Patents

Literature

98results about How to "Low electronic conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Battery and process for preparing the same

InactiveUS20010005562A1Supplement low electronic conductivityLow electronic conductivityPrimary cell maintainance/servicingElectrode carriers/collectorsElectrical resistance and conductanceConductive materials

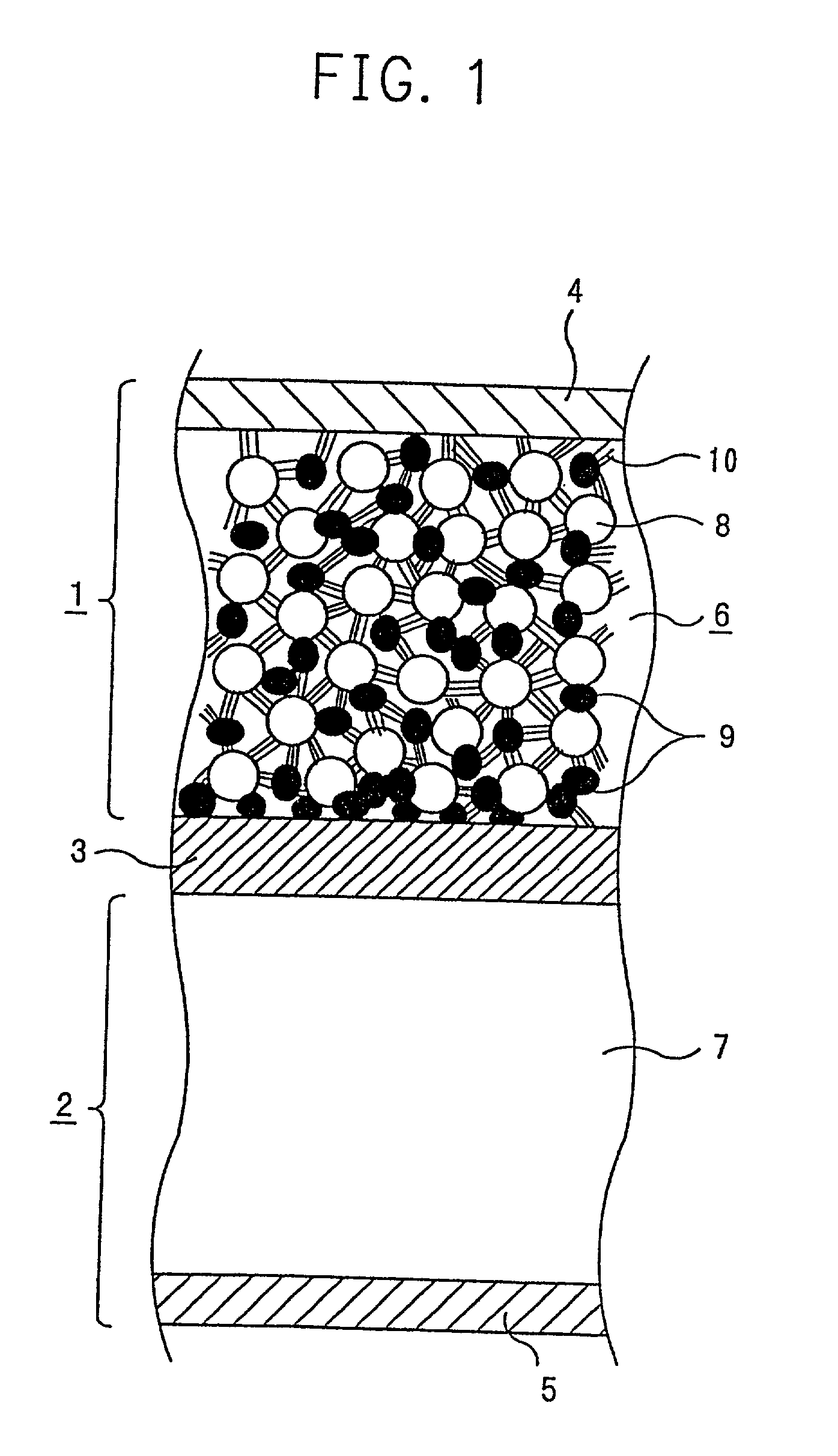

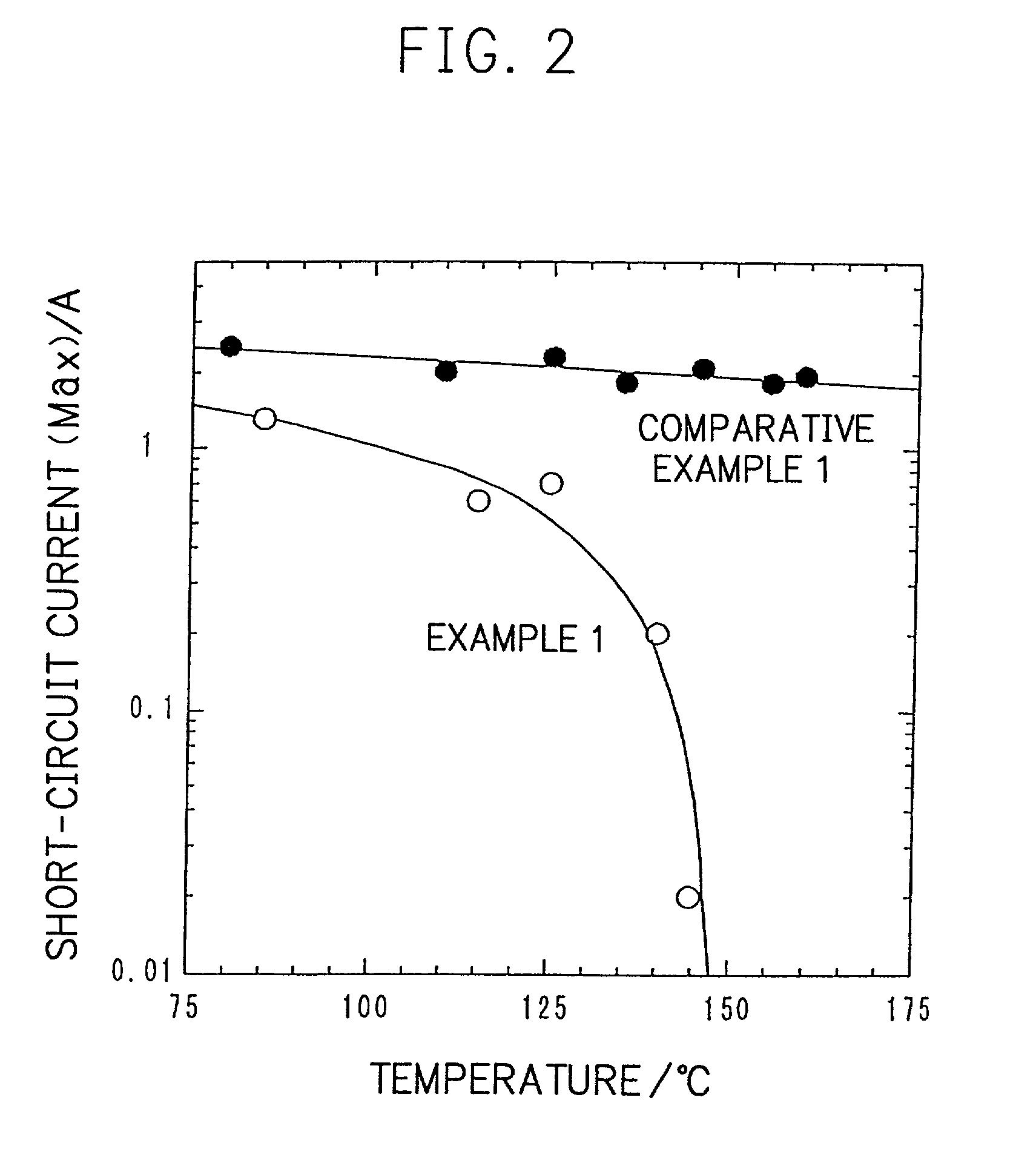

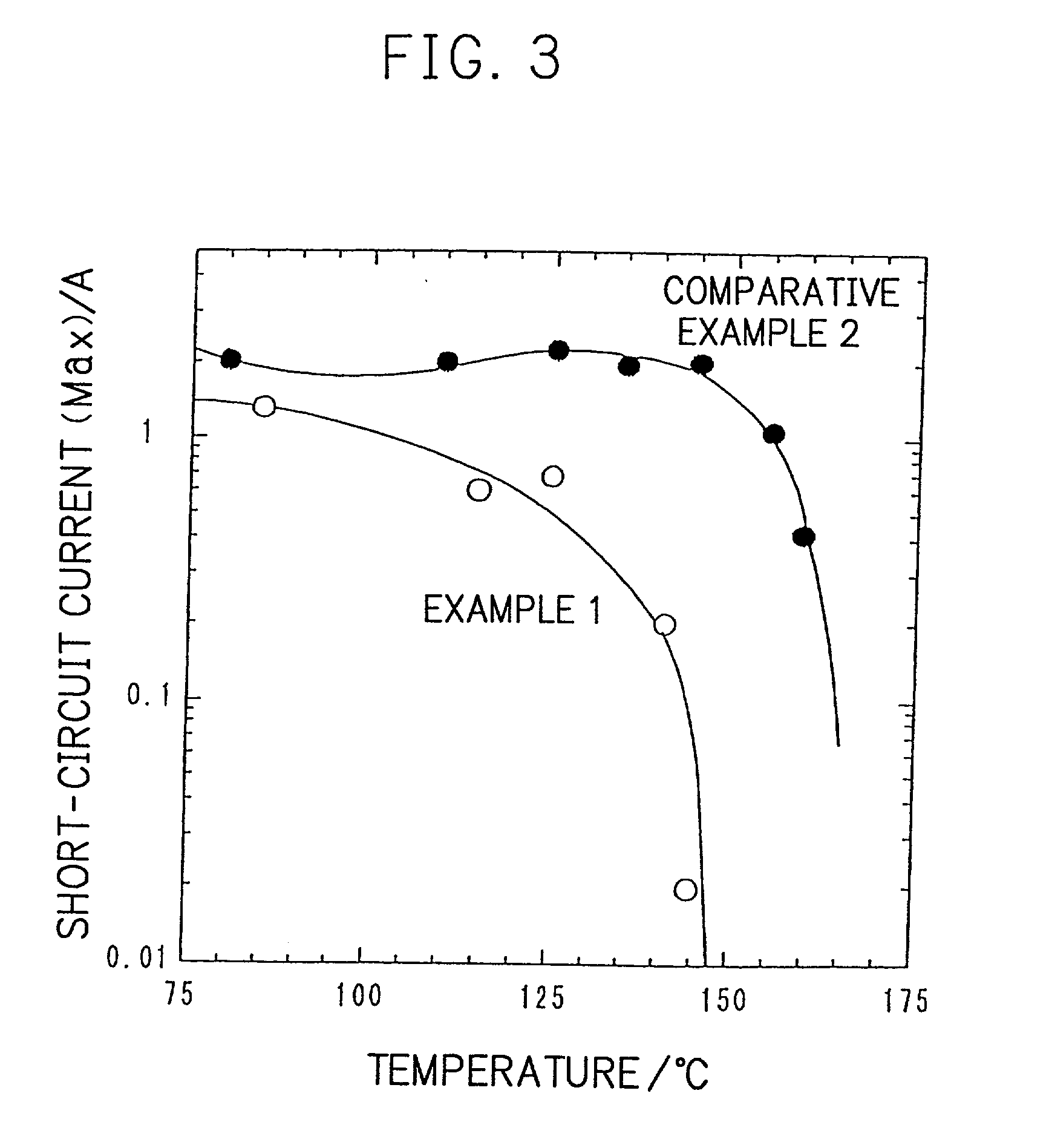

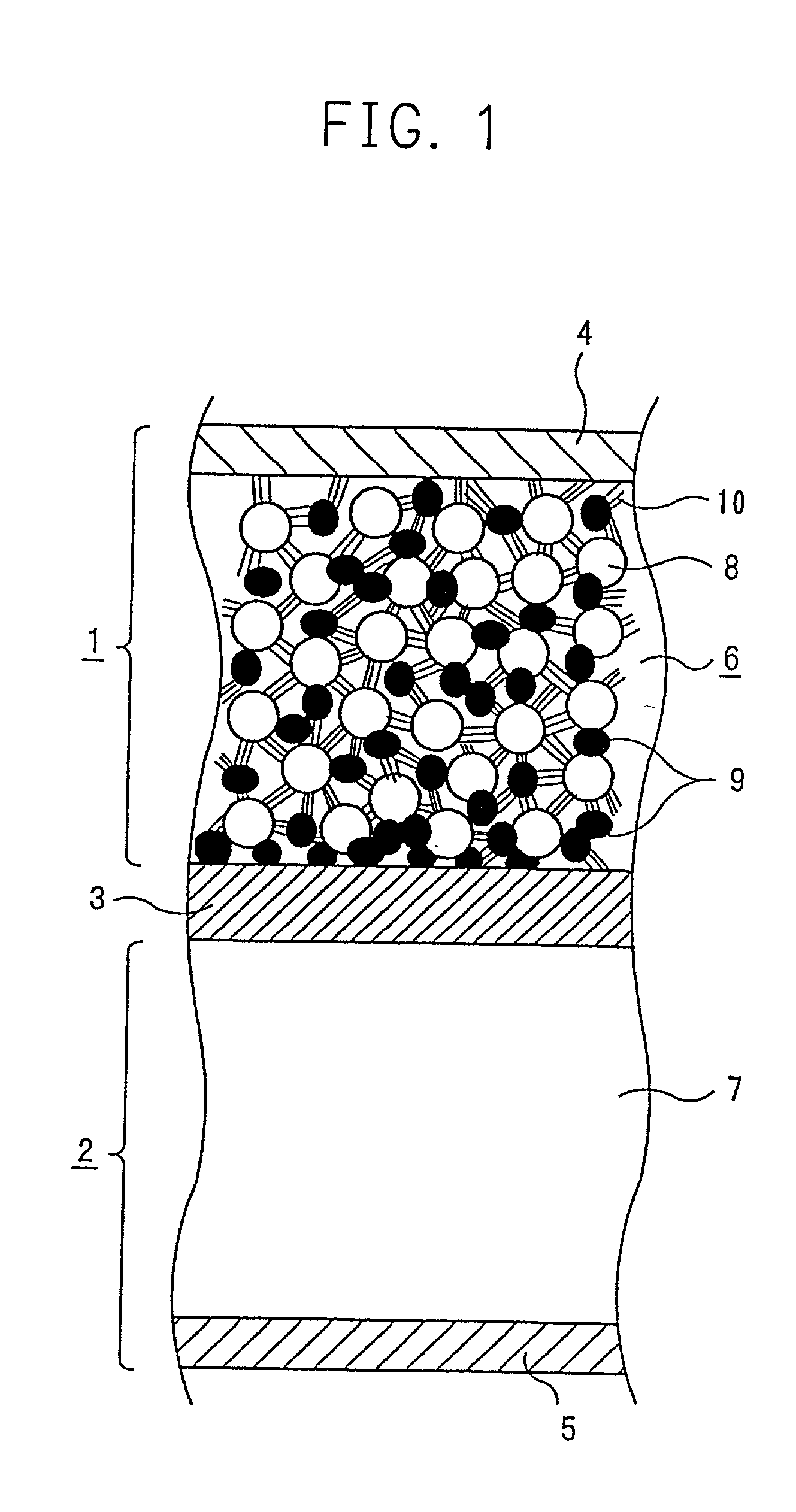

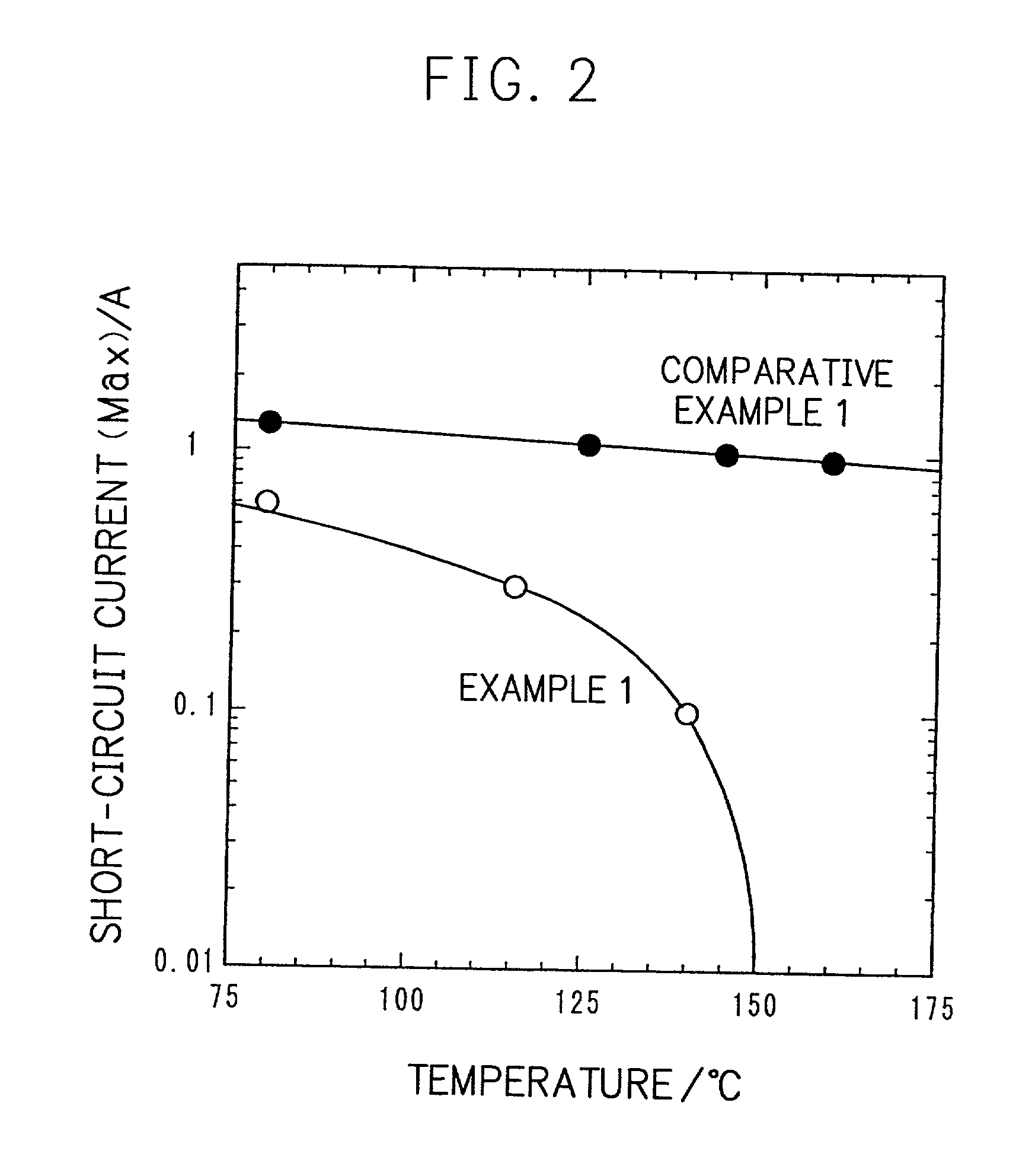

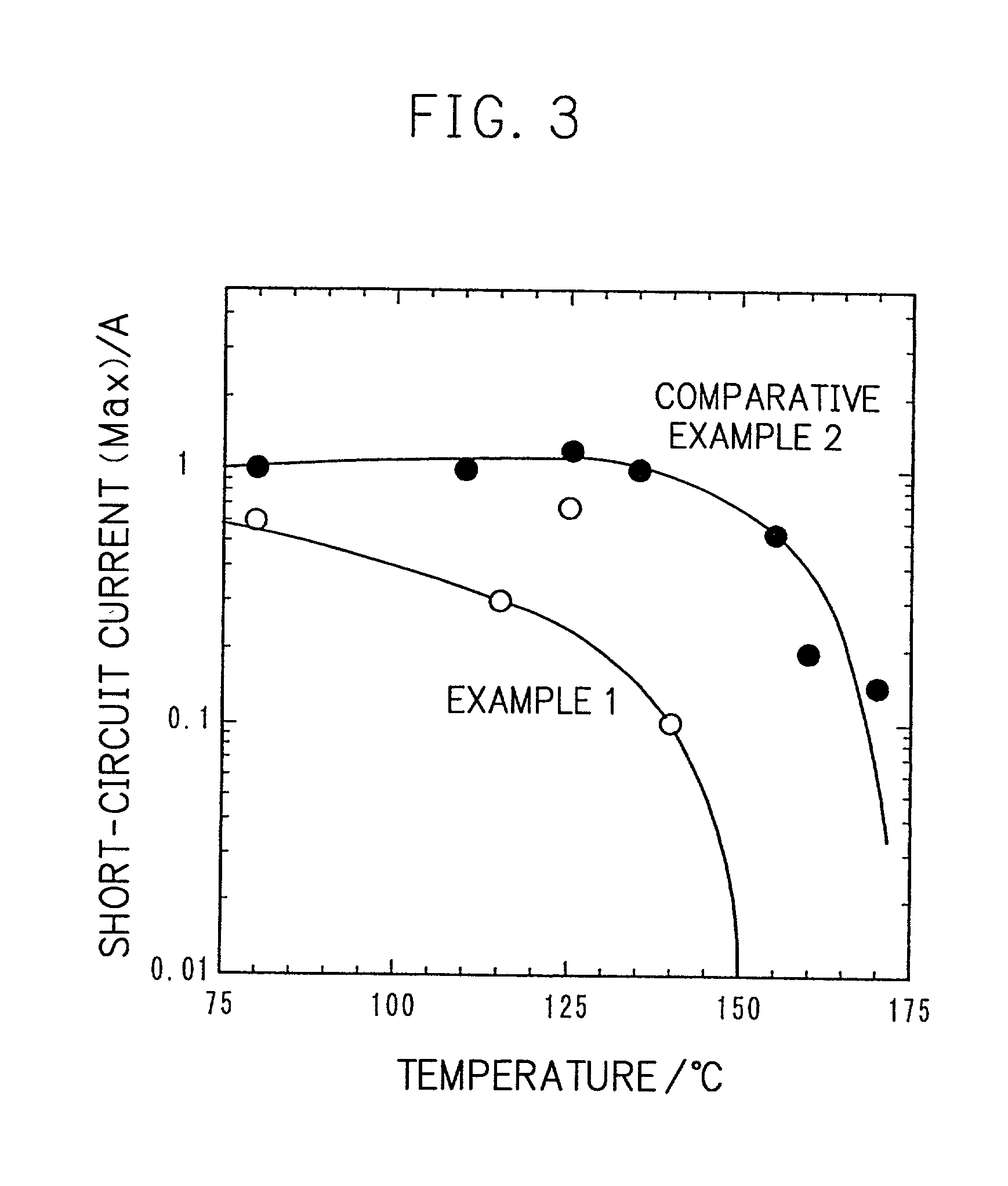

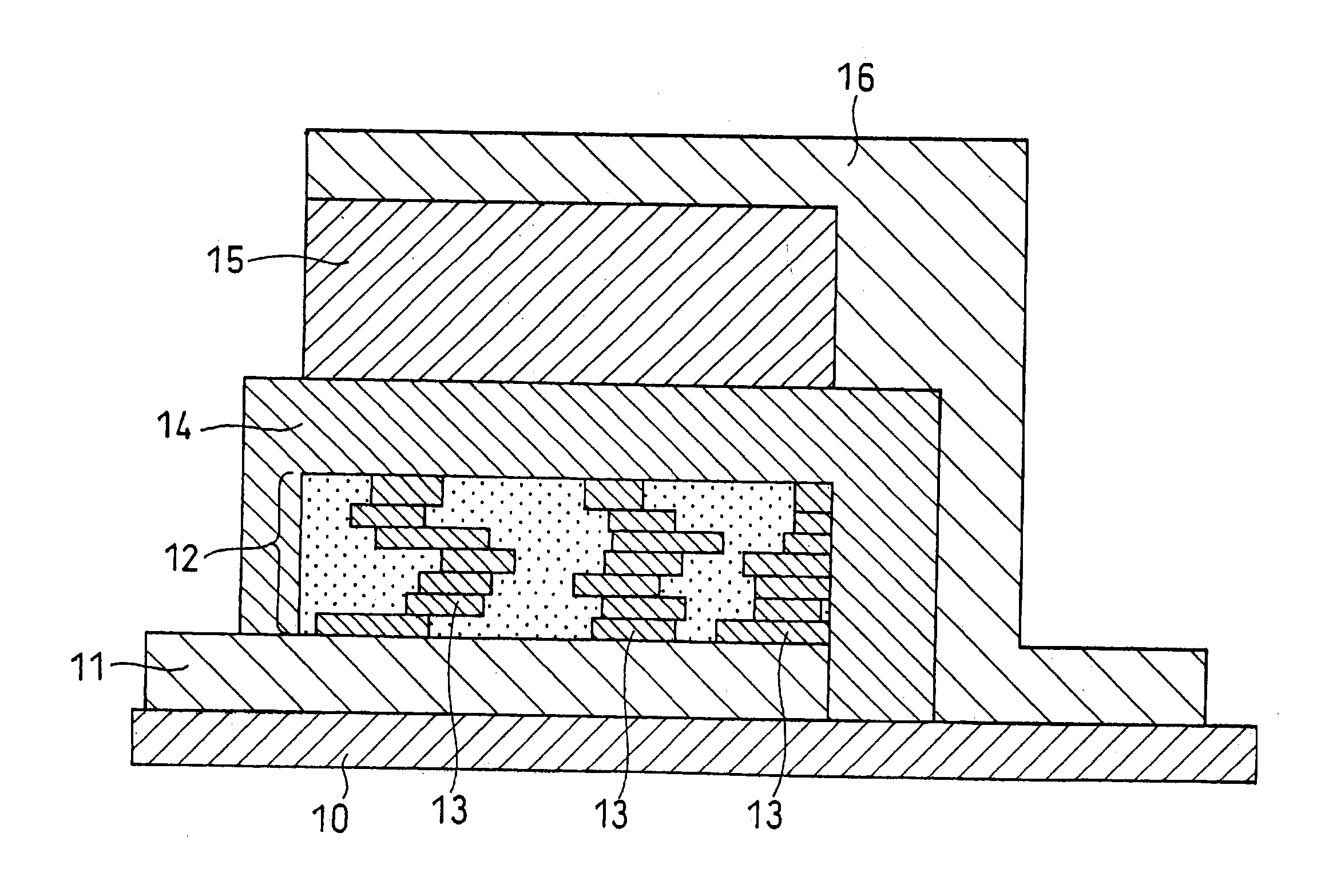

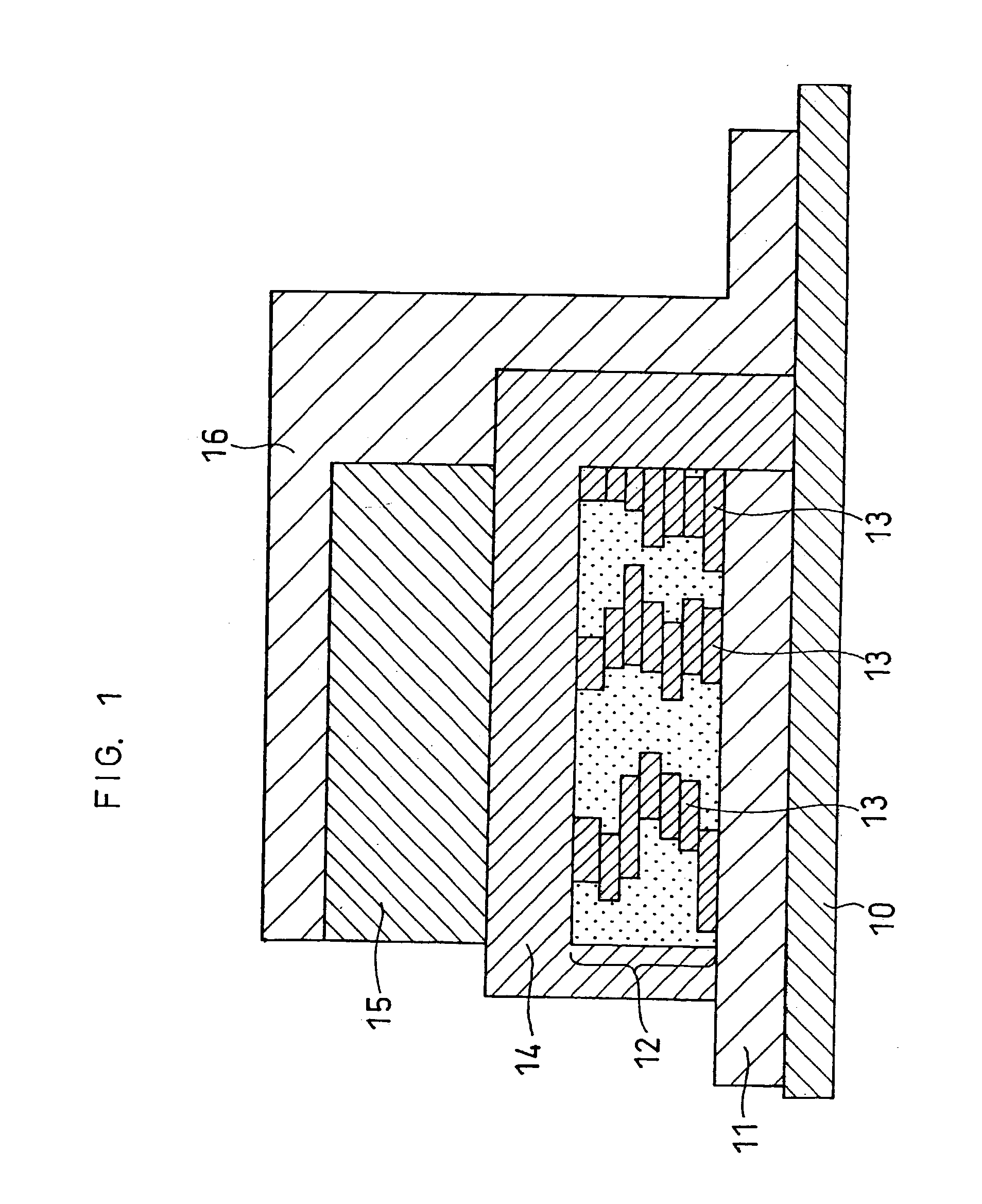

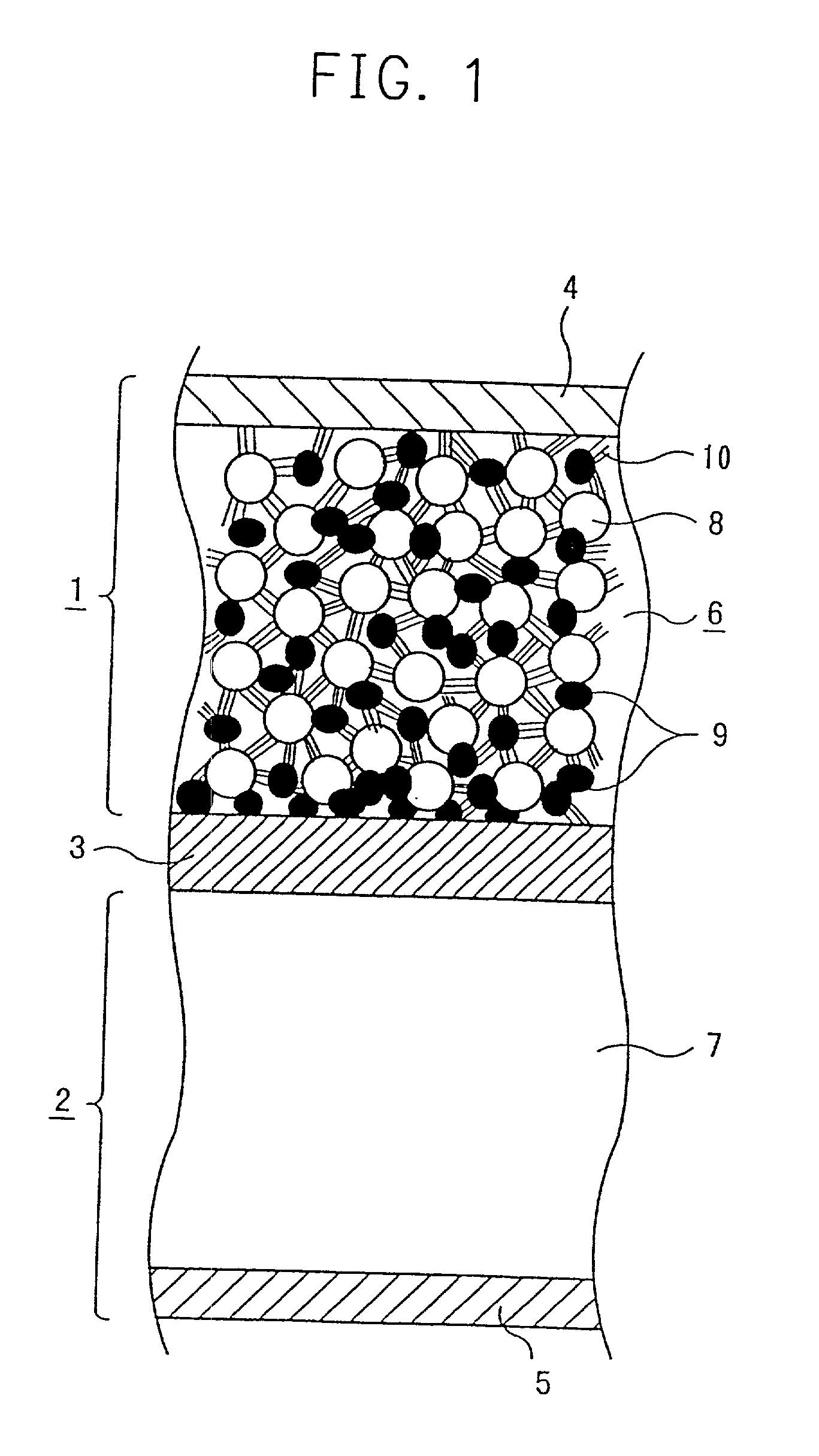

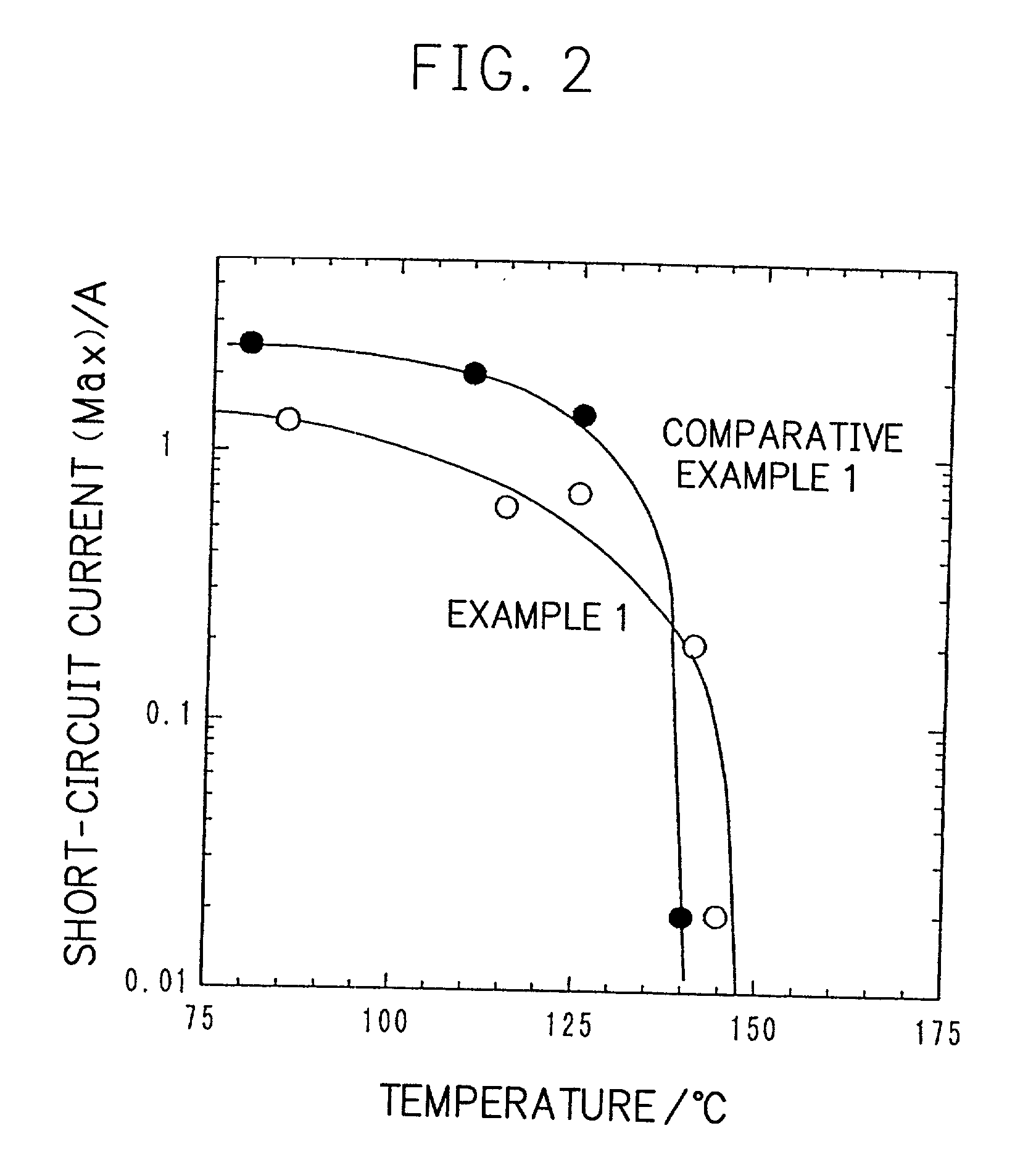

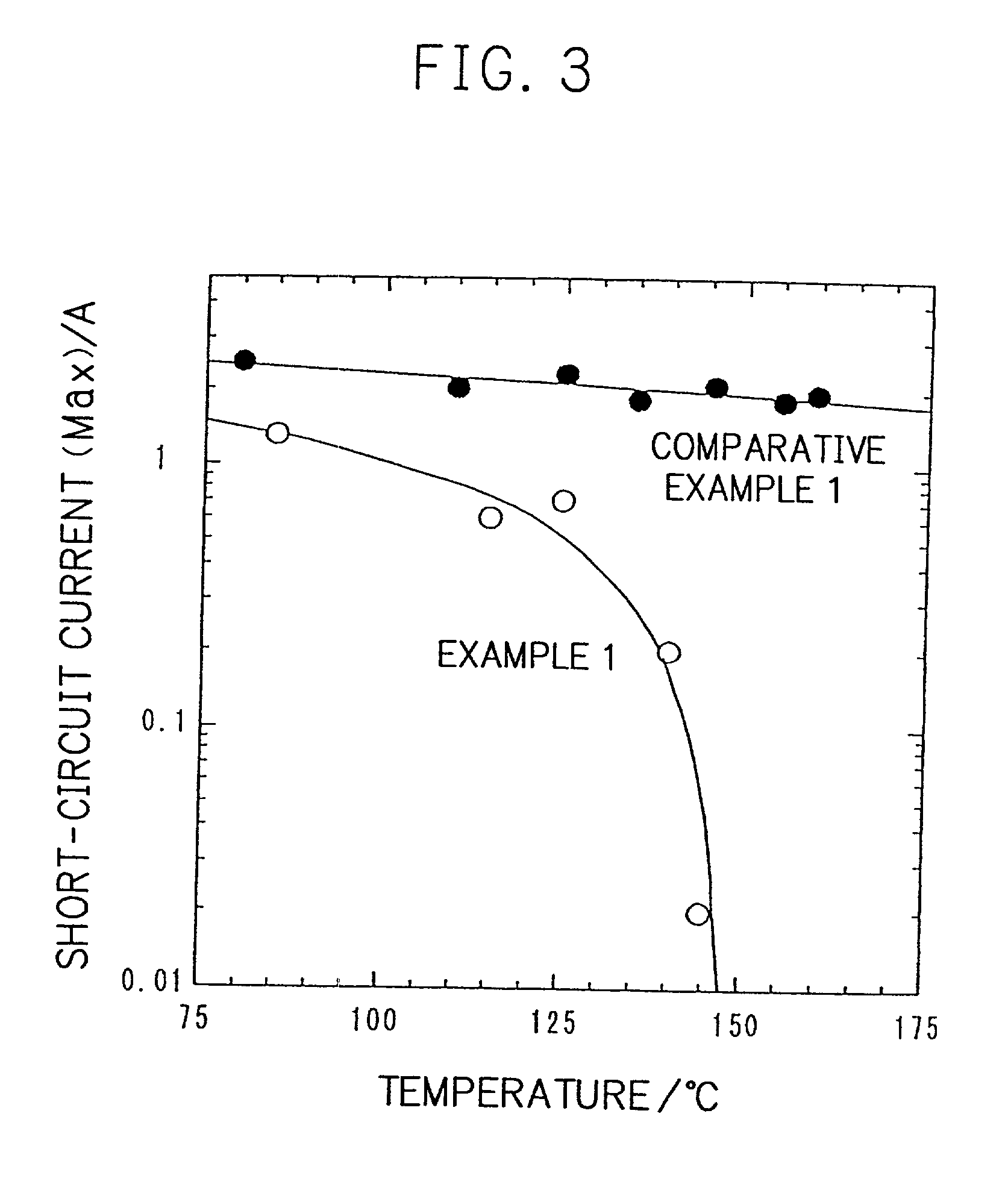

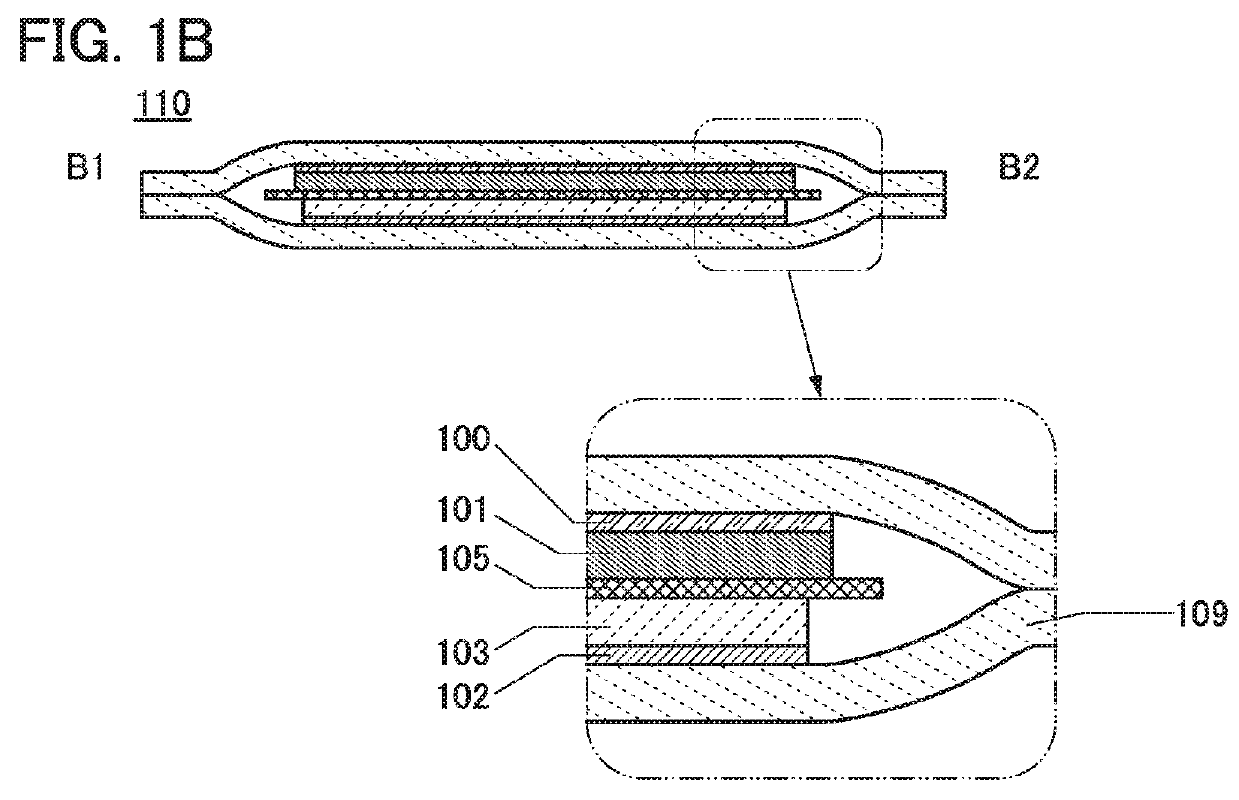

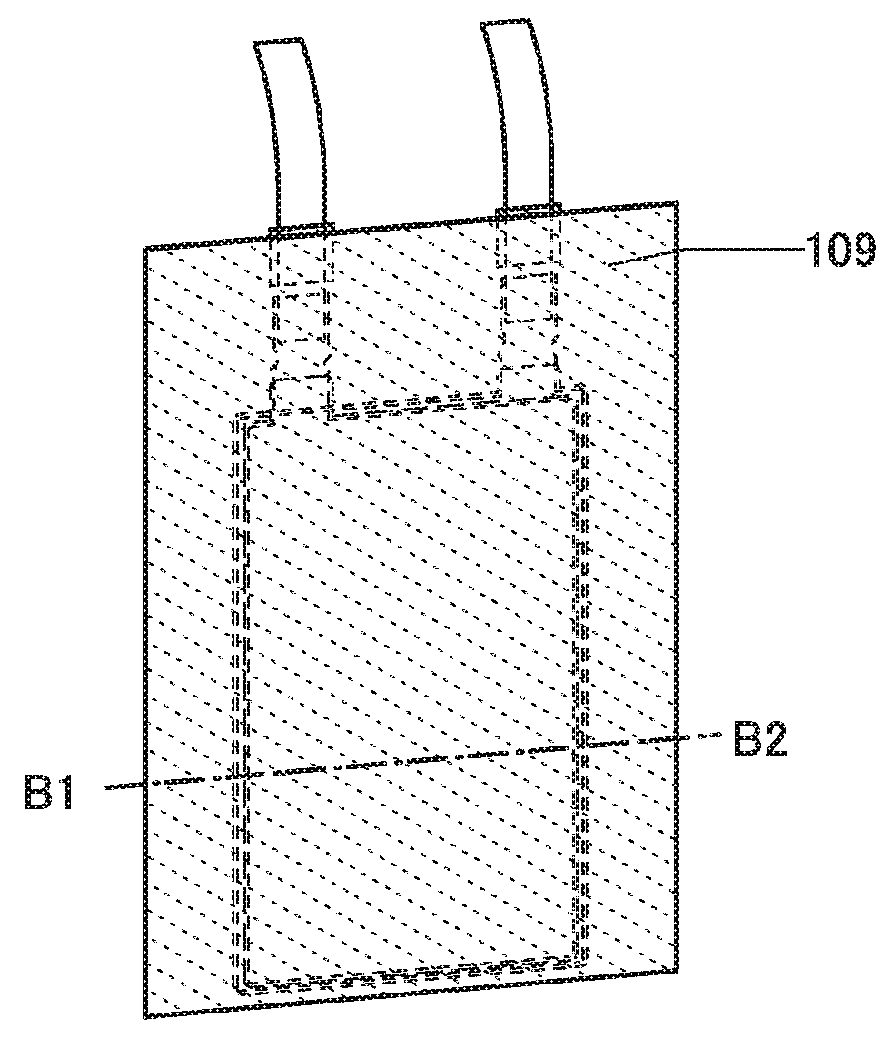

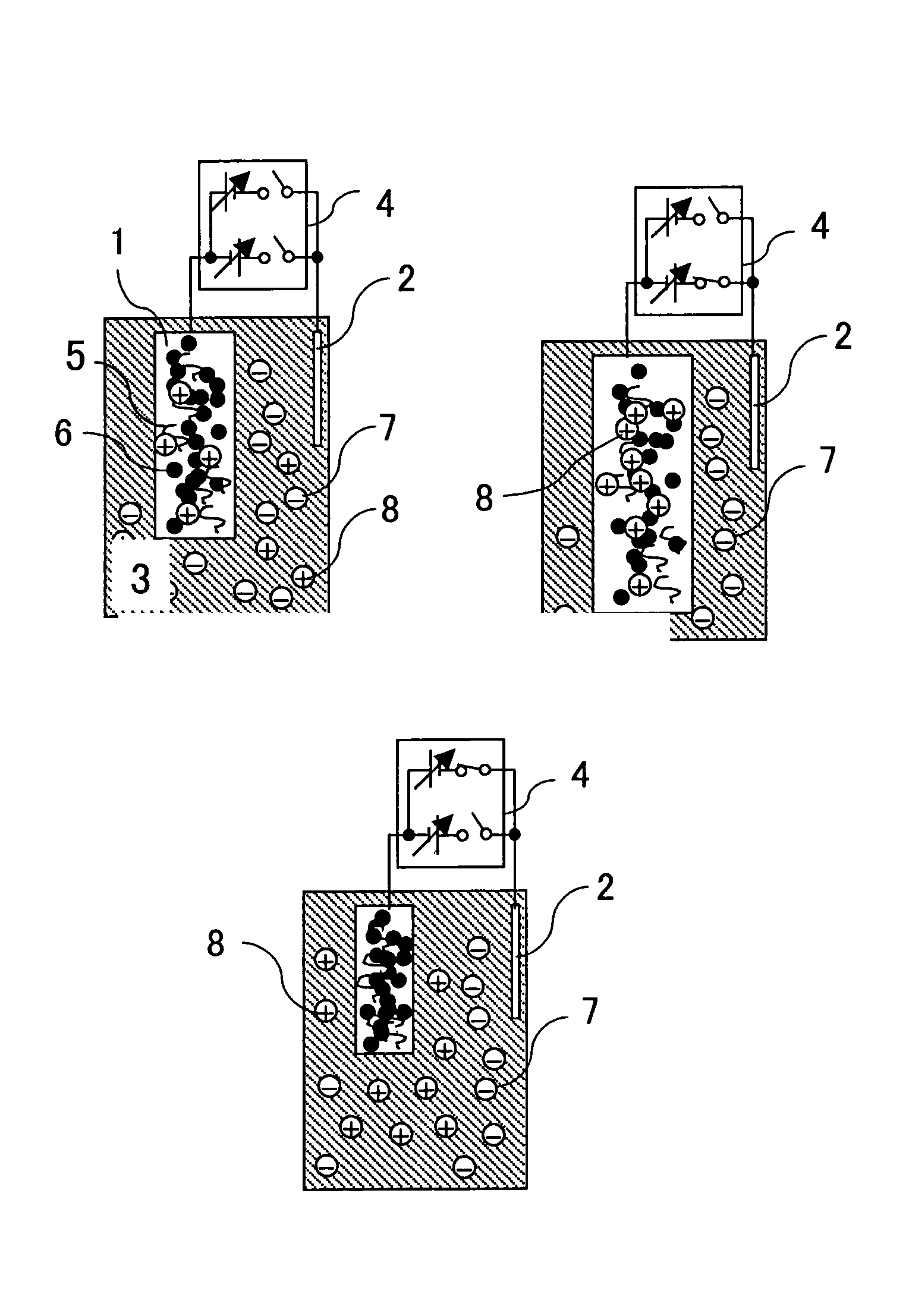

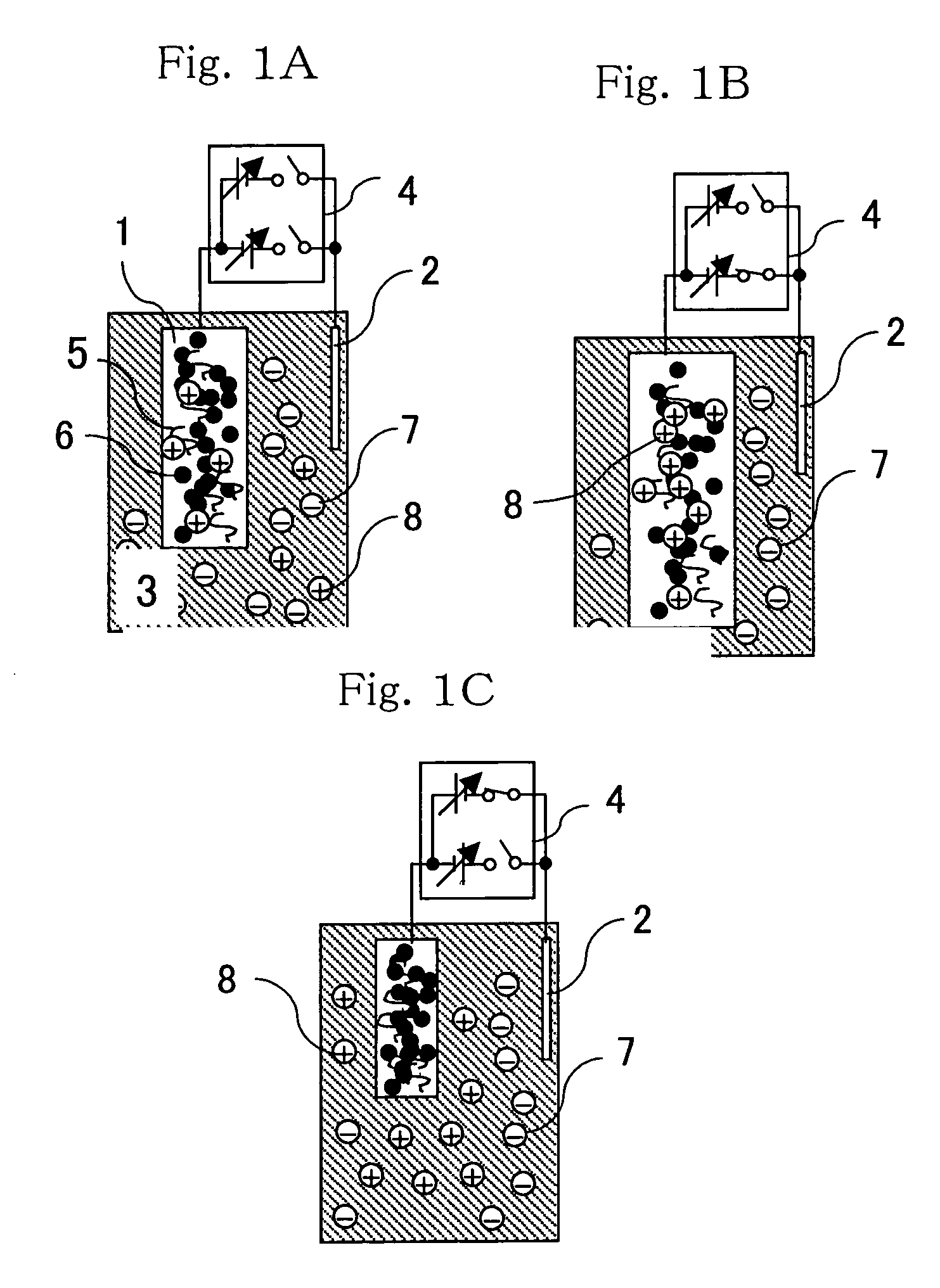

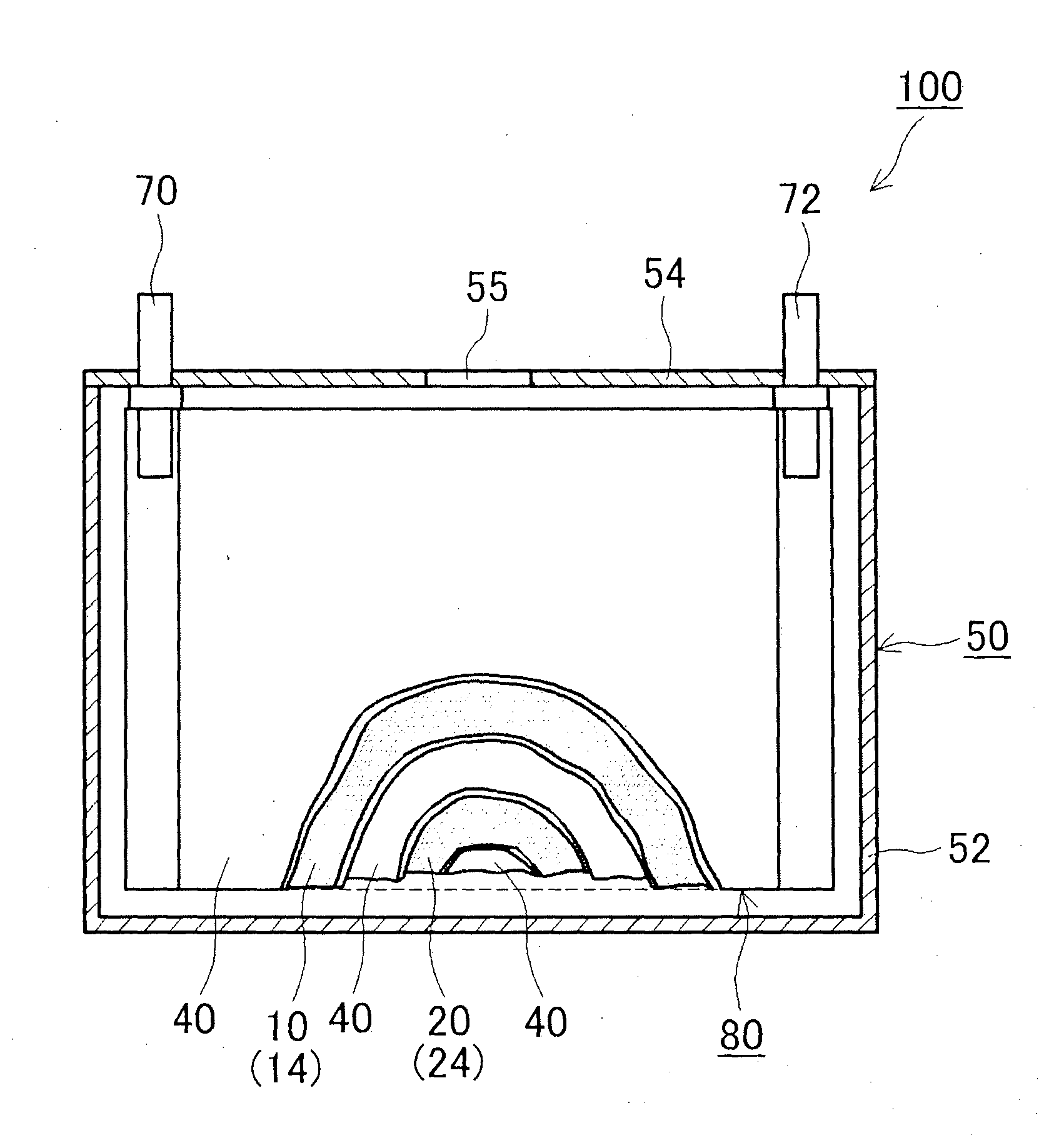

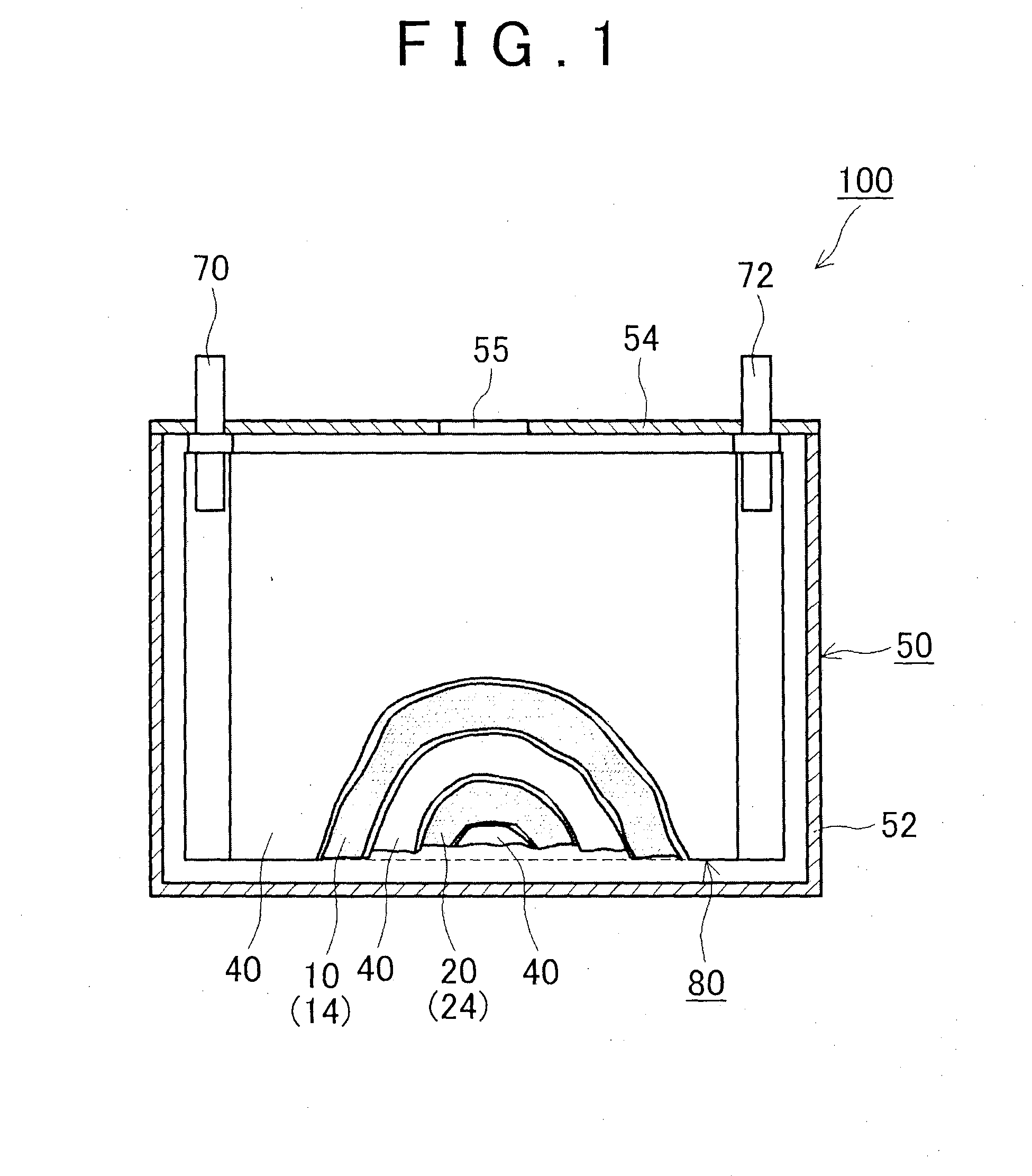

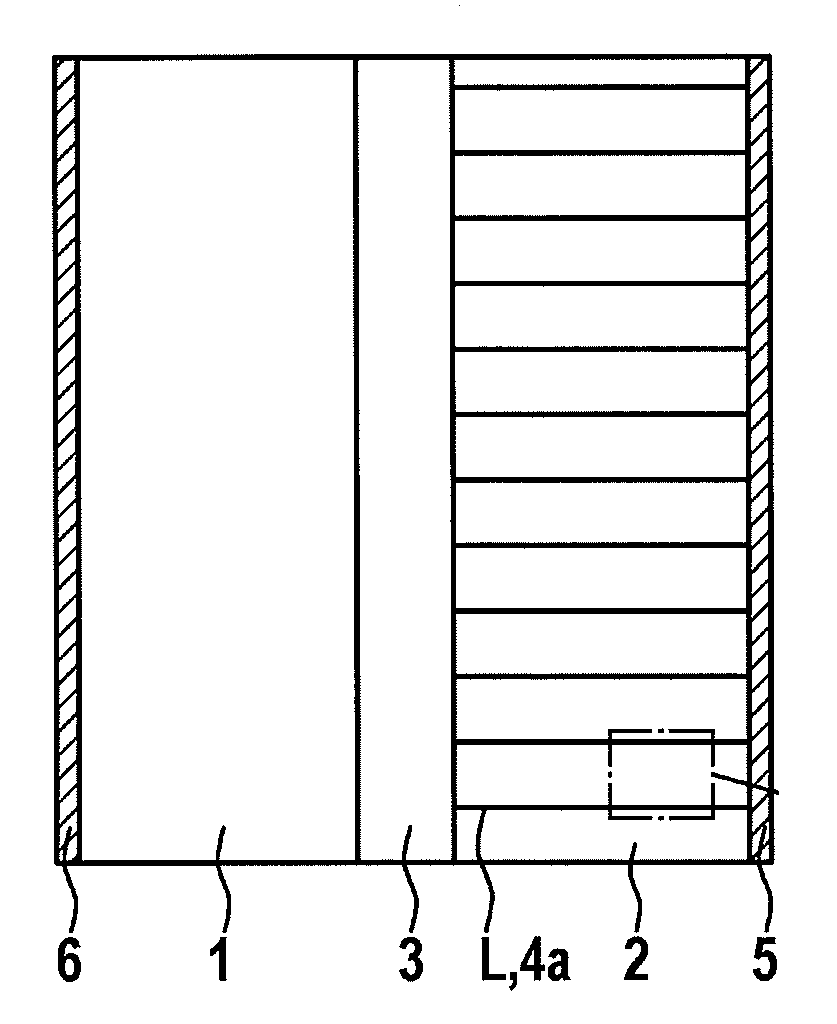

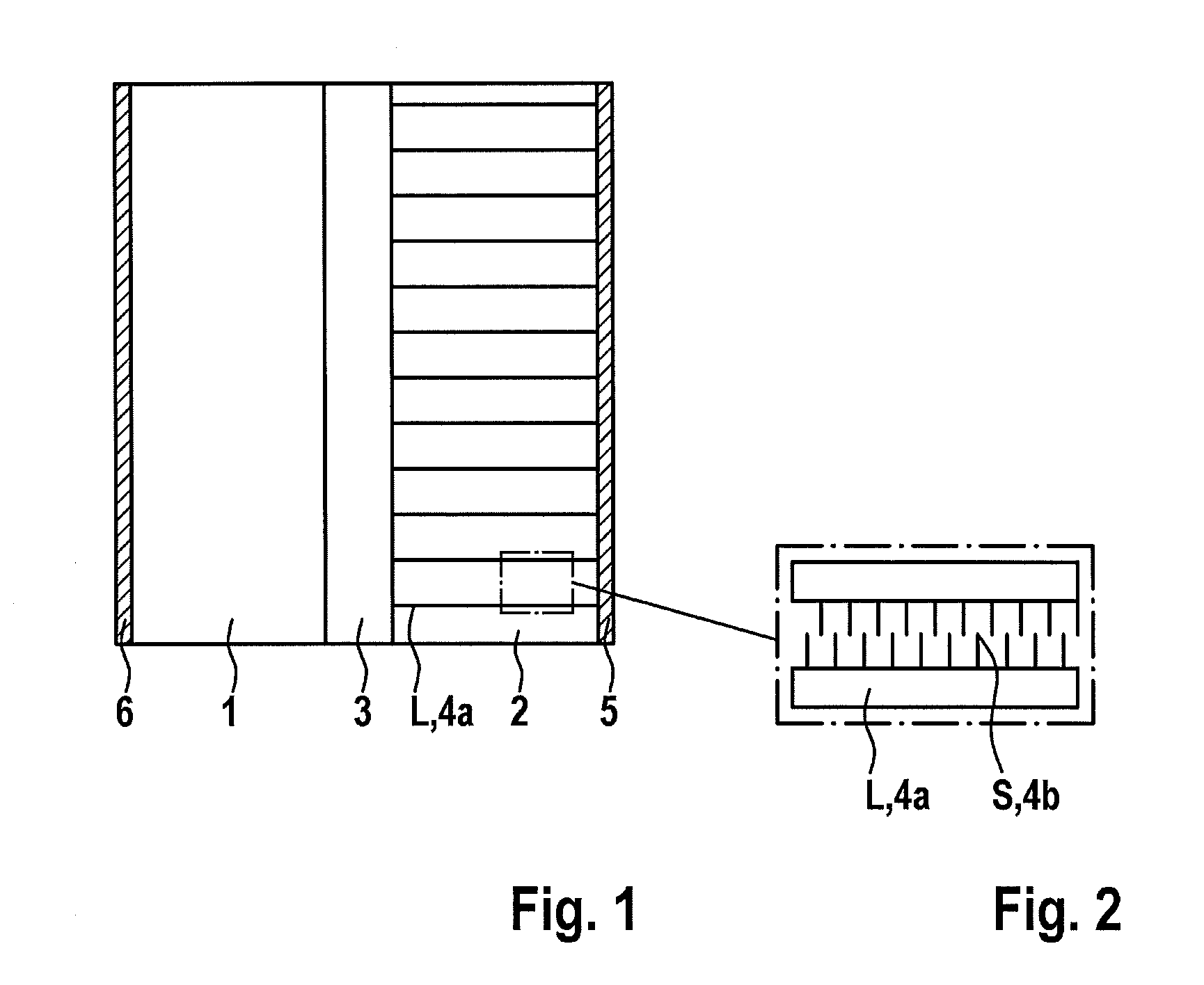

