Patents

Literature

127results about How to "Good clamping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

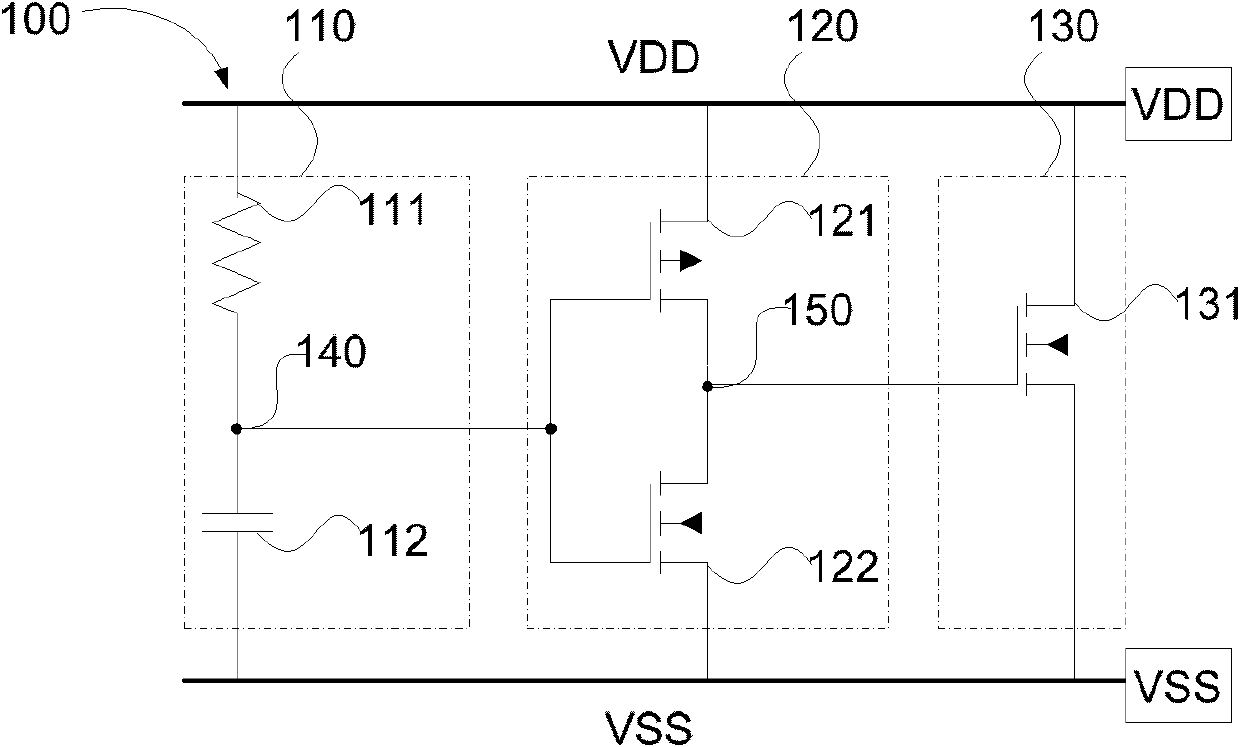

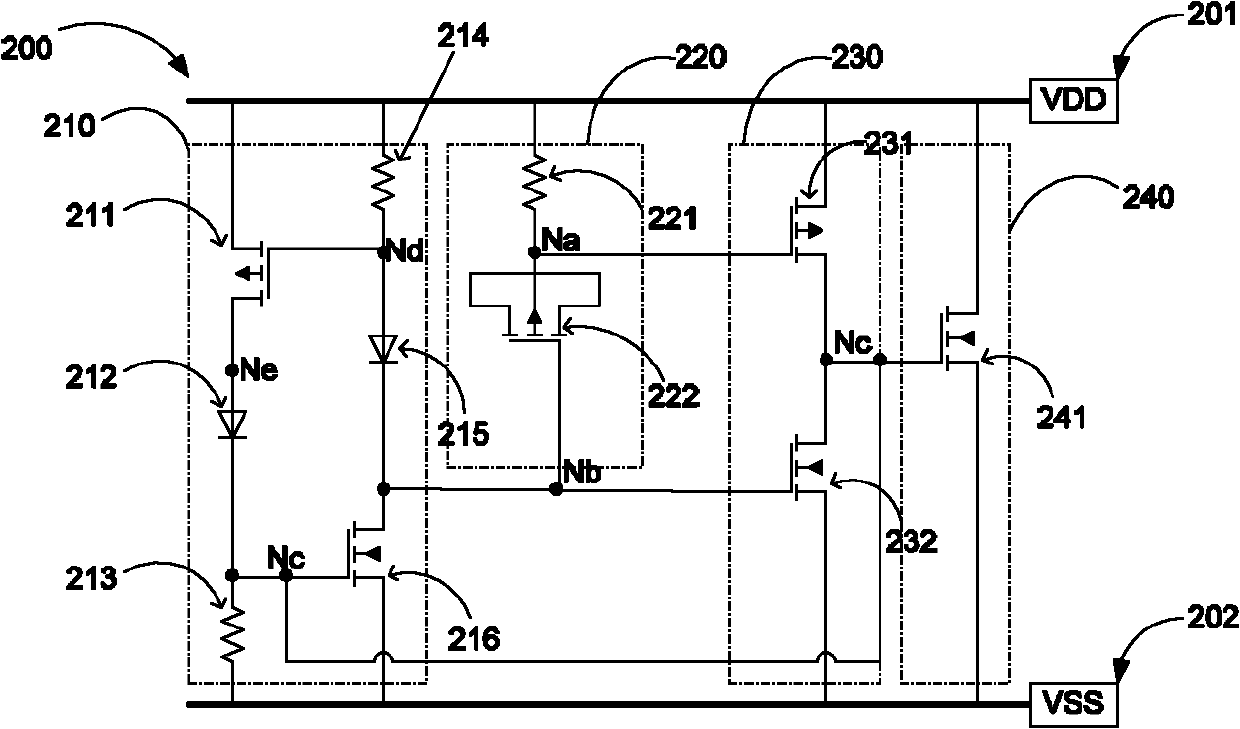

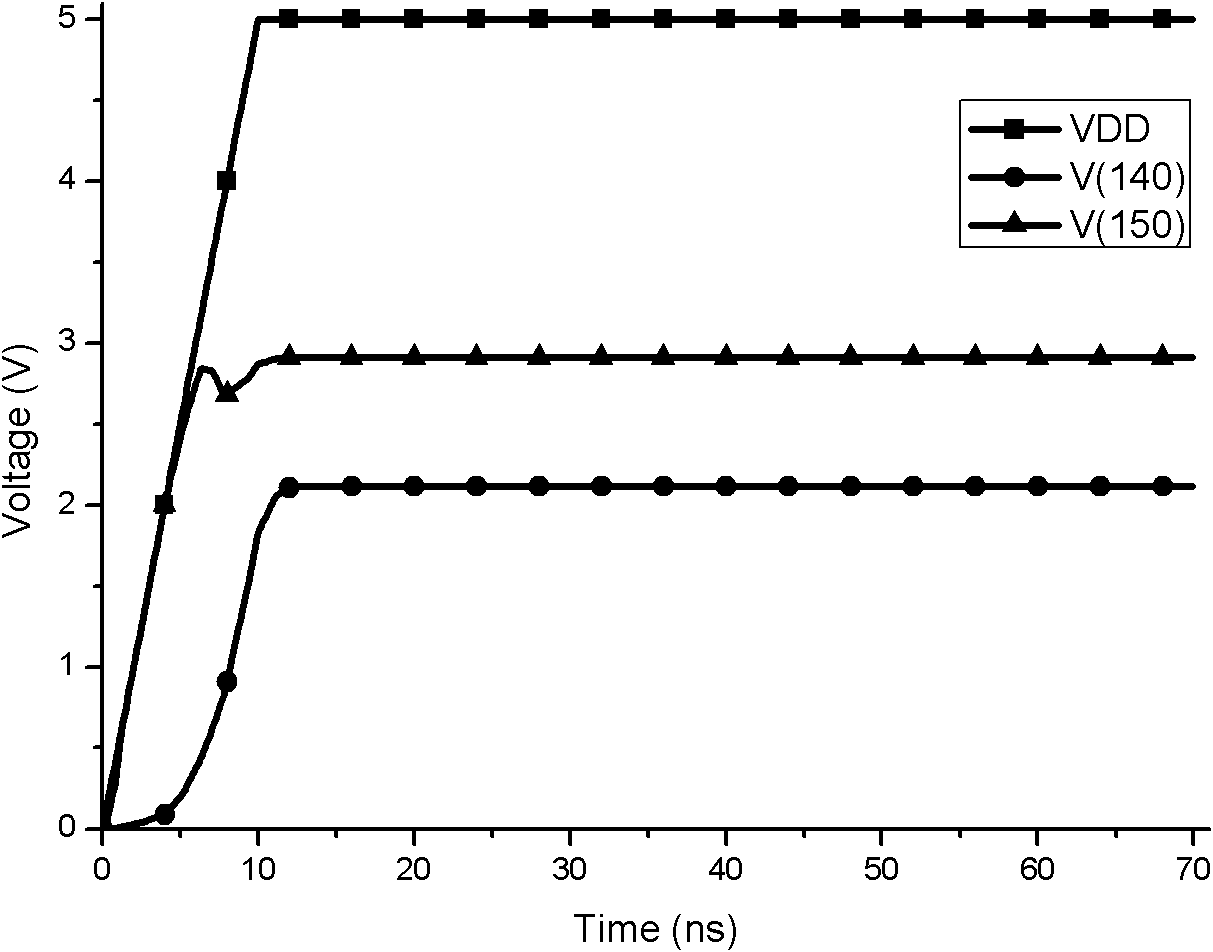

Power supply clamping position ESD (electronic static discharge) protecting circuit

ActiveCN102170118AReduce leakage currentAvoid risks such as false triggeringEmergency protective arrangements for limiting excess voltage/currentResistance capacitanceVoltage

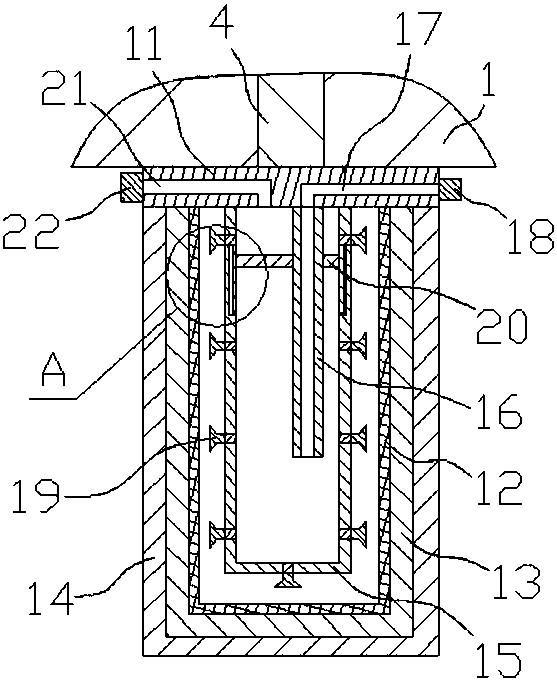

The invention provides a power supply clamping position ESD (electronic static discharge) protecting circuit, comprising a power supply pin, a grounding pin, an R-C (resistance-capacitance) circuit, a trigger circuit, a biasing circuit and a clamping position circuit. The R-C circuit is used for inducting an ESD voltage and comprises an impedance component which is connected between the power supply pin and a first node, and a capacitive reactance component which is connected between the first node and a second node, wherein, the second node is not directly connected with the grounding pin; the trigger circuit is connected among the power supply pin, the grounding pin and the R-C circuit and is used for generating an ESD triggering signal according to the electrical levels of the first node and the second code; the biasing circuit is connected between the power supply pin and the grounding pin and is used for providing a biasing voltage for the second node; and the clamping circuit isconnected among the power supply pin, the grounding pin and the trigger circuit and is used for providing a low reluctance channel between a power supply and the ground after the ESD triggering signal is received so as to discharge an electrostatic current. The electric leakage current of an electronic static discharge protecting circuit can be effectively restrained by the power supply clamping position ESD protecting circuit, and an inner circuit is effectively protected to avoid the damage by static electricity.

Owner:PEKING UNIV

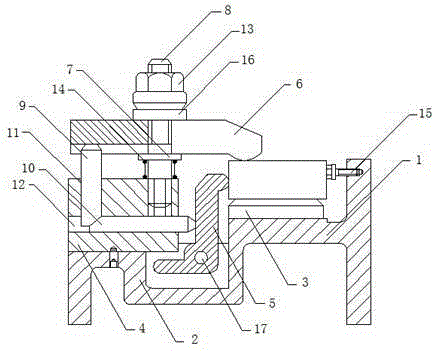

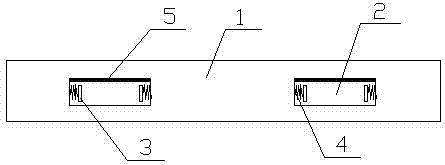

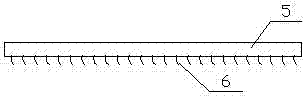

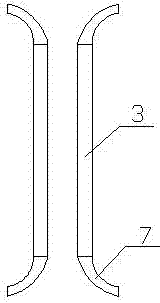

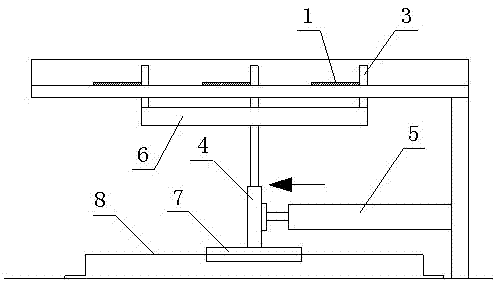

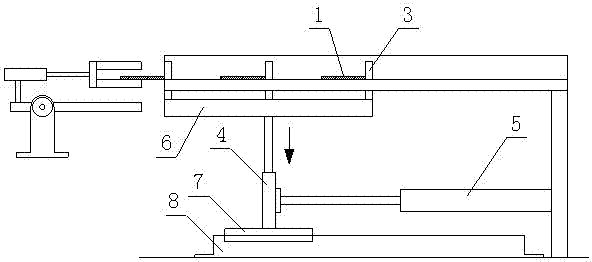

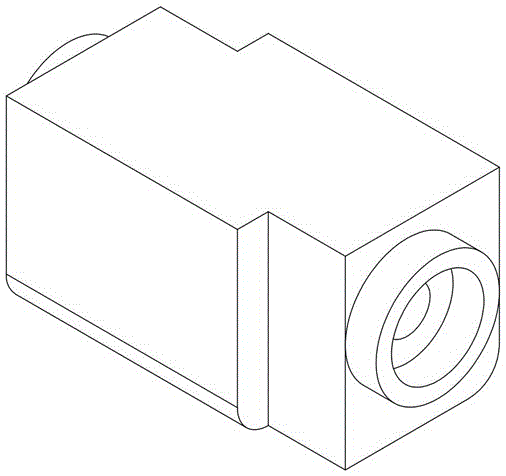

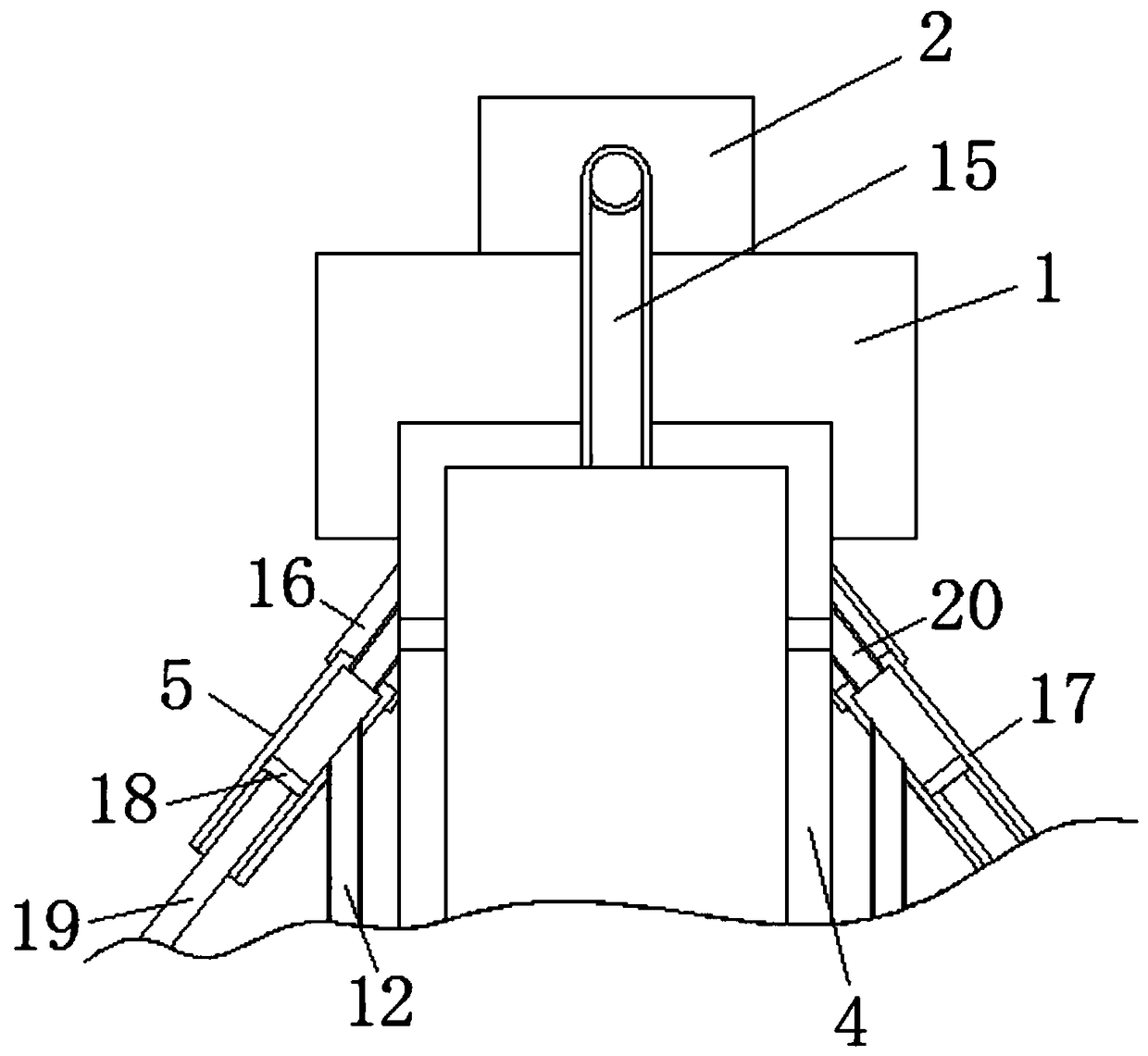

Pressing plate type floating clamp

InactiveCN105345495AThe overall structure is simpleGood clamping effectWelding/cutting auxillary devicesWork holdersEngineeringScrew cap

Owner:重庆市永川区植成家俱厂

Convenient floating clamp

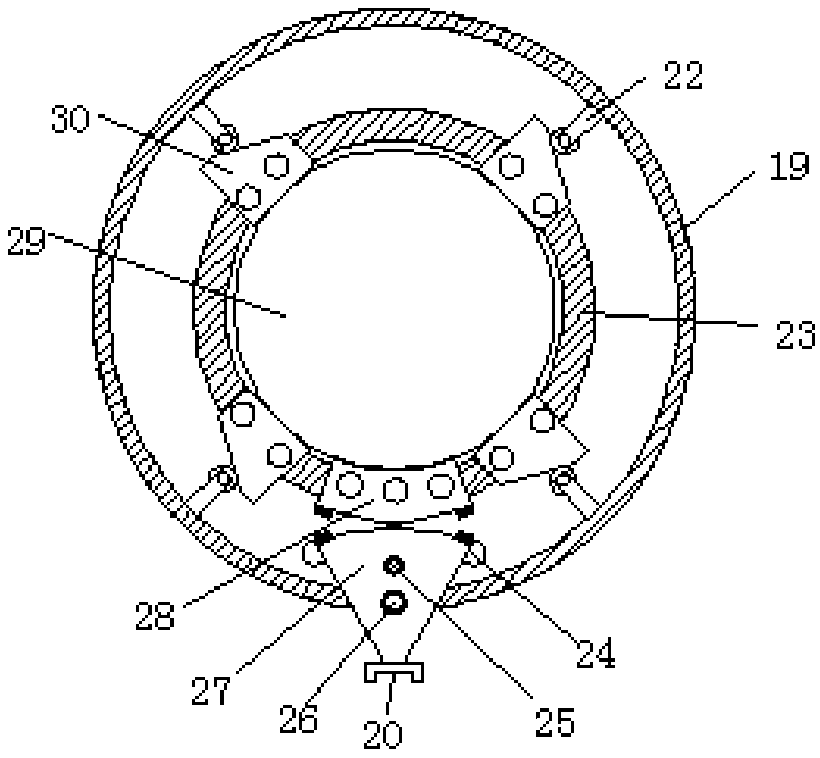

InactiveCN104476338AGood clamping effectEven distribution of clamping forceRevolution surface grinding machinesGrinding work supportsEngineering

The invention provides a convenient floating clamp, belonging to the technical field of machinery. The convenient floating clamp comprises a fixed turnplate with a hollow structure, a movable turnplate movably arranged behind the fixed turnplate and a top tip coaxial with the fixed turnplate; three involute clamping jaws around the axial line of the fixed turnplate are arranged in front of the fixed turnplate and respectively connected with the movable turnplate; the movable turnplate is capable of driving the three clamping jaws to swing, so that the three clamping jaws are gathered inward or expanded outward; a fisheye bearing is installed at the middle part of the fixed turnplate; the top tip is penetrated in the movable turnplate and the fisheye bearing in sequence and partially stretches out of the fixed turnplate. The convenient floating clamp has good clamping effect and a fine-tuning function.

Owner:NINGBO MEIDE ROBOT

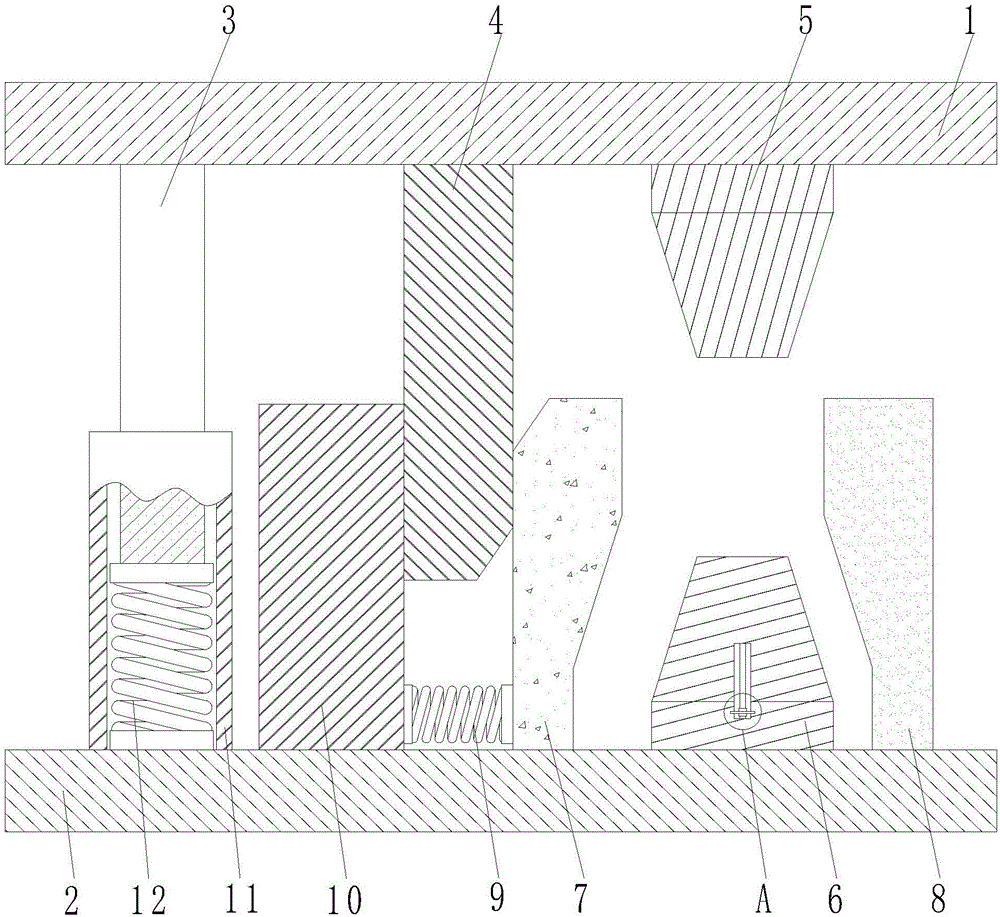

Flaring mold for two ends of pipe

ActiveCN106238579AEasy to use and save timeGood clamping effectShaping toolsEngineeringPosition shift

The invention discloses a flaring mold for two ends of a pipe. The flaring mold comprises an upper mold plate and a lower mold plate. A guide rod, a tapered wedge and an upper convex mold are fixedly connected to the lower surface of the upper mold plate in sequence from left to right. A lower convex mold is symmetrically arranged at the position, corresponding to the upper convex mold, of the lower mold plate. A left movable clamp plate and a right movable clamp plate are arranged on the two sides of the lower convex mold correspondingly. The bottom of the left movable clamp plate and the bottom of the right movable clamp plate are both fixedly connected to the upper surface of the lower mold plate. The lower side of the side face, far away from the lower convex mold, of the left movable clamp plate is fixedly connected with one end of a first spring. According to the flaring mold, through the arrangement of the tapered wedge, when the tapered wedge is pressed, the left movable clamp plate moves rightwards, and the pipe is clamped; through the arrangement of a guide pipe and the guide rod, position shift cannot happen when the upper mold plate is pressed; through the arrangement of the upper convex mold, the lower convex mold, the left movable clamp plate and the right movable clamp plate, the effect of flaring the two ends of the pipe is achieved; and the two ends of the pipe are flared by the upper convex mold and the lower convex mold at the same time, and during use, greater convenience is achieved, and more time is saved.

