Patents

Literature

88 results about "Gaseous mercury" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gaseous mercury is also found in some electron tubes, including ignitrons, thyratrons, and mercury arc rectifiers. It is also used in specialist medical care lamps for skin tanning and disinfection. Gaseous mercury is added to cold cathode argon-filled lamps to increase the ionization and electrical conductivity.

High capacity materials for capture of metal vapors from gas streams

Metal ions are adsorbed or absorbed by a combination of a binding ligand and an ionic liquid effective to dissolve the metal complex. The ligand is preferably bound to a solid surface which is coated with the ionic liquid. This method is particularly suitable for adsorbing gaseous mercury, lead, zinc and cadmium.

Owner:UNIVERSITY OF CINCINNATI

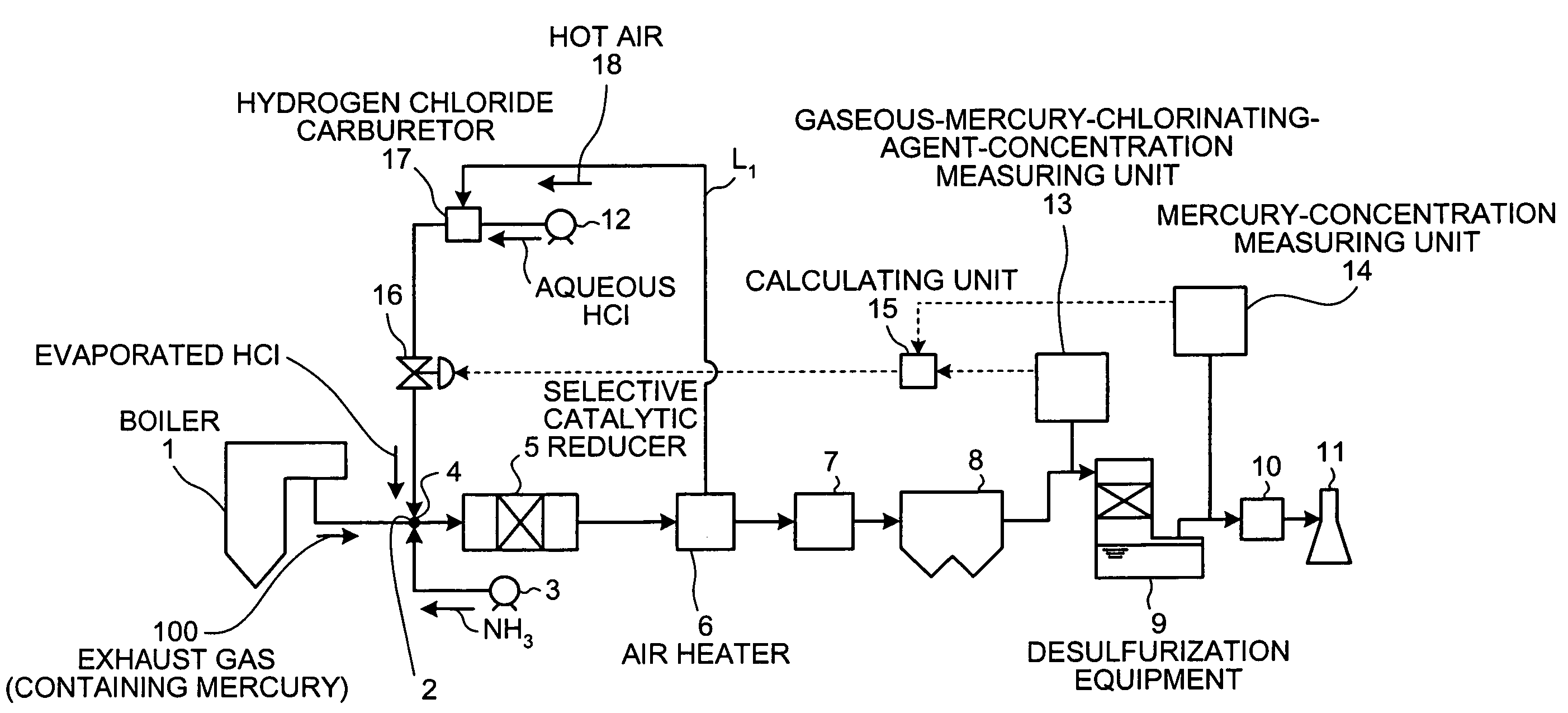

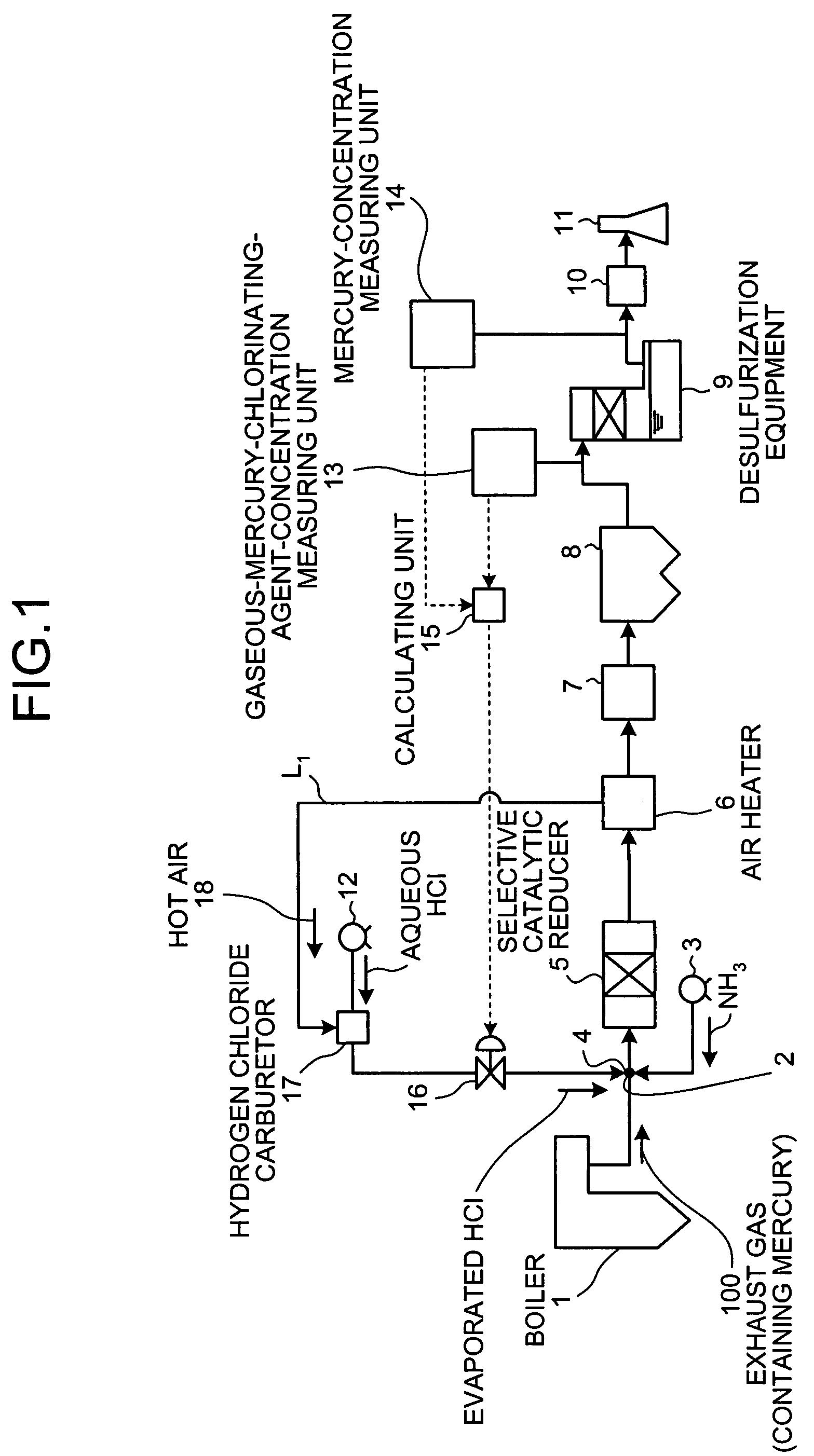

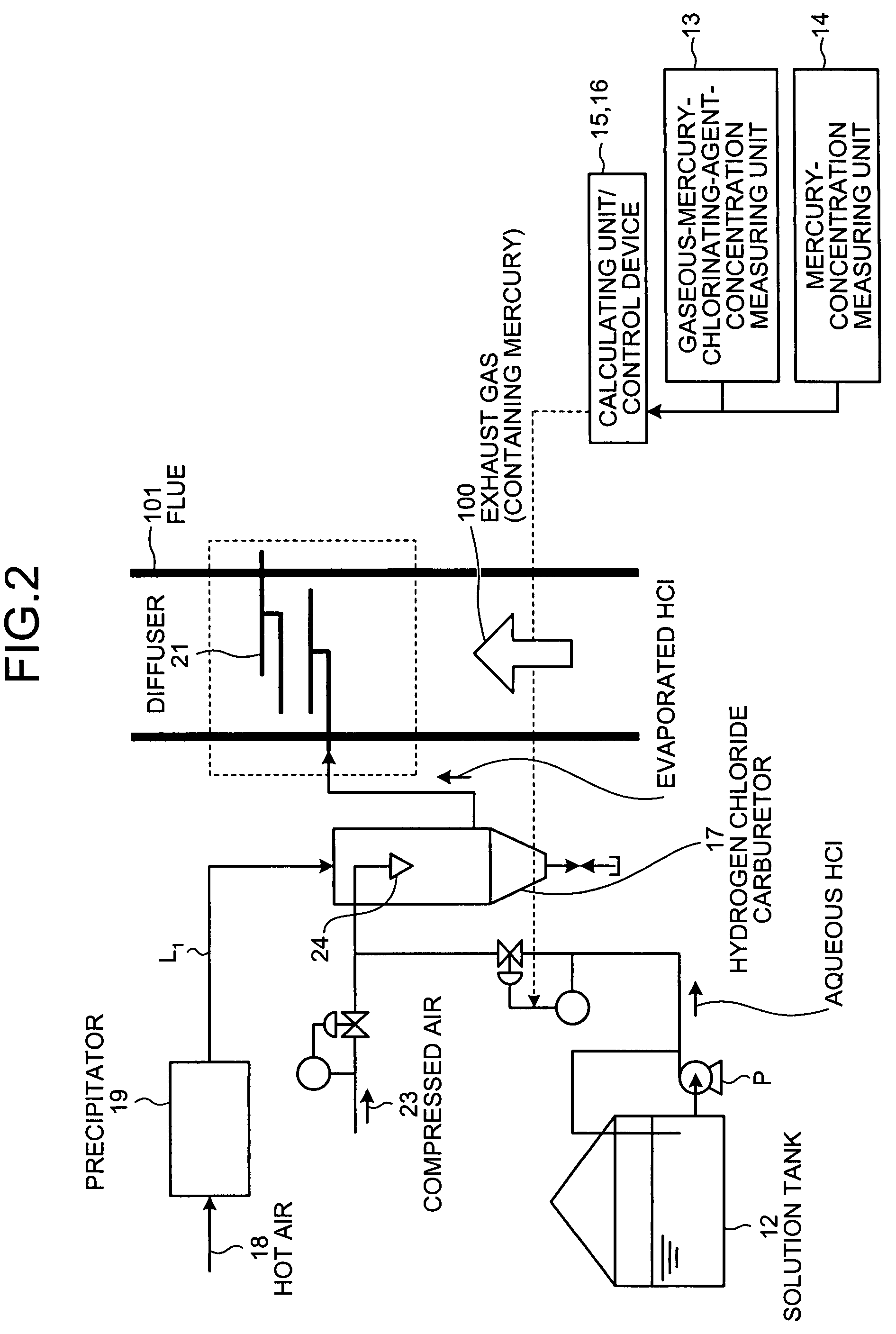

Method and device for removing mercury

Owner:MITSUBISHI POWER LTD

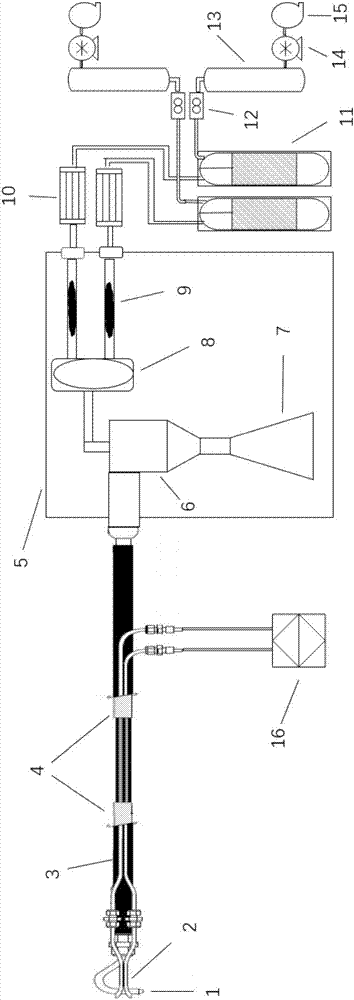

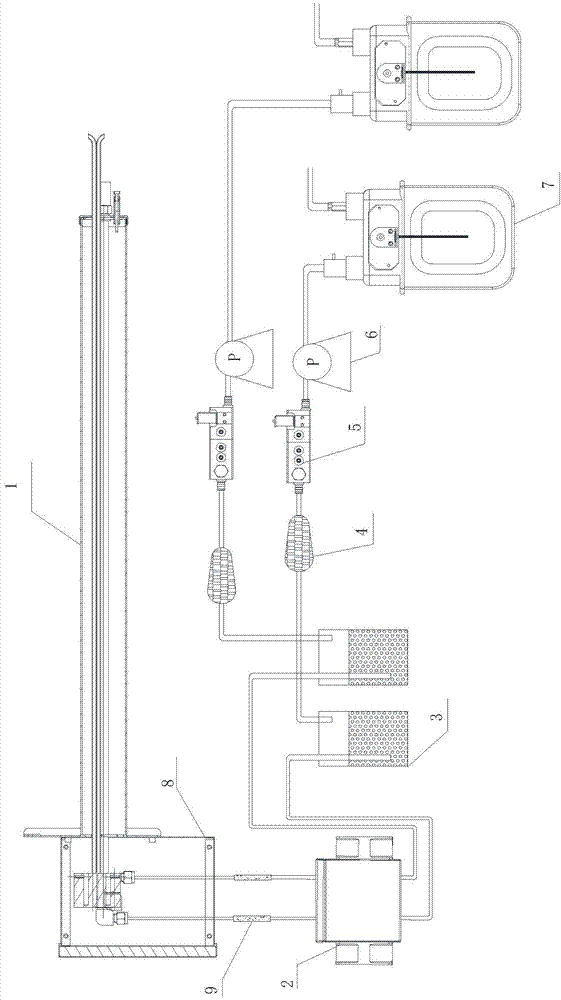

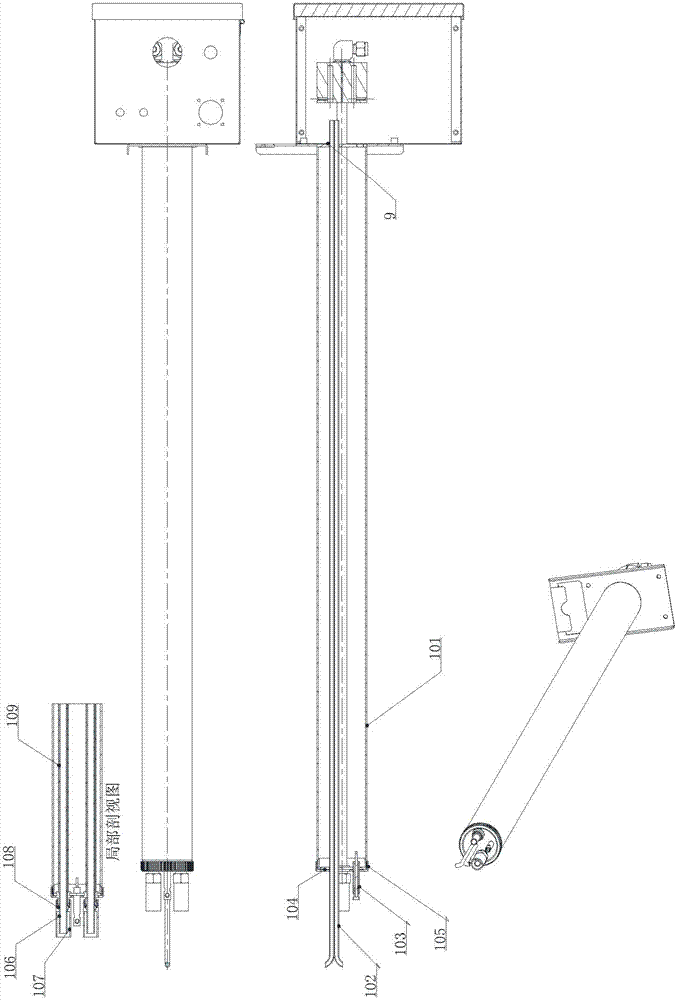

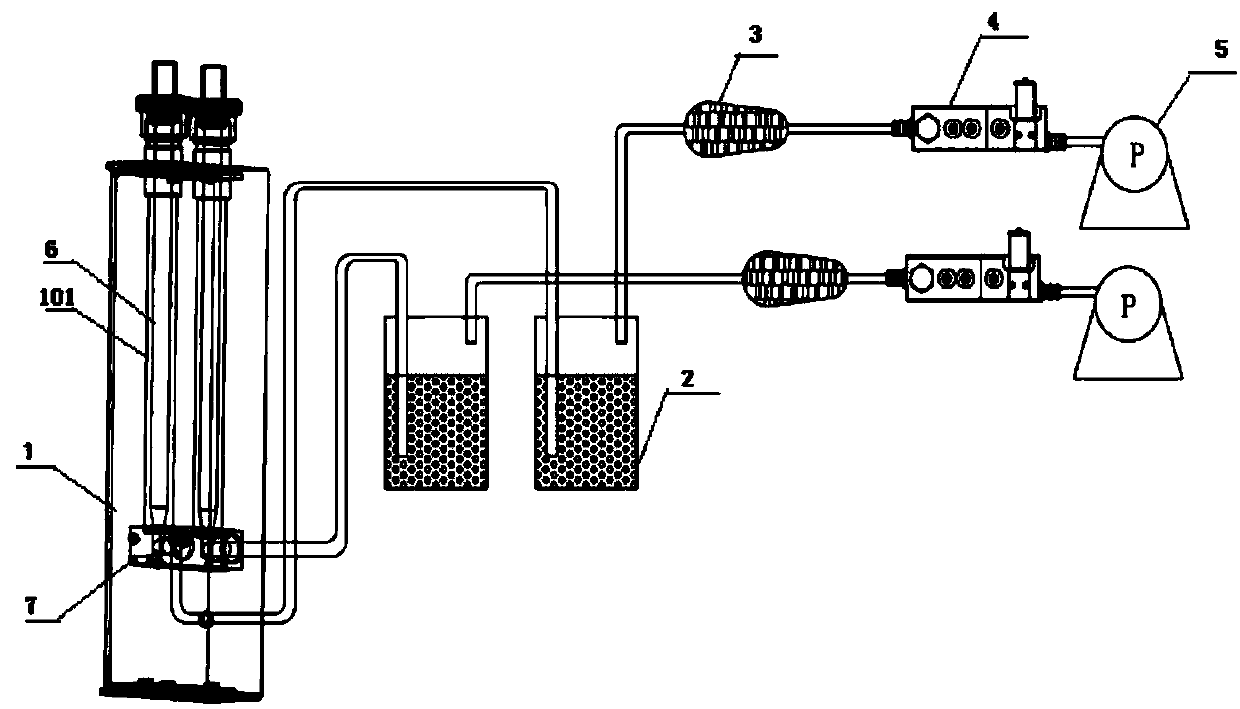

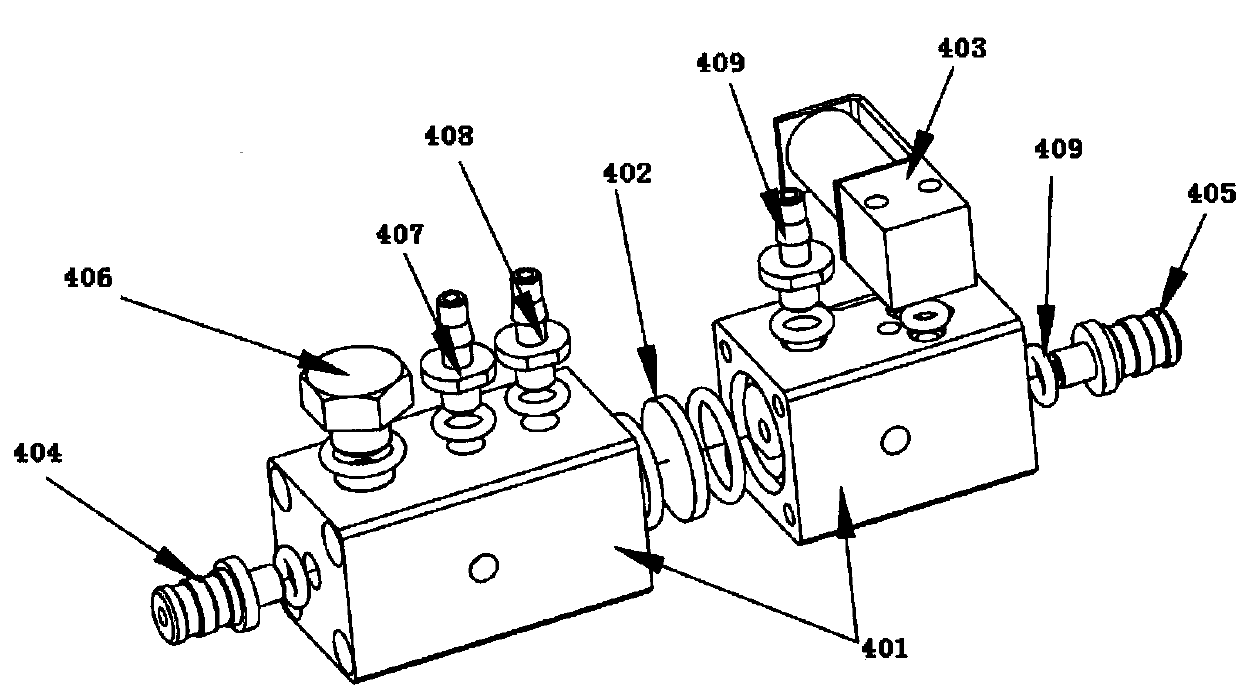

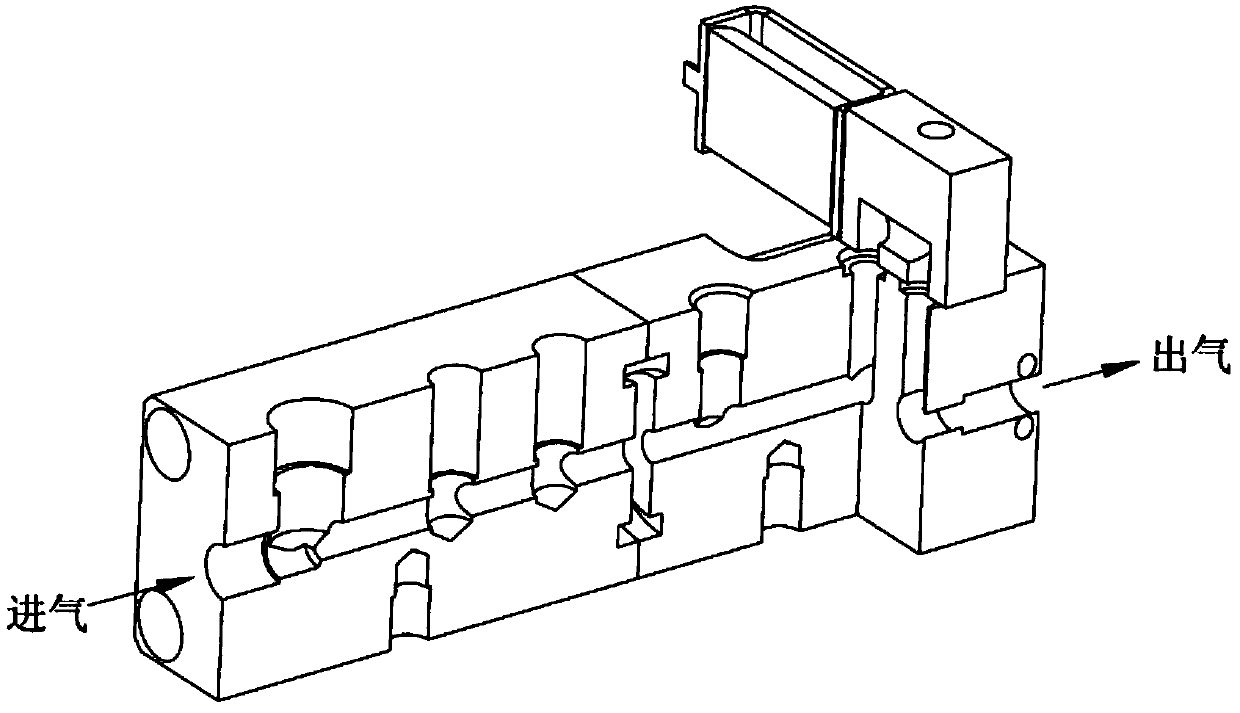

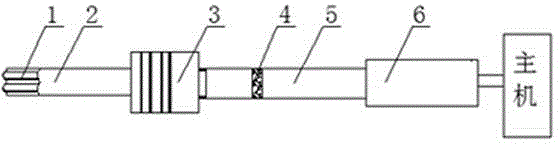

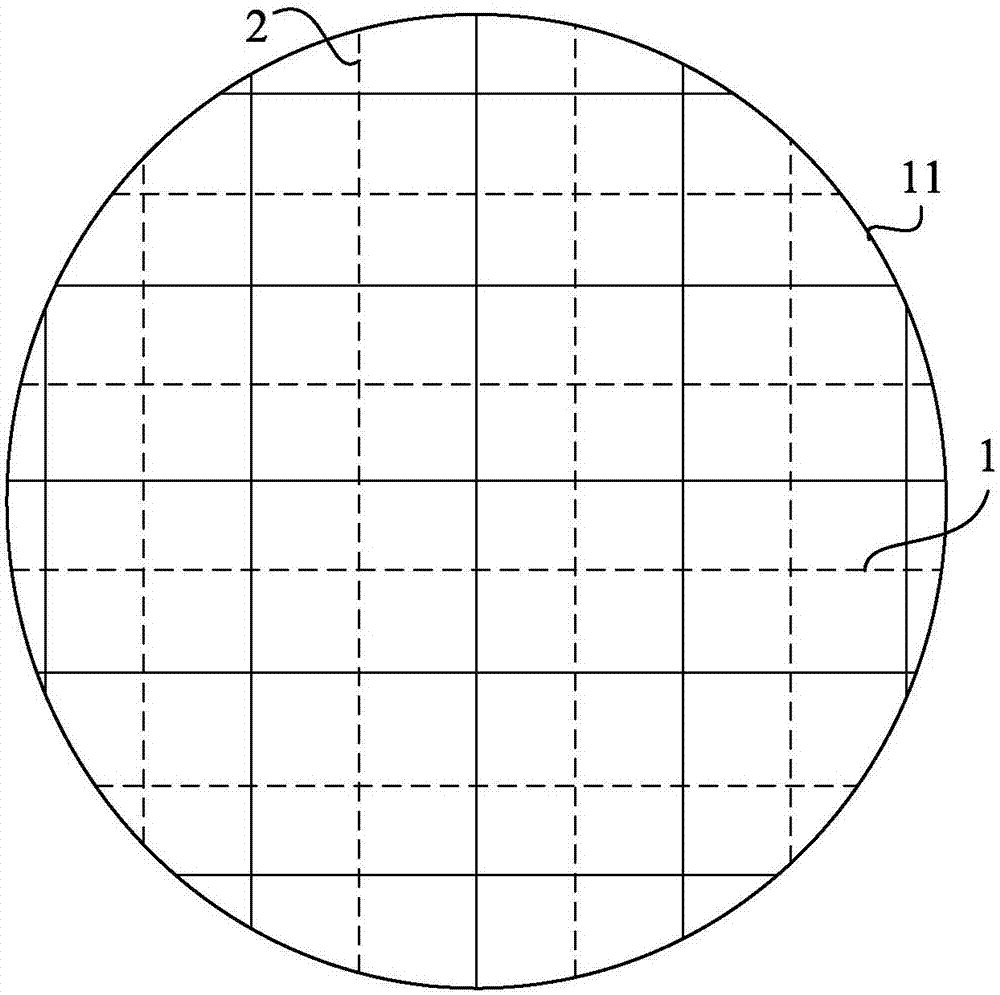

Isokinetic sampling device for particle mercury and gaseous mercury from stationary pollution source and isokinetic sampling method

PendingCN106855472AAvoid Adsorption LossImprove sampling efficiencyCombination devicesGas treatmentCycloneActivated carbon

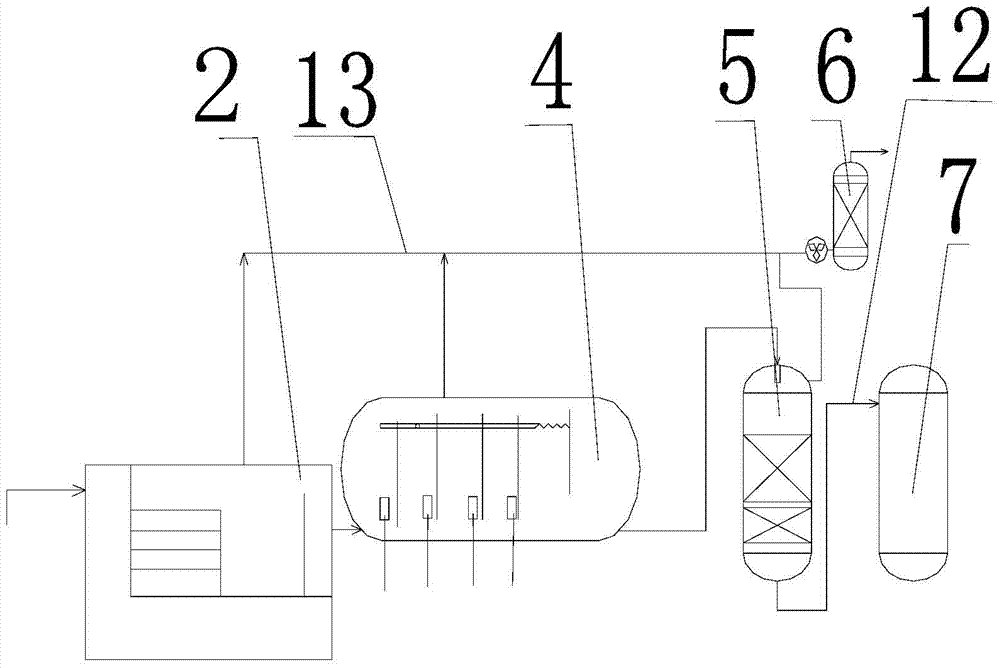

The invention discloses a sampling device for particle mercury and gaseous mercury from a stationary pollution source and a sampling method. The device comprises a sampling nozzle, a sampling gun, a cyclone separator, an ash hopper, a fine particle filter, a gaseous mercury sampling pipe, refrigerators, dryers, flow controllers, activated carbon mercury removers, vacuum pumps and cumulative volume meters, which are connected in sequence, wherein the sampling gun is arranged in a heating sleeve; the cyclone separator, the fine particle filter and an activated carbon adsorption pipe are arranged in an incubator. The invention also discloses the sampling method of the device. The sampling device and the sampling method, disclosed by the invention, have the following advantages: firstly, a particle mercury sample and a gaseous mercury sample are simultaneously collected; secondly, a sampling process is insulated, so that mercury loss and mercury speciation transformation are prevented, and further sampling representativeness is improved; thirdly, by two-stage dust removal of the cyclone separator and the fine particle filter, the sampling representativeness in a high dust-containing environment is guaranteed; fourthly, isokinetic sampling is guaranteed by the volume flow controllers; fifthly, by the postposed activated carbon mercury removers, residual mercury is prevented from being exhausted into atmosphere.

