Patents

Literature

133results about How to "Simple molecular structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

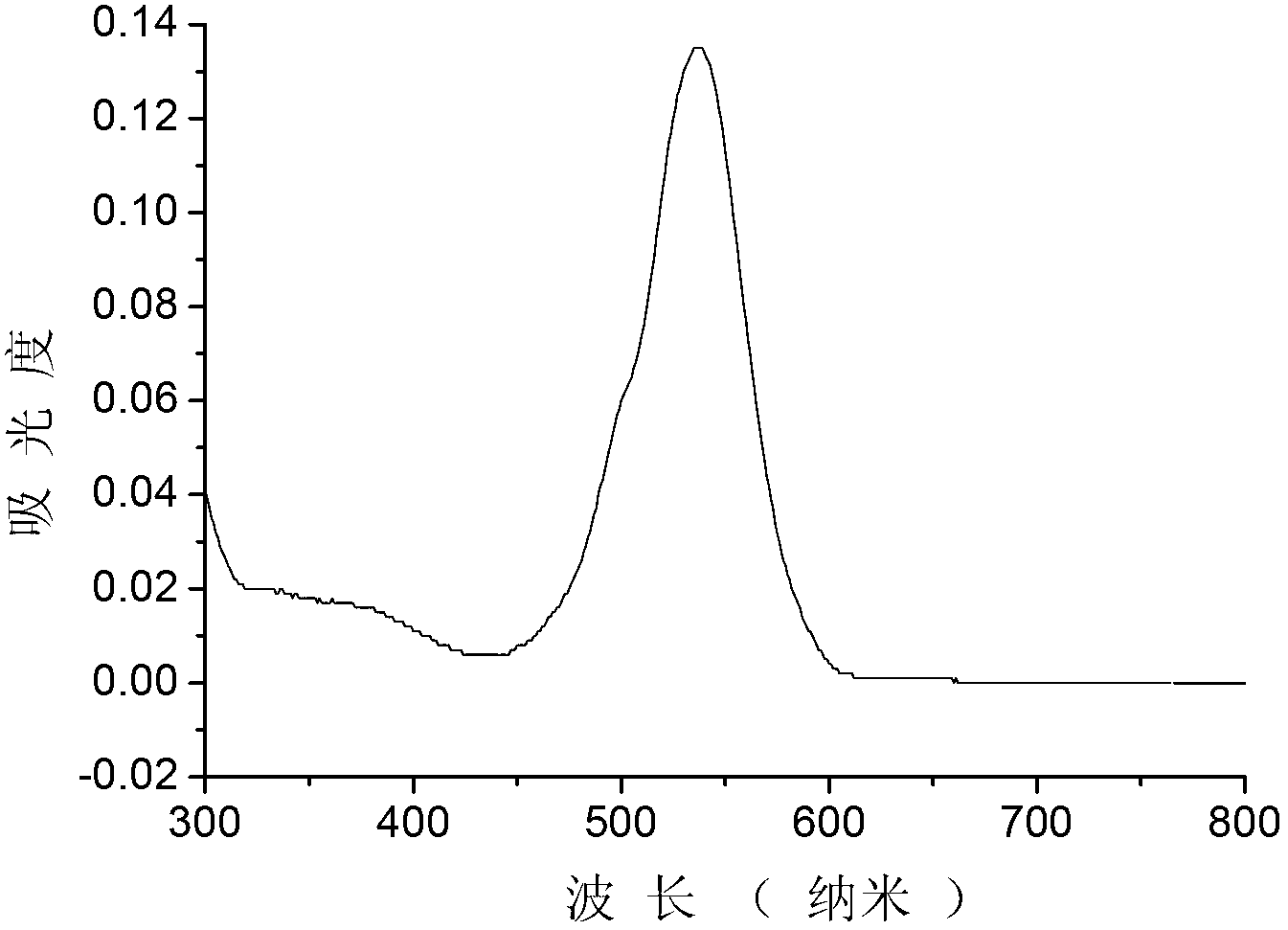

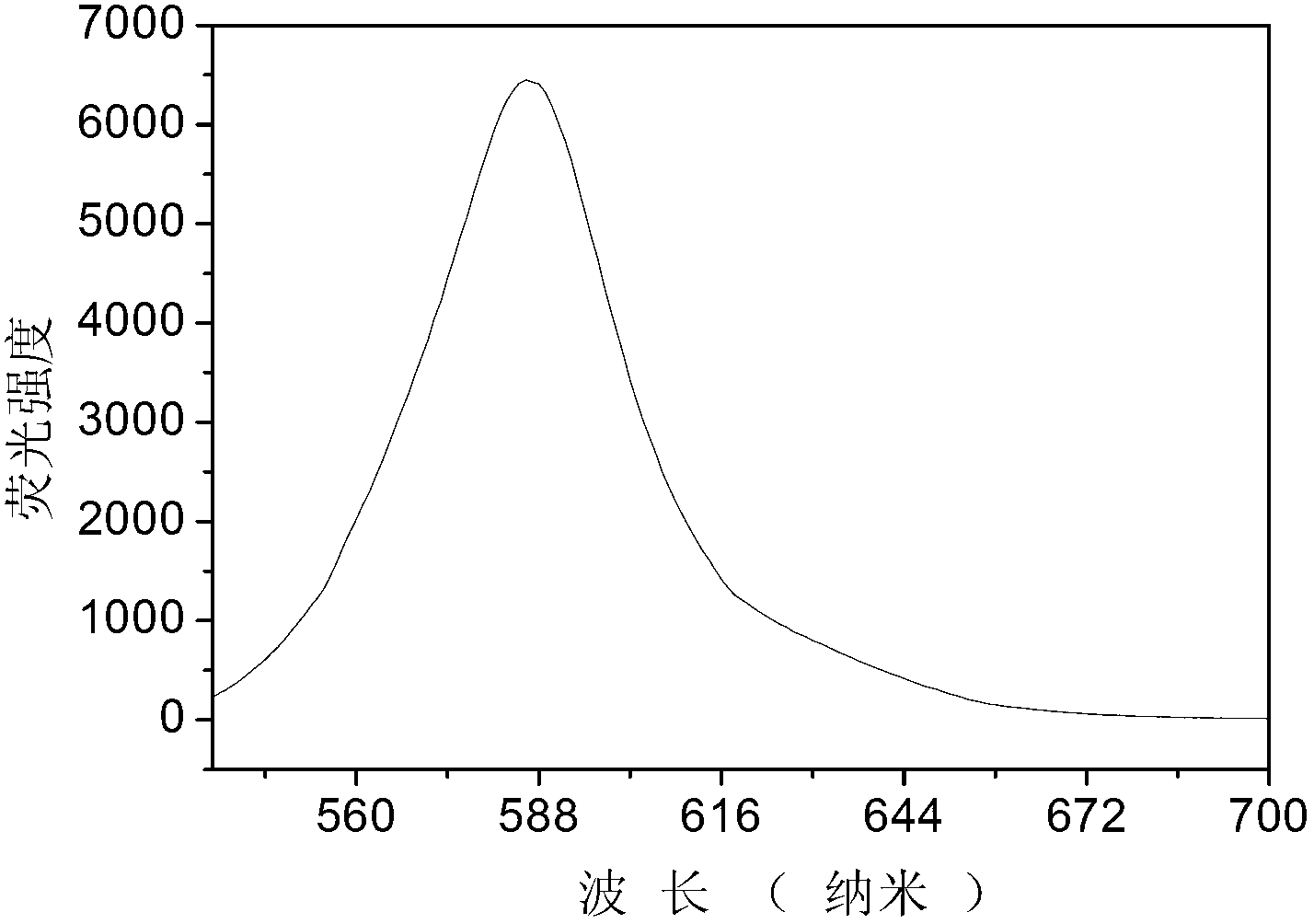

Novel red BODIPY fluorescent dye and preparation method and application thereof

InactiveCN102702768ANarrow absorbencyNarrow fluorescence emission spectrumMethine/polymethine dyesMicrobiological testing/measurementChemical reaction1,4-Benzoquinone

The invention relates to a novel red BODIPY fluorescent dye with the chemical formula of C10+mH7+nBF2N2+xOy, wherein m, n, x and y are integers from 0 to 100. The preparation method comprises the following steps: dissolving pyrrole with substituent groups R1, R2 and R3 in an organic solution; adding ethyl glyoxylate together with nitrogen to the organic solution for a chemical reaction by using trifluoroacetic acid or toluenesulfonic acid as a catalyst; adding 2,3-dichloro-5,6-dicyano-1,4-benzoquinone oxidative dehydrogenation; and adding organic amine and a boron trifluoride diethyl ether solution for another reaction. After the reaction solution is concentrated, chromatography is performed with a silicagel column to obtain the fluorescent dye. The fluorescent dye can be used for cell imaging, fluorescent probe or laser dye. The fluorescent dye has the advantages that the ultraviolet-visible absorption spectrum and the fluorescence emission spectrum of the fluorescent dye are narrow; fluorescent quanta has high efficiency and good light stability; and the fluorescent dye has simple molecular structure and can be synthesized easily, so as to facilitate popularization and application.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

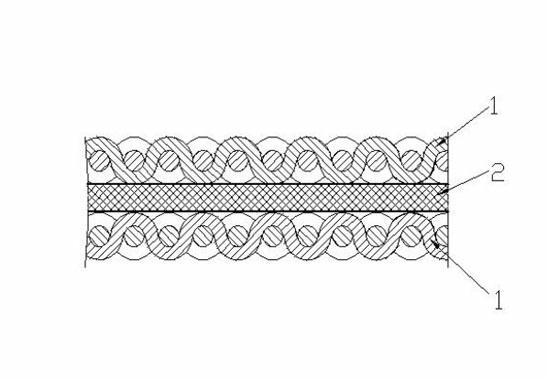

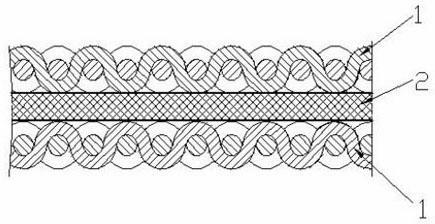

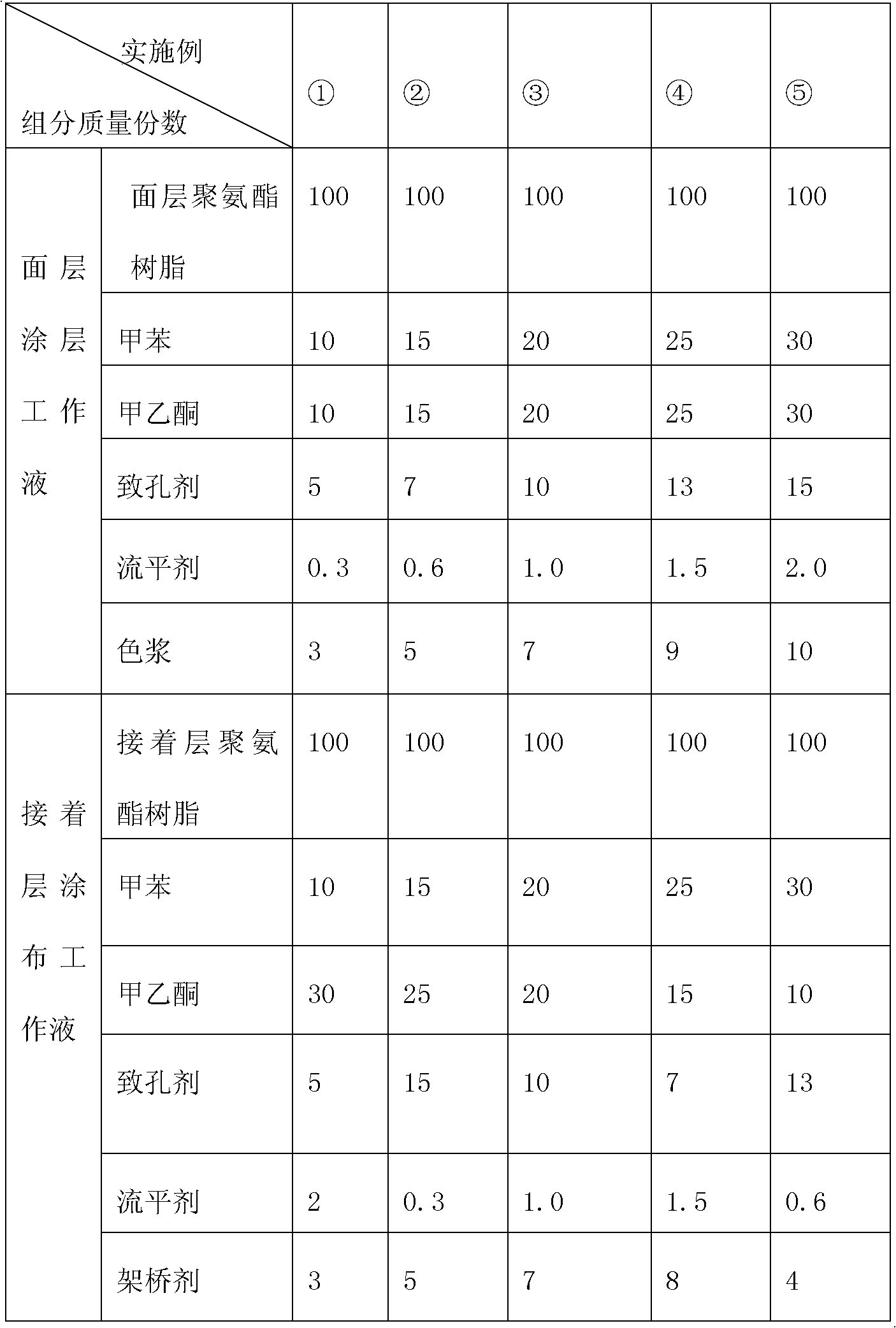

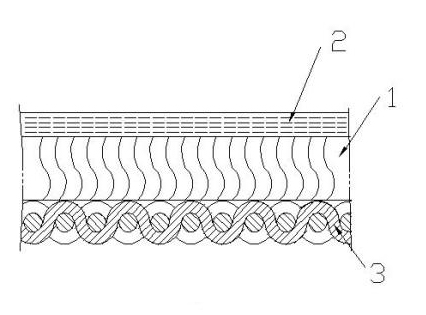

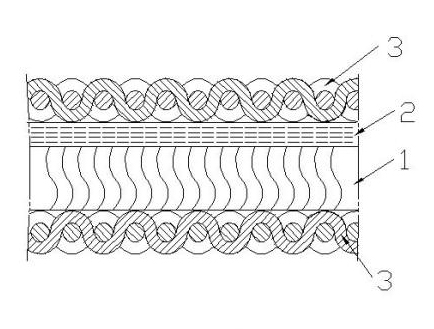

Polyurethane windproof air-permeable coat compounded textile fabric and preparation method thereof

ActiveCN102173154ASoft touchEasy to takeSynthetic resin layered productsPolyurea/polyurethane coatingsCompound aSurface layer

The invention discloses a polyurethane windproof air-permeable coat compounded textile fabric and a preparation method thereof. The preparation method comprises the following steps: on a transfer coat compounding device, compounding a solvent-type polyurethane slurry with phenylmethane, methylethylketone, porogen, a leveling agent, color paste and the like to form a surface layer coating working slurry; coating the surface layer coating working slurry onto a transfer carrier to form a polyurethane micropore structure layer; coating the solvent-type polyurethane binding resin, which is matched with the phenylmethane, methylethylketone, porogen, bridging agent, leveling agent and the like, on the surface layer to form a porous air-permeable binding layer; compounding textile cloth on the polyurethane coat resin, and curing by drying; separating from the transfer carrier to obtain a roll which is a semi-finished product; and compounding another kind of textile cloth on one side of the polyurethane coat in a dotted or reticular sizing mode on the compounding device to form the windproof air-permeable coat compounded textile fabric. The compounded fabric has the advantages of windproof property and air permeability.

