Visible light initiating system capable of initiating free radical/cation polymerization

A technology of initiating system and visible light, which is applied in the field of visible light initiating system, can solve the problems of complex structure, expensive, limited to theoretical research, etc., and achieve the effect of improving free radical initiating ability, improving application performance and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A visible light initiation system that initiates free radicals and cationic polymerization, its components are as follows:

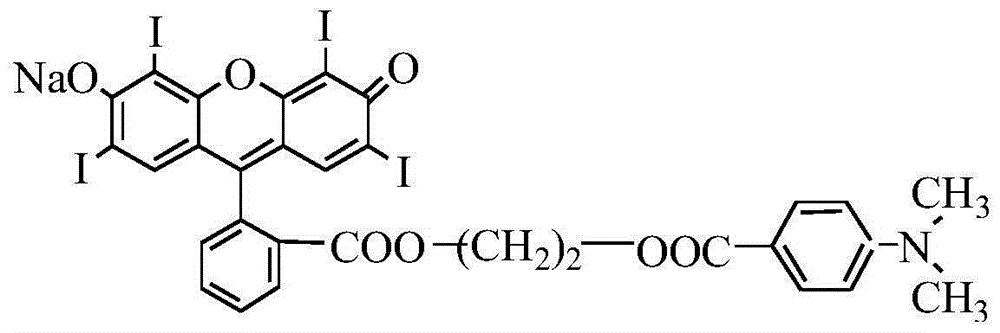

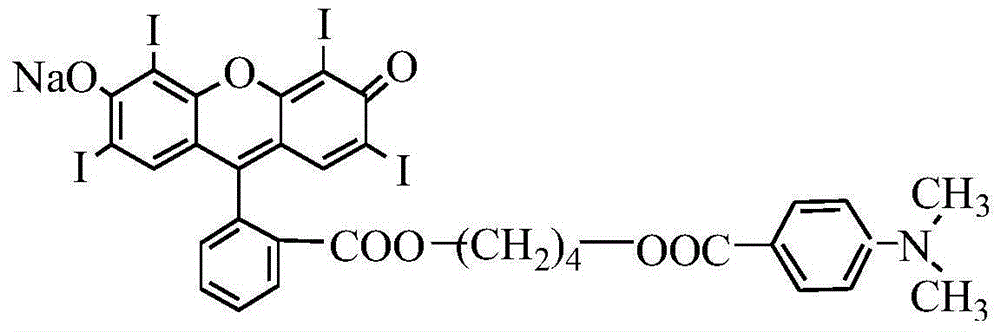

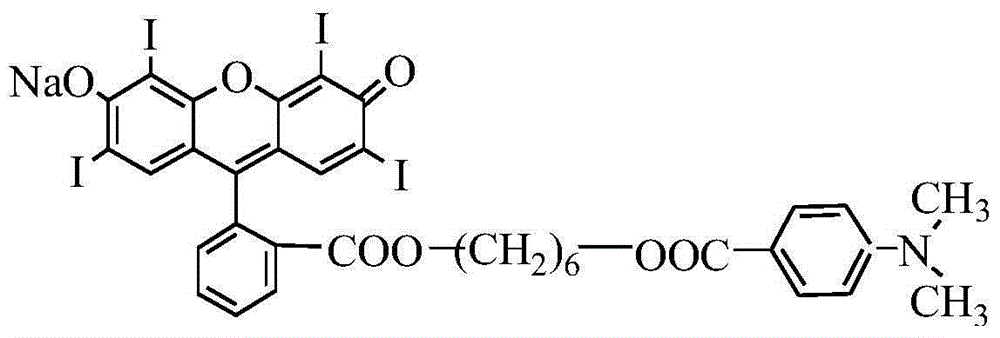

[0035] The first component: integrated photosensitizer (self-made) 0.5%, its structure is as follows:

[0036]

[0037] Second component: co-initiator, ethyl 4-dimethylaminobenzoate 0.5%;

[0038] The third component: synergist, diphenyliodonium hexafluorophosphate 2.6%;

[0039] Prepare the visible light triggering system according to the above-mentioned ratio, and add the visible light triggering system to the free radical polymerizing monomer: 1,6-hexanediol diacrylate based on the weight of the free radical polymerizing monomer as 100%, and mix thoroughly to obtain a transparent Clear light curing reaction solution.

[0040] The synthetic method of self-made integrated photosensitizer is divided into the following steps:

[0041] In the first step, 24mmol of 18-crown-6, 60mmol of anhydrous potassium fluoride and 120mmol of 1,2-dibromoethan...

Embodiment 2

[0048] The ratio of each component of a visible light initiation system for initiating free radical and cationic polymerization is the same as that of Example 1.

[0049] Based on the weight of the polymerized monomer as 100%, add the photoinitiating system to the cationic polymerized monomer: 3,4-epoxycyclohexylmethyl 3,4-epoxycyclohexyl carboxylate, and mix thoroughly to obtain a transparent and clear Photocuring reaction solution.

[0050] The photopolymerization reaction was the same as in Example 1.

Embodiment 3

[0052] The ratio of each component of a visible light initiation system for initiating free radical and cationic polymerization is the same as that of Example 1.

[0053] Based on the total weight of the cationic monomer and the free radical monomer as 100%, the photoinitiating system is added to 50% of the cationic monomer: 3,4-epoxycyclohexylmethyl 3,4-epoxycyclohexyl carboxylate , 50% free radical monomer: 1,6-hexanediol diacrylate hybrid resin system is fully mixed to obtain a transparent and clear photocuring reaction solution.

[0054] The photopolymerization reaction is the same as in Example 1, except that the photopolymerization space of Photo-DSC is filled with high-purity air, and only the photopolymerization of the hybrid system in air is investigated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com