Self-repairing water-based coating based on PU/PUF micro-capsules and PCL micro-capsules and preparation method thereof

A water-based coating and microcapsule technology, applied in microcapsule preparation, microsphere preparation, coating, etc., can solve the problems of irreversible damage, difficult to detect and monitor deep defects and damage of coatings, reduce costs, prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

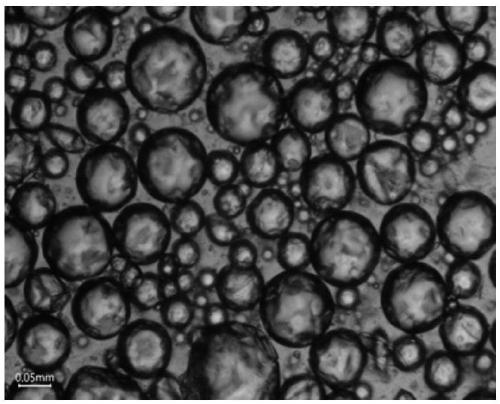

[0050] The specific process of preparing PU / PUF double-shell microcapsules is as follows:

[0051] 1) At 22°C, take 110mL of 14.3wt% gum arabic solution; then add 2.12g of urea, 0.23g of ammonium chloride and 0.19g of resorcinol to the gum arabic solution; then, add acid to raise the pH to 3.4; Then add a defoamer to remove surface air bubbles to obtain a mixed solution;

[0052] 2) Under the protection of an inert gas, dissolve 4.23g of TDI (toluene diisocyanate prepolymer) curing agent in 4mL of ethyl acetate, add 29.63g of IPDI after the curing agent is completely dissolved, and mix evenly to obtain a mixture;

[0053] 3) Then pour the mixture into the mixed solution, stir for 10-30 minutes, add 5.86g of formaldehyde, and raise the temperature to 55°C. After continuous stirring for 3.3 hours, cool to room temperature; after several times of filtration, dry in a fume hood at room temperature to obtain PU / PUF microcapsules.

