Patents

Literature

74results about How to "Guaranteed adsorption efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

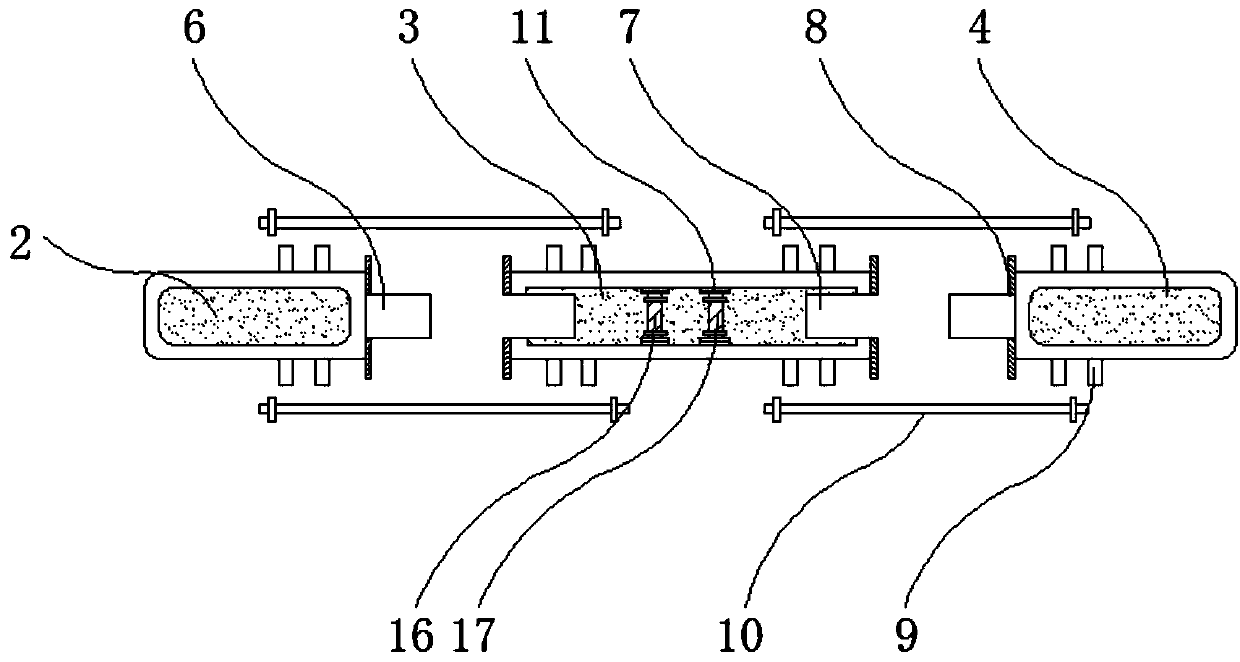

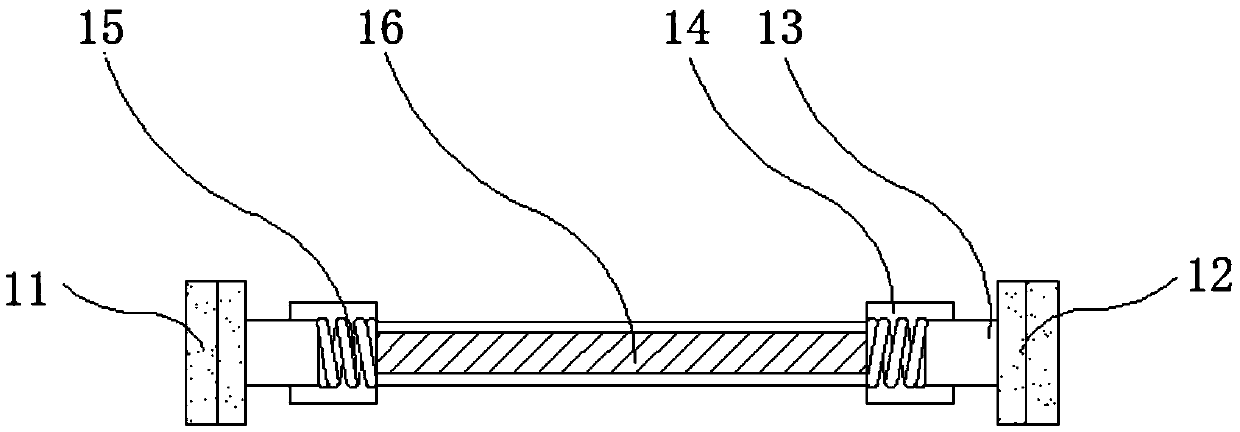

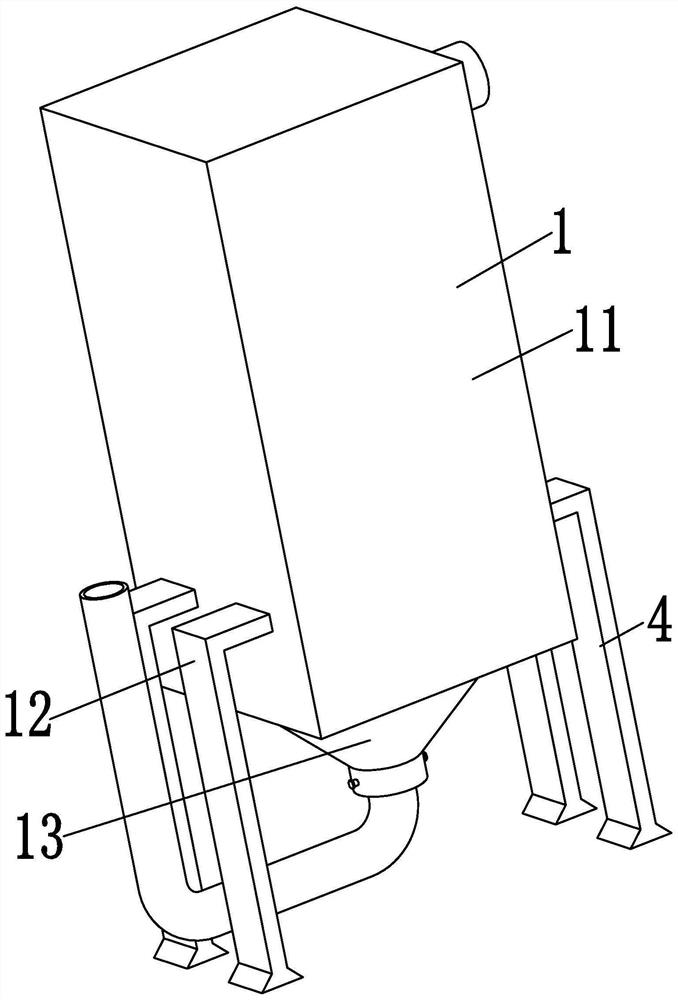

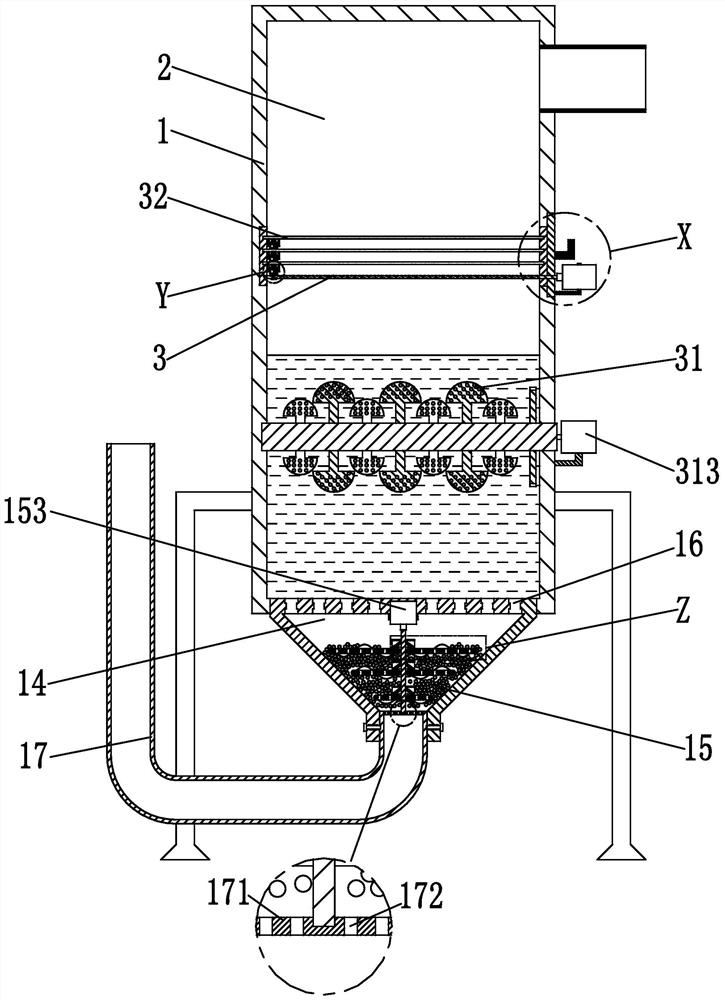

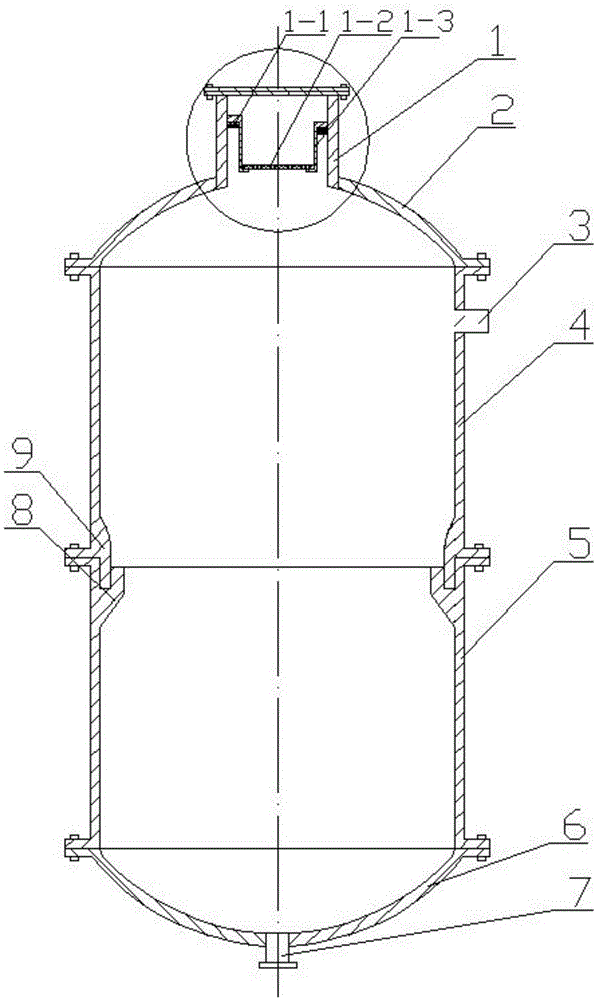

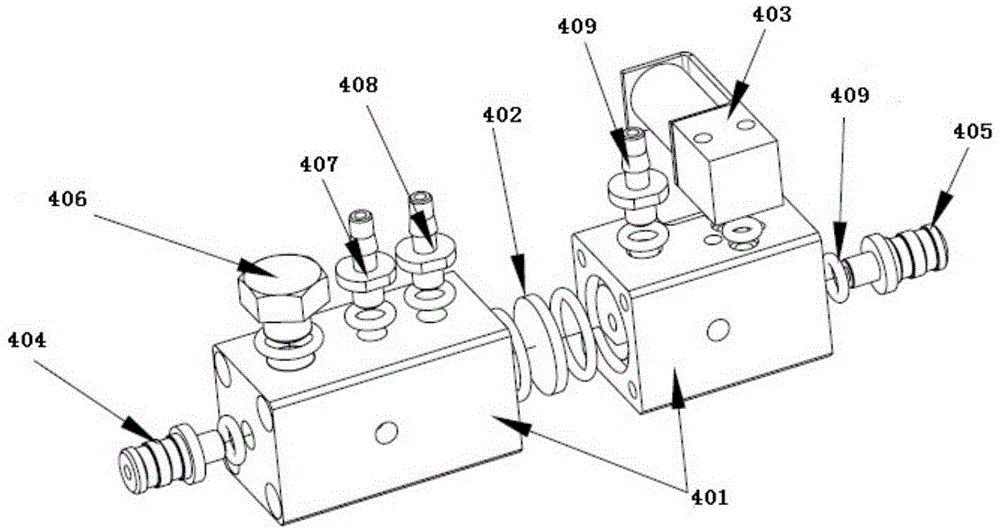

High-efficiency energy-saving activated carbon fiber organic waste gas recycling system

