction blocks by molding each concrete U-wall construction block from concrete poured about a block cage made from reinforcing material while said block cage is loaded within said machine

ActiveUS8888481B2Avoiding shortcoming and drawbackLiquid surface applicatorsMouldsForm linerArchitectural engineering

A machine for and method of manufacturing concrete U-wall construction blocks, each having a front wall portion and a pair of stem portions extending from said front wall portion. The method involves providing a system of molding jacket panels, including a core molding assembly having a pair of inside stem jacket panels that are adjustably supportable in a substantially parallel manner during a molding process, and arranged is such a manner that the front wall portion is molded in downwardly facing direction toward a horizontal support surface and completely enclosed in one or more molding jacket panels. Before block molding operations, the thickness of the front wall portion of the U-wall construction block is set by determining the thickness of a front wall surface liner and installing the front wall surface forming liner within the system of molding jacket panels. Also, thickness of the stem portions of the U-wall construction block is set by determining the proper distance between the pair of said inside stem jacket panels supported in a parallel manner during the block molding process. Thereafter, concrete is poured or injected through pour openings provided in the molding jacket apparatus to form the front wall portion and stem portions of the concrete U-wall block.

Owner:STABLE CONCRETE STRUCTURES +1

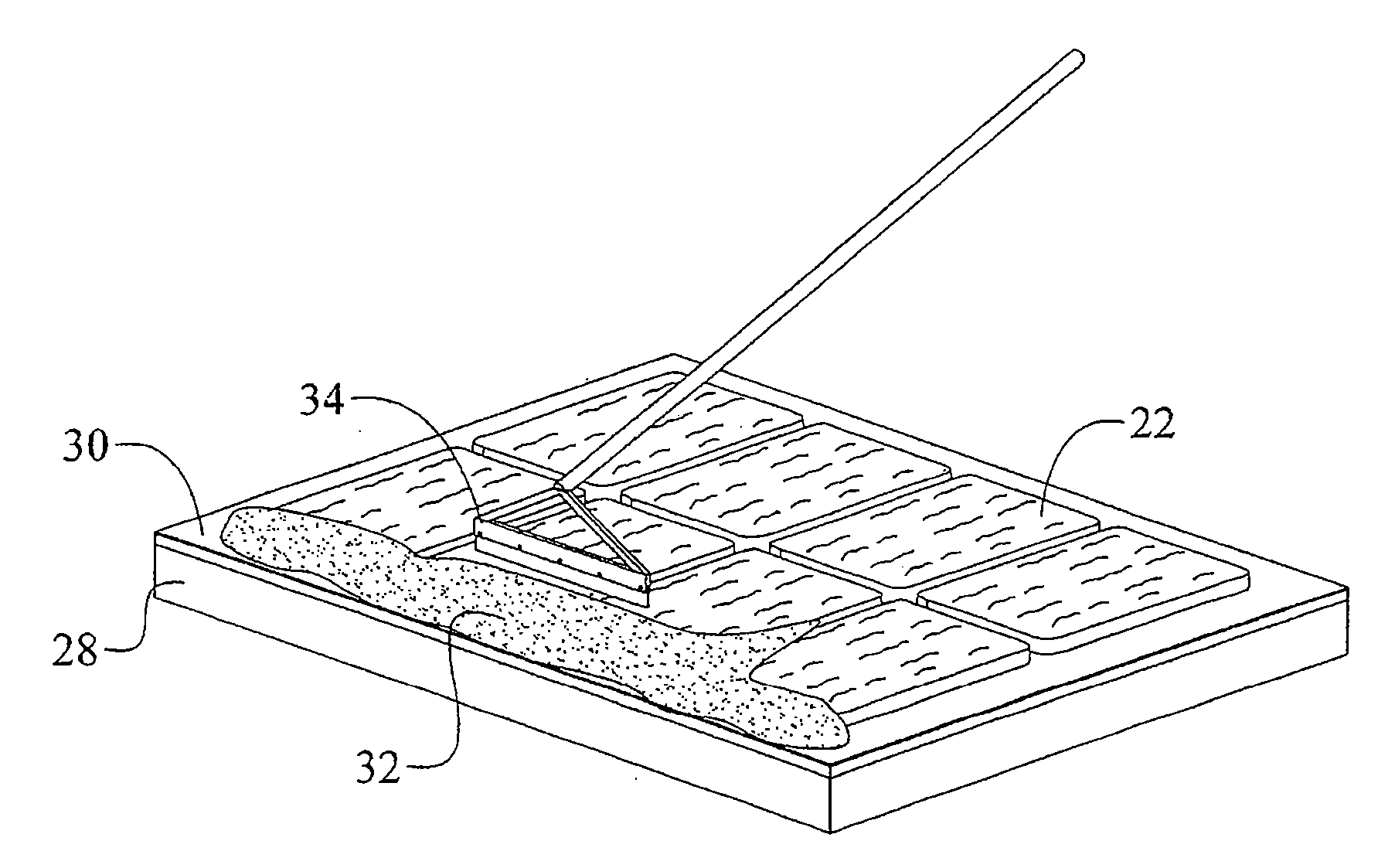

Coating for architectual pieces, coated peces, and methods of making and using them

InactiveUS20100108235A1Efficient removalDissipate quicklyCarboxylic acid esters preparationOrnamental structuresForm linerBrick

A peelable thermoplastic coating (36) applied to one face of an architectural piece (14) such as brick, concrete paver and veneer, and tile. A spray applicator (10) automatically applies the coating substantially edge-to-edge of the face of the piece. A method for grouting the architectural pieces includes applying the grout over the coated faces of pieces arranged in spaced-apart patterns and spreading the grout into the spaces, and peeling the coating from the pieces. In another embodiment, the coated faces are adhered to a form liner, grout or cement is applied to the backs of the pieces and between them, and the form liner and coatings are stripped from the pieces.