A conventional battery has a problem that a large short-circuit current is generated with temperature rise due to internal short-circuit, and therefore, the temperature of the battery further increases due to heat and the short-circuit current is increased. Also, there is a problem in safety that the sealed part can be easily opened with temperature rise in case of using the aluminum laminated bag as the outer body for sealing the battery body. The present invention has been carried out in order to solve the above problems. The battery of the present invention is a battery wherein at least one of the positive electrode 1 and the negative electrode 2 comprises the active material layer 6 containing the active material 8 and the electronically conductive material 9 contacted to the active material 8; wherein the battery body 11 is constructed by containing the electrolytic layer 3 between the above positive electrode 1 and negative electrode 2, and the above battery body is sealed with the outer body 14 comprising the aluminum 13 and the thermal fusion resin 12; and wherein the electronically conductive material 9 comprises the electrically conductive filler and the resin so that the resistance increases in accordance with temperature rise.

Owner:MITSUBISHI ELECTRIC CORP

Battery and process for preparing the same

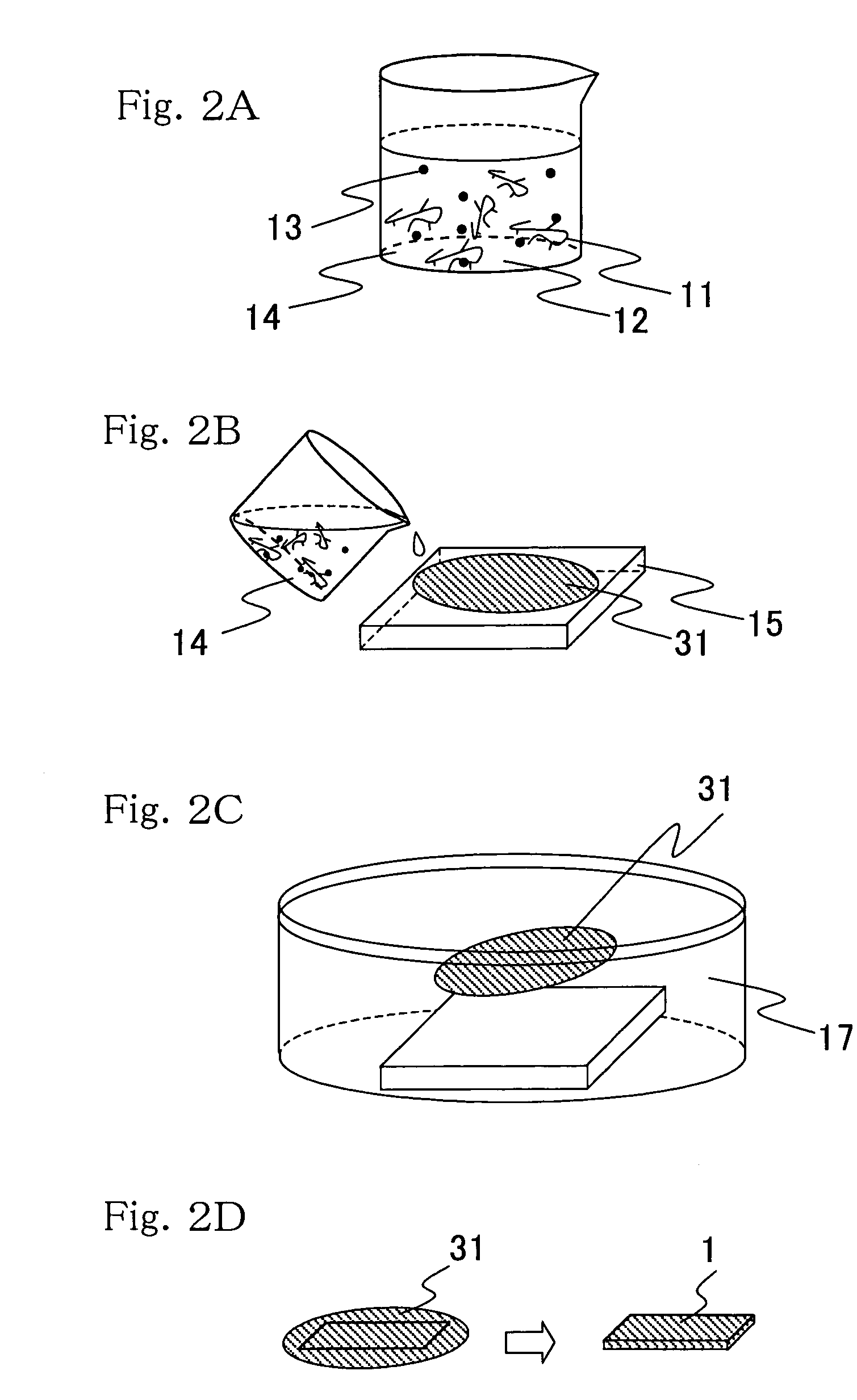

InactiveUS20010005558A1Supplement low electronic conductivityLow electronic conductivityPrimary cell maintainance/servicingFinal product manufactureElectrical resistance and conductanceElectrolysis