Owner:HUANENG CLEAN ENERGY RES INST

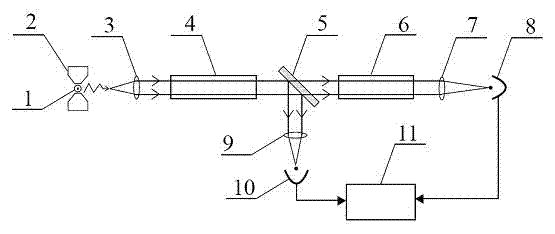

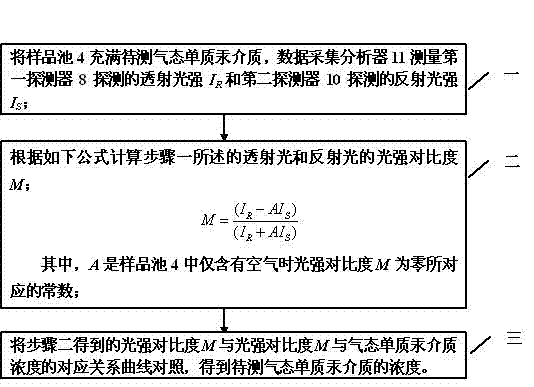

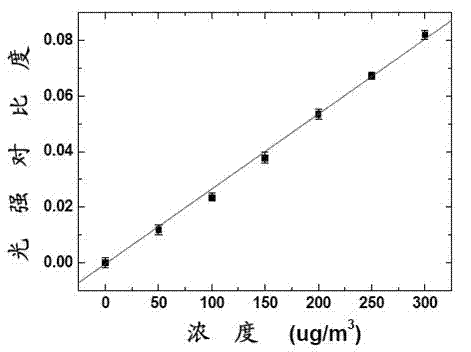

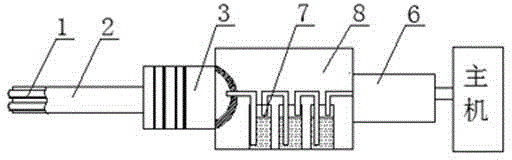

Continuous monitoring device and method of gaseous elemental mercury concentration

InactiveCN101819140AEliminate distractionsImplement selective probingColor/spectral properties measurementsBeam splitterGaseous mercury

The invention provides a continuous monitoring device and a method of gaseous elemental mercury concentration, relating to the gas concentration measurement field and solving the problems of low sensitivity, complex system and overhigh cost of the existing gaseous elemental mercury monitoring technology. To the monitoring device in the invention, a mercury element lamp is arranged in a magnetic field of a magnet, the output light is subjected to transmission to obtain parallel light via a collimation lens, the parallel light enters into a spectroscope via a sample pool, the transmission light enters into a first convex lens via a reference pool and is focused on a first detector, the reflecting light enters into a second convex lens and is focused on a second detector, and the first detector and the second detector are connected with a data collection analyzer. The method is implemented as follows: 1) determining a constant A corresponding to the light intensity contrast ratio M when being zero; 2) drawing a correspondence curve of the light intensity contrast ratio M and gaseous elemental mercury medium concentration; and 3) measuring the light intensity contrast ratio M of the gaseous elemental mercury medium to be measured, and comparing with the correspondence curve to obtain the concentration of the gaseous elemental mercury medium. The invention is used for monitoring the gaseous mercury concentration.

Owner:HARBIN INST OF TECH

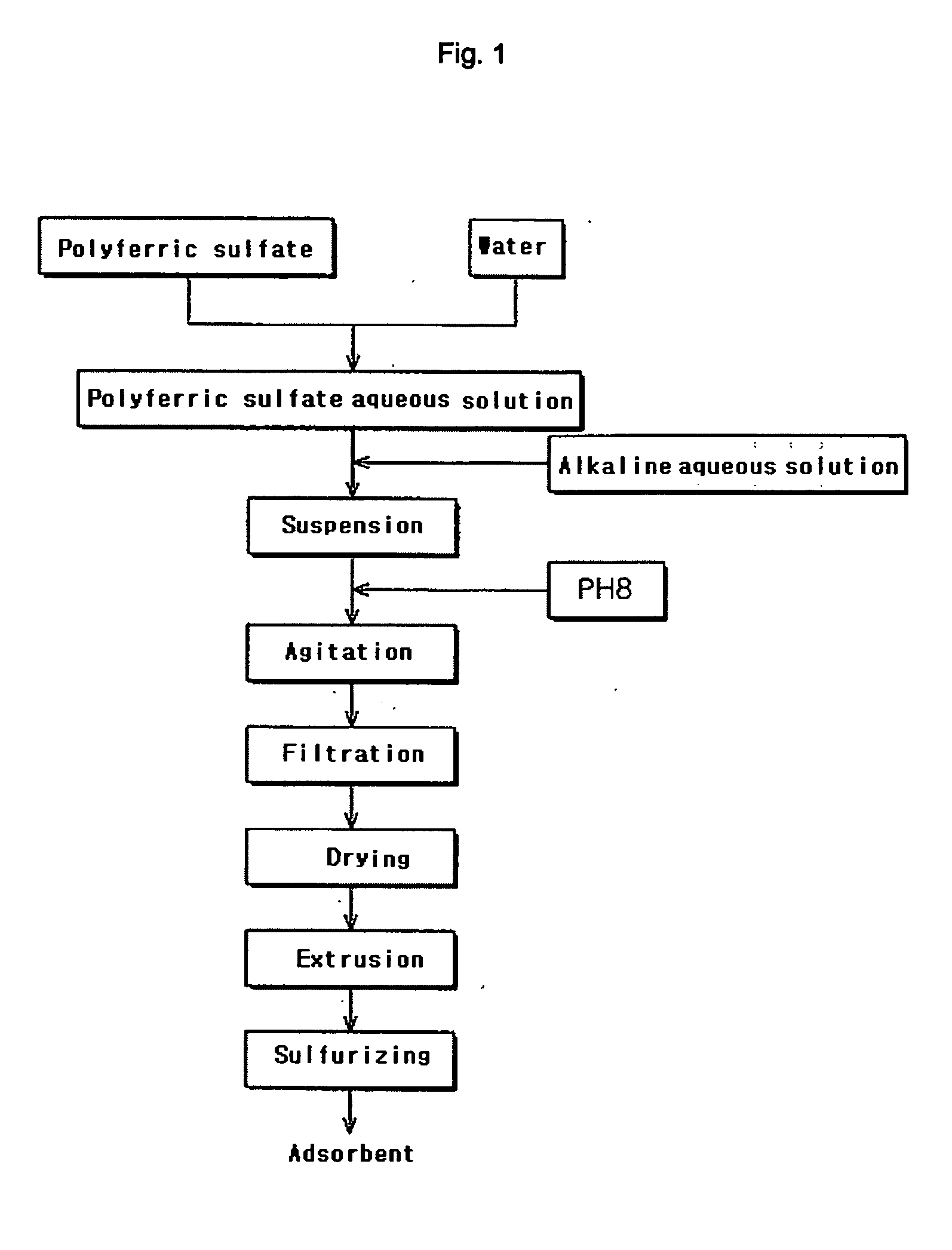

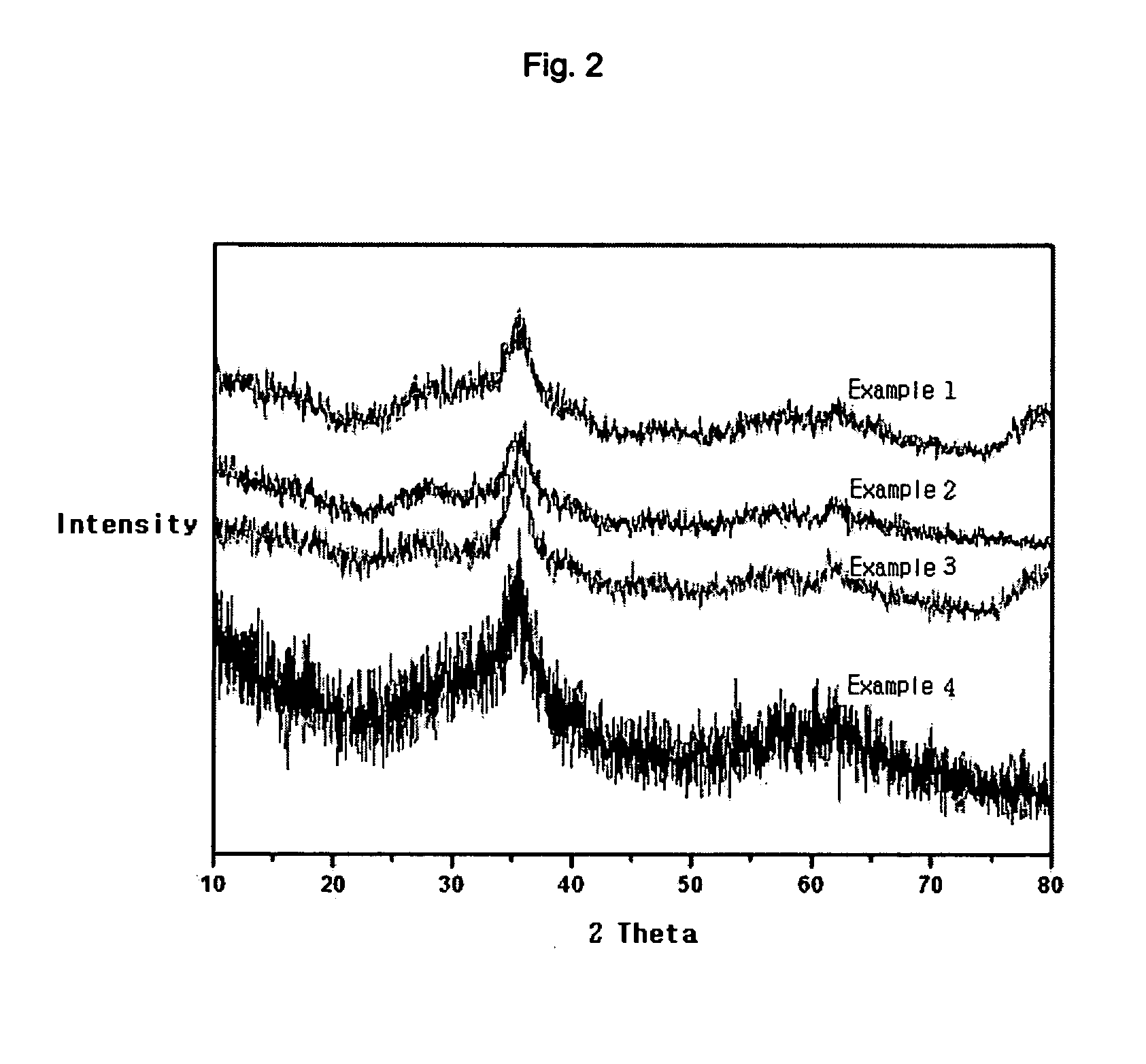

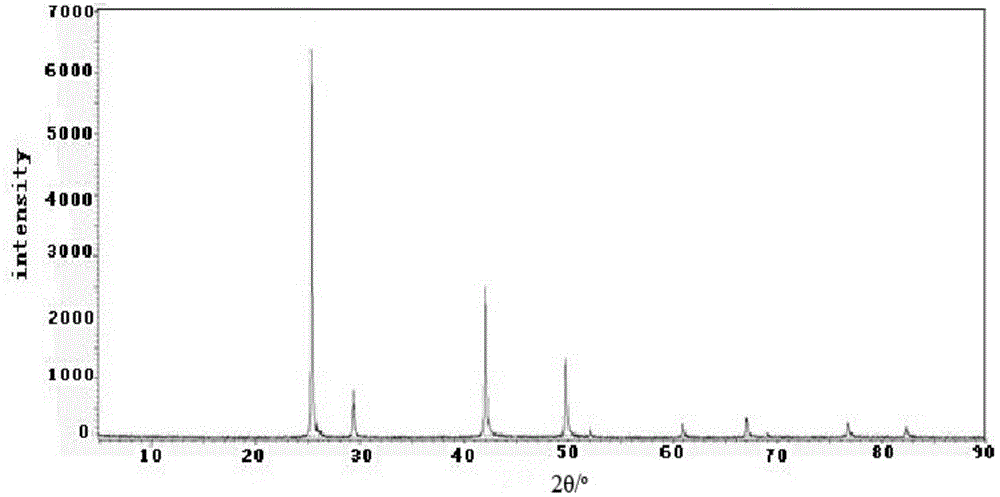

Adsorbent for removing mercury using sulfided iron compounds containing oxygen and method of producing same

Disclosed herein is an adsorbent for removing mercury, which comprises sulfided iron compounds containing oxygen. In the adsorbent, iron compounds containing oxygen are sulfided to accumulate sulfur therein, thereby removing gaseous mercury.