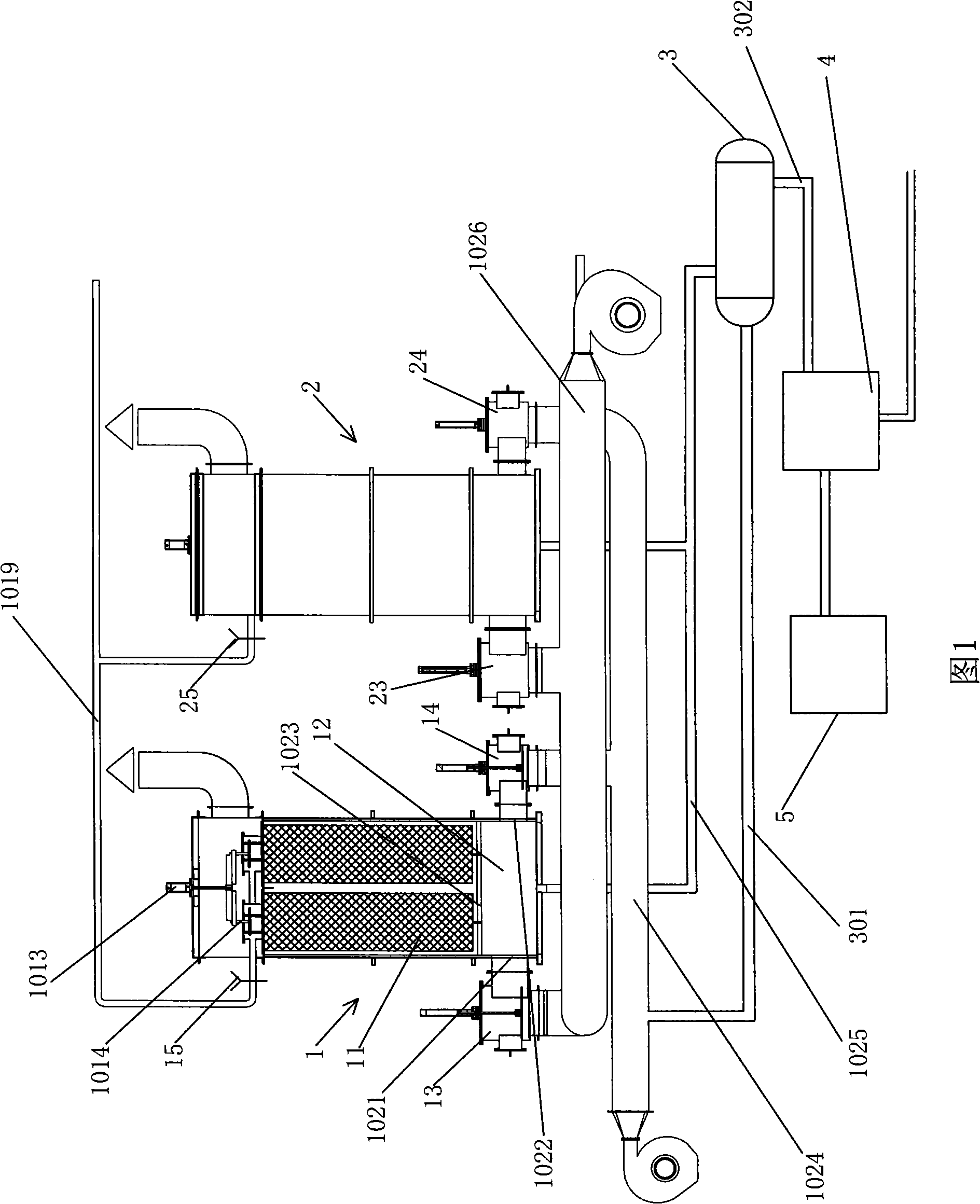

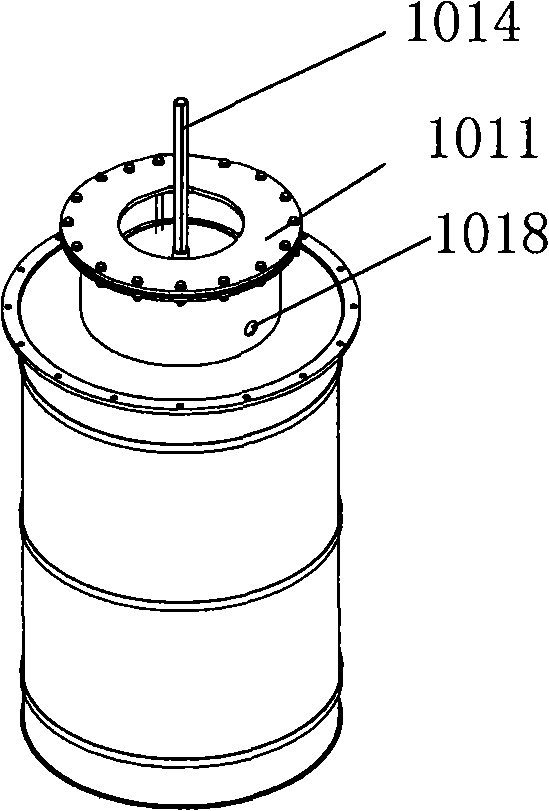

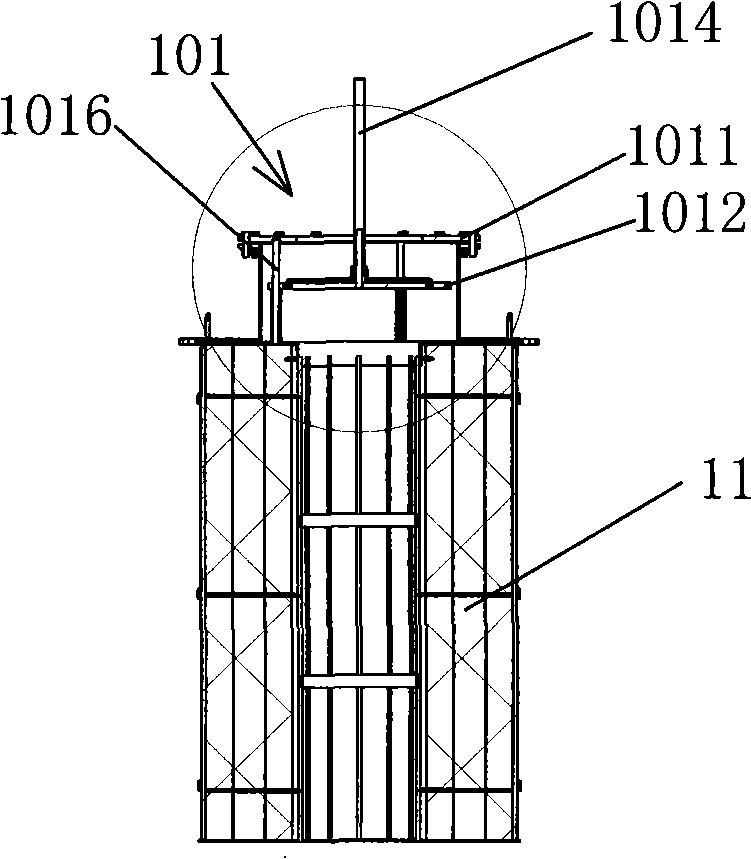

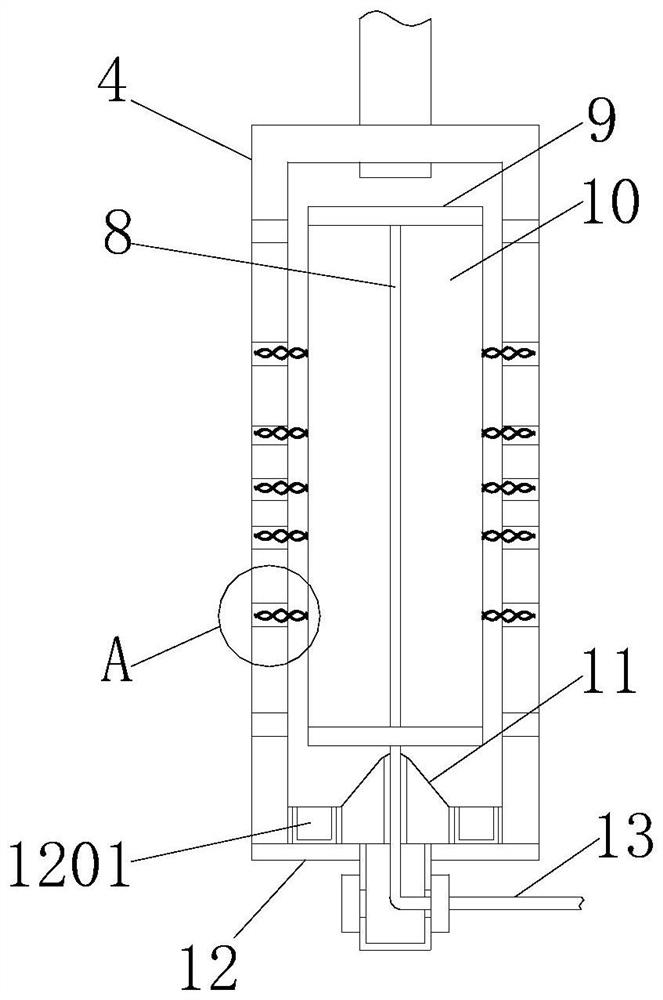

The invention disclose a high-efficient energy saving type activated carbon fiber organic exhaust gas recovery system, comprising at least two active charcoal adsorbers, an adsorption filter element arranged inside the active charcoal adsorbers, a valve provided with an embedded type valve core for the adsorption filter element; the valve comprises a flange, a sealing pad and an unsealing air cylinder; the flange is fixed above the adsorption filter element; the sealing pad as the valve core is arranged in a cavity which is composed of the flange and the adsorption filter element; the unsealing air cylinder is fixed above the sealing pad and is connected with the sealing pad by a connecting rod; the size of the sealing pad is adapted with the caliber of the flange. The sealing pad is arranged in the cavity which is composed of the flange and the adsorption filter element; the sealing pad is controlled by the unsealing air cylinder to seal a flange port from bottom to top; a sealing direction of the sealing pad is the same as an impact direction of the vapor in the course of the adsorption; therefore, the higher a vapor pressure is, the better the sealing effectiveness is.

