Tubular Member Coupling and Lining Systems and Methods

a technology of tubular member and coupling system, which is applied in the direction of wellbore/well accessories, drilling accessories, fluid removal, etc., can solve the problems of significant wear of production tubing, more difficult and costly replacement than a coupler, and the coating may quickly wear away

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

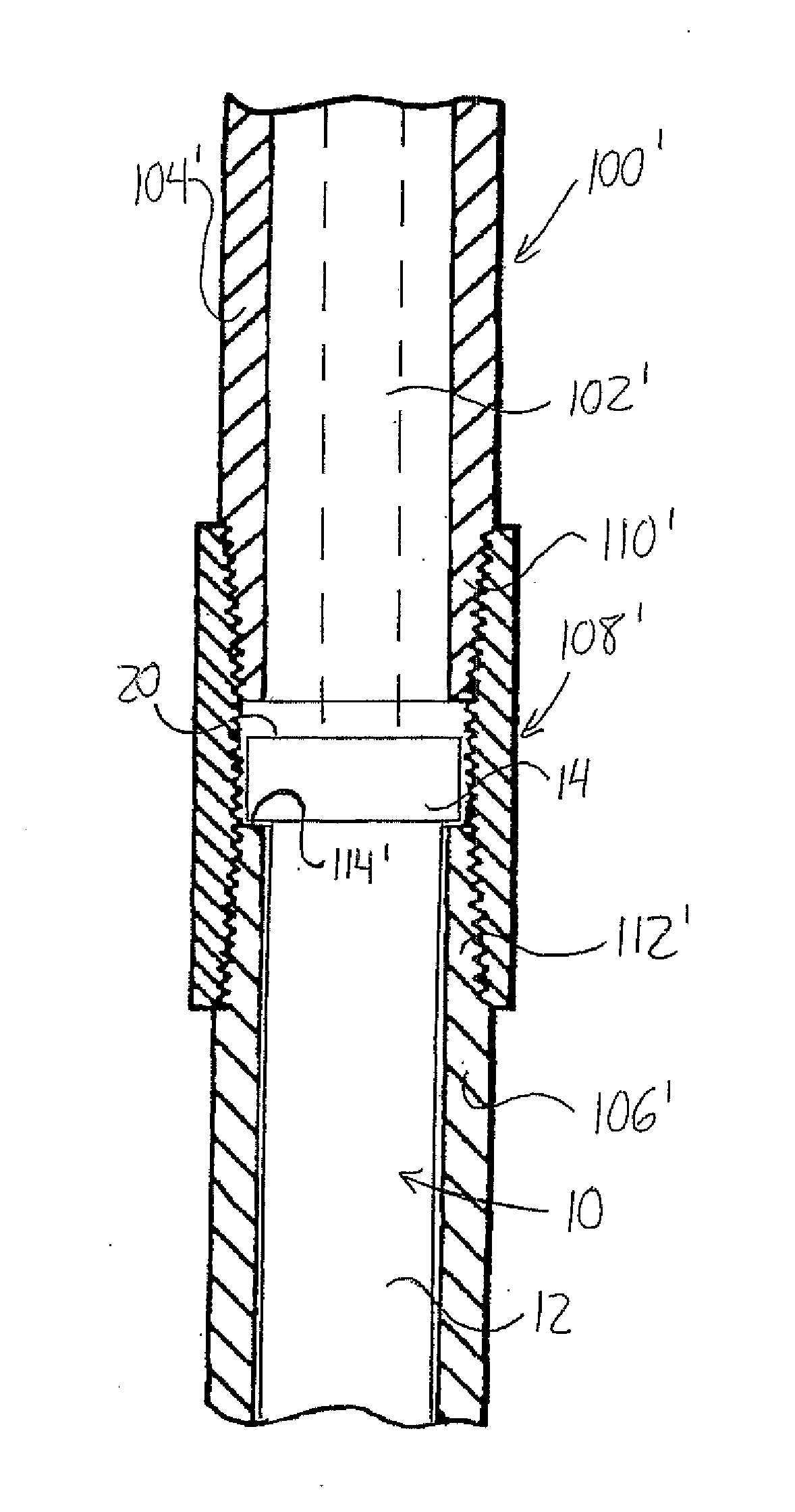

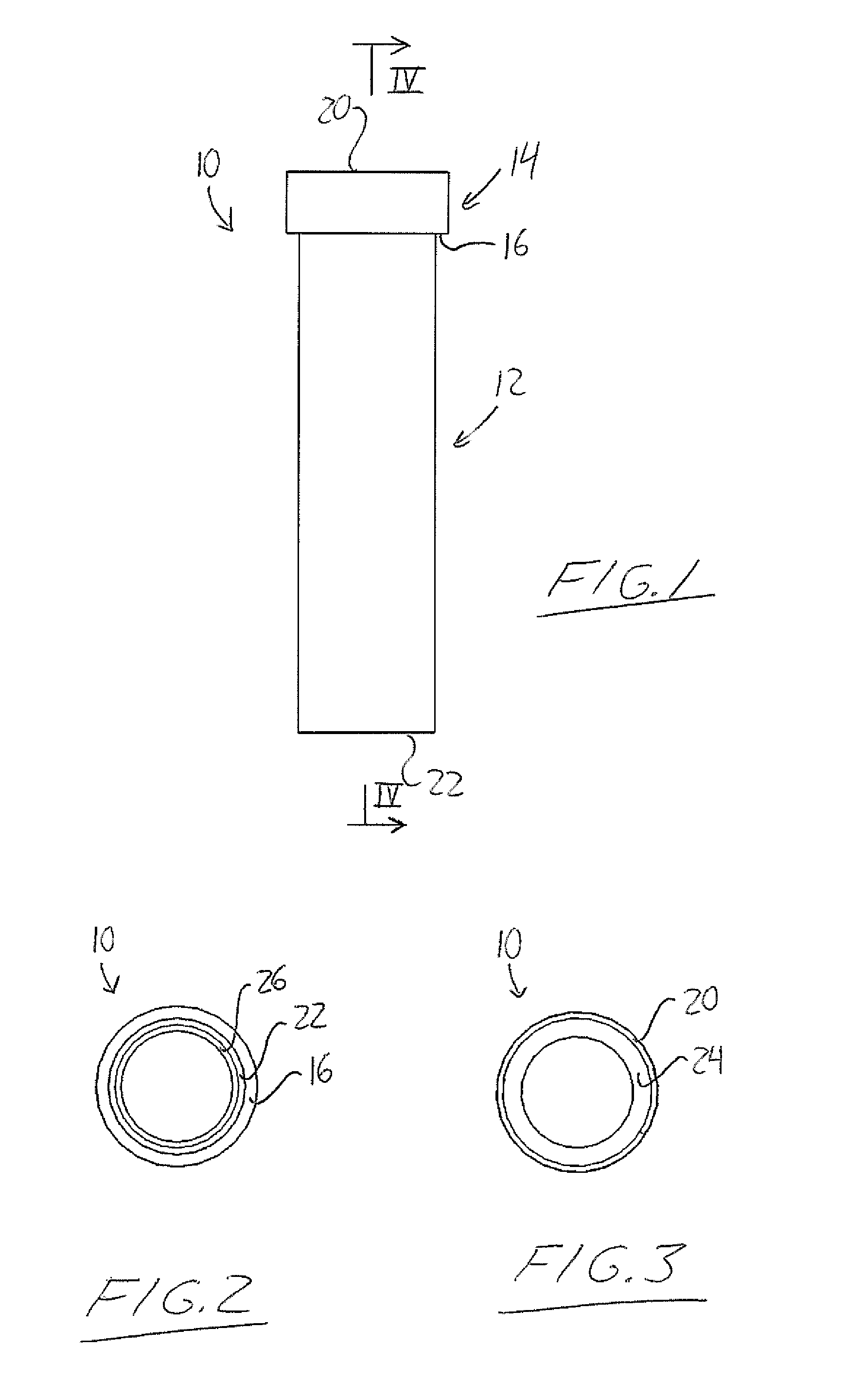

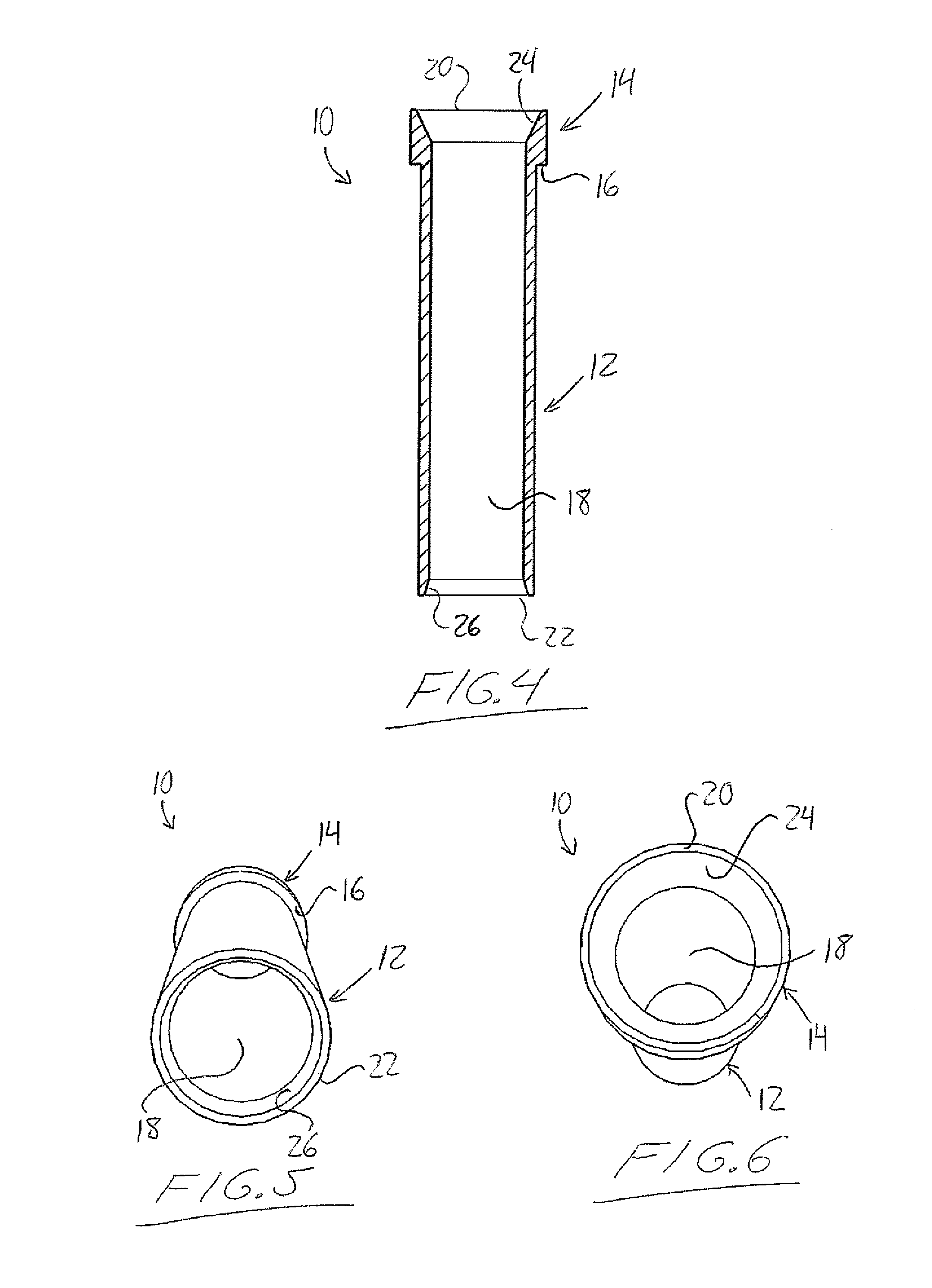

[0046]With reference to FIG. 7, the drawings show an embodiment of a liner insert 10 arranged to be placed within a section of a production tubing string 100 for a well so that a sucker rod string 102 to be extended downward through the tubing 100 for operation of a downhole pump in the wellbore is prevented from contacting the internal surface of the tubing string 100 at the location of the insert 10. The assembled conventional tubing string 100 features adjacent tube joints or sections 104, 106 situated one over the other in axial alignment and coupled together by means of an internally threaded collar or box coupler 108 that engages an externally threaded lower upset portion 110 of the upper tubing section 104 and an externally threaded upper upset end portion 112 of the lower tubing section 106. These conventional EUE (externally upset end) tubing sections are each of uniform inner diameter from end to end, and of uniform outer diameter between the opposite externally threaded u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com