Method for manufacturing coralline nanometer cobalt by using octreotide acetate as a template

An octreotide acetate, coral-like technology is applied in the field of preparation of nanomaterials, can solve the problems of inability to obtain particle size, single component, good dispersibility, etc., and achieves the effects of low preparation cost, simple preparation process and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

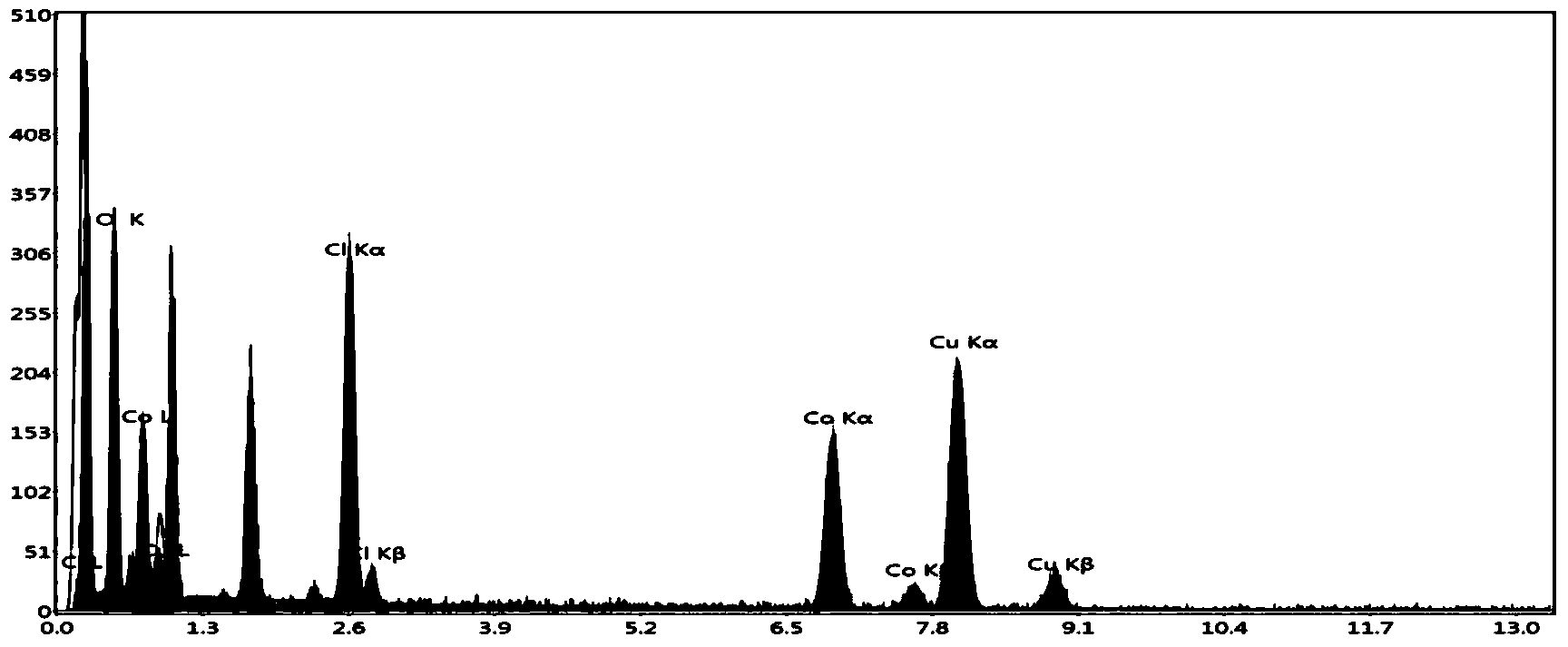

[0019] Take 0.4 mg of octreotide acetate (produced by Jill Biochemical Shanghai Co., Ltd.), and dissolve it in 1 mL of hydrochloric acid solution of pH 2, so that the pH of the octreotide acetate solution is 2; Reagent Co., Ltd.); put the above-prepared solution into a water bath constant temperature oscillator, incubate at 100rpm., 13°C for 26h, then add 50mM reducing agent sodium borohydride (produced by Beijing Zhongsheng Huateng Technology Co., Ltd. ) 80 μL for reduction, making it from light pink to deep black, namely to obtain octreotide acetate-nano-cobalt particles.