Owner:PARMLEY RONALD L

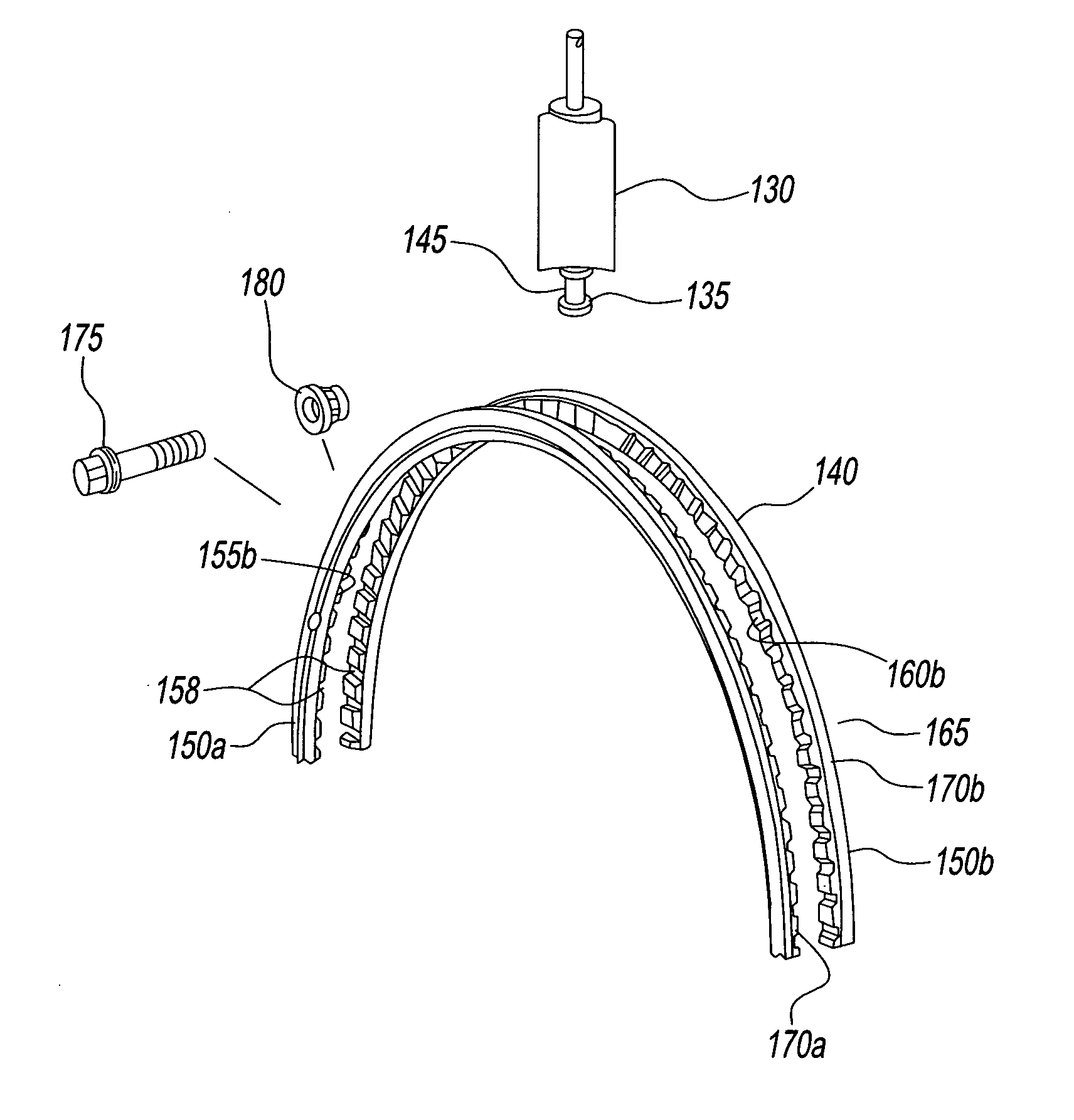

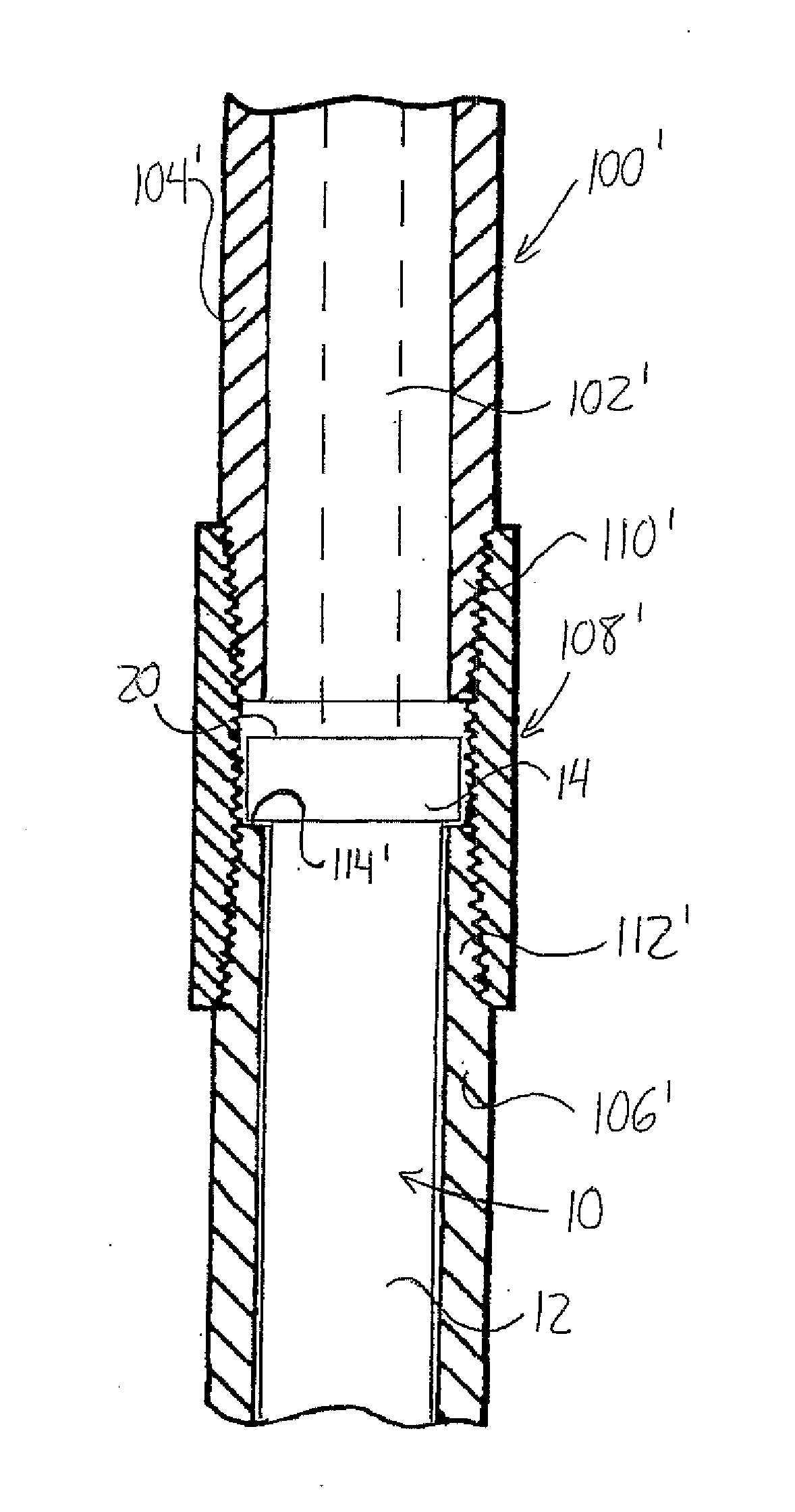

Tubular Member Coupling and Lining Systems and Methods

For use in assembling a tubing string for a production well, a rigid pre-formed liner is configured for simple drop-in place installation at each tubing joint during assembly of the tubing string in to protect the inside of the tubing string from wear caused by operation of a sucker rod inside the same. At a threaded connection in the finished tubing string, where an externally threaded top end of a section of production tubing is engaged with an internally threaded bottom end of a box coupler or collar, the tubular portion of a respective liner hangs downward from a larger-diameter collar portion of the liner that sits atop the annular top end of the section of production tubing. The liner is installed by simply dropping its tubular portion into the section of tubing and then threading the box coupler onto the section tubing around the upper end of the liner.

Owner:INNOVATIVE TOOL TECH

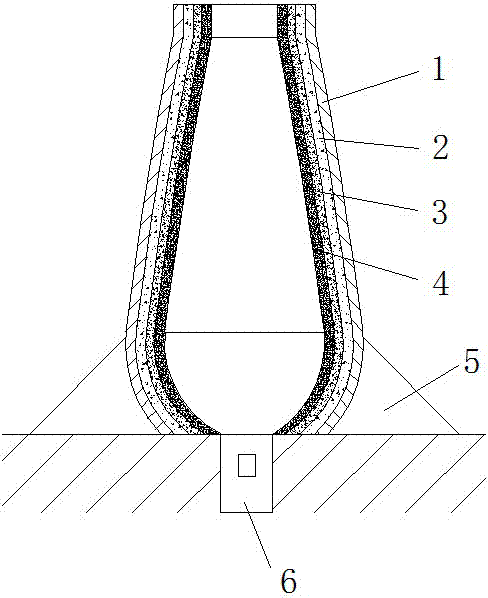

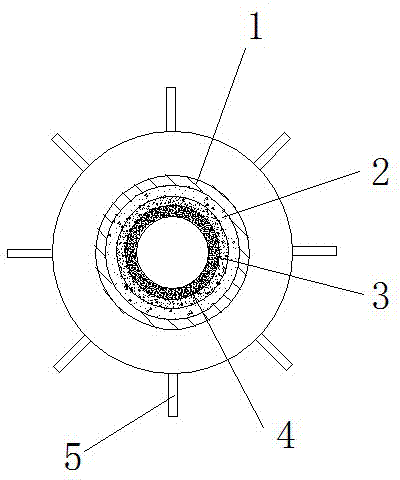

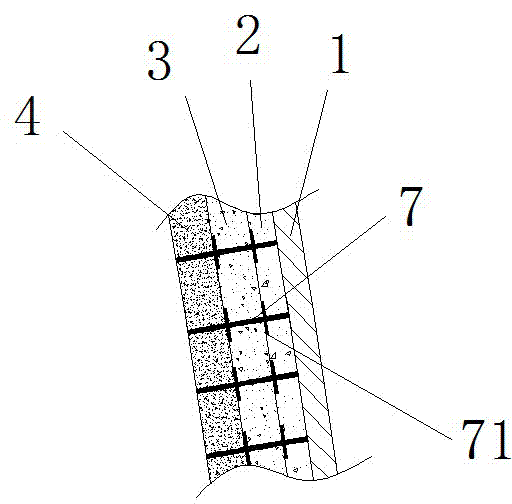

Lime calciner paint liner and forming method thereof

The invention relates to a lime calciner paint liner and a forming method thereof. The lining comprises a thermal insulation layer, a middle lining layer and a working layer which are sequentially attached to the inner wall of the shell of the lime calciner, wherein the middle lining layer and the working layer are sequentially combined into an integral body and are respectively a paint layer according to a certain formula. The forming method comprises the following steps: thoroughly mixing the raw materials of the paint uniformly, adding into a feed hopper of a pneumatic rotary spray gun, sending the raw materials in the feed hopper into the spray gun by compressed air through a rubber tube, mixing the raw materials with high-pressure water in the spray gun to form a slurry, and spraying the slurry onto a construction working surface layer by layer. The invention provides a novel liner and a forming method thereof for the lime calciner, thereby greatly enhancing the forming efficiency of the lime calciner liner, lowering the production cost, greatly enhancing the quality of the lime calciner liner, and greatly prolonging the service life of the lime calciner liner; and the method can also be efficiently used for repairing local damage of a lime calciner paint liner or refractory cast-forming liner.

