Electrode material, electrode and electrode material manufacturing method

A technology of electrode materials and electrode active substances, which is applied in the direction of electrode manufacturing, battery electrodes, electrode heat treatment, etc., can solve the problem of low electronic conductivity, reduce the unevenness of electronic conductivity, reduce internal resistance, internal resistance small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

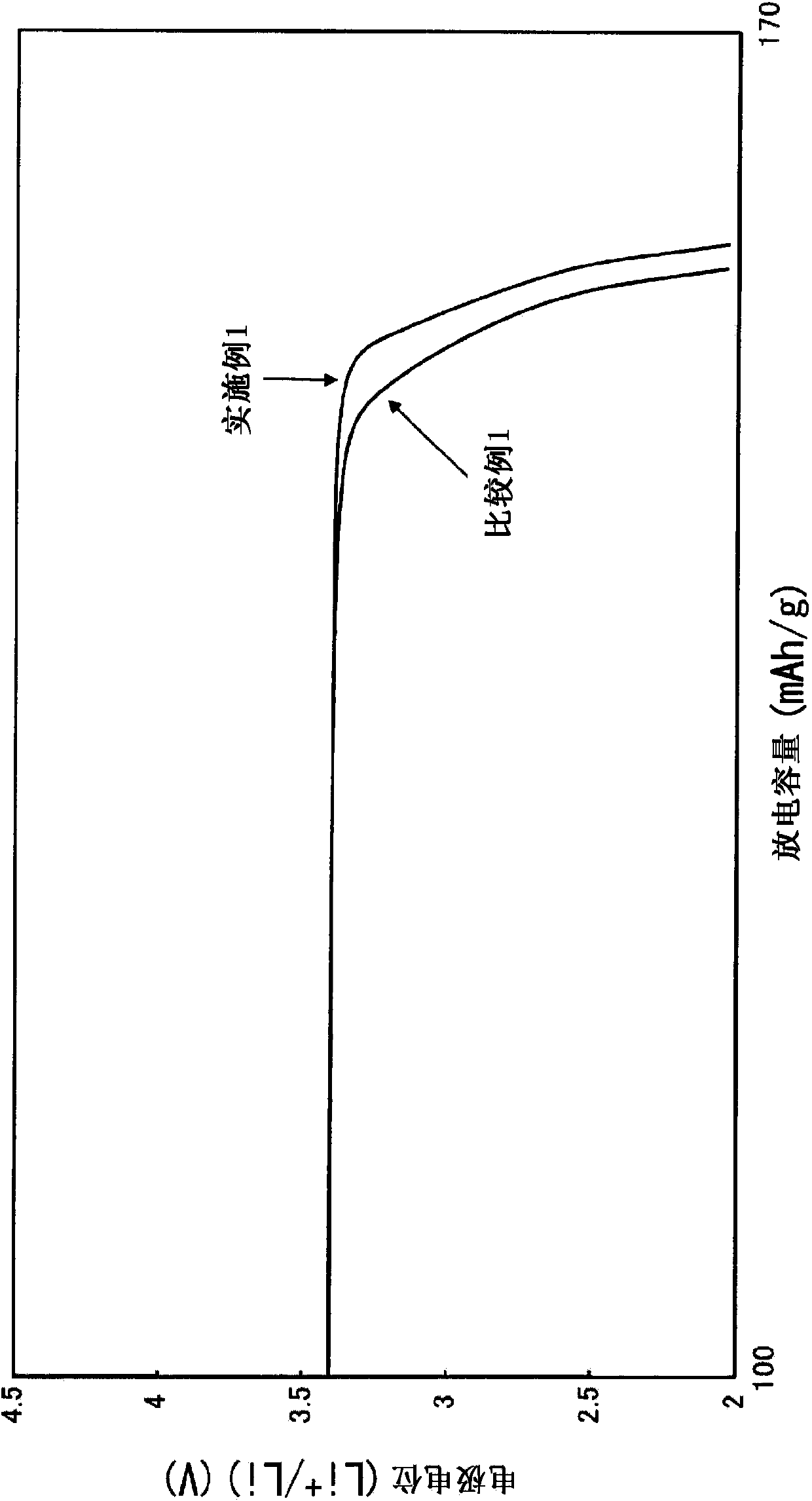

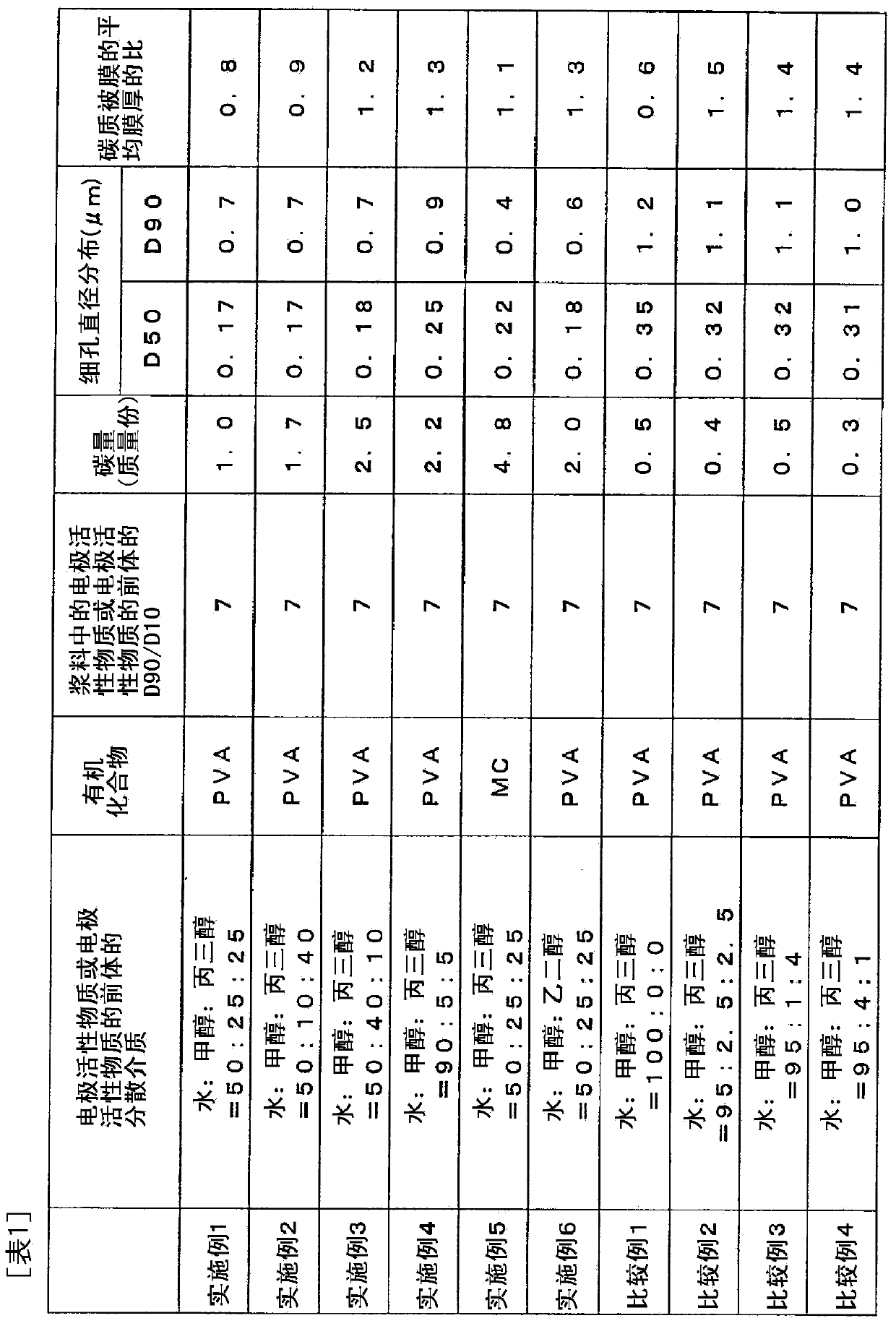

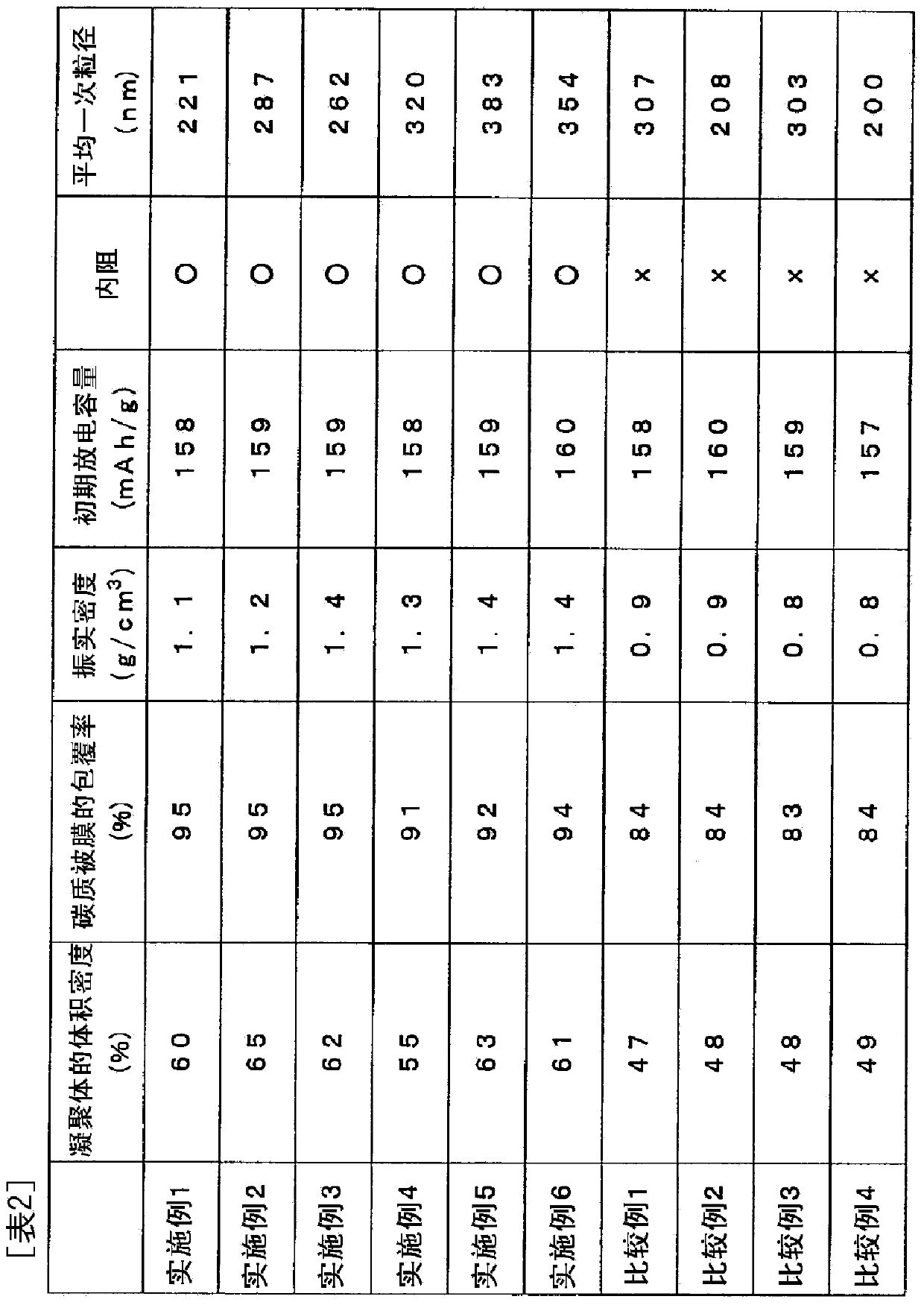

Embodiment 1

[0114] (Production of Electrode Material)

[0115] Mix 4 mol of lithium acetate (LiCH 3 COO), 2mol of iron (II) sulfate (FeSO 4 ), 2mol of phosphoric acid (H 3 PO 4 ) to prepare a homogeneous slurry-like mixture.

[0116] Next, this mixture was stored in a pressure-resistant airtight container with a capacity of 8 L, and hydrothermal synthesis was performed at 120° C. for 1 hour.

