Nano MFI/MOR eutectic molecular sieve and synthesis method of nano Ti-MFI/MOR eutectic molecular sieve

A synthesis method and molecular sieve technology, applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, crystalline aluminosilicate zeolite, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: synthetic MFI / MOR eutectic molecular sieve

[0039] Step (1): Synthesis of Zeolite Seed Crystals

[0040] Add 290g of deionized water and 210g of tetrapropyl ammonium hydroxide (25wt%) into a plastic beaker in turn, and after stirring evenly, add 150g of tetraethyl orthosilicate under stirring, then stir and age at room temperature for 3 hours to obtain mixture 1, mixture 1 The initial material composition is SiO 2 :TPAOH:H 2 O=1:0.36:35 (molar ratio); the mixture 1 was transferred to a hydrothermal synthesis kettle, and crystallized at 140° C. for 10 h to obtain zeolite seed crystals.

[0041] Step (2): Synthesis of MFI / MOR co-crystal molecular sieves

[0042] Add 462g of deionized water and 44.0g of sodium hydroxide into the plastic beaker in turn, after stirring evenly, add 18.0g of sodium aluminate under stirring state, after stirring until clarified, add 420g of silica sol (30wt%), the sol composition is SiO 2 : NaO 2 :Al 2 o 3 :H 2 O=1:0.3:0....