Owner:JIANGSU HENGKANG ELECTRICAL

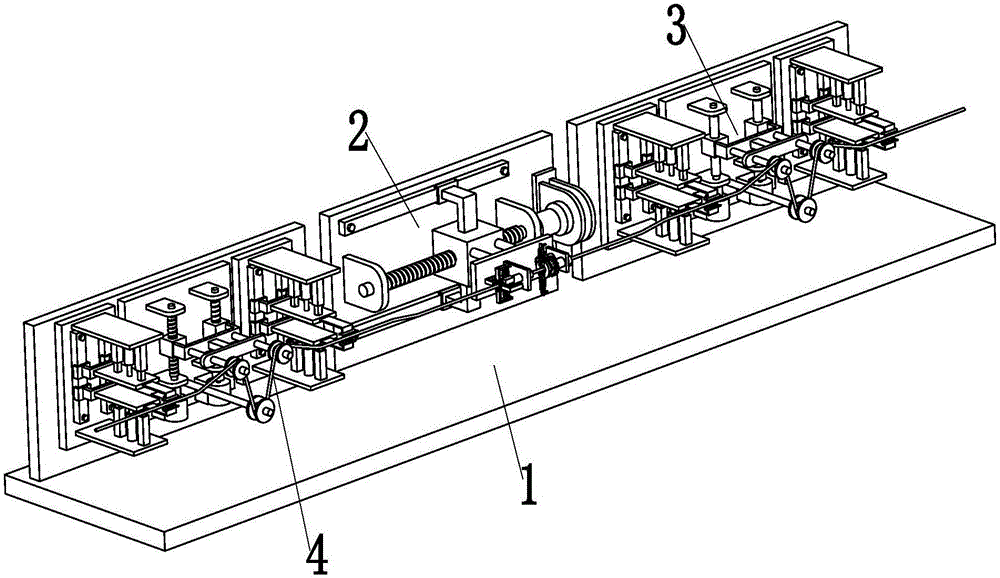

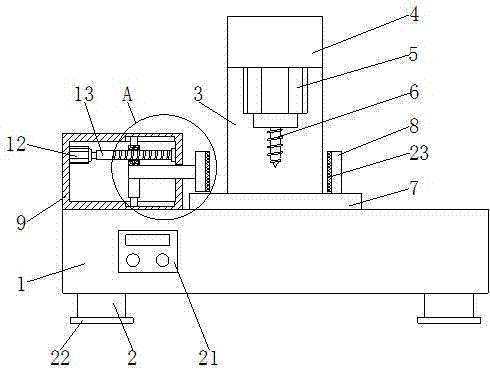

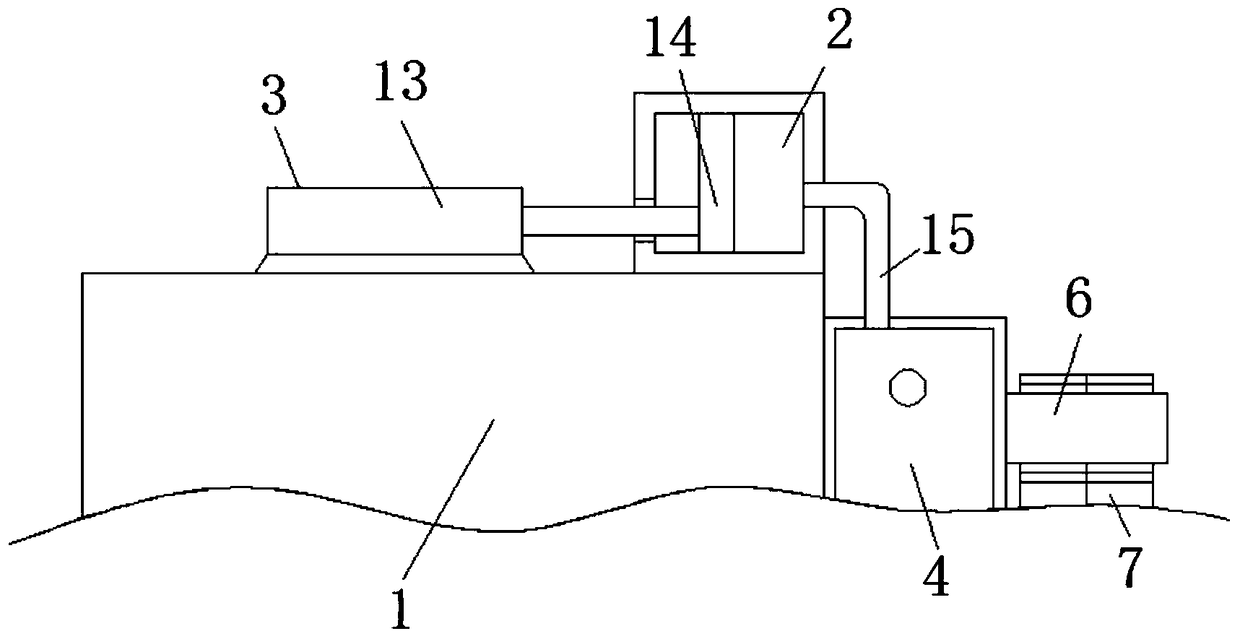

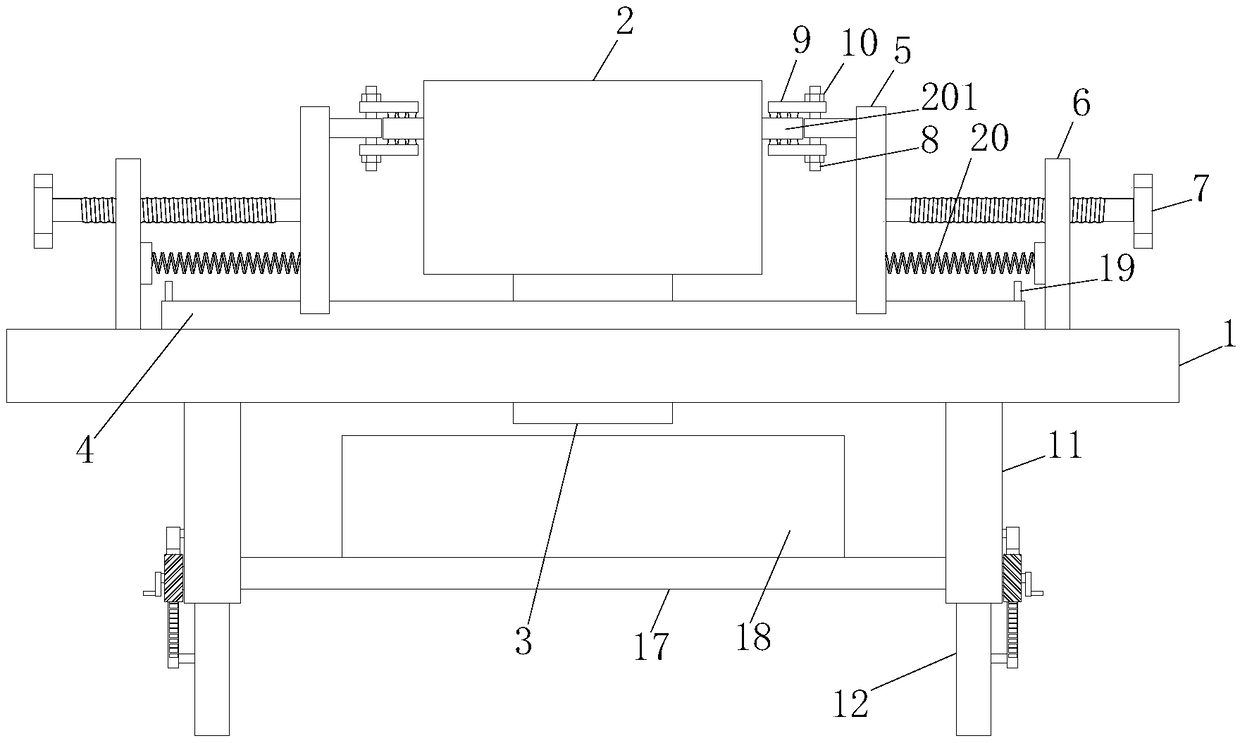

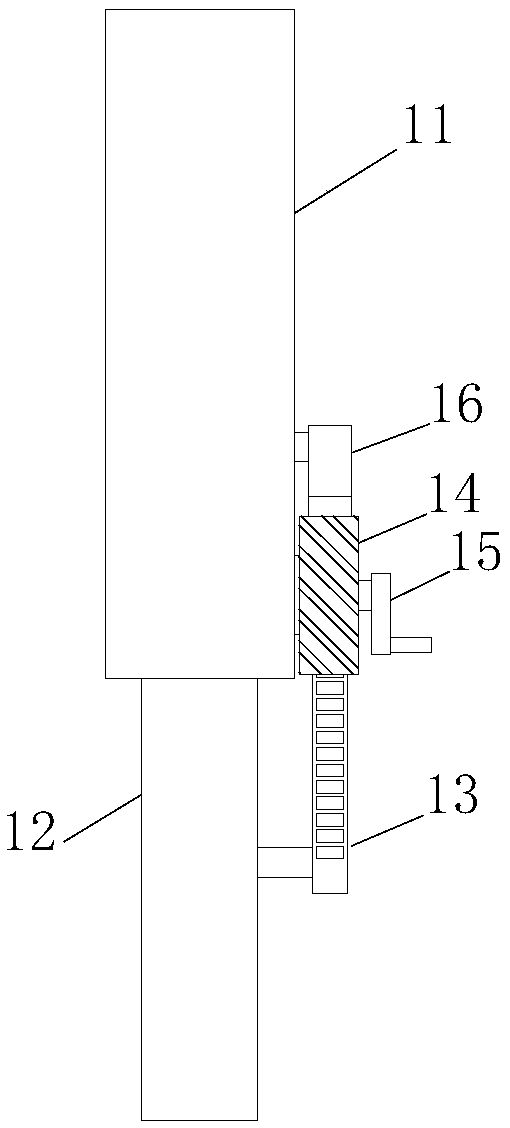

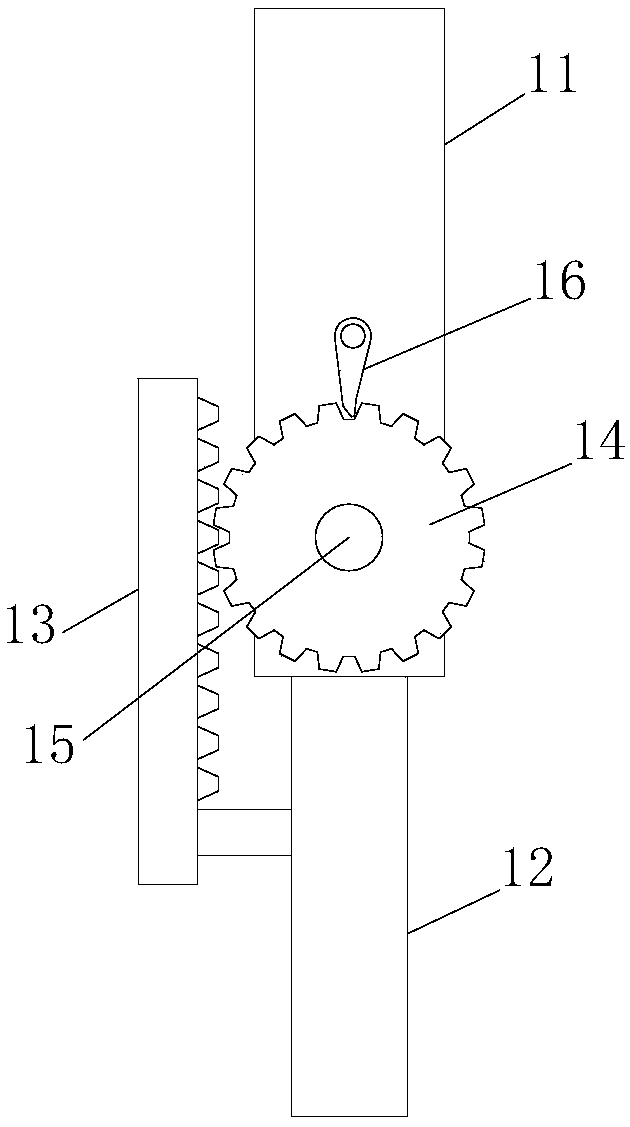

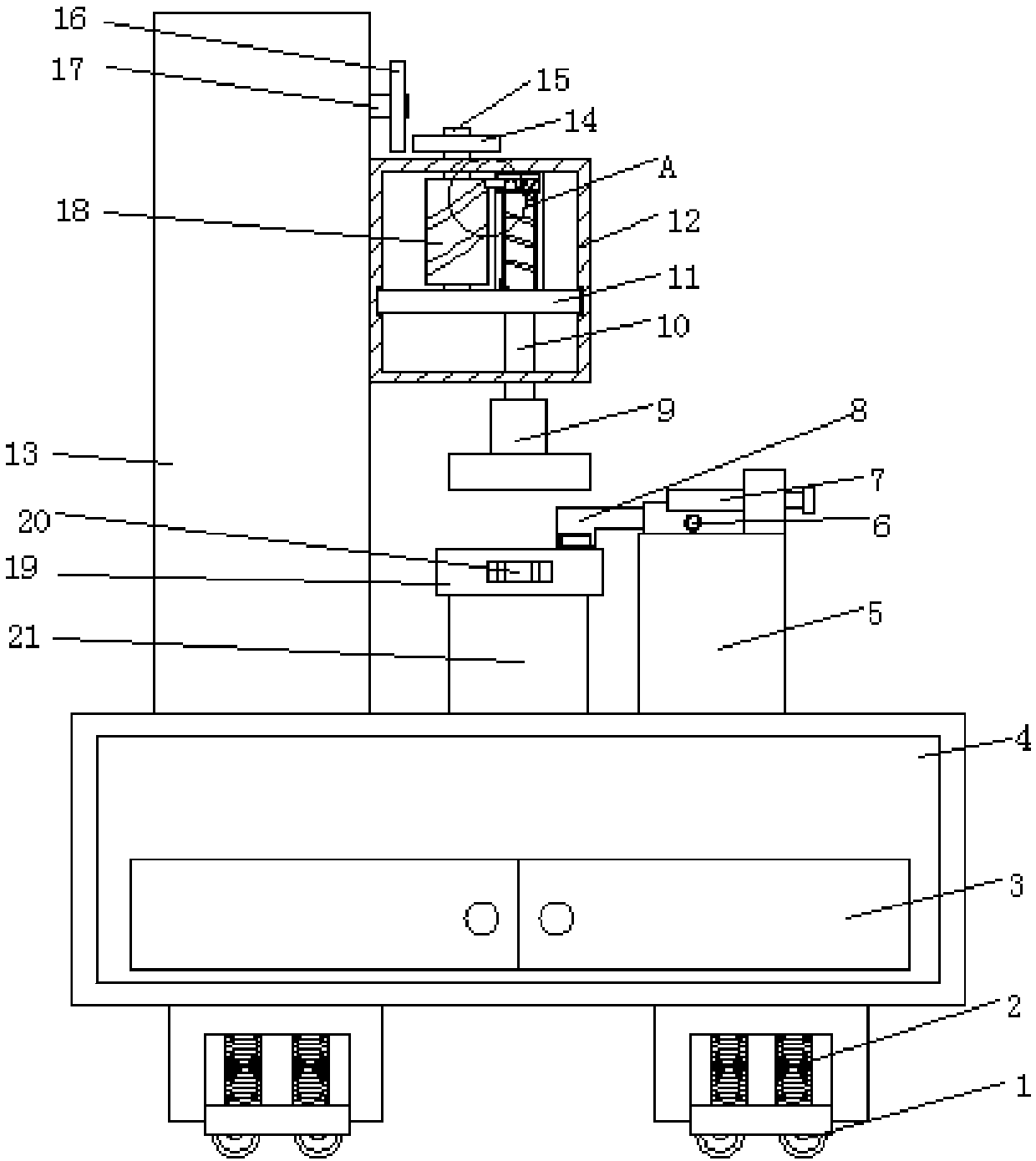

Vehicle wire harness full-automatic processing device

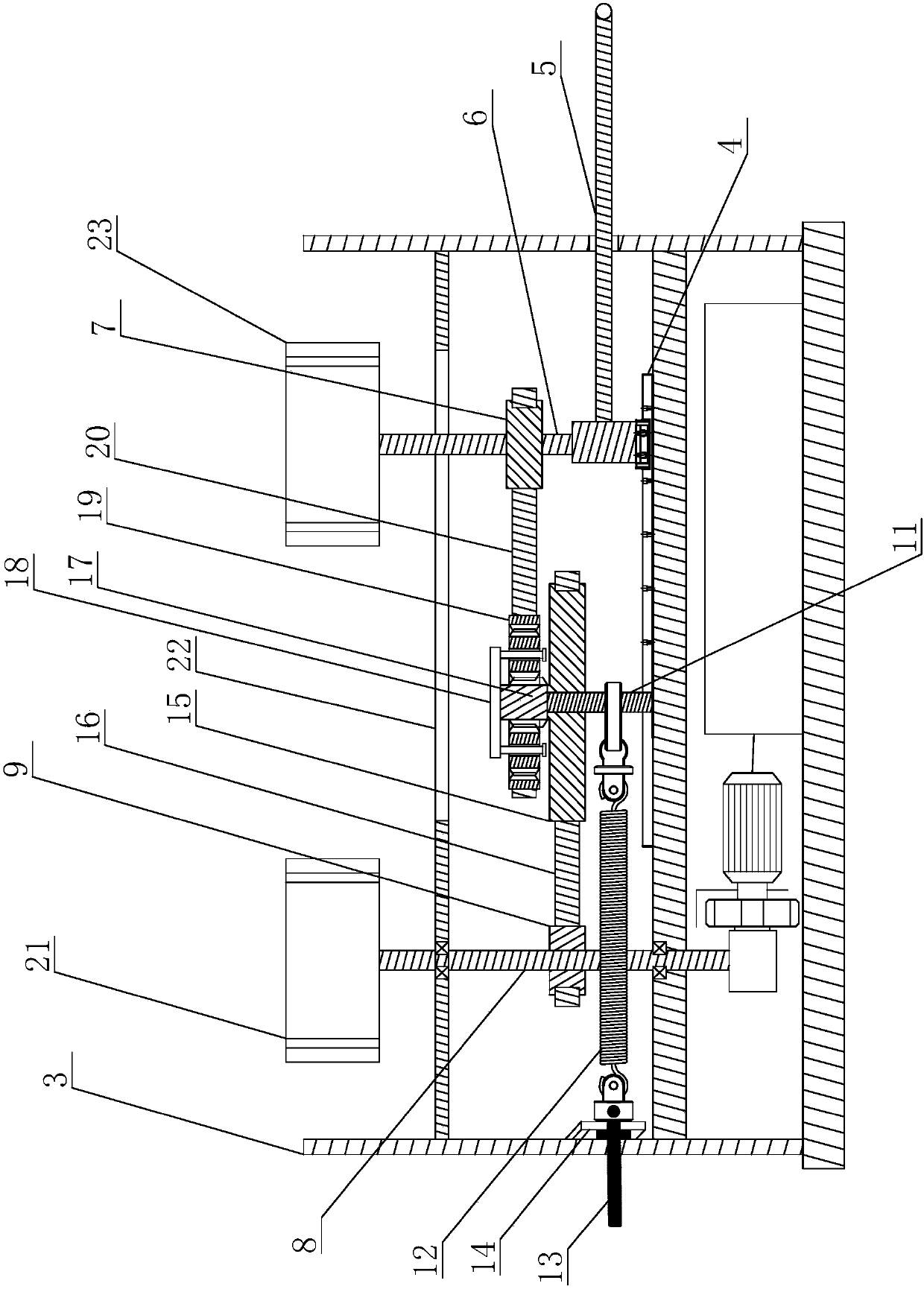

InactiveCN106129779AGood clamping effectFast and even automatic strippingVehicle connectorsLine/current collector detailsAutomatic processingCable harness

The invention relates to a fully automatic processing equipment for vehicle wire harnesses, comprising a base plate and a wire harness body, a ring cutting and stripping device is installed in the middle of the upper end surface of the base plate, and two clamping and tensioning devices are symmetrically installed on both sides of the upper end surface of the base plate; the wire harness body The two ends of the wire harness are passed through two clamping and tensioning devices respectively, and the middle part of the wire harness body is passed through the ring cutting and stripping device. The ring cutting and stripping device can realize the automatic ring cutting and wire stripping function during the processing of the wire harness body. The tensioning device can realize the automatic tensioning and clamping functions during the processing of the wire harness body. The invention can realize the integrated processing functions of automatic tensioning, clamping, ring cutting and wire stripping during the processing of vehicle wire harness, without manual operation, manual ring cutting, manual stripping, manual adjustment of tension force, and manual adjustment The clamping force has the advantages of good automatic ring cutting effect, good wire stripping quality, high wire stripping efficiency, good tension adjustment performance, good tension adjustment effect, poor clamping effect and high work efficiency.

Owner:YJH ELECTRICAL EQUIP

Simple blow-molding tray

The invention relates to the technical field of plastic products, in particular to a simple blow-molded tray, which includes a tray main body provided with two sockets, and splints for clamping forklift rods are elastically connected to the inner walls on both sides of the sockets, and the splints pass through the sockets, and The end of the splint is provided with an extended arc-shaped plate, and the arc-shaped plates of the splints on both sides form a bell mouth for the extension of the forklift rod. The splints at both ends are fixedly connected with the inner wall of the jack, and the upper edge of the jack is bonded with a silicone plate, and the splint connected by the spring clamps the forklift pole. The barb is beneficial to increase the friction with the forklift rod, thus effectively preventing the forklift rod from coming out.

