Channel elbow with wearable liner and lining method thereof

A pipe elbow and wear-resistant lining technology, which is applied in another purpose field, can solve the problems of high cost, troublesome manufacturing, poor wear resistance, etc., and achieve the effect of simple construction, easy construction and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

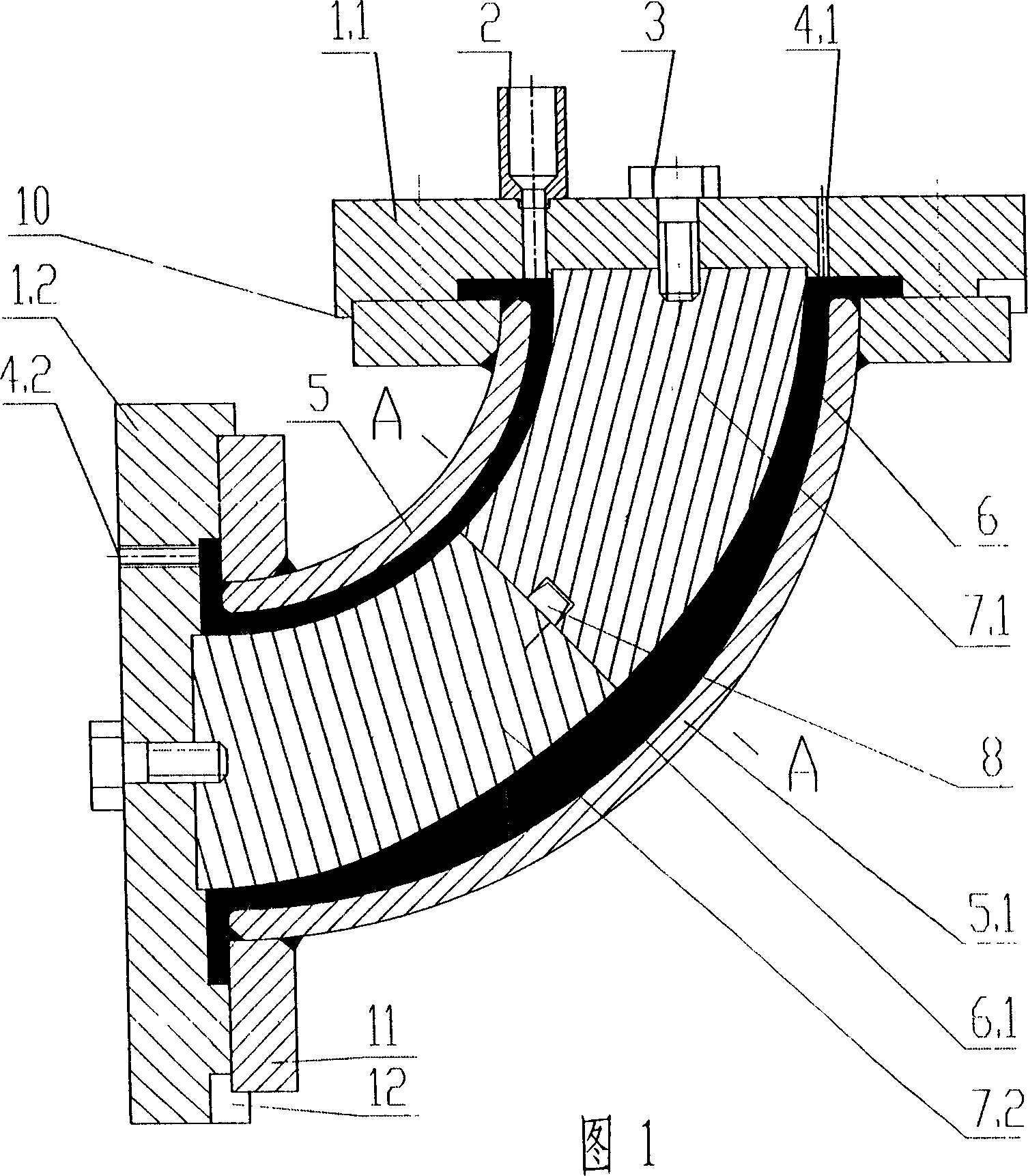

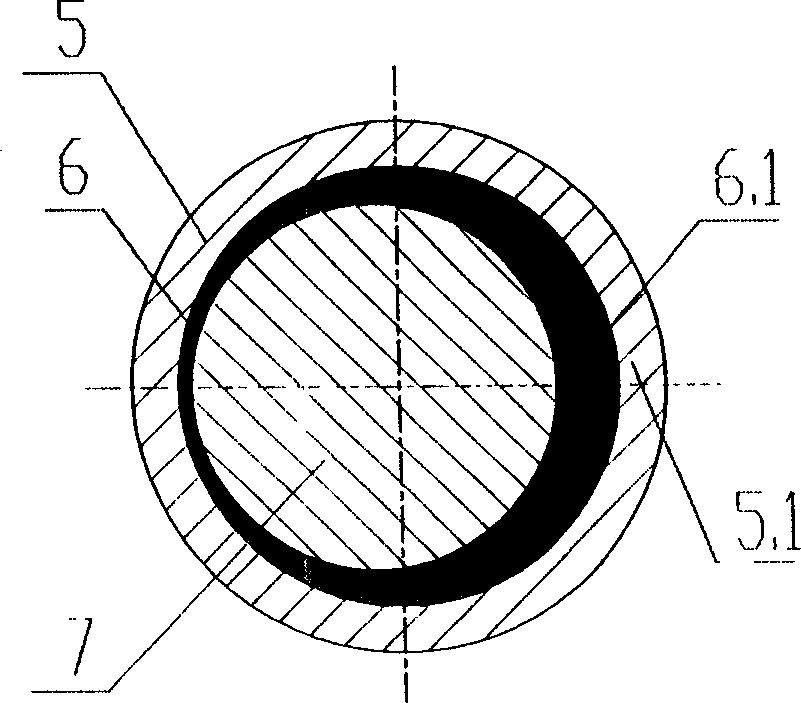

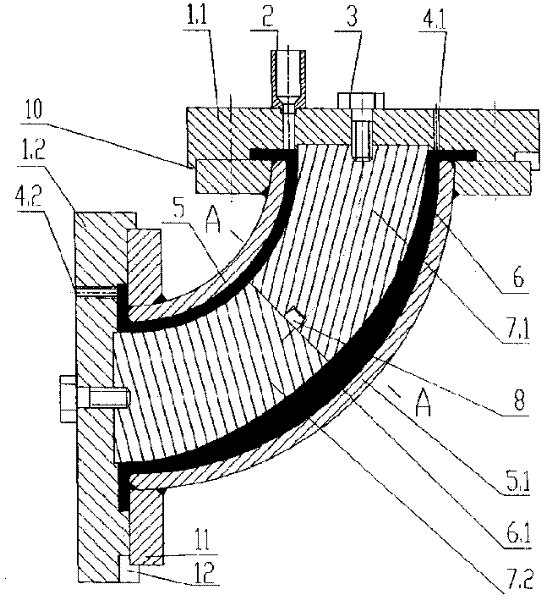

[0012] Embodiment 1: Referring to the accompanying drawings, the right-angle elbow 5 of the lined pipeline is used as the outer mold, and the inner cavity is painted with Kemlok (brand CF218) adhesive, and the inner hole is fixed with a combination of a semicircle and a semiellipse (or an ellipse). ) The outer surface is coated with a release agent such as the lining mandrel 7 of a silane release agent, and the mandrel 7 has two sections 7.1 and 7.2 in the axial direction to form, and is positioned by the positioning boss 8 (also can be positioned by other positioning methods). There are caps 1.1 and 1.2 on the two ends of the elbow respectively, which are positioned and connected with the mandrel 7 through the bolt 3. The capping function is to form a lining layer baffle; provide help. There is a protruding positioning ring cover edge 10 on the outer periphery of the cover 1, which forms a positioning with the elbow flange. The edge of the cover is provided with a demoulding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com