Patents

Literature

622results about "Alkali metal sulfides/polysulfides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

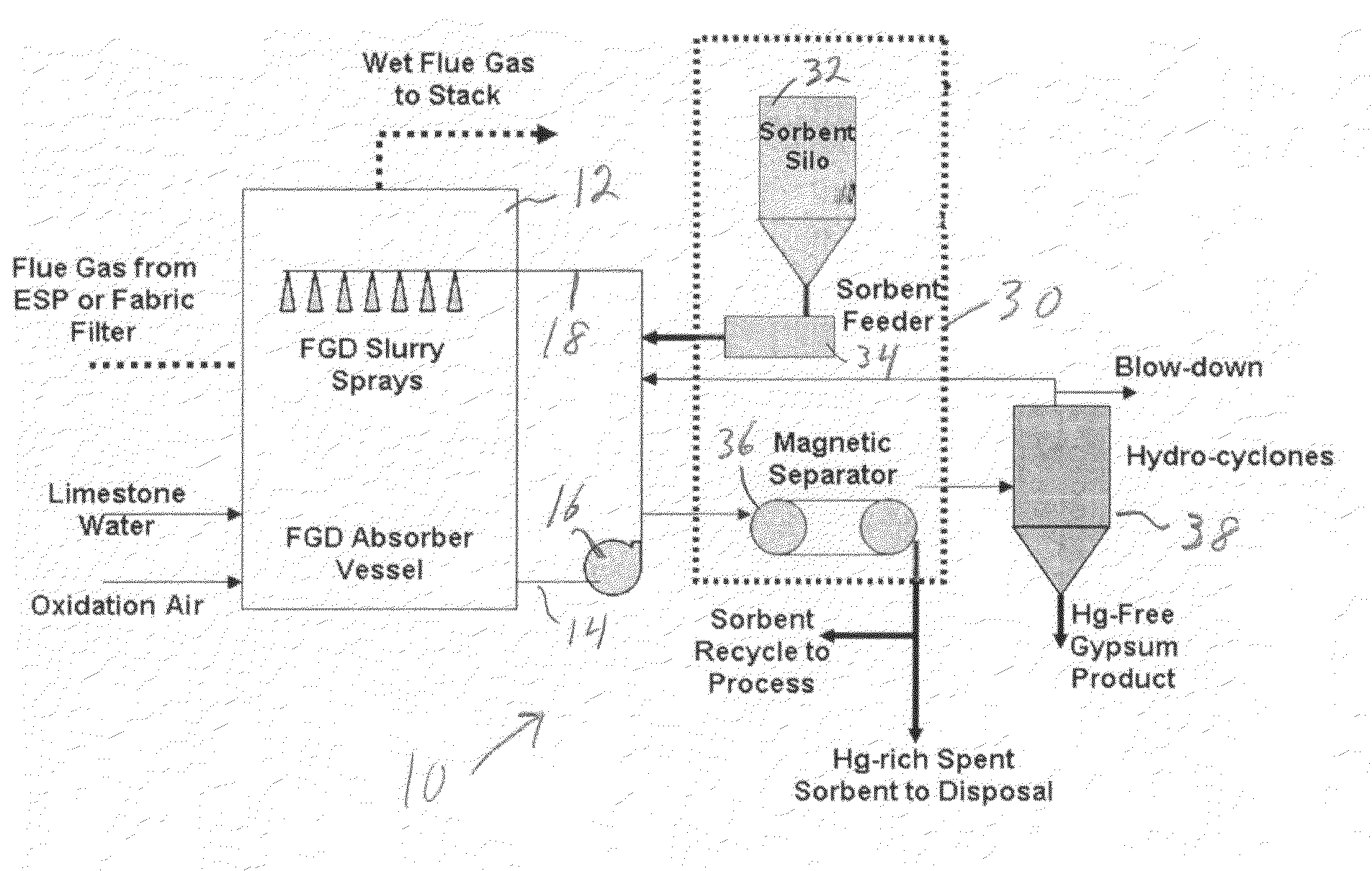

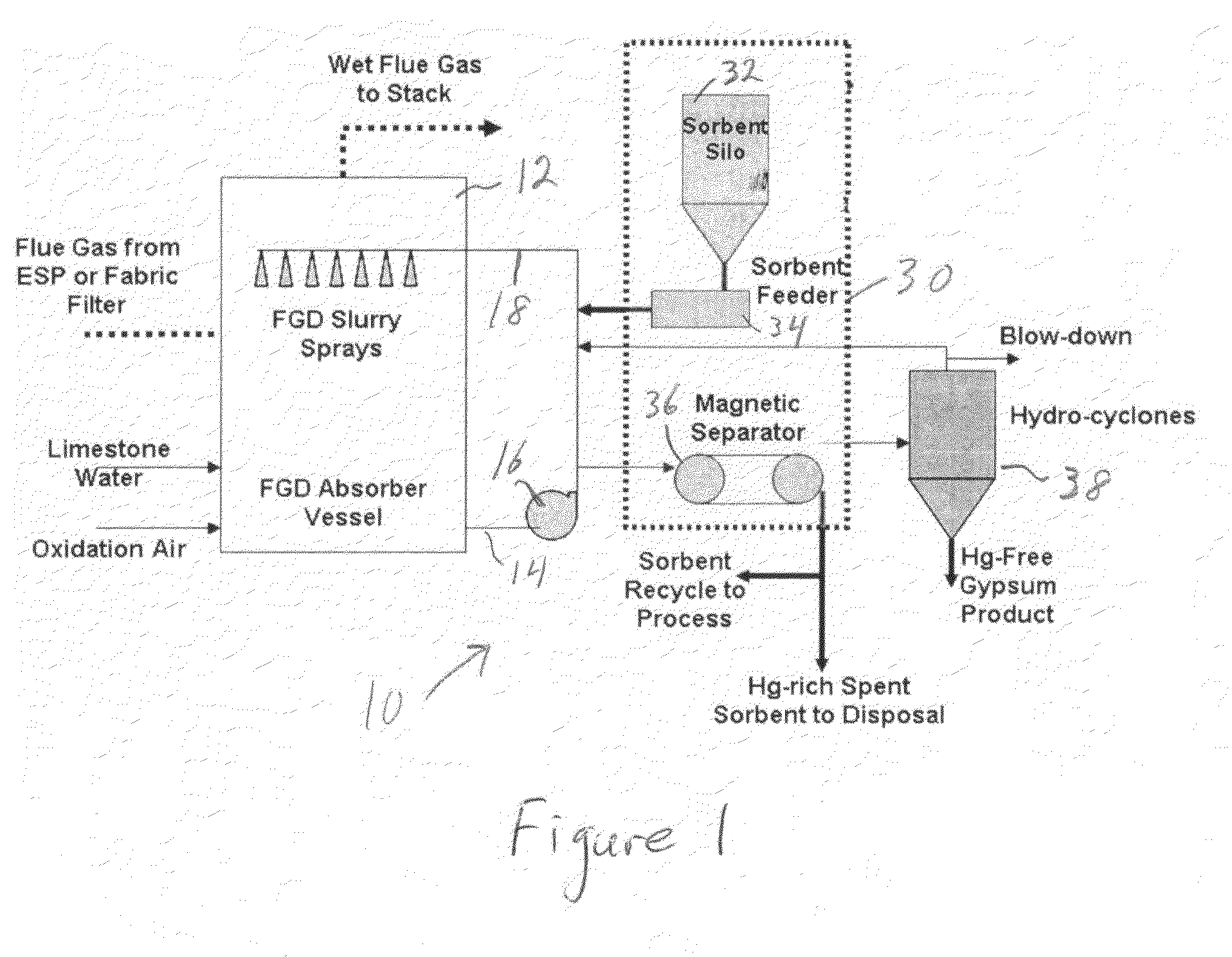

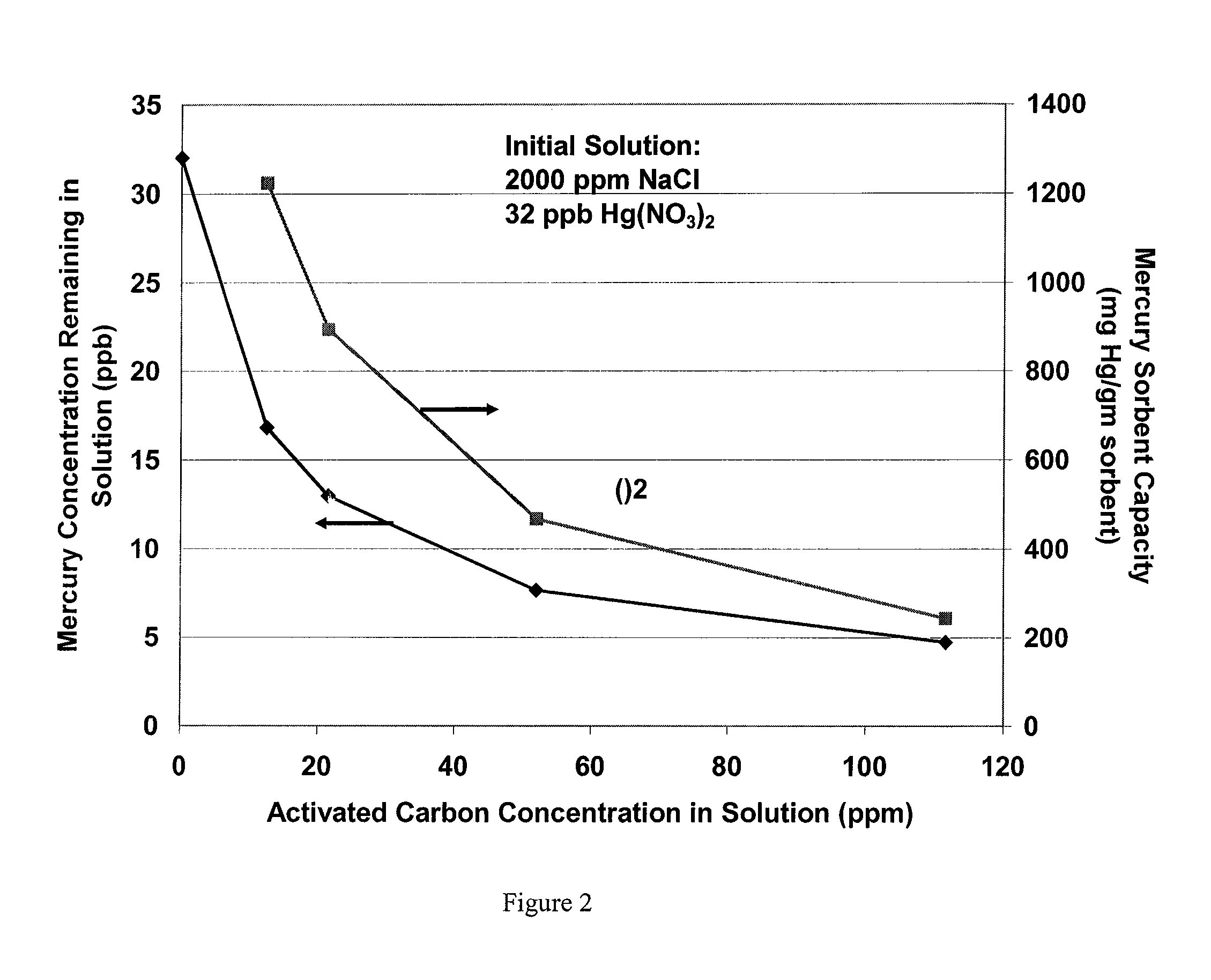

System and method for sequestration and separation of mercury in combustion exhaust gas aqueous scrubber systems

ActiveUS7722843B1Emission reductionMinimize re-emissionCombination devicesExhaust apparatusCombustionSorbent

A process, system and sorbent for removal of mercury from a combustion exhaust gas stream in a combustion exhaust gas purification scheme that includes a combustion exhaust scrubber system that uses an aqueous liquid to remove acid gases from the combustion exhaust gas. A powdered mercury sorbent is used. The sorbent is introduced into the aqueous scrubber liquid in the scrubber system. After introduction of the mercury sorbent into the scrubber liquid, at least some of the mercury sorbent is separated from the scrubber liquid.

Owner:SRINIVASACHAR SRIVATS

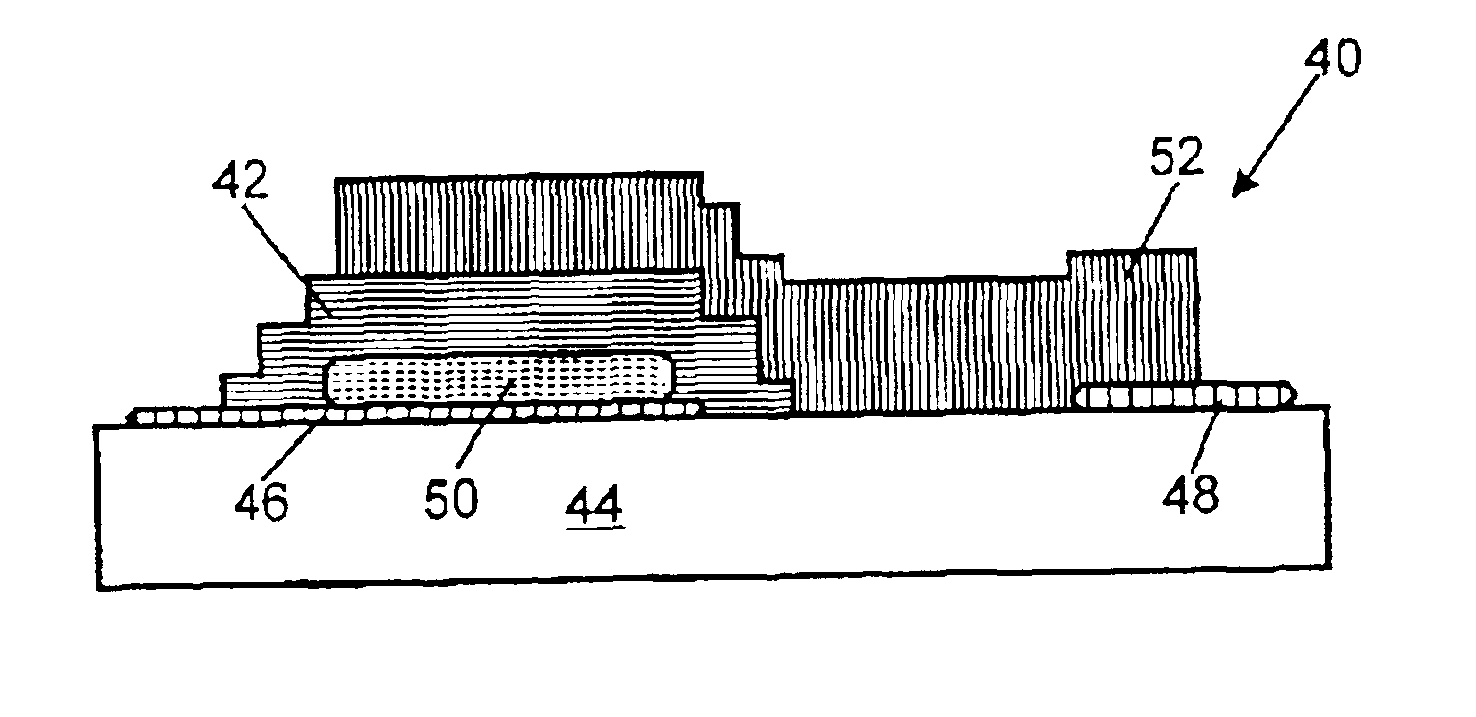

Thin film battery and electrolyte therefor

A solid amorphous electrolyte composition for a thin-film battery. The electrolyte composition includes a lithium phosphorus oxynitride material containing a sulfide ion dopant wherein the atomic ratio of sulfide ion to phosphorus ion (S / P) in the electrolyte ranges greater than 0 up to about 0.2. The composition is represented by the formula: where 2x+3y+2z=5+w, x ranges from about 3.2 to about 3.8, y ranges from about 0.13 to about 0.46, z ranges from greater than zero up to about 0.2, and w ranges from about 2.9 to about 3.3. Thin-film batteries containing the sulfide doped lithium oxynitride electrolyte are capable of delivering more power and energy than thin-film batteries containing electrolytes without sulfide doping.

Owner:OAK RIDGE MICRO ENERGY

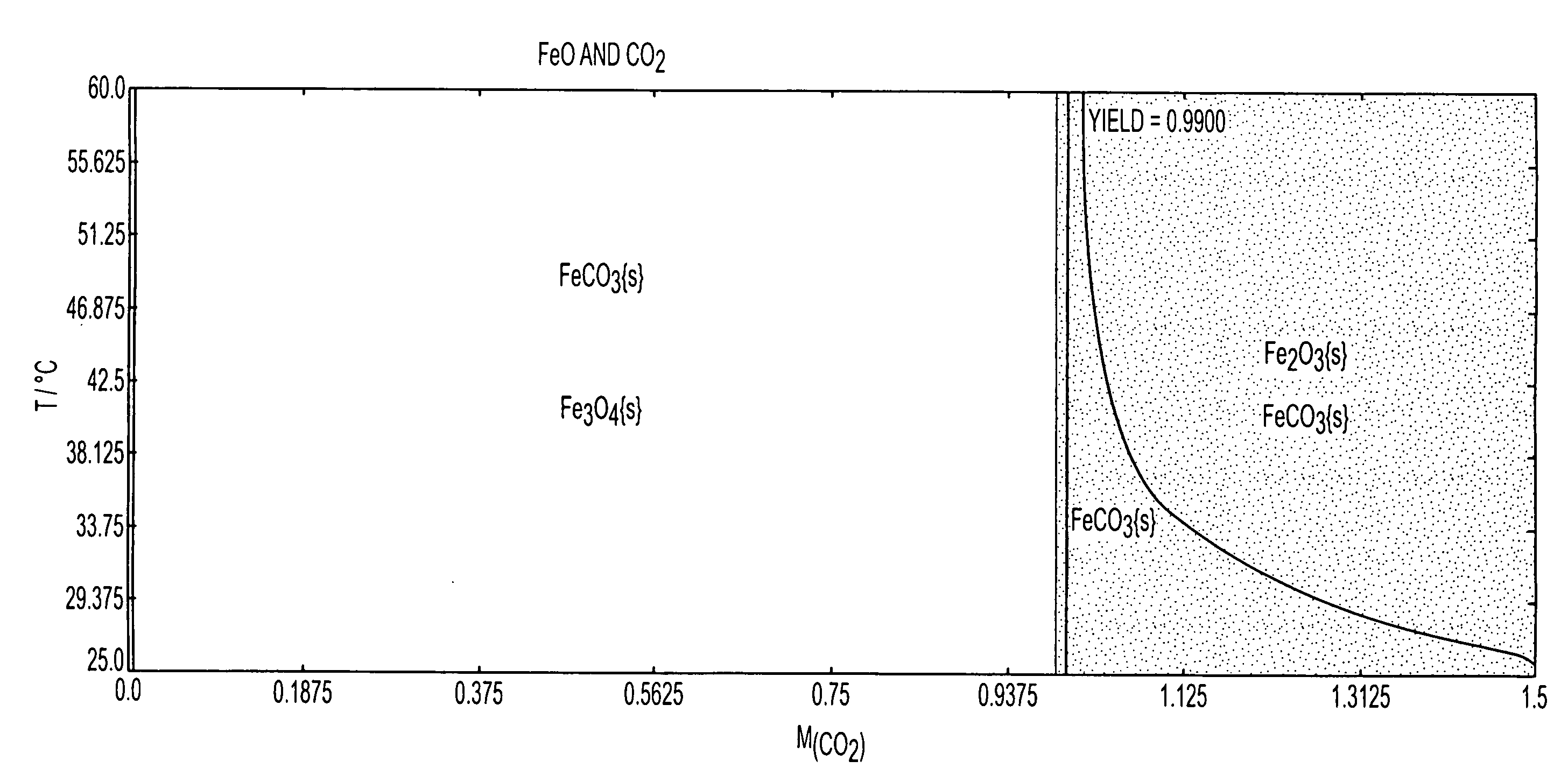

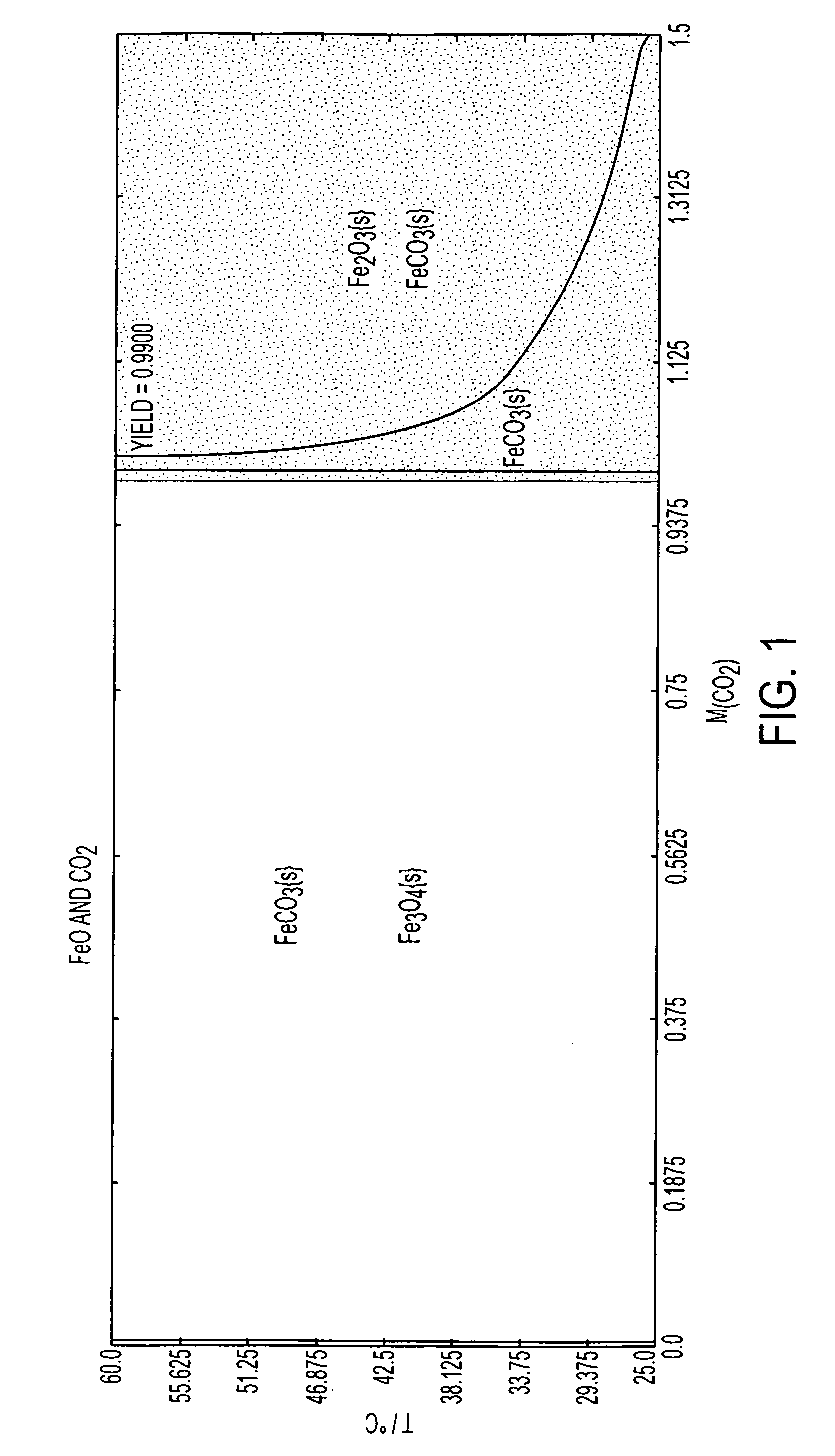

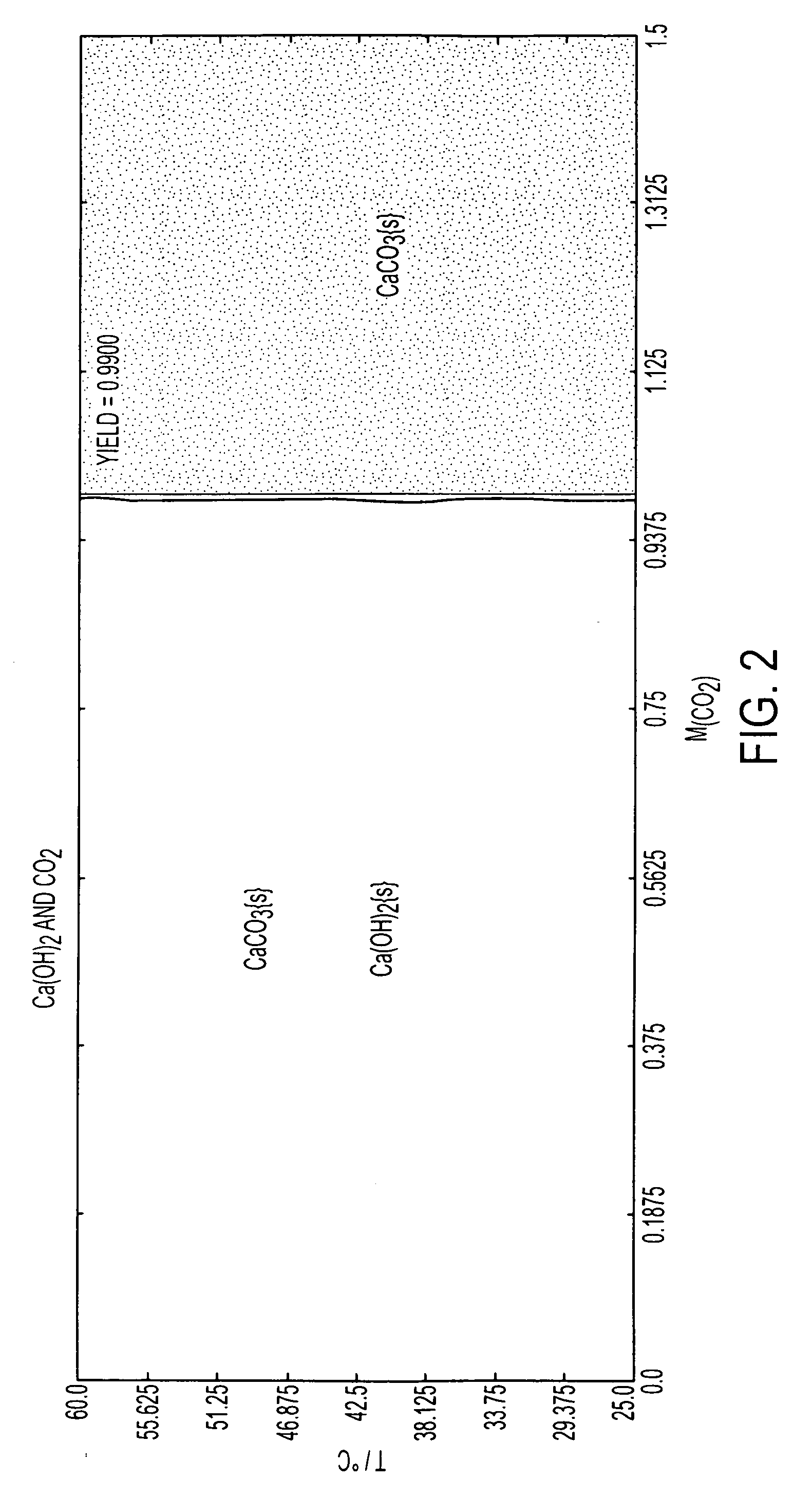

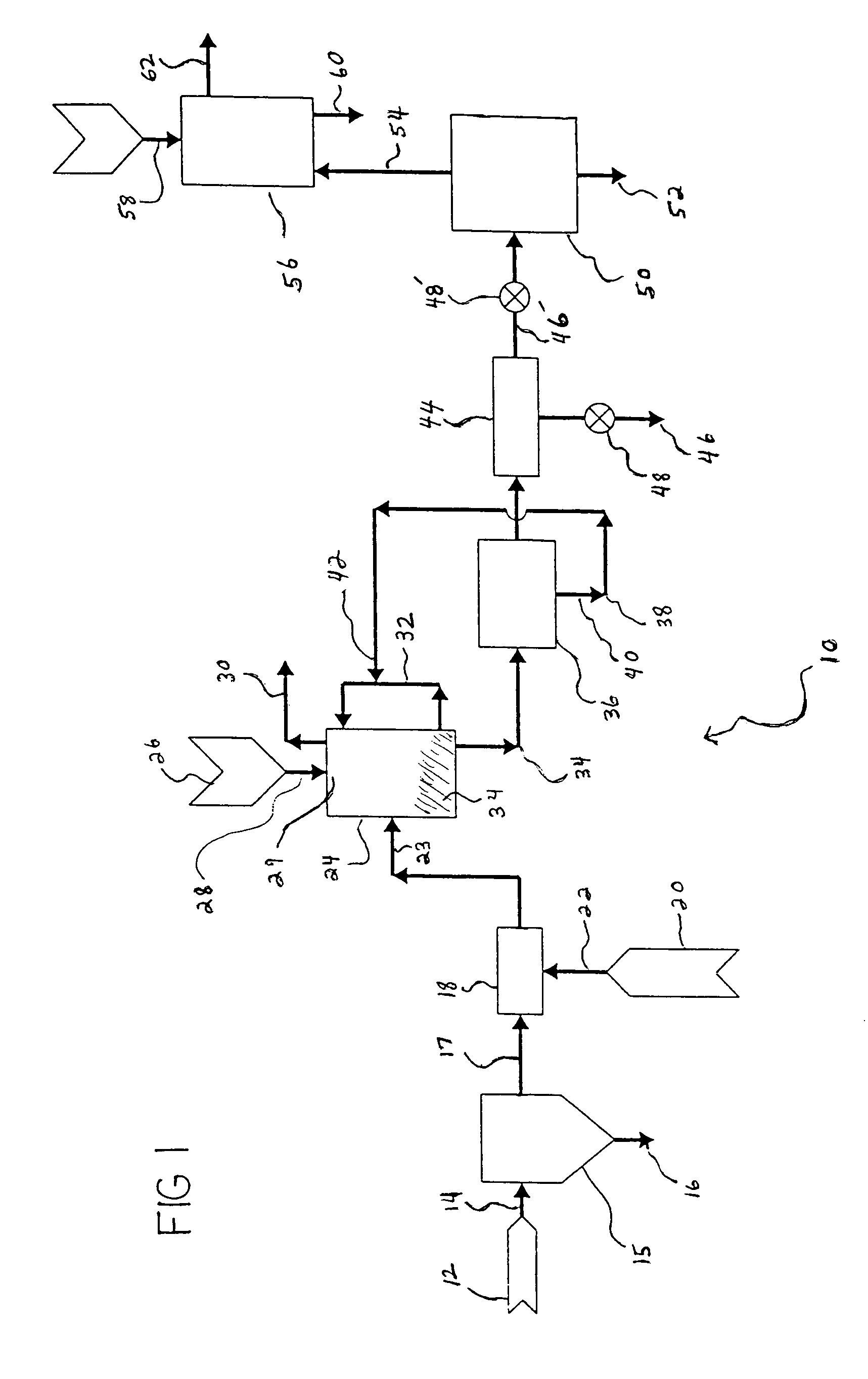

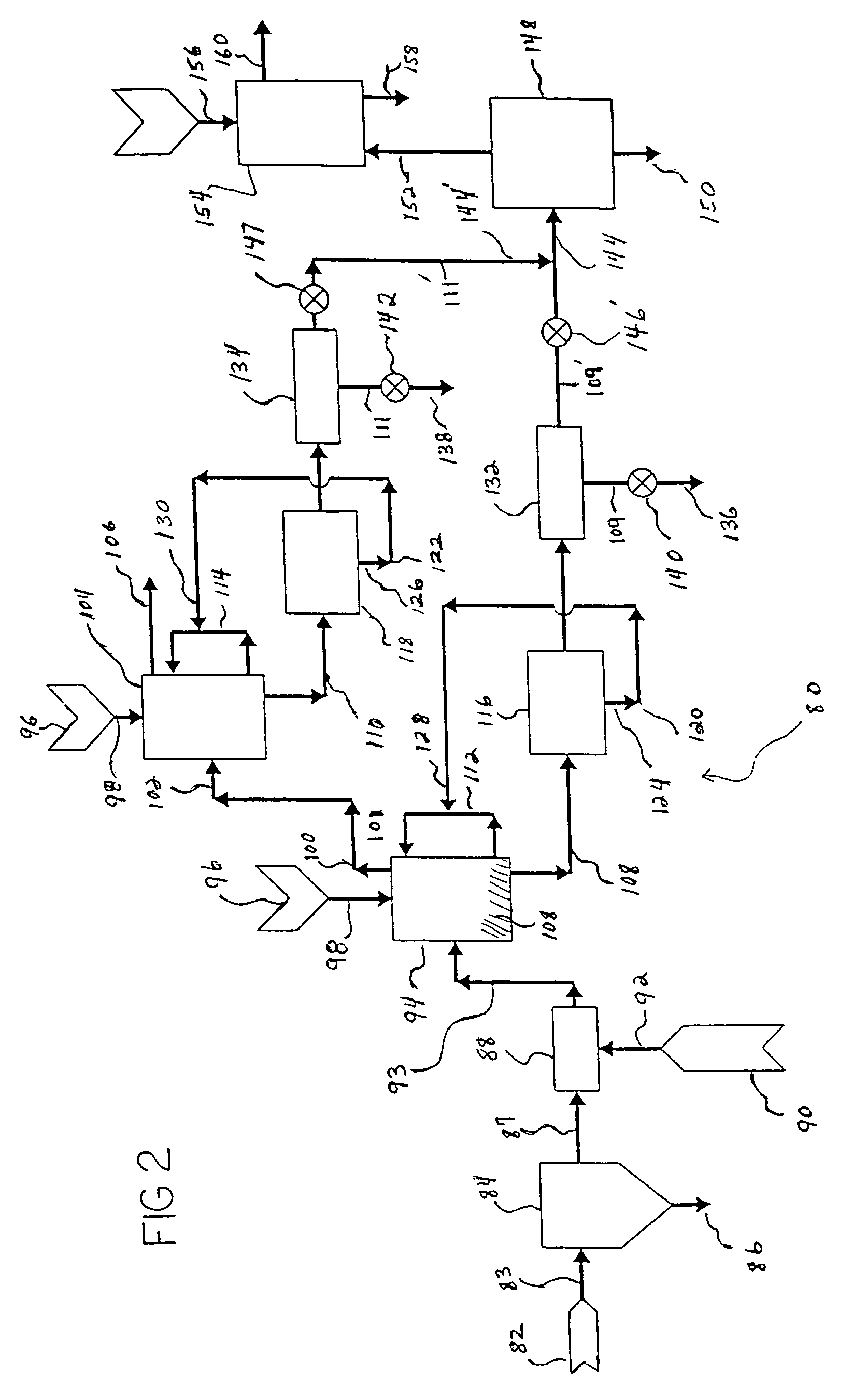

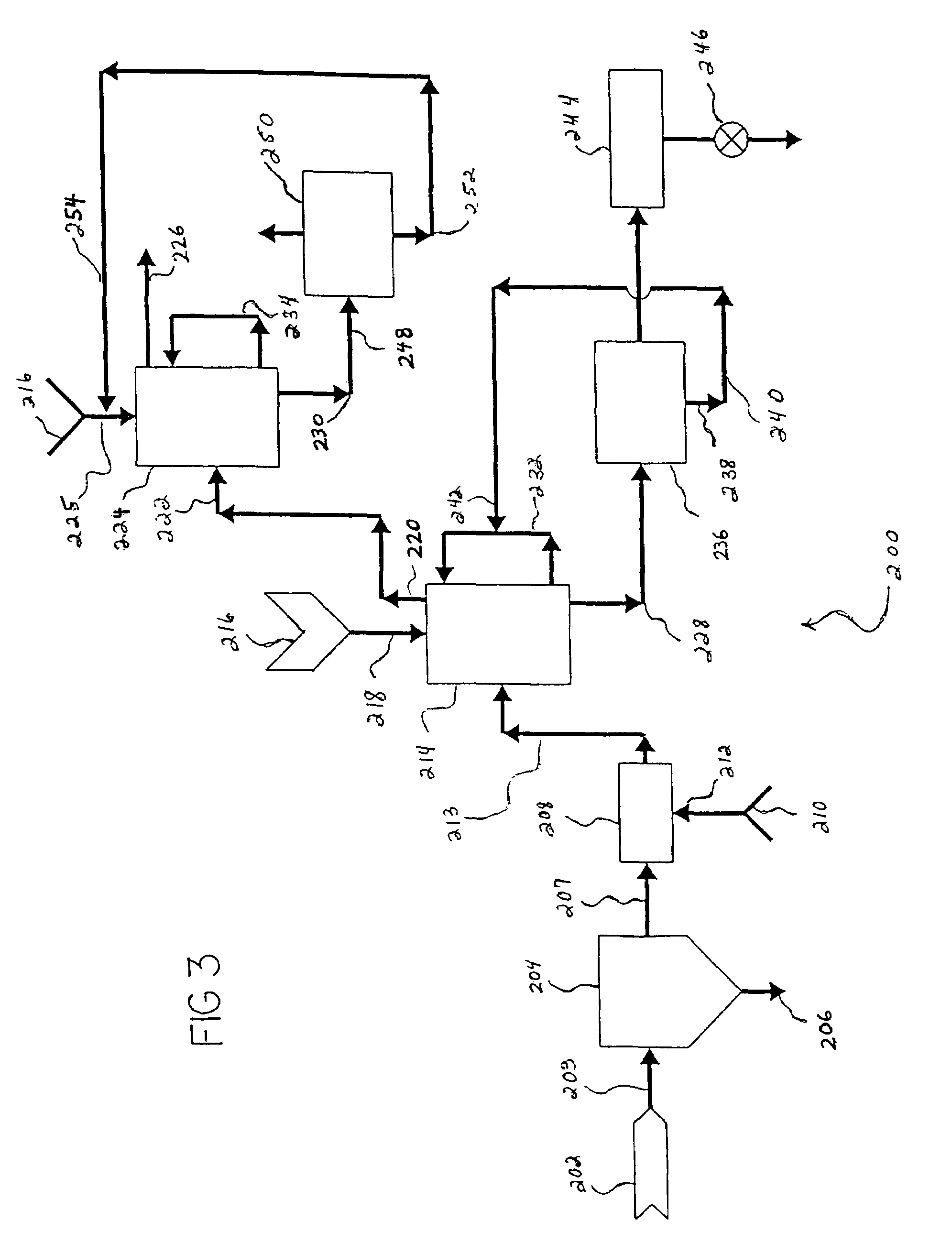

Systems and methods for carbon capture and sequestration and compositions derived therefrom