Owner:陈有兵

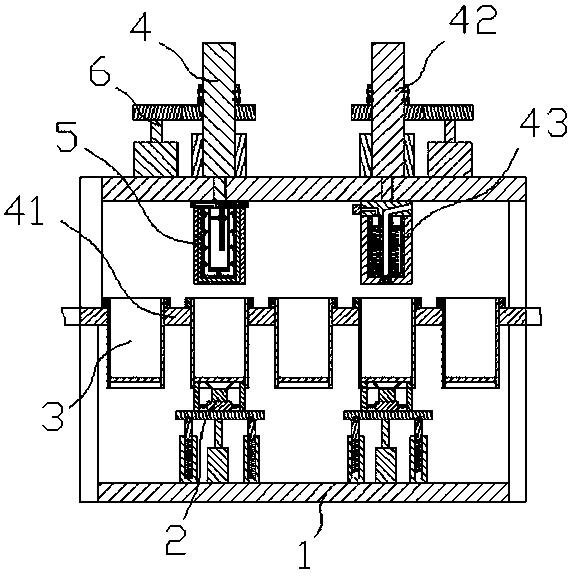

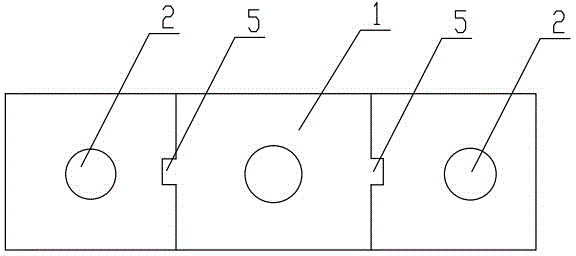

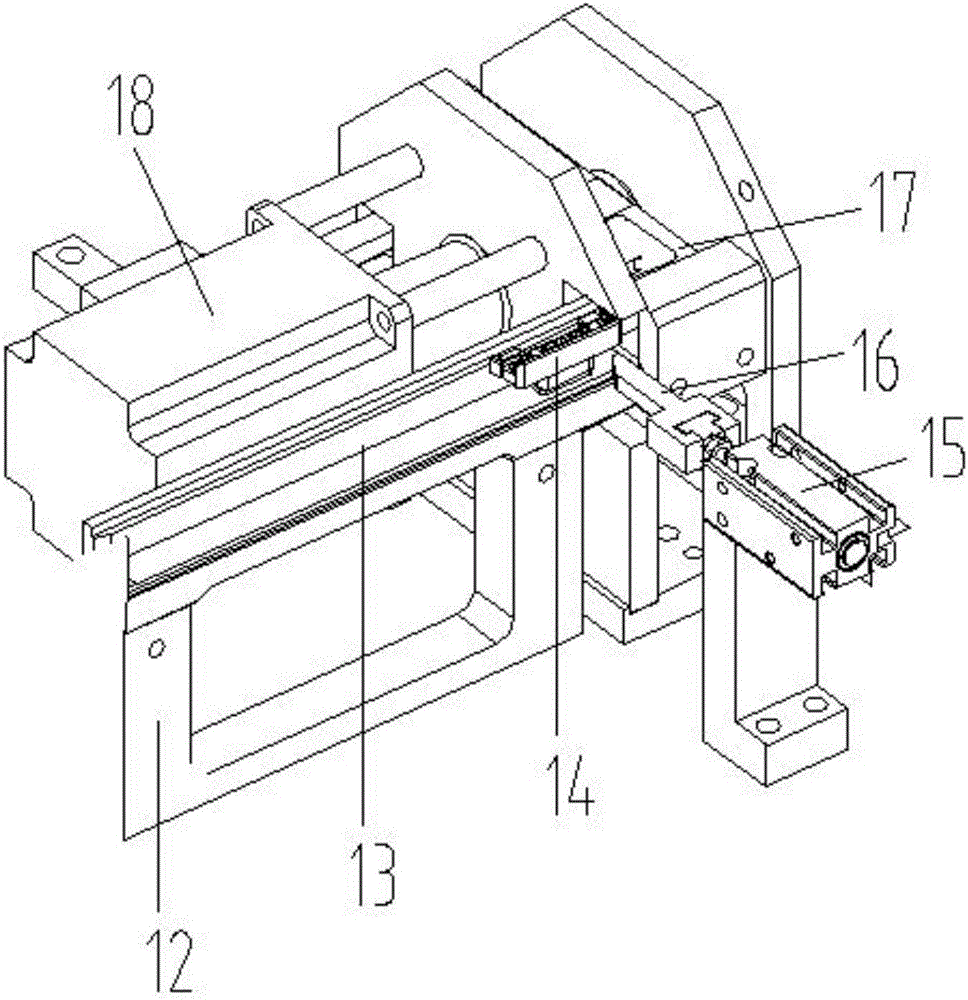

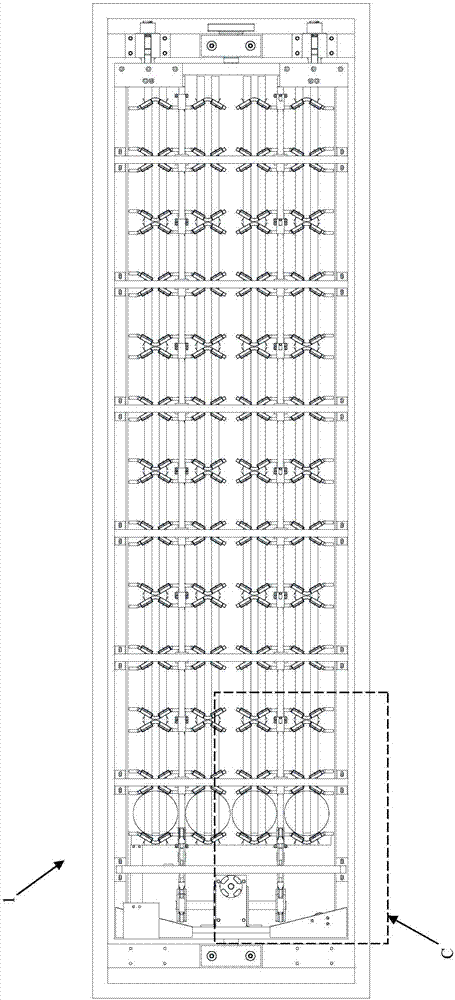

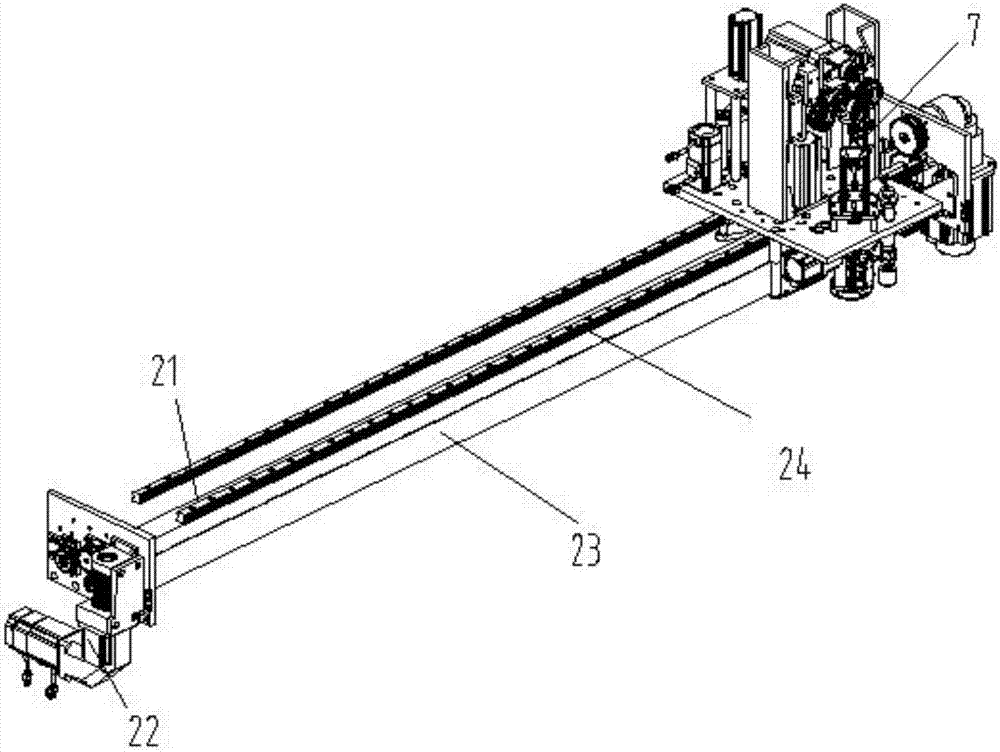

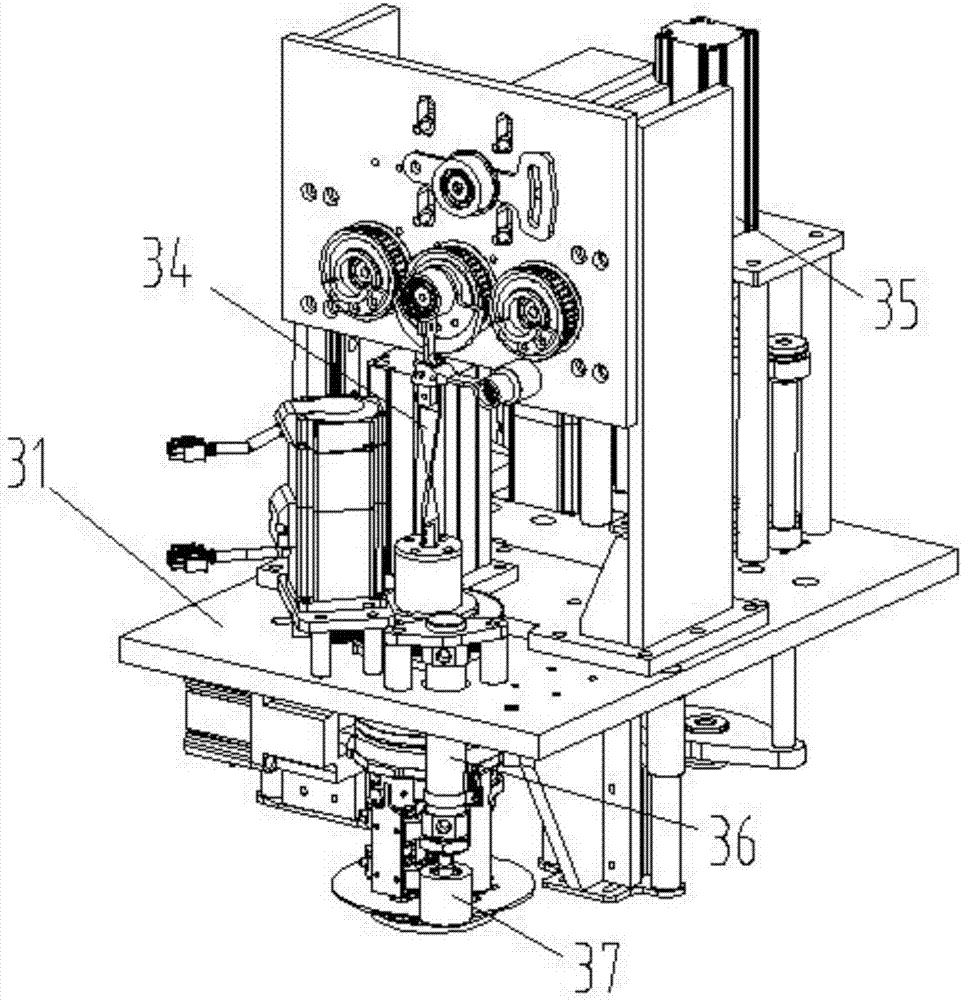

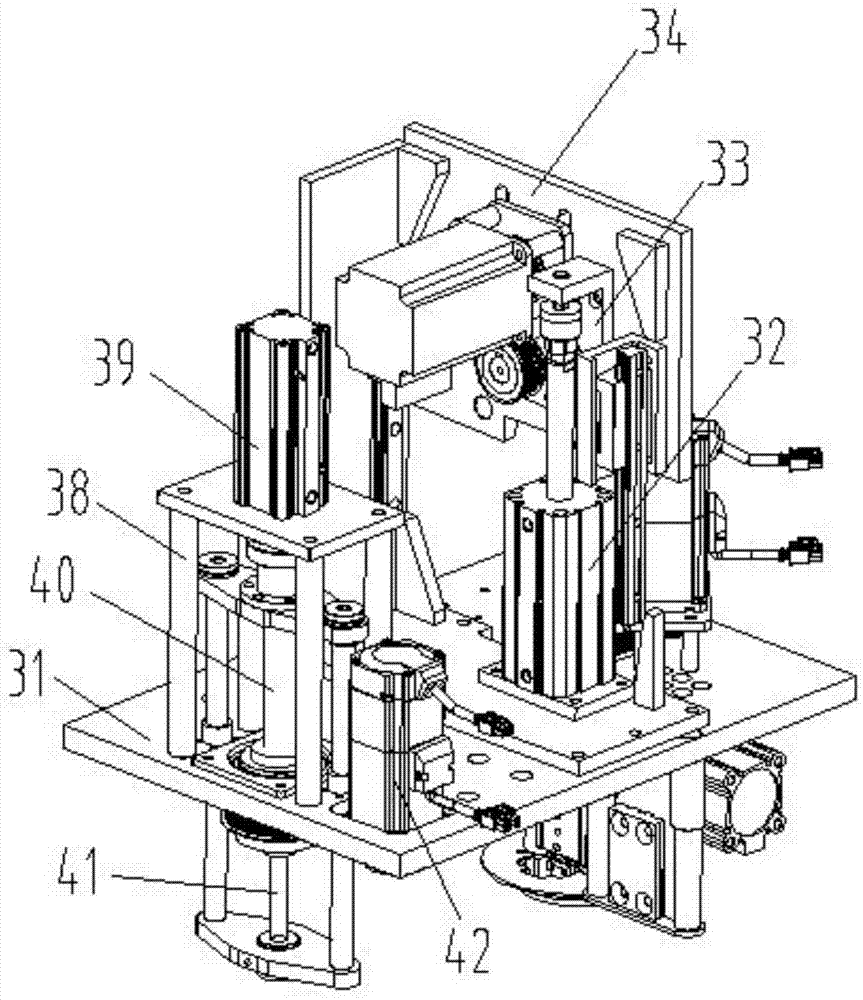

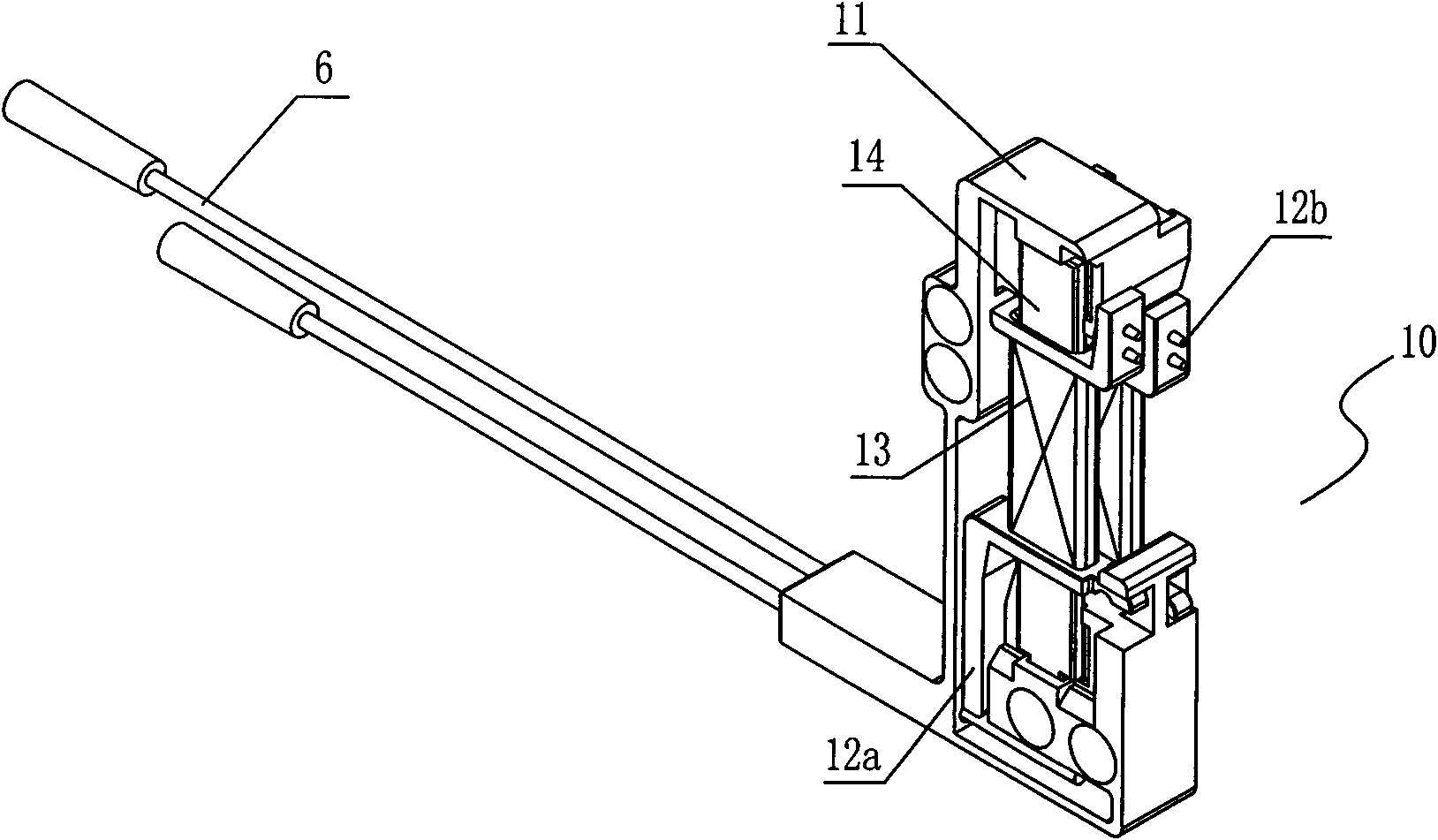

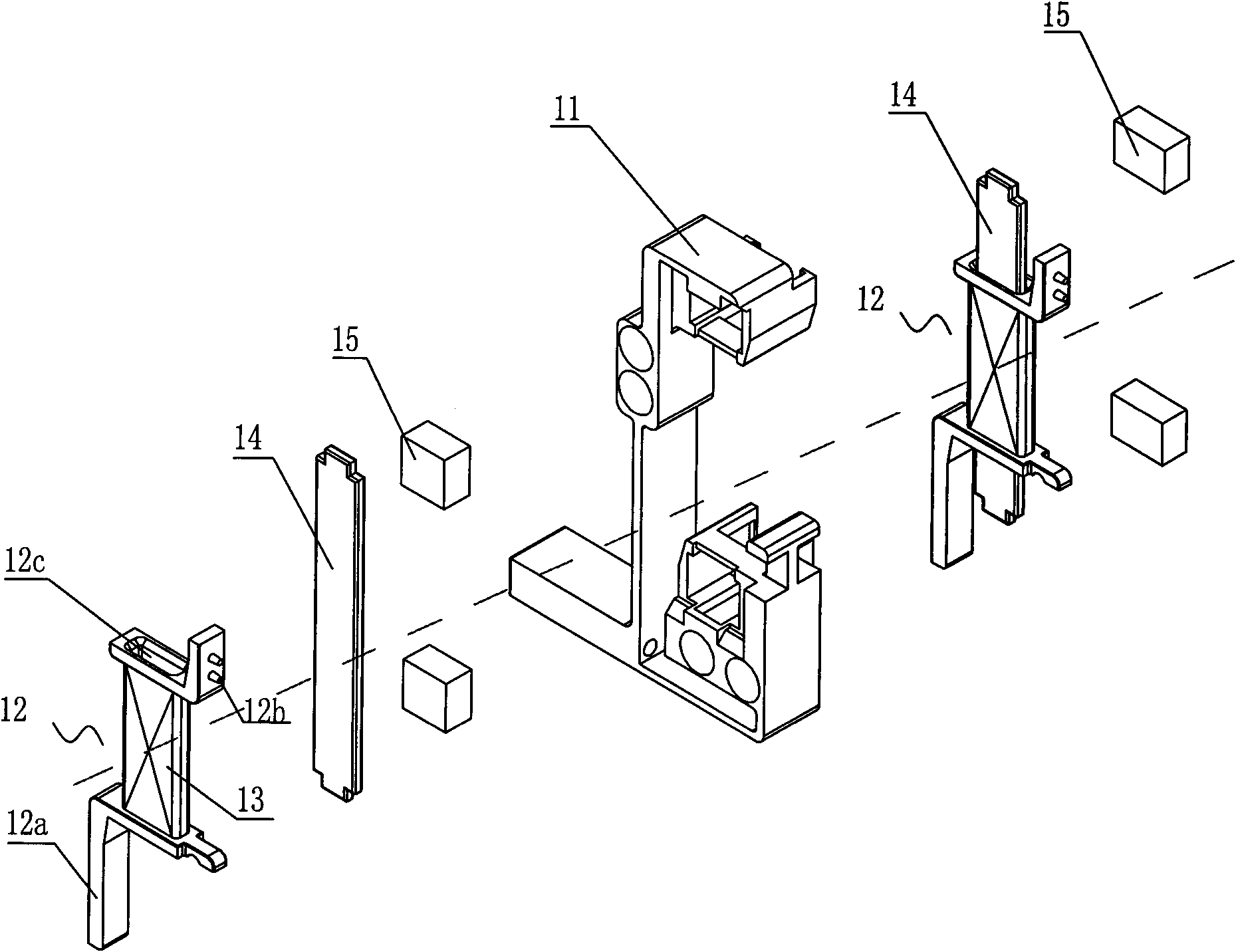

Clamping and conveying device and method for wafer pin electroplating

The invention discloses a clamping and conveying device and method for wafer pin electroplating. The clamping and conveying device comprises a feeding device, a conveying belt clamping device and a discharging device, wherein the feeding device comprises a wafer disc pushing device and a wafer disc clamping and turnover device, the wafer disc pushing device is used for pushing a wafer disc (1) to the wafer disc clamping and turnover device, the wafer disc clamping and turnover device is used for clamping and turning over the wafer disc (1) to the conveying belt clamping device to complete feeding, the conveying belt clamping device is used for clamping the wafer disc (1) to a conveying belt (17) to achieve wafer pin electroplating, and the discharging device is used for discharging the electroplated wafer disc (1) from the conveying belt (17). The clamping and conveying device is high in intelligent degree and improves production efficiency, when the wafer disc is fed in a clamped mode, the whole wafer disc clamping and turnover device moves in the conveying direction of the conveying belt at the speed matched with the conveying speed of the conveying belt, the effect that two clamping plates are static relative to the conveying belt can be ensured, friction is reduced, and abrasion on the wafer disc can be avoided.

Owner:SICHUAN BLUE COLOR ELECTRONICS TECH

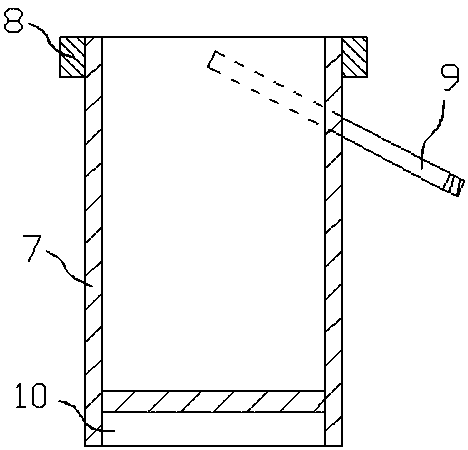

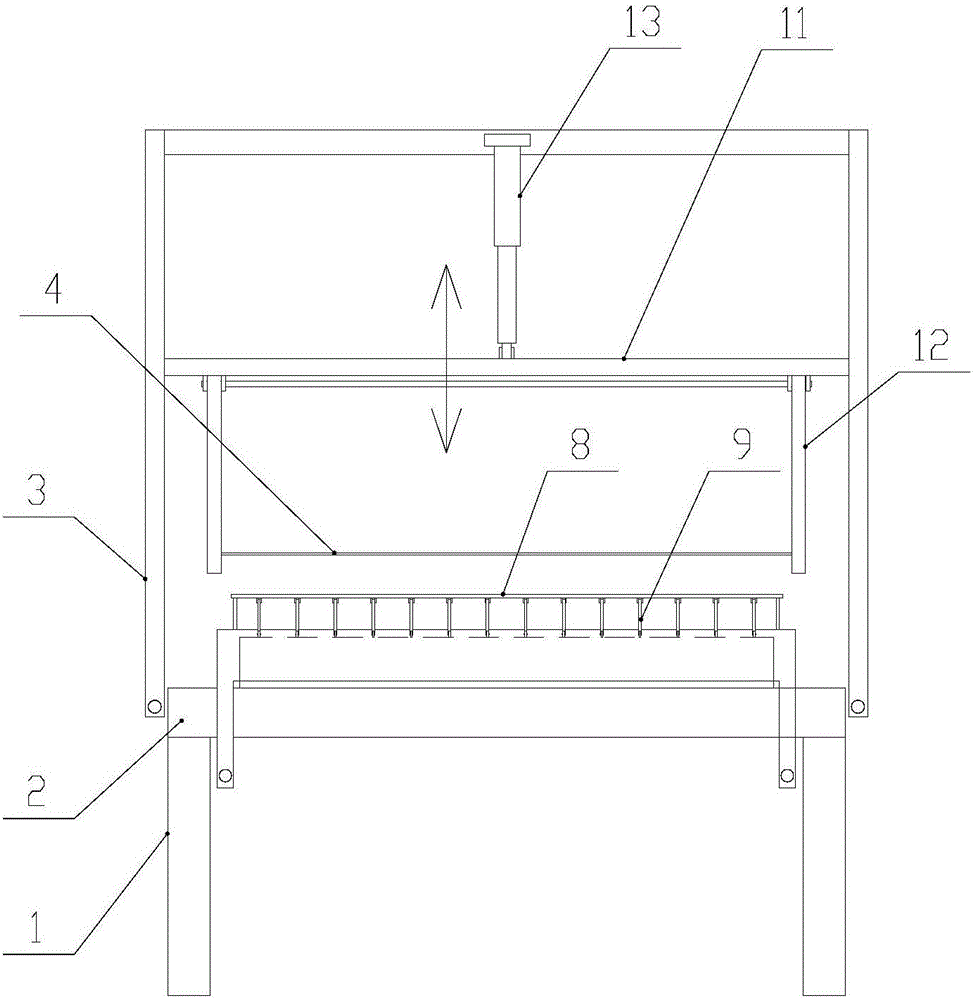

Washing and wipe dry integrated machine for coating barrel

InactiveCN108746126AImprove cleaning and drying efficiencySimple structureDrying solid materials without heatHollow article cleaningEngineeringMechanical engineering

The invention relates to a washing and wipe dry integrated machine for a coating barrel. The washing and wipe dry integrated machine comprises a rack and a conveying carrier band, the conveying carrier band is provided with a carrying opening matched with the coating barrel, the upper portion of the rack is sequentially provided with a washing mechanism and a wipe dry mechanism, and clamping devices are arranged at the positions, at the lower portions of the washing mechanism and the wipe dry mechanism, of the rack; the washing mechanism comprises a washing lifting air cylinder arranged on therack, the lower portion of the washing lifting air cylinder is connected with a washing device matched with the coating barrel, and the washing lifting air cylinder is matched with an air cylinder rotating device arranged on the rack; and the wipe dry mechanism comprises a wipe dry lifting air cylinder arranged on the rack, the lower portion of the wipe dry lifting air cylinder is connected witha wipe dry device matched with the coating barrel, and the wipe dry lifting air cylinder is matched with the air cylinder rotating device on the rack. According to the washing and wipe dry integratedmachine, the conveying carrier band tightened for conveying is used as a carrier of continuous movement of the coating barrel, the washing mechanism and the wipe dry mechanism are used in cooperationto achieve continuous and automatic washing and wipe dry, and the washing and wipe dry efficiency of the coating barrel is greatly improved.

