Patents

Literature

376results about "Phosphorus sulfur/selenium/tellurium compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

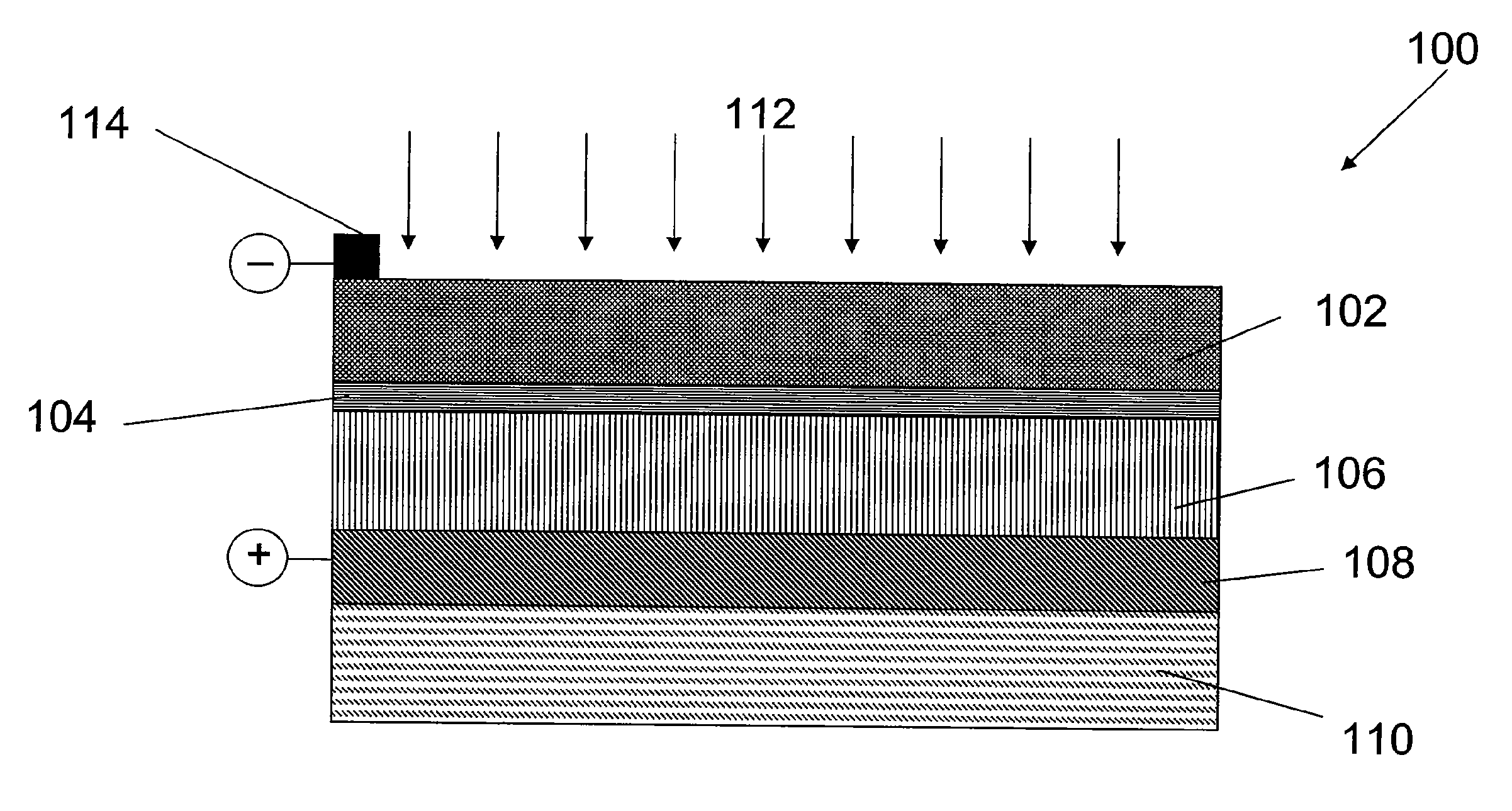

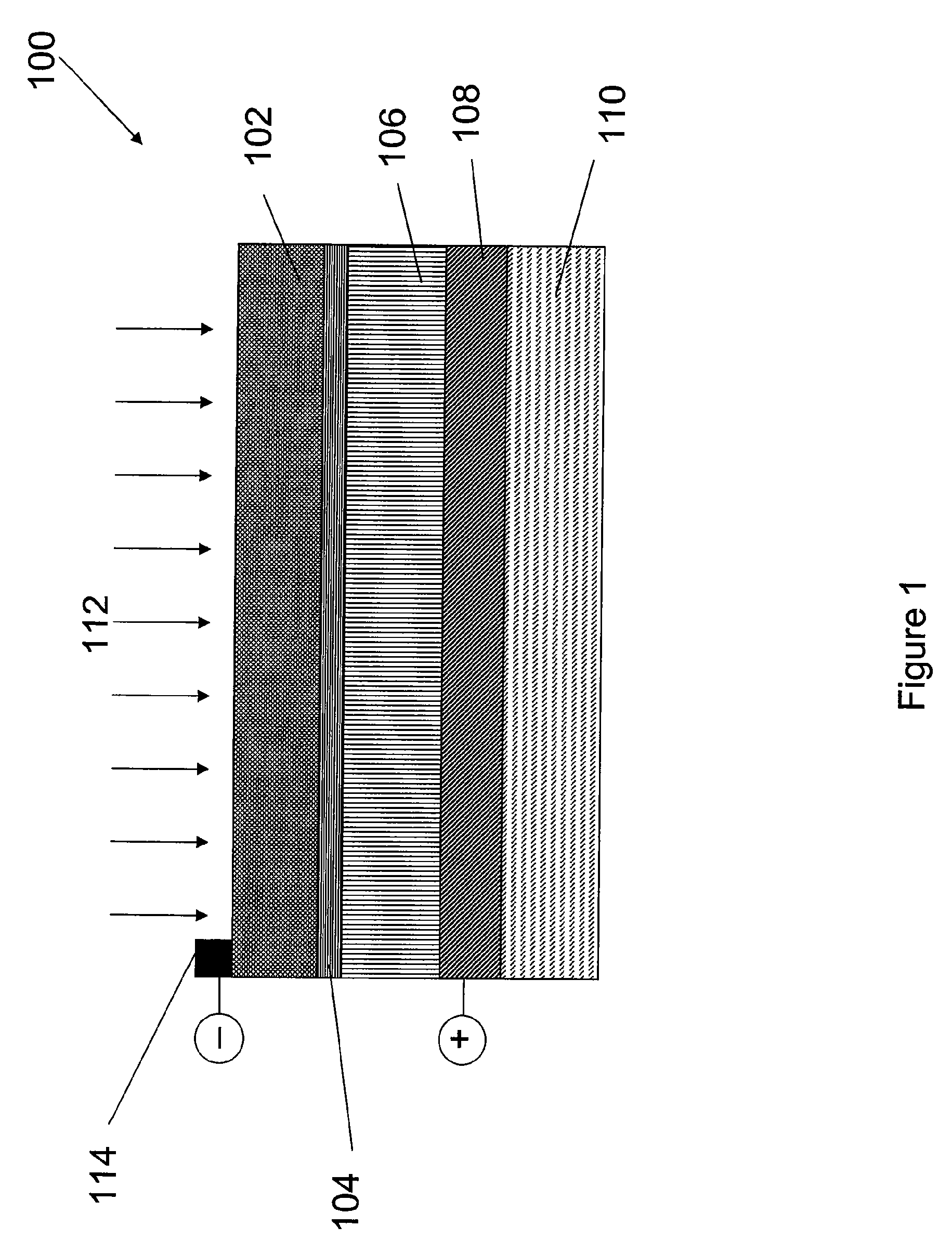

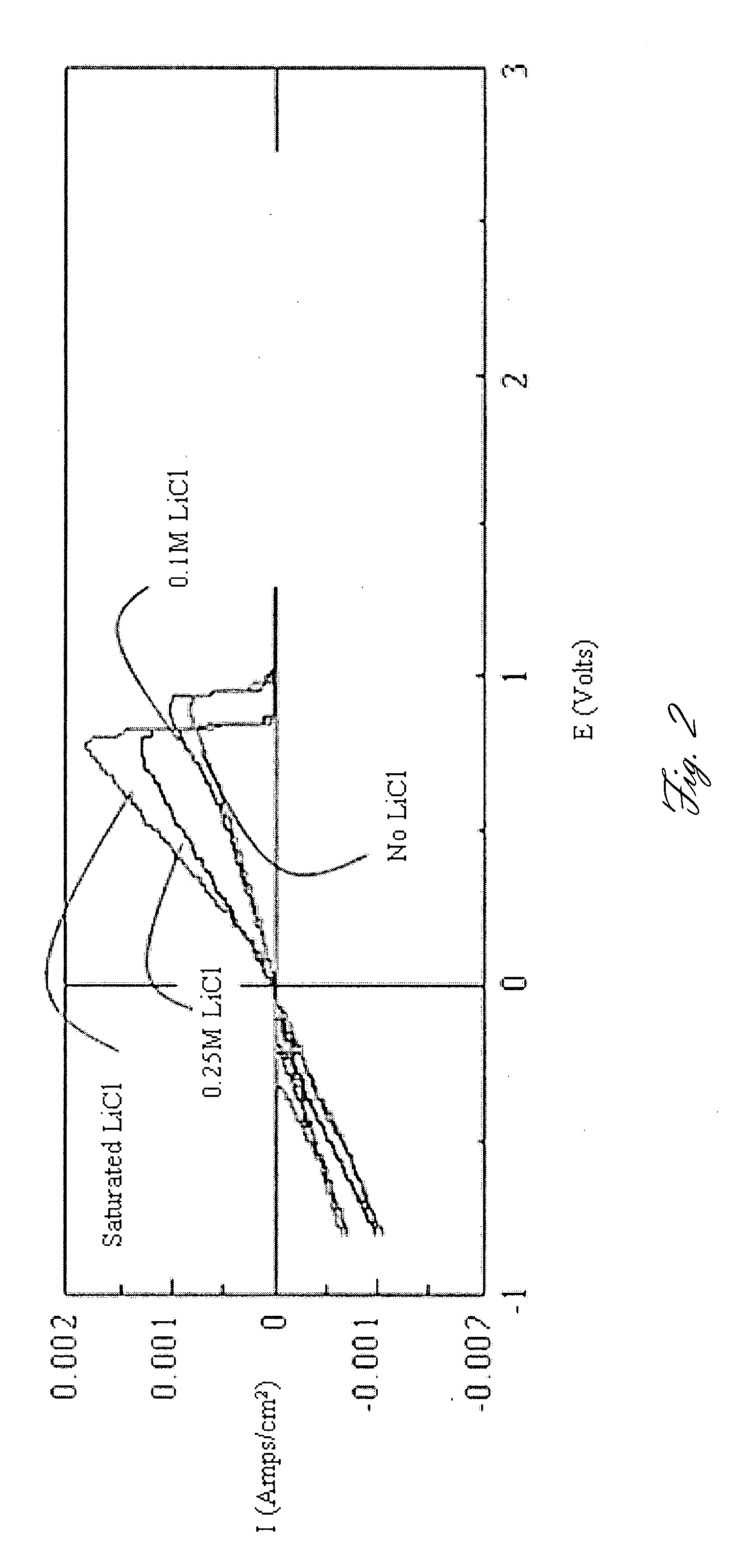

Chemical Treatments to Enhance Photovoltaic Performance of CIGS

InactiveUS20090235987A1Enhance solar cell conversion efficiencyReduce surface defect densityLighting and heating apparatusPhosphorus sulfur/selenium/tellurium compoundsChemical treatmentSolvent

The present invention provides method of treating semiconductor surfaces (e.g., CIGS) using various solvents (including ionic solvents and eutectics), and methods preparing photovoltaic cells comprising treated CIGS materials.

Owner:NEW MILLENNIUM SOLAR EQUIP CORP

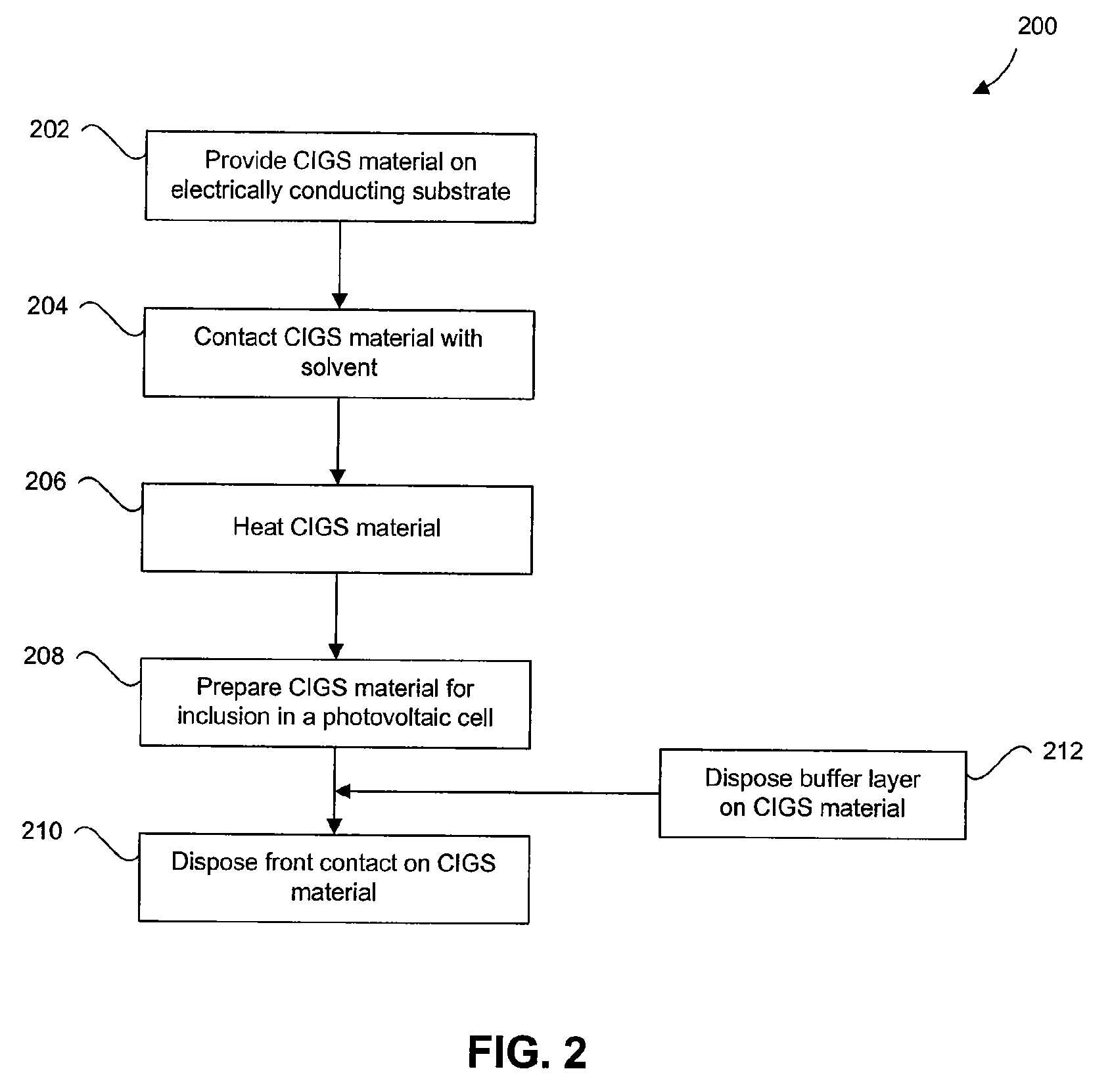

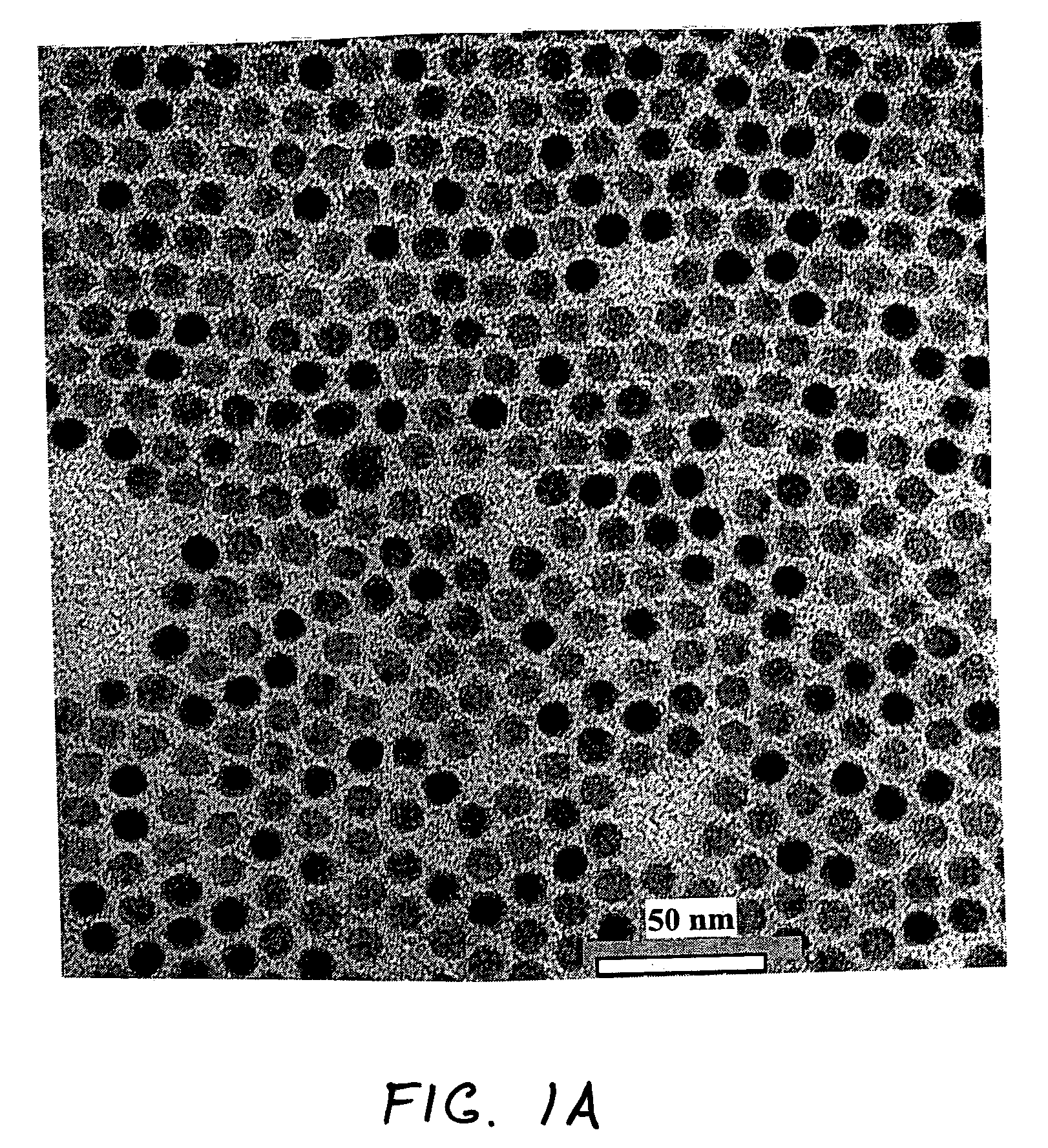

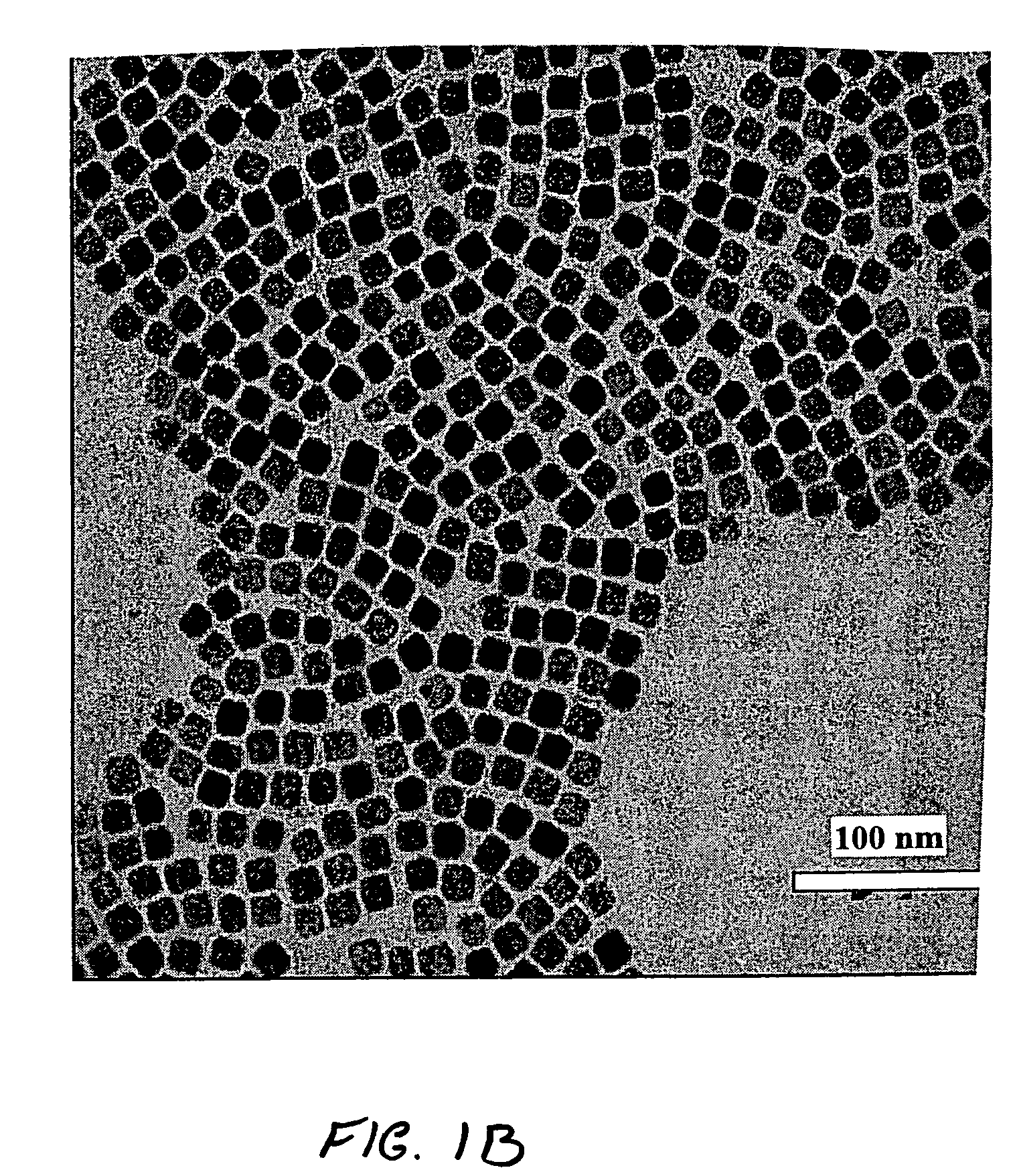

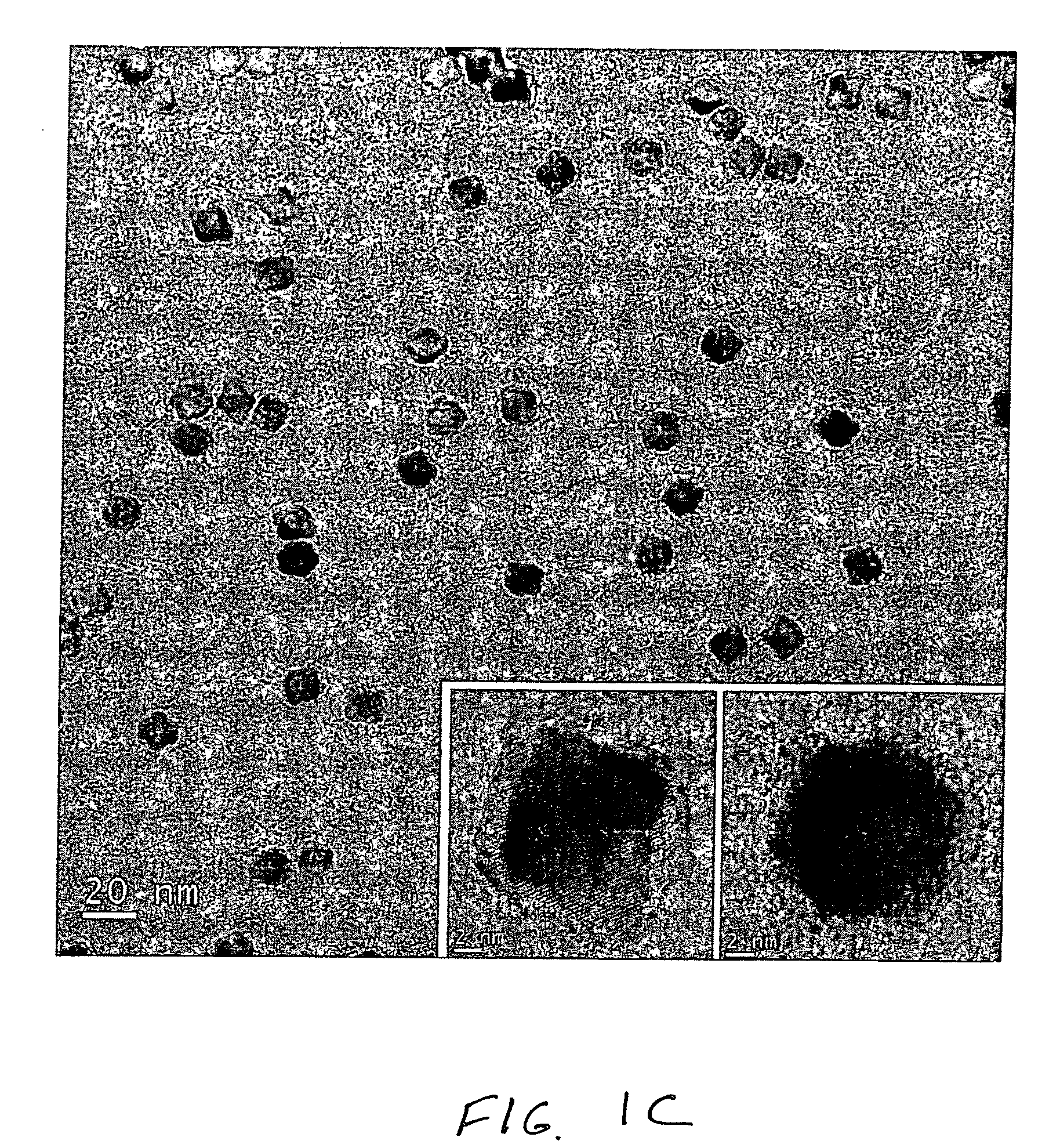

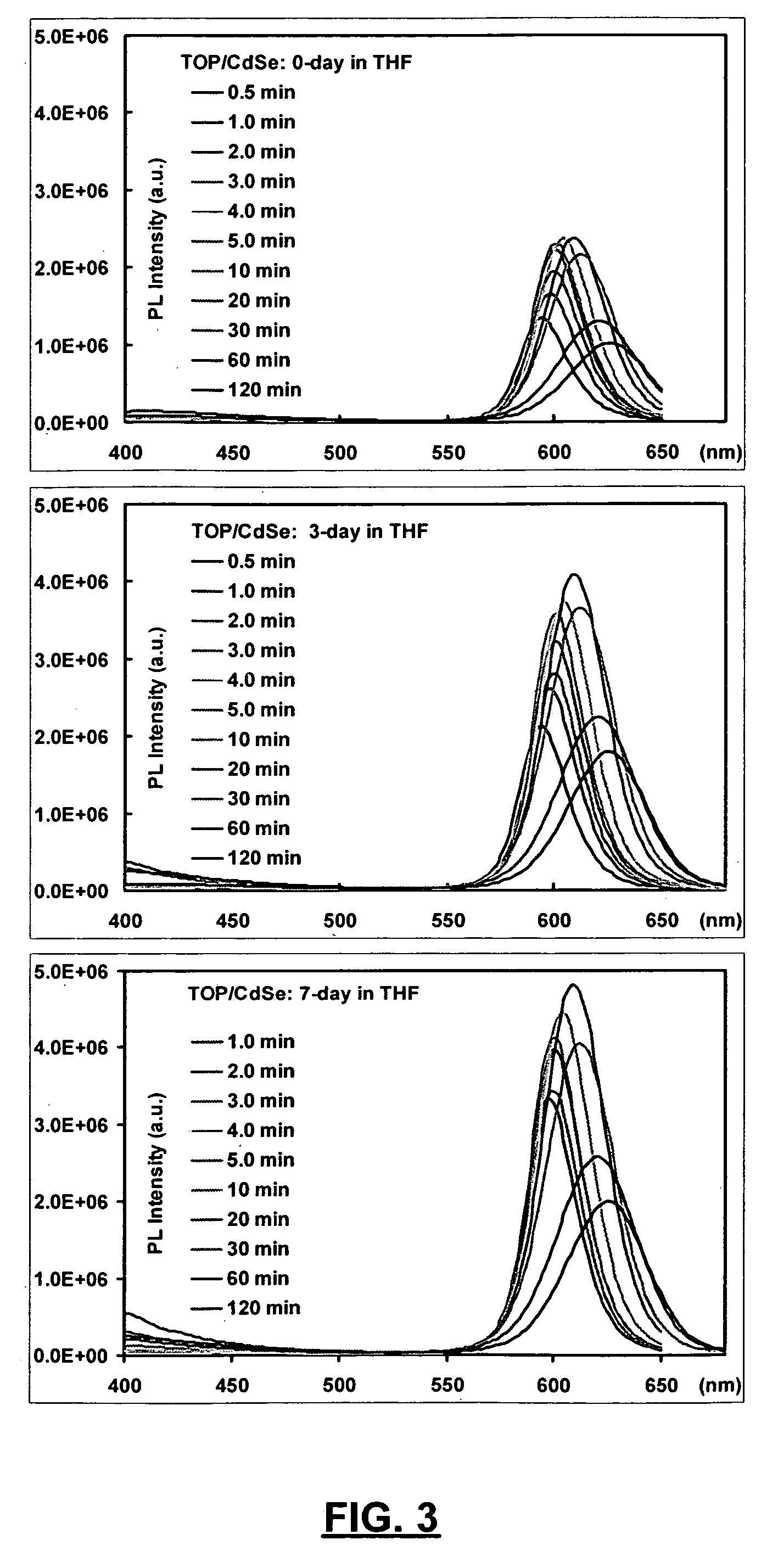

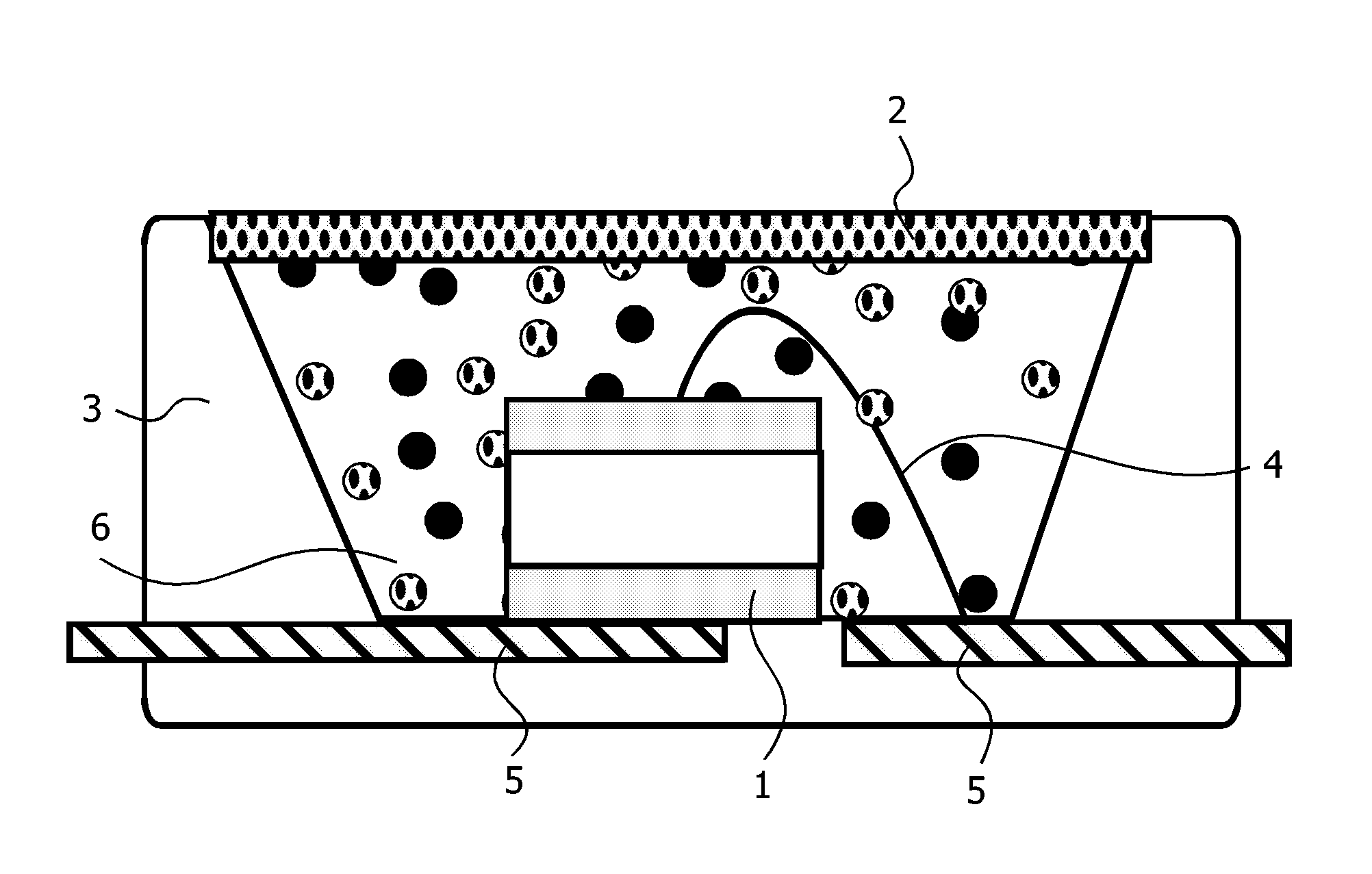

Alloyed semiconductor quantum dots and concentration-gradient alloyed quantum dots, series comprising the same and methods related thereto

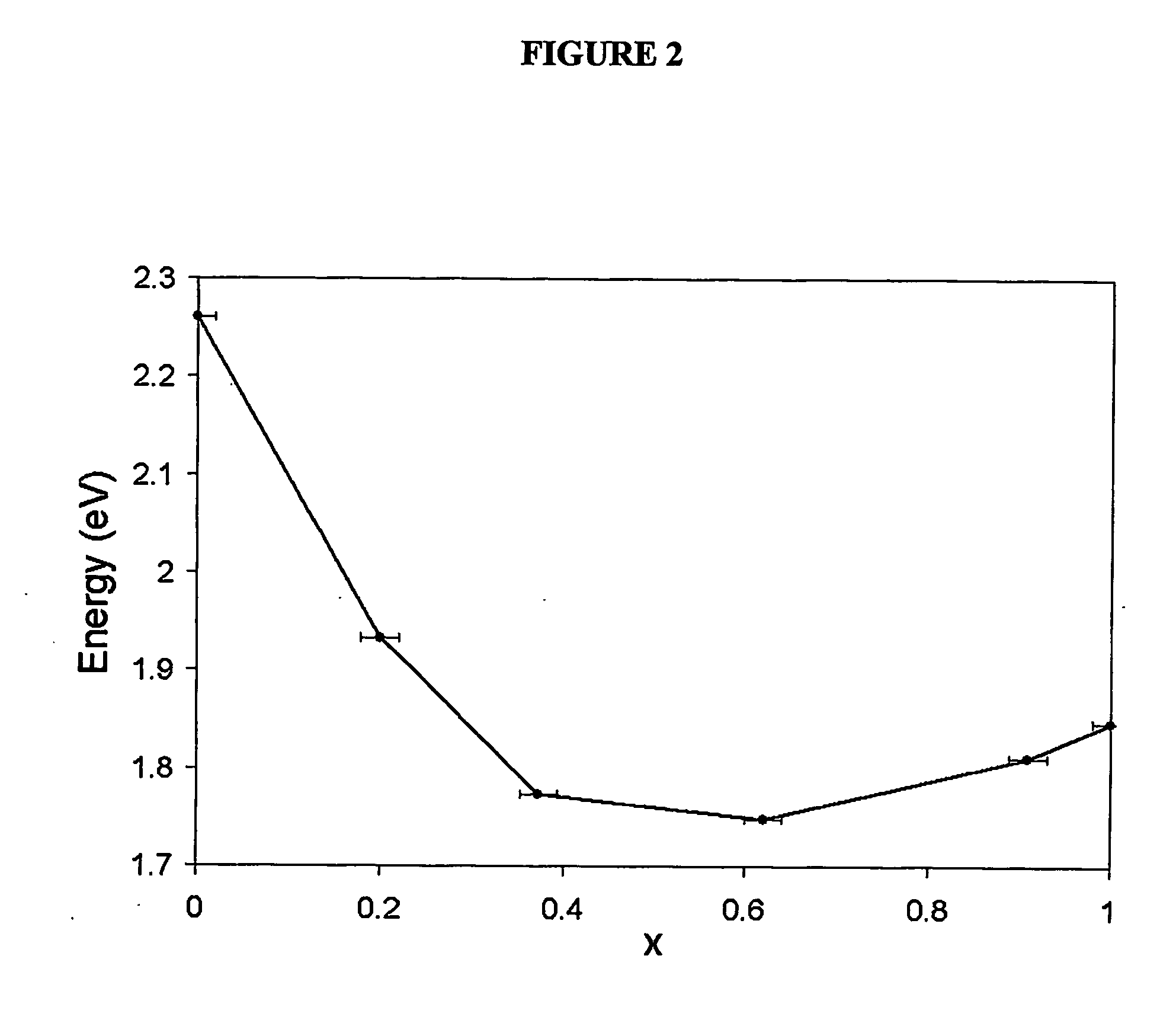

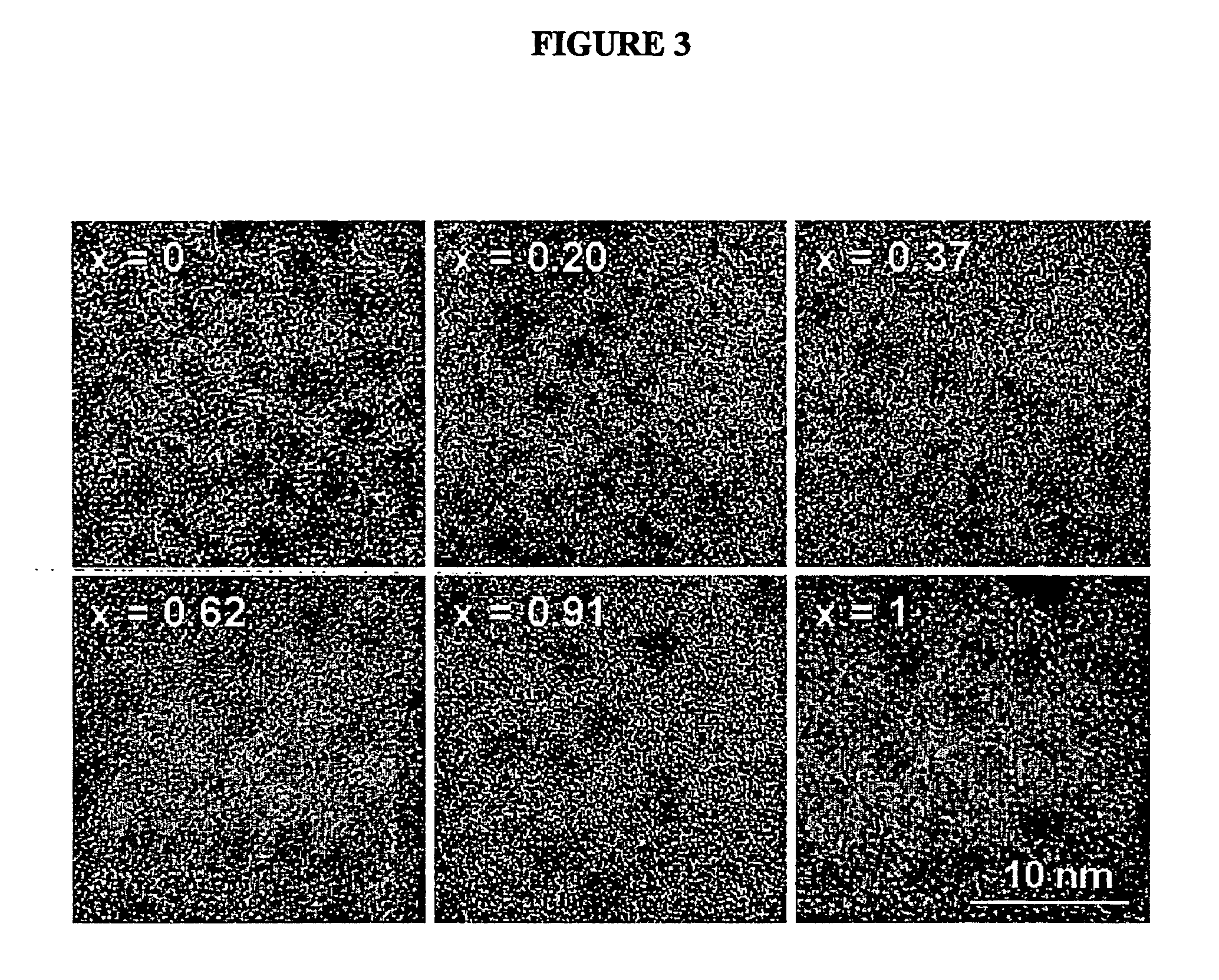

An alloyed semiconductor quantum dot comprising an alloy of at least two semiconductors, wherein the quantum dot has a homogeneous composition and is characterized by a band gap energy that is non-linearly related to the molar ratio of the at least two semiconductors; a series of alloyed semiconductor quantum dots related thereto; a concentration-gradient quantum dot comprising an alloy of a first semiconductor and a second semiconductor, wherein the concentration of the first semiconductor gradually increases from the core of the quantum dot to the surface of the quantum dot and the concentration of the second semiconductor gradually decreases from the core of the quantum dot to the surface of the quantum dot; a series of concentration-gradient quantum dots related thereto; in vitro and in vivo methods of use; and methods of producing the alloyed semiconductor and concentration-gradient quantum dots and the series of quantum dots related thereto.