Owner:昆山华富新材料股份有限公司

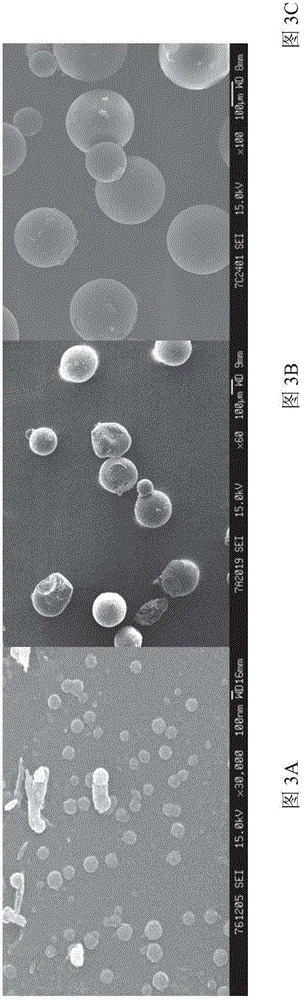

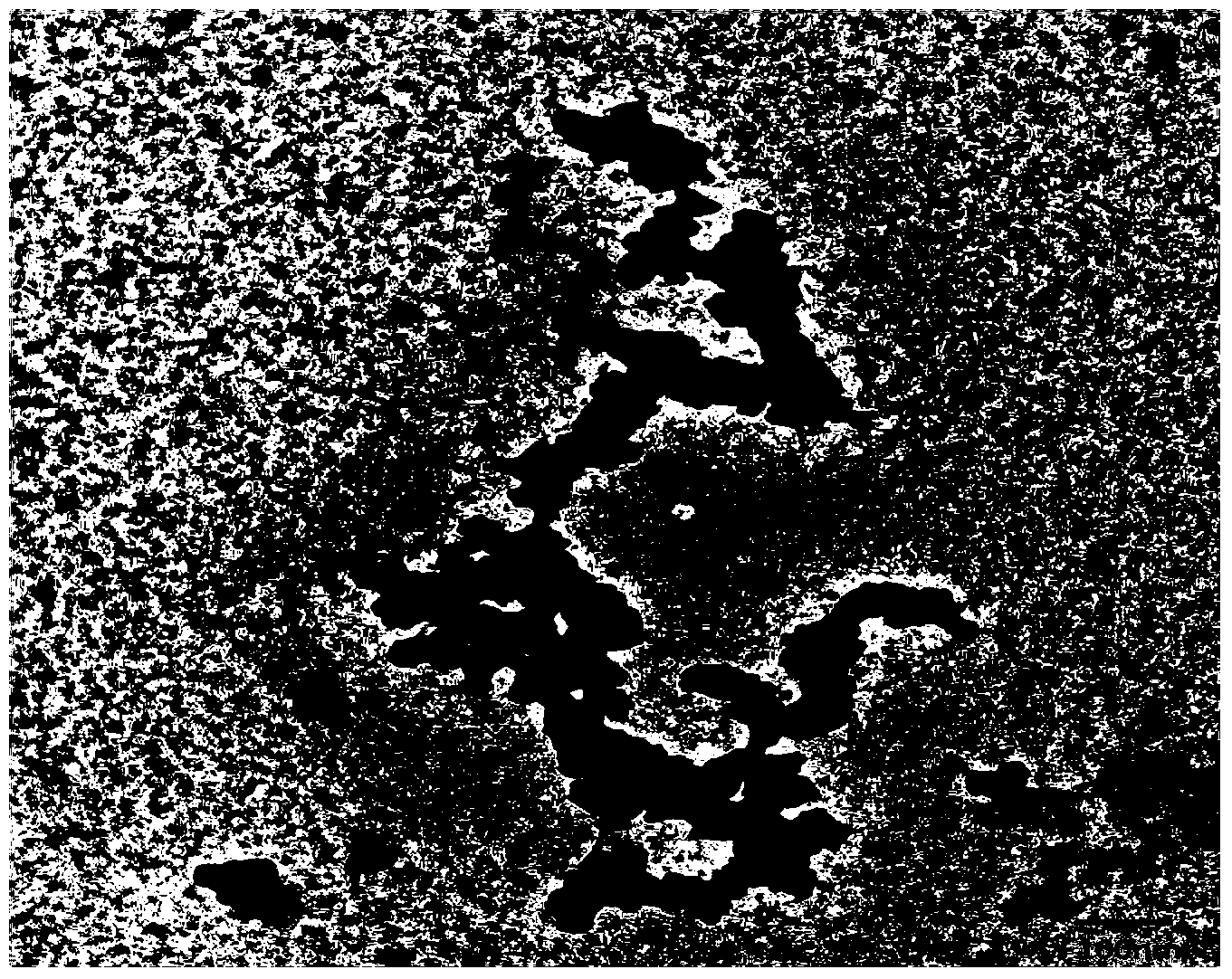

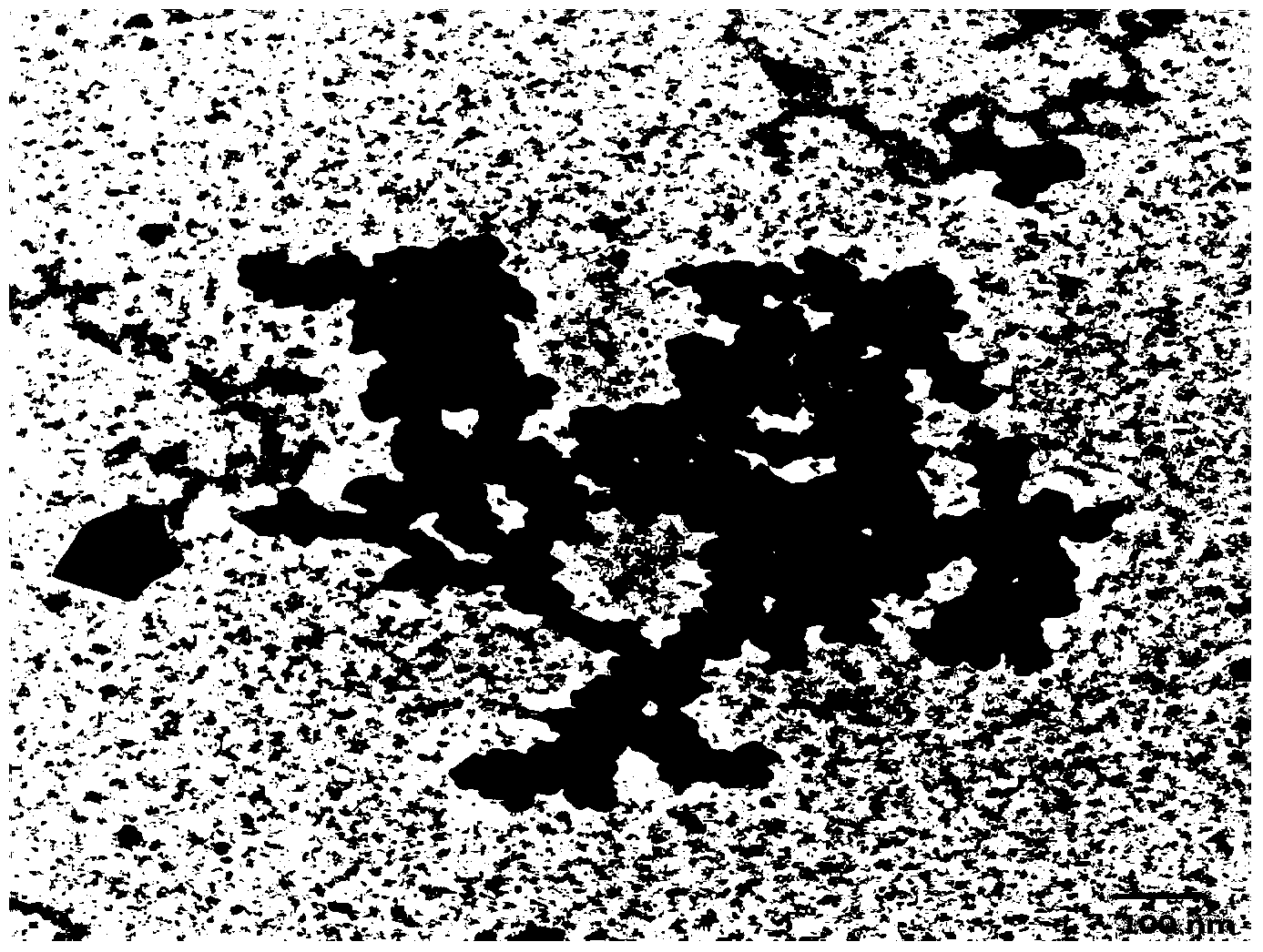

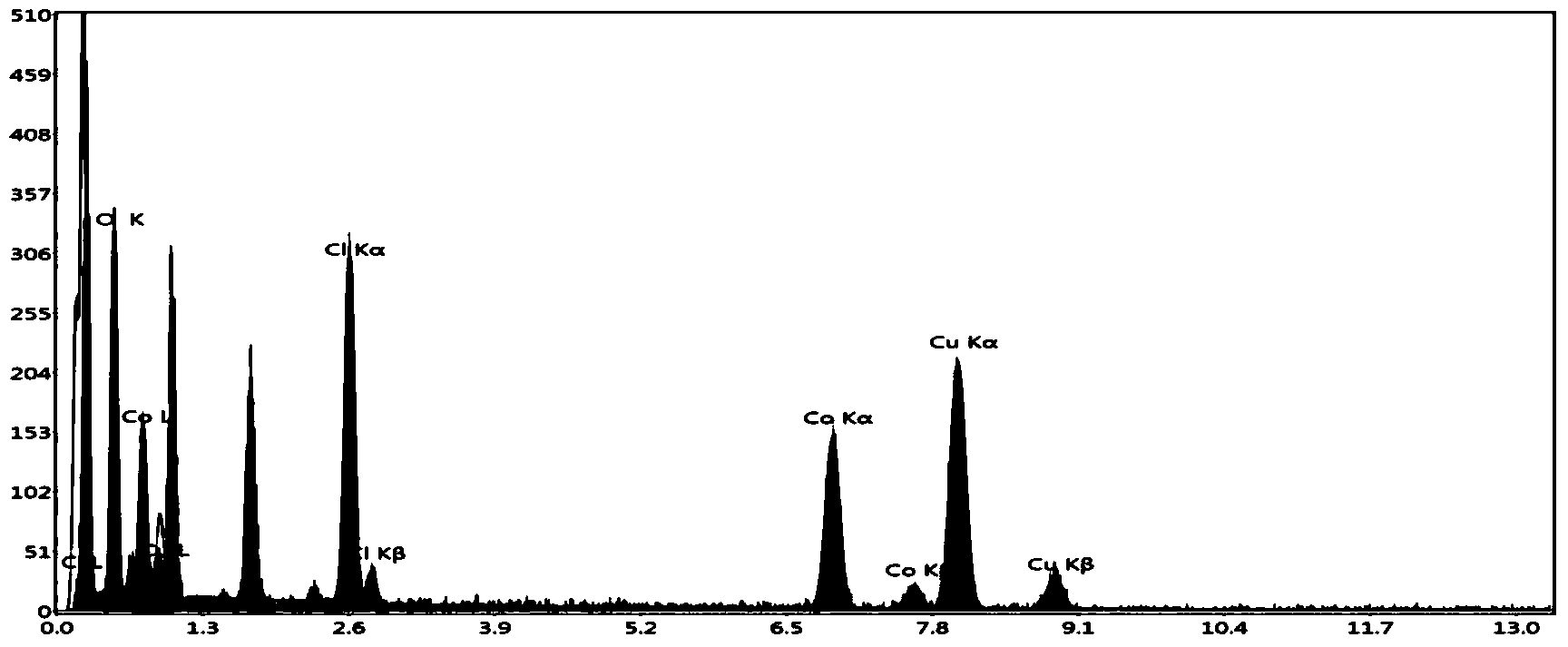

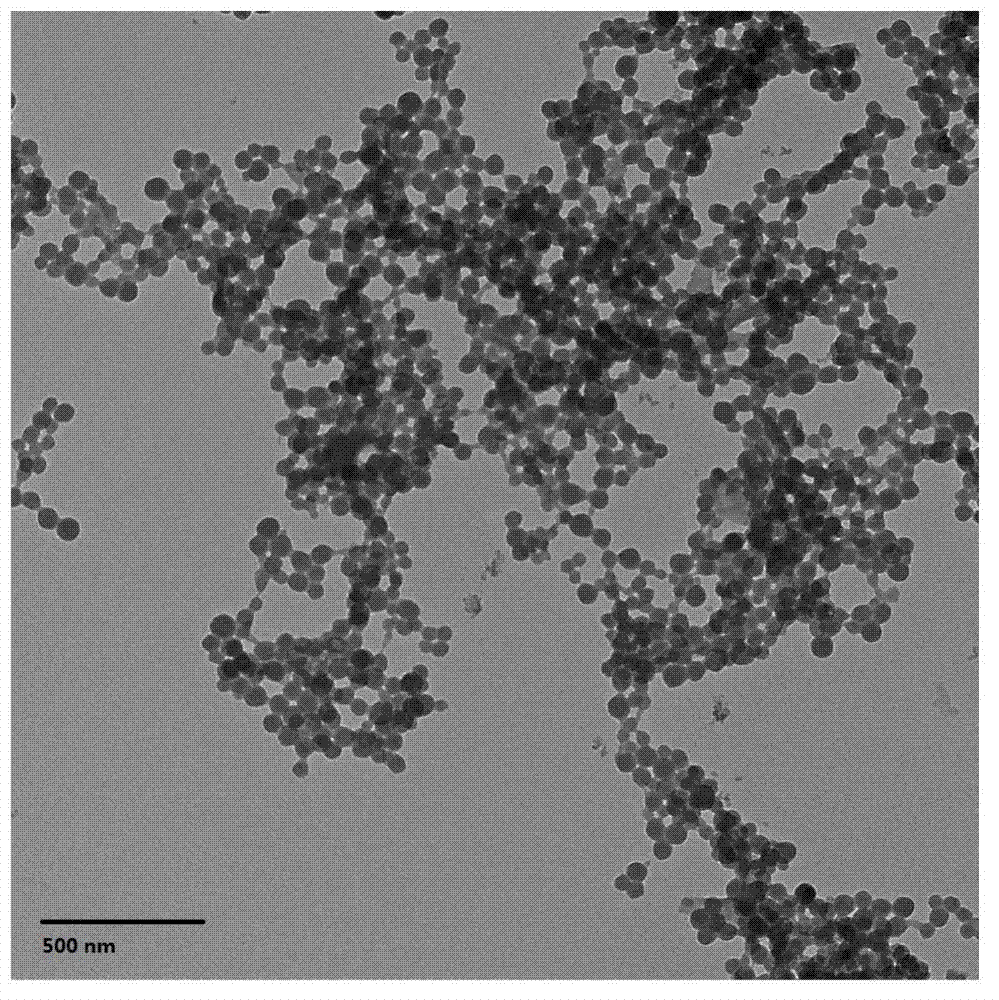

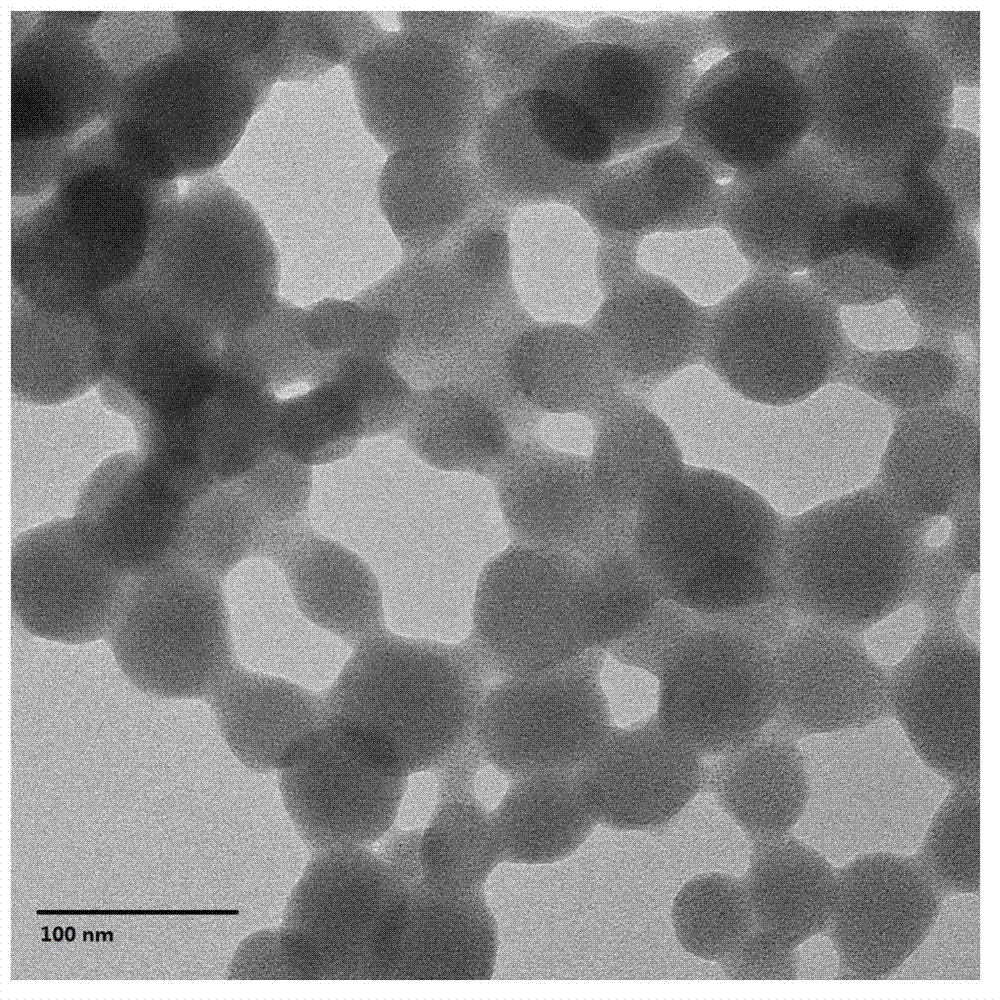

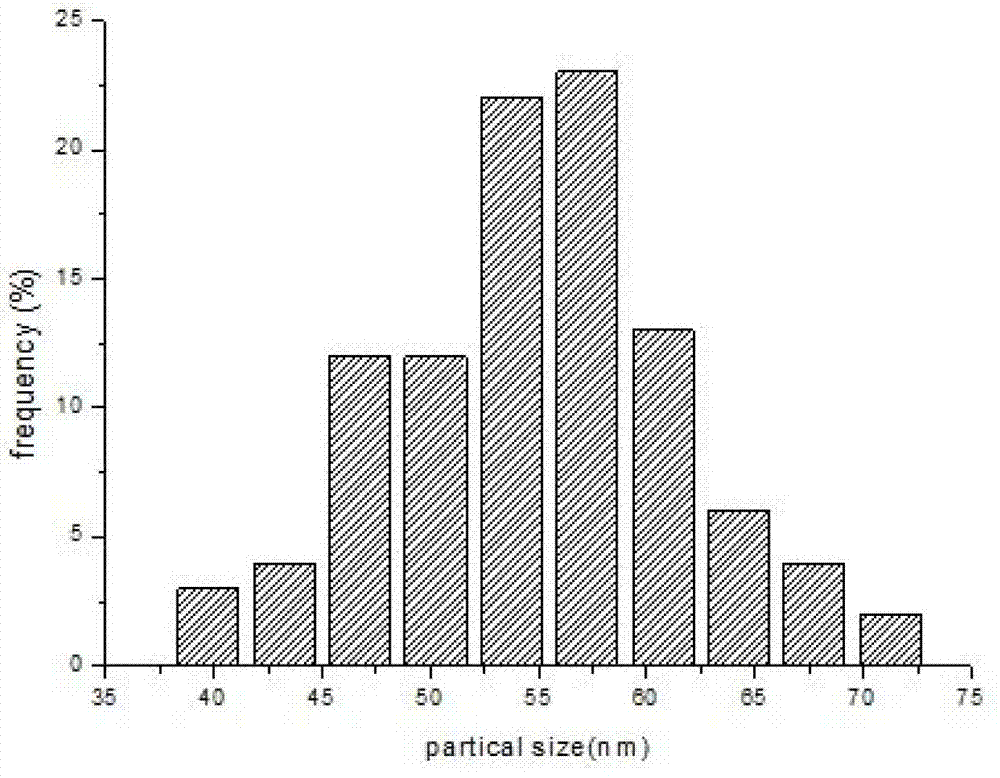

Method for manufacturing coralline nanometer cobalt by using octreotide acetate as a template

InactiveCN104014811ASimple molecular structureActive group clearMaterial nanotechnologyMole ratioCobalt chloride

A method for manufacturing coralline nanometer cobalt by using octreotide acetate as a template mainly comprises the steps that the octreotide acetate is dissolved through pH2-3 hydrochloric acid, the octreotide acetate is regulated into an acid solution, a cobalt chloride solution is added in the regulated solution with the mole ratio of 1:10-20, the solution is then put in a water bath constant temperature oscillator, and hatching is carried out for 20-26 hours under the temperature of 13-25 DEG C at 100-200 rpm.; then, the reducing agent sodium borohydride is added in the hatched solution at a time so that the hatched solution is changed into dark black from light pink, and the black product is octreotide acetate-nanometer cobalt particles, wherein the mole ratio of the reducing agent sodium borohydride and the cobalt chloride is 1:25-35. The method for manufacturing the coralline nanometer cobalt by using the octreotide acetate as the template has the advantages that the manufacturing technology is simple, conditions are mild, the coralline nanometer cobalt is cheap and easy to obtain, the reaction is easy to control, and the productivity is high.

Owner:YANSHAN UNIV

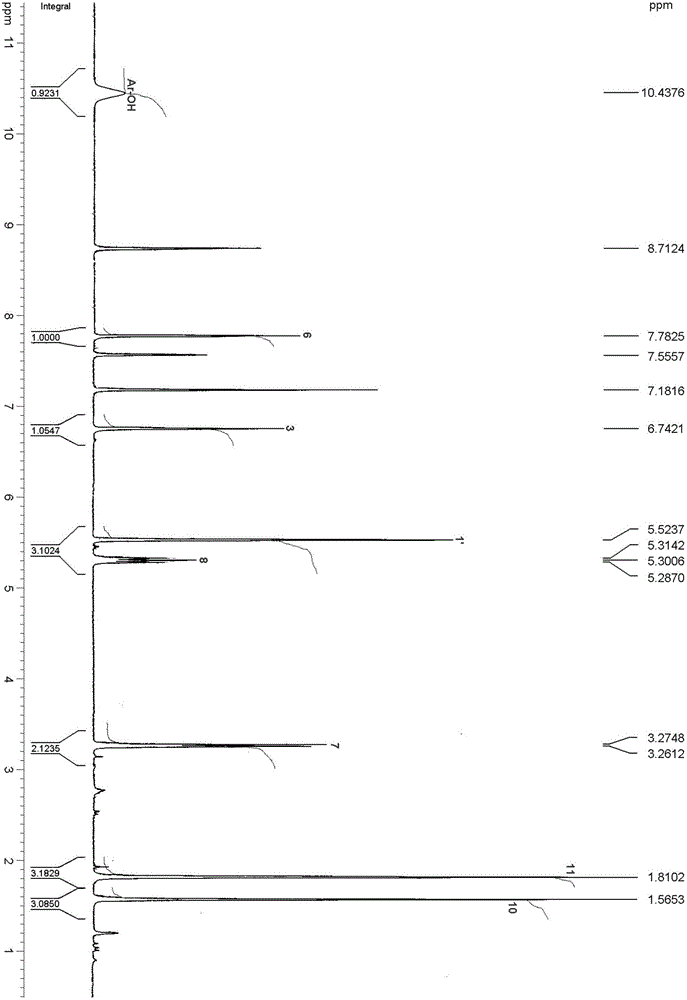

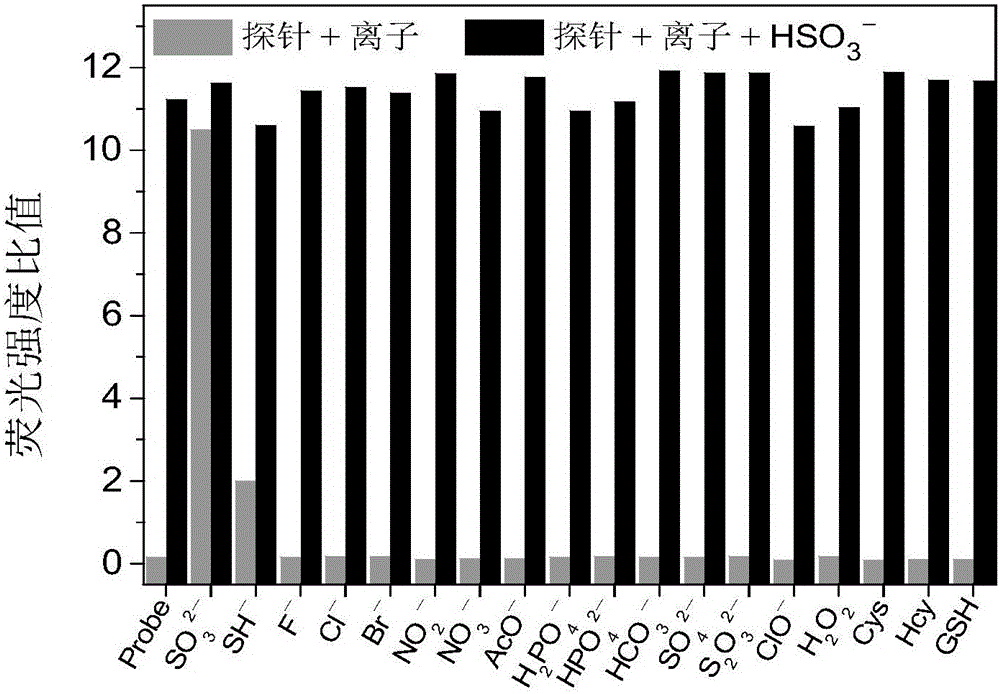

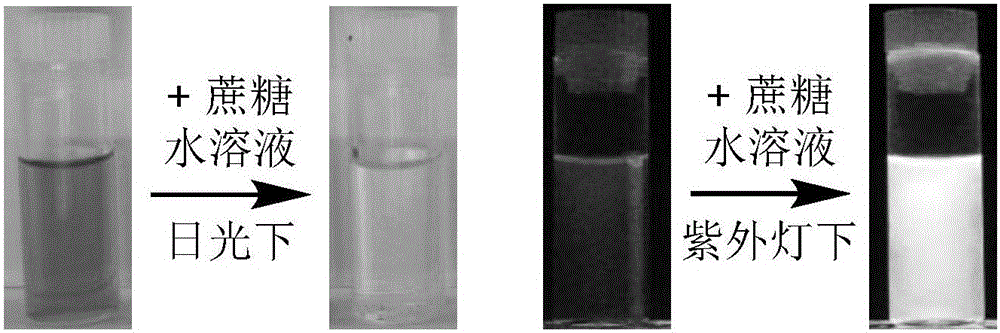

Fluorescent probe used for sulfite or bisulphate and preparation method and application thereof

InactiveCN105733566AShort response timeHigh measurement sensitivityOrganic chemistryFluorescence/phosphorescenceQuinolineLinearity

A class of fluorescent probes for the detection of sulfite (hydrogen) salts, consisting of benzoindole quaternary ammonium salts, and the molecule has the following structure: Wherein: R is a kind of in alkyl, aryl, nitro, ester group and ether group of 1-18 carbons independently or at the same time, or benzene, naphthalene, anthracene, pyrene, pyridine, pyrrole, indole, One of coumarin, fluorescein, carbazole, rhodamine, fluorene and quinoline and derivatives thereof; n is 0-20; X ‑ for F ‑ , Cl ‑ , Br ‑ or I ‑ , + is a positive charge. The advantages of the invention are: the fluorescent probe has good selectivity to sulfite, and the fluorescence intensity of the fluorescent probe solution and the concentration of sulfite are in the range of 0-8×10 ‑6 The linear relationship in the molar / liter range is good, showing good practical applicability; the fluorescent probe has a short response time, high detection sensitivity, simple molecular structure, and simple synthesis method, which makes it extremely easy for practical application.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

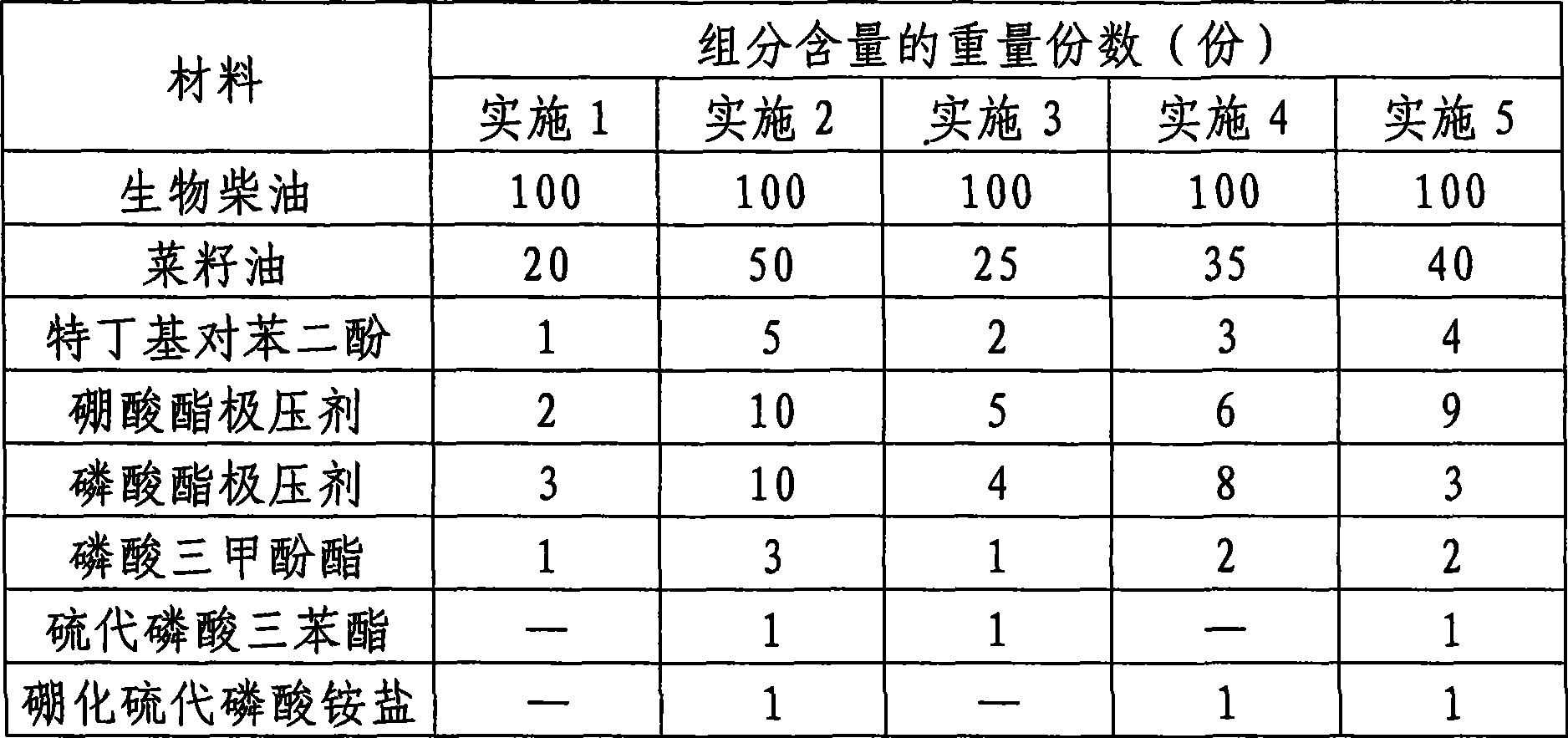

Drawing oil special for aluminum wire and production process thereof

The invention relates to special wire drawing oil for an aluminum wire, which is characterized in that the special wire drawing oil for the aluminum wire comprises biodiesel, colza oil, an antioxidant, a polyester extreme pressure agent and a phosphor-bearing antiwear agent, wherein the compositions by mass portion of the special wire drawing oil for the aluminum wire are: 100 portions of the biodiesel, 20 to 50 portions of the colza oil, 1 to 5 portions of the antioxidant, 5 to 20 portions of the polyester extreme pressure agent and 1 to 5 portions of the phosphor-bearing antiwear agent. The invention relates to a method for manufacturing the special wire drawing oil for the aluminum wire, which comprises the following steps: a. weighing up the biodiesel, the colza oil, the antioxidant, the polyester extreme pressure agent and the phosphor-bearing antiwear agent for standby according to the weight proportion; b. adding the biodiesel into a container at normal temperature, and adding the colza oil into the container, so as to form a solution after uniform stirring; and c. adding the antioxidant, the polyester extreme pressure agent and the phosphor-bearing antiwear agent to the solution in the step b, and uniformly stirring the solution until no deposit exists. The special wire drawing oil for the aluminum wire has low kinematic viscosity, good fluidity, good lubricating effect and strong safety.

Owner:GUANGDONG WEIQI ELECTRIC MATERIAL

Method for preparing hammer-shaped palladium nanoparticle by utilizing octreotide acetate as template

InactiveCN103203461AExcellent biological templateSimple molecular structureOctreotide acetateSodium borohydride

Owner:YANSHAN UNIV

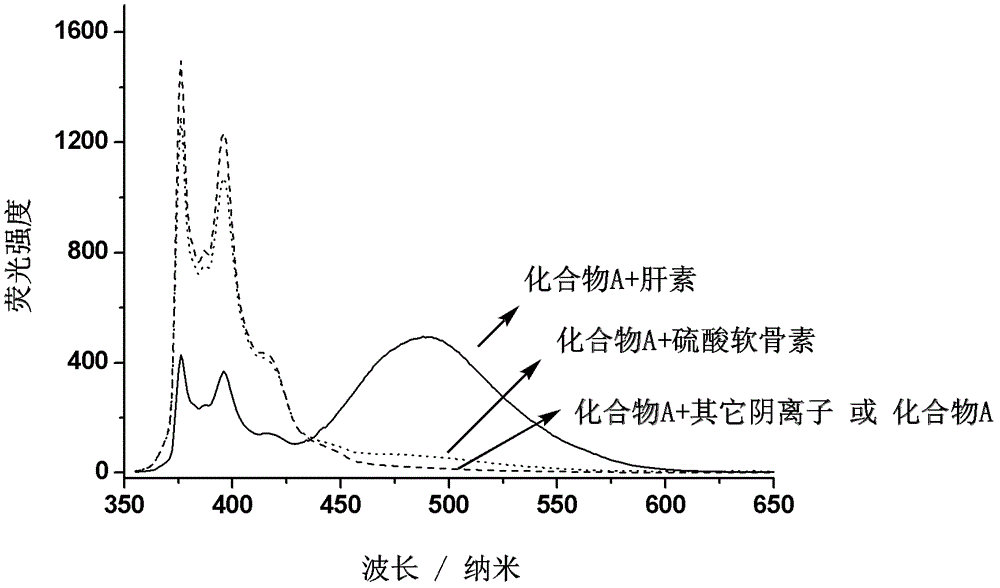

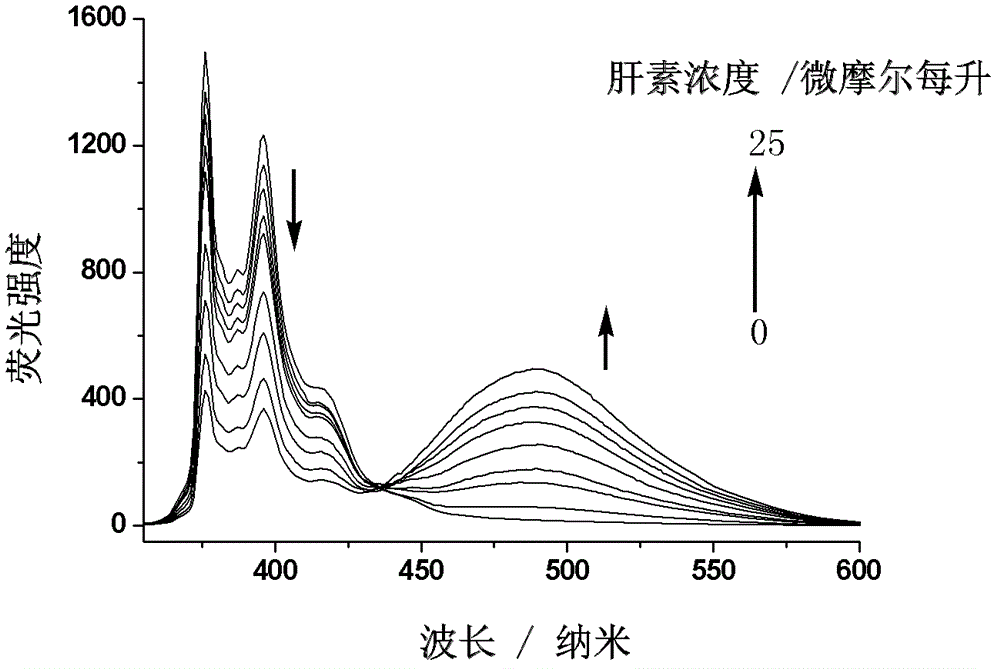

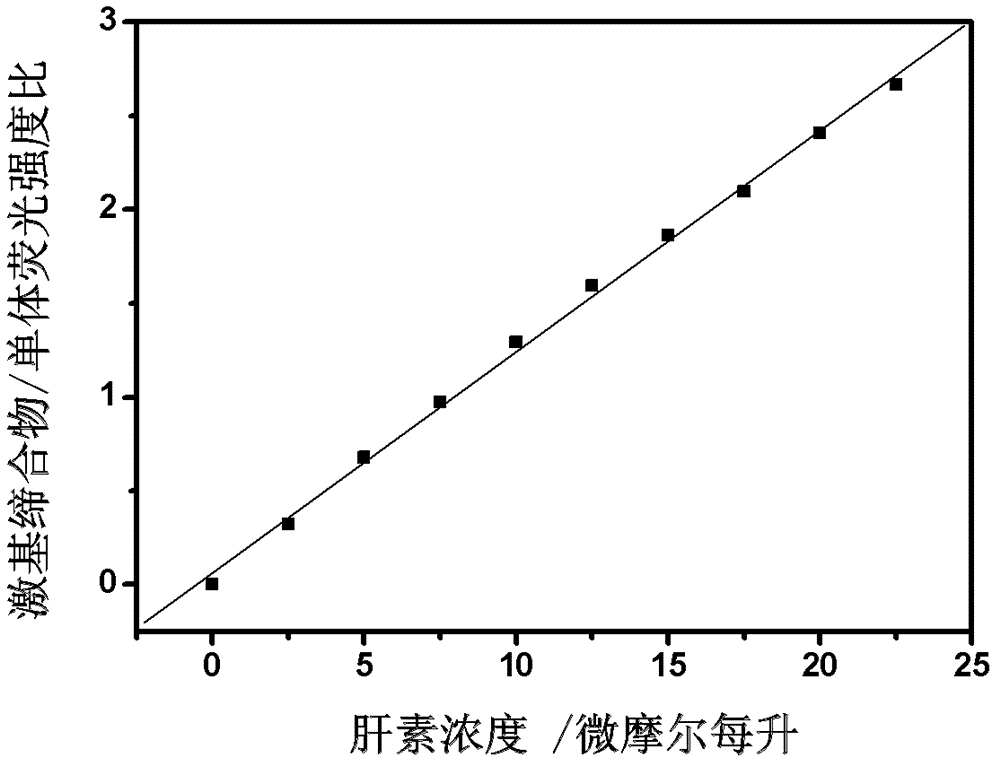

Fluorescent probe for quantitatively detecting heparin, and synthesis method and application thereof

