Integrally-formed strip nail

A one-piece, nailing technology, applied in the direction of nails, U-shaped nails, connecting components, etc., can solve the problems of difficult processing, unevenness, high cost, etc., and achieve the effect of good clamping effect and straight structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples illustrate the possible implementation forms of the present invention, but are not intended to limit the scope of protection of the present invention.

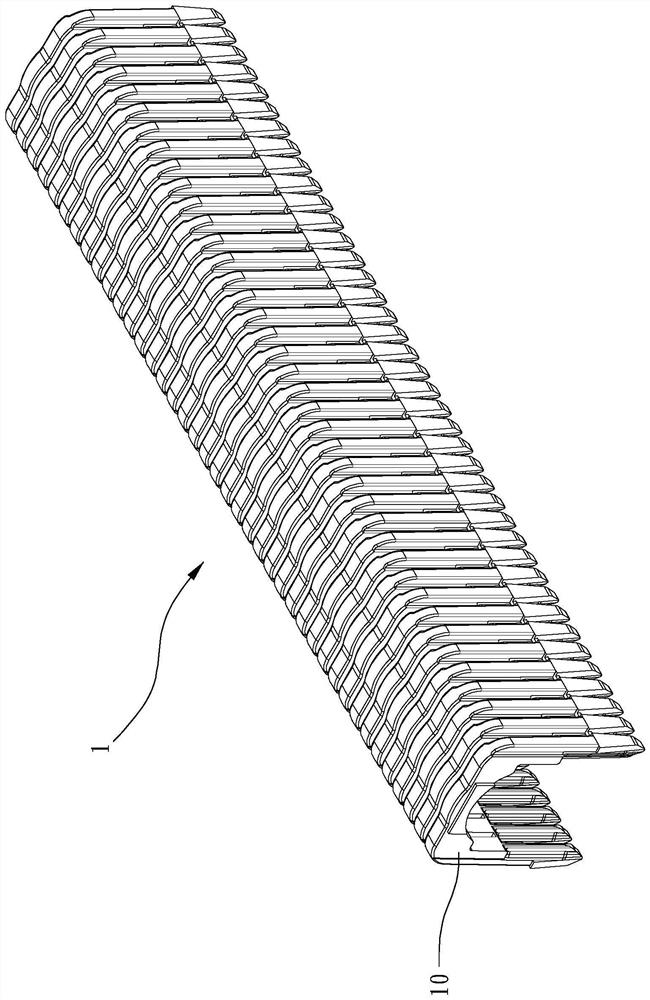

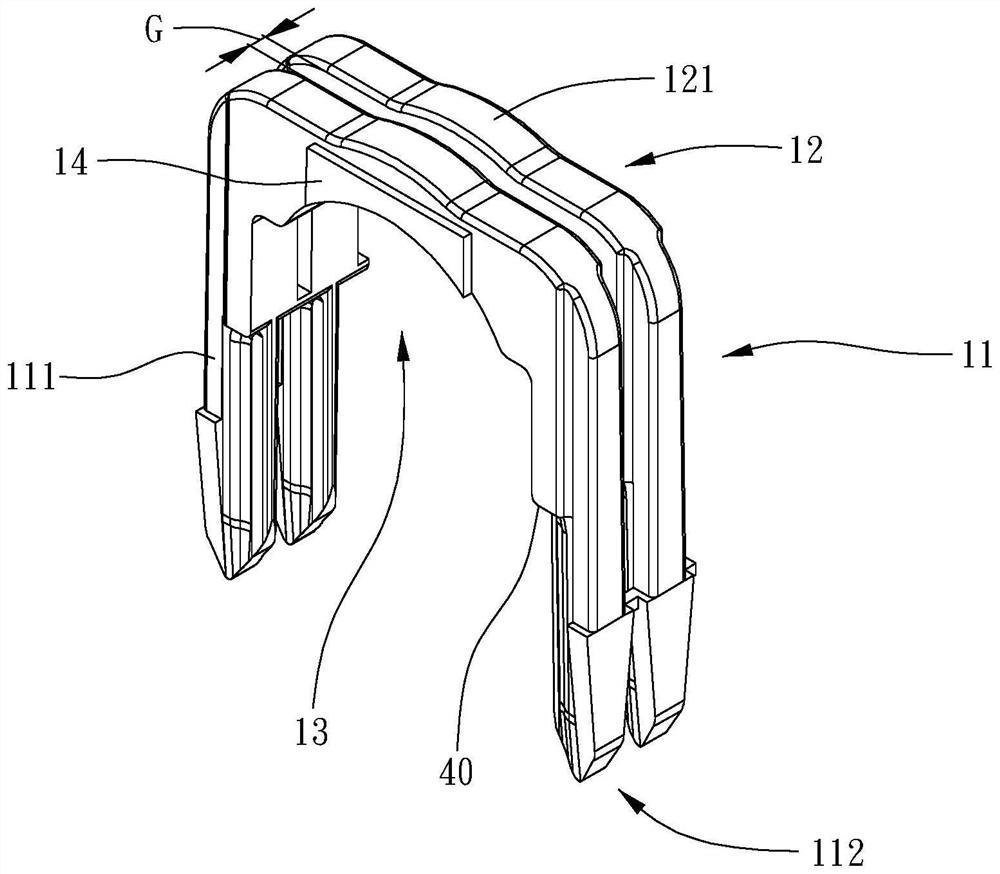

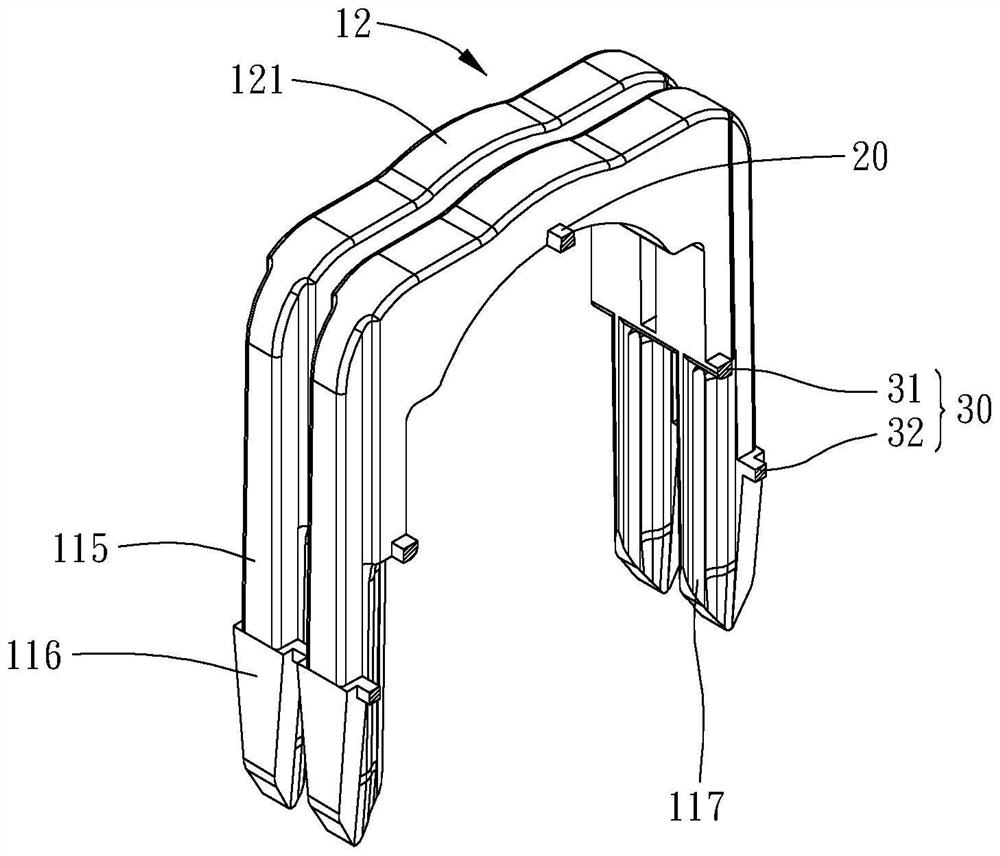

[0028] Please refer to Figures 1 to 7 , which shows a preferred embodiment of the present invention, the integrally formed nail row 1 of the present invention includes a plurality of nail needles 10 , a connecting portion and a stop portion 40 . The integrally formed nail row 1 is, for example, made of plastic, and can also be made of other materials.

[0029] Each of the nails 10 includes two legs 11 and a crown 12 connecting the two legs 11; the connecting portion is connected between two adjacent nails 10; the stopper 40 is on each of the legs of the nails 10 The portion 11 protrudes laterally and defines a receiving space 13 for receiving a cable with the crown portion 12 ; wherein, each of the leg portions 11 includes a spike 111 extending from the stop portion 40 . Thereby, it can ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com