A kind of treatment process of esterification wastewater

A technology of esterification wastewater and treatment process, which is applied in natural water treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. In order to achieve the effect of reducing the dosage of the chemical, no requirement for the salinity of the influent water, and improving the biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

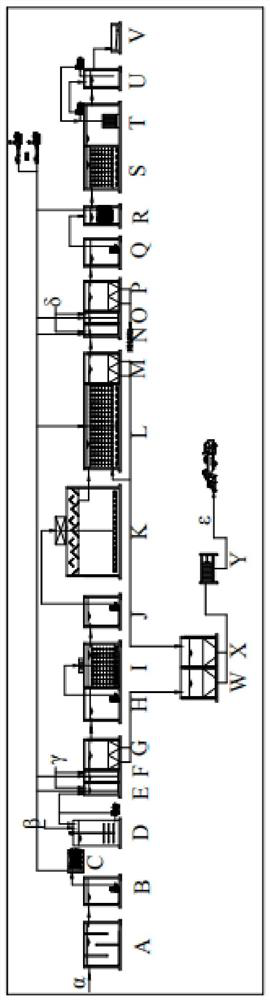

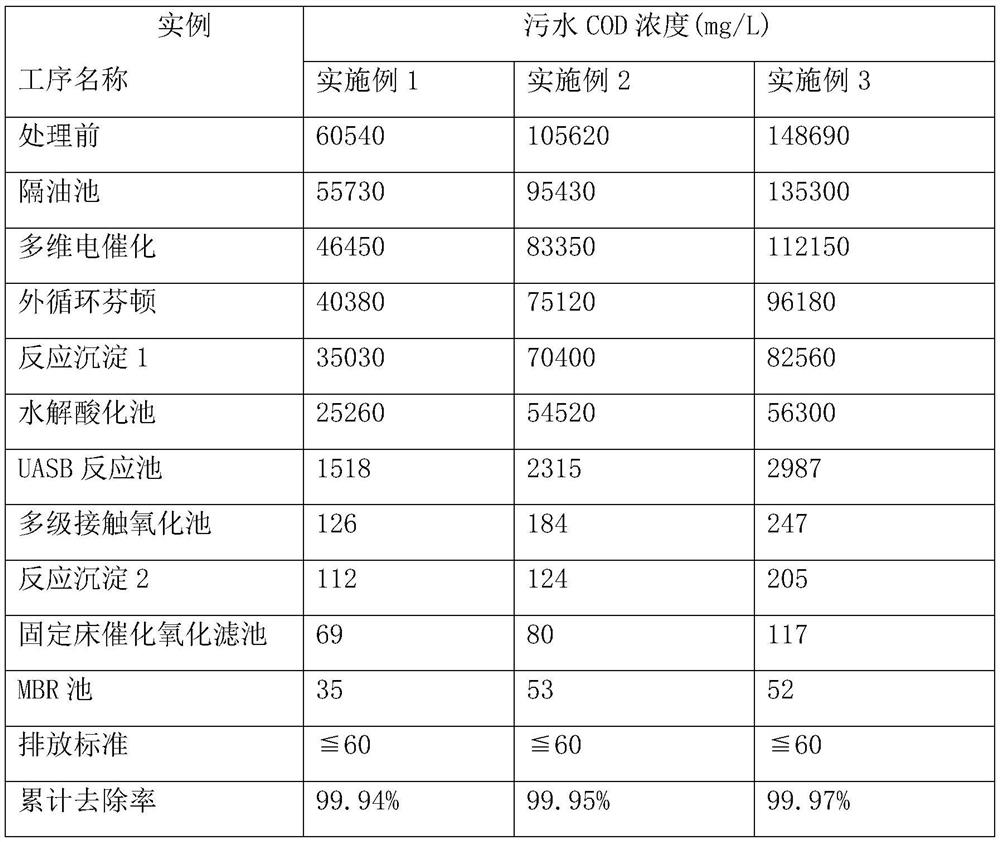

[0053] Embodiment 1 A kind of esterification wastewater treatment process

[0054] Include the following steps:

[0055] (1), the esterification wastewater is passed into a grease trap, and the grease in the wastewater is removed through the grease trap to obtain sewage 1.