Owner:HUZHOU ZHEBAO METALLURGY AUX MATERIALS

Formliner Bridge

A form liner system comprises a first form liner, a second form liner and a bridge member. Each form liner comprises a plurality of raised portions defining a plurality of cells and at least one partial cell. The form liners are arranged such that the partial cells form a collective cell. The bridge member can be oriented in said collective cell, wherein a first portion of the bridge member is oriented in the first liner partial cell and a second portion of the bridge member is oriented in the second liner partial cell.

Owner:ADVANCED FORMLINERS

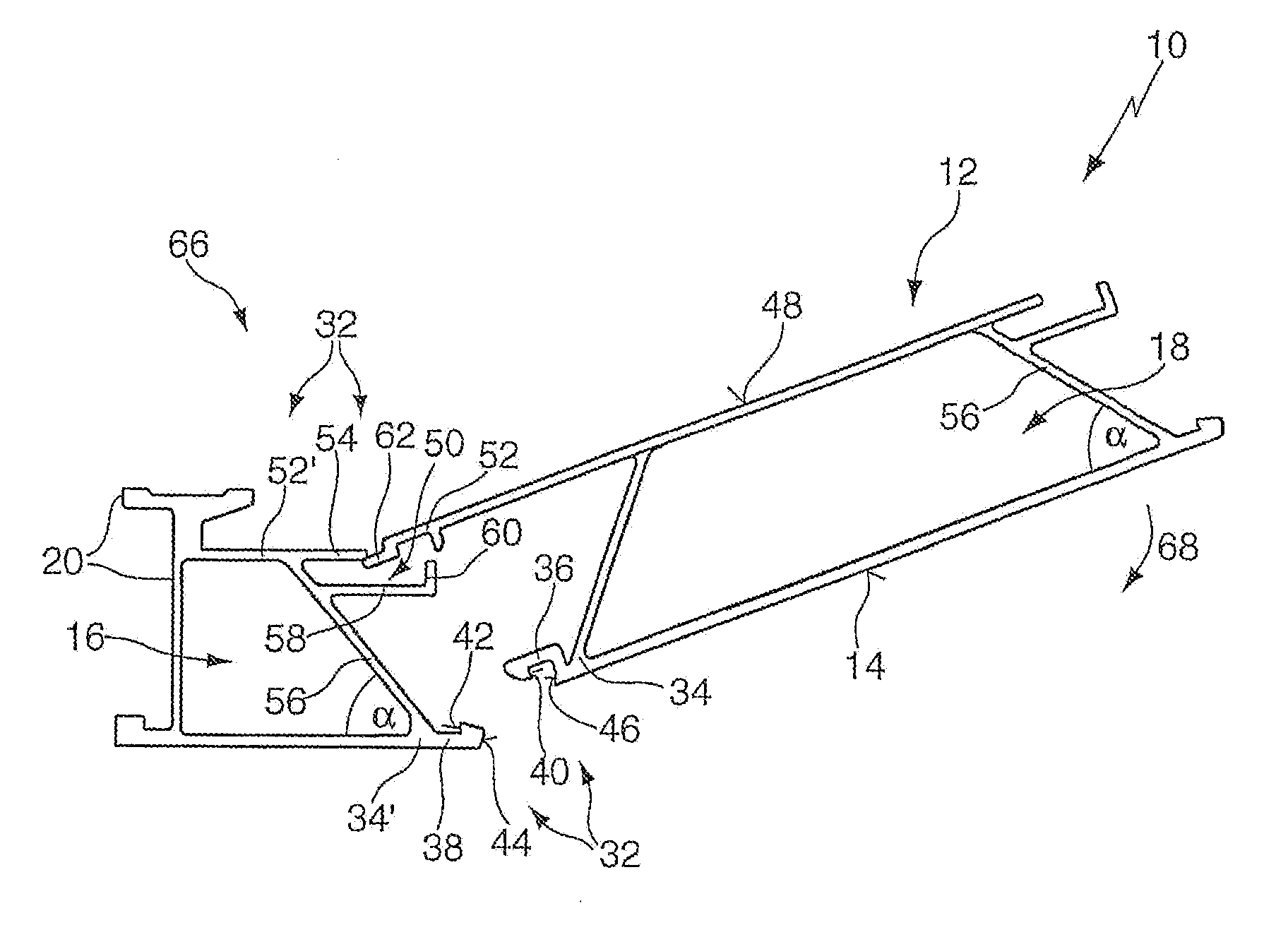

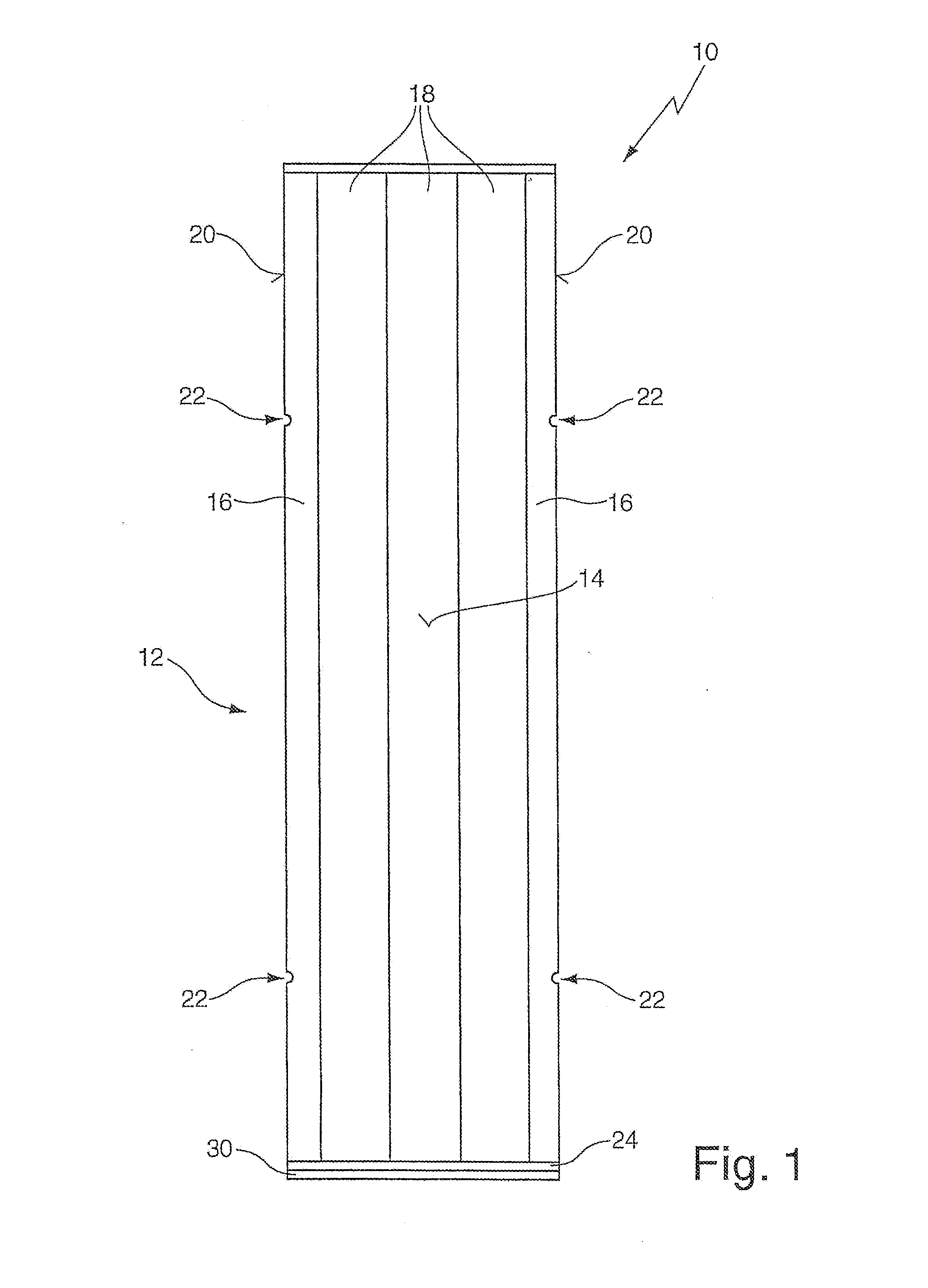

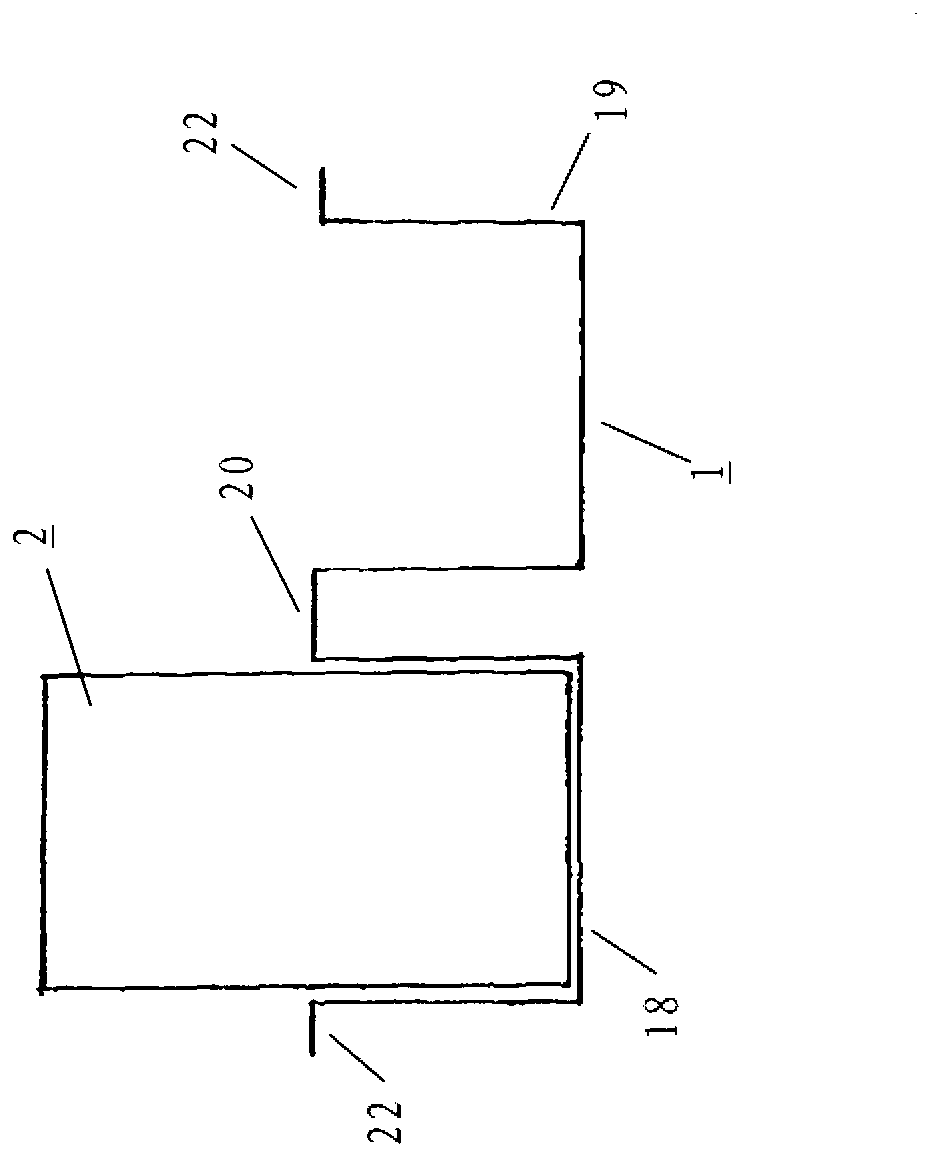

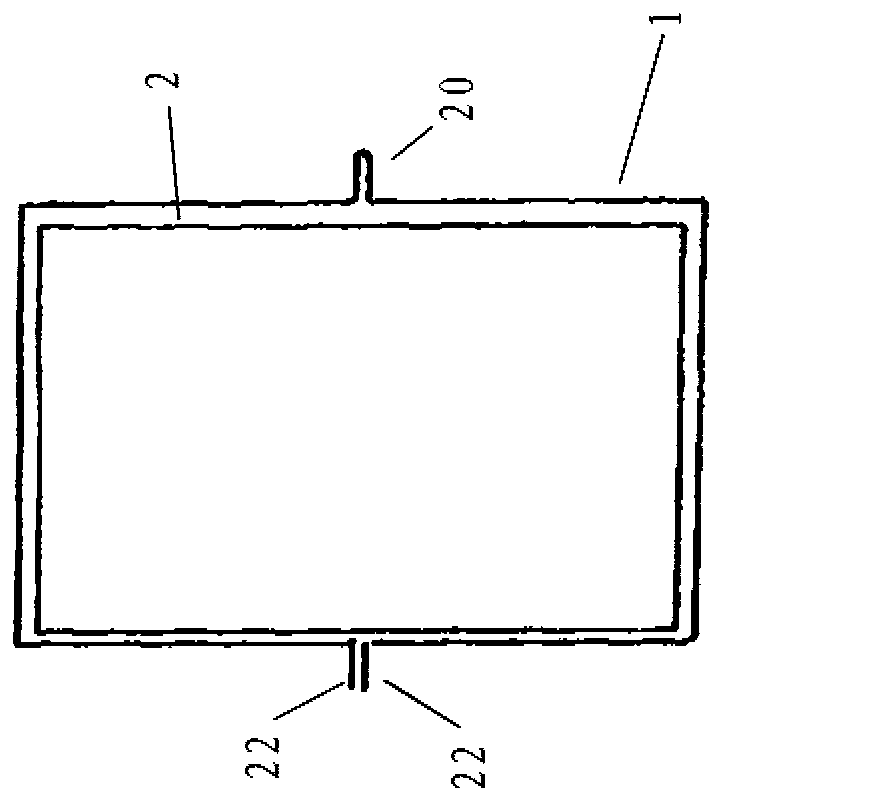