Owner:DONGGUAN UNIV OF TECH

Clamping instrument

PendingCN113456297AImprove capture success rateGood clamping effectAnnuloplasty ringsPhysicsEngineering

Owner:SHANGHAI HUIHE MEDICAL CO LTD +1

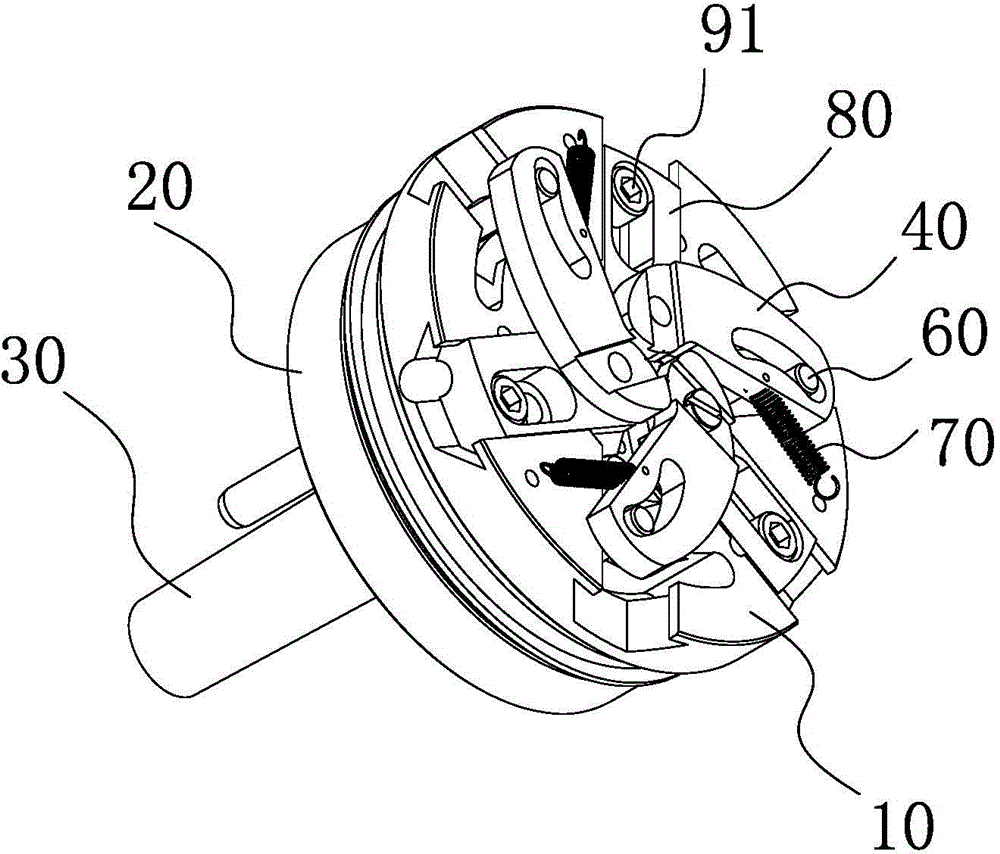

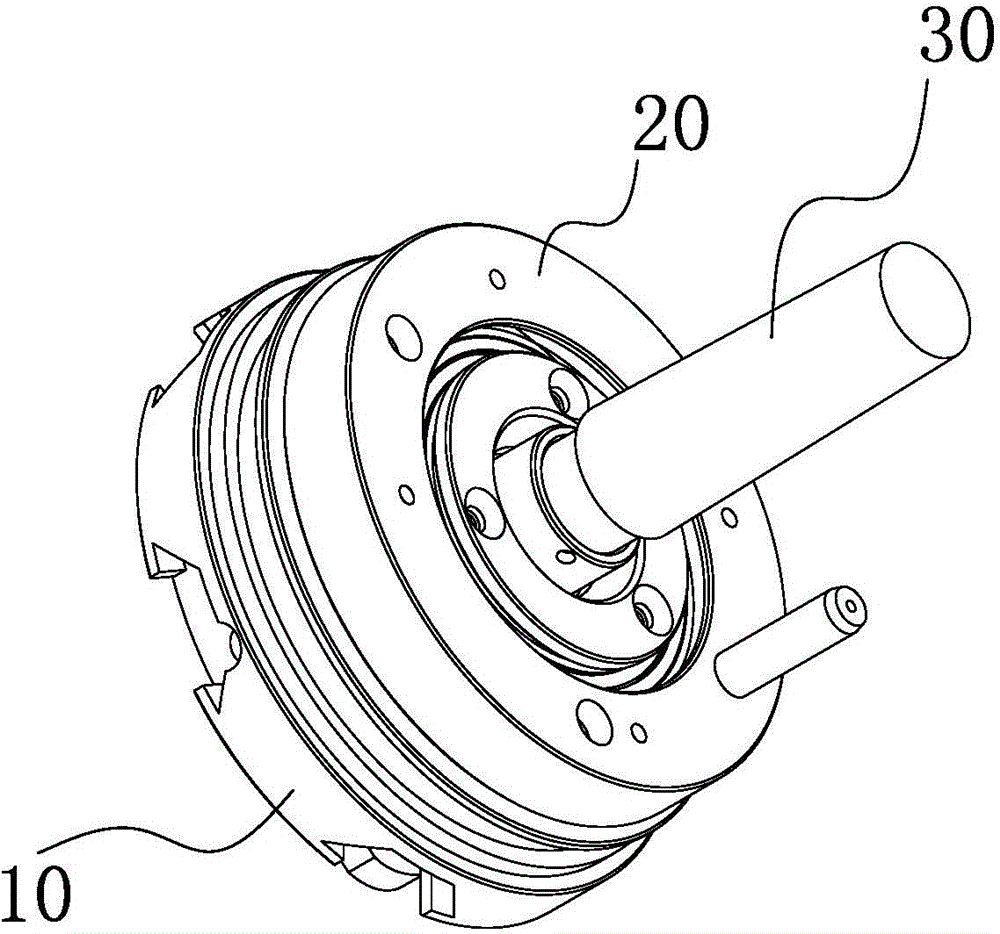

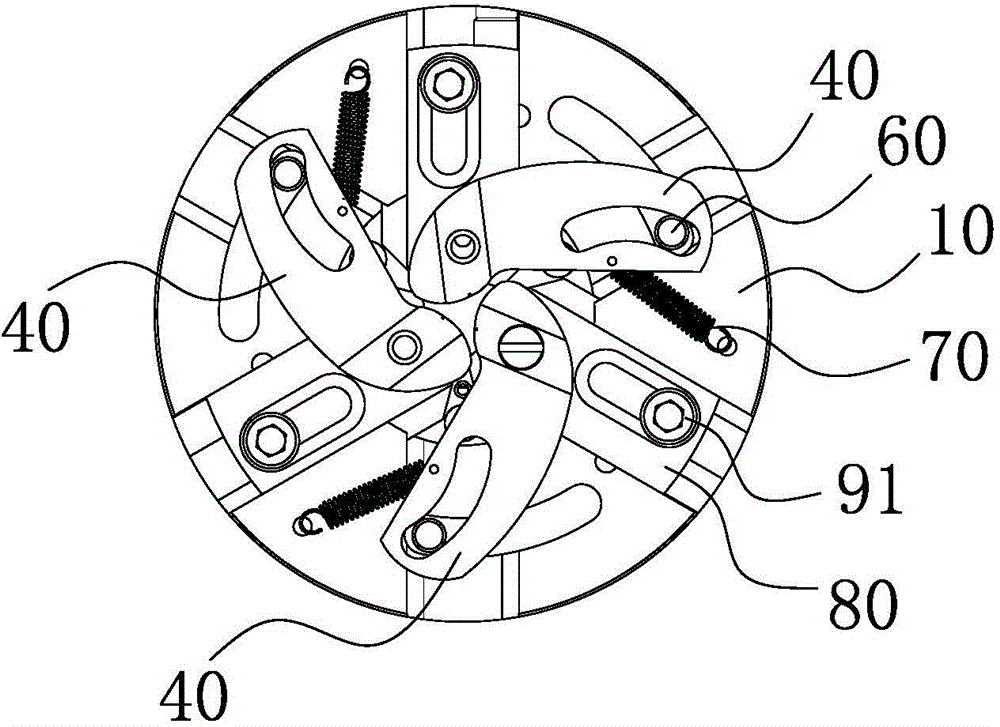

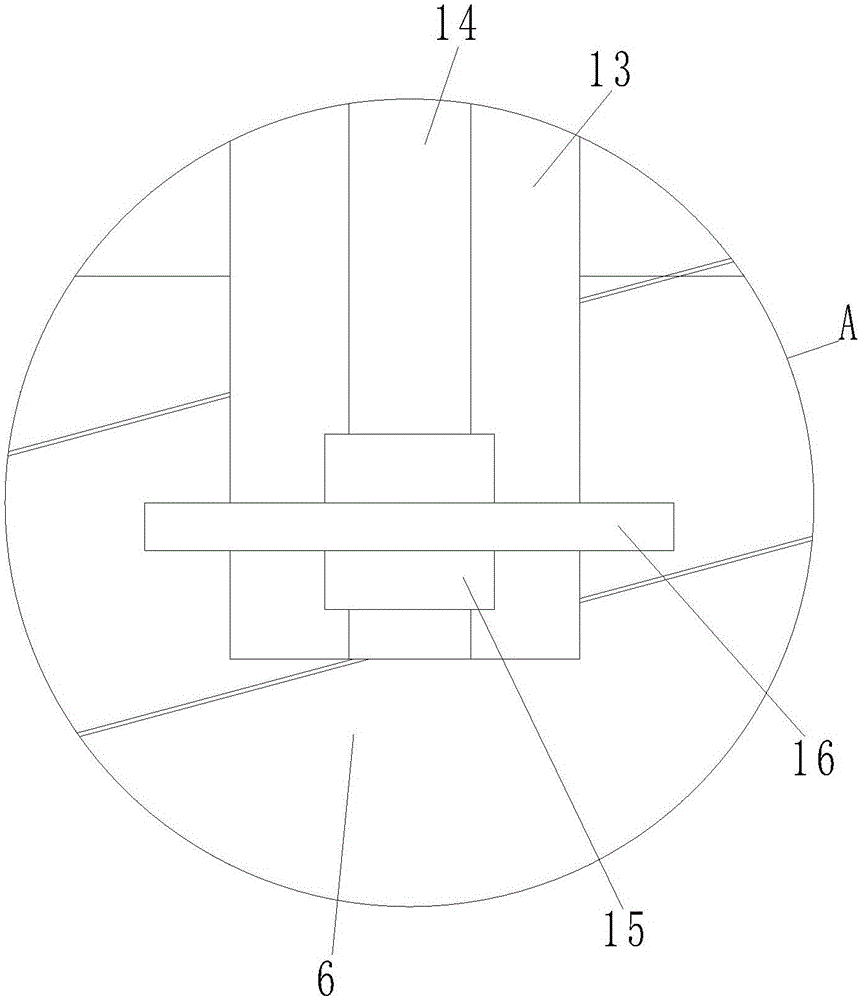

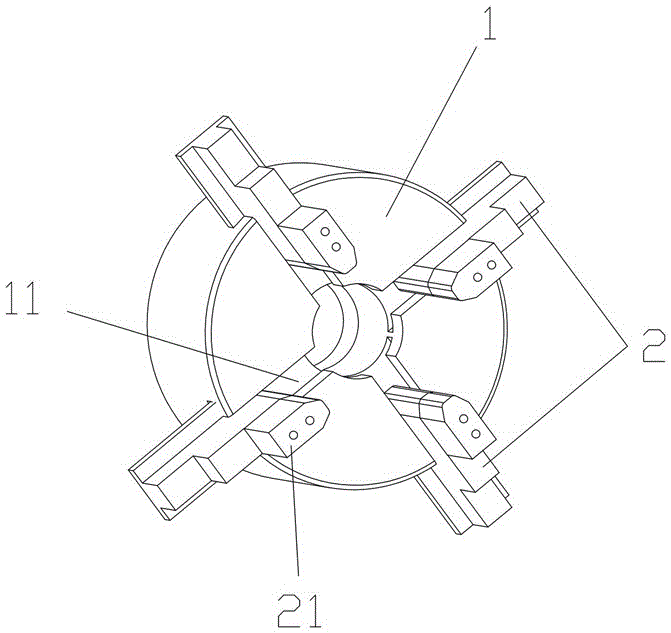

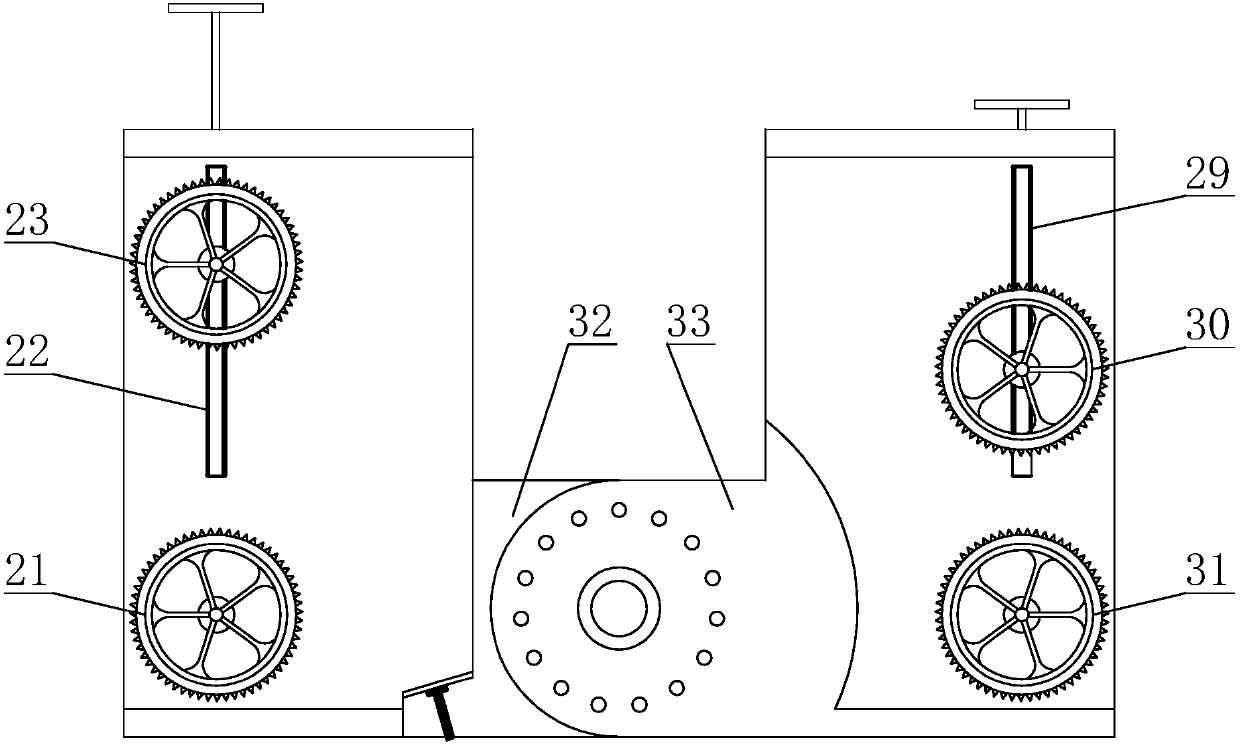

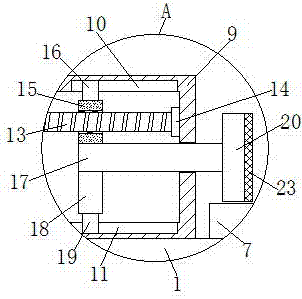

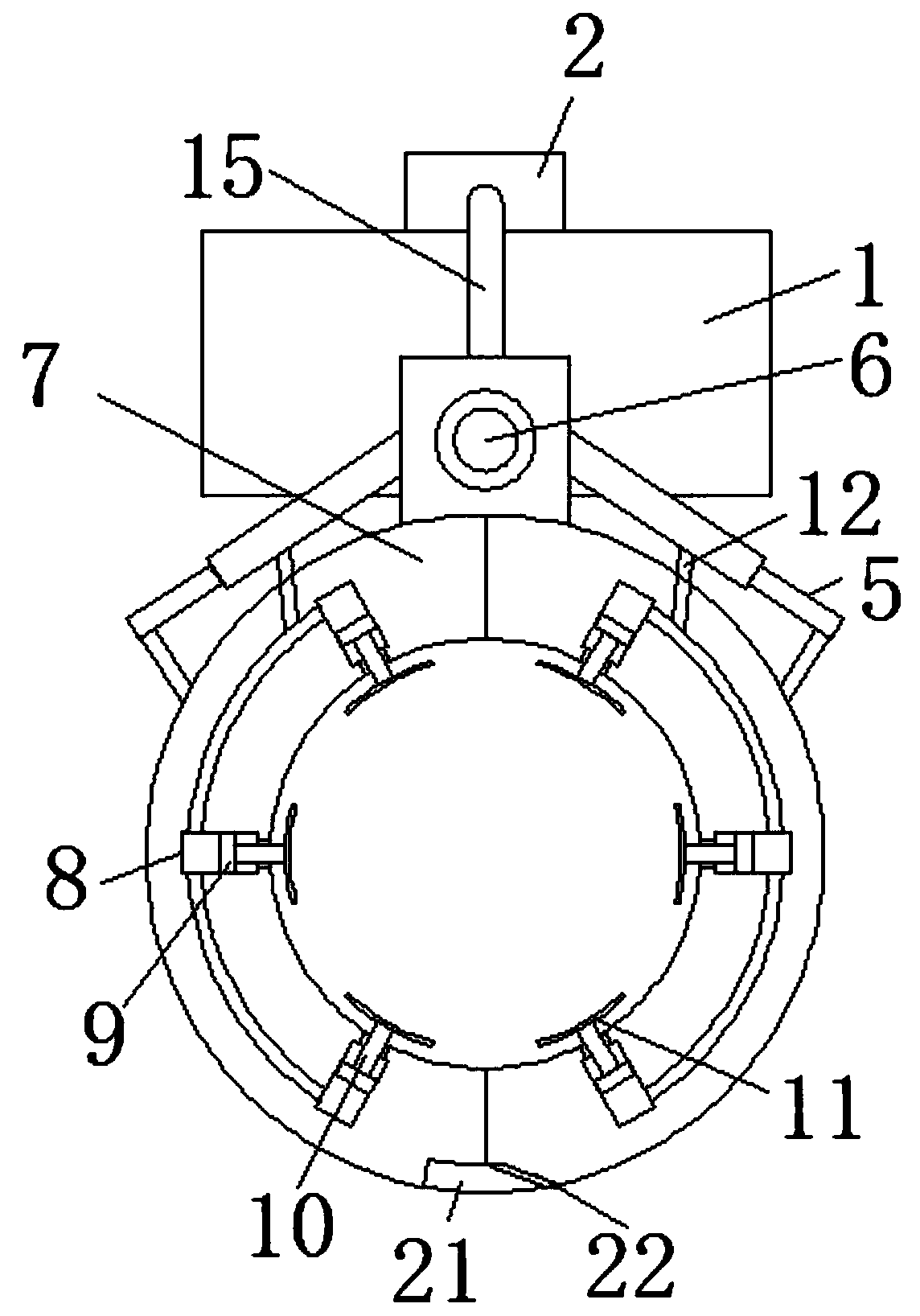

Self-centering multi-claw chuck device

The invention discloses a self-centering multi-claw chuck device which is used for being matched with a machine tool after clamping a workpiece so as to enable the machine tool to machine the clamped workpiece. The self-centering multi-claw chuck device comprises a chuck base, the chuck base is sequentially provided with multiple clamping claws in the circumferential direction, a fixing cavity where the workpiece is placed is defined by the multiple clamping claws, the multiple clamping claws can independently move forwards and backwards in the radial direction of the chuck base so as to clamp the workpiece in the fixing cavity, the bottom of the fixing cavity is provided with a centering center assembly used for being matched with a tailstock center on the machine tool, and the central axis of the centering center assembly coincides with the central axis of the tailstock center. In the working process, the tailstock center and the centering center assembly abut against the center points at the two ends of the workpiece correspondingly, then, the multiple clamping claws are sequentially adjusted to clamp and fix the workpiece, and therefore the workpiece is machined after being centered. The self-centering multi-claw chuck device has the advantages of being simple and compact in structure, low in production cost, convenient and fast to operate, and capable of effectively ensuring the coaxiality of two-end inner hole and outer circle machining of the workpiece, particularly an irregular workpiece.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Rapid cable fixing device

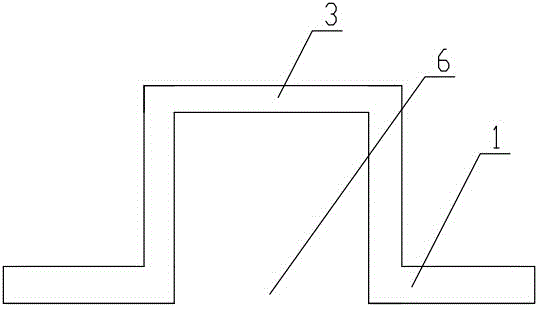

InactiveCN104410017ASmall wall areaGood clamping effectElectrical apparatusEngineeringMetal framework

The invention discloses a rapid cable fixing device and relates to the technical field of devices for mounting cables or wires on the surface or in the interior of a building. The fixing device comprises a metal framework shaped like a Chinese character ji, wherein grooves are formed in the left and right side walls of the interior of the projection, the two ends of an arc-shaped plate are positioned in the grooves, the arc-shaped plate can slide up and down along the grooves, a metal plate is arranged at the opening part, the metal plate is a straight plate, one end of the metal plate is connected with a side shaft on the left side or the right side of the metal framework shaped like the Chinese character ji, via holes corresponding to fixing holes are formed in the left and right two sides of the metal plate, the other end of the metal plate is a free end, and the curvature radius of the arc-shaped plate is larger than the radius of a clamped cable. The fixing device has the characteristics of long service life, great fixing effect and low maintenance cost.

Owner:STATE GRID CORP OF CHINA +3

Prefabricated building beam-column joint connection structure

ActiveCN111502035AImprove stabilityGood clamping effectBuilding constructionsSlide plateArchitectural engineering

The invention relates to the technical field of building beam-column joint connection, in particular to a prefabricated building beam-column joint connection structure. The prefabricated building beam-column joint connection structure comprises a bearing block and a sliding plate. The sliding plate is connected with the bearing block and located over the bearing block. A space is reserved betweenthe sliding plate and the bearing block. A first auxiliary fixing mechanism is arranged on the sliding plate. The first auxiliary fixing mechanism comprises a locking bar, a first nut block, a secondnut block, a pressing threaded rod and a pressing block. The locking bar is rotatably connected to the sliding plate. The locking bar is provided with threads with the opposite directions. The first nut block and the second nut block are in screwed connection with the threads with the opposite directions on the locking bar. The first nut block and the second nut block are in sliding fit with the sliding plate. The sliding plate is provided with an adjusting opening. The pressing threaded rod is in threaded connection with the first nut block and the second nut block and penetrates through theadjusting opening. The pressing block is arranged on the pressing threaded rod and located between the sliding plate and the bearing block. The prefabricated building beam-column joint connection structure is good in clamping effect and can improve the beam-column stability.