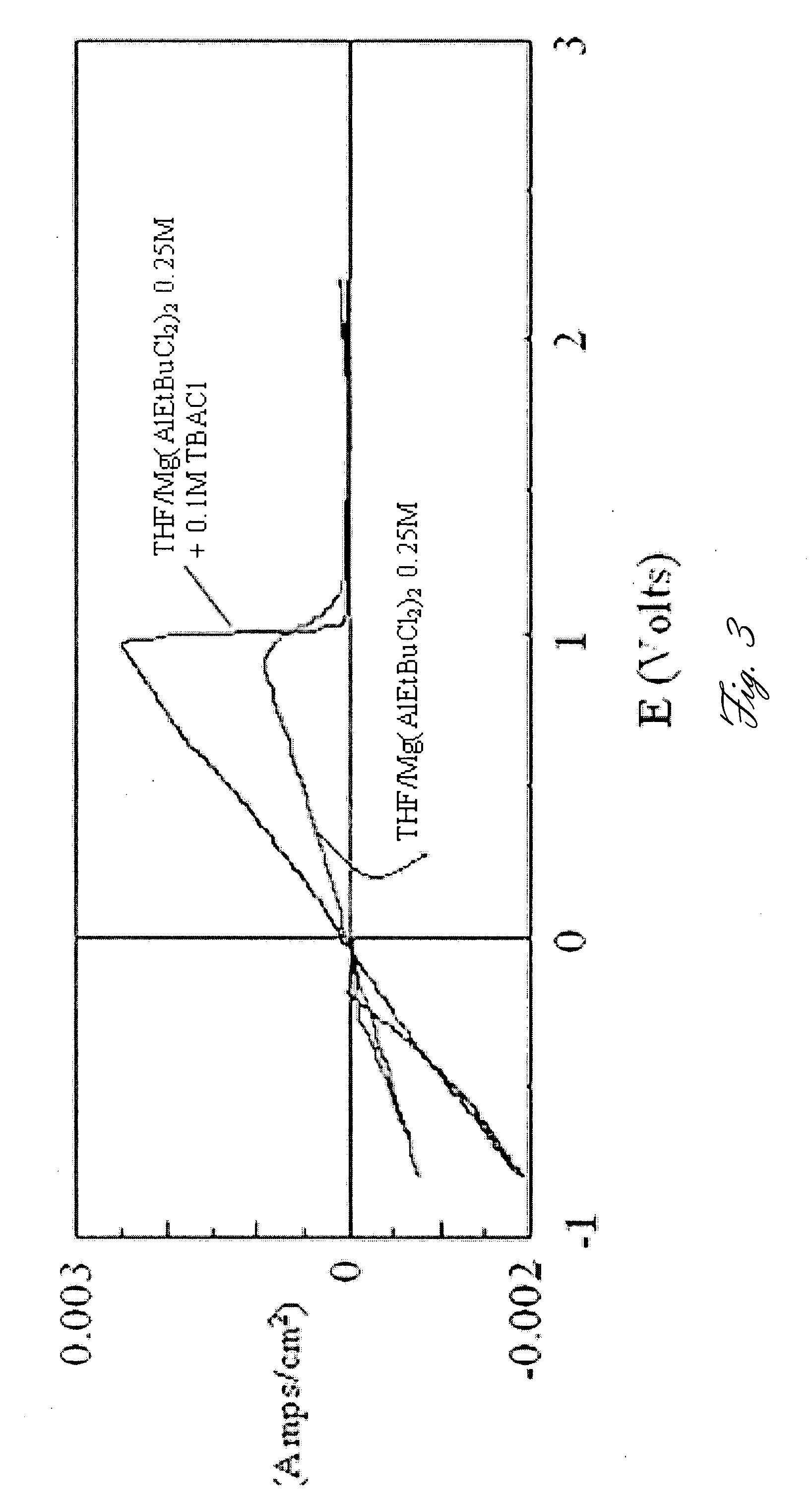

Rechargeable magnesium battery

ActiveUS20080182176A1Improved kineticsImprove conductivityMaterial nanotechnologyPhosphorus sulfur/selenium/tellurium compoundsElectrochemical windowCopper

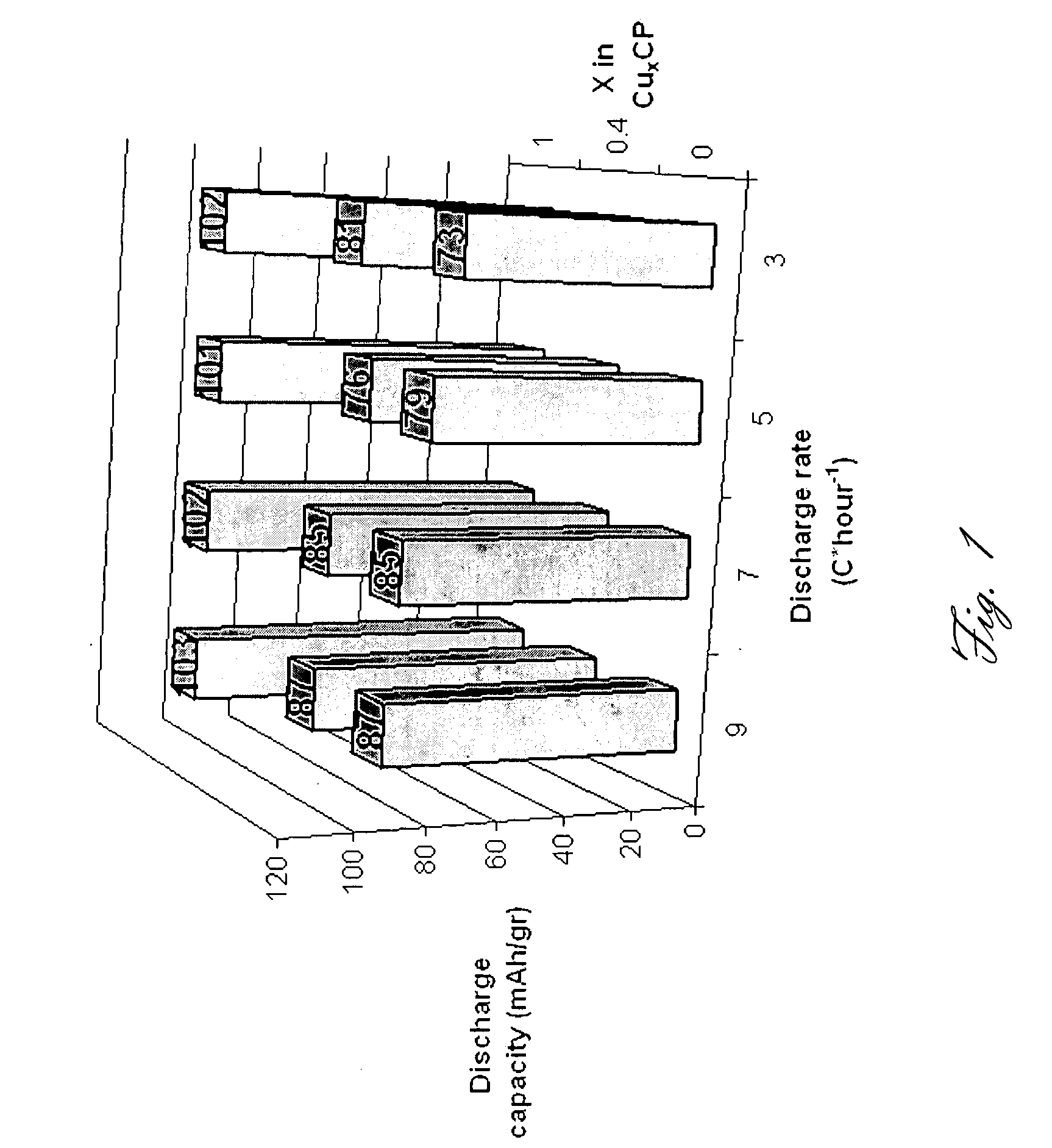

This invention generally relates to electrochemical cells utilizing magnesium anodes, new solutions and intercalation cathodes. The present invention is a new rechargeable magnesium battery based on magnesium metal as an anode material, a modified Chevrel phase as an intercalation cathode for magnesium ions and new electrolyte solution from which magnesium can be deposited reversibly, which have a very wide electrochemical window. The Chevrel phase compound is represented by the formula Mo6S8-YSeY in which y is higher than 0 and lower than 2 or by the formula MXMo6S8 in which M is selected from the group comprising of copper (Cu), nickel (Ni), silver (Ag) and / or any other transition metal; further wherein x is higher than 0 and lower than 2.

Owner:BAR ILAN UNIV

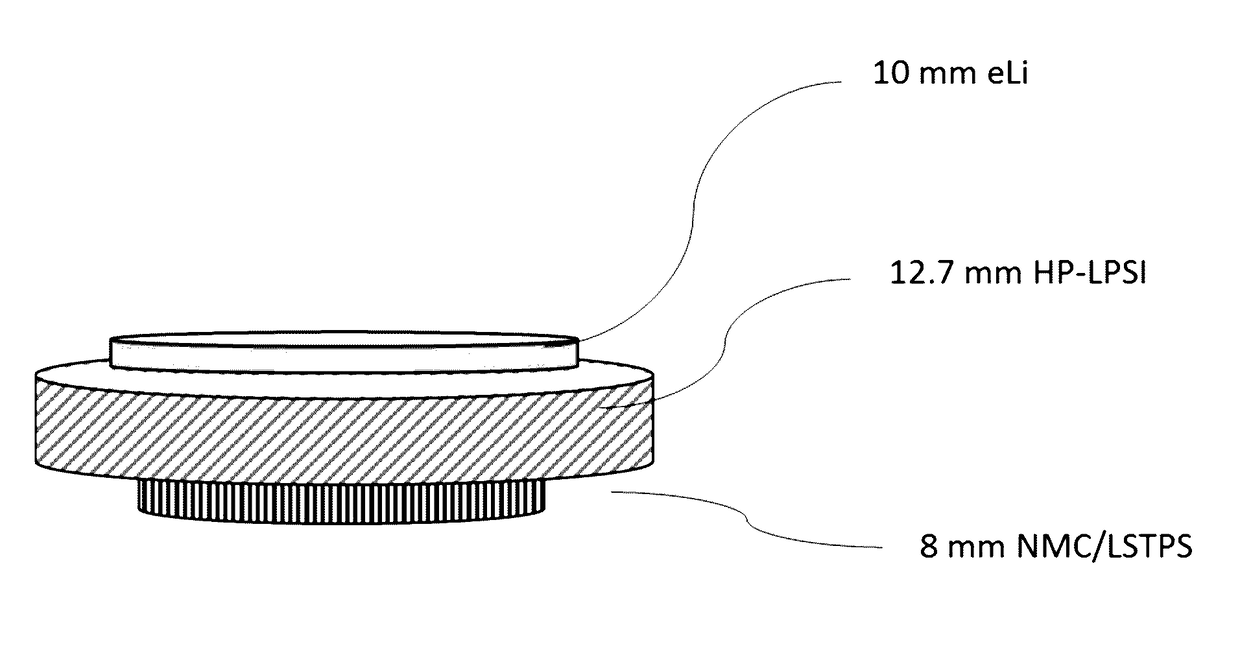

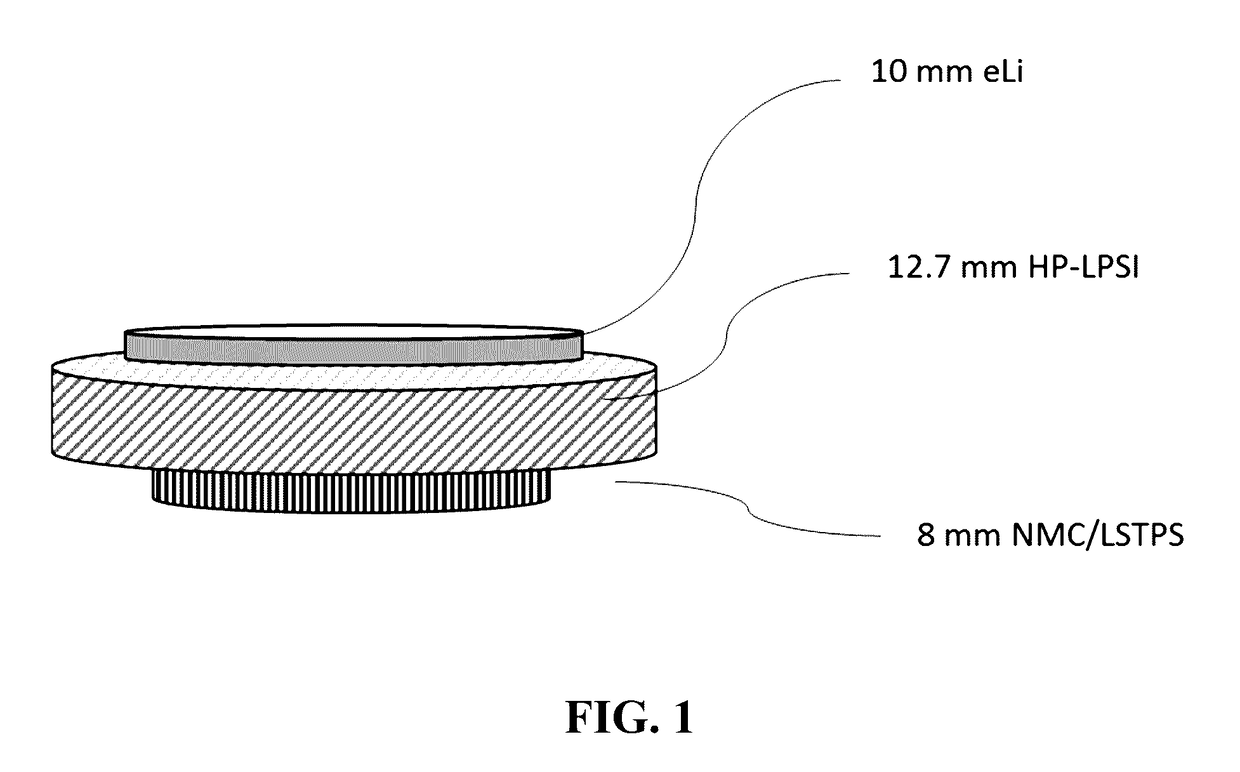

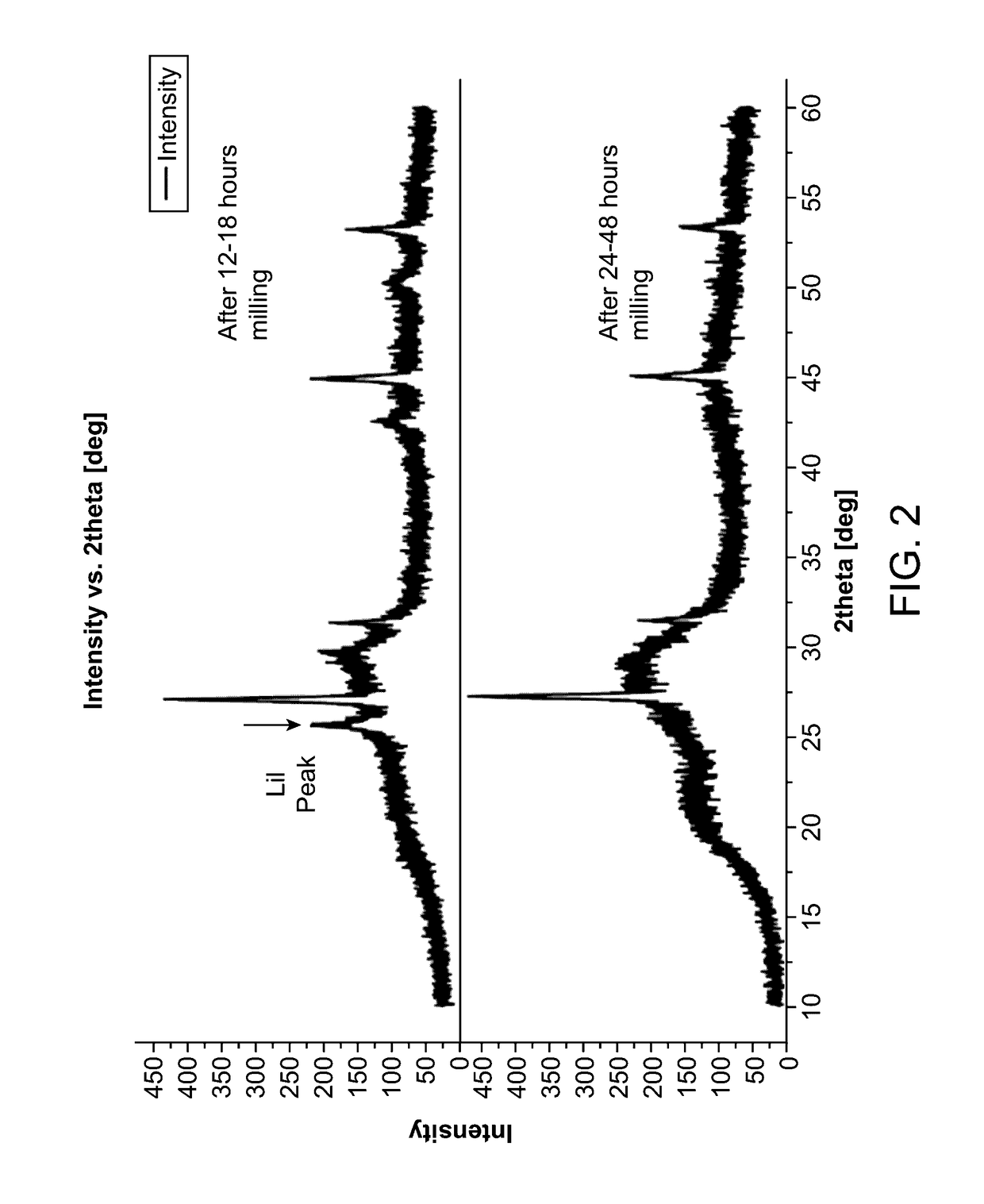

Lithium, phosphorus, sulfur, and iodine including electrolyte and catholyte compositions, electrolyte membranes for electrochemical devices, and annealing methods of making these electrolytes and catholytes

ActiveUS20170162901A1Solid electrolytesPhosphorus sulfur/selenium/tellurium compoundsElectrical conductorElectrochemistry

The present disclosure sets forth battery components for secondary and / or traction batteries. Described herein are new solid-state lithium (Li) conducting electrolytes including monolithic, single layer, and bi-layer solid-state sulfide-based lithium ion (Li+) conducting catholytes or electrolytes. These solid-state ion conductors have particular chemical compositions which are arranged and / or bonded through both crystalline and amorphous bonds. Also provided herein are methods of making these solid-state sulfide-based lithium ion conductors including new annealing methods. These ion conductors are useful, for example, as membrane separators in rechargeable batteries.

Owner:QUANTUMSCAPE BATTERY INC

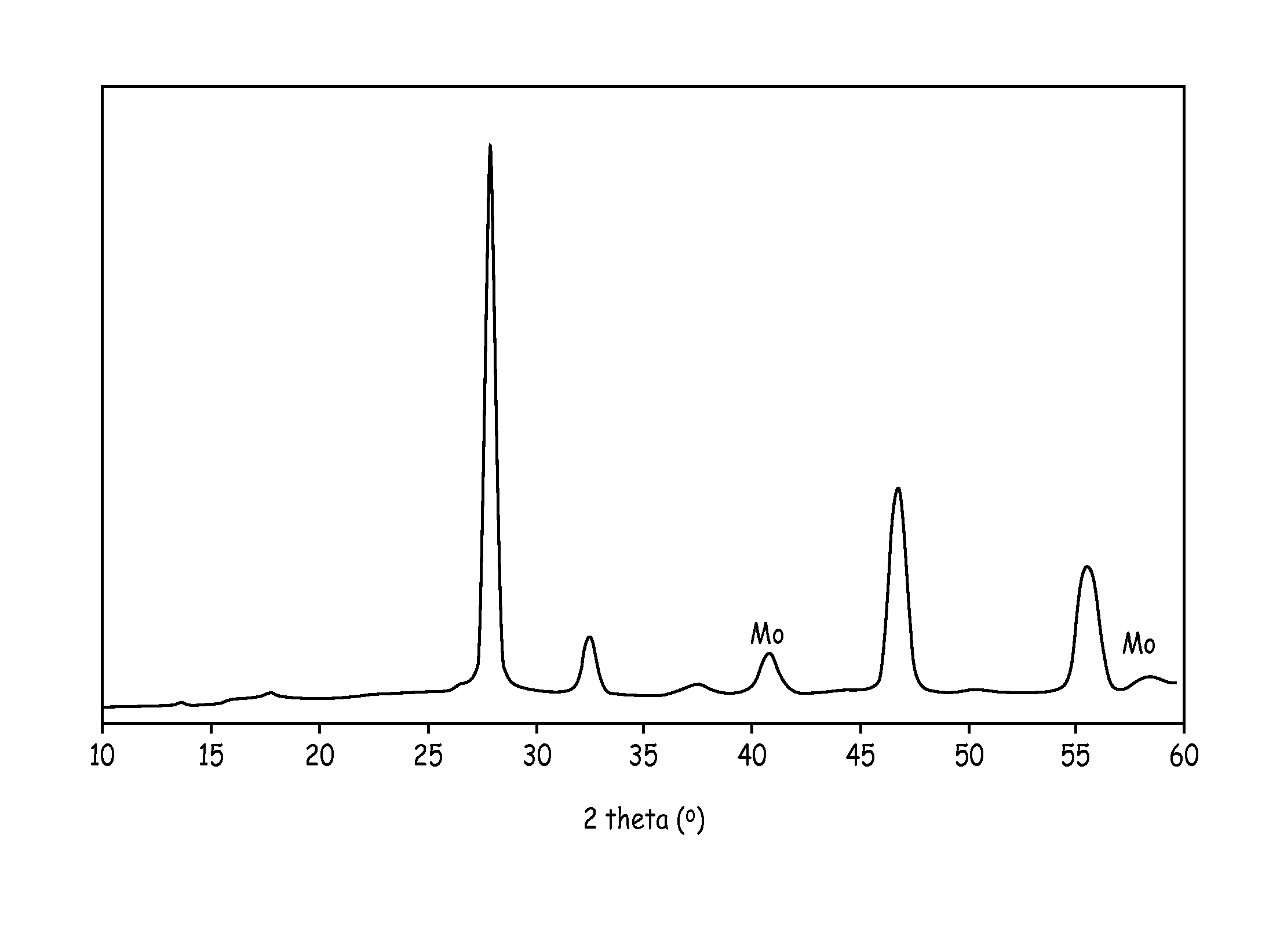

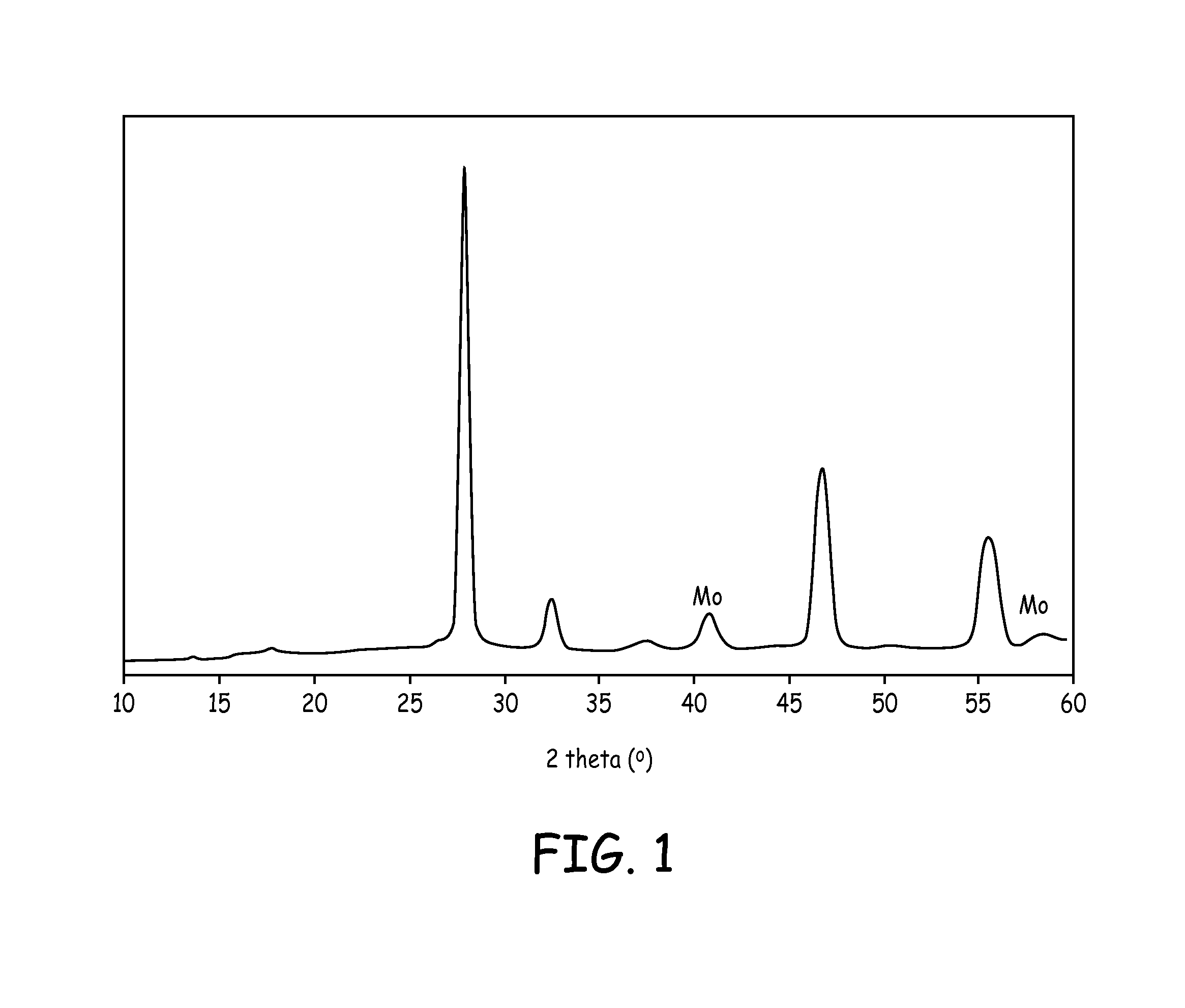

Lithium ion conductive sulfide-based solid electrolyte and all-solid lithium battery using same

InactiveUS20090159839A1Improve lithium ion conductivityImprove conductivityPhosphatesFinal product manufactureElectrolyteAnalytical chemistry

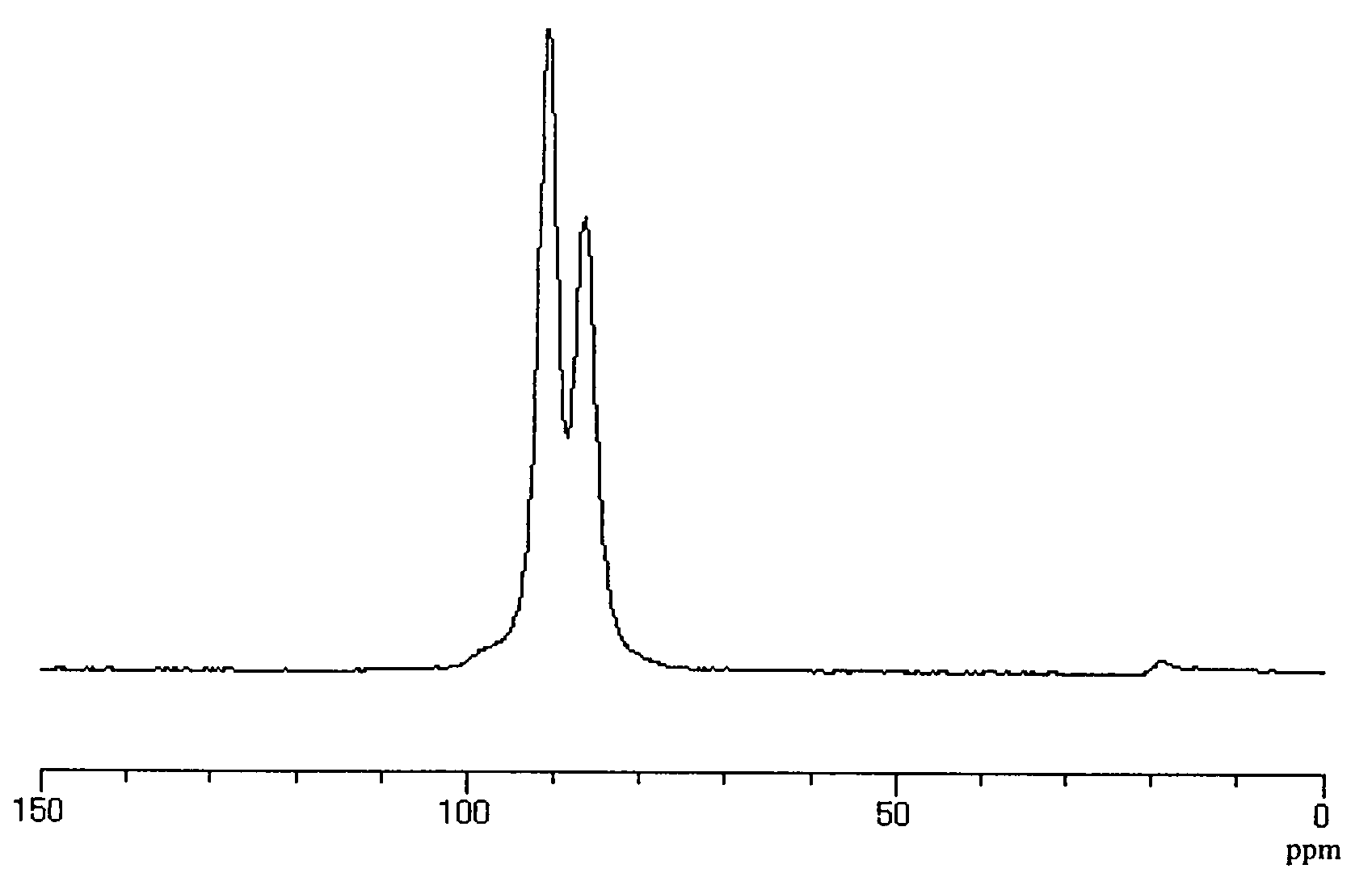

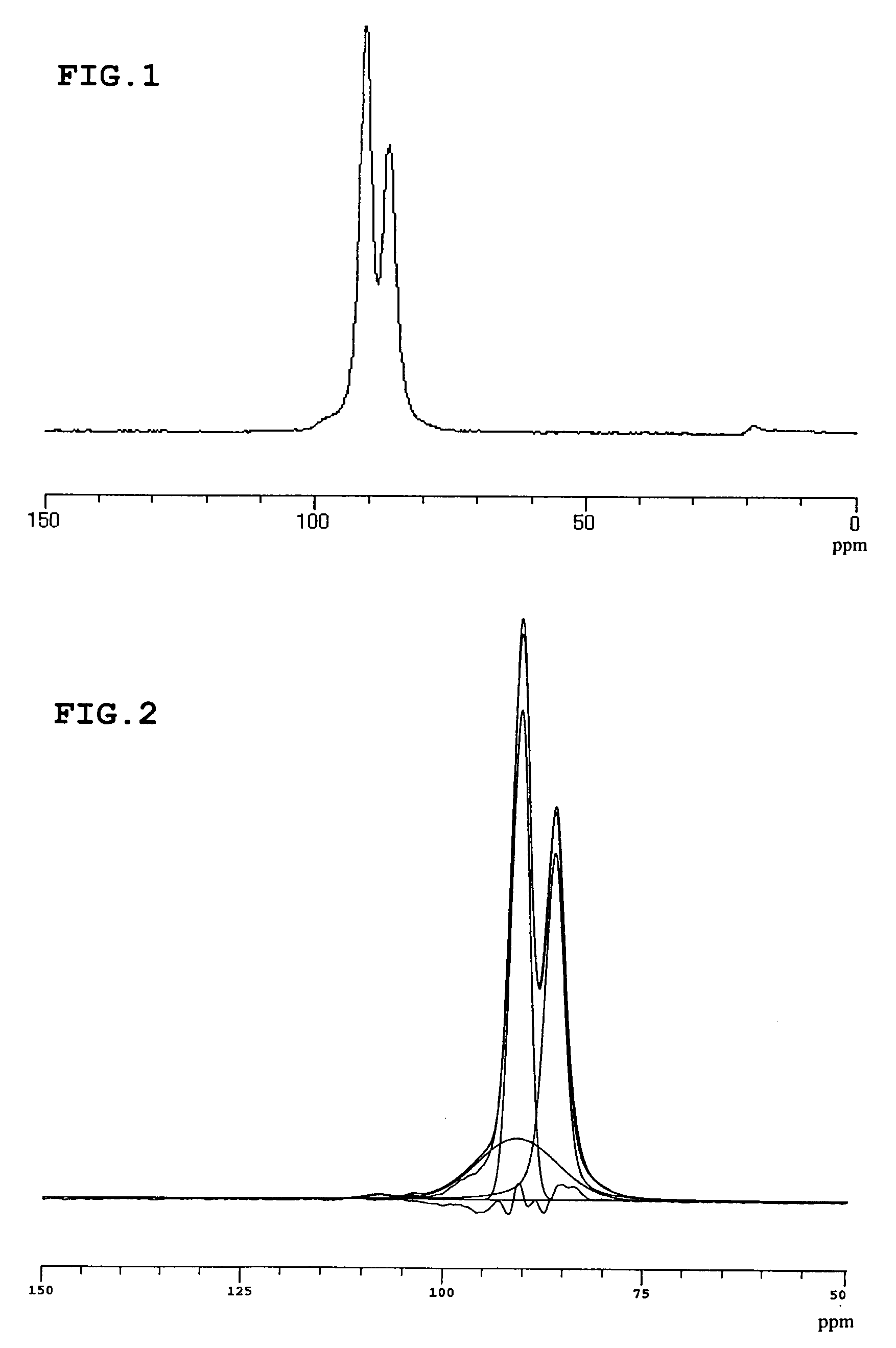

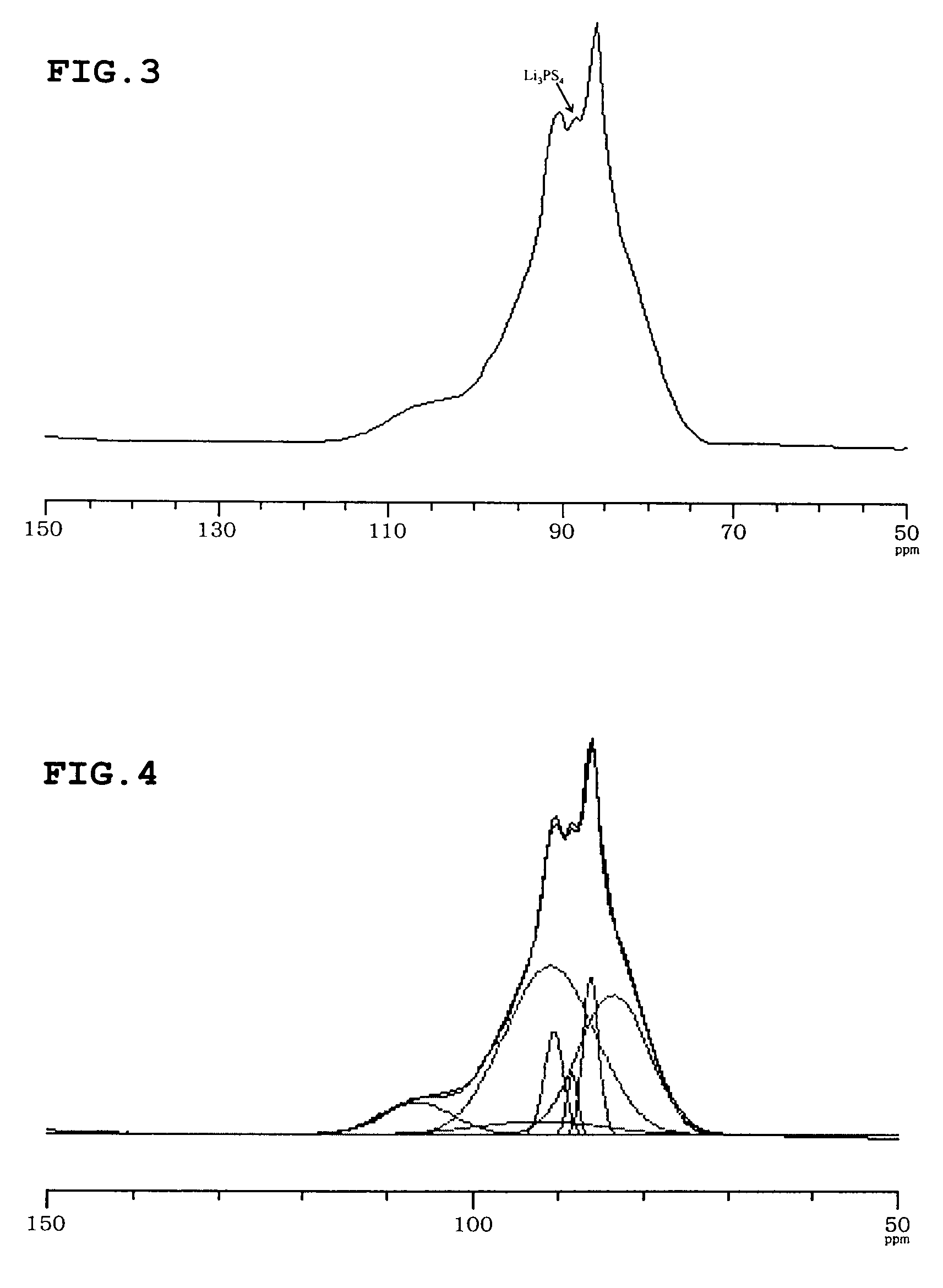

A solid electrolyte including a lithium (Li) element, a phosphorus (P) element and a sulfur (S) element, the 31P MAS NMR spectrum thereof having a peak ascribed to a crystal at 90.9±0.4 ppm and 86.5±0.4 ppm; and the ratio (xc) of the crystal in the solid electrolyte being from 60 mol % to 100 mol %.

