Drawing oil special for aluminum wire and production process thereof

A wire drawing oil and aluminum wire technology, applied in the petroleum industry, base materials, lubricating compositions, etc., can solve the problems of poor surface finish, affecting the lubricating effect of wire drawing oil, low combustion flash point temperature, etc., and achieve fluidity and lubricating effect Good, enhance safety and stability, improve the effect of burning flash point temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

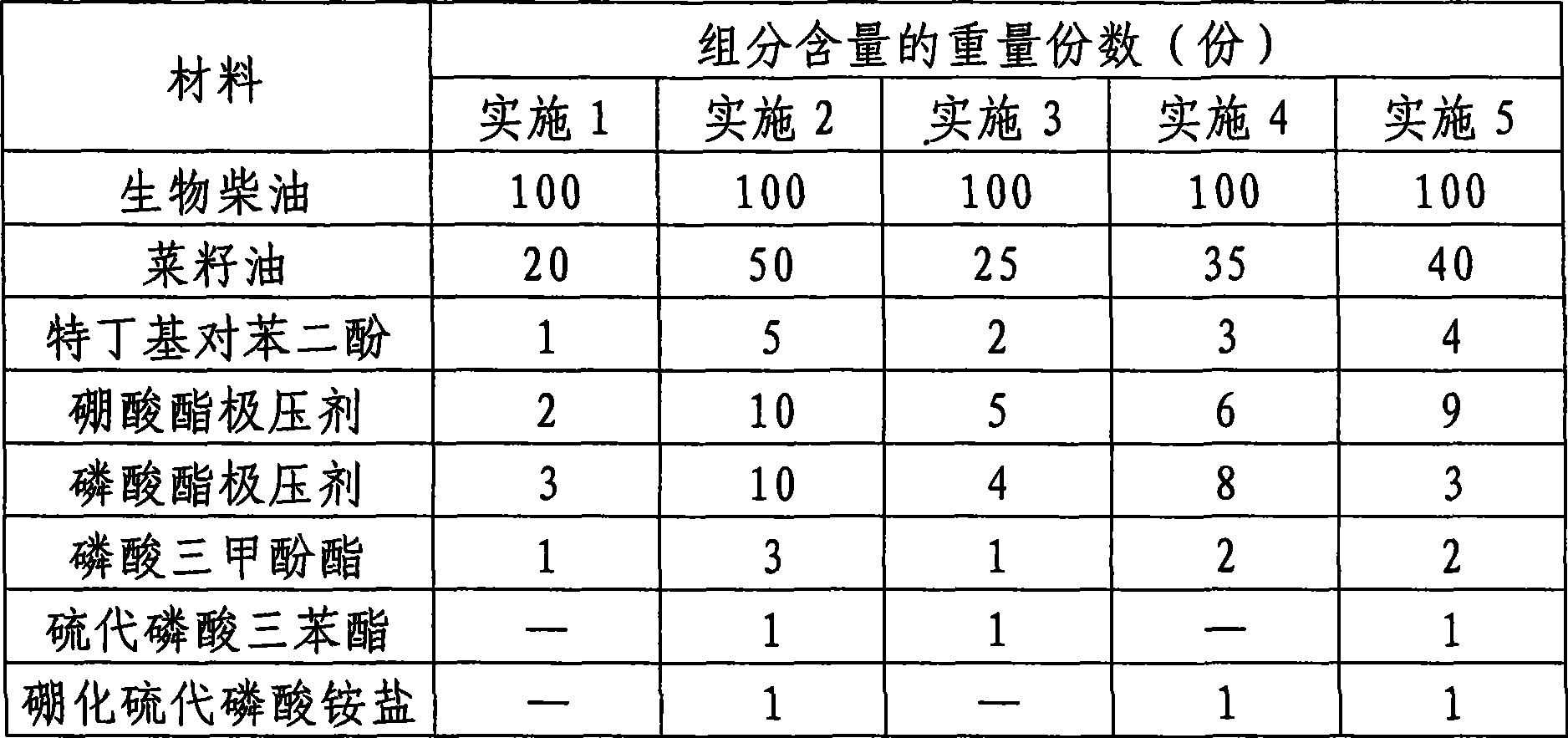

[0025] The special drawing oil for aluminum wire of the present invention includes biodiesel, rapeseed oil, tert-butyl hydroquinone, borate extreme pressure agent, phosphate extreme pressure agent and tricresyl phosphate. The components are calculated in parts by mass: 100 parts of biodiesel, 20 parts of rapeseed oil, 1 part of tert-butyl hydroquinone, 2 parts of borate extreme pressure agent, 3 parts of phosphate ester extreme pressure agent, phosphoric acid 1 part of tricresyl ester. The method for making the special-purpose drawing oil for the aluminum wire of this embodiment is as follows:

[0026] a. Weigh biodiesel, rapeseed oil, tert-butyl hydroquinone, borate extreme pressure agent, phosphate extreme pressure agent and tricresyl phosphate by weight proportion for use;

[0027] b. At room temperature, add biodiesel to the container, and add rapeseed oil and stir to form a solution;

[0028] c. Add tert-butyl hydroquinone, borate extreme pressure agent, phosphate extre...

Embodiment 2

[0031] The special drawing oil for aluminum wire of the present invention includes biodiesel, rapeseed oil, tert-butyl hydroquinone, borate extreme pressure agent, phosphate extreme pressure agent, tricresyl phosphate, triphenyl thiophosphate and boron ammonium thiophosphate. The components are calculated in parts by mass: 100 parts of biodiesel, 50 parts of rapeseed oil, 5 parts of tert-butyl hydroquinone, 10 parts of borate extreme pressure agent, 10 parts of phosphate ester extreme pressure agent, phosphoric acid 3 parts of tricresyl ester, 1 part of triphenyl thiophosphate, and 1 part of ammonium boronated thiophosphate. The method for making the special-purpose drawing oil for the aluminum wire of this embodiment is as follows:

[0032] a. Weigh biodiesel, rapeseed oil, tert-butyl hydroquinone, borate extreme pressure agent, phosphate extreme pressure agent, tricresyl phosphate, triphenyl thiophosphate and sulfur boride in proportion by weight Substitute ammonium phosph...

Embodiment 3

[0037] The special drawing oil for aluminum wire of the invention includes biodiesel, rapeseed oil, tert-butyl hydroquinone, borate extreme pressure agent, phosphate extreme pressure agent, tricresyl phosphate and triphenyl thiophosphate. The components are calculated in parts by mass: 100 parts of biodiesel, 25 parts of rapeseed oil, 2 parts of tert-butyl hydroquinone, 5 parts of borate extreme pressure agent, 4 parts of phosphate ester extreme pressure agent, phosphoric acid 1 part of tricresyl ester, 1 part of triphenyl thiophosphate. The method for making the special-purpose drawing oil for the aluminum wire of this embodiment is as follows:

[0038] A. Weigh biodiesel, rapeseed oil, tert-butyl hydroquinone, borate extreme pressure agent, phosphate extreme pressure agent, tricresyl phosphate and triphenyl thiophosphate by weight ratio for subsequent use;

[0039] b. At room temperature, add biodiesel to the container, and add rapeseed oil and stir to form a solution;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com