Owner:KOCAT +1

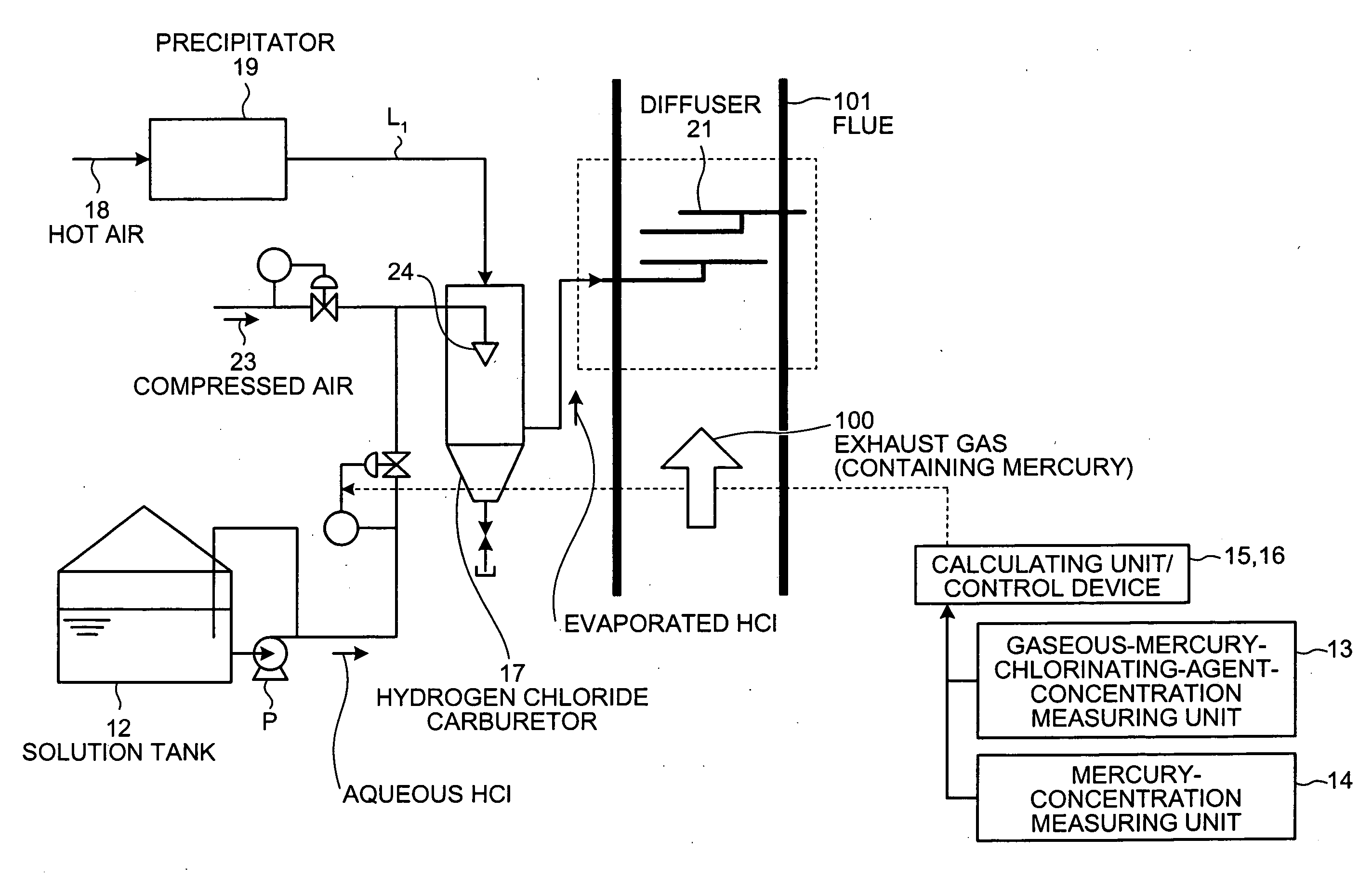

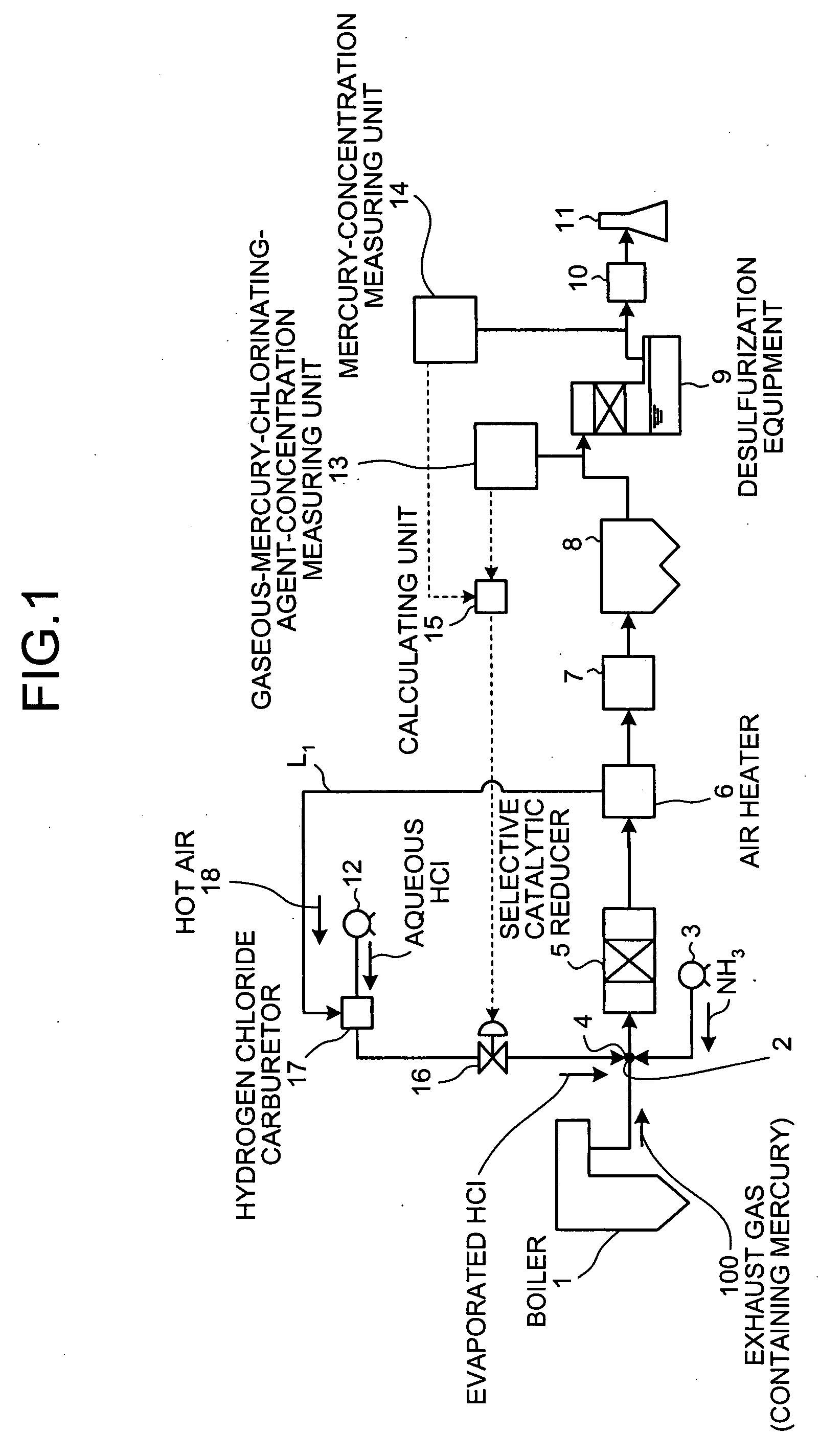

Method and device for removing mercury

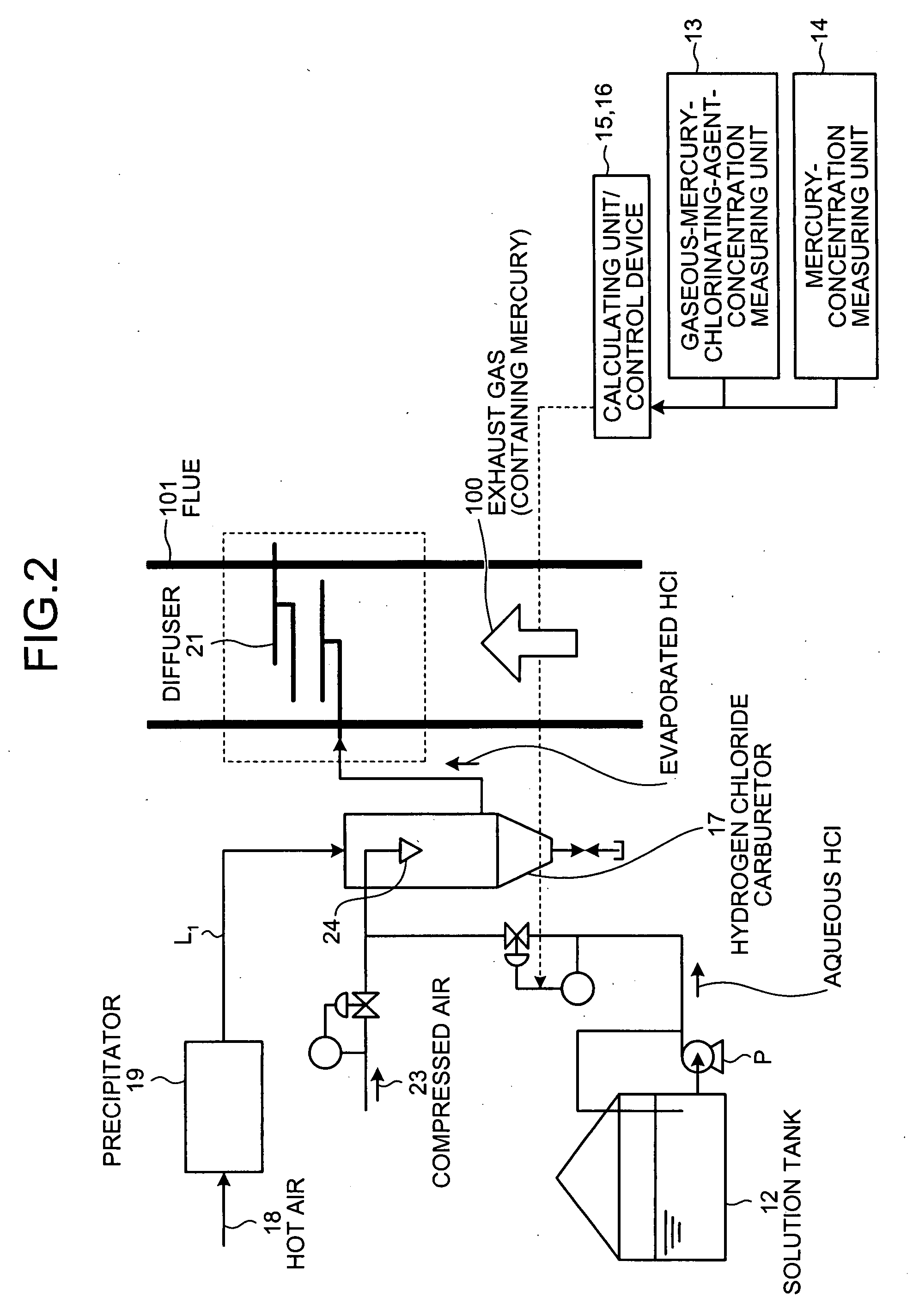

ActiveUS20080138264A1Solve problemsCombination devicesNitrogen compoundsRoom temperatureGaseous mercury

A mercury removing device includes a gasification unit that converts a non-gaseous-mercury-chlorinating agent, which is non-gaseous at room temperature and normal pressure, into gaseous-mercury-chlorinating agent by heating the non-gaseous-mercury-chlorinating agent with heat of hot air generated by using the exhaust gas or hot air generated by using an air heater installed in a flue that conveys the exhaust gas. The gaseous-mercury-chlorinating agent produced in this manner is supplied to the exhaust gas in the flue.

Owner:MITSUBISHI POWER LTD

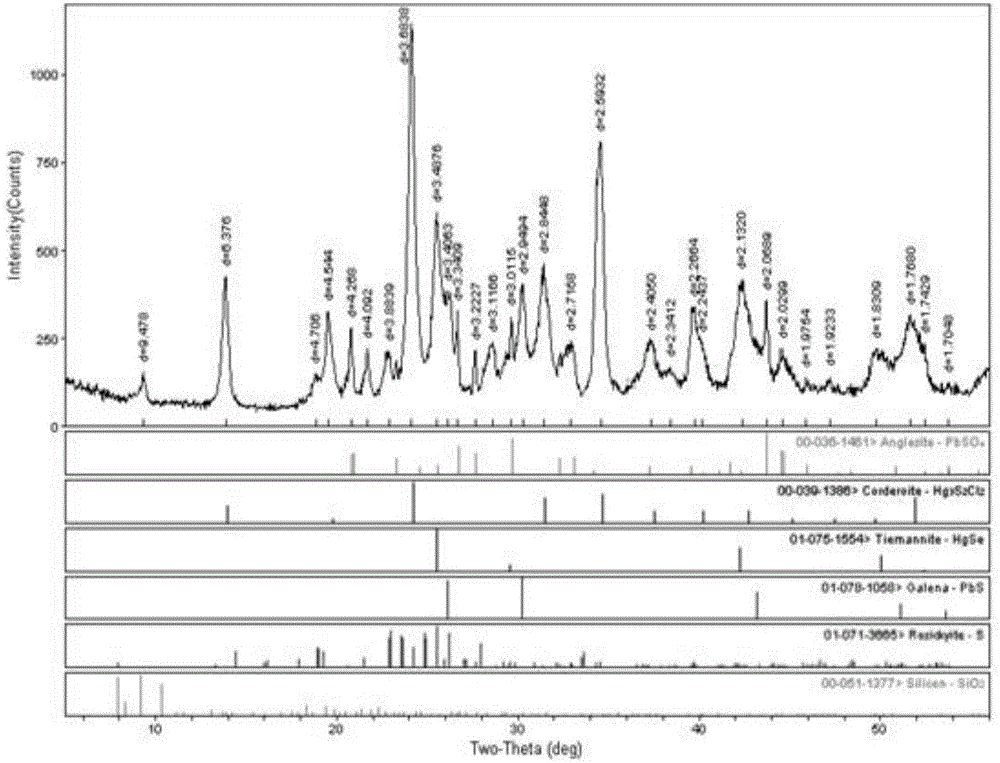

Method for recovering selenium, mercury, gold and silver from acid sludge

ActiveCN104805297AHigh recovery rateReduce pollutionProcess efficiency improvementBinary selenium/tellurium compoundsTube furnaceFlue gas

The invention discloses a method for recovering selenium, mercury, gold and silver from acid sludge. The method comprises the steps: (1) putting the acid sludge, generated from a sulfide ore roasting flue gas acid preparing process, into a tubular furnace, and carrying out roasting treatment under the condition of a protective atmosphere, so as to obtain roasting slag and flue gas containing gaseous mercury selenide; (2) cooling the flue gas, so as to cool the gaseous mercury selenide in the flue gas into solid-state mercury selenide and recover selenium and mercury from the acid sludge; (3) extracting gold and silver from the roasting slag obtained in the step (1) by adopting a cyanidation method, so as to recover gold and silver from the acid sludge. According to the method, the solid-state mercury selenide with high added value is obtained by adopting a protective atmosphere roasting process, and gold and silver are recovered by adopting the cyanidation method, so that the method has the advantages of brief flow, high product added value, high purity, high valuable element recovery ratio and little environmental pollution.

Owner:西安西北有色地质研究院有限公司

Gaseous mercury sampling device for stationary pollution source

ActiveCN104122123AEasy to removeAvoid cloggingVolume measurement apparatus/methodsWithdrawing sample devicesFlue gasGaseous mercury

The invention relates to a gas sampling device, belongs to the field of environmental monitoring, and particularly relates to a gaseous mercury sampling device for a stationary pollution source. The gaseous mercury sampling device for the stationary pollution source comprises a smoke pipe, a refrigerator, dryers, particulate matter filters, flow rate controllers, gas pumps and accumulative volume meters which are connected sequentially, wherein the tail part of the smoke pipe is provided with a temperature preservation box; a gas outlet of the refrigerator is connected with a gas discharge end of the smoke pipe by a heat tracing pipe. The gaseous mercury sampling device for the stationary pollution source has the following advantages: 1. the device is better in stability, heats up uniformly because of heat tracing of the smoke pipe in the whole process, and can prevent pipeline blocking; 2. the sampling quality is higher, a mode that a stainless steel coil pipe is cast by high-heat-capacity metal is adopted for the refrigerator, and moisture in flue gas can be removed well; 3. the sampling flow rate is more stable, and the special volume flow rate controllers can acquire wider sampling flow rate, so that air flow is more stable; 4. the sampling volume metering is more accurate, counting pulses are collected by a precise photoelectric encoder, and thus the metering precision of the sampling volume is improved substantially.