Owner:IDEMITSU KOSAN CO LTD

Thermoelectric material and thermoelectric converting element using the same

Compounds are expressed by general formula of AxBC2-y where 0<=x<=2 and 0<=y<1, and have CdI2 analogous layer structures; A-site is occupied by at least one element selected from the group consisting of Li, Na, K, Rb, Cs, Mg, Ca, Sr, Ba, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Zr, Nb, Mo, Ru, Rh, Pd, Ag, Cd, Hf, Ta, W, Re, Ir, Pt, Au, Sc, rare earth elements containing Y, B, Al, Ga, In, Tl, Sn, Pb and Bi; B-site is occupied by at least one element selected from the group consisting of Ti, V, Cr, Zr, Nb, Mo, Hf, Ta, W, Ir, and Sn; C-site is occupied by at least one element selected from the group consisting of S, Se and Te; the compounds exhibit large figure of merit so as to be preferable for thermoelectric generator / refrigerator.

Owner:NEC CORP

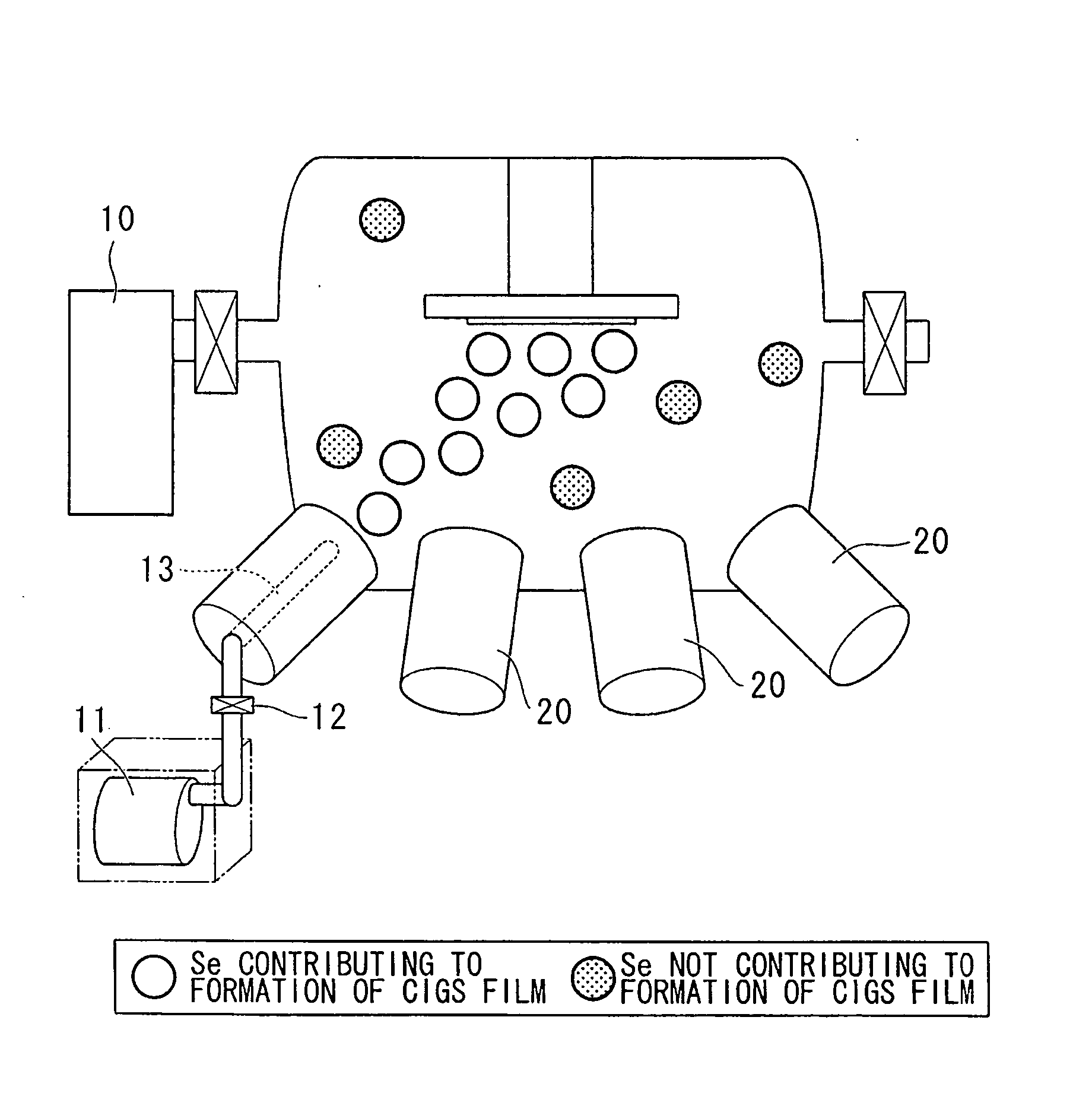

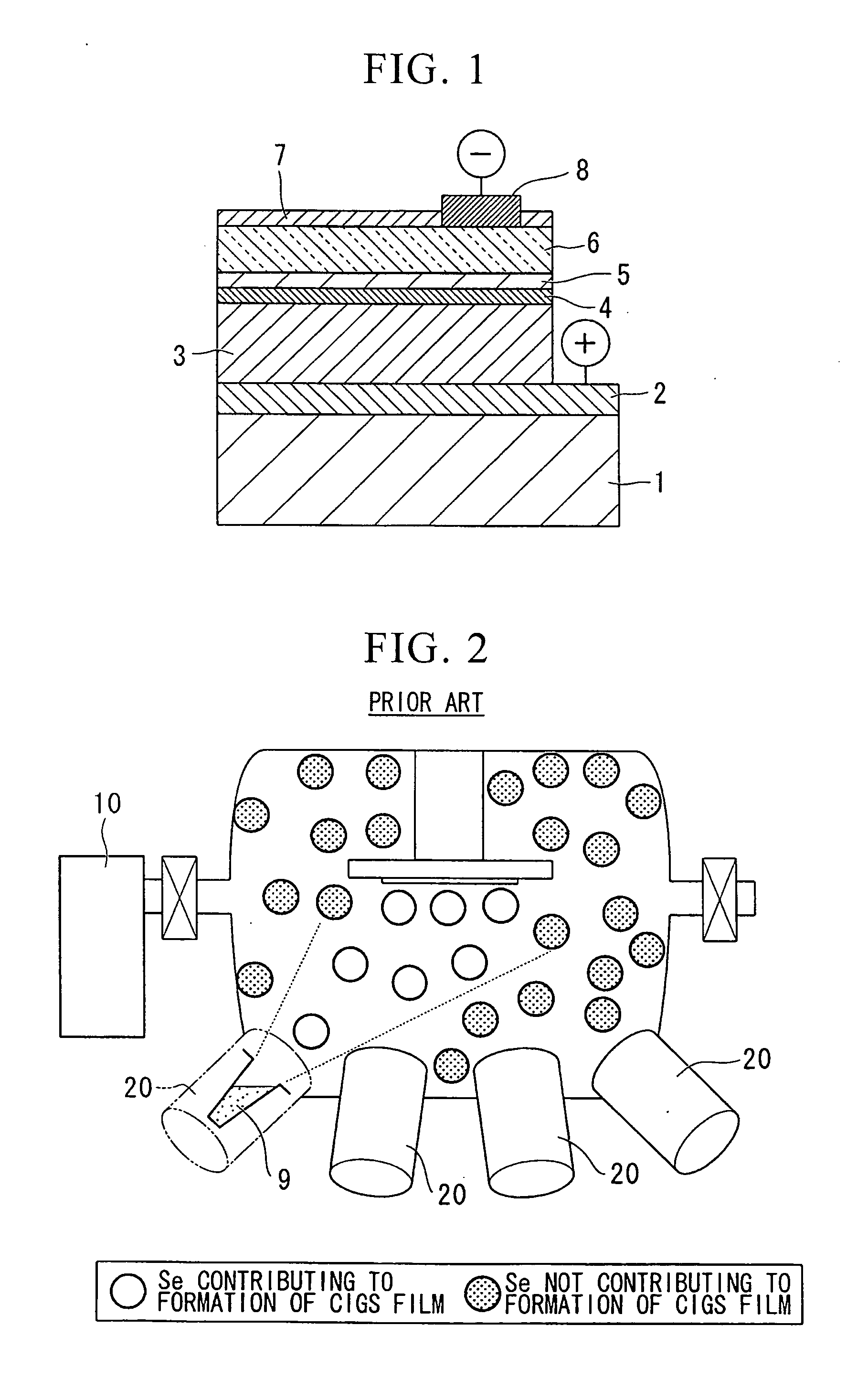

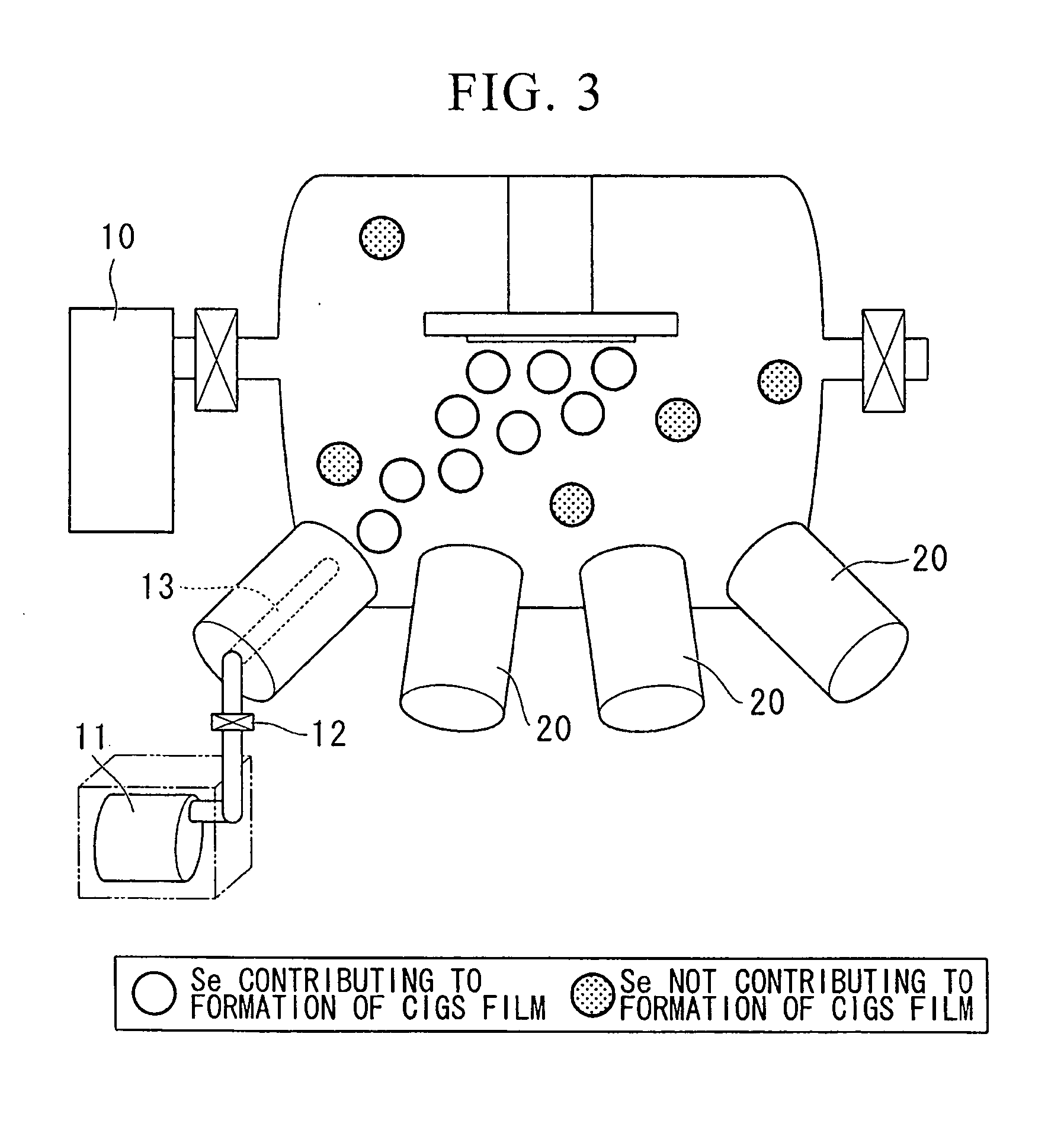

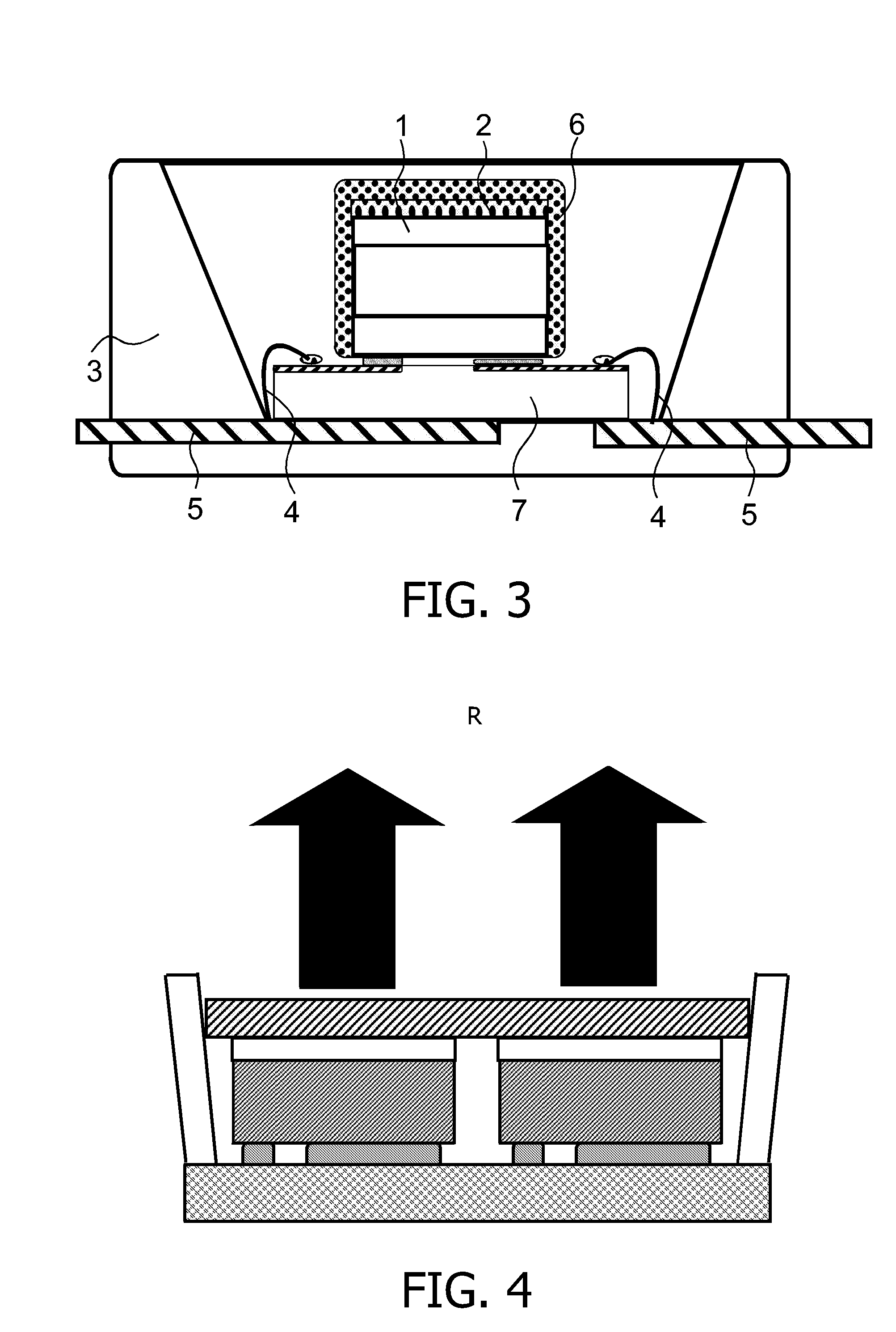

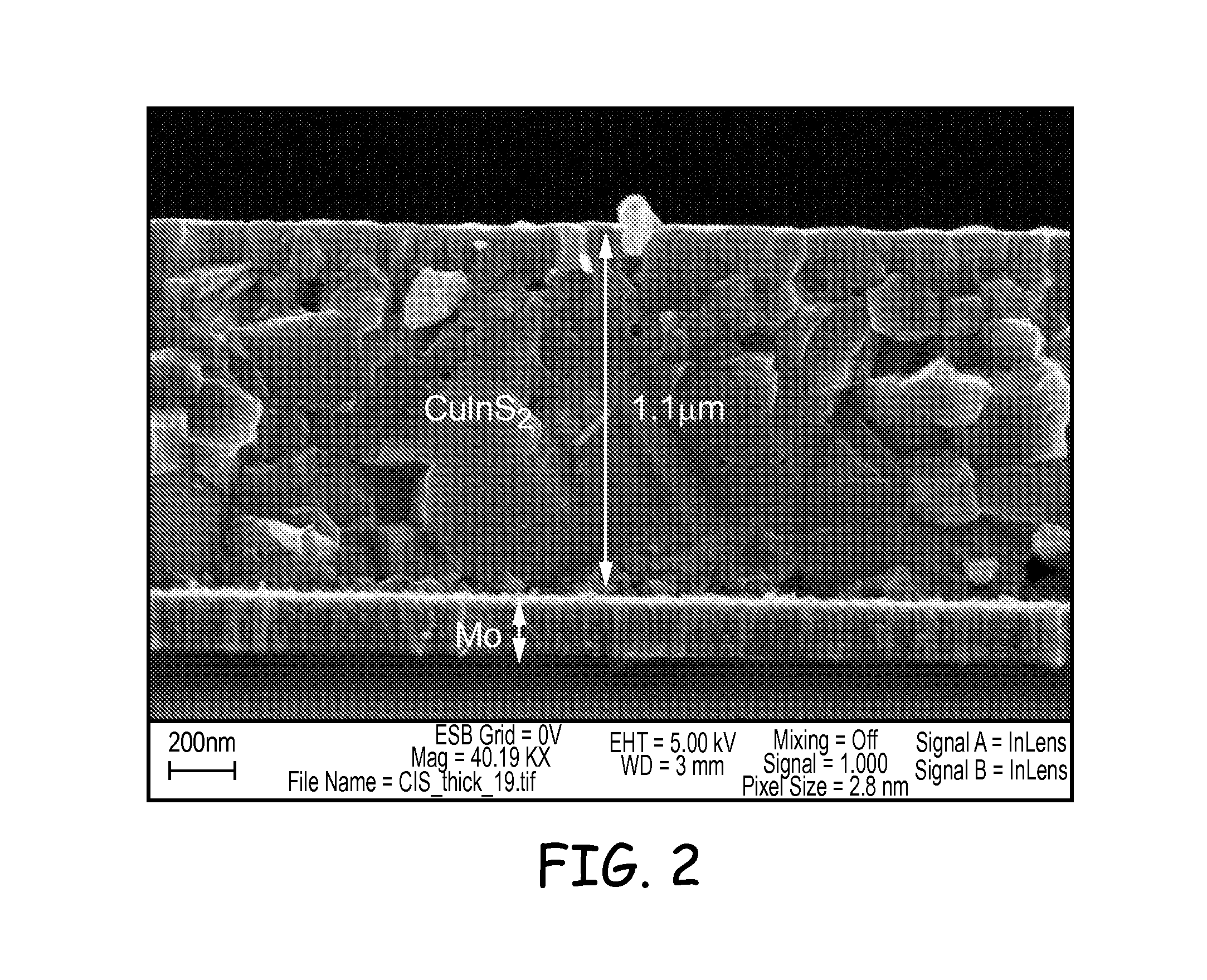

Method and apparatus for producing semiconductor films, photoelectric conversion devices and method for producing the devices

InactiveUS20080072962A1Prevent and suppress adhesionPhosphorus sulfur/selenium/tellurium compoundsFinal product manufacturePhotoelectric conversionGroup element

A method for producing a semiconductor film having a chalcopyrite structure including a Ib group element, a IIIb group element and a VIb group element including selenium, the method including cracking selenium with plasma to generate radical selenium, and using the radical selenium in the process of forming the semiconductor film.

Owner:NAT INST OF ADVANCED IND SCI & TECH

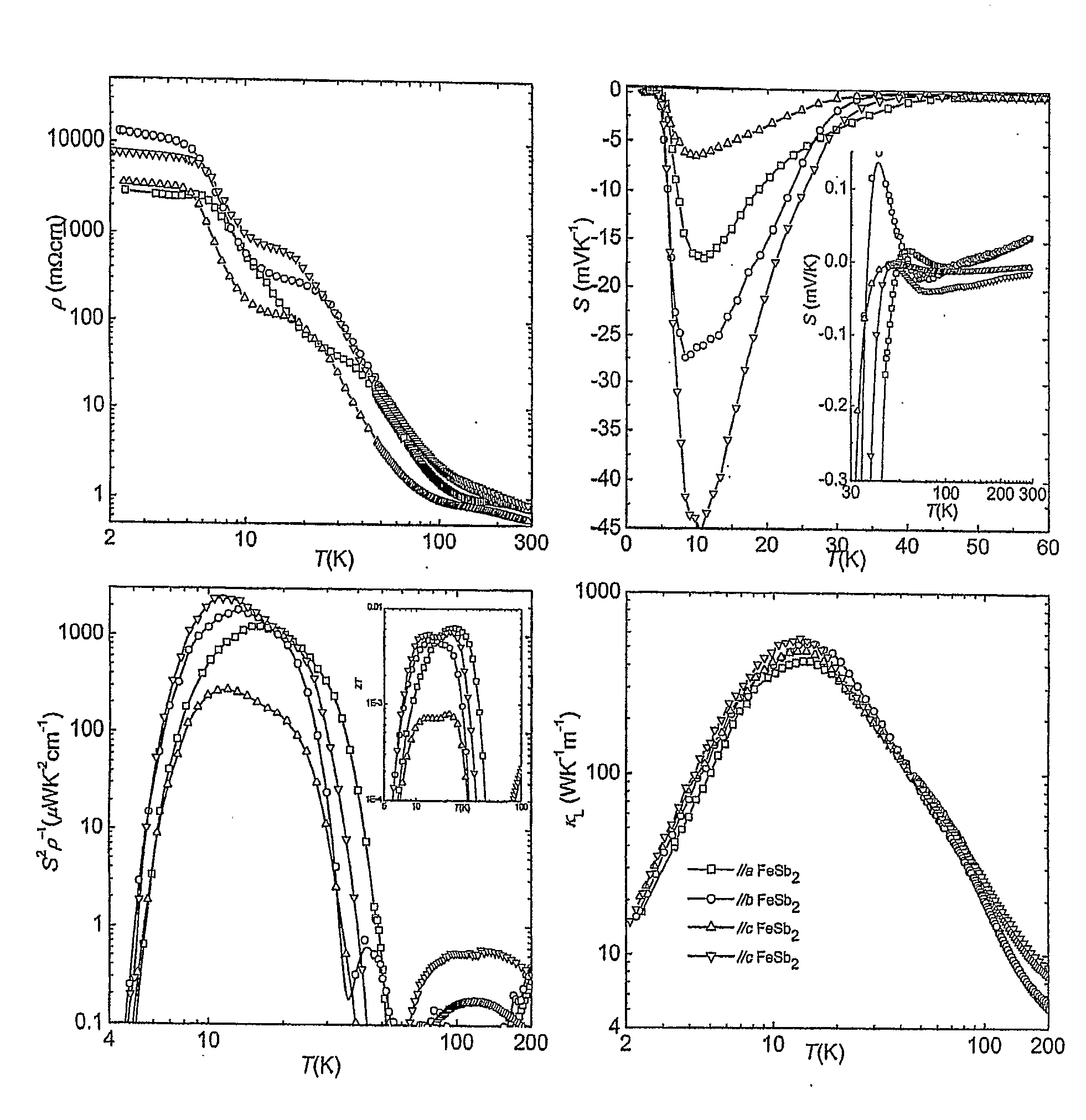

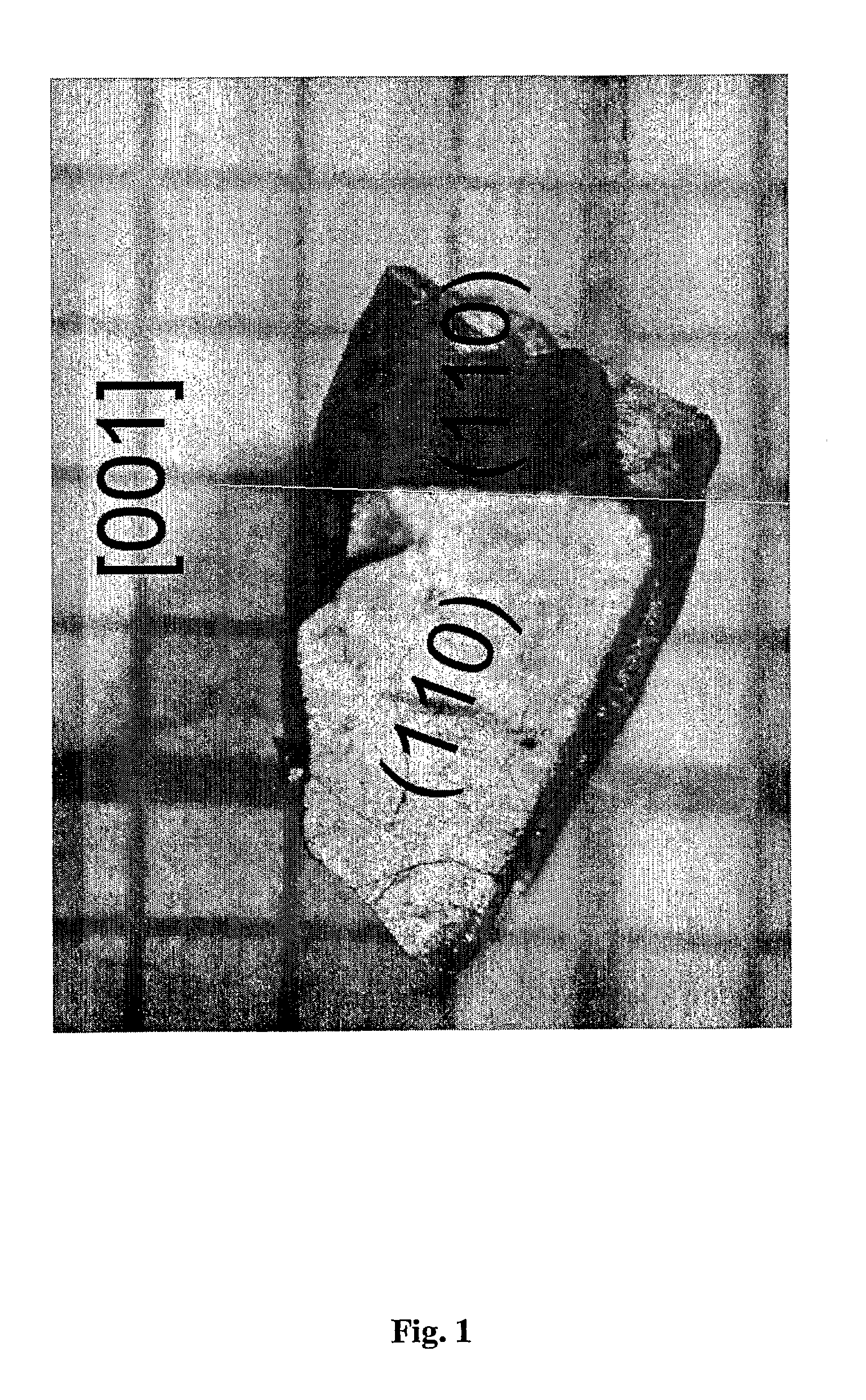

Use of thermoelectric materials for low temperature thermoelectric purposes

InactiveUS20100139730A1Polycrystalline material growthSelenium/tellurium compundsThermoelectric materialsPower factor

The invention relates to the use of a thermoelectric material for thermoelectric purposes at a temperature of 150 K or less, said thermoelectric material is a material corresponding to the stoichiometric formula FeSb2, wherein all or part of the Fe atoms optionally being substituted by one or more elements selected from the group comprising: Sc, Ti, V, Cr, Mn, Co, Ni, Cu, Zn, Y, Zr, Nb, Mo, Tc, Ru, Rh, Pd, Ag, Cd, La, Hf, Ta, W, Re, Os, Tr, Pt, Au, Hg, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu and a vacancy; and wherein all or part of the Sb atoms optionally being substituted by one or more elements selected from the group comprising: P, As, Bi, S, Se, Te, B, Al, Ga, In, Tl, C, Si, Ge, Sn, Pb and a vacancy; with the proviso that neither one of the elements Fe and Sb in the formula FeSb2 is fully substituted with a vacancy, characterised in that said thermoelectric material exhibits a power factor (S2σ) of 25 μW / cmK2 or more at a temperature of 150 K or less. The invention also relates to thermoelectric materials per se falling within the above definition.

Owner:AARHUS UNIV +1

Metal chalcogenide composite nano-particles and layers therewith

A metal chalcogenide composite nano-particle comprising a metal capable of forming p-type semiconducting chalcogenide nano-particles and a metal capable of forming n-type semiconducting chalcogenide nano-particles, wherein at least one of the metal chalcogenides has a band-gap between 1.0 and 2.9 eV and the concentration of the metal capable of forming p-type semiconducting chalcogenide nano-particles is at least 5 atomic percent of the metal and is less than 50 atomic percent of the metal; a dispersion thereof; a layer comprising the nano-particles; and a photovoltaic device comprising the layer.