ActiveUS20090143211A1Promote formationCalcium/strontium/barium carbonatesNitrogen compoundsInterior spaceProduct formation

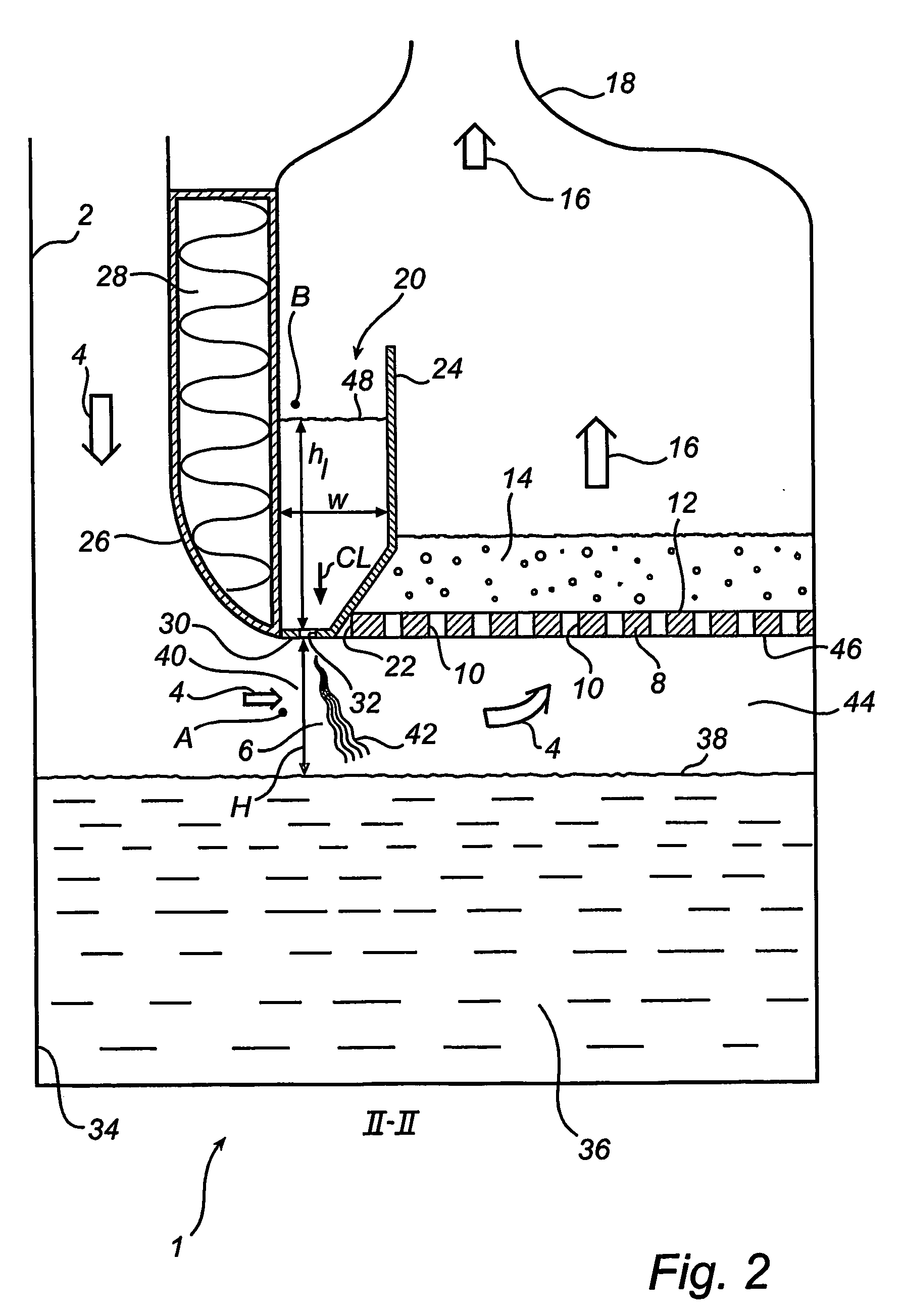

A method of sequestering a greenhouse gas is described, which comprises: (i) providing a solution carrying a first reagent that is capable of reacting with a greenhouse gas; (ii) contacting the solution with a greenhouse gas under conditions that promote a reaction between the at least first reagent and the greenhouse gas to produce at least a first reactant; (iii) providing a porous matrix having interstitial spaces and comprising at least a second reactant; (iv) allowing a solution carrying the at least first reactant to infiltrate at least a substantial portion of the interstitial spaces of the porous matrix under conditions that promote a reaction between the at least first reactant and the at least second reactant to provide at least a first product; and (v) allowing the at least first product to form and fill at least a portion of the interior spaces of the porous matrix, thereby sequestering a greenhouse gas.

Owner:RUTGERS THE STATE UNIV

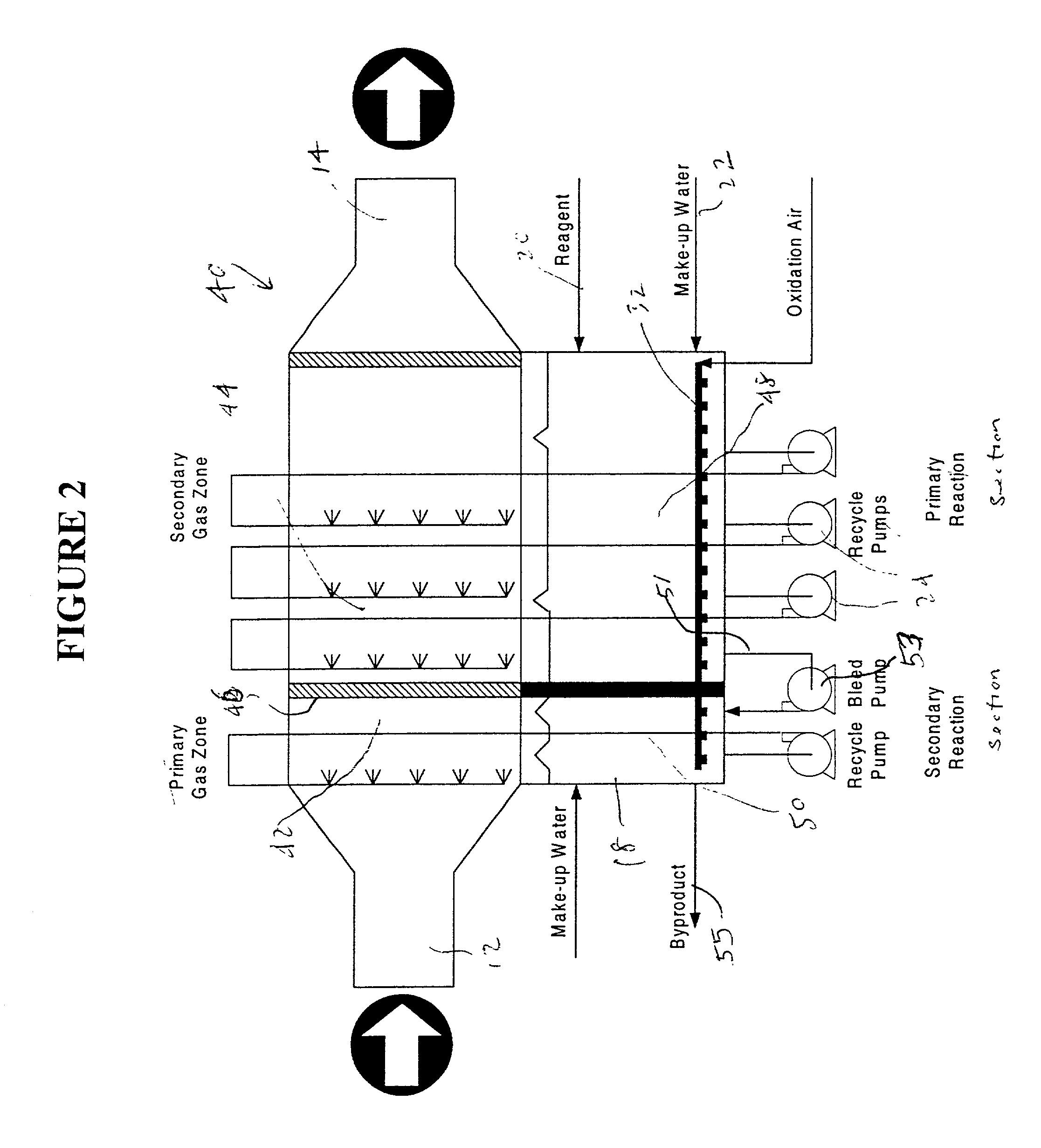

Multi-component removal in flue gas by aqua ammonia

InactiveUS7255842B1Regeneration process is less-costlyIncrease load capacityGas treatmentNitrogen compoundsNitric oxideSlurry

A new method for the removal of environmental compounds from gaseous streams, in particular, flue gas streams. The new method involves first oxidizing some or all of the acid anhydrides contained in the gas stream such as sulfur dioxide (SO2) and nitric oxide (NO) and nitrous oxide (N2O) to sulfur trioxide (SO3) and nitrogen dioxide (NO2). The gas stream is subsequently treated with aqua ammonia or ammonium hydroxide which captures the compounds via chemical absorption through acid-base or neutralization reactions. The products of the reactions can be collected as slurries, dewatered, and dried for use as fertilizers, or once the slurries have been dewatered, used directly as fertilizers. The ammonium hydroxide can be regenerated and recycled for use via thermal decomposition of ammonium bicarbonate, one of the products formed. There are alternative embodiments which entail stoichiometric scrubbing of nitrogen oxides and sulfur oxides with subsequent separate scrubbing of carbon dioxide.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

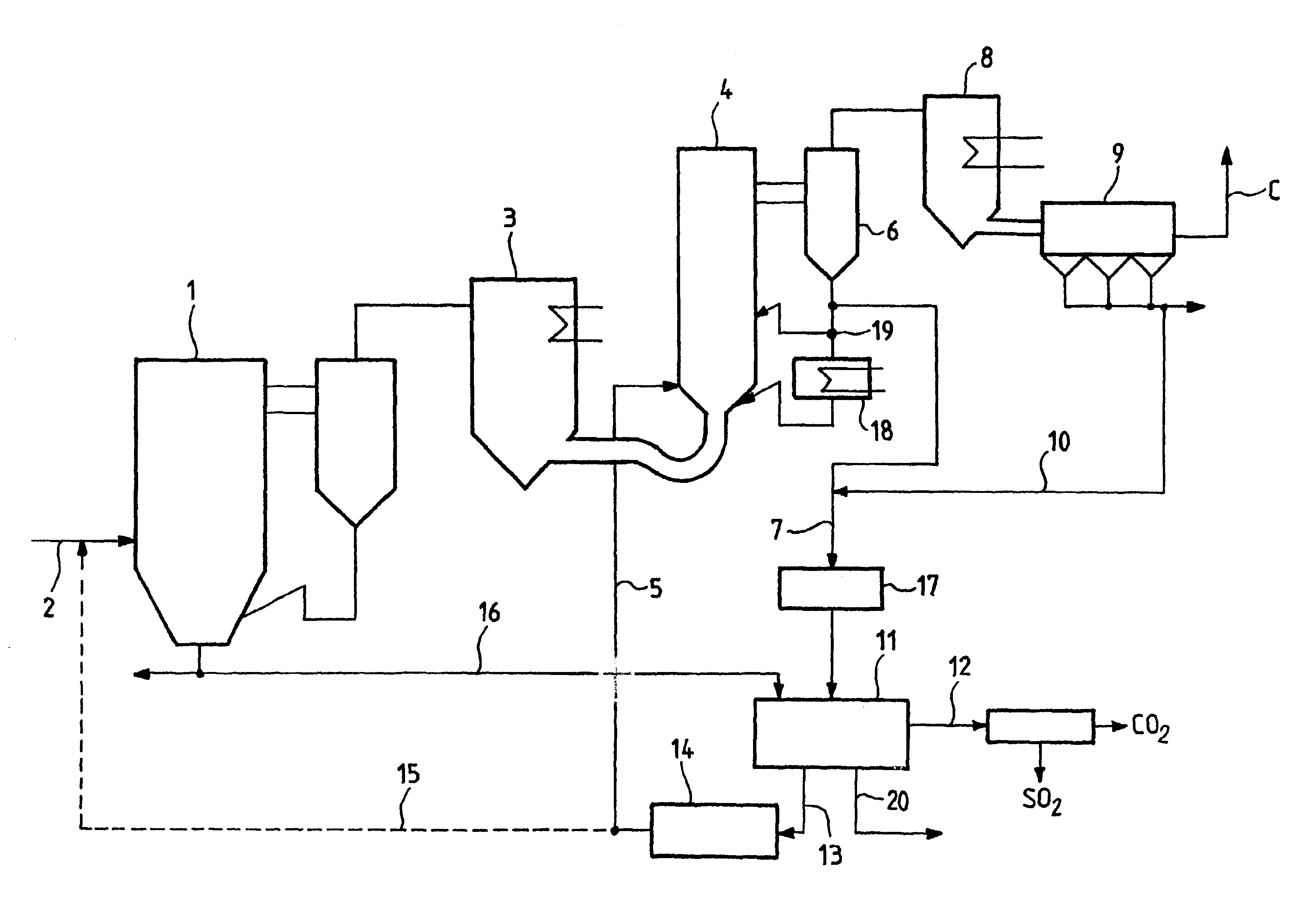

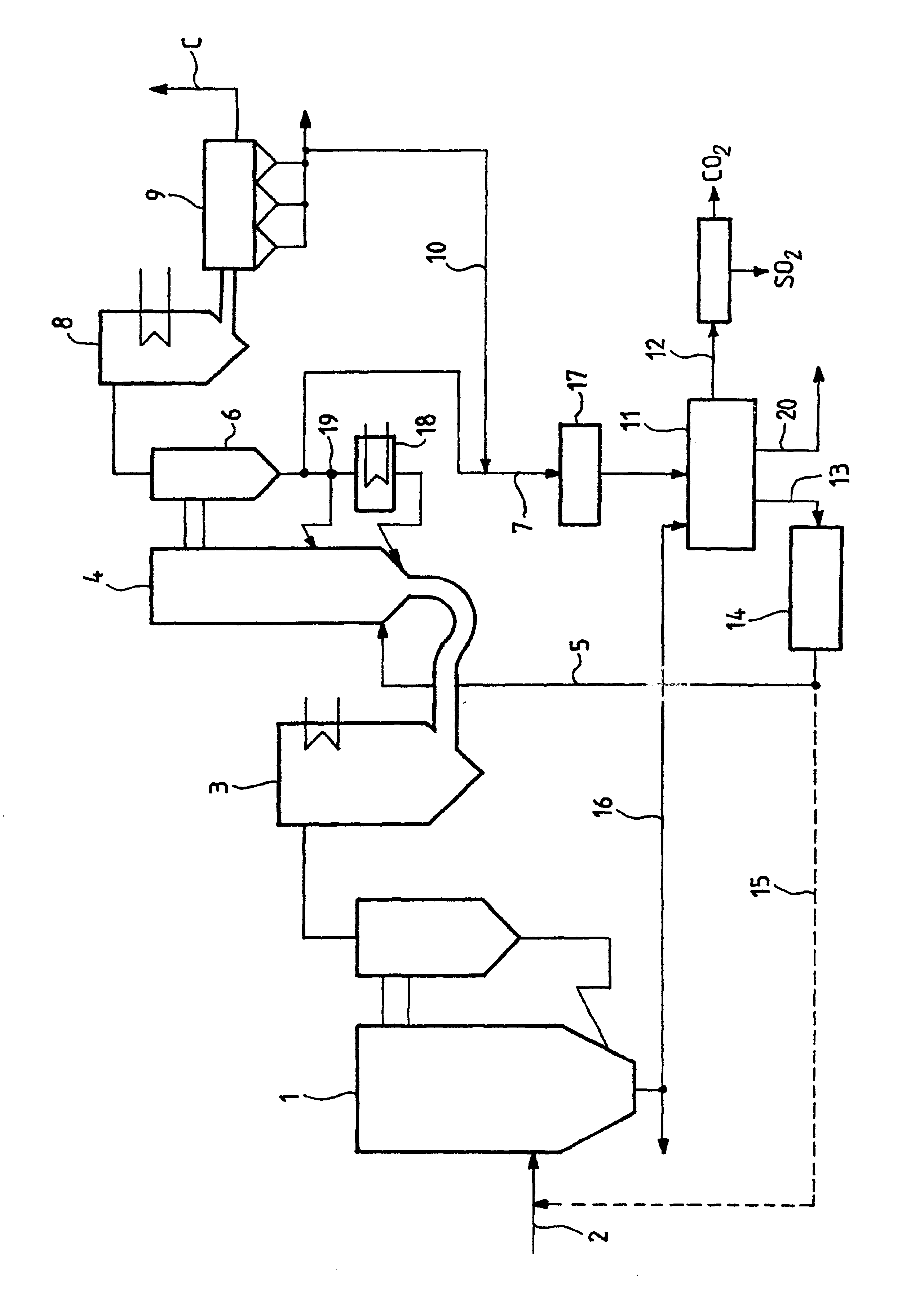

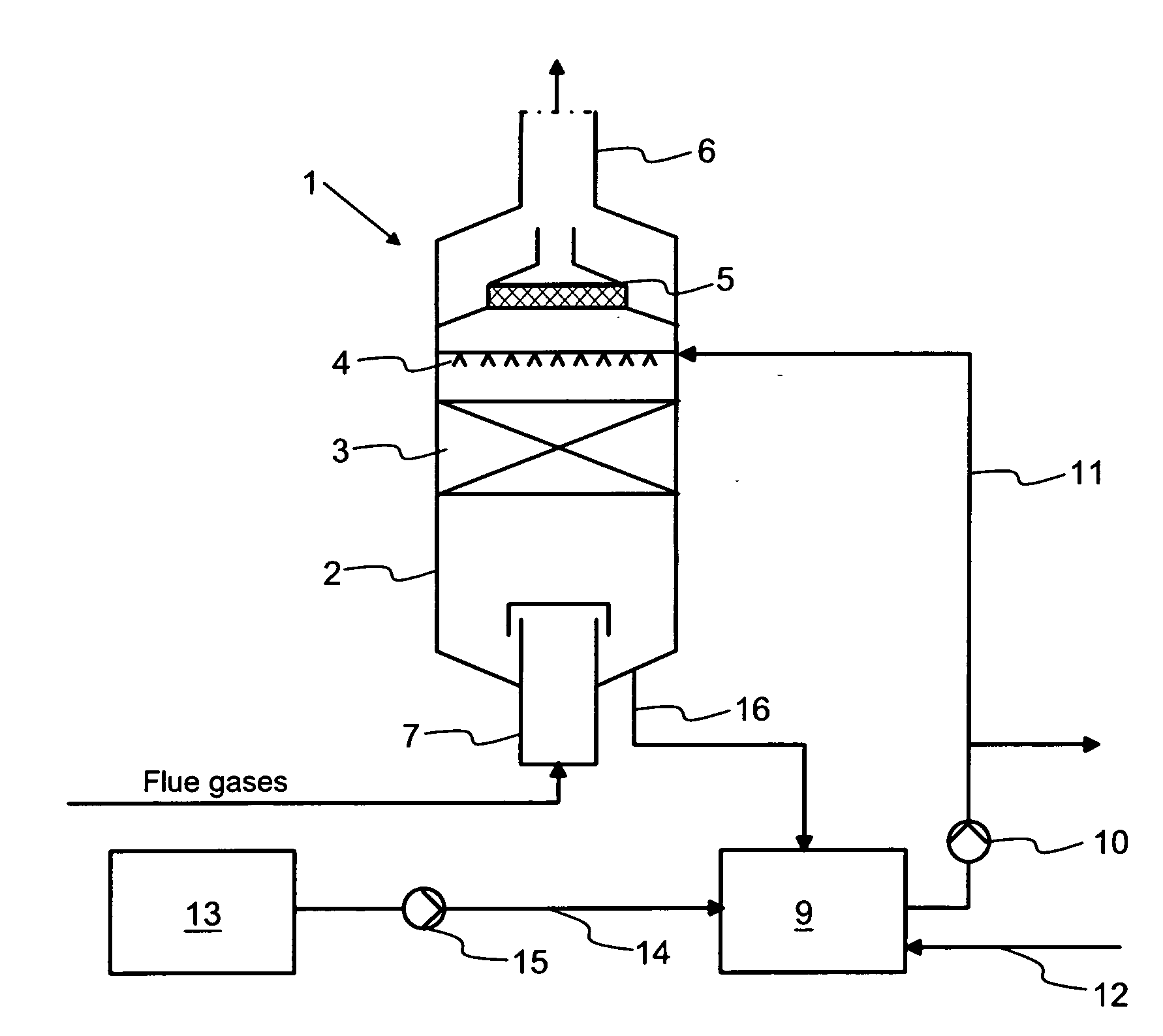

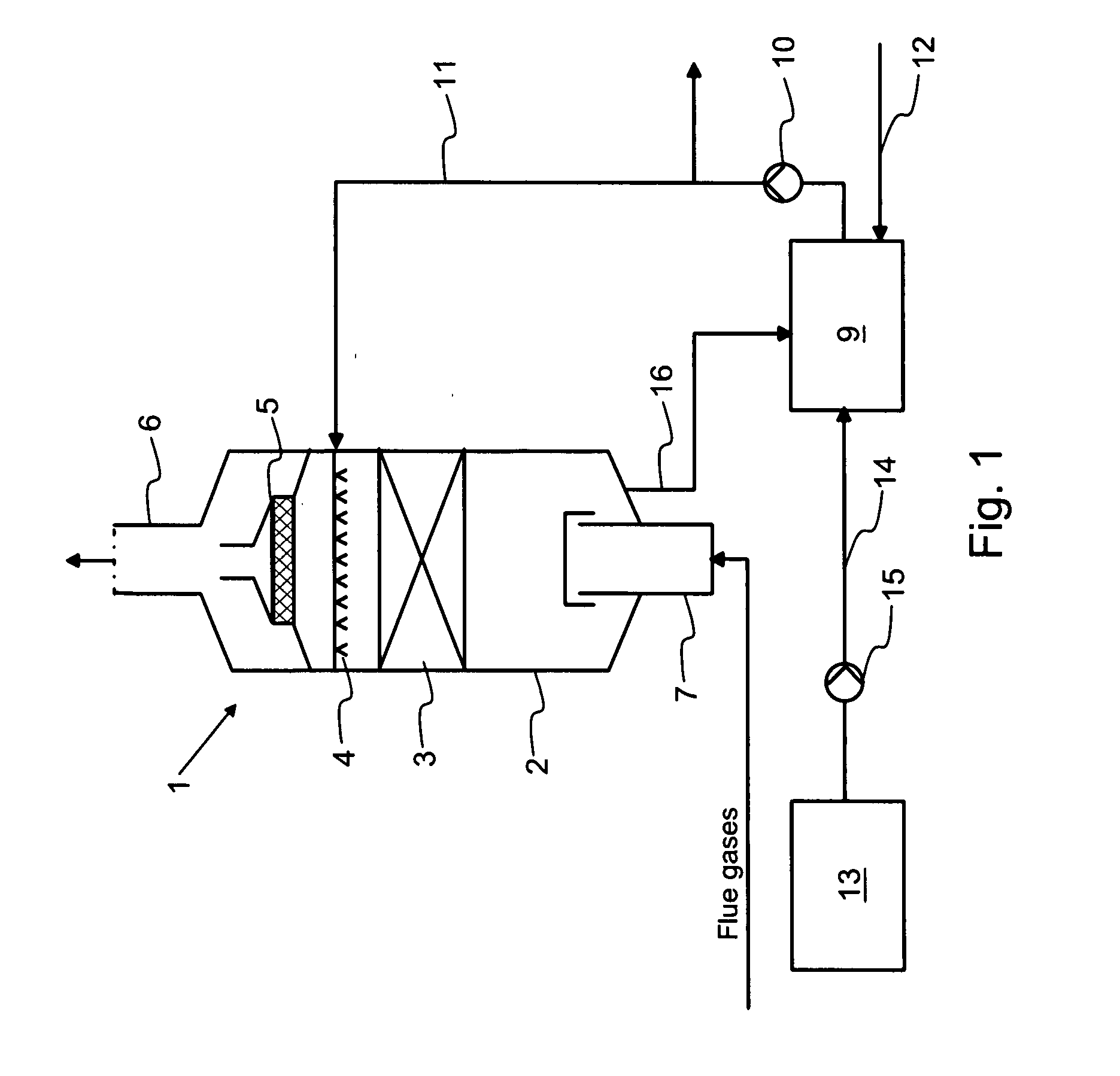

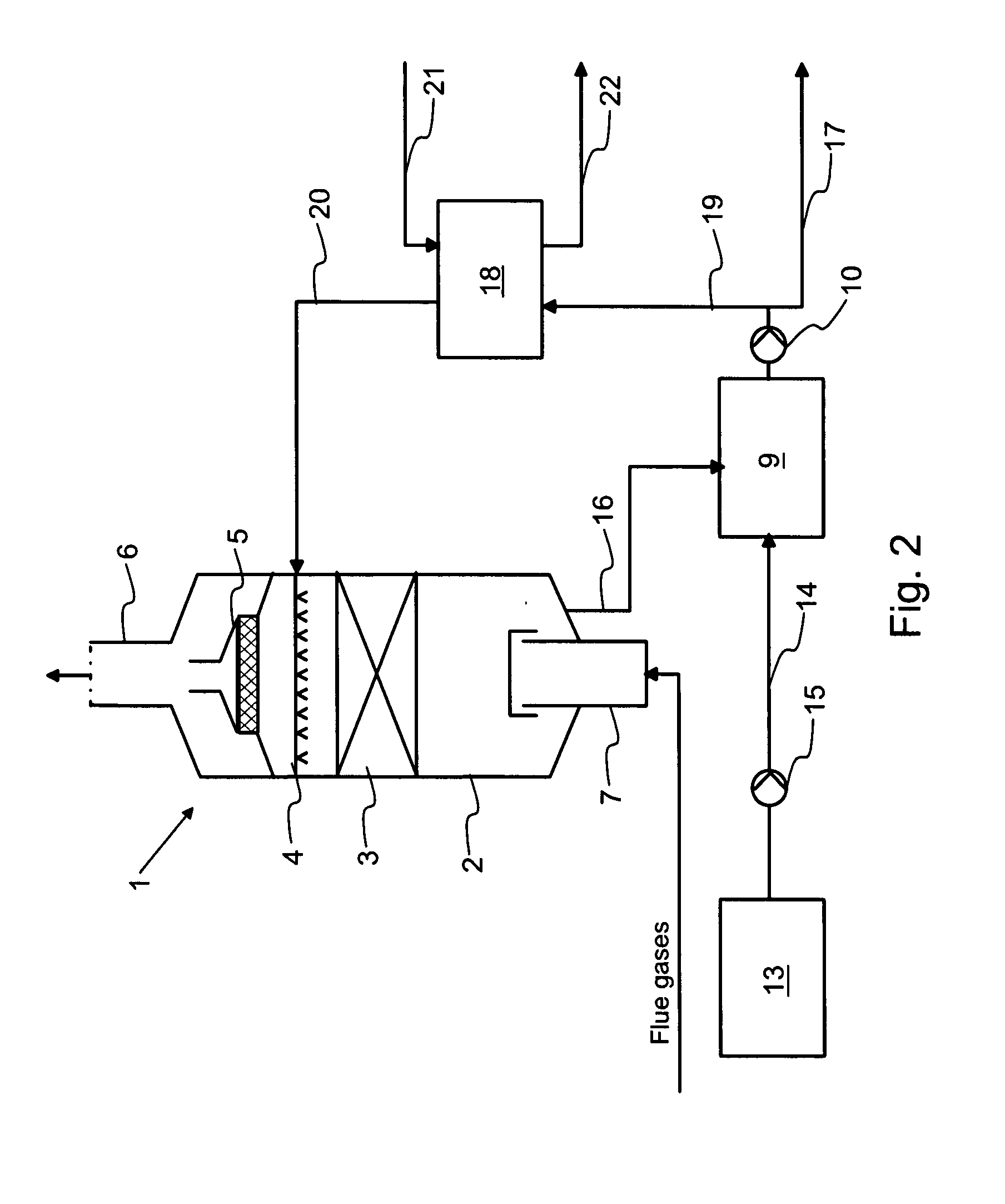

Method of simultaneously reducing CO2 and SO2 emissions in a combustion installation

InactiveUS6737031B2Reduce carbon dioxide emissionsFluidized bed combustionGas treatmentCombustionFlue gas

The method of simultaneously reducing carbon dioxide (CO2) emissions and sulfur dioxide (SO2) emissions produced by the combustion of carbon-containing matter in a hearth consists in injecting into the hearth a calcium-based agent, a fraction of which absorbs SO2 after decarbonization, and then, after the flue gases have been subjected to intermediate cooling, in causing them to transit via a first reactor and in putting them in contact therein with the other fraction of the absorbant that has not reacted with SO2 so as to capture CO2 from the flue gases by carbonization, then, in a separator, in extracting the solids contained in the flue gases output from the first reactor so as to subject them to heat treatment in a second reactor in order to extract CO2 therefrom by decarbonization and in order to recycle the resulting regenerated CO2 absorbant to the first reactor.