Owner:QINGDAO HSJ ENVIRONMENTAL PROTECTION TECH CO LTD

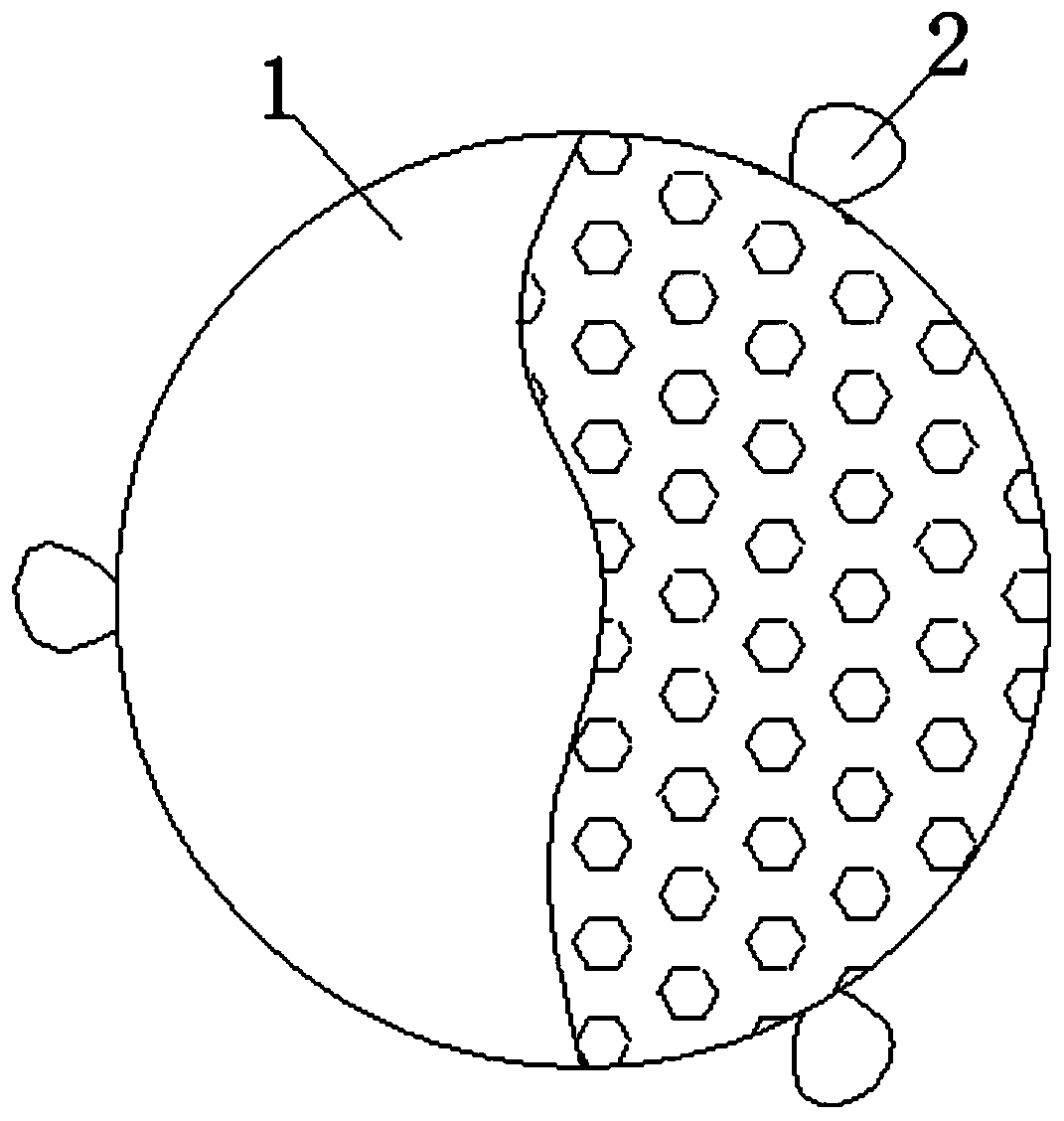

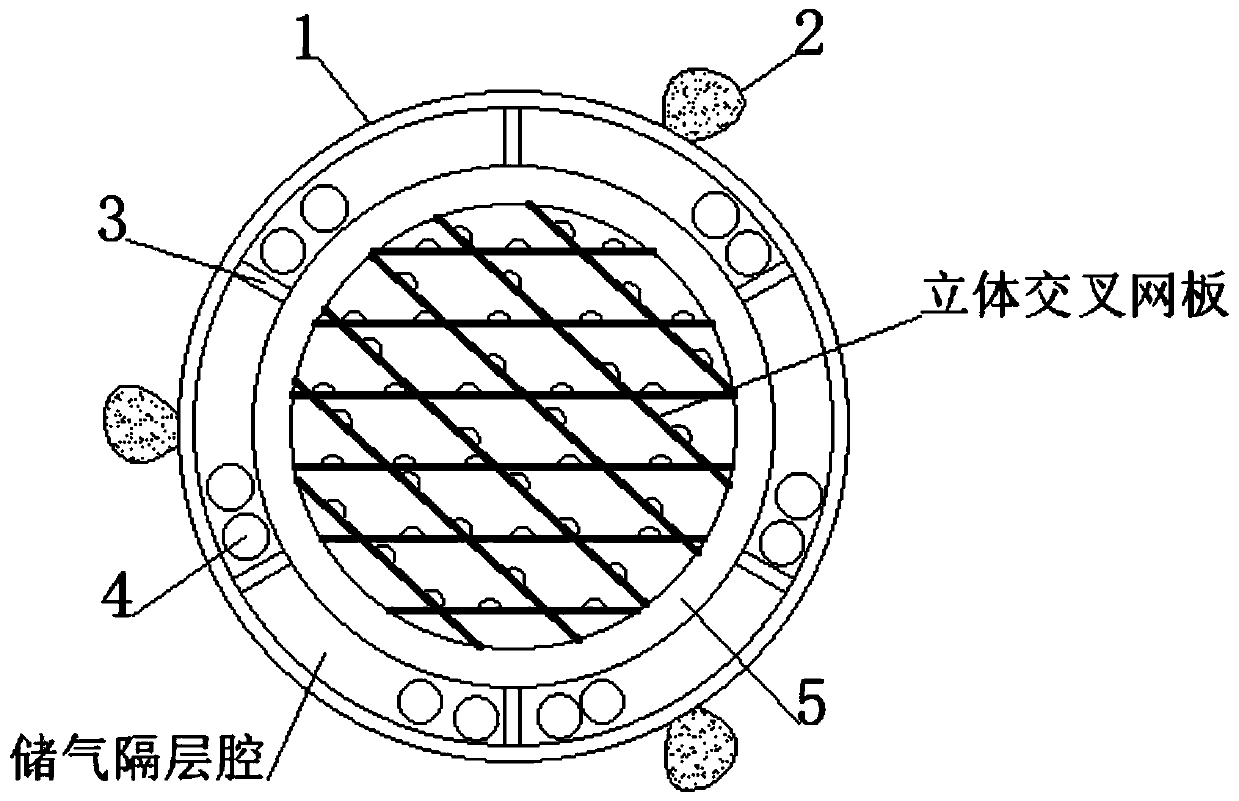

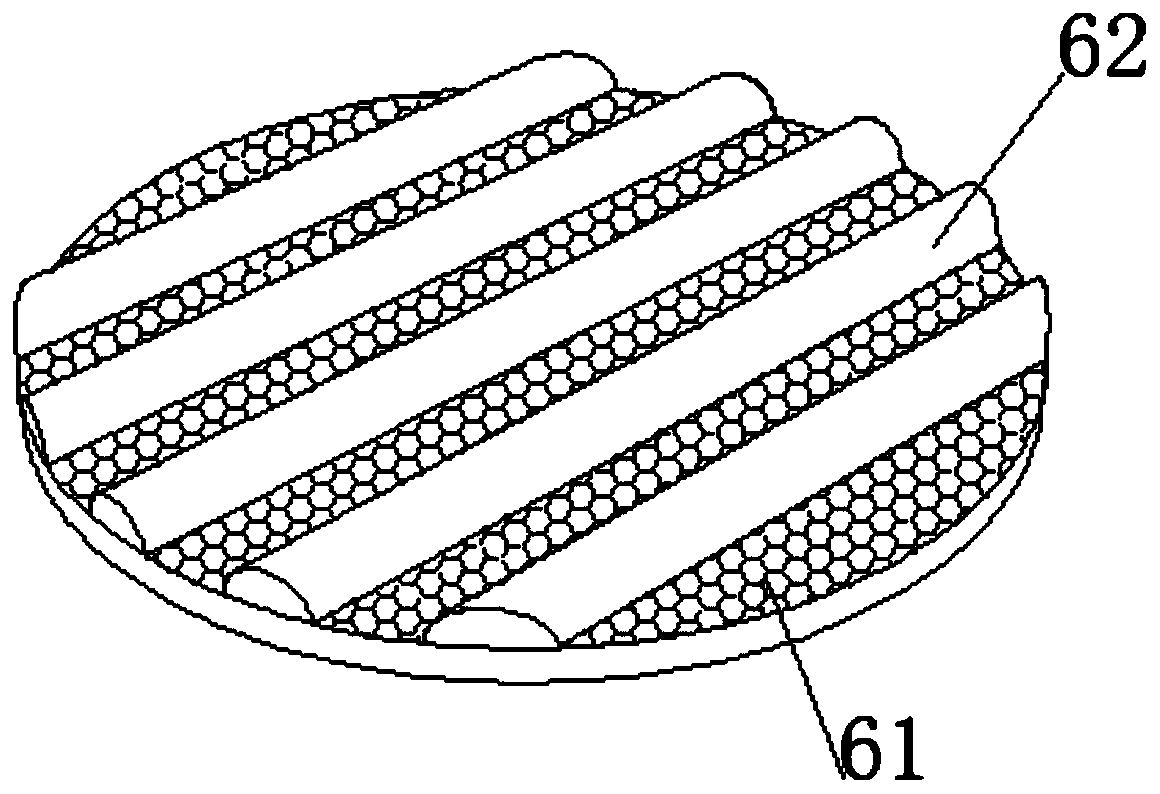

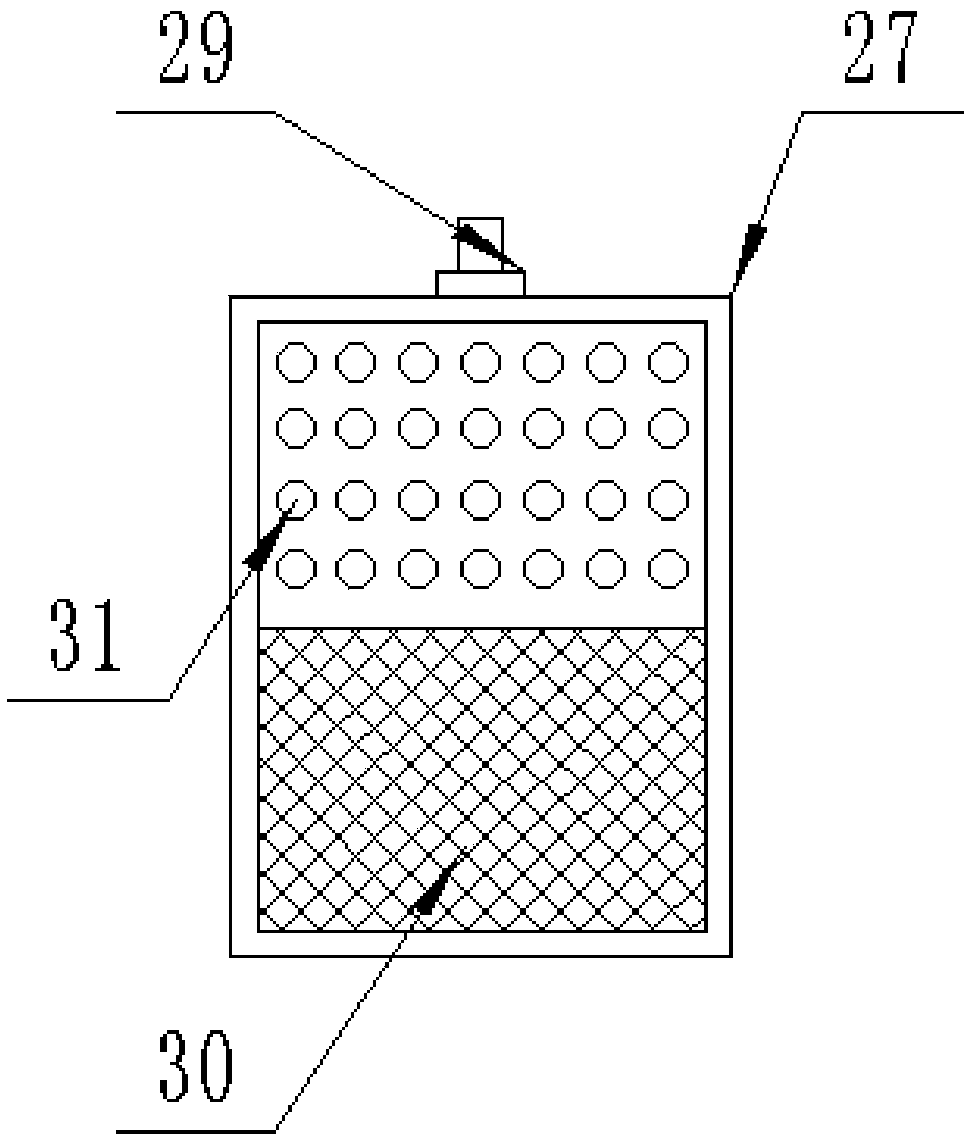

Laminated adsorption ball for flue gas filtration

InactiveCN110711440AGuaranteed adsorption efficiencyNot easy to gatherDispersed particle filtrationFlue gasFiltration

The invention discloses a laminated adsorption ball for flue gas filtration, and belongs to the field of flue gas adsorption environmental protection. According to the laminated adsorption ball for flue gas filtration, a plurality of outer interval vertex angles can be arranged, and when a plurality of the adsorption balls are placed together, a gap is formed between every two adsorption balls, sothat flue gas can smoothly enter the plurality of adsorption balls, the adsorption balls are unstable under the impact of flue gas, the effect of the steel balls in a gas storage interlayer cavity ismatched to allow the adsorption balls to shake, the position of an adsorbent in the adsorption balls can be changed along with the shaking of the adsorption balls all the time so that the adsorbent can adsorb flue gas more uniformly, and the adsorption efficiency is improved. After the flue gas enters three-dimensional crossed net plates, the permeability between the three-dimensional crossed netplates enables the liquidity between the flue gas to be good, then the time of the flue gas passing through the adsorbent in the inner transparent shell is effectively prolonged, and therefore the flue gas adsorption effect is further improved.

Owner:徐州顺平生物科技有限公司

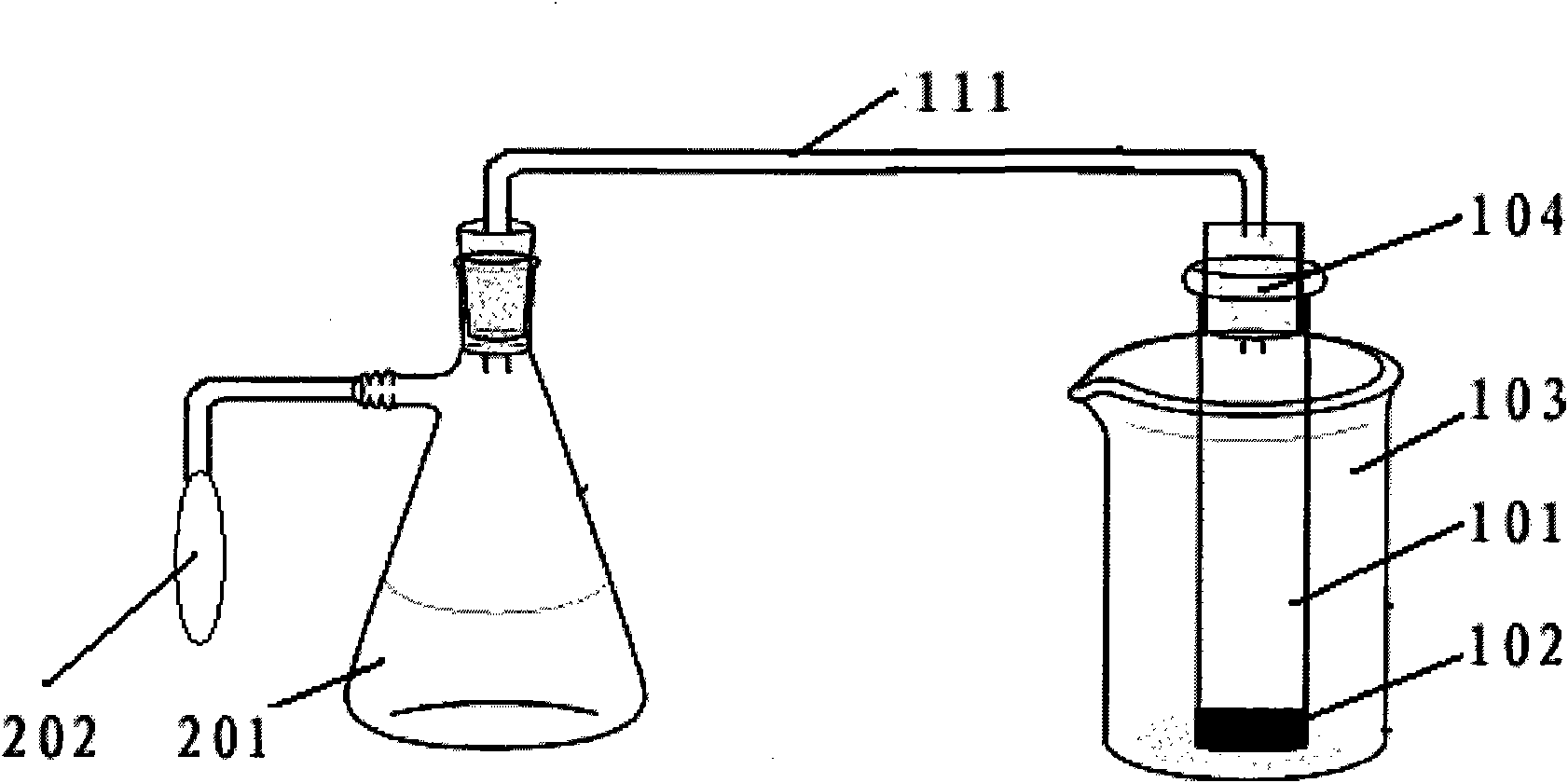

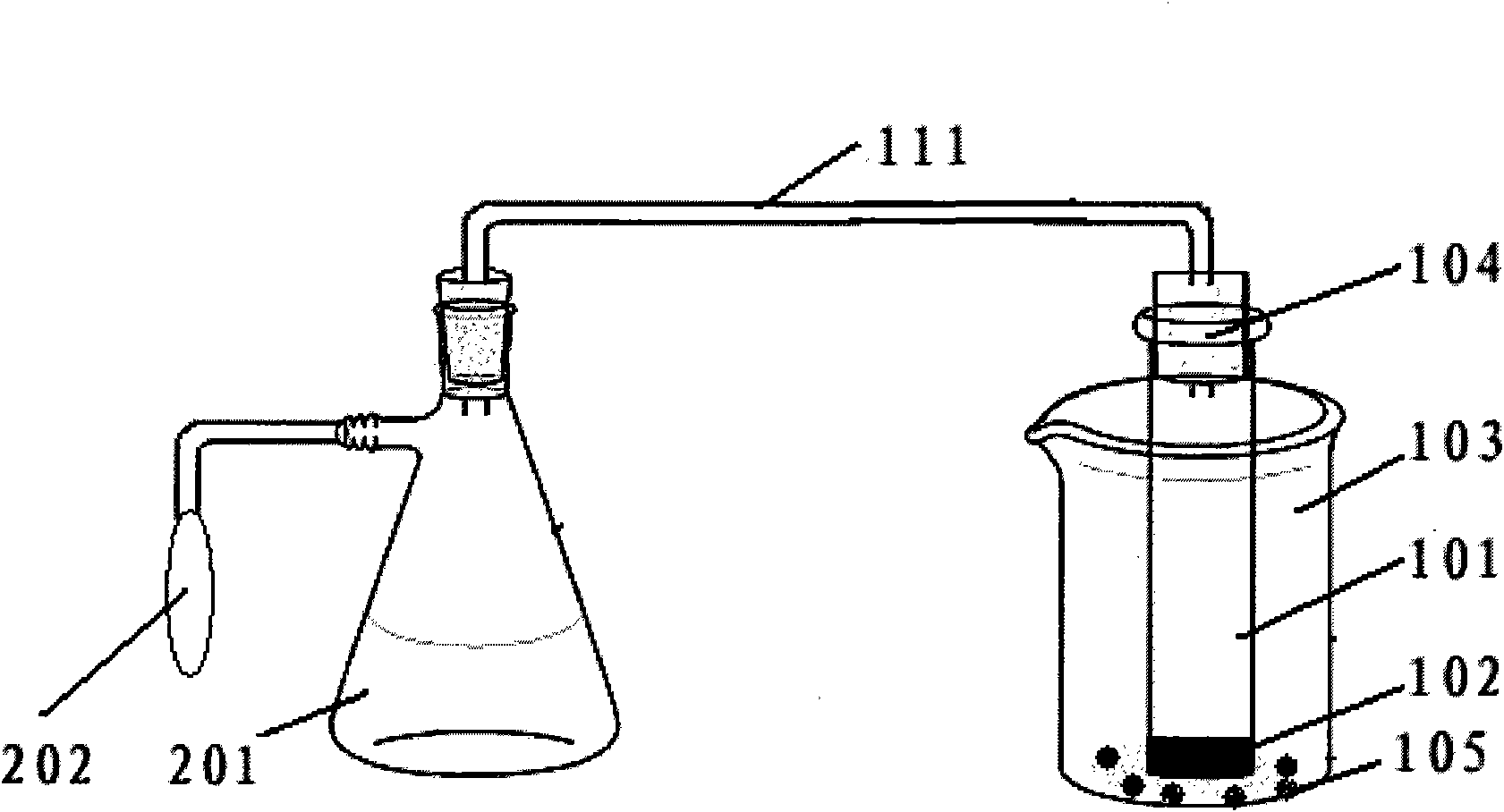

Monolithic silica gel adsorption column, and solid phase extraction device and application thereof

InactiveCN101628223AIncreased convective mass transfer speedGuaranteed adsorption efficiencyComponent separationOther chemical processesChemistrySol-gel

The invention relates to a monolithic silica gel adsorption column, and a solid phase extraction device and application thereof. The monolithic silica gel adsorption column is prepared by a sol-gel method. The solid phase extraction device comprises a container, a solid phase extraction column, a filter flask, and a water circulating vacuum pump; and the lower end of the solid phase extraction column is provided with the monolithic silica gel adsorption column. The monolithic silica gel adsorption column is applied to solid phase extraction; compared with the common particle filler, the convective mass transfer speed of the monolithic silica gel adsorption column is greatly improved, samples can be quickly distributed in balance between a mobile phase and a fixed phase, and the monolithic silica gel adsorption column ensures purification and enrichment effects and realizes quick purification and enrichment of analyzed substances.

