Front clamping jaw conveying mechanism for automatic sheet conveying mechanism

A technology of automatic feeding and conveying mechanism, applied in the direction of conveyor objects, transportation and packaging, furnaces, etc., can solve the problems of clamping devices without sheet materials, etc., and achieve the effect of firm clamping and good clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

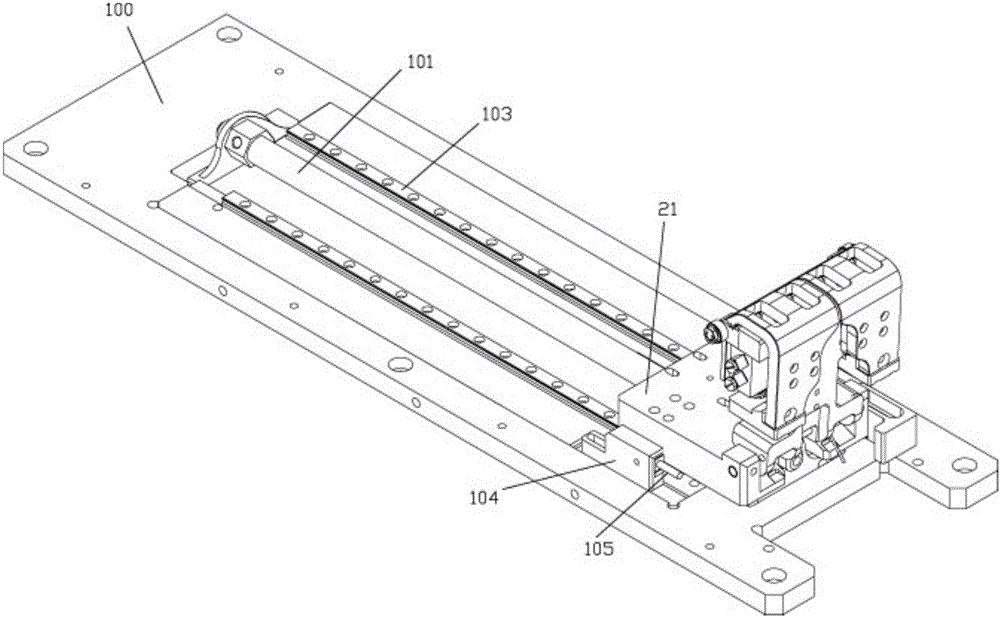

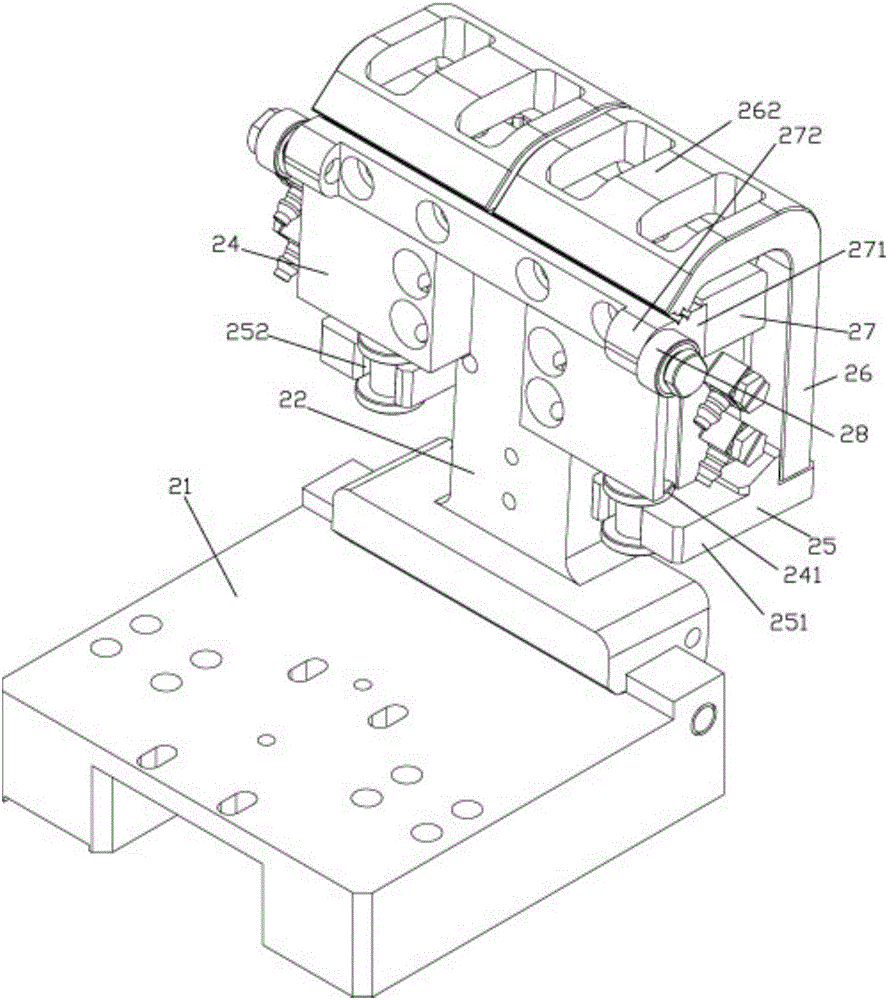

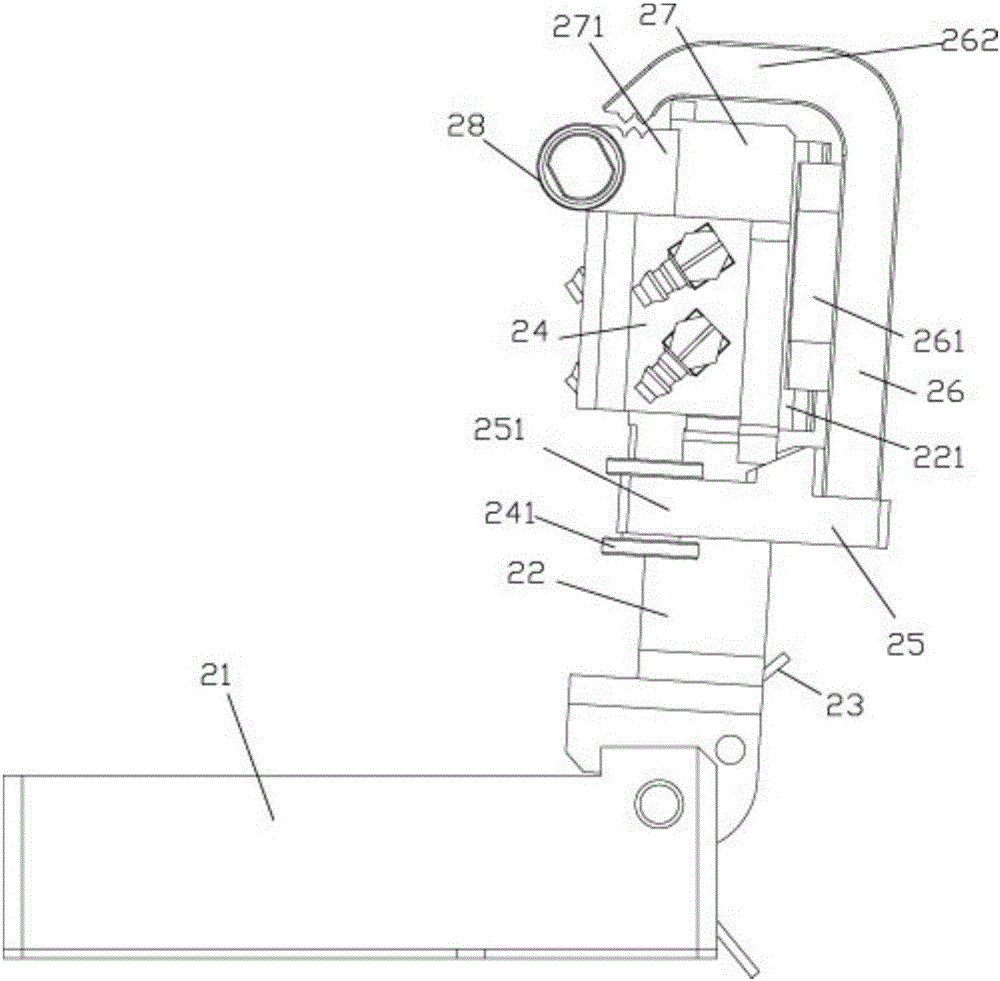

[0013] Examples, see e.g. Figures 1 to 7 As shown, a front jaw conveying mechanism for an automatic sheet material feeding mechanism includes a base plate 100 and a front jaw base 21, a rodless cylinder 101 is fixed in the middle of the base plate 100, and a slider 102 of the rodless cylinder 101 is fixed on There are front jaw bases 21, two sliding rails 103 are fixed on the base plate 100 on both sides of the rodless cylinder 101, and lateral moving blocks 29 are fixed on both sides of the bottom of the front jaw base 21, and the lateral moving blocks 29 are inserted into the sliding on track 103;

[0014] The right end of the front jaw base 21 is hinged with a rotating clamp base 22 through a pin shaft, and a torsion spring 23 is arranged on the pin shaft. One end of the torsion spring 23 is pressed against the rotating clamp base 22, and the other end is pressed against the front jaw base 21. On the front and rear sides of the rotating clamp seat 22, two front jaw cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com