Owner:GENERAL ELECTRIC TECH GMBH

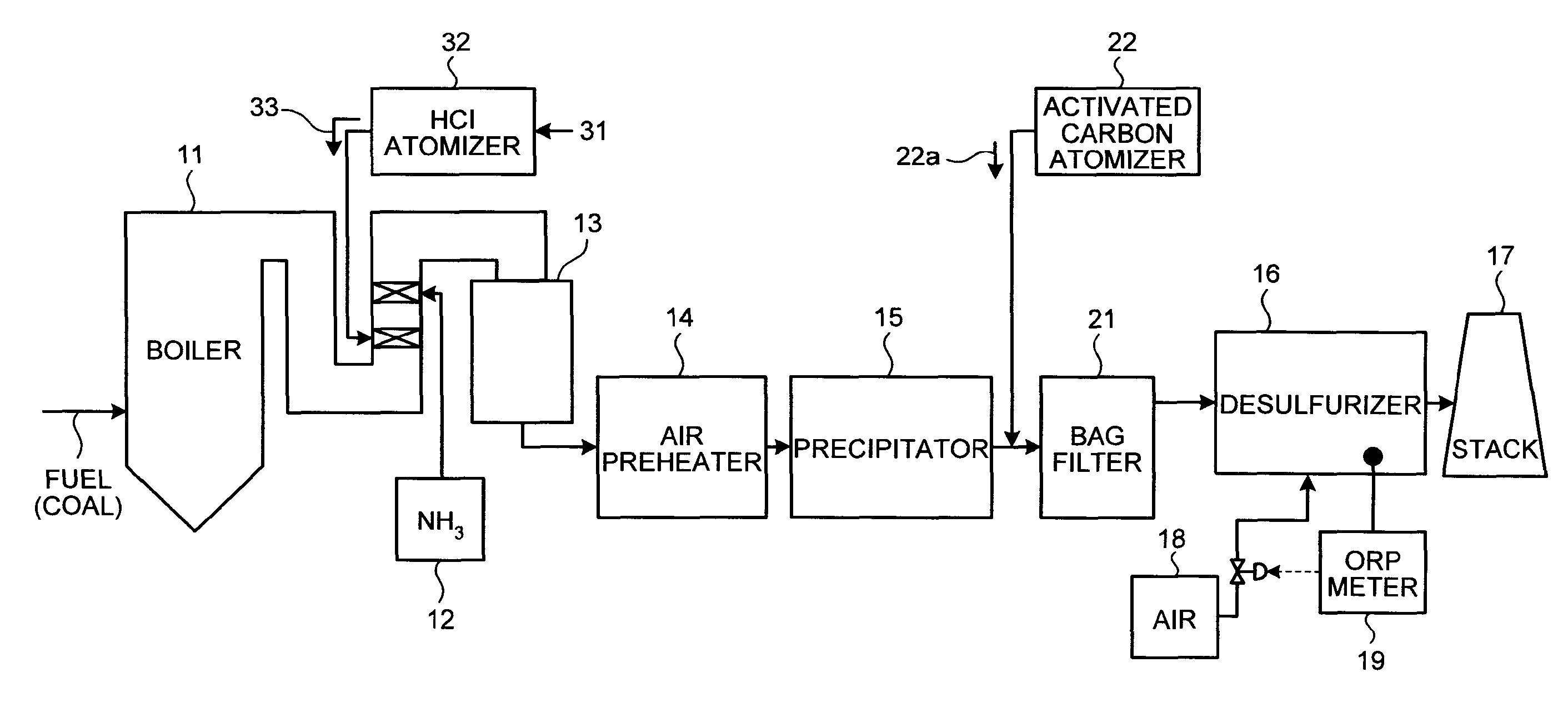

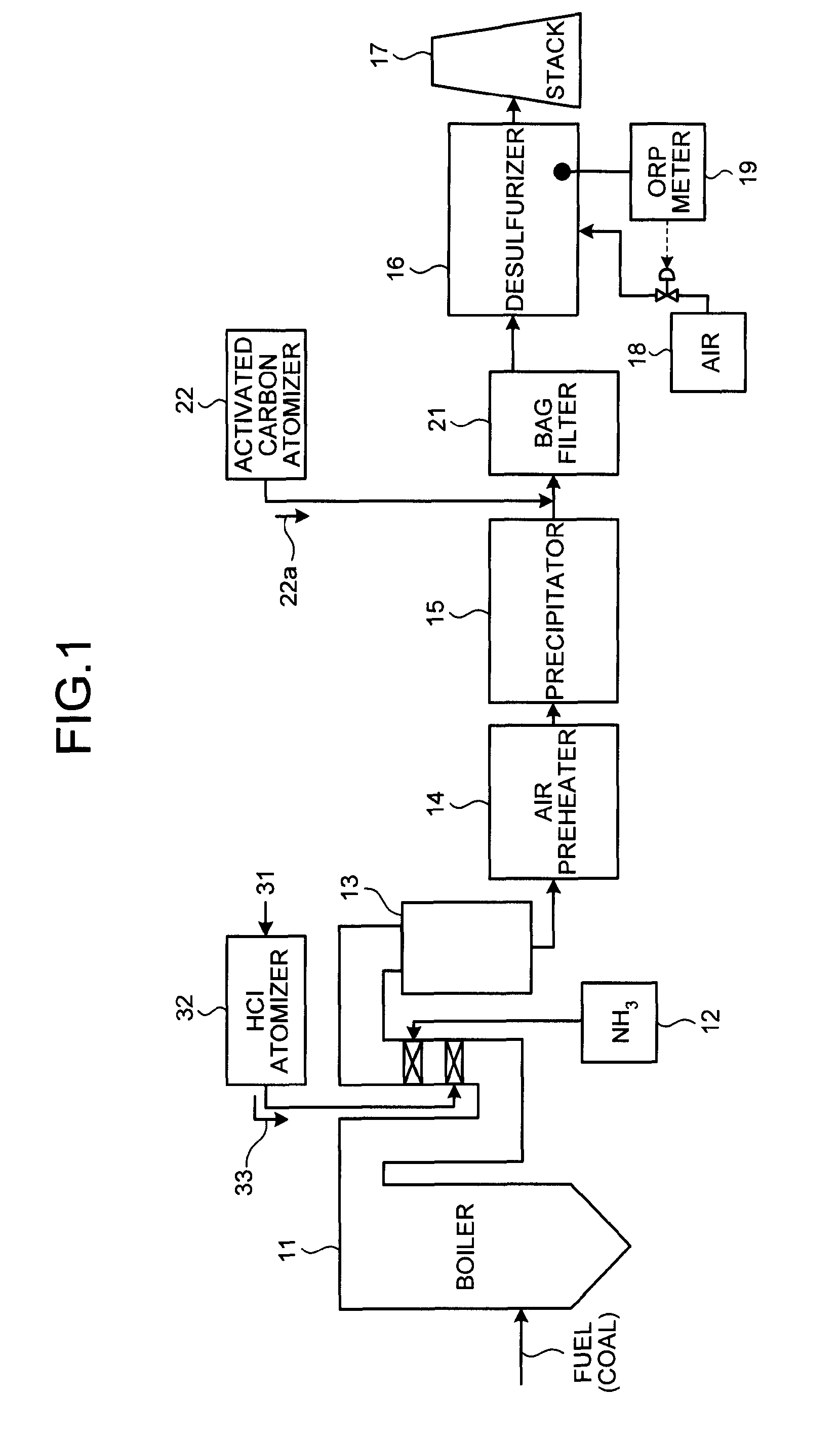

Flue gas control system of coal combustion boiler and operating method thereof

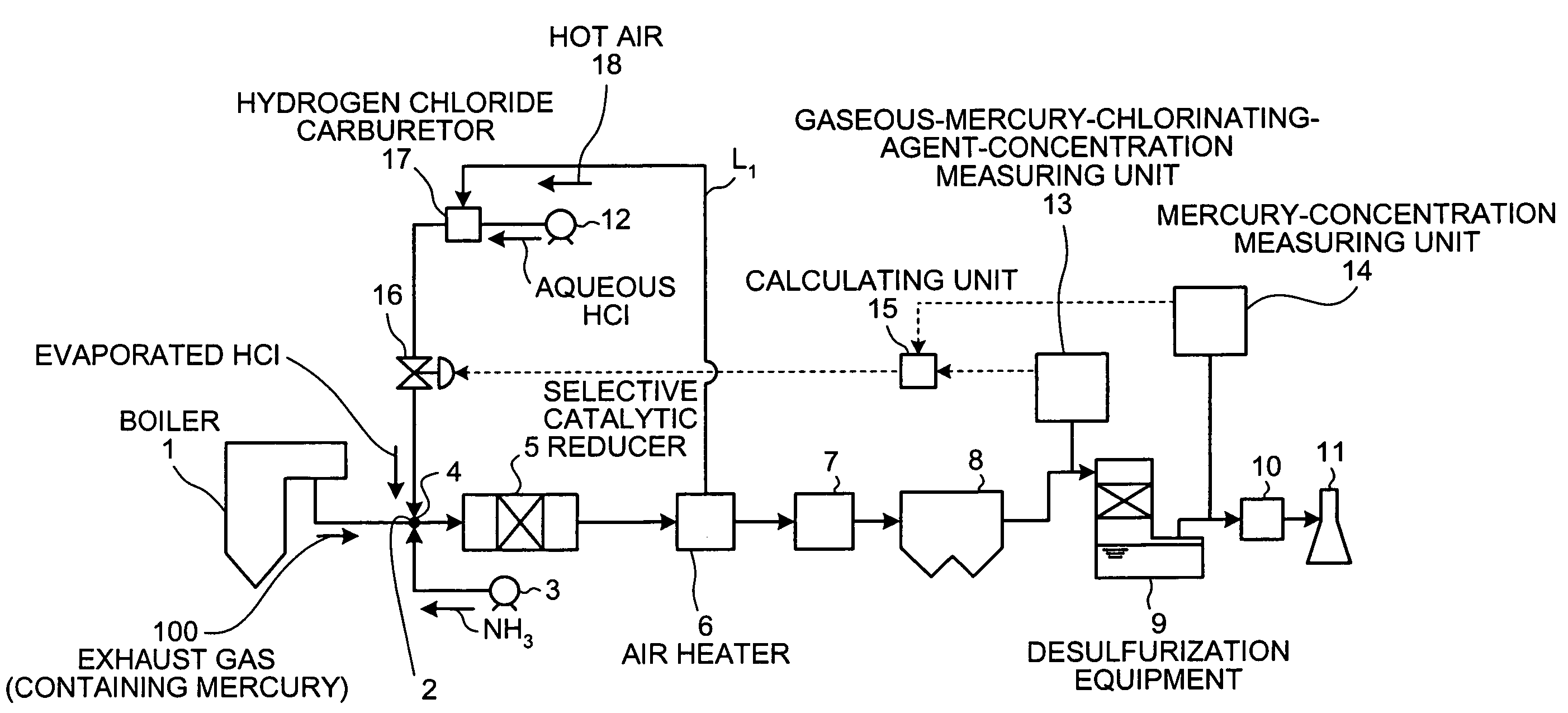

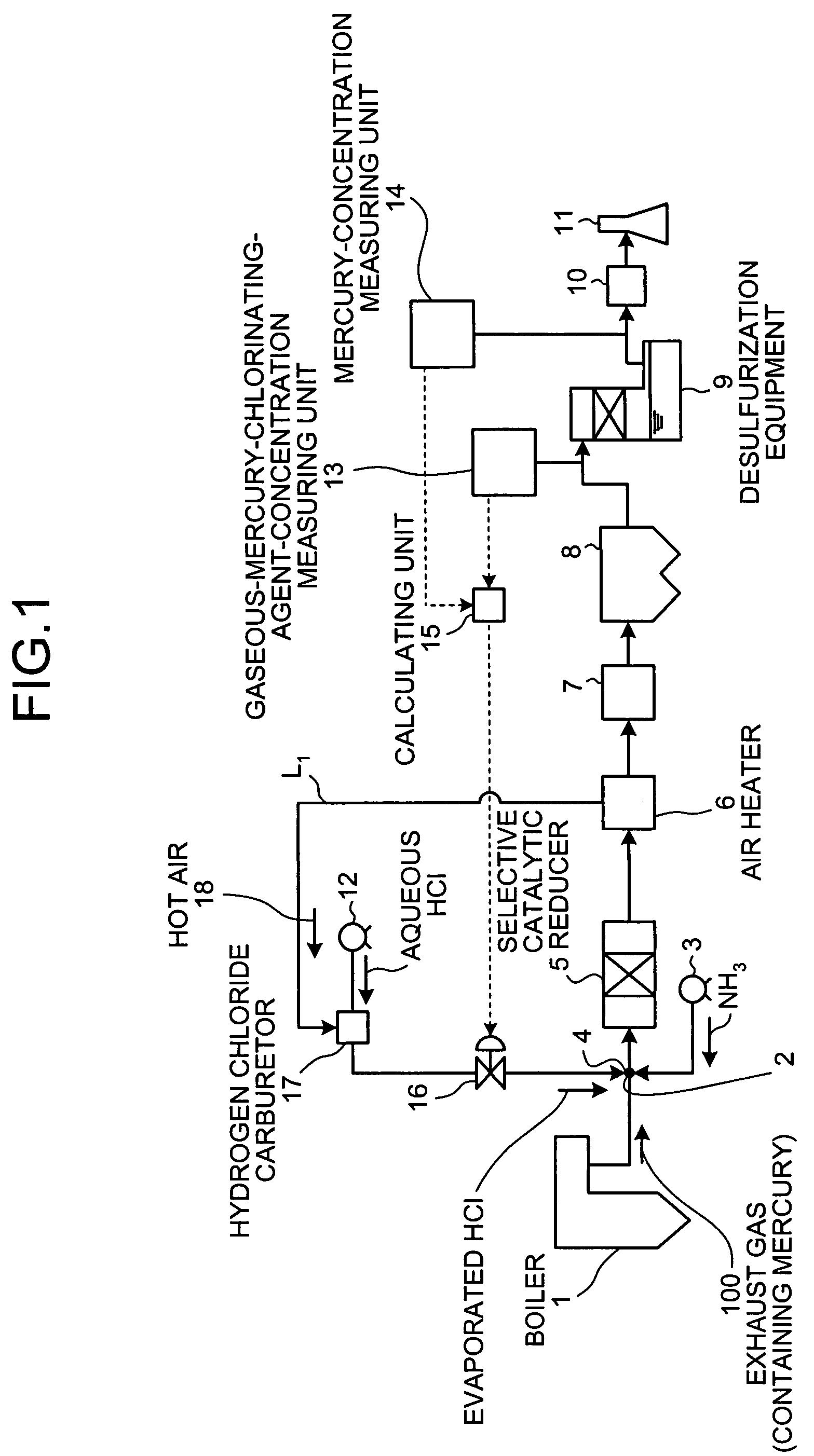

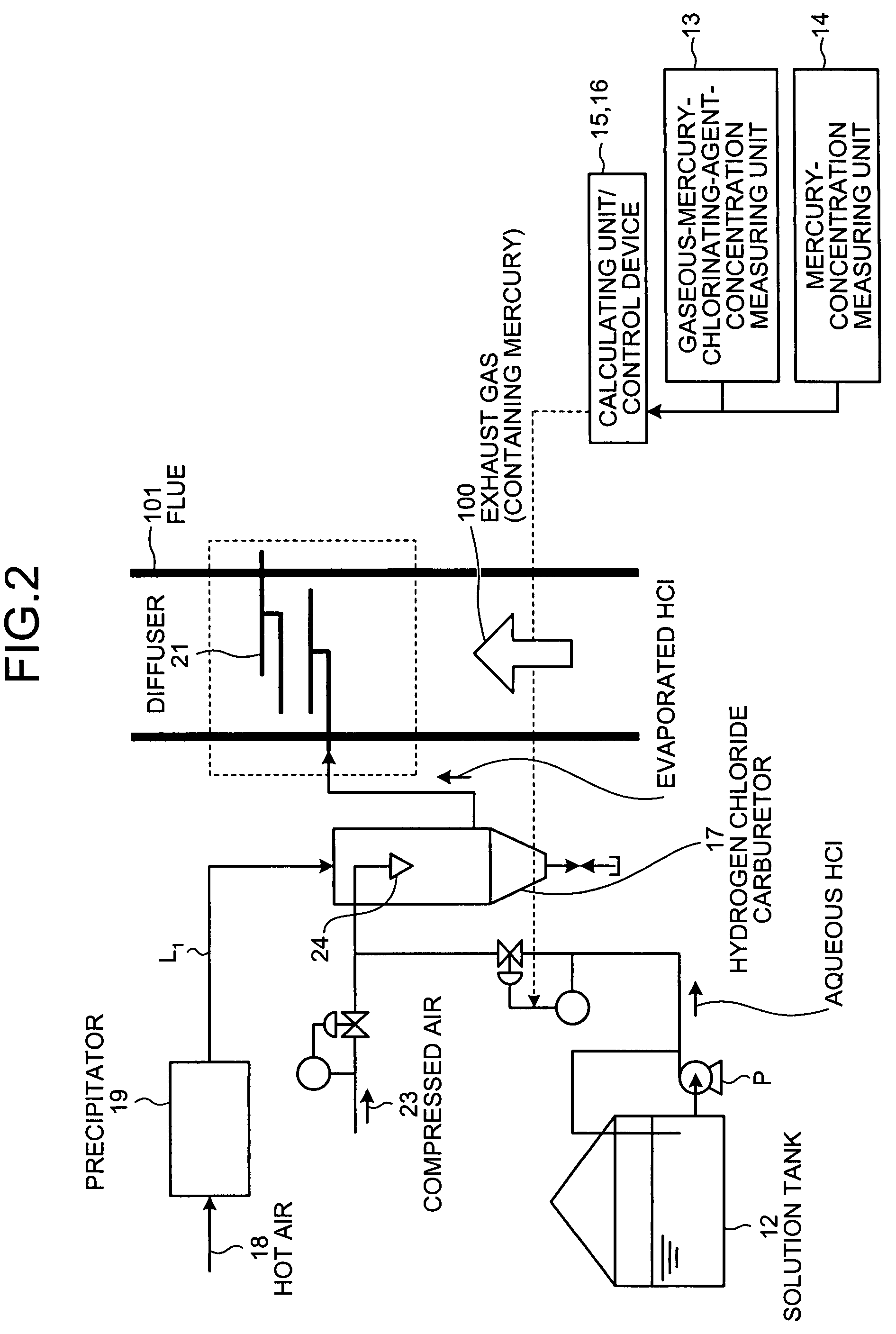

ActiveUS8071060B2Reduce operating costsCombination devicesNitrogen compoundsAir preheaterParticulates

A flue gas control system of a coal combustion boiler comprises an HCl atomizer that sprays hydrogen chloride to flue gas from a coal combustion boiler that uses coal as a fuel; NOx removing apparatus that removes nitrogen oxides by ammonia denitration by adding ammonia to the flue gas after spraying hydrogen chloride and oxidizes mercury; an air preheater that recovers heat in the gas after removal of nitrogen oxides; a precipitator that removes particulates in the gas; an activated carbon atomizer that sprays activated carbon into the gas after particulate collection; a bag filter that collects activated carbon having adsorbed mercury; a desulfurizer that removes sulfur oxides in the flue gas after removal of activated carbon; a stack that discharges the gas which has undergone desulfurization to outside; and an ORP meter that measures an oxidation reduction potential for feeding air to a slurry absorbent in the desulfurizer.

Owner:MITSUBISHI HEAVY IND LTD

Use of so2 from flue gas for acid wash of ammonia

ActiveUS20080178733A1Efficient and environmentally acceptableGas treatmentDispersed particle filtrationSulfateFlue gas

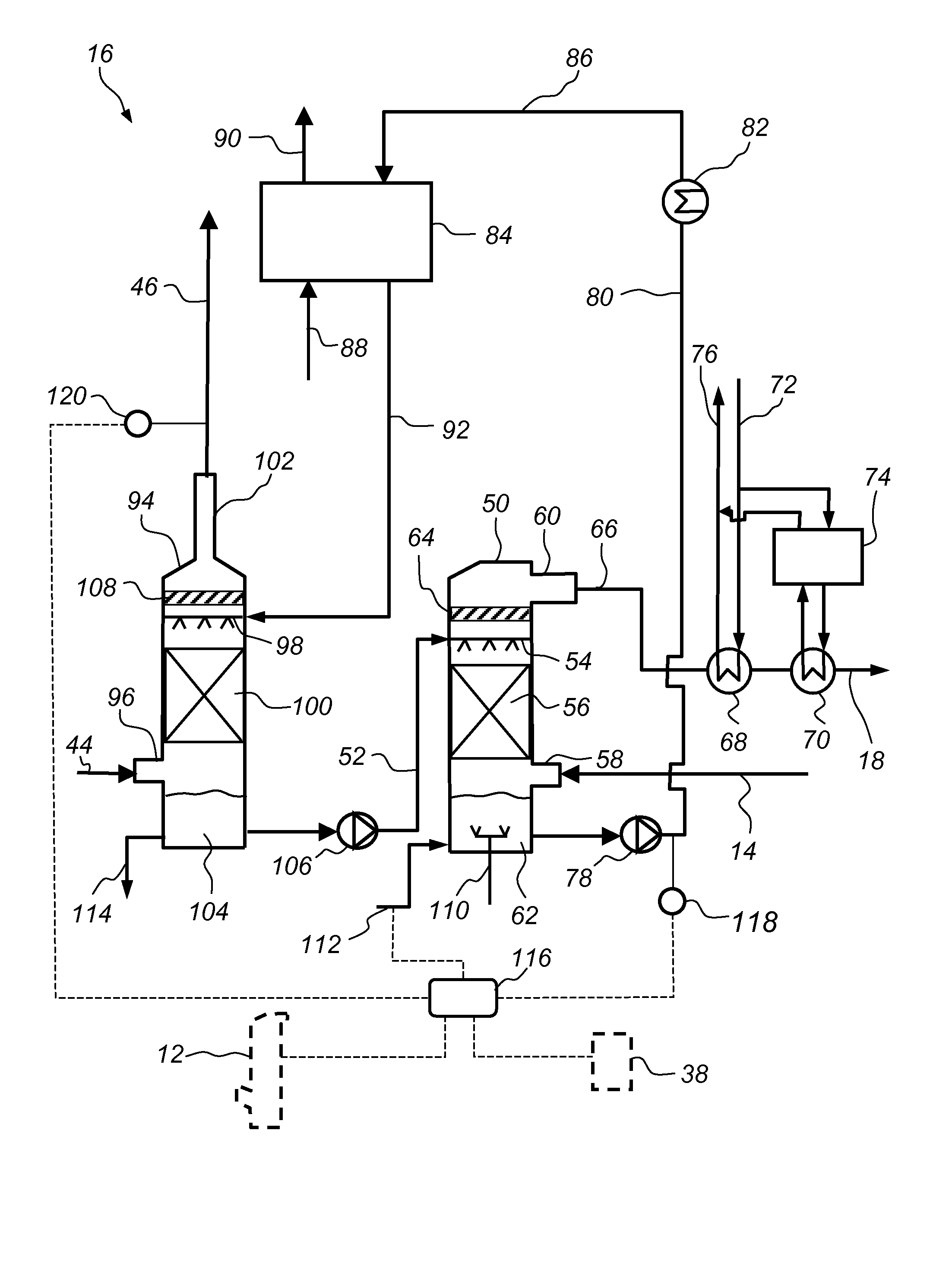

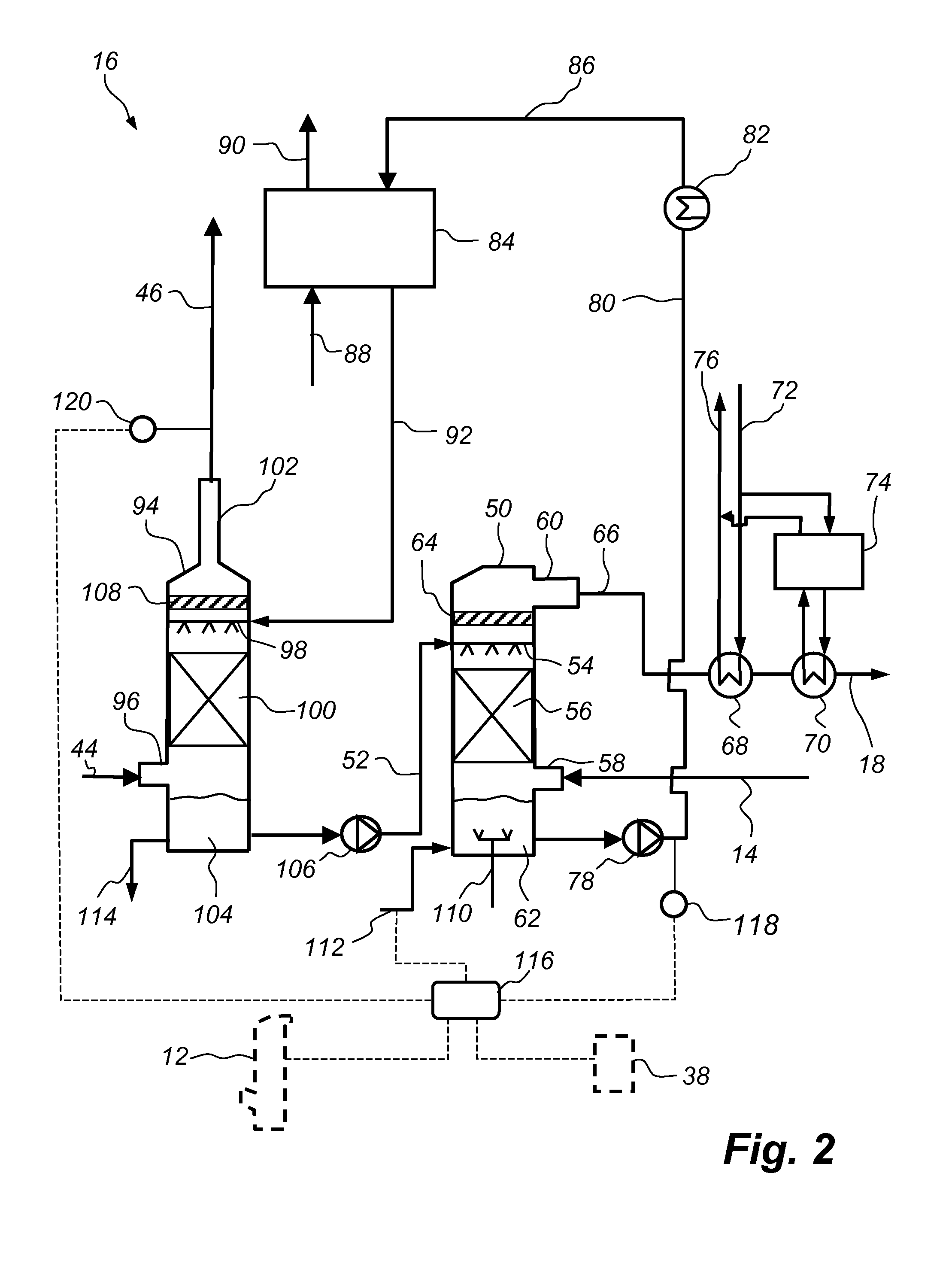

A gas cleaning system, which is operative for cleaning a process gas containing carbon dioxide and sulphur dioxide, comprises a combined cooling and cleaning system (16), and a CO2-absorber. The combined cooling and cleaning system (16) comprises a first gas-liquid contacting device (50) located upstream of the CO2-absorber and operative for cooling the process gas by means of a cooling liquid, and for absorbing into the cooling liquid sulphur dioxide of the process gas, such that a cooling liquid containing sulphate is obtained. The combined cooling and cleaning system (16) further comprises a second gas-liquid contacting device (94) located downstream of the CO2-absorber and operative for removing ammonia from the process gas, which has been treated in the CO2-absorber, by means of bringing the process gas containing ammonia into contact with the cooling liquid containing sulphate.

Owner:GENERAL ELECTRIC TECH GMBH

Purification of carbon dioxide

SO2 and / or NOx are removed from gaseous CO2 at elevated pressure(s) in the presence of molecular oxygen and water and, when SO2 is to be removed, NOx, to convert SO2 to sulfuric acid and / or NOx to nitric acid. The sulfuric acid and / or nitric acid is / are then removed from the gaseous carbon dioxide to produce SO2-free, NOx-lean carbon dioxide gas. The invention has particular application in the removal of SO2 and / or NOx from carbon dioxide flue gas produced in an oxyfuel combustion process, for example, in a pulverized coal fired power station.

Owner:AIR PROD & CHEM INC

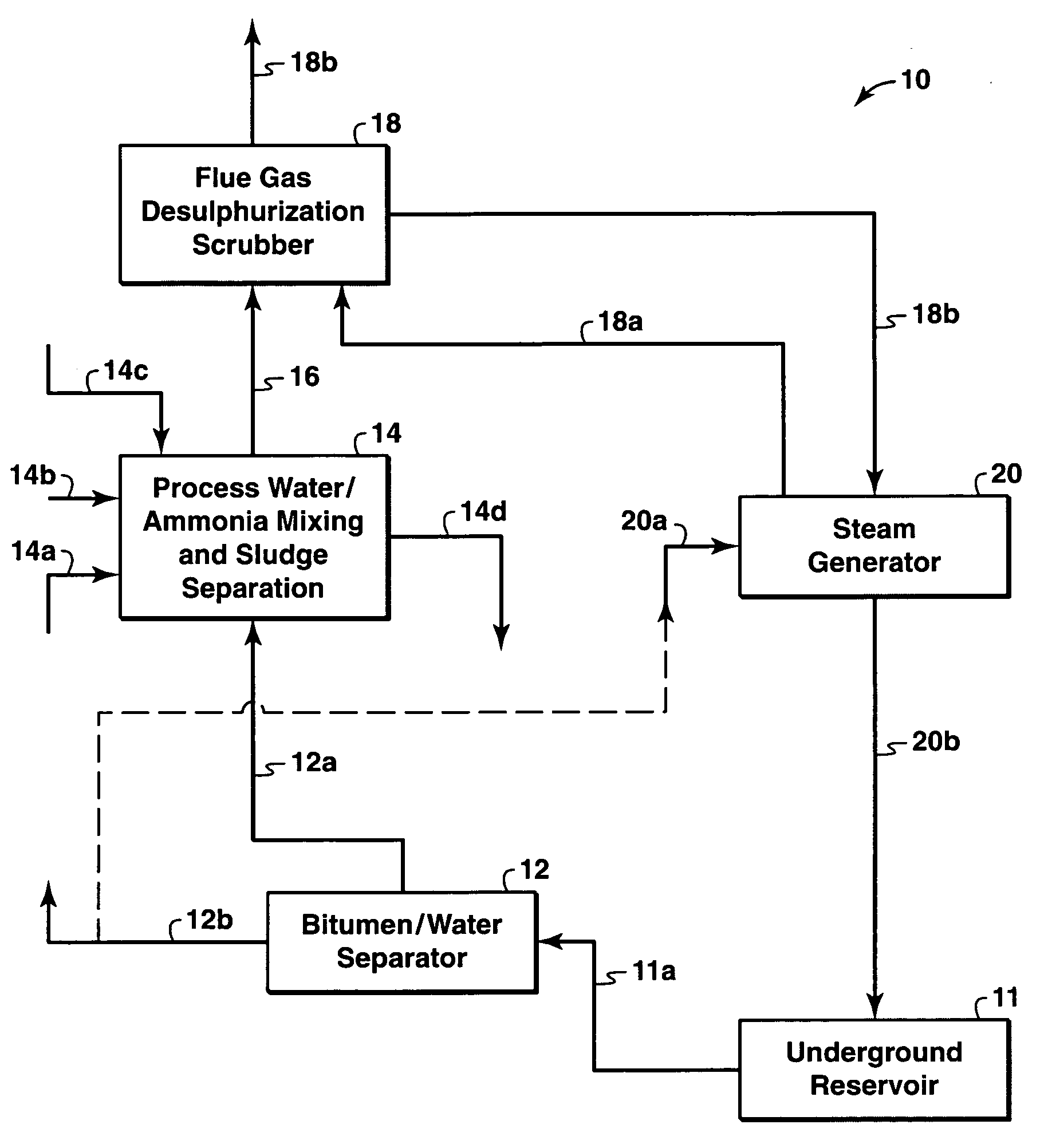

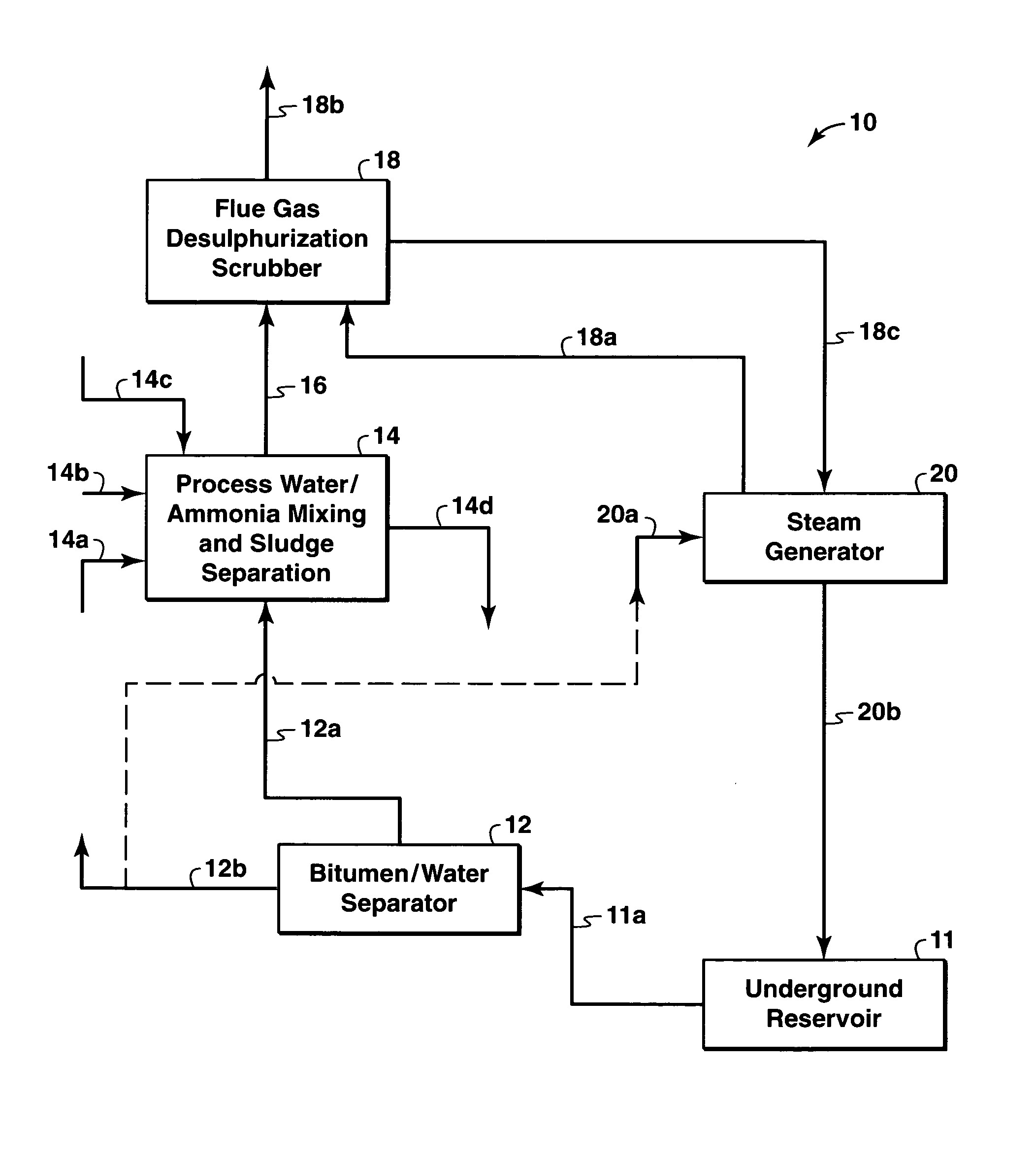

Integrated water treatment and flue gas desulfurization process

A water stream containing hardness minerals is subjected to a water treatment process using an alkali agent to precipitate the hardness minerals and to produce a softened water stream is used to create an integrated water treatment and flue gas desulfurization process. Thereafter, the softened, alkaline water stream is utilized in a scrubber to scrub a flue gas containing sulfur dioxide to produce a sulfur-lean flue gas. The invention may be applied to a steam-based bitumen recovery operation where bitumen, sour produced gas or other sulfur containing fuels are burned for producing steam for bitumen recovery. More specifically, the associated produced water from the bitumen recovery process may be softened for re-use and for utilization as a scrubbing agent for high-sulfur containing flue gas arising from the steam generators. The process provides an economically favorable process while minimizing waste disposal requirements.