A conventional battery has a problem that a large short-circuit current was generated with temperature rise due to internal short-circuit or the like, and therefore, the temperature of the battery further increases due to exothermic reaction to increase the short-circuit current. The present invention has been carried out in order to solve the above problems. The battery of the present invention is a battery wherein at least one of a positive electrode 1 and a negative electrode 2 comprises an active material layer 6 containing an active material 8 and an electronically conductive material 9 contacted to the active material 8, wherein a solid electrolytic layer 3 is interposed between the above positive electrode 1 and the negative electrode 2, and wherein the above electronically conductive material 9 comprises an electrically conductive filler and a resin so that resistance increases with temperature rise.

Owner:MITSUBISHI ELECTRIC CORP

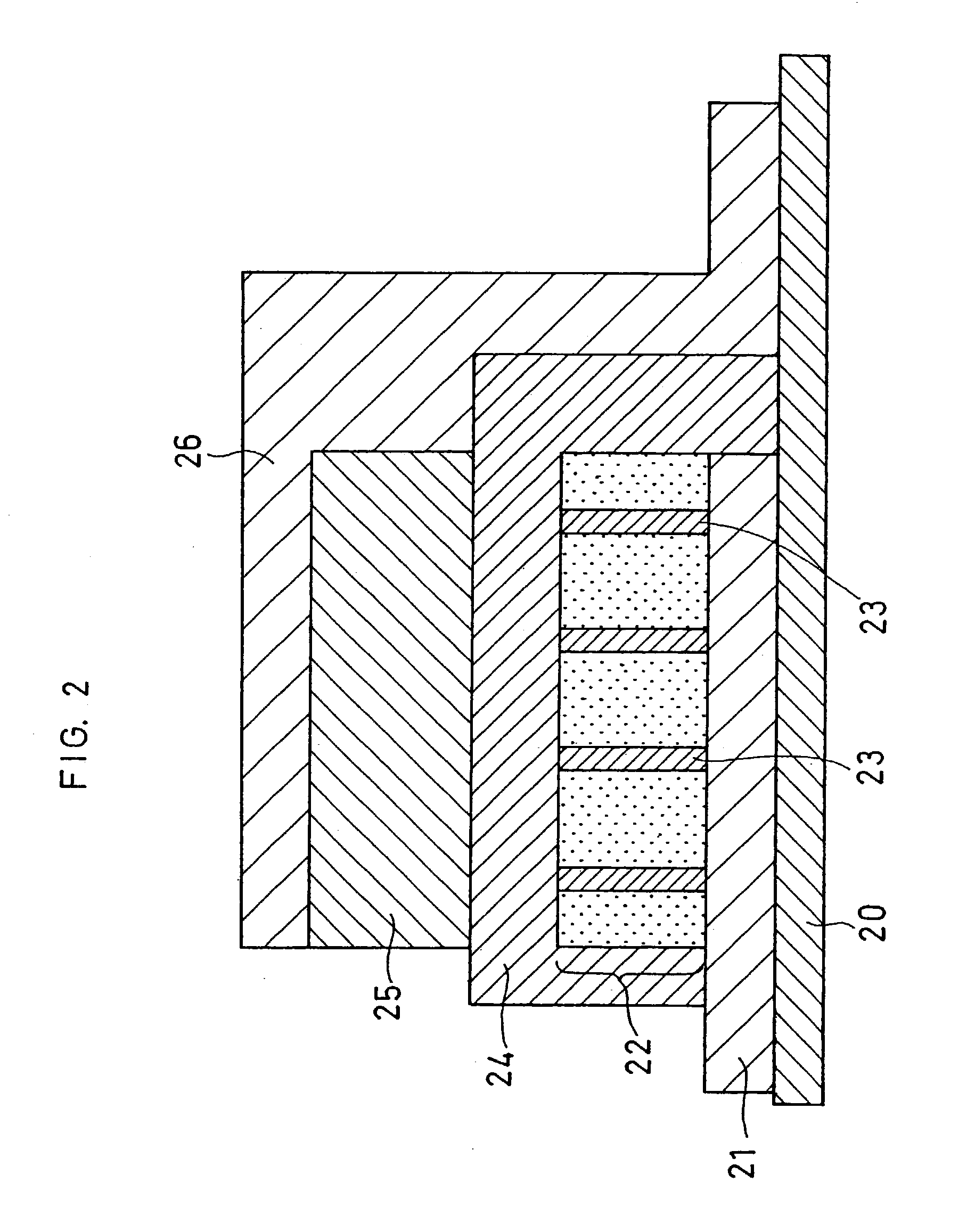

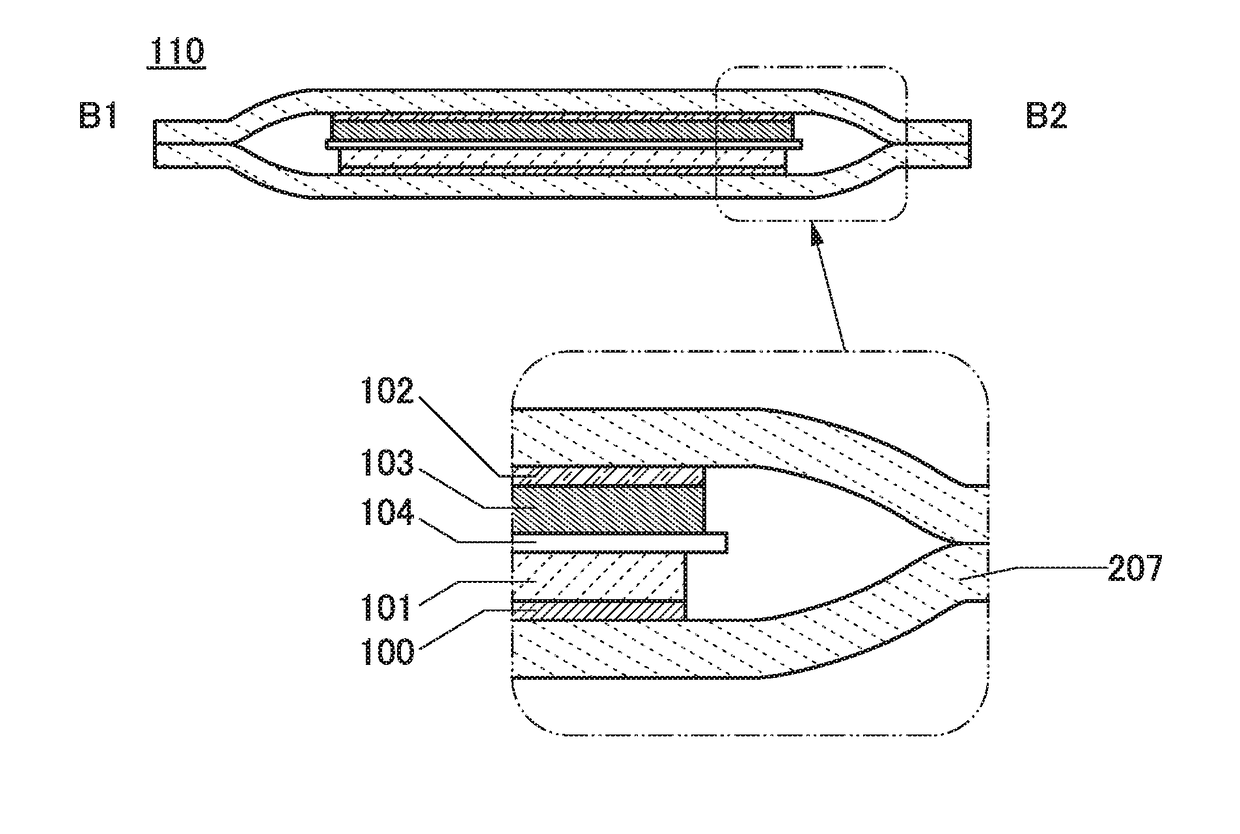

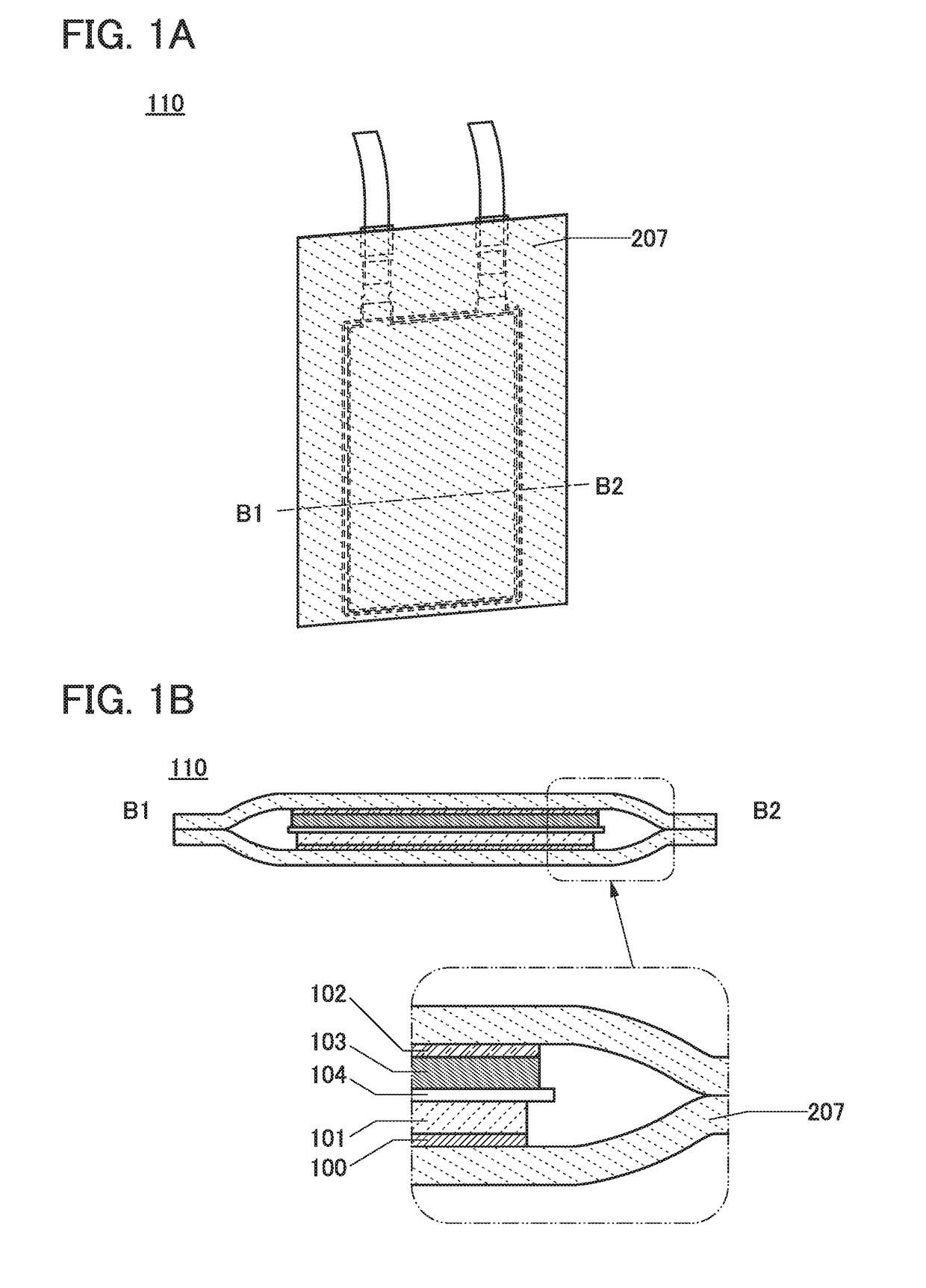

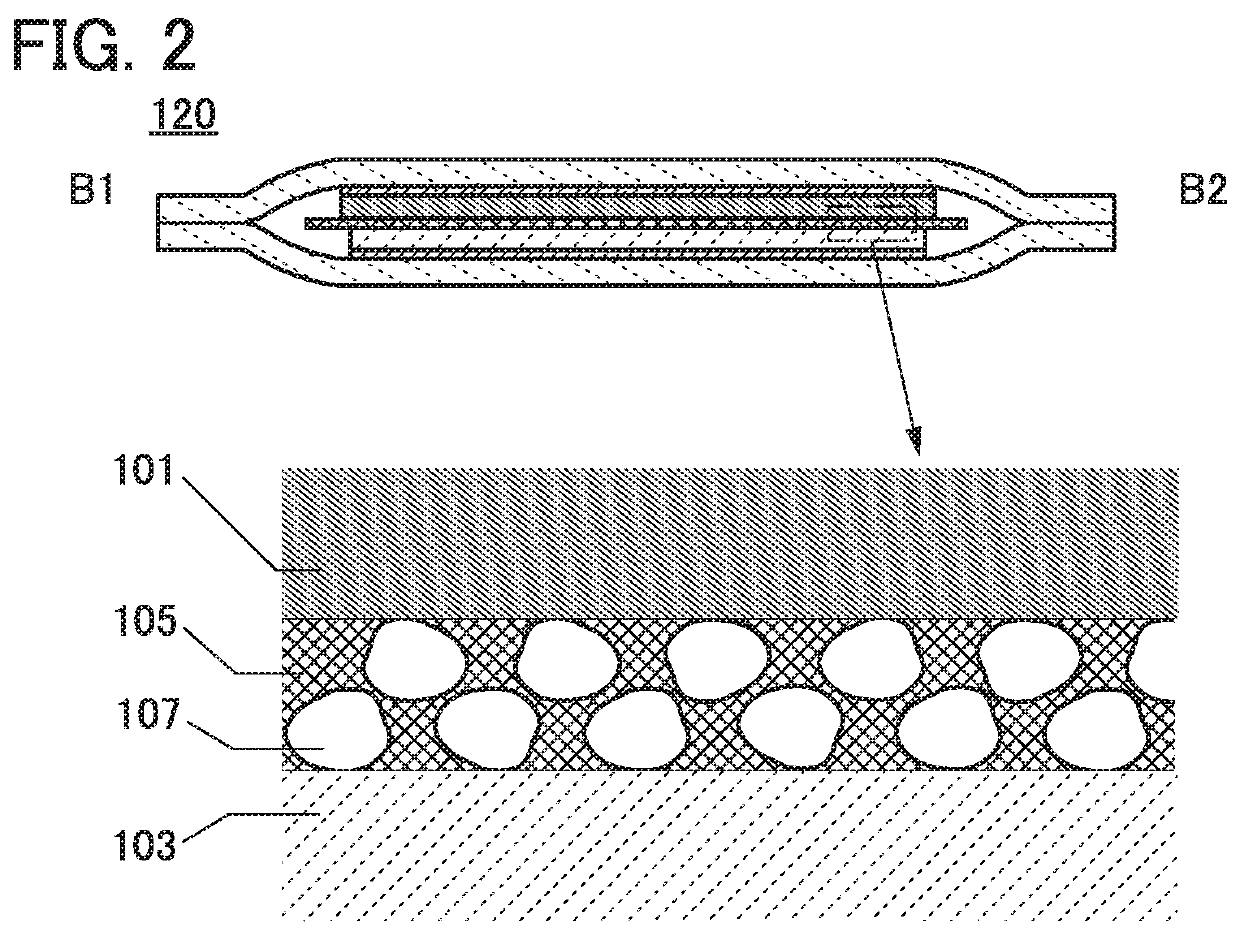

Secondary battery and method of producing the same

ActiveUS20030175585A1Increase thicknessIncrease battery capacitySolid electrolytesFinal product manufactureIonCurrent collector

