Short-line-method box girder section prefabricated longitudinal full-length prestressed duct positioning device and construction method

A construction method and positioning device technology are applied in the field of short-line method box girder segment prefabricated longitudinal full-length prestressed tunnel positioning devices, which can solve the problems of inaccurate positioning, poor construction quality, and uneven tunnel structure, and improve work efficiency. Efficiency, wide range of applications, and the effect of ensuring project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

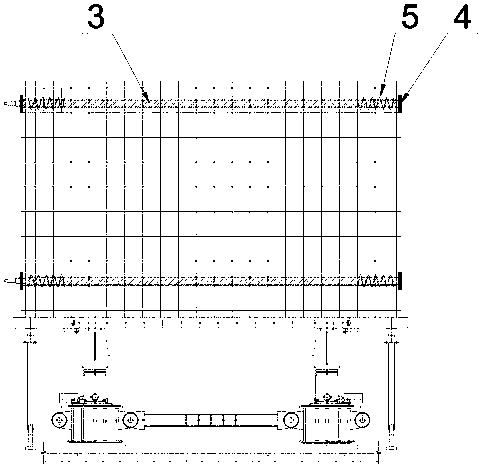

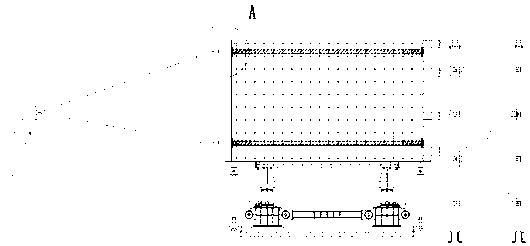

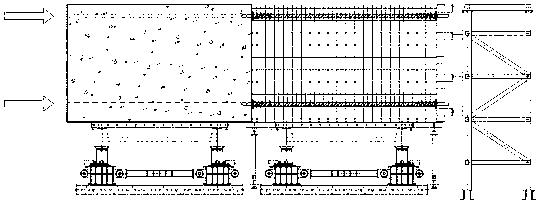

[0024] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as Figure 1 to Figure 7 Shown: a prefabricated longitudinal prestressed tunnel positioning device for box girder segments by short-line method, including a steel pipe 1, the diameter of the end of the steel pipe 1 is gradually reduced, the outer diameter of the steel pipe 1 is R, and the diameter of the end of the steel pipe 1 is 0.3R, a PE pipe 2 is arranged outside the steel pipe 1, and the steel pipe 1 and the PE pipe 2 together form a lining pipe, and the PE pipe 2 is movably connected in the corrugated pipe 3 embedded in the concrete, and the corrugated pipe 3 An anchor plate 4 and a spiral steel bar 5 are provided at the end of the pipe; the outer diameter of the steel pipe 1 is R, and the end diameter of the steel pipe 1 is 0.3R; the outer diameter of the PE pipe 2 is 0.7-0.8 times the inner diameter of the bellows 3 .

[0025] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com