Owner:AGFA GEVAERT AG

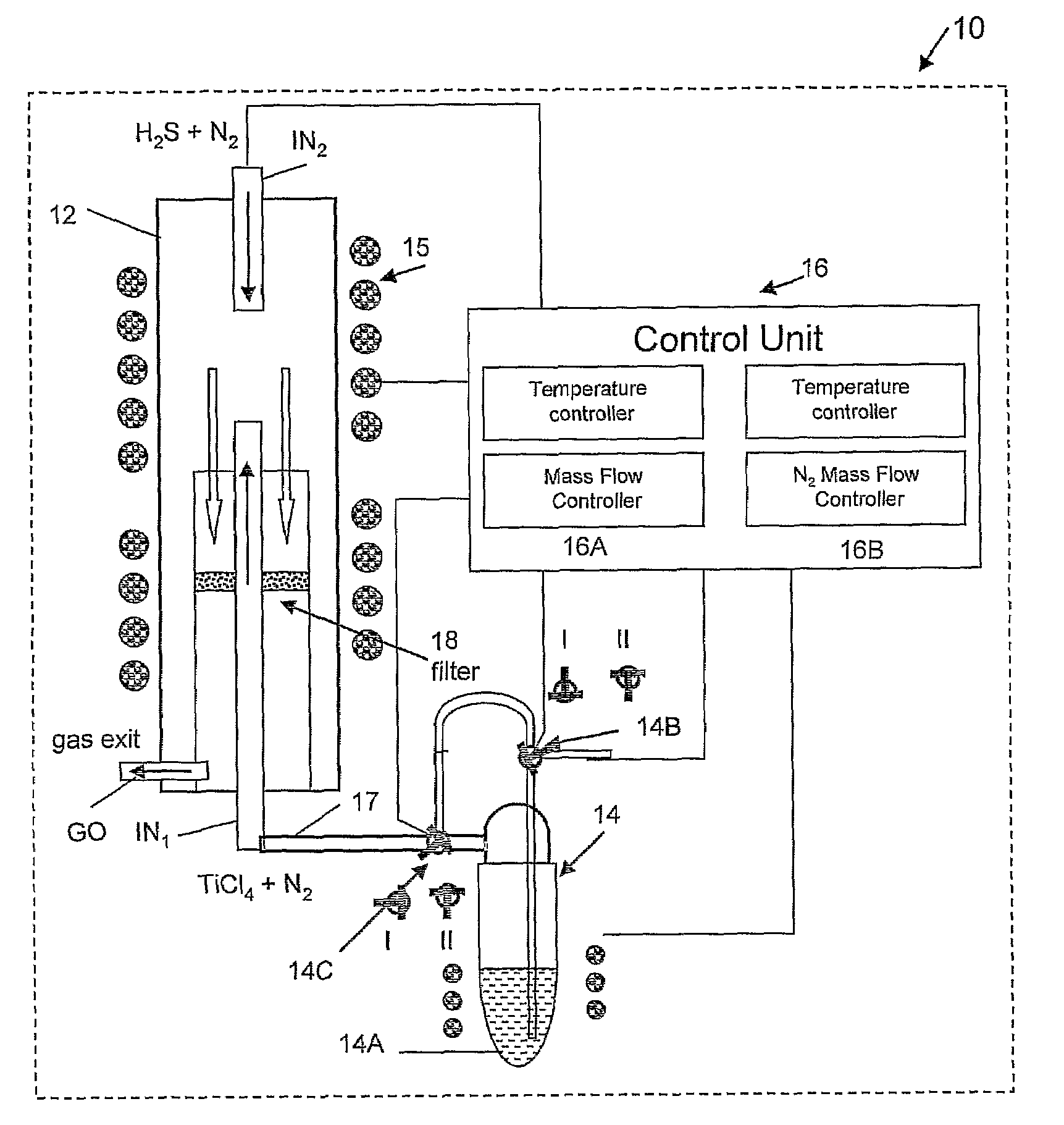

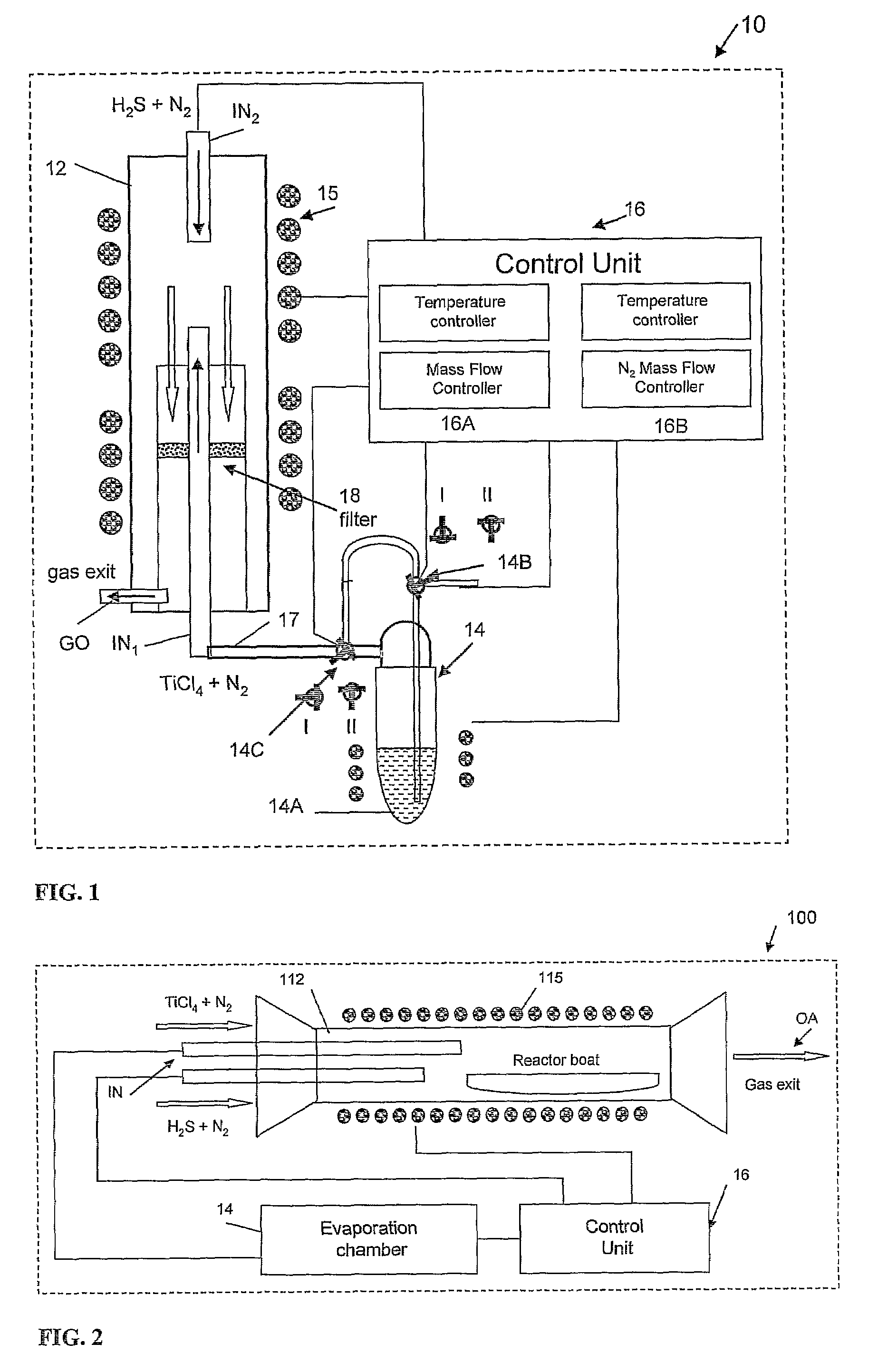

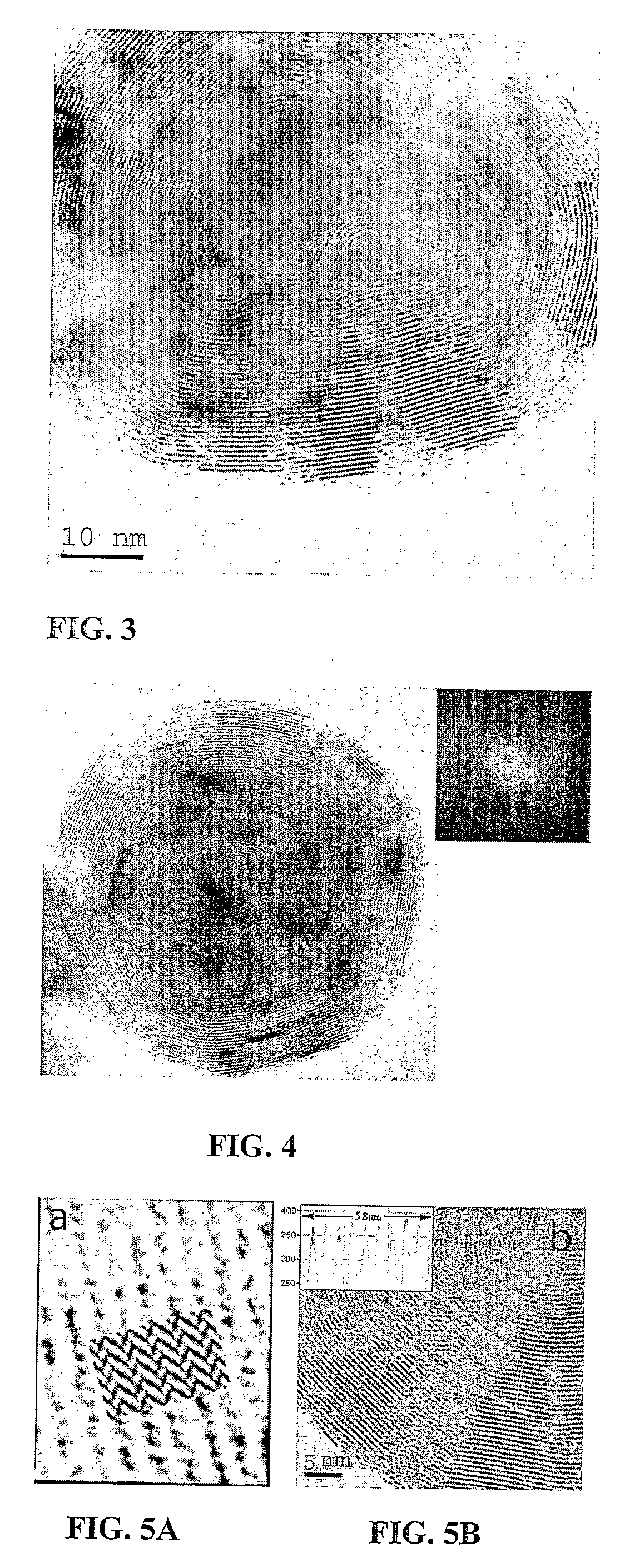

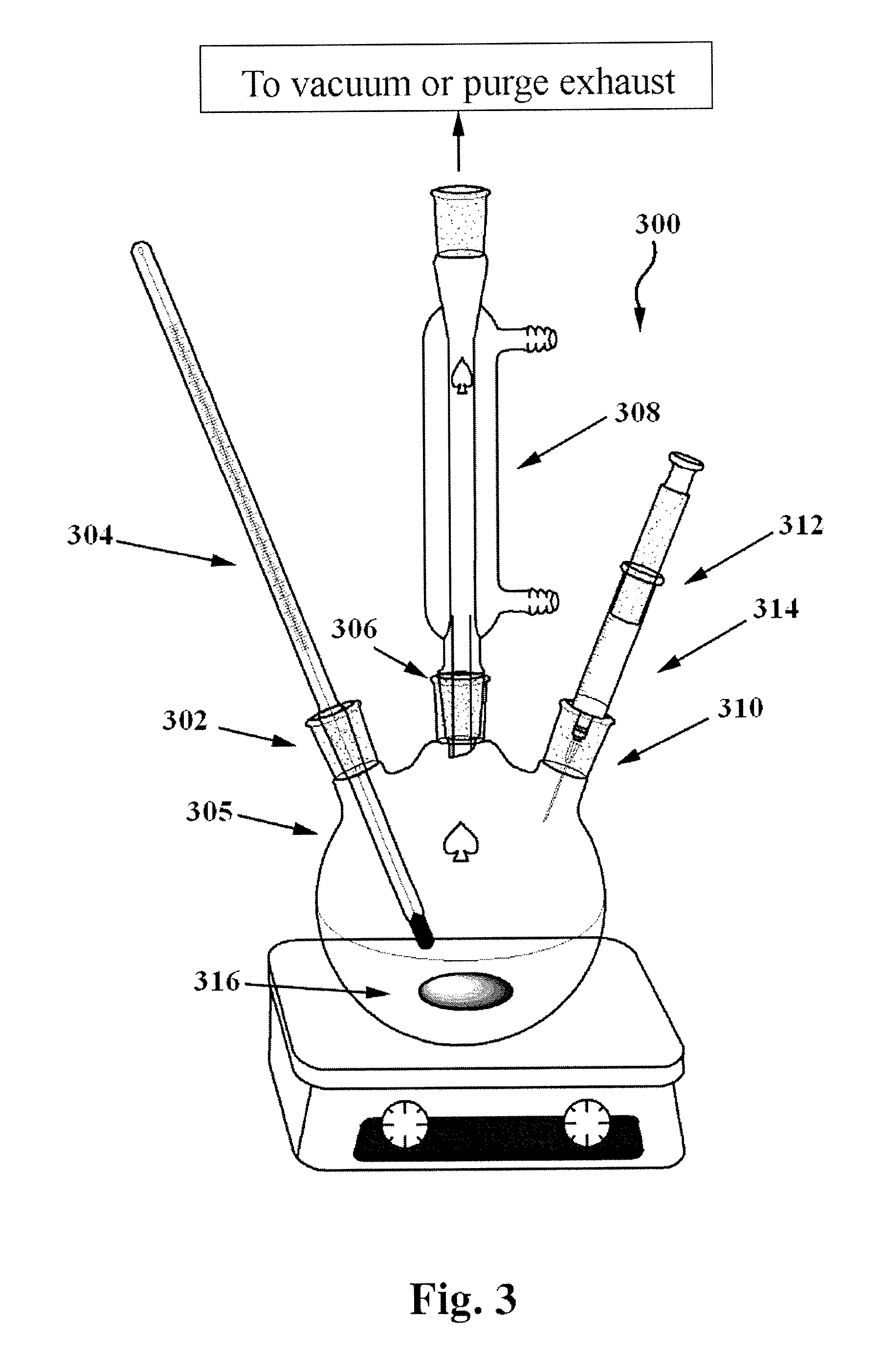

Process and apparatus for producing inorganic fullerene-like nanoparticles

ActiveUS7641886B2Easy to produceImproved propertyMaterial nanotechnologyNanostructure manufactureGas phaseMetal chalcogenides

The present invention provides a process for obtaining fullerene-like metal chalcogenide nanoparticles, comprising feeding a metal precursor (INi) selected from metal halide, metal carbonyl, organo-metallic compound and metal oxyhalide vapor into a reaction chamber (12) towards a reaction zone to interact with a flow of at least one chalcogen material (IN2) in gas phase, the temperature conditions in said reaction zone being such to enable the formation of the fullerene-like metal chalcogenide nanoparticles product. The present invention further provides novel IF metal chalcogenides nanoparticles with spherical shape and optionally having a very small or no hollow core and also exhibiting excellent tribological behavior. The present invention further provides an apparatus for preparing various IF nanostructures.

Owner:A Y Y T TECHCAL APPL & DATA UPDATE +1

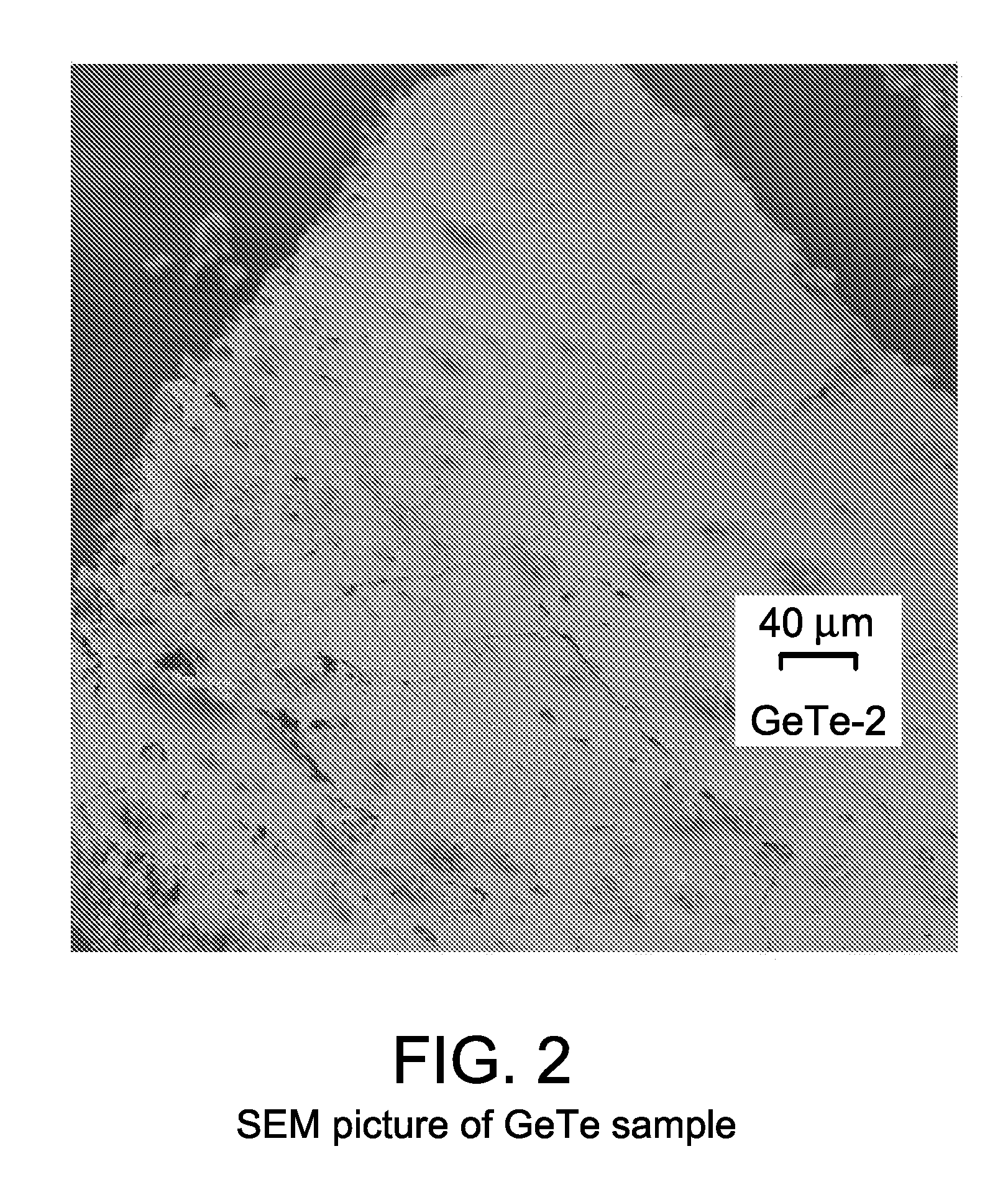

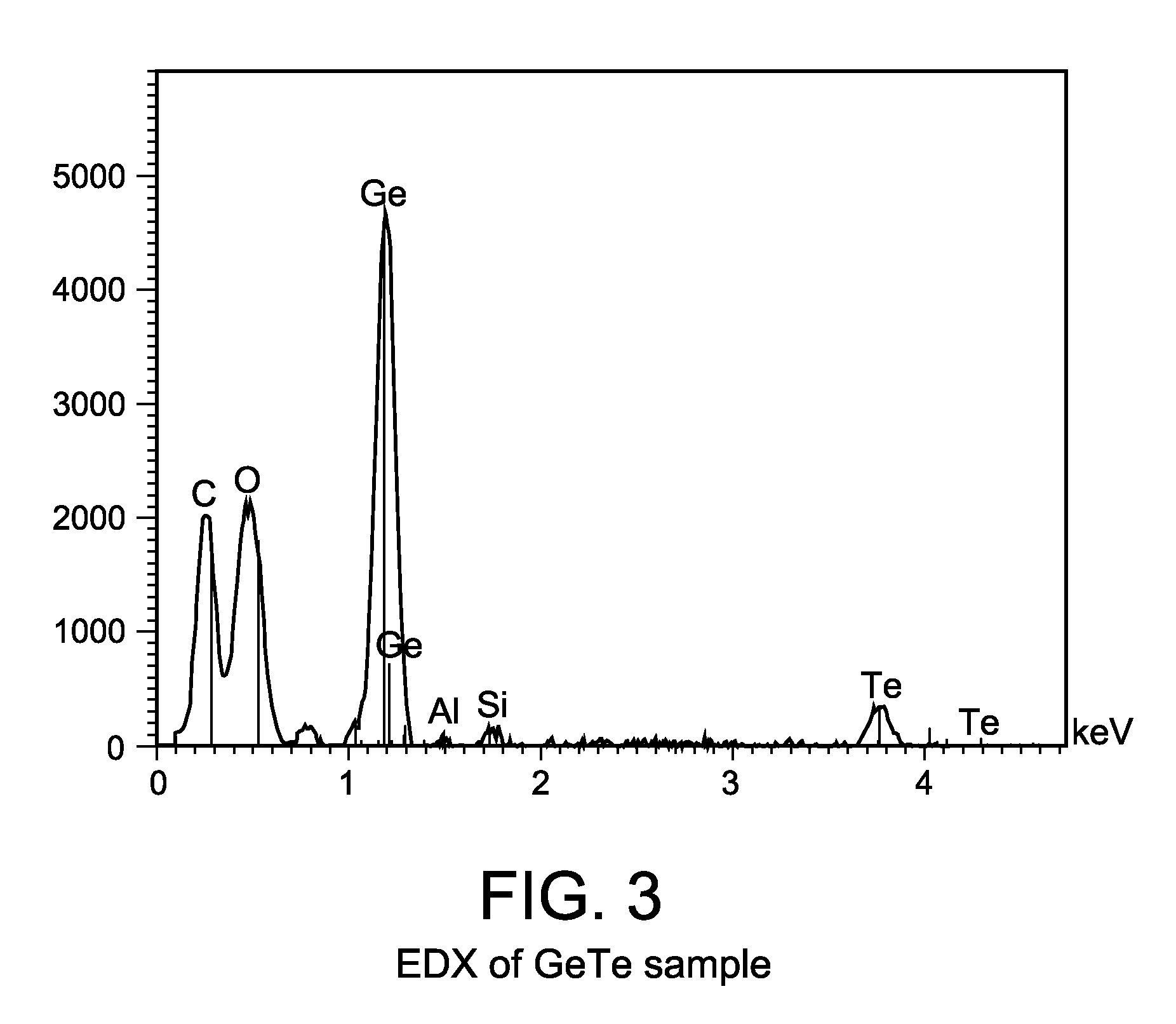

Binary and Ternary Metal Chalcogenide Materials and Method of Making and Using Same

ActiveUS20090280052A1Silicon organic compoundsPhosphorus sulfur/selenium/tellurium compoundsPhase-change memoryMetal chalcogenides

This invention discloses the synthesis of metal chalcogenides using chemical vapor deposition (CVD) process, atomic layer deposition (ALD) process, or wet solution process. Ligand exchange reactions of organosilyltellurium or organosilylselenium with a series of metal compounds having neucleophilic substituents generate metal chalcogenides. This chemistry is used to deposit germanium-antimony-tellurium (GeSbTe) and germanium-antimony-selenium (GeSbSe) films or other tellurium and selenium based metal compounds for phase change memory and photovoltaic devices.

Owner:VERSUM MATERIALS US LLC

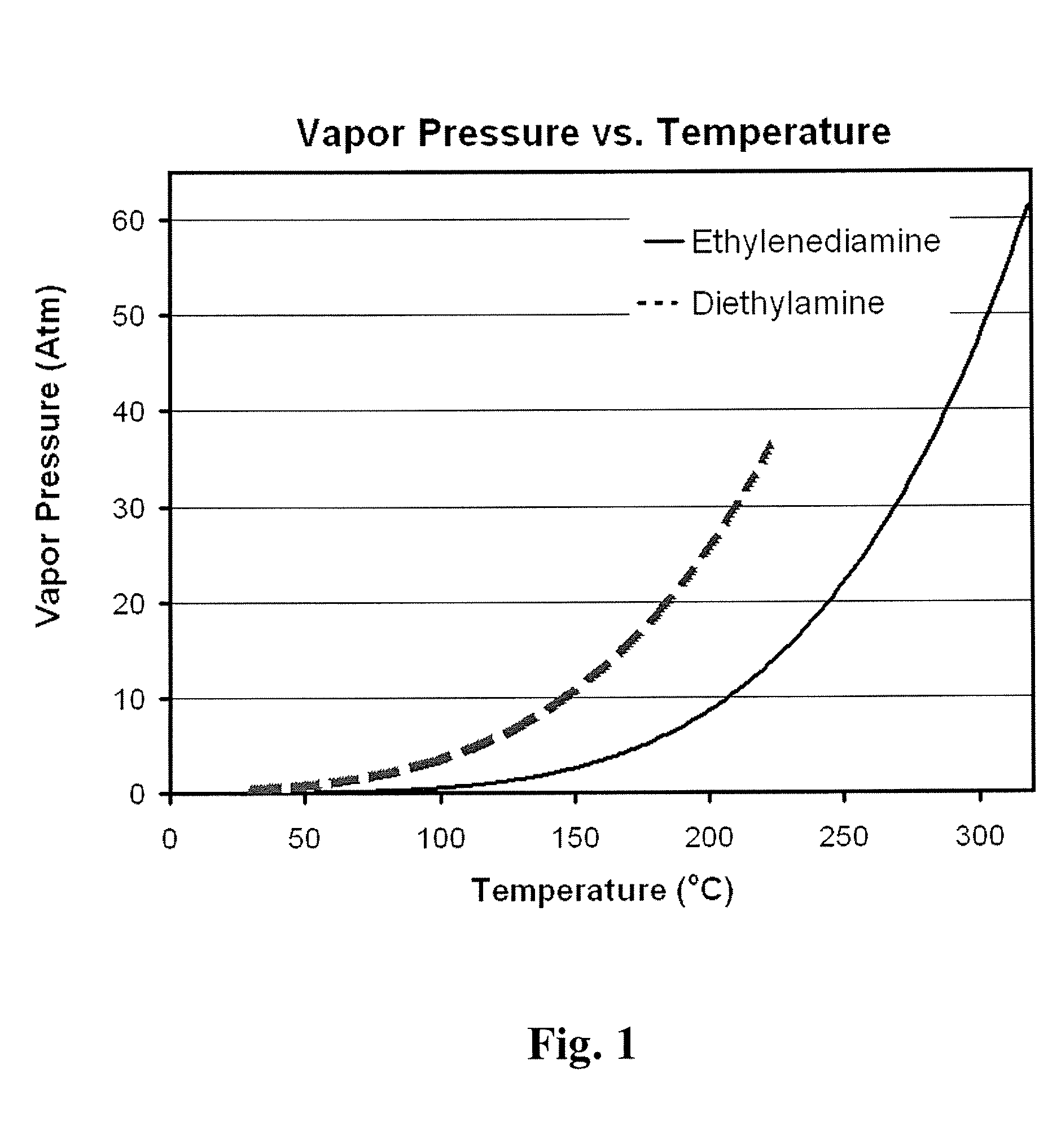

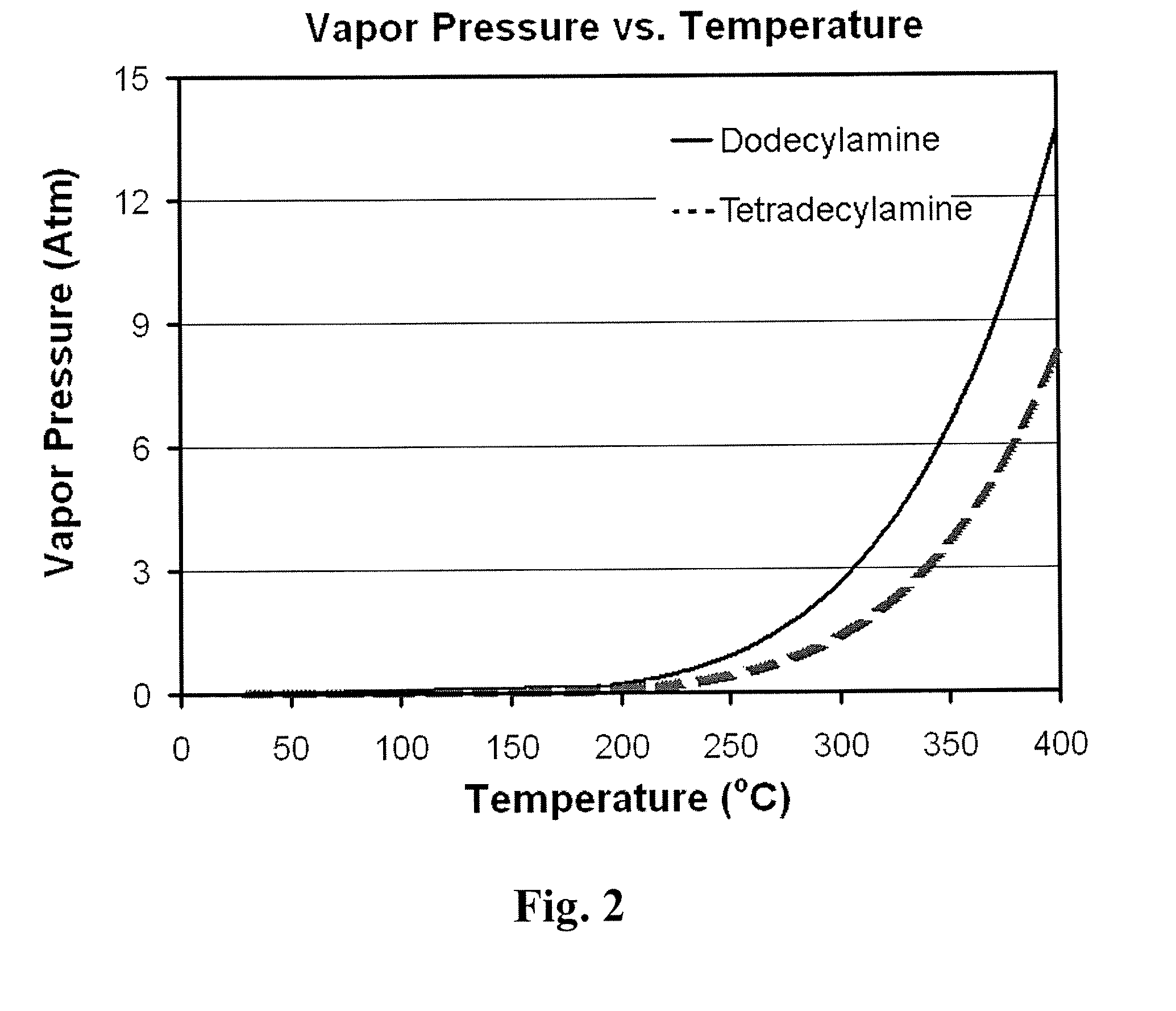

Rapid synthesis of ternary, binary and multinary chalcogenide nanoparticles

InactiveUS20100003187A1Rapid responseEasy to handleMaterial nanotechnologyPhosphorus sulfur/selenium/tellurium compoundsOrganic solventSulfur

A method for synthesizing a chalcogenide nanoparticle is provided. The method comprises reacting a metal component with an elemental chalcogen precursor in the presence of an organic solvent. The chalcogenide nanoparticles include ternary, binary and / or multinary chalcogenide nanoparticles and the metal component comprises metal halides or elemental metal precursors. The alkylamine solvent has a normal boiling temperature of above about 220° C. and an average particle size of from about 5 nm to about 1000 nm.

Owner:PURDUE RES FOUND INC

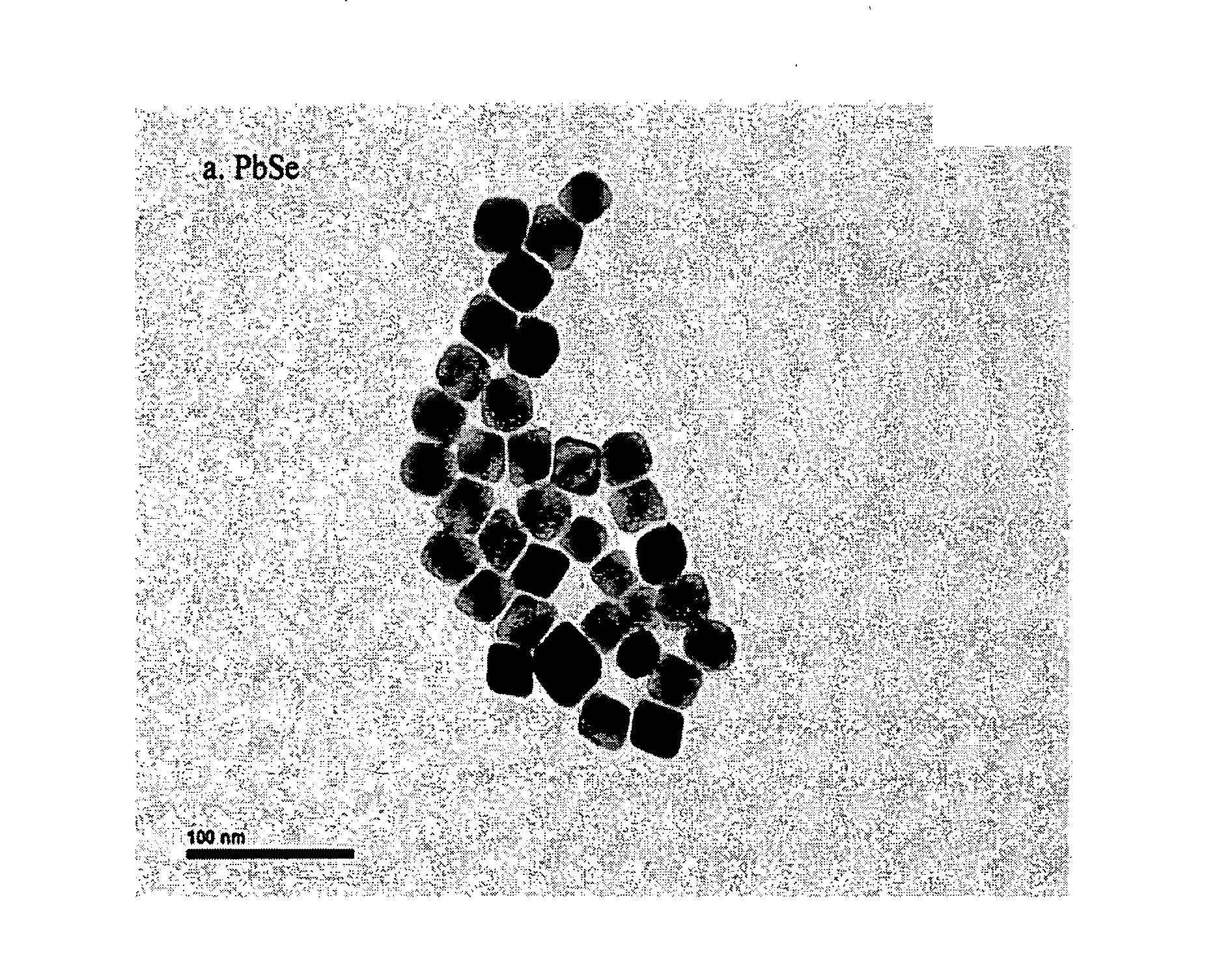

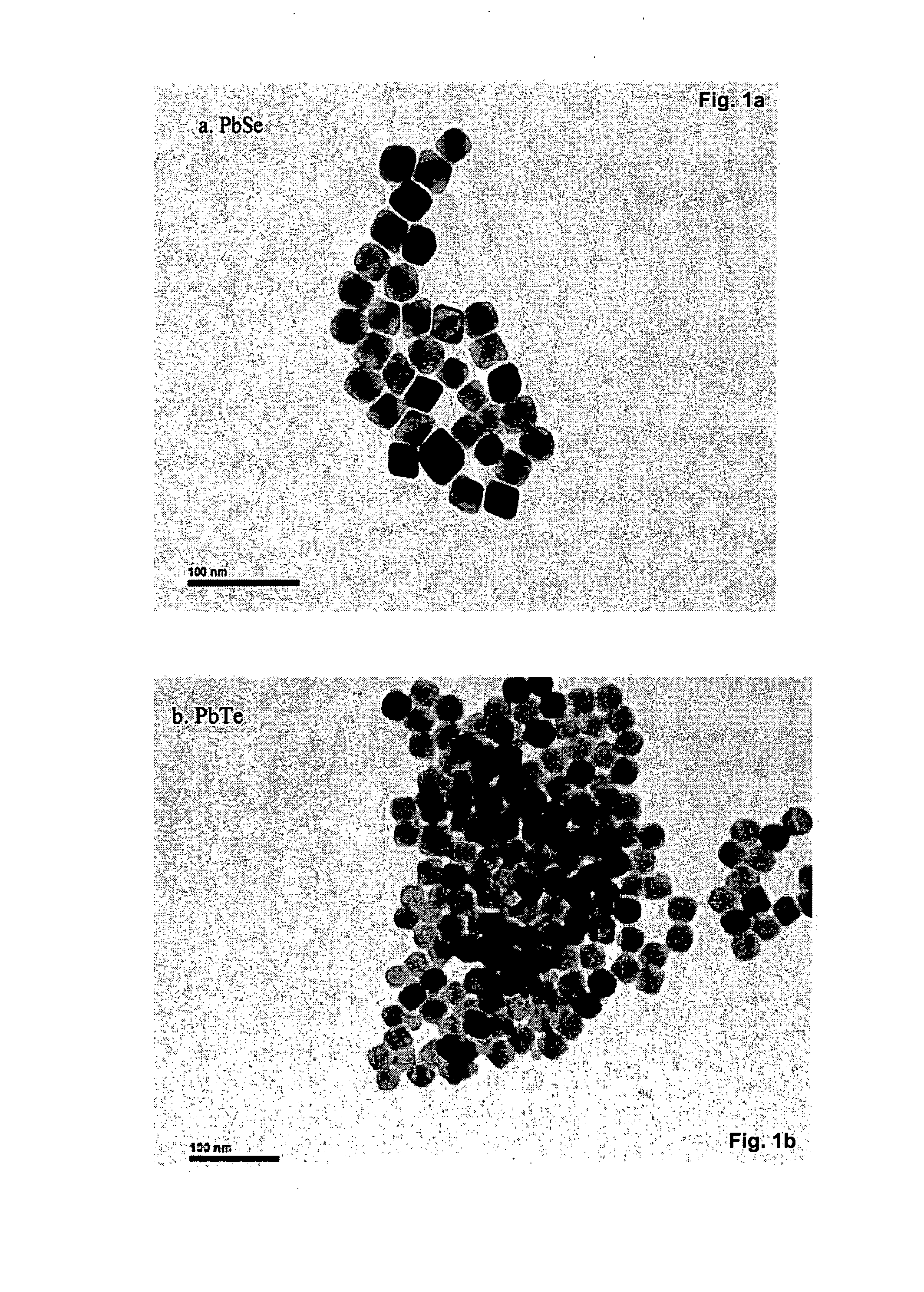

Method for the preparation of IV-VI semiconductor nanoparticles

InactiveUS20060110313A1Controlled in sizeControl shapeMaterial nanotechnologyNitrogen compoundsOrganic solventQuantum dot

A high temperature (on the order of about 90° C. or above) non-aqueous synthetic procedure for the preparation of substantially monodisperse IV-VI semiconductor nanoparticles (quantum dots) is provided. The procedure includes first introducing a first precursor selected from the group consisting of a molecular precursor of a Group IV element and a molecular precursor of a Group VI element into a reaction vessel that comprises at least an organic solvent to form a mixture. Next, the mixture is heated to a temperature of about 90° C. or above and thereafter a second precursor which is different from the first precursor and is selected from the group consisting of a molecular precursor of a Group IV element and a molecular precursor of a Group VI element is added into the heated mixture. The reaction mixture is then mixed to initiate nucleation of IV-VI nanocrystals and the temperature of the reaction mixture is controlled to provide substantially monodispersed IV-VI nanoparticles having a diameter of about 20 nm or less.