InactiveCN102796511AGood choiceDetection without interferenceAmino preparation from aminesOrganic compound preparationArylAnthracene

The invention discloses a fluorescent probe which has the following structural formula, wherein R1, R2, R3, R4 and R5 are selected from C1-C18 alkyl group, aryl group, ester group or ether group; n and m are selected from 0-8; Ar is selected from naphthalene, anthracene or pyrene; and X<-> is selected from F<->, Cl<->, Br<-> or I<->. The invention also discloses a synthesis method and application of the fluorescent probe. The fluorescent probe can be used for detecting heparin in blood, and has the advantages of simple molecular structure, short response time, high detection sensitivity and simple synthesis method.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

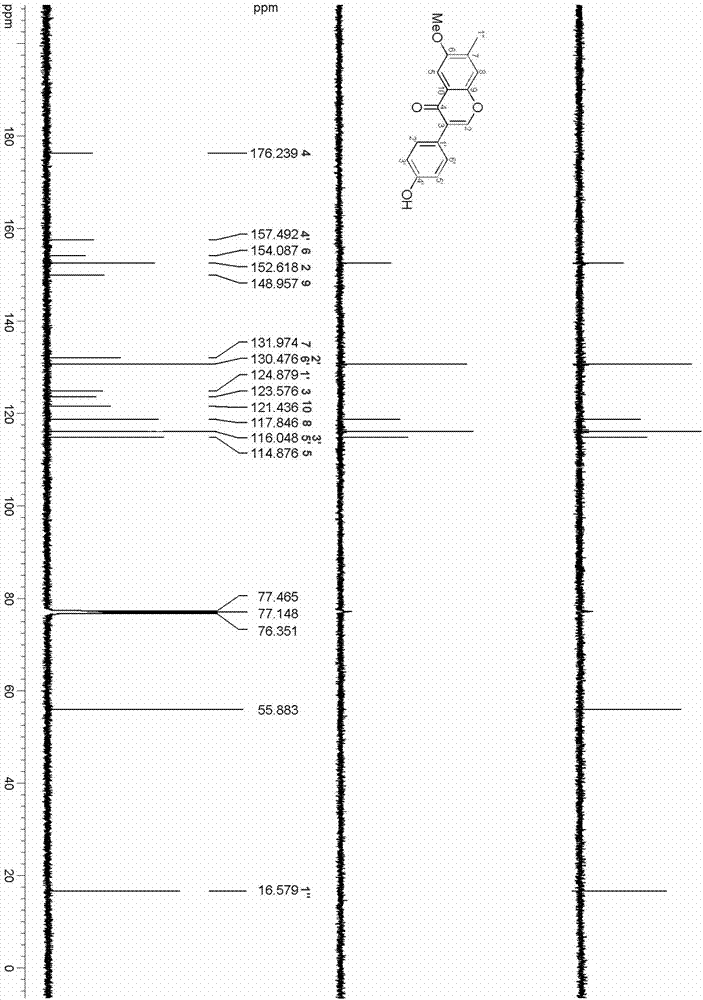

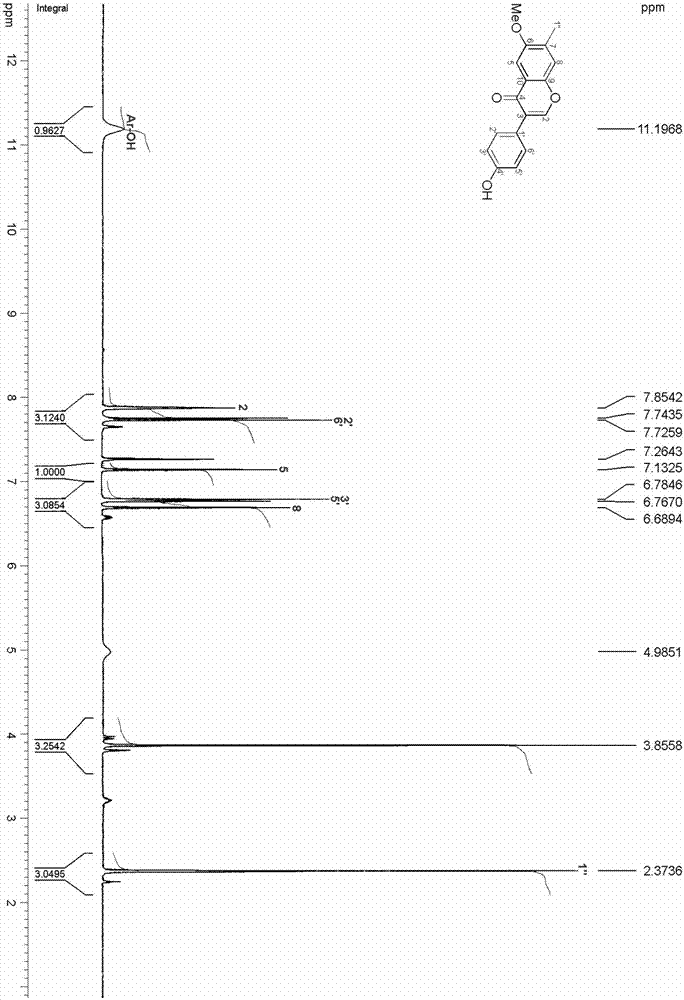

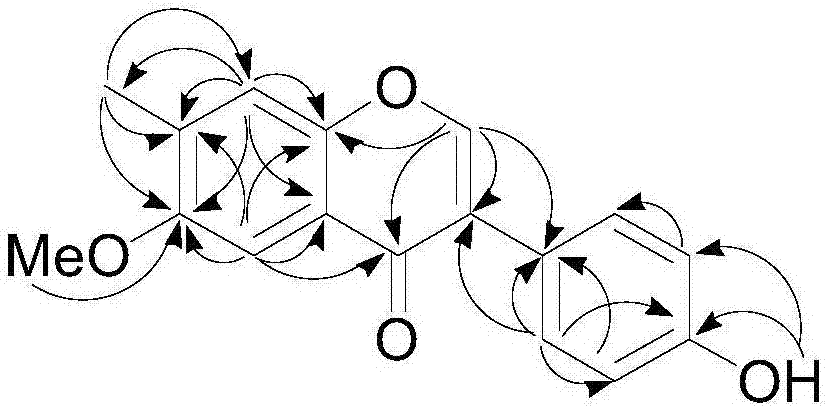

An isoflavone compound having antibacterial activity and a preparing method and applications thereof

ActiveCN107098879ARaw materials are easy to getSimple extraction methodBiocideOrganic chemistryAntibacterial activityIsoflavones

The invention relates to an isoflavone compound having antibacterial activity and a preparing method and applications thereof, and belongs to the technical field of phytochemistry. The structure of the compound is shown as a formula (I). The formula (I) is shown in the specification. The compound is prepared from kudzu vine root that is a traditional medicinal and edible plant and through steps of extractum extraction, column chromatography on silica gel and separation and purification through high performance liquid chromatography. Activity tests prove that the compound has a good bacteriostatic function; when the compound is added into a tobacco material solution, the compound can effectively inhibit microbe growth in the material solution and can prolong the shelf life of the solution; when the compound is used for cigarette tipping paper, the compound can eliminate or reduce the possibility of bacterium breeding and reproduction in the cigarette tipping paper; and the compound has a wide application prospect.

Owner:CHINA TOBACCO YUNNAN IND

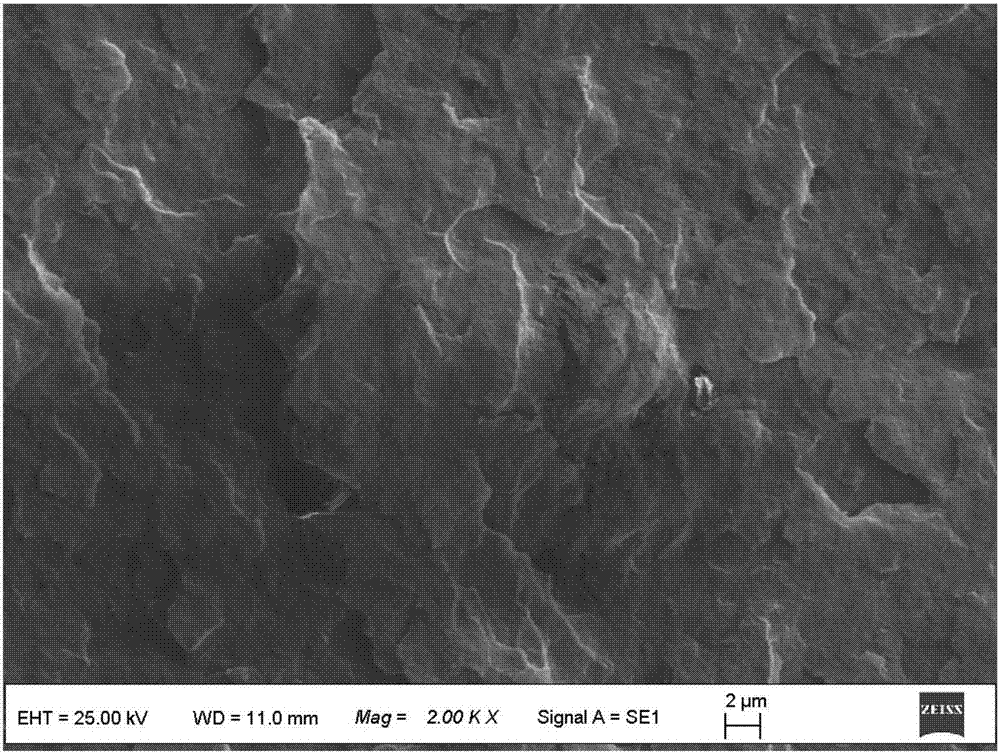

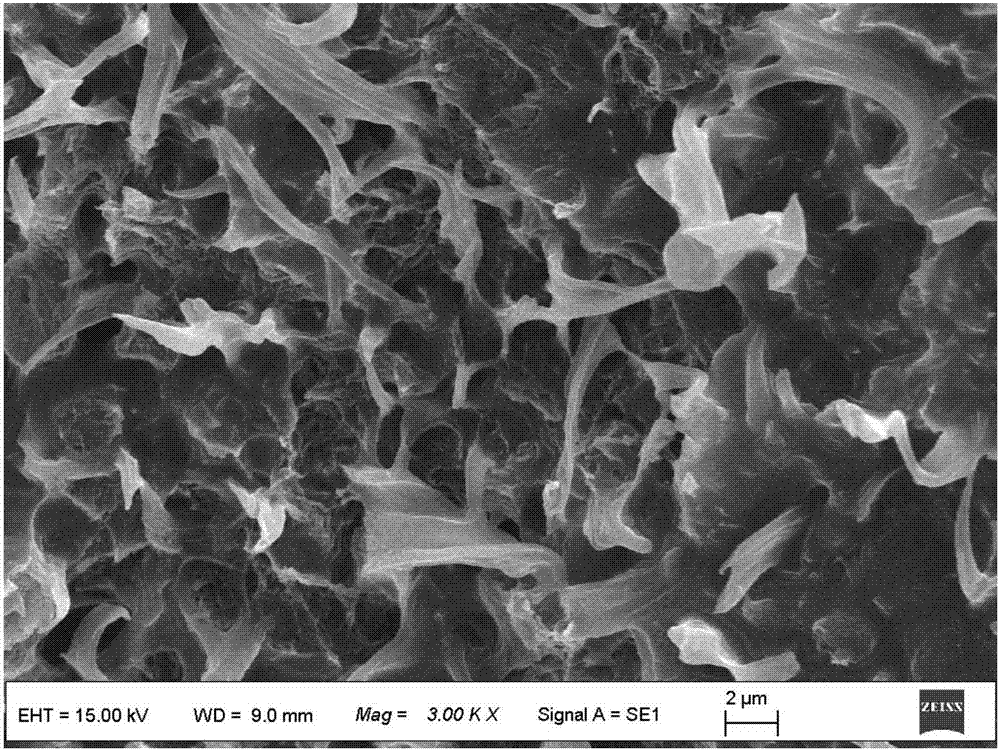

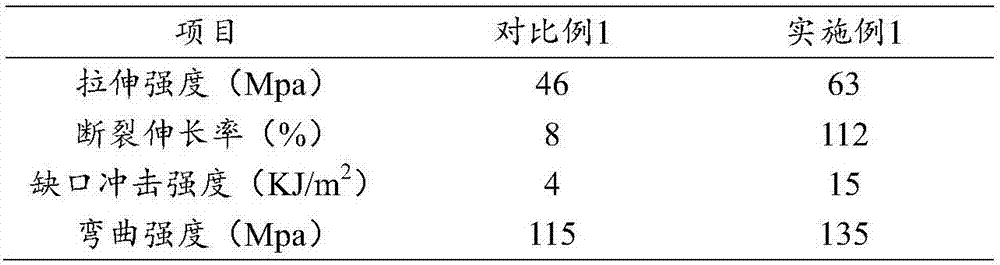

Reinforcing and toughening polylactic acid material and preparation method thereof

The invention provides a reinforcing and toughening polylactic acid material and a preparation method thereof, and relates to the field of polymer materials. The preparation method comprises the steps of mixing layered double hydroxides with epsilon-caprolactone and obtaining reactants, and after a ring opening polymerization, obtaining polycaprolactone modifier; conducting addition polymerization on the polycaprolactone modifier and diisocyanate, and obtaining prepolymer; making the prepolymer react with chain extender, and obtaining polyurethane modifier; melting and mixing the polyurethane modifier and polylactic acid, and obtaining the reinforcing and toughening polylactic acid material. Flexible chain segments of the polyurethane modifier improve the elasticity and flexibility of the material, rigid chain segments of the polyurethane modifier improve the strength and heat resistance of the material, and finally the overall mechanical property of the material is improved. Since the layered double hydroxides with a laminated structure are dispersed in a base material, the bending strength and stretching strength of the material are improved, and the anchoring effect of the material can avoid the modifier compatibility and migration problem which is easily generated from simple physical blending.

Owner:HUNAN UNIV OF TECH

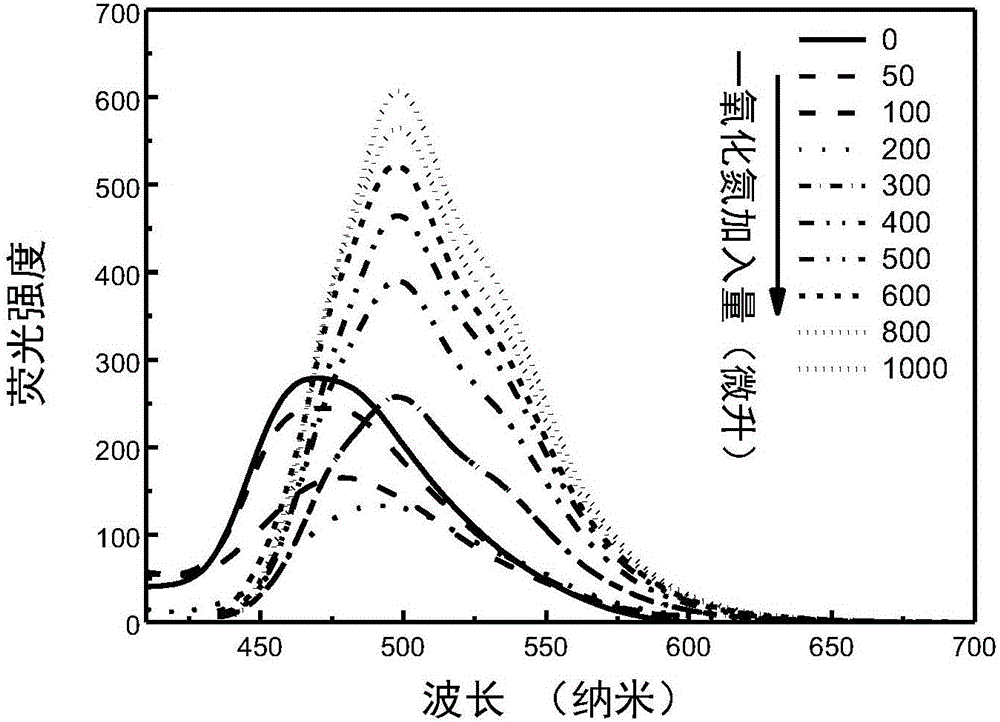

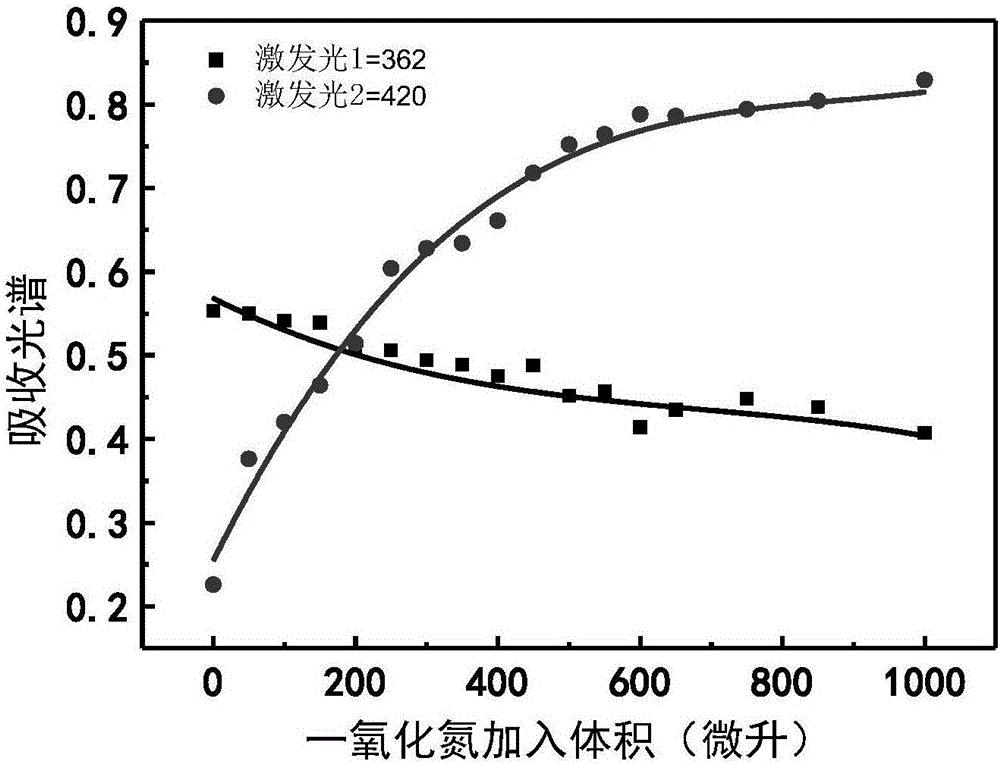

Nitric oxide probe based on fluorescent double-response mechanism and synthesis and application thereof

InactiveCN106432178AHigh sensitivityGood choiceOrganic chemistryFluorescence/phosphorescenceFluorescenceDirect observation

The invention discloses a molecular design and preparation method of a nitric oxide fluorescent probe based on a double-response mechanism. The structure of the nitric oxide fluorescent probe can be represented by a general formula (I) (please see the formula in the description), wherein Spacer represents a single bond or acetylene bond or thiophene or substituted aryl unit, Ar represents one of an aryl group, a substituted aryl group, a heterocyclic aryl group and substituted aryl amine, and the substituted group can be one of a hydrophilic ether chain, a sulfonic acid group, quaternary ammonium salt and the like. The key steps of synthesis of the probe molecule can be achieved through a Suzuki coupling reaction or a C-H activation coupling reaction and the like. The probe molecule has the advantages of being high in sensitivity, good in selectivity, short in response time, good in membrane permeability, low in background noise, capable of achieving direct observation and fluorescence-ultraviolet-visible spectrum dual-band response and the like, is a brand-new sensing detection platform and has a good application prospect.

Owner:NANJING UNIV OF TECH

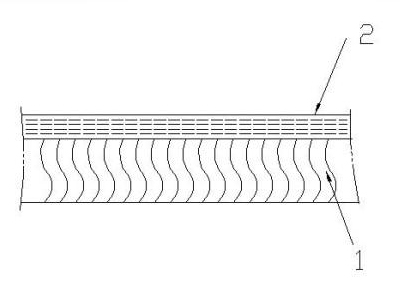

Polyurethane microporous water-proof and moisture permeable film prepared by using solidification method and preparation method thereof

ActiveCN102174211AIncrease water pressureGood moisture permeabilitySynthetic resin layered productsCoatingsMoisture permeabilityAqueous solution

The invention discloses a polyurethane microporous water-proof and moisture permeable film prepared by using a solidification method and a preparation method thereof. The method comprises the following steps of: firstly, preparing a wet coating working liquid and a dry direct coating working liquid; then coating the wet coating working liquid on a transfer carrier, solidifying in the aqueous solution of dimethylformamide (DMF) at mass concentration of 16-22 percent to form a film, washing, drying and coiling to obtain a polyurethane microporous film layer; coating the dry direct coating working liquid on the polyurethane microporous film layer and drying to form a protective layer; and separating the polyurethane microporous film layer and the protective layer from the transfer carrier together so as to form the polyurethane microporous water-proof and moisture permeable film. The film has a two-layer structure, wherein one layer is the polyurethane microporous layer and the other layer is the protective layer. The film structurally has a microporous form and has performances such as non-swelling, water-proofing, moisture permeability, air permeability and the like.