Owner:EAST CHINA UNIV OF SCI & TECH

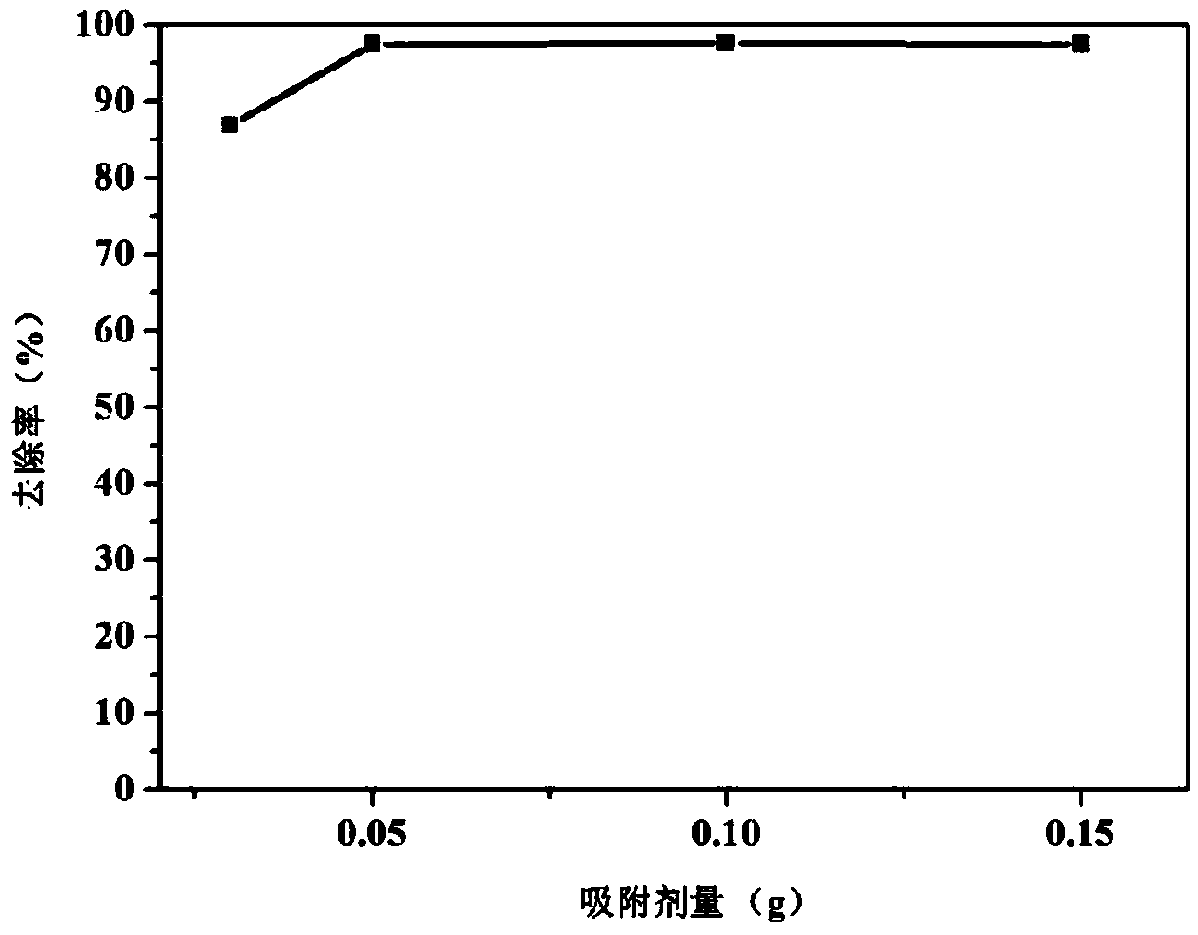

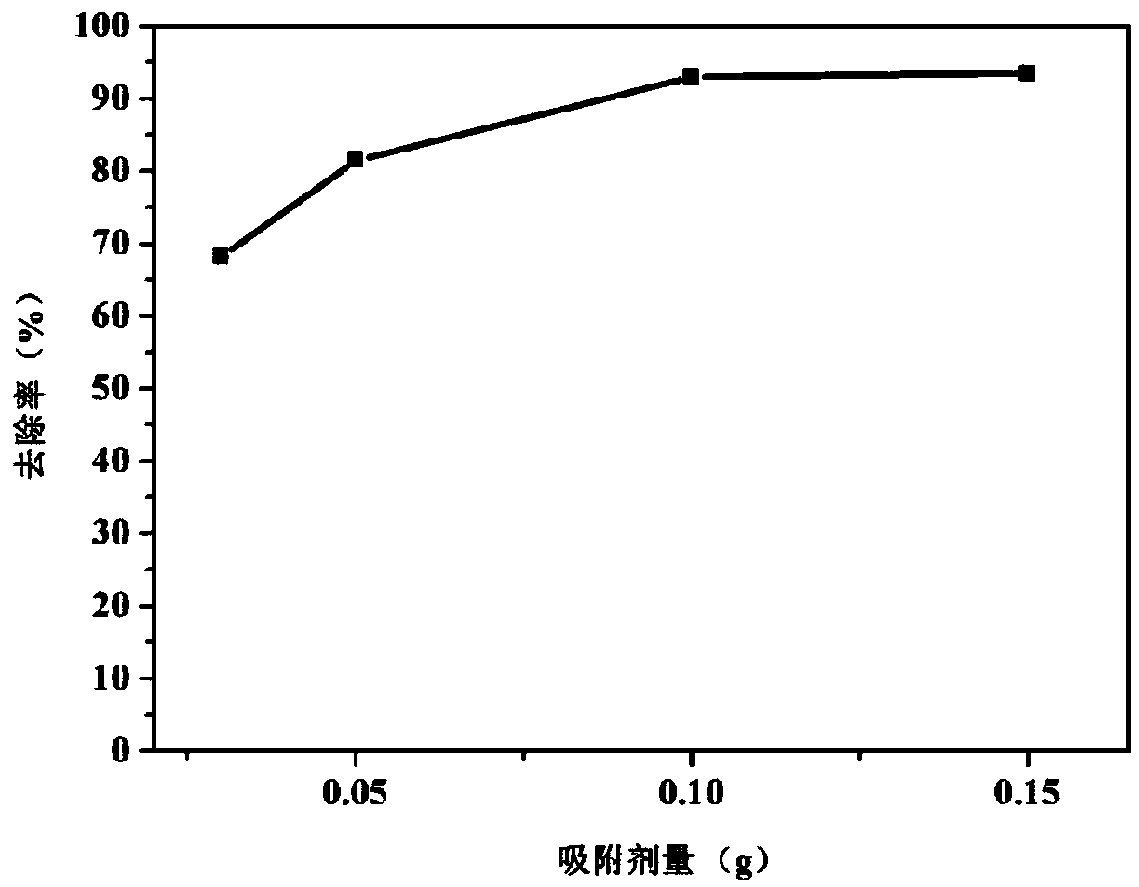

Heavy metal ion porous adsorbent as well as preparation method and application thereof

ActiveCN107446096AControl Aperture SizeLow densityOther chemical processesWater contaminantsSorbentAdsorption effect

The invention provides a heavy metal ion porous adsorbent as well as a preparation method and application thereof. The preparation method of the heavy metal ion porous adsorbent comprises the following steps: (1) dropwise adding a dispersion phase containing an initiator and an electrolyte into a continuous phase containing ethyl glycidyl acrylate, divynyl benzene and an emulsifier, thus obtaining concentrated emulsion; (2) carrying out polymerization reaction on the concentrated emulsion, and washing and drying a polymerization reaction product, thus obtaining a porous polymer; (3) carrying grafting reaction on polyacrylic acid and the porous polymer under the existence of a catalyst, thus obtaining the heavy metal ion porous adsorbent. The heavy metal ion porous adsorbent provided by the invention has good adsorption effect on various heavy metal ions.

Owner:CRRC TANGSHAN CO LTD

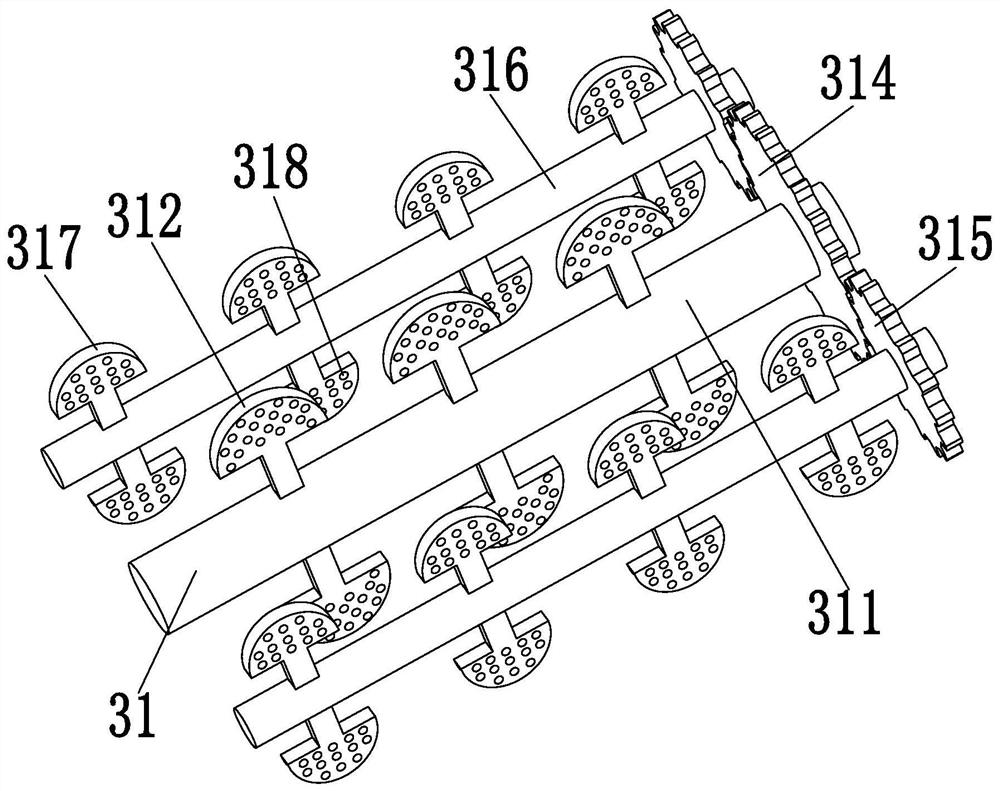

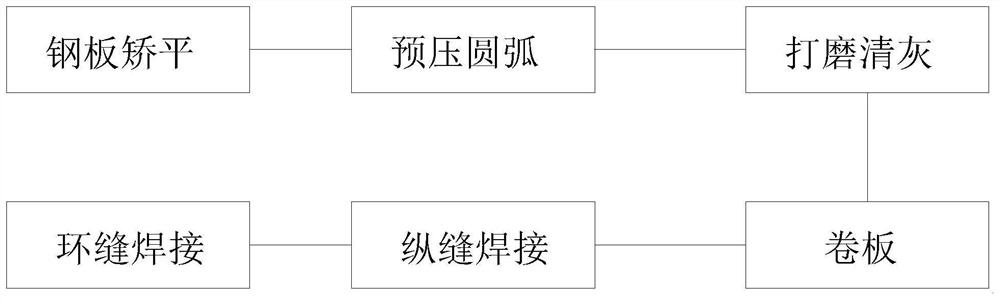

Worrkpiece polishing device

InactiveCN108515451AReduce energy consumptionReduce manufacturing costGrinding carriagesGrinding work supportsEngineeringMechanical engineering

The invention belongs to the technical field of polishing equipment, and particularly discloses a worrkpiece polishing device. The worrkpiece polishing device comprises a machine frame. A workbench and a supporting plate are arranged on the machine frame, a fixing plate and a suction disc are arranged on the workbench, an air cylinder, a fixing block and a guide rail are arranged on the fixing plate, and a transverse rod is arranged on a piston rod of the air cylinder. A ratchet and pawl structure is arranged on the piston rod, and a ratchet in the ratchet and pawl structure meshes with a rack. A sliding hole is formed in the fixing block, a sliding rod is arranged in the sliding hole and connected with the rack, and hole channels are connected between the sliding hole and through holes. Aservo motor is arranged on a track, a polishing disc and a second gear are arranged on an output shaft of the servo motor, and the second gear meshes with convex teeth. Switches which control the servo motor to backwards rotate are arranged at the two ends of the track. The worrkpiece polishing device is mainly used for polishing parts, and solves the problem that due to the fact that a pluralityof clamping power mechanisms are arranged when parts are polished, the processing cost is increased.

Owner:宁波鑫神泽汽车零部件有限公司

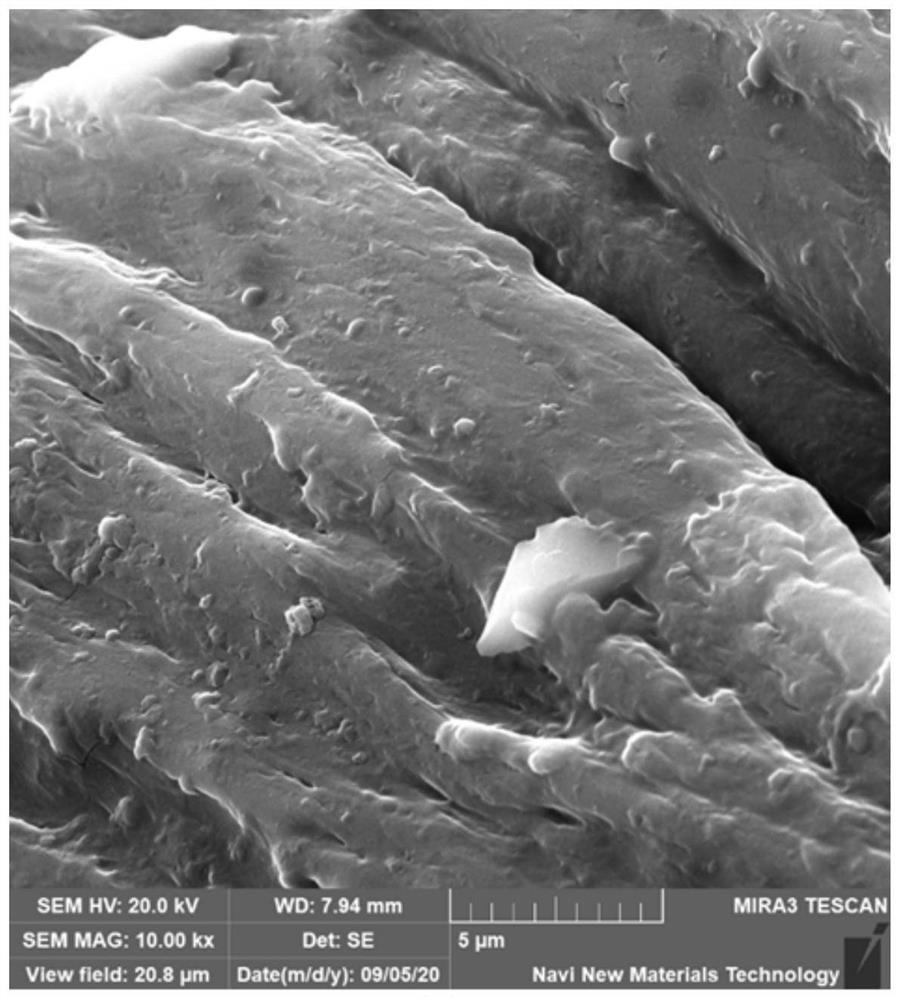

Layer-by-layer self-assembled coating modified cotton fiber heavy metal ion adsorption material and preparation method thereof

InactiveCN108854978ASimple processEasy to operateOther chemical processesWater contaminantsFiberAqueous solution

The invention relates to a layer-by-layer self-assembled coating modified cotton fiber heavy metal ion adsorption material. The adsorption material consists of a base material and a modified layer, wherein the base material is cotton fibers, the modified layer comprises one or more groups of layer-by-layer self-assembled coatings, and the layer-by-layer self-assembled coating is an electropositiveassembled layer and an electronegative assembled layer which are modified on the surface of the base material by virtue of an electrostatic layer-by-layer self-assembled coating. The modified cottonfiber not only has higher adsorption efficiency, but also overcomes the problems that the existing heavy metal adsorption material is difficult to recycle in an aqueous solution after completing the adsorption, and is high in application prospect.