Owner:无锡锡晟建设有限公司

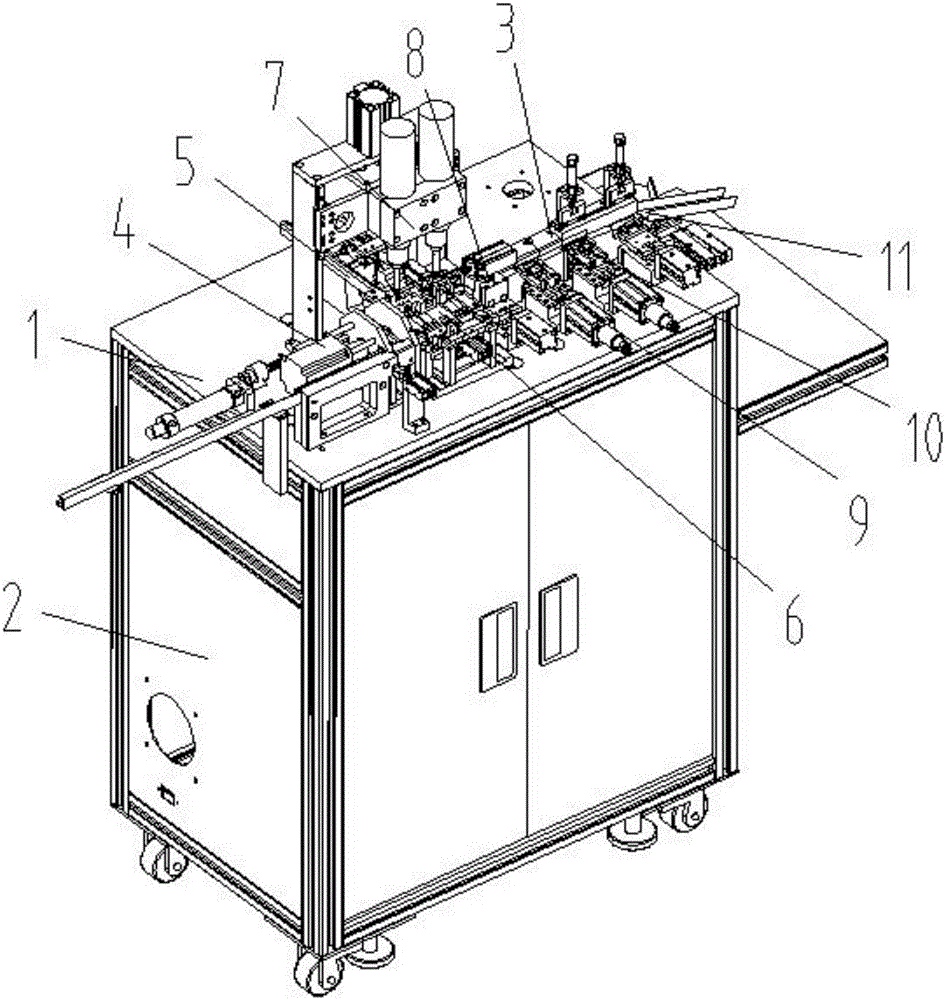

Full-automatic integrated processing machine of video graphics array (VGA) interface

ActiveCN106684669APrecise bending angleRealize automatic integrated processingContact member manufacturingContact member assembly/disassemblyGraphicsDistribution control

The invention relates to a full-automatic integrated processing machine of a video graphics array (VGA) interface. The full-automatic integrated processing machine comprises a rack and a power distribution control box, wherein a transmission groove is formed in the rack and is matched with a product, a clamping device, a bolt loading device and a bolt locking device are arranged at a left part of the transmission groove and are matched with one another, an upper bending device and a lower bending device are arranged at a right part of the transmission groove and are matched, detection devices are arranged at a left side of the upper bending device and a right side of the lower bending device, the upper bending device comprises an upper bending air cylinder, an upper bending block is connected with the upper bending air cylinder and is provided with a bending inclined surface inclining at an angle of 45 degrees at an outer side, the lower bending device comprises a lower bending air cylinder, and a lower bending block is connected with the lower bending air cylinder and is provided with a bending inclined surface inclining at an angle of 45 degrees at an inner side. By the full-automatic integrated processing machine, automatic integrated processing is achieved, meanwhile, the accurate bending angle of a terminal can be ensured, detection leakage is prevented, and the processing efficiency is improved.

Owner:秦轩汽车科技(天长)有限公司

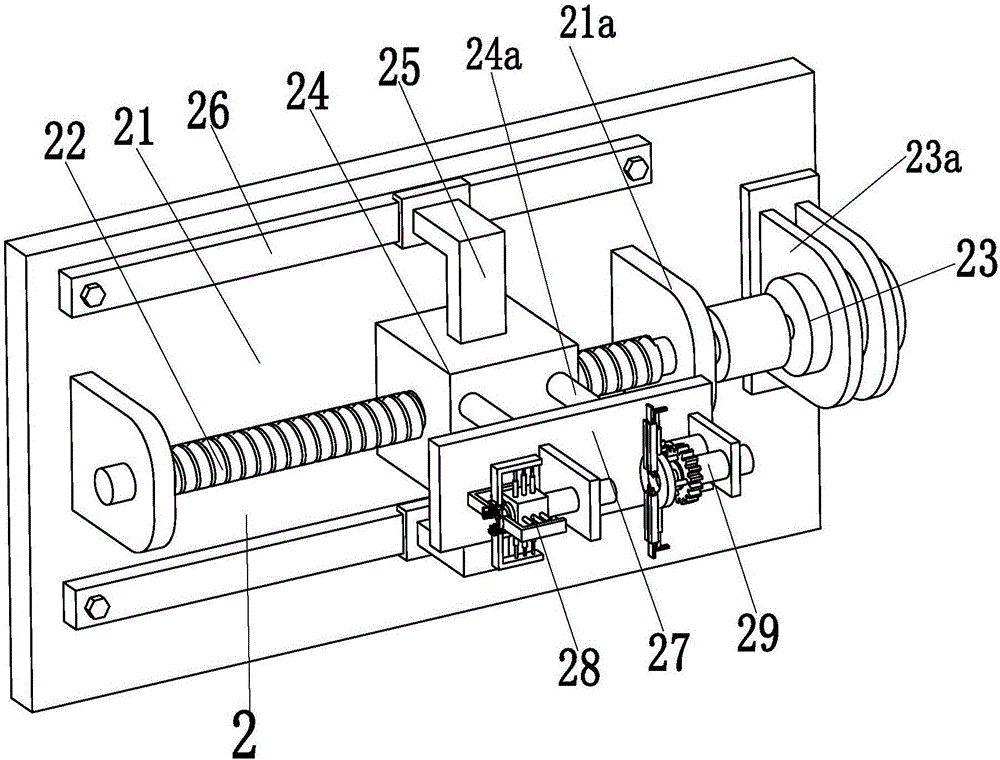

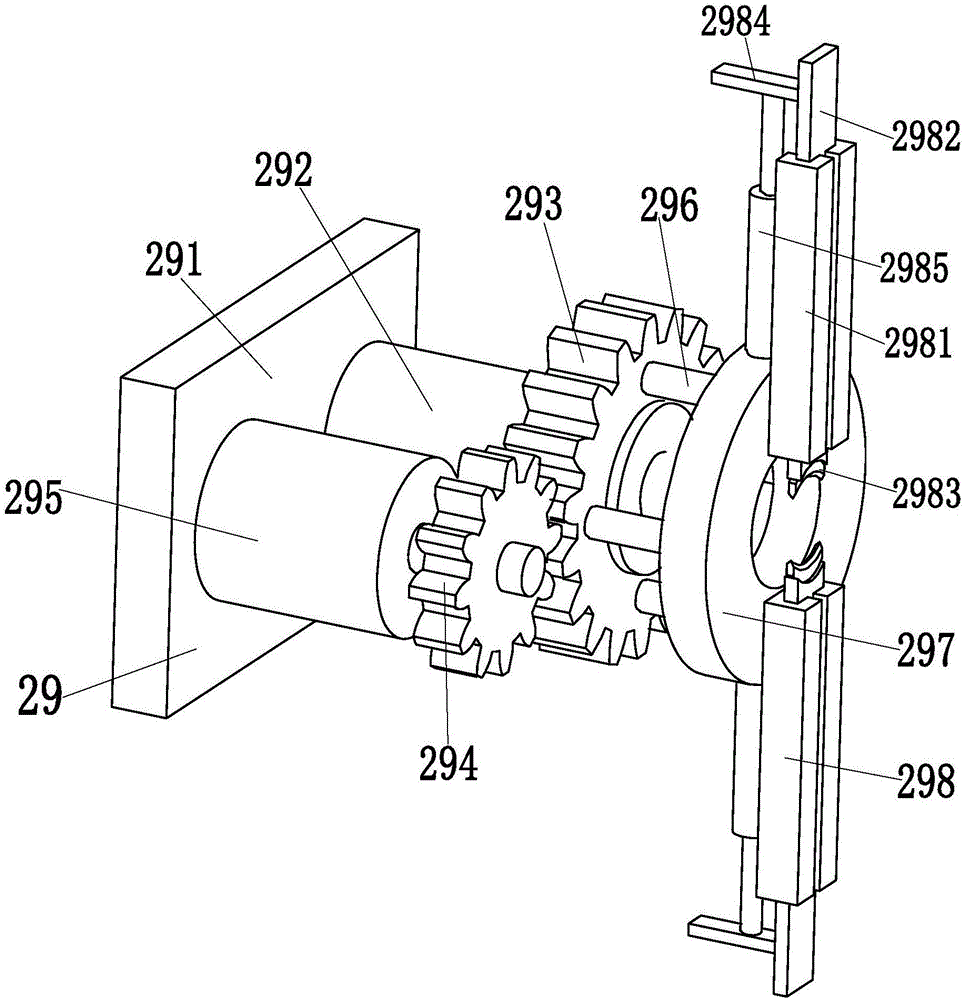

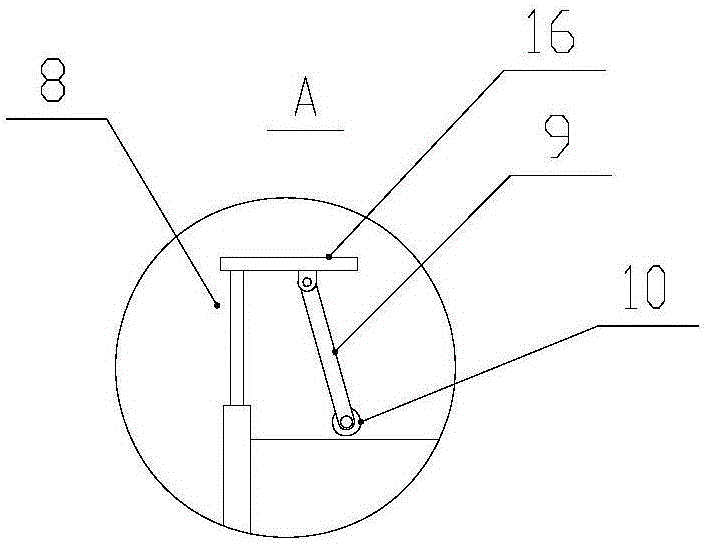

Adjustable automatic wire feeding device

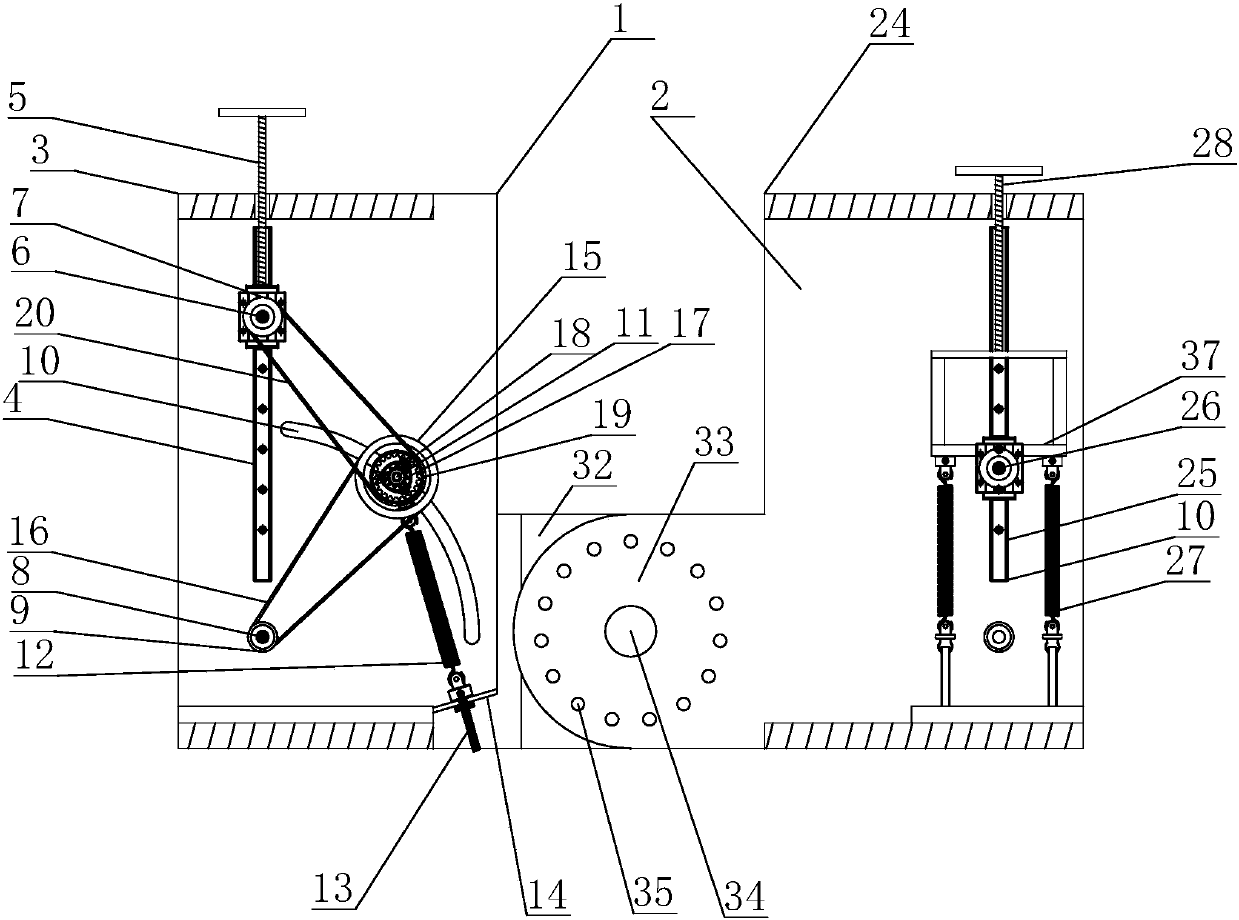

InactiveCN105947779AReduce construction costsGood clamping effectFilament handlingFinish lineWheel drive

The invention discloses an adjustable automatic wire feeding device, and mainly relates to the field of power construction facilities. The adjustable automatic wire feeding device comprises a drive mechanism and a driven mechanism. The drive mechanism is connected to one side of the driven mechanism in a hinged manner, and a limiting pin used for fixing the hinge angle is arranged at the hinged position. The drive mechanism is provided with a power wheel driven by a motor, and a first clamping wheel in reverse transmission through a planetary wheel set so that a cable can be clamped and conveyed, and the driven mechanism is provided with a fixed wheel and a second clamping wheel matched with the fixed wheel so that the turning angle can be assisted. The adjustable automatic wire feeding device has the beneficial effects that the adjustable automatic wire feeding device can be easily matched with various complex power transmission lines to finish line conveying, and meanwhile the cable can be well protected.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO PINGYUAN POWER SUPPLY CO +1

Universal joint axle hole locating fixture

InactiveCN102962690ASimple structureGood clamping effectPositioning apparatusMetal-working holdersEngineeringScrew thread

The invention relates to a universal joint axle hole locating fixture, which comprises an adjusting support and a locating seat which are fixed on a base plate, wherein the adjusting support and the locating seat are located on the same axial line; an axle hole is processed on the locating seat; a cylindrical locating pin shaft is arranged in the axle hole; a locating sleeve is arranged on the adjusting support; the center of the locating sleeve and the axle hole of the locating seat are located on the same axial line; screw threads are process on an inner surface of the locating sleeve; an adjusting screw rod is arranged to penetrate through the locating sleeve; and an arc-shaped face is arranged on a top part of the adjusting screw rod. According to the universal joint axle hole locating fixture, the axle hole of a universal joint is located through the adjusting support, the locating seat, the locating pin shaft on the locating seat, and the adjusting screw rod on the adjusting support; and the adjusting screw rod can be controlled through a rocking handle on a tail end of the adjusting screw rod.

Owner:WUXI NEW GREAT POWER ELECTRICAL MACHINE

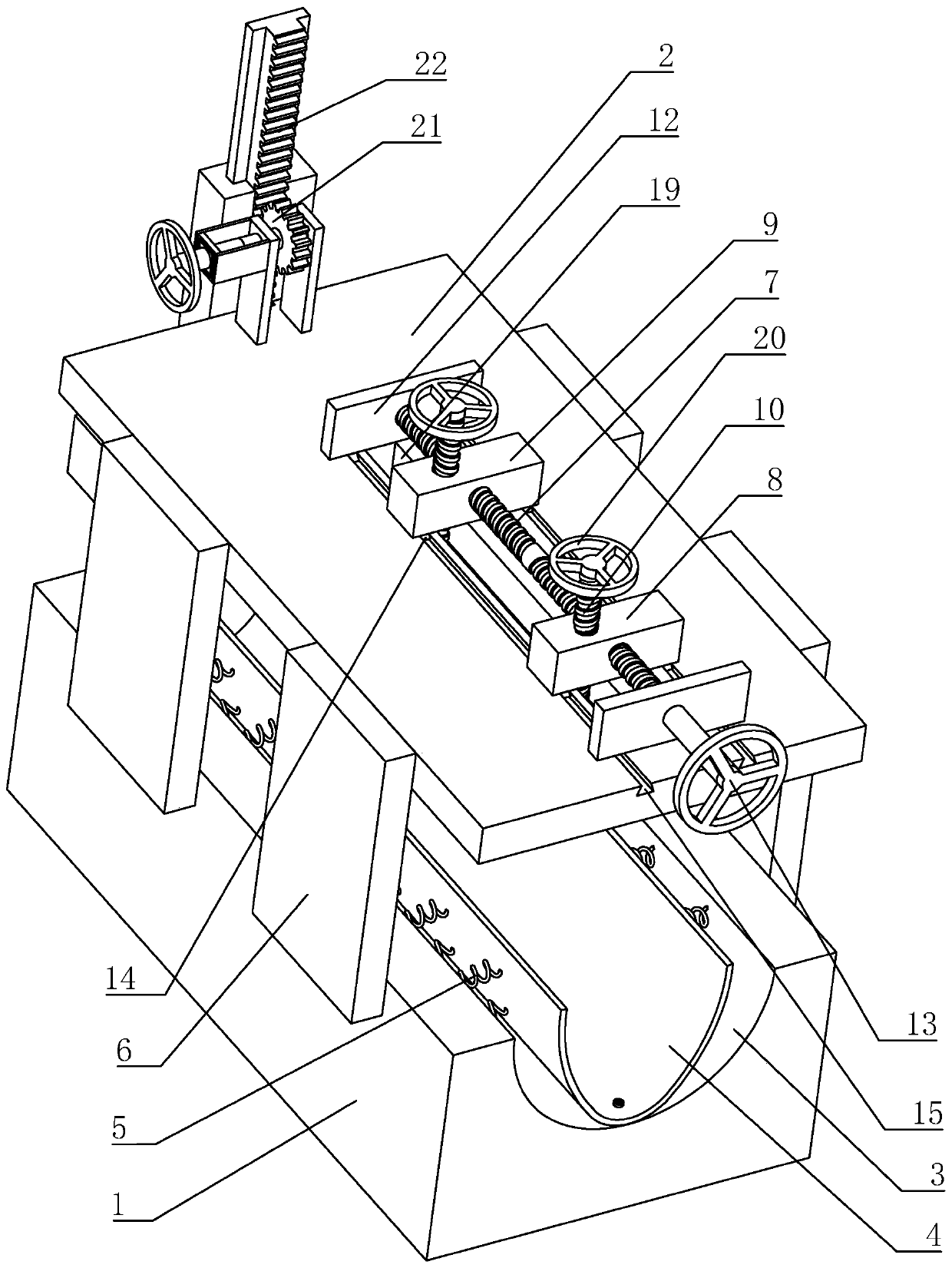

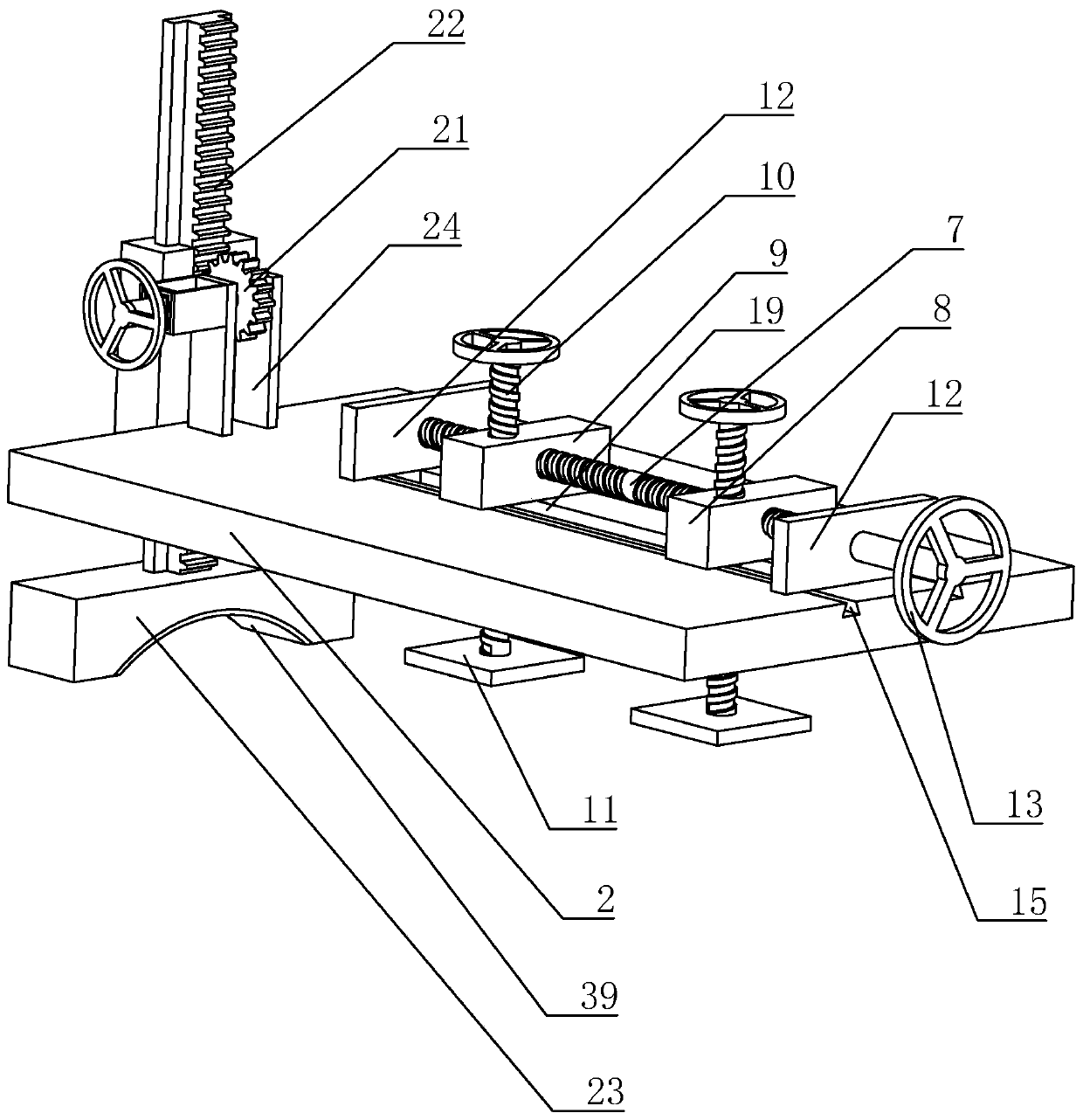

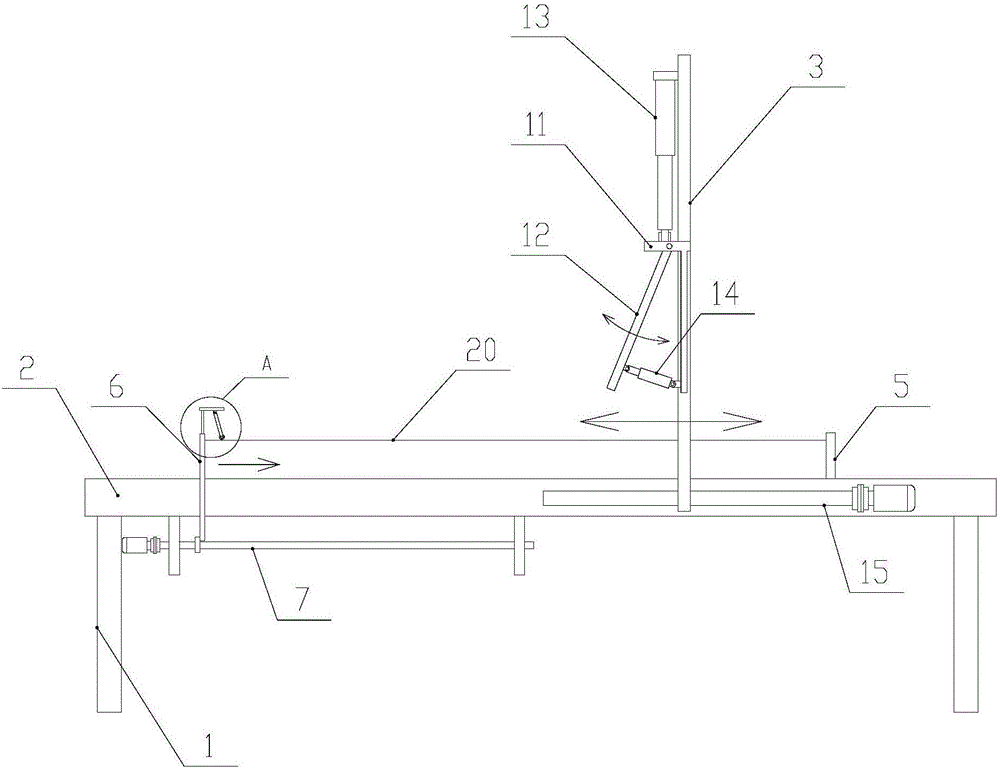

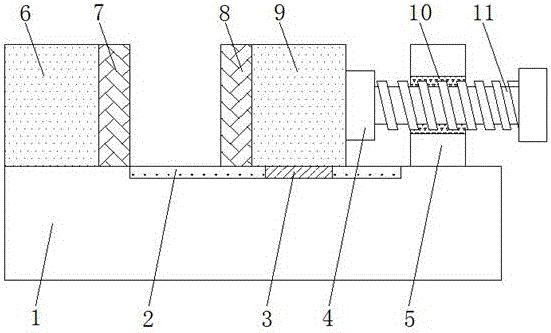

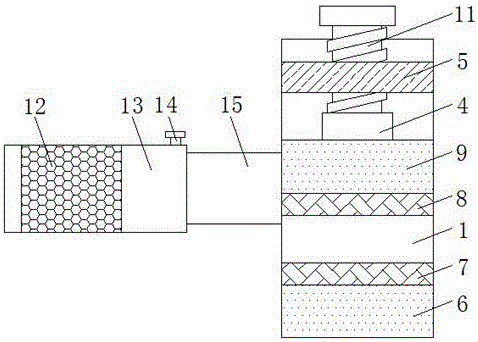

Foam cutting machine

ActiveCN106142223AGood clamping effectHigh positioning accuracyMetal working apparatusElectric heatingIndustrial engineering

The invention discloses a foam cutting machine. The foam cutting machine comprises a base, a workbench, a movable seat and an electric heating wire. The workbench is installed on the base. The movable seat can be installed on the workbench in the length direction of the workbench movably. The electric heating wire is located above the movable seat. The workbench is provided with a fixed baffle and a movable baffle in the length direction of the workbench. The fixed baffle is fixedly installed on the workbench. The movable baffle is driven by a ballscrew mechanism and can move relative to the fixed baffle. The two ends of a foam board can be clamped by the movable baffle and the fixed baffle. According to the foam cutting machine, foam board is clamped by the fixed baffle and the movable baffle on the workbench, the clamping effect is good, and the locating precision is high.