Owner:EXXONMOBIL UPSTREAM RES CO

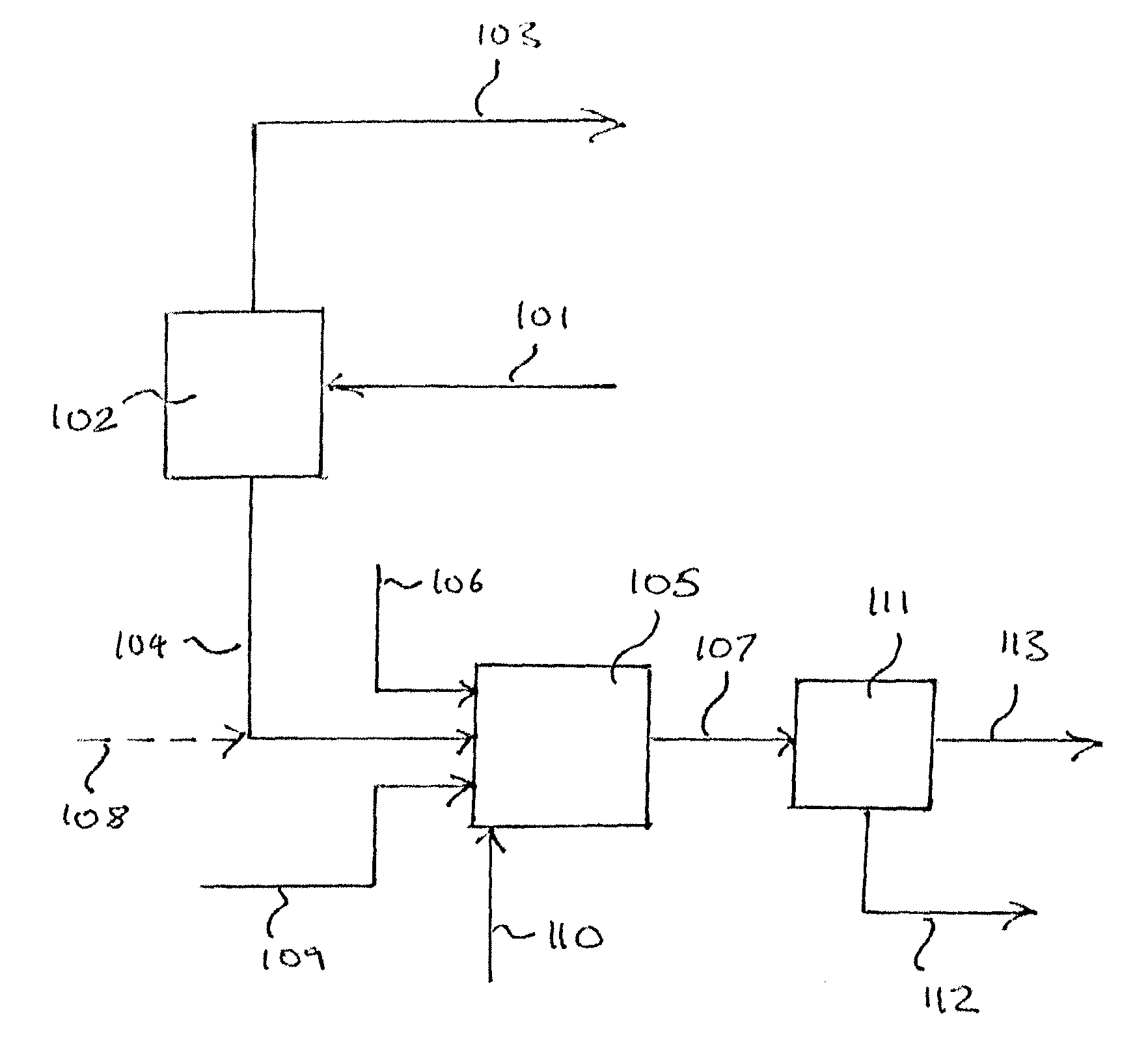

Method of deacidizing a gas with a fractional regeneration absorbent solution

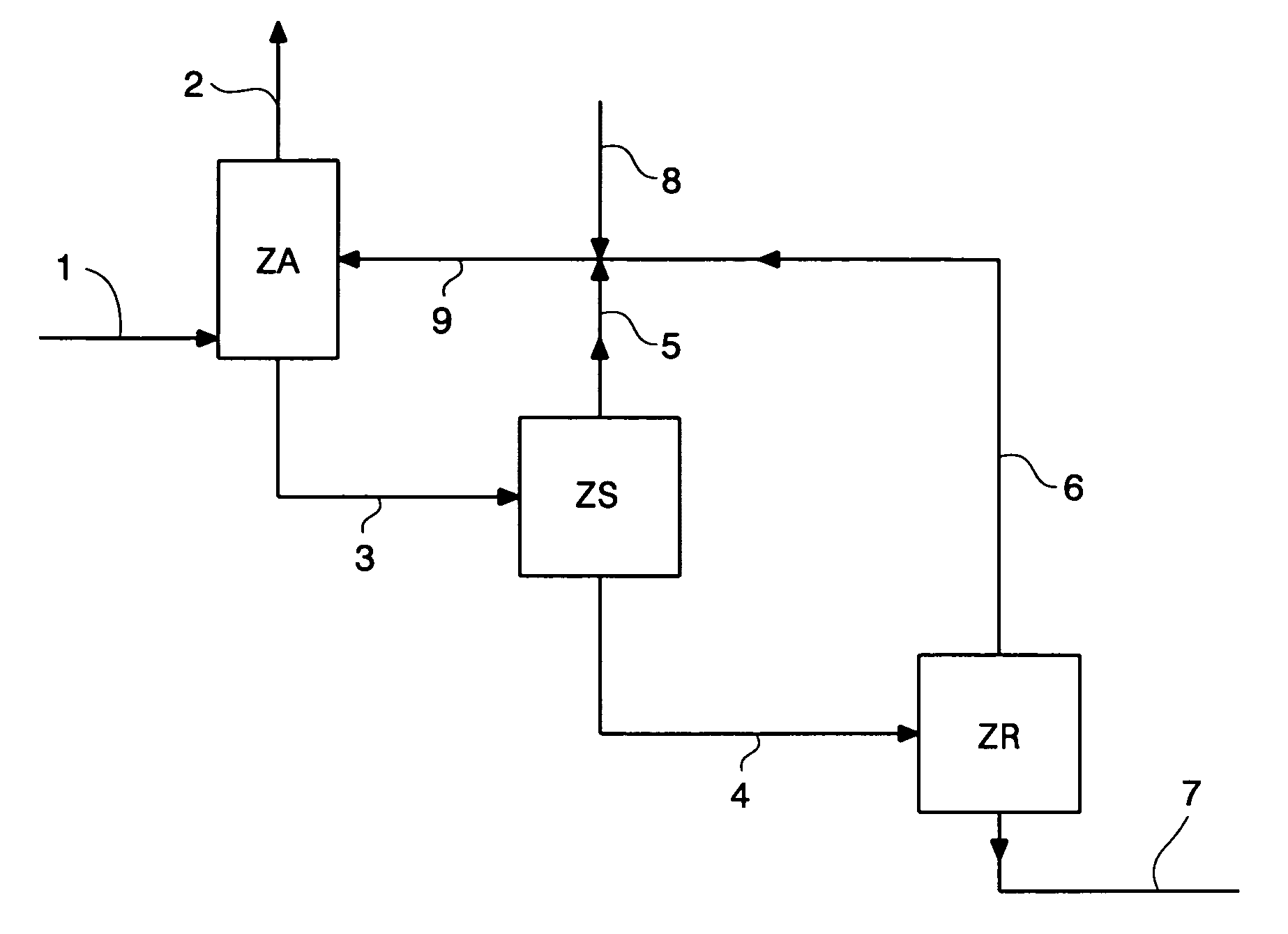

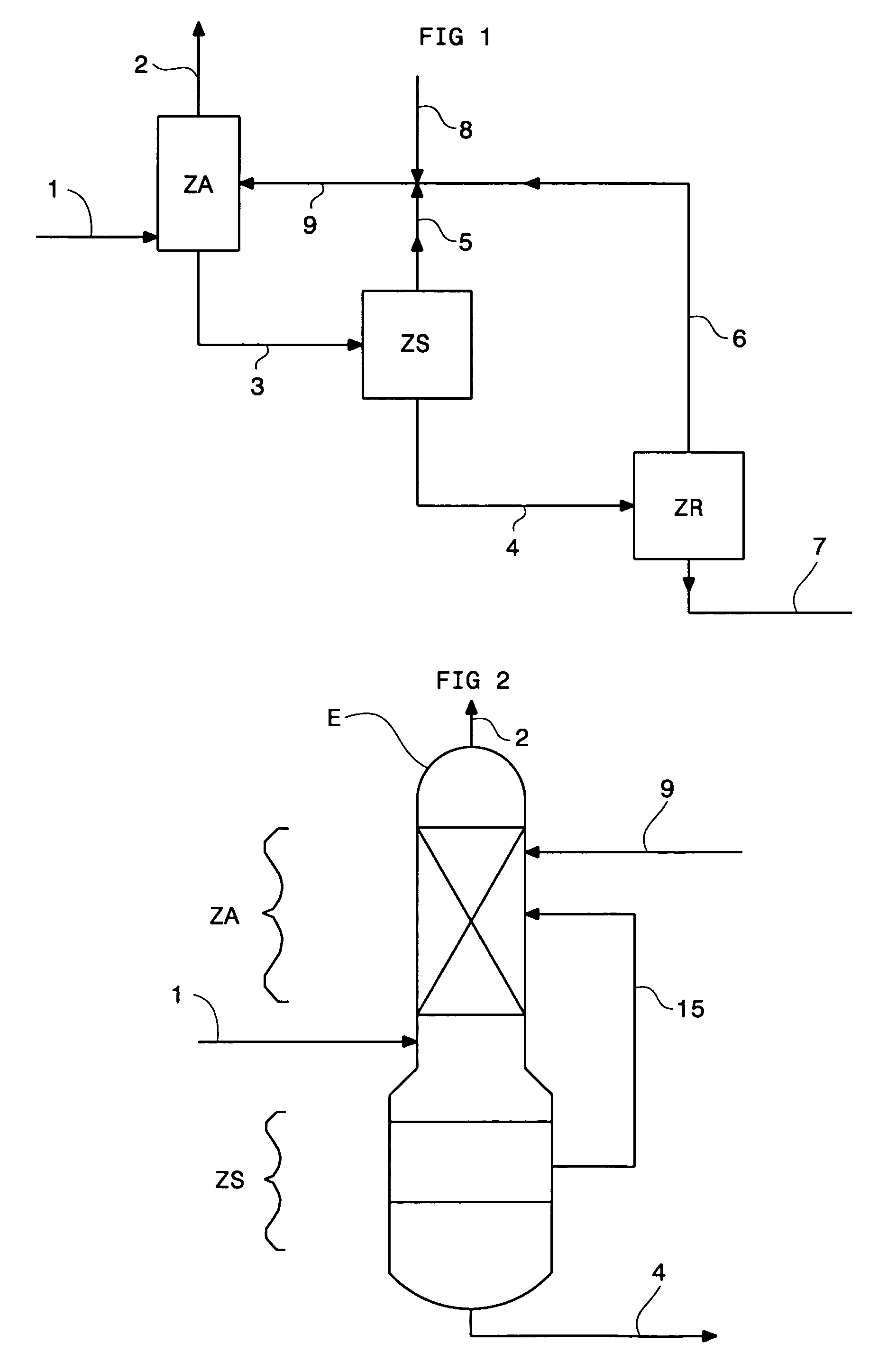

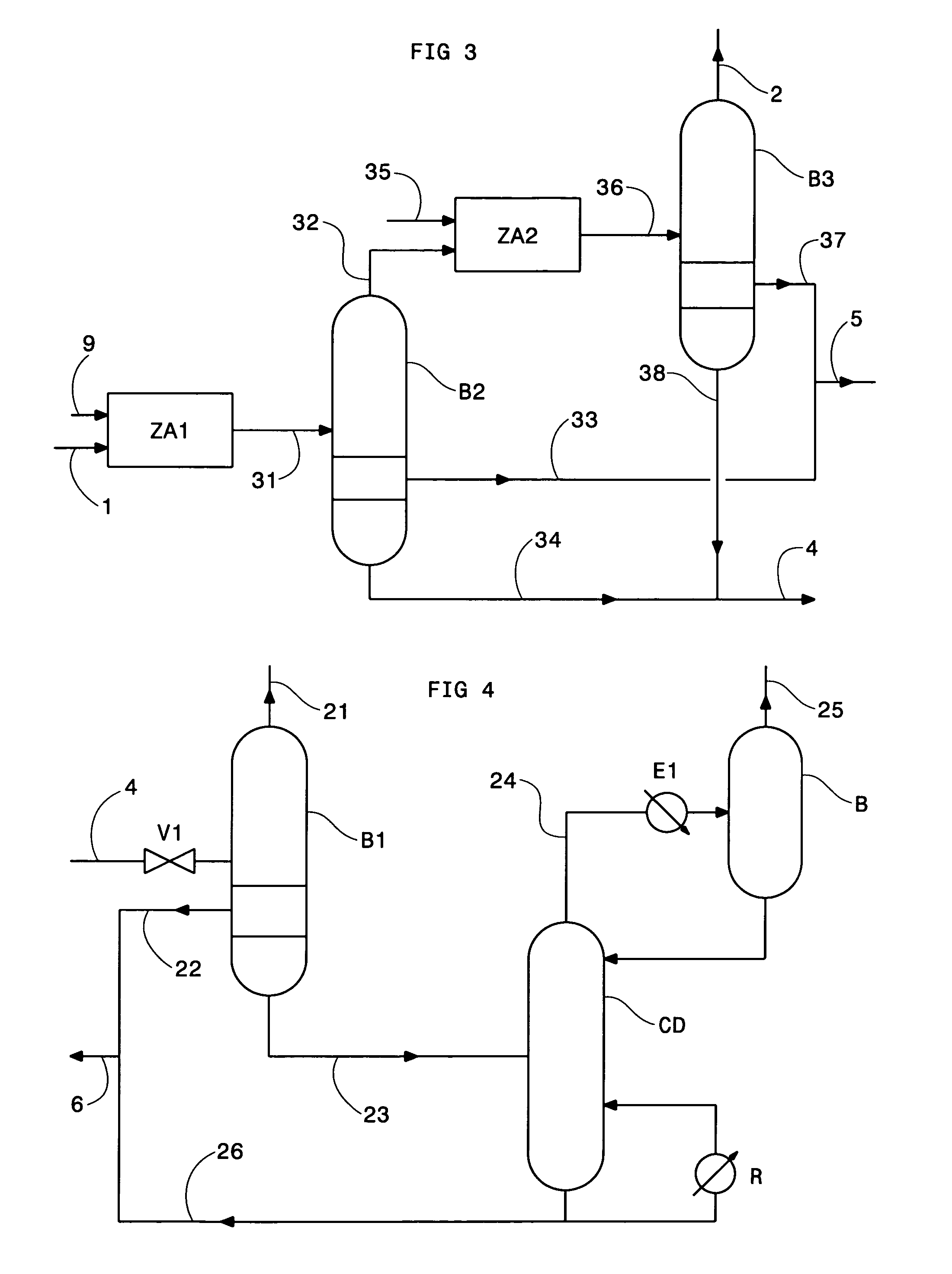

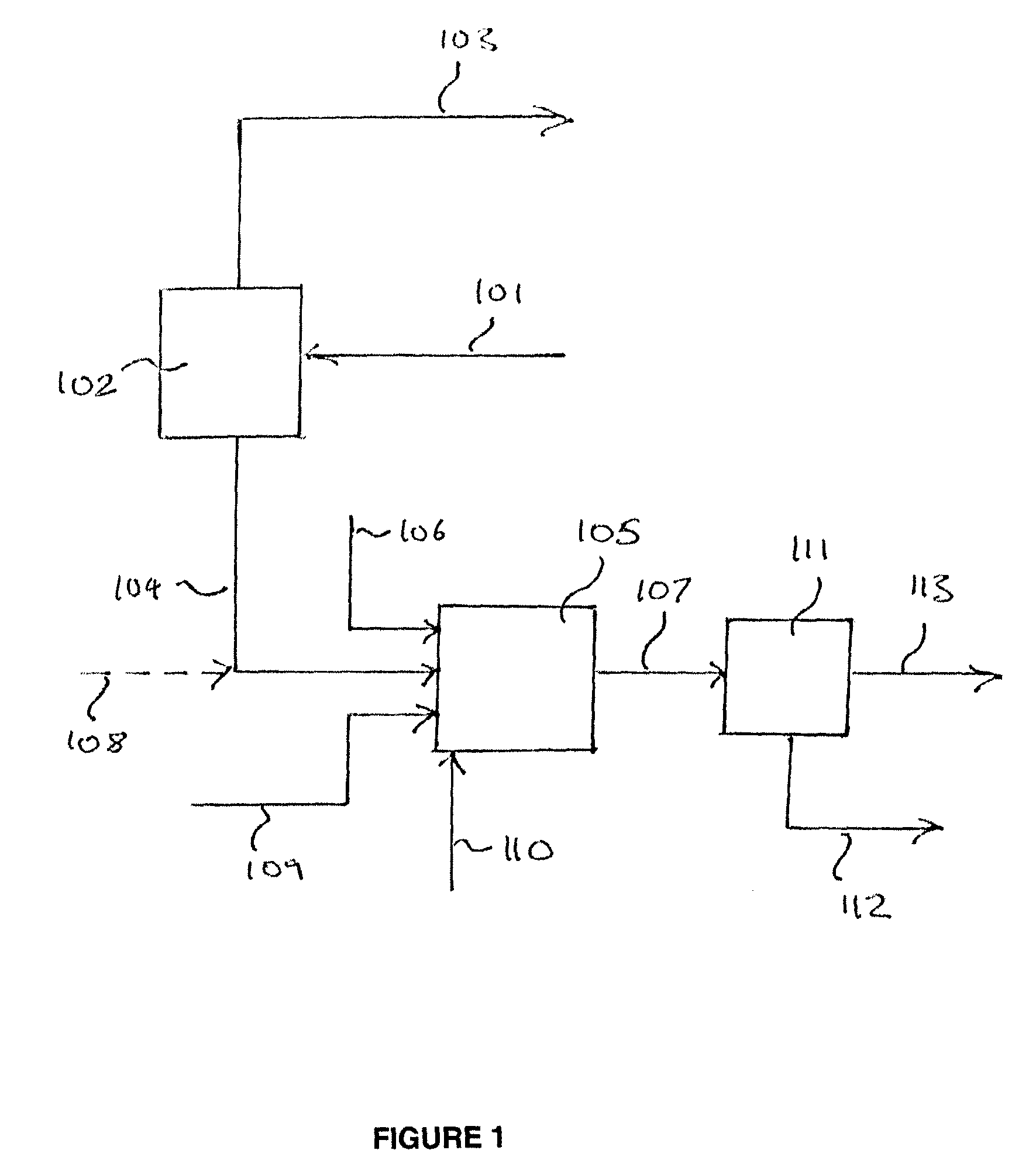

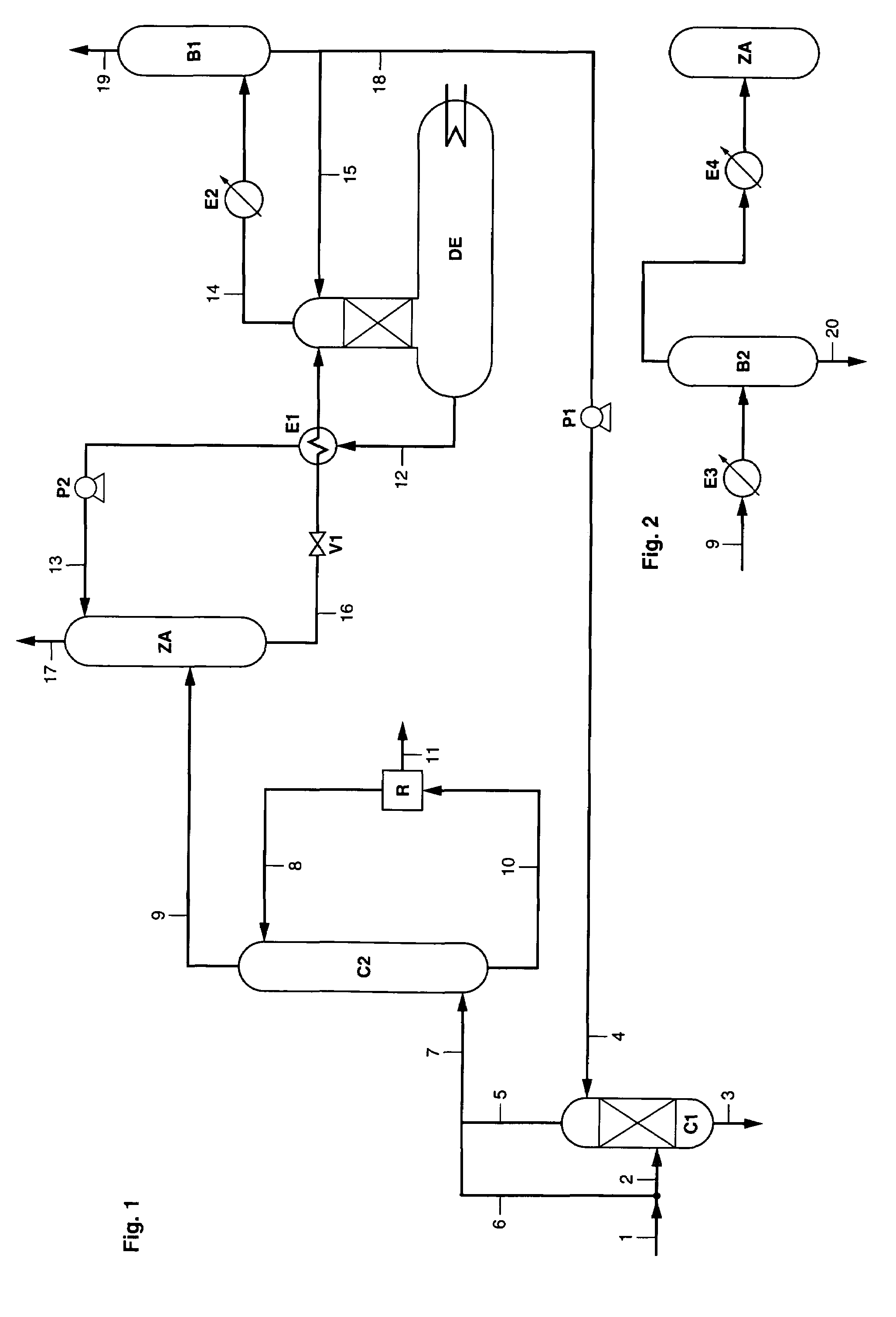

The gaseous effluent flowing in through line 1 is contacted in absorption zone ZA with the liquid absorbent solution flowing in through line 9. The gaseous effluent depleted in acid compounds is discharged through line 2. The absorbent solution laden with acid compounds is discharged through line 3. The absorbent solution once laden with acid compounds comprises two phases: a first phase poor in acid compounds and a second phase rich in acid compounds. The two phases are separated in zone ZS. The first phase is recycled through lines 5 and 9 to absorption zone ZA. The second phase is fed through line 4 into regeneration zone ZR. In zone ZR, the acid compounds are separated from the absorbent solution. The acid compounds are discharged through line 7. The regenerated absorbent solution is recycled through lines 6 and 9 to zone ZA.

Owner:INST FR DU PETROLE

Simultaneous use of peroxygen and olefin compound in odor reduction

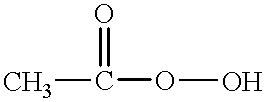

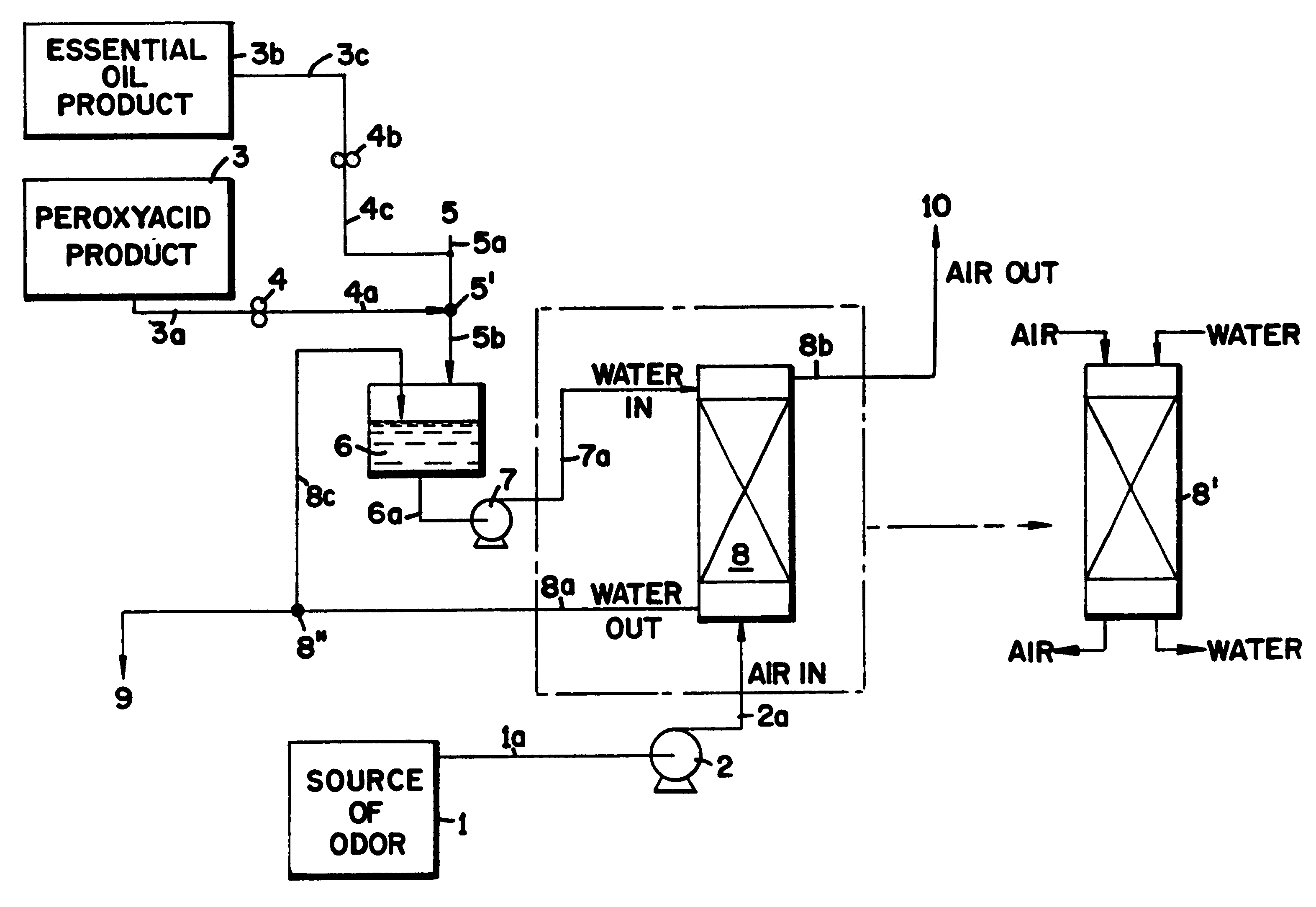

InactiveUS6277344B1Improved malodor removalEnhanced mass transferCyanogen compoundsOrganic chemistryGas phasePeroxy acid

Disclosed is a process for the treatment of a plant fluid effluent containing odor compounds including an alkyl mercaptan or an alkyl thiol, an amine compound, ammonia, hydrogen sulfide and mixtures thereof by contacting the plant effluent in either a counterflow or cocurrent flow process. In the process, the effluent is contacted with an aqueous solution comprising a peroxyacid compound and one or more essential oils. When contacted with the peroxyacid, odor compounds in the effluent are oxidized and converted from the gaseous phase into a chemically modified highly aqueous soluble phase in the aqueous treatment. In this way, odor removal from the gas is preferred and odor compounds are efficiently transferred into the aqueous treatment solution. The use of such a process produces a significant improvement in odor quality index as measured by a conventional process using an expert panel when compared to conventional treatment methods.

Owner:ECOLAB USA INC

Methods and devices for reducing hazardous air pollutants

ActiveUS20090081093A1Reduce pollutionReduce the amount requiredCombination devicesCyanogen compoundsSlagSolid particle

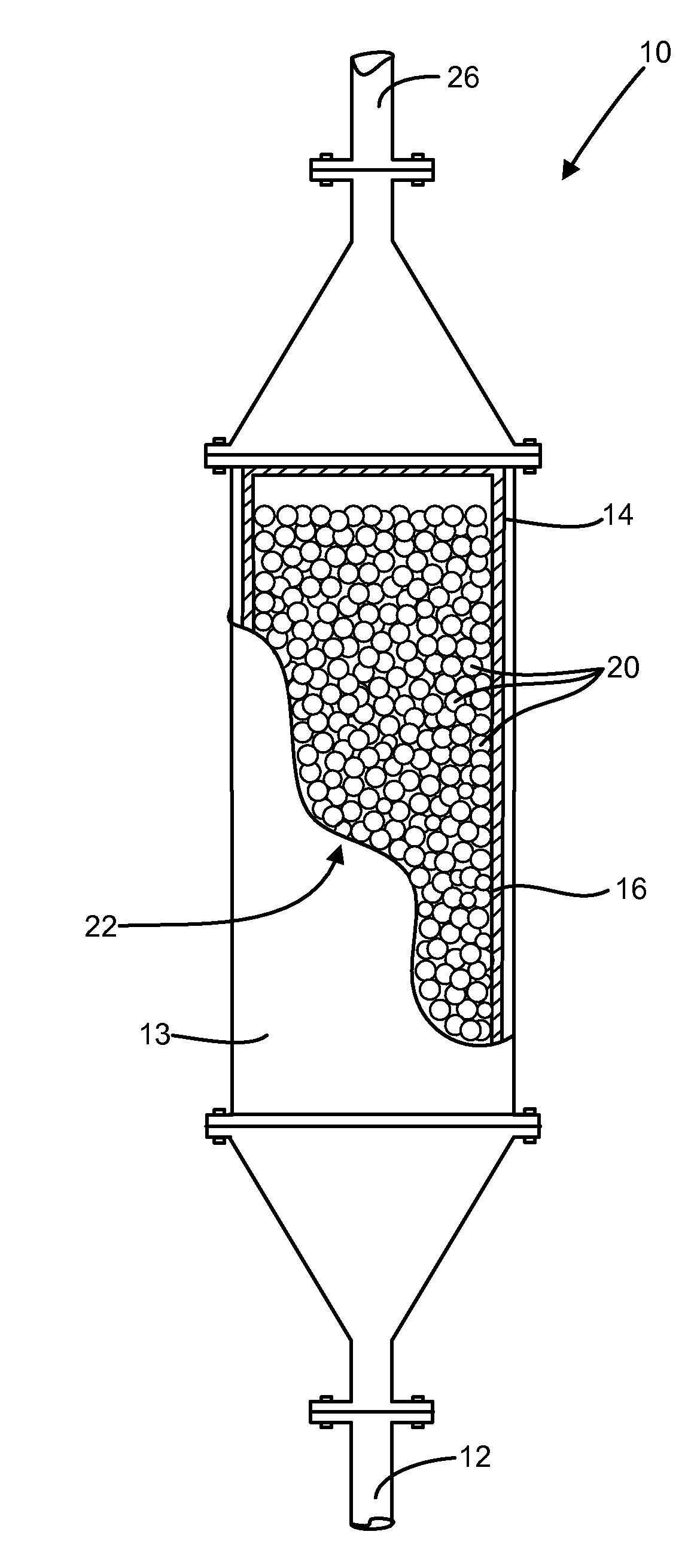

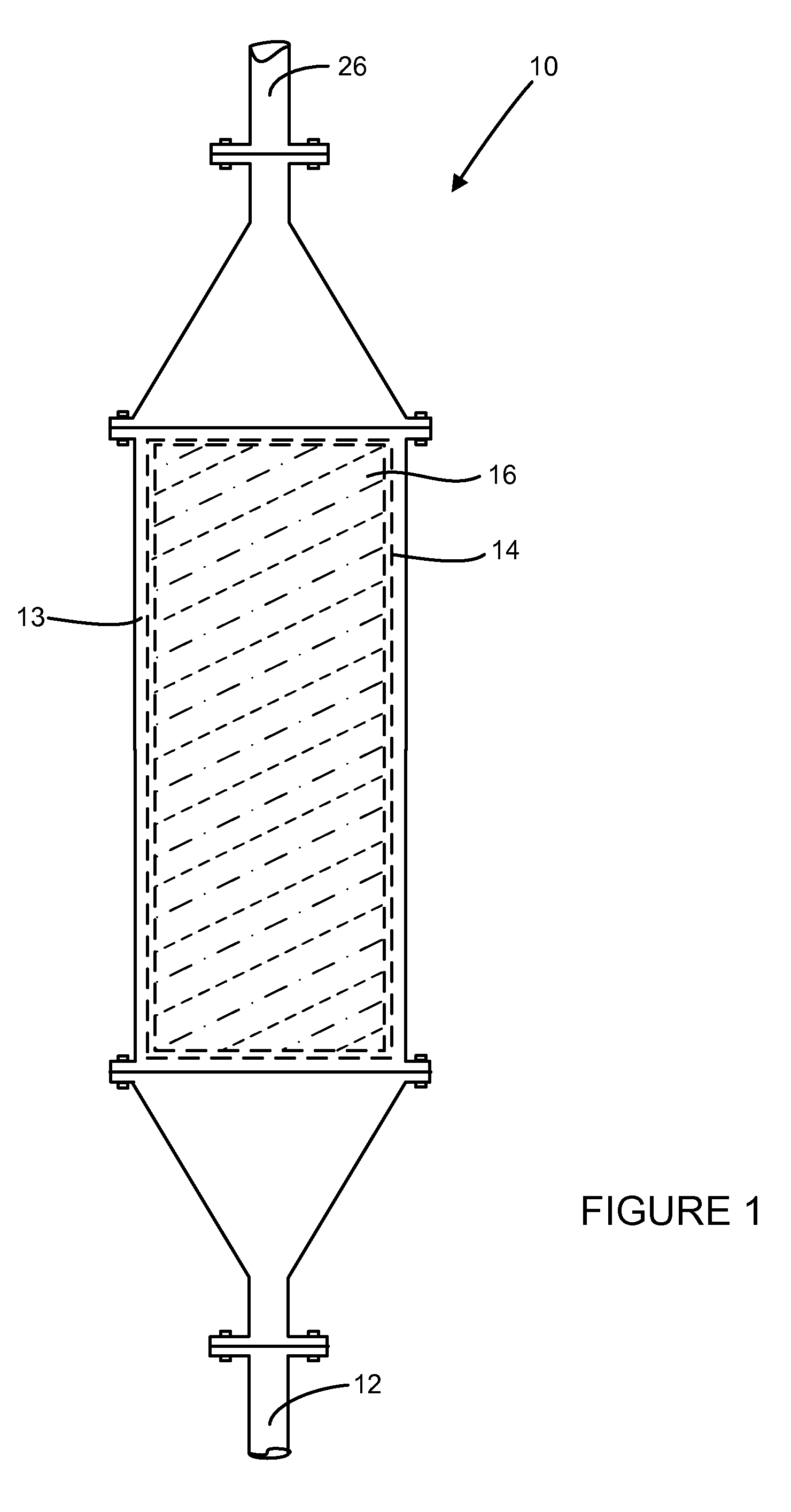

The disclosure provides methods and systems for sequestering and / or reducing sulfur oxides, nitrogen oxides and / or carbon dioxide present in industrial effluent fluid streams. A solid particulate material comprising a slag component, a binder component (distinct from the slag component), and optionally water is formed and then contacted with the effluent fluid stream to reduce at least one of the sulfur oxides, nitrogen oxides, and / or carbon dioxide. The contacting of the effluent stream may occur in a packed bed reactor with the solid dry particulate material. Methods of reducing pollutants from exhaust generated by combustion sources, lime and / or cement kilns, iron and / or steel furnaces, and the like are provided.

Owner:C QUEST TECH

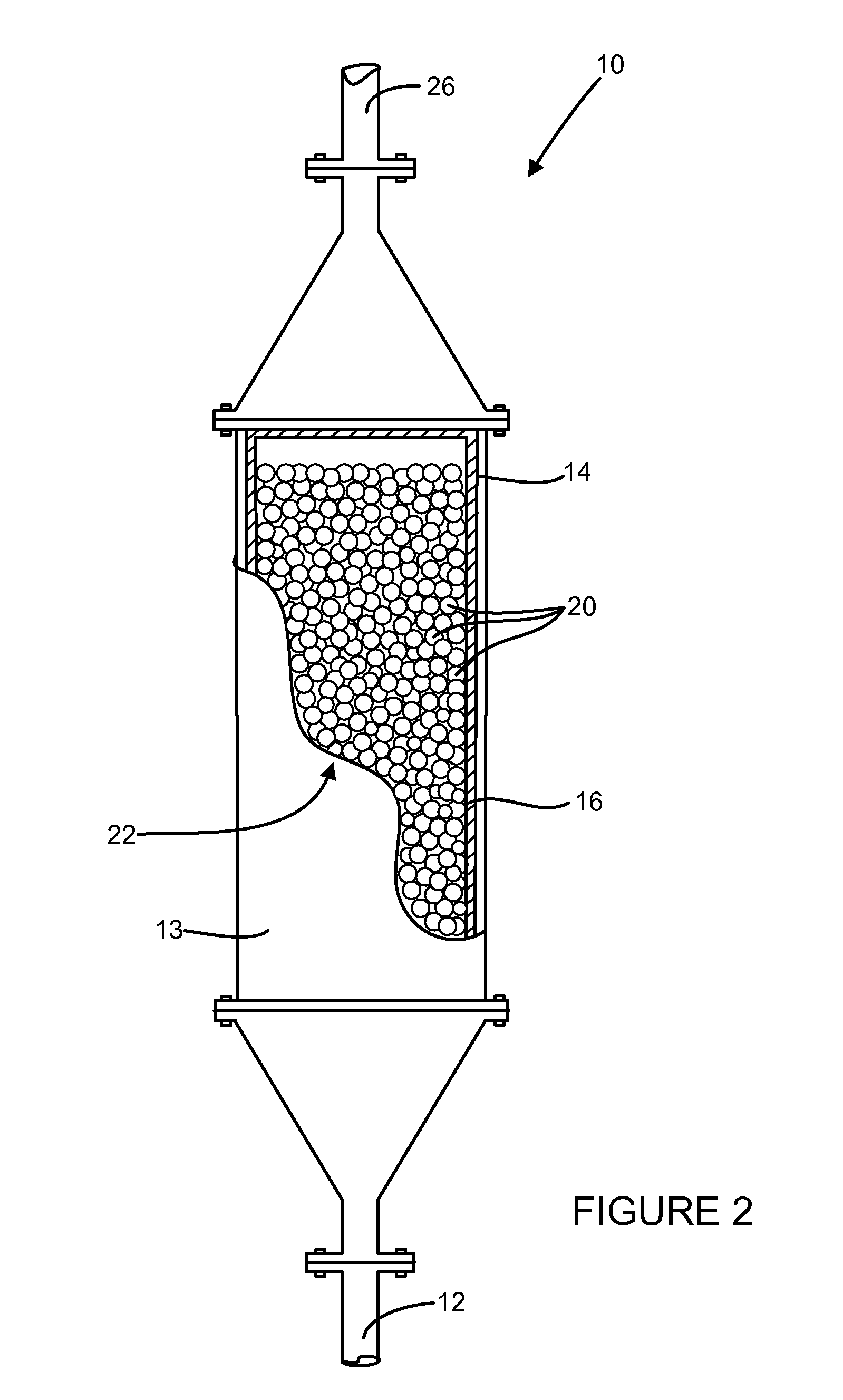

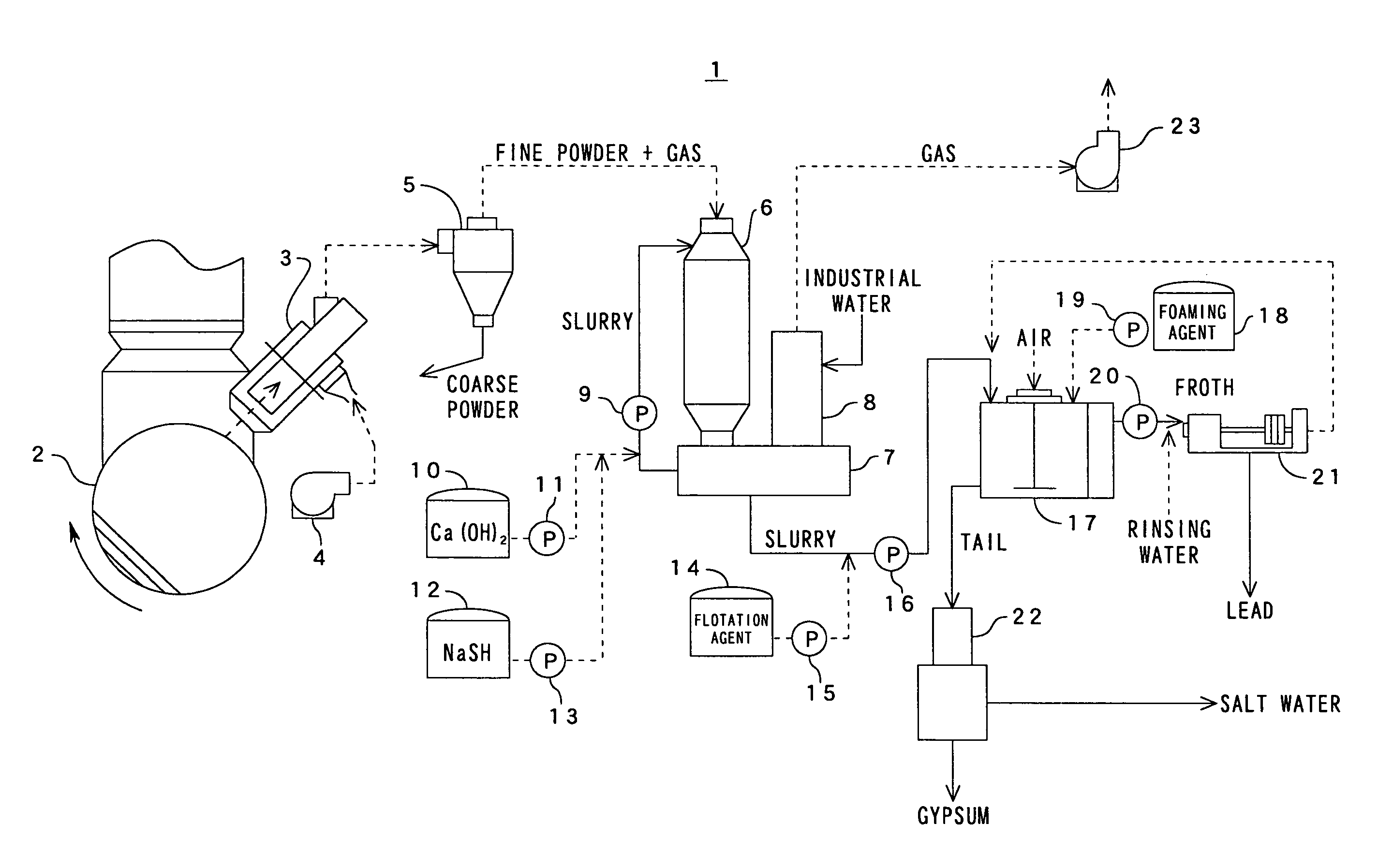

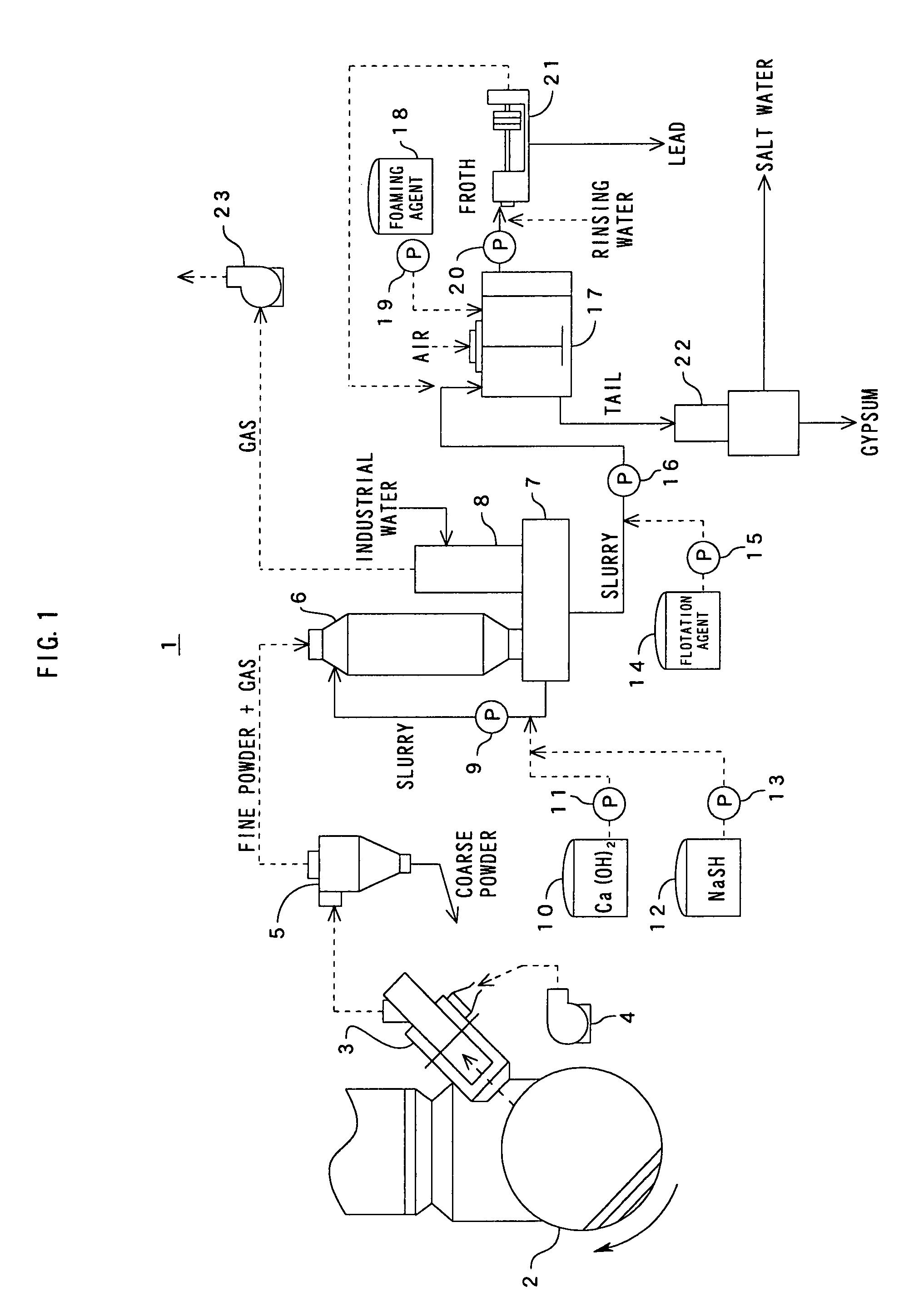

System and method for treating dust contained in extracted cement kiln combustion gas