A secondary battery comprising: a substrate; a first current collector; a first electrode; a solid electrolyte; a second electrode; and a second current collector; the first current collector being formed on the substrate and serving as a current collector of the first electrode, the first electrode being formed on the first current collector, the solid electrolyte being formed on the first electrode, the second electrode being formed on the solid electrolyte, the second current collector being formed on the second electrode and serving as a current collector of the second electrode, at least one electrode selected from the group consisting of the first electrode and the second electrode containing at least one material selected from the group consisting of an ion conductive material and an electron conductive material.

Owner:PANASONIC CORP

Battery and process for preparing the same

InactiveUS20010005559A1Improve battery safetyImprove securityPrimary cell maintainance/servicingCell temperature controlElectrical resistance and conductanceElectrolysis

A conventional battery has a problem that since a device having PTC function was placed outside the battery or outside the electrode of the battery as a safety device in case of temperature rise due to short-circuit current generated by external short-circuit or the like, a large short-circuit current was generated with temperature rise due to internal short-circuit. And therefore, a temperature of the battery further increases due to exothermic reaction to increase the short-circuit current. Also, there is a problem that structure of the battery become complicated and volume energy density is lowered. The present invention has been carried out in order to solve the above problems. The battery of the present invention is a battery wherein at least one of a positive electrode (1) and a negative electrode (2) comprises an active material layer (6) containing an active material (8) and an electronically conductive material (9) contacted to the active material (8), and the battery body has an electrolytic layer (3) between the above positive electrode (1) and the negative electrode (2), wherein the electronically conductive material (9) comprises an electrically conductive filler and a resin and resistance thereof can be increased with temperature rise, and wherein the battery body is sealed with the outer can (20) without forming extra space.

Owner:MITSUBISHI ELECTRIC CORP

Negative electrode member for lithium battery and process for producing the same

InactiveUS7416815B2Improve the level ofLow electronic conductivityFinal product manufactureElectrode carriers/collectorsMetallic lithiumHigh energy

Affords high-stability, high-safety lithium secondary batteries of high energy density and superlative charge / discharge cyclability, in which shorting due to the growth of dendrites from the metallic-lithium negative electrode is kept under control.A lithium secondary battery negative-electrode component material, formed by laminating onto a substrate a metallic lithium film and an inorganic solid-electrolyte film, the lithium secondary battery negative-electrode component material characterized in that the inorganic solid-electrolyte film incorporates lithium, phosphorous, sulfur, and oxygen, and is represented by the compositional formula noted below.aLi·bP·cS·dO(Li: lithium; P: phosphorous; S: sulfur; O: oxygen), wherein the ranges of the atomic fractions in the composition are:0.20≦a≦0.45;0.10≦b≦0.20;0.35≦c≦0.60;0.03≦d≦0.13;(a+b+c+d=1).

Owner:SUMITOMO ELECTRIC IND LTD

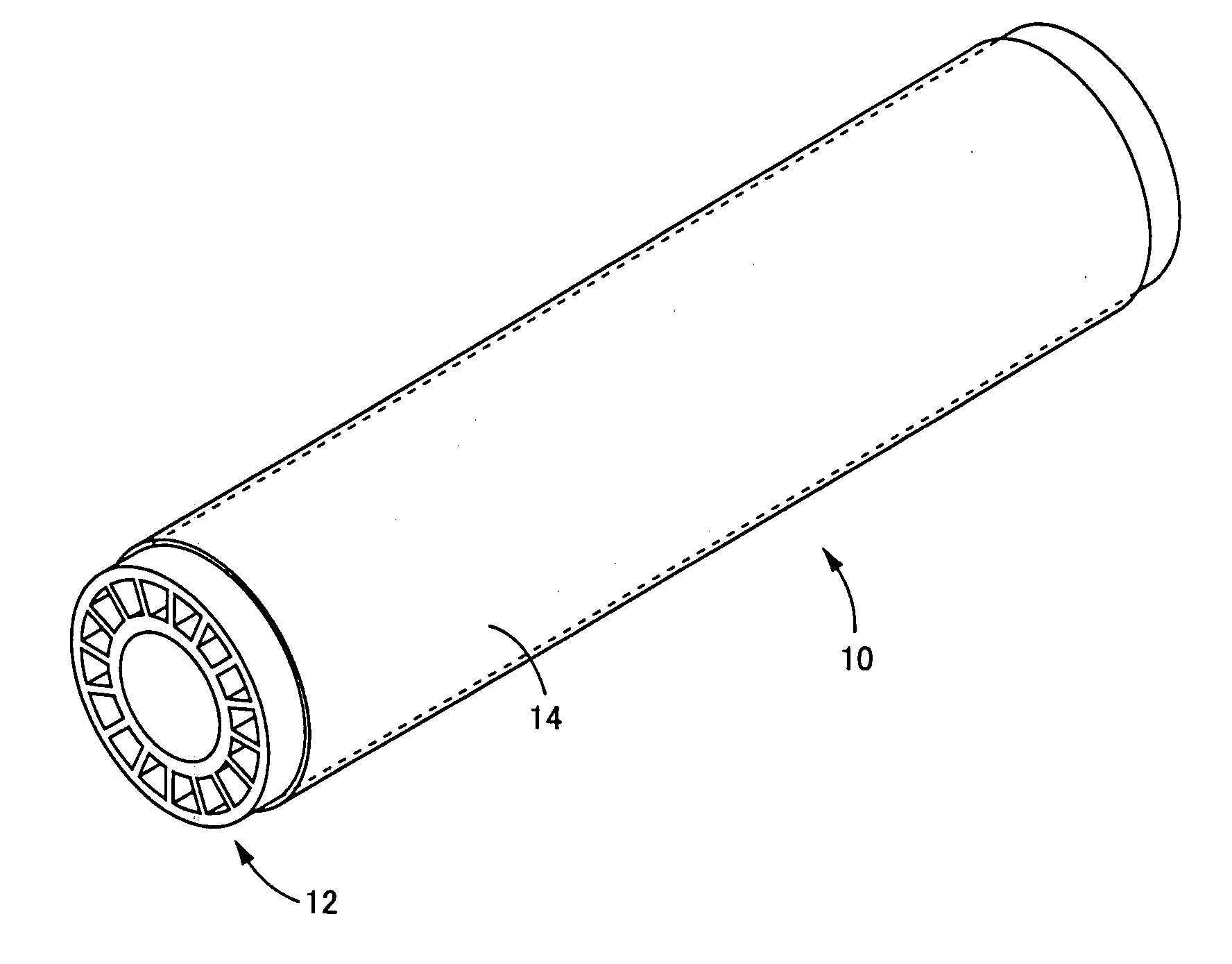

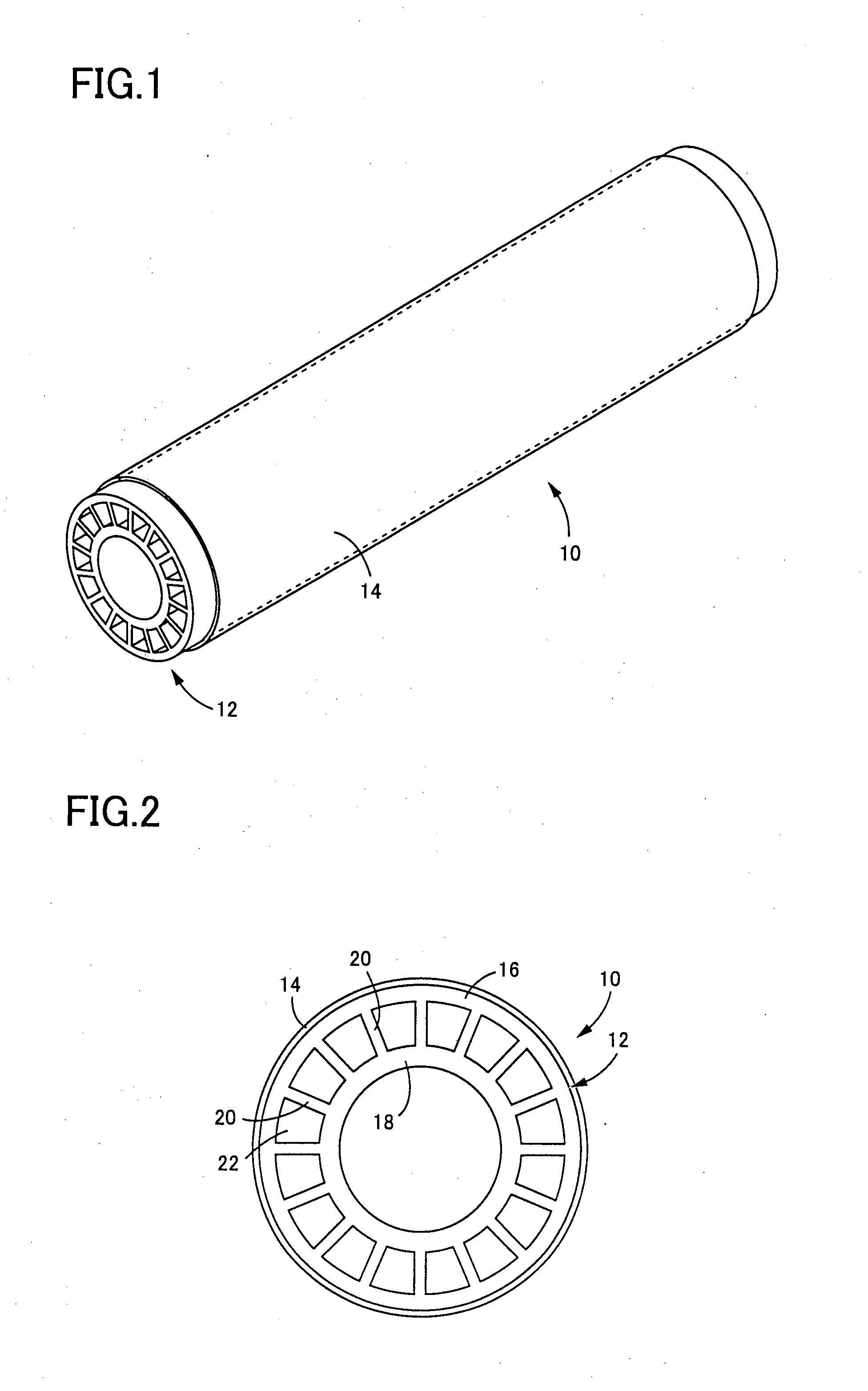

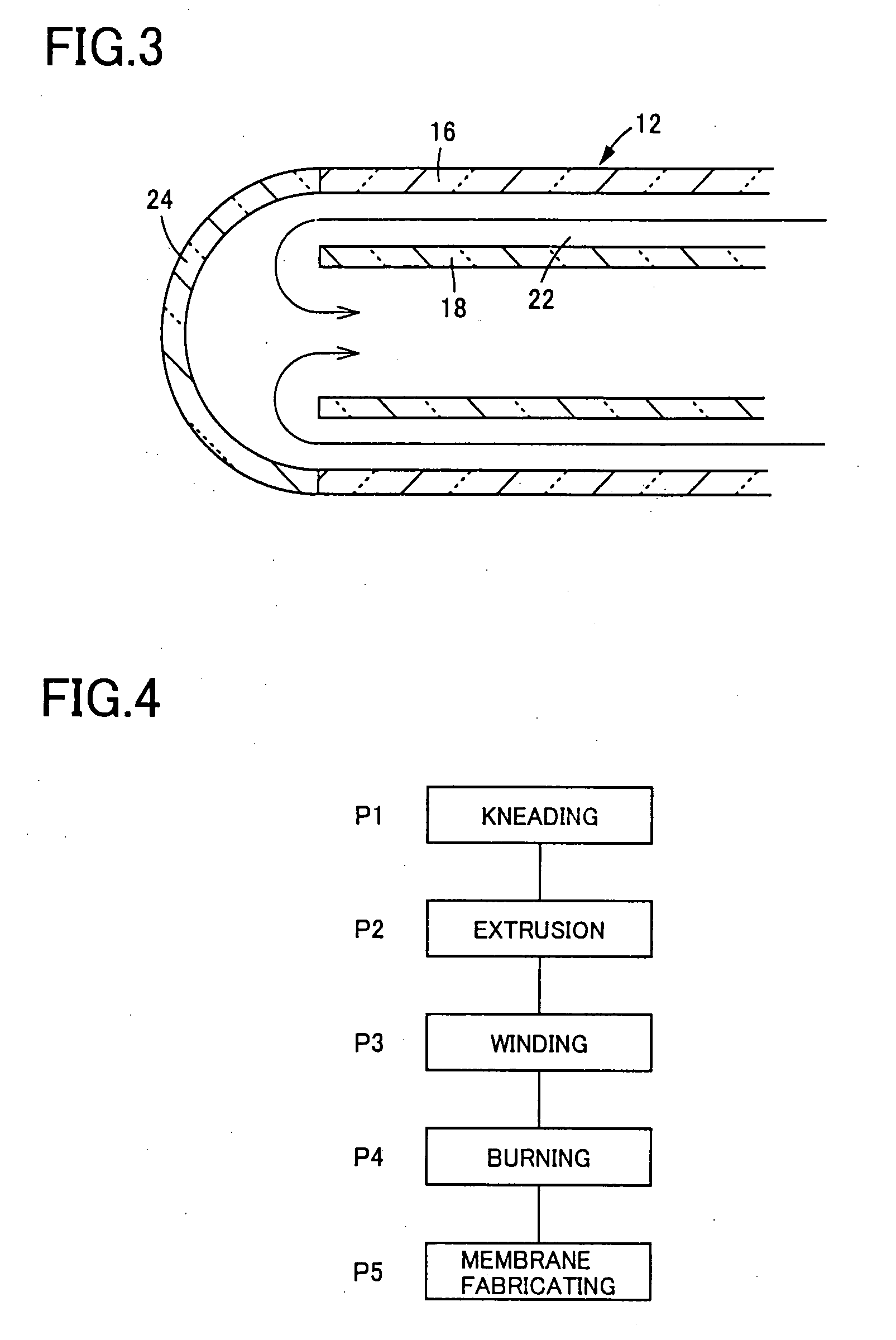

Support for oxygen separation membrane element and the element using the same

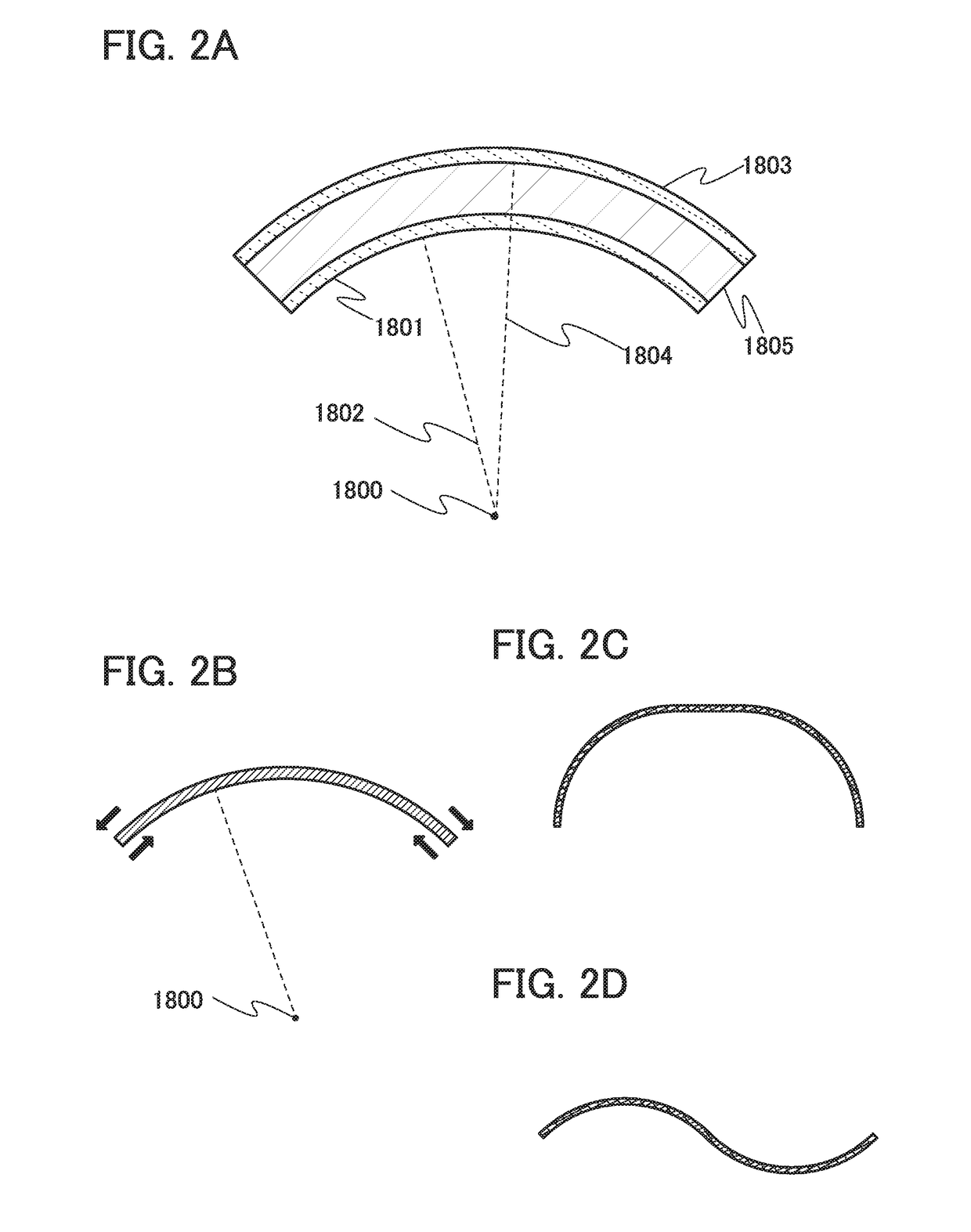

InactiveUS20080078675A1Easy to makeWell formedCellsSemi-permeable membranesOxygen ionsMembrane configuration

A support for an oxygen separation membrane element to support a dense and cylindrical electrolytic membrane having oxygen ion permeability, comprises a base axially extending and having a cylindrical surface extending axially, and a plurality of ribs formed on the cylindrical surface of the base, radially projecting and axially extending, for supporting the electrolytic membrane at their ends being radially distant from the cylindrical surface of the base.