Owner:HANGZHOU DIANZI UNIV

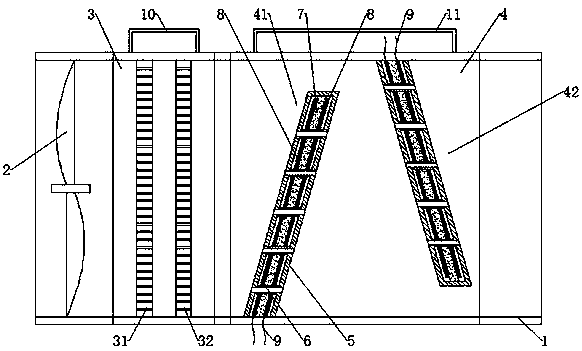

Clean sealed boiler flue gas desulfurization and denitration device with filtering function

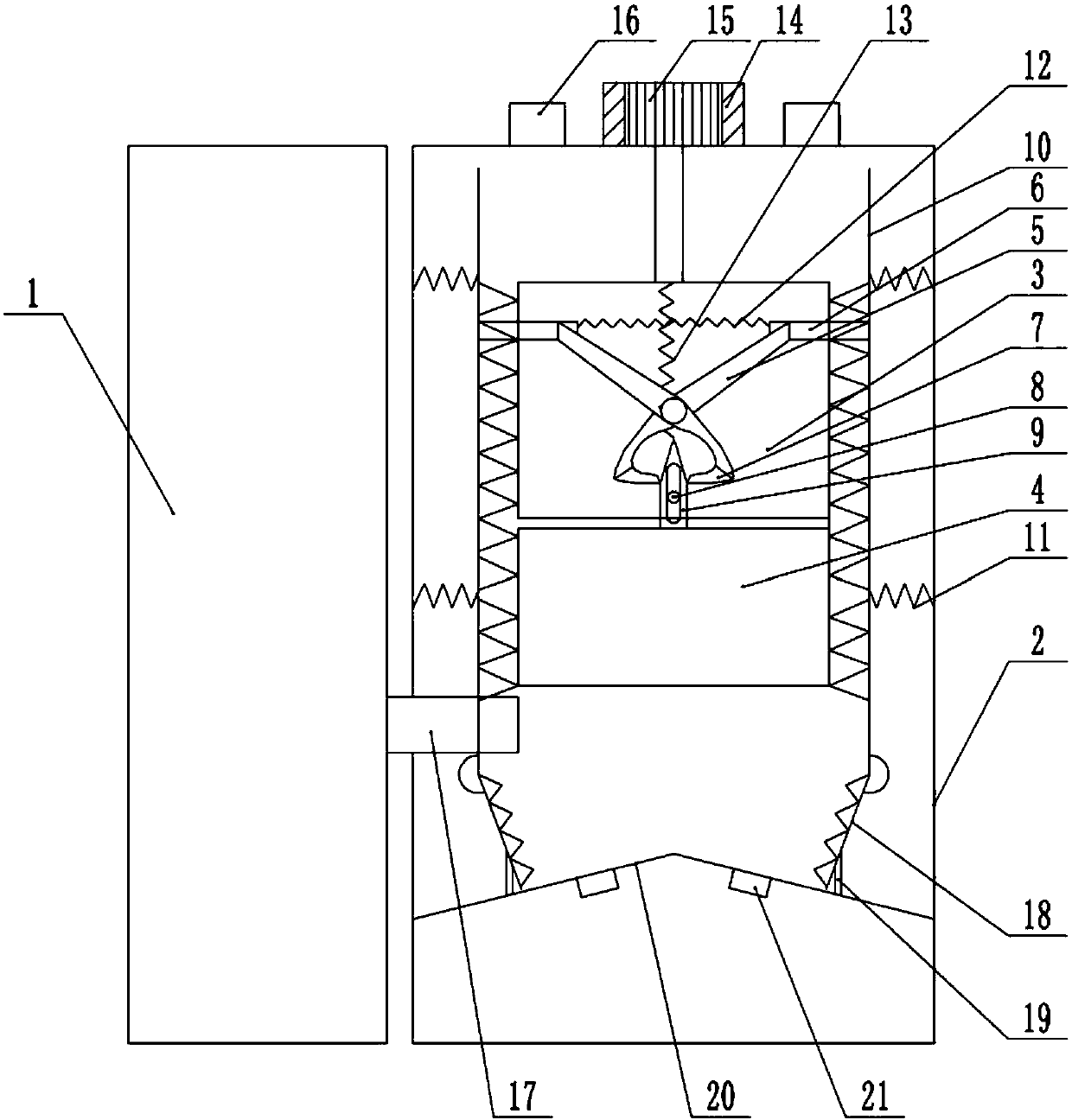

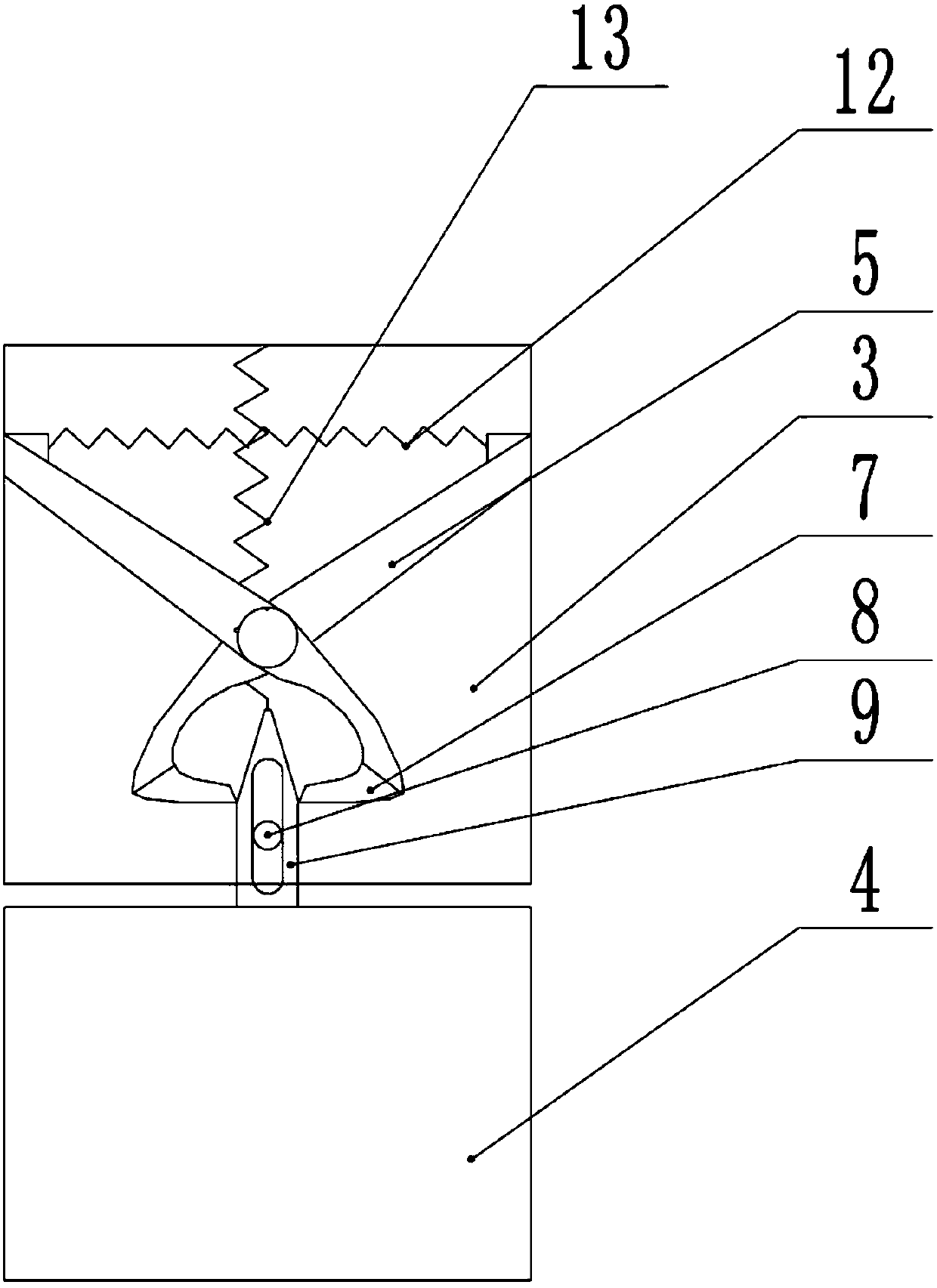

InactiveCN109248550AEasy to clean and unclogImprove sealing performanceDispersed particle filtrationHollow article cleaningDrive motorEngineering

The invention discloses a clean sealed boiler flue gas desulfurization and denitration device with a filtering function. The device comprises a boiler body, a placement strip, a cooling tower, a fixing ring, and a water pump, the upper end of the boiler body is seamlessly connected with a smoke-outlet pipe, the outer wall of the cooling tower is seamlessly connected to the input end of a smoke-inlet pipe, the output end of a driving motor is flanged to a rotating shaft, the fixing ring is fixedly welded to the inner bottom end of the cooling tower, and the output end of a condensing tube is injection-connected to a collecting pipe. The clean sealed boiler flue gas desulfurization and denitration device with filtering function has a connection manner of slot connection between the smoke-outlet pipe and the connecting pipe and between the connecting pipe and the smoke-inlet pipe, a user can conveniently perform disassembly and assembly between the smoke-outlet pipe and the connecting pipe and between the connecting pipe and the smoke-inlet pipe, the situation that the pipe connection is too long and the inside is prone to blockage is avoided, so that the user can timely dredge and clean the inside of the pipe, and a sealing gasket is beneficial to increase of the sealing performance between the pipes.

Owner:余汉锡

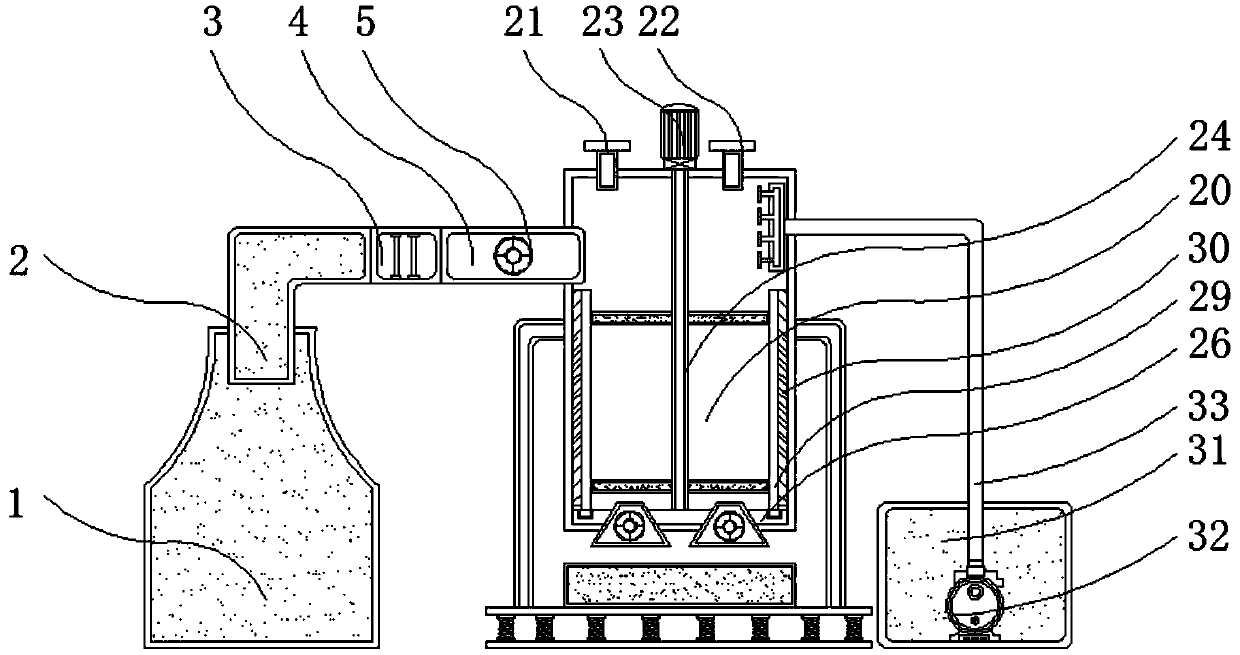

Operation method of recycling process system for treating VOCs (volatile organic compounds) waste gas

ActiveCN109675410ALower ignition pointImprove the heating effectGas treatmentOther chemical processesProcess systemsDesorption

The invention relates to the technical field of environmental protection, and particularly to an operation method of a recycling process system for treating a VOCs (volatile organic compounds) waste gas. The operation method is characterized in that the effective treatment of the VOCs waste gas and the recycling of an adsorbent are realized through a desorption thermal decomposition furnace, a chain drive grate bed and an adsorbent moving bed.