Owner:江苏唐古拉聚合材料有限公司

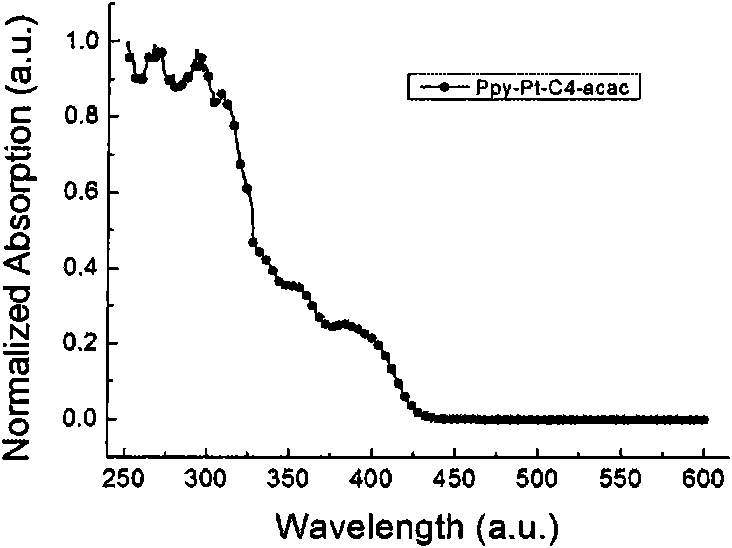

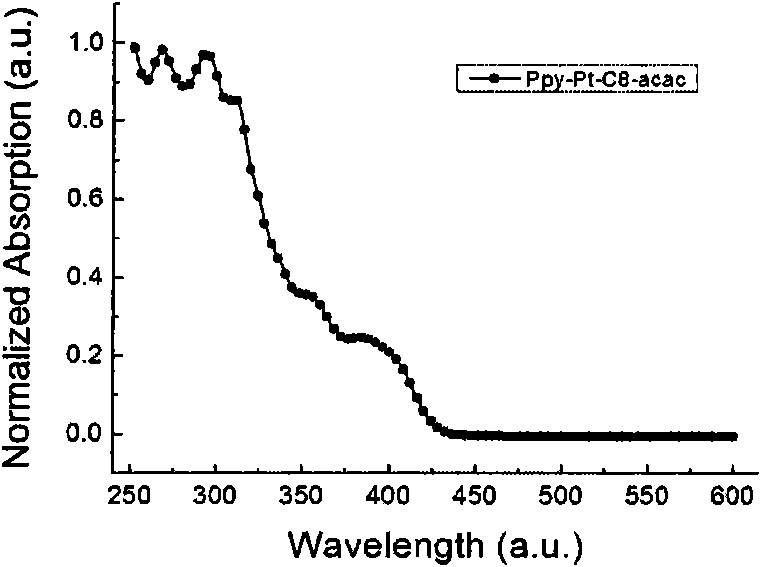

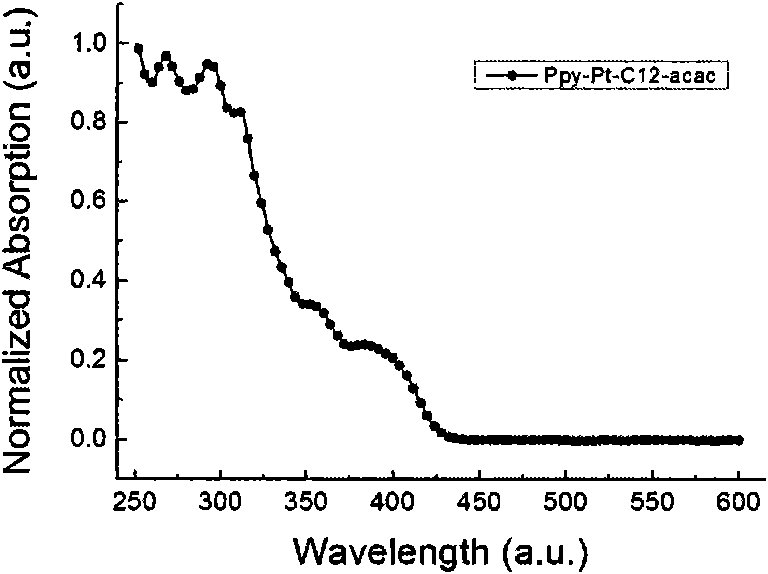

Cyclometalated platinum complexes liquid crystal polarized luminescent material and application thereof

InactiveCN101613315AThe synthesis process is simpleImprove luminous efficiencyLiquid crystal compositionsGroup 8/9/10/18 element organic compoundsLiquid crystallinePt element

The invention discloses a cyclometalated platinum complexes liquid crystal polarized luminescent material which is based on that phenylpyridine derivatives liquid crystal material is used as cyclomedtalating ligand and acetylacetone is used as anion ligand, and an application thereof. The material is prepared by the following steps: introducing alkoxy to benzene C-4 of the traditional cyclomedtalating ligand phenylpyridine C-2 and introducing alkoxymelthyl to pyridine C-5 to form C^N cyclomedtalating ligand of dialkoxy chain with liquid crystalline properties or in addition introducing fluorine to benzene C-3 to form fluorine-containing C^N cyclomedtalating ligand of dialkoxy chain with liquid crystalline properties, and then using acetylacetone as anion ligand to synthesizing a kind of new cyclomedtalating platinum complex which adopts phenylpyridine derivatives as cyclomedtalating ligand. Compared with the traditional cyclomedtalating platinum luminescent material which adopts functionalized phenylpyridine as cyclomedtalating ligand, the material of the invention has not only high-efficiency luminous performance, but also good liquid crystalline properties and polarisation luminous performance. The material of the invention provides a new way to obtain liquid crystal polarization organic electrophosphorescent material.

Owner:XIANGTAN UNIV

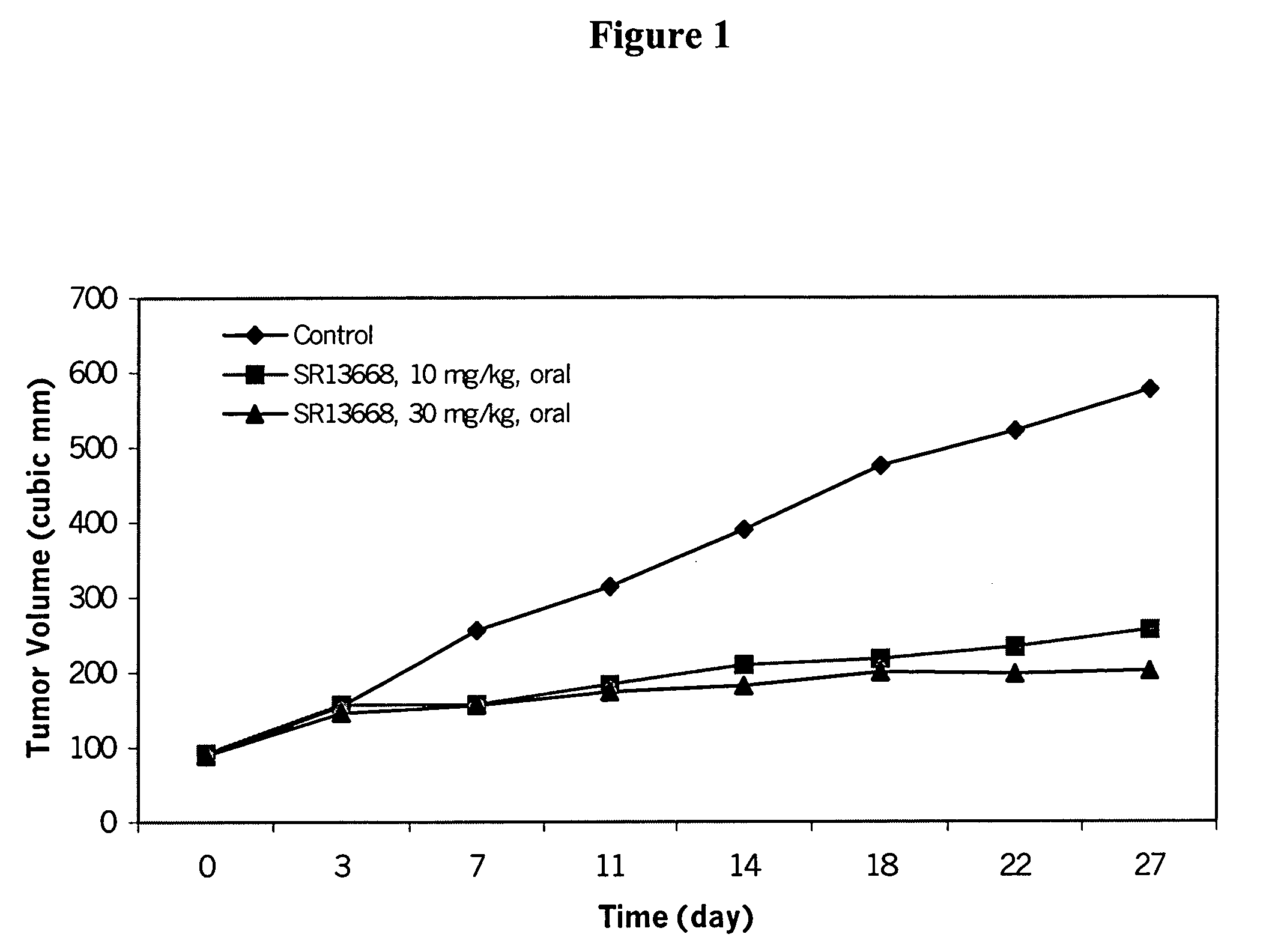

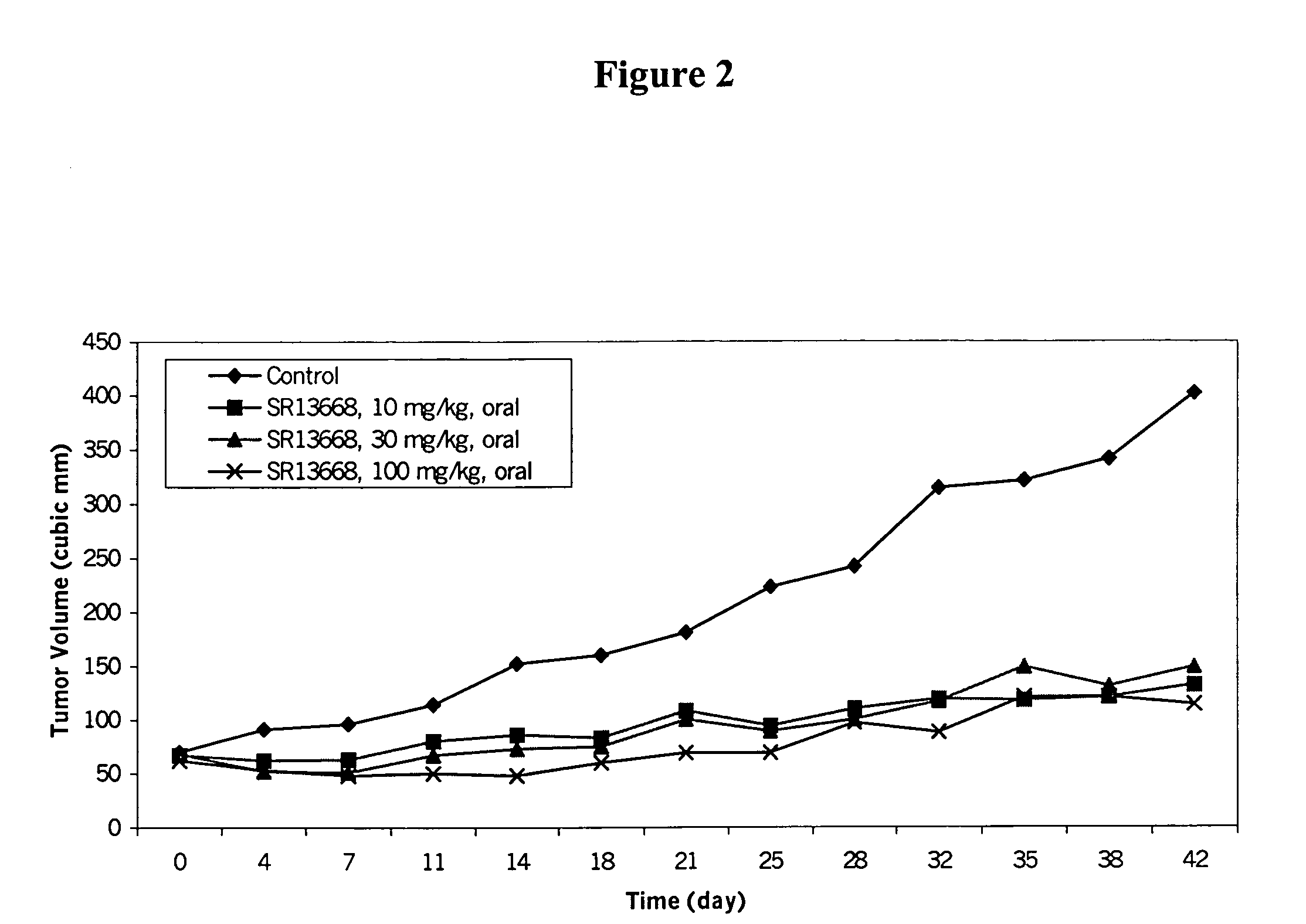

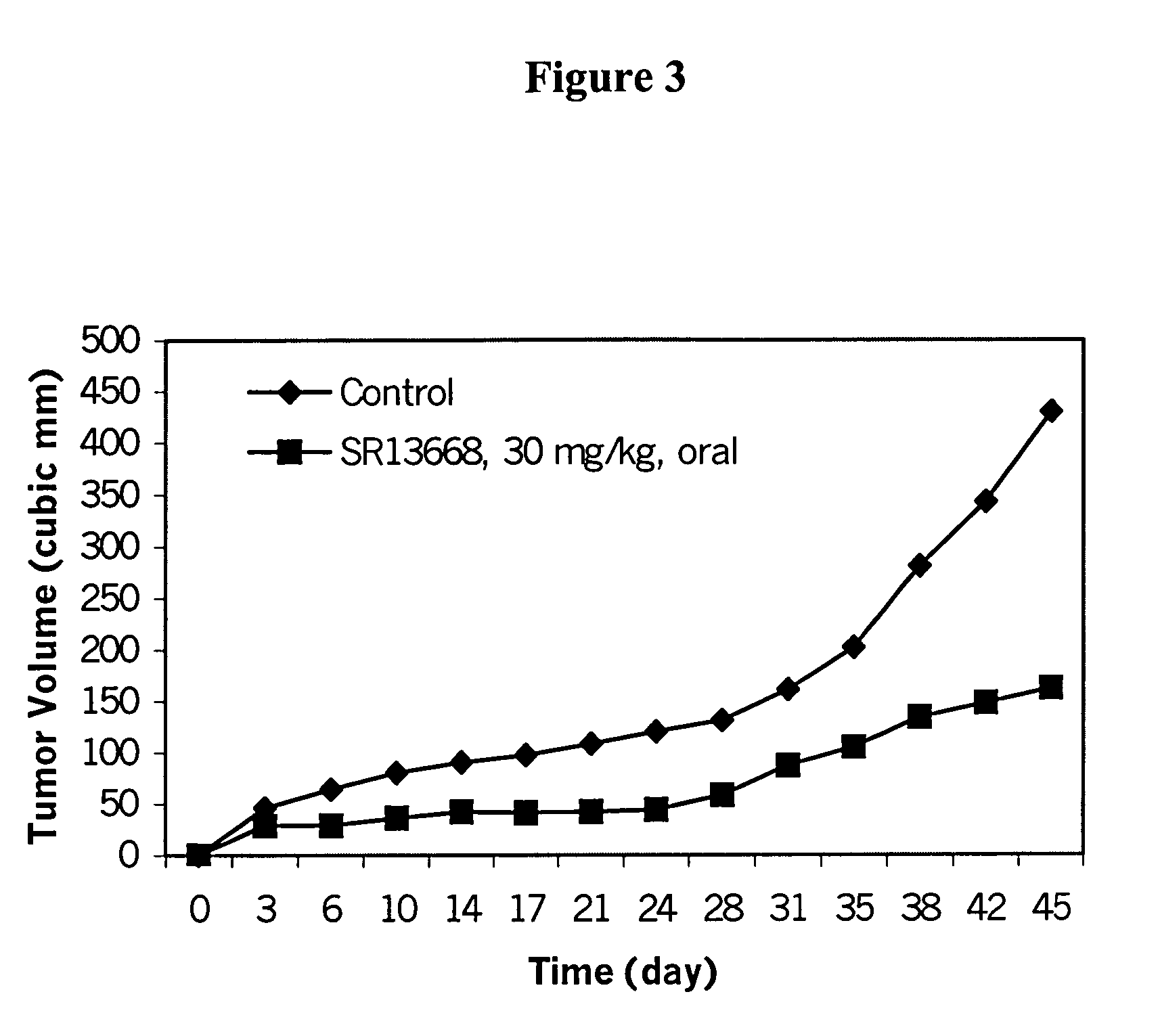

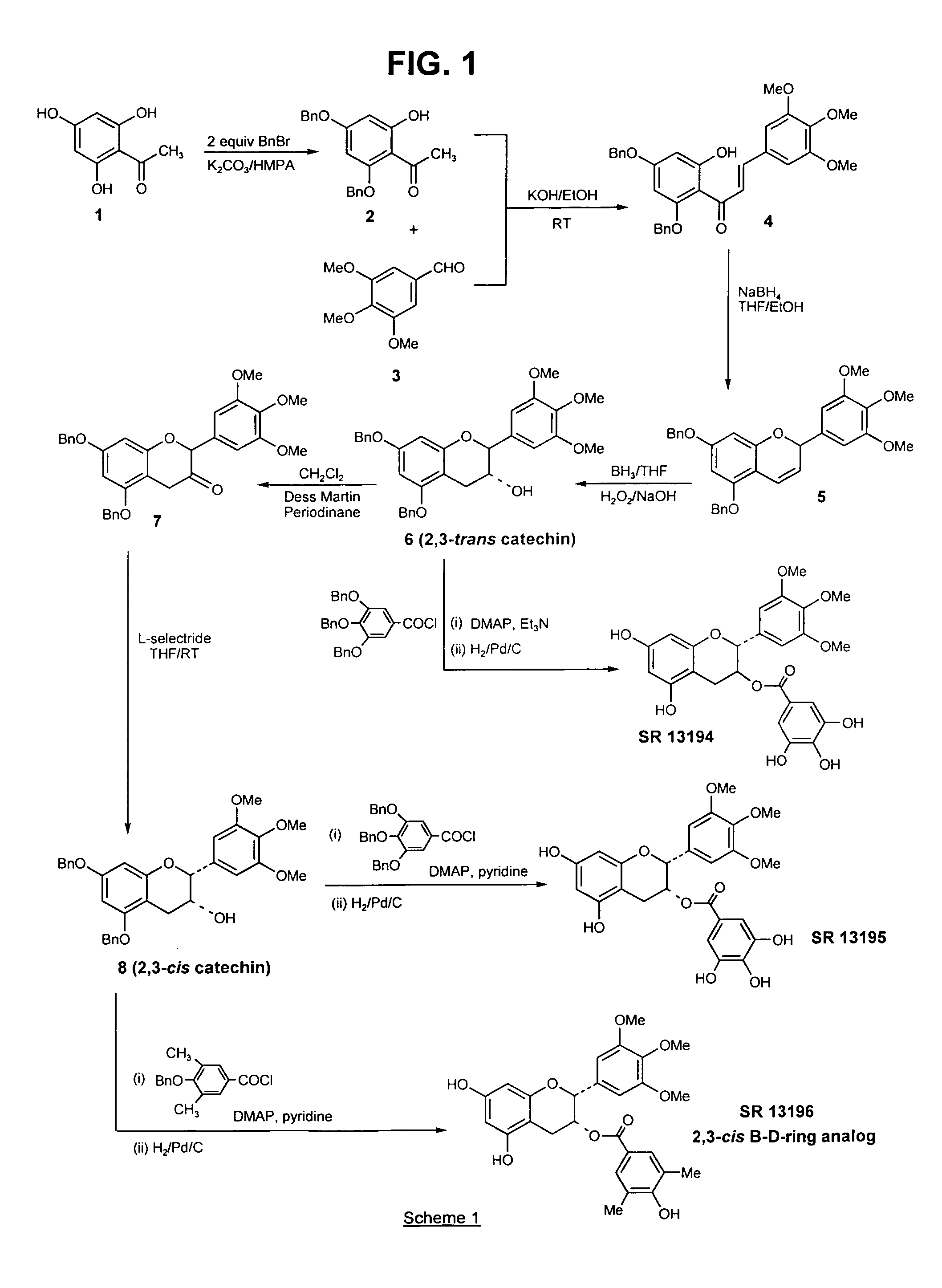

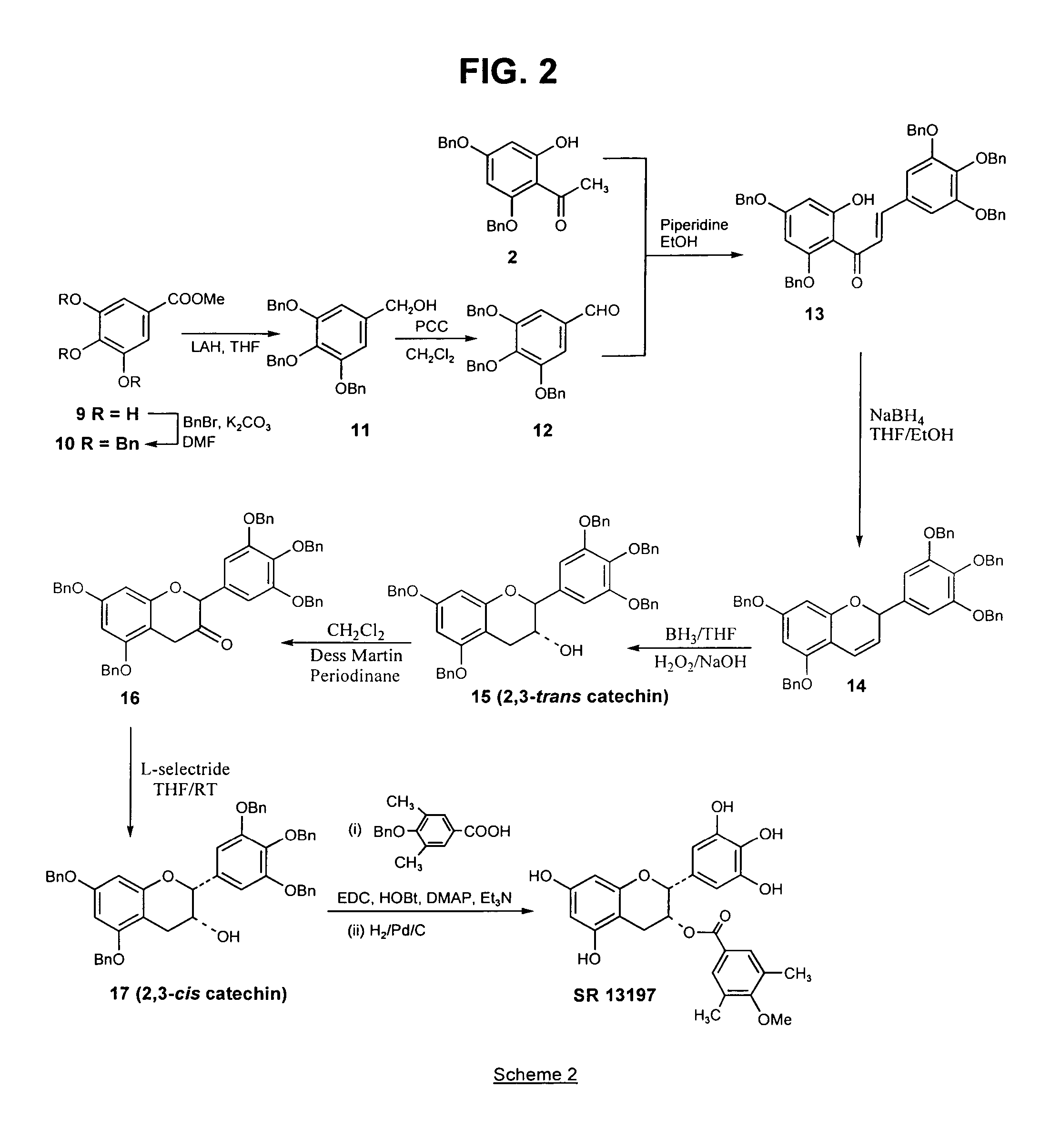

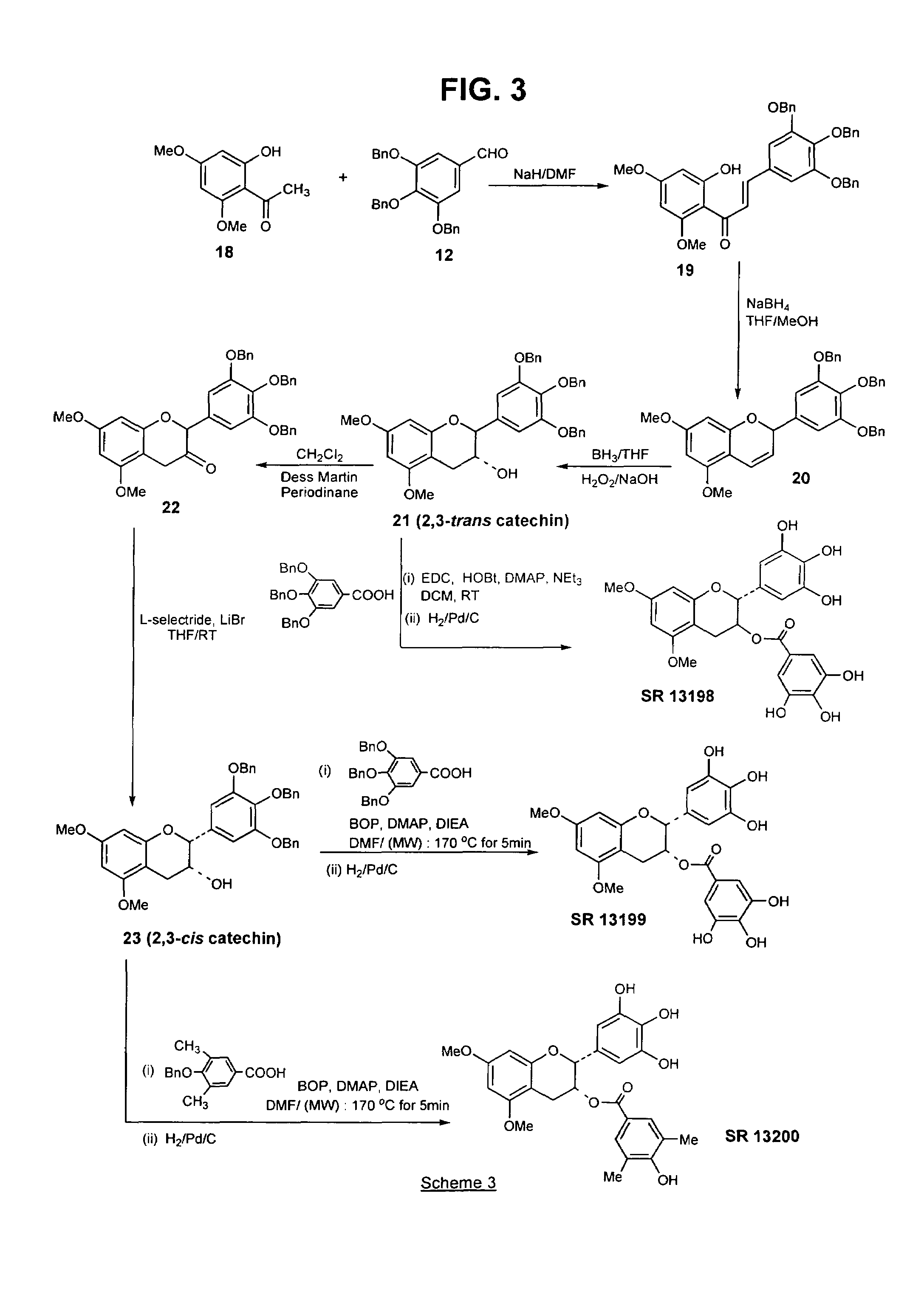

Analogs of green tea polyphenols as chemotherapeutic and chemopreventive agents

InactiveUS7109236B2Improve oral bioavailabilitySimple molecular structureBiocideOrganic chemistryGreen Tea PolyphenolsGallate

Novel compounds useful as chemotherapeutic and chemopreventive agents are provided. The compounds are analogs of polyphenol catechins that occur in green tea, such as epigallocatichin-3-gallate (EGCG), and have the structure of formula (I)wherein R1 through R11 are defined herein. Preferred R4 moieties are selected from O, S, NH and CH2, and in exemplary compounds, R4 is O and R5 is a tri-substituted aroyloxy substituent, such as a 3,4,5-substituted benzoyloxy group. Pharmaceutical compositions are provided as well, as are methods of chemotherapy and chemoprevention.

