Waste organic glass continuous cracking device

A technology of plexiglass and cracking device, applied in the field of waste plexiglass continuous cracking device, can solve the problems of waste of cracking resources, high production cost, easy to cause accidents, etc., and achieve the effect of simple overall structure, control of production cost, and improvement of safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

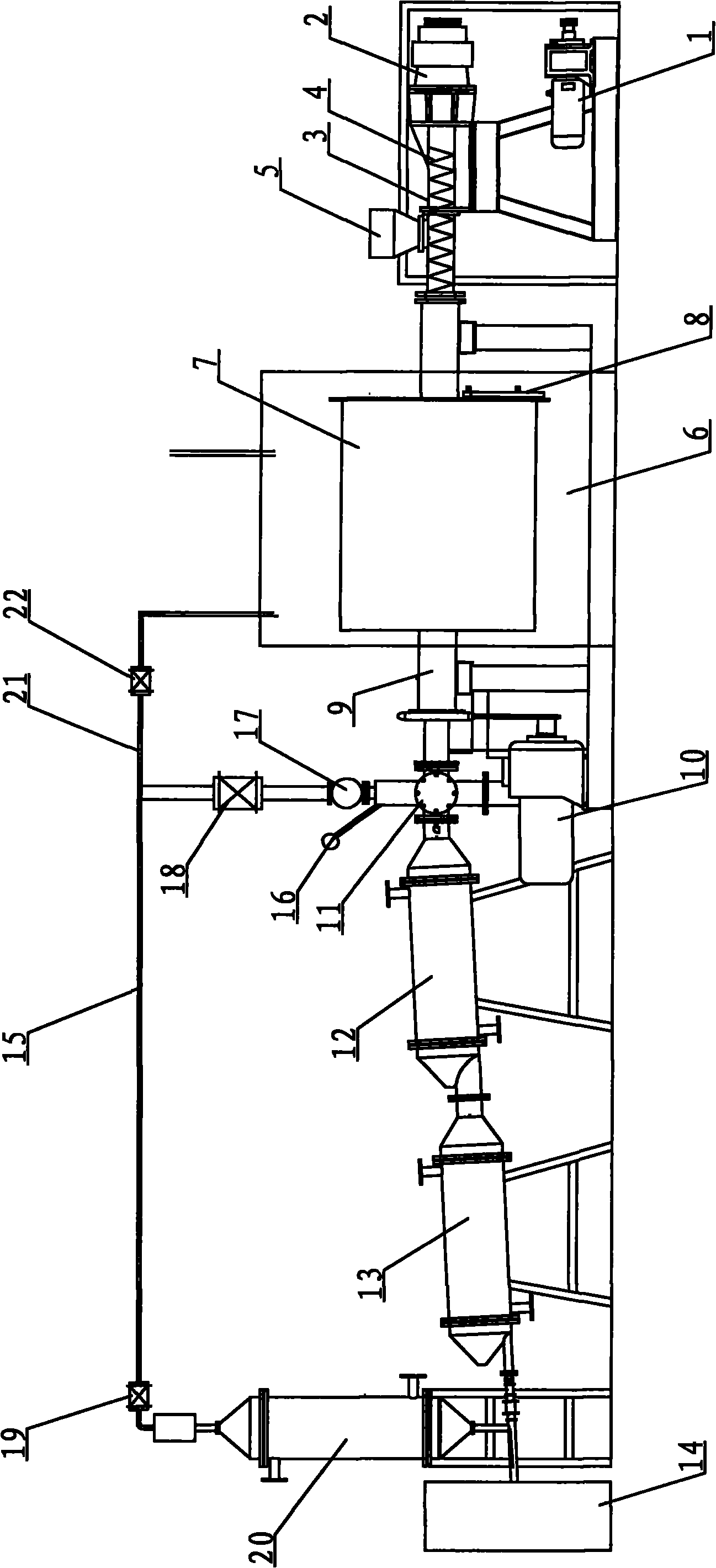

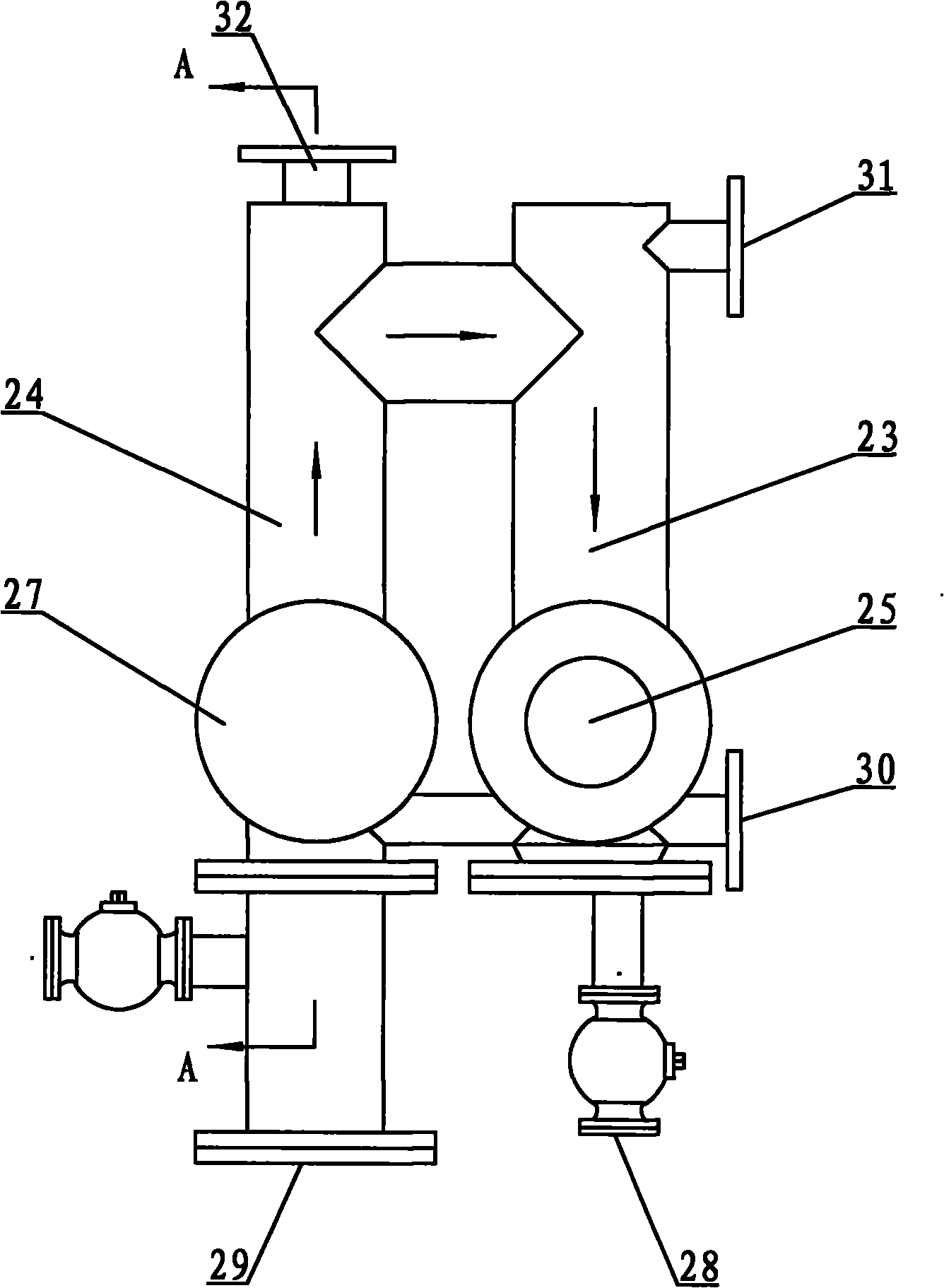