Owner:陕西安进科技发展有限责任公司

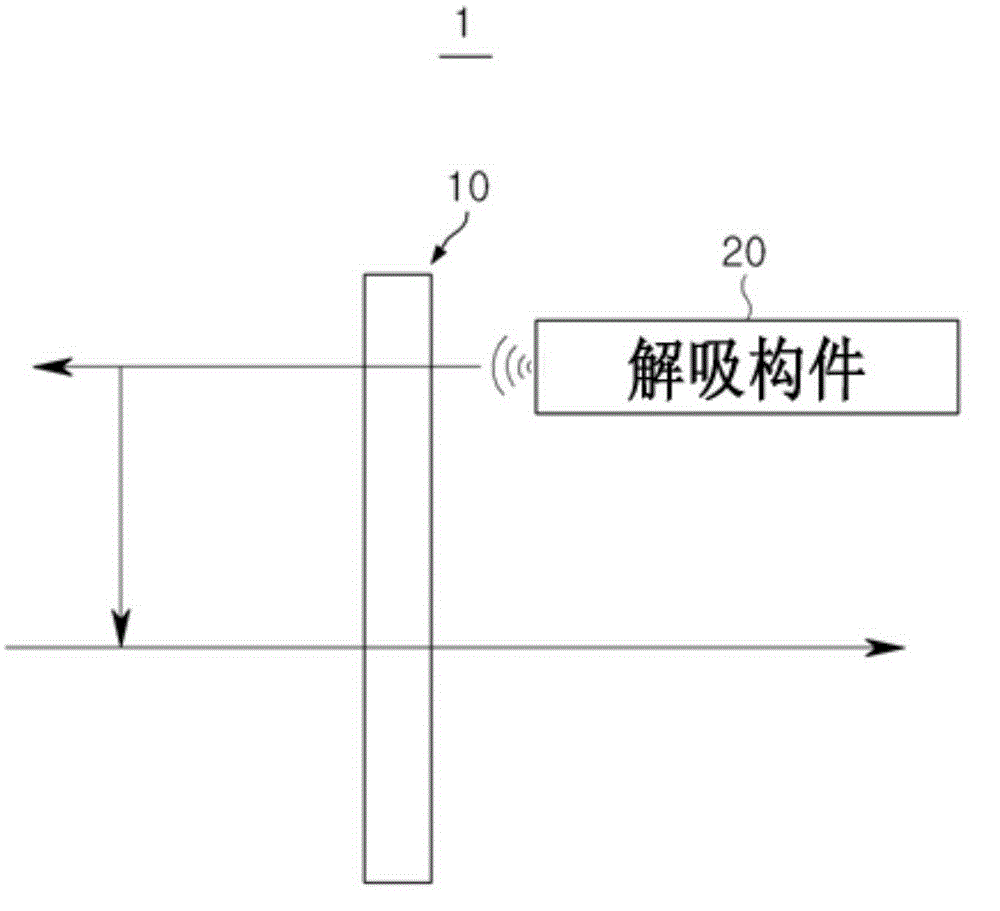

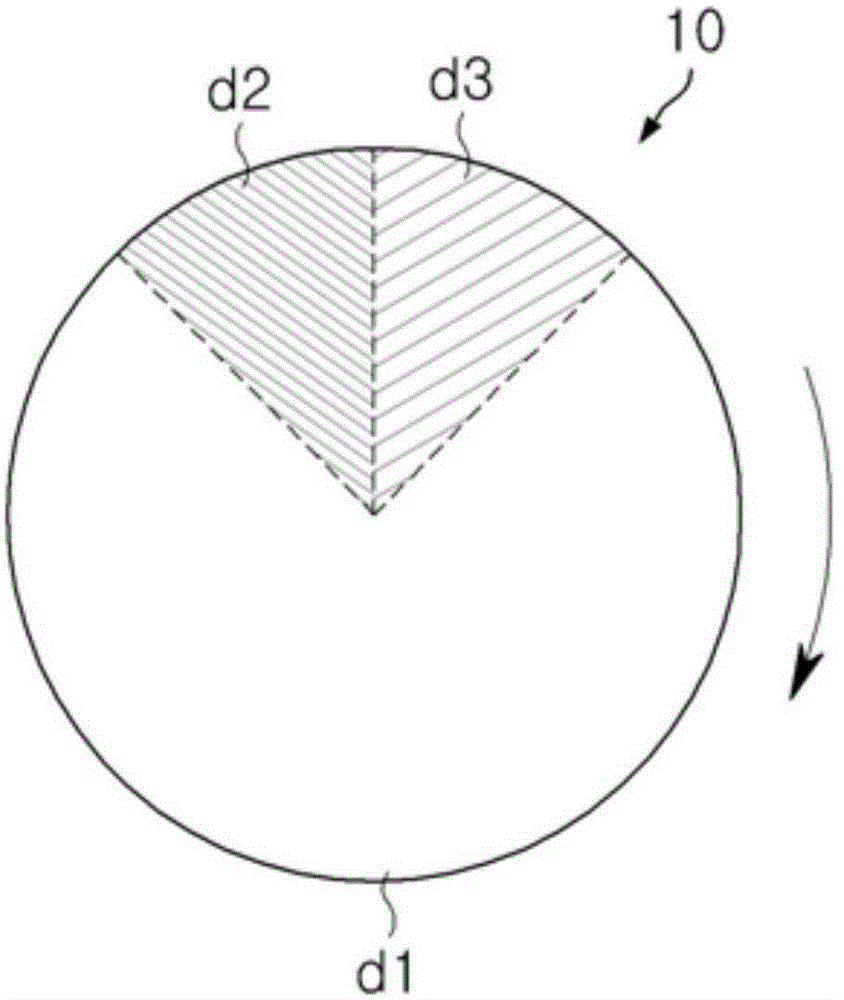

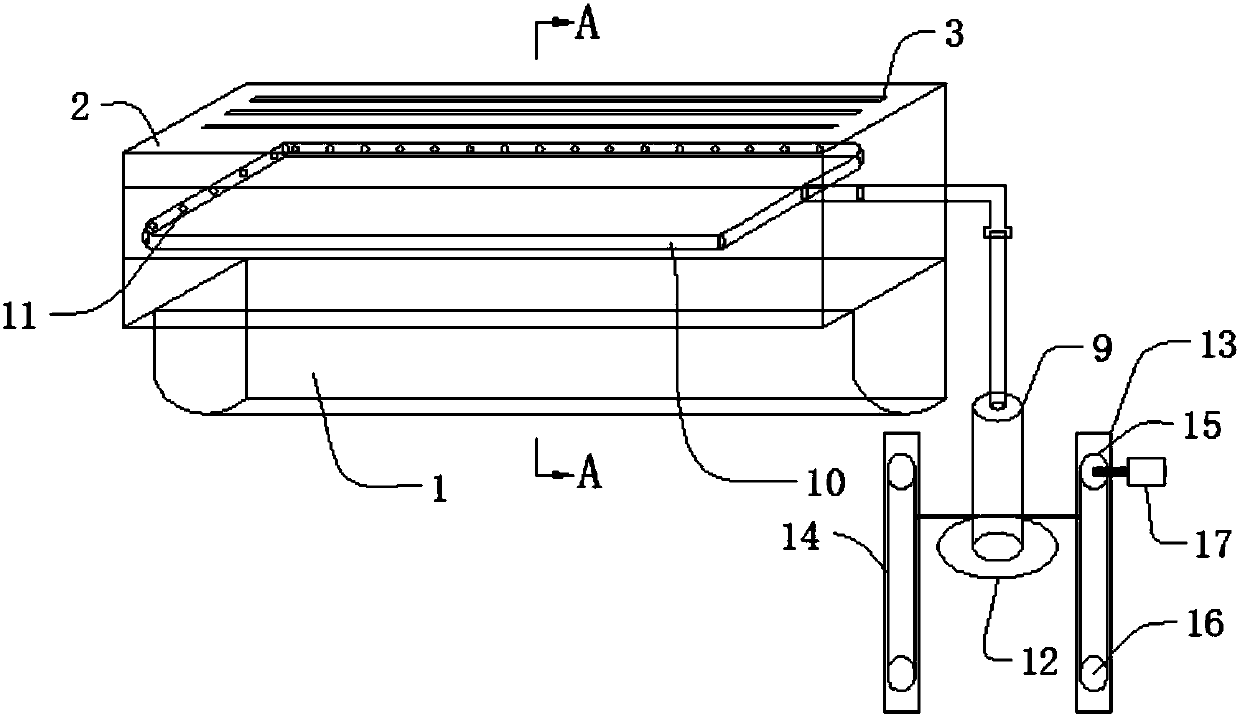

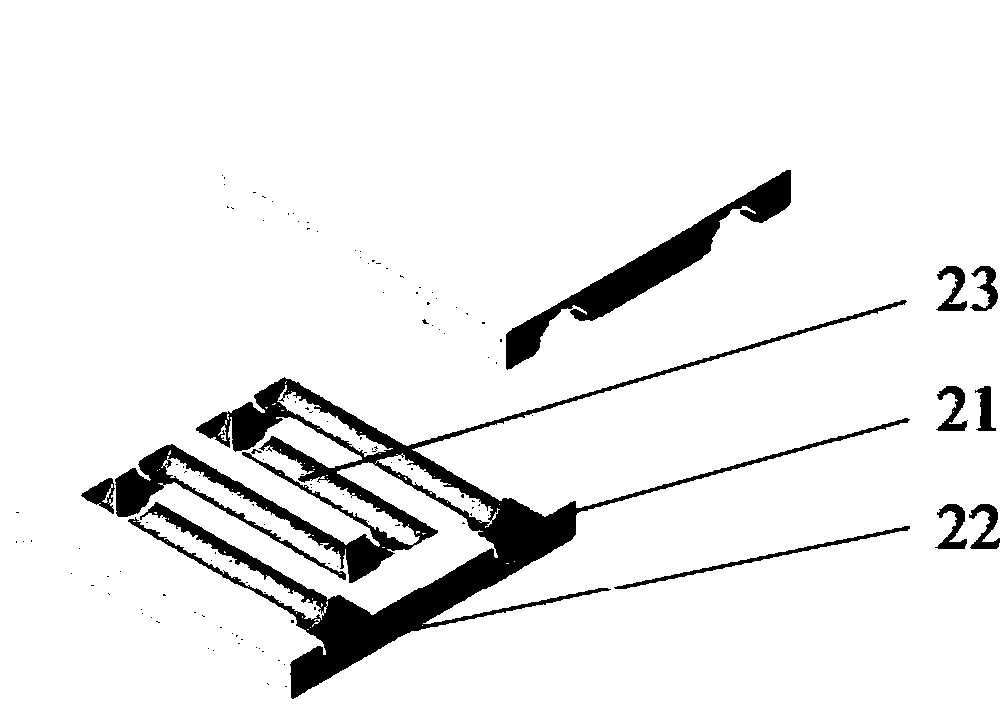

Air purification device

ActiveCN105188883AGuaranteed adsorption efficiencyExtended service lifeGas treatmentDispersed particle separationMicrowaveDesorption

The present invention relates to an air purification device. The present invention comprises: a purifying member for adsorbing and purifying gaseous pollutants contained in the air introduced from the outside; and a desorption means for decomposing and desorbing the gaseous pollutants adsorbed on the purifying member, by microwave heating, wherein the purifying member comprises: an adsorbent for adsorbing the gaseous pollutants; a dielectric substance for absorbing the microwave; and an oxidation catalyst for oxidizing the adsorbed gaseous pollutants. According to the present invention, the gaseous pollutants contained in the polluted air introduced from the outside are continuously or intermittently adsorbed, desorbed and purified, and thus, the purifying member can be regenerated. Thus, the present invention has an effect of sustainedly maintaining adsorption efficiency of the purifying member and, at the same time, greatly improving the lifetime thereof.

Owner:ENBION

Novel air flue type PTC heater

The invention provides a novel air flue type PTC heater which comprises a square air pipe. A fan, a filter area and at least one heating area are sequentially arranged in the square air pipe from leftto right. The filter area comprises a primary filter net plate and a secondary filter net plate which are vertically arranged, the heating area comprises a first PTC porous heating plate and a secondPTC porous heating plate which are arranged in a left-right mode, the top of the first PTC porous heating plate is inclined rightwards, a gap is reserved between the top and the inner wall of the square air pipe, the bottom of the second PTC porous heating plate is inclined rightwards, and a gap is reserved between the bottom and the inner wall of the square air pipe. The novel air flue type PTCheater has the advantages that gas sequentially passes through the filter area and the heating area from left to right under the effect of the fan, the gas is filtered by the filter area before reaching the heating area, accordingly, dust and steam in gas can be effectively filtered, dust accumulation and dirt forming are avoided on the inner wall of the square air pipe and the PTC porous heatingplates in the heating area, influences of dust accumulation on heating efficiency are reduced, and the dust removal frequency and the maintenance cost are reduced.

Owner:NANJING LVZHICHENG PATENT TECH DEV CO LTD

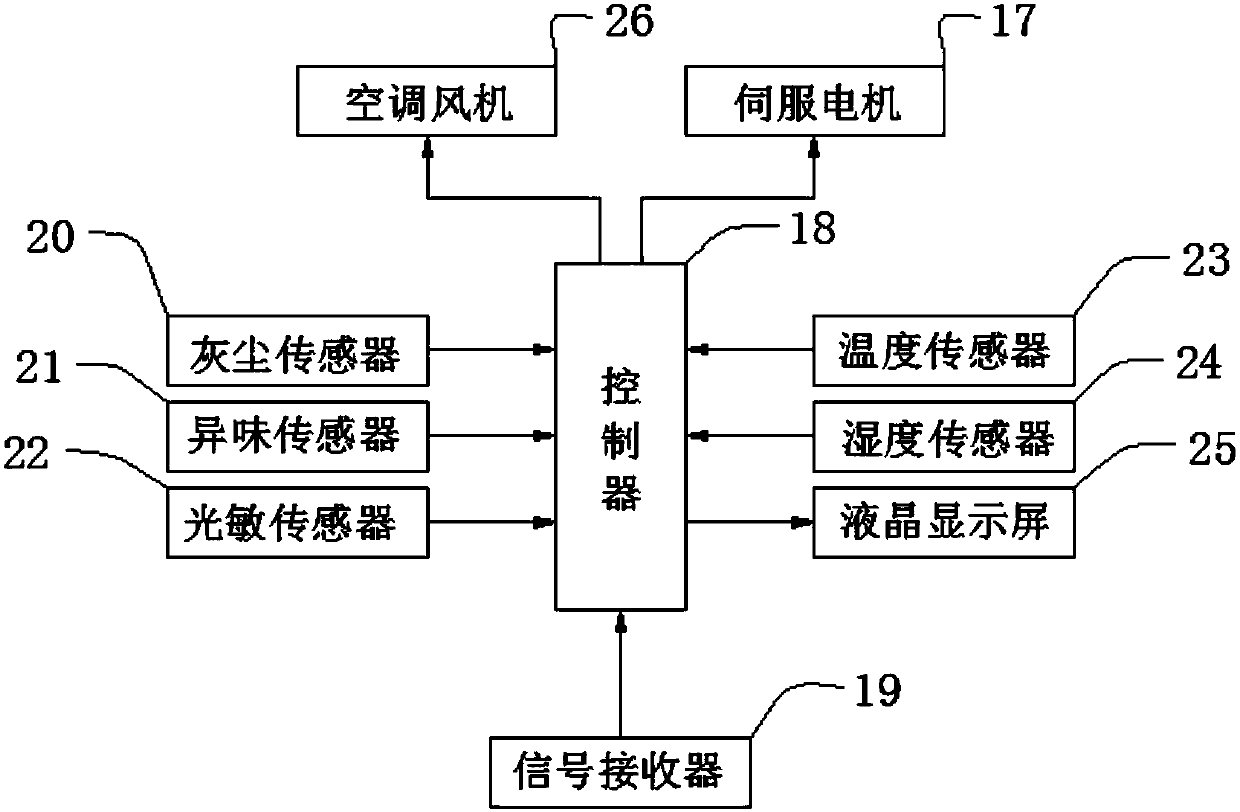

Air purifier of air conditioner

PendingCN107906638AEfficient purificationImprove adsorption capacityMechanical apparatusSpace heating and ventilation safety systemsHEPAActivated carbon filtration

The invention discloses an air purifier of an air conditioner. The air purifier comprises a humidification device, a casing communicating with an air inlet of the air conditioner as well as a purification device arranged in the casing; an air inlet is formed in the top of the casing; the purification device comprises a primary filter net, a first PET filter net, an activated carbon filter net, anHEPA filter net and a second PET filter net which are arranged sequentially in the air flowing direction; the humidification device comprises a humidifier and a humidification pipeline; the humidifieris arranged on the side wall of the casing; an inlet of the humidification pipeline is connected with an outlet of the humidifier; the humidification pipeline penetrates through the side wall of thecasing to be arranged in the casing; multiple air outlets are evenly distributed in the humidification pipeline; and the humidification pipeline is arranged between the activated carbon filter net andthe HEPA filter net. The air purifier of the air conditioner can filter pollutants such impurities, formaldehyde and the like in air effectively and has the humidification function.