Owner:WUHAN TIANHONG INSTR

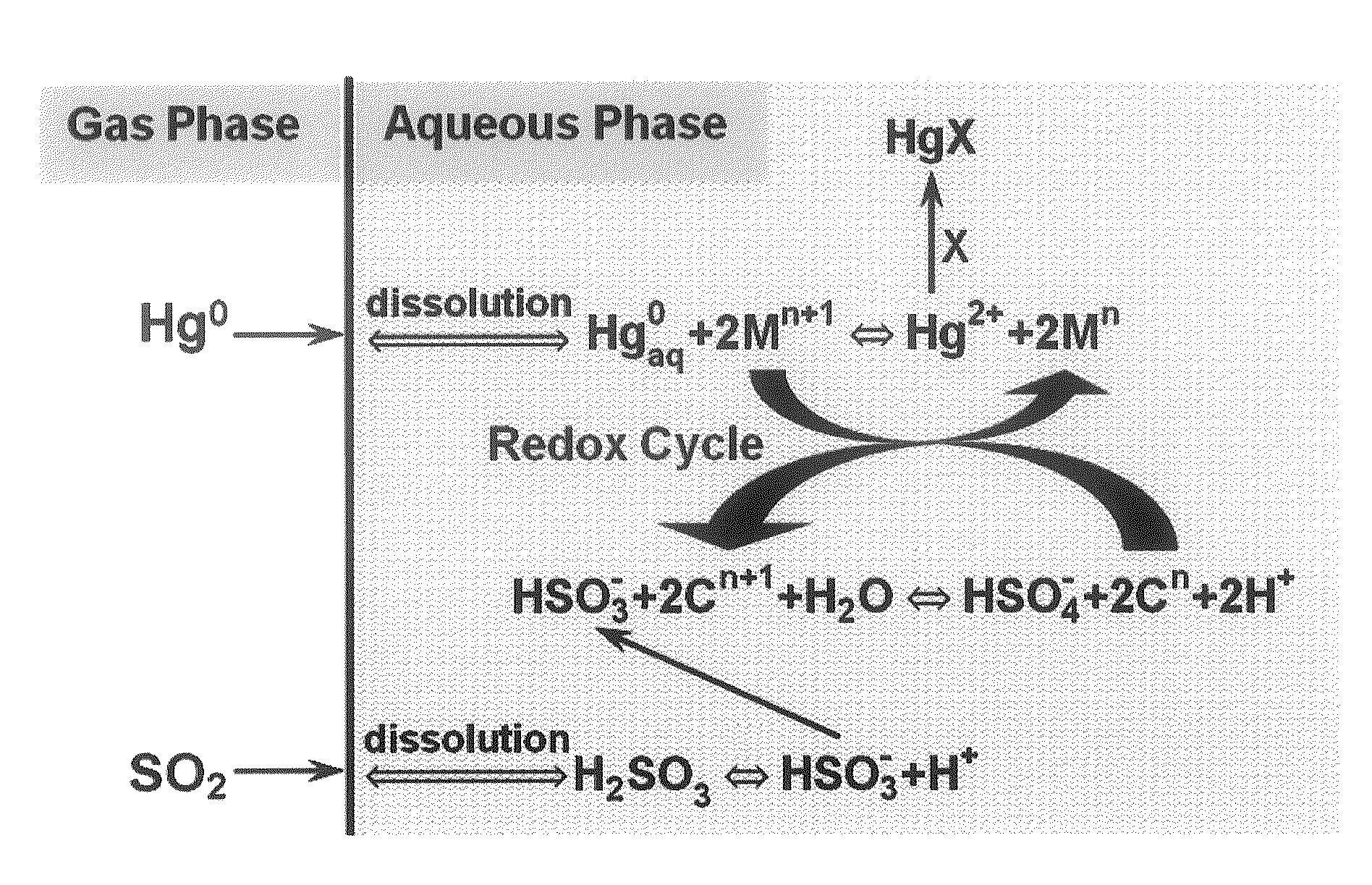

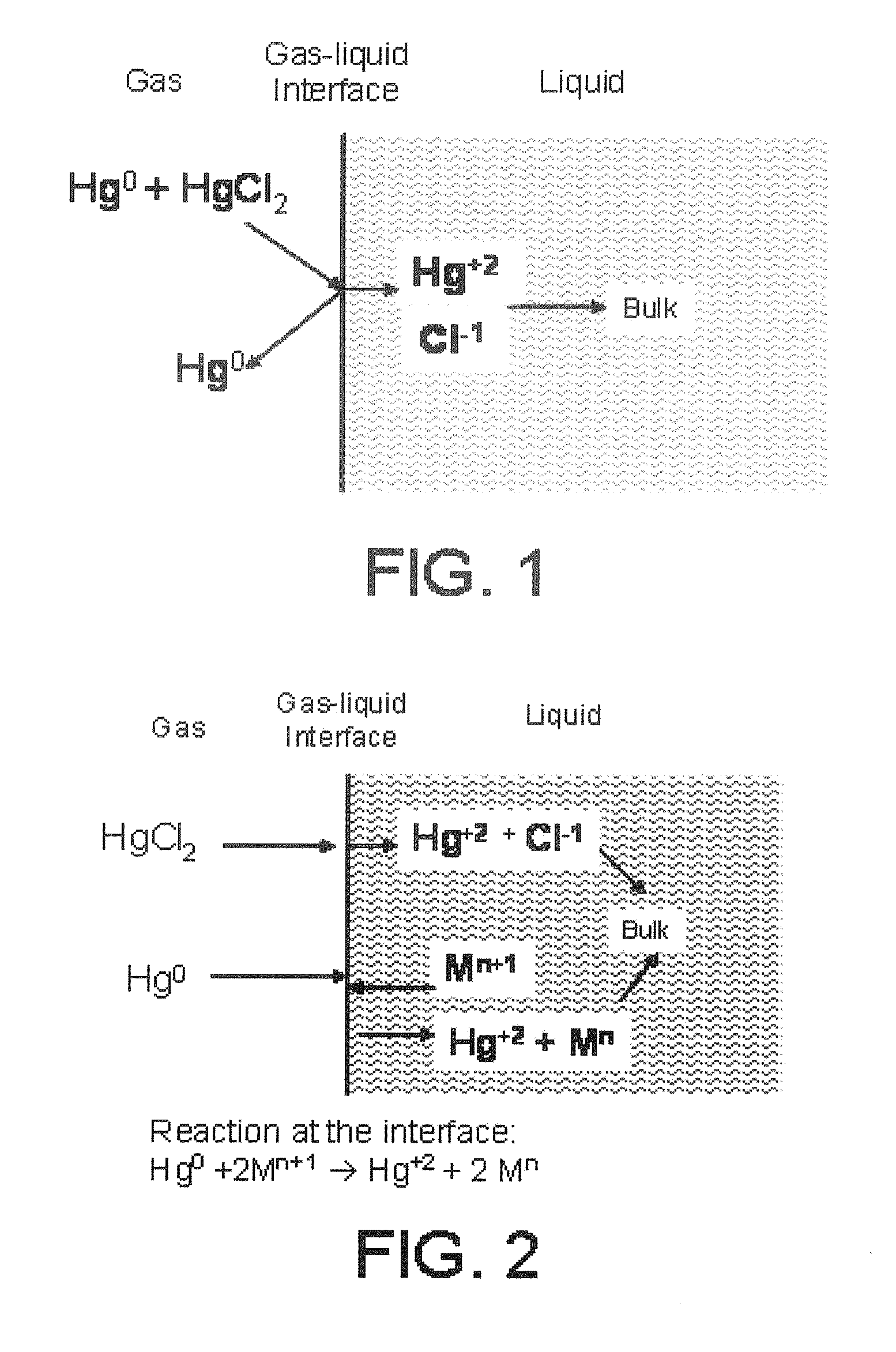

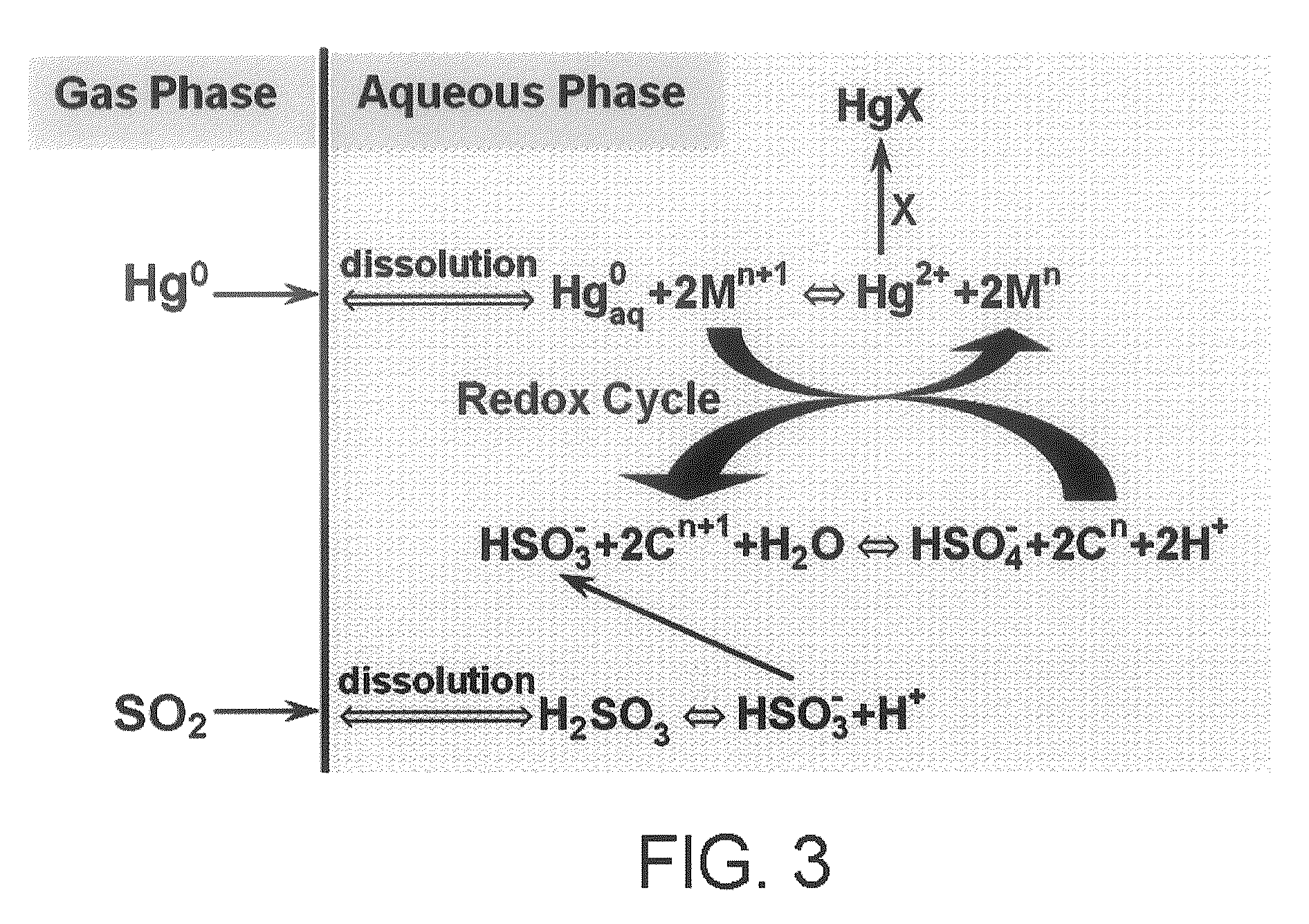

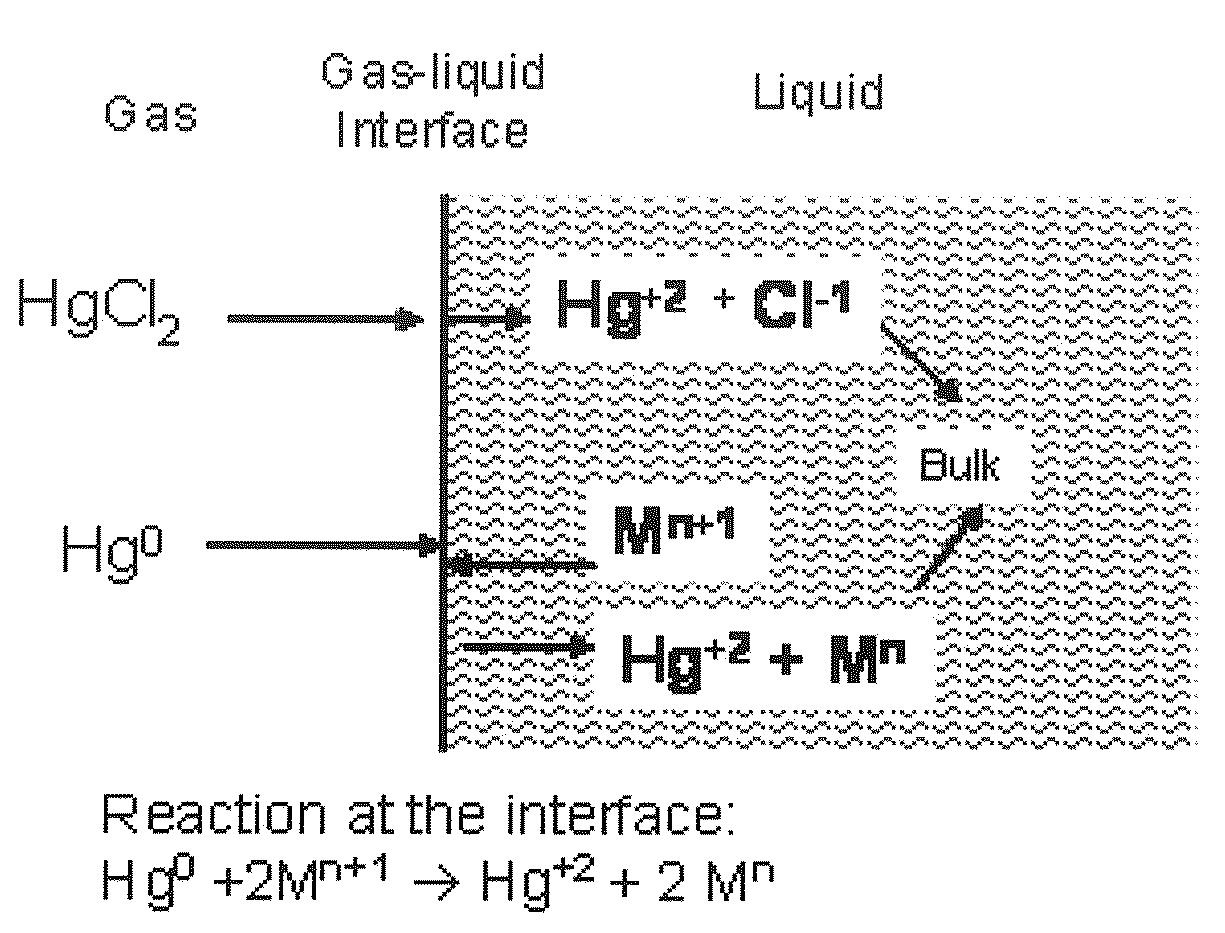

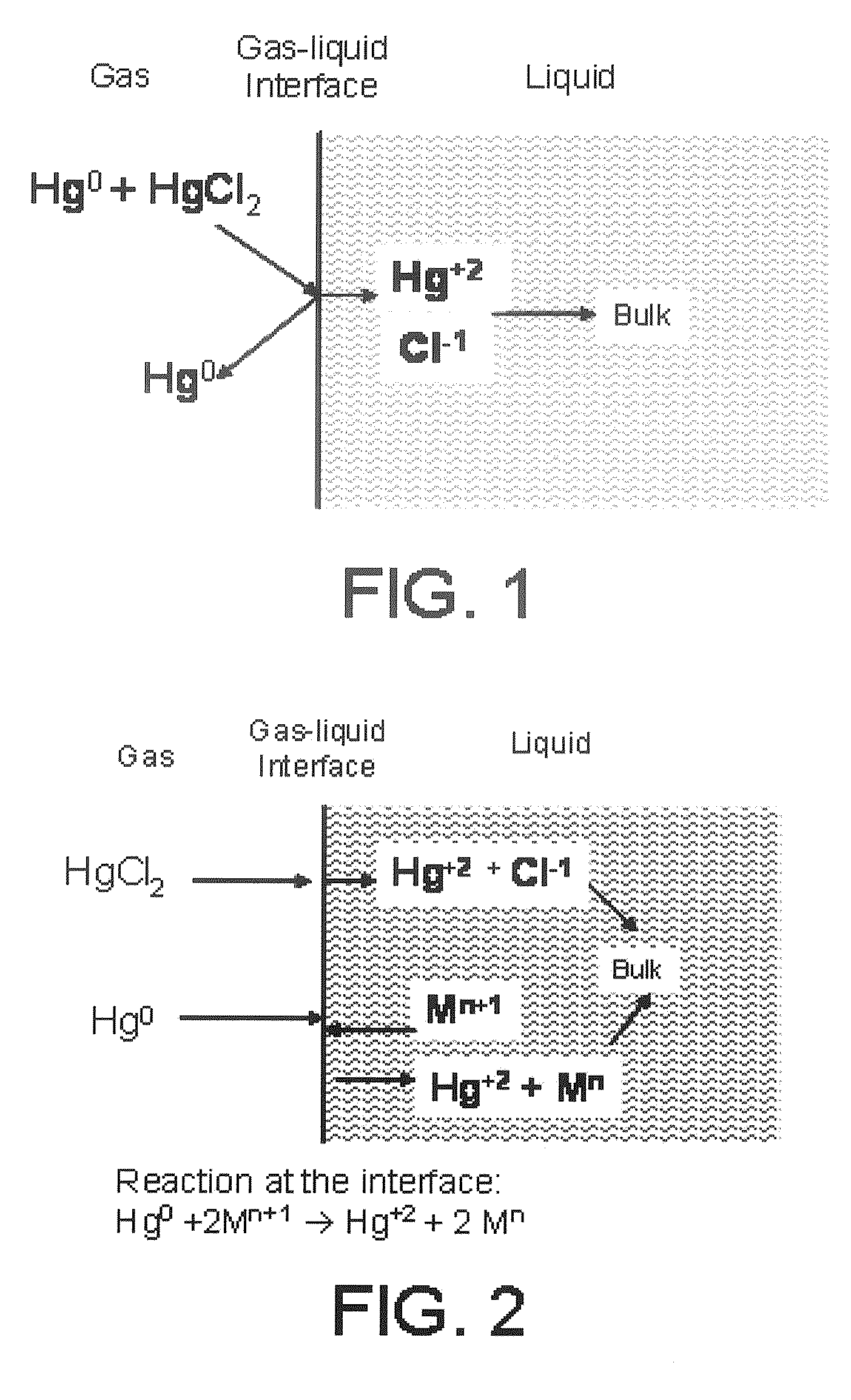

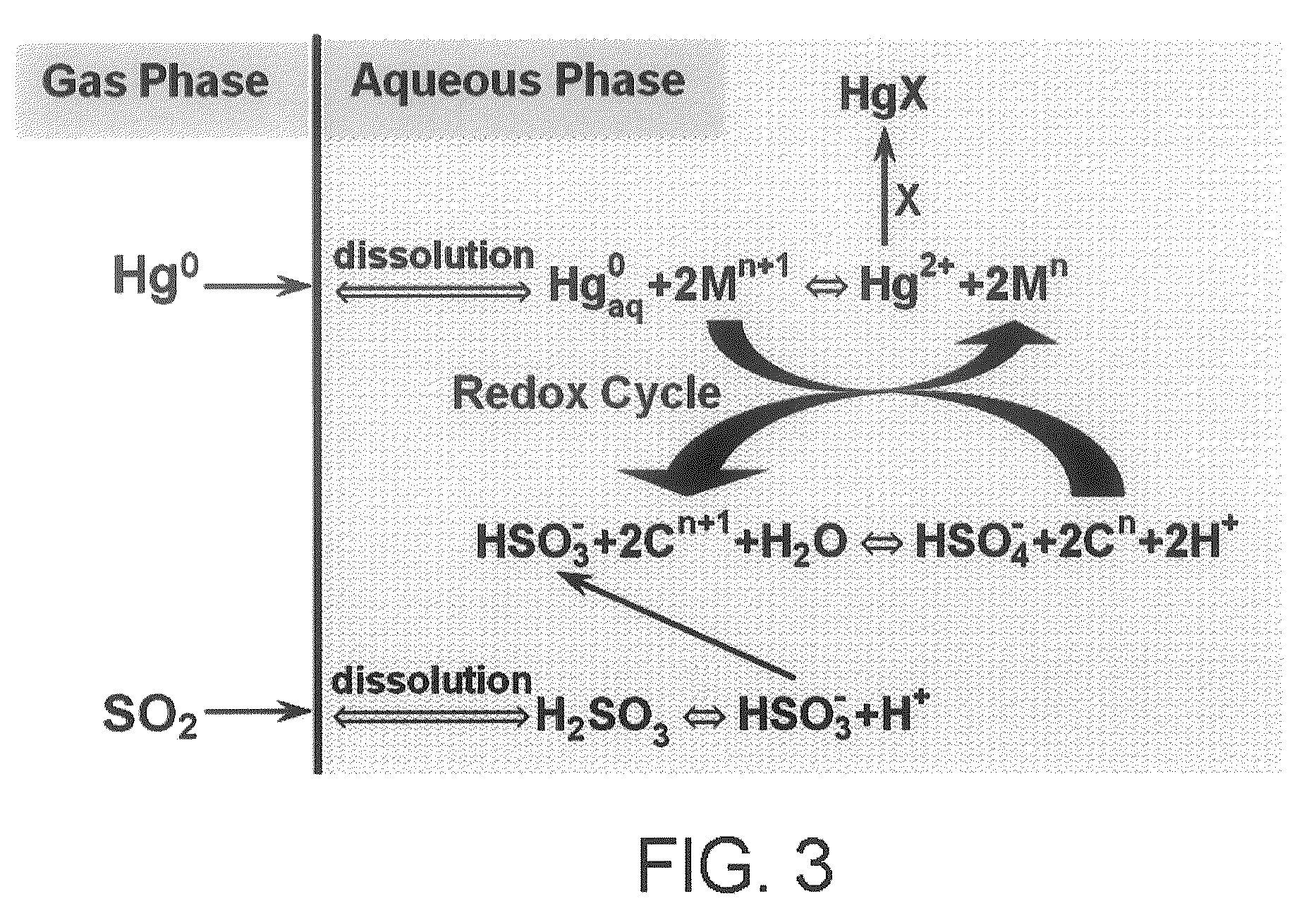

Redox method for capture of total gaseous mercury by wet fgd

ActiveUS20110014104A1Gas treatmentUsing liquid separation agentGaseous elementOxidation-Reduction Agent

A method for capturing gaseous elemental mercury in a flue gas wherein a soluble mercury oxidizer is utilized to oxidize gaseous elemental mercury at a gas-liquid interface of a wet scrubber, and oxidized mercury product is removed prior to re-emission.

Owner:THE BABCOCK & WILCOX CO

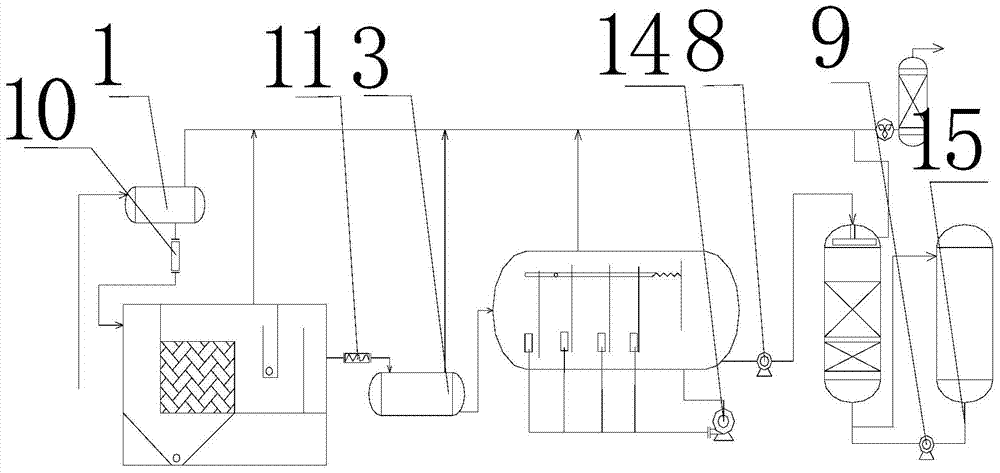

Fly ash mercury removal device and mercury removal method

InactiveCN108237137AEfficient mercury removalEfficient resource processingGas treatmentTransportation and packagingThermal desorption spectroscopyGaseous mercury

The invention provides a fly ash mercury removal device which comprises a thermal desorption unit, a plasma reactor and an adsorption unit, wherein the thermal desorption unit is used for volatilizingmercury in fly ash to form gaseous mercury; the plasma reactor is used for oxidizing gaseous mercury to form oxidative mercury; and the adsorption unit is used for adsorbing oxidative mercury. The invention further provides a fly ash mercury removal method. By adoption of the fly ash mercury removal device and method provided by the invention, a thermal desorption process of the fly ash and a super-oxidation process of mercury can be organically combined, the efficient desorption of mercury from the fly ash can be ensured, and then mercury can be efficiently removed from the fly ash.

