Method for synthesizing lithium sulfide

A lithium sulfide and lithium iodide technology, applied in the directions of alkali metal sulfide/polysulfide, lithium storage battery, electrochemical generator, etc., can solve the problems of low solvent selectivity, harsh preparation conditions, complex synthesis process, etc. Simple and easy process steps and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Weigh 30.842 g of biphenyl and dissolve it in a corresponding volume of anhydrous ethylene glycol dimethyl ether solvent at a concentration of 1 mol / L. After the biphenyl is completely dissolved, add 1.3882 g of lithium metal with a length of 1 cm and a width of 1 mm Silk, let it stand until it is completely dissolved;

[0032]Step 2: Weigh 3.206 g of elemental sulfur into the above lithiated solution, and stir at room temperature for 6 h;

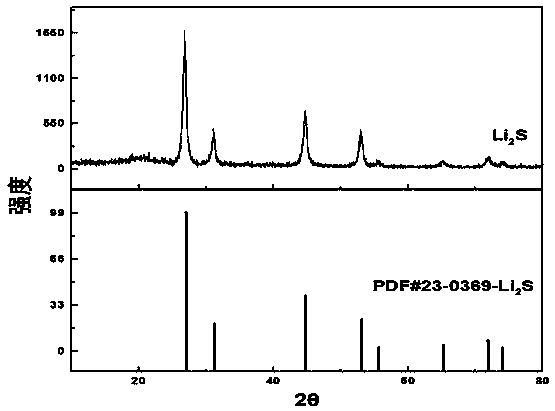

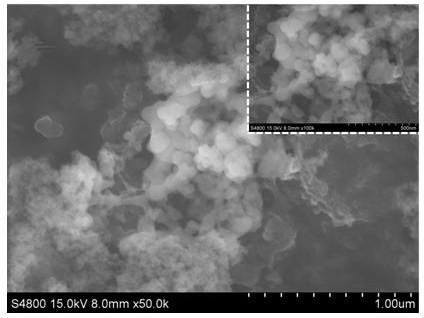

[0033] Step 3: Take out the product, separate the precipitate and supernatant with a centrifuge, the speed is 8000 r / min, and the centrifugation time is 20min, and the supernatant is recovered for reuse; the precipitate is centrifuged with anhydrous ethylene glycol xylene solvent Wash 3 times at 6000r / min, centrifuge for 10 min; dry in a vacuum oven at 100 °C for 16 h, and heat-treat at 200 °C for 8 h under the protection of argon to remove residual solvent to obtain lithium sulfide material. figure 1 is the XRD pattern of ...

Embodiment 2

[0035] Step 1: Weigh 25.636 g of naphthalene and dissolve it in a corresponding volume of anhydrous tetrahydrofuran solvent at a concentration of 0.1 mol / L. After the biphenyl is completely dissolved, add 1.3882 g of lithium metal with a length of 2 mm, a width of 2 mm, and a thickness of 0.5 mm. Let it stand until it dissolves completely;

[0036] Step 2: Weigh 3.206 g of elemental sulfur into the above lithiated solution, and stir at room temperature for 4 h;

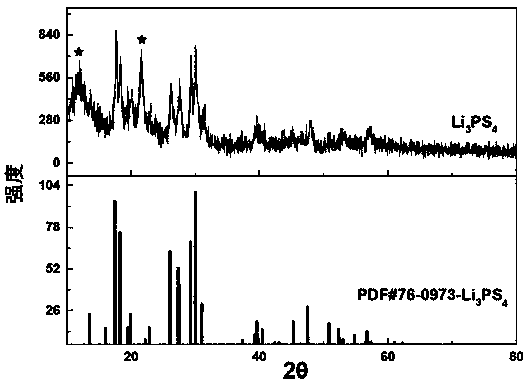

[0037] Step 3: Take out the product, separate the precipitate and supernatant with a centrifuge at a speed of 8000 r / min, and centrifuge for 20 minutes, recover the supernatant for reuse, and wash the precipitate with anhydrous tetrahydrofuran solvent for 3 times, The rotational speed was 6000 r / min, and the centrifugation time was 10 min; the samples were dried on a heating platform at 60 °C for 24 h under the protection of argon, and then heat-treated in a vacuum oven at 180 °C for 12 h to remove residual solvents t...

Embodiment 3

[0039] Step 1: Weigh 26.7692 g of lithium iodide and dissolve it in a corresponding volume of ultra-dry acetonitrile solvent at a concentration of 10 mol / L;

[0040] Step 2: Weigh 3.206 g of elemental sulfur into the above lithiated solution, and stir at room temperature for 8 h;

[0041] Step 3: Take out the product, separate the precipitate and supernatant with a centrifuge at a speed of 8000 r / min, and the centrifugation time is 20 min. The precipitate is centrifuged and washed 3 times with an ultra-dry acetonitrile solvent at a speed of 6000 r / min, and the centrifugation time is 10 min; followed by drying in a vacuum oven at 140 °C for 12 h, and heat treatment at 320 °C under argon protection for 6 h to remove residual solvents to obtain lithium sulfide materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com