Owner:SRI INTERNATIONAL

Fluorine-substituted organic micro-molecular hole-transport material and application thereof

InactiveCN108467402AIncrease energy levelGood hole transport propertiesOrganic chemistrySolid-state devicesSolubilityBenzene

The invention discloses a fluorine-substituted organic micro-molecular hole-transport material and an application thereof. The material provided by the invention has a simple molecular structure, wherein benzodithiophene and derivatives thereof are used as a central core; different heterocycle-containing units are introduced to capping groups; and the central core and the capping groups are linkedby different fluorine-substituted phenyl groups. The material provided by the invention has the advantages of simple synthesis steps, easiness in purification, good solubility in an organic solvent,proper molecular energy levels, high hole mobility and electrical conductivity, and good hydrophobicity, is applied to perovskite solar cells with good stability and high short-circuit current densityand energy conversion efficiency, and has extensive application prospects.

Owner:TAIYUAN UNIV OF TECH

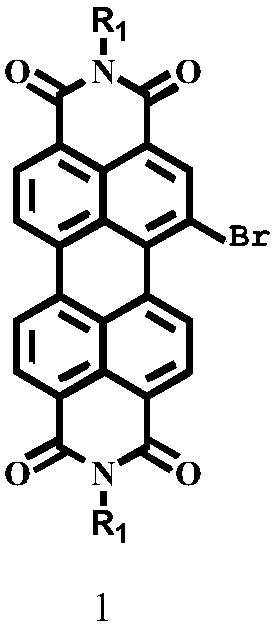

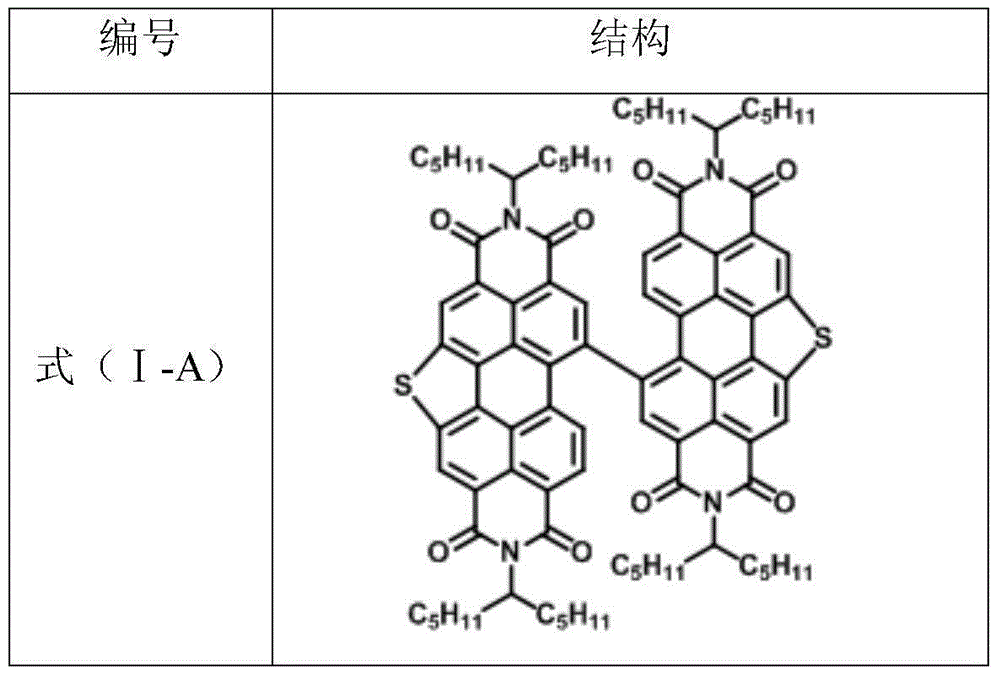

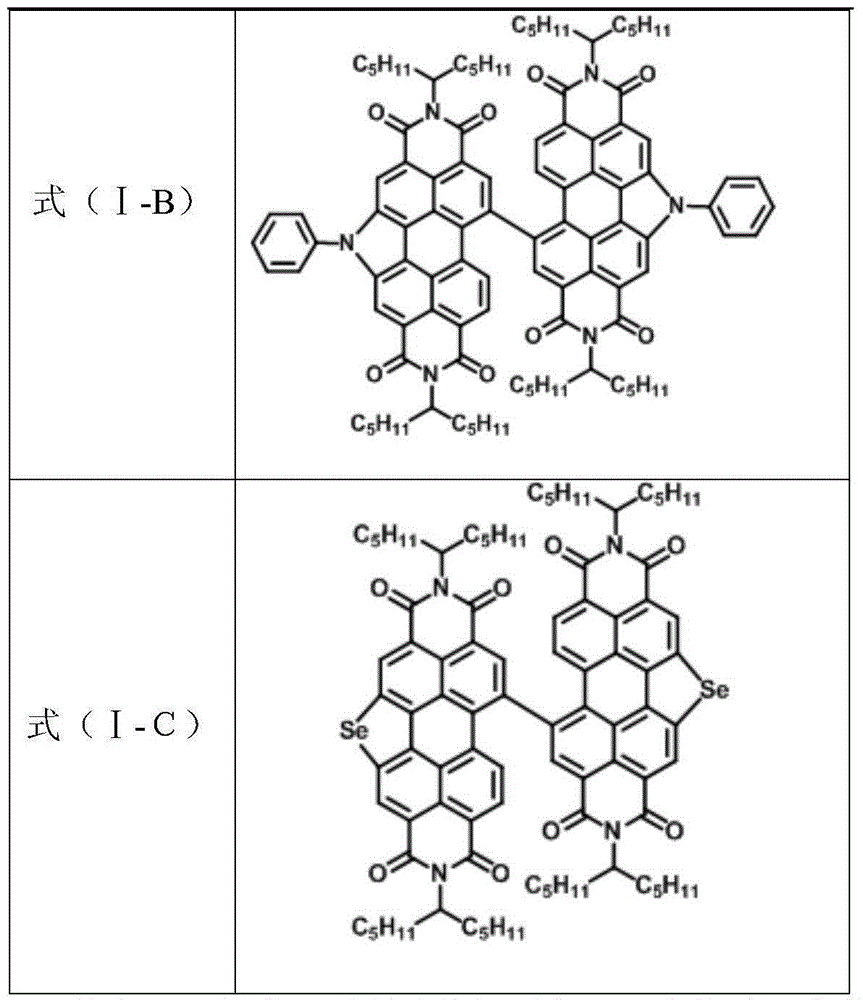

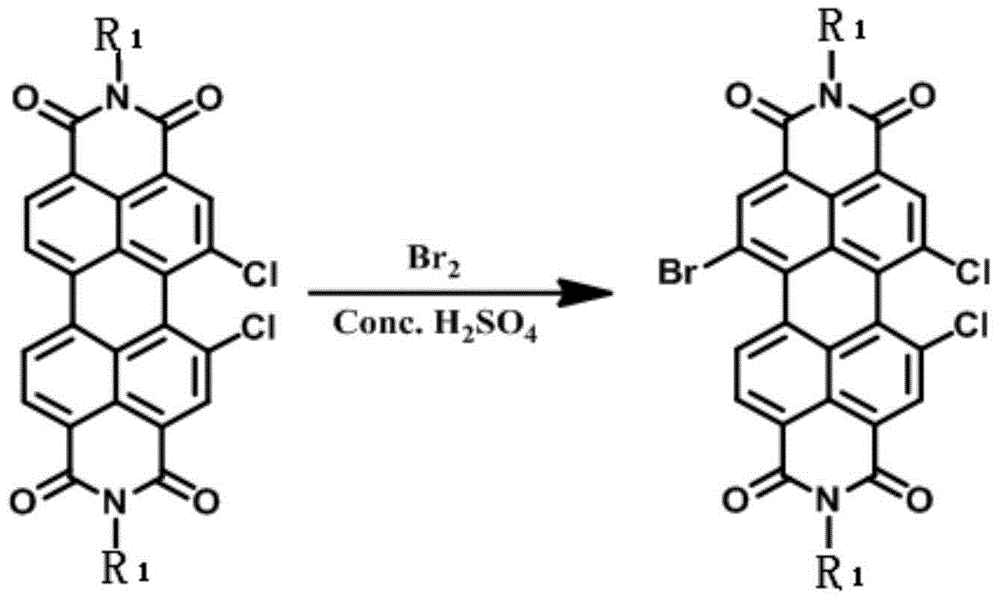

Novel heterocycle perylene imide dimer compound as well as preparation method and application thereof

InactiveCN105037400AImprove photoelectric conversion efficiencyReasonable design ideasOrganic chemistrySolid-state devicesSingle bondSolid-state

The invention provides a novel heterocycle perylene imide dimer compound with the structure shown in a formula (I) and a preparation method thereof as well as an application of the perylene imide dimer as an electron acceptor in an organic photovoltaic material. The compound shown in the formula (I) has the advantages that the problem that molecules aggregate owing to a very large acting force among the molecules when the traditional perylene imide molecules are in a solid state is solved, and heteroatoms are introduced at four positions, namely 6, 7, 6' and 7', of perylene diimide dimer in a single bond chain, so that close packing among the molecules can be effectively prevented, the crystallinity of a material is inhibited, the amorphous form performance is improved, the open-circuit voltage and light absorption efficiency are improved, and the photoelectric conversion efficiency is high.

Owner:INST OF CHEM CHINESE ACAD OF SCI

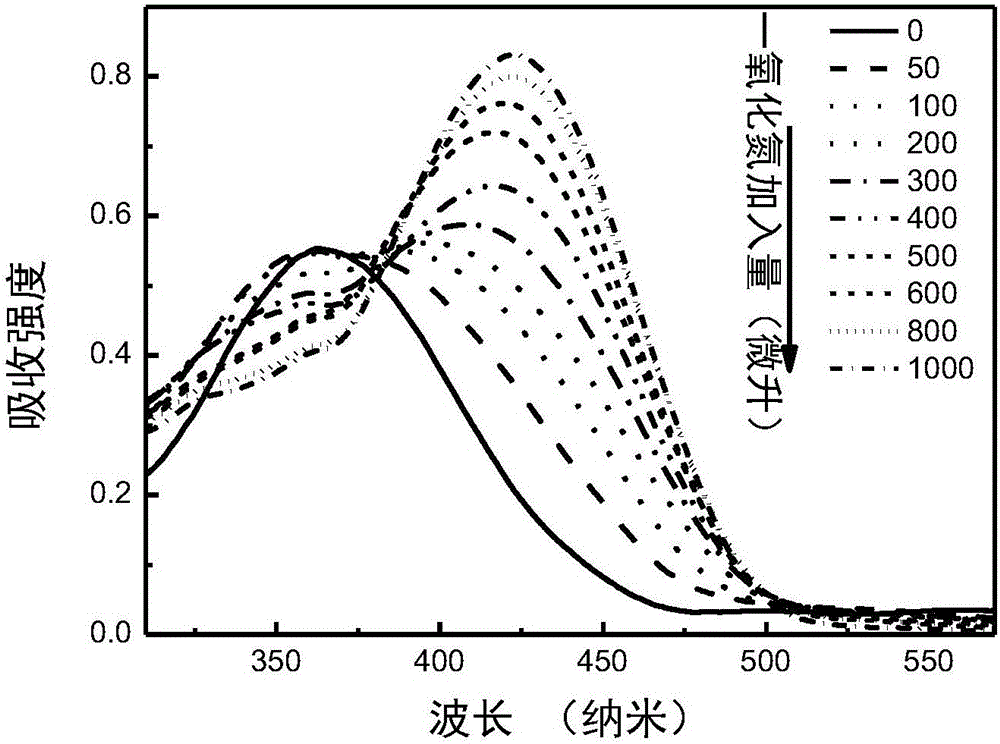

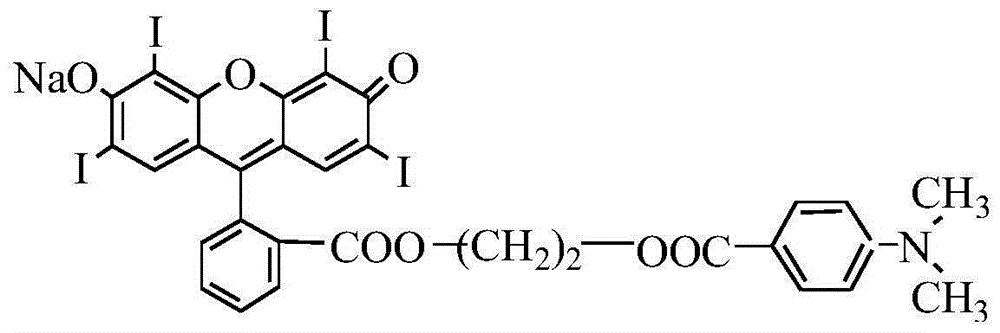

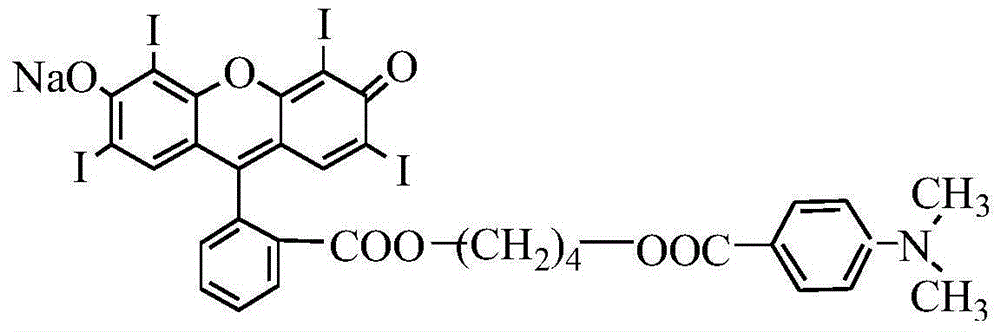

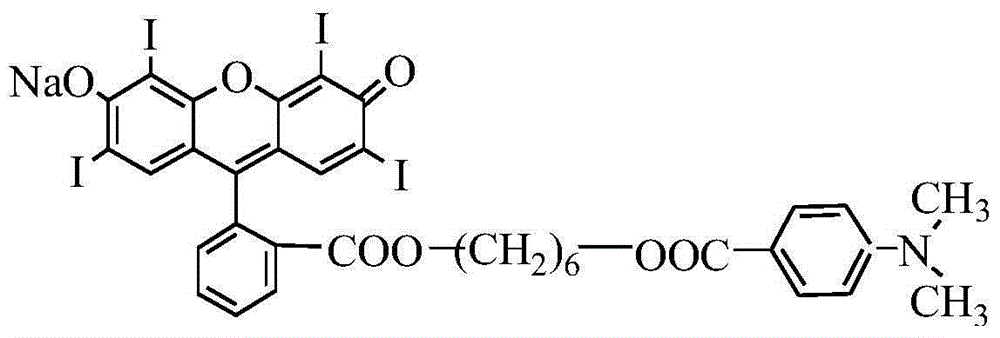

Visible light initiating system capable of initiating free radical/cation polymerization

InactiveCN105218708AEfficient visible light absorption performanceImprove initiation performanceMaterial heat developmentPhosphonium saltFatty amine

The invention belongs to the technical field of visible light curing, and particularly relates to a visible light initiating system capable of initiating free radical / cation polymerization. The system comprises the following components in parts by weight: 0.5-1 part of an integral photosensitizer as a first component, 0.5-1 part of a coinitiator as a second component and 1-3 parts of a photosensitive synergist as a third component, wherein the formula of the integral photosensitizer is shown in the description; the coinitiator is one of fatty amine and aromatic amine derivative; the photosensitive synergist is one of iodonium salt, sulfonium salt and phosphonium salt. Compared with the common reported visible light initiating system, the visible light initiating system has the advantages that the light sensitive wave band is longer, the light absorption capability is stronger, the molecular structure is simple, the preparation is easy, the cost is low, and the visible light initiating system has good compatibility with hydrophobic light-cured resin, can effectively initiate free radical / cation photopolymerization, and has industrialized application potential.

Owner:ZHEJIANG SCI-TECH UNIV

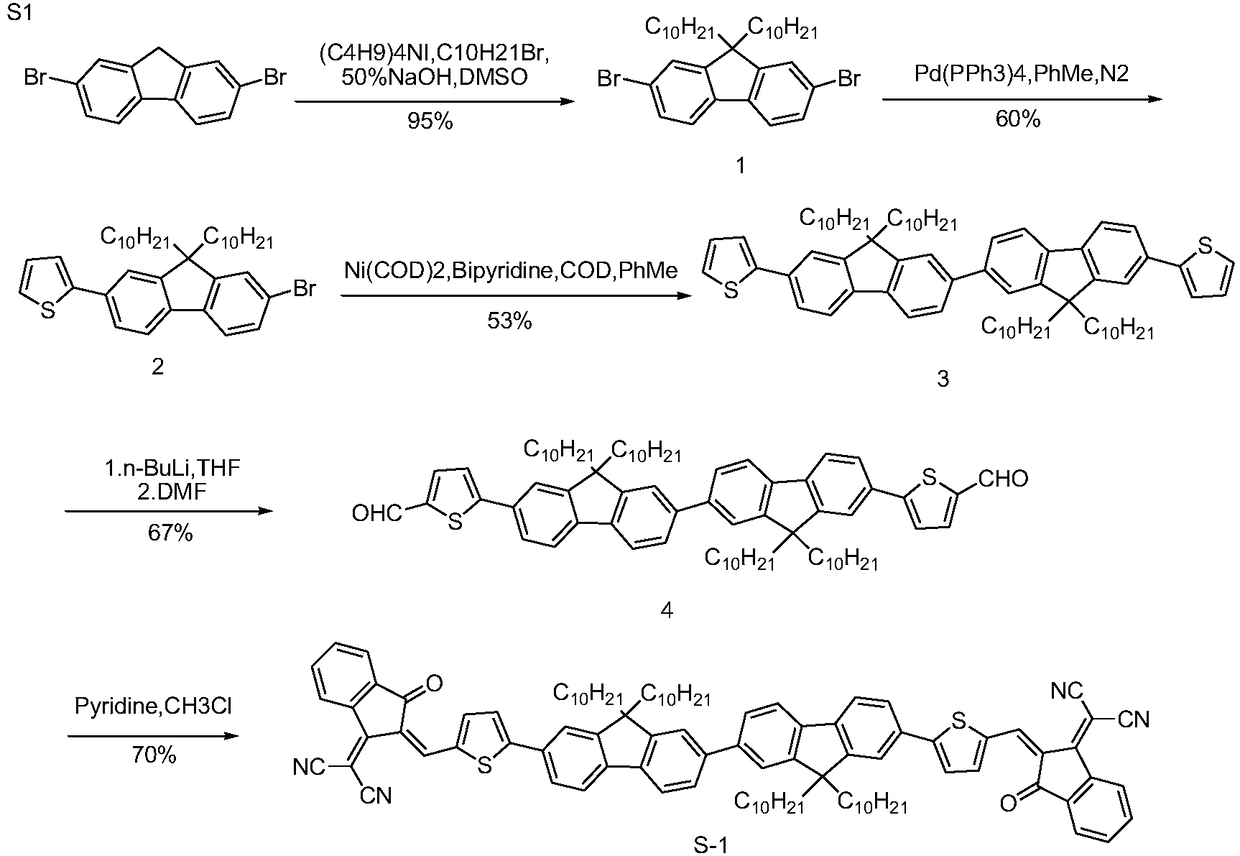

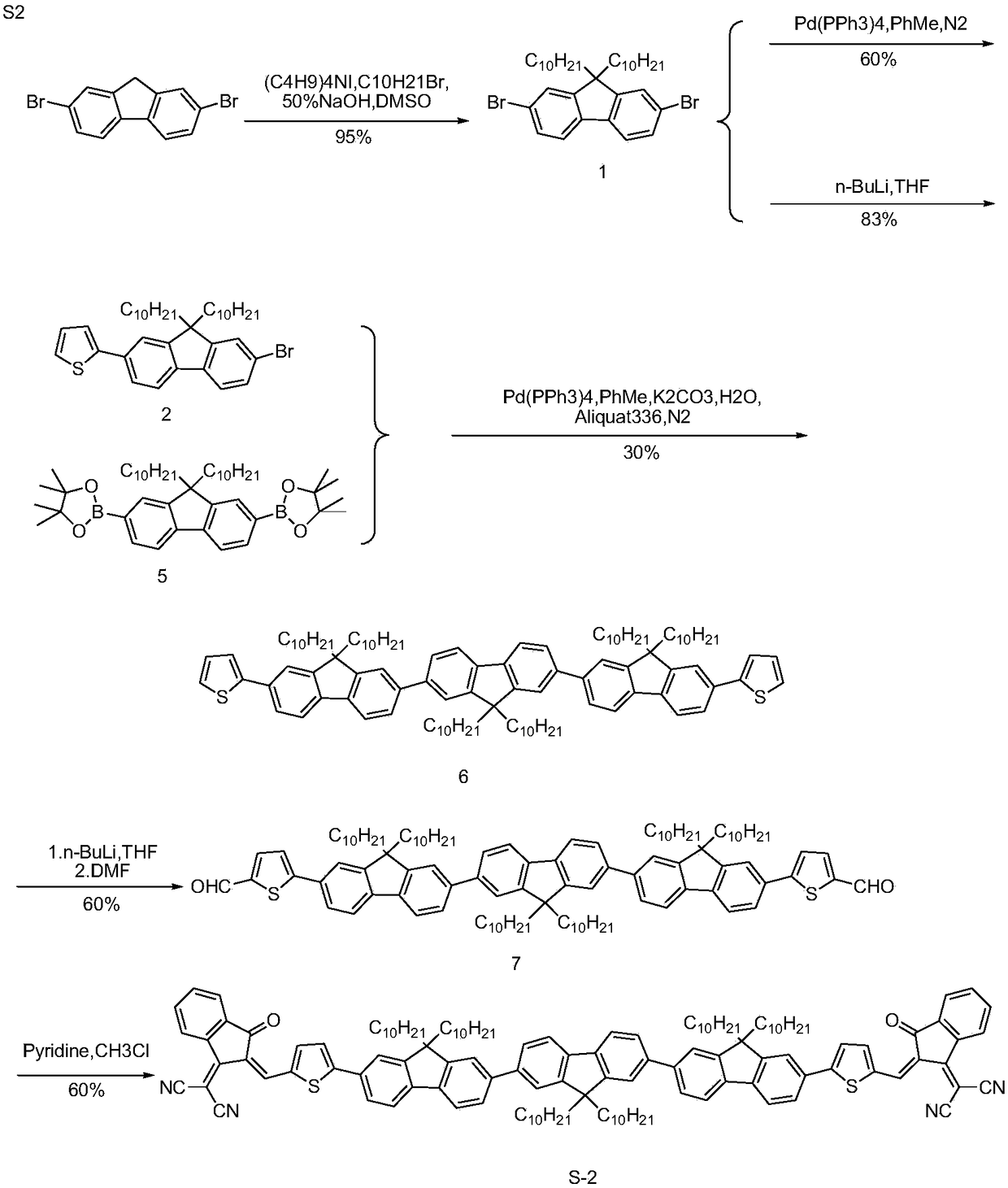

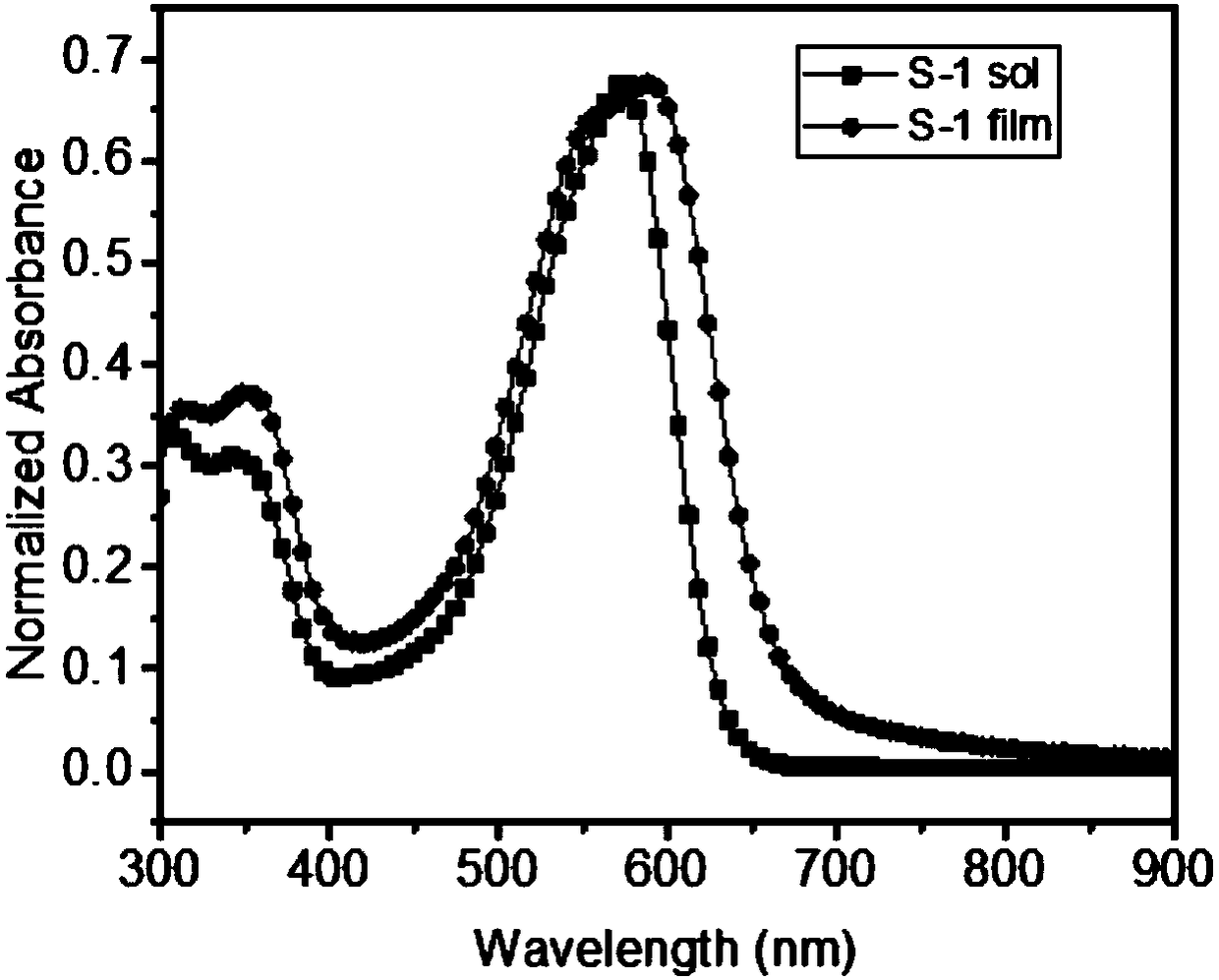

Novel fluorine organic solar battery acceptor material as well as preparation method and application thereof

InactiveCN108129447ASimple molecular structureSmall molecular weightOrganic chemistryFinal product manufactureChemistryHigh absorption

The invention belongs to the technical field of organic solar battery materials and in particular relates to a novel fluorine organic solar battery acceptor material as well as a preparation method and application thereof. Aiming at the defects that a conventional non-fullerene micromolecule acceptor material is complex in molecule structure, relatively large in molecular weight, hard in preparation process, expensive in synthesis raw material, not beneficial to commercial application, and the like, the invention provides the novel fluorine organic solar battery acceptor material, a fluorine organic solar battery acceptor material S-1 and a fluorine organic solar battery acceptor material S-2 are of simple linear structures, are simple in molecular structure, small in molecular weight, small and simple in preparation step, cheap and easy in synthesis raw material obtaining, wide in visible light absorption range and high in absorption strength; when the fluorine organic solar battery acceptor materials are applied to an organic solar battery photovoltaic device, the manufacturing cost of the device is greatly reduced on the basis that a wide absorption range and high absorption strength of the device are ensured, and soon commercial application of an organic solar battery can be facilitated.

