Sewage recycling system for concrete stirring station

A technology of sewage recycling and mixing station, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, centrifuged water/sewage treatment, etc. It can solve the problems of natural environment pollution, reduce waste of resources, reduce The effect of production cost, easy installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

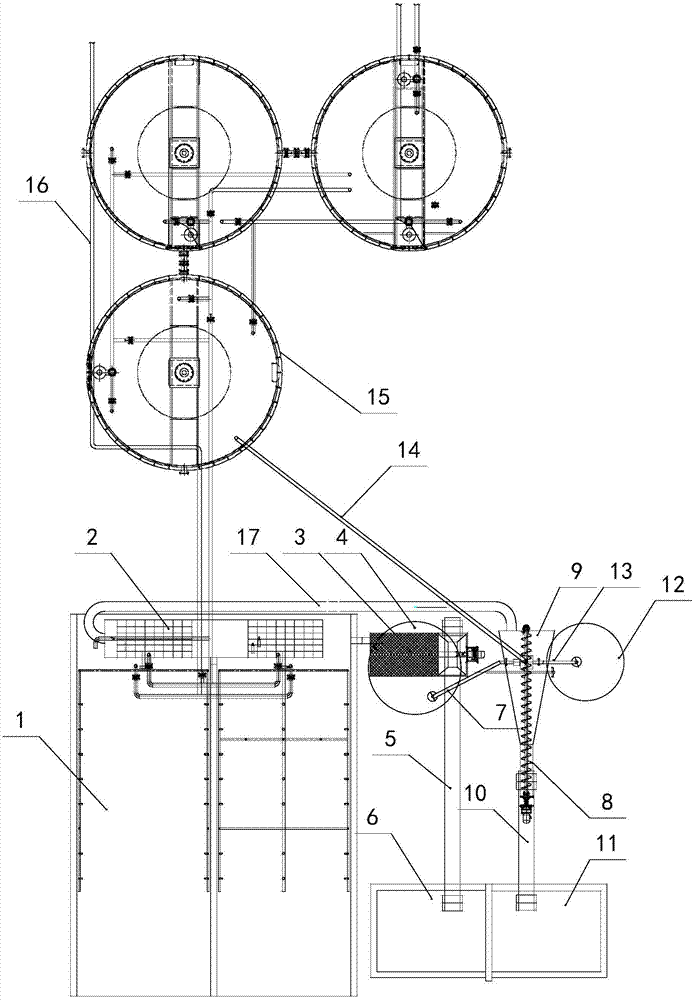

[0013] The sewage recycling system of the concrete mixing plant of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] Such as figure 1 As shown, the sewage recycling system of the concrete mixing plant of the present invention is mainly composed of a sump 2, a sand separator 3, a sand-water separation device 8, a mortar tank 4, a grit chamber 12 and a water storage adjustment tank 15, wherein , the inlet of the sump 2 collects the sewage from the cleaning equipment of the concrete mixing station, and the outlet of the sump 2 is connected to the sand and gravel separator 3. In this embodiment, the entrance of the sump 2 is connected to the car washing point 1 in the mixing station through the sewer . The sand-stone separator 3 is provided with a feed tank connected to the outlet of the water collection tank 2, and a stone outlet and a mortar outlet for outputting large stones and sand-water mixed slurry after separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com