InactiveUS7789944B2Effectively remove dustLow facility requirementsCombination devicesUsing liquid separation agentCycloneSlurry

A treatment system to efficiently remove lead from dust contained in extracted cement kiln combustion gas while reducing facility and running costs. A treatment system 1 comprising: a probe 3 for extracting a part of combustion gas, while cooling it, from a kiln exhaust gas passage, which runs from an inlet end of a cement kiln to a bottom cyclone; a classifier 5 for separating coarse powder from dust contained in the combustion gas extracted by the probe 3; a wet dust collector 6 for collecting dust from the extracted gas containing fine powder discharged from the classifier 5; and devices 12, 13 for feeding sulfurizing agent for sulfurizing lead contained in the kiln exhaust gas to the wet dust collector 6, and others. From the sulfurizing-agent feeders 12, 13 are preferably added the sulfurizing agents to a circulation liquid tank 7 or a pump 9 for circulating slurry. The slurry obtained by the wet dust collector 6 is separated into froth including lead and tail side slurry including gypsum by a flotation facility 14, 17, 18.

Owner:TAIHEIYO CEMENT CORP

Method of treating a gaseous mixture comprising hydrogen, carbon dioxide and hydrogen sulphide

A gaseous mixture, comprising CO2, H2, H2S and optionally CO, is separated into an H2 or H2 and CO product stream (H2 / CO product stream), and a CO2 enriched stream containing at least one combustible component selected from H2S, H2, CO and any additional combustible components present in the gaseous mixture. A support fuel stream, comprising one or more combustible components, is combusted to form a stable flame, and the CO2 enriched stream and flame are contacted in the presence of sufficient O2 to combust all or substantially all of the combustible component(s) present in said CO2 enriched stream. A CO2 product stream is formed from said combustion effluent. The support fuel stream may be generated from the process of generating or separating the gaseous mixture or from the H2 / CO product stream. Where the CO2 enriched stream contains H2S, the support fuel stream may also be a stream obtained off-site that comprises H2S.

Owner:AIR PROD & CHEM INC

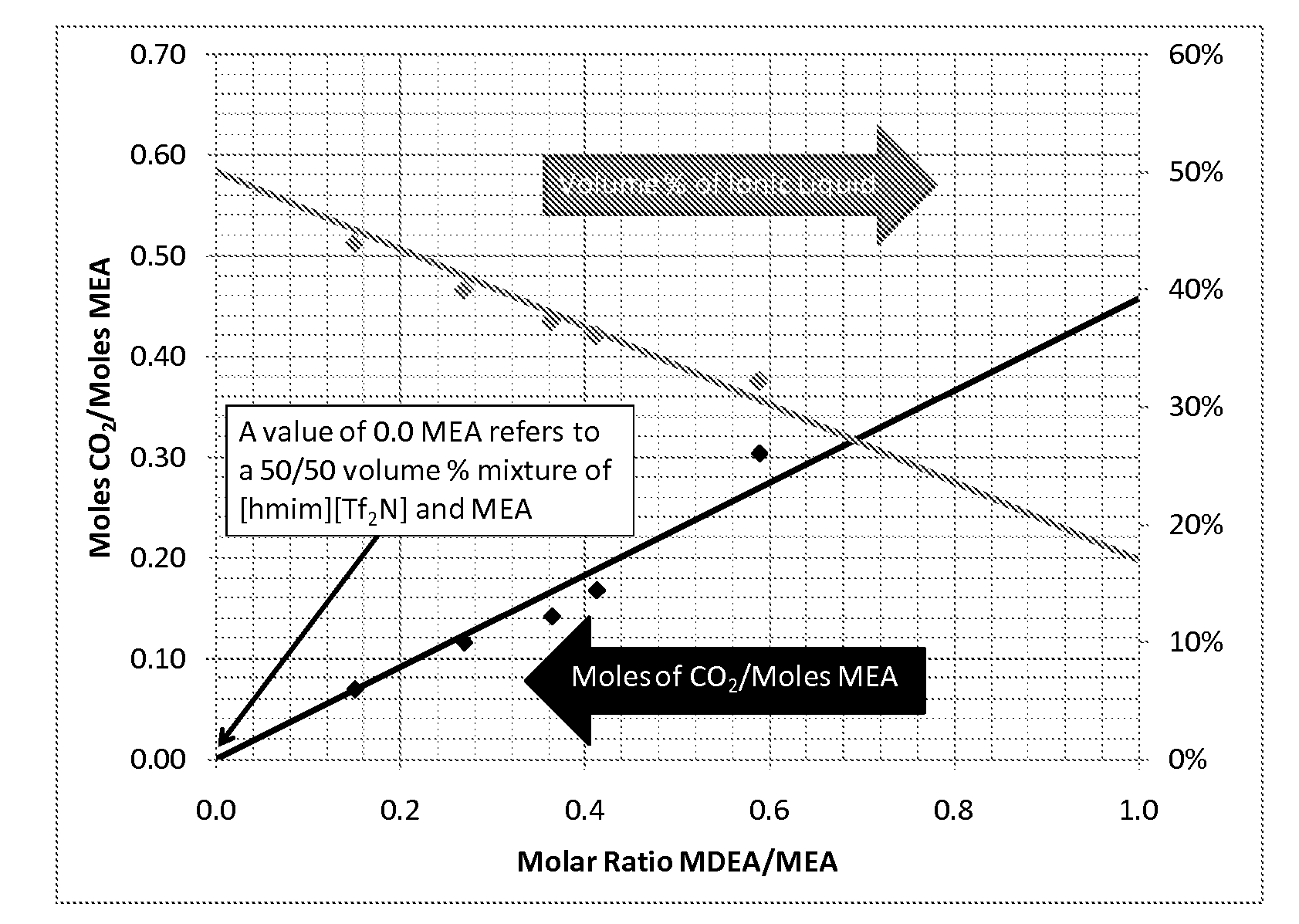

Ionic Liquids and Methods For Using the Same

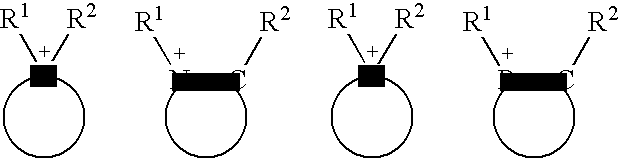

InactiveUS20090291872A1Reducing and removing impurityReducing and removing and materialOrganic detergent compounding agentsLiquid degasification with auxillary substancesSolid substrateIonic liquid

The present invention provides compositions comprising ionic liquids and an amine compound, and methods for using and producing the same. In some embodiments, the compositions of the invention are useful in reducing the amount of impurities in a fluid medium or a solid substrate.

Owner:UNIV OF COLORADO THE REGENTS OF

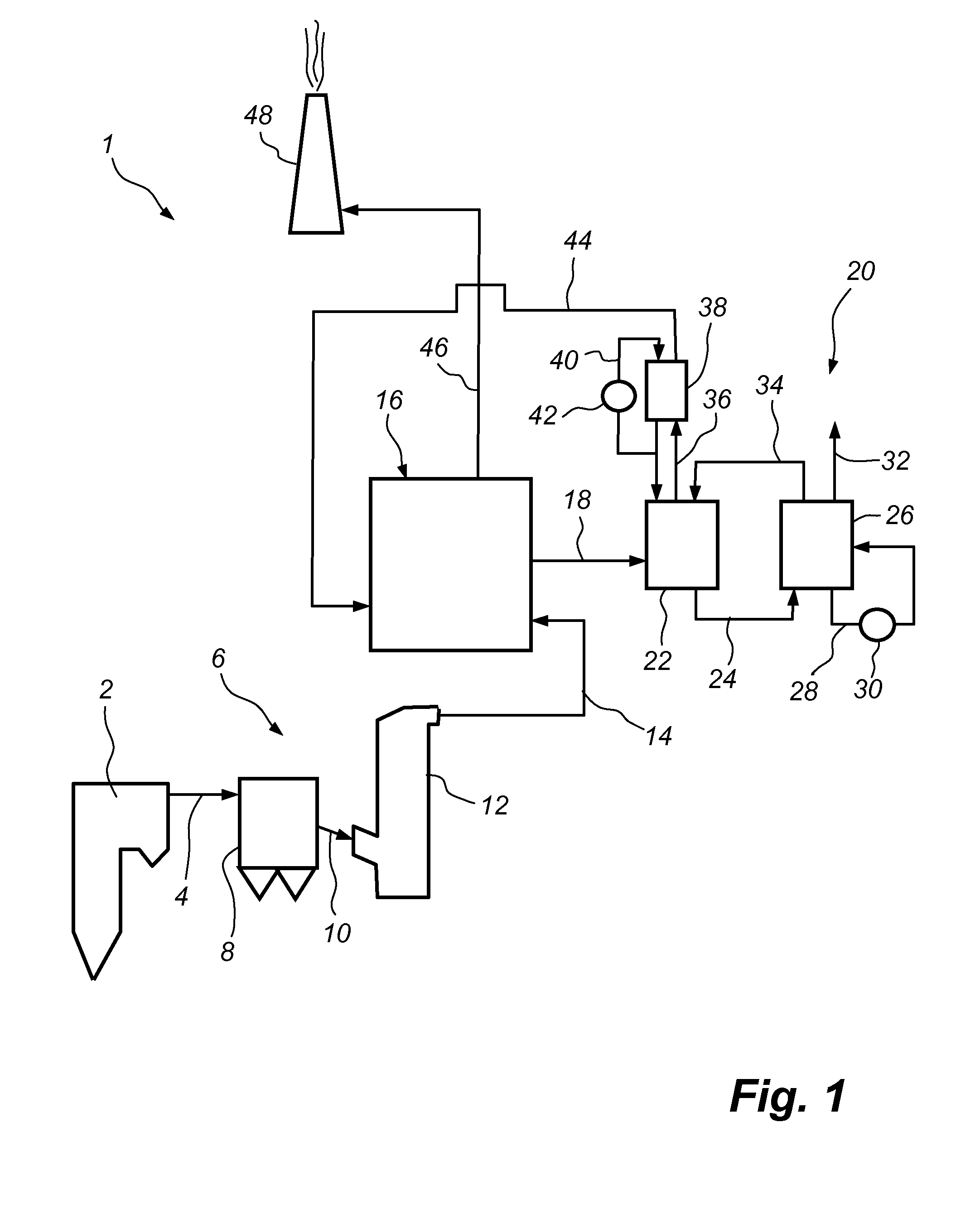

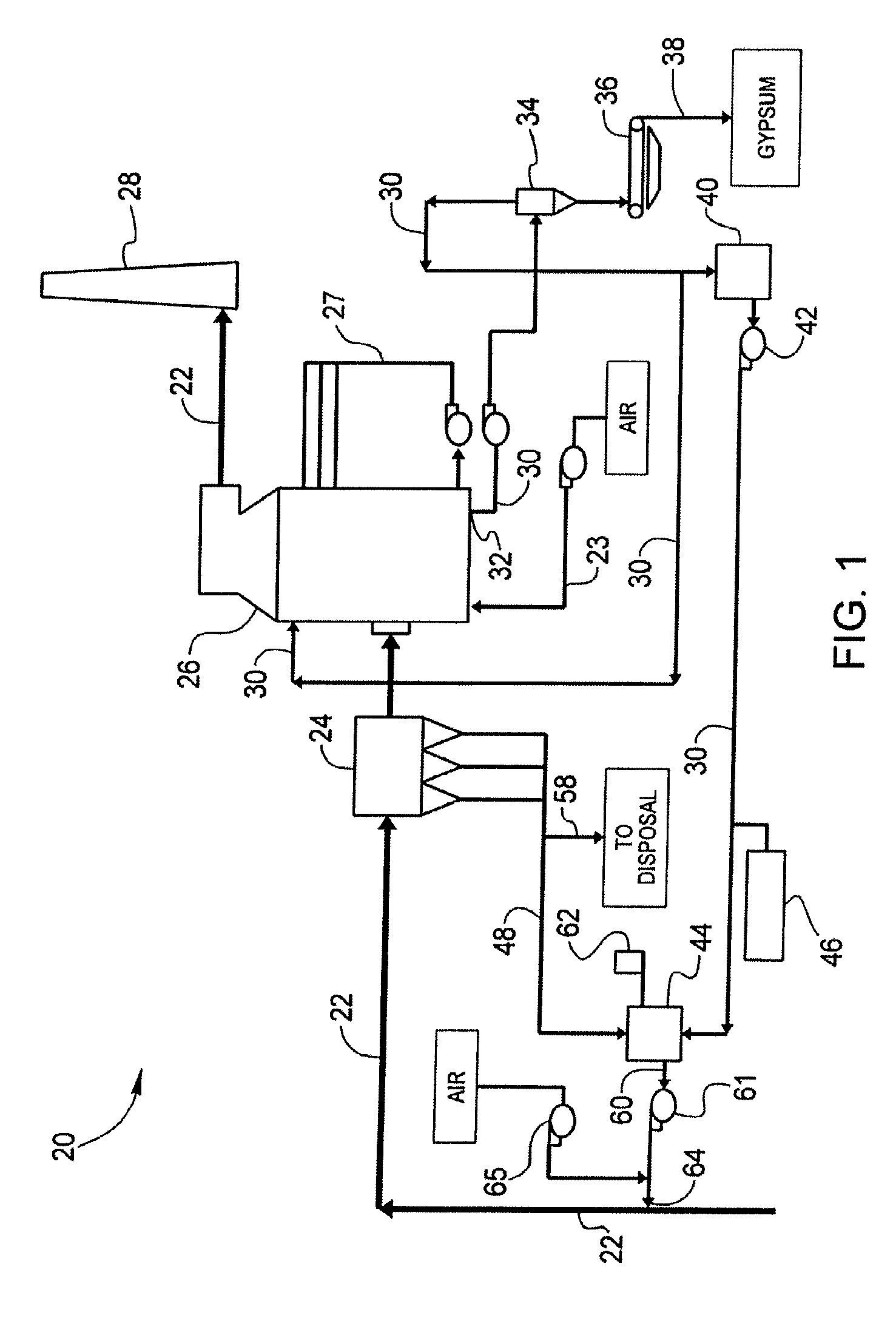

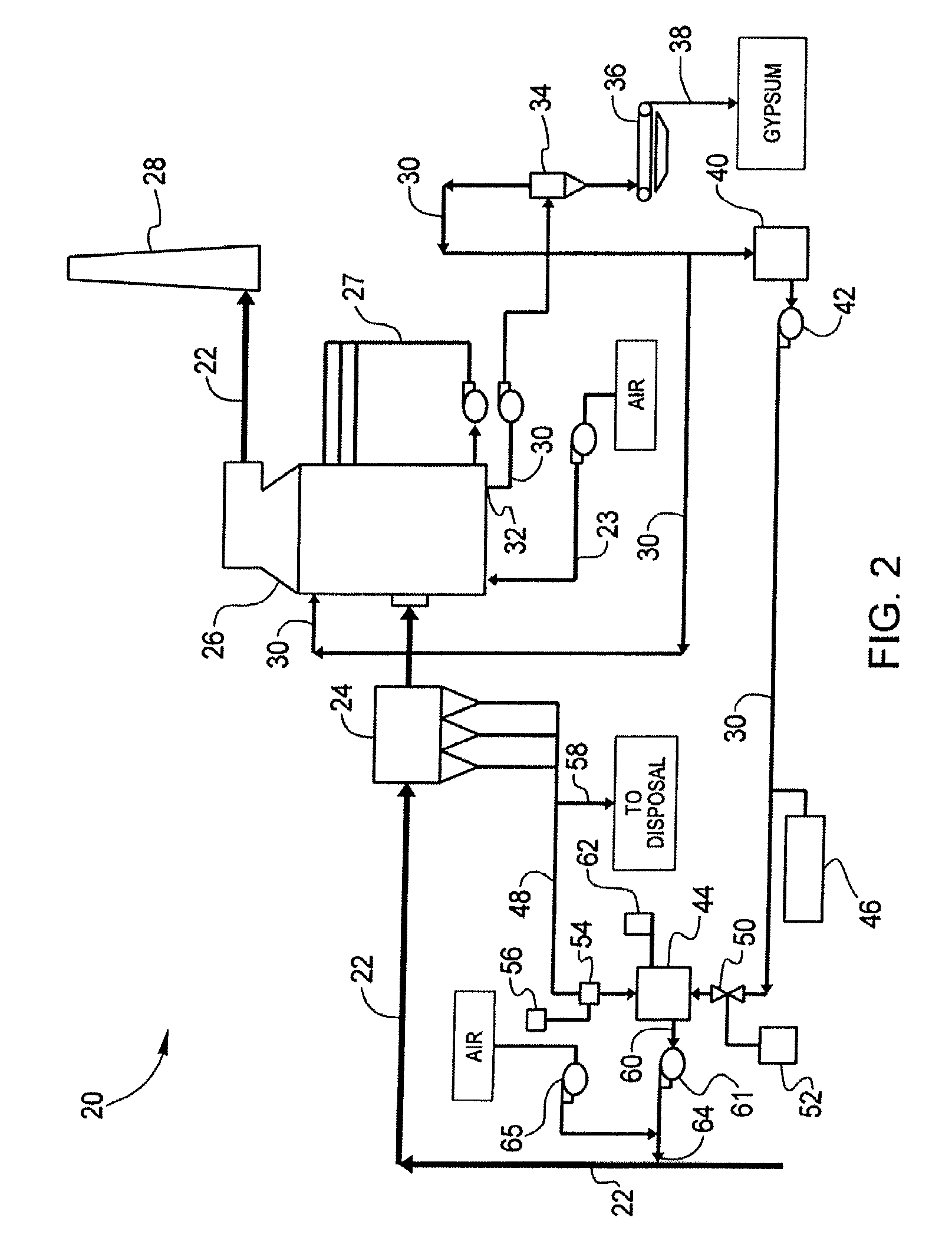

Reduced liquid discharge in wet flue gas desulfurization

One aspect of the invention relates to a method for removing contaminants from a flue gas stream (22). The method includes: removing fly ash from a flue gas stream (22) utilizing a particle collector (24); contacting the flue gas stream with an alkaline reagent in a wet scrubber (26); discharging a purge liquid (30) from the wet scrubber (26); and, combining at least a portion of the purge liquid with at least a portion of fly ash circulating within a dry circulating fluid bed scrubber (48) to form moistened fly ash (60).