Owner:WUHAN UNIV OF TECH

Complete biodegradable starch-containing TPU (thermoplastic polyurethane) mulch and preparation method thereof

InactiveCN103571176AHigh strengthImprove toughnessCoatingsPlant protective coveringsMasterbatchAntioxidant

The invention discloses a complete biodegradable starch-containing TPU (thermoplastic polyurethane) mulch. The complete biodegradable starch-containing TPU mulch comprises the following components in parts by mass: 20-90 parts of TPU particles, 10-80 parts of starch, 0.05-20 parts of antioxidant, 0.05-3 parts of ultraviolet light absorber, 0-5 parts of modified nano auxiliary, 0-20 parts of environmental protection plasticizer, 0-3 parts of calcium stearate, 0-2 parts of stearic acid and 0-0.5 part of black colour masterbatch; the complete biodegradable starch-containing TPU mulch has high starch content, can be completely degraded and is strong in controllability. Besides, herbicide can be coated on one single face of the complete biodegradable starch-containing TPU mulch, and an effect of preventing insect pests can be realized.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

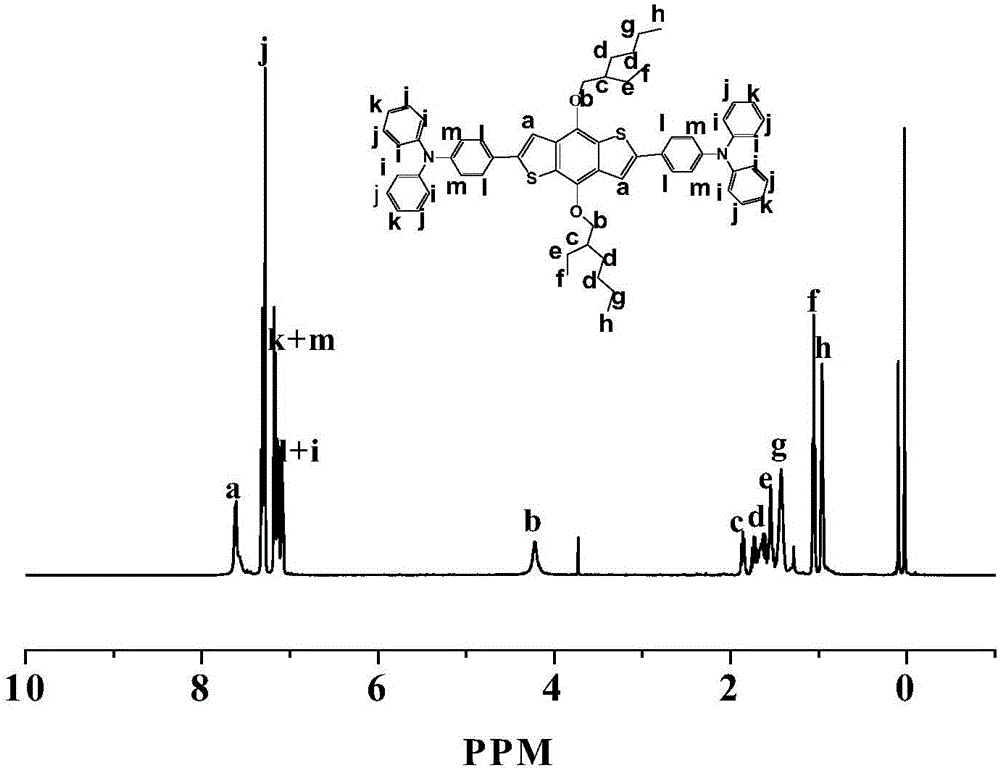

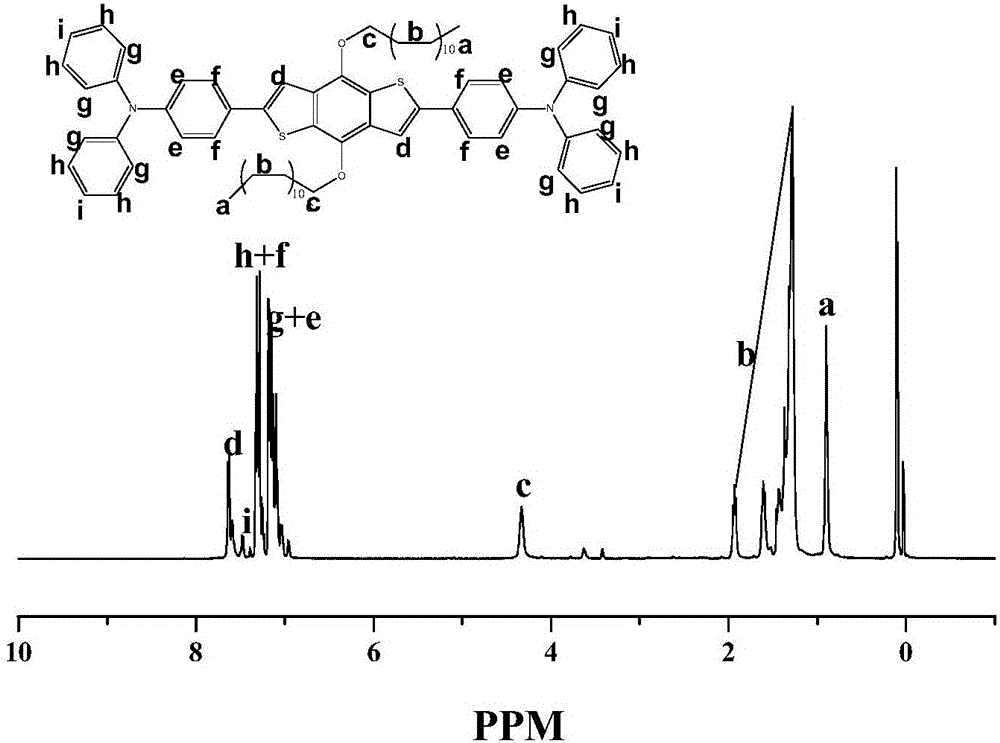

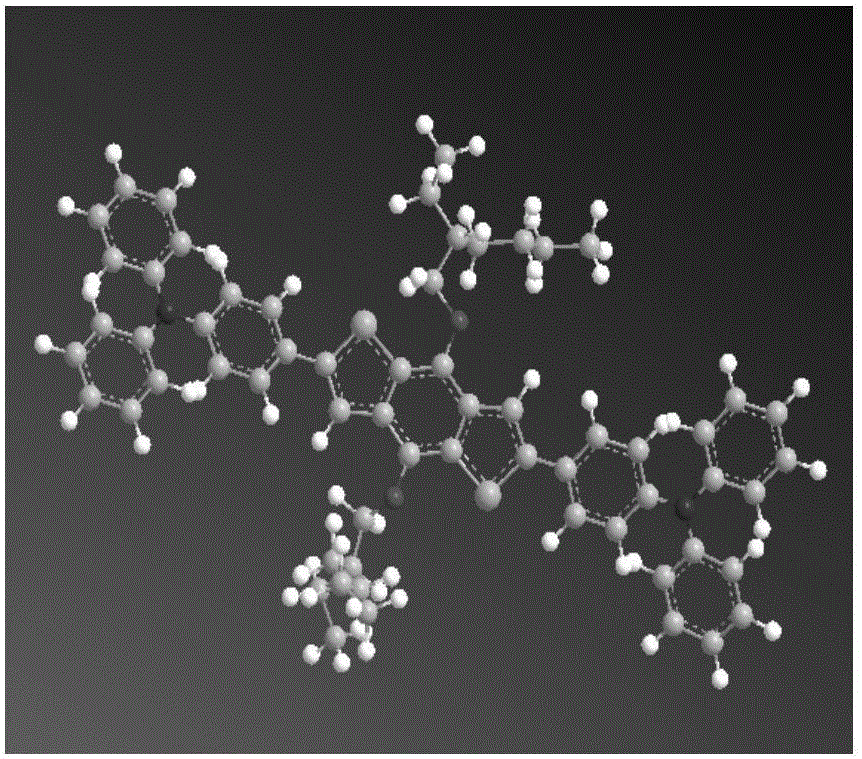

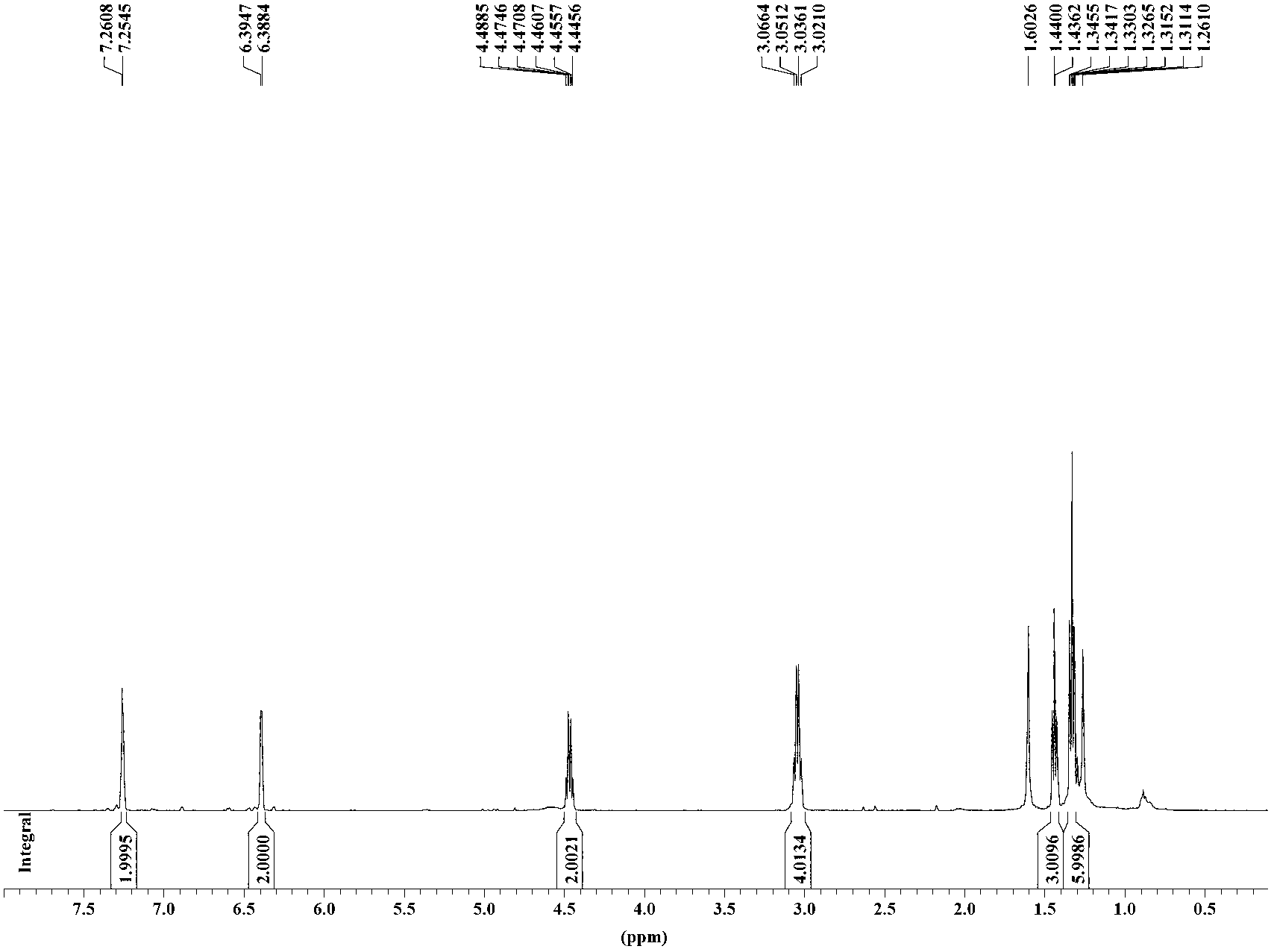

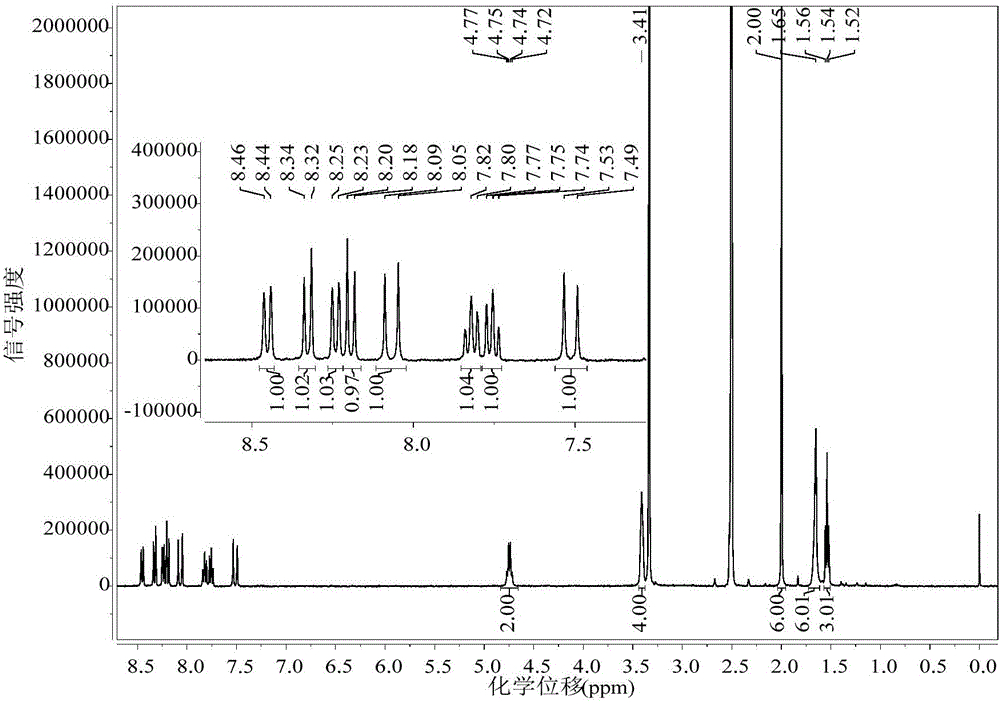

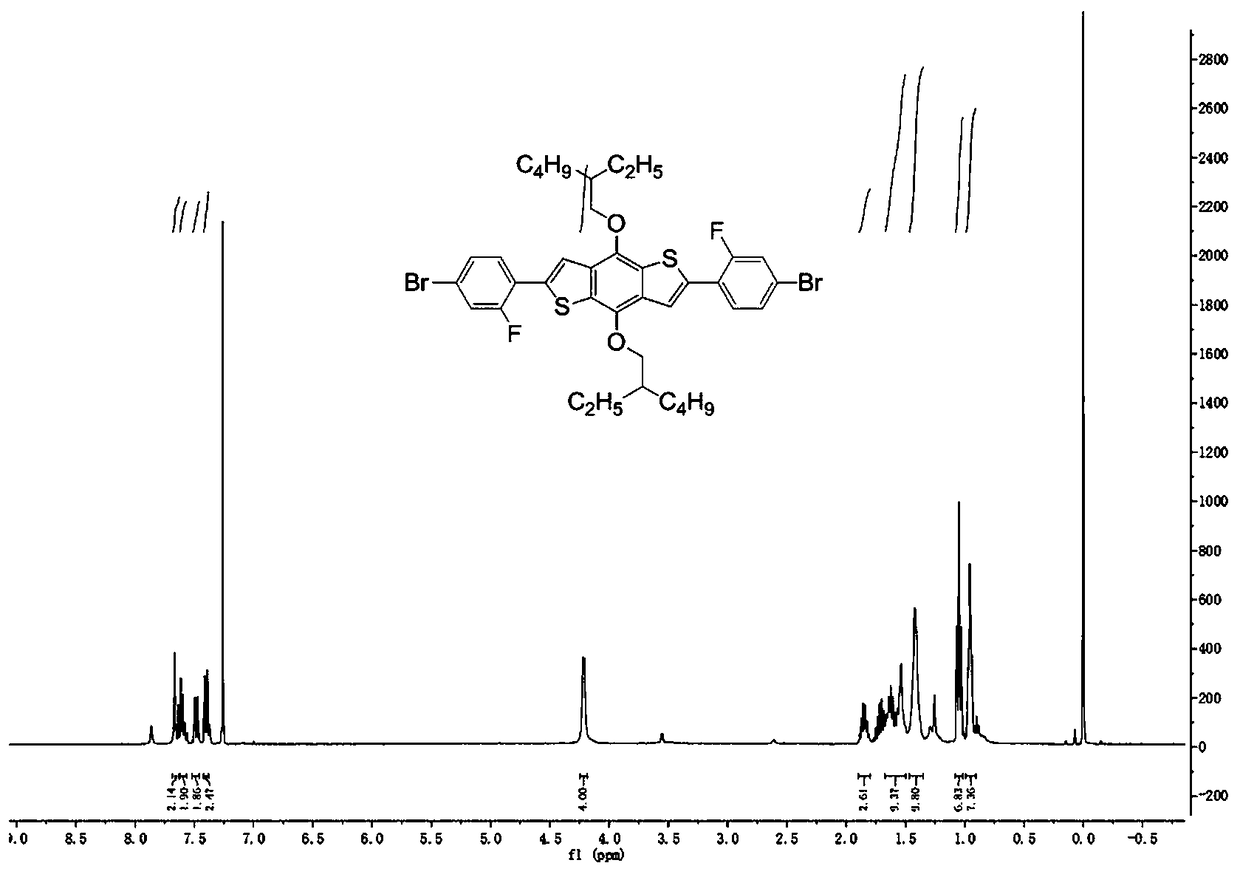

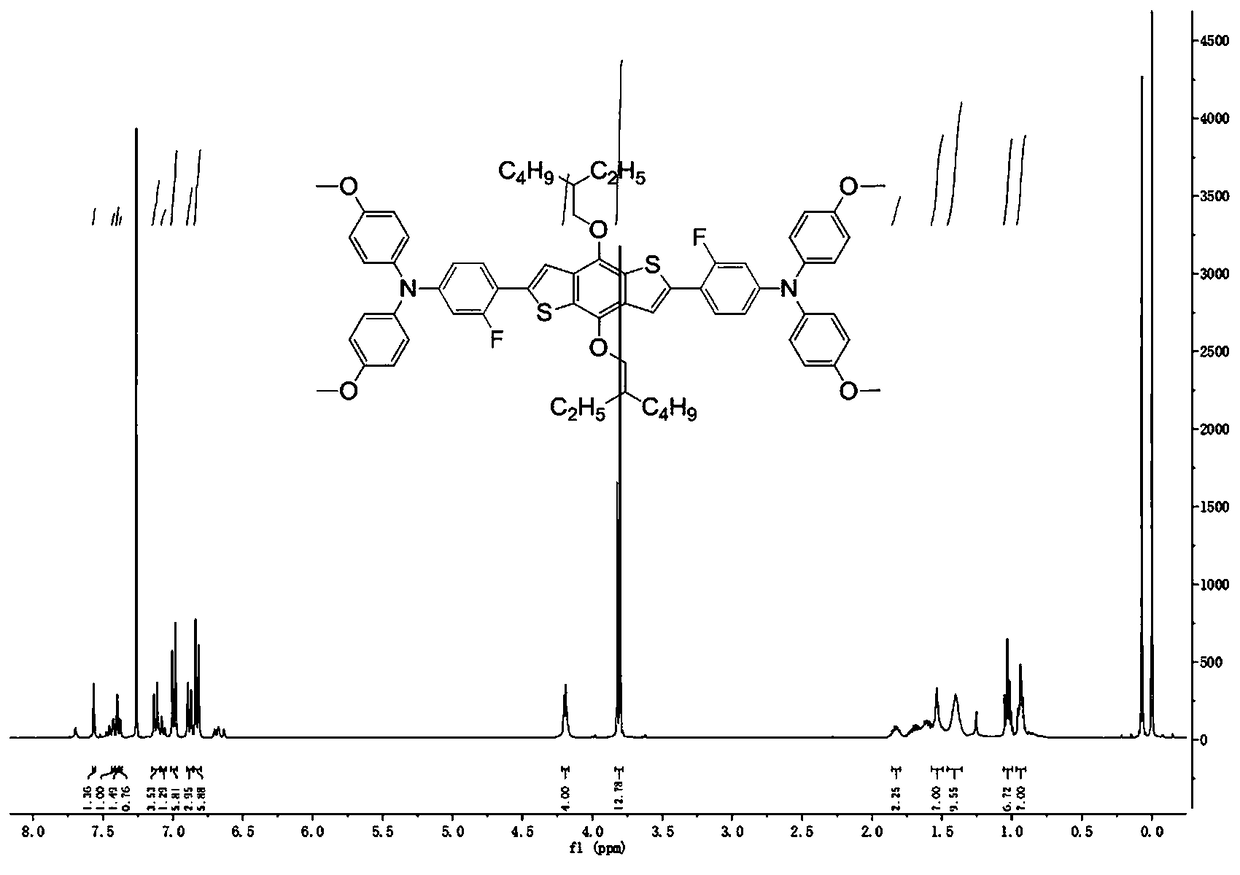

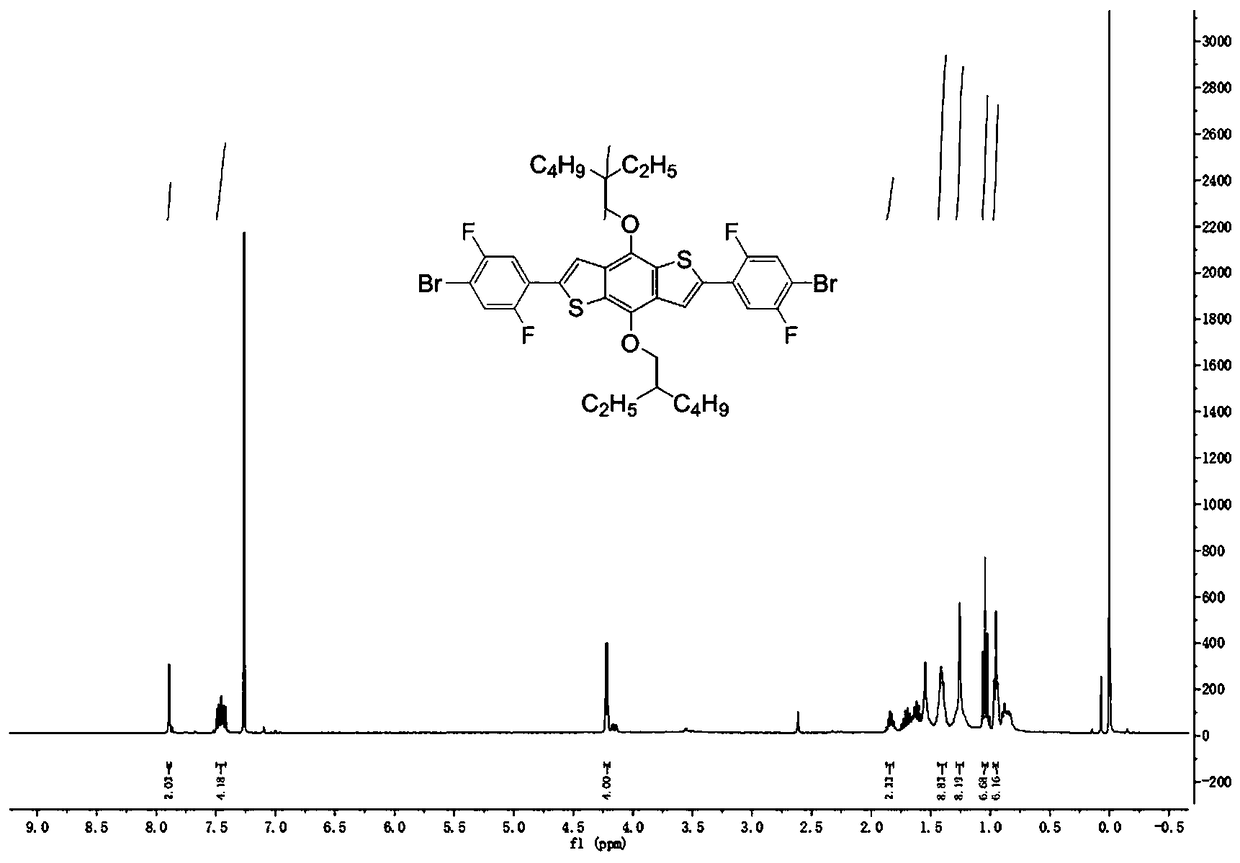

2,6-bis(triphenylamine)-4,8-bis(alkoxy)benzo[1,2-b:4,5-b']bithiophene and preparation for same

InactiveCN105968124ASimple molecular structureAchieving hole mobility coordinationOrganic chemistrySolid-state devicesPerovskite solar cellElectrical battery

The invention discloses a hole transport material 2,6-bis(triphenylamine)-4,8-bis(alkoxy)benzo[1,2-b:4,5-b']bithiophene for a perovskite solar cell. The hole transport material has a simple molecular structure, a lateral group to which an aromatic functional group can be introduced, high hole mobility, high efficiency, high electrical conductivity and high dissolubility, and the perovskite solar cell prepared from the hole transport material can be matched with a perovskite energy level. The invention also discloses a preparation method for the hole transport material. The hole transport material for the perovskite solar cell is prepared by an SUZUKI reaction step from raw materials 2,6-dibromo-4,8-bis(alkoxy)benzo[1,2-b:4,5-b']dithiophene and 4-(diphenylamino)phenylboronicacid. The preparation method has the characteristics of simplicity in operation, readily available raw materials, easiness for separation and high yield.