Owner:蒋顺成

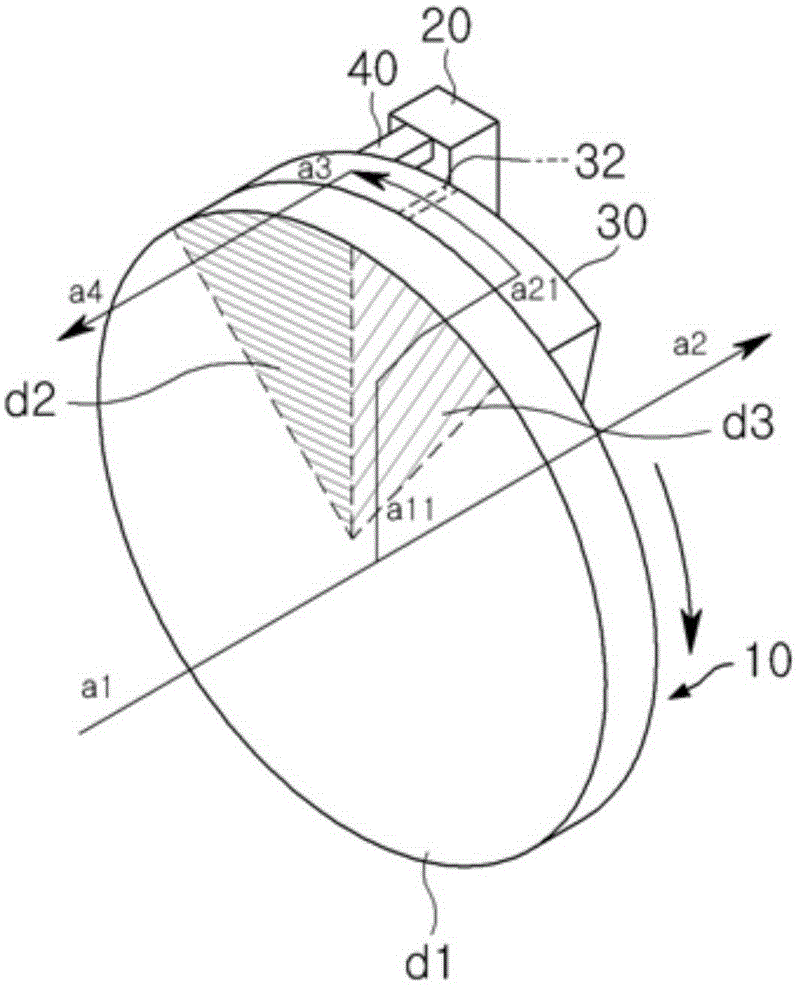

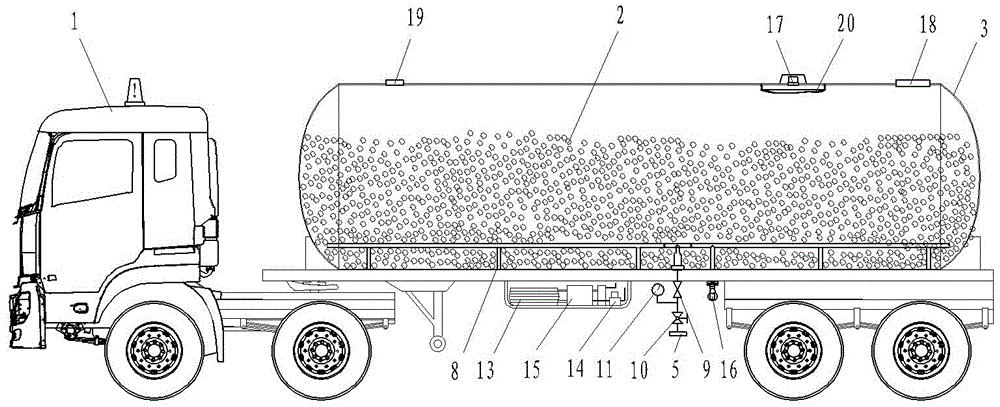

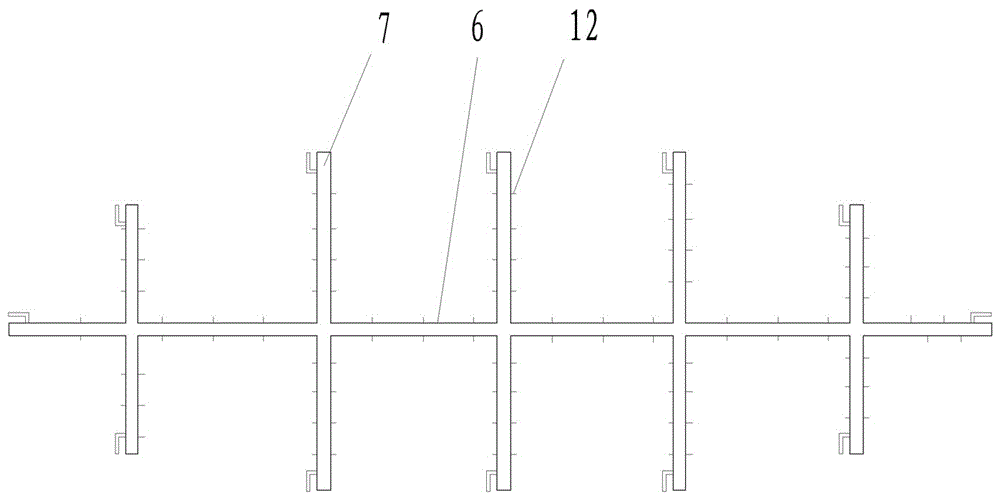

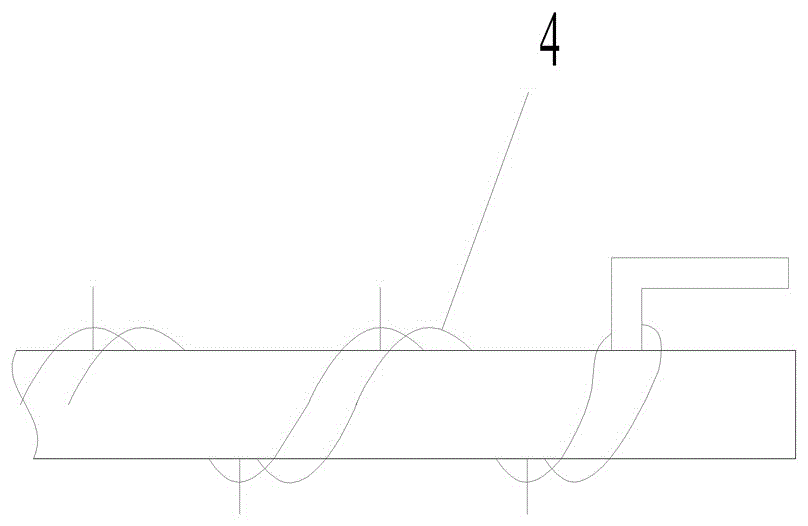

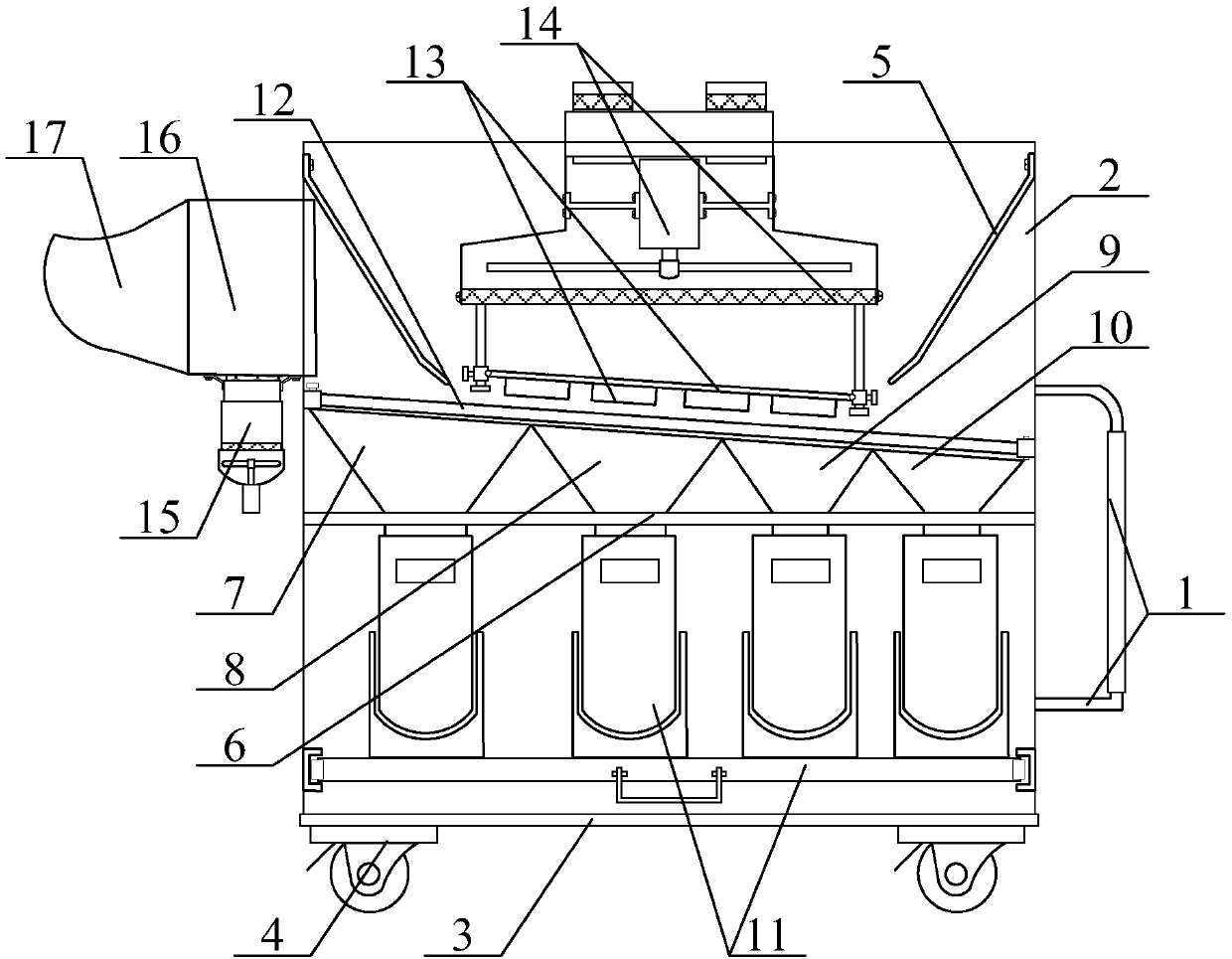

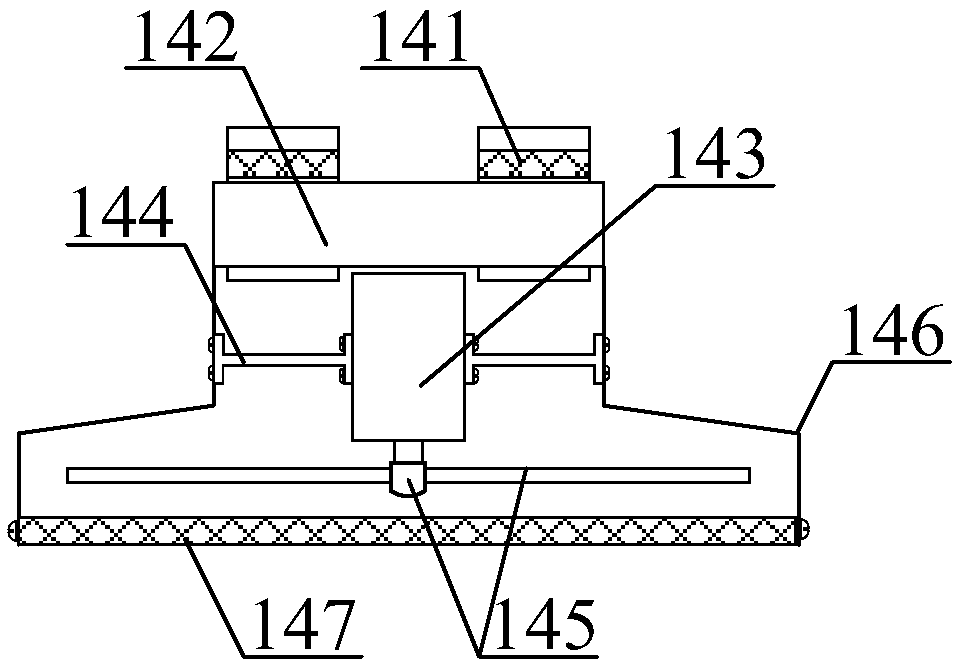

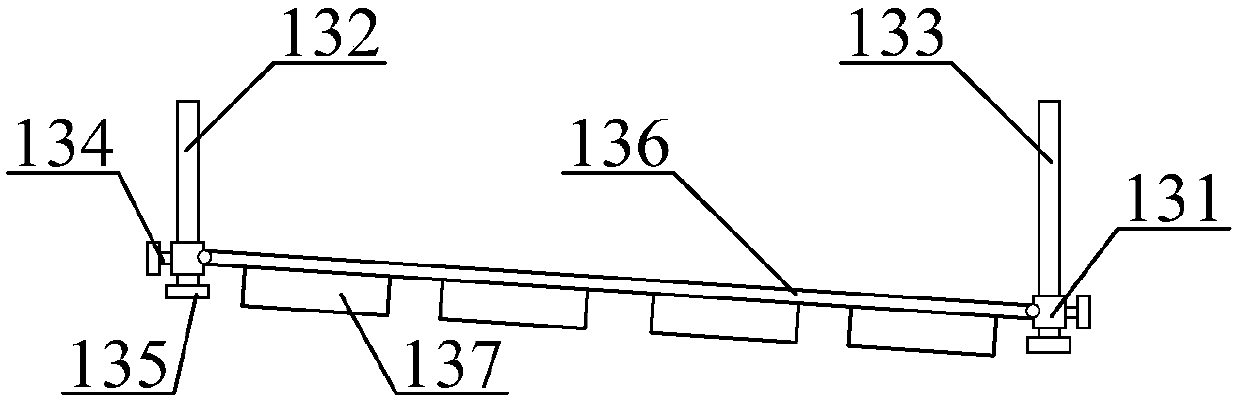

ANG transport cart

ActiveCN105987279AGuaranteed adsorption efficiencyGuaranteed desorption efficiencyVessel mounting detailsContainer filling methodsNatural gas storageWarm water

The invention discloses an ANG transport cart, and relates to the field of natural gas storage and transport devices. The ANG transport cart comprises a transport cart body and an ANG tank body which is fixed to the transport cart body and filled with adsorbent. The key is that an inflation and deflation pipeline is arranged in the 1 / 6-1 / 3 height position, inside the ANG tank body, of the ANG tank body, and extends to end sockets on two sides of the ANG tank body in the axial direction of the ANG tank body. A heat exchange pipeline is wound outside the inflation and deflation pipeline and connected with a heat exchange system of the transport cart body. The ANG transport cart has the beneficial effects that the stability of heat in the adsorption and desorption process of the natural gas is guaranteed through a heat exchange mode, the whole transport cart forms a relatively independent system, and other external equipment is not needed; even in the adsorption process, the water in the heat exchange pipeline is cold water, and the heat exchange pipeline wound on the inflation and deflation pipeline cools the inflated natural gas and the adsorbent; and in the deflation process, the water in the heat exchange pipeline is warm water, and the adsorption and desorption efficiency of the adsorbent is guaranteed.