Owner:中国科学院北京综合研究中心

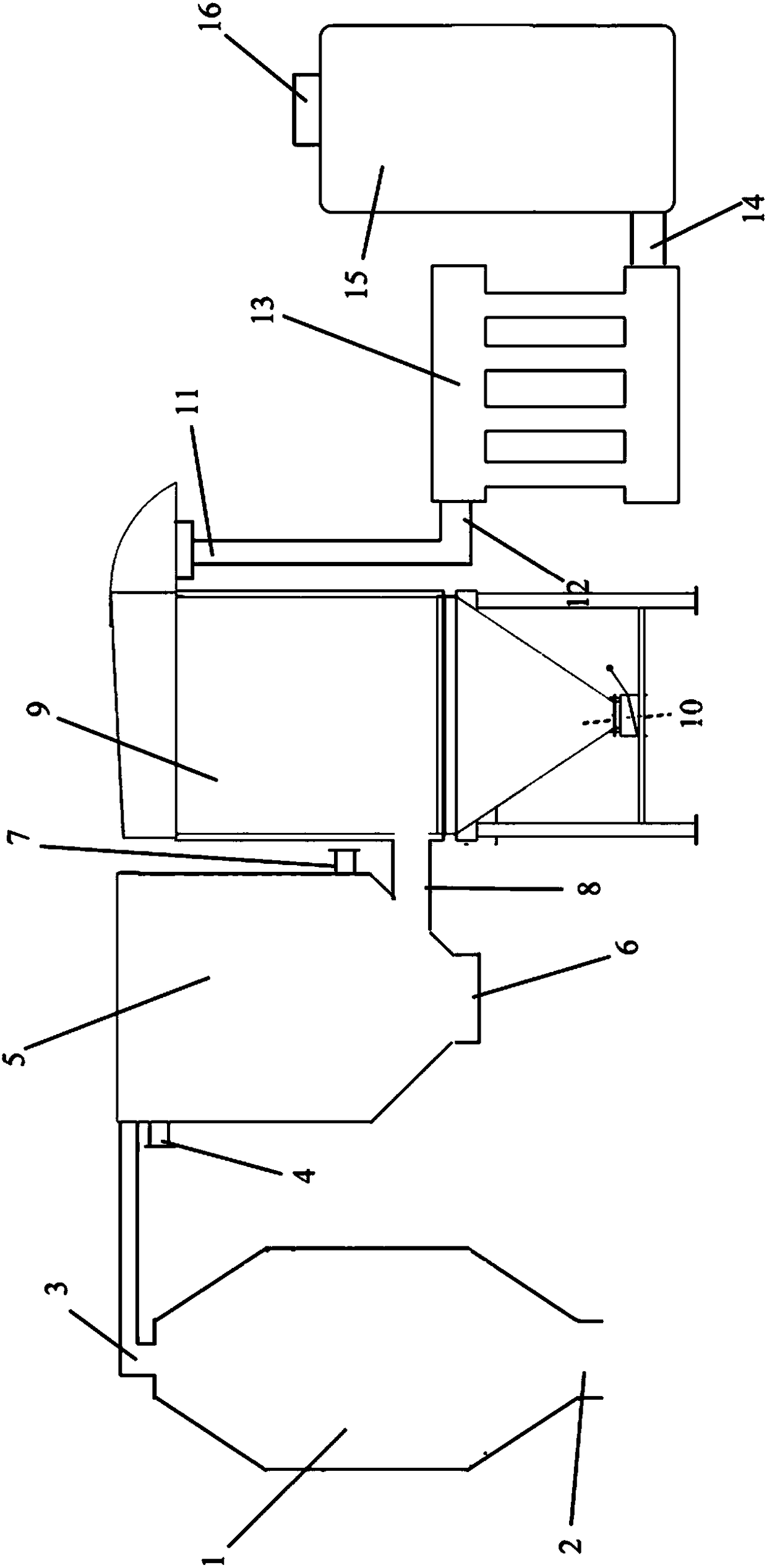

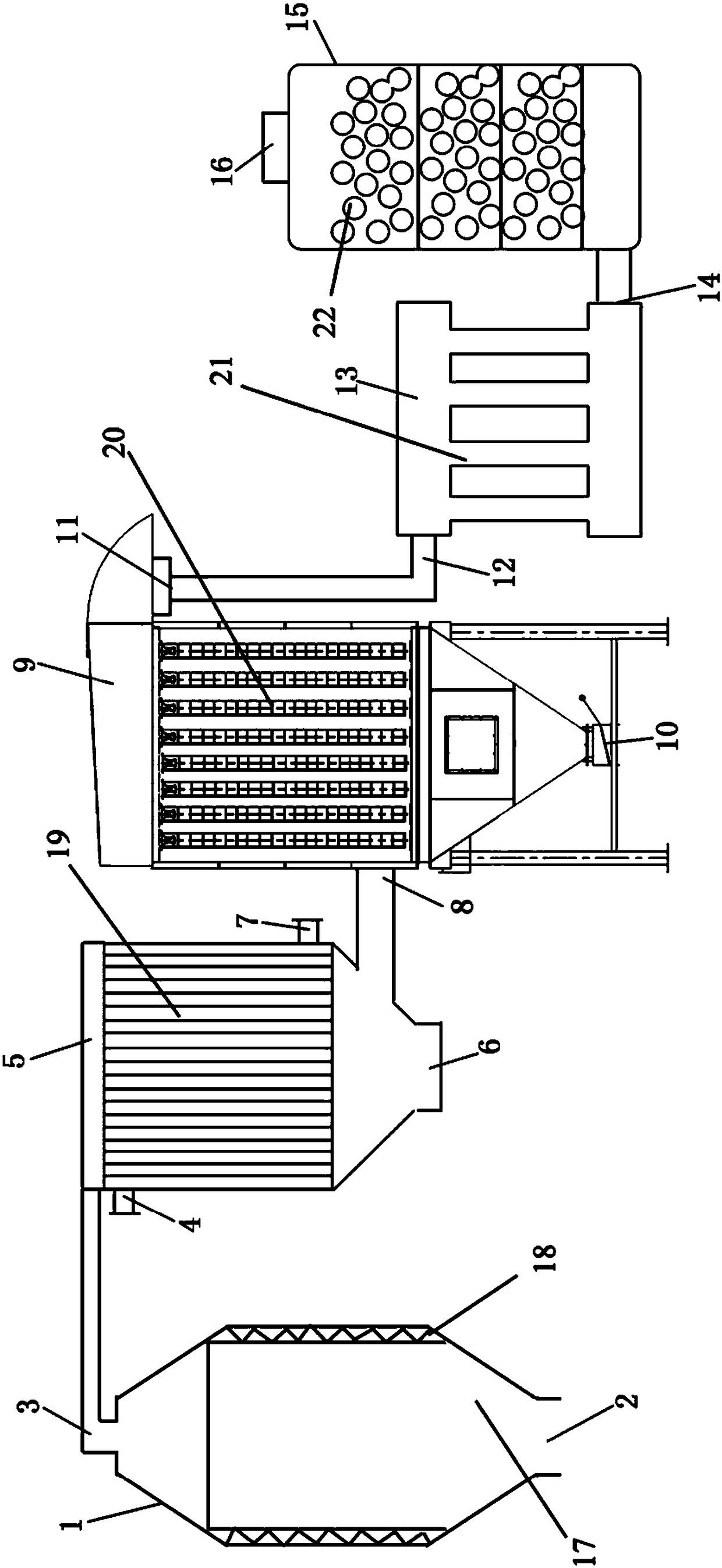

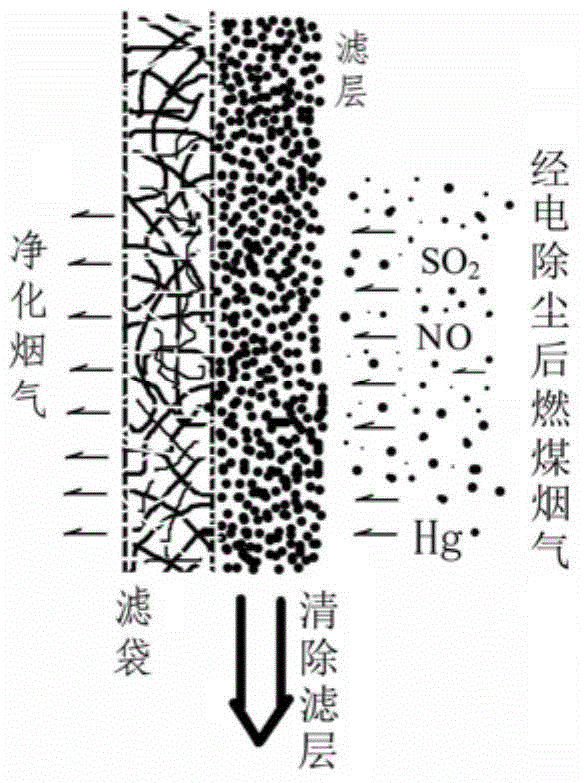

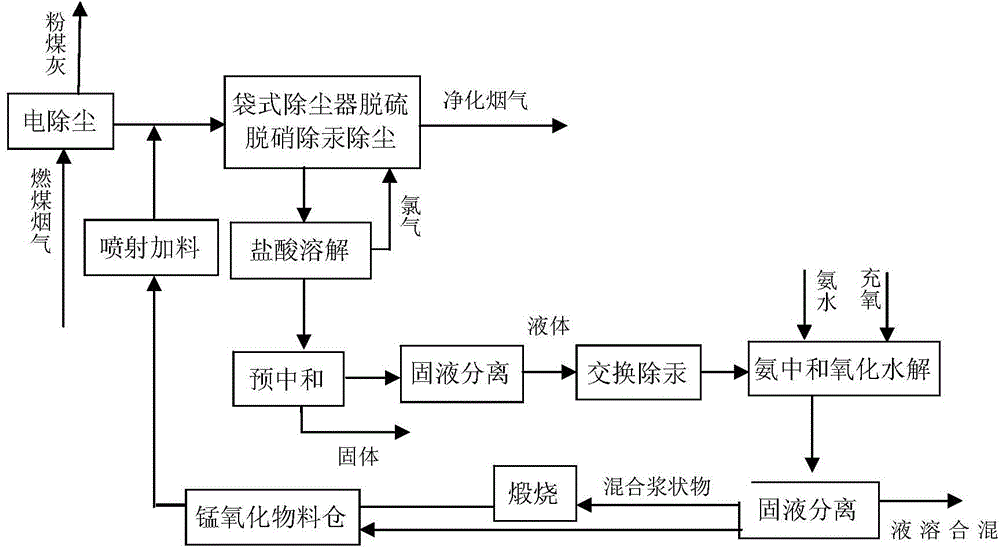

Method for synchronous desulfurization, denitrification, mercury removal and dust removal in bag type dust collector

ActiveCN104162359AReduce loadImprove corrosion resistanceDispersed particle filtrationAir quality improvementParticulatesGaseous mercury

The invention discloses a method for synchronous desulfurization, denitrification, mercury removal and dust removal in a bag type dust collector. The method is characterized in that the bag type dust collector is taken as a reaction device for the synchronous desulfurization, denitrification, mercury removal and dust removal, manganese oxide is taken as an active material for the synchronous desulfurization, denitrification and mercury removal, and manganese oxide slurry or powder and an oxidation accelerator are jetted into a flue gas transmission pipeline; the manganese oxide can react respectively with sulfur dioxide, nitric oxide and gaseous mercury under the synergistic effect of the oxidation accelerator, so as to be converted into manganese sulfate, manganous nitrate and mercuric chloride particulate matters respectively; smoke, the unreacted manganese oxide as well as particulate products of the manganese oxide after being subjected to the desulfurization, denitrification and mercury removal are retained by a filter bag, so that a filtering layer is formed; and a material of the filtering layer is recovered at fixed period, so that the manganese oxide can be recycled. The desulfurization, denitrification, mercury removal and dust removal for coal-fired flue gas can be synchronously realized in the bag type dust collector in an integrated way.

Owner:HEFEI UNIV OF TECH

Method for preparing gaseous mercury absorbing and purifying agent

InactiveCN101301602AImprove applicabilityDispersed particle separationSilicon compoundsSorbentGaseous mercury

The present invention relates to a preparation of an absorbent for absorbing and purifying the gaseous elementary mercury, which is made from the vermiculite which is modified by hydrochloric acid, namely, mixing 2-6 mol / L hydrochloric acid and the vermiculite as the solid-to-liquid ratio of 1:2-4,laying for 6-8 hours, putting the mixture into the mill furnace at the temperature of 105-110 degree C, activating for 20-24 hours, taking out and grinding to less than 200 meshes, drying in the mill furnace until the water ratio is less than 5%, and then the modified vermiculite adsorption is obtained. The absorption effect of the sorbent of the present invention is better than the active carbon for trace gaseity elementary mercury in the coom smoke gas or the other industrial tail gas. When purifying the tail gas containing elementary mercury less than 100ug / m<3>, the absorption capability of the elementary mercury can reach 3.2ug / g-6.0ug / g. The preparation of the present invention is especially used for occasions need to control mercury in the tail gas, such as coal-fired power plant, garbage incinerator and some chemical production factories.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of efficient adsorbent for gaseous mercury sampling

ActiveCN103977763AImprove the capture effectReduce escape rateOther chemical processesWithdrawing sample devicesActivated carbonHalogen

The invention relates to a preparation method of an efficient adsorbent for gaseous mercury sampling, and particularly relates to a preparation method of the efficient adsorbent for gaseous mercury sampling. According to the invention, except halogen and compounds thereof, iodine bromide and dimercaptosuccinic acid are used for modifying; by relevant experiment, the result shows that activated functional groups of carbonyl, halogen and the like which are increased on the surface of modified activated carbon are beneficial to chemical adsorption of the element mercury and divalent mercury, and especially a symmetrical stable structure formed by the combination of dimercaptosuccinic acid and mercury enables the adsorption capability of the modified activated carbon on mercury to be improved greatly.

Owner:WUHAN TIANHONG INSTR

Redox method for capture of total gaseous mercury by wet FGD

A method for capturing gaseous elemental mercury in a flue gas wherein a soluble mercury oxidizer is utilized to oxidize gaseous elemental mercury at a gas-liquid interface of a wet scrubber, and oxidized mercury product is removed prior to re-emission.

Owner:THE BABCOCK & WILCOX CO

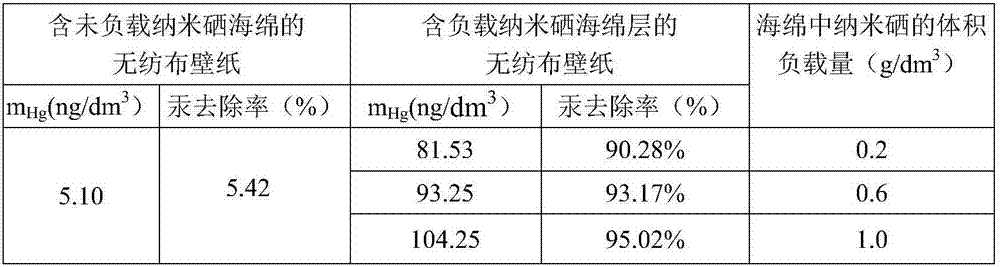

Mercury removing wallpaper for workshops of high mercury industry and preparation method thereof

The invention discloses mercury removing wallpaper for workshops of high mercury industry and a preparation method thereof, the mercury removing wallpaper is prepared as follows: dispersing dopamine hydrochloride in deionized water, stirring evenly, completely reacting at room temperature to obtain a polydopamine water solution; adding a sponge into the polydopamine water solution for impregnation to obtain an impregnation mixture; dispersing sodium selenite in the impregnation mixture, stirring evenly, adding ascorbic acid, stirring for reacting completely, taking the treated sponge out, and drying to obtain a nano-selenium-supported sponge; wrapping the surface of the sponge with a non-woven fabric to obtain the mercury removing wallpaper; nano selenium prepared by a chemical synthesis method is attached to a sponge layer, and the gaseous mercury adsorption capability of the mercury removing wallpaper is simply and efficiently developed. The high-efficiency mercury removal efficiency of the mercury removing wallpaper is 97%-99% or so when the initial mercury concentration is 20000-30000ng / m<3>, and the mercury removing wallpaper has great social and economic benefits.

Owner:ZHEJIANG UNIV OF TECH

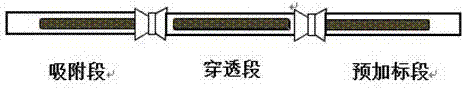

Atmospheric gaseous mercury sampling device

ActiveCN104181014AGuaranteed adsorption efficiencyGuaranteed PenetrationWithdrawing sample devicesGaseous mercuryAtmospherics

The invention relates to a gas sampling device, belongs to the field of environment monitoring, and in particular relates to an atmospheric gaseous mercury sampling device. The atmospheric gaseous mercury sampling device comprises a constant-temperature box, dryers, filters, flow controllers and gas pumps which are connected with one other in sequence, and adsorption gas pipes partially positioned in the constant-temperature box, wherein a gas suction opening of each adsorption gas pipe is fixed outside the constant-temperature box; a gas outlet of each adsorption gas pipe is connected with the corresponding dryer through a gas nozzle. Therefore, the atmospheric gaseous mercury sampling device has the advantages that atmospheric gaseous mercury sampling can be carried out, and the national condition requirement in China can be met; the sampling effect is good, and the constant-temperature heating box guarantees the adsorption efficiency and the penetrating rate of the adsorption pipes, and the special volume flow controllers enable the sampling flow range to be wide and the gas flow to be stable; the precision of the sampling device is high, and by virtue of a stainless steel structure, the reliability of the sampling device is also improved.