Owner:EAST CHINA NORMAL UNIVERSITY

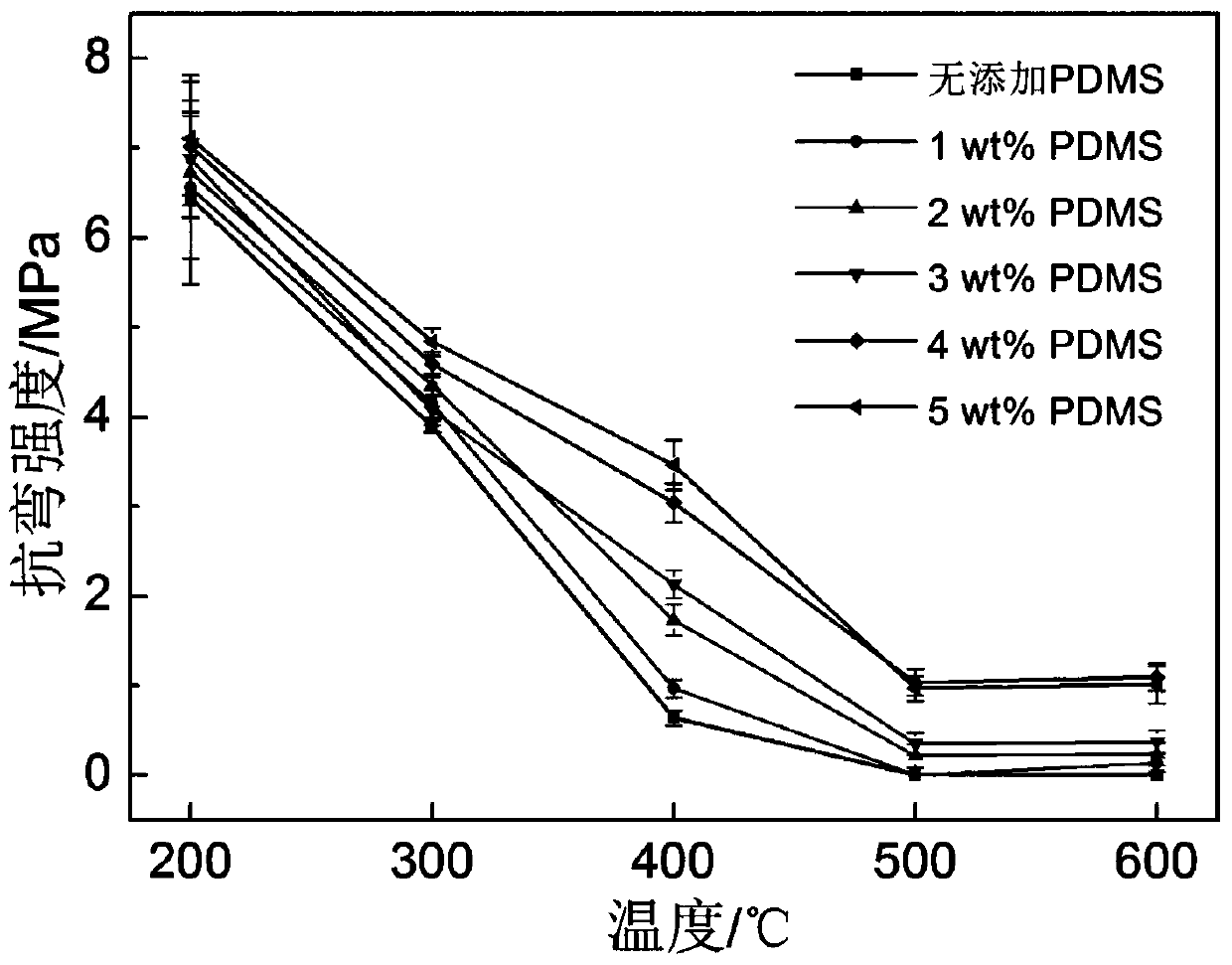

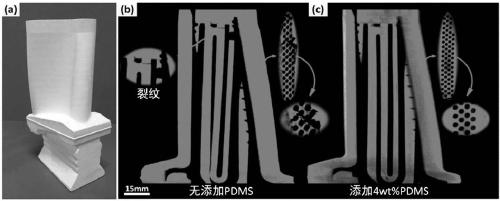

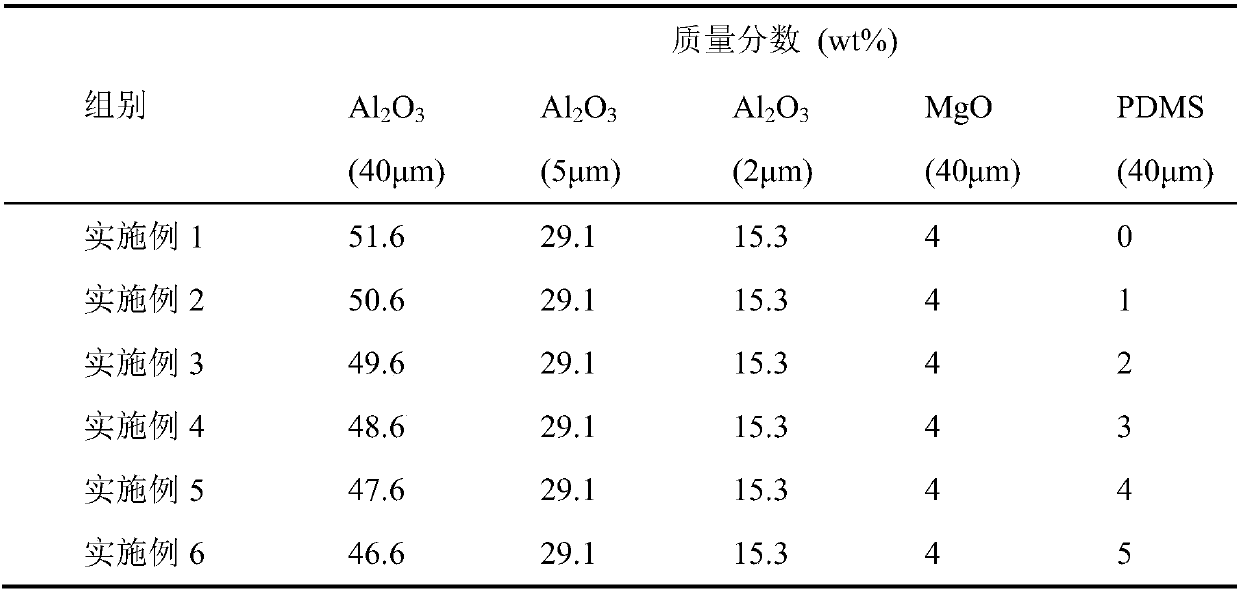

Method for improving degreasing strength of additive manufacturing formed ceramic part

InactiveCN109534794AImprove degreasing strengthSufficient strength marginUltrasound attenuationPrill

The invention discloses a method for improving the degreasing strength of an additive manufacturing formed ceramic part. The method comprises the following steps that polydimethylsiloxane is added into a ceramic powder material, and required raw material powder is obtained after even dispersing; the powder material and a liquid phase solvent are mixed, and ceramic slurry is prepared after even ball-milling; a ceramic part blank is formed through an additive manufacturing method, and after the blank is dried, degreasing and glue discharging are conducted; and in the degreasing heating process,the polydimethylsiloxane is softened and molten to permeate into adjacent ceramic particle gaps, and ceramic particles are wrapped. The polydimethylsiloxane is simple in molecular structure, low in carbon content and low in pyrolysis ignition lost rate, thus the wrapping bonding effect on the ceramic particles is small along with thermal attenuation of the temperature, the degreasing strength of the part can be established, and it is ensured that the blank has the sufficient strength margin to resist damage of gravity and thermal stress in a degreasing technology. The method can be used for improving the degreasing strength of the additive manufacturing ceramic part, and is especially suitable for additive manufacturing forming of ceramic parts of complex structures.

Owner:XI AN JIAOTONG UNIV

Analogs of indole-3-carbinol metabolites as chemotherapeutic and chemopreventive agents

InactiveUS7078427B2Improve oral bioavailabilityBroad therapeutic windowBiocideOrganic chemistryMetaboliteTolerability

Novel compounds useful as chemotherapeutic and chemopreventive agents are provided. The compounds are analogs of indole-3-carbinol metabolites wherein the structures and substituents of the compounds are selected to enhance the compounds' overall efficacy, particularly with respect to therapeutic activity, oral bioavailability, long-term safety, patient tolerability, and therapeutic window. The compounds are useful not only in treatment of cancer but also in prevention of cancer. One preferred class of the novel compounds have the structure of formula (I)wherein R1, R2, R3, R4, R5, R6, R7, R8, R9, R10, R11, and R12 are defined herein. Pharmaceutical compositions are provided as well, as are methods of synthesis and use.

Owner:SRI INTERNATIONAL

Hole transporting material for perovskite solar cell and application thereof

InactiveCN105968125ASimple molecular structureAchieving hole mobility coordinationOrganic chemistrySolid-state devicesPerovskite solar cellSolubility

The invention discloses a hole transporting material 2,6-bistriphenylamine-4,8-bis(alkoxy)benzo[1,2-B:4,5-B']dithiophene for a perovskite solar cell. The hole transporting material has simple molecular structures, high hole mobility, high efficiency, high conductivity and good solubility; aromatic functional radicals can be introduced into lateral groups; the perovskite solar cell prepared from the hole transporting material can be matched with the energy level of perovskite. The invention also discloses a preparation method of the hole transporting material. The hole transporting material for the perovskite solar cell is prepared and obtained by using 2,6-dibromo-4,8-bis(alkoxy)benzo[1,2-B:4,5-B']dithiophene and 4-(Diphenylamino)phenylboronicacid as raw materials through a one-step SUZUKI reaction. The preparation method provided by the invention has the characteristics that the operation is simple, the raw materials are low-cost and easily obtained, the separation is easy, and the yield is high.

Owner:EAST CHINA NORMAL UNIVERSITY +1

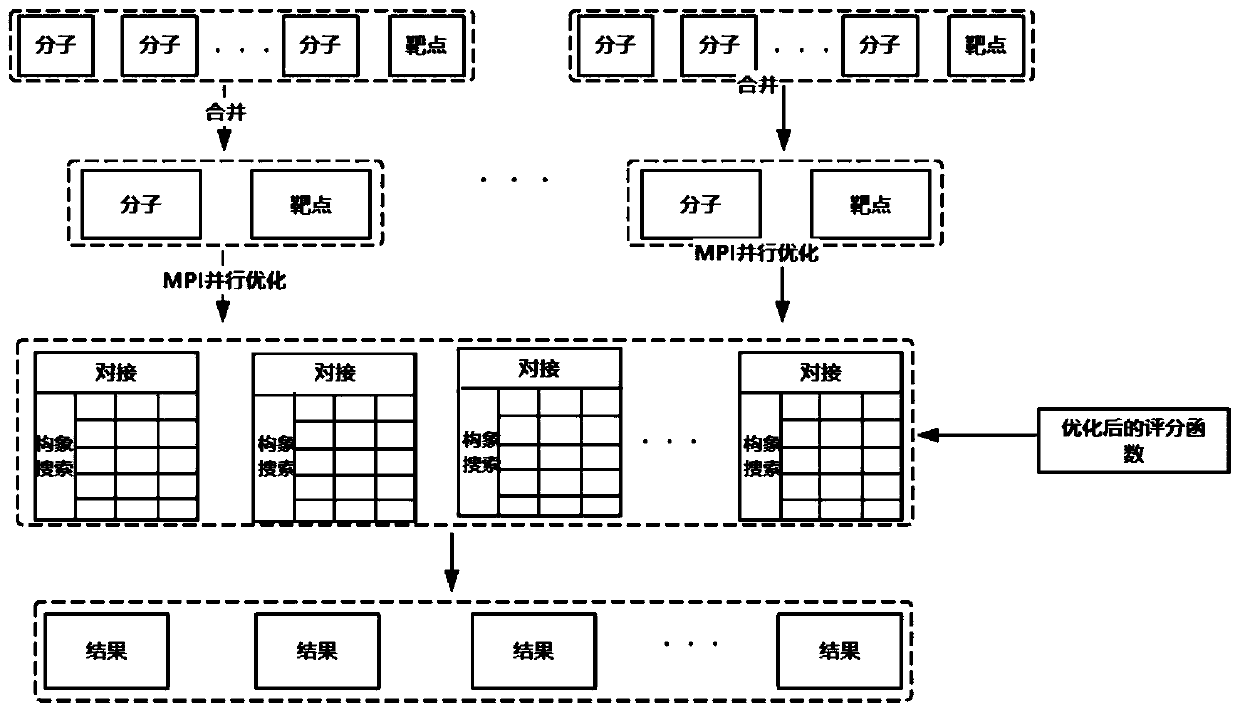

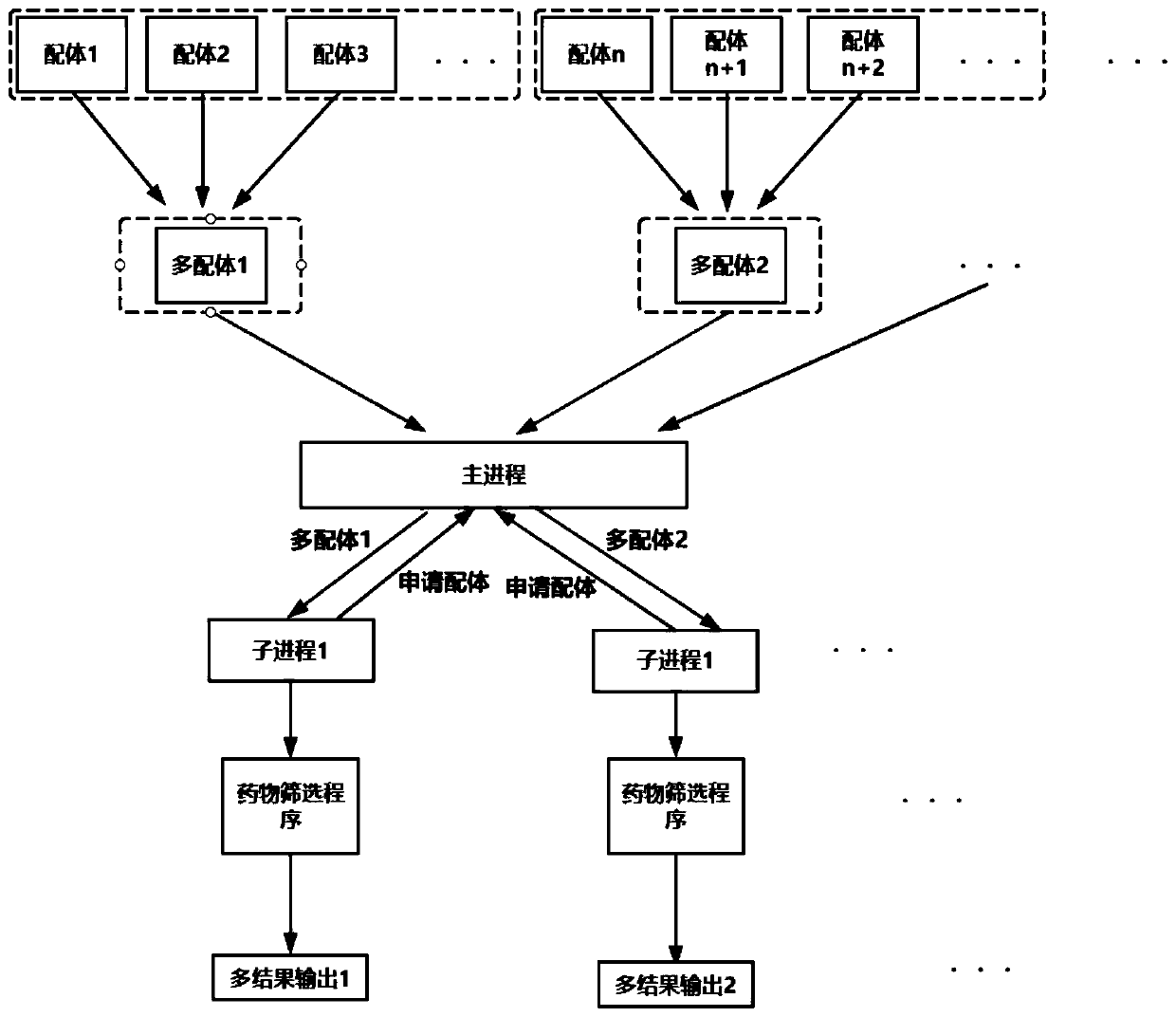

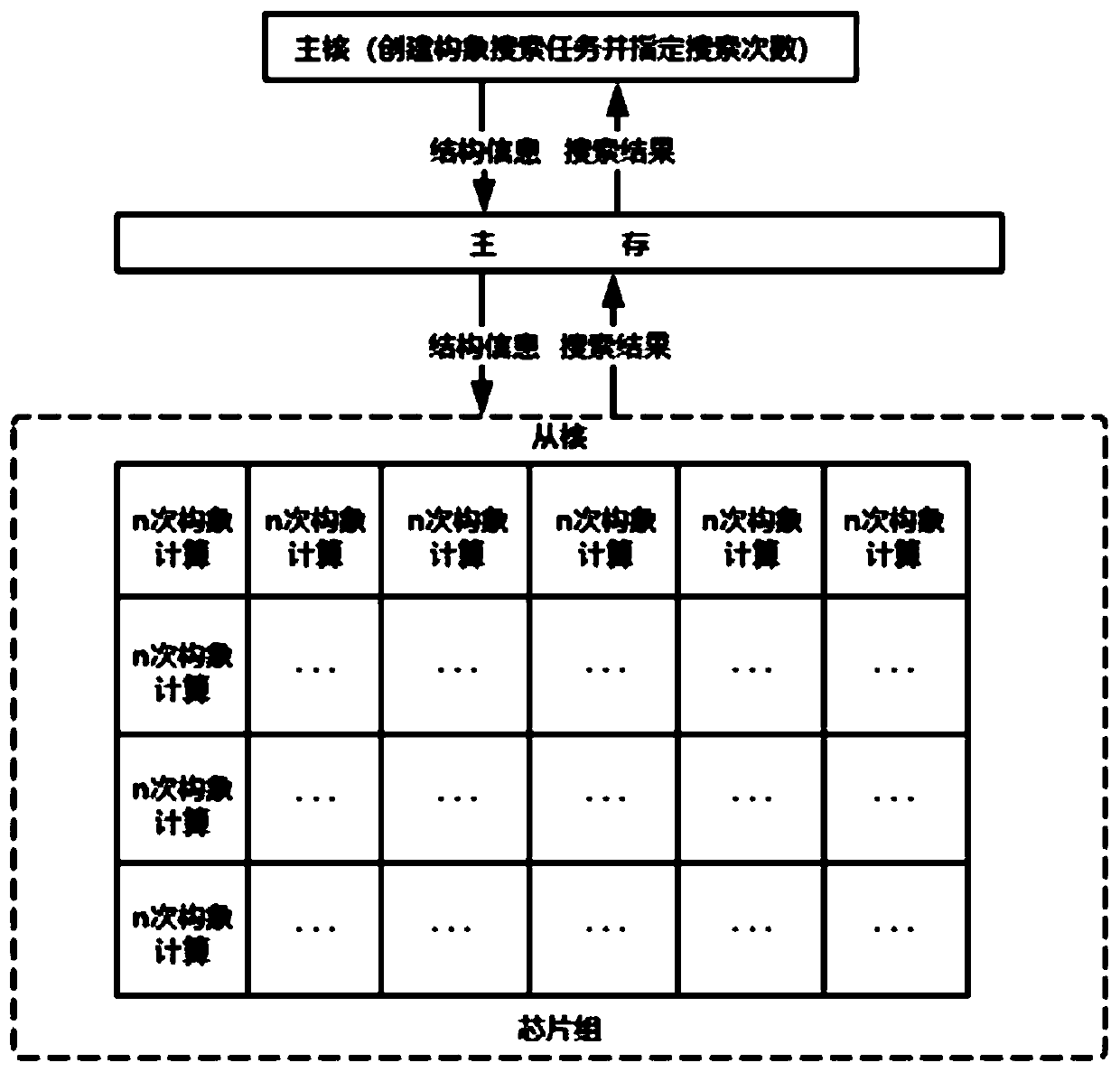

Parallel marine drug screening method based on heterogeneous many-core architecture

ActiveCN111243660AReduce search timeFast dockingInstrumentsMolecular structuresPharmaceutical drugEnvironmental engineering

The invention relates to a parallel marine drug screening method based on a heterogeneous many-core architecture, and belongs to the technical field of drug screening, and the method comprises the steps of constructing a high-performance computing architecture of heterogeneous many cores, inputting, outputting and parallelizing a drug high-throughput screening program, scoring and optimizing a molecular structure. According to the method, the heterogeneous many-core high-performance computing architecture is utilized, so that drug screening is more efficient and accurate, and the finally screened molecular structure is simple and has a good effect on a target point.

Owner:OCEAN UNIV OF CHINA

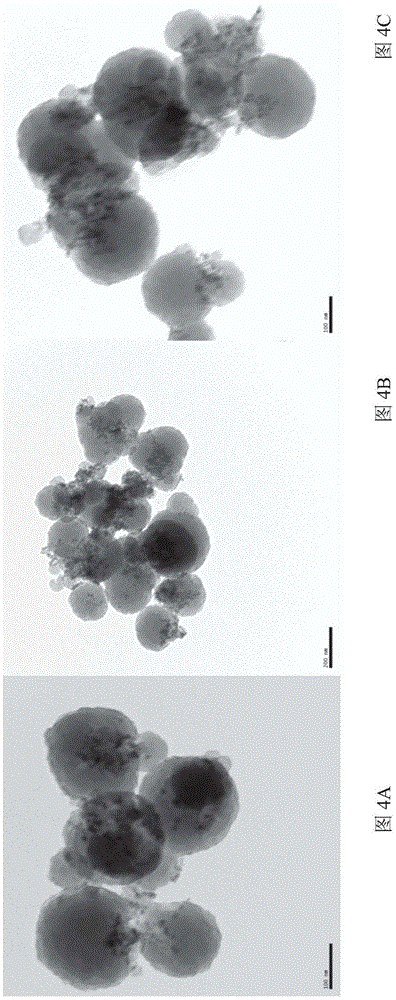

Catalyst for catalyzing oxidation of cyclohexane and preparation method of catalyst

InactiveCN104801344AImprove oxidation efficiencyEasy to recycleOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPropionatePtru catalyst

The invention provides a method for preparing a catalyst for catalyzing oxidation of cyclohexane. The method comprises steps as follows: (A), preparing 5 (p-propionate) phenyl-10,15,20-tri(pyridyl) porphyrin; (B), preparing 5(p-hydroxy) phenyl-10,15,20-tri(pyridyl) porphyrin from 5 (p-propionate) phenyl-10,15,20-tri(pyridyl) porphyrin; (C), preparing metallic coordinated 5-(p-hydroxy) phenyl-10,15,20-tri(pyridyl) porphyrin from 5 (p-hydroxy) phenyl-10,15,20-tri(pyridyl) porphyrin; (D), attaching the metallic coordinated 5-(p-hydroxy) phenyl-10,15,20-tri(pyridyl) porphyrin to at least one magnetic microsphere, and methylating 5-(p-hydroxy) phenyl-10,15,20-tri(pyridyl) porphyrin by the aid of methyl iodide.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

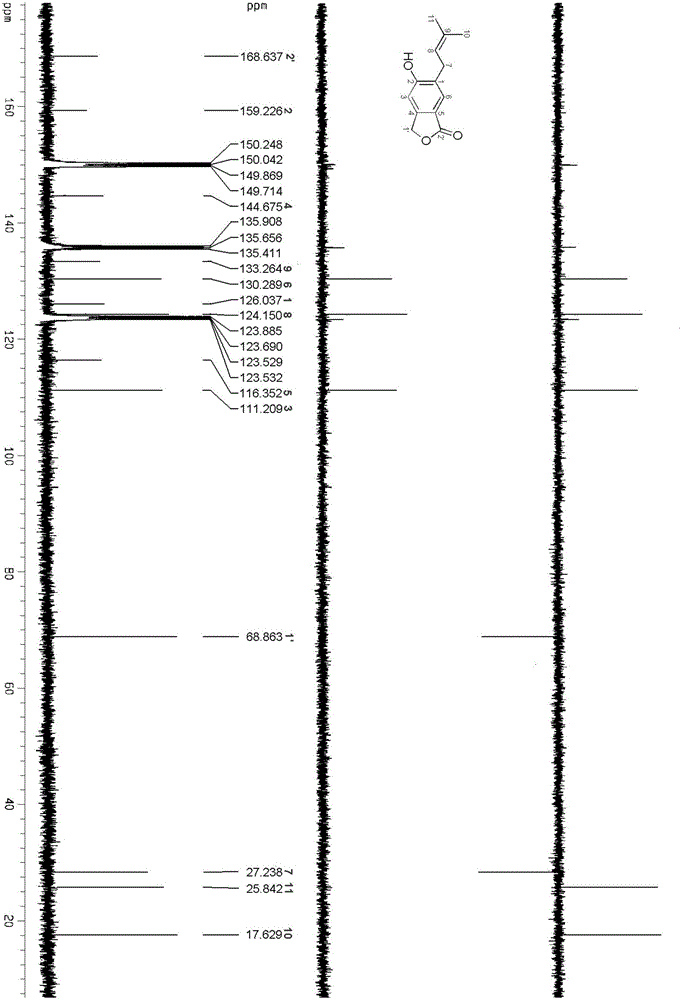

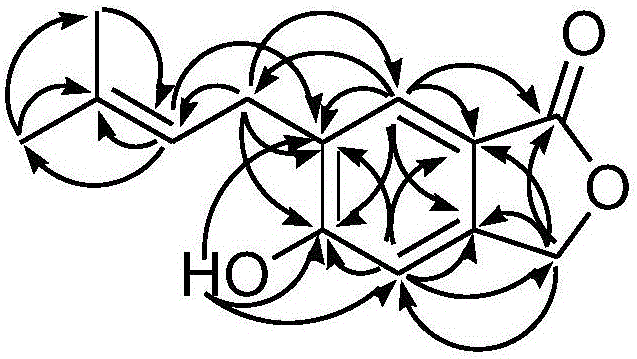

Application and method for preparing isobenzofuran compound with antibacterial activity in tobaccos by supercritical fluid chromatography

ActiveCN106117171ARaw materials are easy to getSimple extraction methodOrganic chemistrySpecial paperIsobenzofuranKetone

The invention discloses an isobenzofuran compound. A structure of the isobenzofuran compound is as shown in the specification, and the isobenzofuran compound is named 2-hydroxyl-1-isopentenyl-isobenzofuran-5(3H)-ketone. The invention further discloses a preparation method of the isobenzofuran compound and application of the isobenzofuran compound to cigarette antibacterial tipping paper.