Formwork Element

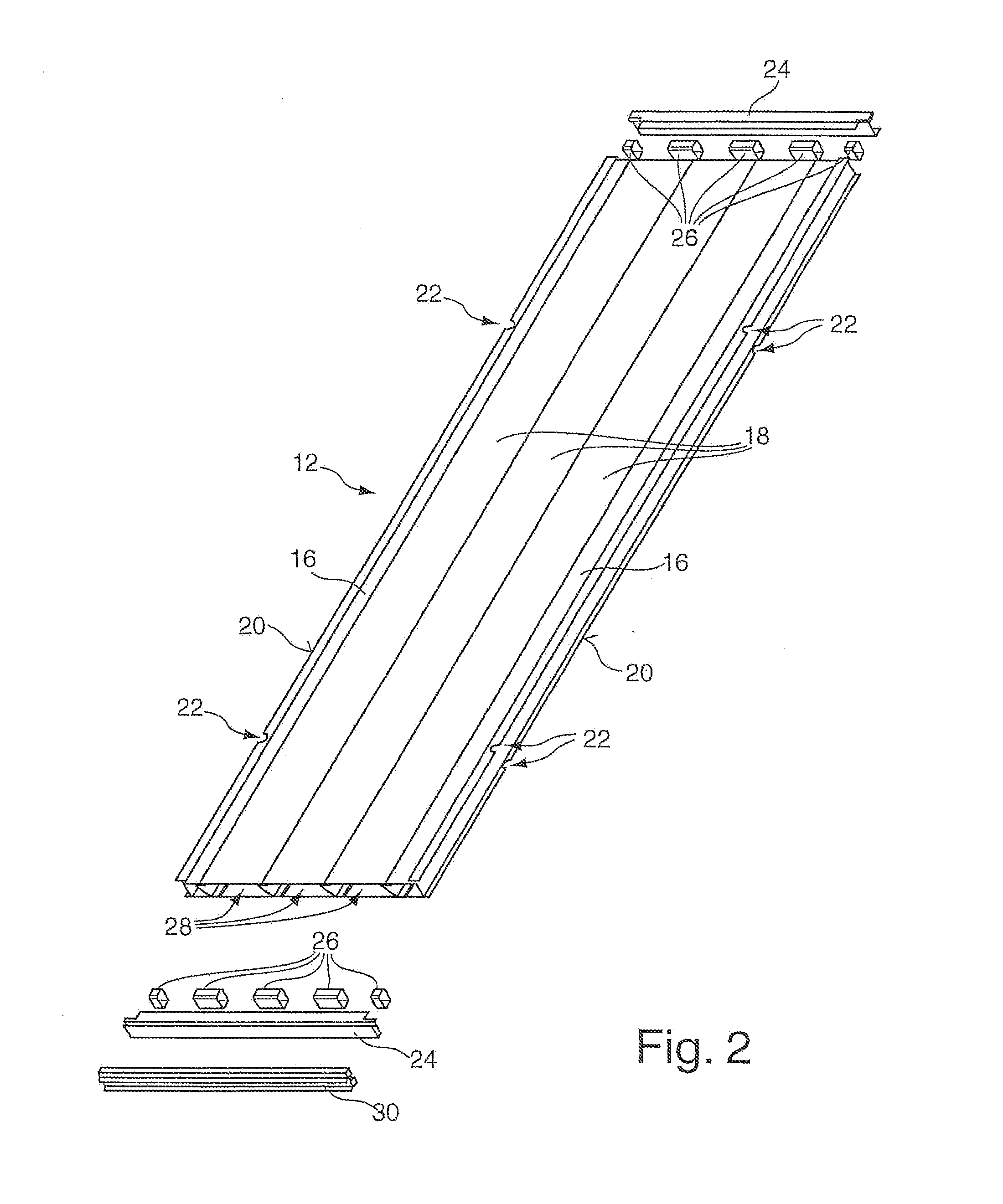

InactiveUS20120223212A1Improve surface qualityMinimize cleaning expenseAuxillary members of forms/shuttering/falseworksForming/stuttering elementsEdge segmentForm liner

A formwork element 10 for concrete structures, has a base body 12 of hollow profile construction having an outer side 14 designed as a form lining. The base body 12 is formed by at least two interlocking subsegments which are permanently connected to one another at their interlocking edge areas. The subsegments, such as edge segment and intermediate segment 16, 18, which are advantageously produced through extrusion, are advantageously hooked to one another to form an inseparable unit in the connected state.