Owner:GLOBALFOUNDRIES INC +1

Metal telluride nanocrystals and synthesis thereof

InactiveUS20080112877A1Material nanotechnologyPhosphorus sulfur/selenium/tellurium compoundsBismuth tellurideLead telluride

A process for synthesizing a metal telluride is provided that includes the dissolution of a metal precursor in a solvent containing a ligand to form a metal-ligand complex soluble in the solvent. The metal-ligand complex is then reacted with a telluride-containing reagent to form metal telluride domains having a mean linear dimension of from 2 to 40 nanometers. NaHTe represents a well-suited telluride reagent. A composition is provided that includes a plurality of metal telluride crystalline domains(PbTe)1-x-y(SnTe)x(Bi2Te3)y (I)having a mean linear dimension of from 2 to 40 nanometers inclusive where x is between 0 and 1 inclusive and y is between 0 and 1 inclusive with the proviso that x+y is less than or equal to 1. Each of the metal telluride crystalline domains has a surface passivated with a saccharide moiety or a polydentate carboxylate. A densified mass having a density of greater than 95% of the theoretical density includes a plurality of lead telluride, tin telluride, bismuth telluride, or a combination thereof of domains having a mean linear dimension of from 2 to 40 nanometers inclusive that have been subjected to hot isotactic pressing.

Owner:TOYOTA MOTOR ENGINEERING & MANUFACTURING NORTH AMERICA +1

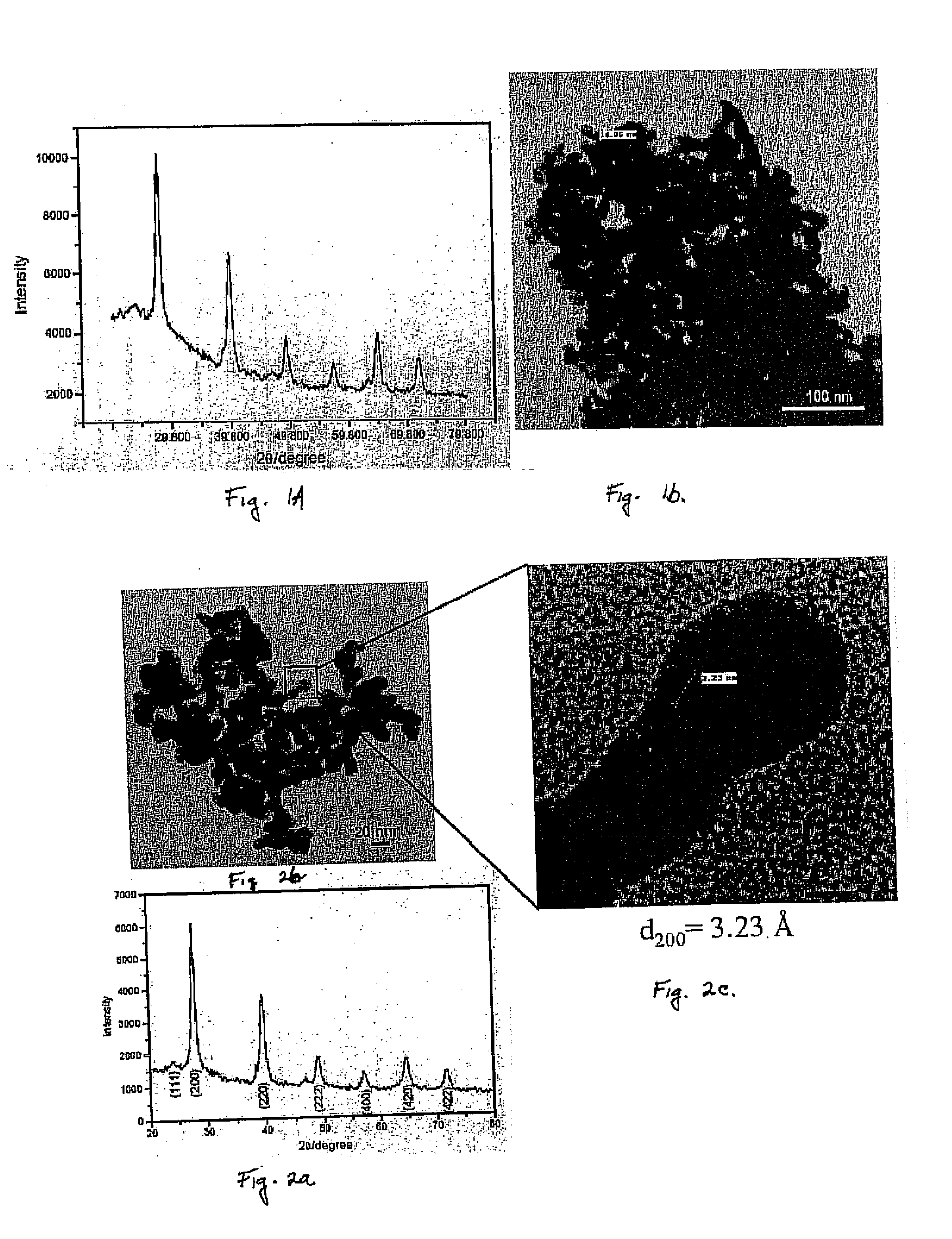

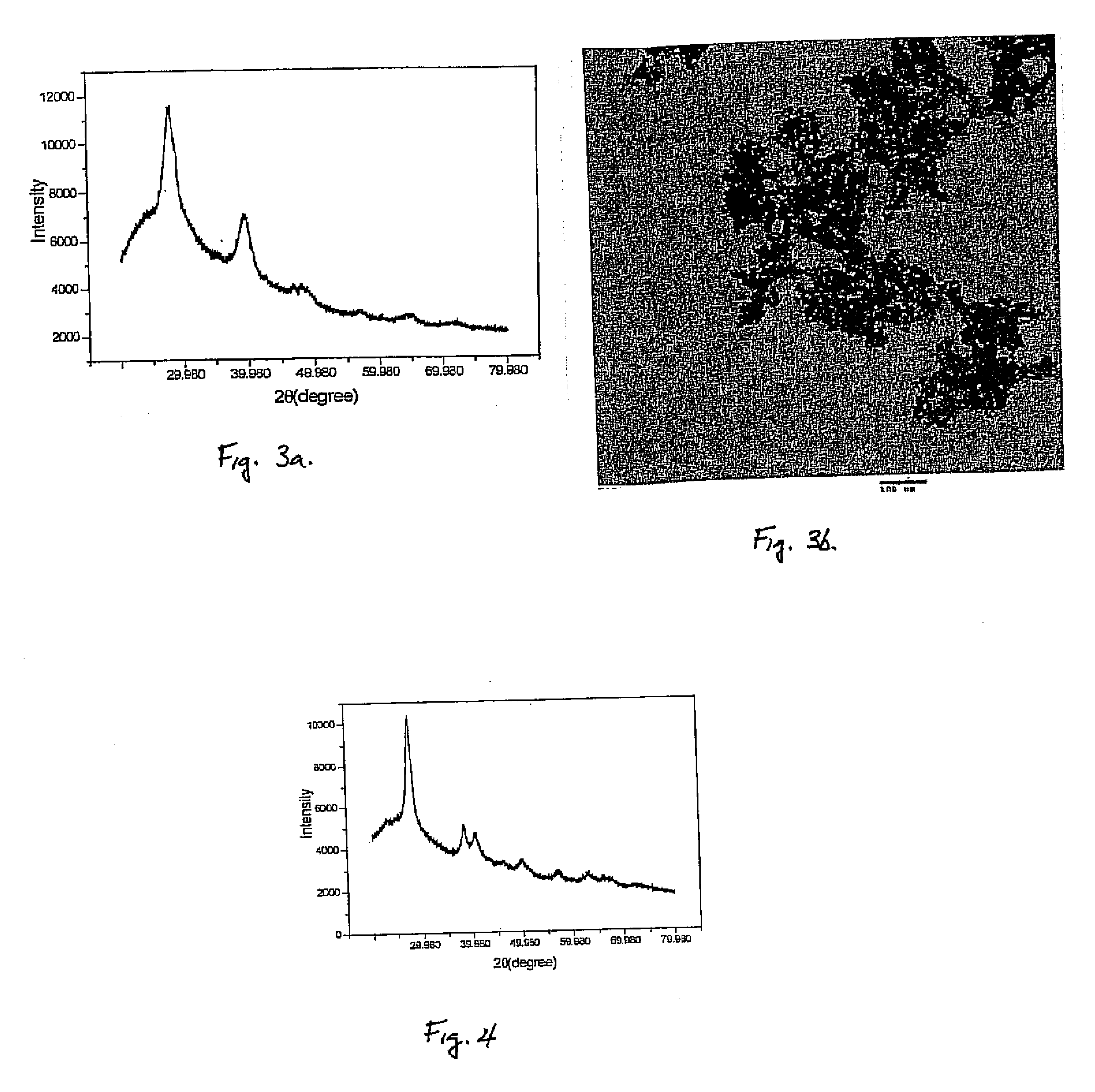

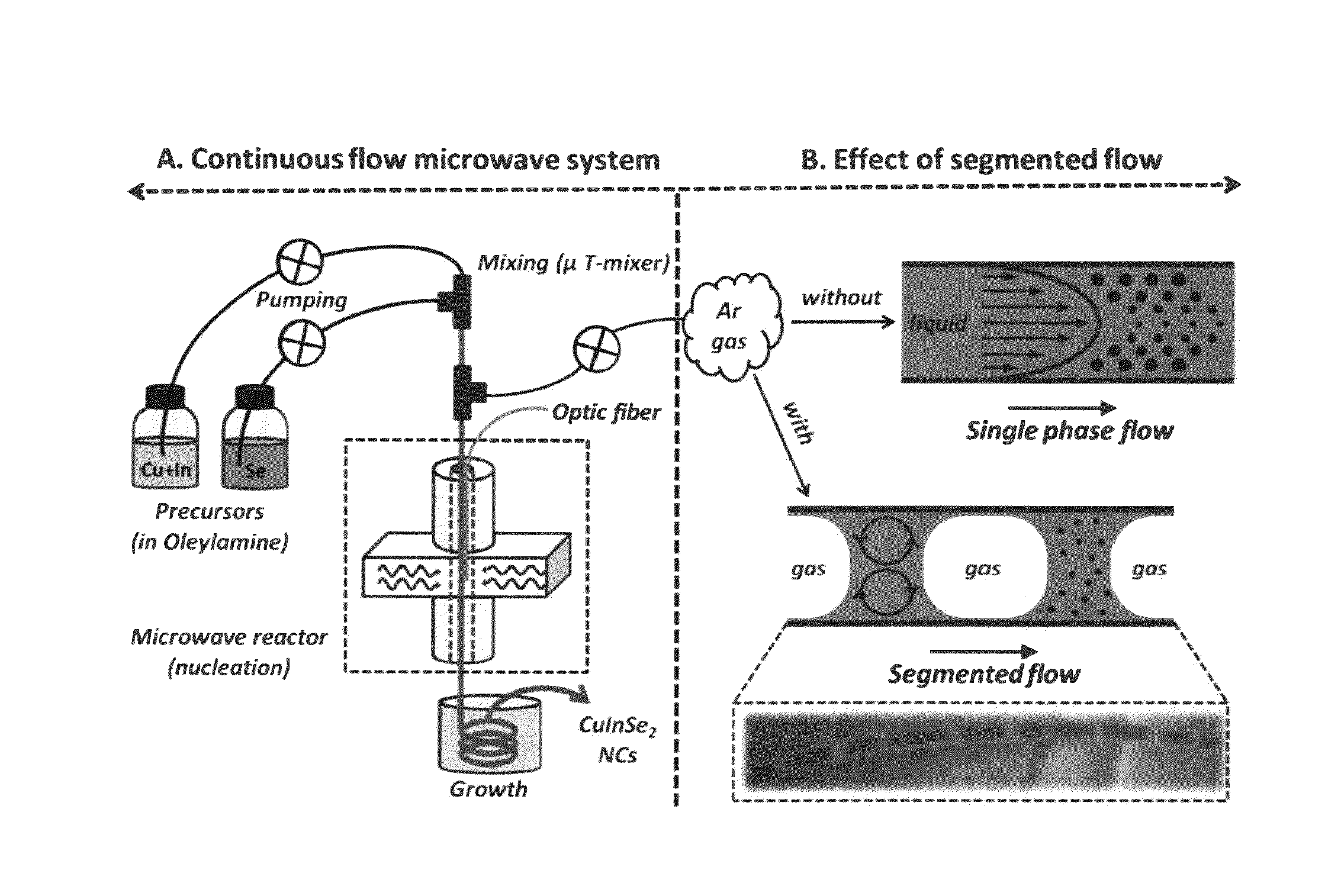

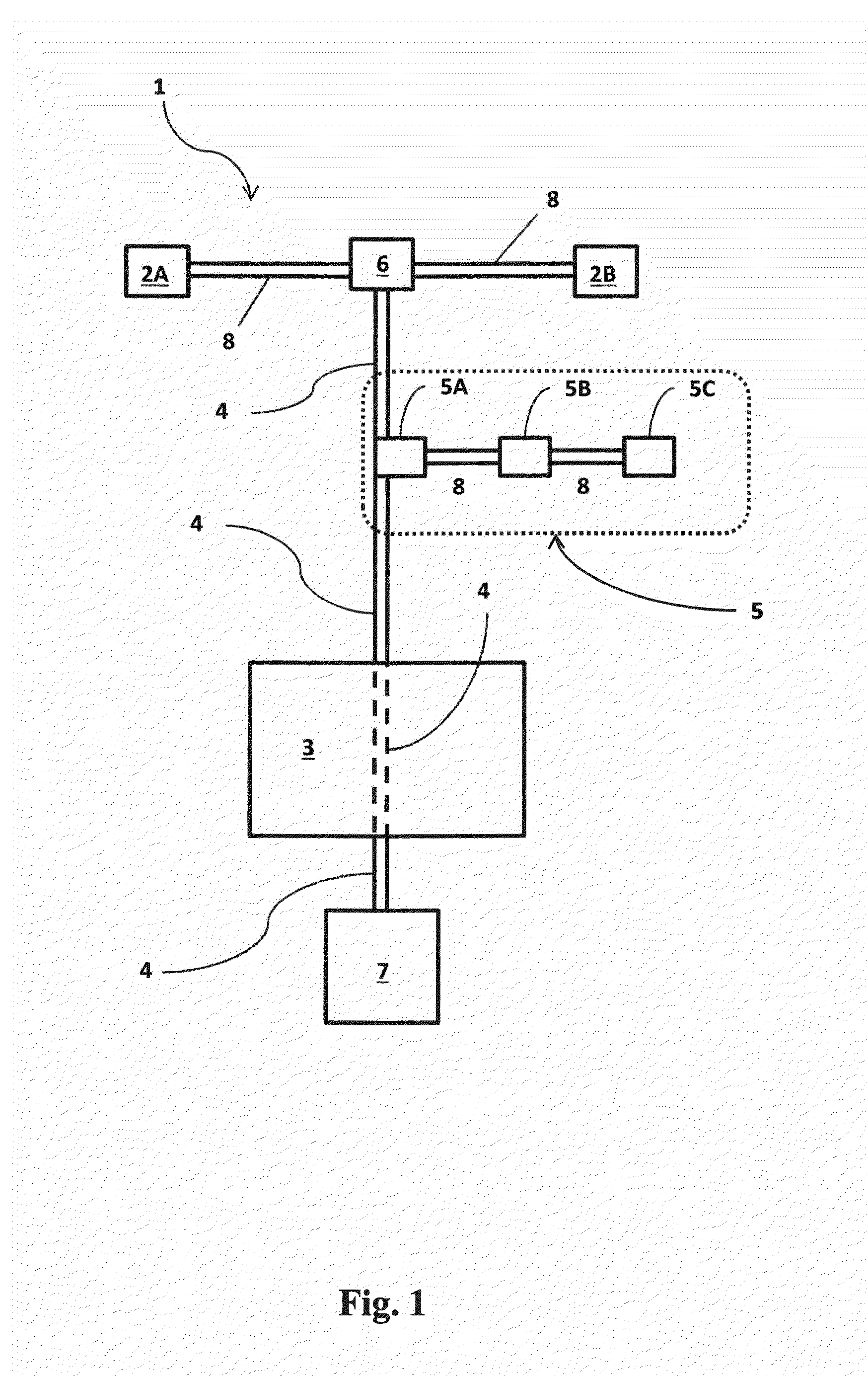

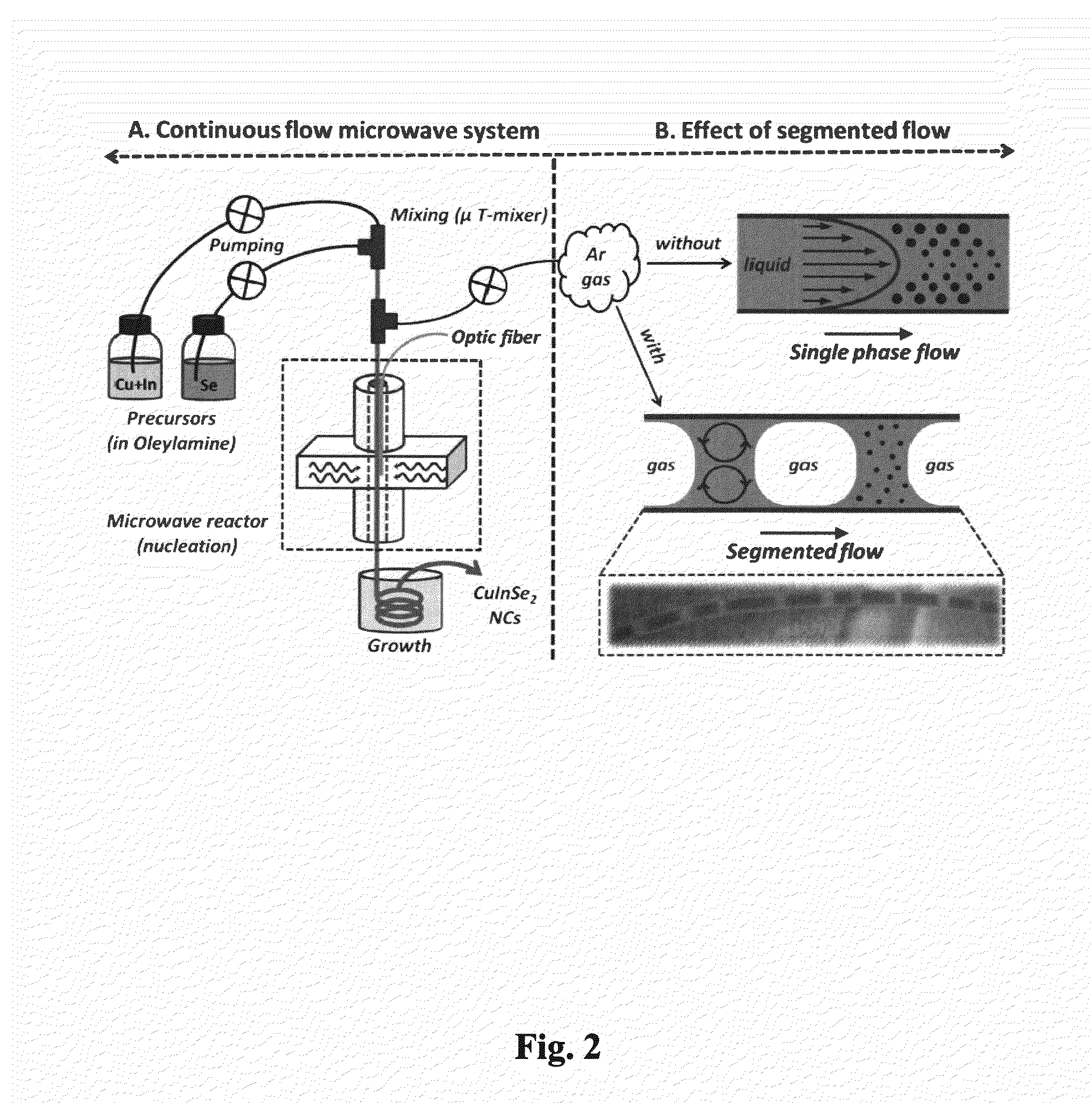

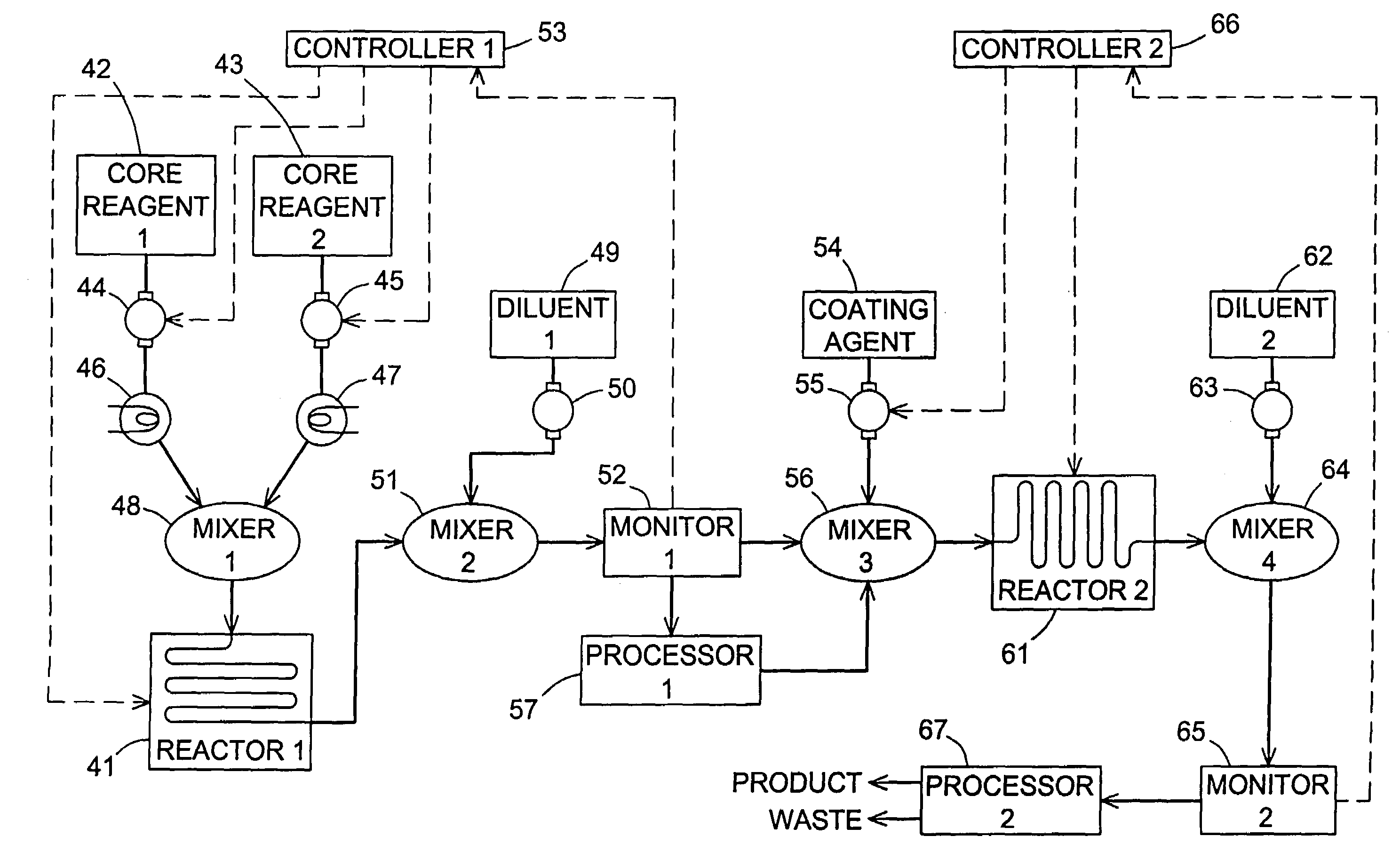

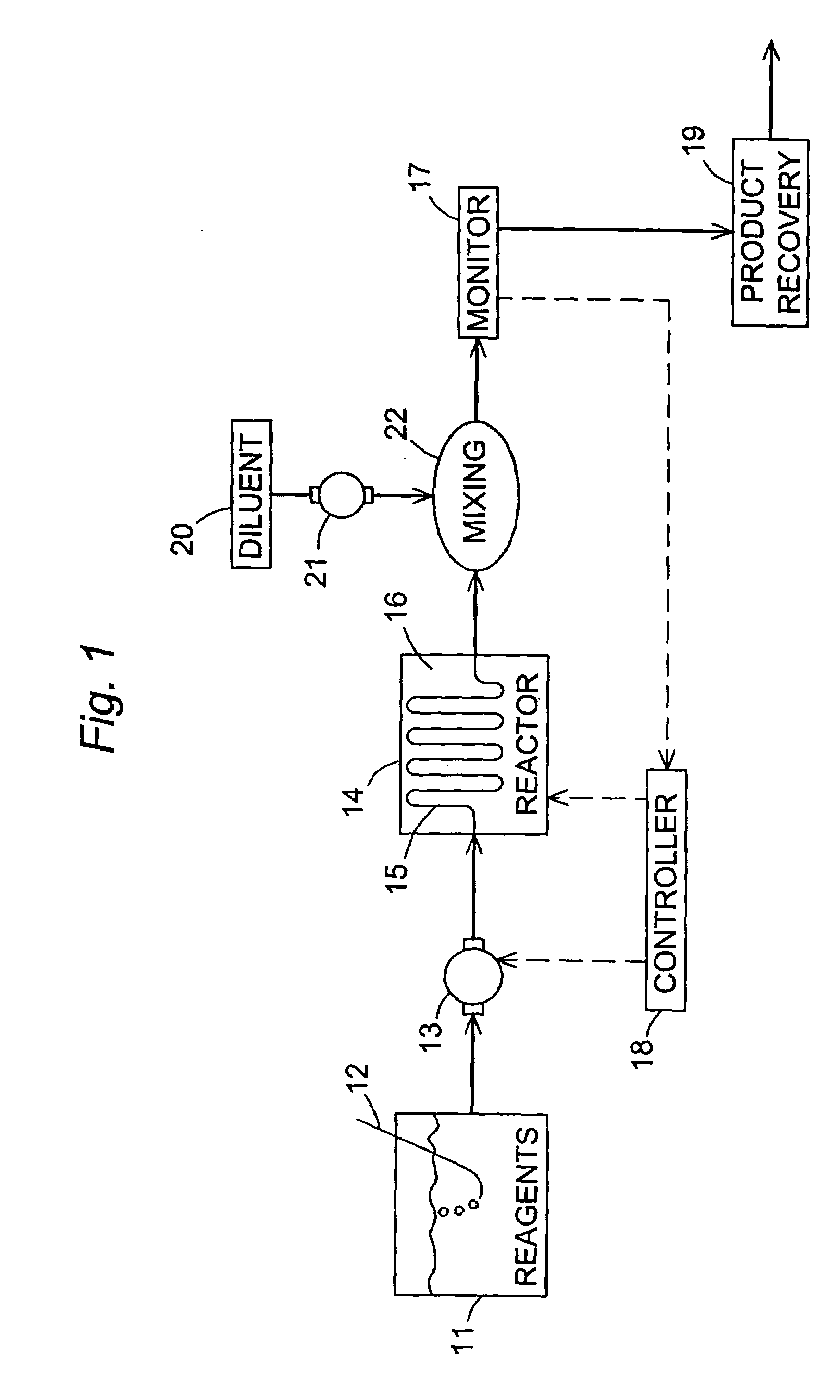

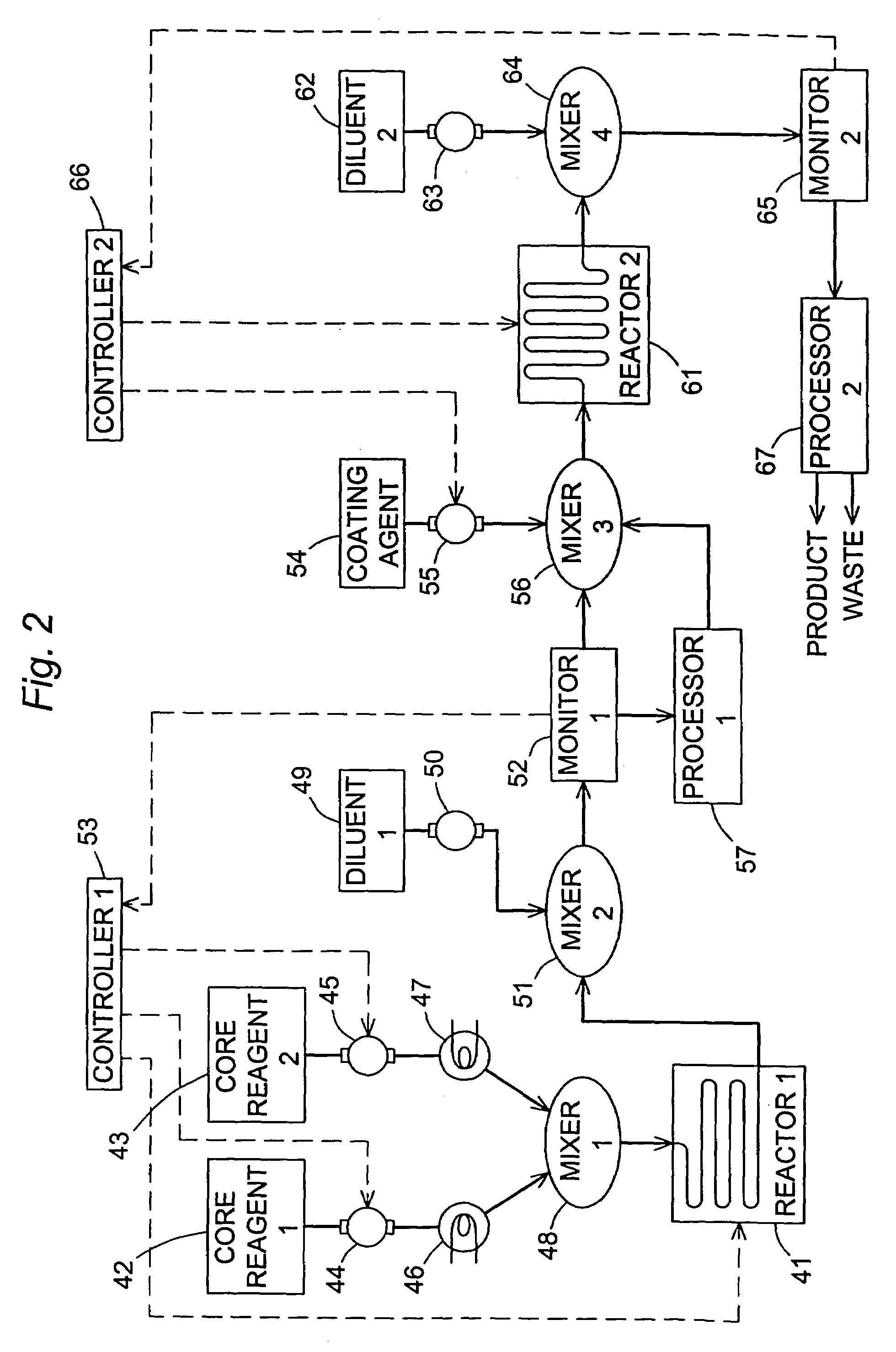

Continuous microwave-assisted segmented flow reactor for high-quality nanocrystal synthesis

ActiveUS20150182936A1Quality improvementTin compoundsPhosphorus sulfur/selenium/tellurium compoundsProcess engineeringContinuous flow

Systems and methods for synthesizing high-quality nanocrystals via segmented, continuous flow microwave-assisted reactor were developed.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

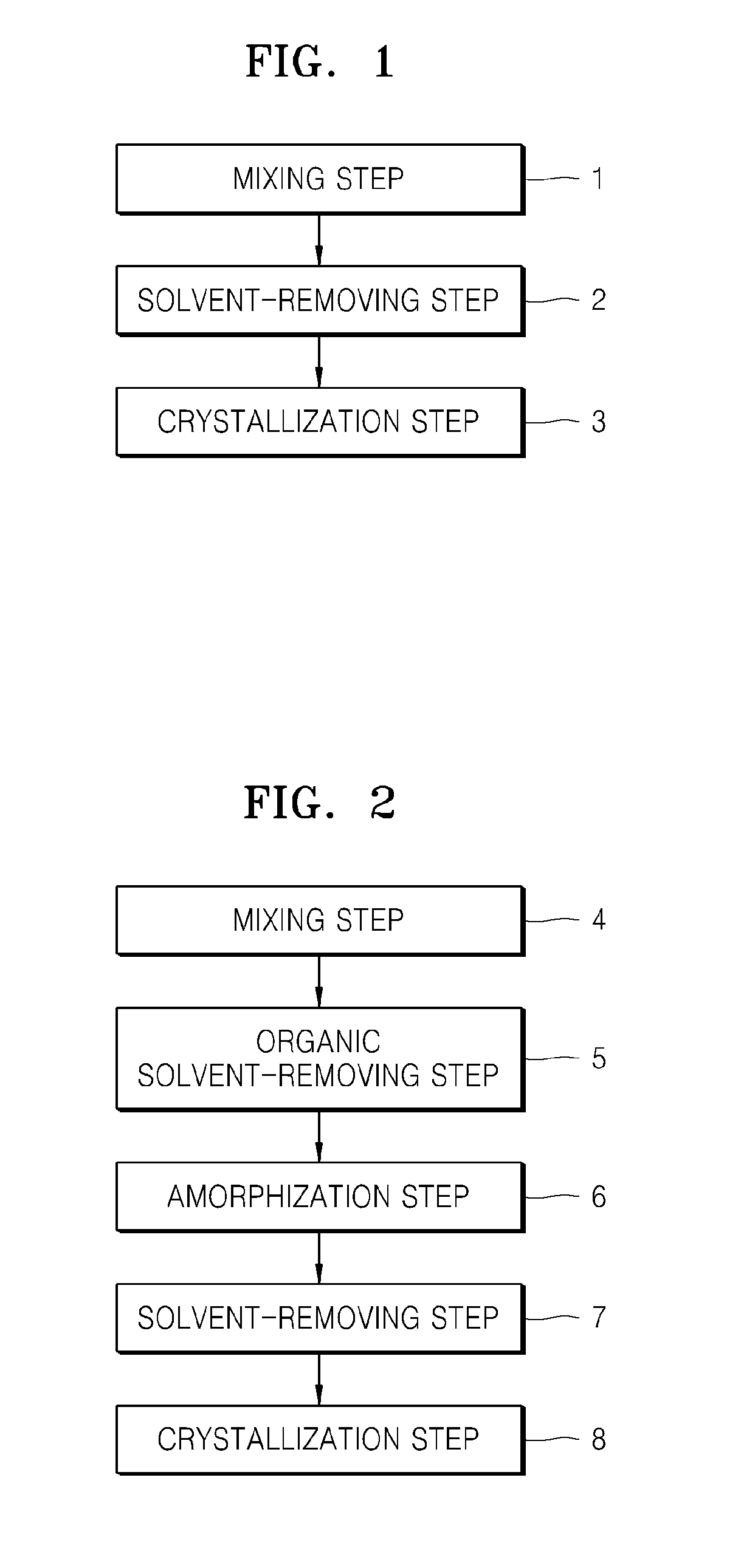

Sulfide solid electrolyte, method of preparing the same, and solid state battery including the same

InactiveUS20150093652A1Reduce manufacturing costImprove ionic conductivitySolid electrolytesPhosphorus sulfur/selenium/tellurium compoundsOrganic solventCyclic ether

A sulfide solid electrolyte including a sulfide product prepared by mixing at least Li2S and P2S5 in an organic solvent, wherein the organic solvent includes a tetrahydrofuran compound optionally substituted with a C1-C6 hydrocarbon group or a C1-C6 hydrocarbon group including an ether group, or a C2-C7 non-cyclic ether compound.

Owner:SAMSUNG ELECTRONICS CO LTD

Metal chalcogenide aqueous precursors and processes to form metal chalcogenide films

InactiveUS20110206599A1Selenium/tellurium compundsPhosphorus sulfur/selenium/tellurium compoundsSimple Organic CompoundsFormate

Metal chalocogenide precursor solutions are described that comprise an aqueous solvent, dissolved metal formate salts and a chalcogenide source composition. The chalcogenide source compositions can be organic compounds lacking a carbon-carbon bond. The precursors are designed to form a desired metal chalcogenide upon thermal processing into films with very low levels of contamination. Potentially contaminating elements in the precursors form gaseous or vapor by-products that escape from the vicinity of the product metal chalcogenide films.

