Construction mold for pouring water-cooled column and water-cooled beam of heating furnace and its pouring construction method

A water-cooled column and water-cooled beam technology, which is applied in the field of heating furnace water-cooled column, can solve the problems of high manufacturing cost of steel mold, easy deviation of water-cooled column, and increase of wooden squares, so as to improve pouring quality, eliminate quality hidden dangers, and enhance versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

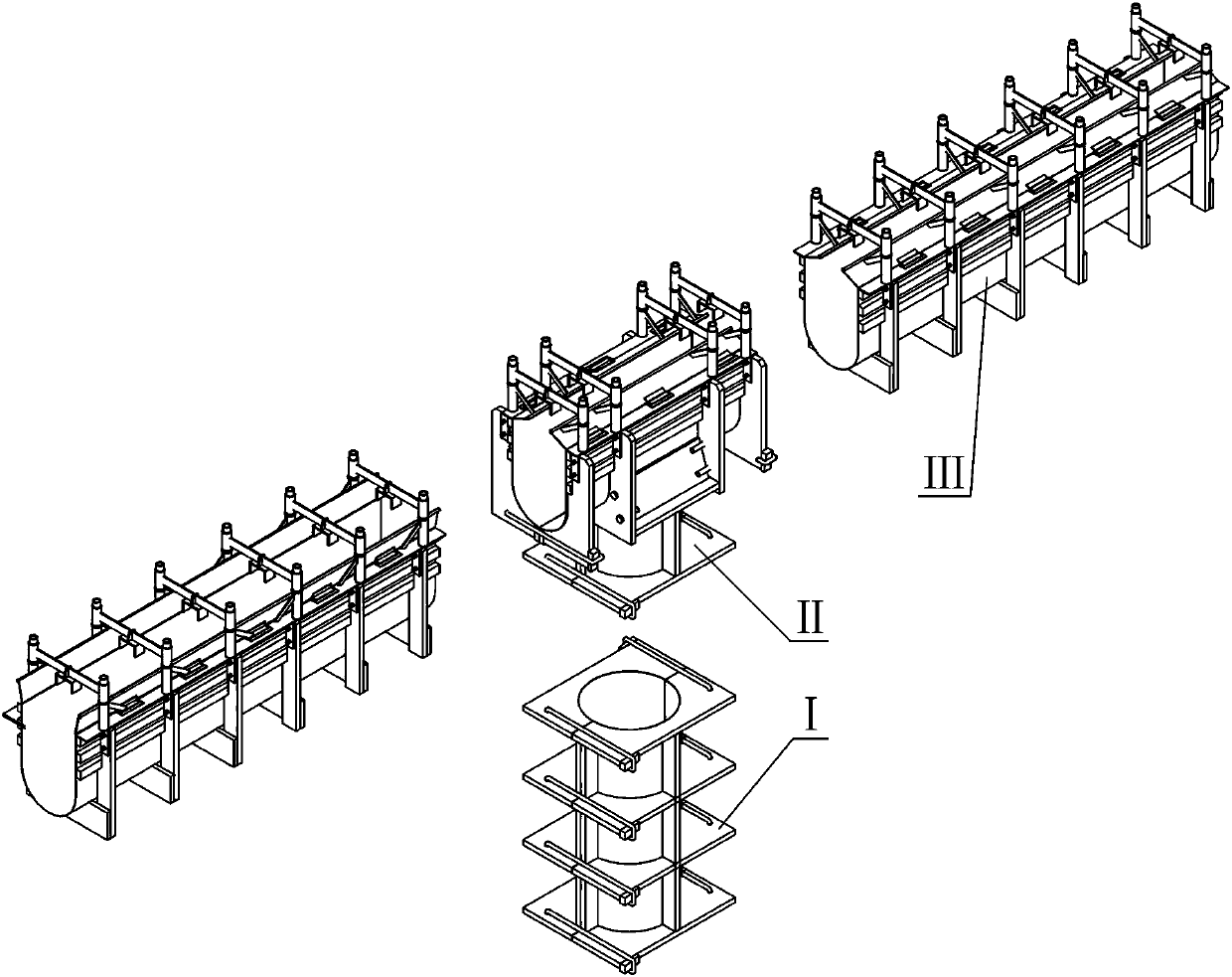

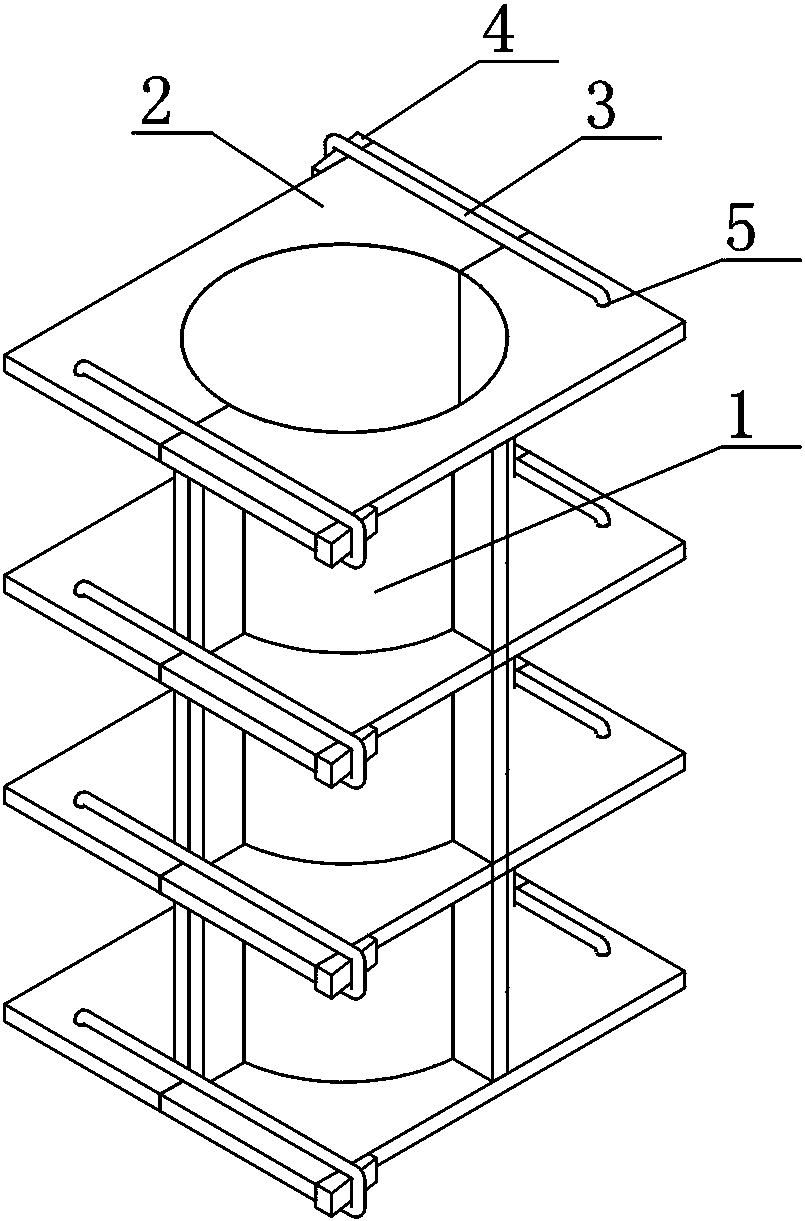

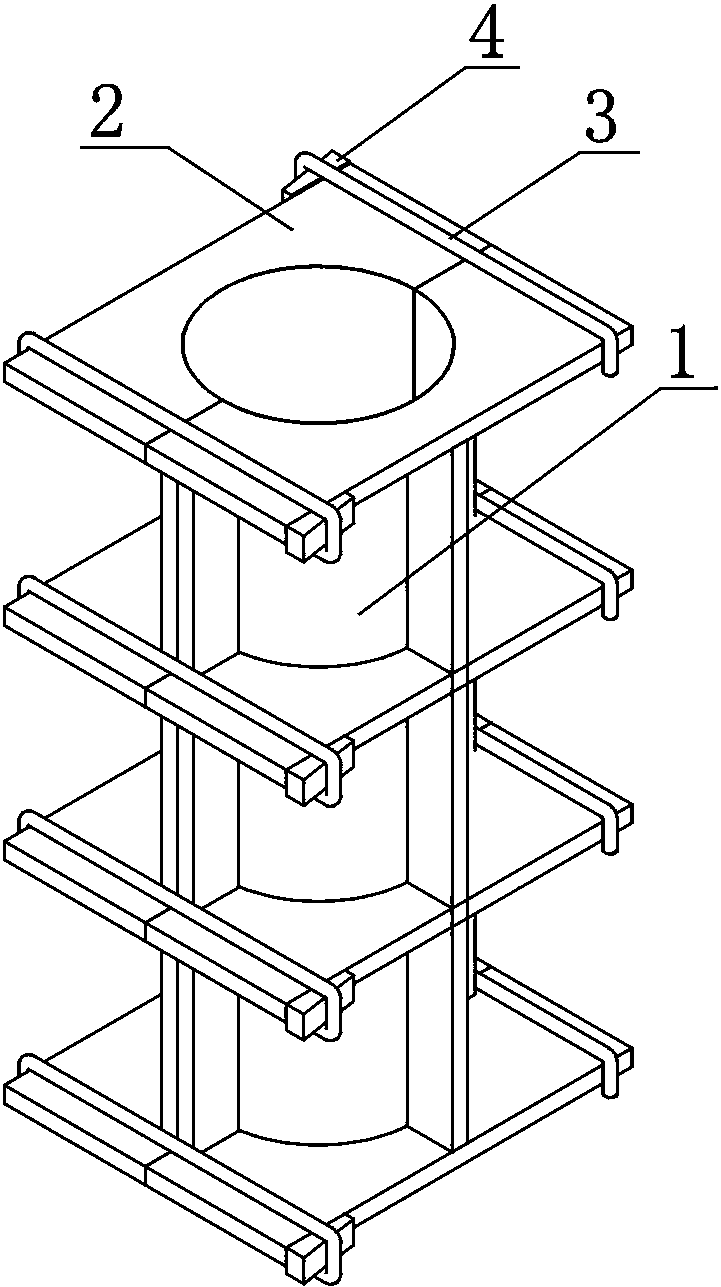

[0054] Such as Figure 1-12 As shown, a heating furnace water-cooled column, water-cooled beam pouring construction mold, it includes water-cooled column mold Ⅰ, tee mold Ⅱ and water-cooled beam mold Ⅲ, such as figure 2 , 3 As shown, the water-cooled column mold I is mainly assembled by a pair of water-cooled column half-molds 1, the outer surface of the water-cooled column half-mold 1 is provided with reinforcing ribs in the axial direction, and a plurality of wooden reinforcement boards 2 are evenly provided in the circumferential direction. (The reinforcing rib is made of wood, which is combined with the wooden rib plate 2 to form a wooden tire frame). A pair of water-cooled column half molds 1 are fixed together by a locking device, and the locking device is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com