Owner:GENERAL ELECTRIC TECH GMBH

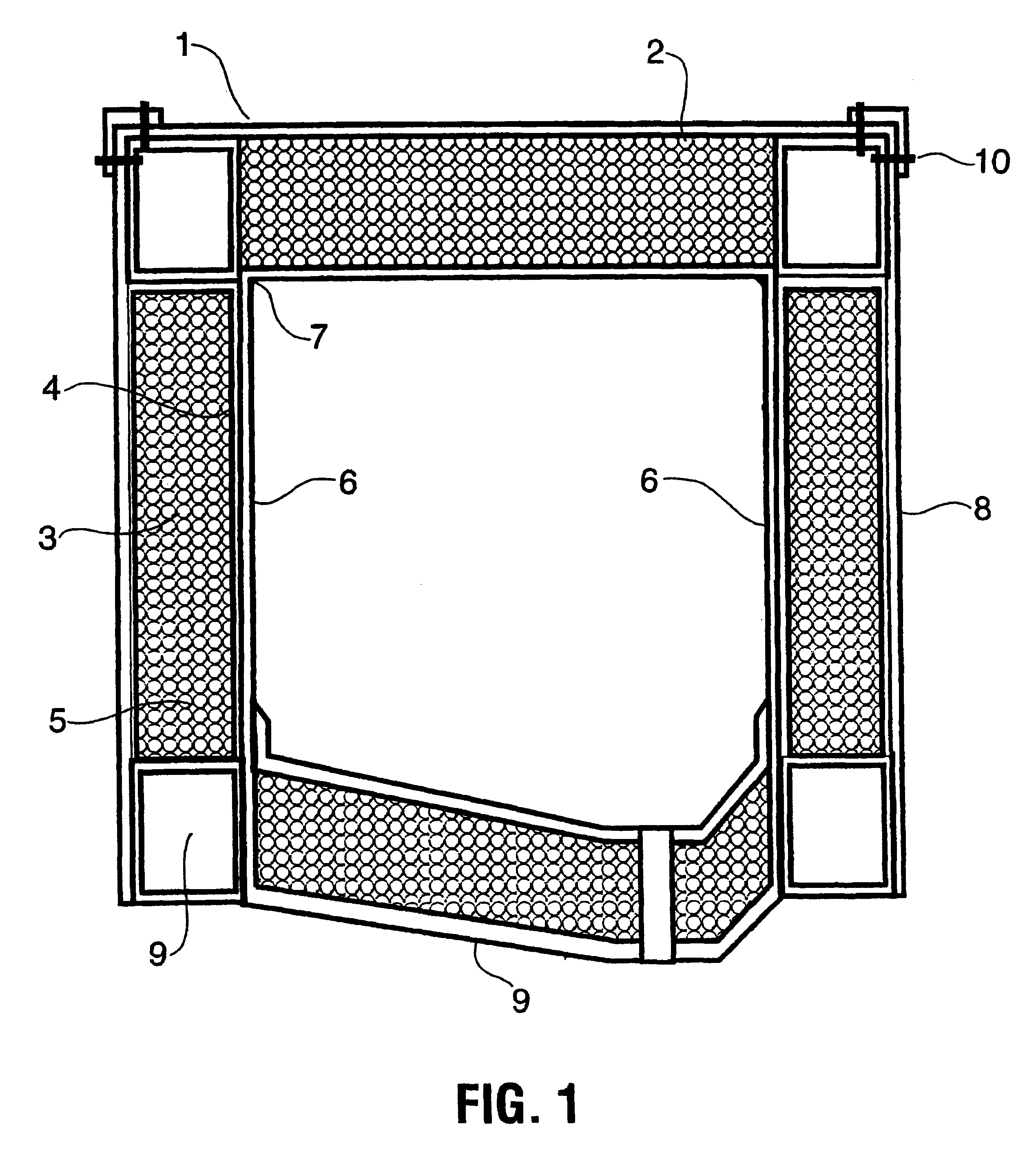

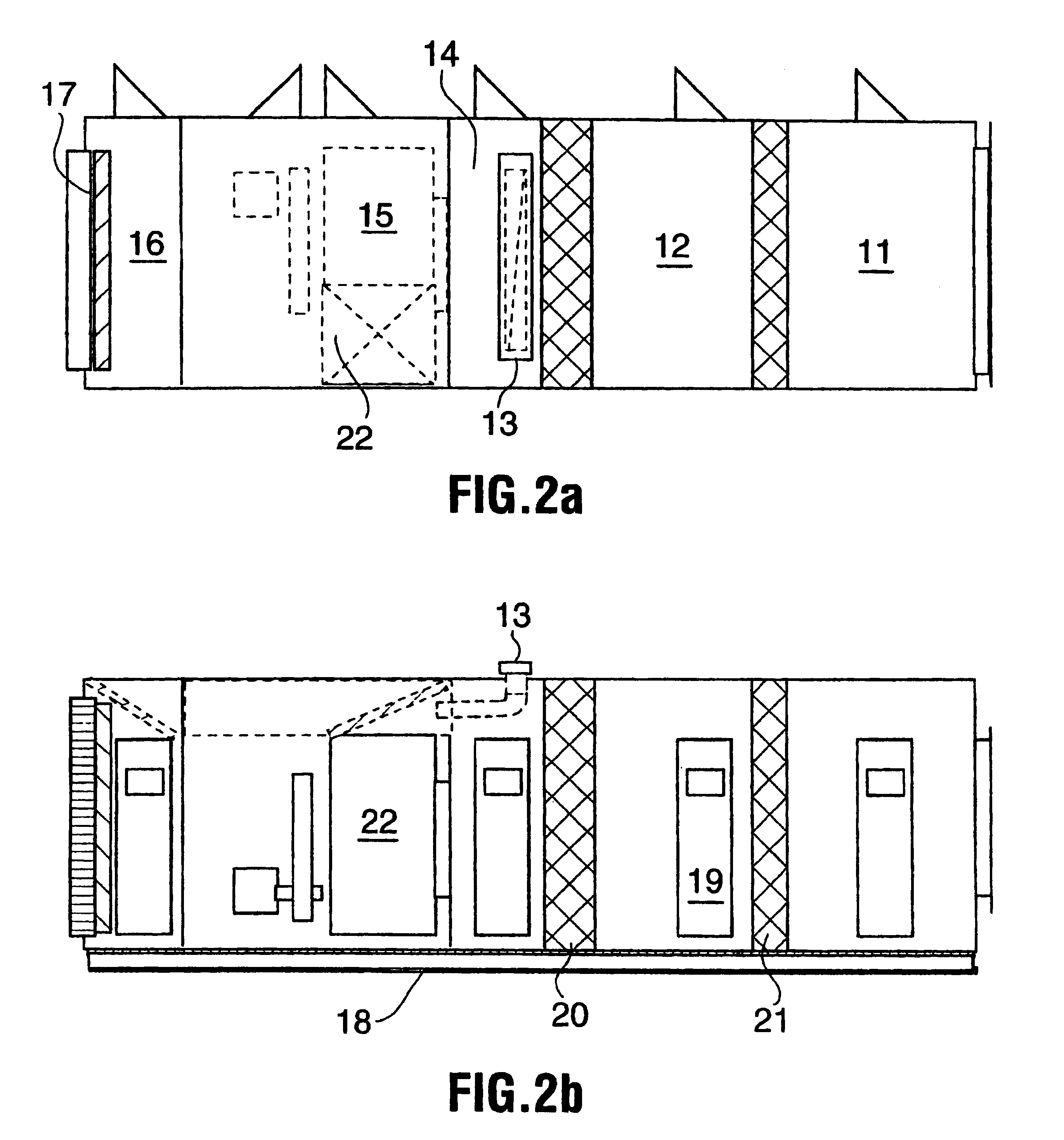

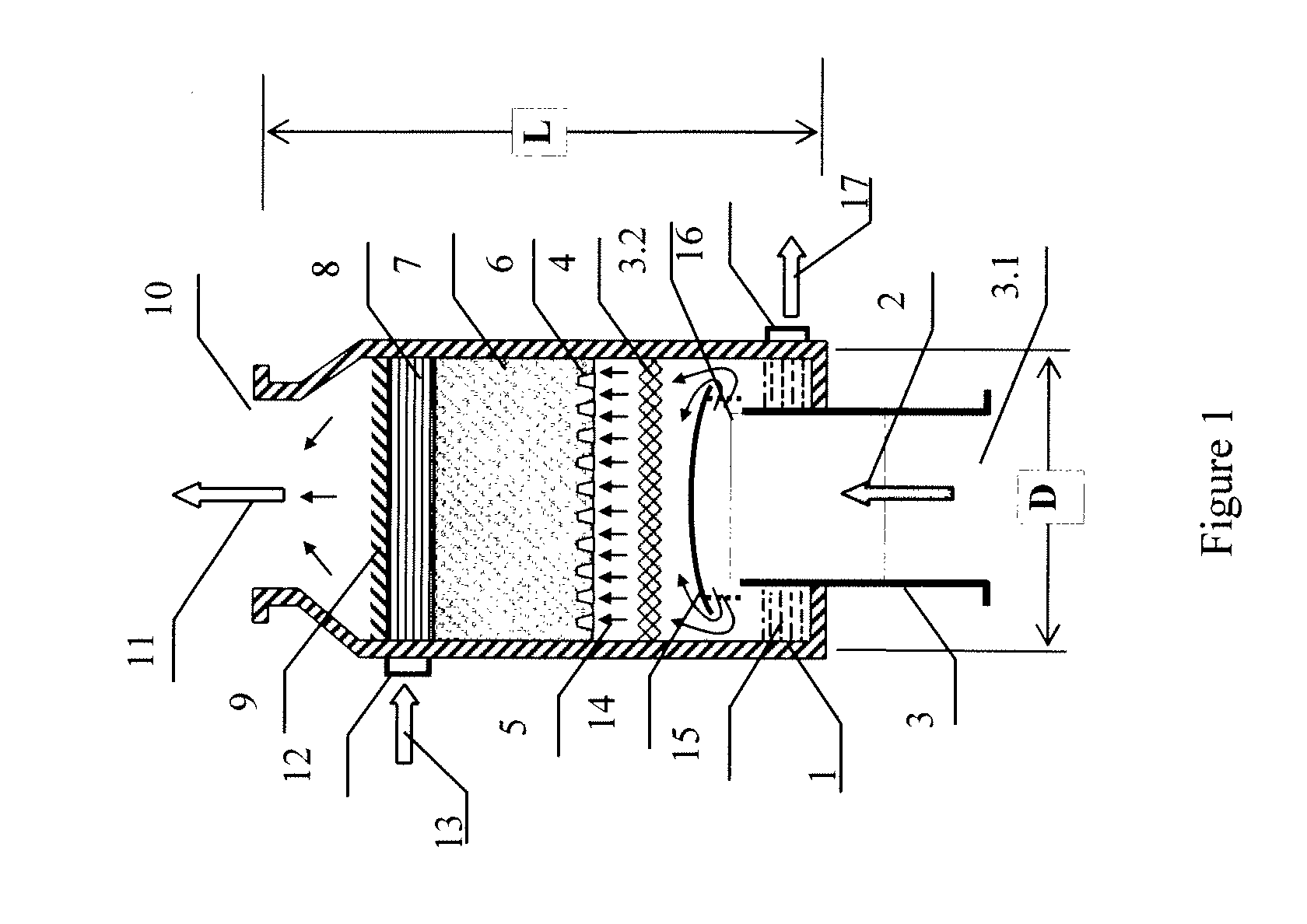

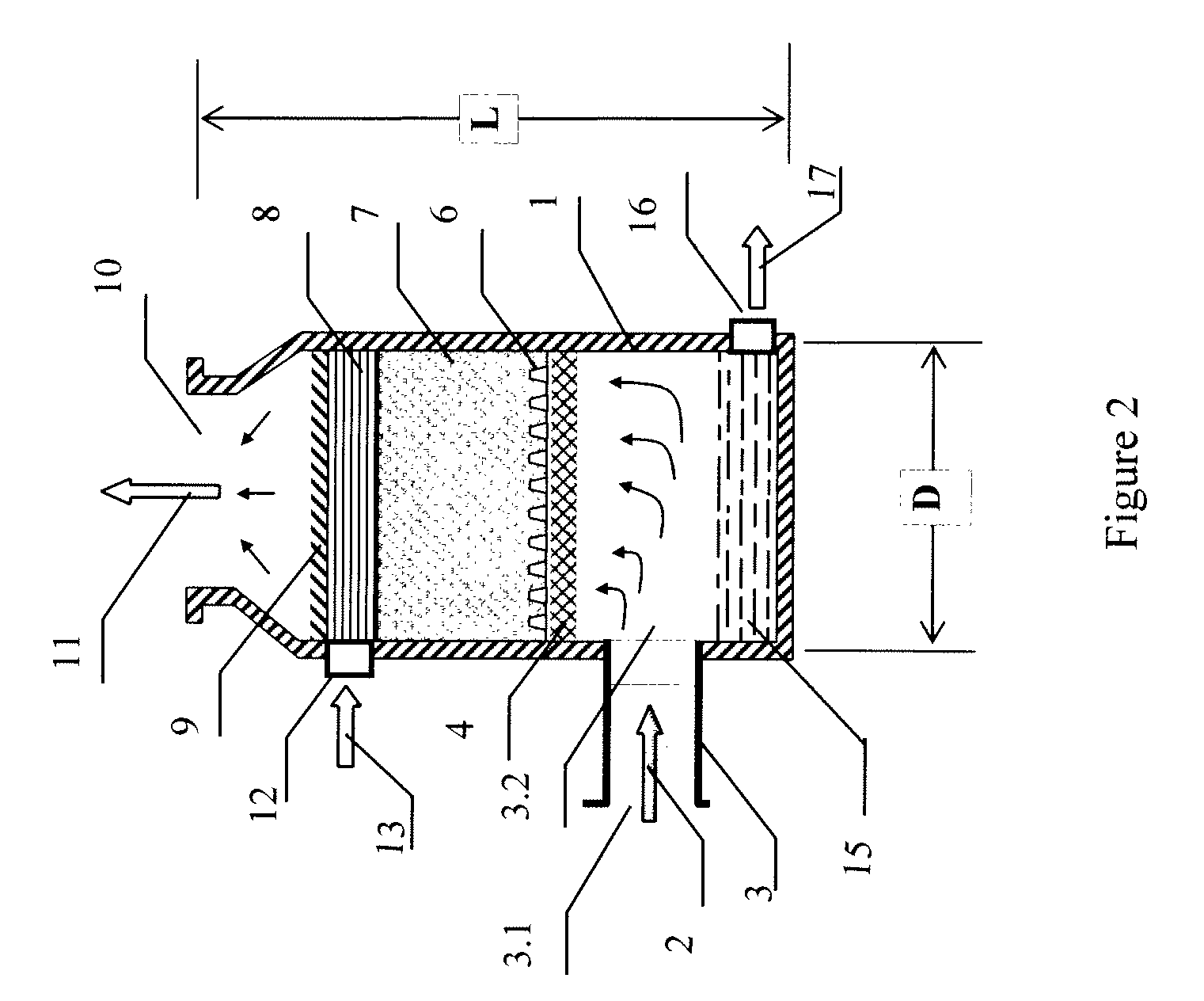

Marine exhaust gas scrubber

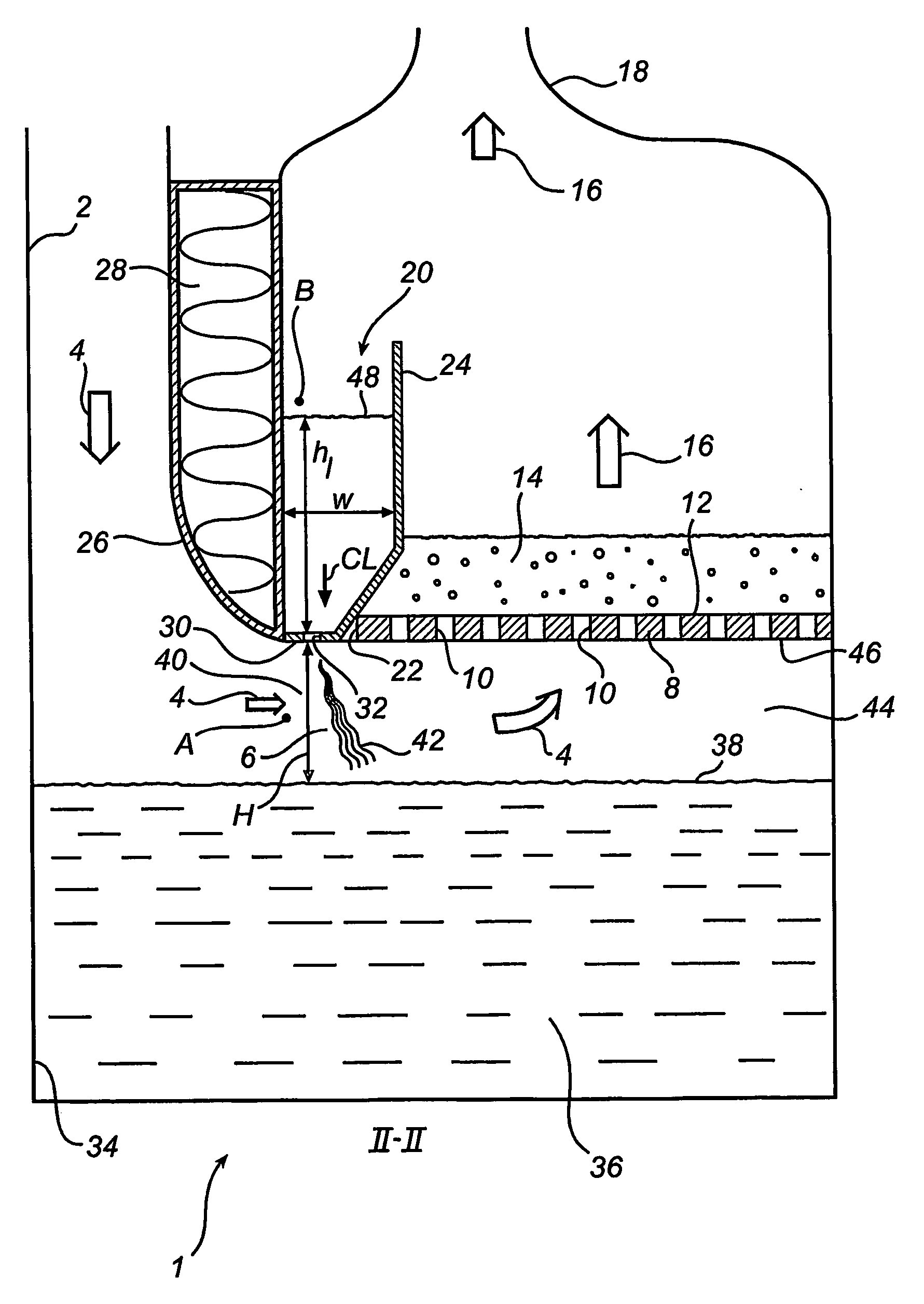

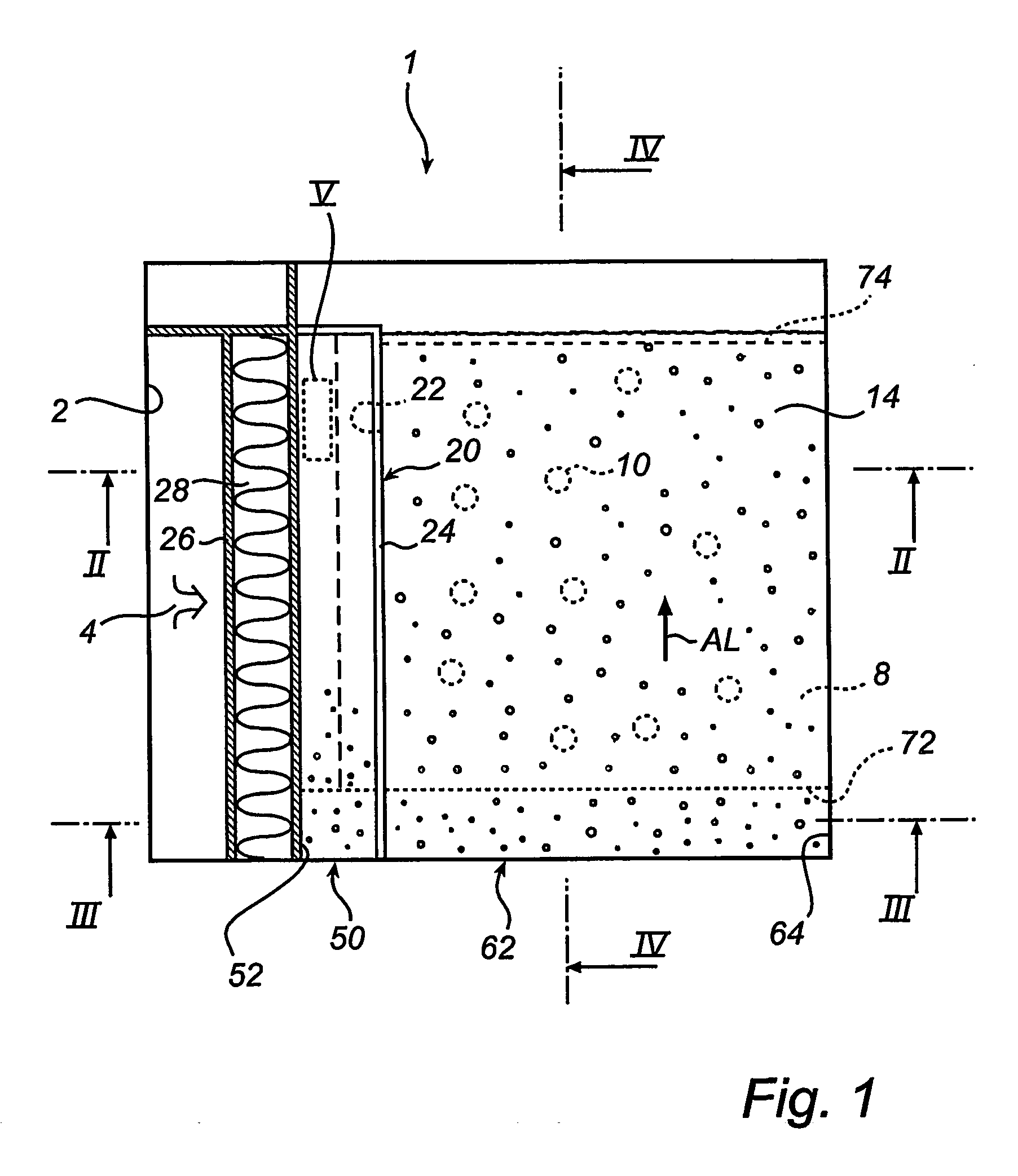

ActiveUS20160016109A1Easy constructionEffective dissolutionCombination devicesGas treatmentExhaust fumesEnvironmental engineering

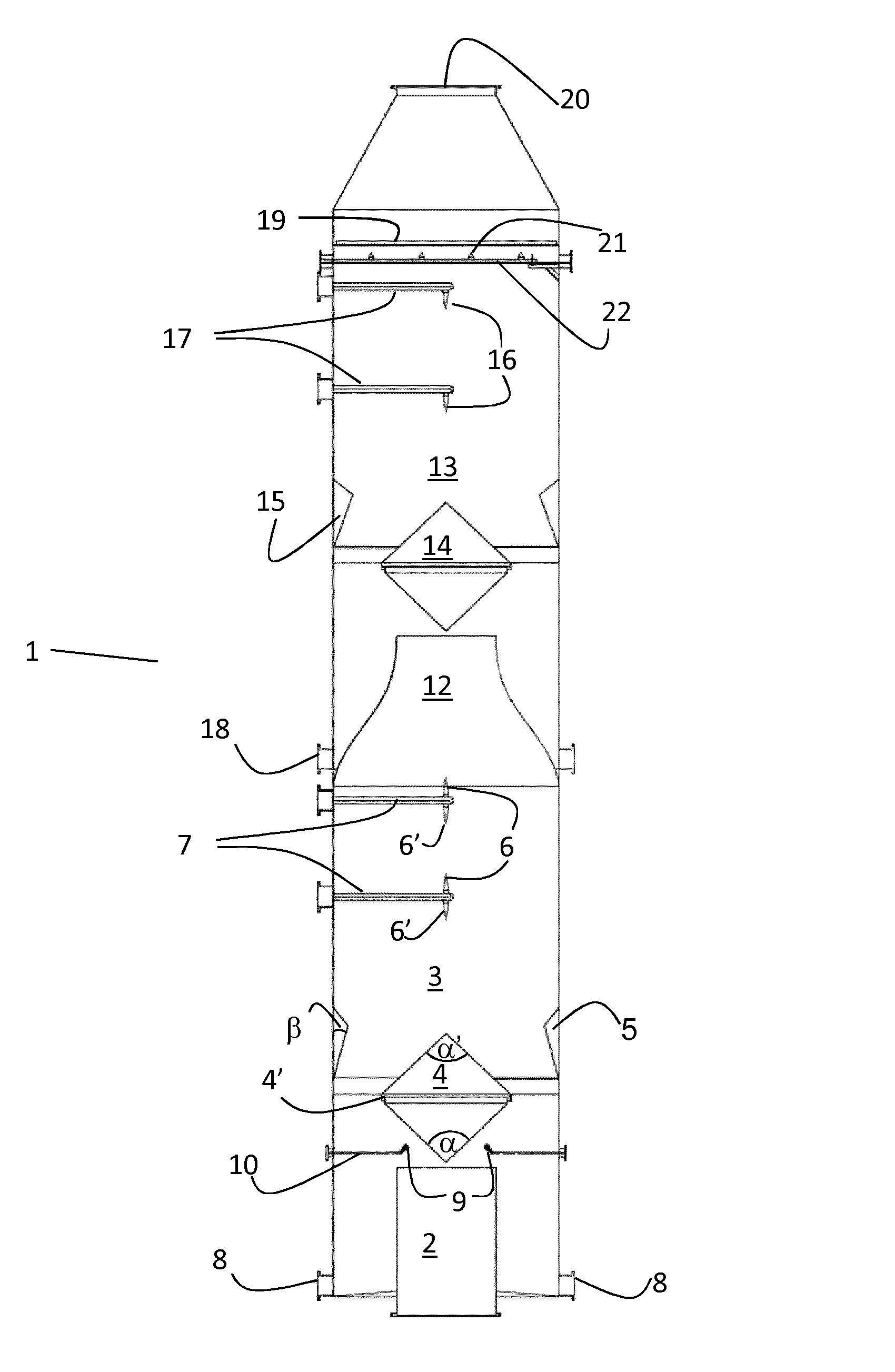

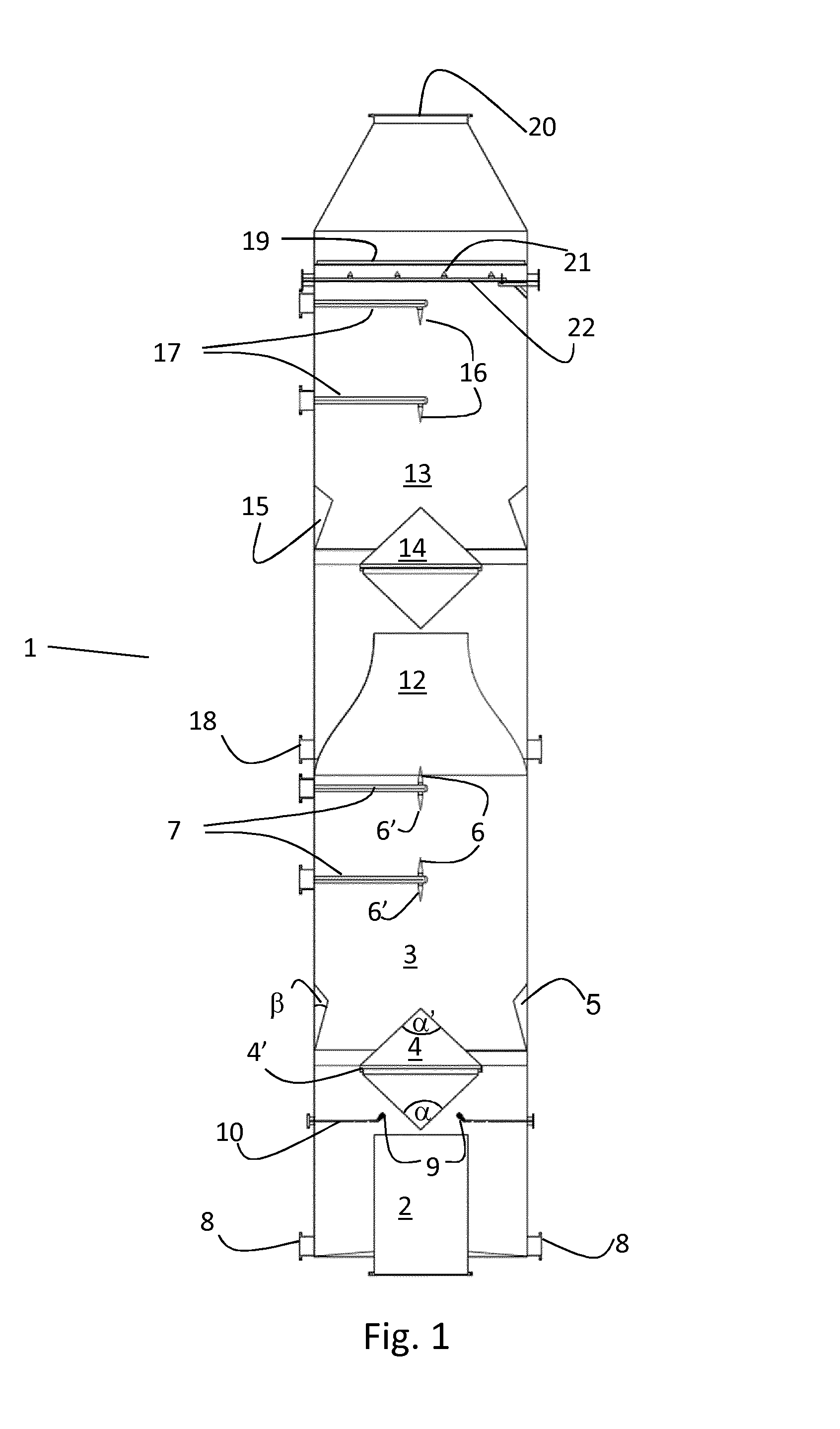

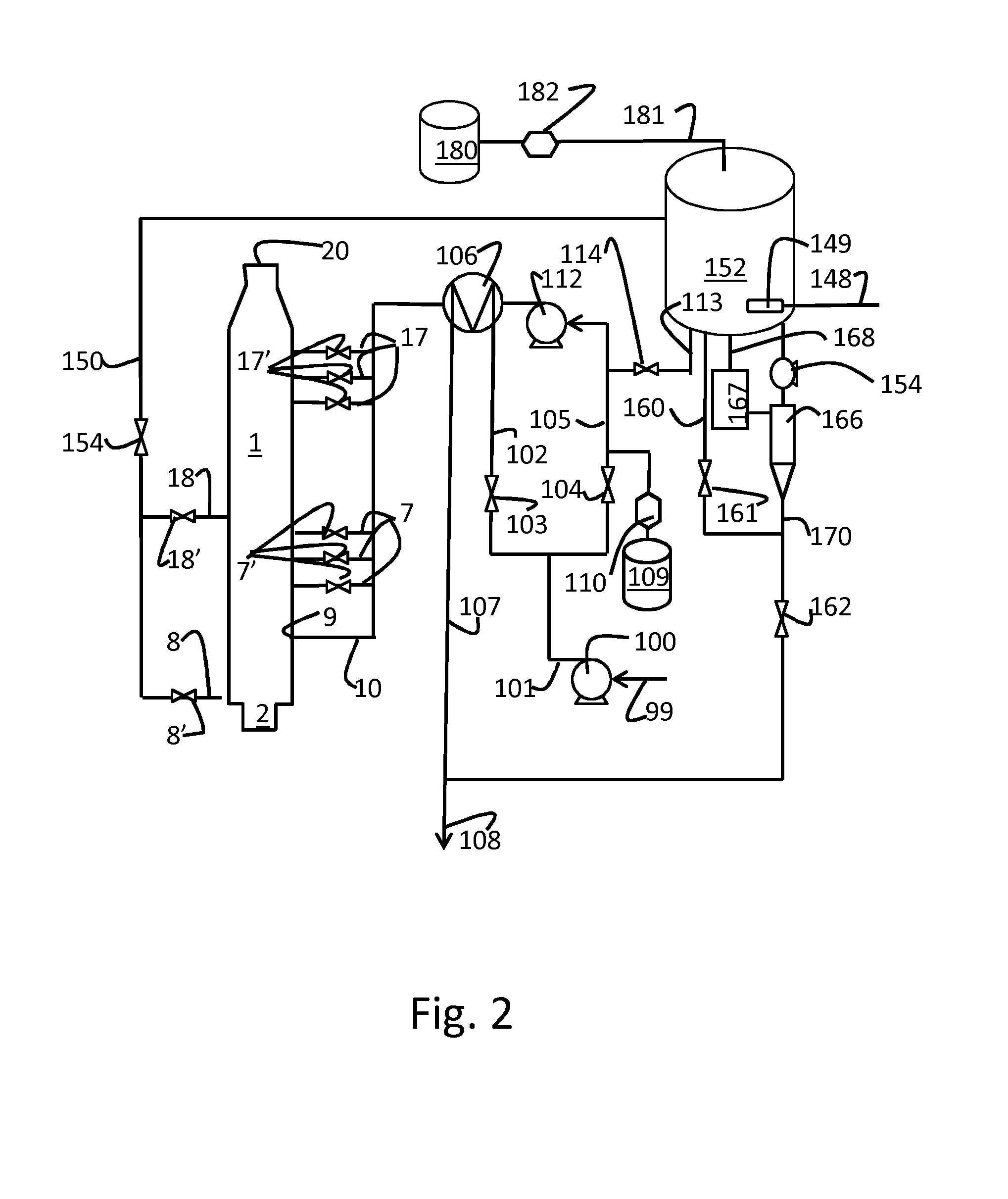

A vertical scrubber (1) for exhaust gas from a marine vessel is described. An exhaust gas tube (2) is substantially coaxially arranged through the bottom of a lower scrubbing chamber (3) and is released though an exhaust gas outlet (20) being coaxially arranged through the top of an upper scrubbing chamber (13). A lower scrubbing chamber deflection body (4) is arranged above the opening of the exhaust gas tube (2) for redirecting the exhaust gas towards the walls of the scrubber and create turbulent gas flow, where one or more lower chamber water injector(s) (6, 6′) is (are) arranged above the lower scrubbing chamber deflection body (4), to introduce scrubbing water, and where a lower chamber exhaust gas outlet (12) is arranged at the top of the lower scrubbing chamber (3) as a coaxial constriction, for withdrawing the partly scrubbed exhaust gas from the first scrubbing chamber and introducing the gas into the upper scrubbing chamber (13).

Owner:MARINE GLOBAL HLDG

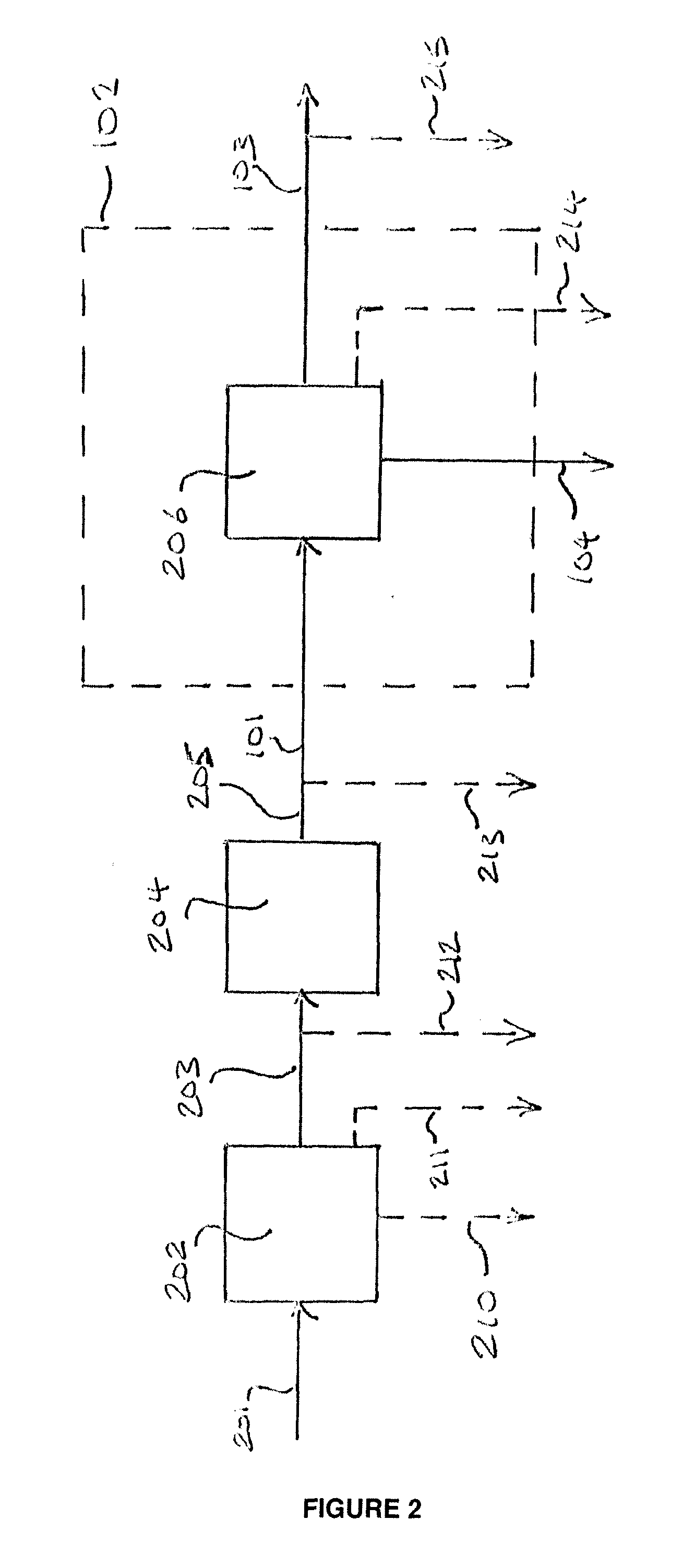

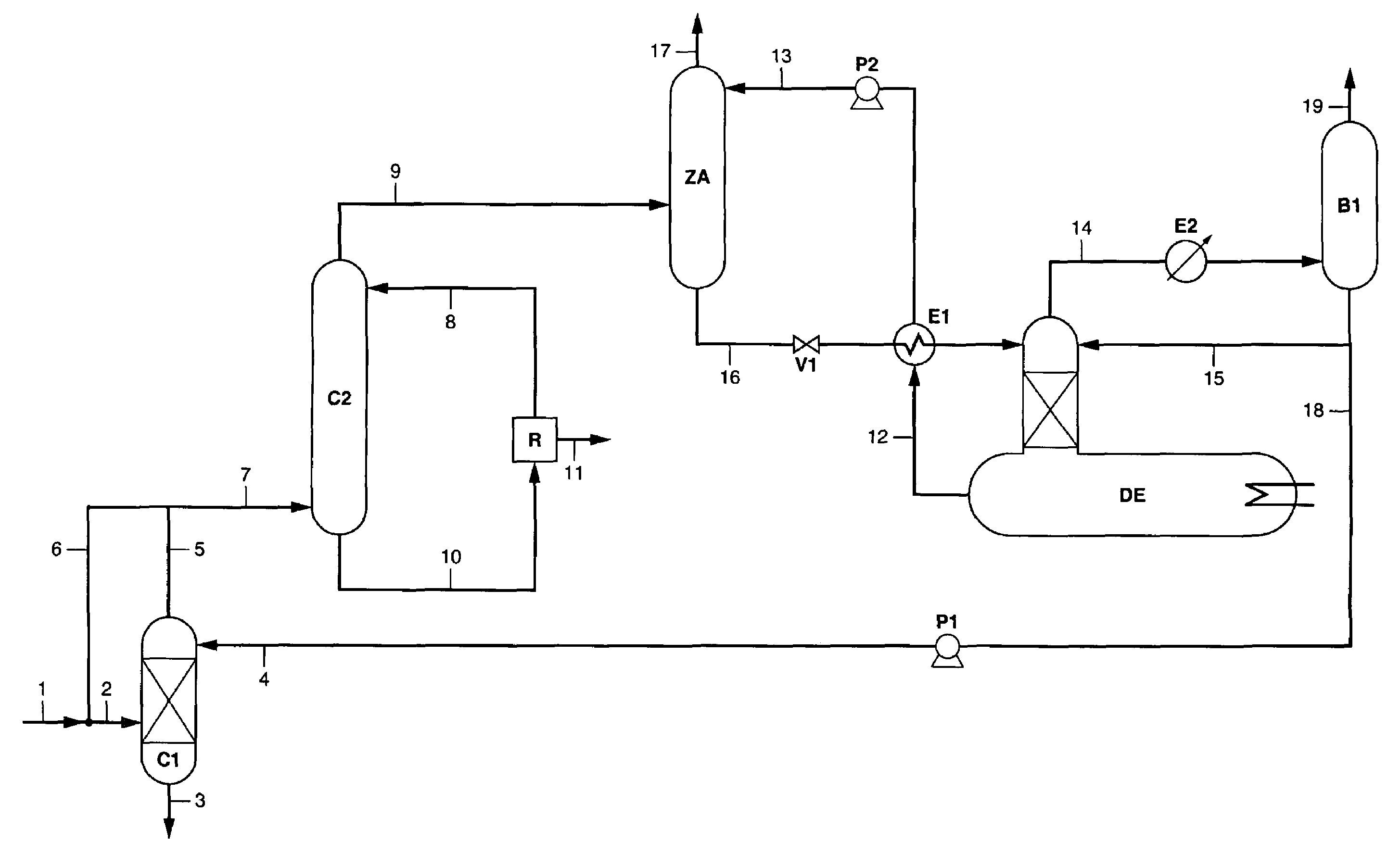

Method of decarbonating a combustion fume with extraction of the solvent contained in the purified fume

InactiveUS20060188423A1High purityNitrogen compoundsUsing liquid separation agentPhosphoniumPhysical chemistry

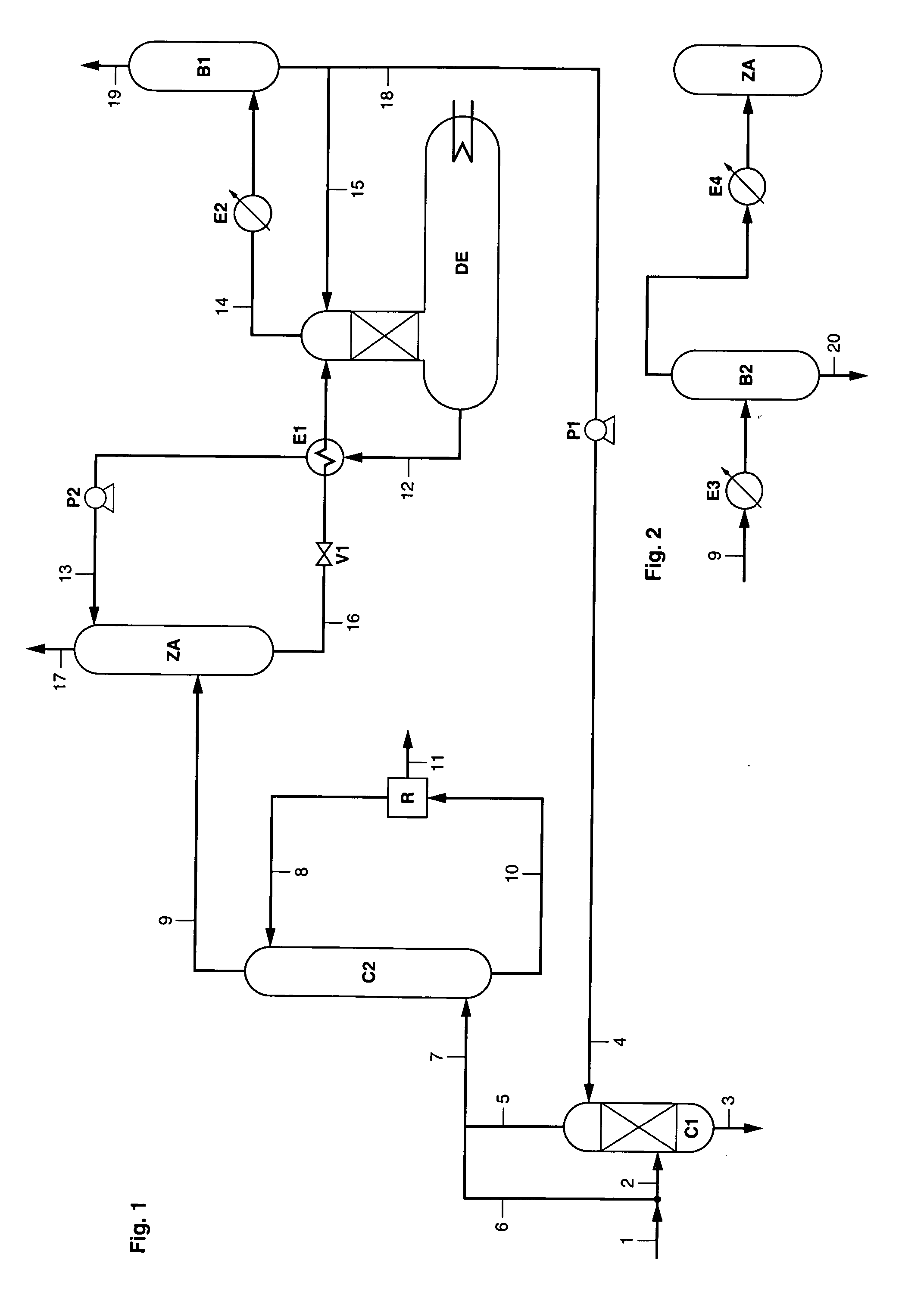

The combustion fume flowing in through line 1 is decarbonated by contacting with a solvent in column C2. The solvent laden with carbon dioxide is regenerated in zone R. The purified fume discharged through line 9 comprises part of the solvent. The method allows to extract the solvent contained in the purified fume. The purified fume is contacted in zone ZA with a non-aqueous ionic liquid of general formula Q+ A−; Q+ designates an ammonium, phosphonium and / or sulfonium cation, and A− an anion likely to form a liquid salt. The solvent-depleted purified fume is discharged through line 17. The solvent-laden ionic liquid is regenerated by heating in evaporation device DE. The solvent separated from the ionic liquid in device DE is recycled.

Owner:INST FR DU PETROLE

Method and an equipment for reducing the sulphur dioxide emissions of a marine engine

ActiveUS20080044335A1Reduce usageEmission reductionCombination devicesInternal combustion piston enginesSulfurFlue gas

A method and an equipment for reducing sulphur dioxide emissions of a marine engine, wherein flue gases are scrubbed with a scrubbing solution in a scrubber. Fresh water with added sulphur removal reagent is used as the scrubbing solution.

