Polyurethane microporous water-proof and moisture permeable film prepared by using solidification method and preparation method thereof

A waterproof and moisture-permeable polyurethane technology, applied in chemical instruments and methods, coatings, layered products, etc., can solve the problems of high price, rapid water pressure drop, loss of water resistance, etc., and achieve good surface strength and low wet resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] A method for preparing a solidified polyurethane microporous waterproof and moisture-permeable film, comprising the following steps:

[0046] 1. Prepare wet coating working fluid and dry direct coating working fluid respectively, wherein, said wet coating working fluid and dry direct coating working fluid respectively comprise the components of mass parts as shown in Table 1; The dry direct coating working solution includes the following components in parts by mass;

[0047] Wherein, the 100% modulus of the polyether polyurethane resin is 60-120kg / cm 2 ;

[0048] The 100% modulus of the waterproof and moisture-permeable polyurethane resin is 30-80kg / cm 2 ;

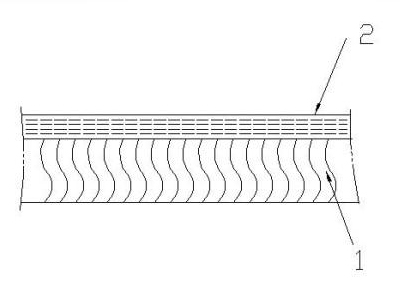

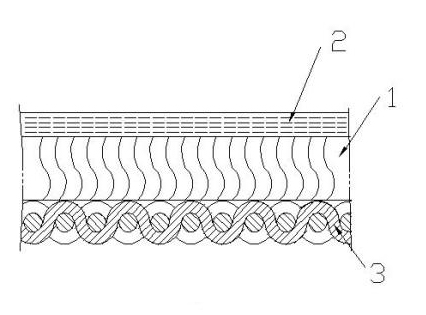

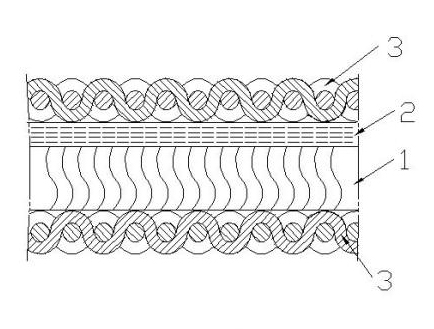

[0049] ② Coat the wet coating working liquid on the transfer carrier, and solidify it into a film in an aqueous solution of dimethylformamide (DMF) with a mass concentration of 16-22%, then wash it with water, and dry it into a roll to obtain a polyurethane microstructure. Porous film layer;

[0050] ③Apply the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com