Owner:WUHAN TIANHONG INSTR

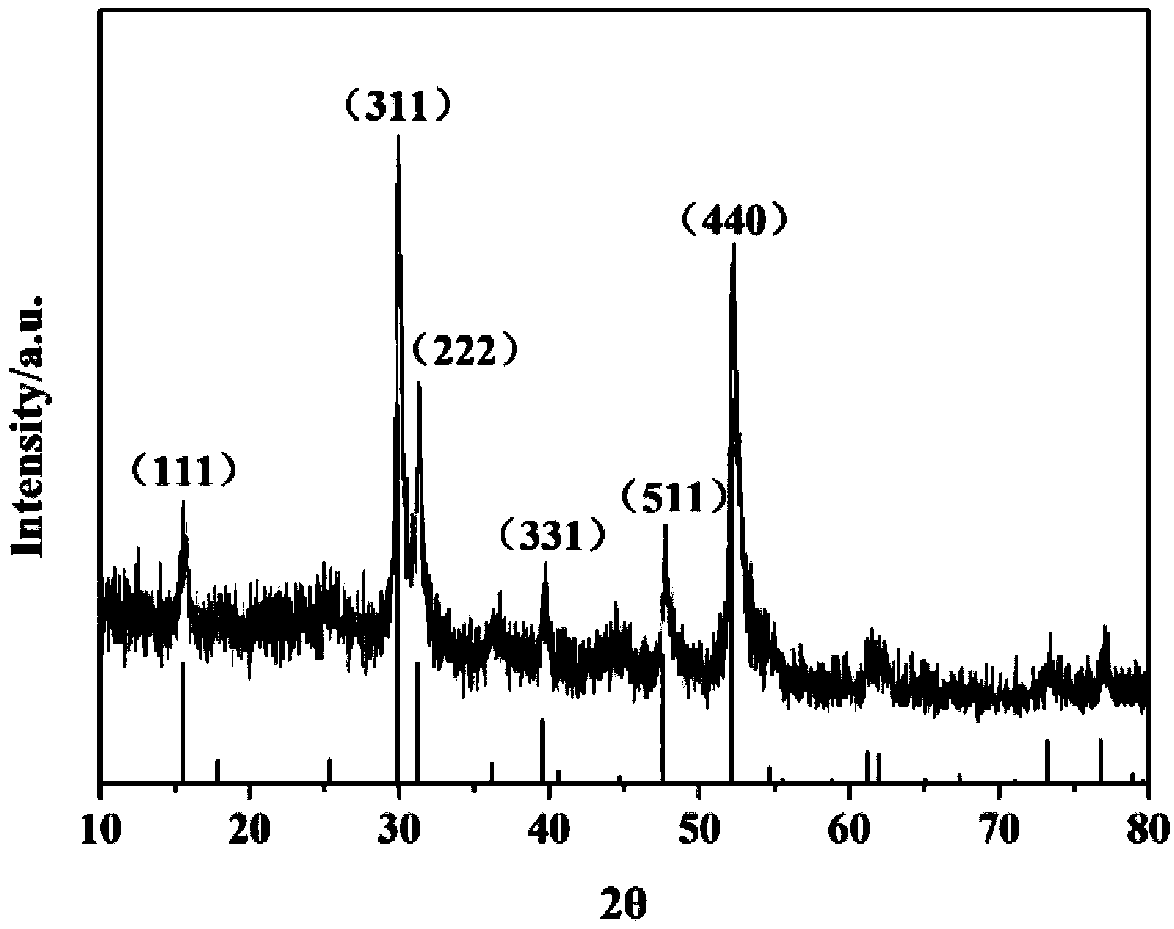

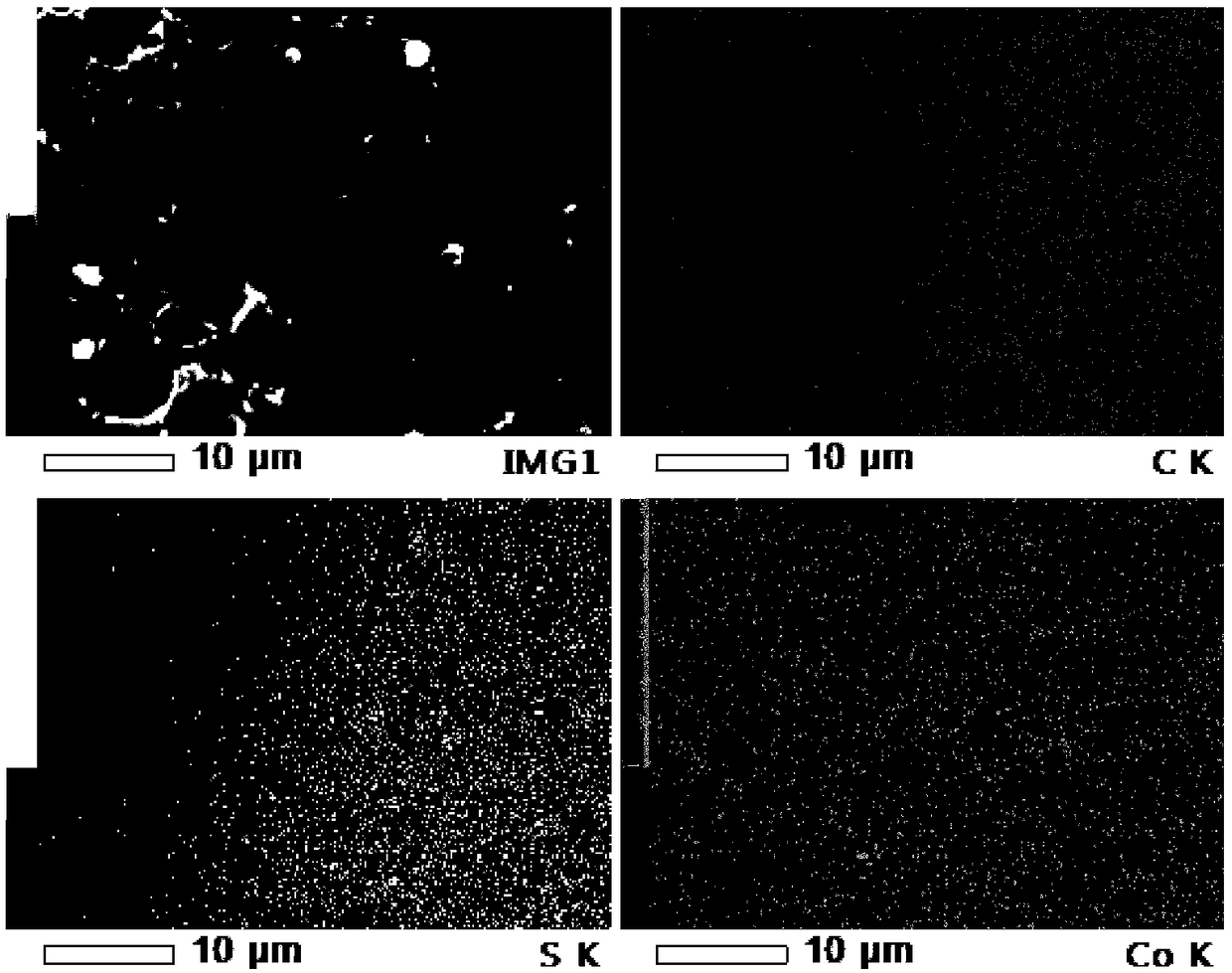

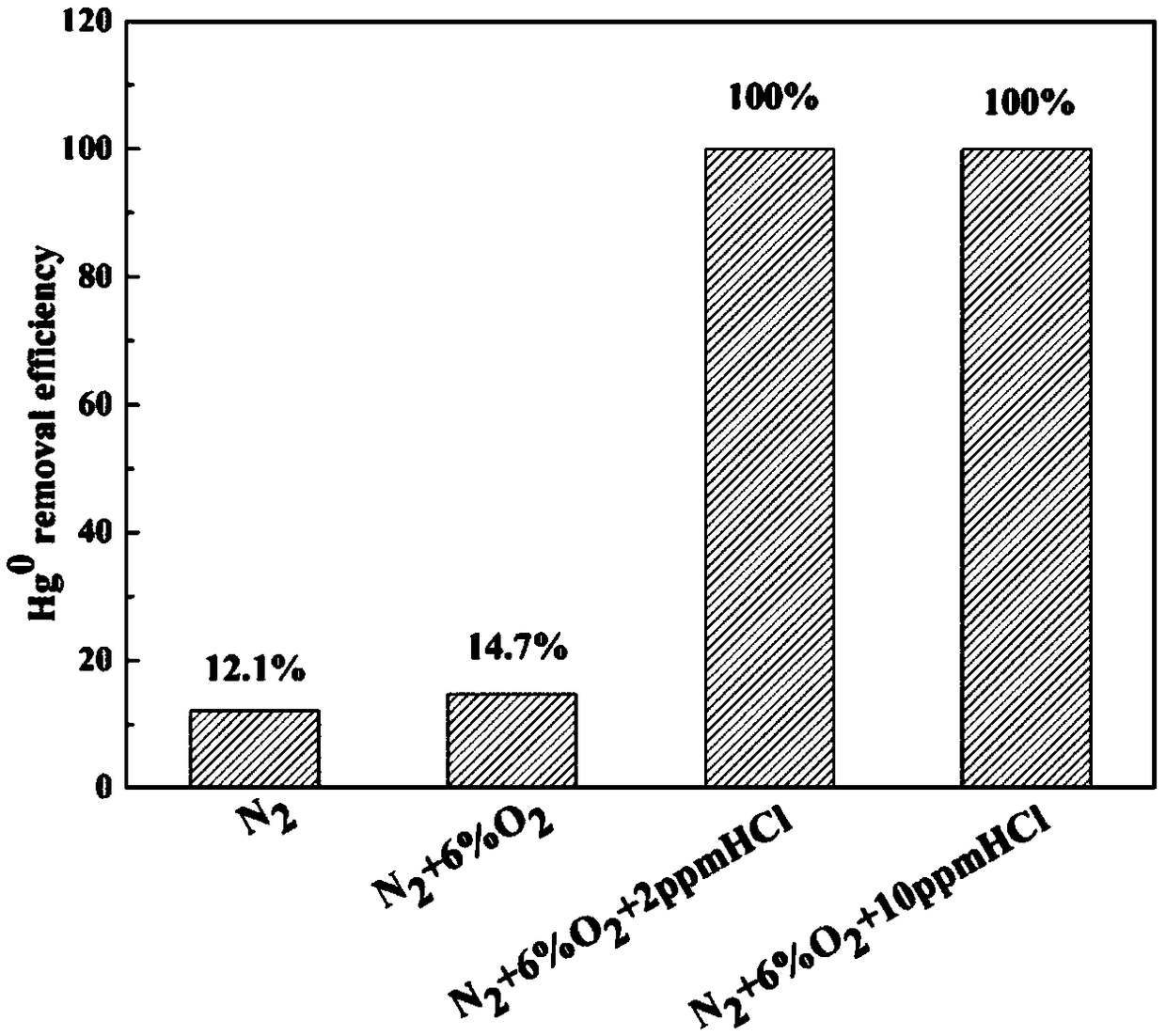

Method for removing gaseous mercury in flue gas through catalytic oxidation of cobalt sulfide/biomass carbon composite material

ActiveCN109200812AStrong loadAchieve decentralizationGas treatmentPhysical/chemical process catalystsHigh concentrationWater vapor

The invention discloses a method for removing gaseous mercury in flue gas through catalytic oxidation of a cobalt sulfide / biomass carbon composite material, which can purify mercury in flue gas of different compositions by converting gas-phase elementary mercury in mercury-containing flue gas through catalytic oxidation of the cobalt sulfide / biomass carbon composite material. The method can realize high-efficiency conversion of elemental mercury under the conditions of high SO2 concentration and low hydrogen chloride concentration, and solves the problem that a traditional mercury removal catalyst is likely to deactivate under high concentration SO2 and relies on HCl; especially, the cobalt sulfide / biomass carbon composite material still has a good mercury removal effect to flue gas containing NO, NH3 and water vapor, exhibits good ammonia and water resistance, and is suitable for treating flue gas with various atmospheric components.

Owner:CENT SOUTH UNIV

Mercury-containing wastewater treatment method and treatment device

The invention provides a mercury-containing wastewater treatment method and a mercury-containing wastewater treatment device. The device comprises an oil-water-mercury separator and a gas main, wherein the gas main is connected with the bottom of a gaseous mercury adsorber, and the gas main is respectively connected with the top of the oil-water-mercury separator, an air-floated mercury removal apparatus and a mercury adsorption-filtration apparatus by pipelines; and the side wall of the oil-water-mercury separator, the side wall of the air-floated mercury removal apparatus and the top of the mercury adsorption-filtration apparatus are sequentially connected by pipelines, and the bottom of the mercury adsorption-filtration apparatus is connected with the upper part of the side wall of a purified water tank by a purified water pipeline. The method comprises the following steps that after being treated by the oil-water-mercury separator, the air-floated mercury removal apparatus, the mercury adsorption-filtration apparatus and the gaseous mercury adsorber, mercury-containing wastewater enters the purified water tank by the purified water pipeline, and exhaust gas discharged from the oil-water-mercury separator, the air-floated mercury removal apparatus and the mercury adsorption-filtration apparatus enters the gaseous mercury adsorber to carry out adsorption treatment. The method and device provided by embodiments of the invention carry out targeted treatment on mercury-containing wastewater occurring in oil and gas exploration, and the mercury content of treated mercury-containing wastewater is less than 10 ppb.

Owner:SOUTHWEST PETROLEUM UNIV +1

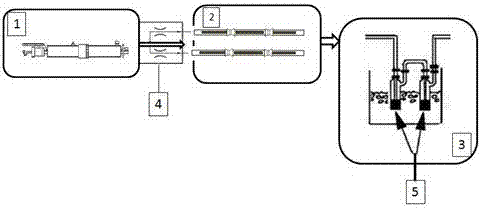

Coal pyrolysis gas elemental mercury sampling system

InactiveCN107991144ALow blank background valueEasy to pack and transportWithdrawing sample devicesForm analysisSorbent

The invention relates to a system for measuring and sampling mercury in pyrolysis gas in a coal pyrolysis utilization process. The invention self-designs and establishes a set of sampling system on the basis of the conventional dry adsorption mercury measuring method. An OHM method and a Method 30B method are combined, and the sampling system comprises a KCl solution and an adsorbent for modifiedactivated carbon, and used for respectively adsorbing gaseous divalent mercury and gaseous zero-valent mercury in flue gas. The system disclosed by the invention is simple in operation and low in cost. The designed sampling system has the characteristics of being low in blank background value of a mercury adsorption tube, small in sampling size, short in sampling time and convenient in sampling equipment package and transport, can realize form analysis of gaseous mercury in the flue gas, and has a certain industrial value.

Owner:NINGXIA UNIVERSITY

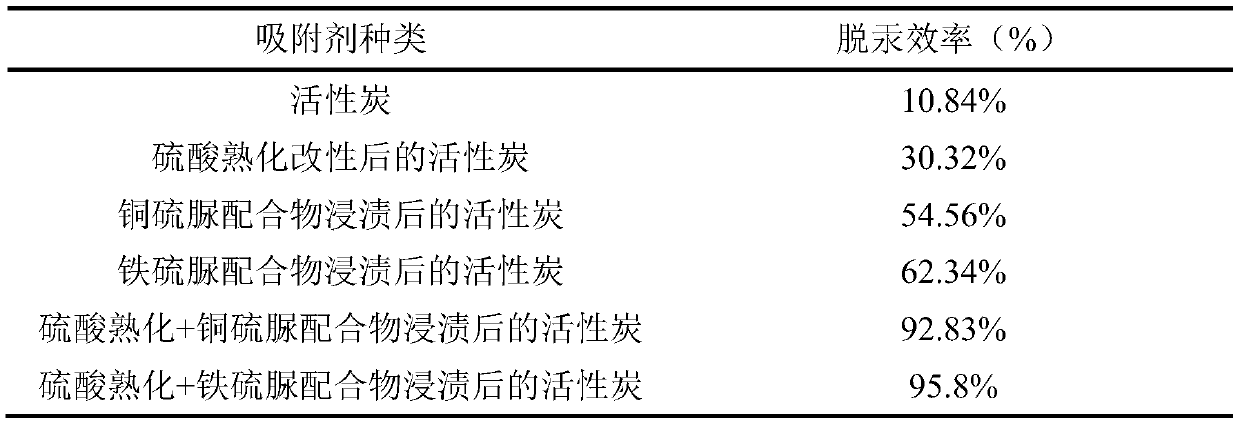

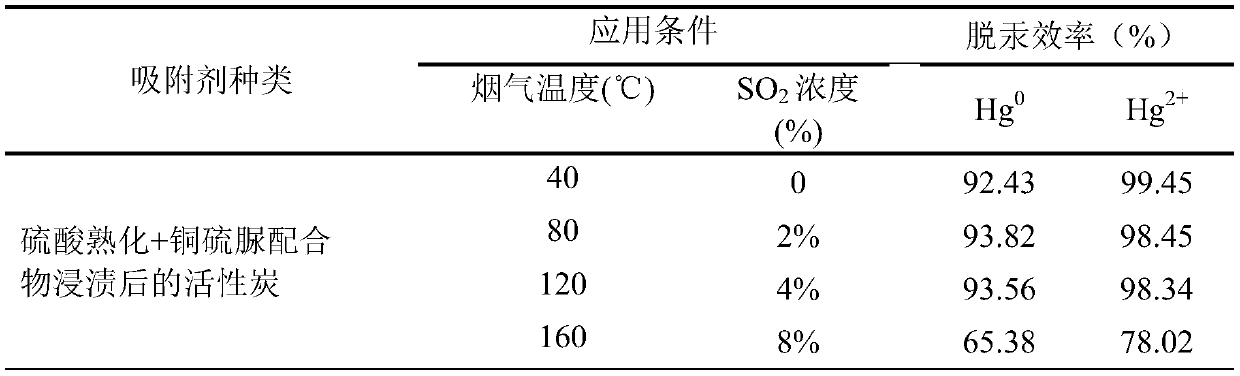

Preparation method and applications of gaseous mercury adsorbent

ActiveCN110252255AImprove sulfur resistanceImprove removal efficiencyGas treatmentOther chemical processesSorbentThiourea

The invention discloses a preparation method of a gaseous mercury adsorbent. The preparation method comprises following steps: (1) mixing active carbon and concentrated sulfuric acid, aging, filtering, and washing to obtain modified active carbon; (2) mixing thiourea and metal salts to obtain a metal thiourea mixed solution, wherein the metal ions of the metal thiourea mixed solution are copper ions and / or iron ions; and (3) mixing modified active carbon and the metal thiourea mixed solution to impregnate modified active carbon, and after impregnation, drying obtained materials in vacuum to obtain the gaseous mercury adsorbent. The invention also discloses an application of the gaseous mercury adsorbent on absorbing gaseous mercury in high sulfur smelting exhaust gas. The prepared gaseous mercury adsorbent can absorb gaseous mercury and divalent mercury in flue gas, has an excellent sulfur-resistant performance, and has high mercury removing efficiency, even if the concentration of sulfur dioxide is high.

Owner:JIANGXI UNIV OF SCI & TECH

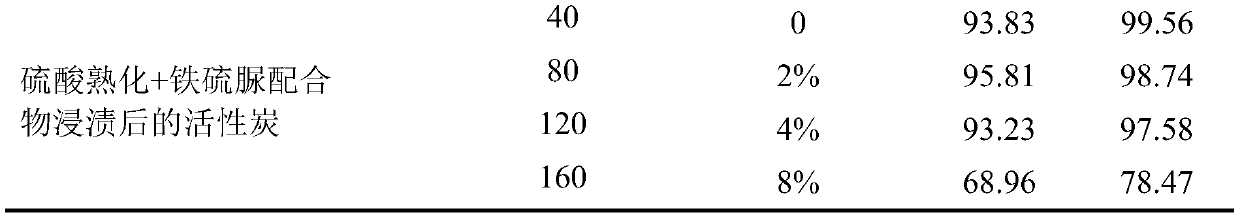

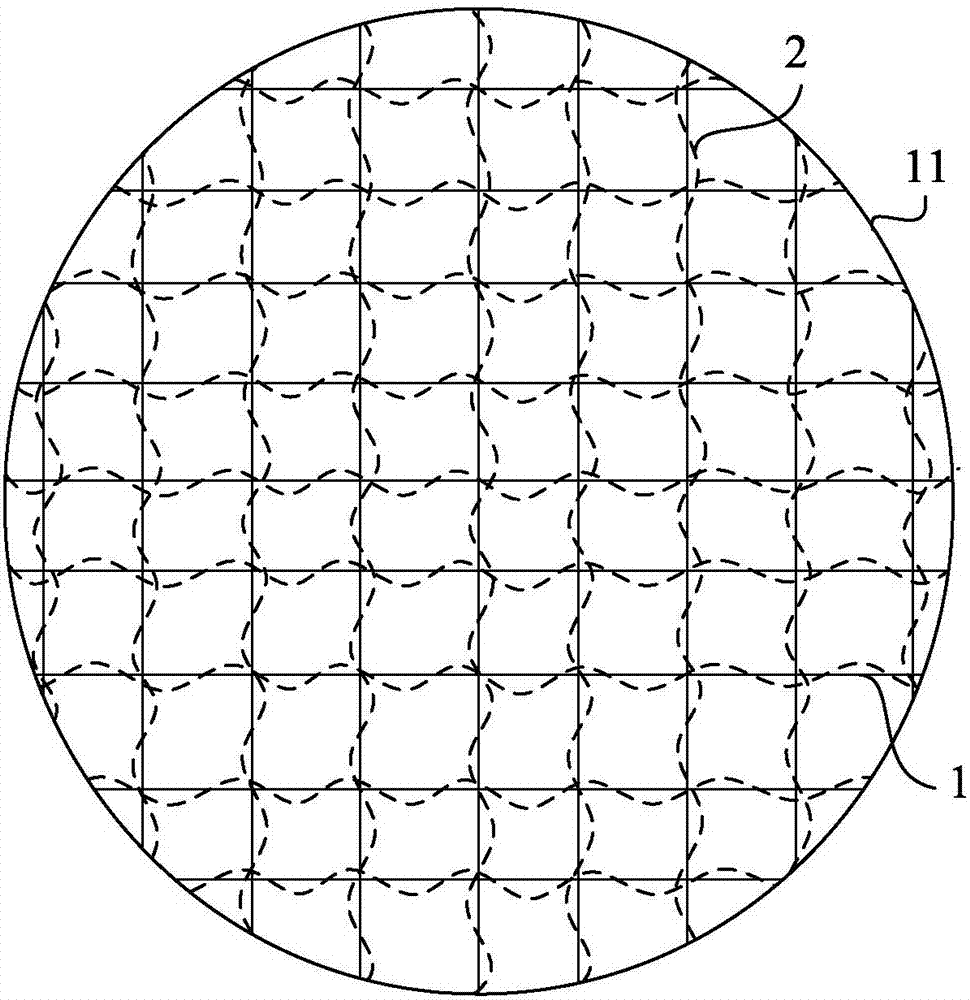

Device for integrally collecting and determining mercury in different forms at atmosphere and sampling method of device

PendingCN107655727AImprove capture efficiencyIncrease contact areaWithdrawing sample devicesProcess efficiency improvementParticulatesSilica particle

The invention provides a device for integrally collecting and determining mercury in different forms at atmosphere and a sampling method of the device. A device main body is internally provided with aparticulate mercury collecting tube, an active gaseous mercury collecting tube, an amalgamation tube and an elemental mercury collecting tube in sequence from top to bottom; a heating device is arranged on each of the outer sides of the device main body, which correspond to the particulate mercury collecting tube, the active gaseous mercury collecting tube, the amalgamation tube and the elementalmercury collecting tube; a cooling tube is arranged between the particulate mercury collecting tube and the active gaseous mercury collecting tube, between the active gaseous mercury collecting tubeand the amalgamation tube and between the amalgamation tube and the elemental mercury collecting tube respectively. When the mercury in the different forms at atmosphere is collected, particulate mercury in atmosphere is collected by a filter membrane, active gaseous mercury and elemental mercury can pass through the filter membrane, then, the active gaseous mercury is collected by quartz granulesplated with potassium chloride, and the elemental mercury is collected by quartz beads plated with gold, so that the mercury in the different forms at atmosphere can be collected.