Owner:甘肃联创建筑节能科技有限公司

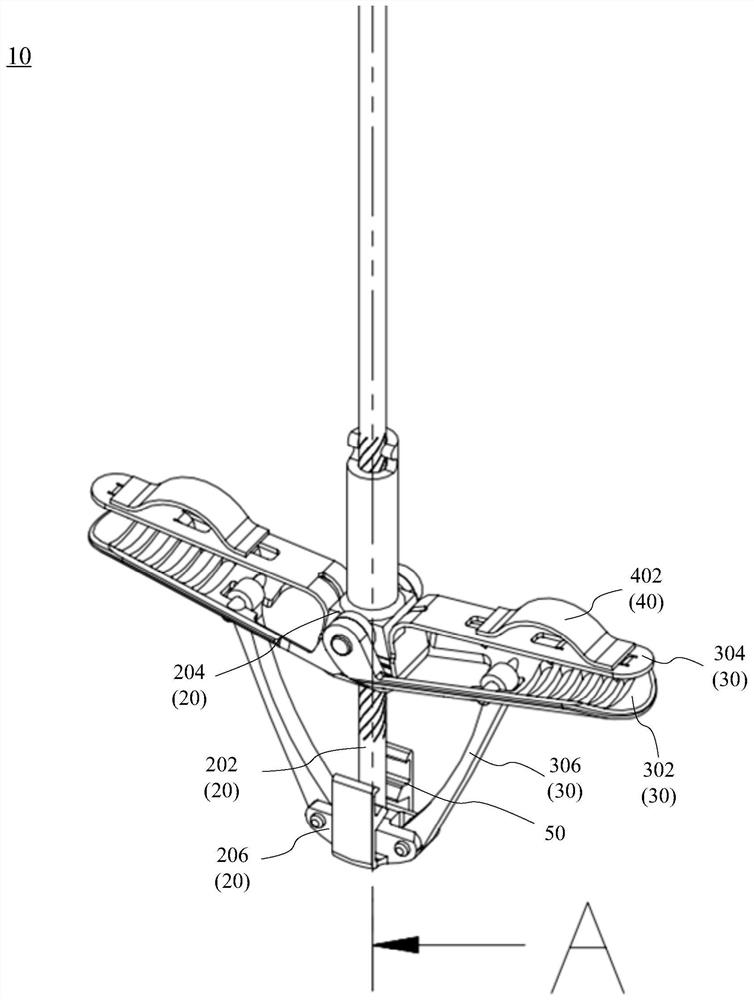

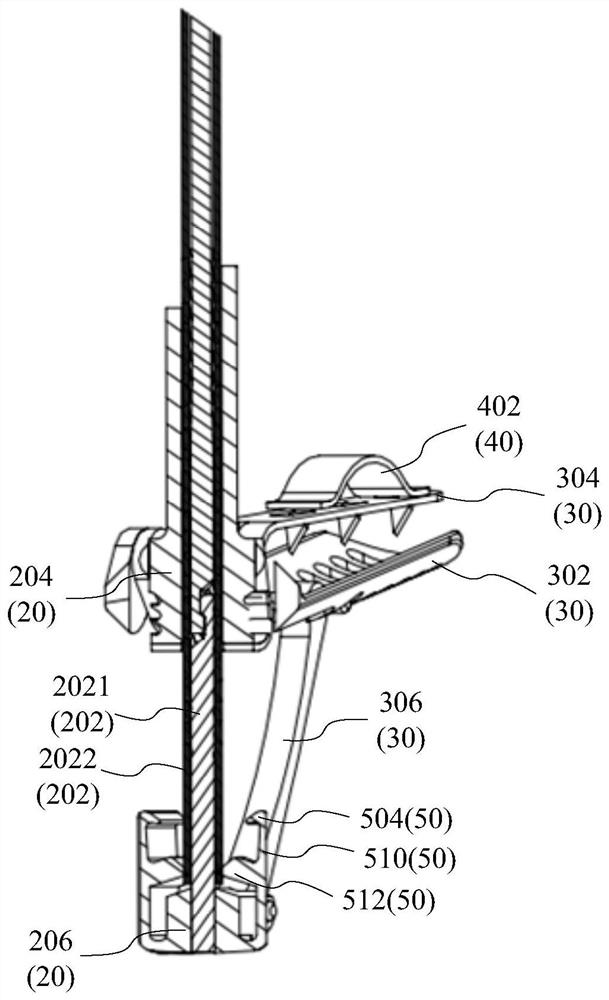

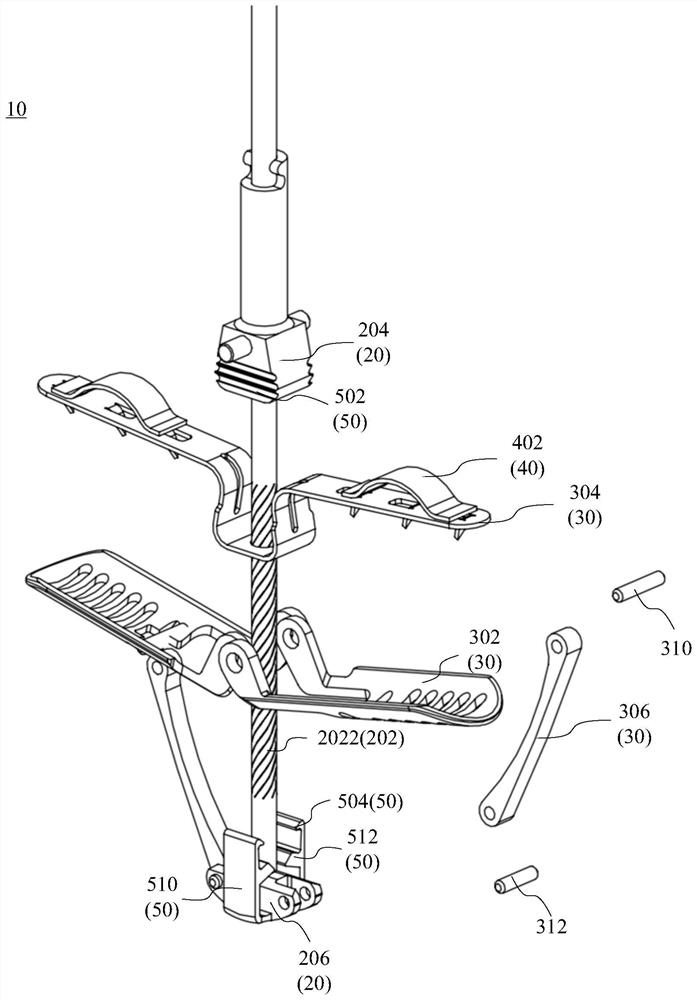

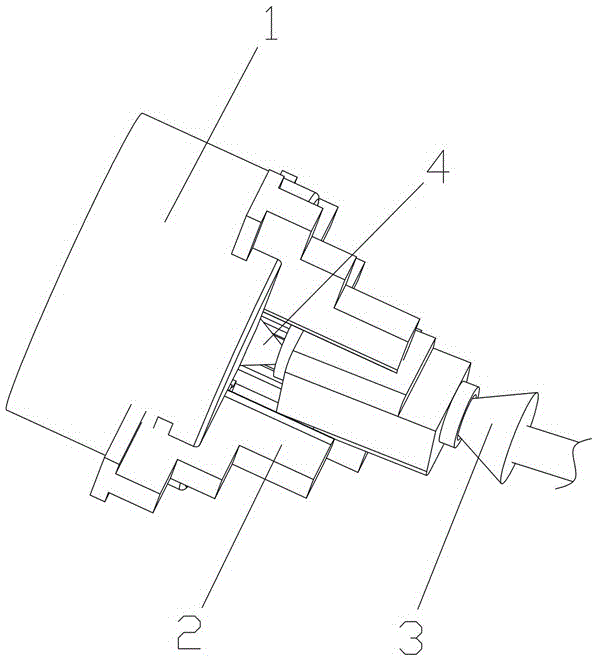

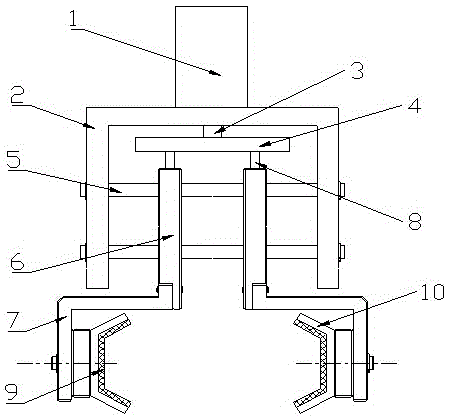

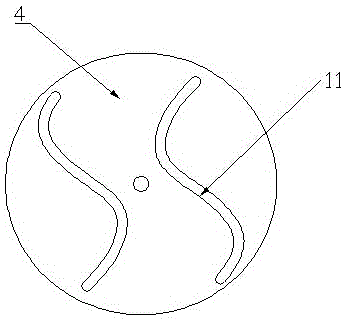

Electric-driven type mechanical hand claw

InactiveCN105108749ASimple structure setupGood clamping effectProgramme-controlled manipulatorGripping headsElectric driveElectric machinery

The invention relates to an electric-driven type mechanical hand claw. The electric-driven type mechanical hand claw comprises a motor, an installing plate and an actuating mechanism, wherein the installing plate is arranged at the lower end of the motor; the actuating mechanism is connected with a motor shaft; the installing plate is N-shaped; the middle part of the upper end of the installing plate is fixedly connected with the motor; the actuating mechanism is arranged in a cavity in the lower end of the installing plate; the actuating mechanism is formed by a rotating plate which is connected with the motor shaft, a pair of parallel guiding columns which are arranged at the lower end of the rotating plate, a pair of sliding blocks which are matched with the parallel guiding columns in an inserting way and a pair of V-shaped claws; the rotating plate is circular; the middle part of the rotating plate is fixedly arranged on the motor shaft; a pair of S-shaped through grooves of which the circle centers are symmetrical are formed in the rotating plate; two through holes which are used for enabling the parallel guiding columns to be inserted to be matching are oppositely formed in the pair of sliding blocks; the middle parts of the upper ends of the sliding blocks are provided with a pair of parallel vertical columns which are inserted into the S-shaped through grooves in a matching way; the lower ends of the sliding blocks are fixedly connected with the pair of V-shaped claws which are oppositely arranged. The electric-driven type mechanical hand claw disclosed by the invention has the advantages that the electric-driven type mechanical hand claw is driven by adopting the motor and slides in the through grooves in the rotating plate through the parallel vertical columns at the upper ends of the sliding blocks, so that opening and closing of the V-shaped claws are realized, and the structure setting is simple and reasonable.

Owner:JIANGSU HUAAN SCI RES DEVICES

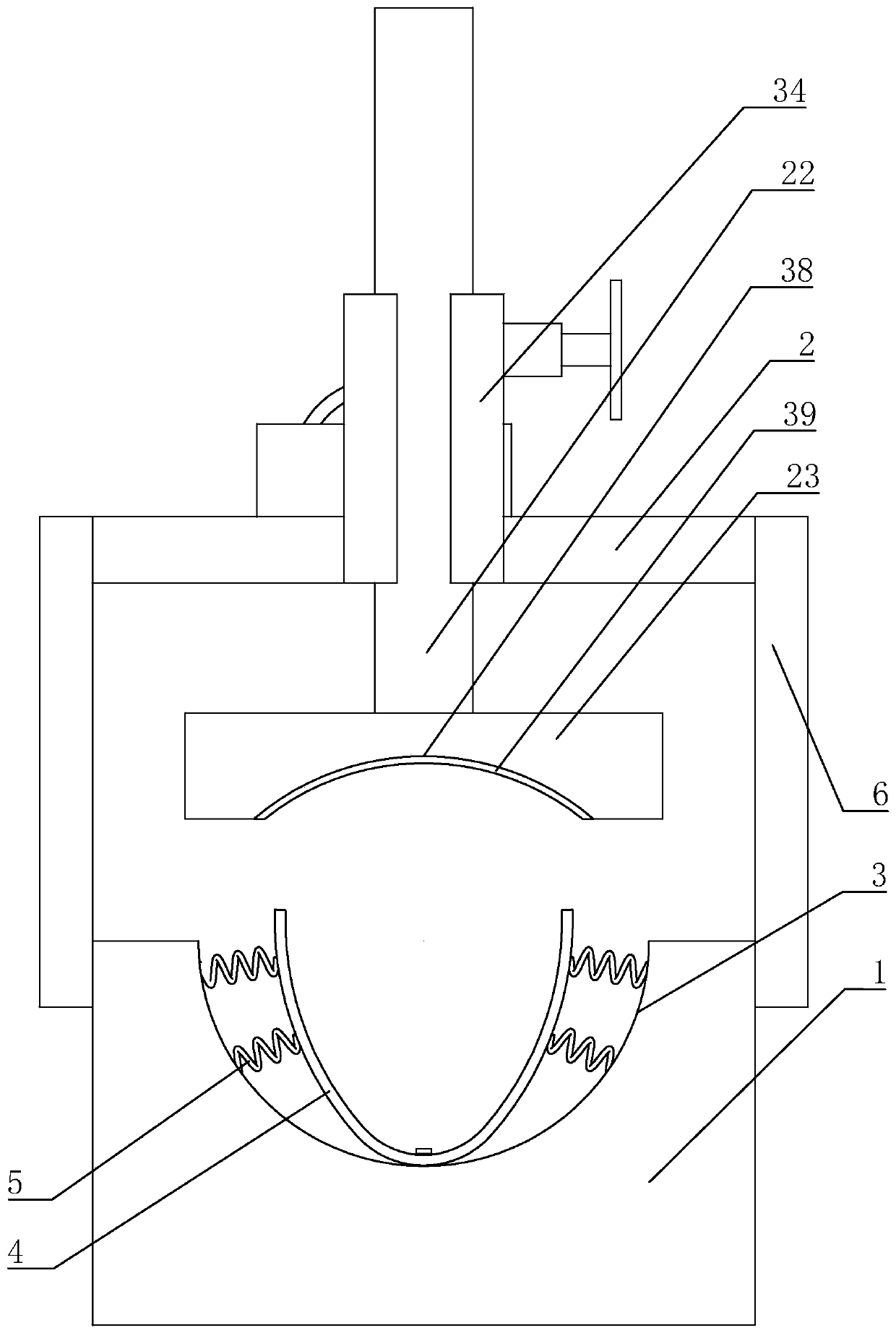

Welding device for machining of general aviation unmanned aerial vehicle

InactiveCN108581282AGood clamping effectImprove accuracyWelding/cutting auxillary devicesAuxillary welding devicesCushionEngineering

The invention discloses a welding device for machining of a general aviation unmanned aerial vehicle. The welding device comprises a tank body, supporting legs are fixedly connected to the two sides of the bottom of the tank body, antiskid pads are fixedly connected to the bottoms of the supporting legs, fixing plates are fixedly connected to the two sides of the top of the tank body, and a top plate is fixedly connected to the tops of the fixing plates. Through cooperation of a first sliding groove, a second sliding groove, an electric telescopic rod, a movable block, a first sliding block, apull rod, a fixed block, a movable plate, a second sliding block, a telescopic column, a spring, a movable plate, a clamping plate, a buffer cushion and a controller, the advantage of good clamping effect is achieved, the problem that due to poor clamping effect of an existing welding device for machining of the general aviation unmanned aerial vehicle, workpieces of the unmanned aerial vehicle are damaged during welding is solved, the general aviation unmanned aerial vehicle does not slide in the welding process, the welding position accuracy is improved, and the number of defective workpieces of the unmanned aerial vehicle is reduced.