Owner:INPRIA CORP

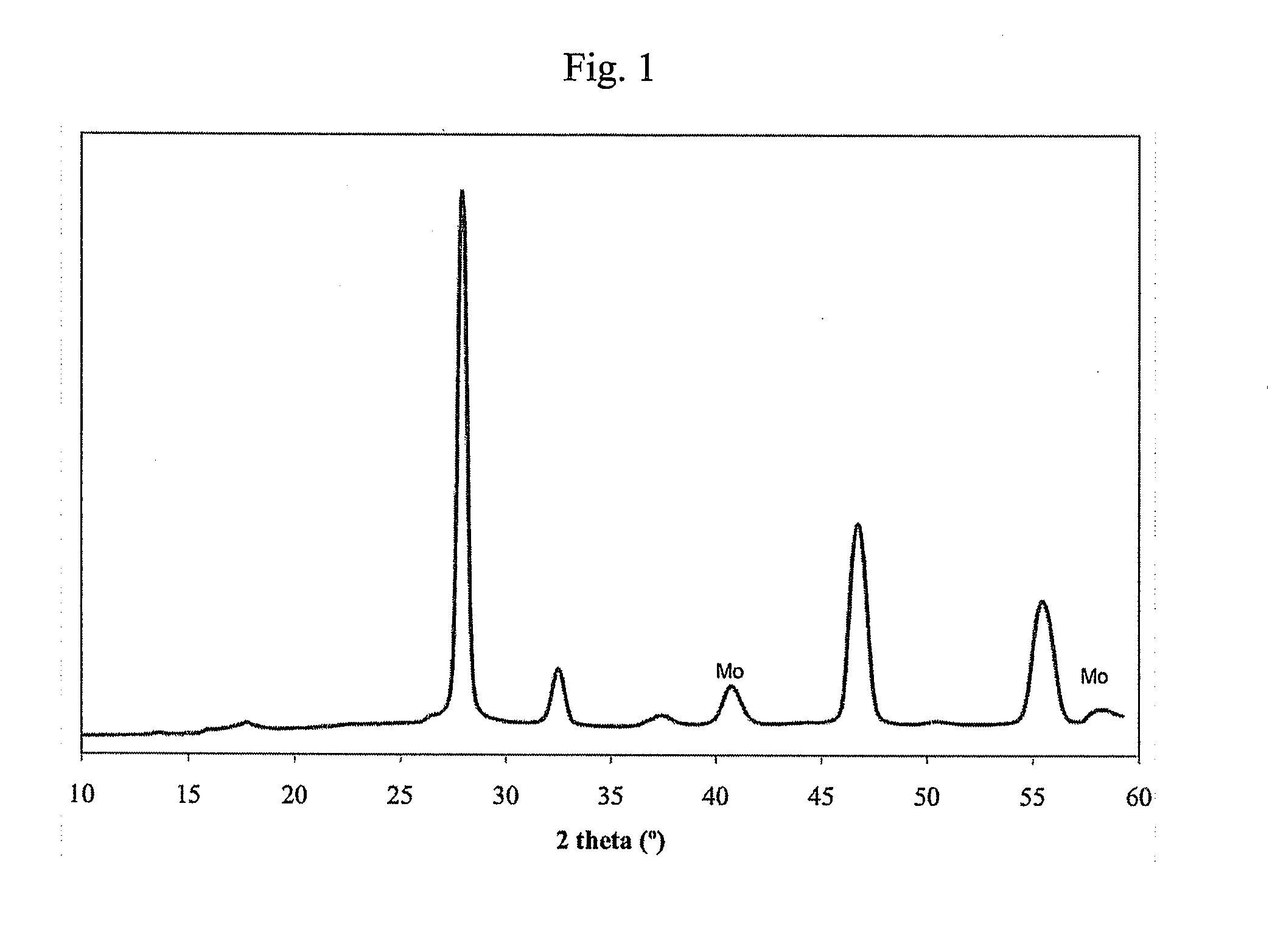

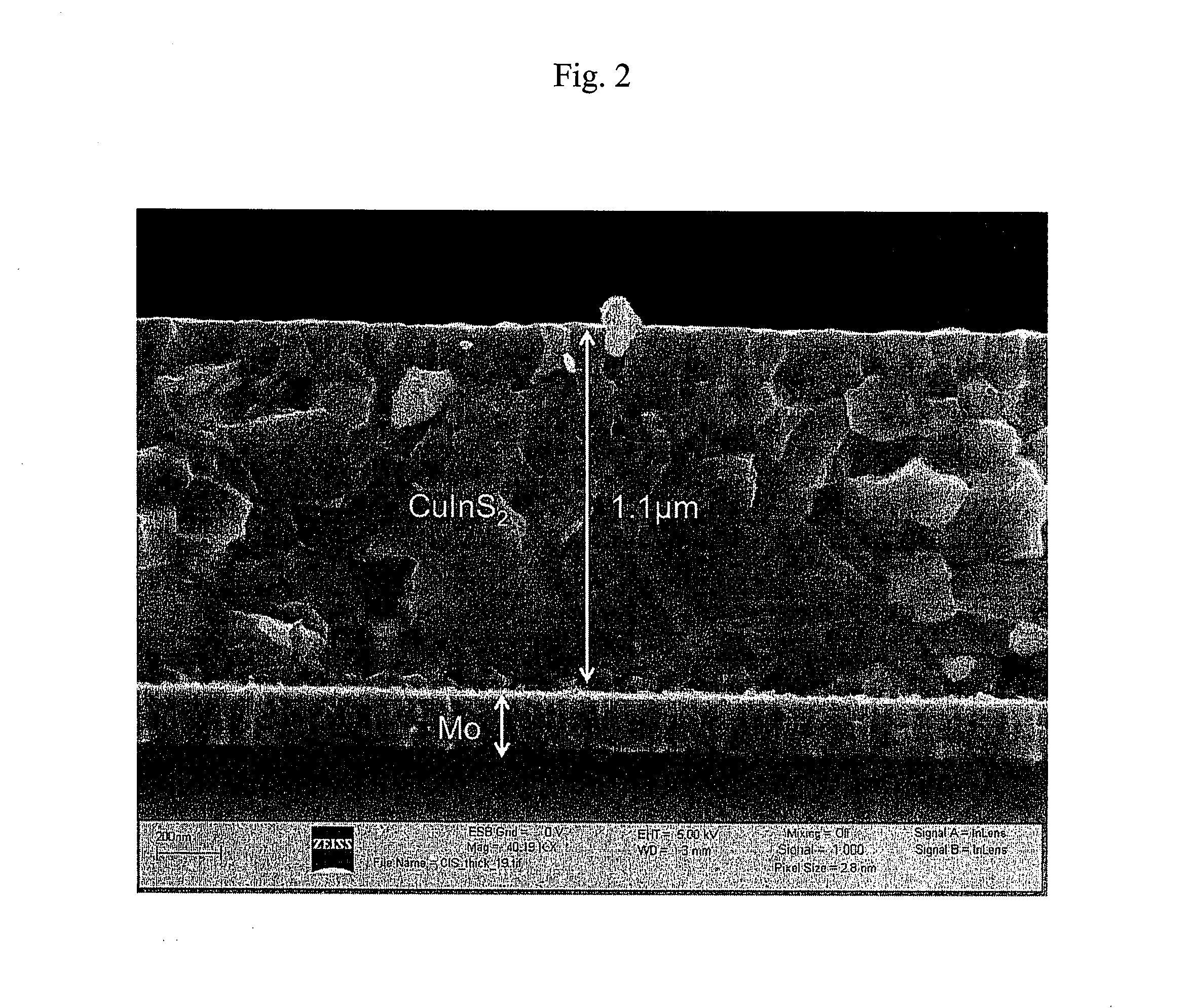

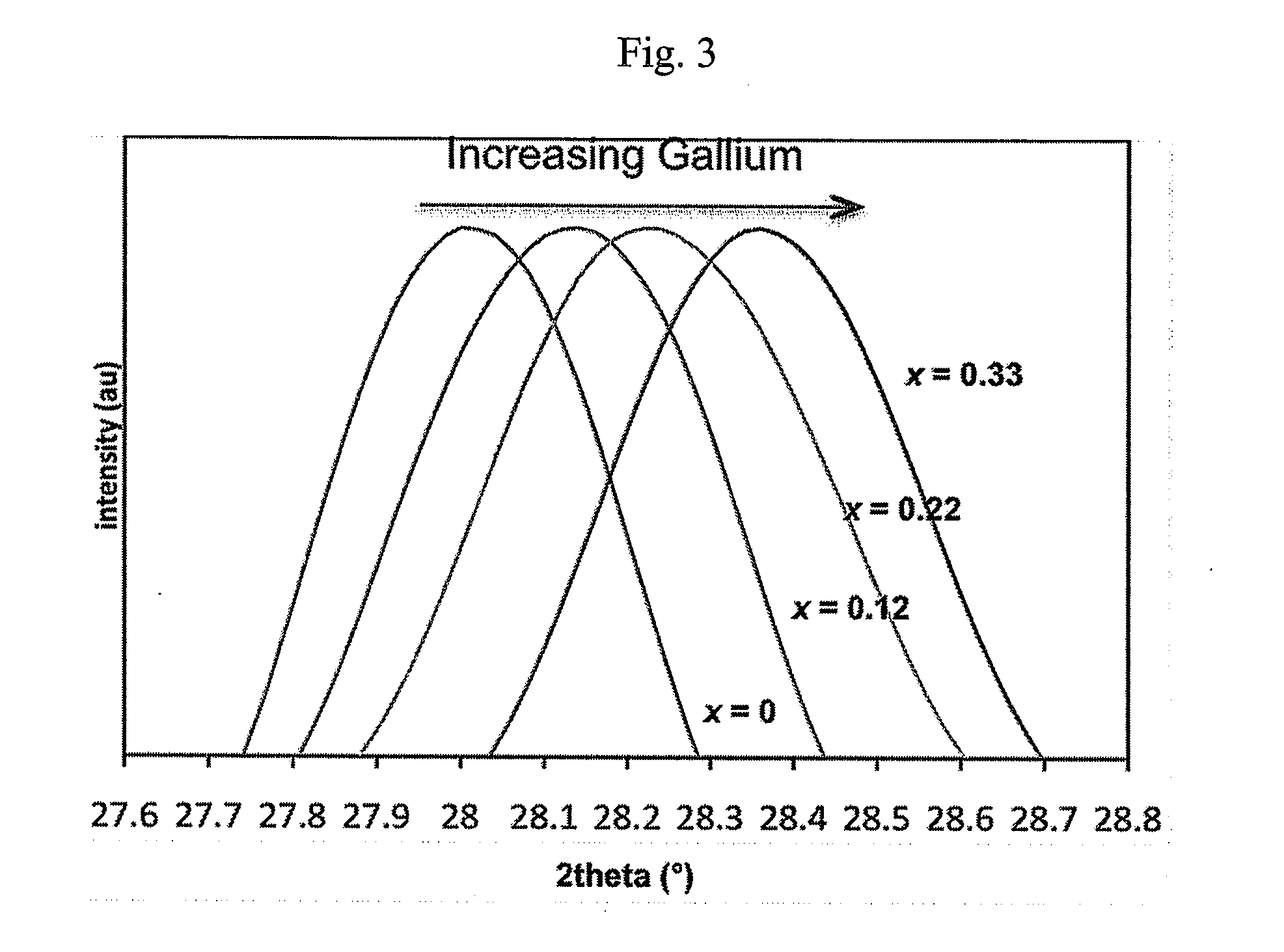

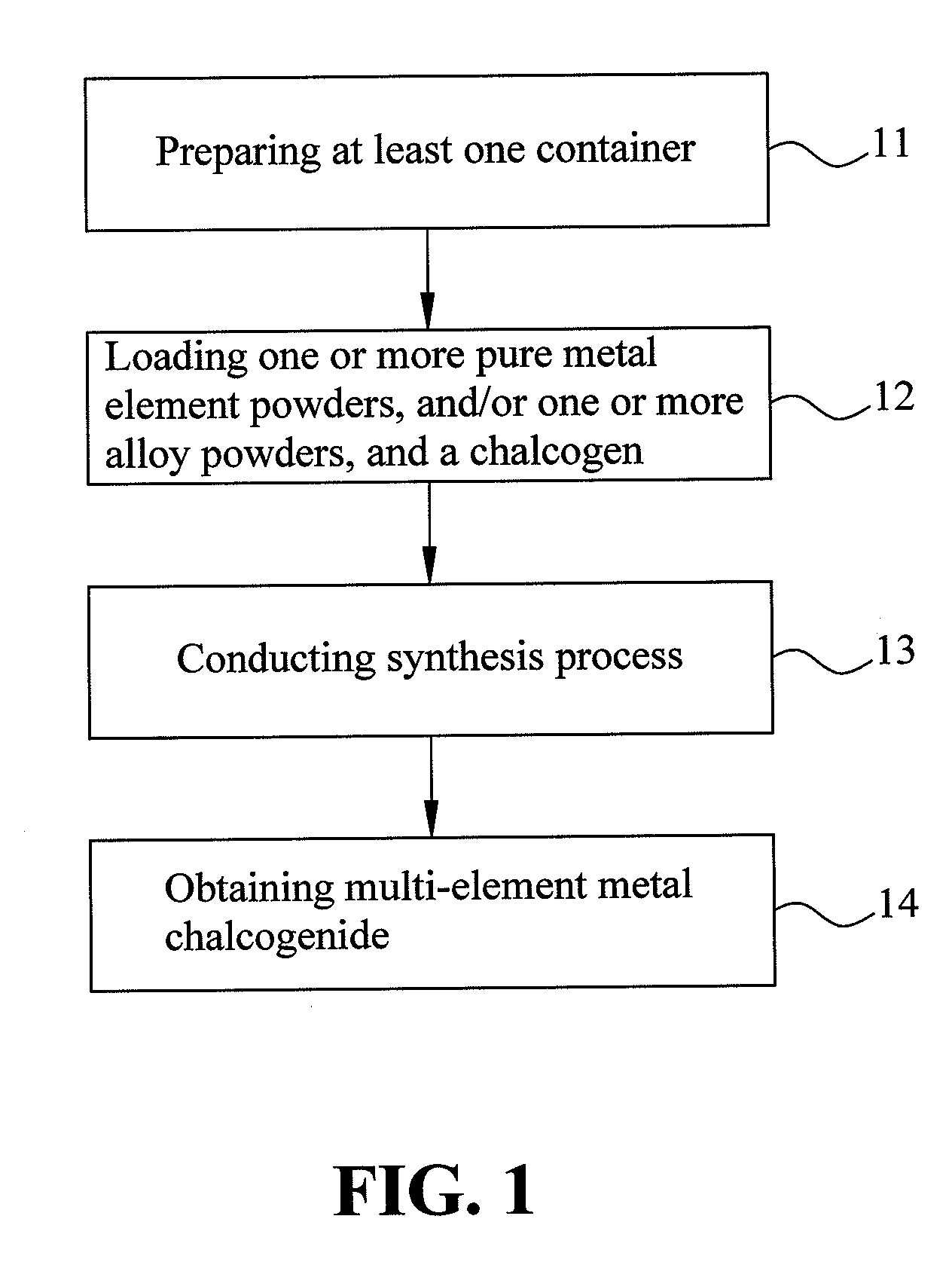

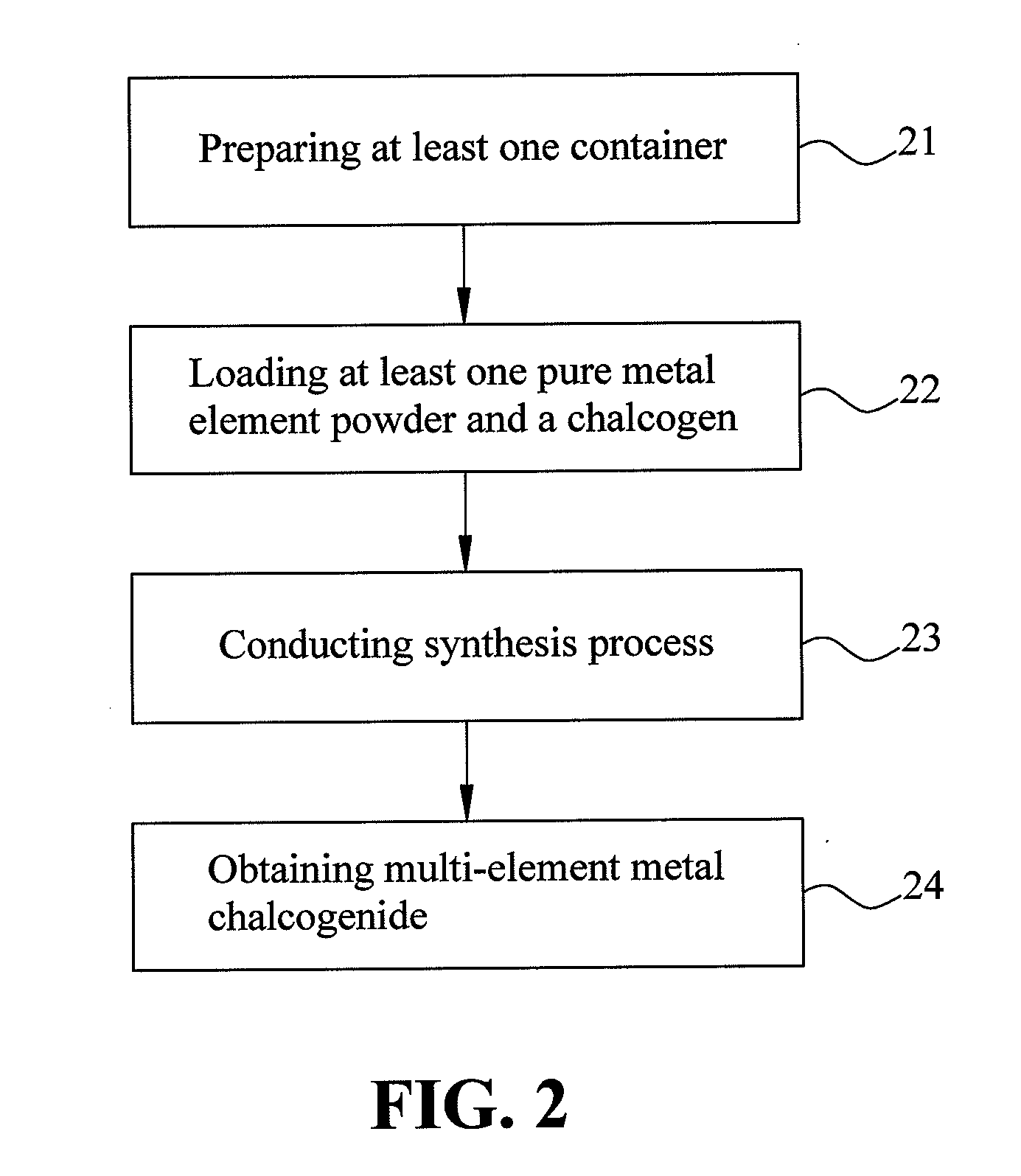

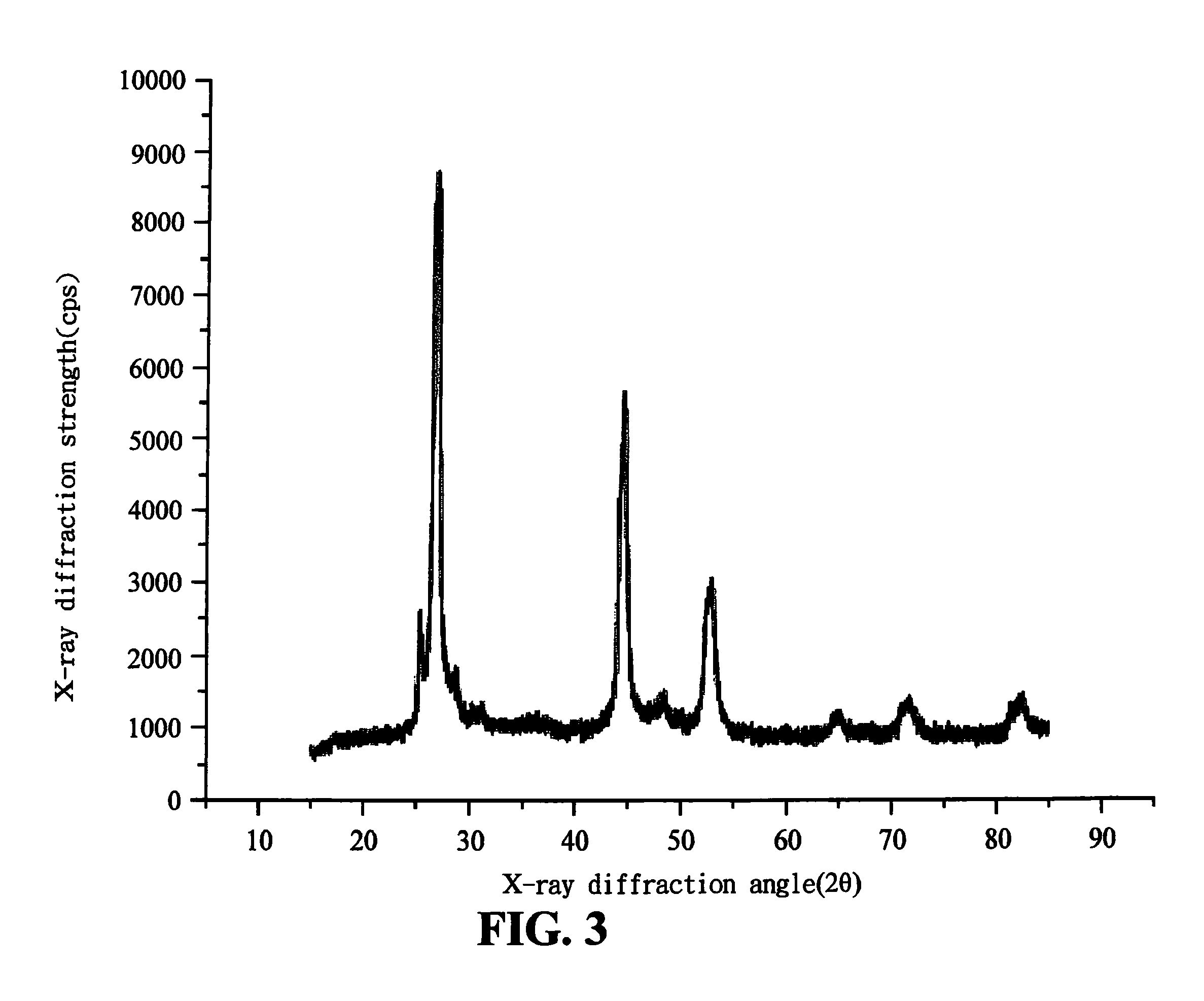

Multi-element metal chalcogenide and method for preparing the same

InactiveUS20100227066A1Simple processLow production costNanotechFinal product manufactureSolution phase synthesisMetal chalcogenides

A multi-element metal chalcogenide and a method for preparing the same are provided. According to the present invention, the multi-element metal chalcogenide includes multiple metal elements. According to the present invention, a multi-element metal chalcogenide powder is prepared, and all of the multiple metal elements of the multi-element metal chalcogenide are derived from simple substance powders of the metal elements, and / or one or more alloy powders mixed in accordance with a mole ratio. Then, a solution phase synthesis of the powder of the multi-element metal chalcogenide is conducted under the normal pressure to prepare the multi-element metal chalcogenide. The multi-element metal chalcogenide can be coated to obtain a film or used to make a target and then bombard the target for sputtering a film. In such a way, a selenization process which is conventional in fabricating the semiconductor solar cell is eliminated, thus improving the production yield and efficiency.

Owner:CHUNG JUN WEN +1

Solid electrolyte and lithium battery including the same

ActiveUS20170040637A1High Li ion conductivityGood chemical stabilitySolid electrolytesPhosphorus sulfur/selenium/tellurium compoundsGroup 12 elementCrystal structure

A solid electrolyte material represented by Formula 1:L1+2x(M1)1-x(M2)(M3)4 Formula 1wherein 0.25<x<1, L is at least one element selected from a Group 1 element, M1 is at least one element selected from a Group 2 element, a Group 3 element, a Group 12 element, and a Group 13 element, M2 is at least one element selected from a Group 5 element, a Group 14 element, and a Group 15 element, and M3 is at least one element selected from a Group 16 element, and wherein the solid electrolyte material has an I-4 crystal structure.

Owner:SAMSUNG ELECTRONICS CO LTD +1

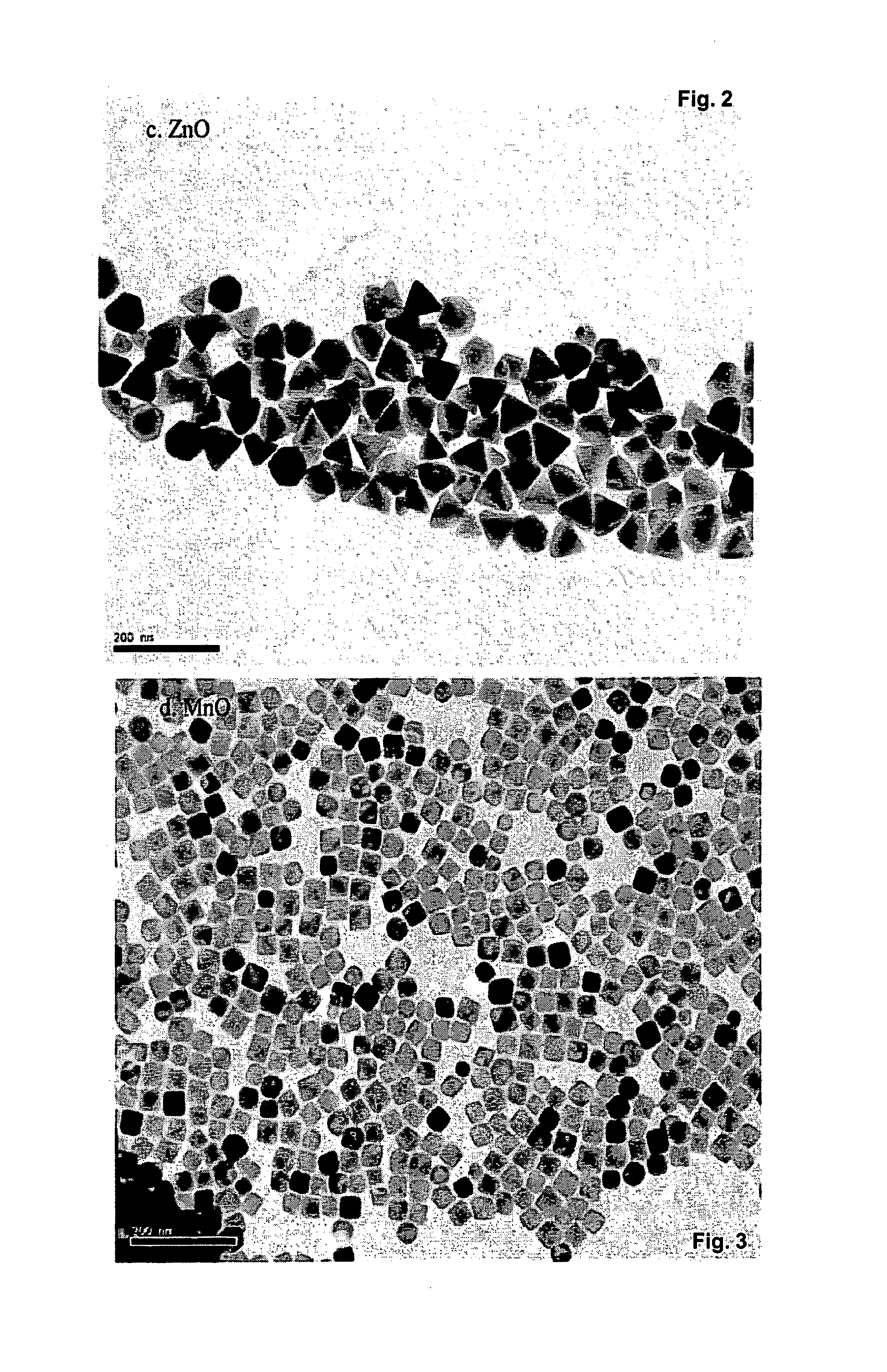

Methods of forming a nanocrystal

InactiveUS20110033368A1Low pour pointMaterial nanotechnologyFrom normal temperature solutionsBoiling pointOxygen donor

Methods of forming a nanocrystal are provided. The nanocrystal may be a binary nanocrystal of general formula M1A or of general formula M1O, a ternary nanocrystal of general formula M1M2A, of general formula M1AB or of general formula M1M2O or a quaternary nanocrystal of general formula M1M2AB. M1 is a metal of Groups II-IV, Group VII or Group VIII of the PSE. A is an element of Group VI or Group V of the PSE. O is oxygen. A homogenous reaction mixture in a non-polar solvent of low boiling point is formed, that includes a metal precursor containing the metal M1 and, where applicable M2. For an oxygen containing nanocrystal the metal precursor contains an oxygen donor. Where applicable, A is also included in the homogenous reaction mixture. The homogenous reaction mixture is under elevated pressure brought to an elevated temperature that is suitable for forming a nanocrystal.

Owner:AGENCY FOR SCI TECH & RES

Flow synthesis of quantum dot nanocrystals

Owner:INVITROGEN

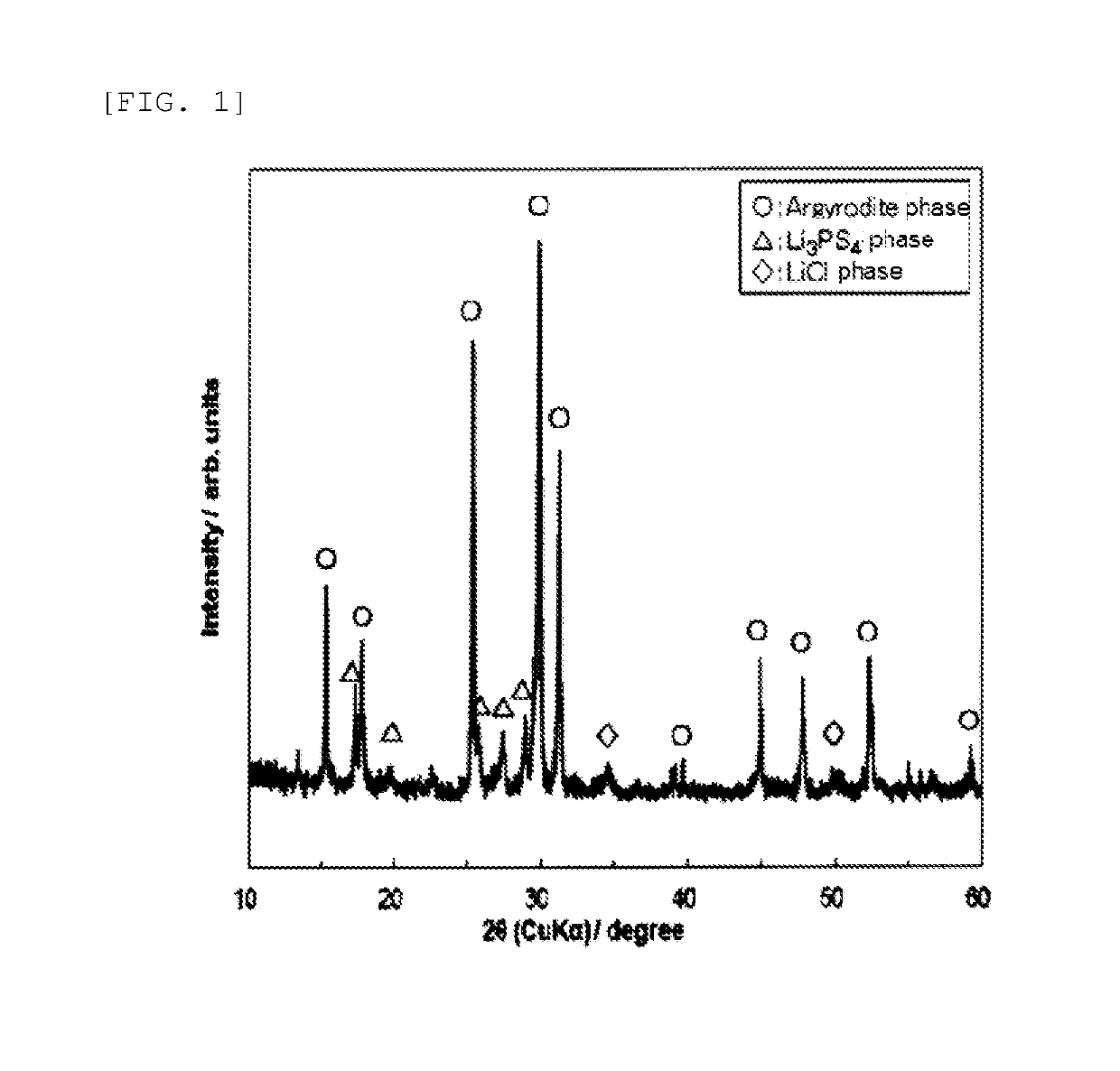

Sulfide-Based Solid Electrolyte for Lithium Secondary Battery

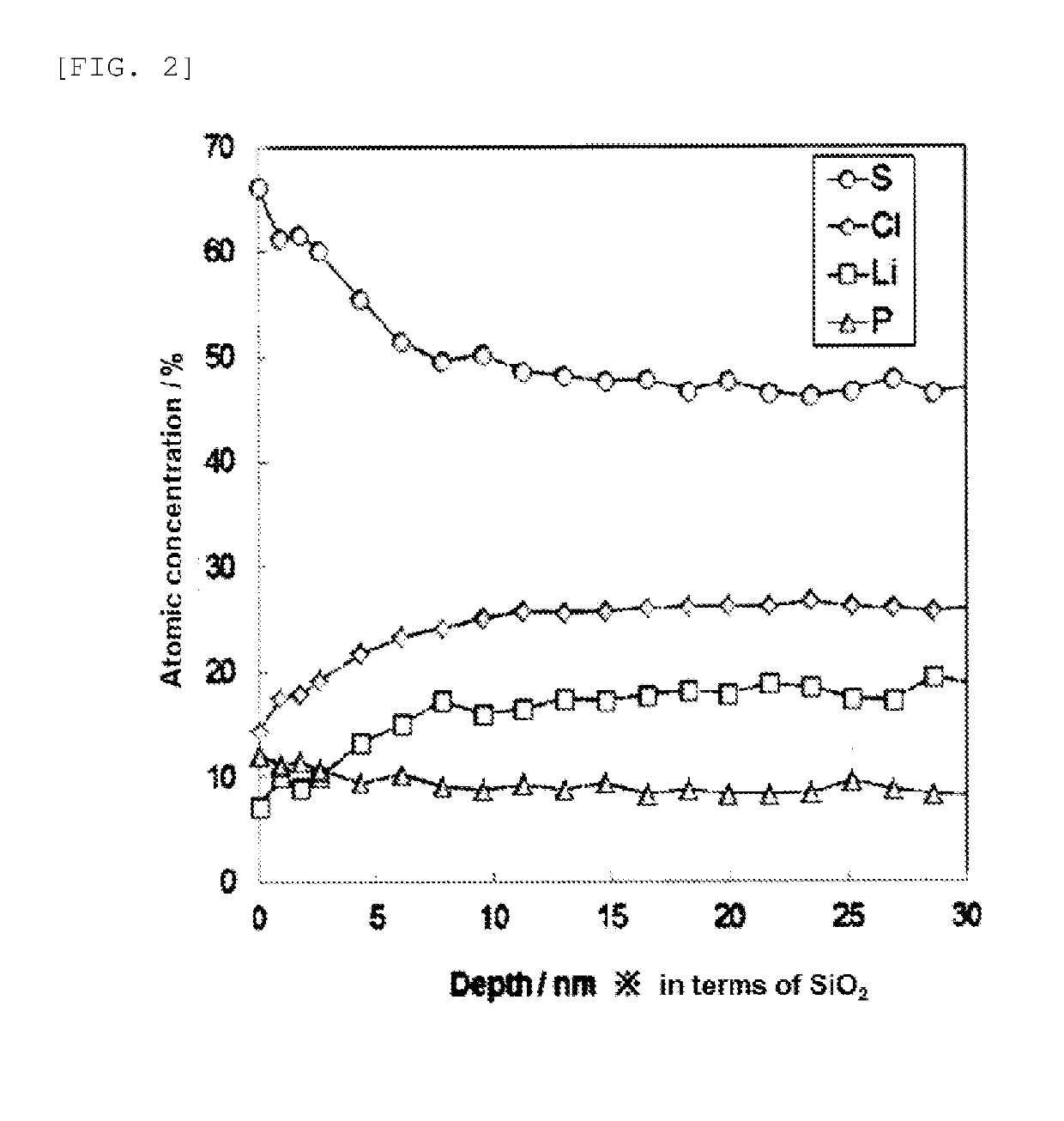

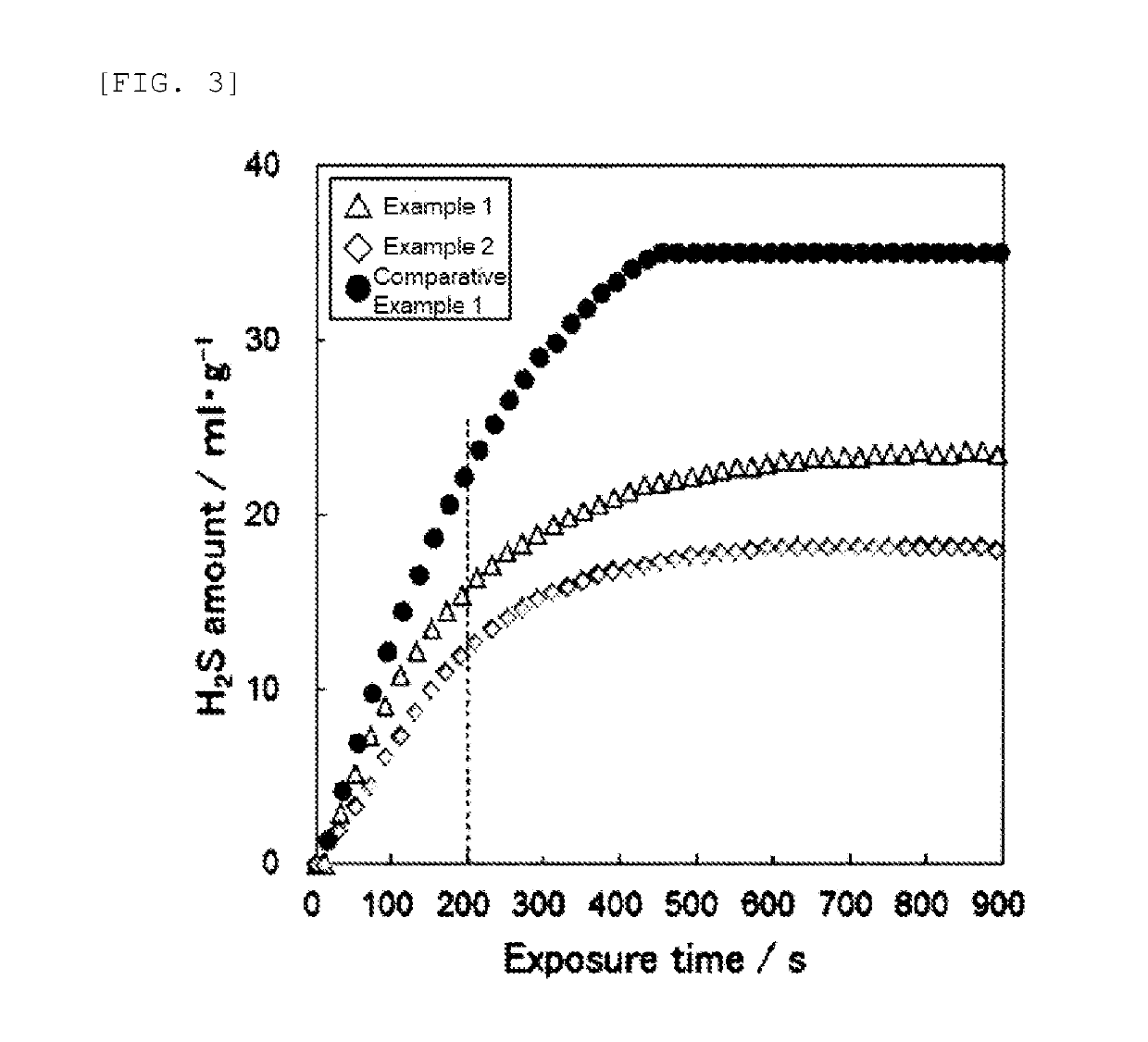

ActiveUS20190312304A1Improve lithium ion conductivityReactivity can be suppressedSolid electrolytesPhosphorus sulfur/selenium/tellurium compoundsLithiumHydrogen

Provided is a sulfide-based solid electrolyte which is capable of suppressing the generation of hydrogen sulfide caused by reaction with moisture even when in contact with dry air in a dry room or the like, and capable of maintaining lithium ion conductivity. Proposed is a sulfide-based solid electrolyte for a lithium secondary battery, wherein the surface of a compound containing lithium, phosphorus, sulfur, and halogen, and having a cubic argyrodite-type crystal structure is coated with a compound containing lithium, phosphorus, and sulfur, and having a non-argyrodite-type crystal structure.