Owner:TIANJIN UNIV

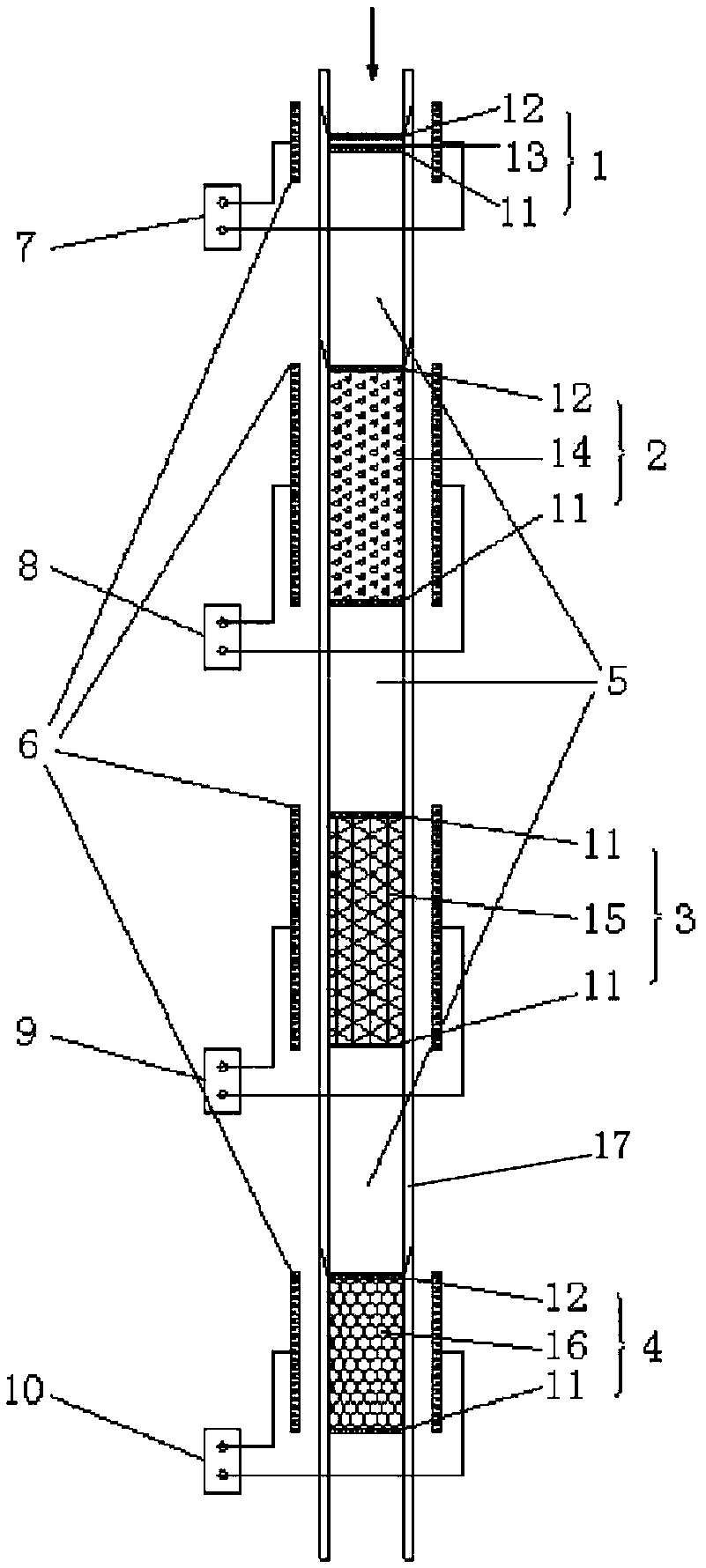

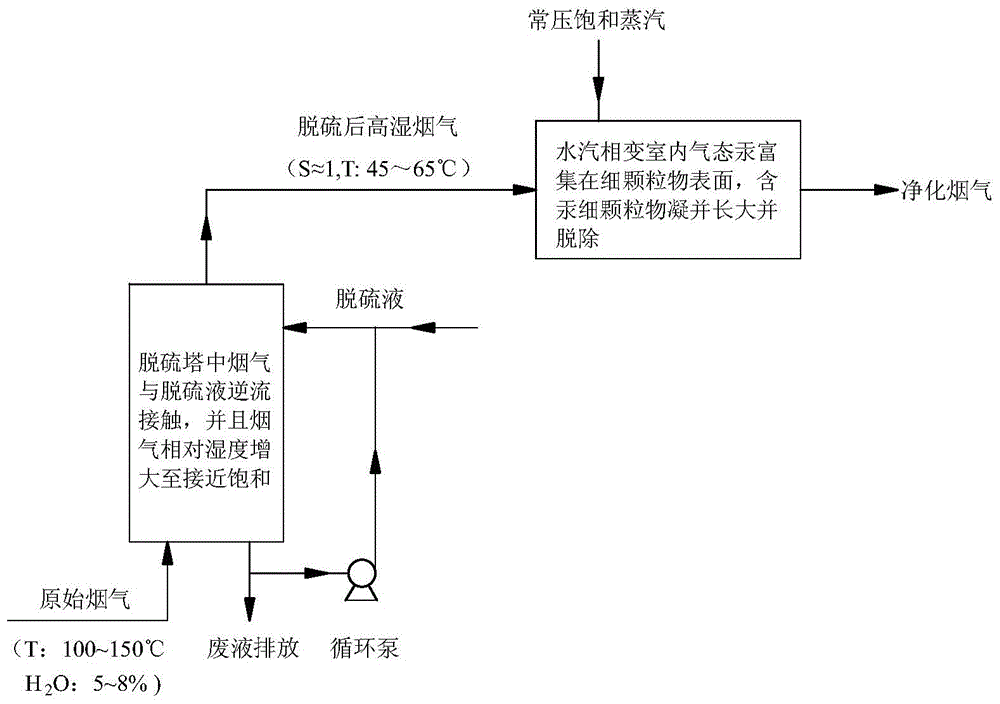

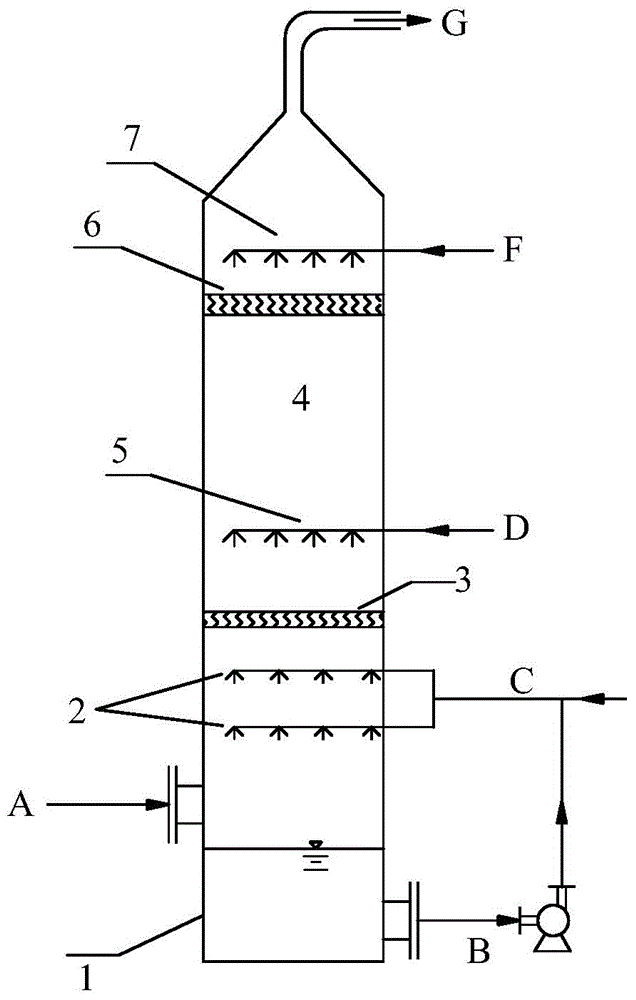

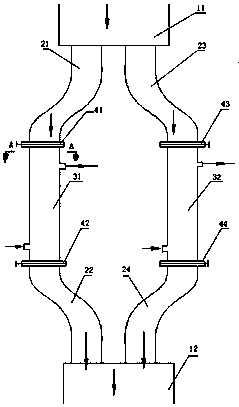

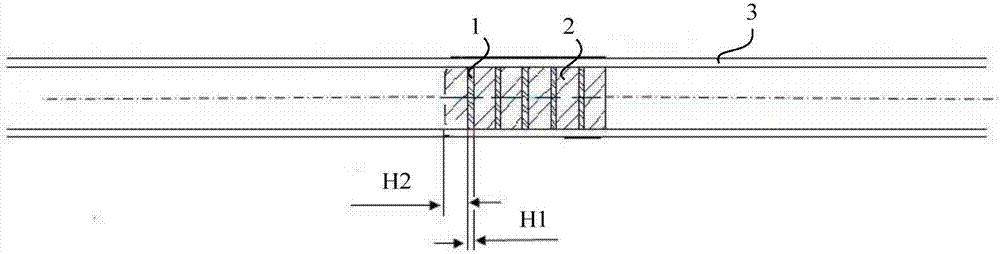

Method and device for promoting simultaneous removal of mercury and fine particulate matters during wet flue gas desulfurization

InactiveCN104941379ALarge particle sizeQuality improvementAuxillary pretreatmentWater vaporGaseous mercury

The invention provides a method and a device for promoting simultaneous removal of mercury and fine particulate matters during wet flue gas desulfurization by use of the water-vapor phase change principle and aims to overcome the shortcomings that flue gas in low in temperature and high in humidity and PM2.5 and mercury cannot be effectively removed after wet desulphurization. Coal-fired flue gas subjected to wet desulphurization enters a water-vapor phase change chamber, and normal-pressure saturated vapor is injected to enable flue gas to be supersaturated; on one hand, the supersaturated water-vapor drags gaseous mercury to be collected on the surfaces of particulate matters through both the thermophoresis and diffusiophoresis actions, and on the other hand, fine particulate matters on which particulate mercury is collected are taken as condensation nucleuses, nucleation and condensation occur on the surfaces of the condensation nucleuses, so that the fine particulate matters are increased in particle diameter and mass, and dust-containing drop mercury which is increased in size by condensation is finally removed by an efficient demister. A conventional coal-fired wet desulphurization device is improved by additionally arranging the water-vapor phase change chamber behind a desulfurization tower, so that once vapor is added, the wet desulphurization device can play the role of simultaneous removal of mercury and fine particulate matters. The method and the device can be widely used for wet flue gas desulfurization in coal-fired power plants and have huge economic benefits and social benefits.

Owner:NANJING NORMAL UNIVERSITY

Dry gaseous mercury removal agent

InactiveCN101879412AQuick responseImprove stabilityDispersed particle separationGaseous mercurySodium salt

The invention relates to a dry gaseous mercury removal agent. The dry gaseous mercury removal agent comprises the following components in weight percentage: 8 to 37.5 percent of sulfur, 0.8 to 16 percent of alkaline compound of Na, 0.1 to 1 percent of mass transfer accelerator and the balance of activated carbon, wherein the sulfur is uniformly distributed in gaps of the activated carbon; the alkaline compound of Na comprises NaHCO3, Na2CO3 and the like; and the mass transfer accelerator comprises chlorine gas, sodium salts of hypochloric acid and acid and the like. For the preparation of the dry gaseous mercury removal agent, the particle-based materials (with the diameter of 1 to 5mm and the length of 3 to 10mm) of the activated carbon are impregnated in the mixed solution of the alkaline compound of Na and the mass transfer accelerator for 1 to 24h to form the dry gaseous mercury removal agent. The dry gaseous mercury removal agent is suitable for an industrial gas mercury removal process at the operation temperature of 0 to 110 DEG C and out of the limit of other conditions; the final conversion product of the gas mercury is environmentally-friendly stable mercuric sulfide free of secondary pollution; and the dry gaseous mercury removal agent has the advantages of simple process, high mercury volume, low investment for mercury removal, low operation cost and the like.

Owner:翟常忠

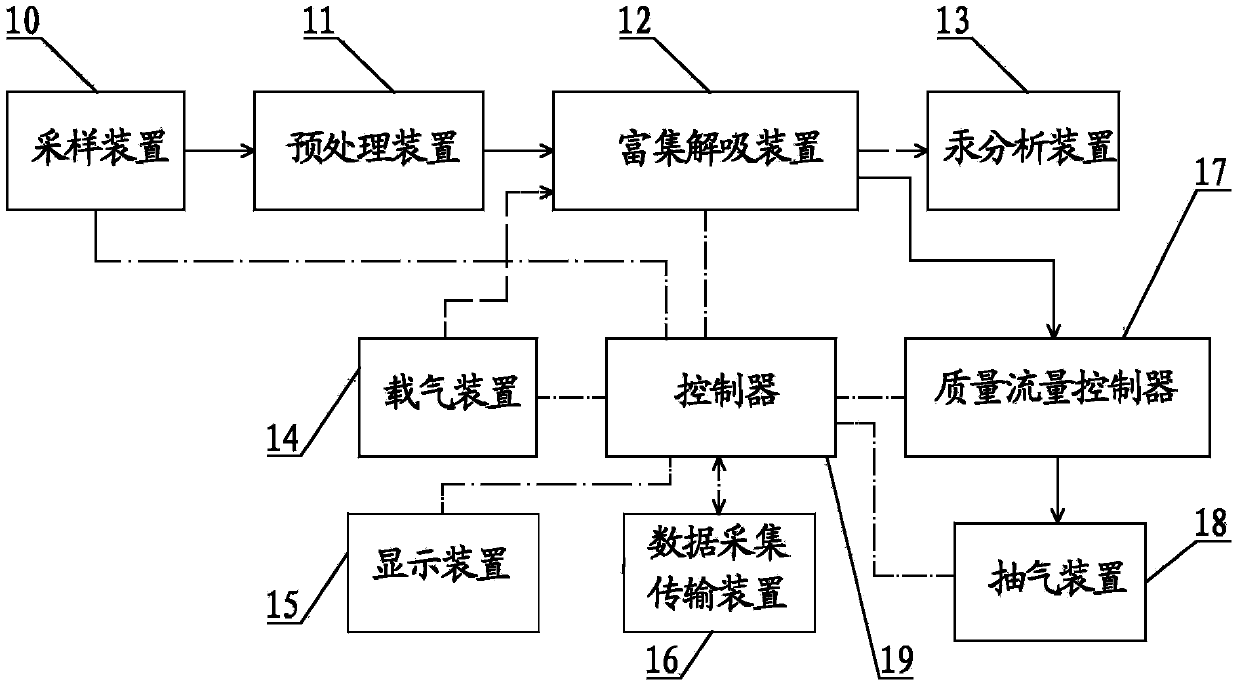

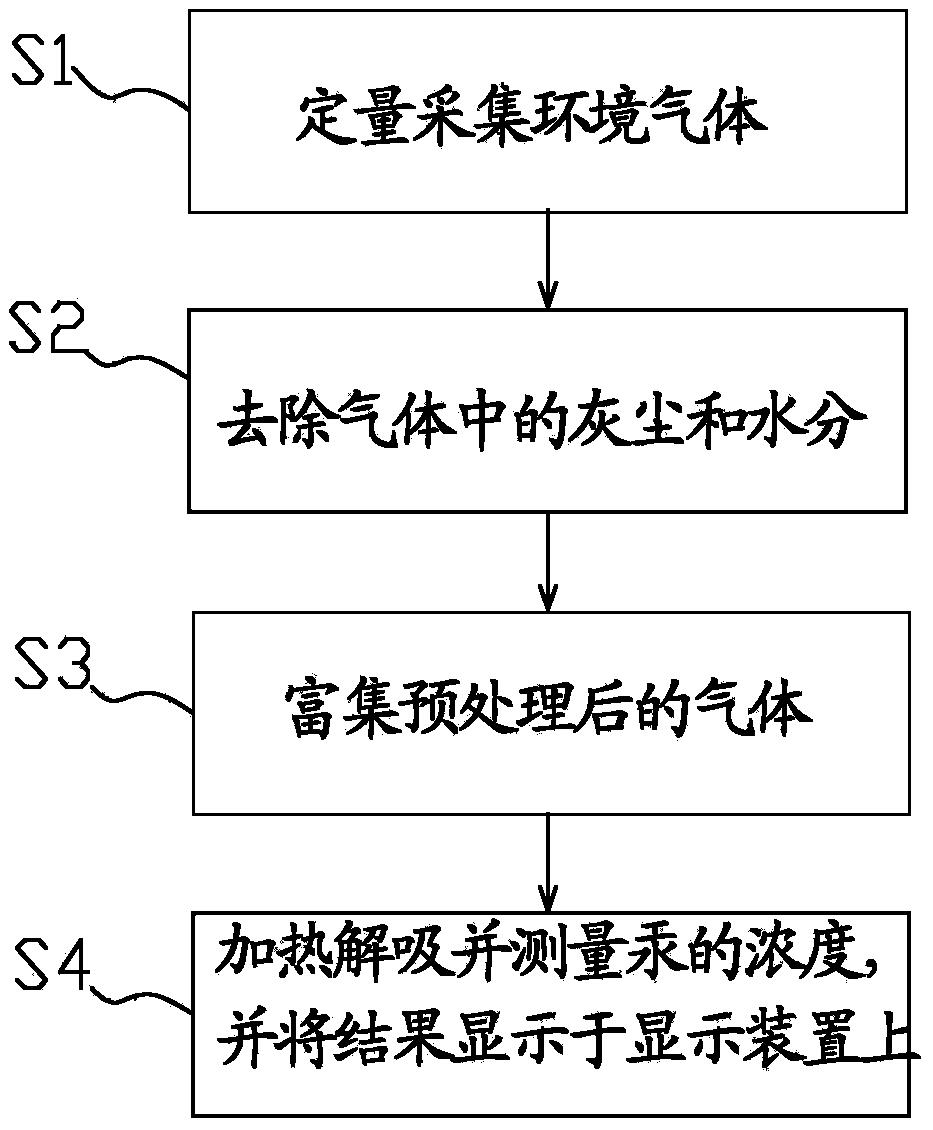

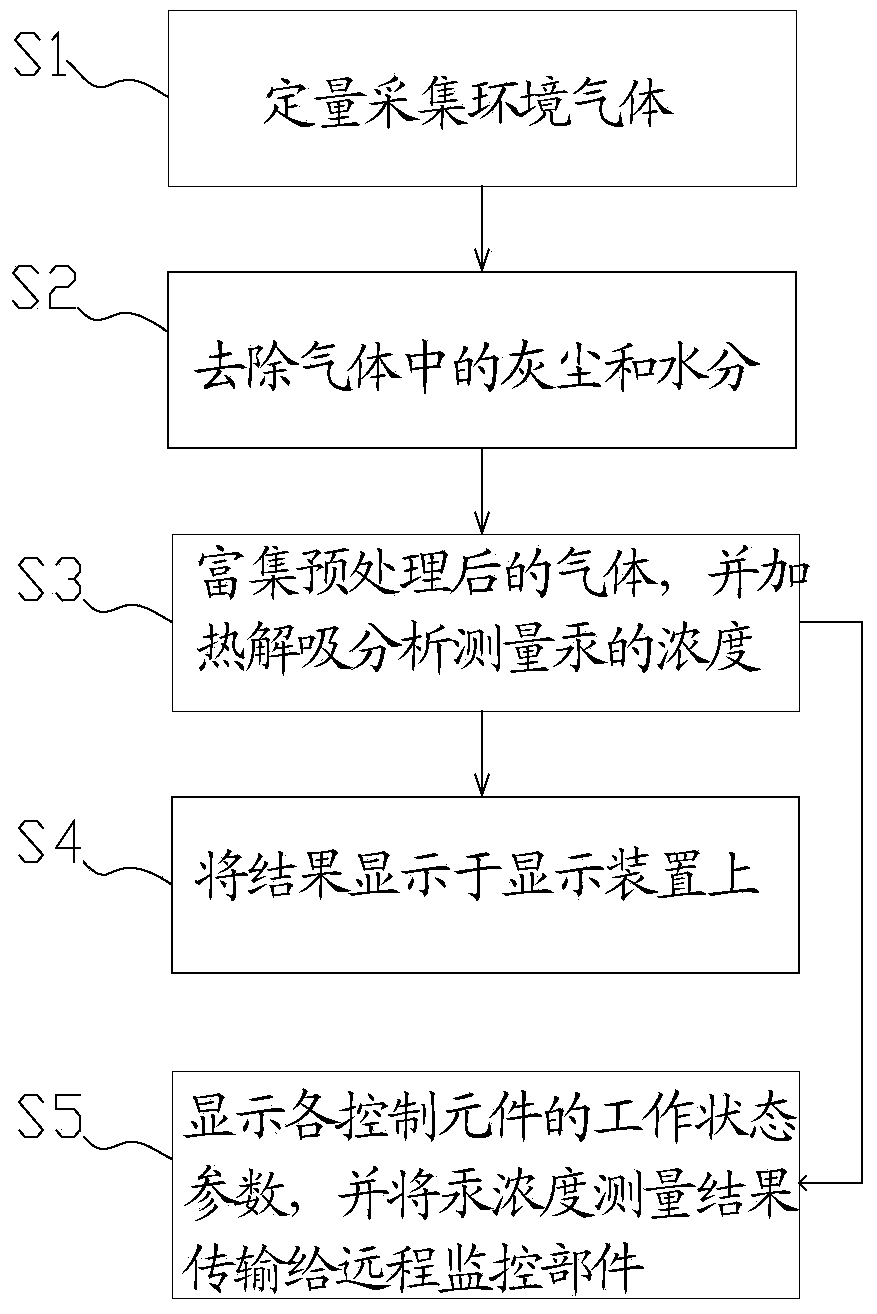

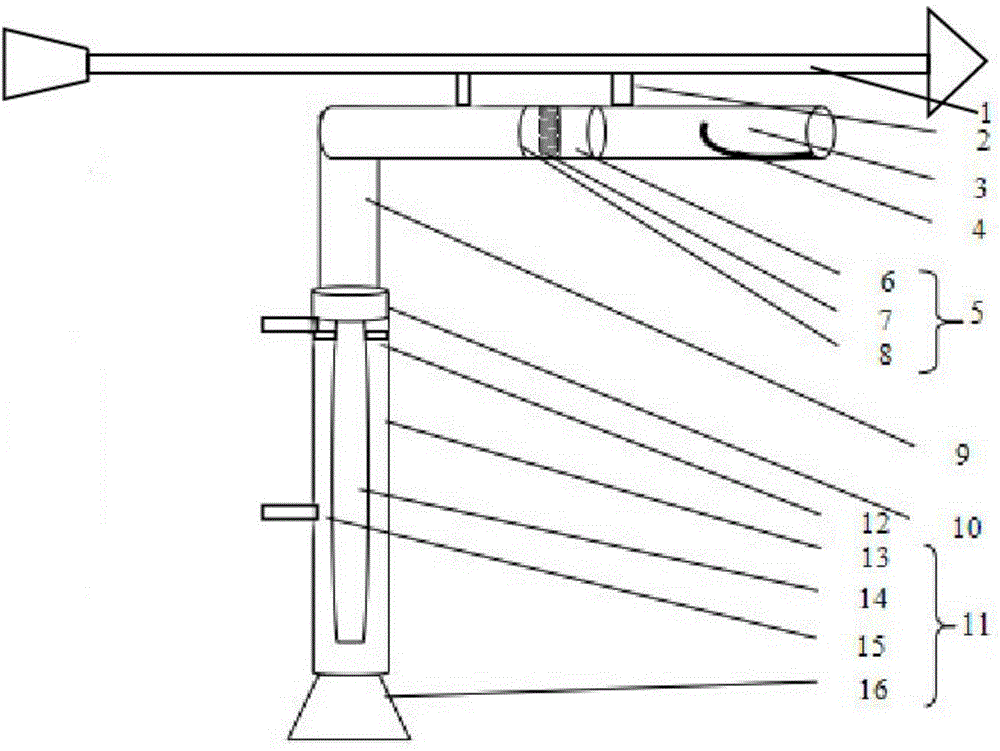

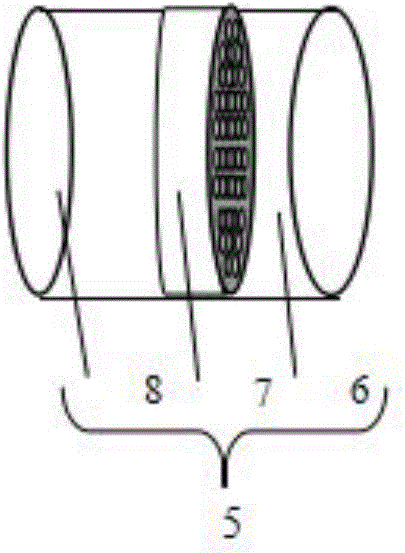

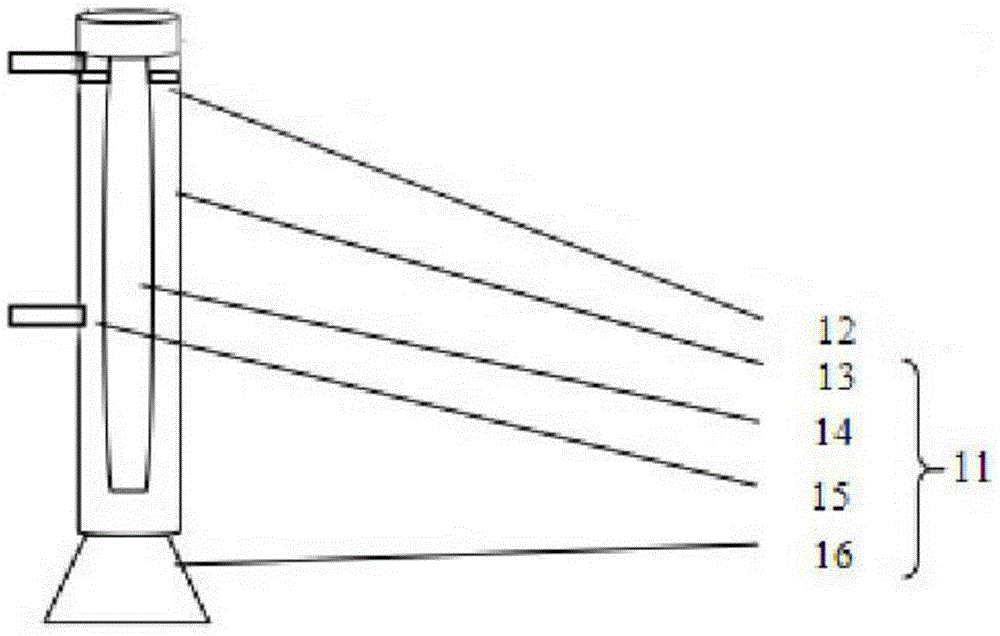

Gaseous mercury monitoring system and control method thereof

The invention discloses a gaseous mercury monitoring system. The gaseous mercury monitoring system comprises a gas carrying device, an enrichment and desorption device, a mercury analysis device, a sampling device, a pretreatment device, a display device and a controller. When the gaseous mercury monitoring system is in a gaseous mercury enrichment state, channels among the sampling device, the pretreatment device and the enrichment and desorption device are communicated and control elements in the devices are started to carry out enrichment; when the gaseous mercury monitoring system is in a desorption state, channels among the gas carrying device, the enrichment and desorption device and the mercury analysis device are communicated and the control elements in the devices are started to carry out desorption measurement; and the display device is connected to a signal output end of the controller and is used for displaying a mercury concentration measurement result produced by the mercury analysis device. The gaseous mercury monitoring system realizes on-line automatic monitoring on environmental gas. The invention also discloses a control method of the gaseous mercury monitoring system.