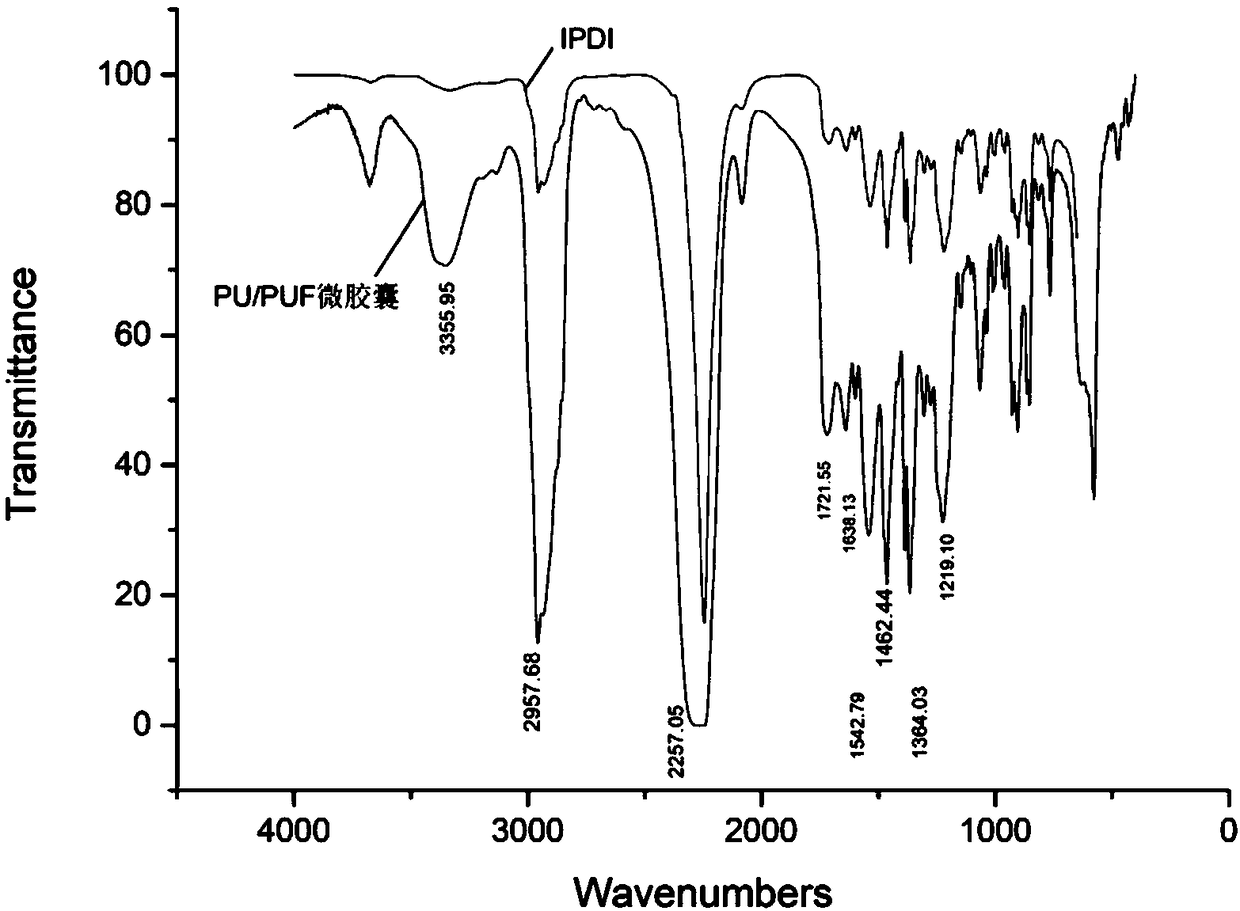

[0054] Such as figure 1 As shown, the spectra o...

Embodiment 2

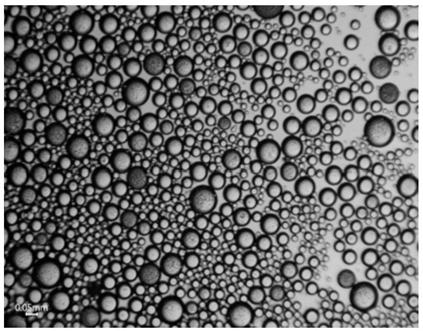

[0067] The specific process of preparing PU / PUF double-shell microcapsules is as follows:

[0068] 1) At 25°C, get 132mL of 12.2wt% chitosan solution; then add 1.99g urea, 0.23g ammonium chloride and 0.22g resorcinol to the chitosan solution; subsequently, add acid to increase the pH to 3.1; Then add defoamer to remove surface air bubbles to obtain a mixed solution;

[0069] 2) Under the protection of an inert gas, 3.96g MDI prepolymer (diphenylmethane diisocyanate prepolymer) curing agent was dissolved in 4.5mL ethyl acetate, and after the curing agent was completely dissolved, 27.52g HDI prepolymer (6 methylene diisocyanate prepolymer), uniformly mixed to obtain a mixture;

[0070] 3) Then pour the mixture into the mixed solution, stir for 10-30 minutes, add 6.19g of formaldehyde, and raise the temperature to 63°C. After continuous stirring for 4.10 hours, cool to room temperature; after several times of filtration, dry in a fume hood at room temperature to obtain PU / PUF m...

Embodiment 3

[0077] The specific process of preparing PU / PUF double-shell microcapsules is as follows:

[0078] 1) At 28°C, take 123mL of 10.1wt% gum arabic solution; then add 2.35g urea, 0.26g ammonium chloride and 0.28g resorcinol to the gum arabic solution; then add acid to raise the pH to 4.5; Then add a defoamer to remove surface air bubbles to obtain a mixed solution;

[0079] 2) Under the protection of an inert gas, dissolve 4.38g of TDI curing agent in 4mL of ethyl acetate, add 26.3g of IPDI after the curing agent is completely dissolved, and mix evenly to obtain a mixture;

[0080] 3) Then pour the mixture into the mixed solution, stir for 10-30 minutes, add 6.4g of formaldehyde, and raise the temperature to 64°C. After continuous stirring for 3.6 hours, cool to room temperature; after several times of filtration, dry in a fume hood at room temperature to obtain PU / PUF microcapsules.

[0081] The specific process of preparing PCL microcapsules is as follows:

[0082] At 28°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com