[0117] Next, the obtained precipitate was washed with water to obtain a cake-like electrode active material precursor.

[0118] Next, 150 g (in terms of solid content) of the precursor of the electrode active material, an aqueous polyvinyl alcohol solution in which 20 g of polyvinyl alcohol (PVA) as an organic compound was dissolved in 100 g of water, 50 g of methanol, 50 g of glycerol, and 500 g of zirconia balls with a diameter of 5 mm as media particles were put into a ball mill, and the stirring time of the ball mill was adjusted so that the D90 / D10 of the particle size distribution of the ...

Embodiment 2

[0156] In addition to using 150 g of the precursor of the electrode active material (in terms of solid content), a polyvinyl alcohol aqueous solution in which 20 g of polyvinyl alcohol (PVA) as an organic compound is dissolved in 100 g of water, and a mixed solution of 20 g of methanol and 80 g of glycerin An electrode material and a positive electrode of a lithium ion battery were produced and evaluated in the same manner as in Example 1, except that the slurry was sprayed and dried as a raw material. The evaluation results are shown in Table 1 and Table 2.

[0157] In addition, also in Example 2, the same voltage drop at the end of discharge as in Example 1 was observed.

Embodiment 3

[0159] In addition to using 150 g of the precursor of the electrode active material (in terms of solid content), an aqueous polyvinyl alcohol solution in which 20 g of polyvinyl alcohol (PVA) as an organic compound is dissolved in 100 g of water, and a mixed solution of 80 g of methanol and 20 g of glycerin An electrode material and a positive electrode of a lithium ion battery were produced and evaluated in the same manner as in Example 1, except that the slurry was sprayed and dried as a raw material. The evaluation results are shown in Table 1 and Table 2.

[0160] In addition, also in Example 3, the same voltage drop at the end of discharge as in Example 1 was observed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com