Hole transporting material for perovskite solar cell and application thereof

A reaction, alkyl chain technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of difficulty in refining, high price, and complex synthesis steps of sprio-MeOTAD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

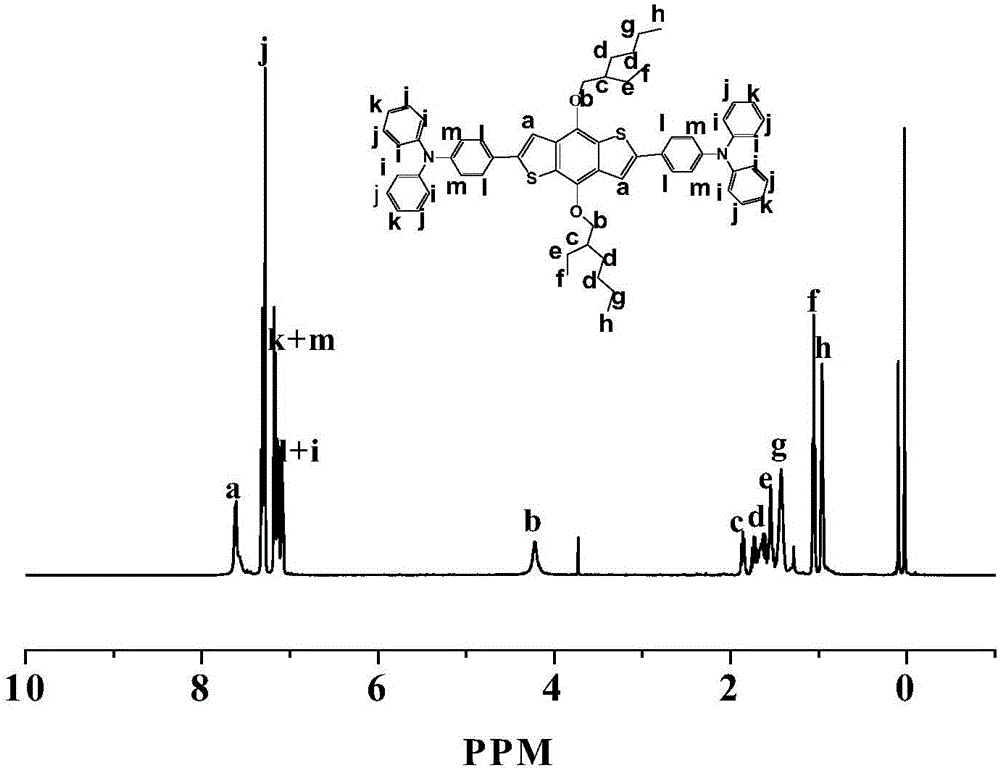

[0088] Preparation of 2,6-bistriphenylamine-4,8-bis(alkoxy)benzo[1,2-b:4,5-b']dithiophene(Ⅲ)

[0089] The synthetic process is shown in route (1'):

[0090]

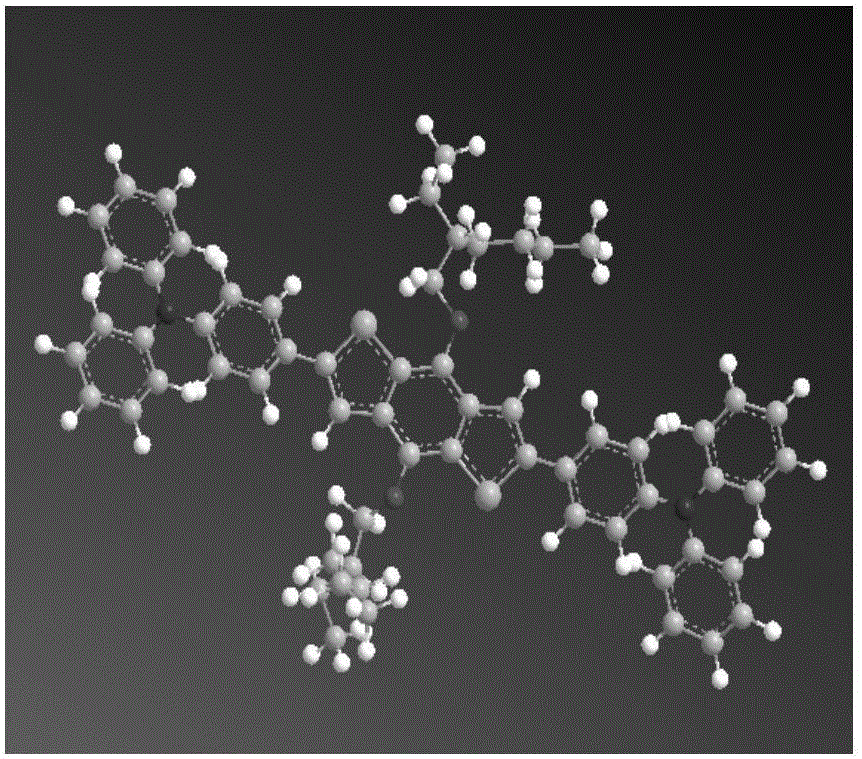

[0091] In this example, the prepared perovskite solar cell hole transport material 2,6-bistriphenylamine-4,8-bis(2-ethyl-hexyloxy)benzo[1,2-b:4 ,5-b']dithiophene takes benzodithiophene as the core, and connects triphenylamine at its two ends. The structural formula is as shown in formula (IIIa), that is, the R group in formula (III) contains 8 carbons The alkyl chain (2-ethyl-hexyl), its structural formula is as follows:

[0092]

[0093] The specific synthesis steps are as follows:

[0094] (1) Alkylation: Preparation of 4,8-bis(2-ethyl-hexyloxy)benzo[1,2-b:4,5-b']dithiophene (Ia)

[0095] Weigh 2.2g of benzo[1,2-b:4,5-b']dithiophene-4,8-dione into a single-necked flask, add 1.5g of zinc powder, 6g of sodium hydroxide, 35g of distilled water, and heat to reflux , the temperature of the oil bath was controlled ...