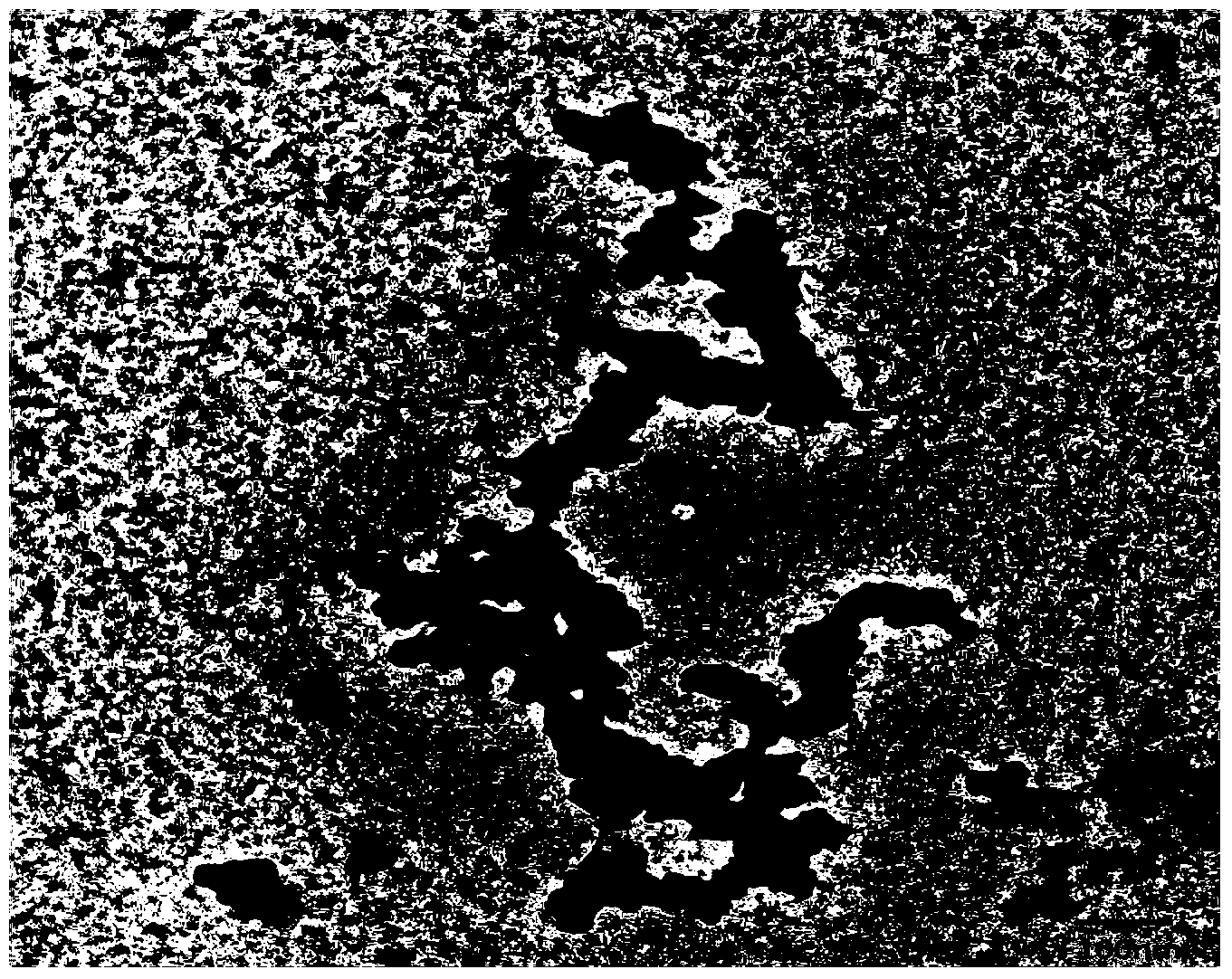

[0020] Morphological characterization of coral-like cobalt nanoparticles using transmission electron microscopy, such as figure 1 As shown, the diameter of the coral-like nano-cobalt particles is about 55nm, the shape is regular, and the distribution is uniform.

Embodiment 2

[0022] Take 0.6 mg of octreotide acetate (produced by Jill Biochemical Shanghai Co., Ltd.), and dissolve it in 1 mL of pH 2.5 hydrochloric acid solution, so that the pH of the octreotide acetate solution is 2.5; take 200 μL of the above-mentioned octreotide acetate solution, add 200 μL of 6 mM cobalt chloride solution ( Shanghai West Asia Reagent Co., Ltd.); put the above-mentioned prepared solution into a water-bath constant temperature oscillator, and after incubating at 150rpm., 20°C for 24h, add 40mM reducing agent sodium borohydride (Beijing Zhongsheng Huateng Technology Co., Ltd. Produced by the company) 90 μL was reduced to make it change from light pink to deep black, and octreotide acetate-nano-cobalt particles were obtained.