Owner:NORITAKE CO LTD +1

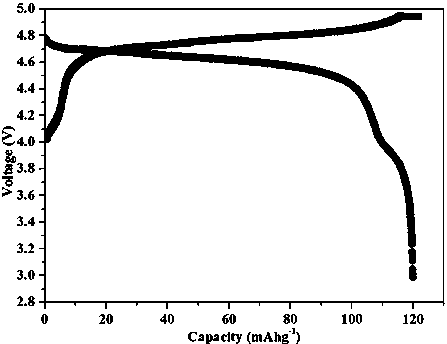

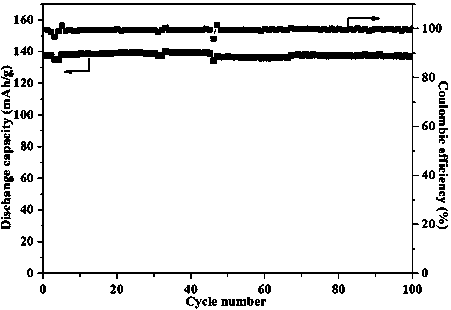

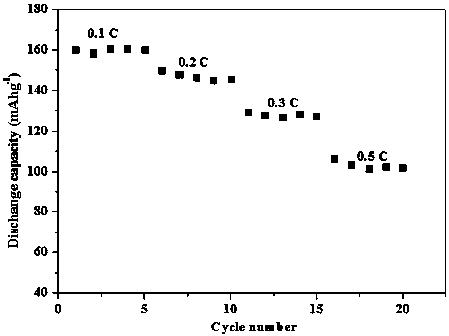

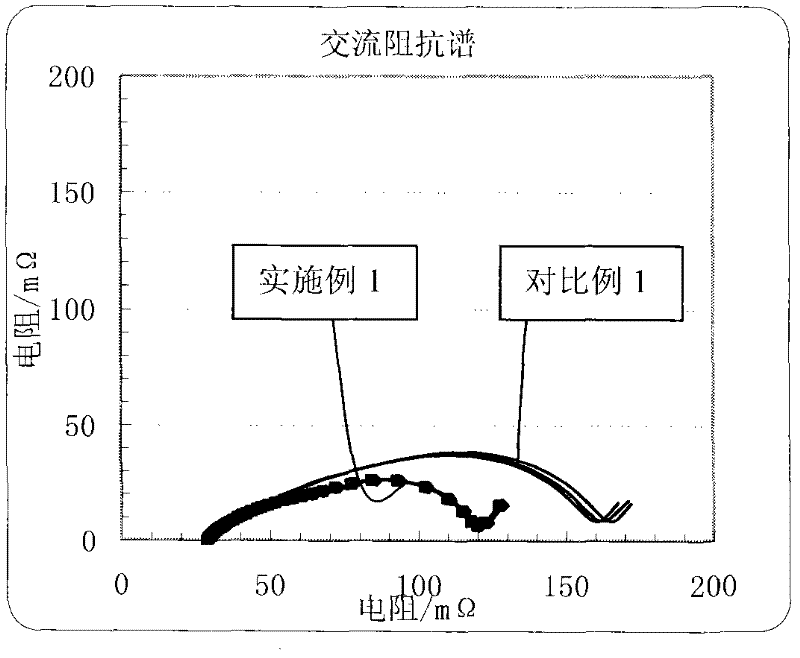

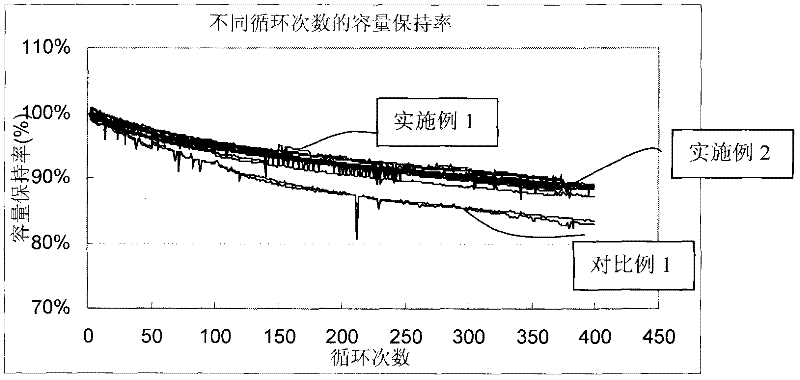

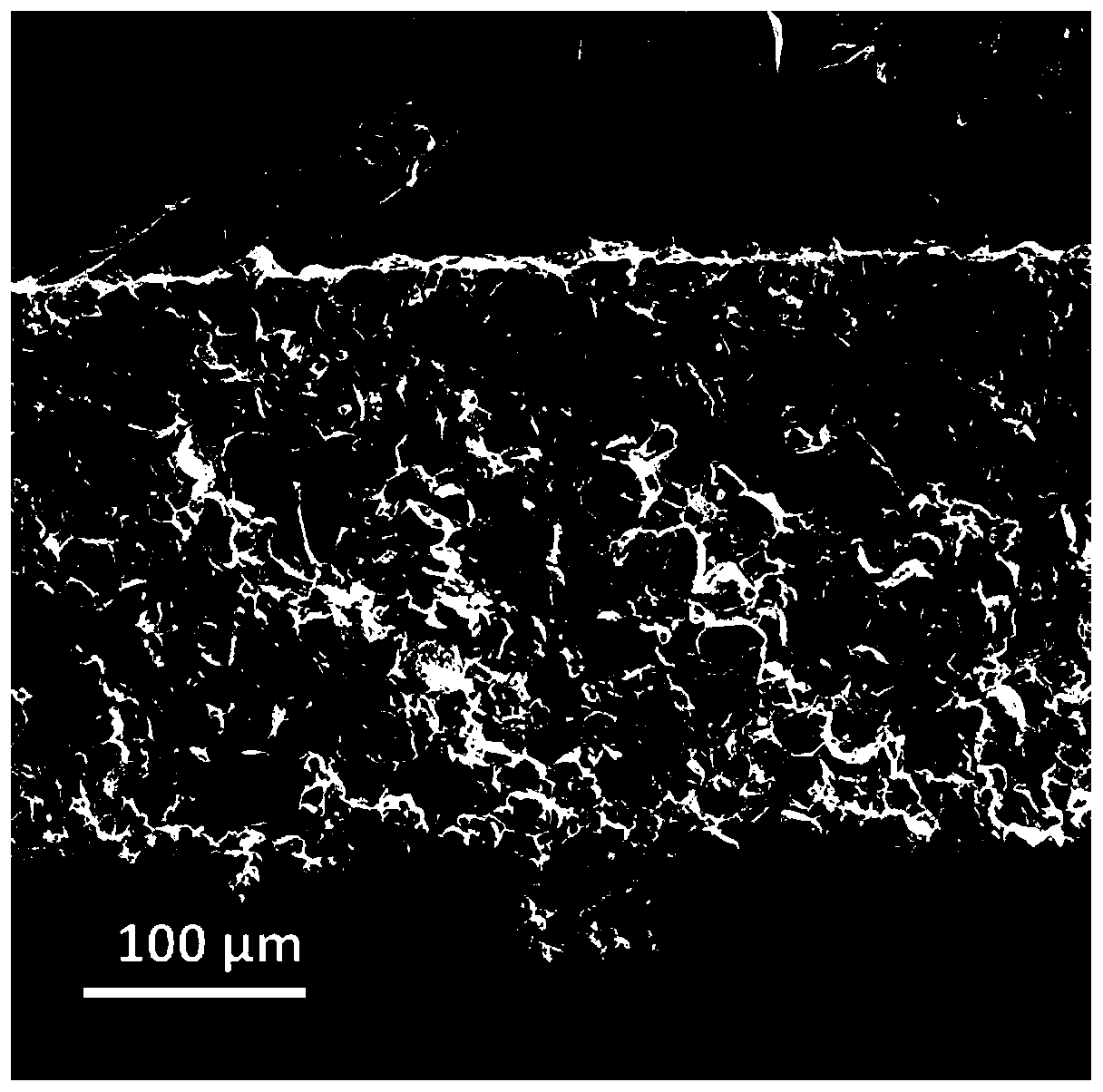

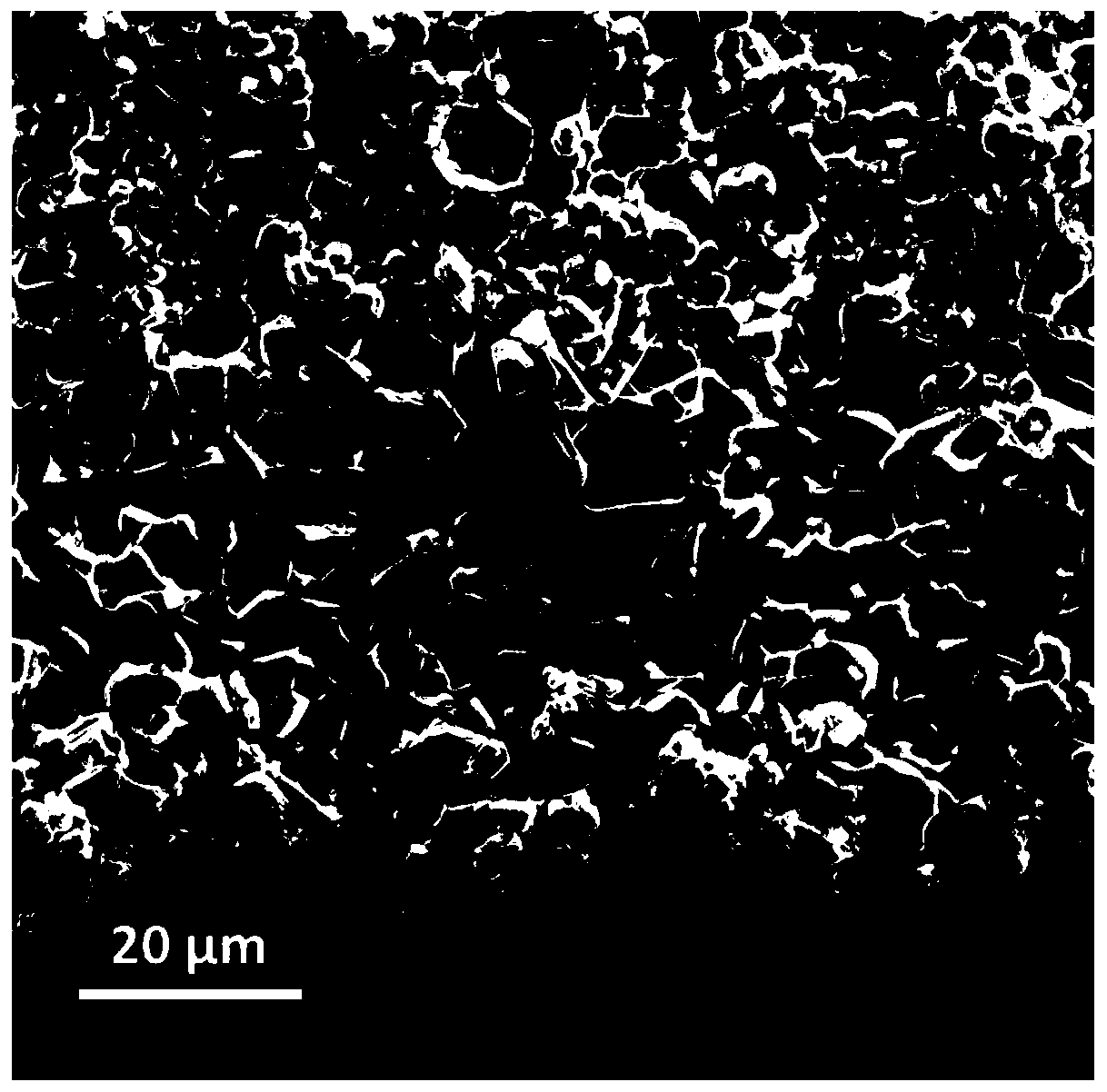

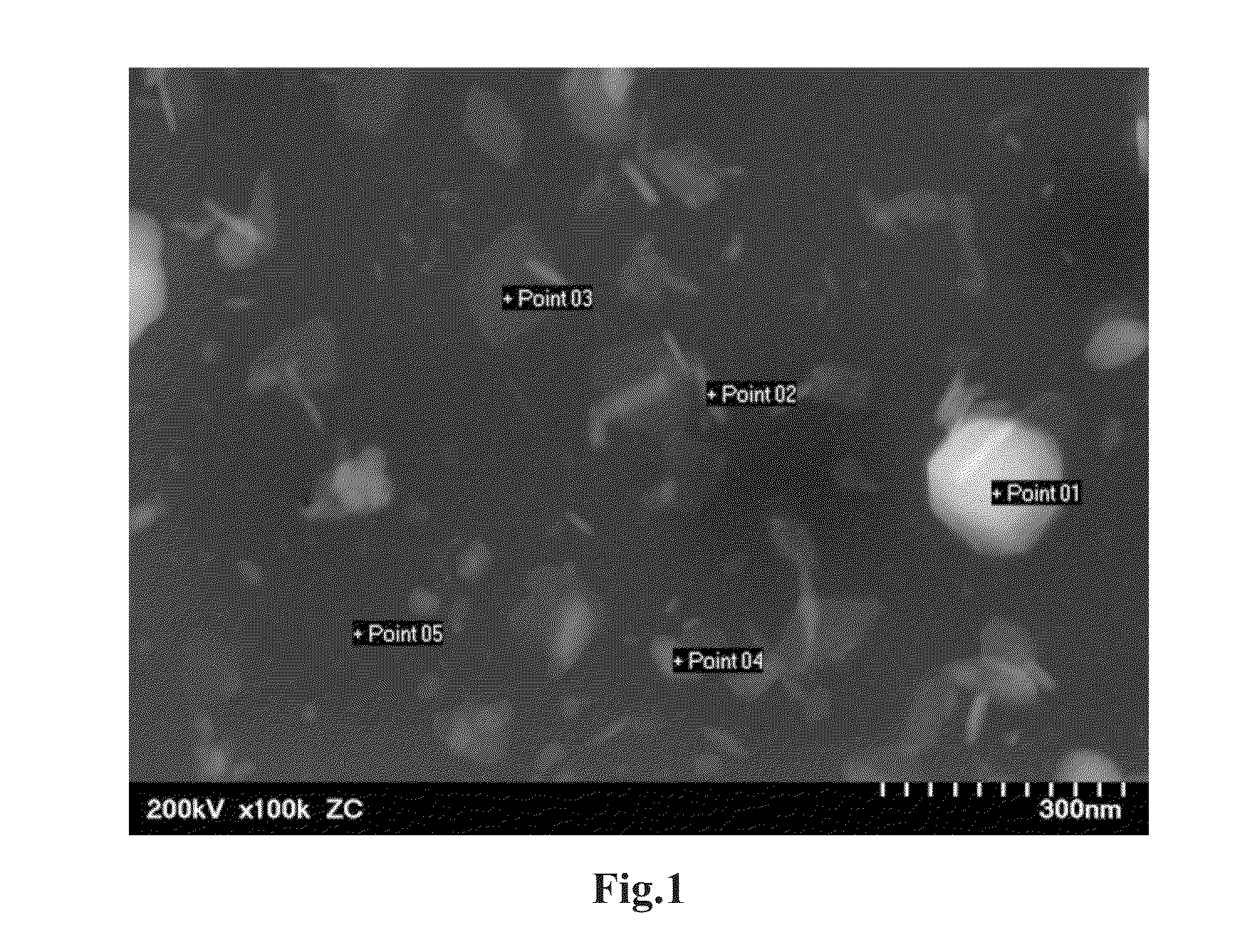

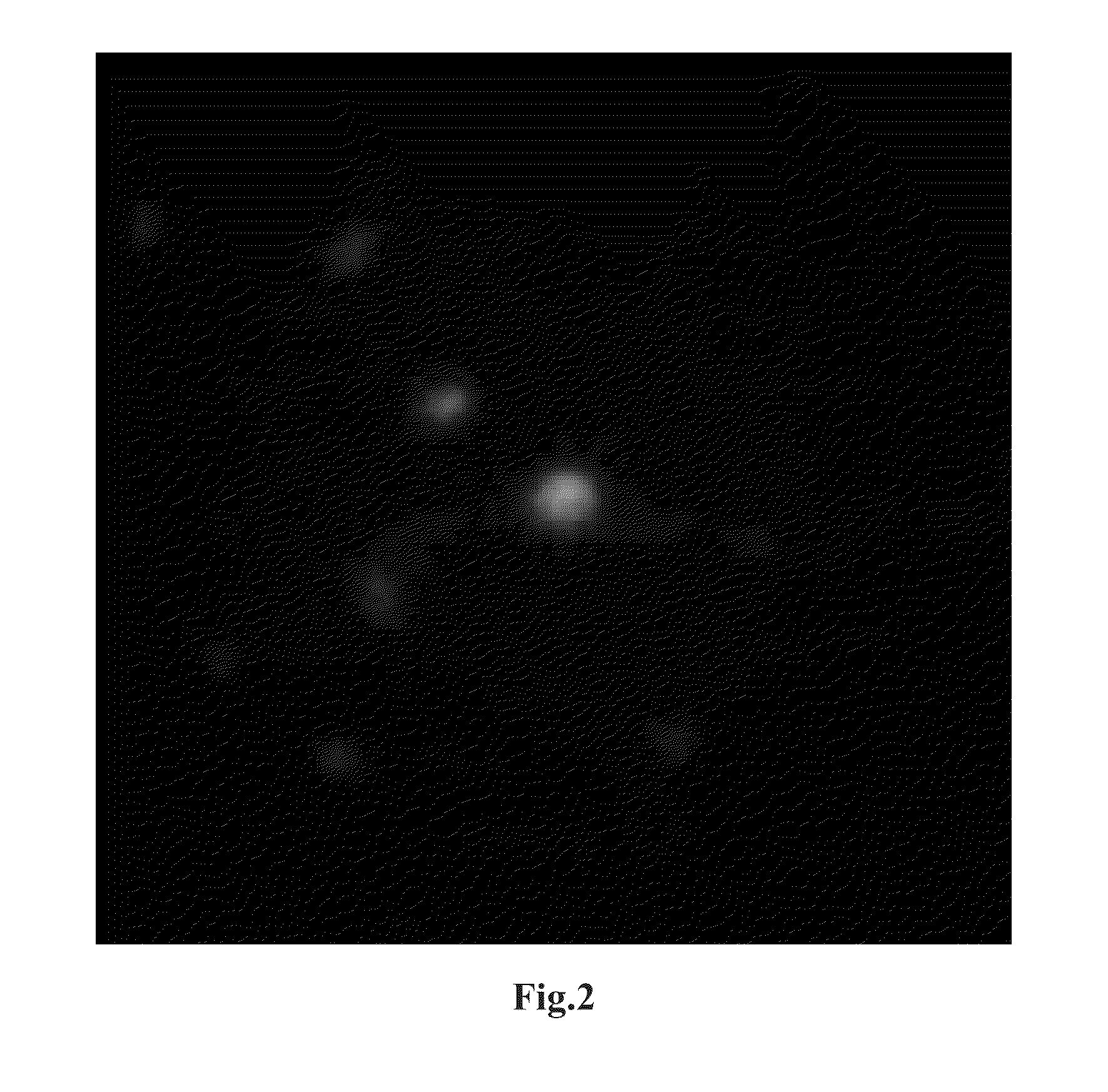

Solid electrolyte containing polymer with main chain containing sulfur, solid secondary lithium battery formed by solid electrolyte as well as preparation method and application of solid electrolyte

ActiveCN108232288ALow electronic conductivityImprove ionic conductivitySolid electrolytesFinal product manufactureSolid state electrolyteElectrochemical window

The invention relates to a solid polymer electrolyte , in particular to a solid electrolyte containing a polymer with a main chain containing sulfur, a solid secondary lithium battery formed by the solid electrolyte as well as a preparation method and application of the solid electrolyte. The solid electrolyte comprises the polymer with the main chain containing sulfur, lithium salt and a porous supporting material; the thickness of the solid electrolyte is 20-800 microns, the mechanical strength of the solid electrolyte is 10-80MPa, the room-temperature ionic conductivity of the solid electrolyte is 5*10<-5>-7*10<-4>S / cm, and the electrochemical window of the solid electrolyte is 4.5-7V. The polymer solid electrolyte provided by the invention is liable to prepare, simple to form and goodin mechanical performance, has higher ionic conductivity and wider electrochemical window at the same time, can effectively inhibit growth of cathode lithium dendrites and can improve the interface stability and the long cycle performance of the battery.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Negative electrode member for lithium battery and process for producing the same

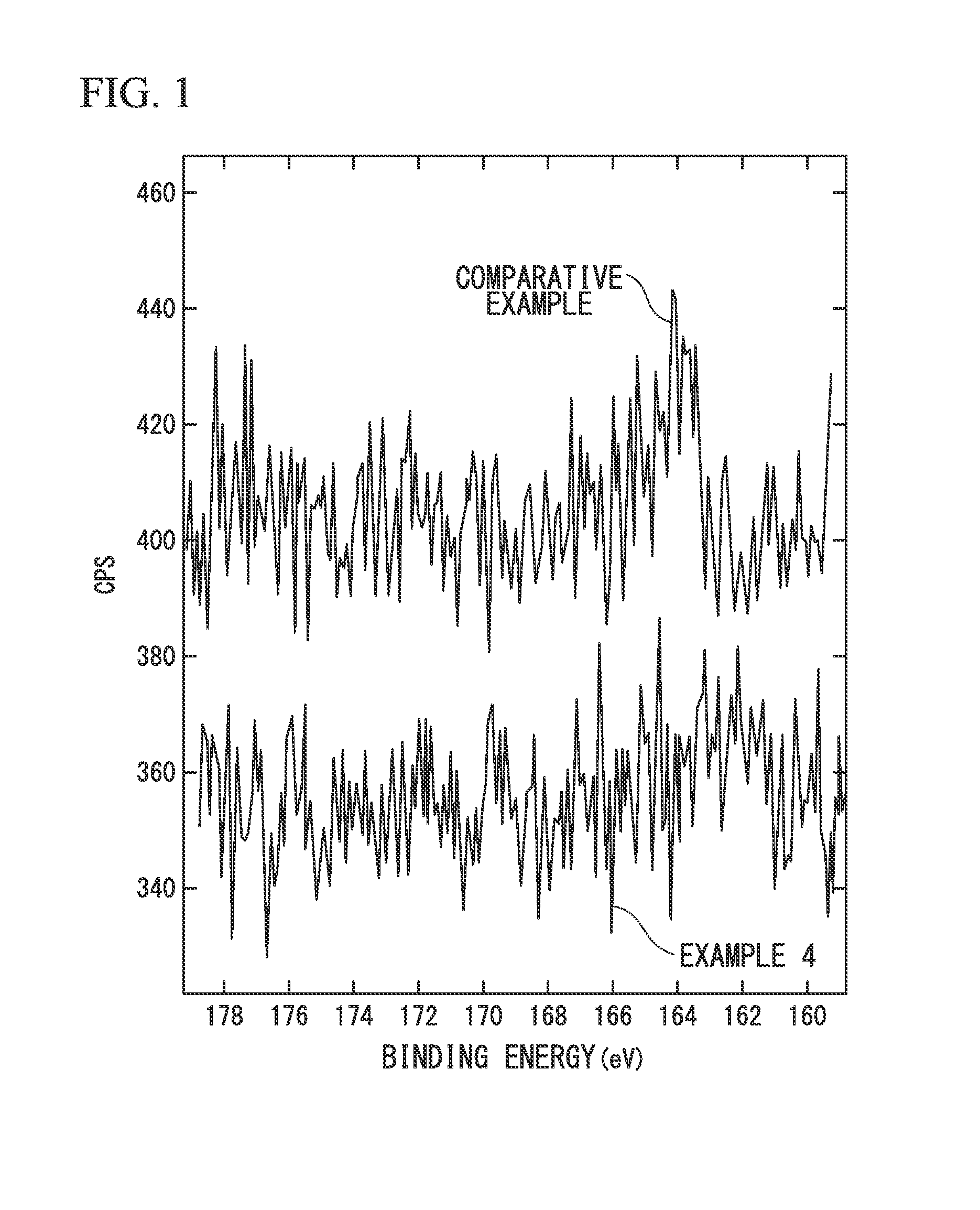

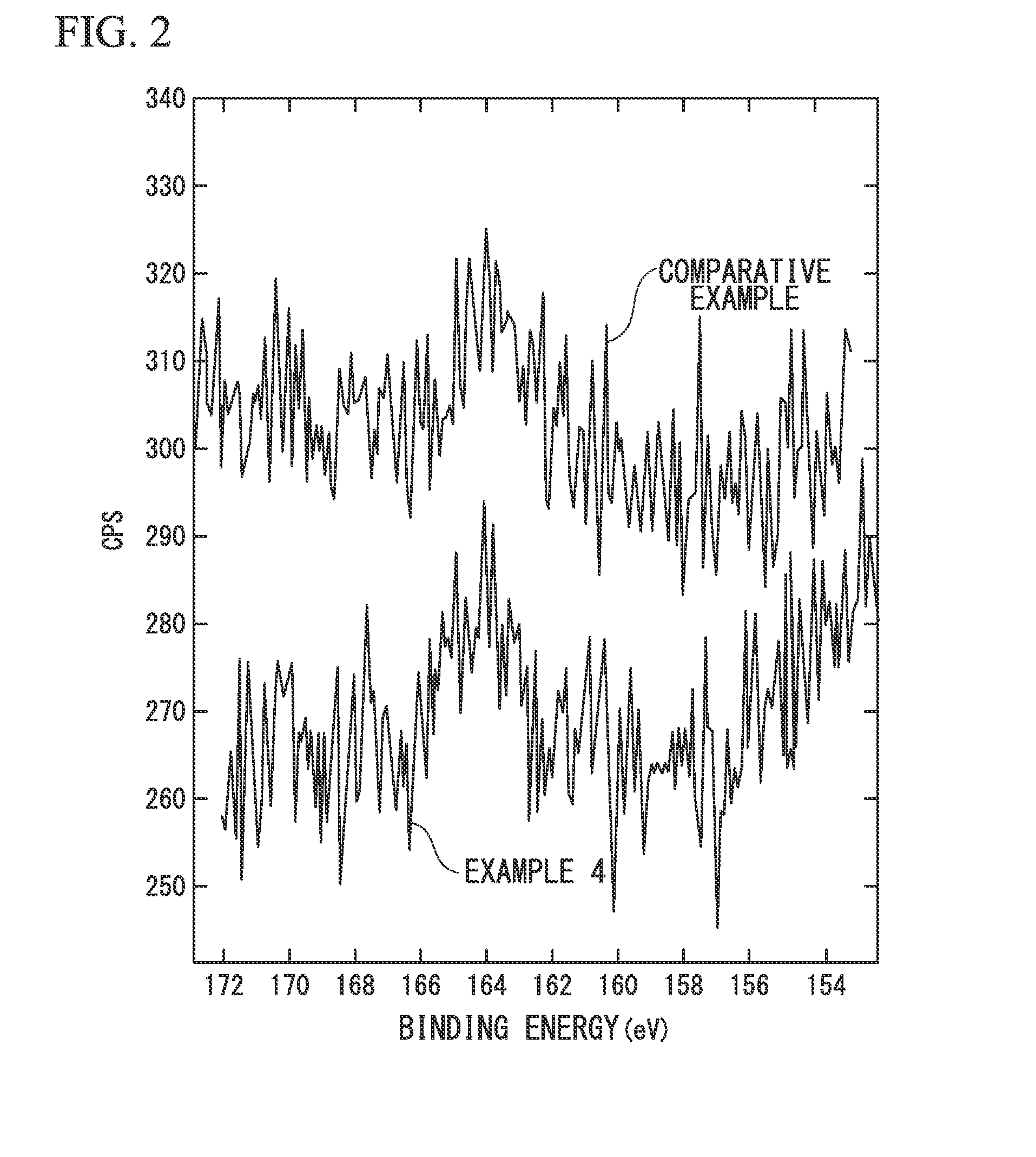

InactiveUS20060127772A1Degree of improvementIncrease rangeFinal product manufactureElectrode carriers/collectorsMetallic lithiumSulfur

Affords high-stability, high-safety lithium secondary batteries of high energy density and superlative charge / discharge cyclability, in which shorting due to the growth of dendrites from the metallic-lithium negative electrode is kept under control. A lithium secondary battery negative-electrode component material, formed by laminating onto a substrate a metallic lithium film and an inorganic solid-electrolyte film, the lithium secondary battery negative-electrode component material characterized in that the inorganic solid-electrolyte film incorporates lithium, phosphorous, sulfur, and oxygen, and is represented by the compositional formula noted below. aLi·bP·cS·dO (Li: lithium; P: phosphorous; S: sulfur; O: oxygen), wherein the ranges of the atomic fractions in the composition are: 0.20≦a≦0.45; 0.10≦b≦0.20; 0.35≦c≦0.60; 0.03≦d≦0.13; (a+b+c+d=1).

Owner:SUMITOMO ELECTRIC IND LTD

Graphene compound, method for forming graphene compound, and lithium-ion storage battery

ActiveUS20170256817A1Prevent short-circuitingImprove conductivitySolid electrolytesGraphiteNitrogen gasSilylation

A material that can be used in a wide temperature range is provided. A graphene compound includes graphene or graphene oxide and a substituted or unsubstituted chain group, the chain group includes two or more ether bonds, and the chain group is bonded to the above graphene or graphene oxide through a Si atom. Alternatively, a method for forming a graphene compound includes a first step and a second step after the first step. In the first step, graphene oxide and a base are stirred under a nitrogen stream. In the second step, the mixture is cooled to room temperature, a silylating agent that has a group having two or more ether bonds is introduced into the mixture, and the obtained mixture is stirred. The base is butylamine, pentylamine, hexylamine, diethylamine, dipropylamine, dibutylamine, triethylamine, tripropylamine, or pyridine.

Owner:SEMICON ENERGY LAB CO LTD

High-voltage anode material for lithium ion battery and lithium ion battery comprising same

ActiveCN103066282AImprove cycle performanceImprove securityCell electrodesSecondary cellsElectrical batterySodium-ion battery

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a high-voltage anode material for a lithium ion battery. The anode material comprises a material A and a material B, wherein the material A has a core-shell structure, a core layer material is lithium cobalt oxide particles formed by primary particles, the median particle diameters D50 of the lithium cobalt oxide particles are 15-25 microns, and the structure formula of a core-shell material is LixNiyMnzPO4; the material B has a core-shell structure, the core layer material is the lithium cobalt oxide particles formed by secondary particles, and the median particle diameters D50 of the lithium cobalt oxide particles are is 3-9 microns; and the structure formula of the core-shell material is LiwAlpZrqO2, and the mass ratio of the material A to the material B is (0.1-10) to 1. Compared with the prior art, the high-voltage anode material for the lithium ion battery provided by the invention has the advantages that the large and small lithium cobalt oxide particles are combined reasonably, different core layer materials can be arranged on the surfaces of the lithium cobalt oxide particles, and the secondary particles are selected as the small lithium cobalt oxide particles, so that the cycle performance and the safety performance of the anode material under high voltage are notably improved.

Owner:DONGGUAN AMPEREX TECH

Graphene compound and manufacturing method thereof, electrolyte, and power storage device

ActiveUS20180108944A1Prevent internal short circuitImprove conductivityMaterial nanotechnologyGroup 4/14 element organic compoundsLithiumEther

To provide a graphene compound having an insulating property and an affinity for lithium ions. To increase the molecular weight of a substituent included in a graphene compound. To provide a graphene compound including a chain group containing an ether bond or an ester bond. To provide a graphene compound including a substituent containing one or more branches. To provide a graphene compound including a substituent including at least one of an ester bond and an amide bond.

Owner:SEMICON ENERGY LAB CO LTD

High-safety power lithium ion battery adopting anode sheet mixing lithium titanate with graphite

InactiveCN106299332AImprove thermal stabilityHigh lithium extraction potentialCell electrodesSecondary cells servicing/maintenanceInsulator (electricity)Electrical battery

The invention provides a high-safety power lithium ion battery adopting an anode sheet mixing lithium titanate with graphite. The high-safety power lithium ion battery is characterized in that an anode material is included, the anode material is prepared from an anode active material, an anode conducting agent and an anode bonding agent, and the graphite, lithium titanate, the anode conducting agent, the anode bonding agent and an anode solvent are uniformly dispersed and mixed to form anode slurry, wherein the mass ratio of lithium titanate to the anode active material ranges from 0.5% to 10%. According to the high-safety power lithium ion battery, when the battery has a partial short-circuit fault, the heat stability of the lithium ion battery anode sheet adopting anodes mixing lithium titanate with the graphite is high, lithium titanate particles in the anode sheet are instantaneously subjected to lithium removal to form an empty-electricity-state insulator, the resistance of the anode sheet is increased, the short-circuit current is significantly decreased, and the safety of the battery is significantly improved.

Owner:TIANJIN ENERGIES

Full-solid electrochromic window, solid electrochromic glass and preparing method thereof

ActiveCN108254989ABoost rateImprove cycle lifeNon-linear opticsSolid state electrolyteRare-earth element

The invention relates to a solid electrolyte material. The chemical composition of the solid electrolyte material is LixSiyRezSmOn, wherein x is larger than or equal to 2 and smaller than or equal to3, y is larger than or equal to 0.5 and smaller than or equal to 2, z is larger than or equal to 0.3 and smaller than or equal to 0.6, (m+n) is larger than (x+4y+3z) / 2.1 and smaller than or equal to (x+4y+3Z) / 1.8, and Re is selected from rare earth elements Y, Gd, Gy or Sm. The solid electrolyte material is high in lithium ion conductivity, high in electron conductivity, wide in electrochemical window and high in temperature resistance. The invention further relates to a solid electrochromic device. An electrolyte is selected from the solid electrolyte material, an electrochromic layer is selected from at least one of tungsten oxide, bismuth trioxide, molybdenum trioxide or nickel oxide, and an ion storage layer is selected from at least one of lithium-embedded vanadium pentoxide, lithium-embedded titanium dioxide, lithium-embedded tungsten trioxide or lithium-embedded nickel oxide. The solid electrochromic device has the advantages of being short in color change response time and stable in performance.

Owner:NINGBO MI RUO ELECTRONICS TECH CO LTD

Lithium ion battery cathode and lithium ion battery therewith

InactiveCN102368543AImprove convenienceImprove adhesionSecondary cellsNon-aqueous electrolyte accumulator electrodesElectrical batteryAlloy

The invention belongs to the field of lithium ion battery materials, and provides a lithium ion battery cathode comprising a current collector and a cathode material coated on eth current collector. The cathode material comprises a carbon material or an alloy material. An adopted binder is carboxymethylcellulose sodium. The carboxymethylcellulose sodium has a substitution degree of 0.6 to 1.2, and a number-average molecular weight of 50 thousands to 1 million. The viscosity of a 1% aqueous solution of carboxymethylcellulose sodium under a temperature of 25 DEG C is 50-1200mPa*s. The mass percentage of carboxymethylcellulose sodium in the cathode material is 1% to 5%. With a lithium ion battery employing the cathode, a defect of over-expended thickness during a battery circulation process is solved. Also, the produced battery is safe, reliable, and has a long circulation life.