Owner:PERI GMBH

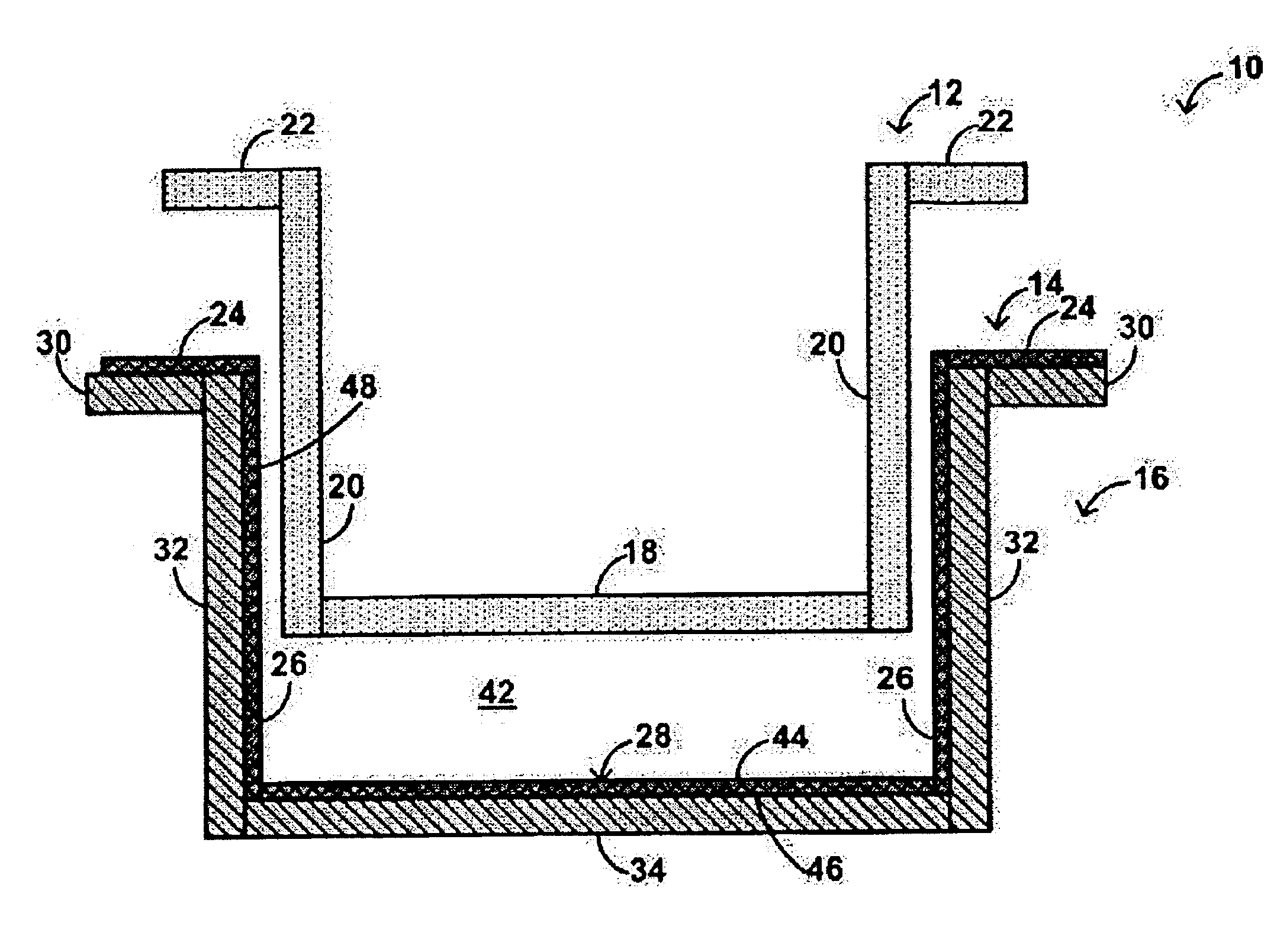

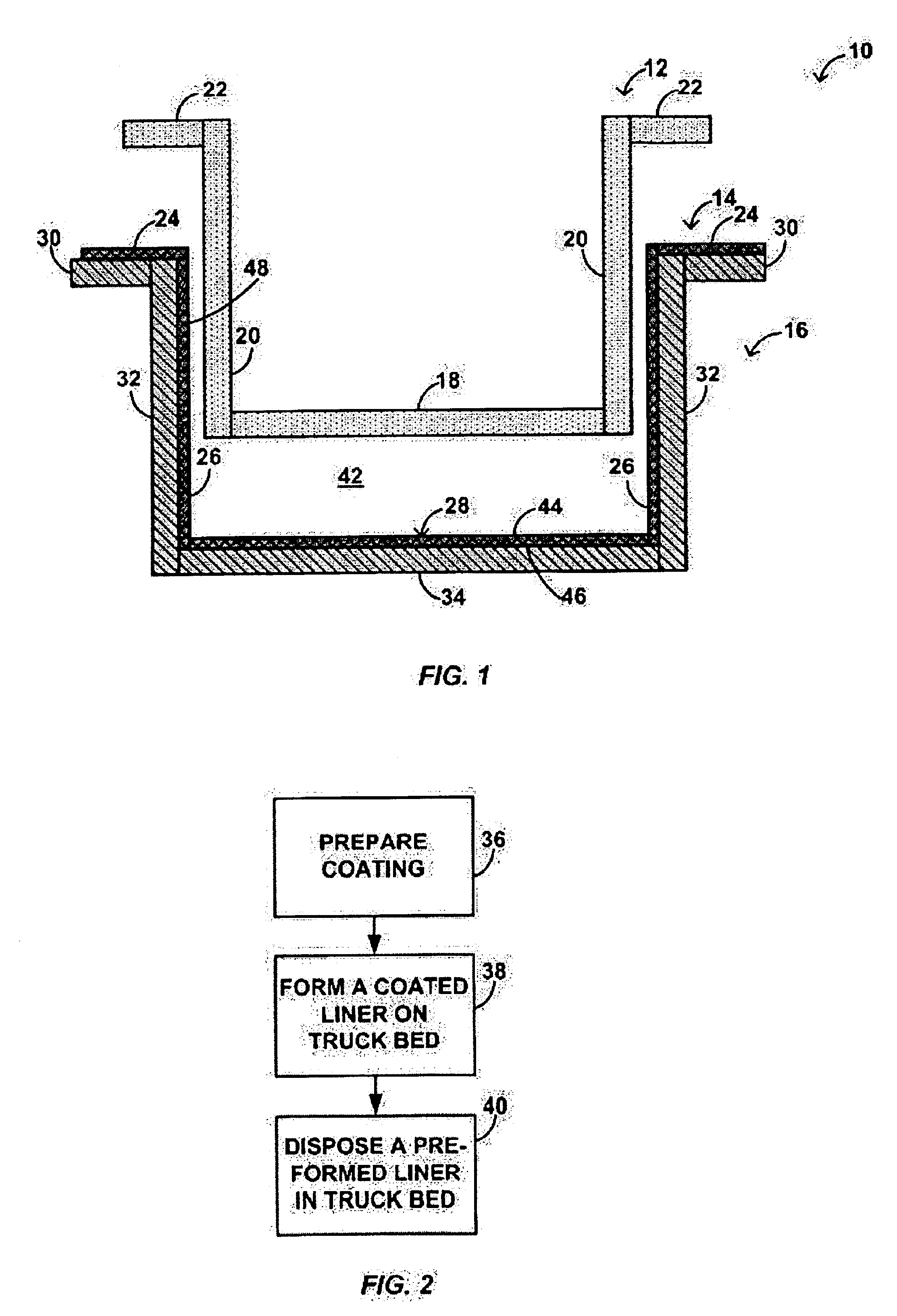

Combination truck bed liner

A protective liner for a truck bed, and a method for making the same. The liner includes a coated liner adhesively coupled to a truck bed, the coated liner having a first surface and a second surface opposite the first surface, the first surface contacting the truck bed and having a transverse section and a bed section, the transverse section and the bed section forming a cavity; and a pre-formed liner disposed within the cavity and at least partially contacting the second surface.

Owner:BURTIN CLAUDIO

Preformed liner adhered to a pipe with an adhesive

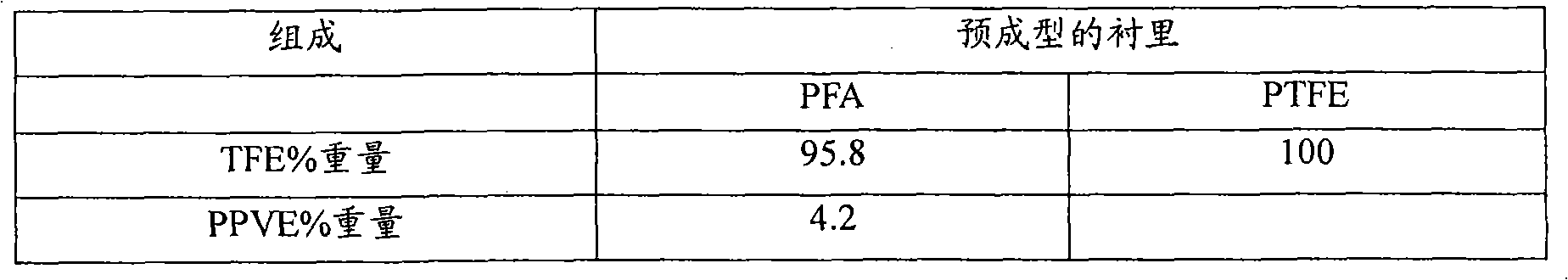

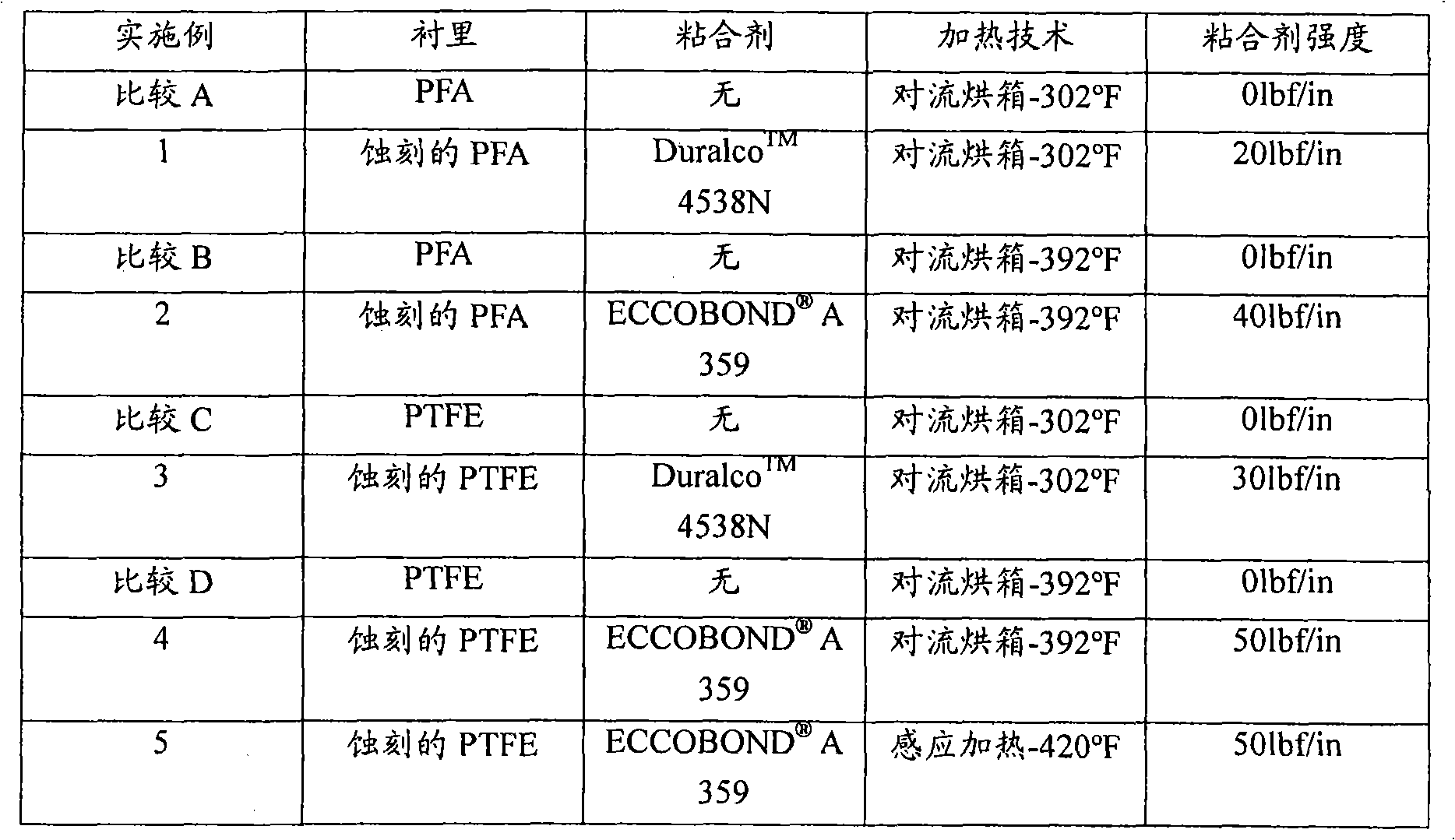

The present invention relates to a preformed liner adhered to the surface of a pipe, and in particular, an oil well pipe, by an adhesive. The liner comprises a polymer, preferably a fluoropolymer. The present invention also relates to a process for adhering the preformed liner to the interior surface of a pipe, and in particular by applying adhesive to the preformed liner. The liner is preferably treated prior to applying the adhesive. A suitable treatment includes etching. The pipe is heated to adhere the preformed liner to the interior surface of the pipe, without buckling the liner. The interior surface of the preformed fluoropolymer liner reduces the deposition of at least one of 1) asphaltenes, 2) paraffin wax, and 3) inorganic scale by at least 40% as compared to the interior surface of the oil pipe without the preformed liner being present.

