Pressing plate type floating clamp

A technology of floating fixtures and pressure plates, which is applied in clamping, manufacturing tools, workpiece clamping devices, etc., can solve problems such as poor clamping effect of workpieces, substandard workpiece quality, and reduced production efficiency, and increase the rate of workpiece quality compliance , processing stability, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

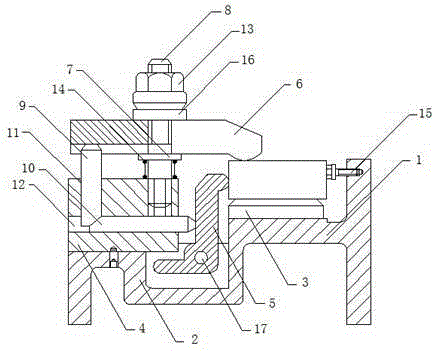

[0013] The reference signs in the drawings of the description include: upper base 1, lower base 2, protrusion 3, positioning block 4, clamping arm 5, pressure plate 6, support plate 7, bolt 8, first ejector rod 9, second Two push rods 10, first hole 11, second hole 12, nut 13, stage clip 14, screw 15, washer 16, bearing pin 17.

[0014] The embodiment is basically as attached figure 1 Shown: Platen type floating fixture, including a fixing mechanism and a clamping mechanism, the fixing mechanism includes a stepped base, a protrusion 3 for clamping the workpiece and a screw 15 for clamping the workpiece, the base includes an upper base 1 and the lower base 2, the protrusion 3 is arranged on the upper base 1, the screw 15 is arranged on the side wall of the upper base 1; the clamping mechanism is arranged on the lower base 2, and the clamping mechanism includes a positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com