Owner:DONGGUAN AMPEREX TECH +1

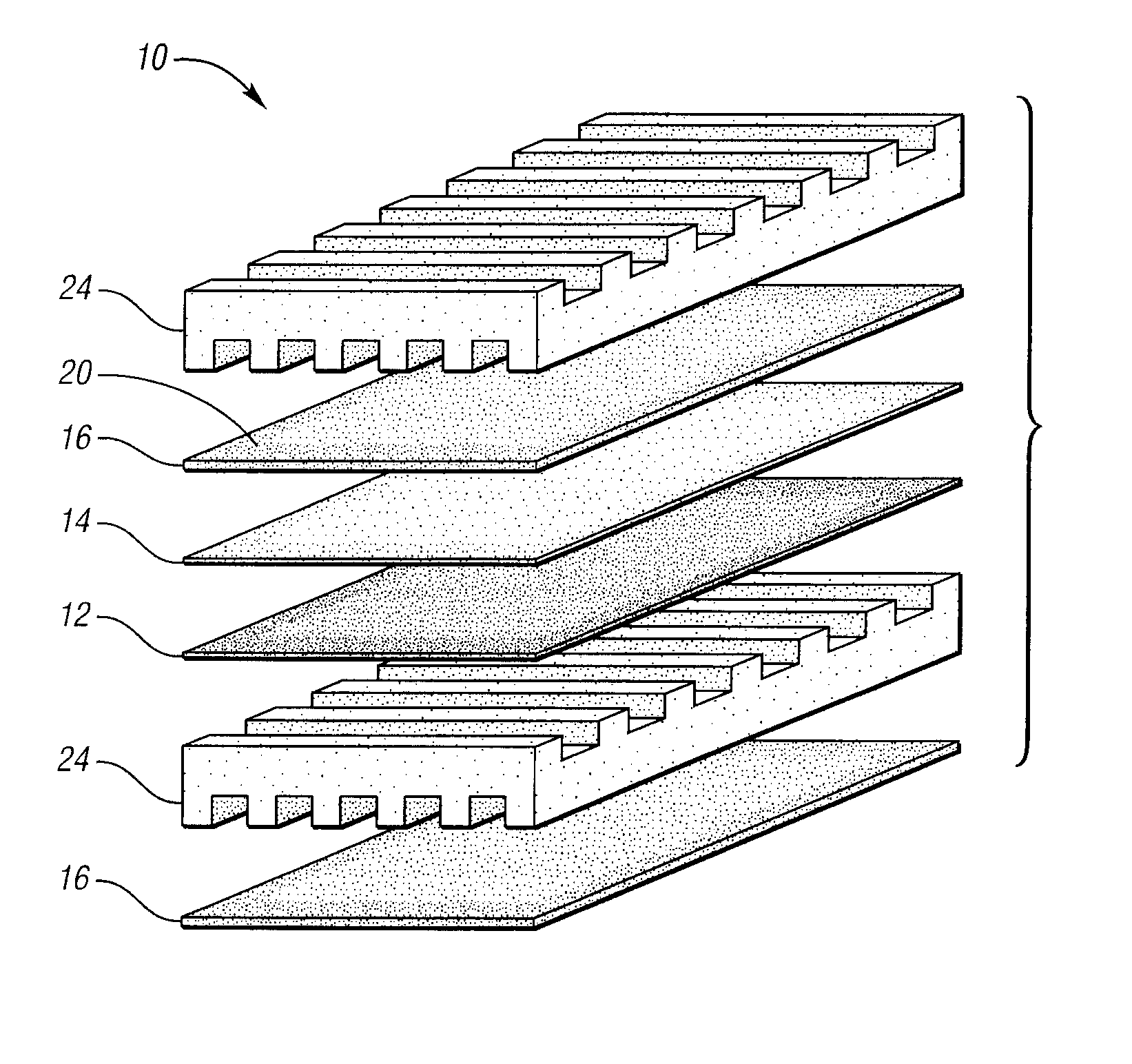

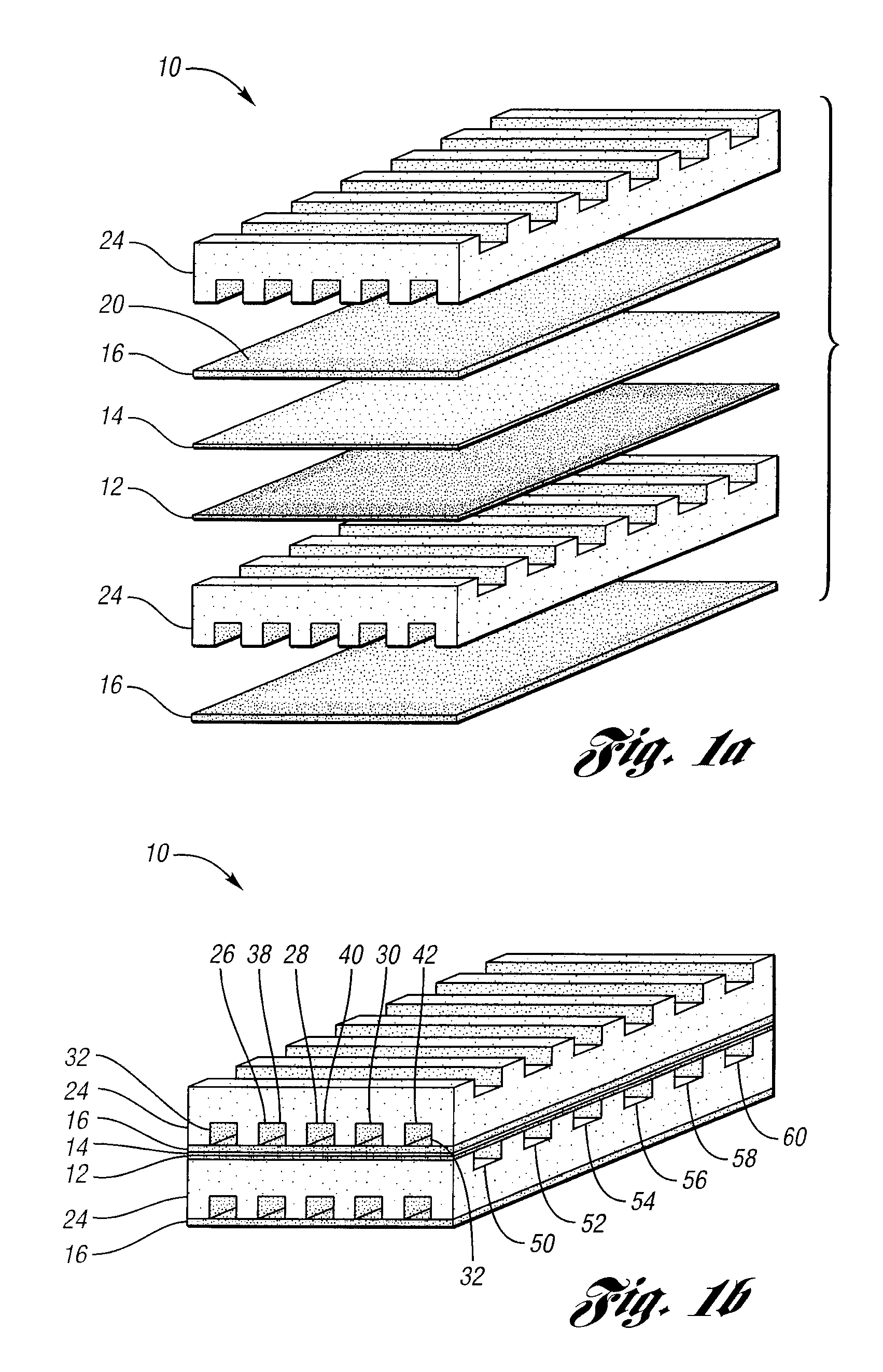

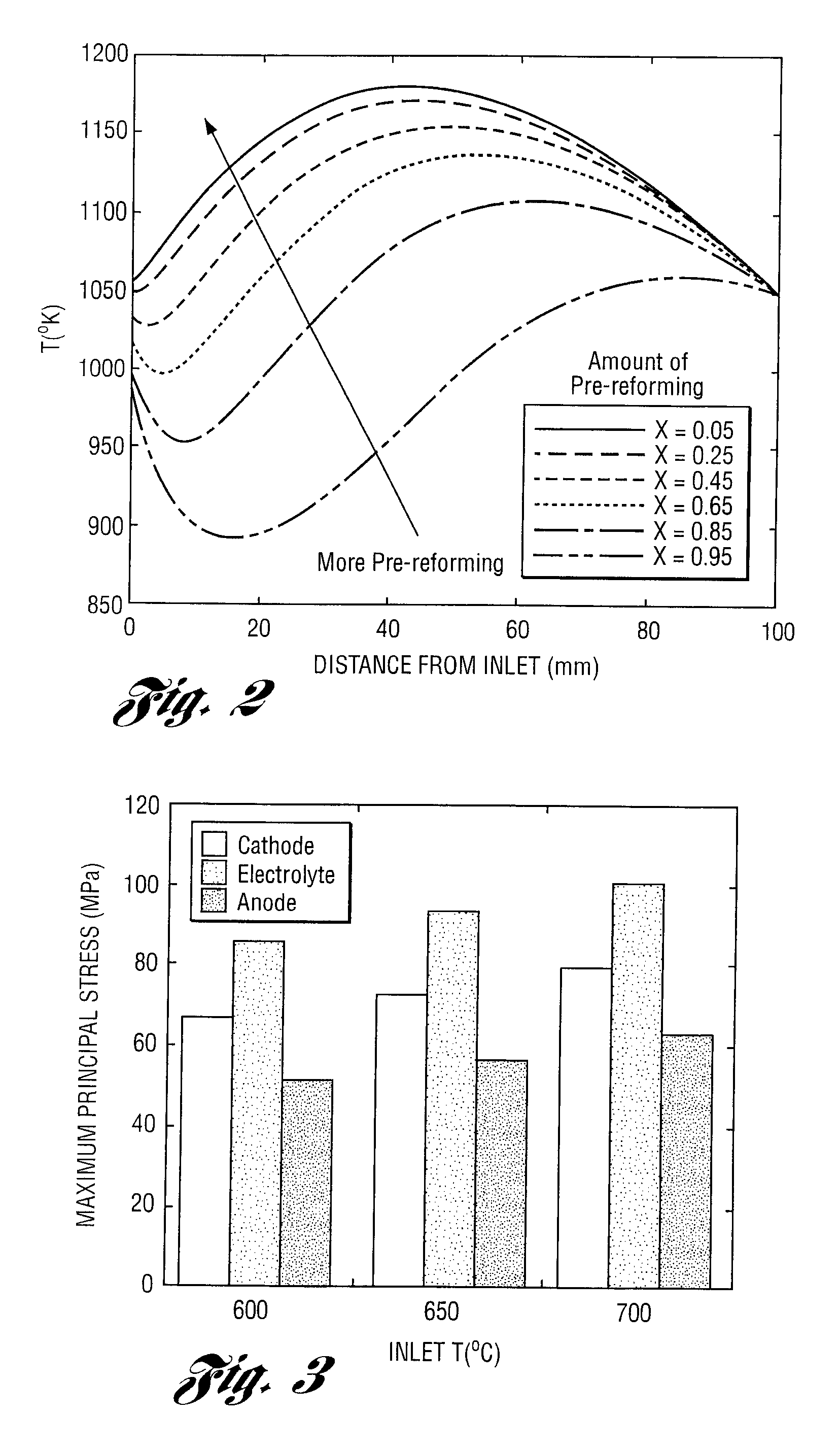

Apparatus and method for controlling kinetic rates for internal reforming of fuel in solid oxide fuel cells

ActiveUS20060014057A1Promote reformSlow reaction rateHydrogenActive material electrodesFuel cellsKinetic rate

The present invention provides a solid oxide fuel cell in which kinetic rates for internal reforming are controlled. The solid oxide fuel cell comprises a cathode, an electrolyte layer adjacent to the cathode, and an anode adjacent to the electrolyte layer. The anode used in the cell of the invention includes a support structure which defines at least a portion of an anode flow channel and a catalyst that promotes reforming. The anode flow channel has an anode flow channel entrance for the introduction of fuel to the solid oxide fuel cell and an anode flow channel exit for removing unreacted fuel and / or by-products. The catalyst is dispersed within or upon the support structure such that the rate of reforming increases at increasing distances from the anode flow channel entrance. The present invention also provides a method of controlling internal reforming kinetic rates in a solid oxide fuel cell.

Owner:FORD MOTOR CO

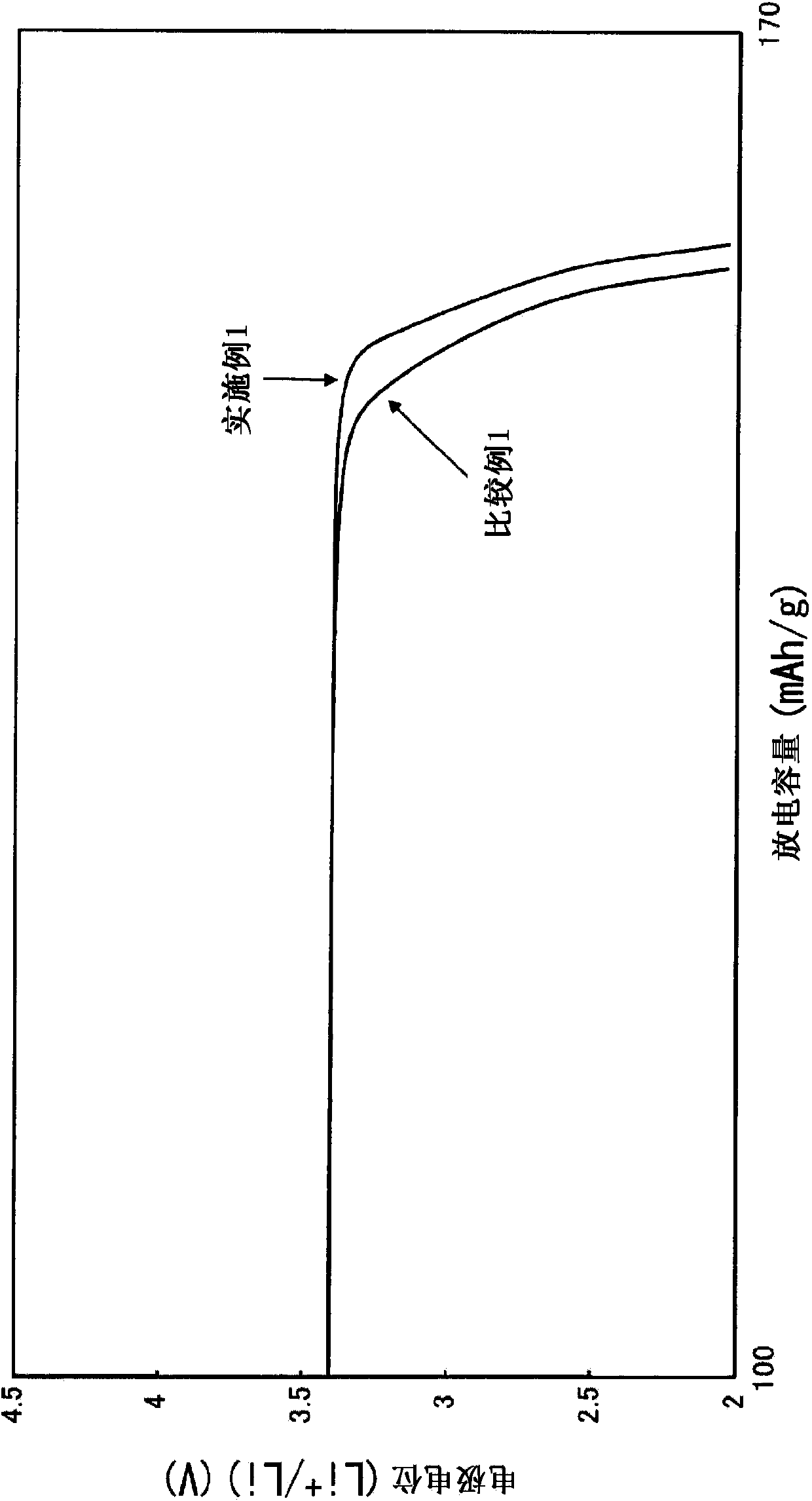

Solid electrolyte, preparation method thereof and lithium ion battery

ActiveCN106299468ALow electronic conductivityAvoid redox reactionsFinal product manufactureElectrolytesSolid state electrolyteElectrochemical window

In order to solve the problem of narrow electrochemical window of a solid electrolyte in the prior art, the invention provides a solid electrolyte. The solid electrolyte comprises a core material and a shell material, wherein the shell material wraps the core material, the core material has the following chemical formula: Li(1+x)MxTi(2-x)(PO4)3, M is selected from at least one of Al, La, Cr, Ga, Y and In, x is more than or equal to 0.05 but less than or equal to 0.4, the ionic conductivity of the shell material is over 10<-6>S / cm, and the electrochemical window of the solid electrolyte is larger than 5 volts. Meanwhile, the invention also discloses a preparation method of the abovementioned solid electrolyte and a lithium ion battery applying the solid electrolyte. The solid electrolyte provided by the invention is wide in electrochemical window and high in the ionic conductivity.

Owner:BYD CO LTD

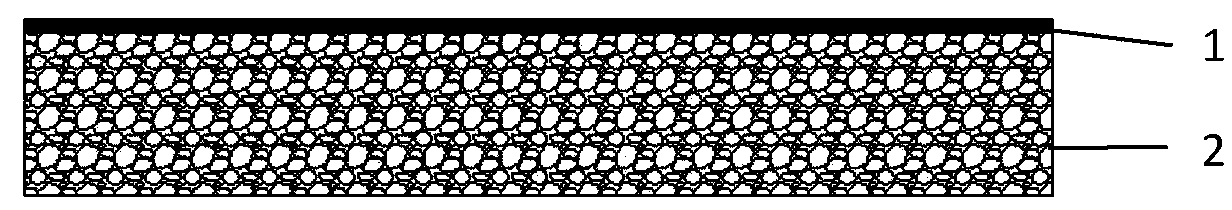

Low-impedance interface processing method of solid-state lithium battery positive electrode and positive electrode structure

ActiveCN109768215AImprove securityAvoid punctureNon-aqueous electrolyte accumulator electrodesSolid state electrolyteEngineering

The invention discloses a low-impedance interface processing method of a solid-state lithium battery positive electrode and a positive electrode structure. By the method, impedance of two interfaces between active material particle in a positive electrode plate and solid-state electrolyte particle and between the positive electrode plate and an electrolyte piece can be effectively reduced, so thatthe capacity of active positive electrode particle in the solid-state lithium battery can be effectively developed. The dual-layer structure ceramic piece comprising a solid-state electrolyte layer and a positive electrode layer and fabricated by the method is excellent in performance and has favorable application prospect in the field of solid-state lithium batteries.

Owner:杭州阳名新能源设备科技有限公司

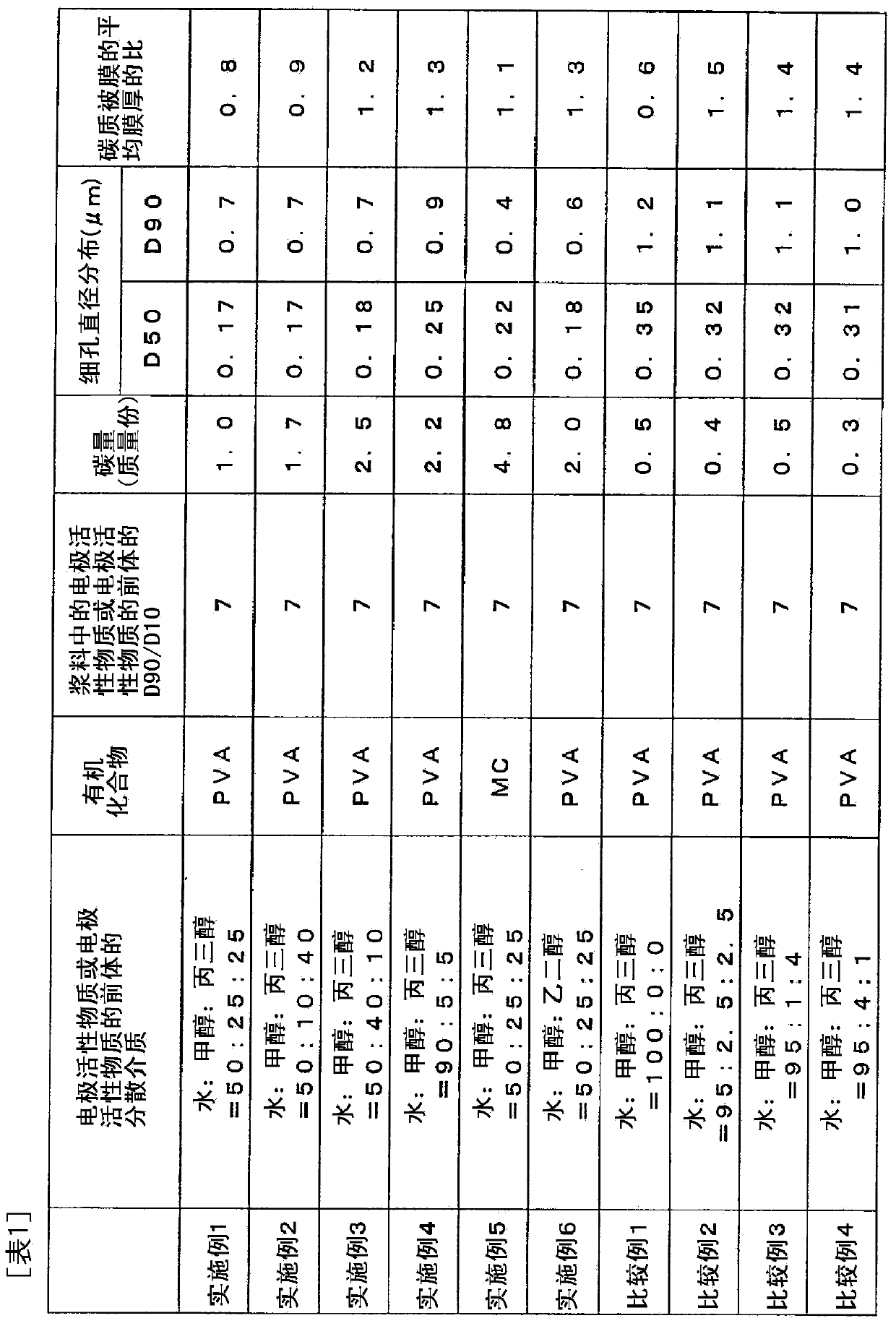

Electrode material, electrode and electrode material manufacturing method

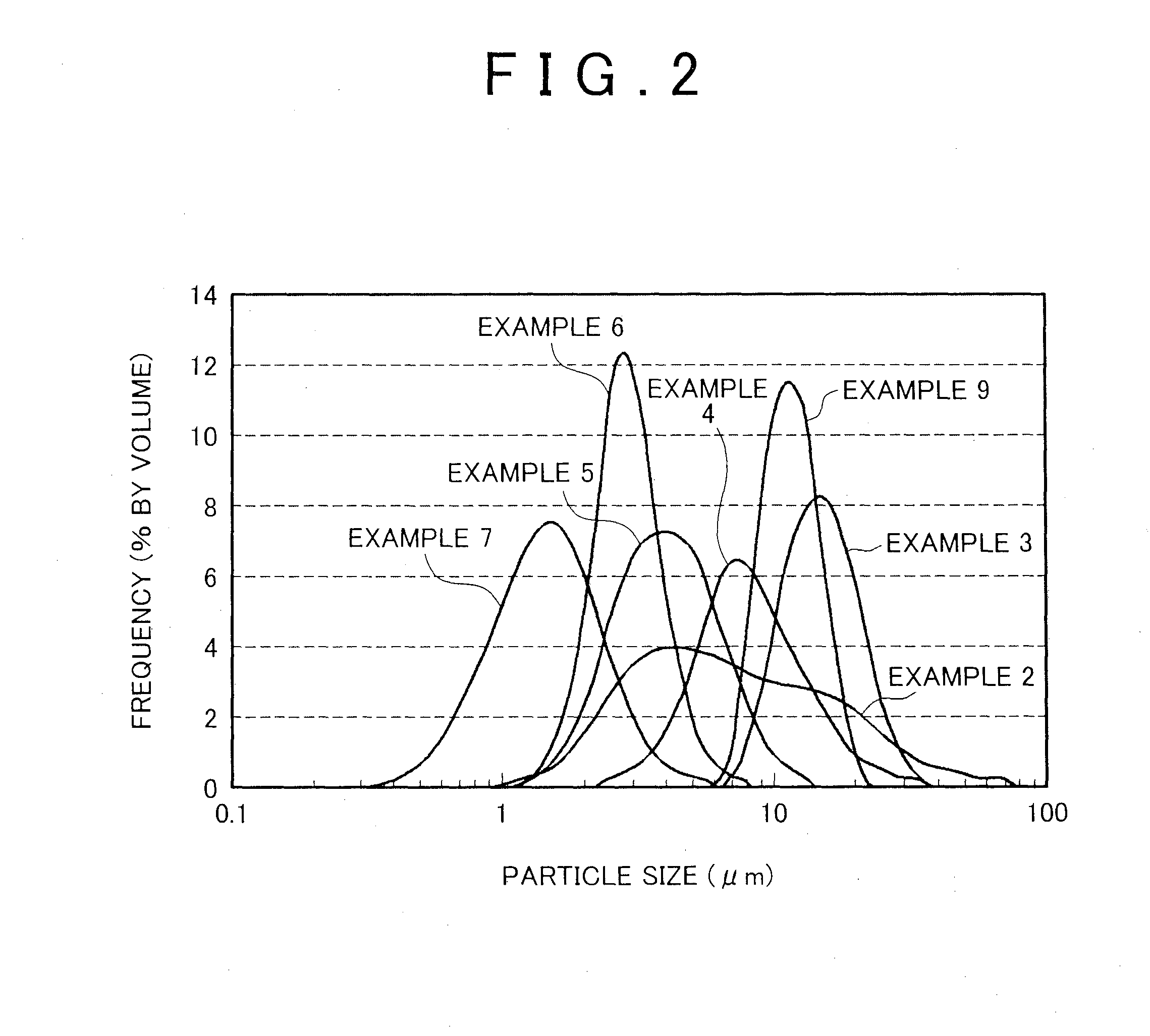

ActiveCN103828102AReduce load unevennessReduce the unevenness of electronic conductivityElectrode thermal treatmentPore distributionPore diameter

Provided are an electrode material, an electrode, and an electrode material manufacturing method for which, when using an electrode active material having a carbonaceous coating formed on the surface thereof as the electrode material, there is little nonuniformity in the amount of loaded carbonaceous coating and which can improve electronic conductivity. Said electrode material comprises aggregates obtained by aggregating electrode active material particles with a carbonaceous coating formed on the surface thereof. The mean particle diameter of the aggregates is 1.0 [mu]m to 100 [mu]m. The volume density is 50 volume% to 80 volume%. The pore distribution of pores present in the aggregates is monophasic and the mean pore diameter in the pore distribution is 0.3 [mu]m or less.