Owner:EI DU PONT DE NEMOURS & CO

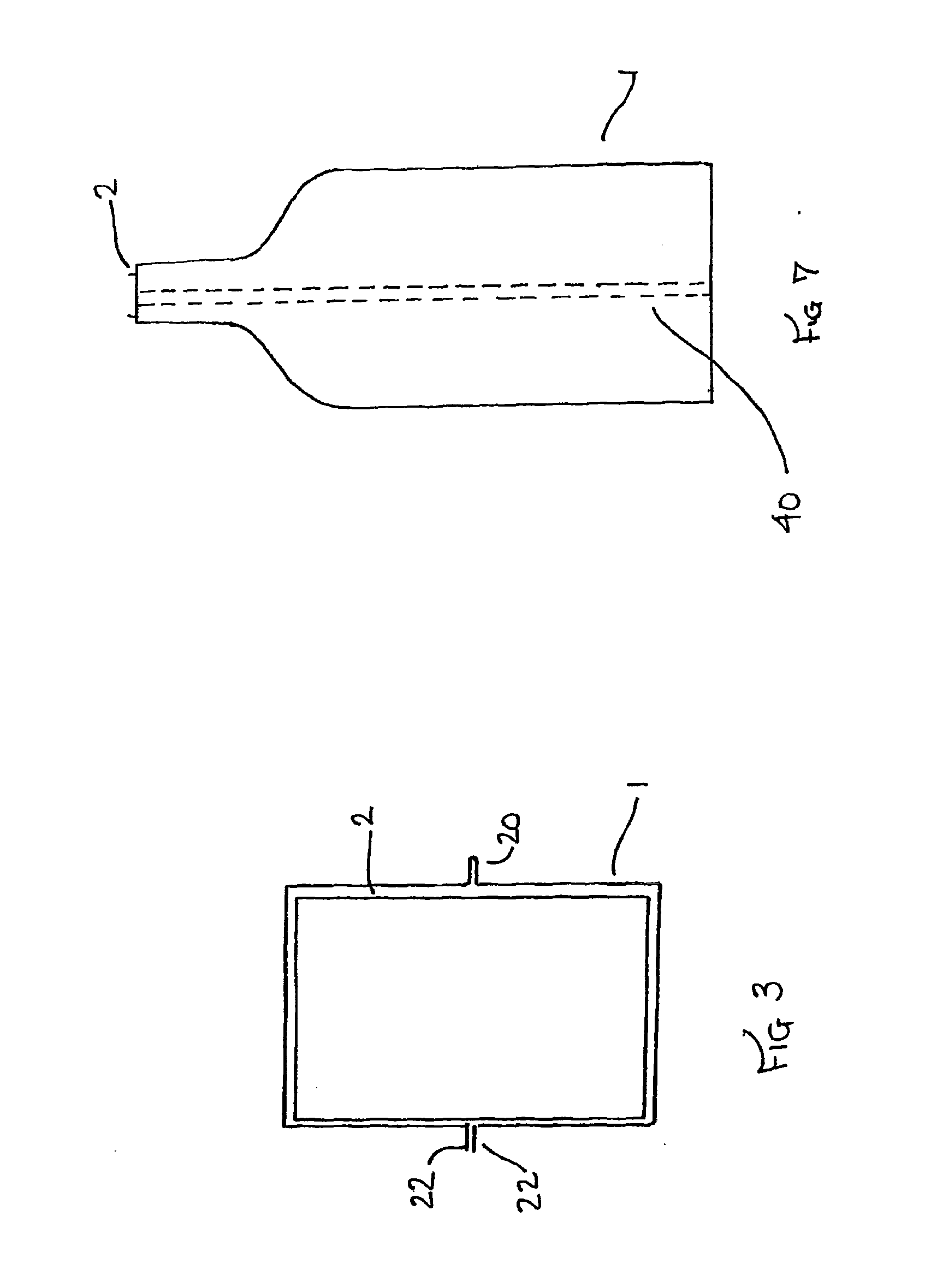

Short-line-method box girder section prefabricated longitudinal full-length prestressed duct positioning device and construction method

ActiveCN108748648AStraight structureHigh positioning accuracyCeramic shaping apparatusForm linerEngineering

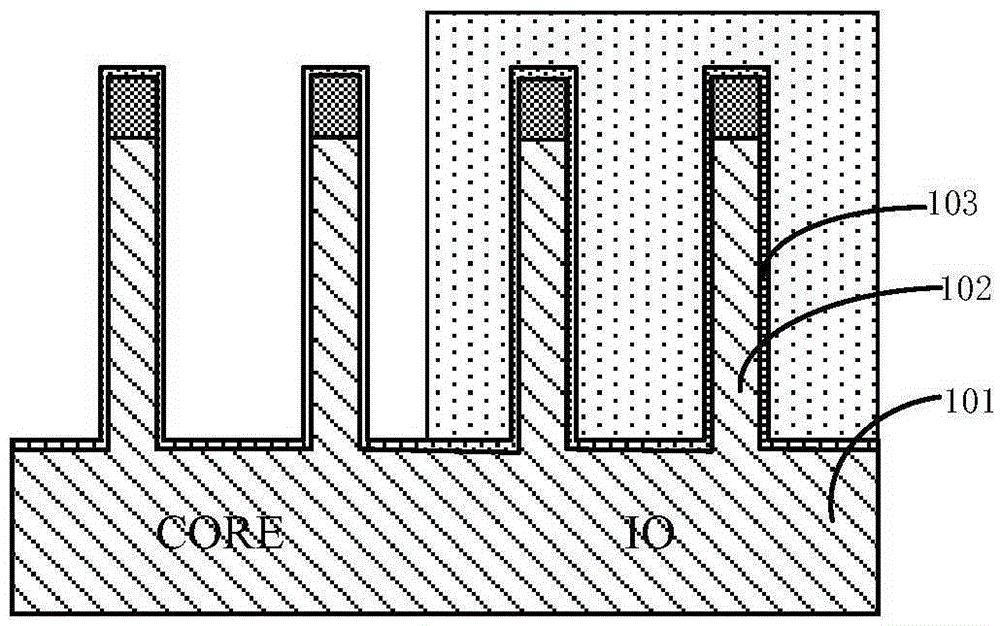

The invention discloses a short-line-method box girder section prefabricated longitudinal full-length prestressed duct positioning device, and meanwhile discloses a method for positioning constructionby utilizing the positioning device. The short-line-method box girder section prefabricated longitudinal full-length prestressed duct positioning device is characterized in that the positioning device comprises steel pipes (1); the end diameters of the steel pipes (1) are gradually decreased; the outer diameters of the steel pipes (1) are R, and the end diameters of the steel pipes (1) are 0.3 R;PE pipes (2) are arranged outside the steel pipes (1), and the steel pipes (1) and the PE pipes (2) together form liner pipes; the PE pipes (2) are movably connected into corrugated pipes (3) in a penetrating mode, wherein the corrugated pipes (3) are buried in concrete; and anchor plates (4) and spiral steel bars (5) are arranged at the ends of the corrugated pipes (3).

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP 1ST ENG

Form liner with object sealant

In some embodiments, a formliner comprises a body comprising a defining a plurality of cavities arranged in a repeating pattern. A sealant is provided in each cavity. The sealant comprises a gel mixture of wax and vegetable oil. In some embodiments, the wax comprises carnauba wax and / or beeswax.