Embodiment 2

[0043] Embodiment 2 synthesizes Ti-MFI / MOR zeolite molecular sieve

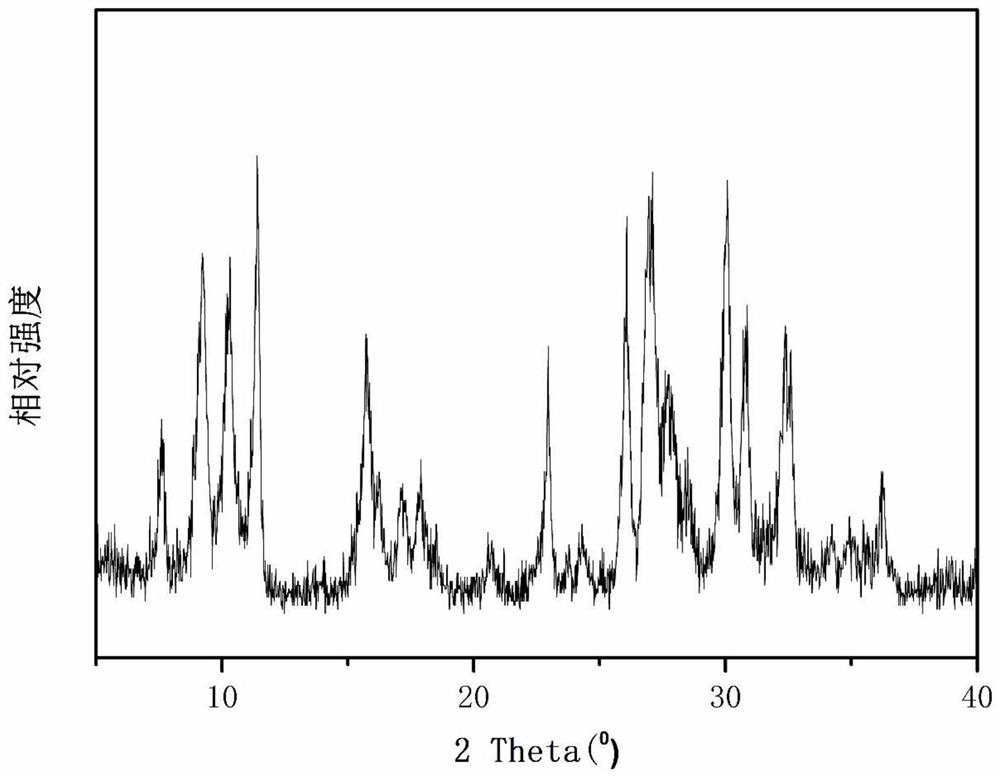

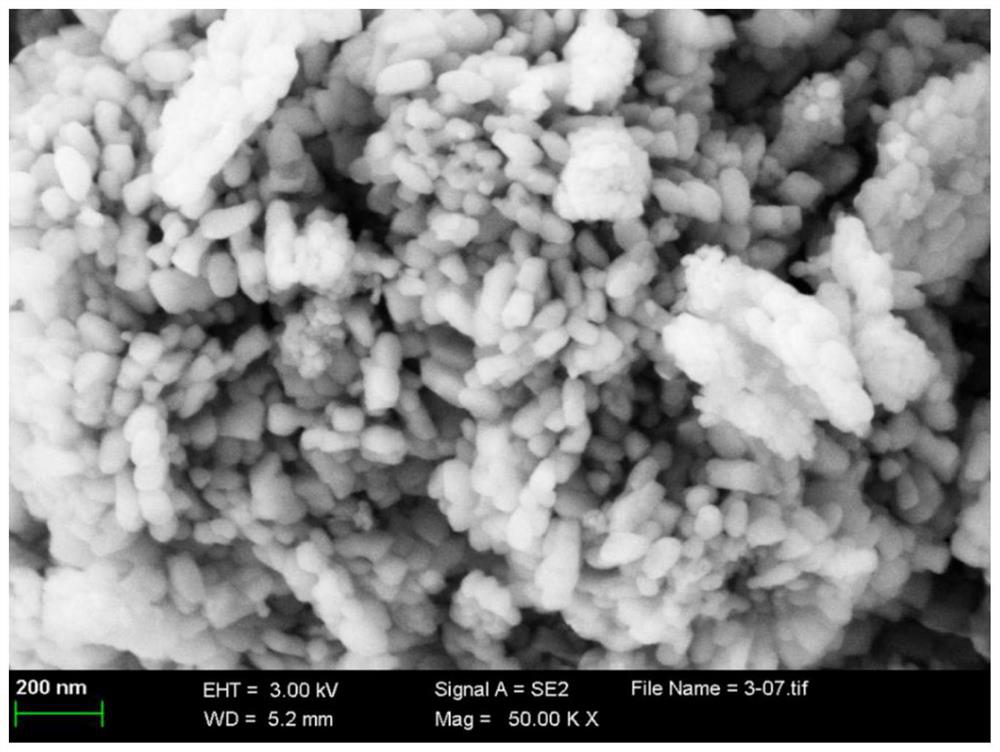

[0044] Take 10 g of the MFI / MOR eutectic molecular sieve synthesized in Example 1, reflux for 10 h in an aqueous solution of nitric acid (6 ml / L) with a solid-to-liquid ratio of 1:10, filter and wash until neutral, and dry at 80 ° C for 12 h to obtain dealuminated Sample: Place the sample in a quartz reaction tube, dehydrate and activate it at 400°C for 2h under a nitrogen atmosphere, then treat it with TiCl steam for 4h, then blow it with nitrogen for 1h, cool to room temperature, wash with deionized water, and dry at 110°C 12h, get the Ti-MFI / MOR eutectic molecular sieve sample, marked as 1#, 1# sample XRD peak figure 1 , which is the eutectic topological structure of MFI and MOR; see the SEM photo figure 2 , showing that the obtained Ti-MFI / MOR zeolite molecular sieve particle size is 80-160nm, and the silicon-titanium ratio is 41 according to XRF analysis.

Embodiment 3

[0045] Embodiment 3 synthesis Ti-MFI / MOR zeolite molecular sieve

[0046] The raw materials and synthesis steps are the same as in Example 2, except that the crystallization temperature in the step (1) of synthesizing the MFI / MOR eutectic molecular sieve is changed to 130°C to obtain a Ti-MFI / MOR zeolite molecular sieve sample, marked as 2 #. According to XRD test and analysis, the crystal phase is MFI / MOR eutectic molecular sieve; after SEM characterization, the particle size of Ti-MFI / MOR zeolite molecular sieve is 60-110nm, and the silicon-titanium ratio is 38 according to XRF analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com