Owner:CHINA TOBACCO YUNNAN IND

Preparation method of flexible sensor electrode modified by molybdenum disulfide quantum dots

InactiveCN107474469AExcellent performanceImprove performanceCoatingsMaterial electrochemical variablesQuantum dotConductive materials

The invention relates to the field of a sensor electrode material. The invention discloses a preparation method of a flexible sensor electrode modified by molybdenum disulfide quantum dots. A flexible conductive thin film is prepared by a solution mixing method, wherein acrylonitrile-butadiene-styrene resin is used as a flexible substrate, poly 3,4-ethylenedioxythiophene-polystyrolsulfon acid-graphene is used as a conductive material, and an electrode is modified by the molybdenum disulfide quantum dots so as to obtain the flexible sensor electrode. The sensor electrode disclosed by the invention has the advantages of more excellent conductivity, high sensitivity and flexibility, and can be applied to the fields of medical biological monitoring, environment and hygienic monitoring and the like.

Owner:ZHEJIANG SCI-TECH UNIV

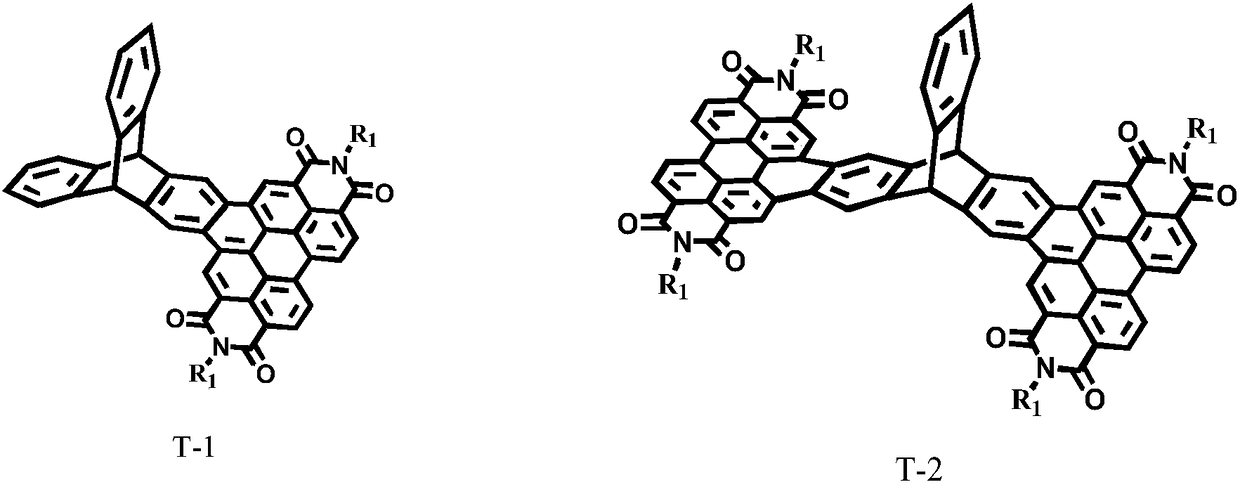

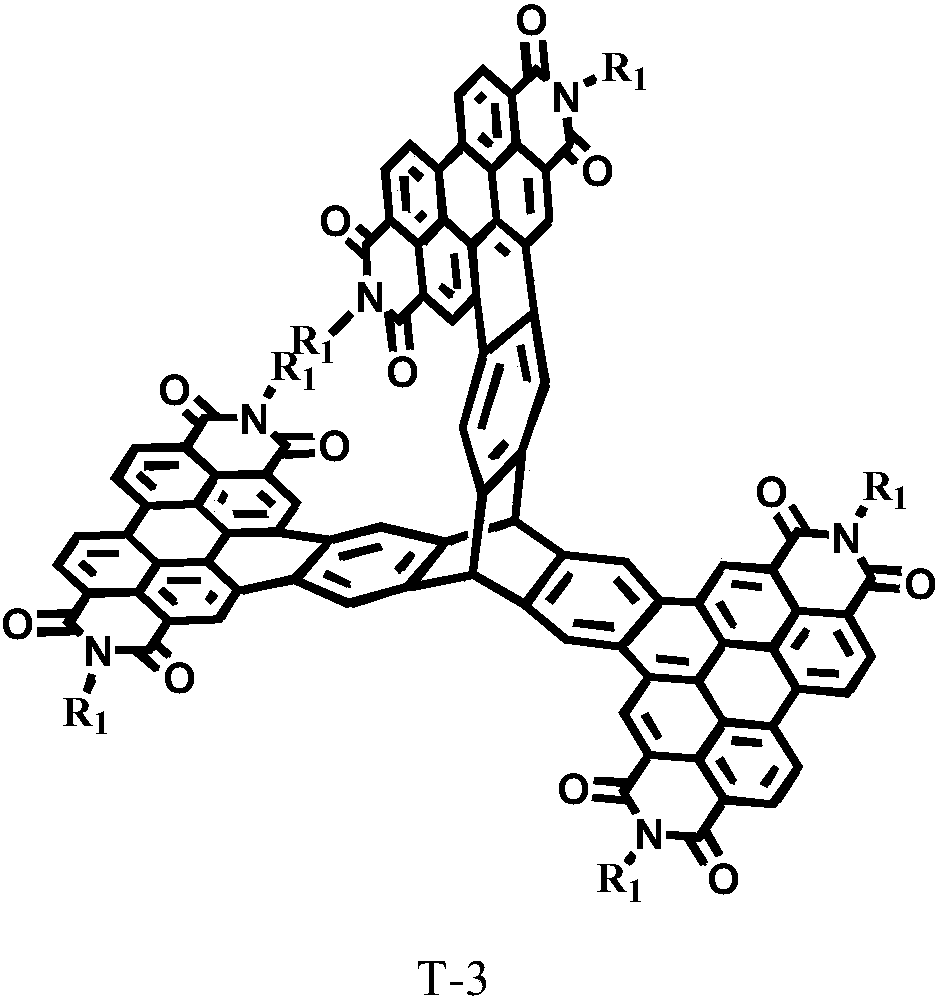

Synthesis and preparation method and applications of triptycene-based perylene imide compound

ActiveCN108424413AImprove photoelectric conversion efficiencyReasonable design ideasOrganic chemistrySolid-state devicesImideOrganic solar cell

The invention relates to the field of organic photovoltaic materials, particularly to a triptycene-based perylene imide compound, a preparation method and applications thereof, wherein the triptycene-based perylene imide compound has the structure formula represented by T-1, T-2 or T-3, and R1 are selected from the following any groups: C2-60 alkyl, substituent-containing alkyl, alkoxy, substituent-containing alkoxy, aryl, substituent-containing aryl, alkyl aryl, substituent-containing alkyl aryl, alkyl heteroaryl, substituent-containing alkyl heteroaryl, alkyl heterocycle group and substituent-containing alkyl heterocycle group, and are the same or different. According to the present invention, with the triptycene-based perylene imide compound, the photoelectric conversion efficiency is significantly improved, the design idea is reasonable and effective, the molecular structure is simple, and the synthesis step is short; and the triptycene-based perylene imide compound is the organicsolar cell material with important application prospects. The formulas T-1, T-2 and T-3 are defined in the specification.

Owner:INST OF CHEM CHINESE ACAD OF SCI

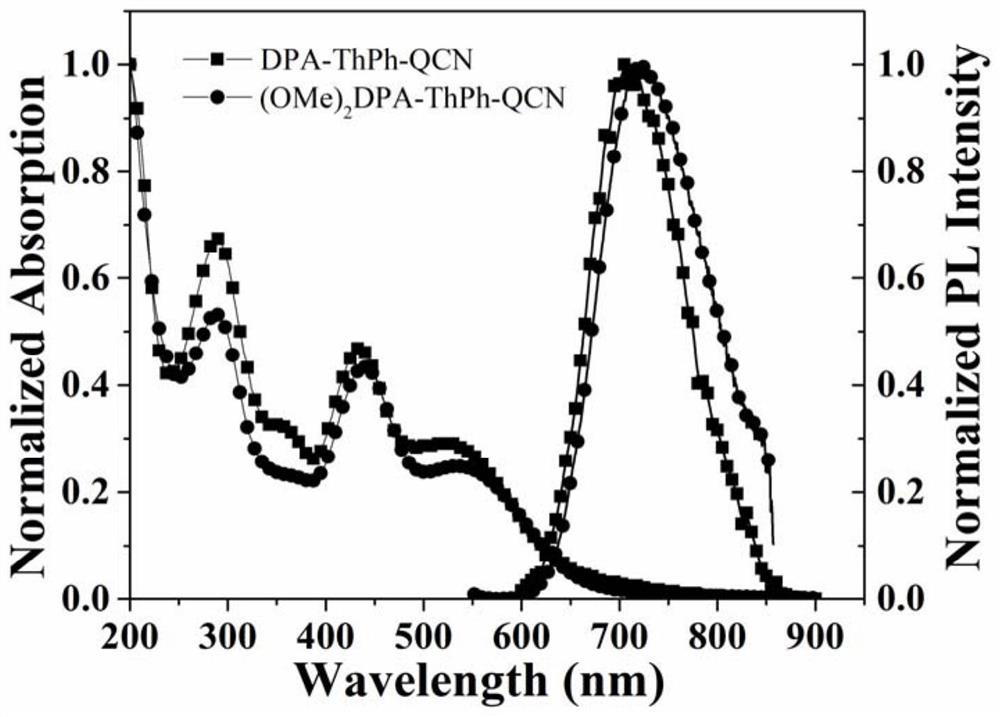

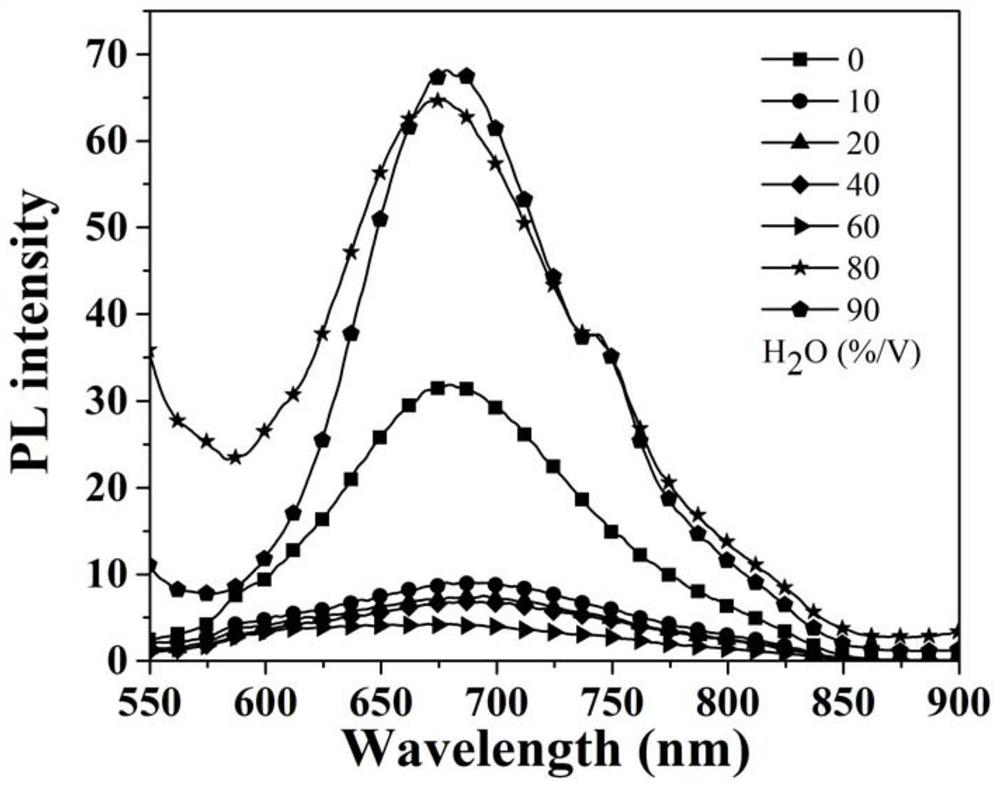

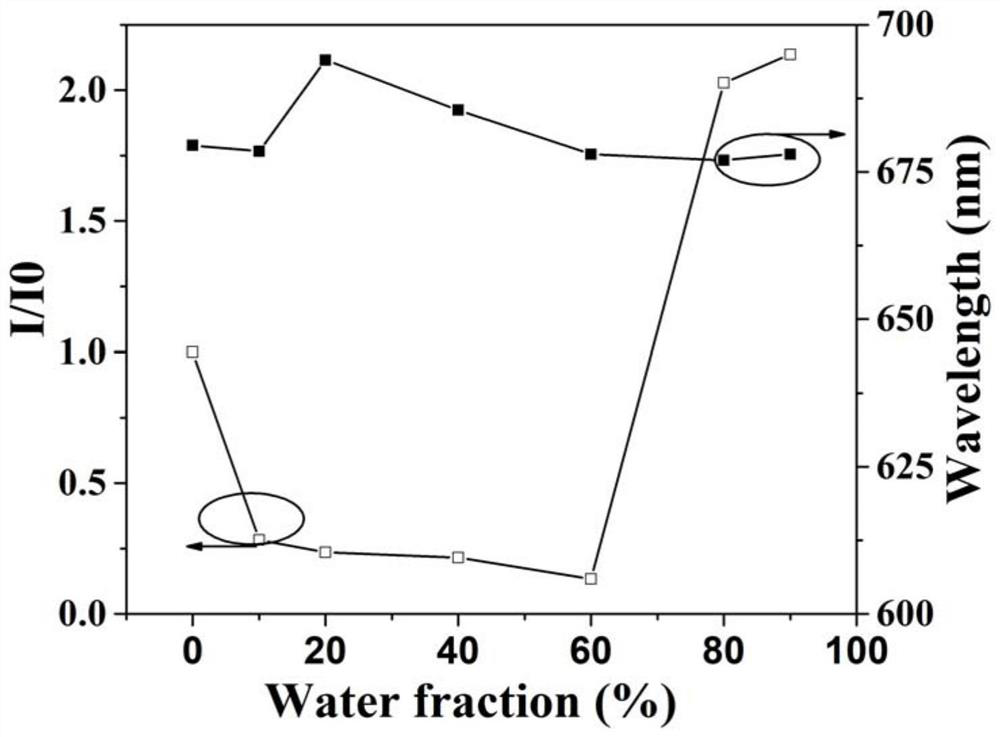

D-pi-A type AIE-TADF near-infrared luminescent material as well as preparation method and application thereof

ActiveCN112898282ASimple molecular structureReduce manufacturing costOrganic chemistrySolid-state devicesQuinoxalinePhotoluminescence

The invention belongs to the technical field of luminescence and display, and particularly relates to a D-pi-A type AIE-TADF near-infrared luminescent material and a preparation method and application thereof. According to the near-infrared luminescent material, phenyl dicyanoquinoxaline with strong electron absorption is used as an acceptor (A) unit, and triarylamine[diphenylthiophenamine, di(4-methoxyphenyl)thiophenamine and di(4-fluorophenyl)thiophenamine] with strong electron donating is used as a donor (D) unit. The near-infrared luminescent material is high in thermal stability and has excellent carrier transport performance and photoluminescence performance, and the fluorescence quantum efficiency of the near-infrared luminescent material is 27%, so that the near-infrared luminescent material is widely applied to the fields of organic electroluminescent displays, biological imaging and the like.

Owner:CHANGZHOU UNIV

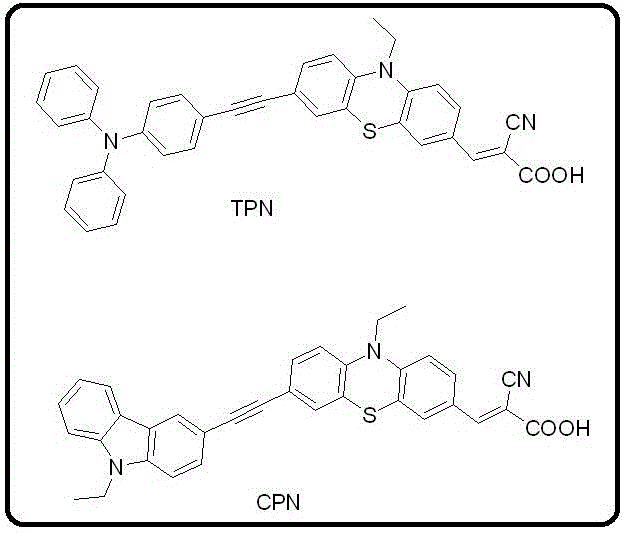

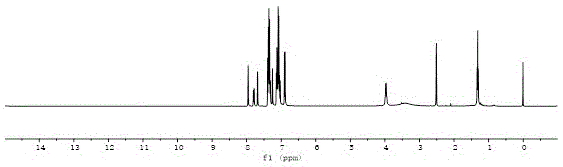

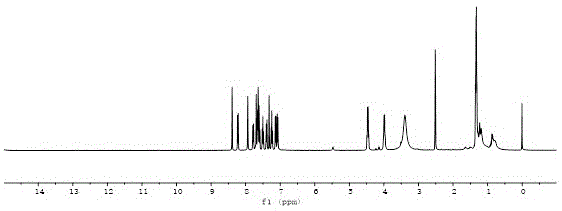

Double-donor aromatic amine photosensitizer and application thereof in LED visible light curing

ActiveCN105669591ALight curing is effectiveSensitive wave lengthOrganic chemistryPhotosensitizerAromatic amine

The invention discloses a double-donor aromatic amine photosensitizer, structurally characterized by having an aromatic amine double-donor conjugated group and a structurally general formula shown as I. Compared with commonly reported visible light initiating systems, this photosensitizer has high absorbability in a visible light area, is simple to synthesize, is applicable to visible LED light source free radicals and cationic curing systems and has application potential.

Owner:BEIJING UNIV OF CHEM TECH

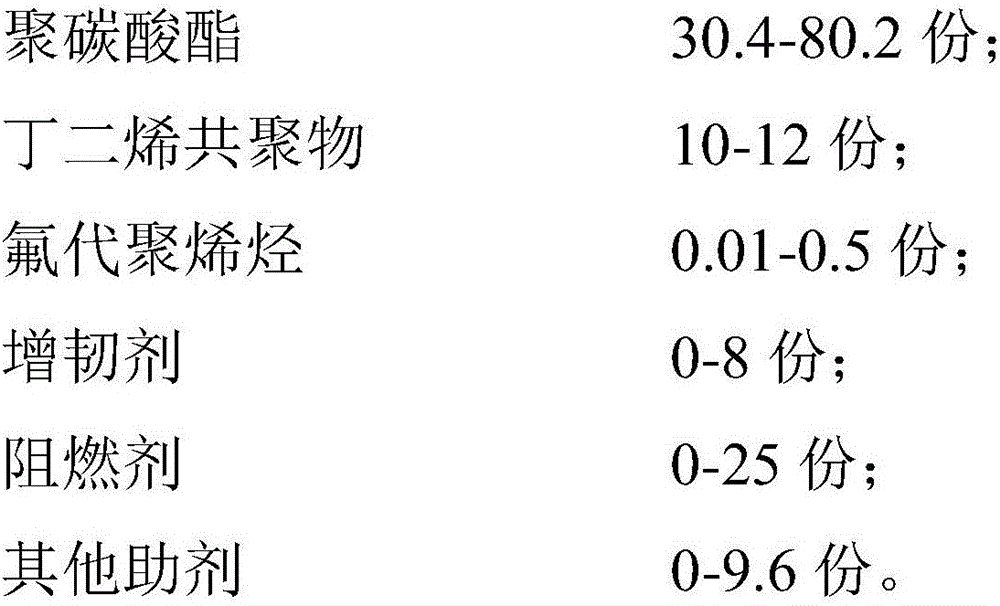

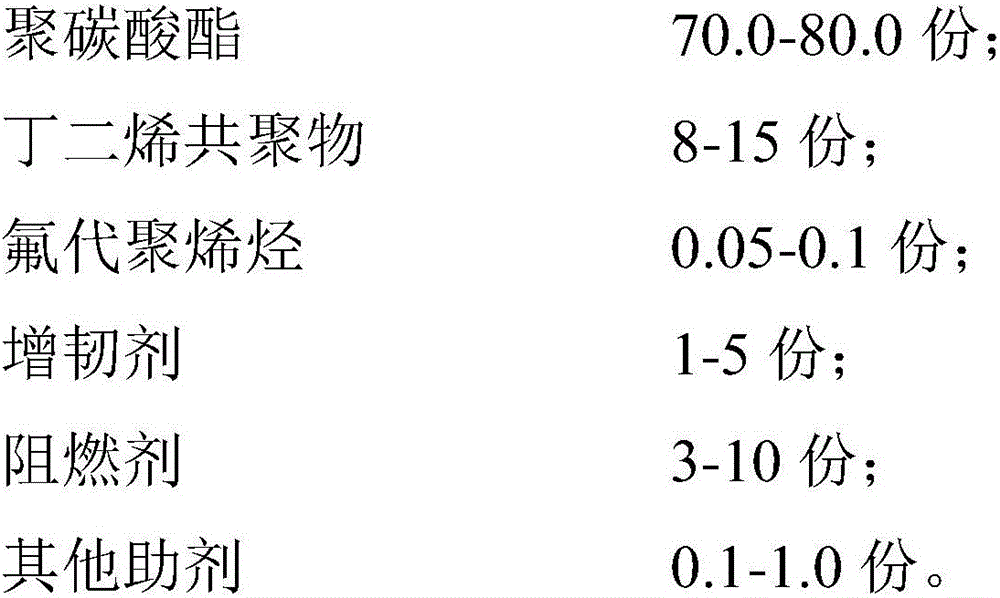

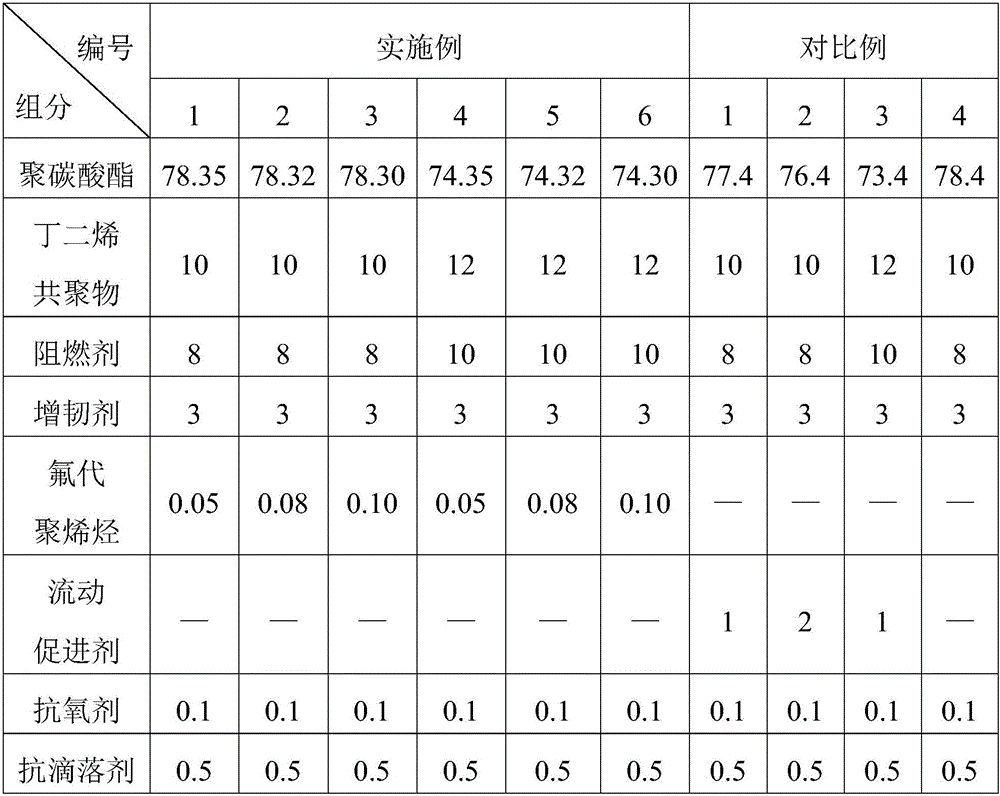

High-fluidity polycarbonate alloy and preparation method thereof

The invention discloses a high-fluidity polycarbonate alloy and a preparation method thereof. The polycarbonate alloy is prepared through the step that low molecular weight fluoro polyolefin which has specific content and is within specific molecular weight is added in a polycarbonate combination composed of polycarbonate, styrene-butadiene copolymers, flexibilizer, flame retardant and other auxiliaries; on the condition that other properties such as flame retardance, a thermal property and a mechanical property of the material of the combination are not changed, the fluidity of the material can be greatly improved, when the production time is prolonged, the improvement of fluidity is more obvious, and the high-fluidity polycarbonate alloy is suitable for occasions high in use environment requirement.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![2,6-bis(triphenylamine)-4,8-bis(alkoxy)benzo[1,2-b:4,5-b']bithiophene and preparation for same 2,6-bis(triphenylamine)-4,8-bis(alkoxy)benzo[1,2-b:4,5-b']bithiophene and preparation for same](https://images-eureka.patsnap.com/patent_img/b7ba0c82-b6f5-4a27-816b-e9ff2f23e578/HDA0000988576790000011.PNG)

![2,6-bis(triphenylamine)-4,8-bis(alkoxy)benzo[1,2-b:4,5-b']bithiophene and preparation for same 2,6-bis(triphenylamine)-4,8-bis(alkoxy)benzo[1,2-b:4,5-b']bithiophene and preparation for same](https://images-eureka.patsnap.com/patent_img/b7ba0c82-b6f5-4a27-816b-e9ff2f23e578/HDA0000988576790000012.PNG)

![2,6-bis(triphenylamine)-4,8-bis(alkoxy)benzo[1,2-b:4,5-b']bithiophene and preparation for same 2,6-bis(triphenylamine)-4,8-bis(alkoxy)benzo[1,2-b:4,5-b']bithiophene and preparation for same](https://images-eureka.patsnap.com/patent_img/b7ba0c82-b6f5-4a27-816b-e9ff2f23e578/HDA0000988576790000021.PNG)