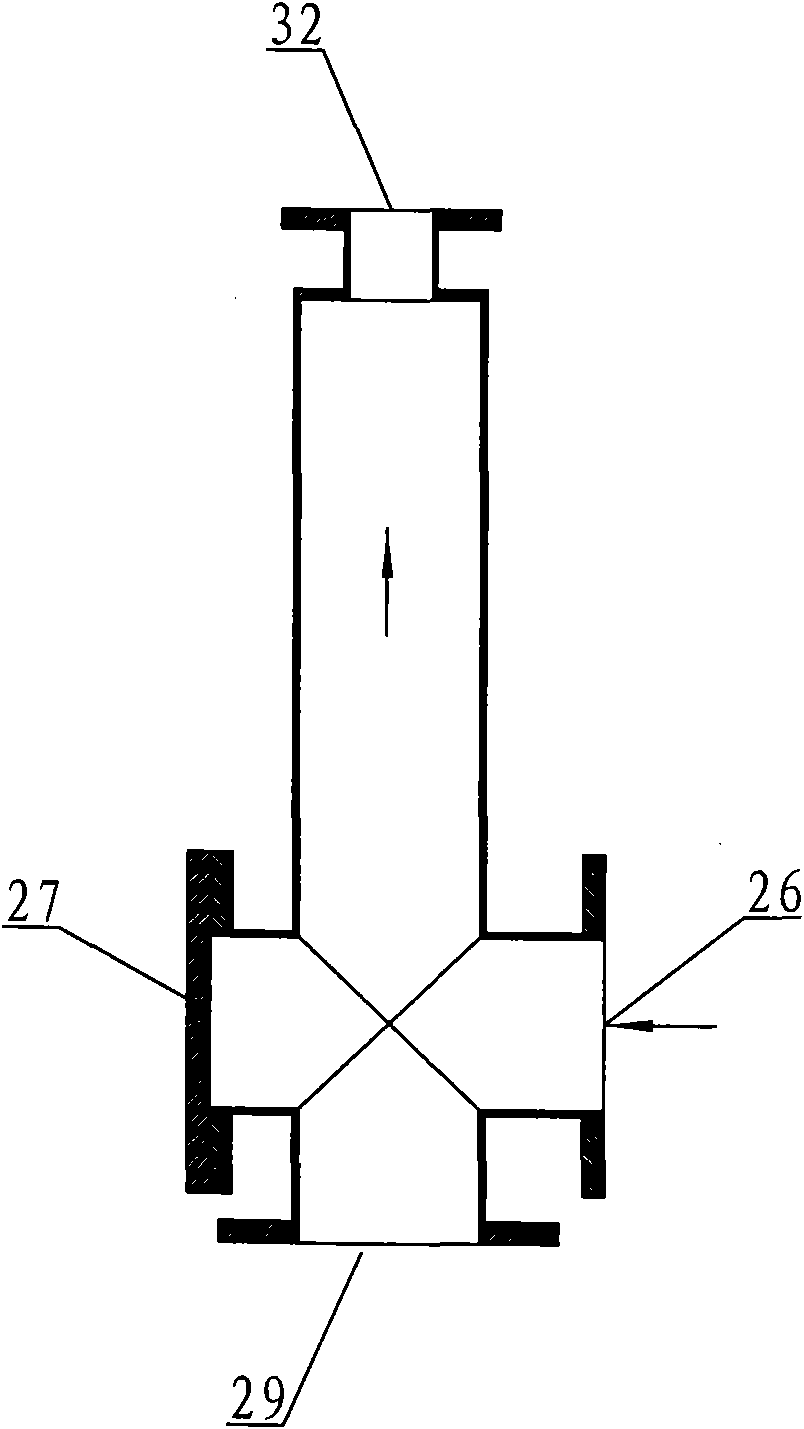

[0014] figure 1 The waste plexiglass continuous cracking device shown mainly includes a feeding device, a melting furnace and a storage tank 14 . The feeding device includes a hopper 5, a feeding pipe 3, a feeding screw 4, a reducer 2 and a feeding motor 1, one end of the feeding pipe 3 is provided with a reducer 2 connected to the feeding motor 1, and the other end of the feeding pipe 3 is connected to In a hot melting furnace, a feeding screw 4 is arranged in the feeding pipe 3, and the feeding screw 4 is connected to the reducer 2, and the feeding pipe 3 is provided with a hopper 5 located above the feeding screw 4; the hot melting furnace includes a furnace body 7, a rotating motor 10 and the incineration chamber 6, the side of the furnace body 7 is provided with a slag outlet 8, the furnace body 7 is placed in the incineration chamber 6, one end of the furnace bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com