Owner:SUMITOMO METAL MINING CO LTD

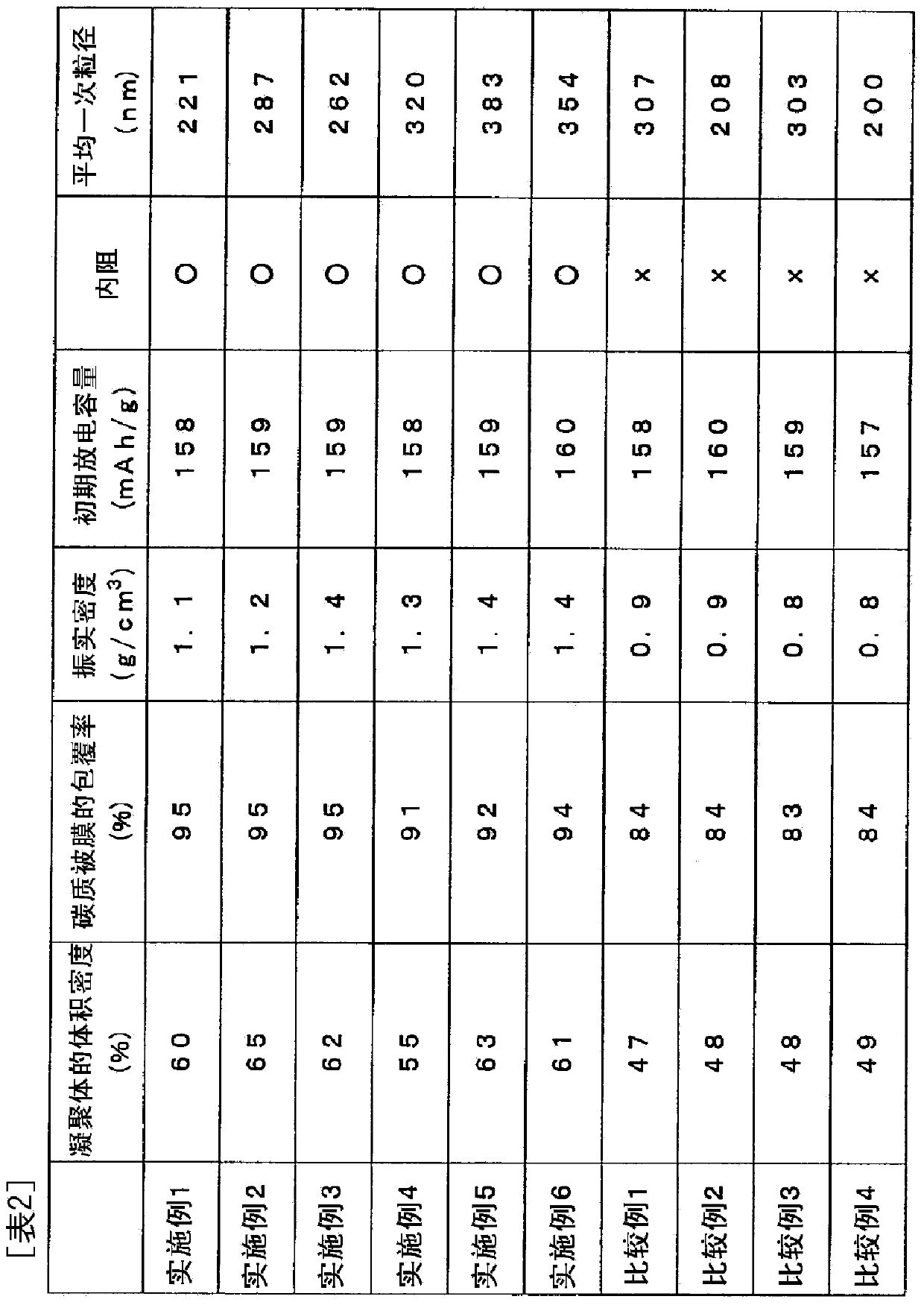

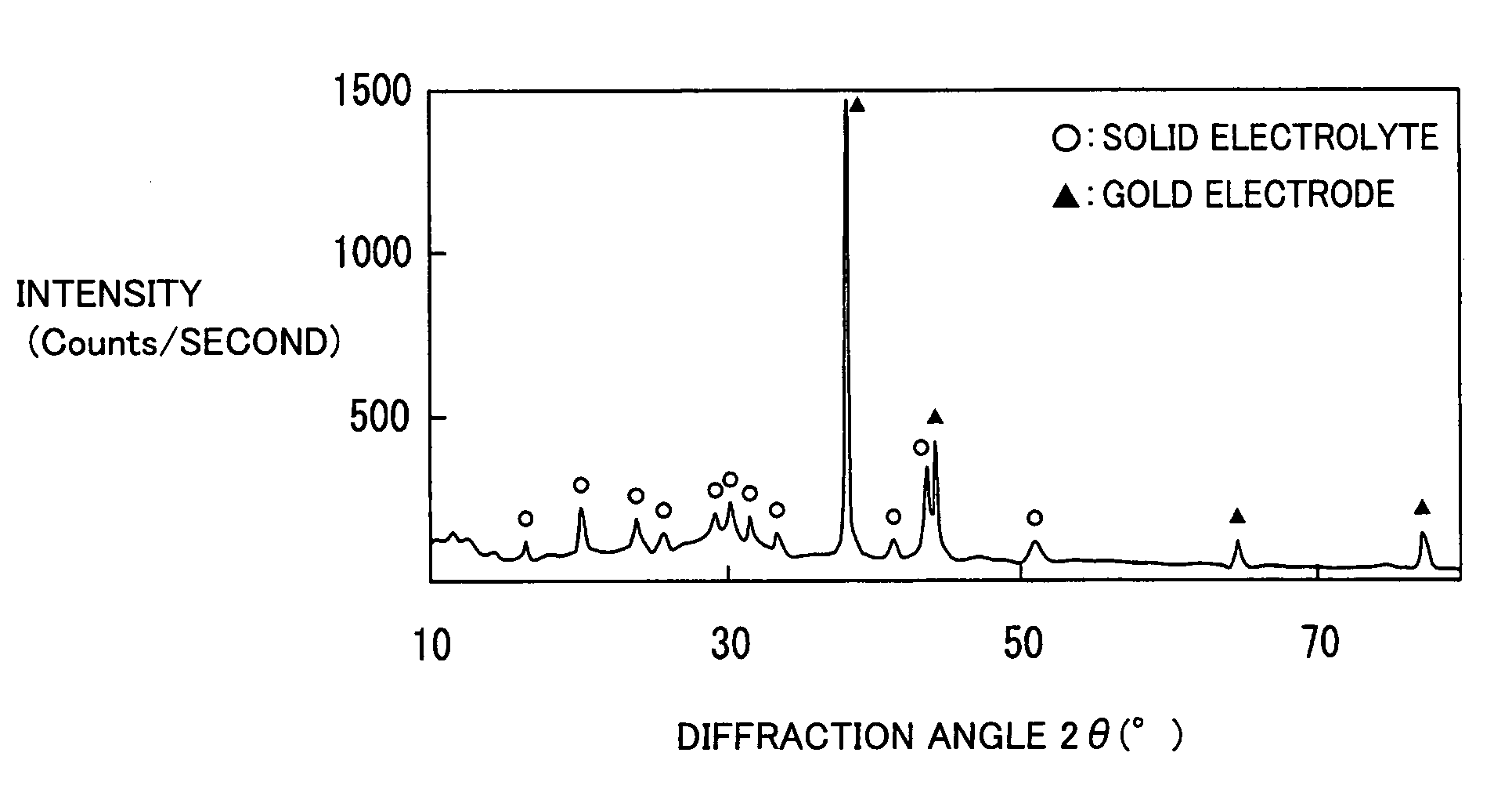

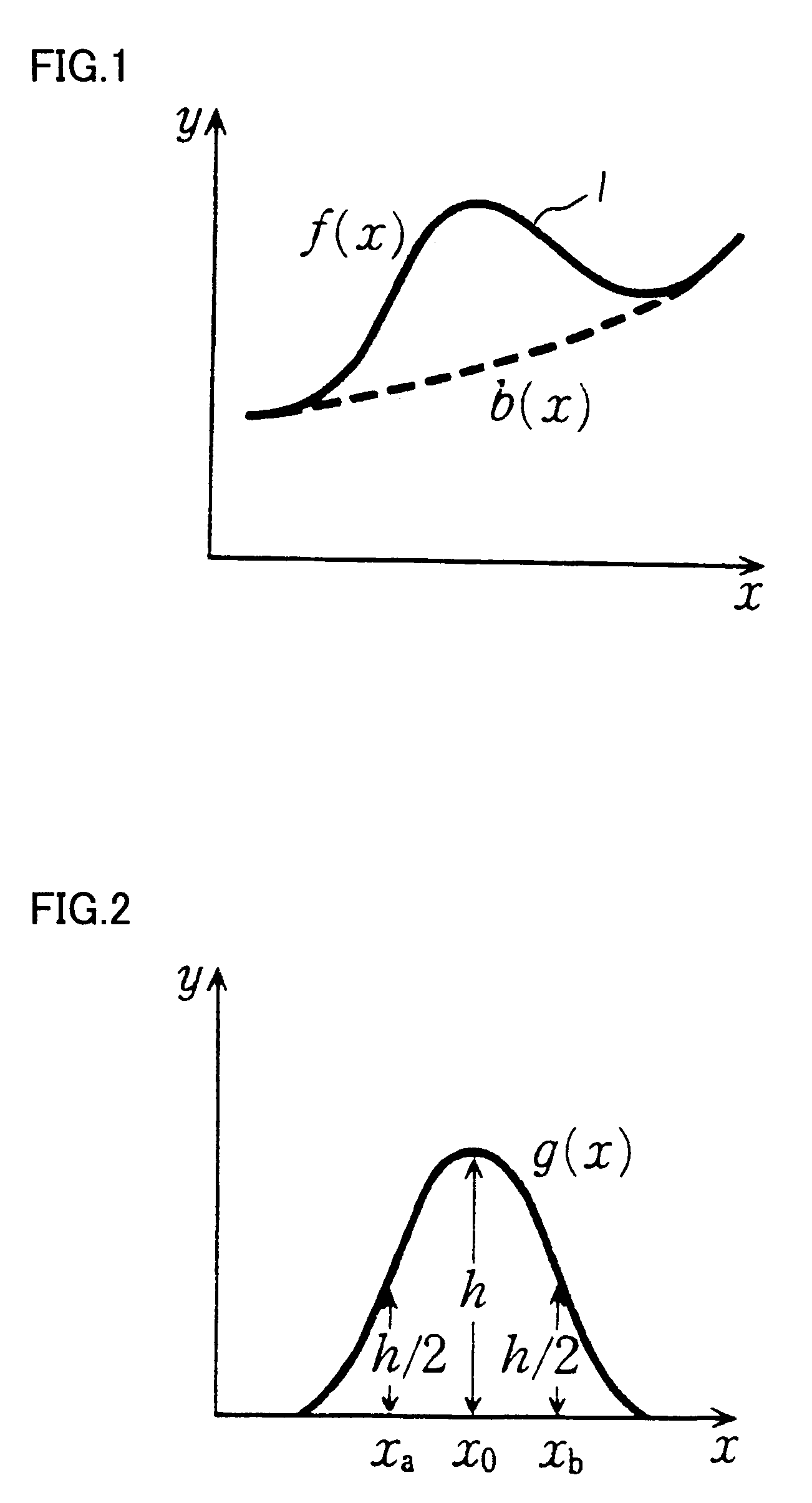

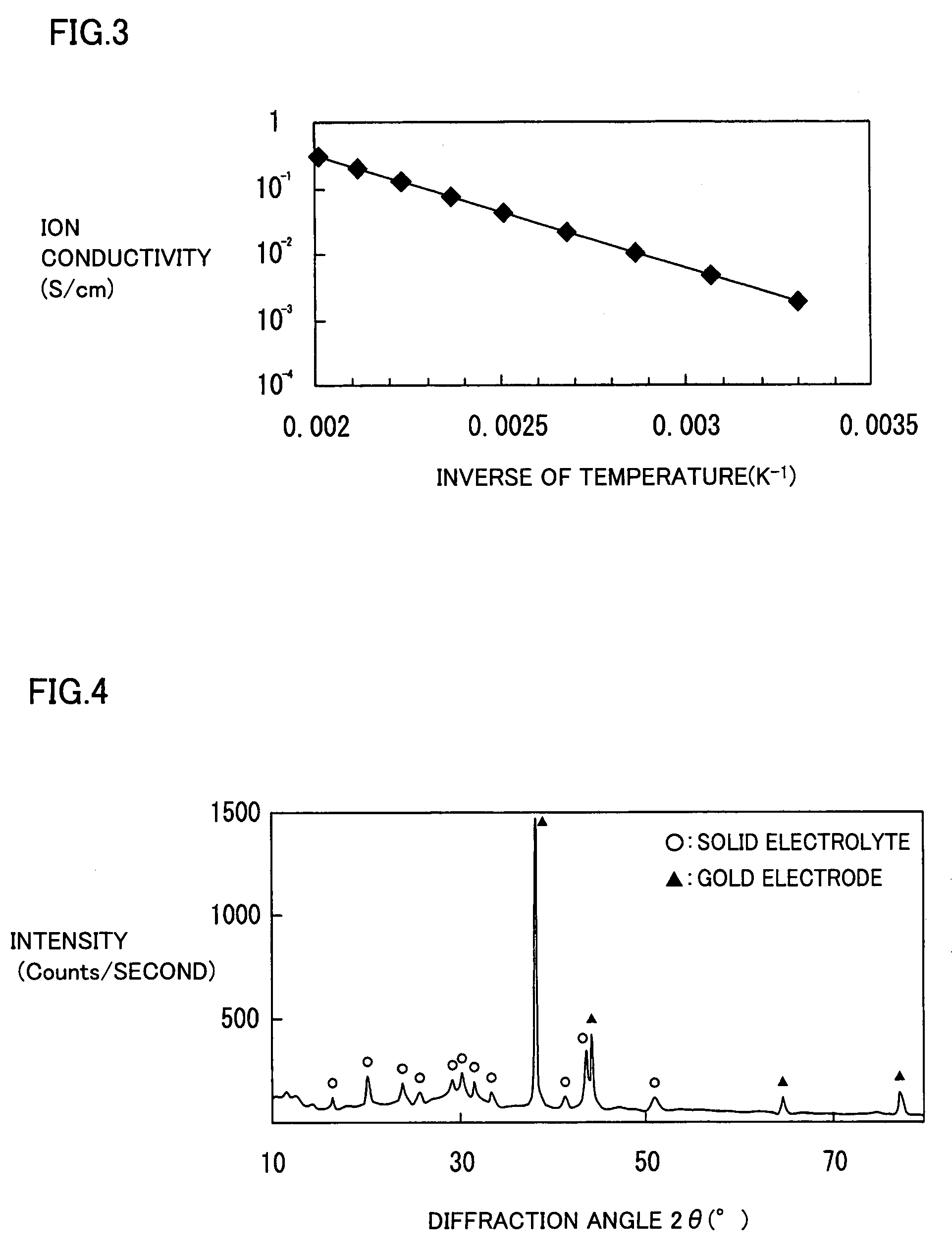

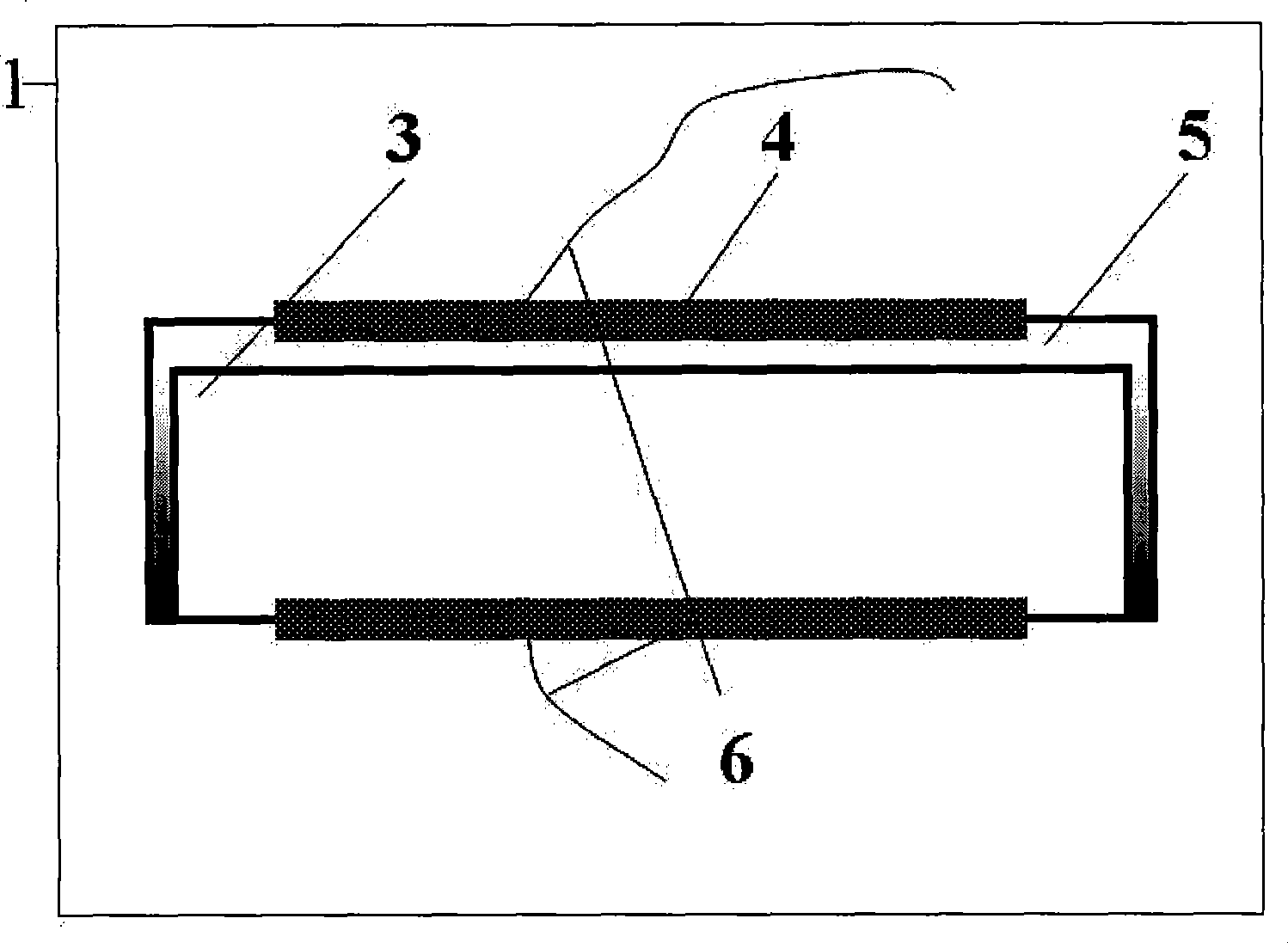

Solid electrolyte and method of producing the same

InactiveUS7901598B2Improve pressure resistanceImprove ionic conductivityConductive materialVacuum evaporation coatingCrystallographyLithium

A solid electrolyte and a method of manufacturing the same are provided. The solid electrolyte contains x atomic % of lithium, y atomic % of phosphorus, z atomic % of sulfur, and w atomic % of oxygen, in whichthe x, the y, the z, and the w satisfy the following expressions (1)-(5):20≦x≦45 (1)10≦y≦20 (2)35≦z≦60 (3)1≦w≦10 (4)x+y+z+w=100 (5), andapexes of X-ray diffraction peaks in an X-ray diffraction pattern obtained by an X-ray diffraction method using a Kα-ray of Cu exist at diffraction angles 2θ of 16.7°±0.25°, 20.4°±0.25°, 23.8°±0.25°, 25.9°, 0.25°, 29.4°±0.25°, 30.4°±0.25°, 31.7°±0.25°, 33.5°±0.25°, 41.5°±0.25°, 43.7°±0.25°, and 51.2°±0.25°, respectively, in the X-ray diffraction pattern, and a half-width of each of the X-ray diffraction peaks is not larger than 0.5°.

Owner:SUMITOMO ELECTRIC IND LTD

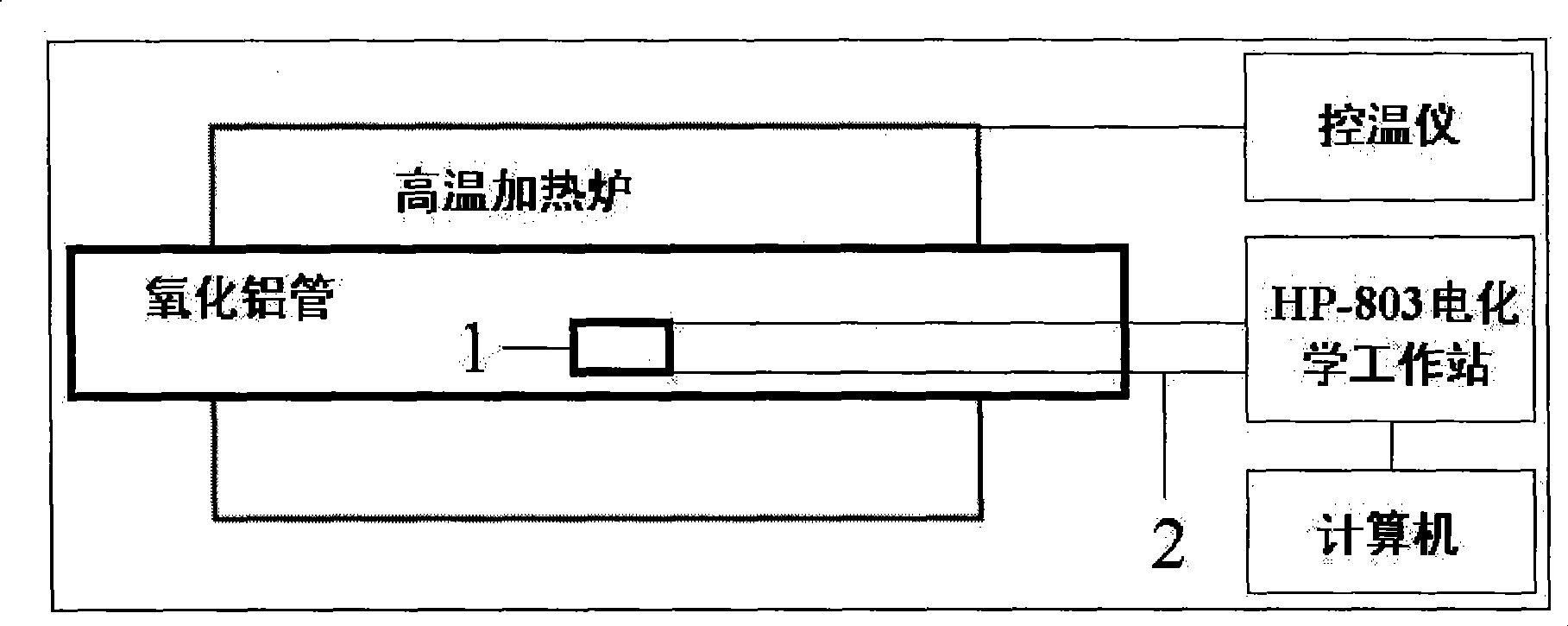

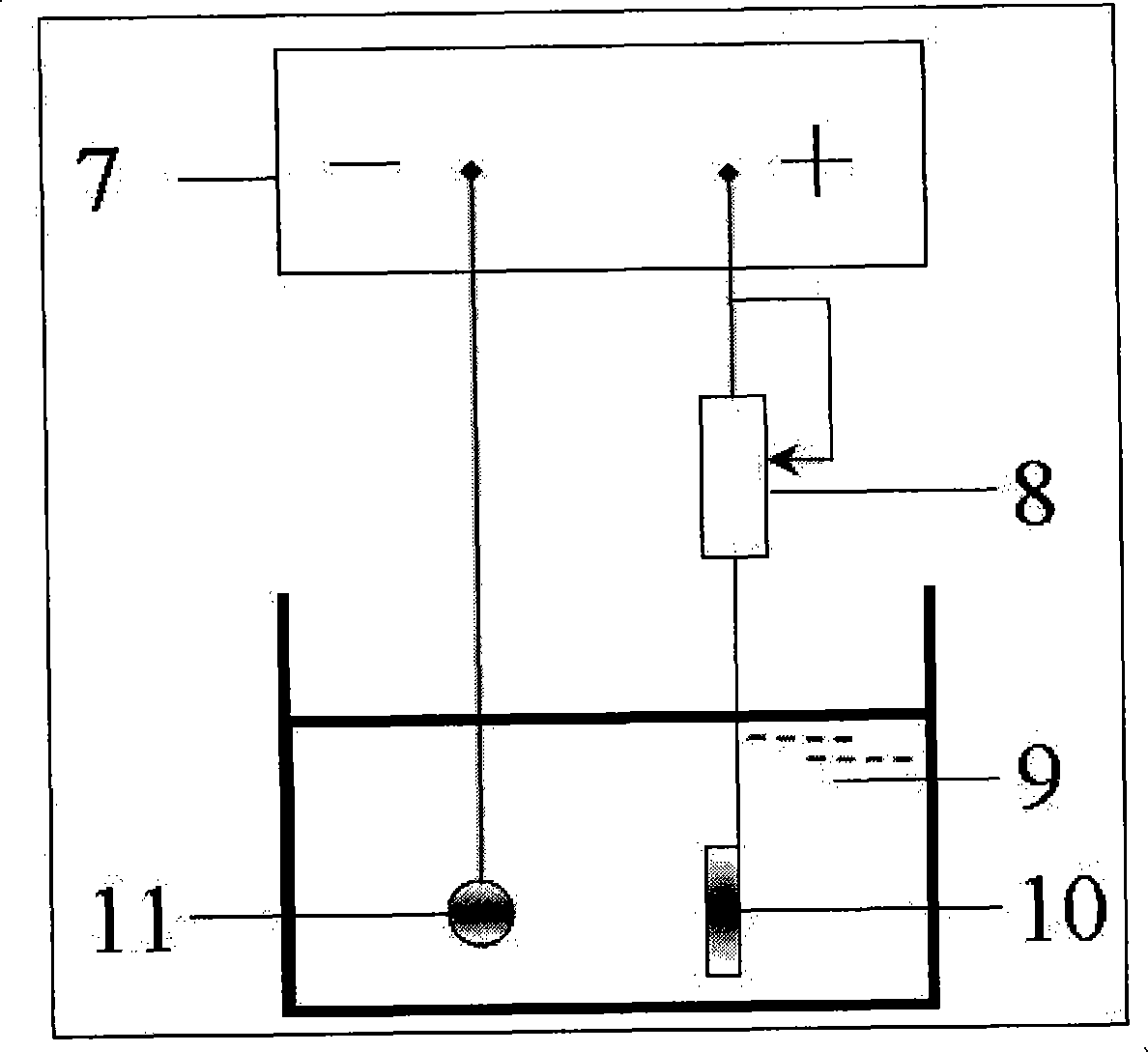

Method of preparing ion blocking electrode battery for measuring electronic conduction

InactiveCN101435835AImprove porosity and porositySolve the binding puzzleResistance/reactance/impedenceElectrical conductorElectrical battery

The invention relates to a method for preparing an ion blocked electrode battery for measuring the electron conductivity of a solid electrolyte material, which can be used for the research and representation of the electrical performance of an ionic conduction material and belongs to the field of detecting the electrical performance of functional ceramics. The invention provides a novel method for preparing the ion blocked electrode battery, that is, the method utilizes the property of high melting point of metal nickel, combines a chemical nickel plating method, solves the problem of the combination between nickel as a metal material and a ceramic material (such as a YSZ solid electrolyte material) and utilizes the electroplating method to solve the problem that the metal nickel of the ion blocked electrode material is loose and porous, thereby forming a dense ion blocked electrode which is tightly combined with a substrate material and has no oxygen leaking gap. Based on the principle of a Hebb-Wagner polarization method, the electron conductivity of an ionic conductor material at high temperature is measured. As a thin blocked electrode layer is tightly combined with the substrate material, has no oxygen leaking gap, stops the factors causing error and thus can ignore an electrode resistance and a contact resistance, thereby obtaining the accurate electron conductivity value.

Owner:SHANGHAI UNIV

Electrode-active material, electrode material, electrode, lithium ion battery, and method of producing electrode material

InactiveUS20140322604A1Low electronic conductivityImprove electronic conductivityNon-aqueous electrolyte accumulator electrodesPhosphorus compoundsRare-earth elementLithium-ion battery

An electrode-active material includes sulfur or a sulfur compound in particles represented by LixAyDzPO4 (wherein A represents one or two or more elements selected from the group consisting of Co, Mn, Ni, Fe, Cu, and Cr; D represents one or two or more elements selected from the group consisting of Mg, Ca, Sr, Ba, Ti, Zn, B, Al, Ga, In, Si, Ge, Sc, Y, and rare earth elements; 0<x<2; 0<y<1; and 0≦z<1.5), in which a sulfur content in the particles is high in the centers of the particles and is low in the vicinity of surfaces of the particles.