Owner:ADVANCED FORMILINERS LLC

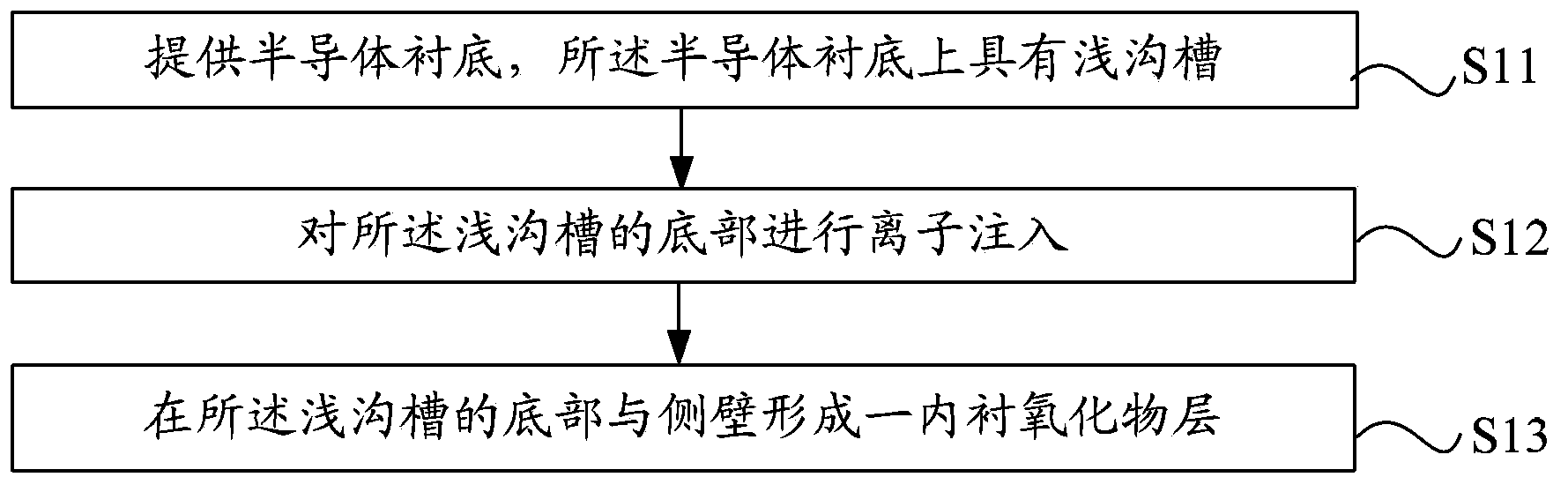

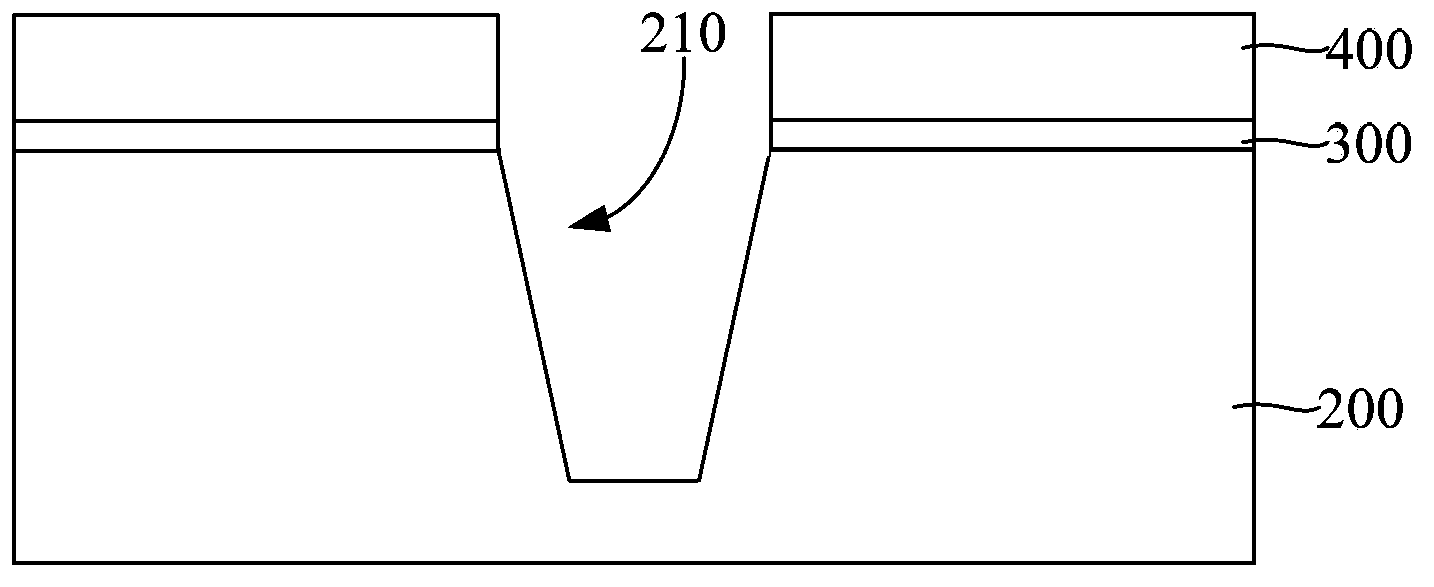

Preparation method of semiconductor device

InactiveCN104347471APrevent Isolation LeakageImprove electrical performanceSemiconductor/solid-state device manufacturingForm linerIon implantation

The invention discloses a preparation method of a semiconductor device. The preparation method of the semiconductor device comprises the following steps: firstly providing a semiconductor substrate, wherein the semiconductor substrate is provided with a shallow trench; then performing ion implantation on the bottom of the shallow trench; finally forming a liner oxide layer on the bottom and the side wall of the shallow trench. According to the preparation method of the semiconductor device, ion implantation is performed on the bottom of the shallow trench so as to form a doping region on the bottom of the trench shallow, and the growth speed of the liner oxide layer in the doping region is greater than that of the liner oxide layer on the side wall of the shallow trench, so that in the finally formed liner oxide layer, the bottom thickness of the liner oxide layer is obviously improved, further the uniformity of the bottom thickness and the sidewall thickness of liner oxides in shallow trench isolation is increased, current leakage of shallow trench isolation is prevented, and thus the electrical property of a shallow trench isolation device is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

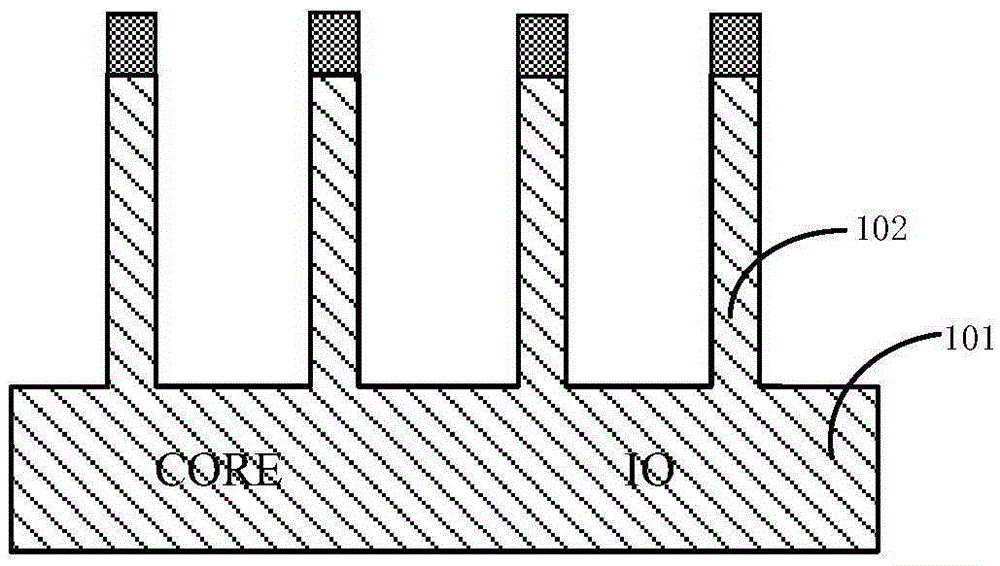

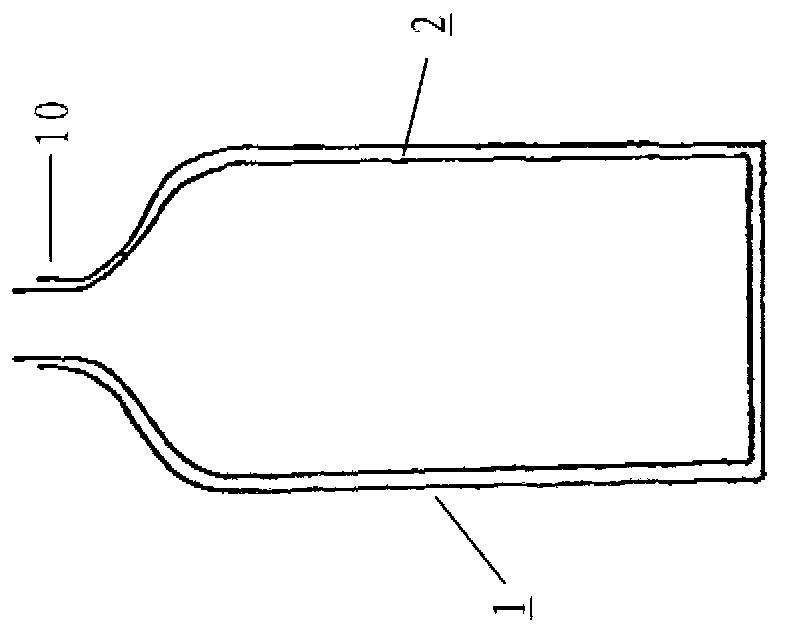

Semiconductor device, preparation method thereof and electronic device

ActiveCN106601620AAvoid overdoseInhibited DiffusionSemiconductor/solid-state device manufacturingSemiconductor devicesForm linerBoron containing

The invention relates to a semiconductor device, a preparation method thereof and an electronic device. The method comprises the steps of (S1) providing a semiconductor substrate which comprises a core area and an input and output area, wherein a plurality of fins is formed in the core area and the input and output area, (S2) forming liner layers on the semiconductor substrate of the input and output area and the side walls of the bottoms of the fins, (S3) orderly forming a boron-containing material layer and a covering layer on the semiconductor substrate of the core area, the surfaces of the fins, the linear layer in the input and output area and the surfaces of the tops of the fins, (S4) forming an isolation material layer on the covering layer to the top of the linear layer or higher so as to partly cover the fins, and (S5) removing the boron-containing material layer and the covering layer on exposed fins, and (S6) executing annealing such that the boron in the boron-containing material layer is diffused to a channel stop area.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Container

Container and method of forming a container comprising an inner liner and an outer shell by providing an open shell that is closeable to provide the outer shell, vacuum forming the liner with a shape conforming generally to at least a portion of the inner volume of the shell from at least one film, positioning the formed liner in the open shell and closing the shell.

Owner:GREENBOTTLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com