Owner:METSO POWER OY

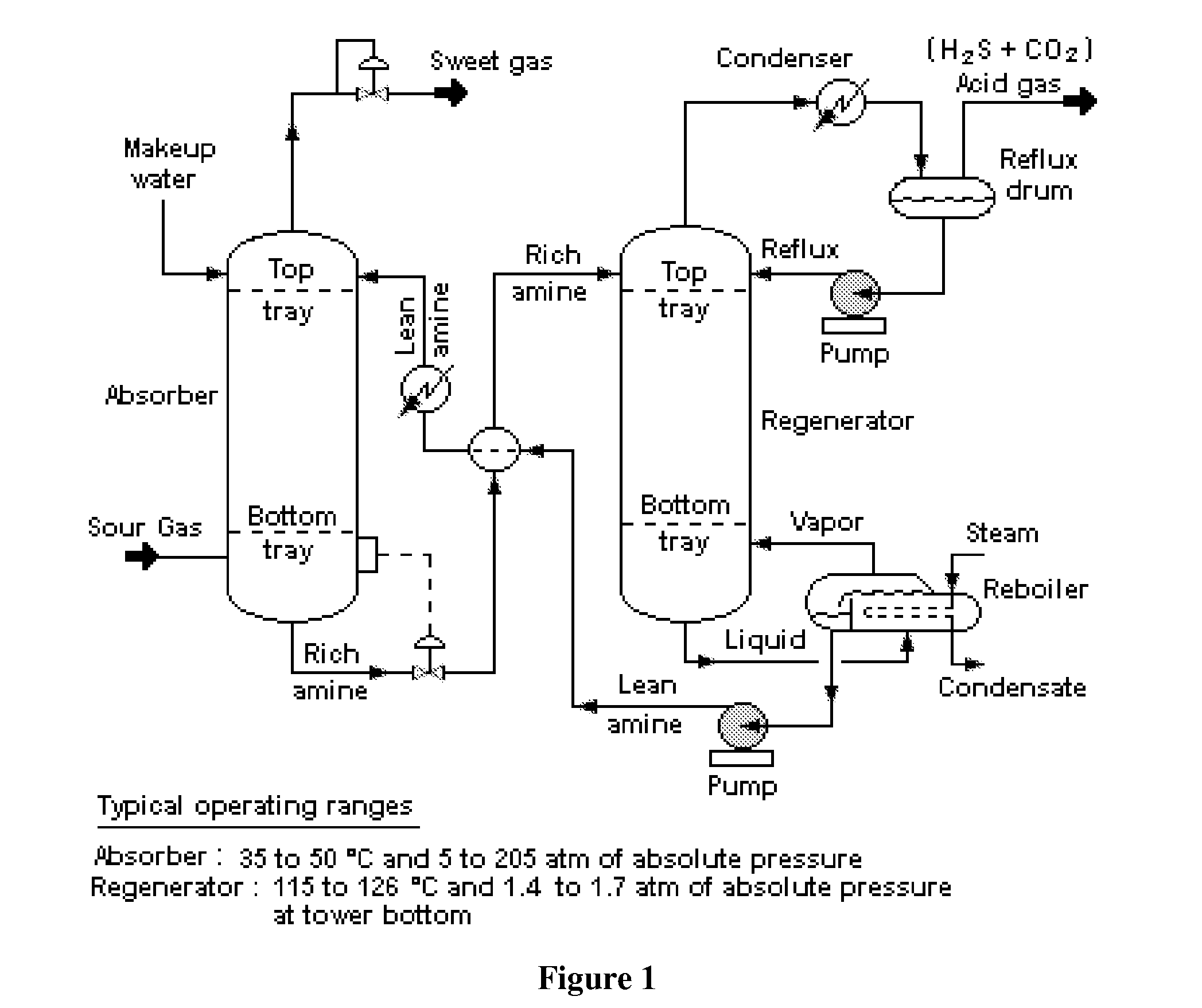

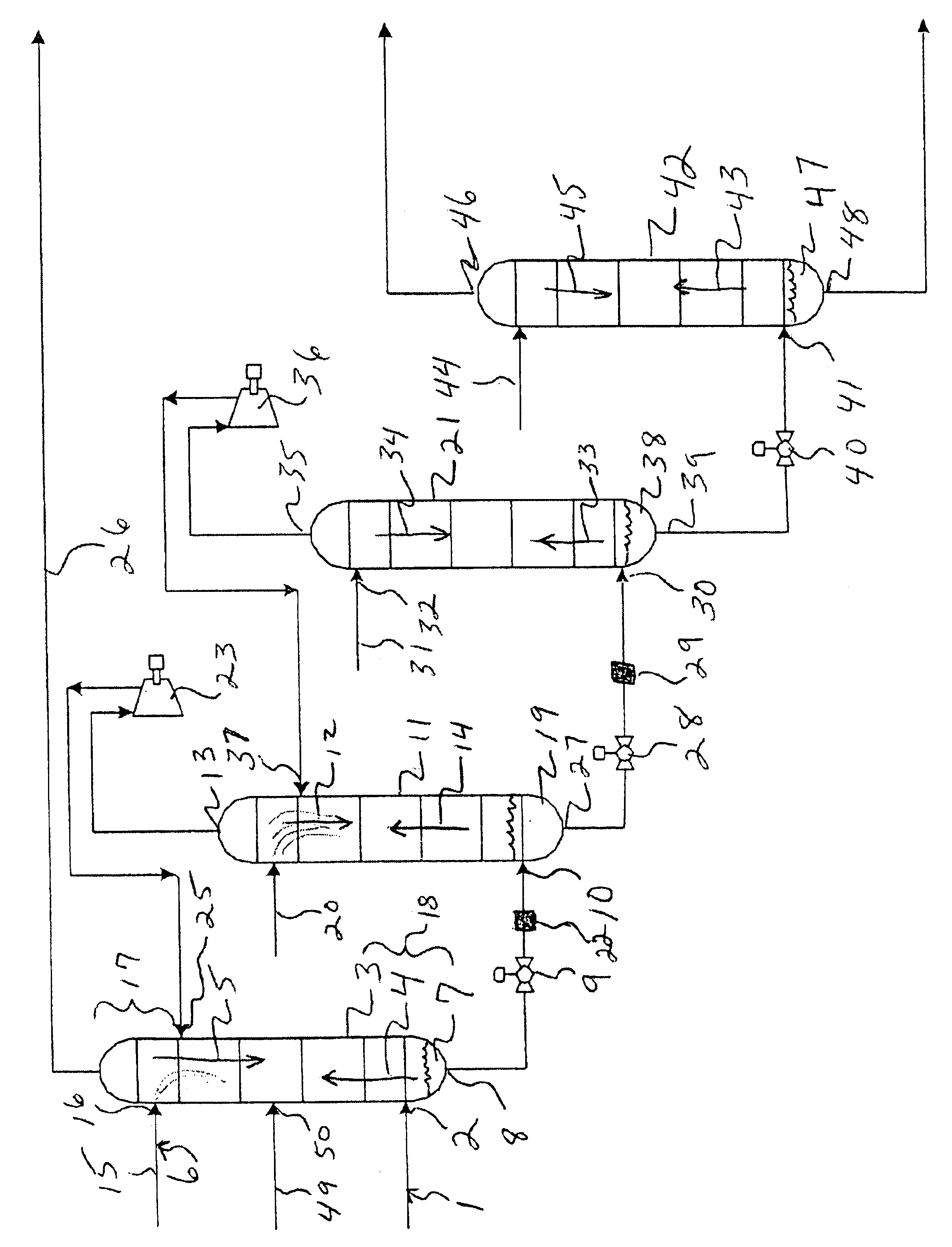

Removal of H2S and CO2 from a hydrocarbon fluid stream

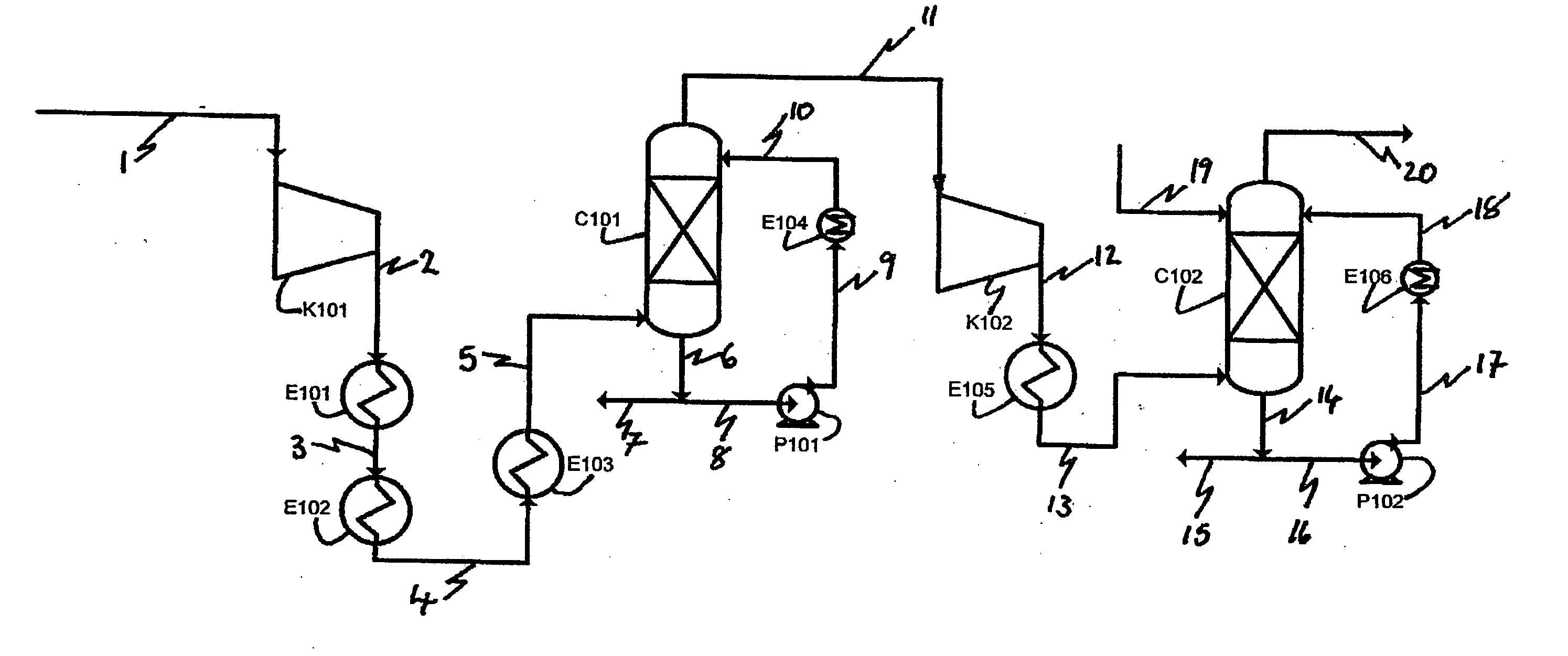

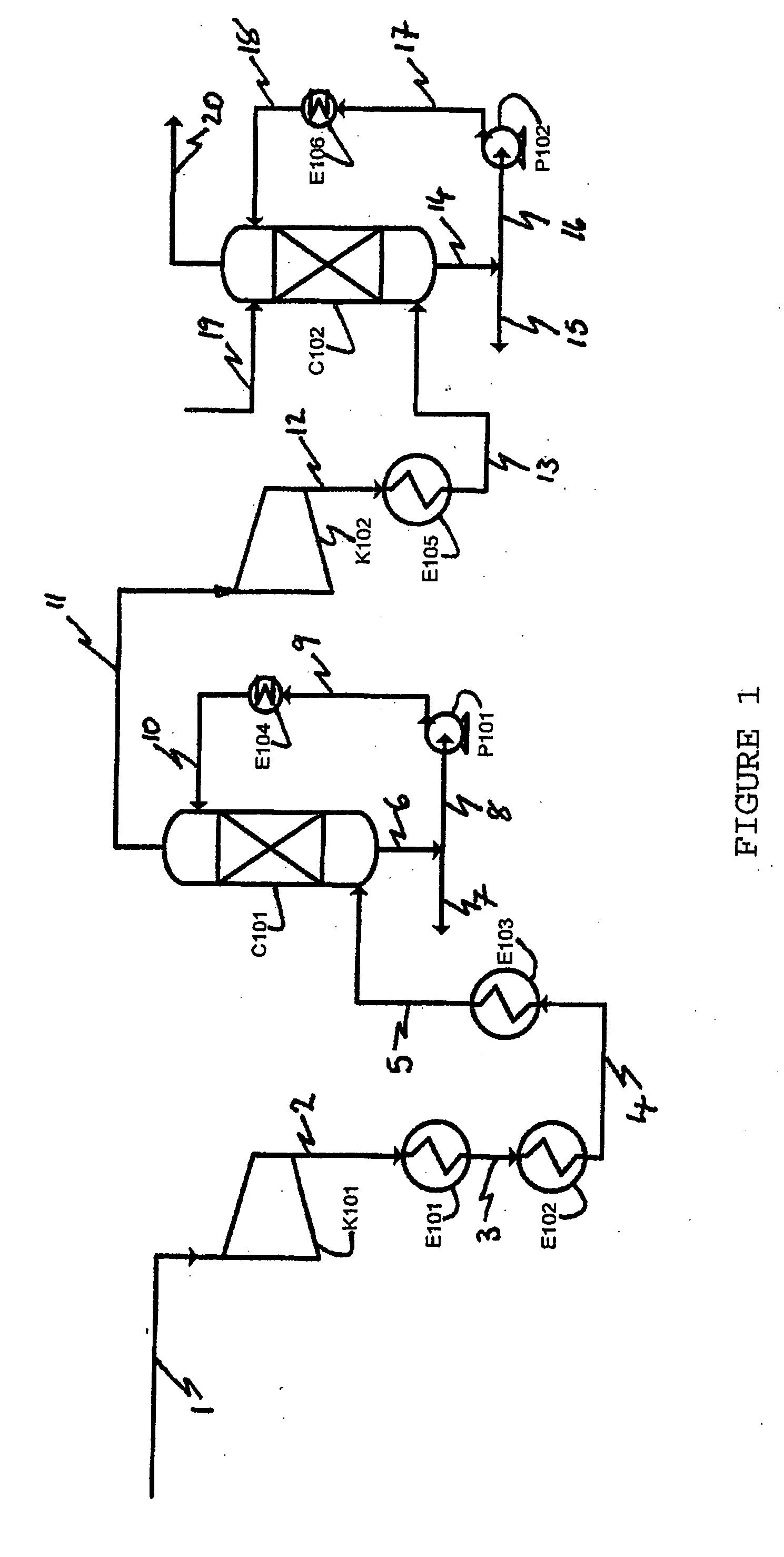

InactiveUS6881389B2Easy to operateLess-costly to buildUsing liquid separation agentHydrogen sulfidesEnergy recoveryImpurity

A system for removal of Hydrogen Sulfide (H2S) and / or Carbon Dioxide (CO2) from natural gas via absorption and disassociation utilizing a sea water contact system. In the preferred embodiment of the present invention, a series of counter current scrubber stages is provided, each configured to remove via absorption / disassociation a portion of the impurities, each stage having less pressure than the predecessor, each stage redirecting the purified gas to the preceding stage, until the contaminant level in the hydrocarbon gas stream has been reduced to an acceptable level. The hydrogen sulfide / carbon dioxide contaminants are thereby sequestered in the sea water utilized in the scrubber, which sea water may be further processed and / or re-introduced into the deep of a body of water, where the contaminants will remain isolated for hundreds of years. The present invention further contemplates and energy recovery system for greatly enhancing the efficiency of the system. Accordingly, the present invention provides an efficient and cost effective method for the purification of natural gas on an offshore platform.

Owner:EDG

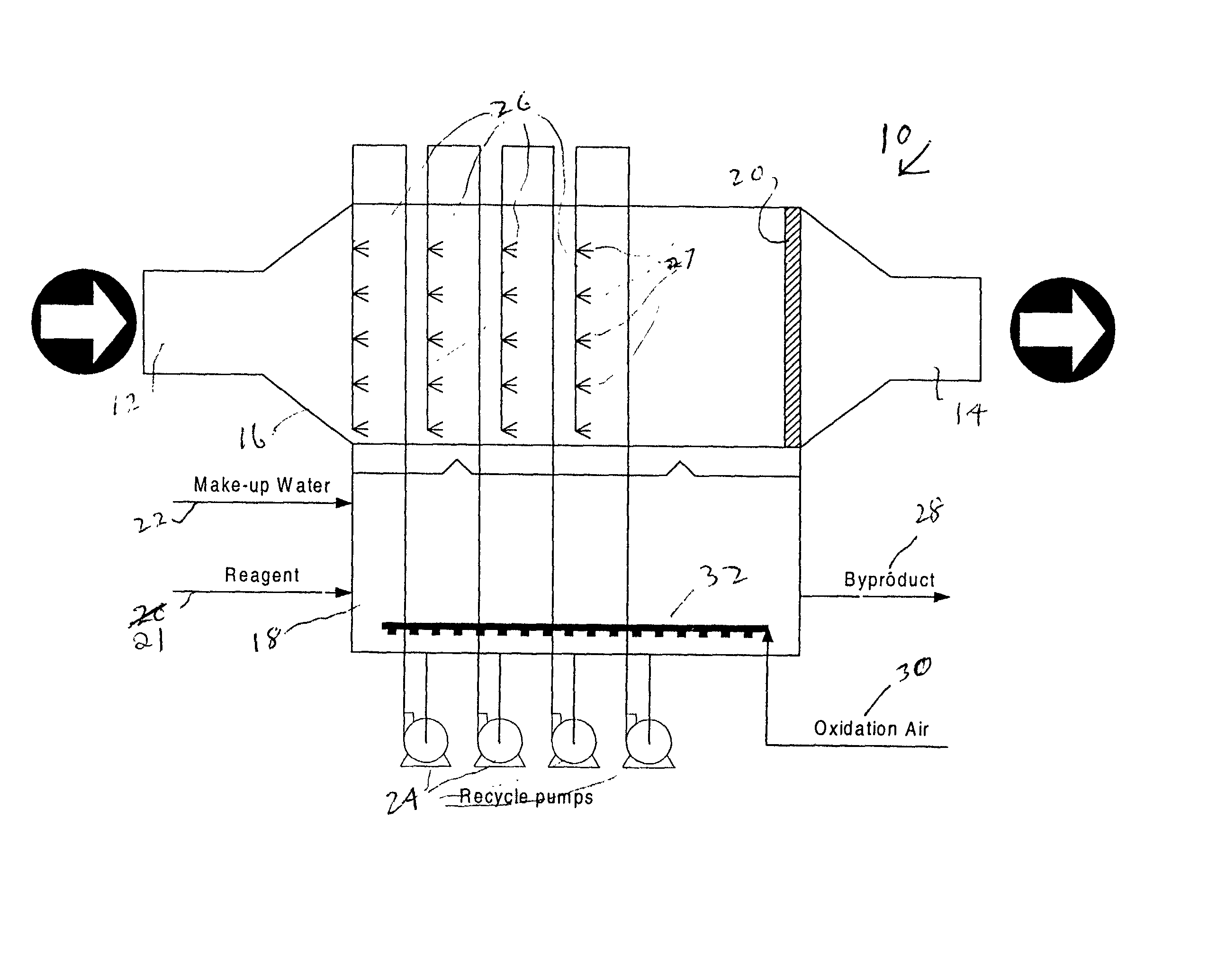

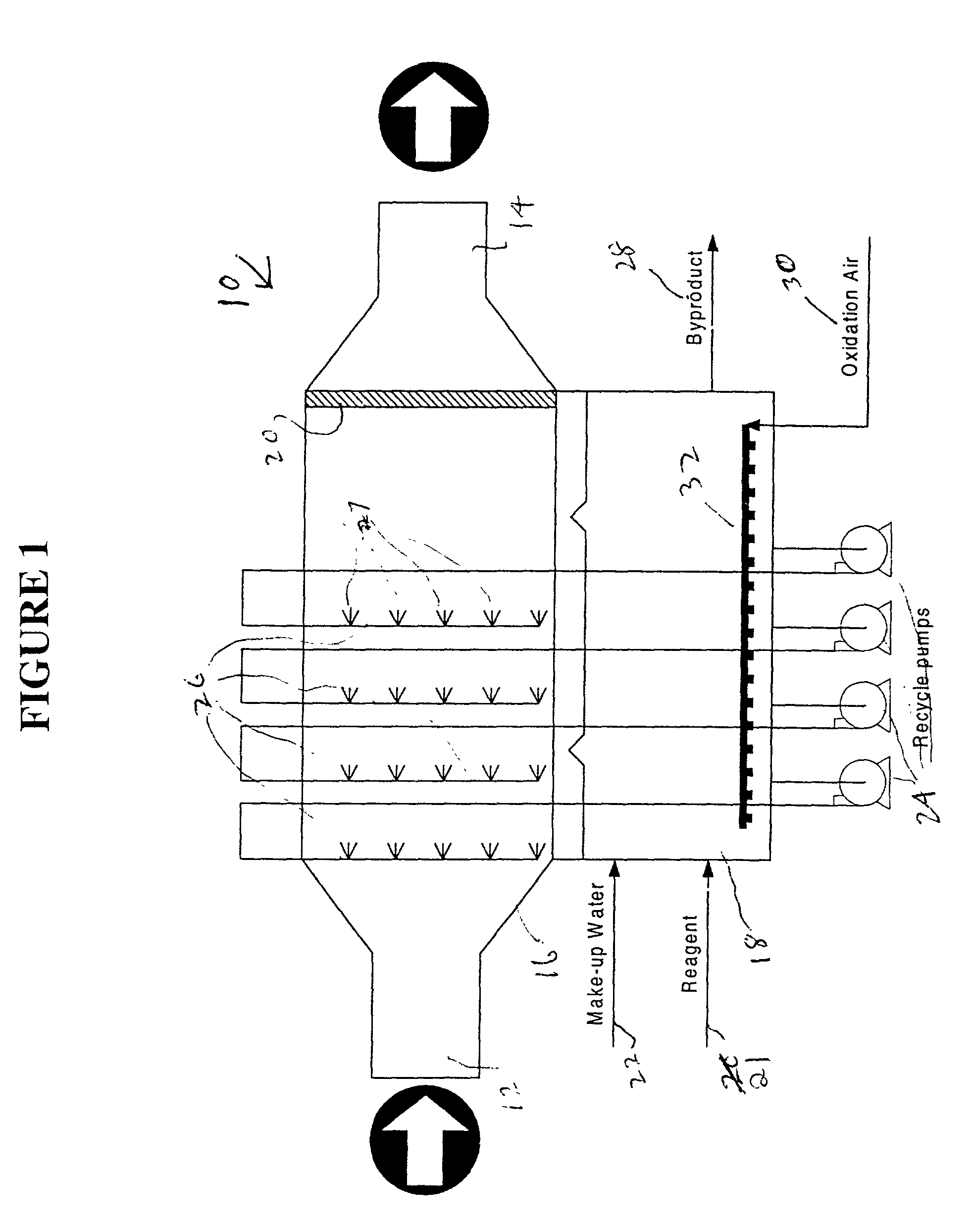

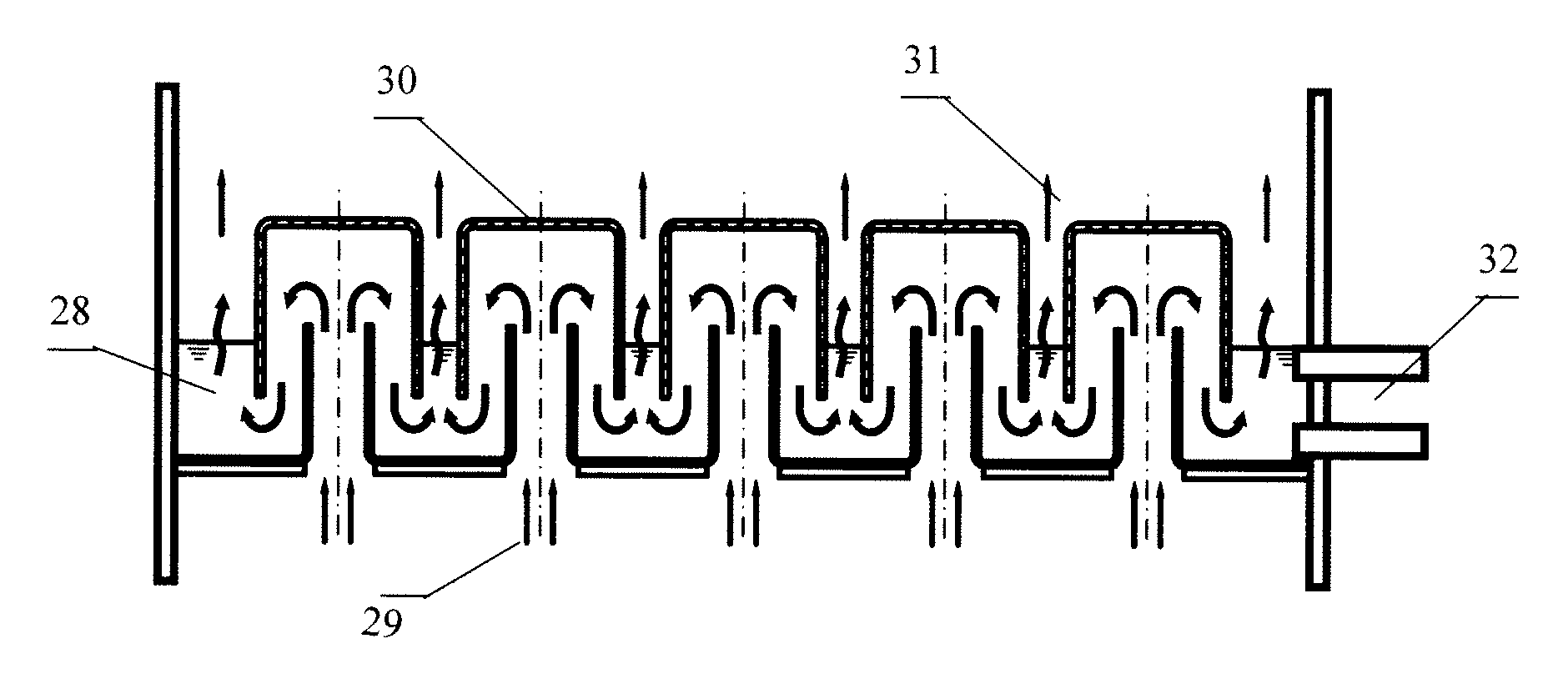

Horizontal scrubber system

InactiveUS20020110511A1Eliminate needHigh gas velocityElectrostatic separationUsing liquid separation agentDifferential pressureProduct gas

A scrubber system is provided which enables a substantially horizontal flow path for the gas which is being subjected to scrubbing. Among other advantages, this permits operation of the absorber with a differential pressure of zero or less. Scrubber composition spray means are positioned in the horizontal gas flow path for spraying an aqueous scrubber composition in a direction which is generally cocurrent with said gas flow. The system is free of means which spray the scrubber composition in directions countercurrent to said gas flow.

Owner:URS

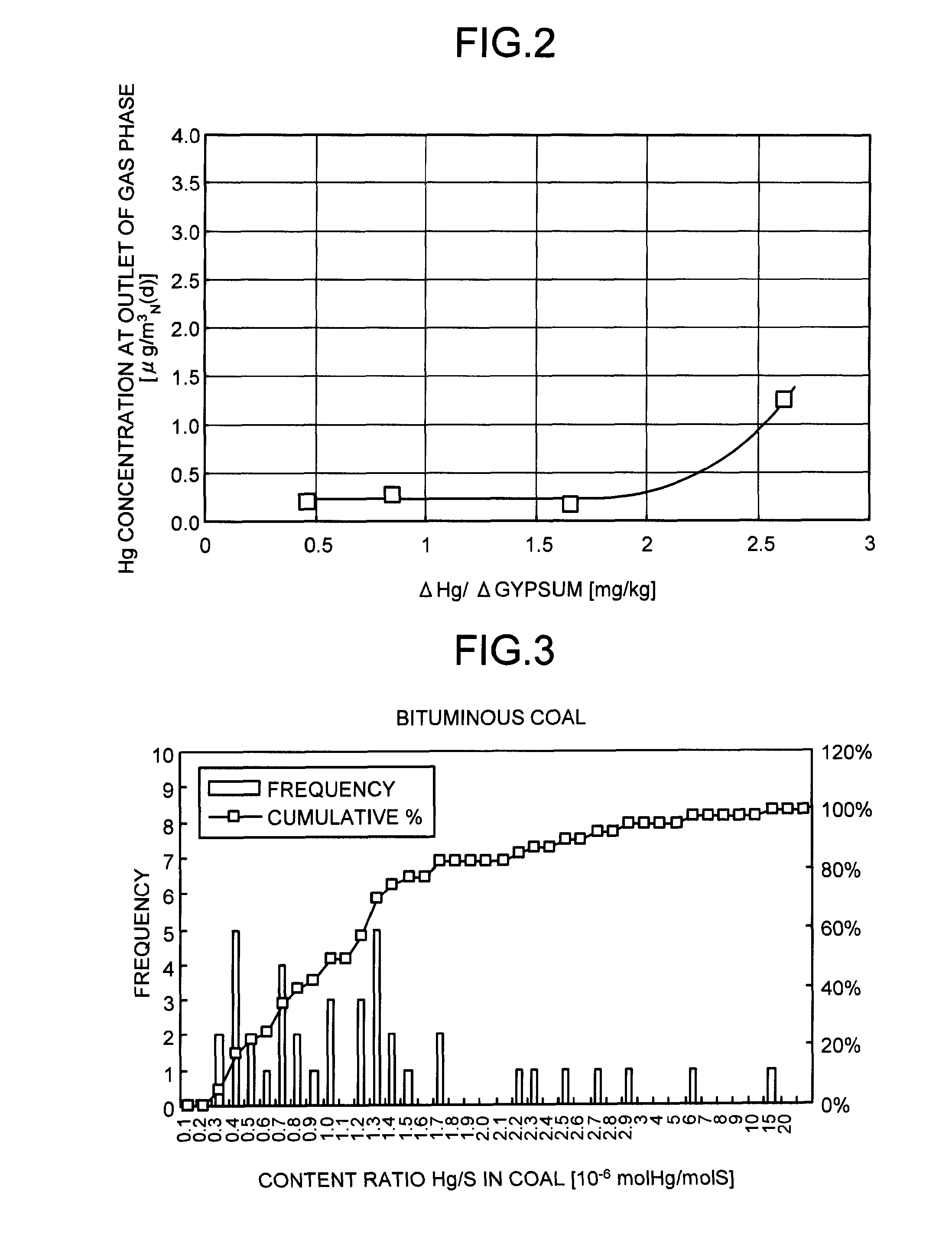

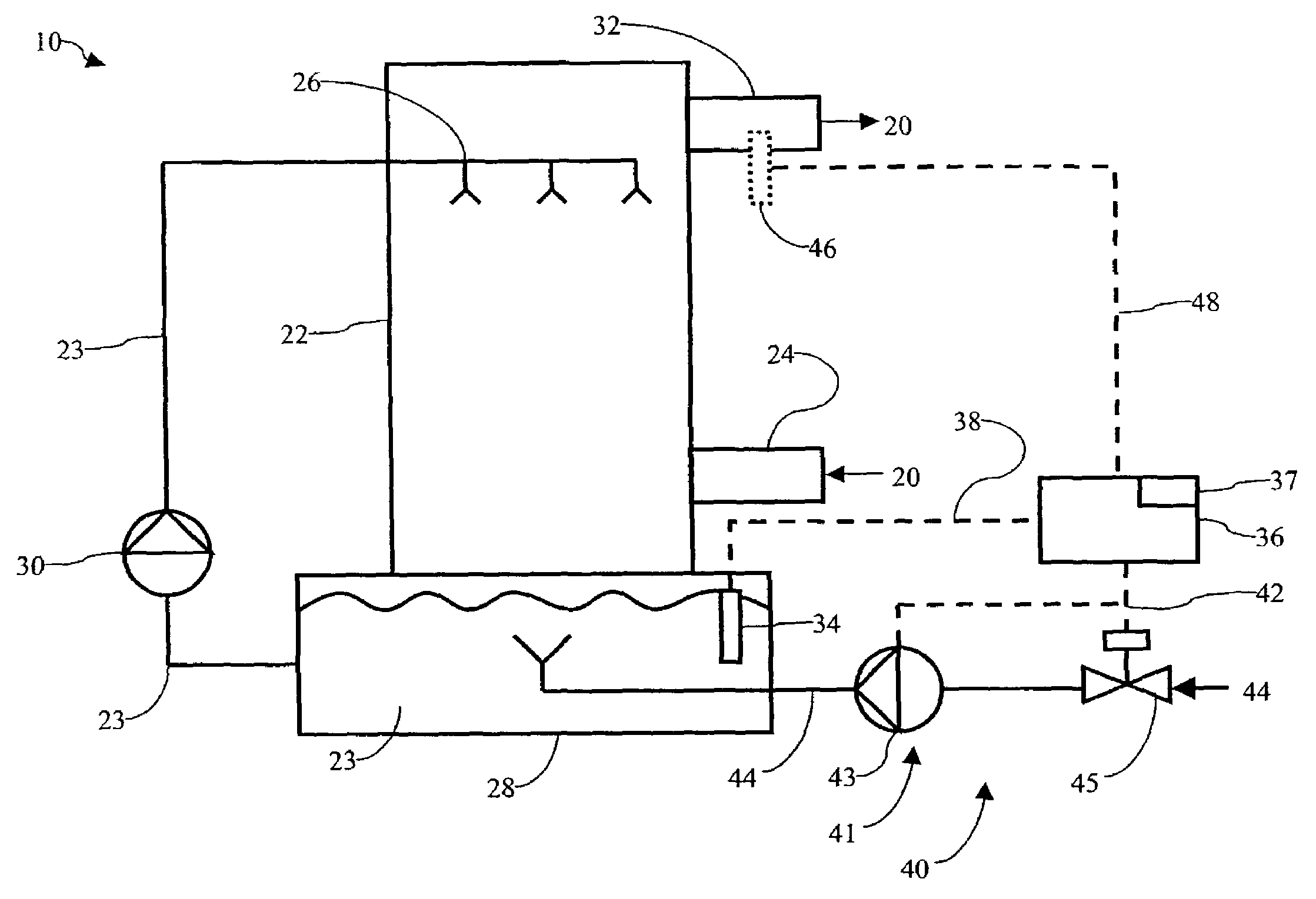

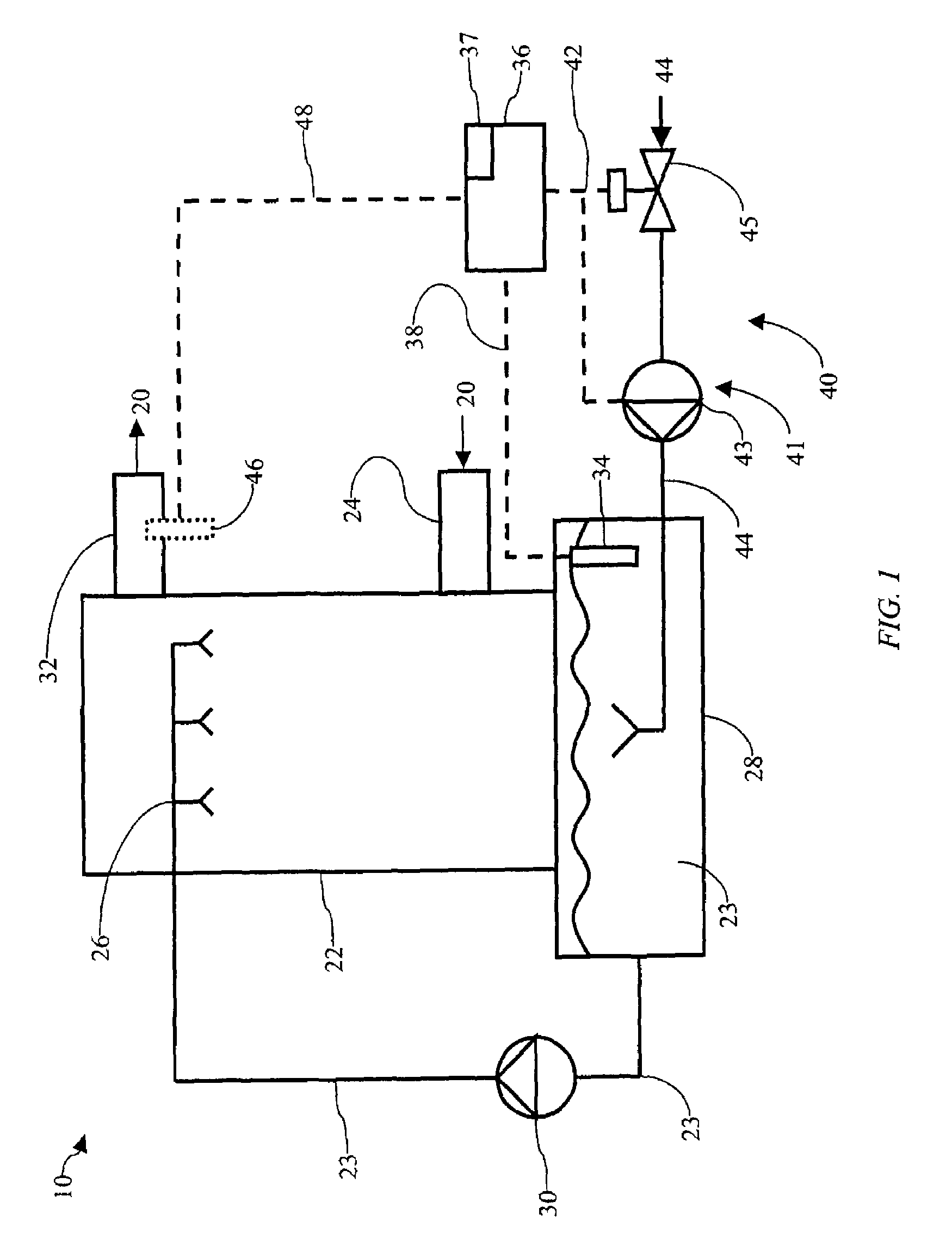

Method of mercury removal in a wet flue gas desulfurization system

Controlling the reductive capacity of an aqueous alkaline slurry (23) in a wet scrubber makes it possible to accurately control the mercury emission from the scrubber to a desired value. One method of controlling the reductive capacity of the slurry is to measure the reduction-oxidation potential (“redox potential”) of the aqueous alkaline slurry (23) and to add or remove substances that affect the redox potential and thus the reductive capacity of the slurry. In wet scrubbers in which limestone is used for absorption of acid gases and where a gypsum slurry is circulated, it has been found to be an attractive solution to control the amount of oxidation air blown into the scrubber in order to control the redox potential and thereby the mercury emissions.

Owner:GENERAL ELECTRIC TECH GMBH

Method of decarbonating a combustion fume with extraction of the solvent contained in the purified fume

InactiveUS7459134B2High purityNitrogen compoundsUsing liquid separation agentPhosphoniumPhysical chemistry

The combustion fume flowing in through line 1 is decarbonated by contacting with a solvent in column C2. The solvent laden with carbon dioxide is regenerated in zone R. The purified fume discharged through line 9 comprises part of the solvent. The method allows to extract the solvent contained in the purified fume. The purified fume is contacted in zone ZA with a non-aqueous ionic liquid of general formula Q+ A−; Q+ designates an ammonium, phosphonium and / or sulfonium cation, and A− an anion likely to form a liquid salt. The solvent-depleted purified fume is discharged through line 17. The solvent-laden ionic liquid is regenerated by heating in evaporation device DE. The solvent separated from the ionic liquid in device DE is recycled.