Owner:SUMITOMO OSAKA CEMENT CO LTD

Actuator film material, actuator film and actuator using the same

ActiveUS7064473B2Light weightLow operating noisePiezoelectric/electrostriction/magnetostriction machinesMachines/enginesConductive polymerActuator

Owner:HITACHI LTD

Nonaqueous electrolyte secondary battery

ActiveUS20160211520A1Reduce conductivityElectron conductivity can be damagedOrganic electrolyte cellsPositive electrodesInorganic phosphateLithium

According to the present invention, a nonaqueous electrolyte secondary battery that includes a positive electrode, a negative electrode and a nonaqueous electrolyte is provided. The positive electrode has an operation upper limit potential of 4.3 V or more based on metal lithium and includes a positive electrode active material and an inorganic phosphate compound that has ion conductivity. The inorganic phosphate compound is in a particle state. A ratio of particles having a particle size of 20 μm or more is 1% by volume or less when an entirety of the inorganic phosphate compound is set to 100% by volume. Further, a ratio of particles having a particle size of 10 μm or more may be 10% by volume or less when an entirety of the inorganic phosphate compound is set to 100% by volume.

Owner:TOYOTA JIDOSHA KK

Solid-state Lithium Ion Conductor And Electrochemical Device

ActiveCN104064774AImprove ionic conductivityLow electronic conductivityCell electrodesSecondary cellsElectrical conductorPhysical chemistry

Owner:TDK CORPARATION

Solid-state lithium ion conductor and electrochemical device

InactiveUS20140272602A1Improve ionic conductivityLow electronic conductivityPhosphorus sulfur/selenium/tellurium compoundsSecondary cellsElectrochemistryMaterials science

Owner:TDK CORPARATION

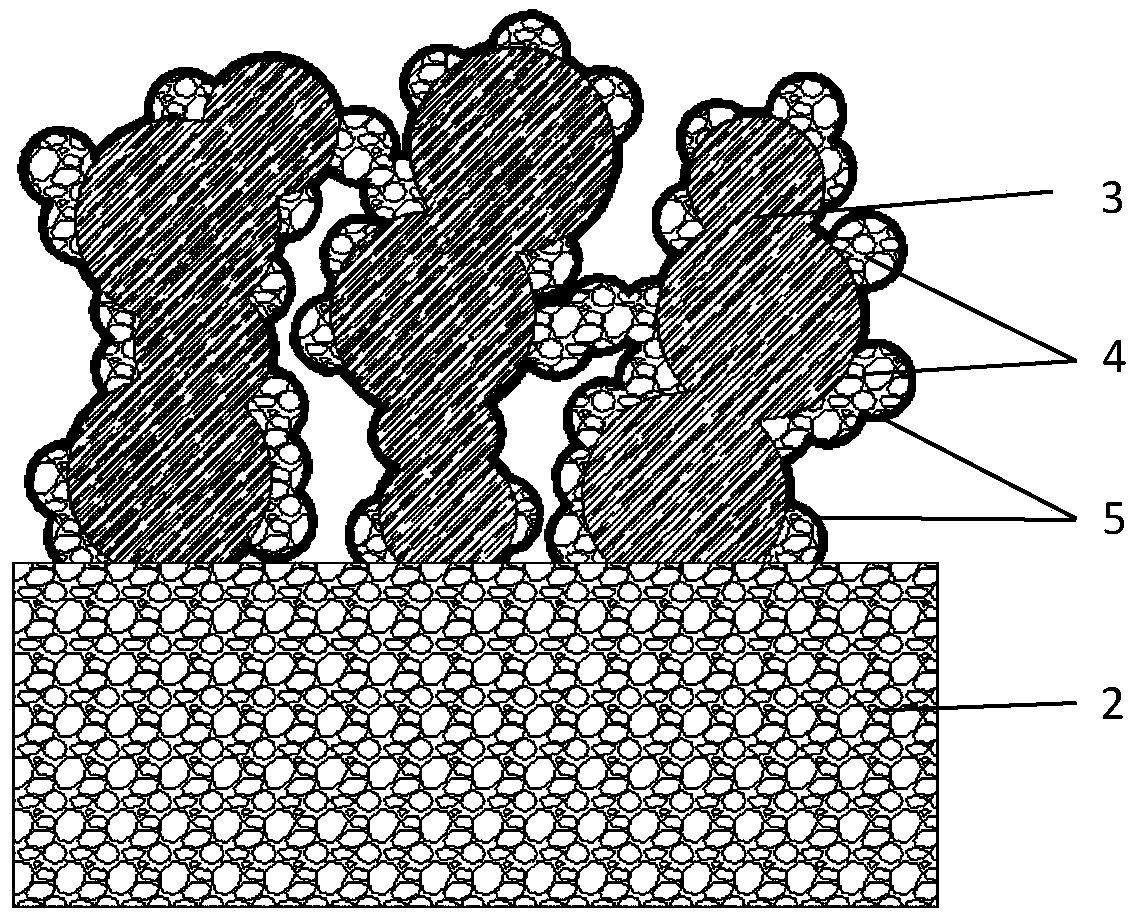

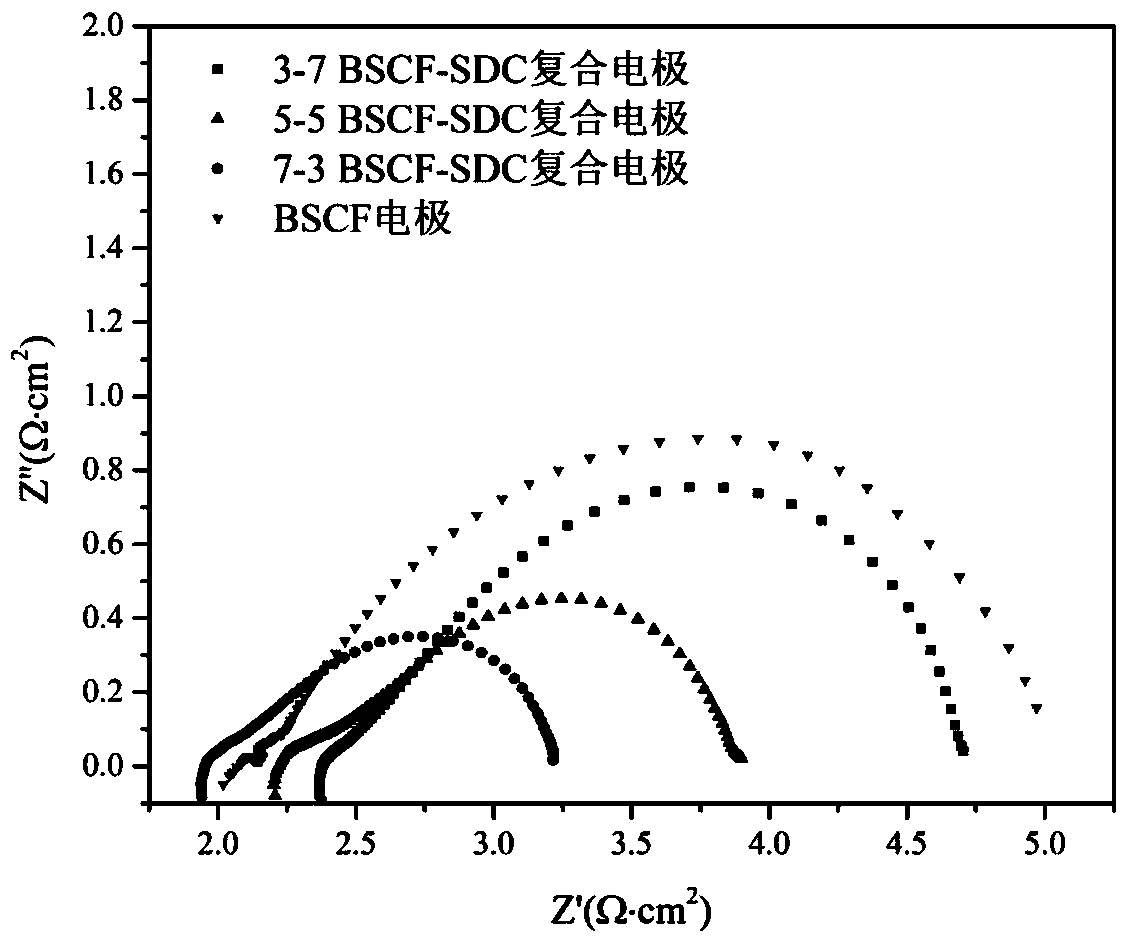

Composite oxygen electrode used for solid oxide electrolytic tank and preparing method of composite oxygen electrode

ActiveCN109468661AImproved electrochemical performance and long-term stabilityIncreased electrochemical reactive areaElectrode shape/formsOxideElectrolyte

The invention discloses a composite oxygen electrode used for a solid oxide electrolytic tank and a preparing method of the composite oxygen electrode. The composite oxygen electrode comprises an electrolyte layer, a substrate layer and active coating layers. The substrate layer is a BSCF-SDC composite porous material and covers the electrolyte layer. The active coating layers cover the outer surface of the BSCF-SDC composite porous material and the inner surfaces of pores. By means of the composite oxygen electrode, the BSCF-SDC composite porous material is adopted as the electrode body material, then the Ln2NiO4 active coating layers with good electric conductivity and CO2 tolerance are formed on the surface of the composite porous material and in the pores, and the electrochemical property and long-term stability of the composite oxygen electrode material are obviously improved.

Owner:CENT SOUTH UNIV

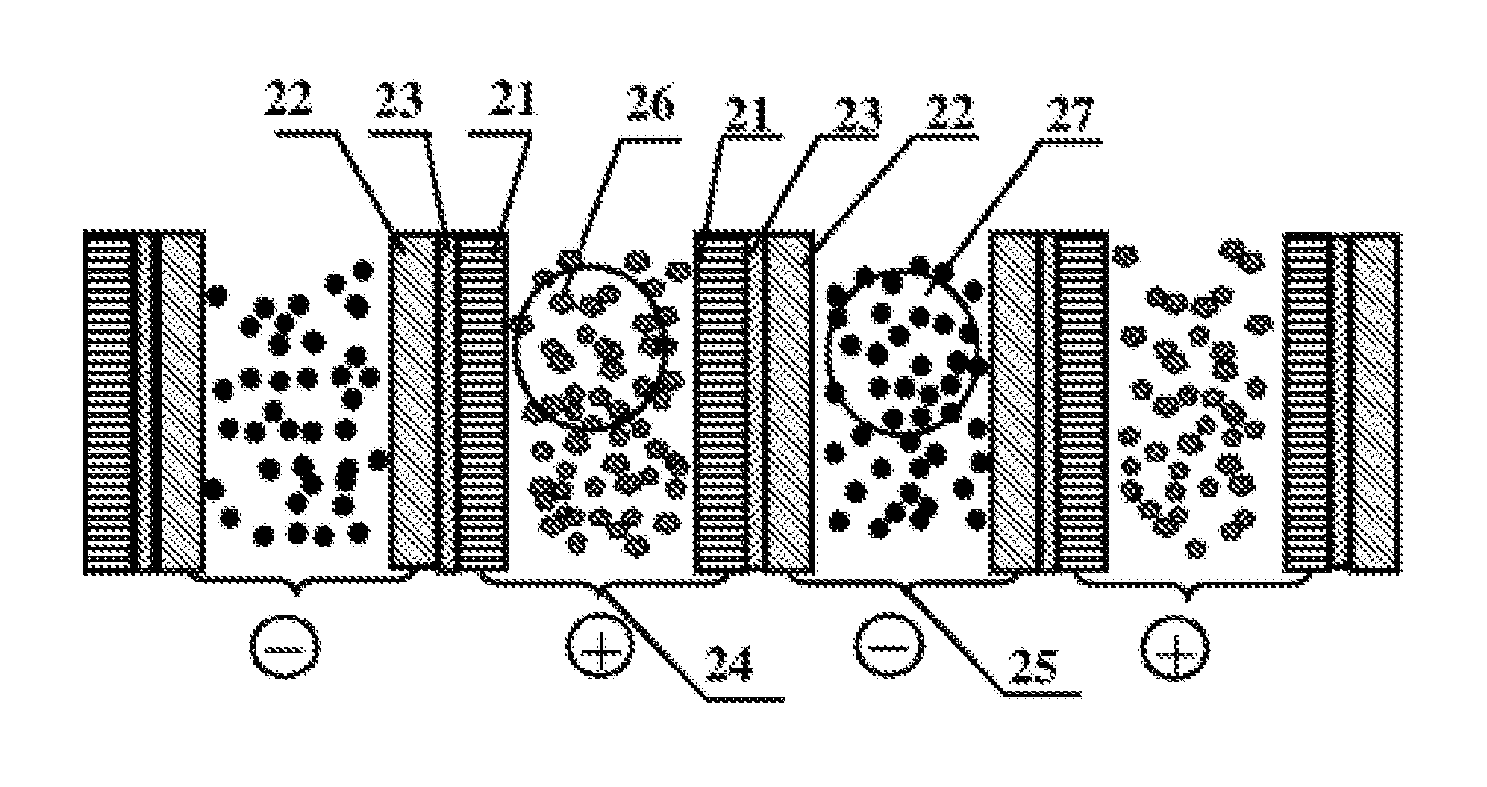

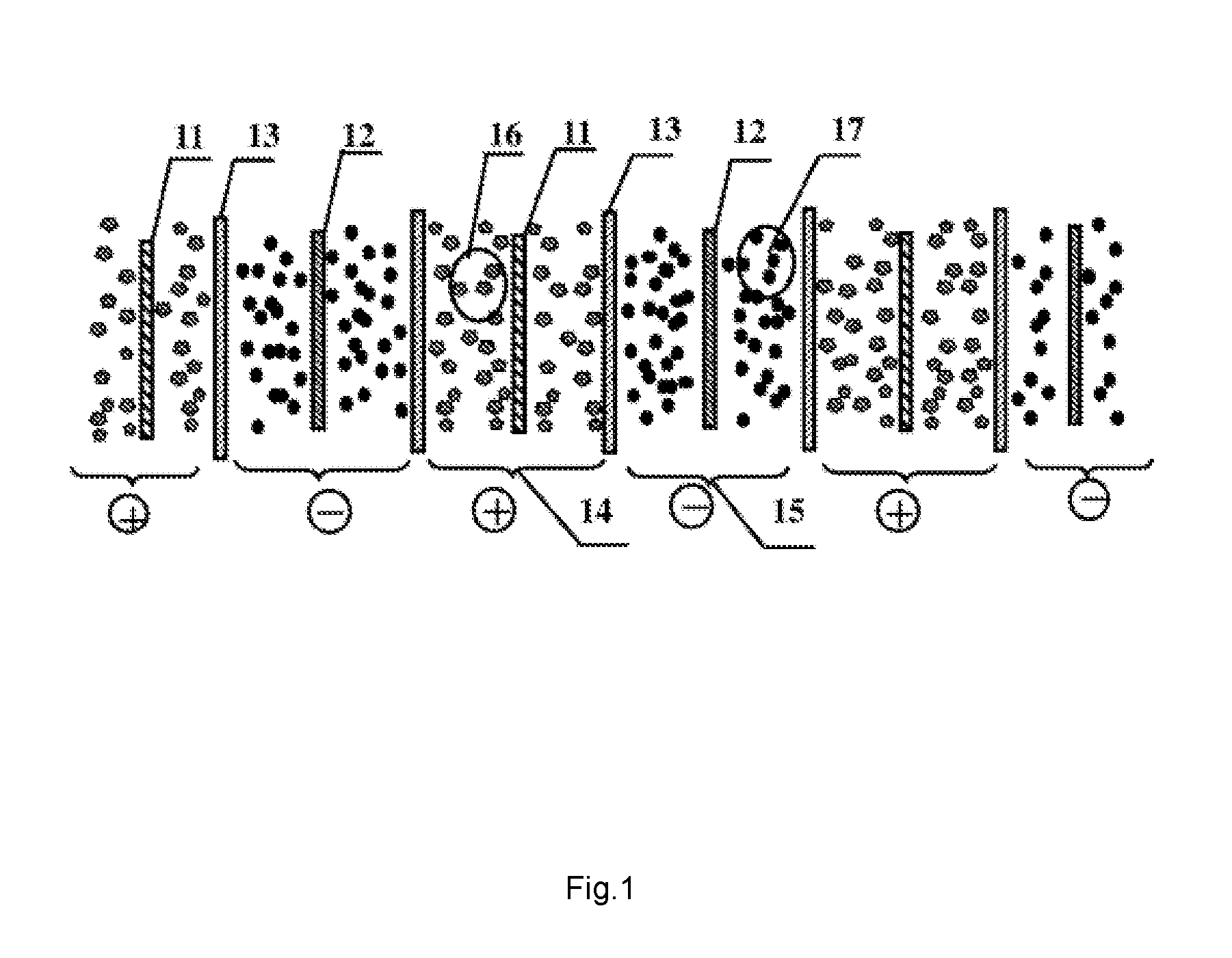

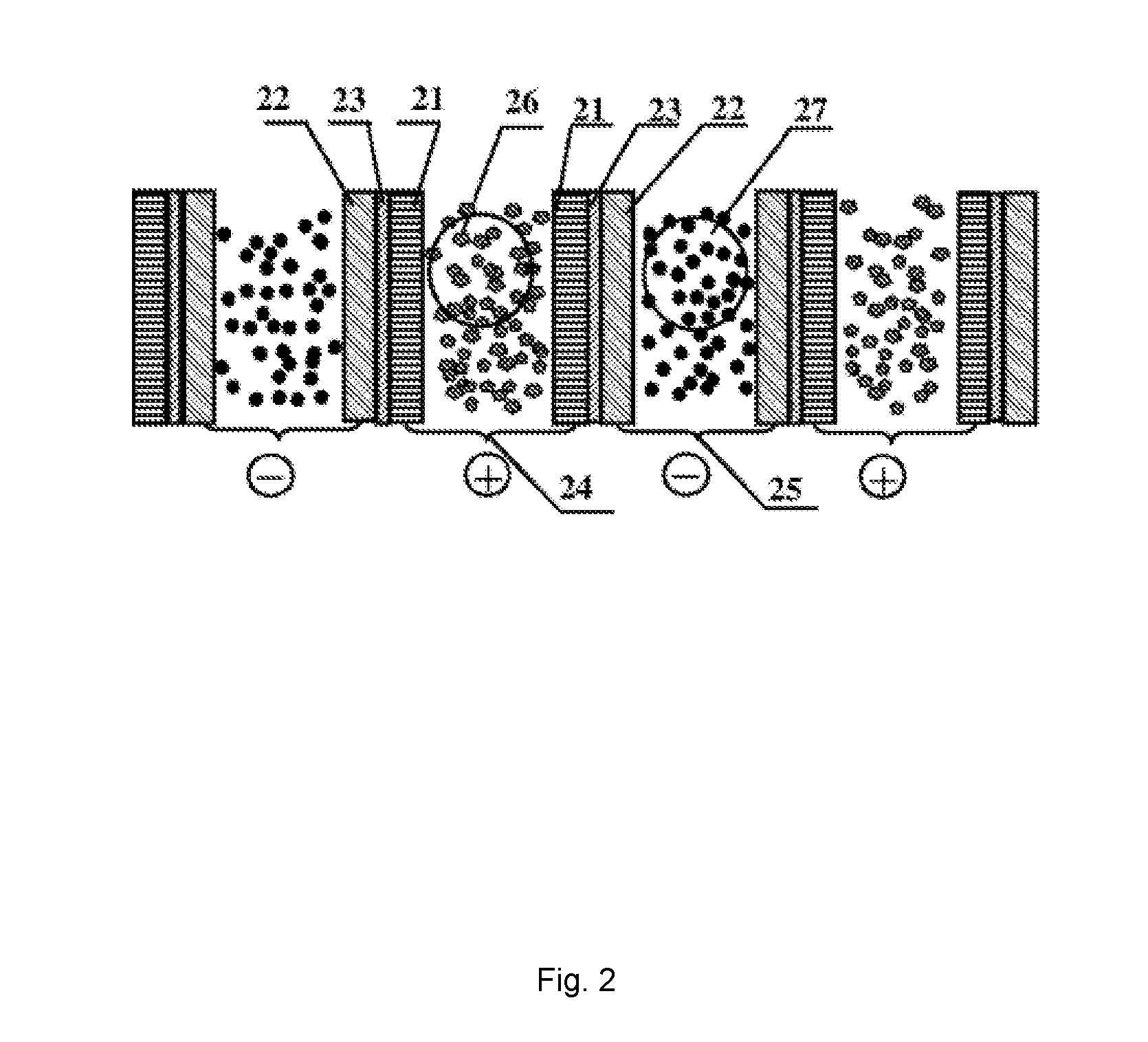

A novel lithium ion flow battery

ActiveUS20160329569A1Current is limitedGood electrical conductionElectrolyte holding meansCell electrodesInternal resistanceElectrical polarity

A lithium ion flow battery comprising cathode current collectors (21), an anode current collector (22), a cathode reaction chamber (24), an anode reaction chamber (25), a separator (23), a cathode suspension solution (26) and an anode suspension solution (27), wherein the cathode and anode current collectors are located at both sides of the separator respectively and are in close contact with the separator to form sandwich composite structure layers of the cathode current collector, the separator and the anode current collector; and in that several sandwich composite structure layers are arranged in sequence in an order that current collectors with the same polarity are oppositely arranged, and the electrode suspension solution continuously or intermittently flows in a battery reaction chamber between adjacent sandwich composite structure layers. Thus, the size of the battery reaction chamber can be flexibly designed according to the viscosity of the electrode suspension solution without increasing the polarization internal resistance of the battery, thereby solving the restriction conflict existing in the existing lithium ion flow battery between the size of the battery reaction chamber and the polarization internal resistance of the battery.

Owner:BEIJING HAWAGA POWER STORAGE TECH

Solid electrolyte and preparation method thereof, and lithium ion battery

ActiveCN109428115AReduce crystallinityLow electronic conductivitySecondary cellsPhosphorus compoundsSolid state electrolyteAluminium-ion battery

The invention relates to the field of lithium ion batteries, and specifically relates to a solid electrolyte and a preparation method thereof, and a lithium ion battery. The solid electrolyte is of acore-shell structure; the core-shell structure comprises a core material and a shell material coated outside the core material; and the core material has a perovskite structure, and the shell materialcontains Li3+yY2SiyP3-yO12, wherein y is greater than or equal to 0.05 but less than or equal to 0.5. The invention further relates to the preparation method of the solid electrolyte. The invention further relates to the lithium iron battery, and the lithium ion battery includes a positive electrode, a negative electrode, and the solid electrolyte disposed between the positive electrode and the negative electrode. The solid electrolyte provided by the invention has a wide electrochemical window and a relatively high ionic conductivity, and has a wide application.

Owner:BYD CO LTD

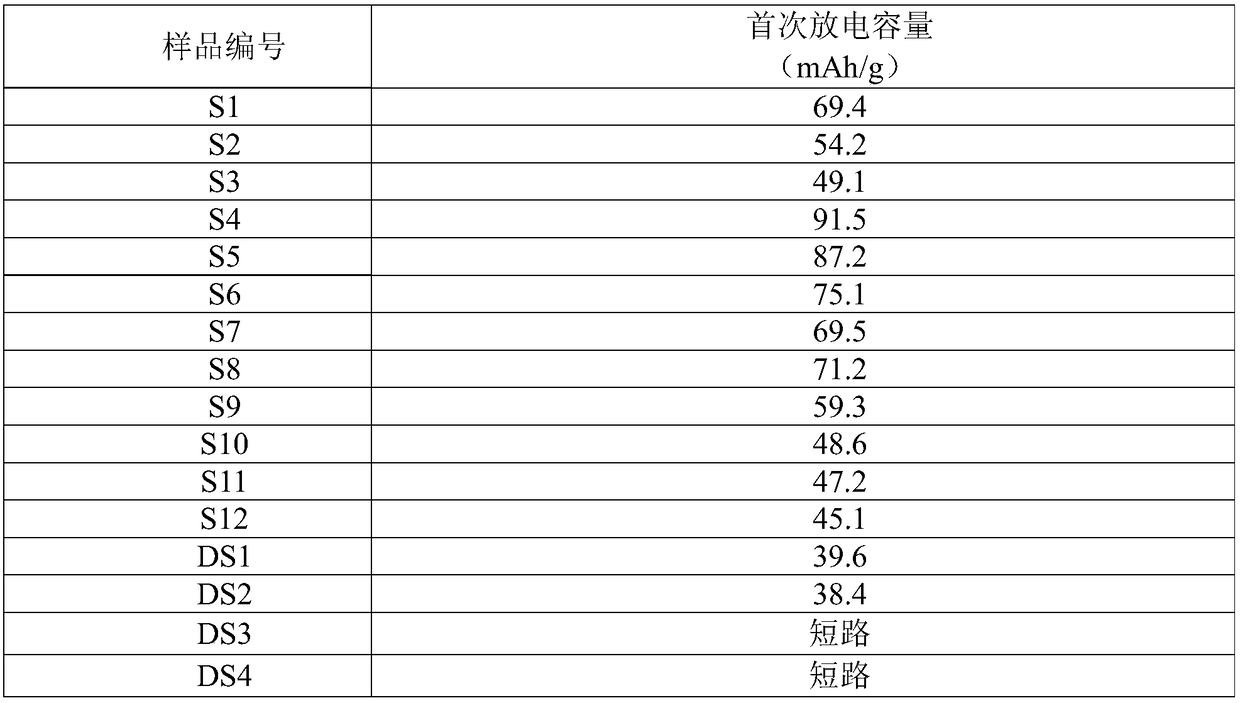

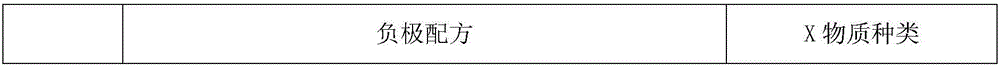

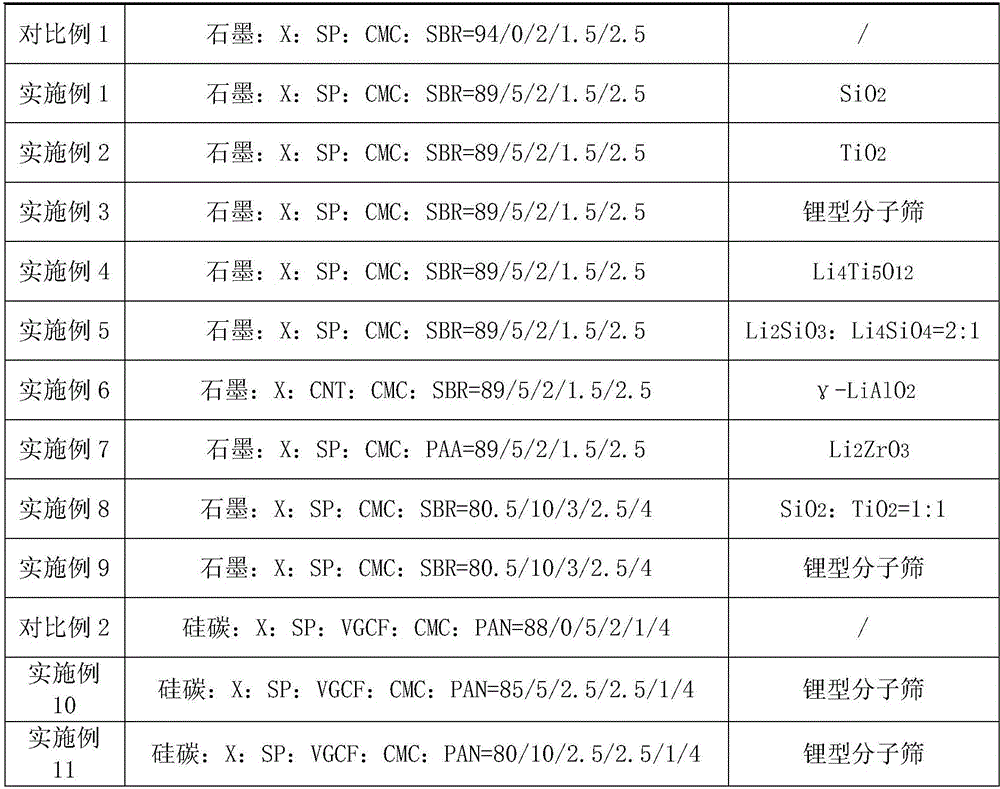

High-safety and high-performance negative electrode of lithium ion battery and battery of negative electrode

InactiveCN106252587ASimple processImprove pass rateNon-aqueous electrolyte accumulator electrodesInorganic compoundElectron

The invention creates a negative electrode of a lithium ion battery. A special inorganic compound is uniformly added to a negative electrode active substance of the negative electrode, and the special inorganic compound is an inorganic substance or a mixture of the inorganic substance which has the characteristics of ion conduction and non-electron conduction in the lithium ion negative electrode. With the negative electrode created by the invention, the situation that the effect of an inorganic insulation coating layer cannot be developed due to acupuncture randomness can be avoided, and the acupuncture safety of a battery cell is remarkably improved.

Owner:TIANJIN ENERGIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com