Owner:BEIJING SDL TECH

Passive sampling device and sampling method of atmospheric reactive gaseous mercury

The invention provides a passive sampling device and a sampling method of atmospheric reactive gaseous mercury. The passive sampling device is characterized in that a wind indicator is respectively connected with a front end air inlet pipe and a rear end air inlet pipe through a fixed bracket, the front end air inlet pipe and the rear end air inlet pipe are connected with each other through an air inlet pipe connecting opening, a concave groove is formed in an inlet of the front end air inlet pipe, the rear end air inlet pipe is in an L-shaped hollow cylindrical structure, a vertical opening of the rear end air inlet pipe is connected to the upper end of a reactive gaseous mercury capture pipe through a rotating shaft, the reactive gaseous mercury capture pipe comprises a capture pipe outer pipe, a capture pipe inner pipe, a fixed bracket and a rain shielding cover, the capture pipe outer pipe is connected with the rotating shaft, the capture pipe outer pipe is connected with the capture pipe inner pipe through an inner-outer pipe bonding point, the outer side of the capture pipe is provided with the fixed bracket, the rain shielding cover is arranged on the lower end of the capture pipe outer pipe, and the inner side of the capture pipe outer pipe and the outer side of the capture pipe inner pipe are respectively in an abrasive structure. By adopting the passive sampling device, no external power supply is needed. After the passive sampling device is arranged on an appropriate site, the guard of people is not needed, and the concentration situation of pollutants within a long time can be monitored.

Owner:TIANJIN UNIV

Sampling gun having filter core for mercury in flue gas

The invention discloses a sampling gun having a filter core for mercury in flue gas. The sampling gun comprises an active carbon adsorption sampling device, the active carbon adsorption sampling device comprises a sampling pipe, a filter screen protecting pipe and a sampler, the sampling pipe is connected with the filter screen protecting pipe through a screw thread, a porous net piece-reeled cylindrical structure is arranged in the filter screen protecting pipe, a rear end of the filter screen protecting pipe is in a convex shape, a front end of the sampler is in a concave shape, the filter screen protecting pipe and the sampler are mutually clamped, a front half part of the sample is an adsorption pipe, a demountable filter membrane is arranged in the adsorption pipe, and an active carbon adsorbent is filled at upper part of the filter membrane. The sampling gun has the advantages of simple operation, low cost, and small volume; a solution absorption sampling device can reflect concentration of gaseous mercury in the flue gas under high temperature and high sulfur environment; and the active carbon adsorption sampling device can reflect concentration of gaseous mercury and particle mercury in low concentration dust environment and the flue gas.

Owner:QINGDAO XINRUNTU NURSERY STOCK SPECIALIZED COOP

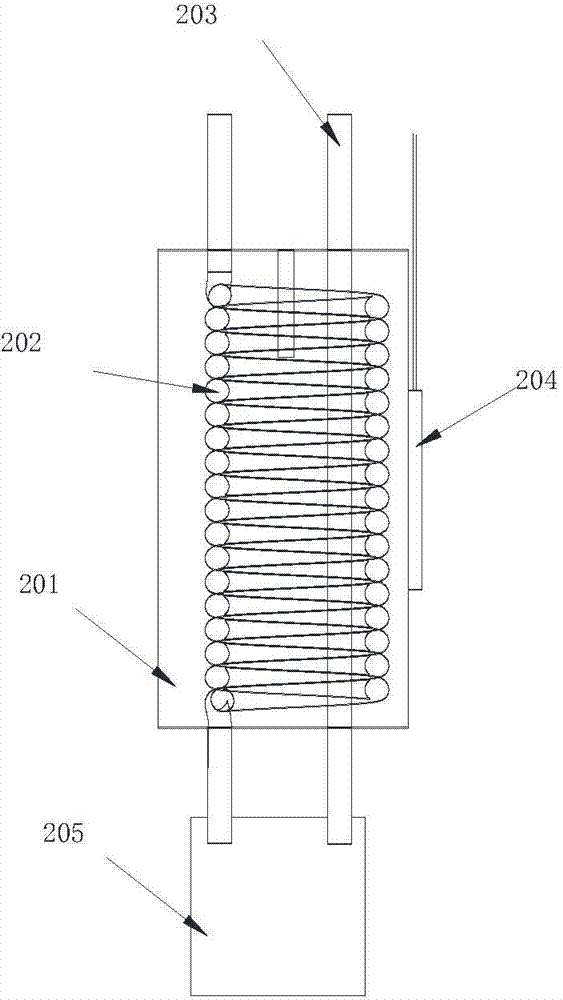

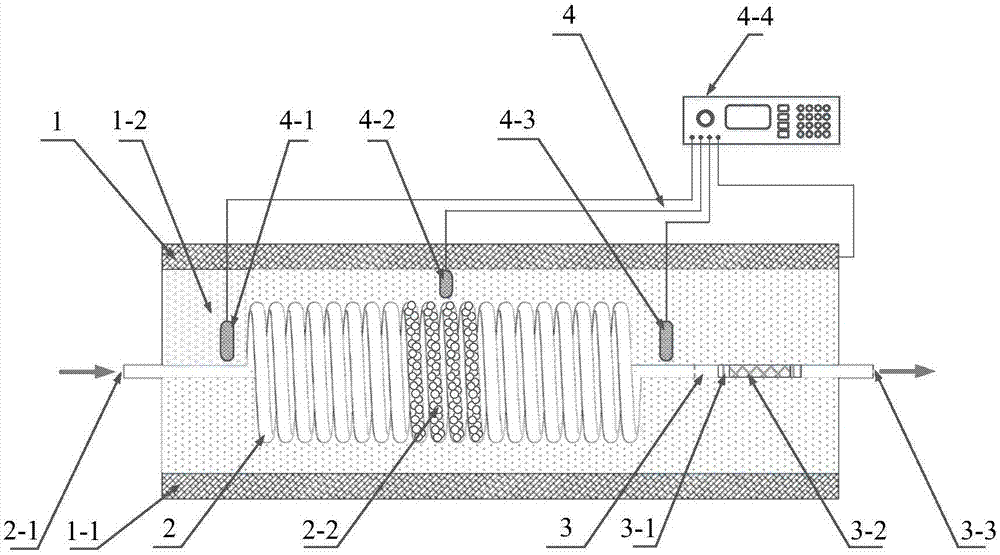

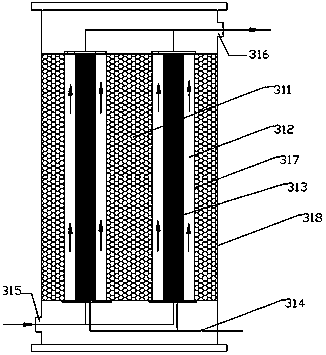

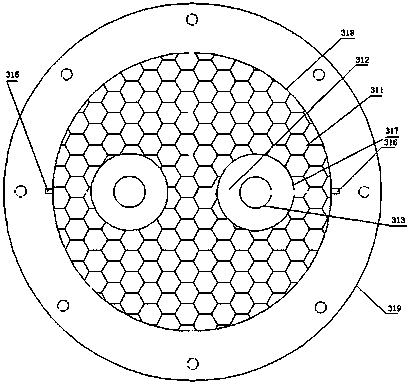

High-temperature pyrolyzing type gaseous mercury form conversion device and method

InactiveCN107238527AAvoid the problem of poison inactivationShort conversion timePreparing sample for investigationFurnace typesHeat fluxTime efficient

The invention discloses a high-temperature pyrolyzing type gaseous mercury form conversion device and a method. The device adopts a high temperature cracking furnace for heating the incoming flue gas on the basis of the high-temperature pyrolyzing characteristic of mercury under oxidation state, the in-furnace pipeline adopts the spiral arrangement for increasing the staying time of the flue gas in the cracking furnace and the heat exchange area of the gas flow in the pipe is expanded; and meanwhile, a granular inertial ceramic heat storage material is filled in a central area of a spiral pipe, the heat flux in the core area is increased, the heating uniformity of the gas flow in the pipe is promoted and the cracking time of the mercury under oxidation state is shortened; and an acidic gas absorbent is filled in a straight pipe on an outlet section of the cracking furnace, so that the secondary oxidation of the mercury under element state is eliminated and the measuring deviation of the mercury concentration is avoided. The device disclosed by the invention can completely realize the conversion of the mercury under oxidation state to the mercury under element state in the gas phase and can realize the real-time efficient conversion and online accurate measurement for the mercury form concentration in the gas phase under a practical flue gas condition.

Owner:SOUTHEAST UNIV

Device for removing gas mercury by photo-catalysis and application thereof

The invention discloses a device for removing gas mercury by photo-catalysis, which adopts the method for loading nanometer TiO2-SiO2 on fibers of a titanium mesh and installing a UV ultraviolet source on the middle part. The gaseous mercury passing through the fibers of the titanium mesh is oxidized as Hg2+ through arranging multi-branched double-cylinder pipe which can be detached in sections in a gas duct, and then the gaseous mercury can be removed through the lime slurry of equipment for removing sulfur by wet process. The reaction sections of the device for removing the gas mercury by photo-catalysis in the invention are separately connected, so the reaction sections can be conveniently detached and changed, the removing efficiency is over 60%, and the economical efficiency is good. Simultaneously the complete device has the advantages of little taken space and good economical efficiency, and the device can be conveniently detached and changed. The device can be applied to the relative fields of removing the gas mercury from power plants, industrial boilers and coal combustion facilities, and has wide prospect on popularization and application of environmental mercury pollution treatment technology.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Gaseous mercury capturing device

ActiveCN107305168AIncrease usageConsistent densityWithdrawing sample devicesAnalysis dataGaseous mercury

The invention relates to a gaseous mercury capturing device which comprises a pipe and a gold wire arranged in the pipe through a limiting support, wherein the melting point of the limiting support is higher than the melting point of the gold wire; and due to the construction of the limiting support, the gaseous mercury can be in contact with the gold wire, so that the gaseous mercury can be adsorbed by the gold wire. According to the invention, the possibility of the change in density on each position caused by the deformation of the gold wire can be controlled and the consistent density of the gold wire on each position can be guaranteed, so that the capability of adsorbing and releasing the mercury after the repeated use of the gaseous mercury capturing device can be guaranteed and the use times of the mercury capturing device can be increased; the reproducibility is high; the analysis data is true and reliable; the reliability of geological interpretation is promoted; the volume is small; and the gaseous mercury capturing device is portable.

Owner:CHINA PETROLEUM & CHEM CORP +1

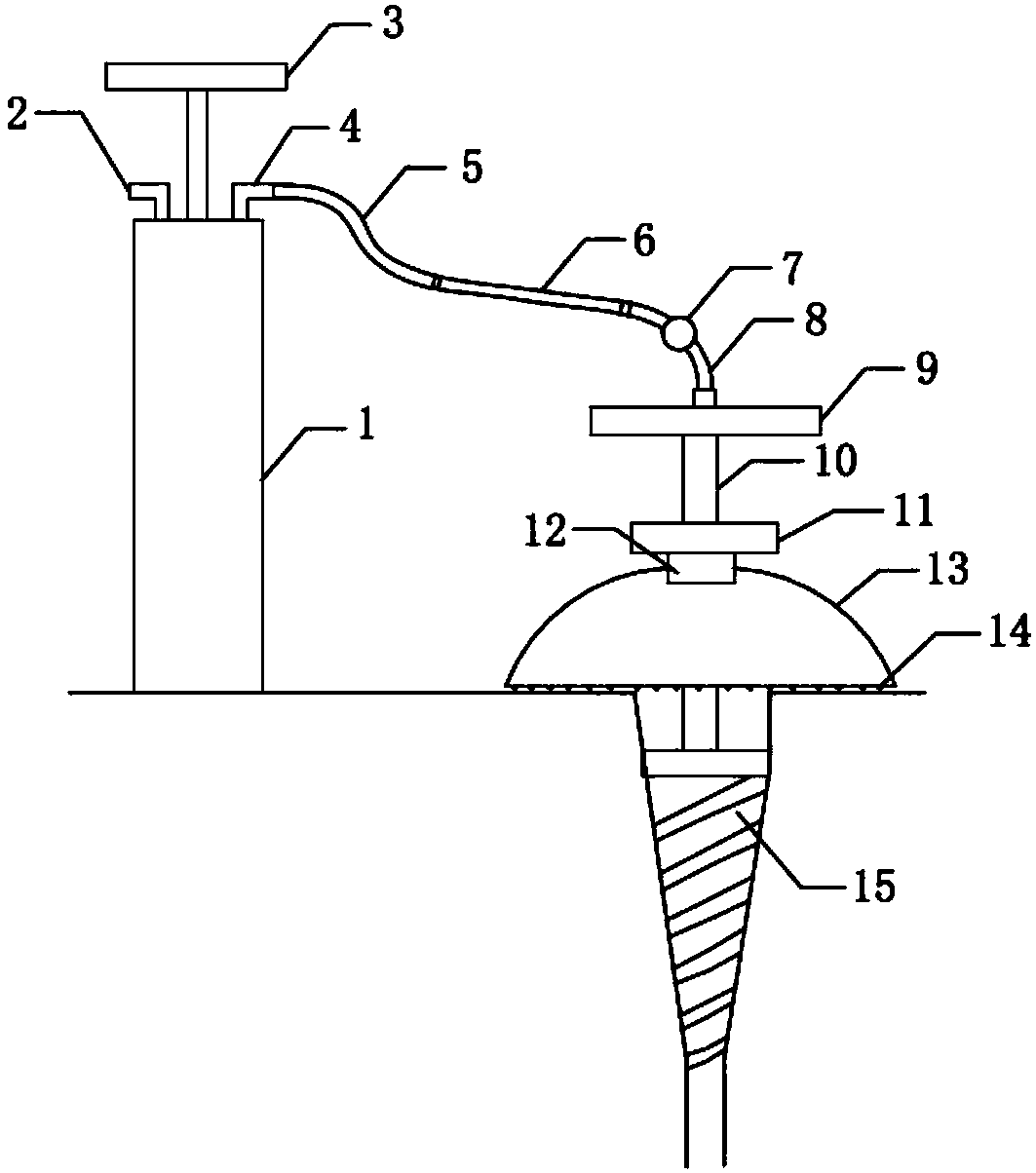

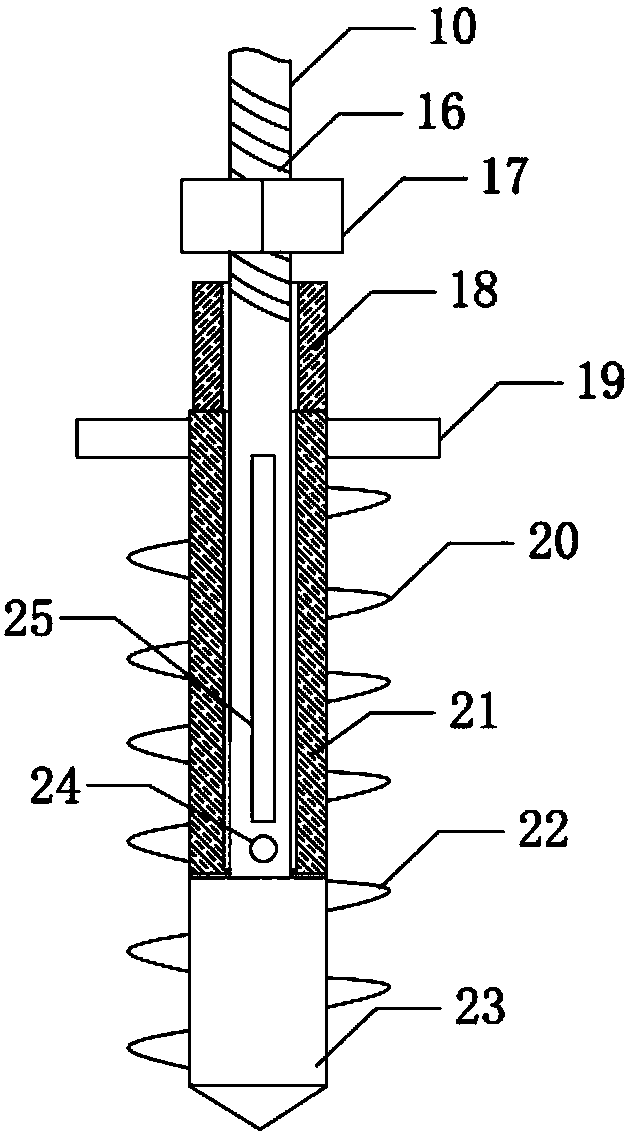

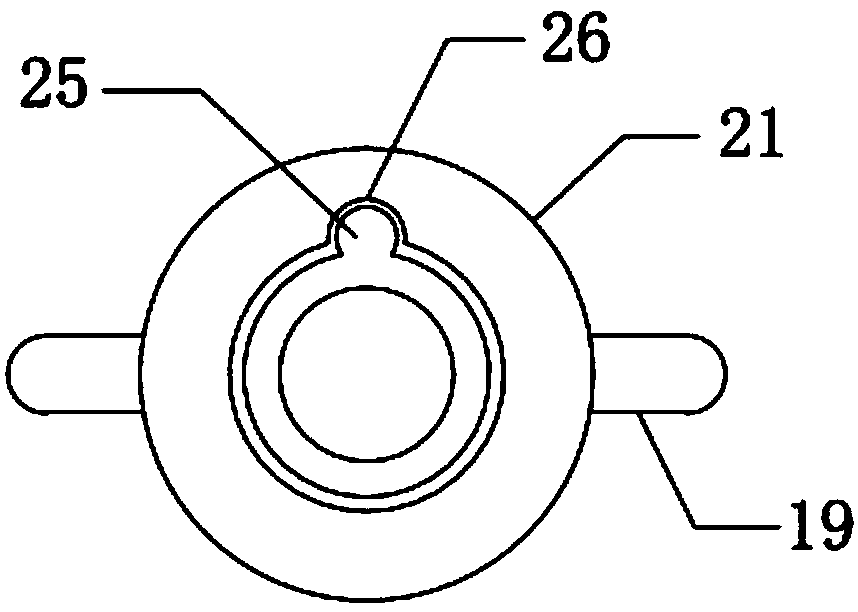

Soil breakage type sampling device for gaseous mercury in soil

InactiveCN108562464AAvoid enteringAccurate collectionWithdrawing sample devicesGaseous mercuryEngineering

The invention discloses a soil breakage type sampling device for gaseous mercury in soil. The soil breakage type sampling device comprises a manual gas extraction pump. A metal wire tube is communicated with an end of a first silicone tube, a second silicone tube is communicated with an end of the metal wire tube, a dust filter is mounted on the second silicone tube, a hollow shaft is communicatedwith an end of the second silicone tube, a slide sleeve slidably sleeves the hollow shaft, a cover is mounted on the slide sleeve, a soil breaking mechanism is mounted on the lower portion of the hollow shaft and comprises a sleeve, the sleeve slidably sleeves the hollow shaft, a drill bit portion is fixedly connected with the lower end of the hollow shaft, a pressing sleeve slidably sleeves thehollow shaft, and a sampling hole is formed in a side of the lower end of the hollow shaft. The soil breakage type sampling device has the advantages that users can acquire gas in the soil without taking out drill bits during sampling, accordingly, the problem of inaccurate sample acquisition due to the fact that gas in air flow into gas in existing soil and is mixed with the gas in the existing soil can be solved, and the gaseous mercury can be conveniently and quickly sampled by the soil breakage type sampling device during sampling.

Owner:山东省地质调查院

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com