Owner:芜湖千创智能科技有限公司

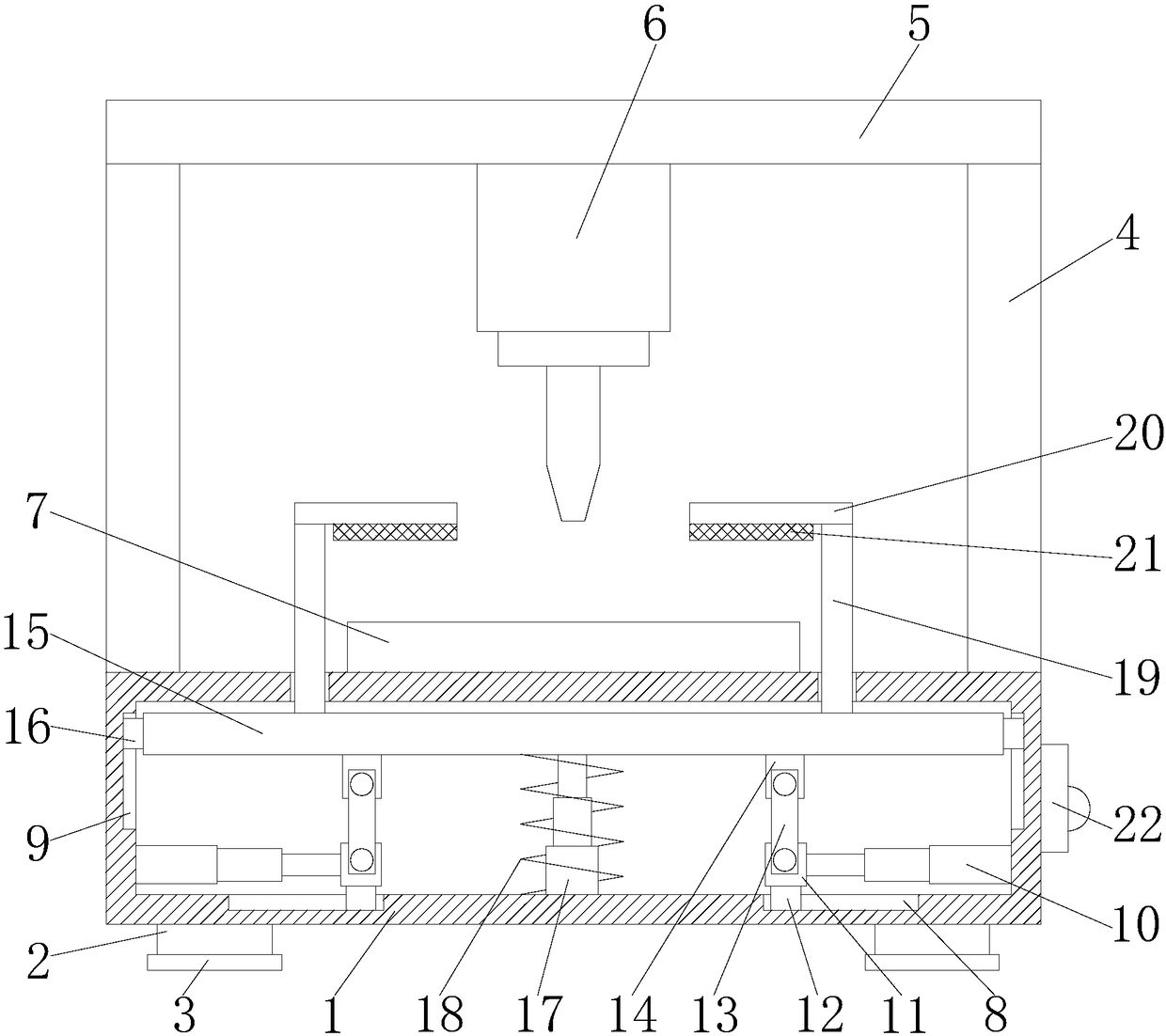

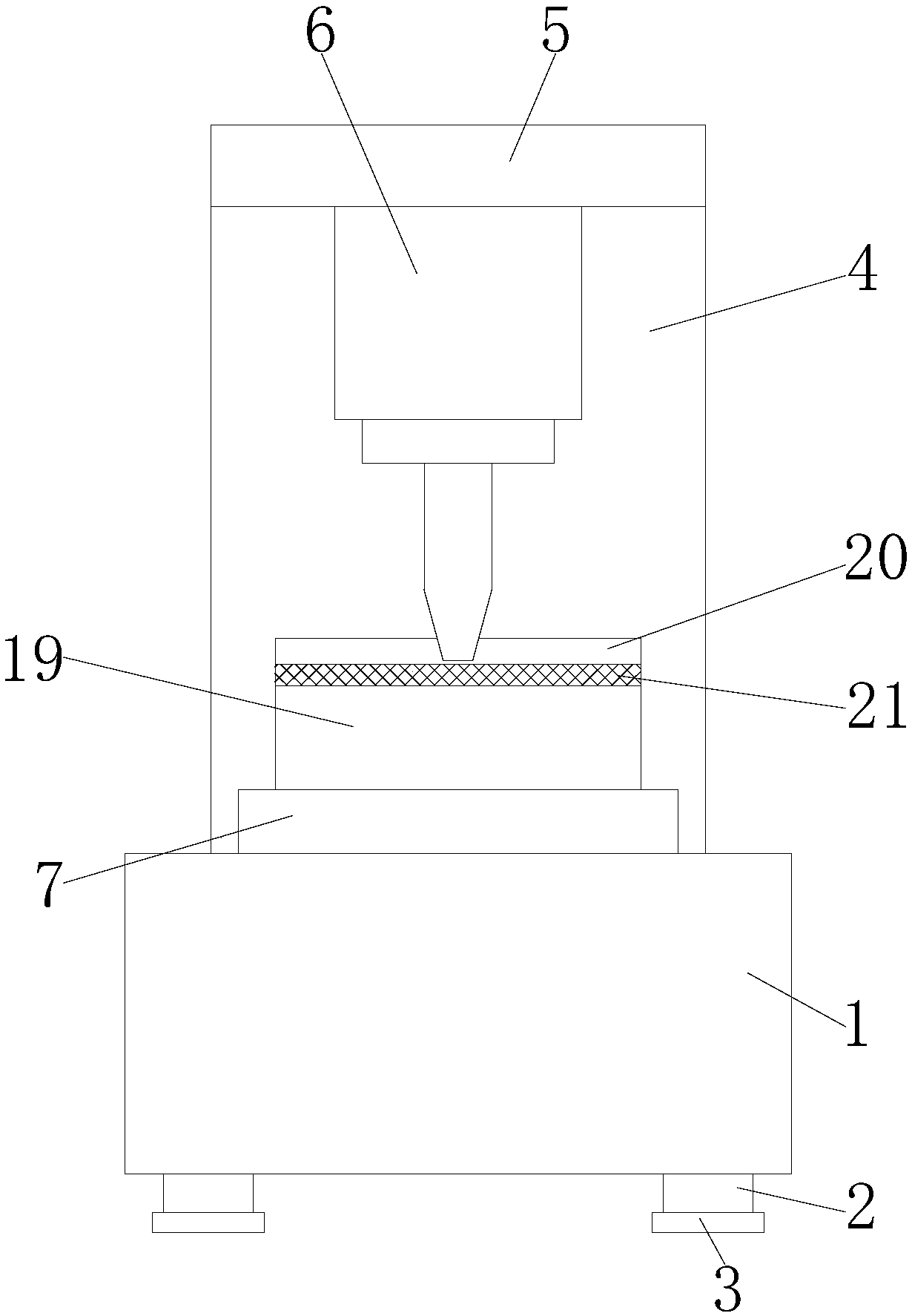

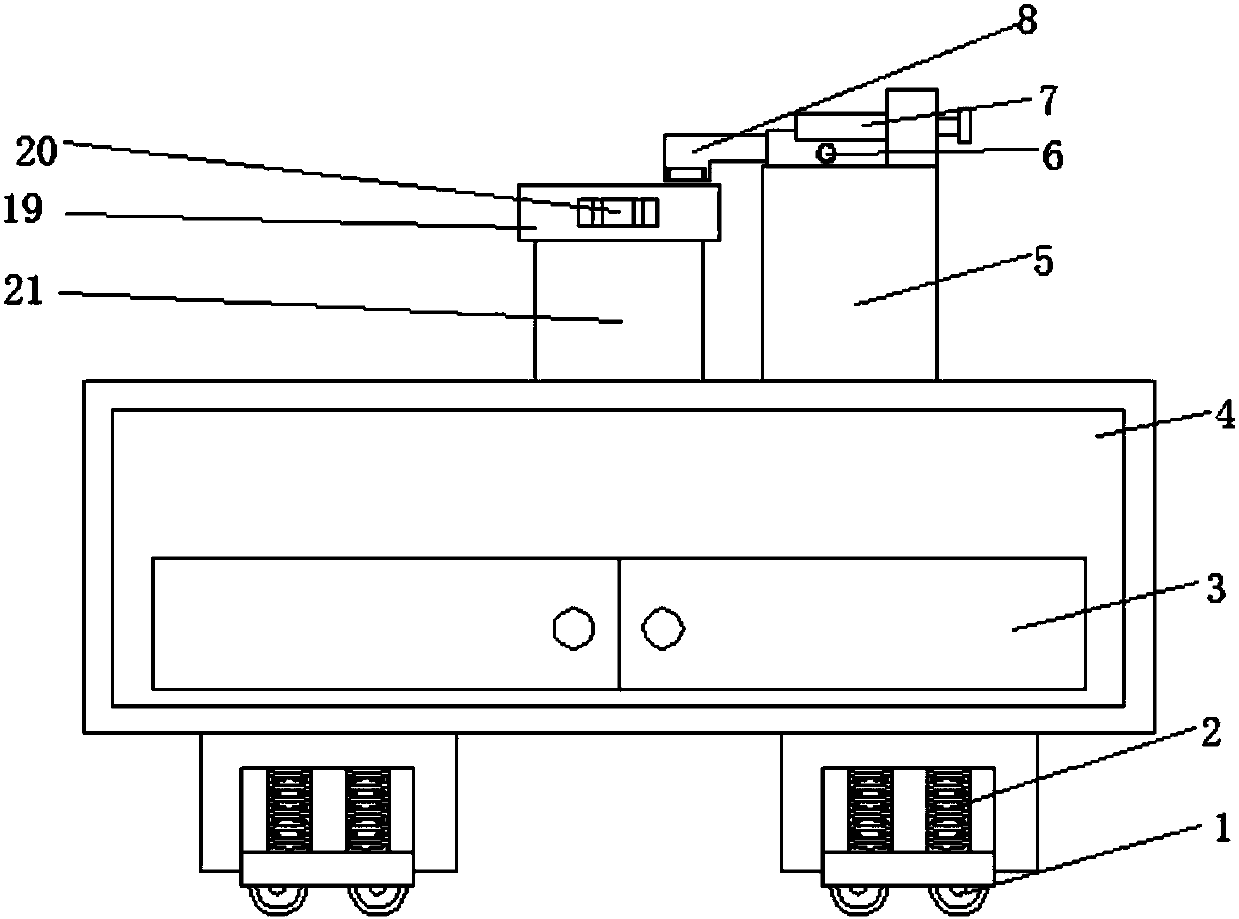

Numerical control machine tool with good clamping effect

InactiveCN107457586AGood clamping effectReduce defective productsLarge fixed membersPositioning apparatusEngineeringDrill bit

The invention discloses a numerically controlled machine tool with a good clamping effect, which includes a workbench, fixed blocks are fixedly connected to both sides of the bottom of the workbench, and a column is fixedly connected to the center of the rear side of the top of the workbench. A cantilever beam is fixedly connected to the top of the column, a first motor is fixedly connected to the bottom of the cantilever beam and the side away from the column, and a drill bit is fixedly connected to the output end of the first motor. The present invention is provided with an operating table, a fixed block, a box body, a first chute, a second chute, a second motor, a screw, a bearing seat, a screw sleeve, a first slider, a moving column, a connecting block, and a second slider. Blocks, movable blocks, controllers and buffer pads cooperate with each other to achieve the advantages of good clamping effect, so that workers can clamp the products when using CNC machine tools to process products, reducing defective products and improving production efficiency. The practicability of CNC machine tools is suitable for promotion and use.

Owner:TAIZHOU LONGXIANG AUTOMATION EQUIP CO LTD

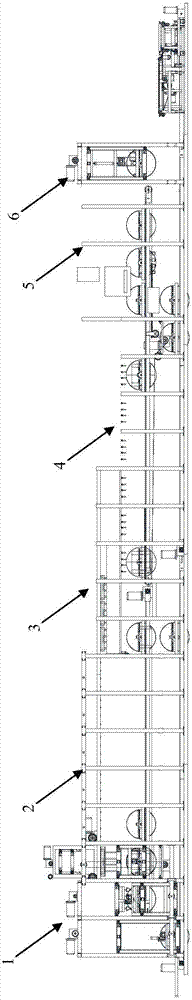

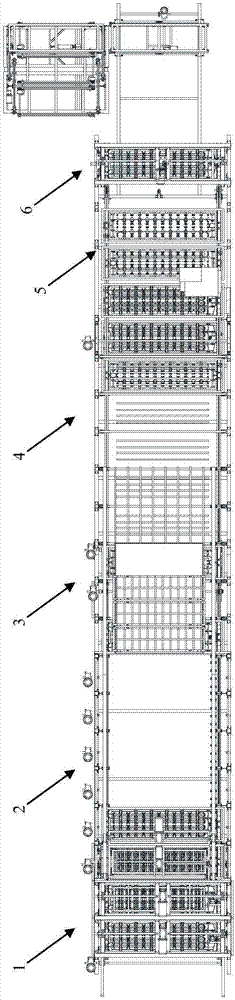

Electroplating production line for vacuum cup

InactiveCN106906502AGood clamping effectStable clampingElectrolysis componentsElectroplatingProduction line

The invention discloses an electroplating production line for a vacuum pump. The electroplating production line comprises a feeding unit, an electrolysis unit, a primary water draining unit, a cleaning unit, a secondary water draining unit and a drying unit. The feeding unit comprises a clamping mechanism. The clamping mechanism comprises a frame, a plurality of fixed clamping plate units, a plurality of movable clamping plate units opposite to the fixed clamping plate units, a fixed rod, a movable rod and a drive device. According to the electroplating production line for the vacuum pump, due to the usage of the improved clamping mechanism, the clamping effect on an inner container of the stainless steel vacuum pump is very good, the outer wall of the inner container cannot be damaged, and clamping is firm; and meanwhile, a plurality of inner containers can be synchronously operated, and the production efficiency is greatly improved.

Owner:梅子俊

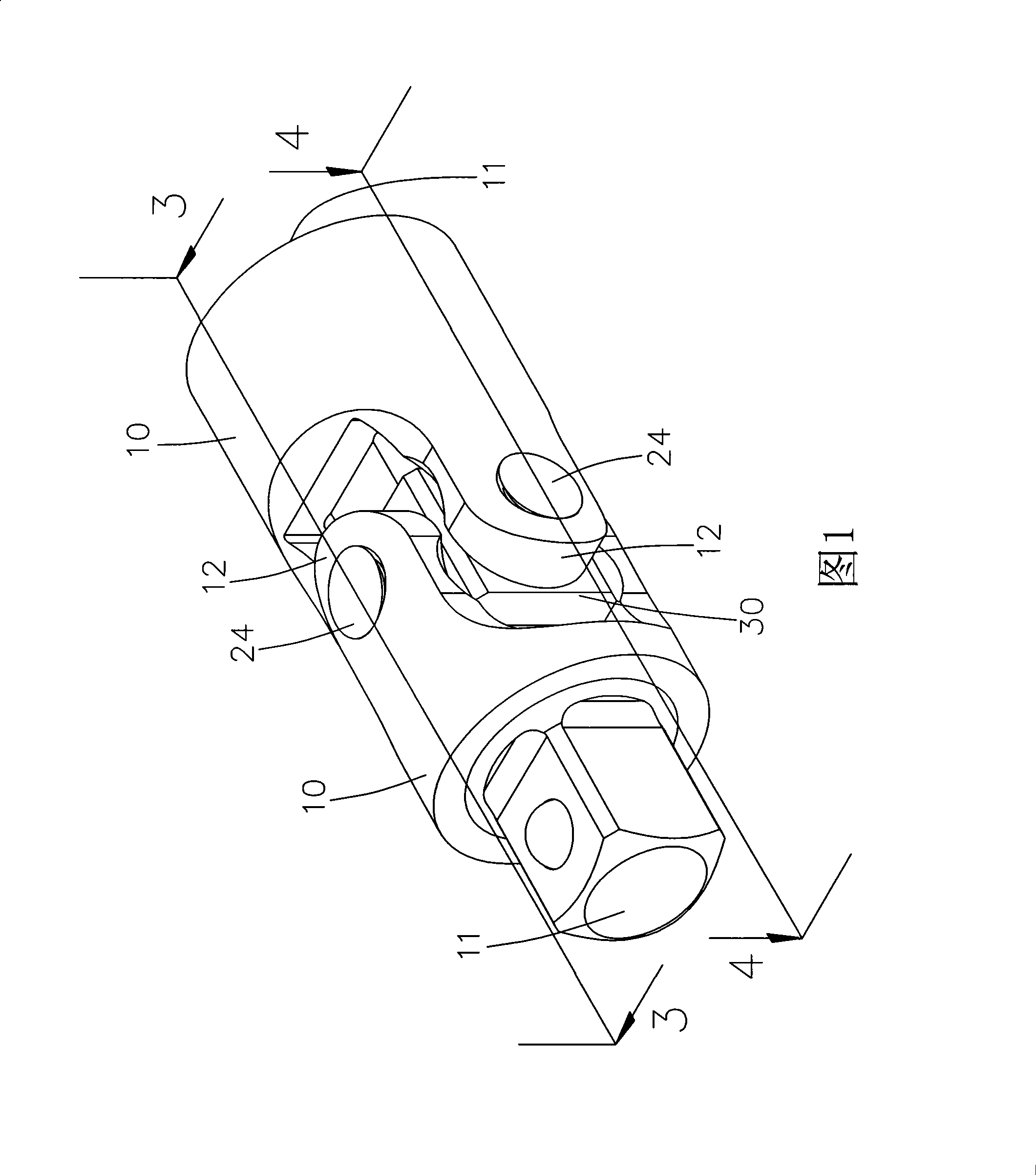

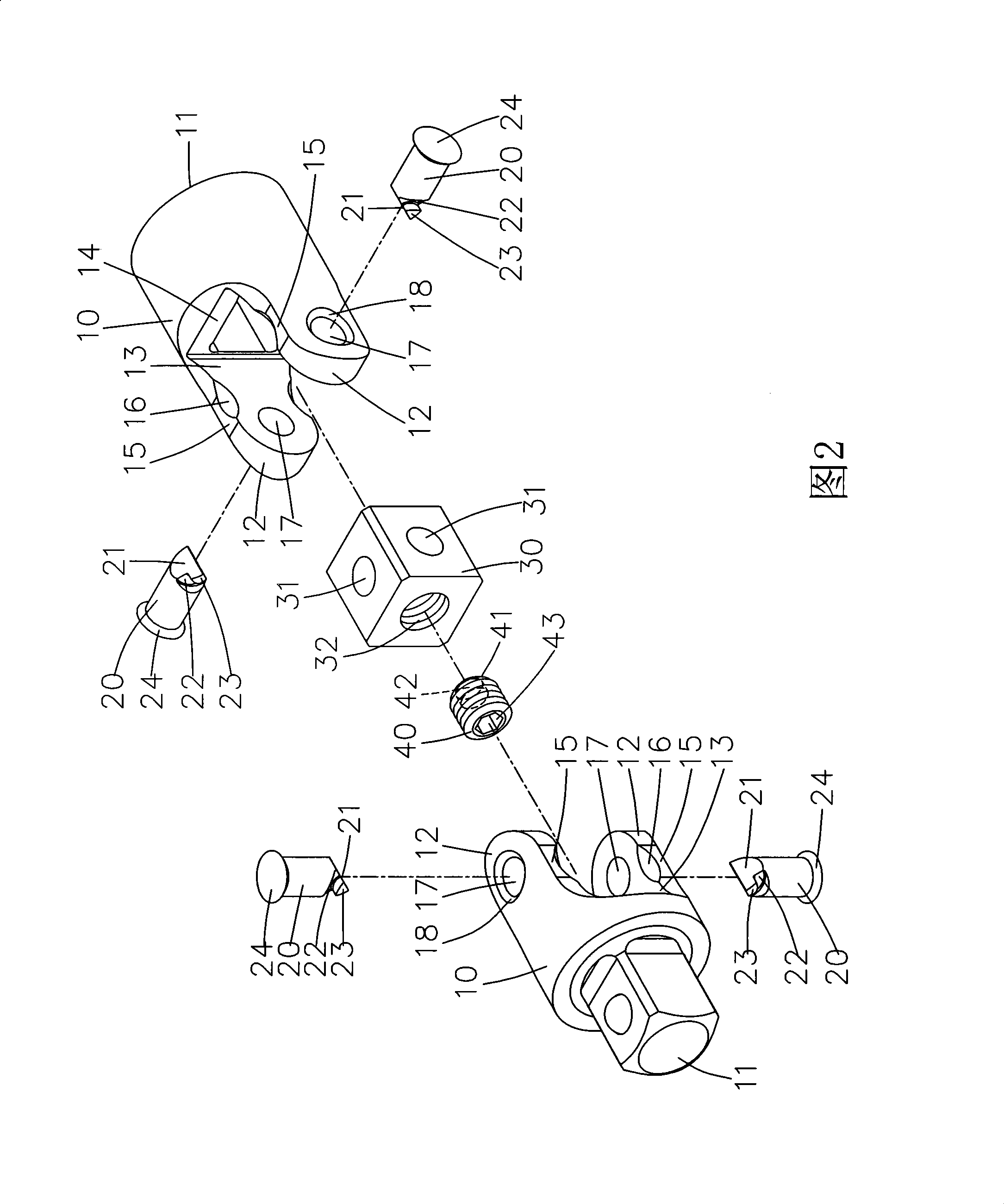

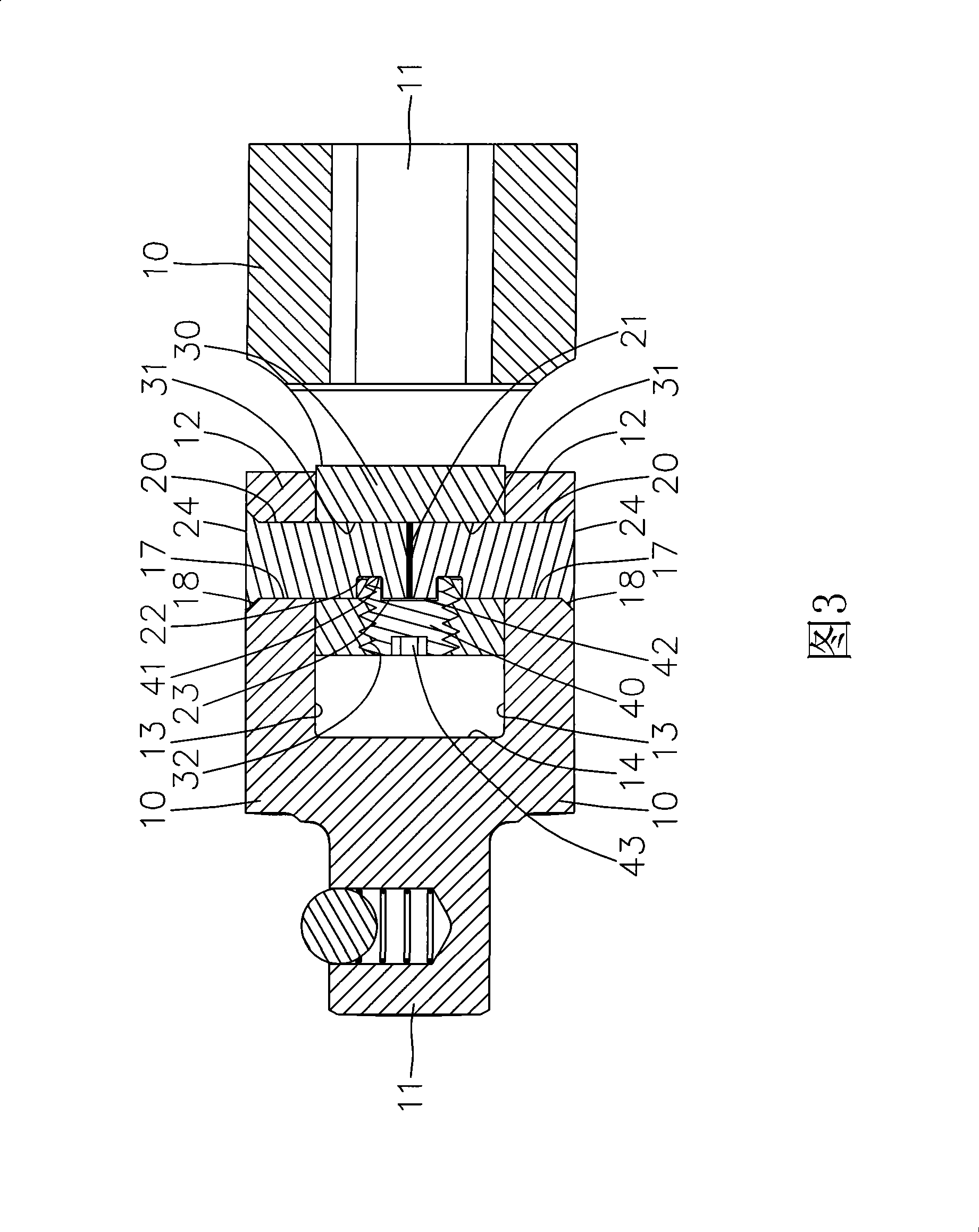

Pin joint structure for universal joint

InactiveCN101363480AGood clamping effectThe pivot structure is stableYielding couplingSpannersUniversal jointEngineering

The invention relates to a pivot joint structure of a universal joint, comprising two driving parts, a connecting piece and a stopper; the driving part is provided with a pivot joint end which is equipped with a pivot hole; the connecting piece is provided with two axle holes which are positioned on the same plane and cross vertically, an axial member is respectively pivotally arranged between two axle holes of the connecting piece and the pivot holes of the two driving parts, thus forming opposite pivot swinging relation between the connecting piece and the driving parts, the front part of the connecting piece is further provided with a locating hole which is communicated with the two axle holes; the stopper is installed in the locating hole of the connecting piece and is combined with the axial member to fix the axial member in the axle hole of the connecting piece, thus achieving the clamping and combining effect of quick combination and stable structure; furthermore, with the stopper which can be quickly assembled and disassembled, the assembly labor hour can be saved, thus achieving the effect of reducing assembly cost.

Owner:胡厚飞

Hydraulic clamping device for hardware numerical control machining

ActiveCN109158906AGood clamping effectGood clampingWork clamping meansPositioning apparatusEngineeringLiquid storage tank

The invention discloses a hydraulic clamping device for hardware numerical control machining. The hydraulic clamping device comprises a mounting member. The top of the mounting member is fixedly connected with a liquid storage tank. The top of the mounting member is fixedly connected with a pushing mechanism of which the front end extends into the liquid storage tank. The front face of the mounting member is fixedly connected with a liquid distribution tank communicating with the liquid storage tank. Pushing rods communicating with the liquid distribution tank are hinged to the left side walland the right side wall of the liquid distribution tank. The front face of the liquid distribution tank is fixedly connected with a rotating shaft. The structure of the hydraulic clamping device is reasonable, hydraulic oil in the pushing rods enters an accommodating groove through a hose and can push a moving plate to move by pouring into the accommodating groove, thus, a squeezing rod and a curved plate are enabled to move through movement of the moving plate, and hardware can be further clamped through movement of the squeezing rod and the curved plate, so that the hardware is clamped morestably, the hardware can be clamped in different directions, and the situation that stress points of the hardware are few, and consequently the outer surface of the hardware is damaged is avoided.

Owner:江苏天佑液压科技有限公司

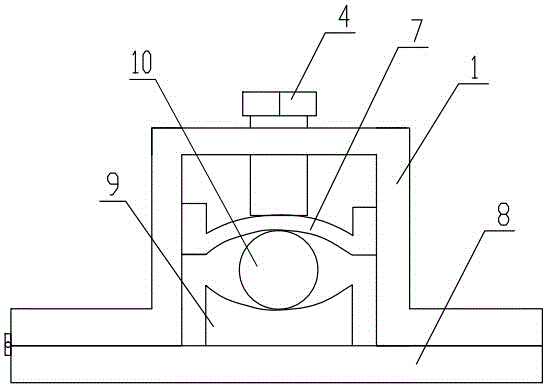

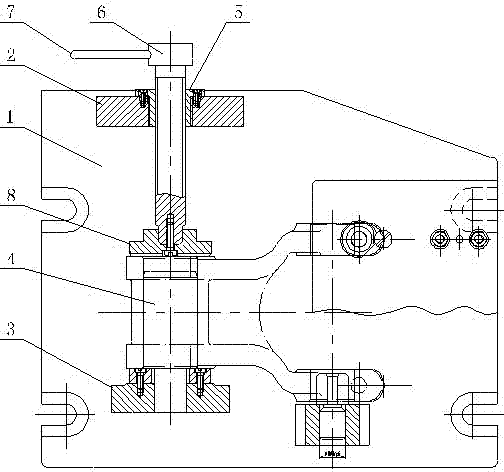

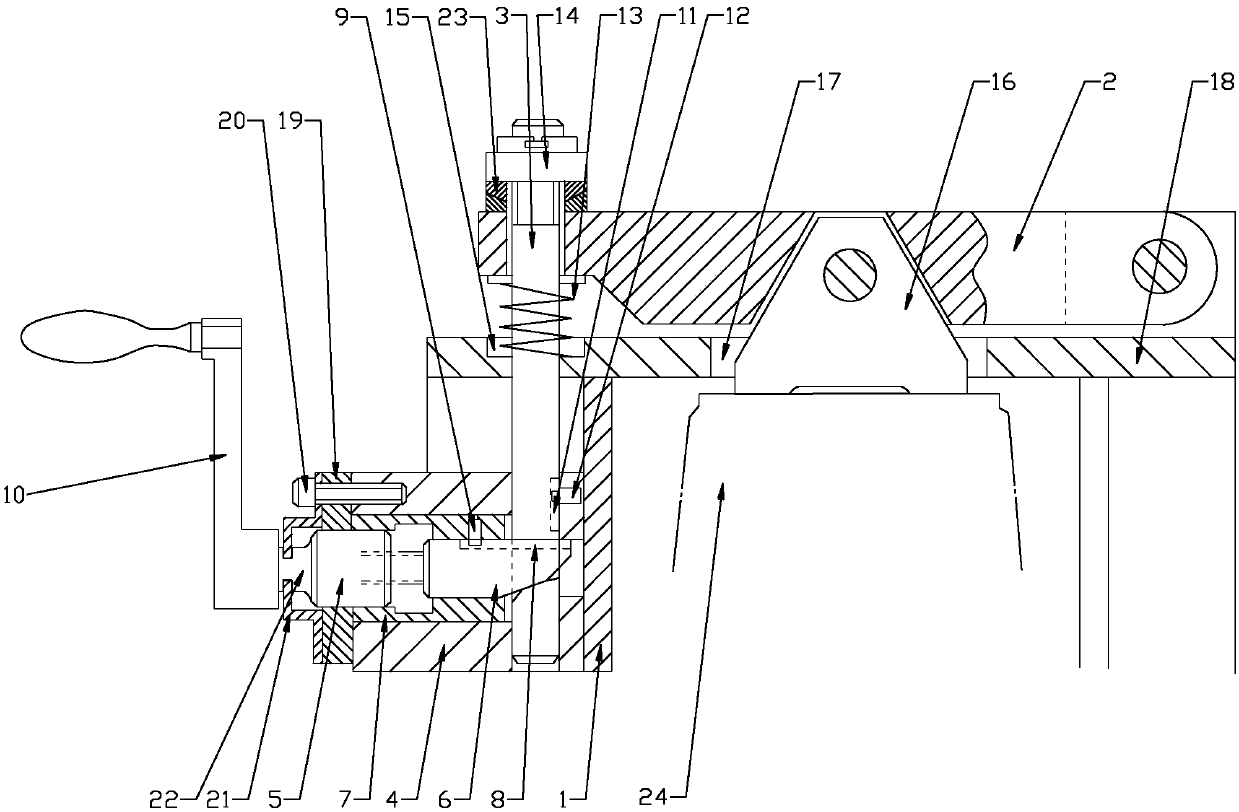

Gland type clamping device

InactiveCN107756079AGood clamping effectEasy to disassemblePositioning apparatusMetal-working holdersSelf lockingEngineering

The invention relates to a clamping device, especially a gland-type clamping device, which includes a base, a gland, a floating column and a driving group, the driving group includes a fixed seat, a threaded sleeve and a wedge block, and the fixed The seat is fixedly connected with the side wall of the base, and a shaft sleeve is horizontally fixed in the fixed seat, and one end of the wedge-shaped block sleeve is threadedly connected with the threaded sleeve, and the outer wall of the threaded sleeve is connected to the threaded sleeve. The inner wall on the left side of the bushing is rotatably connected, and the wedge-shaped block is horizontally slidably matched with the bushing, and the wedge-shaped block is horizontally provided with a limiting groove 1 . The gland type clamping device adopting the technical scheme of the invention has the characteristics of good clamping effect, easy disassembly, good self-locking effect and strong adaptability.