Owner:INST FR DU PETROLE

Method and device for separating sulphur dioxide from a gas

A device (1) for separating sulphur dioxide from a gas (4) by means of an absorption liquid has an inlet (2) for gas (4) containing sulphur dioxide, an outlet (18) for gas (16), from which sulphur dioxide has been separated, and as essentially horizontal apertured plate (8), which is arranged to allow passage from below of sulphur dioxide containing gas (4) and to carry, on its upper side (12), a flowing layer (14) of the absorption liquid. An outlet box (20) beside the apertured plate (8) is arranged to be passed by liquid, which is distributed in the gas (4) coming from the inlet (2). A first pumping means is arranged to feed a coolant flow to the outlet box (20) and a second pumping means is arranged to feed an absorption liquid flow, which is essentially independent of the coolant flow, to the apertured plate (8) to form the flowing layer (14). In a method of separating sulphur dioxide, the above-described device (1) can be used.

Owner:GENERAL ELECTRIC TECH GMBH

Method and device for removing mercury

Owner:MITSUBISHI POWER LTD

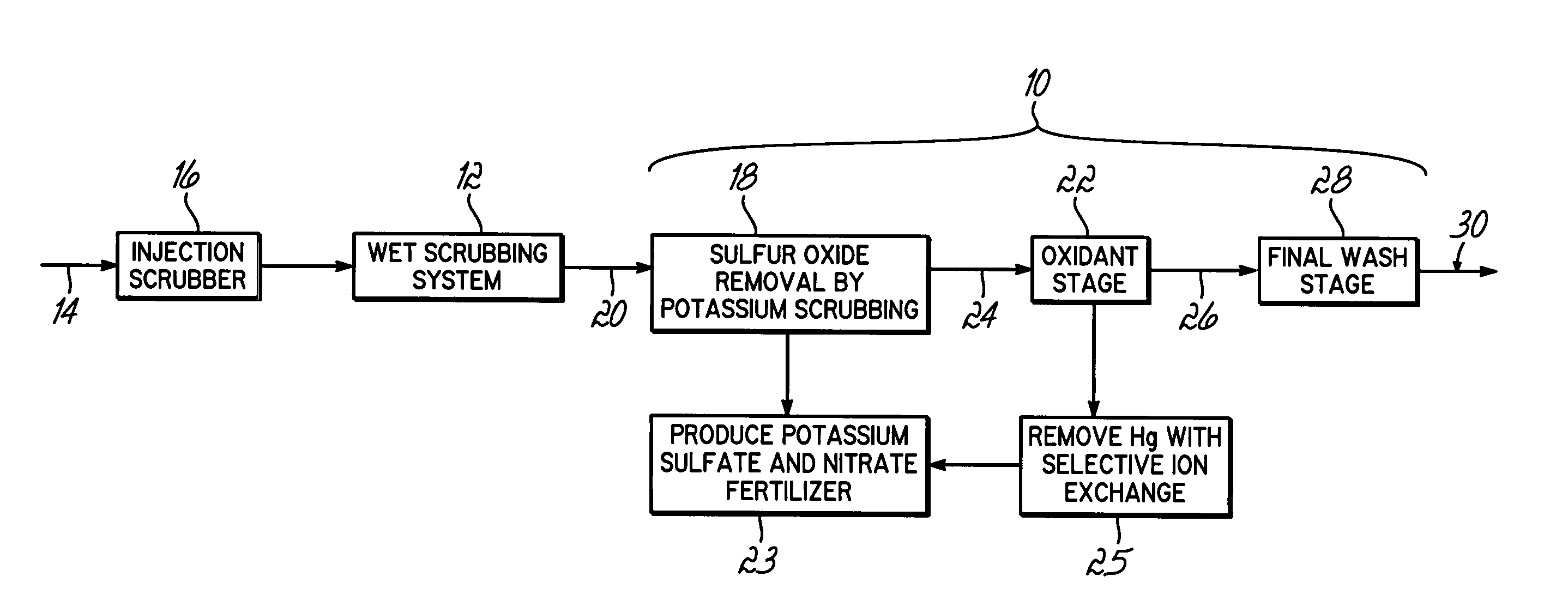

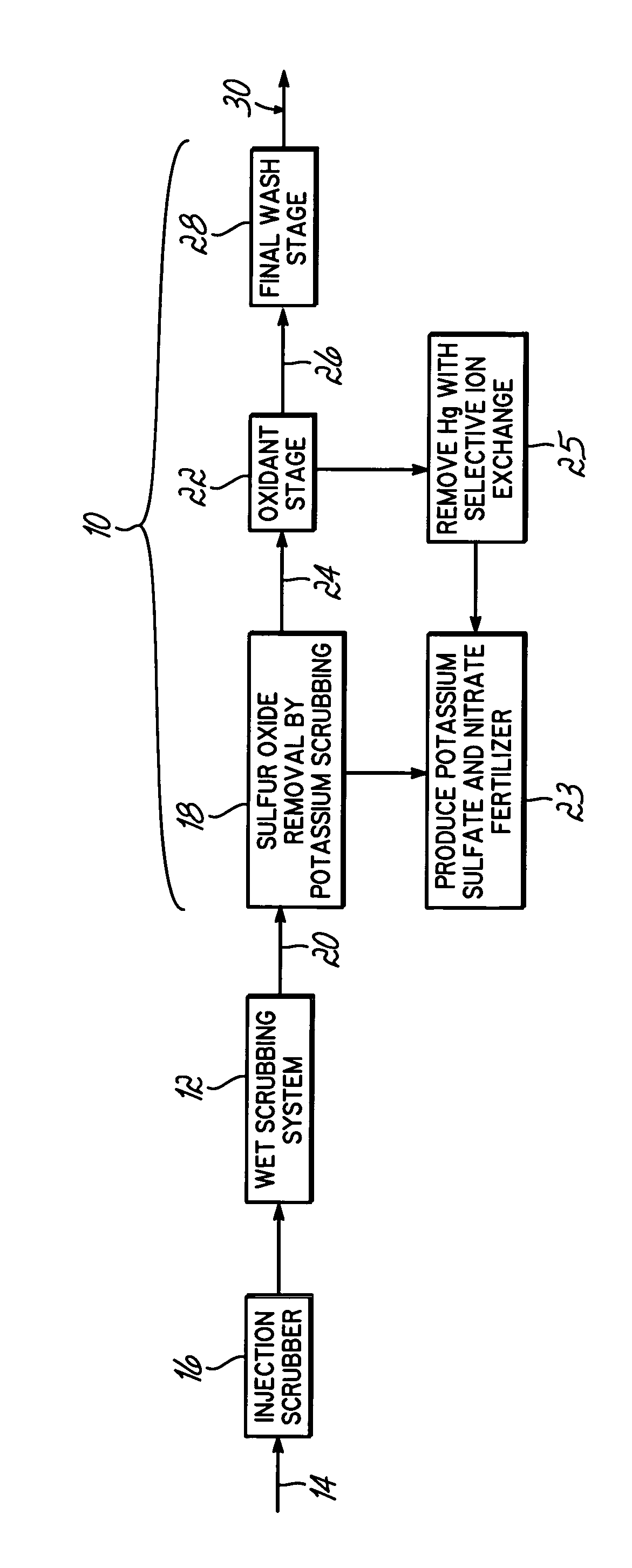

Method for removing sulfur dioxide, mercury, and nitrogen oxides from a gas stream

InactiveUS7514053B2Improve performanceAvoid pollutionAmmonium nitratesNitrogen compoundsNitrogen oxidesSorbent

Methods for scrubbing gas streams to remove acid gases including sulfur dioxide, mercury-containing substances, and / or nitrogen oxides from the gas stream. The gas stream is contacted with a potassium-based sorbent effective for removing at least a portion of the acid gases. The partially cleaned gas stream is then contacted with an oxidant effective to remove at least a portion of the nitrogen oxides and / or mercury-containing substances after partially removing the acid gas substance.

Owner:ENVIROSOLV ENERGY

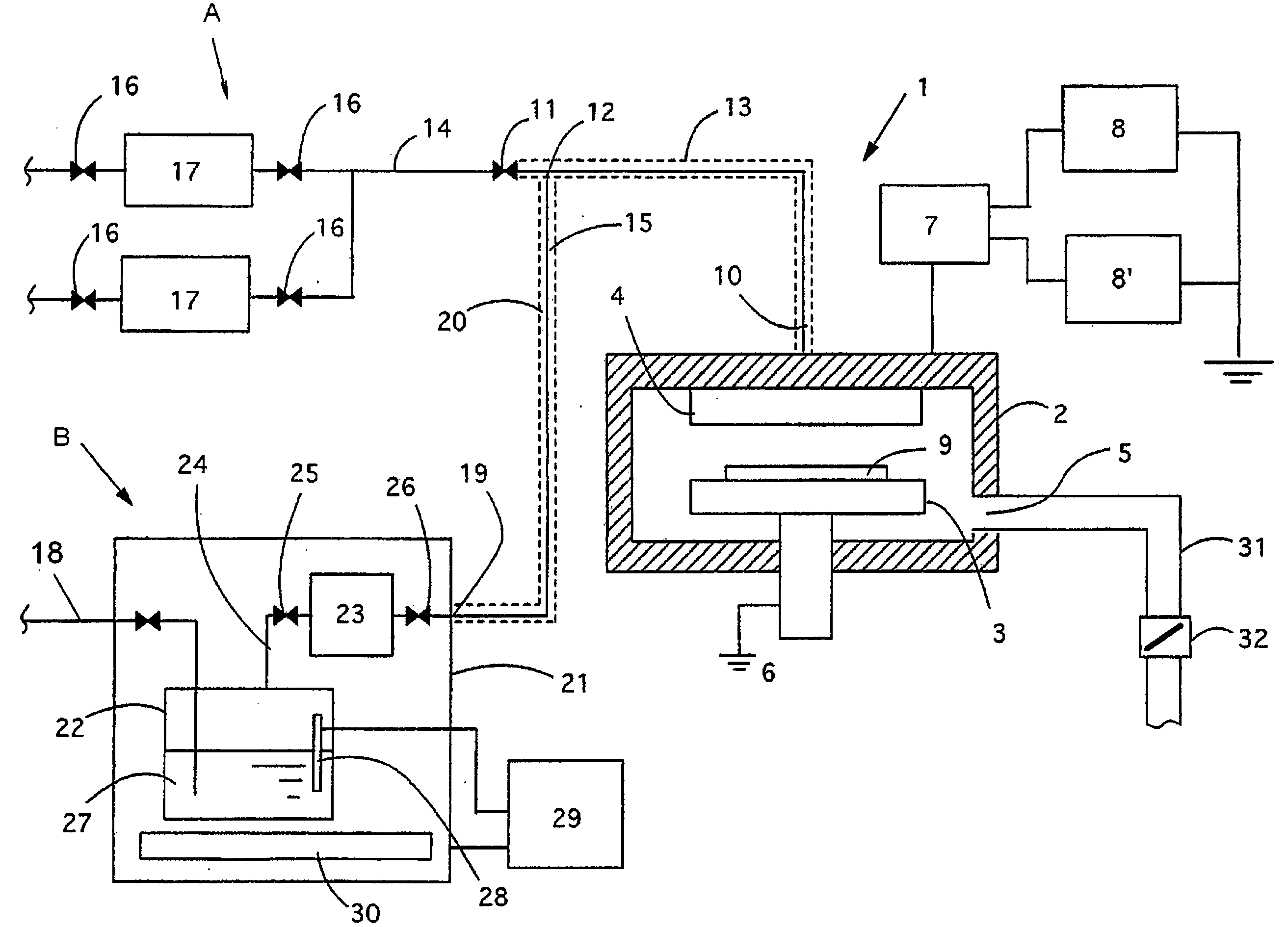

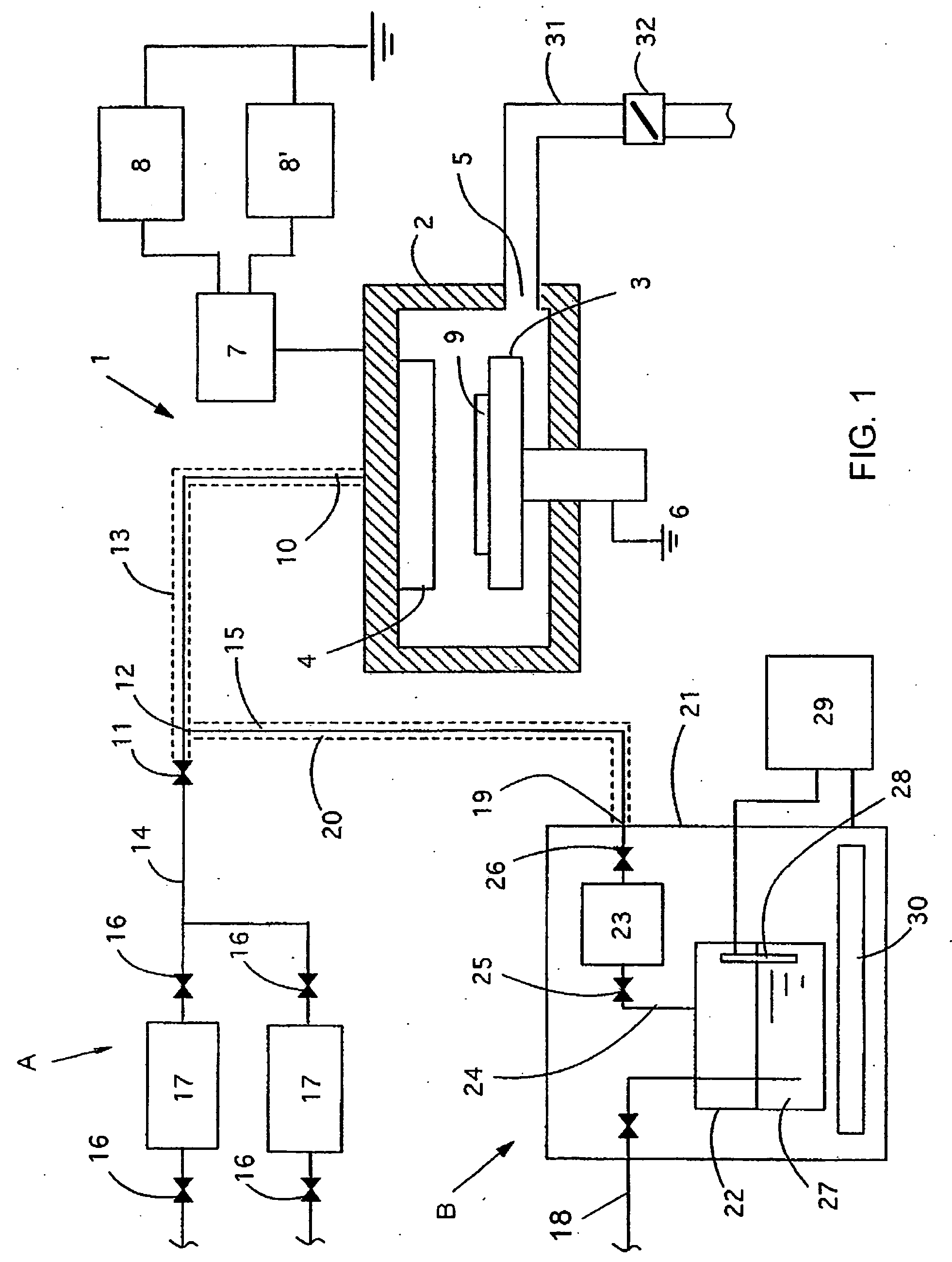

Source gas flow control and CVD using same

InactiveUS20050098906A1Good reproducibilityEnsure efficient flowSemiconductor/solid-state device testing/measurementLighting and heating apparatusSonic nozzleAcoustic wave

A source-gas supply apparatus for supplying a source gas into a CVD reactor includes: a reservoir for storing a liquid material; a gas flow path connected the reservoir and the CVD reactor; a sonic nozzle disposed in the gas flow path, through which the source gas is introduced into the CVD reactor; a pressure sensor disposed in the gas flow path upstream of the sonic nozzle; a flow control valve disposed in the gas flow path upstream of the pressure sensor; and a flow control circuit which receives a signal from the pressure sensor and outputs a signal to the flow control valve to adjust opening of the flow control valve as a function of the signal from the pressure sensor.

Owner:ADVANCED ENERGY JAPAN +1

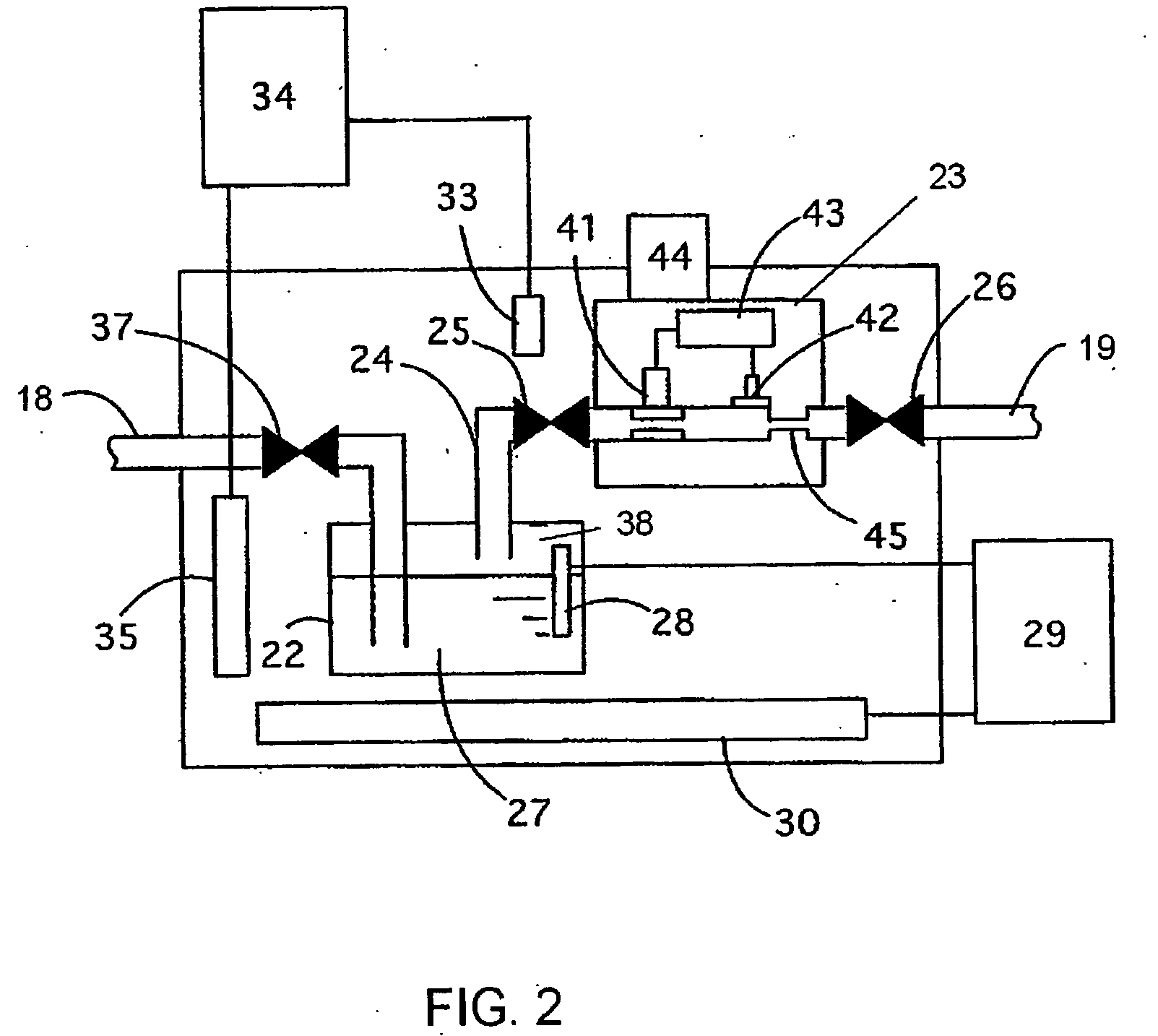

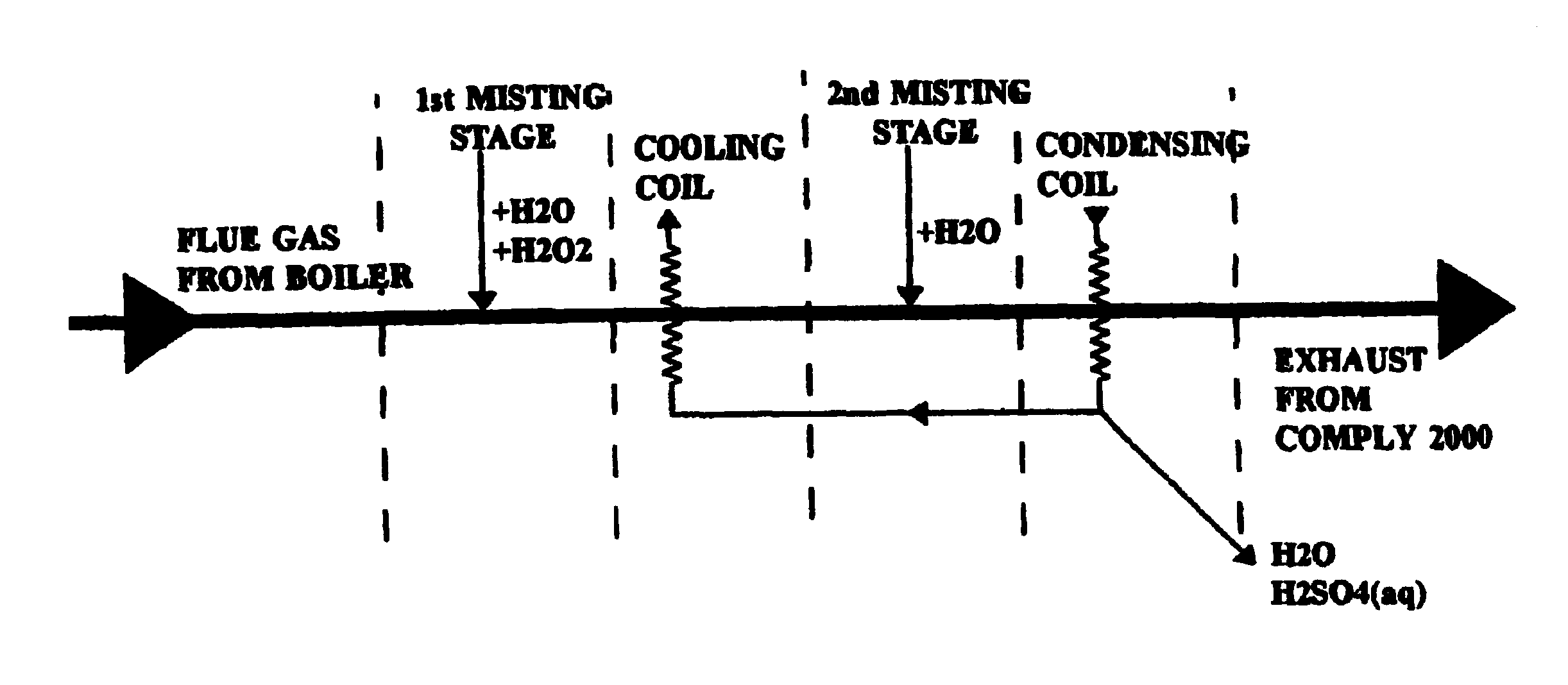

Heat recovery and pollution abatement device

A heat recovery and pollution abatement process with stackless operation for removing the products of combustion from hot boiler flue gas (45) comprising the steps of passing said hot boiler flue gas through a cloud of steam or mist (46), cooling the hot moist flue gas and recovering the heat therefrom (47), passing the partly cooled hot moist flue gas through a second cloud of mist comprised of cold water to total saturation (48), collecting the resulting stream of acid water, forcing the treated flue gas, mixing the treated flue gas with outside air, directing the forced treated air to atmosphere, shutting off the process in the absence of boiler flue gas.

Owner:ALTIRA TECH FUND V

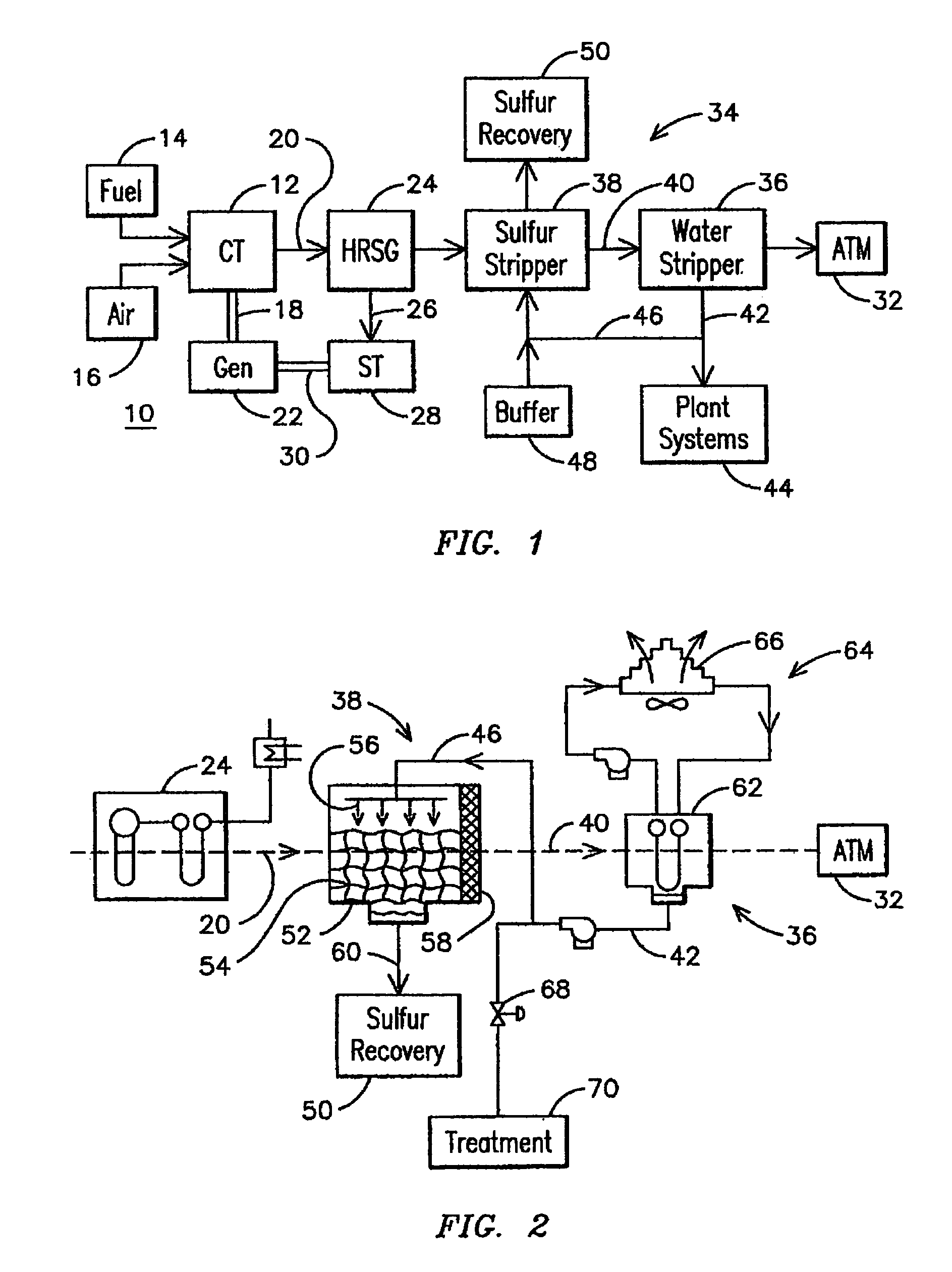

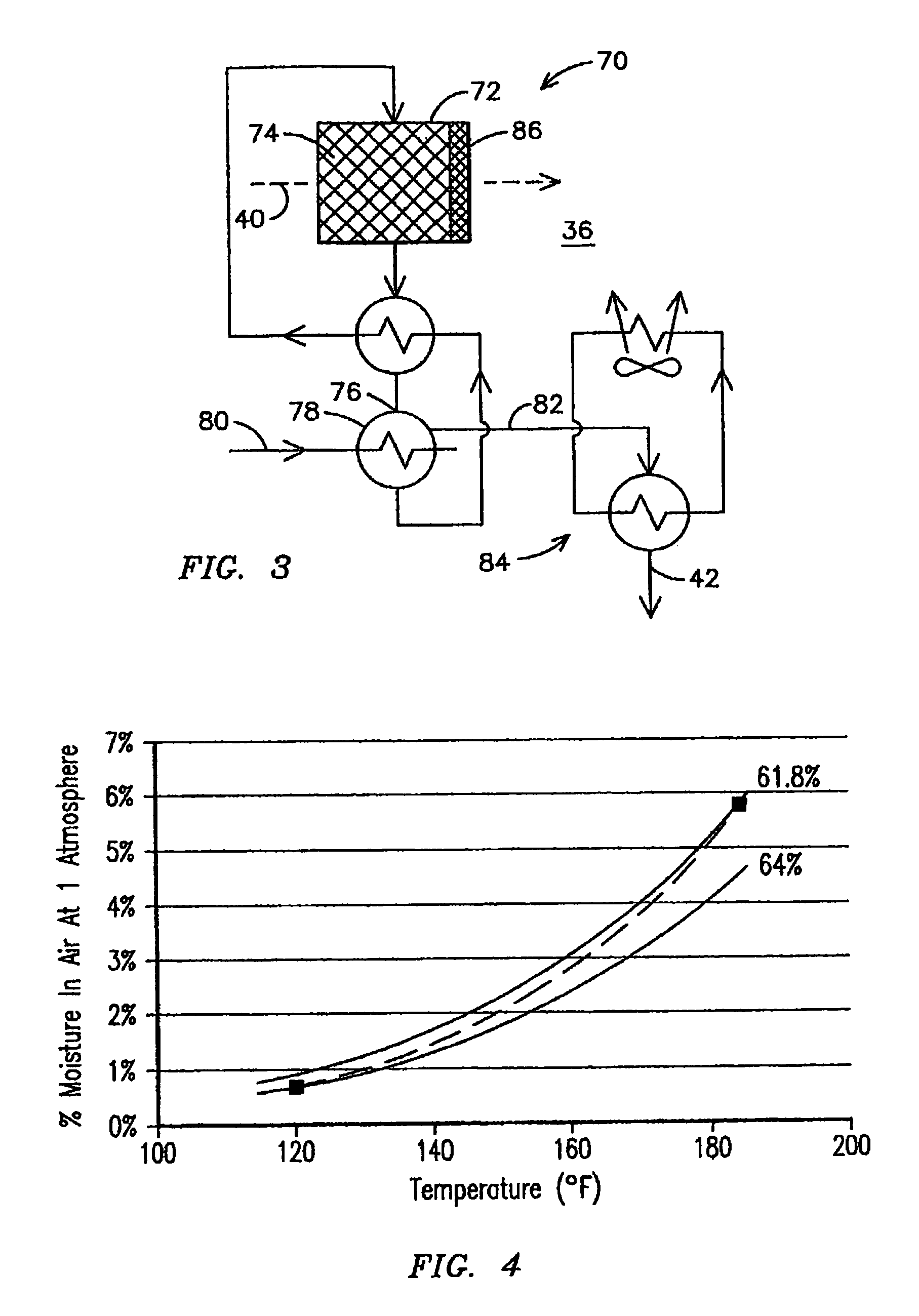

Water and sulfur removal from combustion turbine exhaust

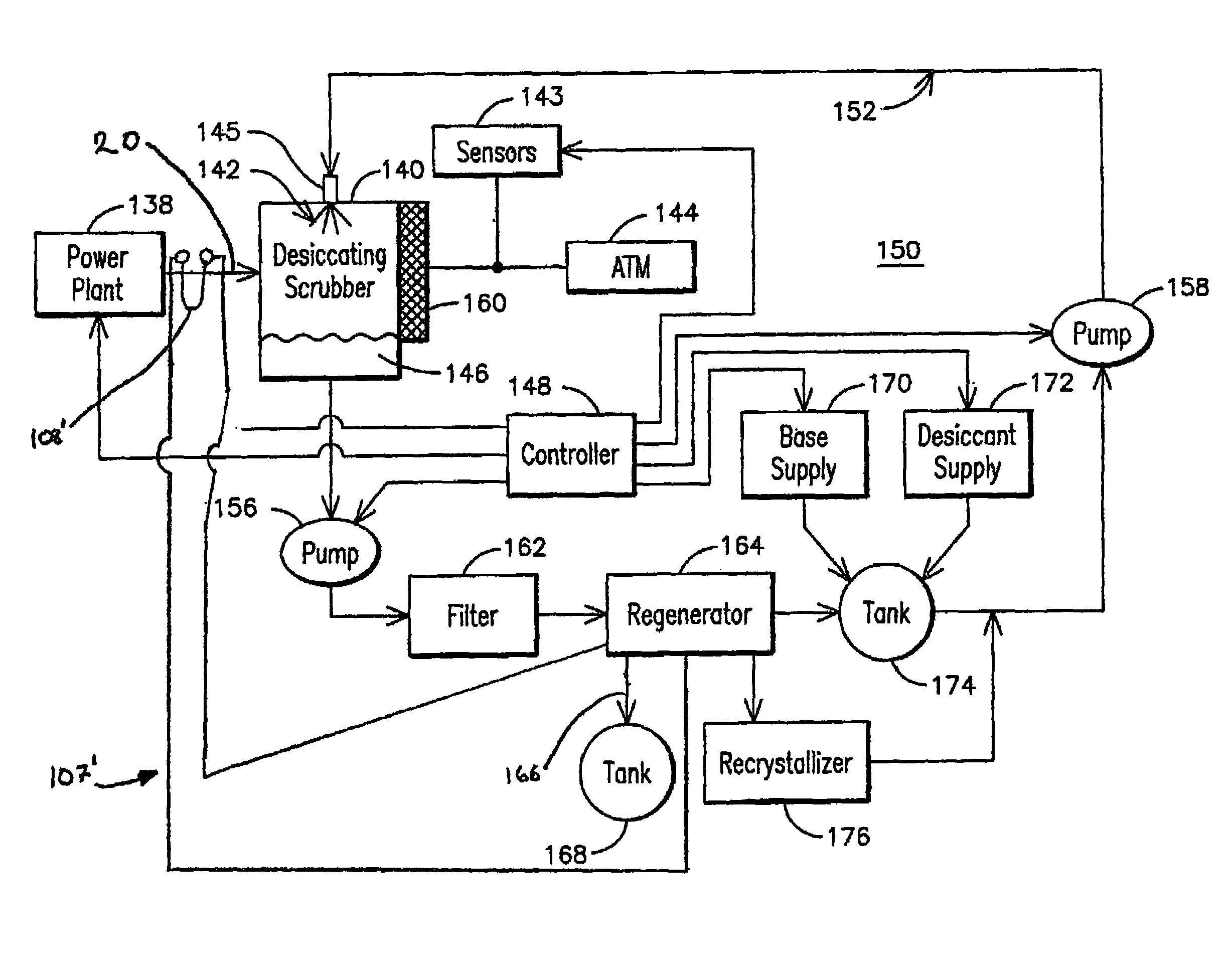

A combustion turbine power plant (10) incorporating a desiccating scrubber (140) for simultaneously removing water and sulfur from a flue gas (20) of the power plant (10). The desiccating scrubber (140) may include an inlet nozzle (145) for spraying an aqueous solution (142) containing a desiccant and a base into flue gas (20) so the aqueous solution (142) makes direct contact with flue gas (20). A filter (162) may be provided to collect sulfur compounds downstream of the desiccating scrubber (140) and a regenerator (164) may be provided for recovering water. A controller (148) may control a base supply (170) and a desiccant supply (172) to regulate the respective amounts of each introduced into the aqueous solution (142). Controller (148) may be responsive to sensors (142) measuring the water and sulfur content of flue gas (20) exhausted to atmosphere (144). The desiccating scrubber (140) may include a demister (160) to entrain carryover droplets from a sprayed aqueous solution (142).

Owner:SIEMENS ENERGY INC

Ship Flue Gas Scrubbing Equipment And Method

InactiveUS20100266472A1Promote resultsOvercomes shortcomingGas treatmentExhaust apparatusFlue gasExhaust fumes

This invention involves a marine ship flue gas scrubbing equipment and scrubbing method. The equipment includes a shell with an upper scrubbing section and a water tank in the lower section. A smoke pipe leads in exhaust gas to an area between the scrubbing section and water tank. Scrubbing seawater is injected through an inlet above the scrubbing section, and a cooler is located along the pathway of the exhaust gas. The method of scrubbing includes leading-in exhaust gas, cooling the exhaust gas, injecting scrubbing seawater, performing scrubbing operation, and discharging clean gas. Embodiments of the invention provide a highly efficient scrubbing equipment and method suitable for high-temperature exhaust gas within a limited usable space. The methods and equipment are highly effective for emission reduction, has low energy consumption, small size, and long life performance.

Owner:PENG SIGAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com