Embodiment 2

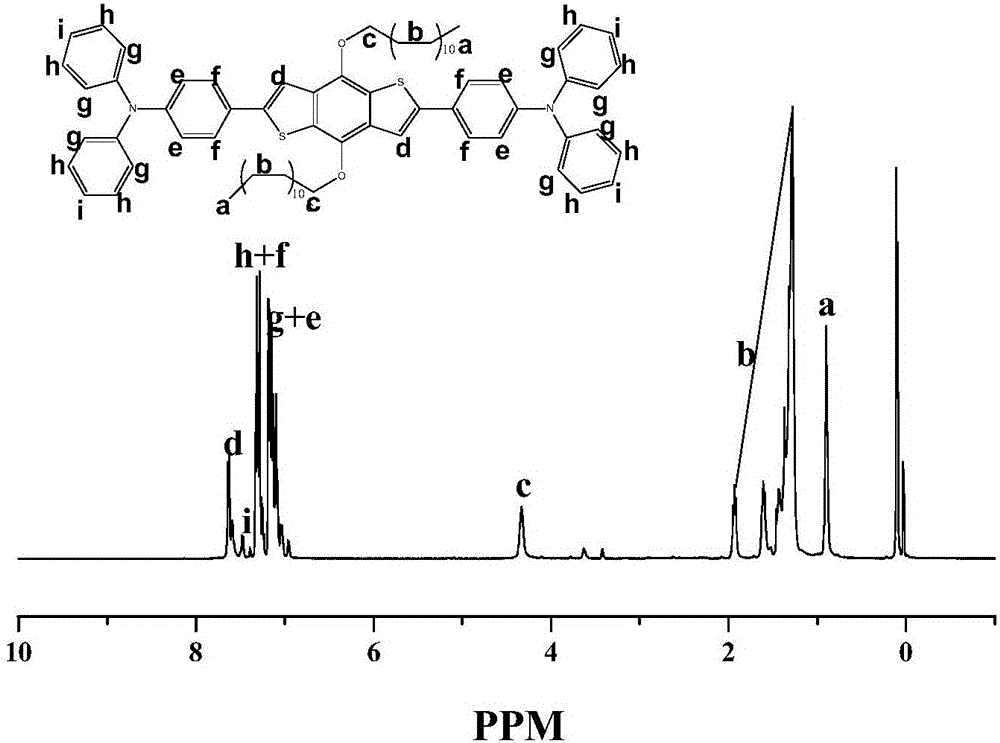

[0113] Preparation of 2,6-bistriphenylamine-4,8-bis(dodecyloxy)benzo[1,2-b:4,5-b']dithiophene (Ⅲb)

[0114] The synthetic process is shown in route (1'):

[0115] In this example, the prepared perovskite solar cell hole transport material 2,6-bistriphenylamine-4,8-bis(alkoxy)benzo[1,2-b:4,5-b' ] Dithiophene, take benzodithiophene as the core, connect triphenylamine at its two ends, the structural formula is as shown in formula (IIIb), that is, the R group in formula (III) is an alkyl chain containing 12 carbons , its structural formula is as follows:

[0116]

[0117] The specific synthesis steps are as follows:

[0118] (1) Alkylation: Preparation of 4,8-bis(dodecyloxy)benzo[1,2-b:4,5-b']dithiophene (Ib)

[0119] Weigh 2.2g of benzo[1,2-b:4,5-b']dithiophene-4,8-dione single-necked flask, add 1.5g of zinc powder, 6g of sodium hydroxide solid, 35g of distilled water, and heat to reflux , the temperature was controlled at 120°C, the solution quickly changed from yellow to...

Embodiment 3

[0137] The preparation of embodiment 3 perovskite solar cells

[0138] (1) Treatment of conductive glass: cut the conductive glass into 20mm×12mm glass pieces, and wash them with detergent, deionized water, ethanol, and acetone in sequence.

[0139] (2) Screen printing step: use a screen printing template to print a layer of dense TiO on the cleaned conductive glass FTO layer 2 The slurry was dried at 80°C and dried at 450°C for half an hour to obtain TiO 2 Thin film, the thickness of the film is about 50nm-150nm; and then print a layer of 20mm×10mm Al on its surface 2 o 3 The particles were dried at 80°C and dried at 450°C for half an hour to obtain TiO 2 Thin film, the thickness of the film is about 150nm-250nm.

[0140] (3) Perovskite filling step: Add 10 mg / ml of perovskite CH dropwise on the above-mentioned device 3 NH 3 PB 3 (dichloromethane or tetrahydrofuran) solution, spin-coated, and dried in a vacuum oven at 80°C for 1 hour.

[0141] (4) Preparation step of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com