Owner:成都液力机械有限公司

Fabric cutting device capable of adapting to belt conveying

ActiveCN106854830AReduce lifting speedAvoid situations that damage the conveyor beltSevering textilesMetal working apparatusEngineeringMechanical engineering

The invention relates to a fabric cutting device capable of adapting to belt conveying. The fabric cutting device comprises a feeding device, the feeding device is provided with a fabric cutting frame, the fabric cutting frame is provided with a cutting device, the cutting device comprises a cutter sleeve on the fabric cutting frame, the lower portion of the cutter sleeve is provided with a cutter groove, the cutter groove is communicated with the cutter sleeve, and a cutter lifting pull rod matched with a cutter in the cutter groove is arranged in the cutter groove, the upper portion of the cutter lifting pull rod is hinged to a cutting rotating base, a cutting rotating rod is further hinged to the cutting rotating base, the other end of the cutting rotating base sleeves a sleeving shaft on a cutting mounting plate on the fabric cutting frame, the other end of the cutting rotating rod is connected to a cutting rotating sleeve, and the cutting rotating sleeve is matched with a cutting lifting motor on the cutting mounting plate. The cutter lifts or descends through the hinged cutter lifting pull rod, the cutting rotating rod and the cutting rotating base, a maximum lifting and descending range is limited, the lifting or descending speed can be slowed down through regulation, and damage to a conveying belt by the cutter is avoided greatly.

Owner:华清(扬州)织物有限公司

Convenient-for-clamping welding rod clamp for rivet welding by lathe worker

InactiveCN106624299AGood clamping effectAvoid burnsElectrode supporting devicesEngineeringBlock match

The invention discloses a convenient-for-clamping welding rod clamp for rivet welding by a lathe worker. The convenient-for-clamping welding rod clamp comprises a baseplate, wherein a first clamping block is fixedly connected with the left side of the upper surface of the baseplate; a limiting plate is fixedly connected with the right side of the upper surface of the baseplate; a threaded hole is formed in the middle of the limiting plate; a snap-in groove is formed in the top of the baseplate, and positioned between the first clamping block and the limiting plate; a second clamping block is arranged at the top of the baseplate; a snap-in block matched with the snap-in groove is fixedly connected with the bottom of the second clamping block, and connected into the snap-in groove in a snap-in manner; and a bearing is fixedly connected with the middle of the side surface, far away from the first clamping block, of the second clamping block. By adoption of the convenient-for-clamping welding rod clamp, a welding rod can be effectively clamped, thereby overcoming the defect that a welding rod needs to be held by a lathe worker in hand for welding, and achieving a good clamping effect; and the length of the convenient-for-clamping welding rod clamp can be adjusted according to the actual demand, thereby effectively protecting the lathe worker from scalding, effectively preventing the welding rod from swinging and twisting, and achieving the high safety performance.

Owner:胡和萍

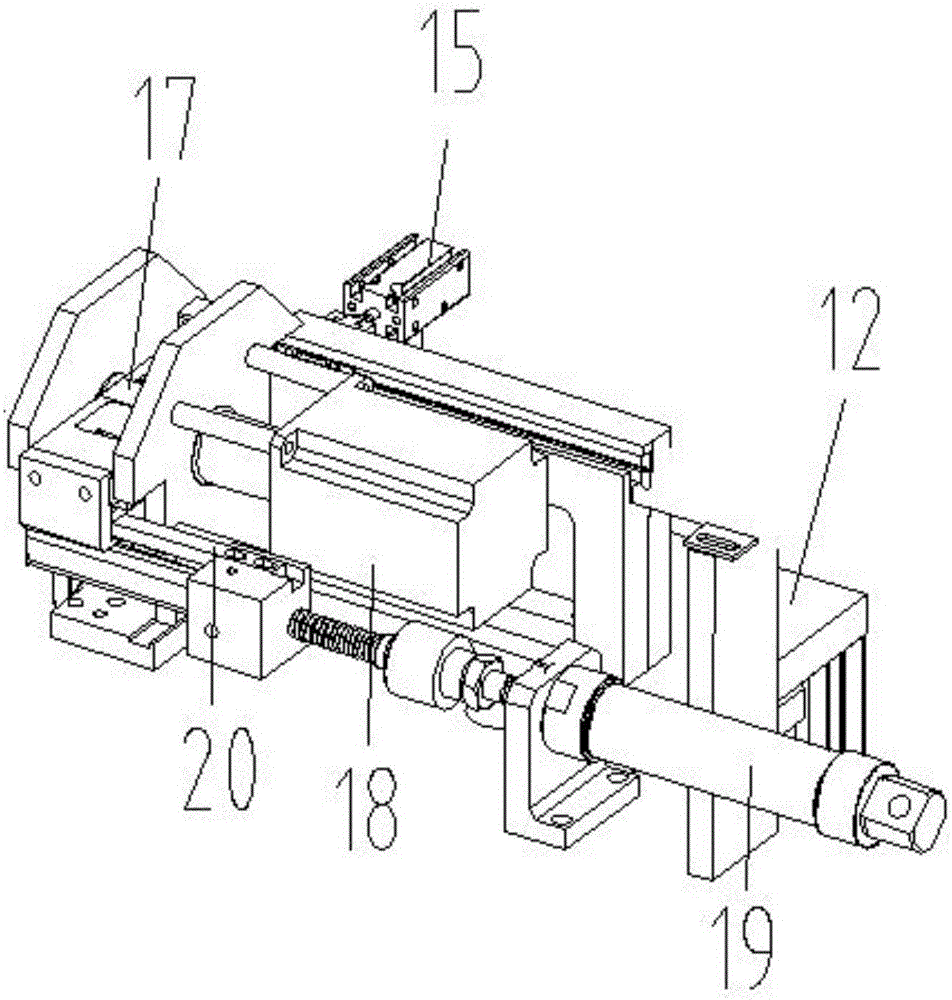

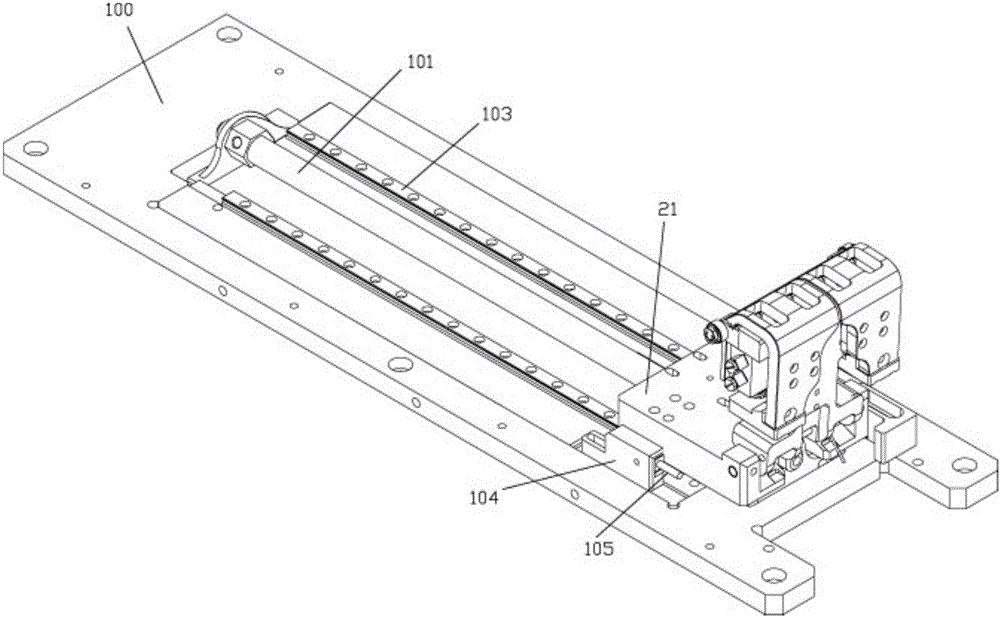

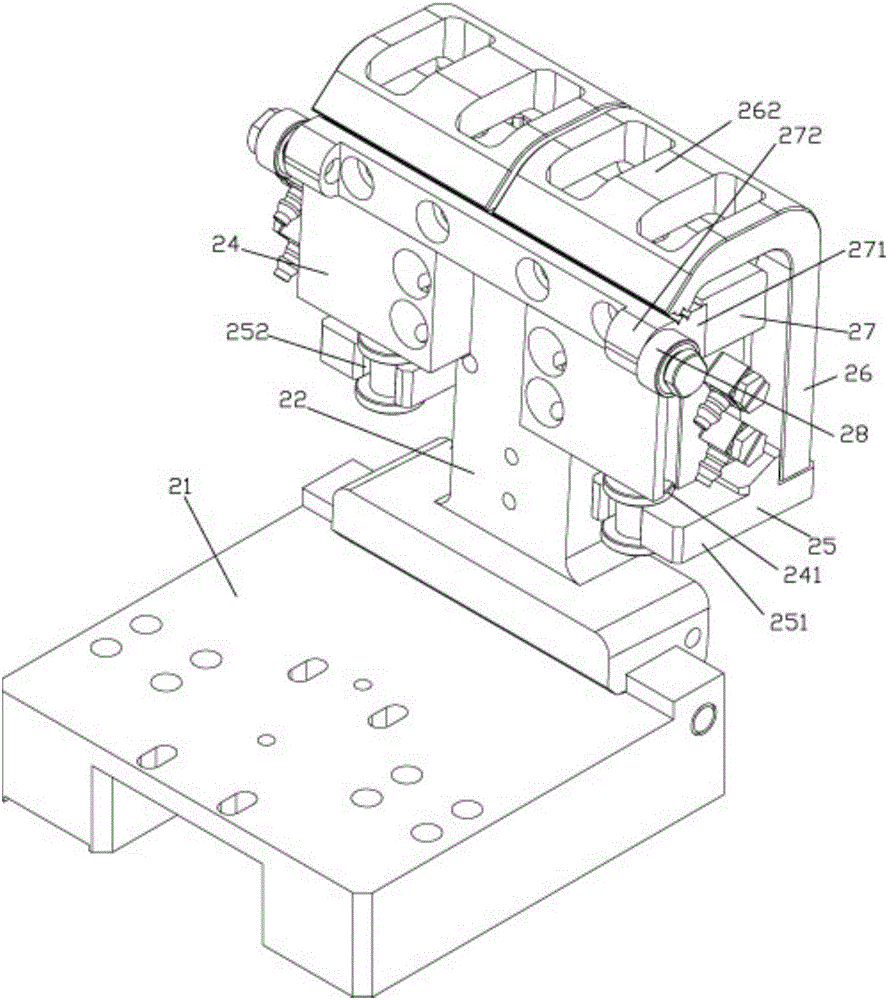

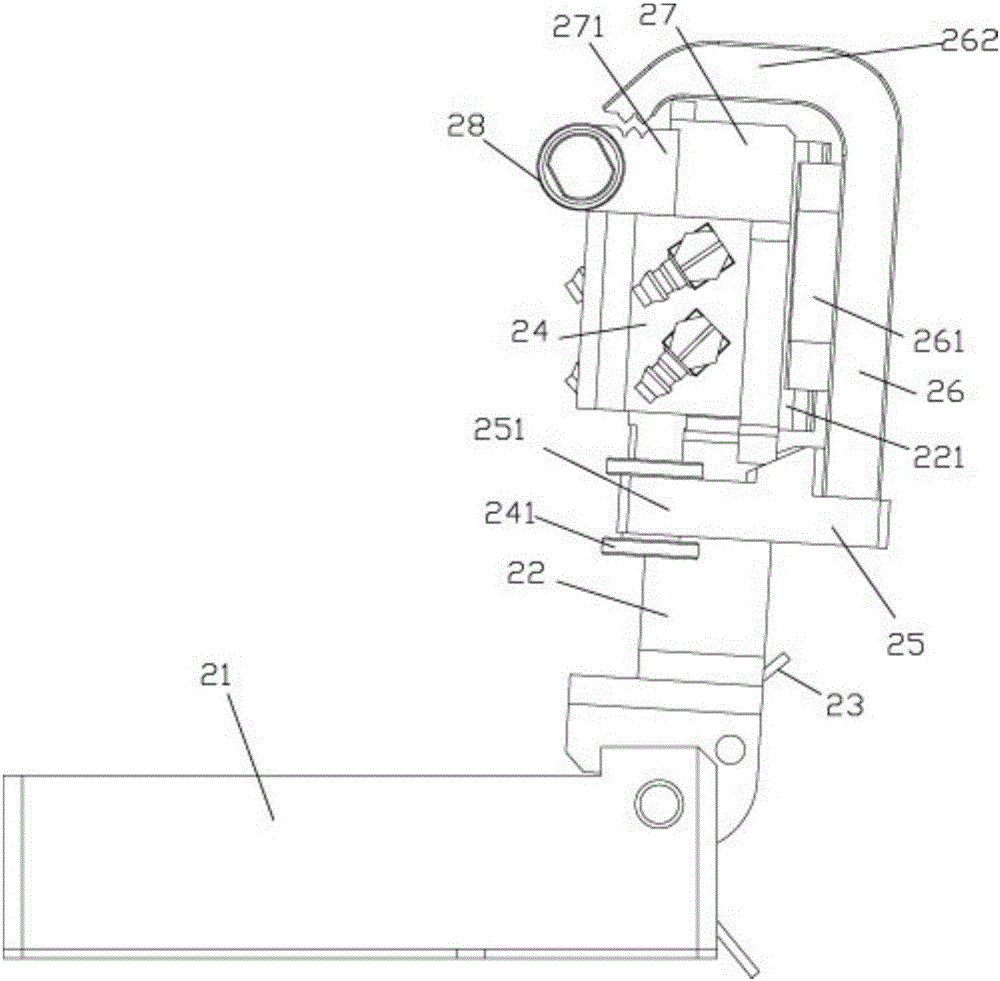

Front clamping jaw conveying mechanism for automatic sheet conveying mechanism

ActiveCN104986549AStable clampingGood clamping effectCharge manipulationConveyor partsMechanical engineeringEngineering

Owner:BOZHON PRECISION IND TECH CO LTD

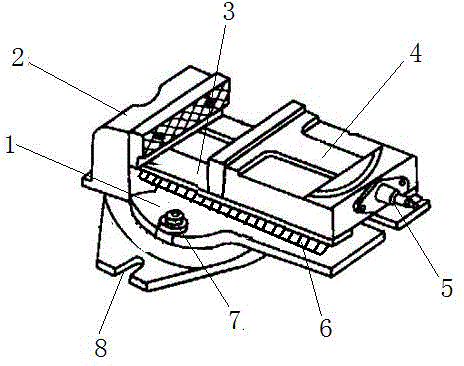

Flat cutting pliers for numerically controlled milling machine

InactiveCN104551783AGood clamping effectSimple structureMeasurement/indication equipmentsPositioning apparatusEngineeringMechanical engineering

The invention discloses a pair of flat cutting pliers for a numerically controlled milling machine. The flat cutting pliers comprise a flat cutting pliers pedestal, wherein a fixed pliers body is arranged on one side of the flat cutting pliers pedestal; a chute is formed in the flat cutting pliers pedestal on one side of the fixed pliers body; a moveable pliers body is arranged on the chute; the moveable pliers body and the fixed pliers body are oppositely arranged; a pushing air cylinder is arranged at the rear end of the moveable pliers body and is used for pushing the moveable pliers body to be close to the fixed pliers body to clamp a workpiece; scale strips are also arranged on the flat cutting pliers pedestal on one side of the chute. According to the flat cutting pliers for a numerically controlled milling machine, the air cylinder automatically pushes the moveable pliers body to clamp the workpiece, so that the clamping effect is good, and time and labor are saved; the width of the clamped workpiece can be directly read; the flat cutting pliers are simple in structure and easy to realize, and has good application prospect.

Owner:滁州用朴合金工具有限公司

Processing table of filtering device for water treatment device

InactiveCN109011801AAchieve clampingGood clamping effectFiltration separationArchitectural engineeringThreaded rod

The invention discloses a processing table of a filtering device for a water treatment device. The processing table comprises a machine table, a filtering device main body is arranged on the top of the machine table, the bottom of the filtering device main body is welded to a discharging hopper, the bottom of the discharging hopper passes through the machine table and extends to outside the bottomof the machine table, the top of the machine table is welded to a sliding rail, the top of the sliding rail is slidingly provided with a vertical plate, the left and right sides of the top of the machine table are welded to fixing plates, the top of the fixing plate is provided with a clamping screw through threads, the top of the vertical plate is welded to a threaded rod, and the top and bottomof the threaded rod are sleeved with clamping plates. Through use of the mechanism easy to clamp, the filtering device main body can be fast clamped and clamping effects are good. Through use of a height adjustment mechanism, the height of the machine table can be adjusted. The whole height adjustment process is convenient and efficient.

Owner:湖州益创环境工程有限公司

Clamping and positioning device for instrument head flanging

InactiveCN107737847AImprove machining accuracyGood clamping effectMetal-working feeding devicesPositioning devicesFlangeSoftware engineering

The invention discloses a clamping and positioning device for the flange of a meter head, which includes a base, a storage device is provided on the base, a shock absorbing device and a moving device are provided on one side of the base, and a shock absorbing device and a moving device are provided on the other side of the base. One side is sequentially installed with a turntable and a workbench from left to right, an annular groove is also provided on the turntable, a limit block is arranged in the annular groove, a slide bar is arranged on one side of the turntable, and the One end of the sliding rod passes through the partition plate and the side wall of the installation shell and is fixedly connected with a pressure plate. The sliding rod is fixedly connected with a movable block, and a sliding groove is arranged in the movable block, and a second sliding groove is arranged in the sliding groove. spring. The present invention improves the processing precision through the interaction of fine adjustment device, coarse adjustment device and wheel device and other structures, and has good clamping effect, simple structure, easy operation, low cost, and is convenient for popularization and use.

Owner:MAANSHAN SHENHUA INSTR

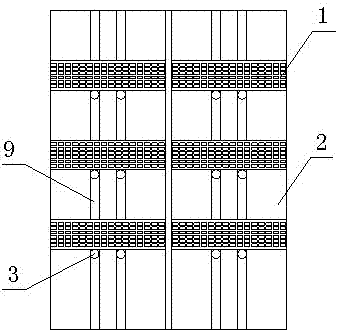

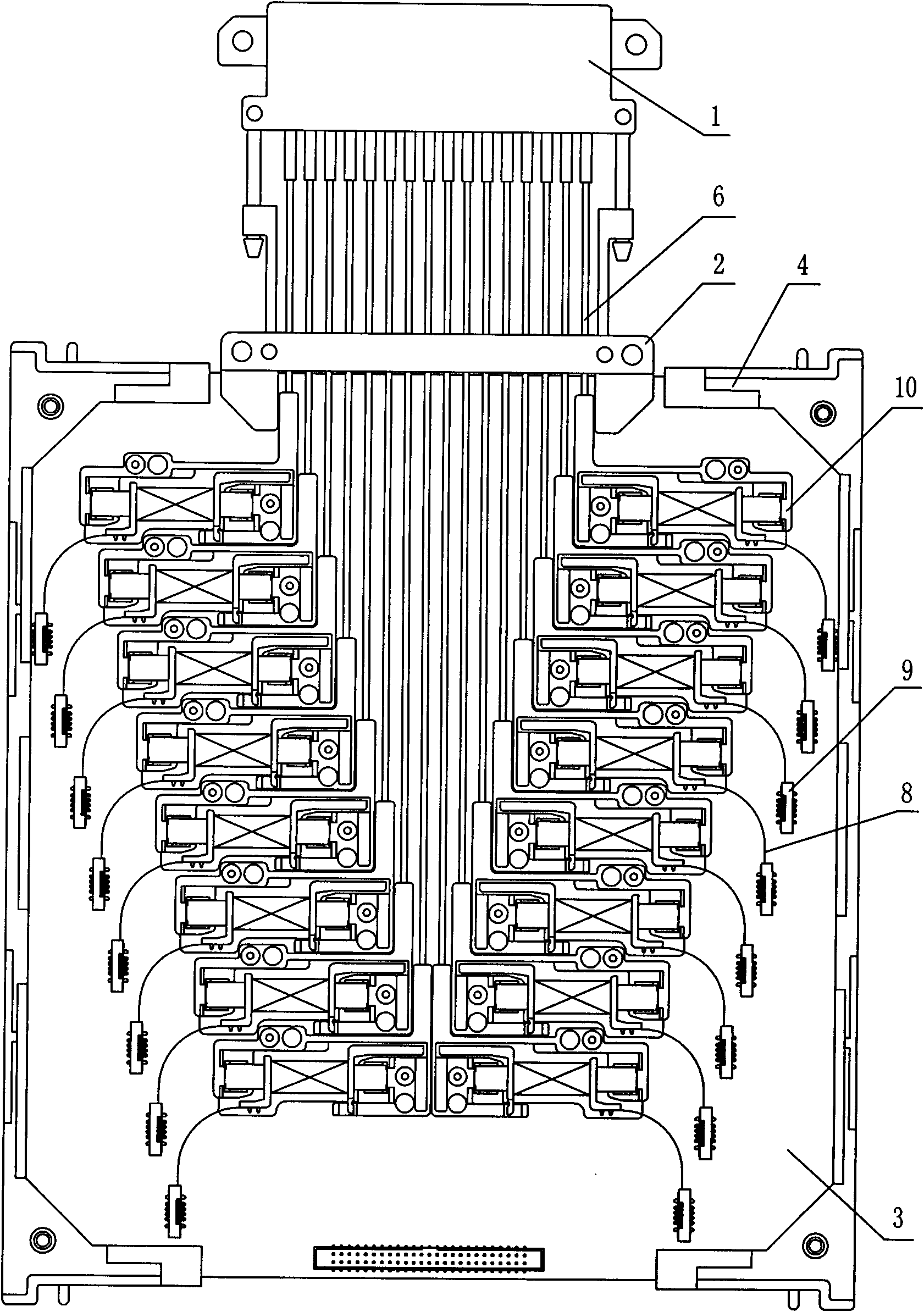

Electronic jacquard card needle-selection drive board

ActiveCN101876117AGood effectEnables detachable connectionsLoomsPattern cardsFlexible circuitsEngineering

The invention discloses an electronic jacquard card needle-selection drive board which comprises a drive circuit board, a bistable needle selection electromagnetic valve, an FPC flexible circuit and at least two fixed pins, wherein an electromagnetic valve fixed seat for the bistable needle selection electromagnetic valve is provided with locating posts; the drive circuit board is provided with locating holes which cooperate with the locating posts; the electromagnetic valve fixed seat is provided with pin holes which cooperate with the fixed pins; the drive circuit board is provided with fixing holes which cooperate with the fixed pins and the pin holes; the electromagnetic valve fixed seat and the drive circuit board are fixed together through the fixed pins; the FPC flexible circuit comprises a flat cable terminal and an FPC connector; the FPC connector is welded on the drive circuit board; and the flat cable terminal cooperates with the slot of the FPC connector. When the bistable needle-selection electromagnetic valve and the FPC flexible circuit on the electronic jacquard card needle-selection drive board go wrong, a customer can conveniently replace bistable needle-selection electromagnetic valve and the FPC flexible circuit, thus the invention saves the cost and does not affect the regular production.

Owner:杭州天迈智能制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com