Owner:MITSUI MINING & SMELTING CO LTD

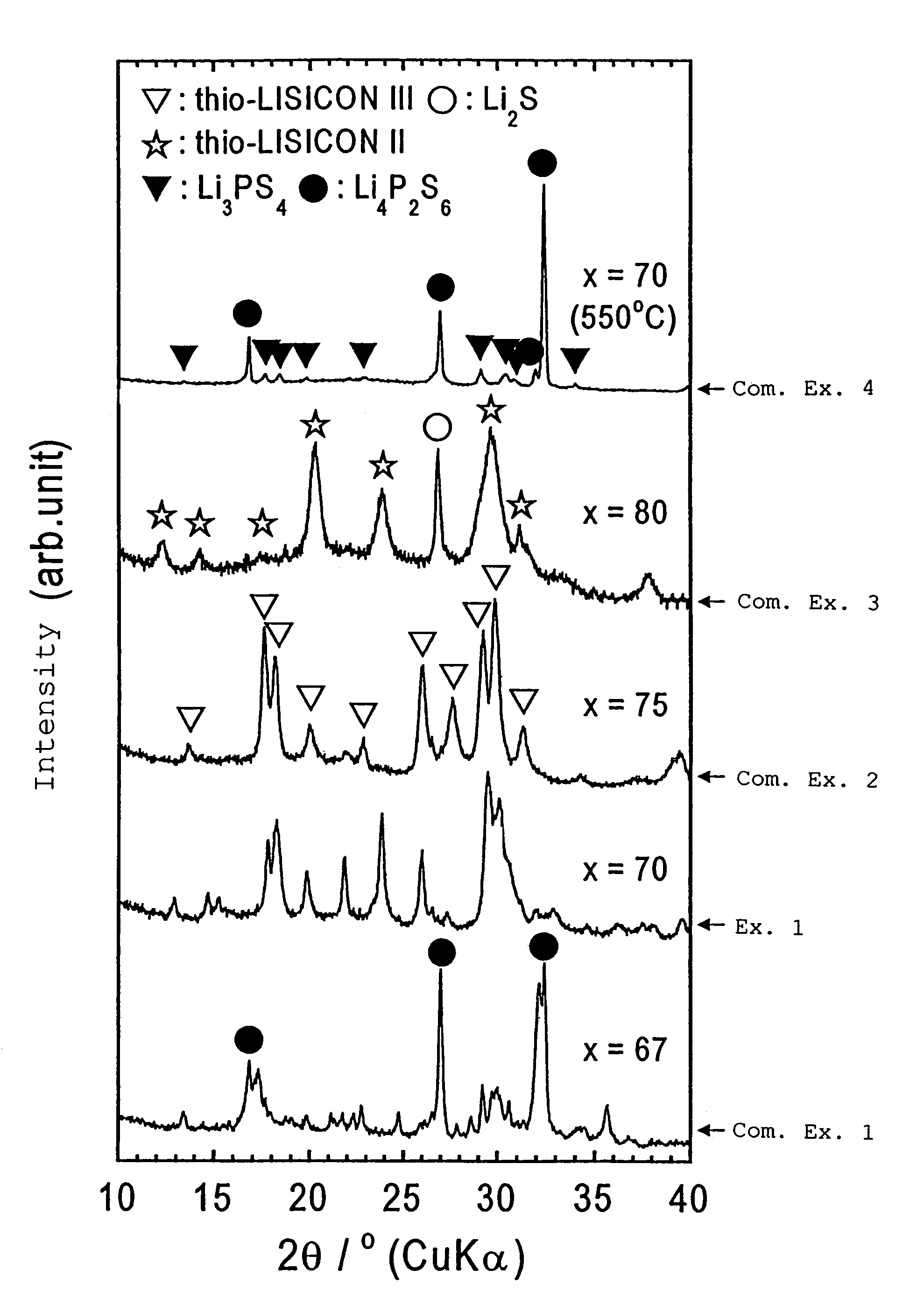

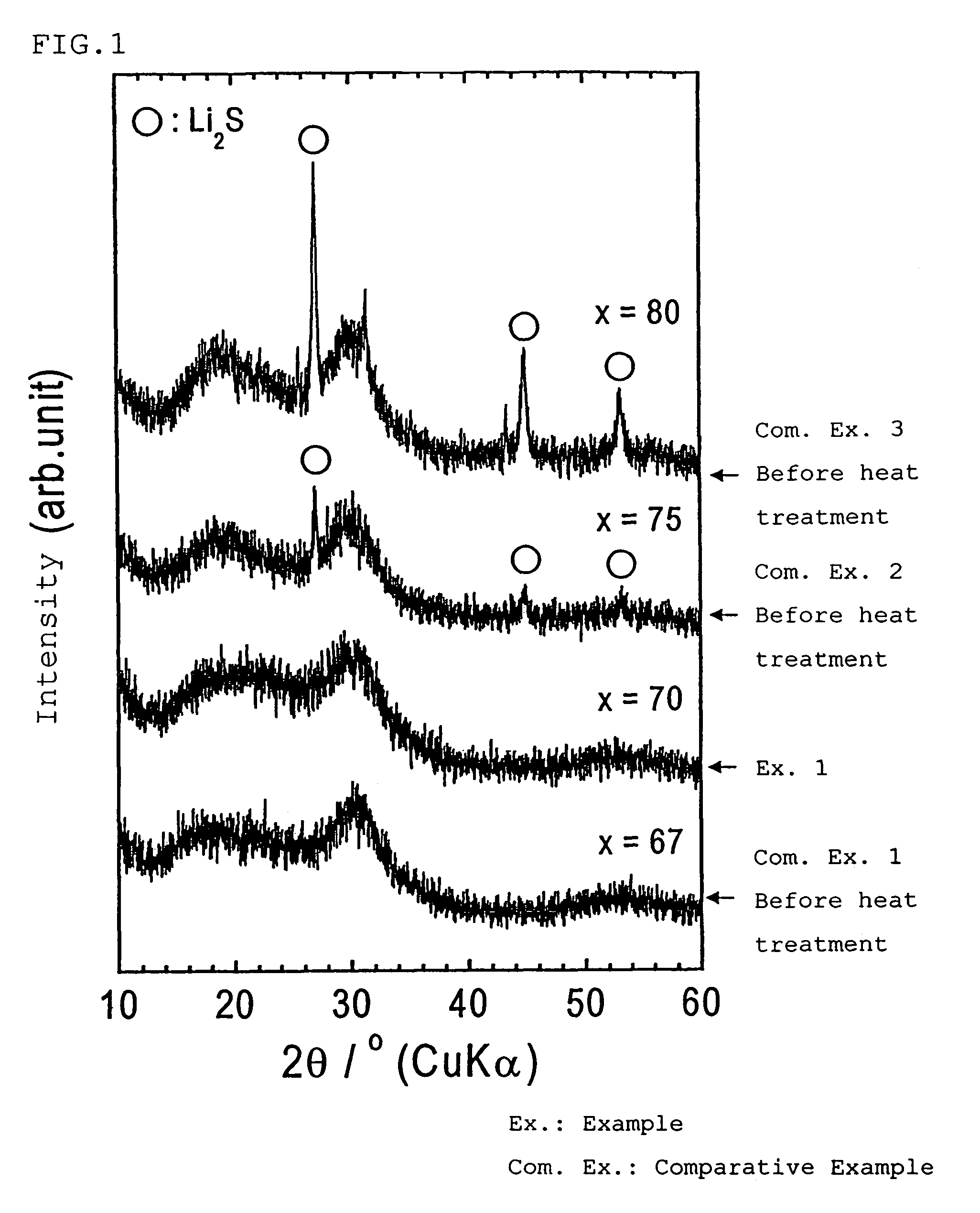

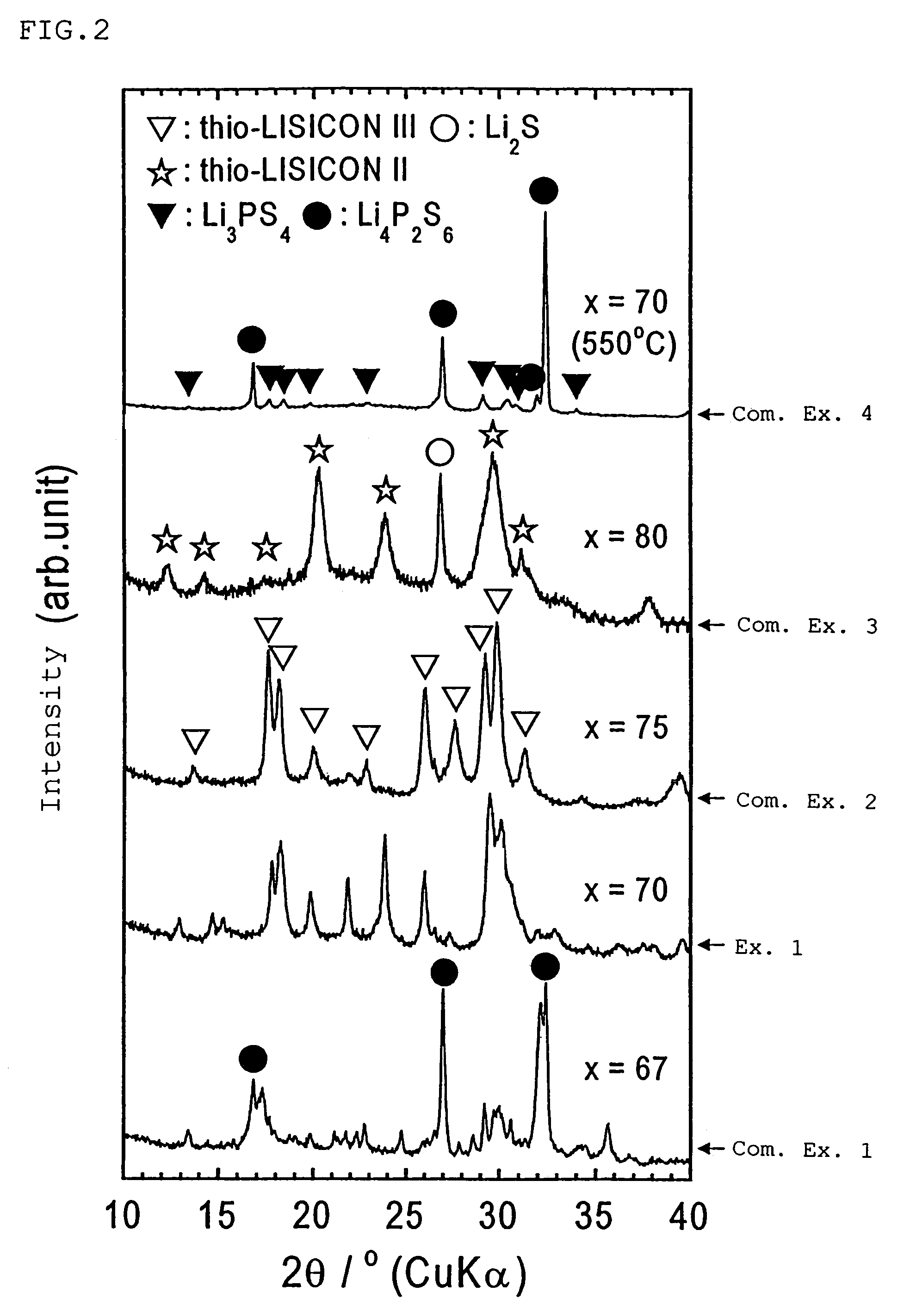

Lithium ion conducting sulfide based crystallized glass and method for production thereof

InactiveUS8962194B2Reduce the amount requiredReduce the temperatureSolid electrolytesPhosphorus sulfur/selenium/tellurium compoundsLithiumX-ray

A lithium-ion-conducting sulfide-based crystallized glass including: lithium (Li), phosphorus (P), and sulfur (S) elements, wherein the glass has diffraction peaks at 2θ=17.8±0.3 deg, 18.2±0.3 deg, 19.8±0.3 deg, 21.8±0.3 deg, 23.8±0.3 deg, 25.9±0.3 deg, 29.5±0.3 deg and 30.0±0.3 deg in X-ray diffraction (CuKα: λ=1.5418 Å).

Owner:MASAHIRO TATSUMISAGO +1

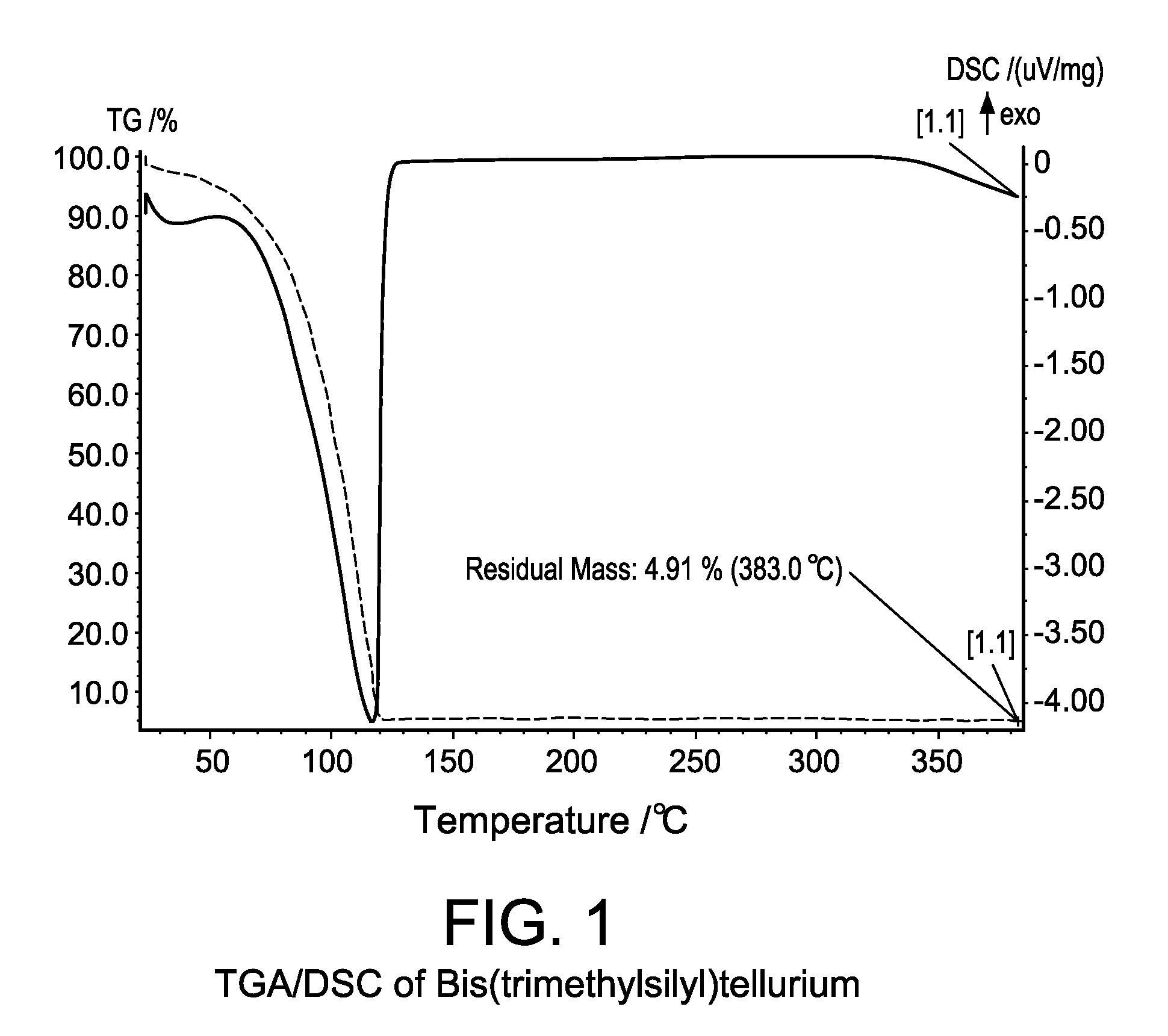

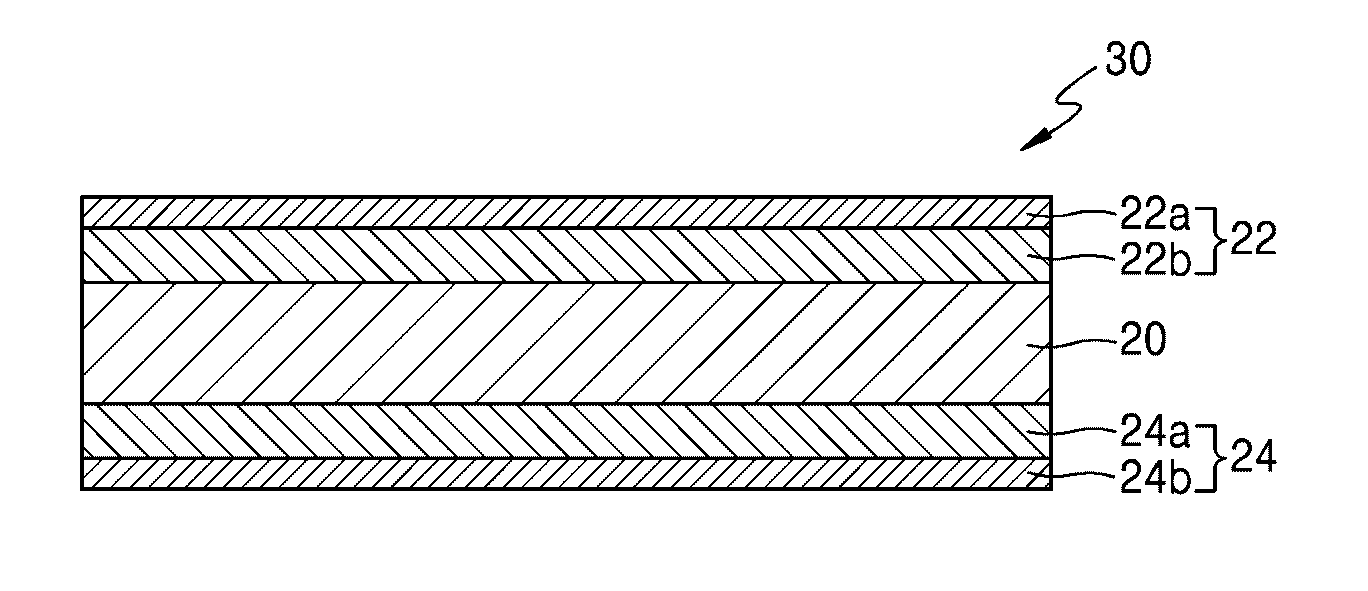

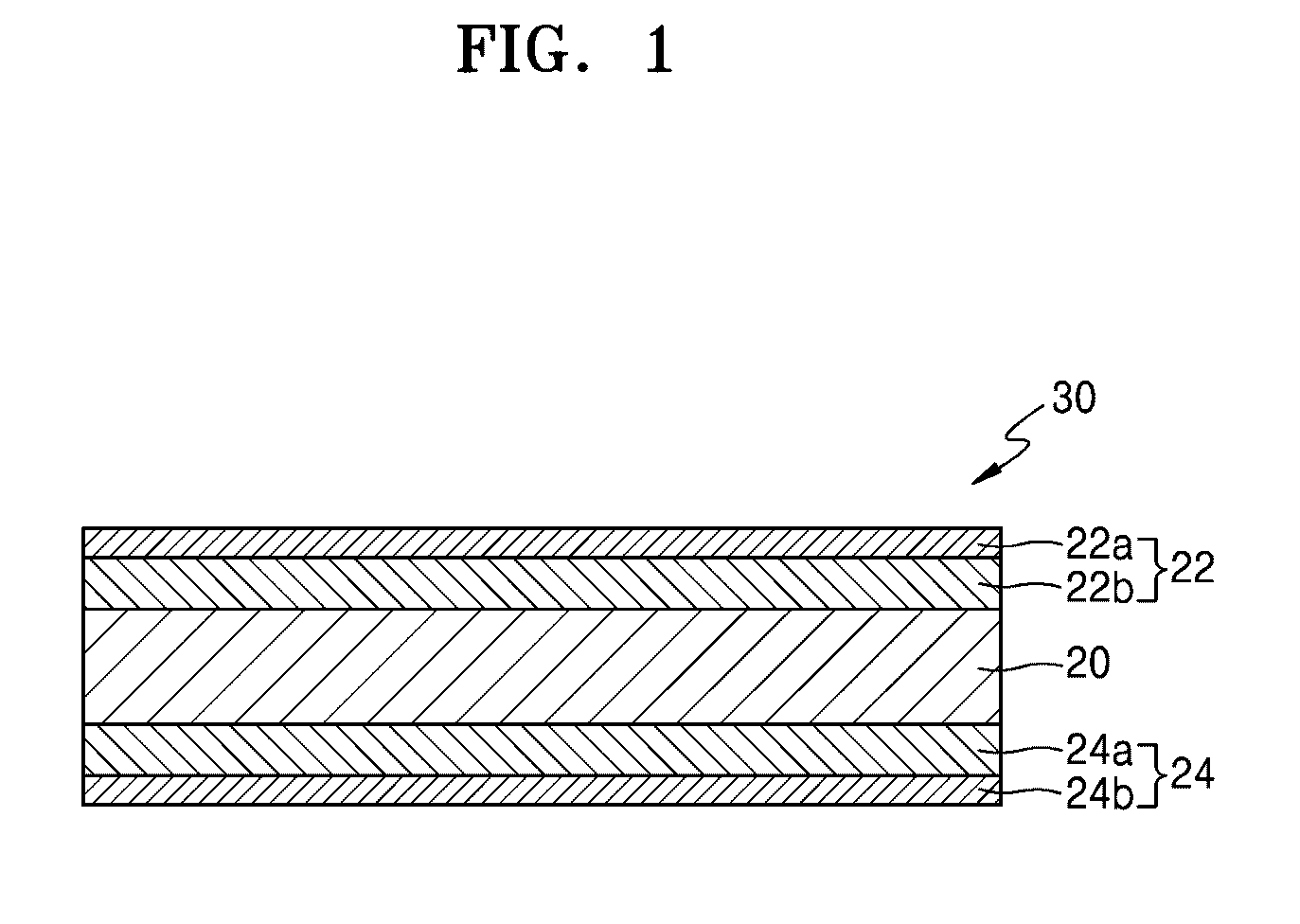

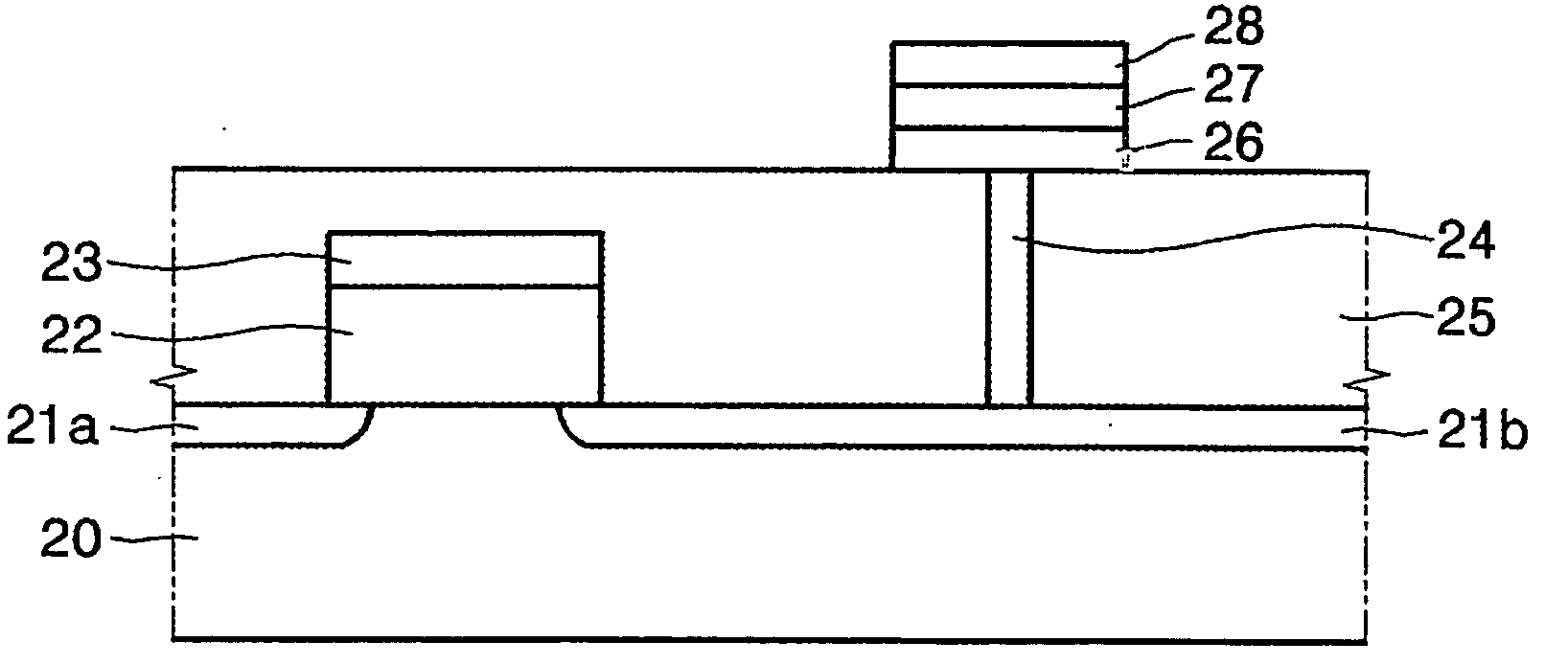

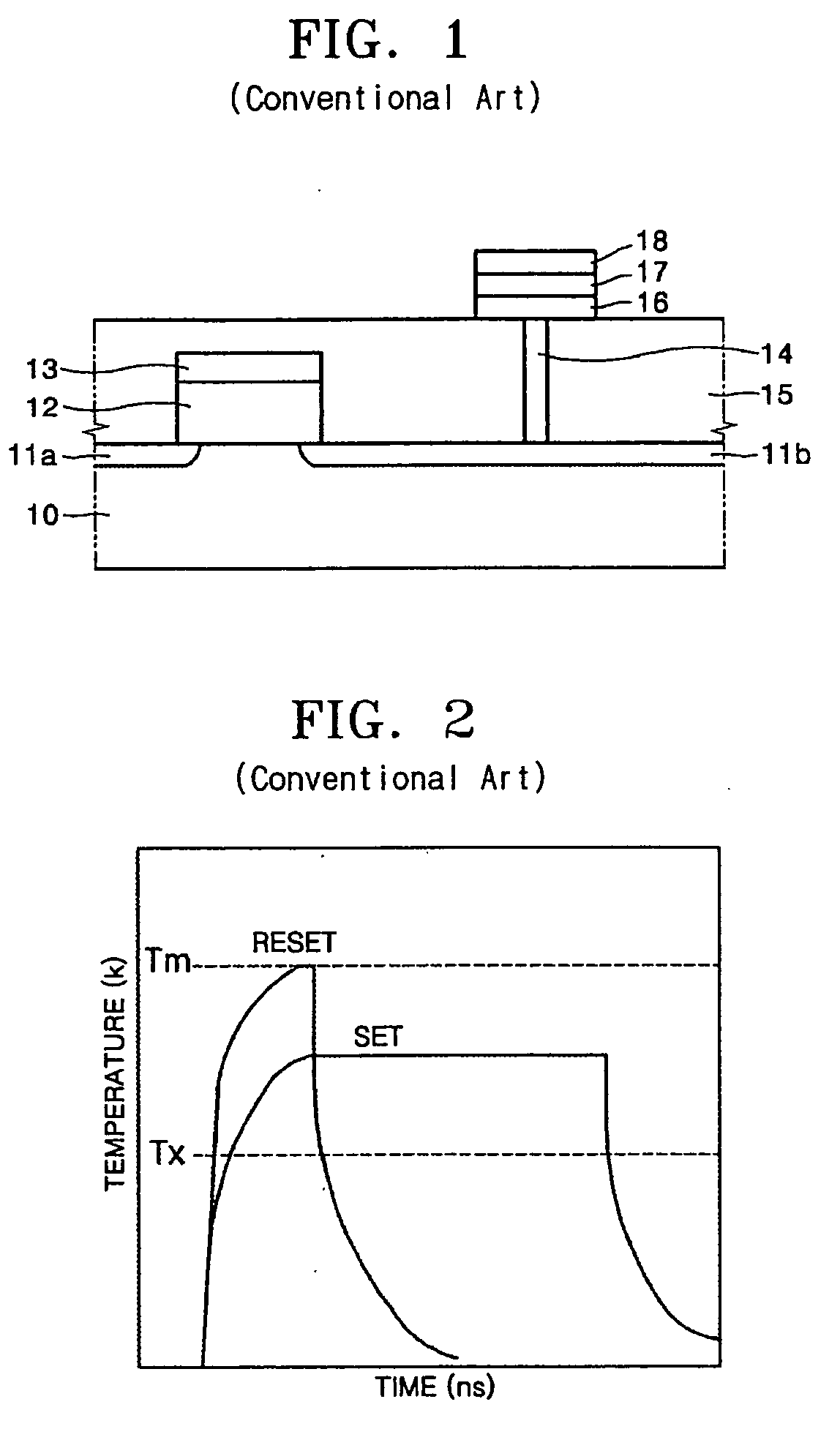

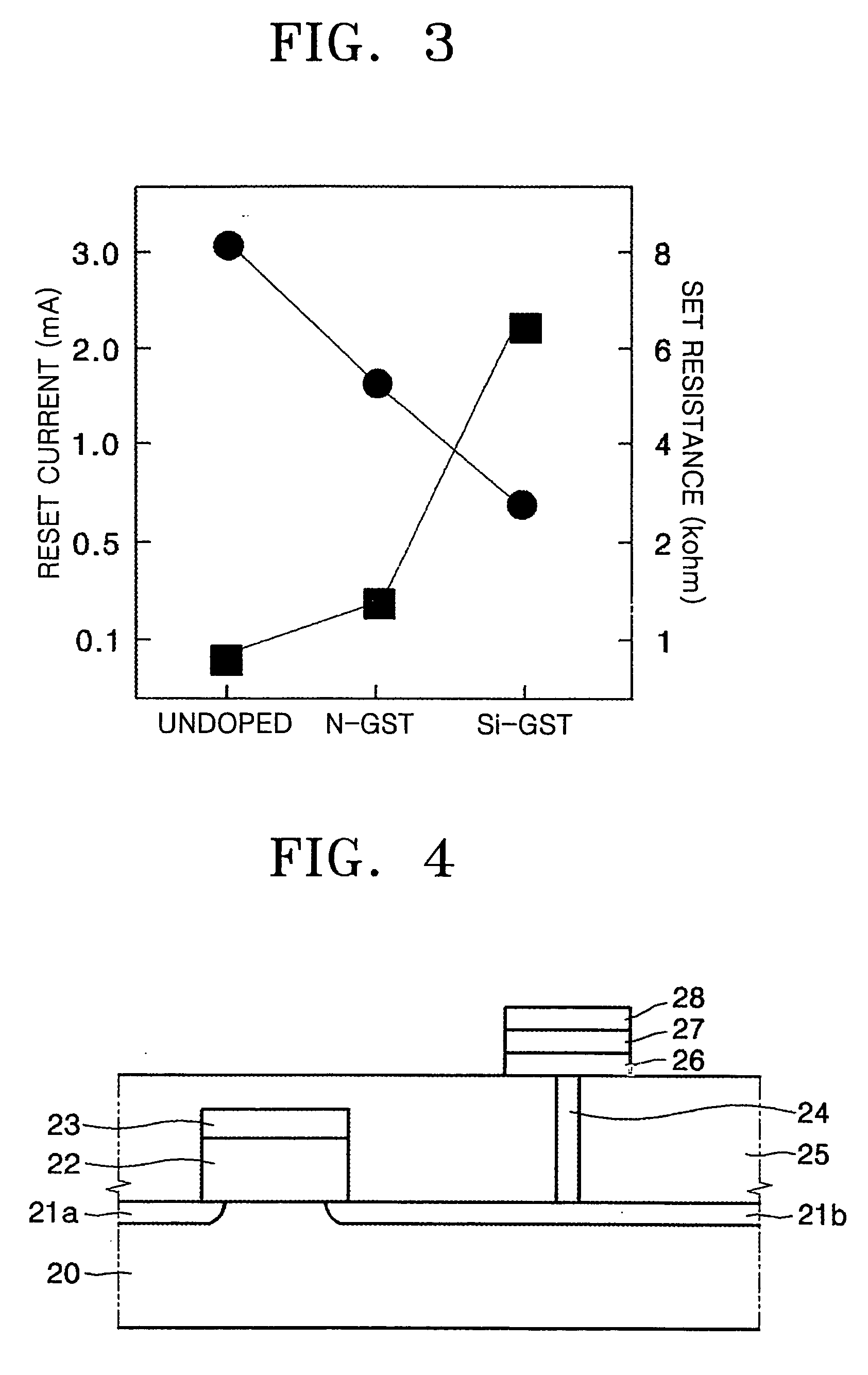

Precursor, thin layer prepared including the precursor, method of preparing the thin layer and phase-change memory device

InactiveUS20080258127A1Uniform thicknessImprove performanceGroup 4/14 element organic compoundsSelenium/tellurium compundsDeposition temperaturePhase-change memory

A Te precursor containing Te, a 15-group compound (for example, N) and / or a 14-group compound (for example, Si), a method of preparing the Te precursor, a Te-containing chalcogenide thin layer including the Te precursor, a method of preparing the thin layer; and a phase-change memory device. The Te precursor may be deposited at lower temperatures for forming a Te-containing chalcogenide thin layer doped with a 15-group compound (for example, N) and / or a 14-group compound (for example, Si). For example, the Te precursor may employ plasma enhanced chemical vapor deposition (PECVD) or plasma enhanced atomic layer deposition (PEALD) at lower deposition temperatures. The GST phase-change layer doped with a 15-group compound (for example, N) and / or a 14-group compound (for example, Si) formed by employing the Te precursor may have a decreased reset current, and thus when a memory device including the same is employed, its integration may be possible, and operation with higher capacity and / or higher speed may be possible.