[0056] (2), adjust the water quality of the sewage 1, pump the sewage into the multi-dimensional electrocatalytic reaction tank and the external circulation Fenton oxidation tank for oxidation reaction, and obtain the sewage 2;

[0057] (3), adjust the pH value of sewage 2 to 7, and then add a mixture of GP01, GP02, GP03, GP04 and GP05 with a mass ratio of 1:2:2:2:1 and polyacrylamide to make the impurities in the sludge The reaction generates sedimentable sludge, and the supernatant flows into the regulating tank after sedimentation in the sedimentation tank to obtain sewage 3;

[0058] (4), Sewage 3 is transported to the hydrolytic acidification tank after being regulated by the regulating tank, and ba...

Embodiment 2

[0065] Embodiment 2 A kind of esterification wastewater treatment process

[0066] Include the following steps:

[0067] (1), the esterification wastewater is passed into a grease trap, and the grease in the wastewater is removed through the grease trap to obtain sewage 1.

[0068] (2), adjust the water quality of the sewage 1, pump the sewage into the multi-dimensional electrocatalytic reaction tank and the external circulation Fenton oxidation tank for oxidation reaction, and obtain the sewage 2;

[0069] (3), adjust the pH value of sewage 2 to 8, and then add a mixture of GP01, GP02, GP03, GP04 and GP05 with a mass ratio of 1:2:2:2:1 and polyacrylamide to make the impurities in the sludge The reaction generates sedimentable sludge, and the supernatant flows into the regulating tank after sedimentation in the sedimentation tank to obtain sewage 3;

[0070] (4), Sewage 3 is transported to the hydrolytic acidification tank after being regulated by the regulating tank, and ba...

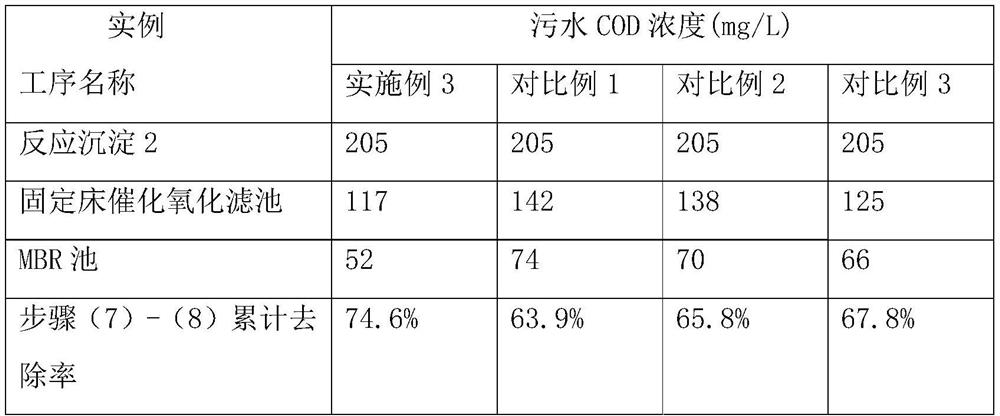

Embodiment 3

[0077] Embodiment 3 A kind of esterification wastewater treatment process

[0078] Include the following steps:

[0079] (1), the esterification wastewater is passed into a grease trap, and the grease in the wastewater is removed through the grease trap to obtain sewage 1.

[0080] (2), adjust the water quality of the sewage 1, pump the sewage into the multi-dimensional electrocatalytic reaction tank and the external circulation Fenton oxidation tank for oxidation reaction, and obtain the sewage 2;

[0081] (3), adjust the pH value of sewage 2 to 7.5, and then add a mixture of GP01, GP02, GP03, GP04 and GP05 with a mass ratio of 1:2:2:2:1 and polyacrylamide to make the impurities in the sludge The reaction generates sedimentable sludge, and the supernatant flows into the regulating tank after sedimentation in the sedimentation tank to obtain sewage 3;

[0082] (4), Sewage 3 is transported to the hydrolytic acidification tank after being regulated by the regulating tank, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com