Polyurethane windproof air-permeable coat compounded textile fabric and preparation method thereof

A windproof and breathable textile fabric technology, applied in polyurea/polyurethane coatings, coatings, chemical instruments and methods, etc., can solve the problems of no active moisture absorption and sweat guiding function, poor wind resistance, hardening and brittleness, etc. Excellent performance, excellent cold resistance, soft touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

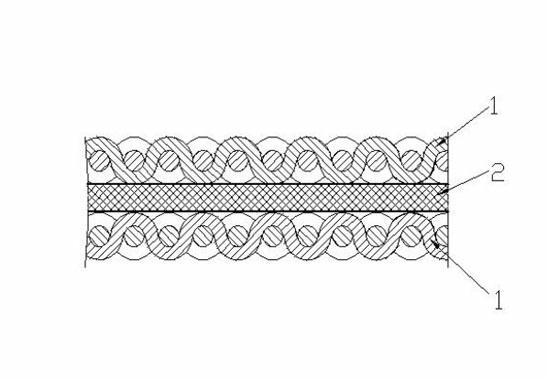

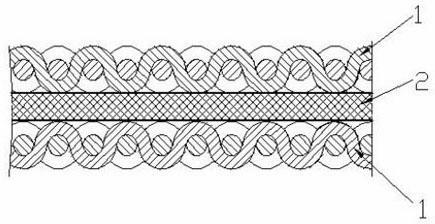

[0053] A polyurethane windproof and air-permeable coated composite textile fabric has a three-layer composite structure, the upper and lower layers are textile cloth layers 1, and the middle layer is a polyurethane microporous structure layer 2.

[0054] The gram weight of the polyurethane microporous structure layer is 20-30g / m 2 .

[0055] The micropore diameter of the polyurethane microporous structure layer is 0.05-0.10mm.

[0056] The peel strength of the polyurethane windproof and breathable coating composite textile fabric is greater than 0.20kg / cm under the test standard of ASTM D2724, and its air permeability is 5-20cm under the test standard of ASTMD737. 3 / cm 2 sec.

[0057] A preparation method of the above-mentioned polyurethane windproof and breathable coating composite textile fabric, which comprises the following steps:

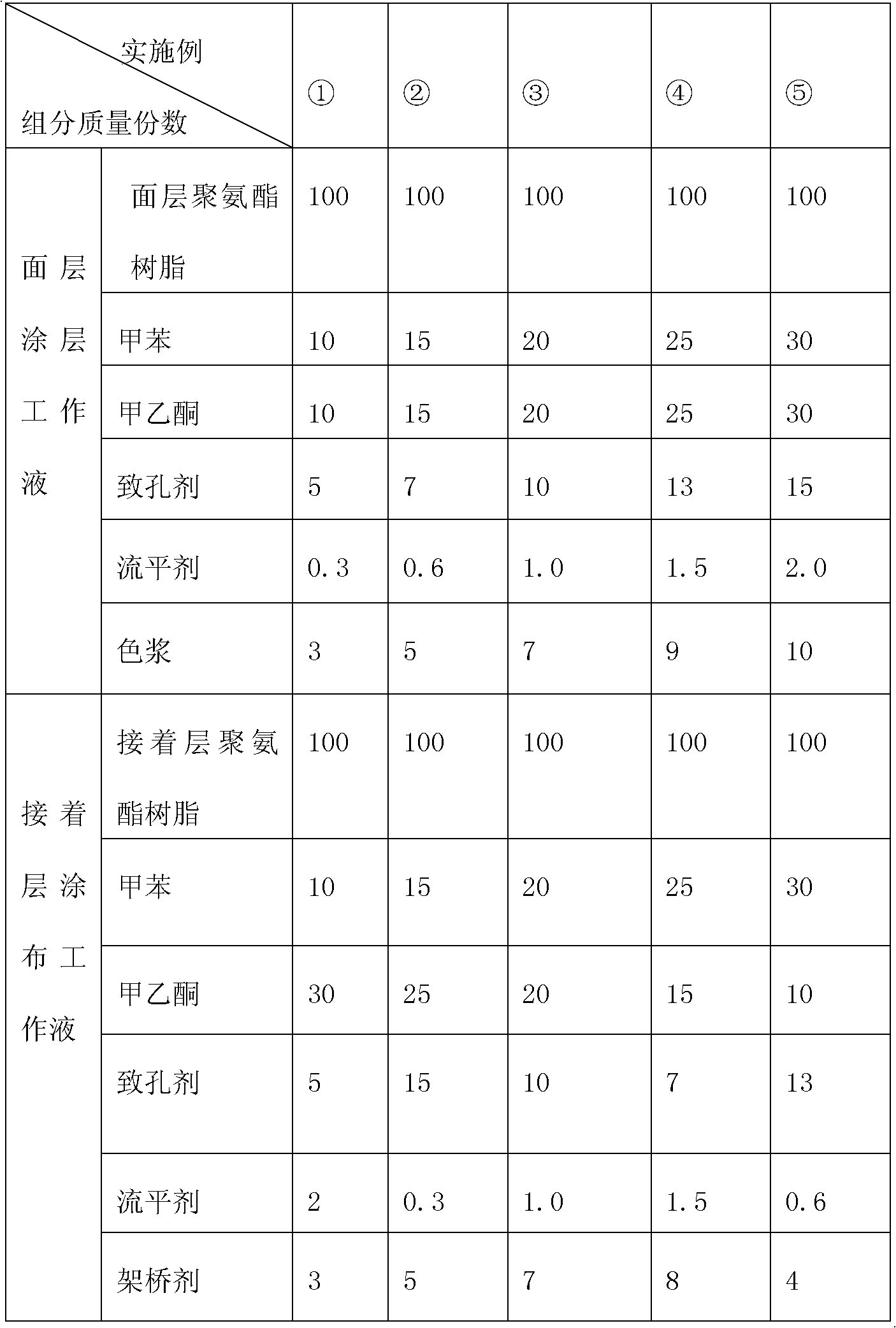

[0058] ① According to the components listed in Table 1 and their mass parts, prepare the surface coating working slurry:

[0059] Wherei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com