Owner:SAMSUNG ELECTRONICS CO LTD

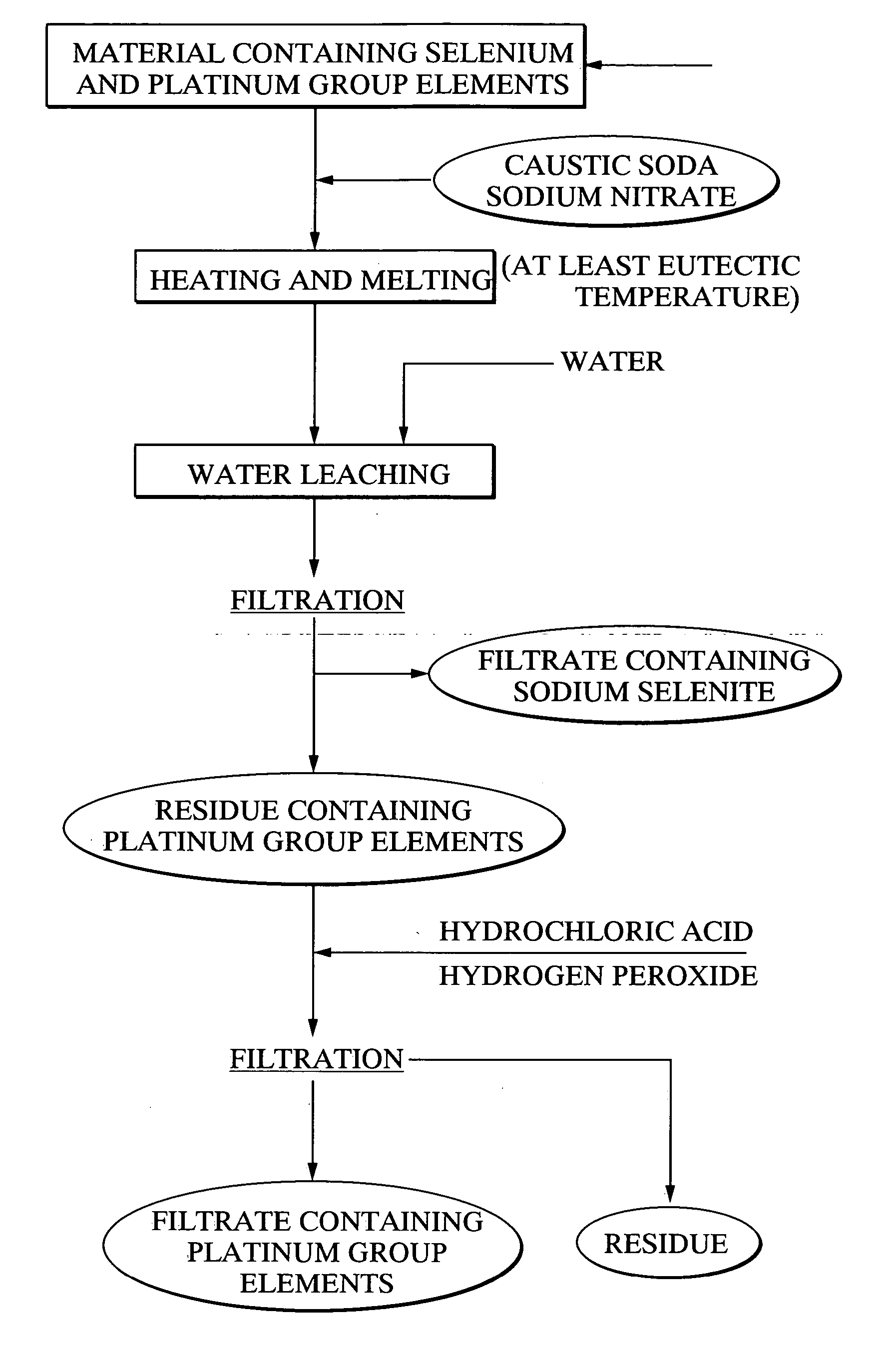

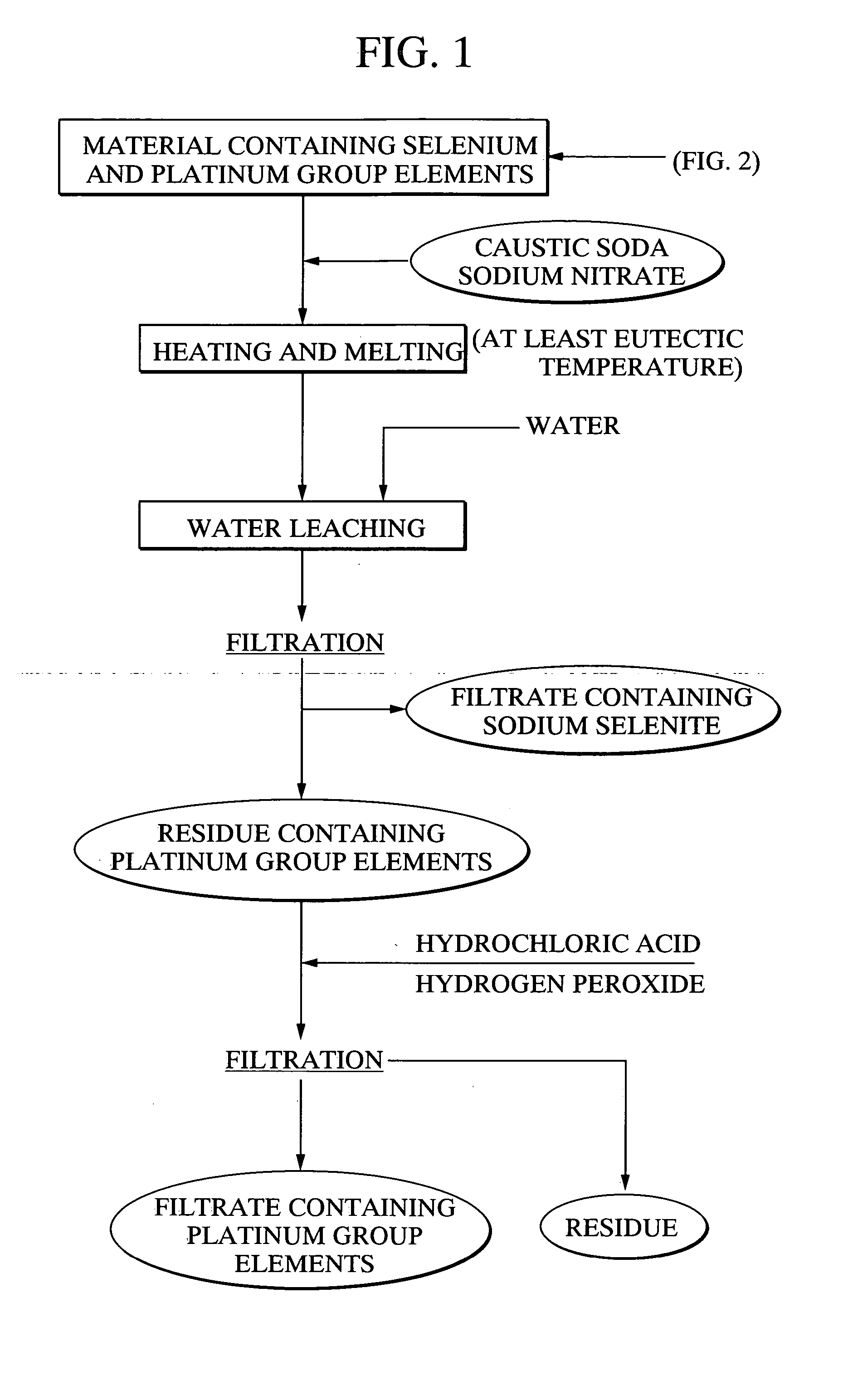

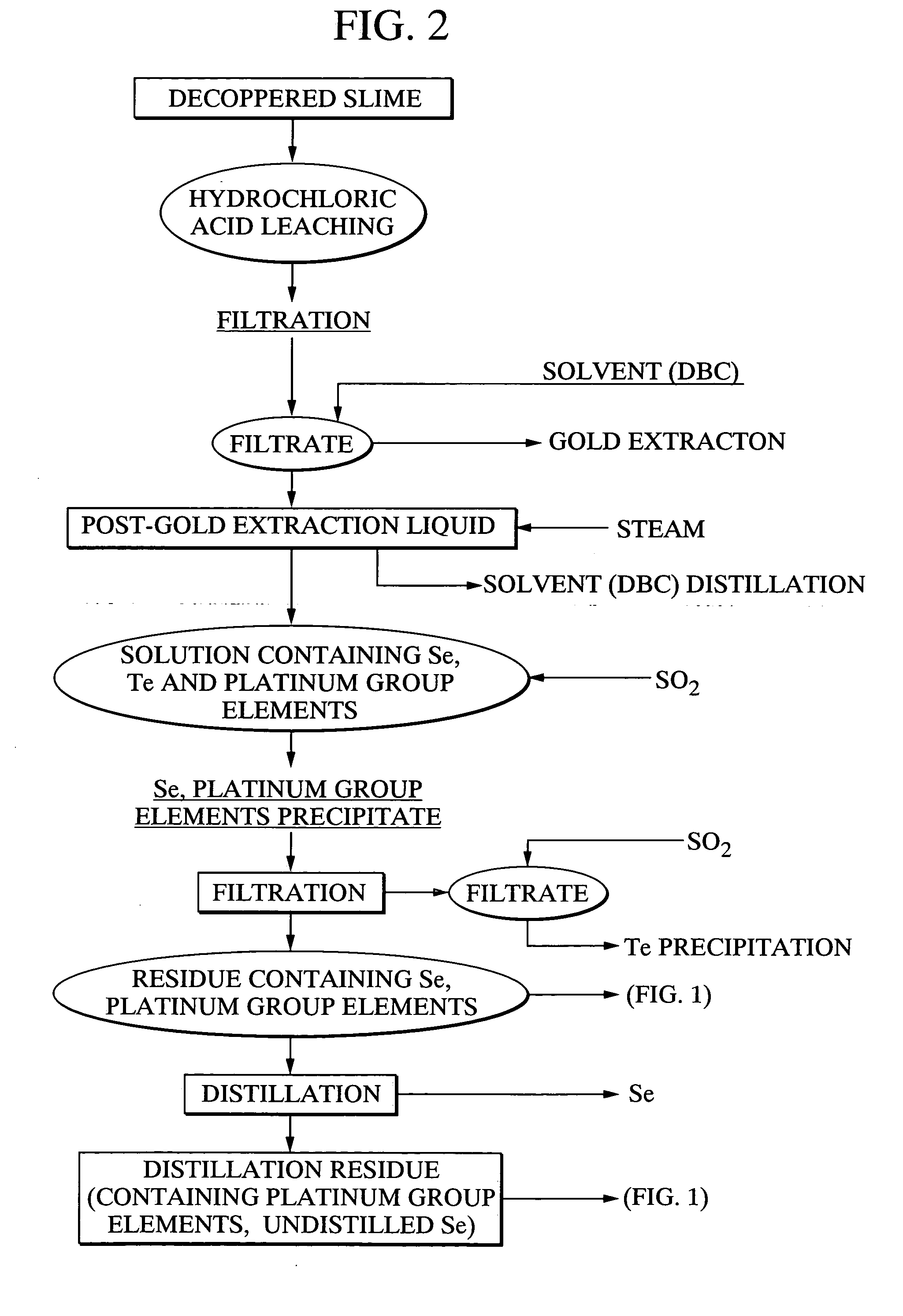

Method for separating platinum group element

InactiveUS20050255017A1Separated and recoveredLow costPhotography auxillary processesPhosphorus sulfur/selenium/tellurium compoundsPhysical chemistryPlatinum group

One object of the present invention is to provide a separation process that enables the efficient separation of selenium, tellurium, and platinum group elements from a material containing selenium / tellurium and platinum group elements. In order to achieve this object, the invention provides a separation process for platinum group elements comprising: a step (A) for treating a material containing selenium / tellurium and platinum group elements with alkali, a step (B) for leaching selenium / tellurium, and a step (C) for separating the platinum group element-containing leaching residue and the selenium / tellurium leachate.

Owner:MITSUBISHI MATERIALS CORP

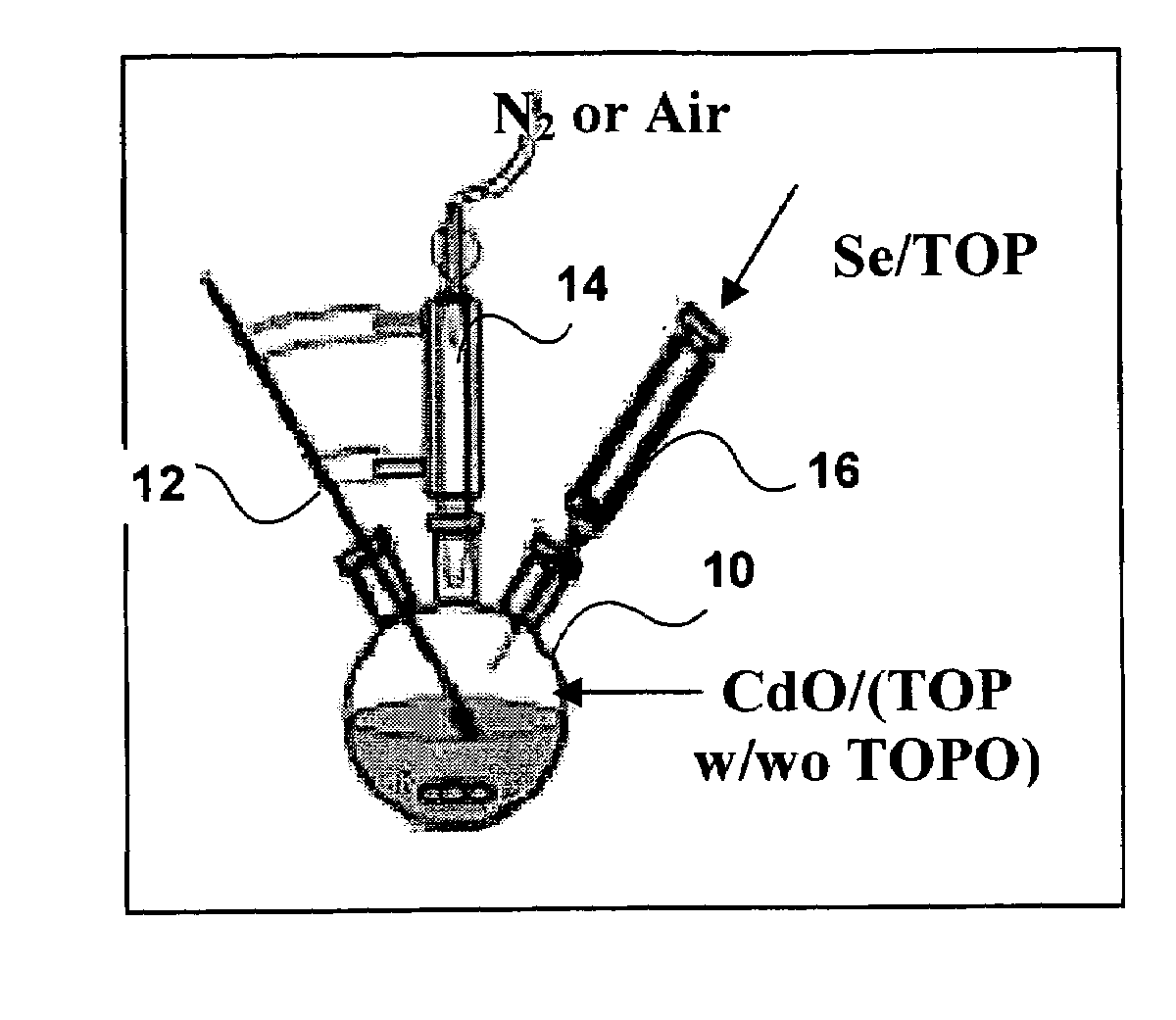

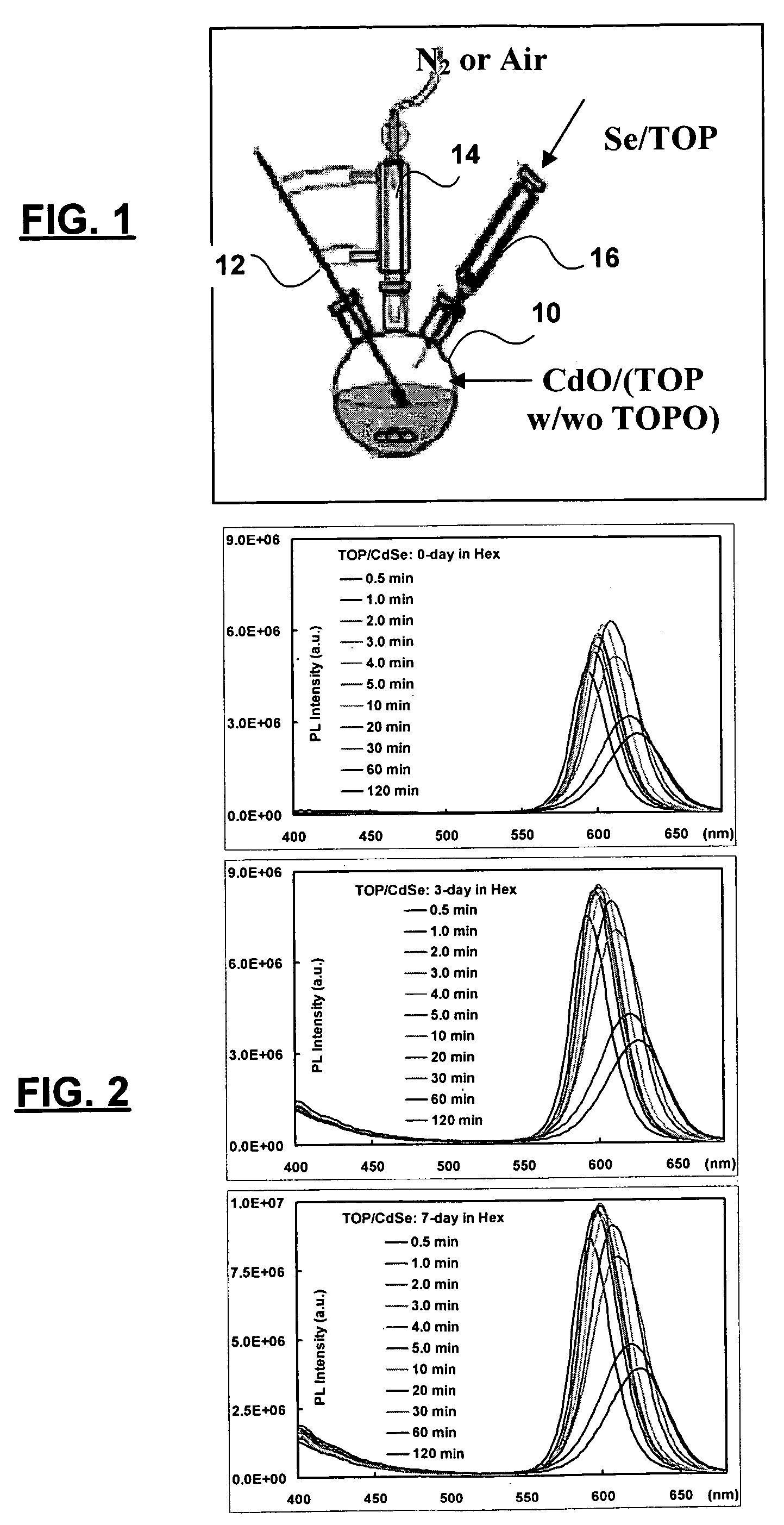

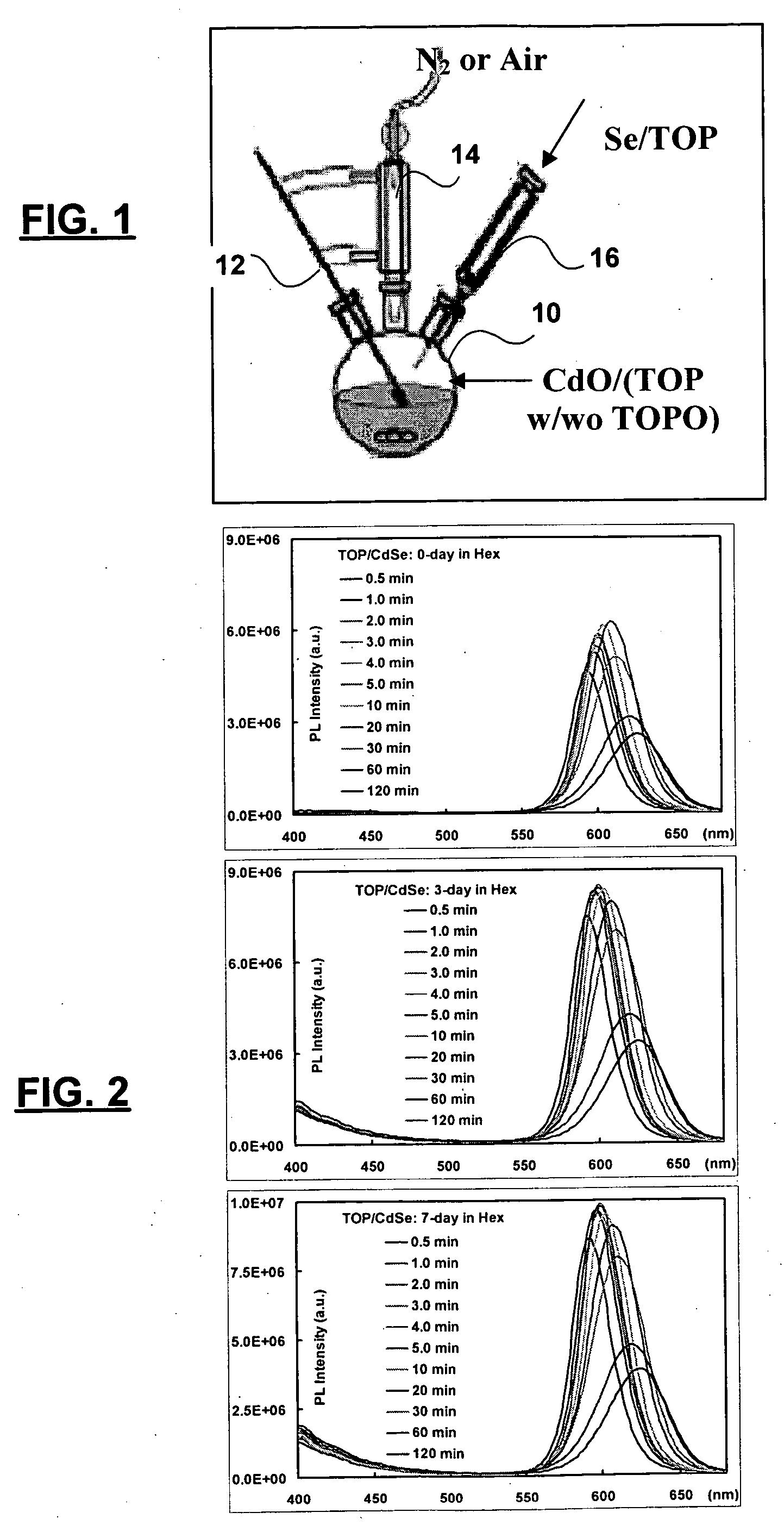

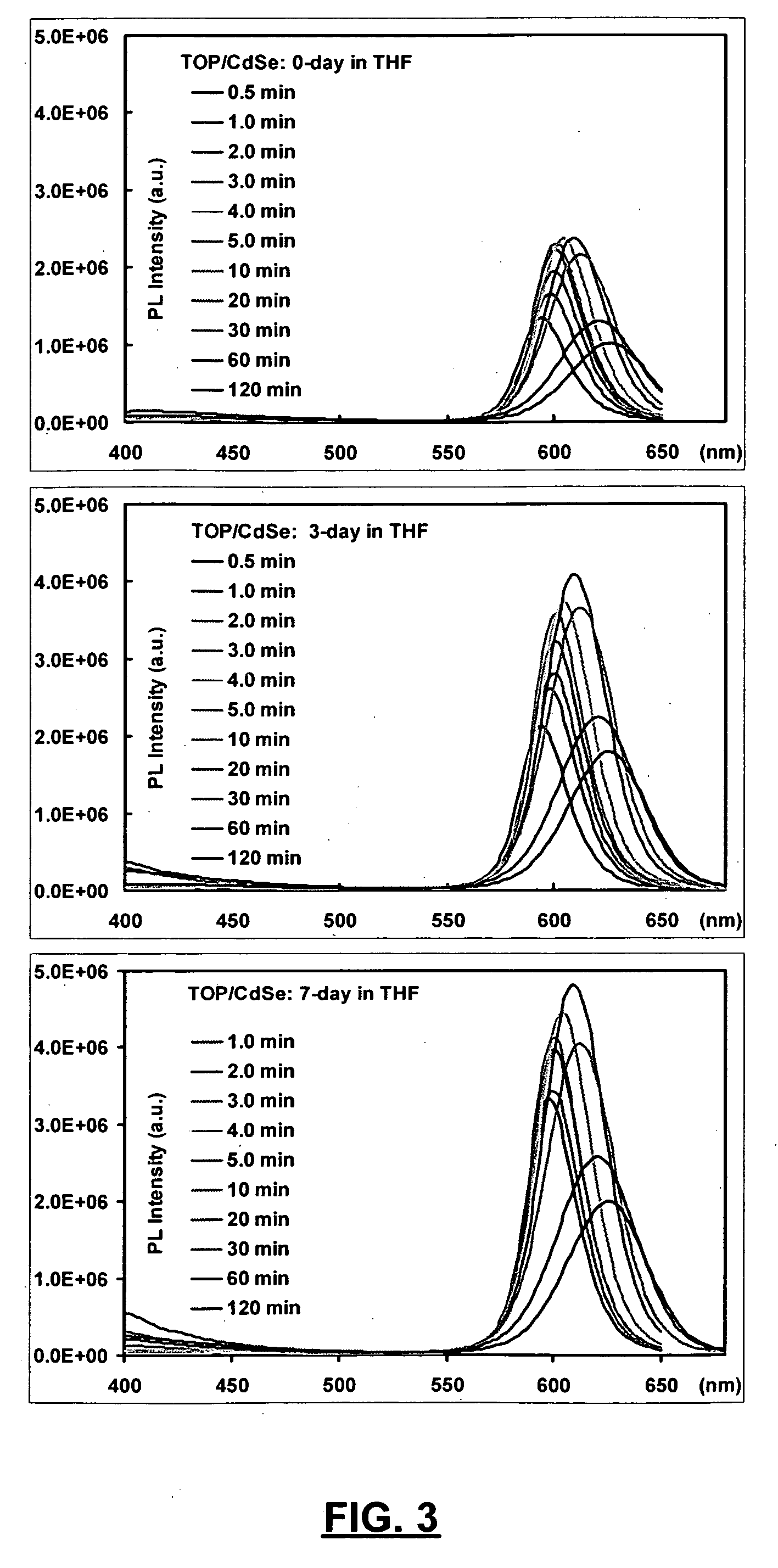

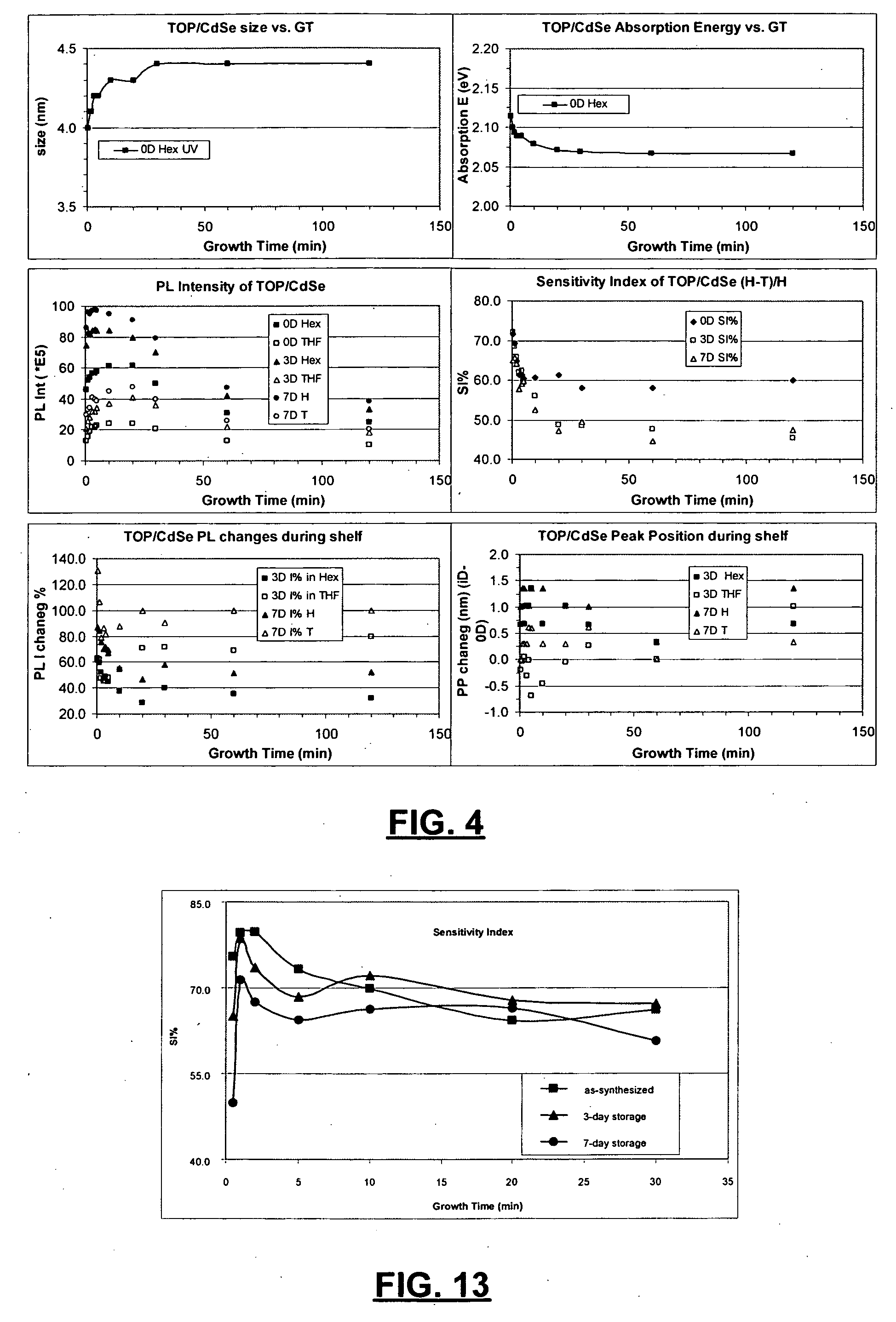

Method of synthesizing colloidal nanocrystals

ActiveUS7267810B2Low costEasy to prepareMaterial nanotechnologyFrom normal temperature solutionsSolventNanocrystal

A method of making nanocrystals involves adding a chalocogen source to a hot solution of a metal-containing non-organometallic compound, such as CdO, in a first ligand solvent, such as TOP, and preferably subsequently cooling the resulting mixture to a lower temperature to grow the nanocrystals at said lower temperature. The method can involve either one ligand or two-ligand systems.

Owner:NAT RES COUNCIL OF CANADA

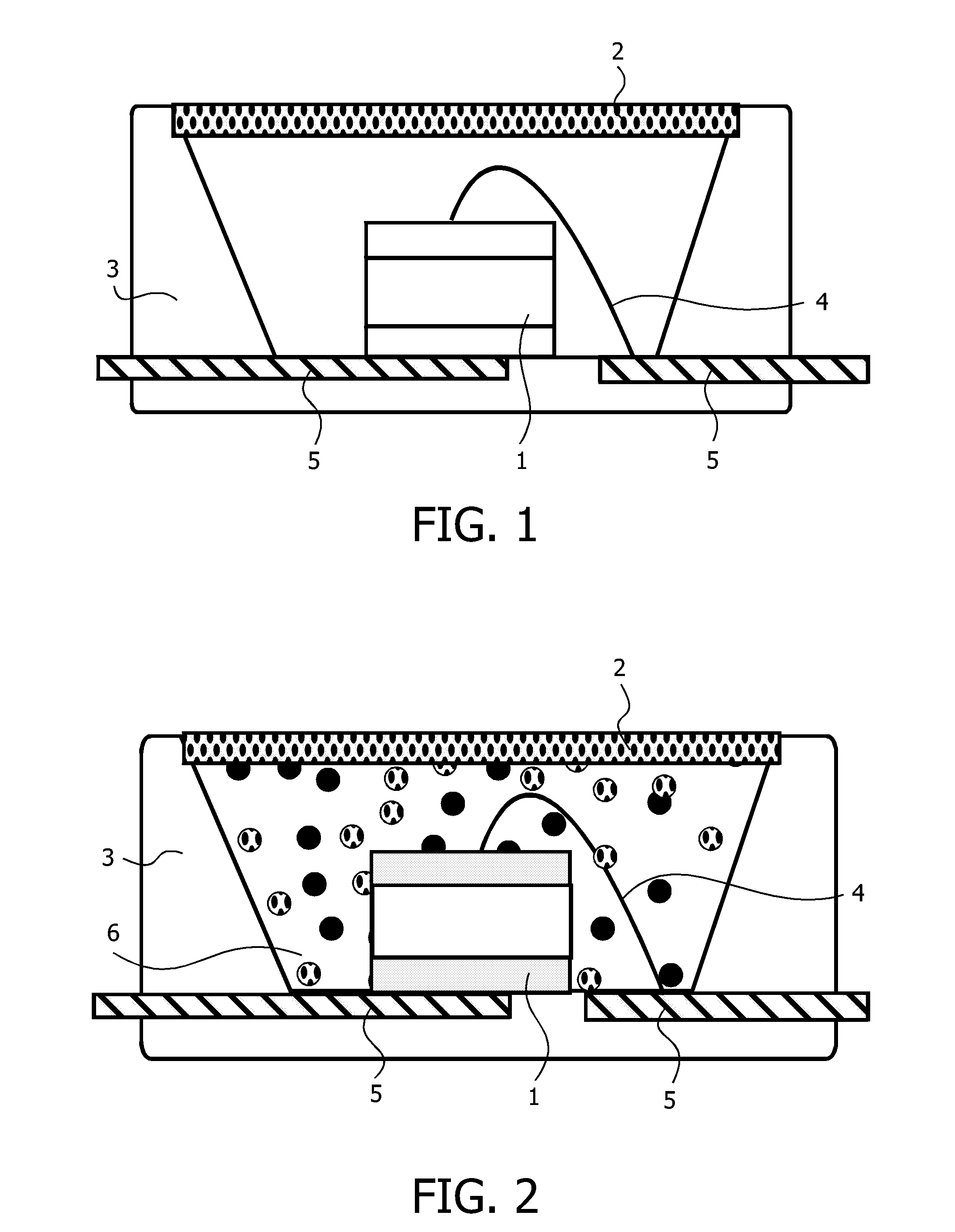

Illumination System Comprising a Ceramic Luminescence Converter

InactiveUS20080191608A1Accurate color renditionDischarge tube luminescnet screensPhosphorus sulfur/selenium/tellurium compoundsAlkaline earth metalPhosphor

An illumination system, comprising a radiation source and a monolithic ceramic luminescence converter comprising at least one phosphor capable of absorbing a part of light emitted by the radiation source and emitting light of wavelength different from that of the absorbed light; wherein said at least one phosphor is an alkaline earth metal sulfide of general formula AE1-zS1-ySey:Az, wherein AE is at least one earth alkaline metal selected from the group of Mg, Ca, Sr and Ba, 0≦y<1 and 0.0005≦z≦0.2, activated by an activator A selected from the group of Eu(II), Ce(III), Mn(II) and Pr(III). is highly efficient, especially if a blue light emitting diode is used as a radiation source, and provides excellent thermal and spectroscopic properties. The invention is also concerned with a monolithic ceramic luminescence converter comprising at least one phosphor capable of absorbing a part of light emitted by the radiation source and emitting light of wavelength different from that of the absorbed light; wherein said at least one phosphor is an alkaline earth metal sulfide of general formula AE1-zS1-ySey:Az, wherein AE is as least one earth alkaline metal selected from the group of Mg, Ca, Sr and Ba, 0≦y<1 and 0.0005≦z≦0.2, activate by an activator A selected from the group of Eu(II), Ce(II), Mn(II) and Pr(III).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Metal chalcogenide aqueous precursors and processes to form metal chalcogenide films

InactiveUS8366967B2Selenium/tellurium compundsPhosphorus sulfur/selenium/tellurium compoundsSulfurCarbon–carbon bond

Metal chalcogenide precursor solutions are described that comprise an aqueous solvent, dissolved metal formate salts and a chalcogenide source composition. The chalcogenide source compositions can be organic compounds lacking a carbon-carbon bond. The precursors are designed to form a desired metal chalcogenide upon thermal processing into films with very low levels of contamination. Potentially contaminating elements in the precursors form gaseous or vapor by-products that escape from the vicinity of the product metal chalcogenide films.

Owner:INPRIA CORP

Method of synthesizing colloidal nanocrystals

ActiveUS20050238568A1Low costEasy to prepareMaterial nanotechnologyFrom normal temperature solutionsNanocrystalSolvent

A method of making nanocrystals involves adding a chalocogen source to a hot solution of a metal-containing non-organometallic compound, such as CdO, in a first ligand solvent, such as TOP, and preferably subsequently cooling the resulting mixture to a lower temperature to grow the nanocrystals at said lower temperature. The method can involve either one ligand or two-ligand systems.

Owner:NAT RES COUNCIL OF CANADA

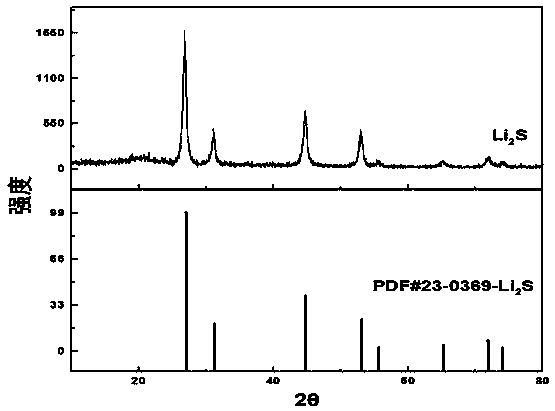

Method for synthesizing lithium sulfide

InactiveCN111517288ASynthetic raw materials are cheap and easy to obtainThe process steps are simpleHybrid capacitor electrodesPhosphorus sulfur/selenium/tellurium compoundsMetallic lithiumN-Butyllithium

The invention mainly relates to the field of lithium battery materials, and provides a method for synthesizing lithium sulfide by taking a lithiation solution and elemental sulfur as raw materials through direct reaction, which comprises the following steps: preparing the lithiation solution, an organic ether solution containing a metal lithium-aromatic compound, a lithium iodide solution and an n-butyl lithium solution; adding elemental sulfur into the lithiation solution for mixing; and sequentially carrying out a room-temperature reaction, separation and precipitation, drying and heat treatment on the mixed solution to obtain the lithium sulfide. The synthesis method of lithium sulfide has the advantages of cheap and easily available raw materials, simple process, no harmful gas generation, and mild and controllable synthesis process.

Owner:TIANMU LAKE INST OF ADVANCED ENERGY STORAGE TECH CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com