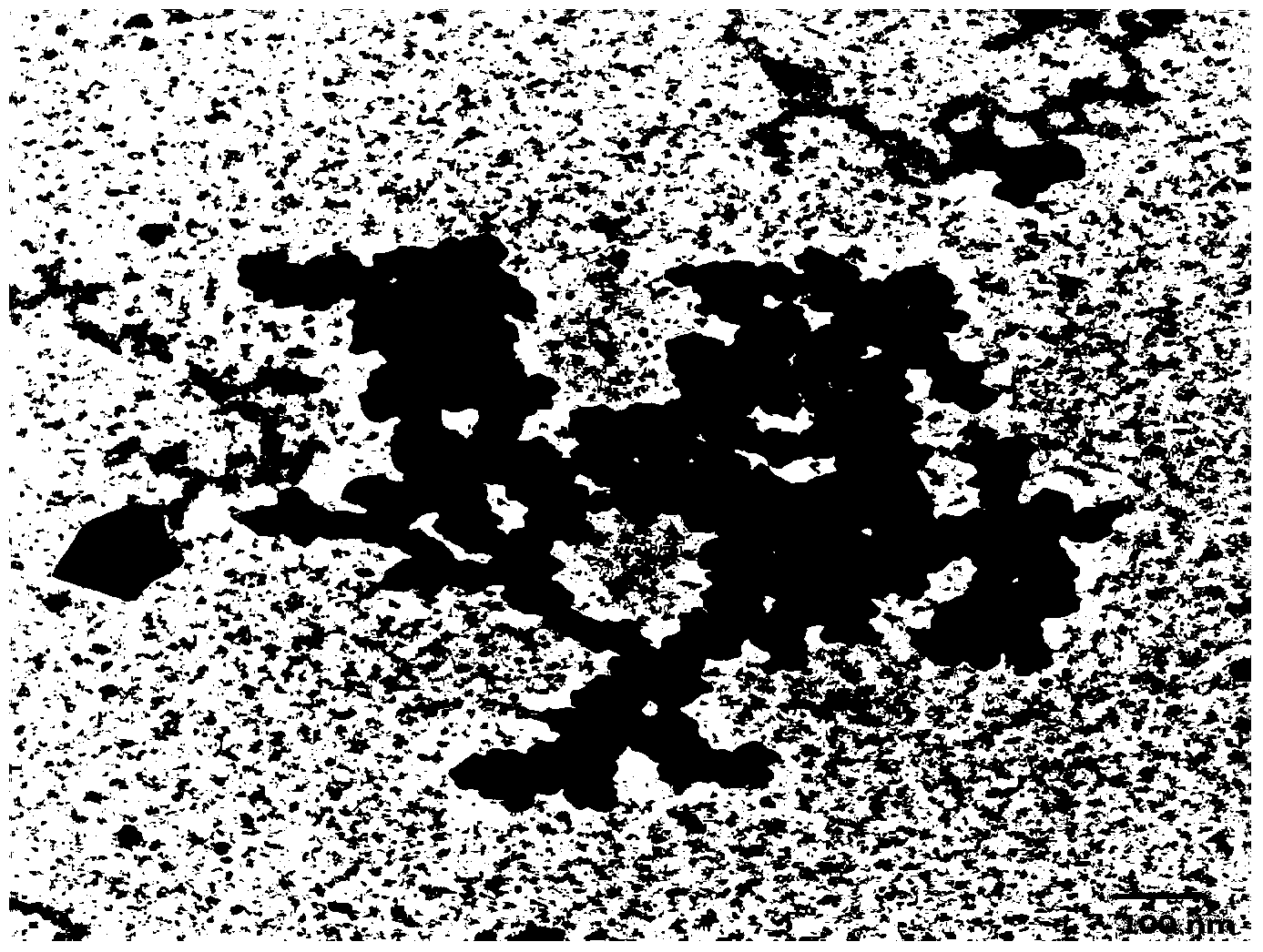

[0023] Morphological characterization of coral-like cobalt nanoparticles using transmission electron microscopy, such as figure 2 As shown, the diameter of the coral-shaped cobalt nanoparticles is about 60-70nm, the shape is regular, and the d...

Embodiment 3

[0026] Take 0.8 mg of octreotide acetate (produced by Jill Biochemical Shanghai Co., Ltd.), and dissolve it in 1 mL of hydrochloric acid solution of pH 3, so that the pH of the octreotide acetate solution is 3; Reagent Co., Ltd.); put the above prepared solution into a water bath constant temperature oscillator, incubate at 200rpm., 25°C for 20h, then add 32mM reducing agent sodium borohydride (produced by Beijing Zhongsheng Huateng Technology Co., Ltd. ) 100 μL for reduction, making it change from light pink to dark black to obtain octreotide acetate-nanocobalt particles.

[0027] Morphological characterization of coral-like cobalt nanoparticles using transmission electron microscopy, such as Figure 4 As shown, the coral-shaped cobalt nano particles have a diameter of about 40-50 nm, regular shape and uniform distribution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com