Owner:SHIJIAZHUANG ENRIC GAS EQUIP

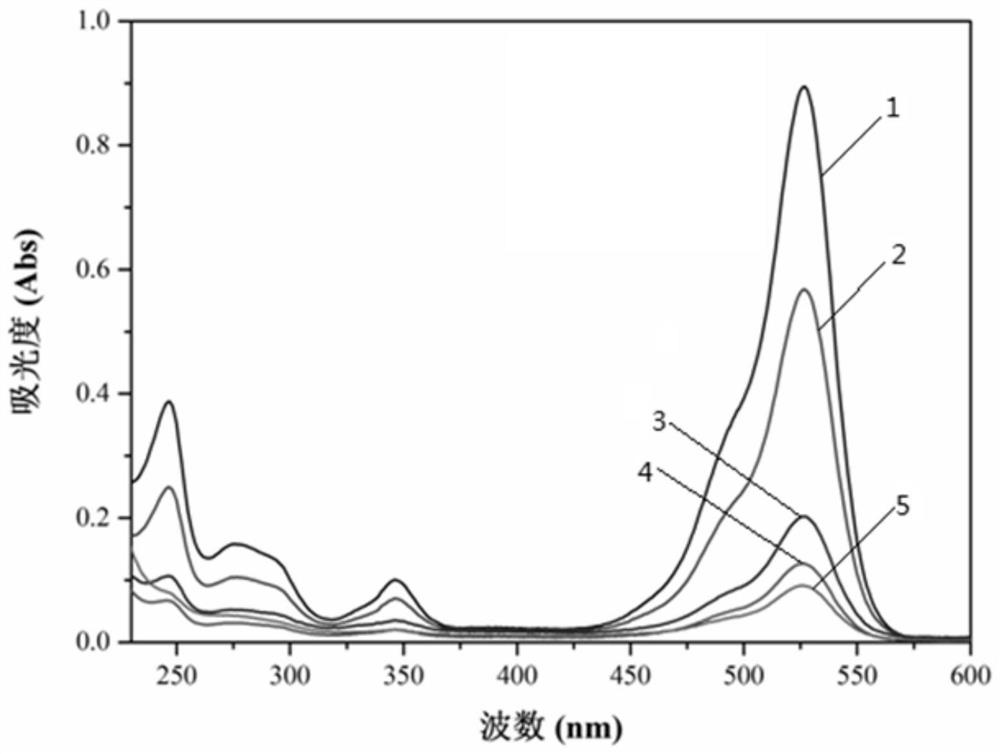

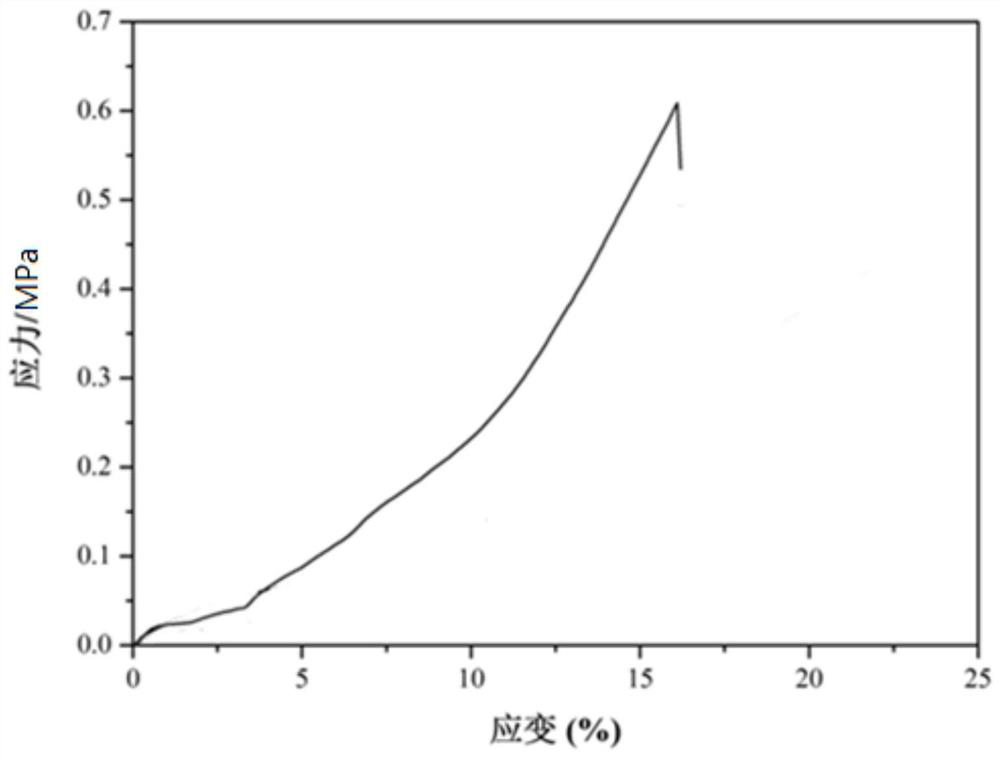

Preparation method of nanocellulose/acrylamide/graphene oxide self-healing hydrogel

ActiveCN112225913AImprove mechanical propertiesRepair mechanical damageOther chemical processesAlkali metal oxides/hydroxidesDye adsorptionMaterials science

The invention discloses a preparation method of nanocellulose / acrylamide / graphene oxide self-healing hydrogel, which relates to a preparation method of hydrogel. The problems that existing cellulose hydrogel is low in mechanical strength, poor in dye adsorption effect and incapable of being repeatedly used and self-healing are solved. The preparation method comprises the following steps of 1, removing lignin, 2, preparing a cellulose dispersion liquid, 3, preparing a nanocellulose-graphene oxide mixed solution, and 4, preparing the hydrogel. The preparation method is used for preparing the nanocellulose / acrylamide / graphene oxide self-healing hydrogel.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Adsorbent for ammonia gas recovery and utilization, and preparation method thereof

InactiveCN109692663AEasy to desorbReduce the effectGas treatmentOther chemical processesActivated carbonChemistry

The invention discloses an adsorbent for ammonia gas recovery and utilization, and a preparation method thereof, wherein the ammonia gas adsorbent comprises, by mass, 30-50% of an active component and50-70% of a carrier, and the active component is one or two selected from alkaline earth metal chlorides. The preparation method comprises: immersing active carbon in a NaOH solution, filtering out the immersing liquid, and drying so as to be spare; preparing an ethanol solution with a certain concentration from an alkaline earth metal chloride; adding the dried active carbon into the ethanol solution, completely immersing, and filtering out the immersing liquid; and curing under an air-isolating condition to prepare the adsorbent for ammonia gas recovery and utilization. According to the present invention, the prepared ammonia gas adsorbent can adsorb a large amount of ammonia gas under normal temperature and low temperature conditions, wherein the adsorption capacity can be up to 0.56 g / g; the desorption is easy after the ammonia gas adsorbent adsorbs ammonia gas, such that the ammonia gas adsorbent can be recycled so as to achieve the environmental protection; and the ammonia gas adsorbing effect is not significantly reduced after 50 cycles of recycling.

Owner:SINOPEC YANGZI PETROCHEM +1

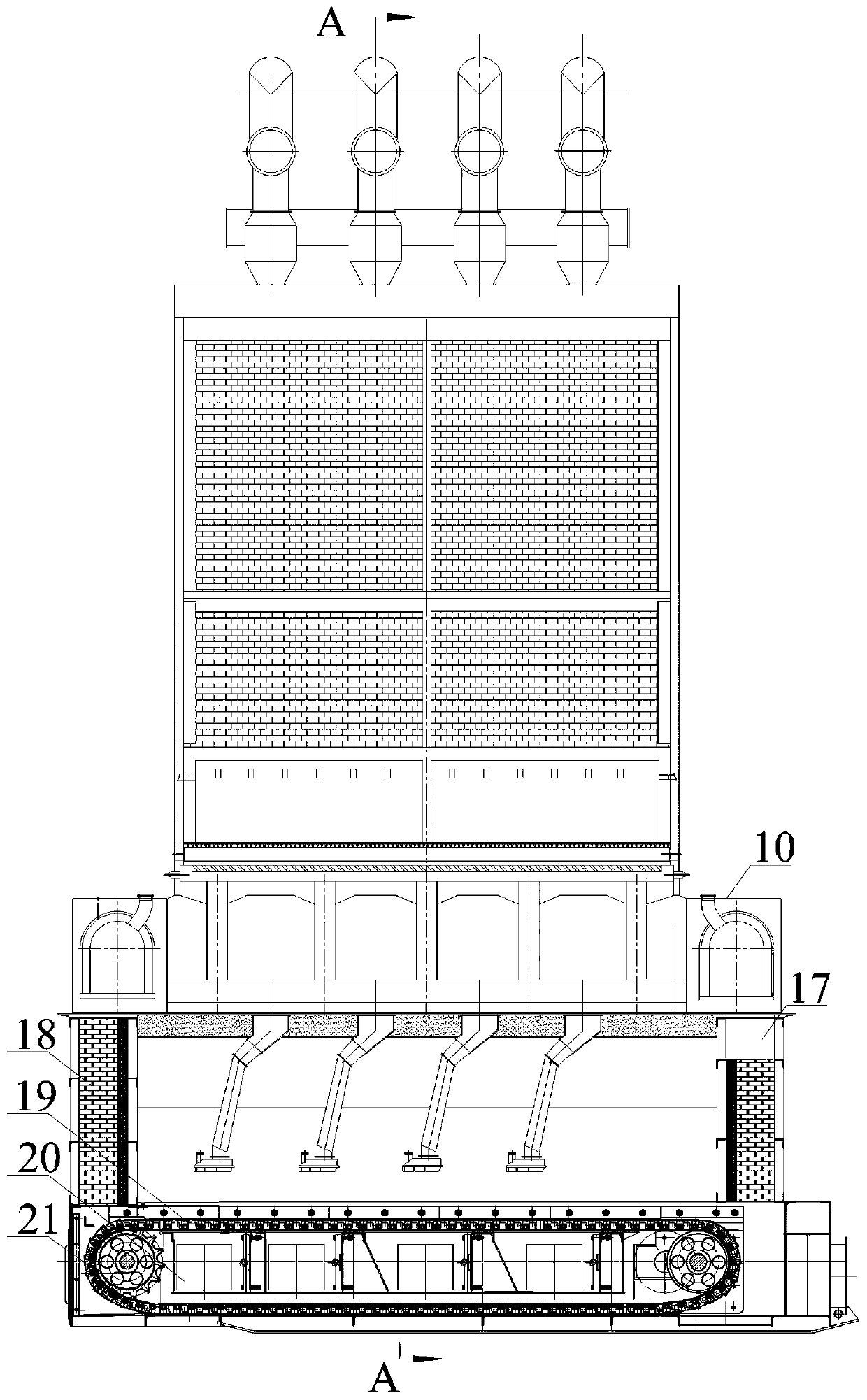

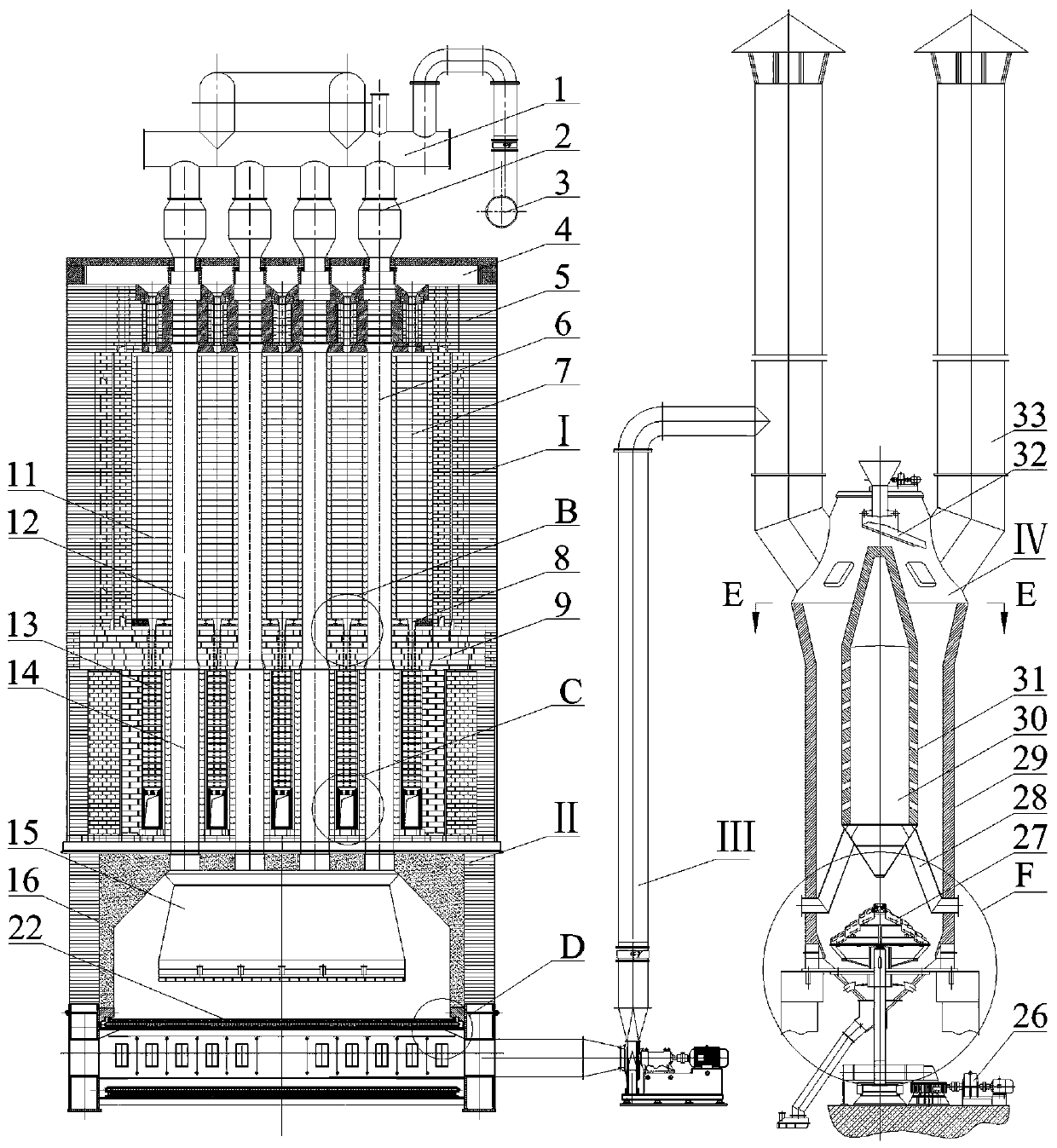

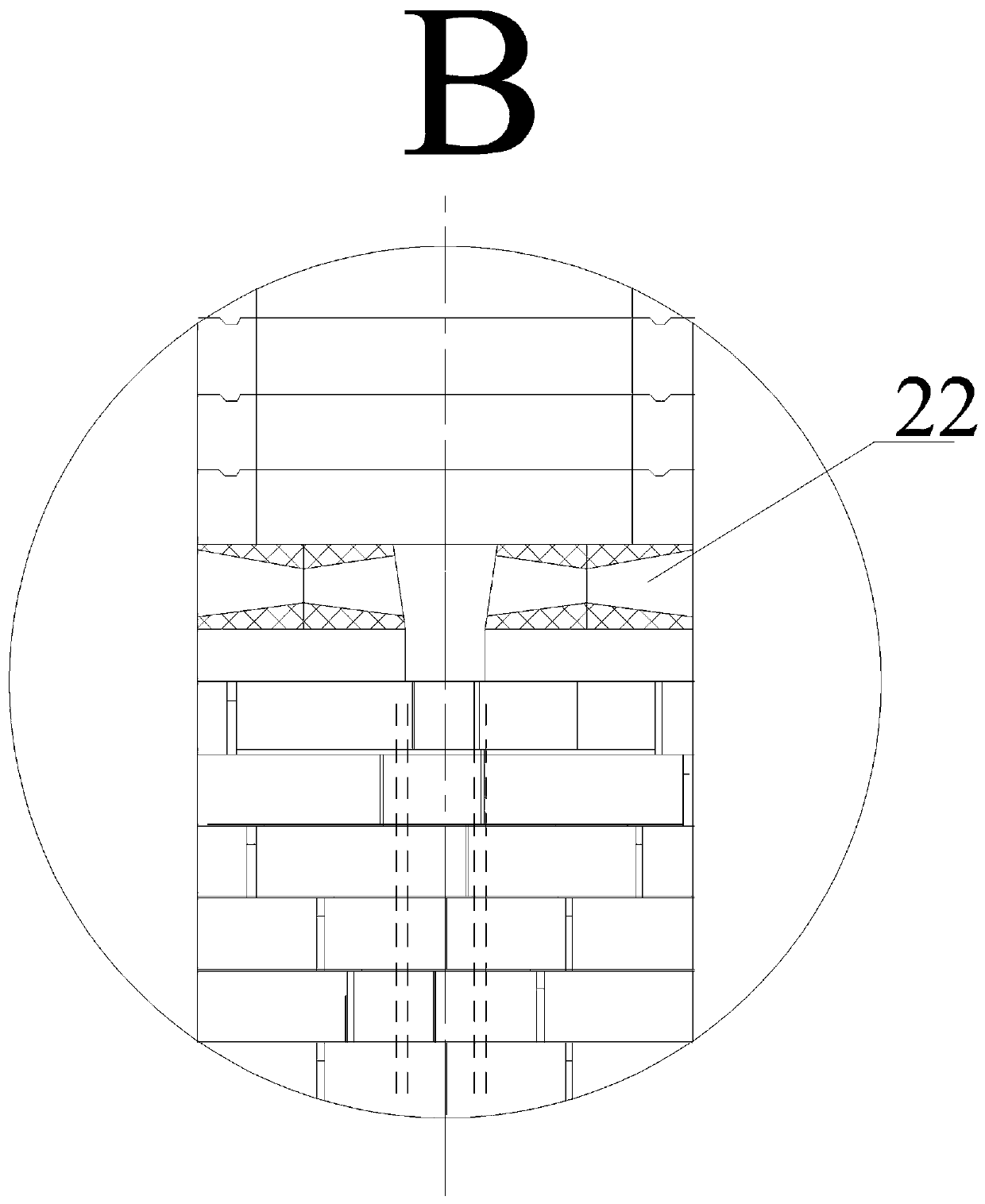

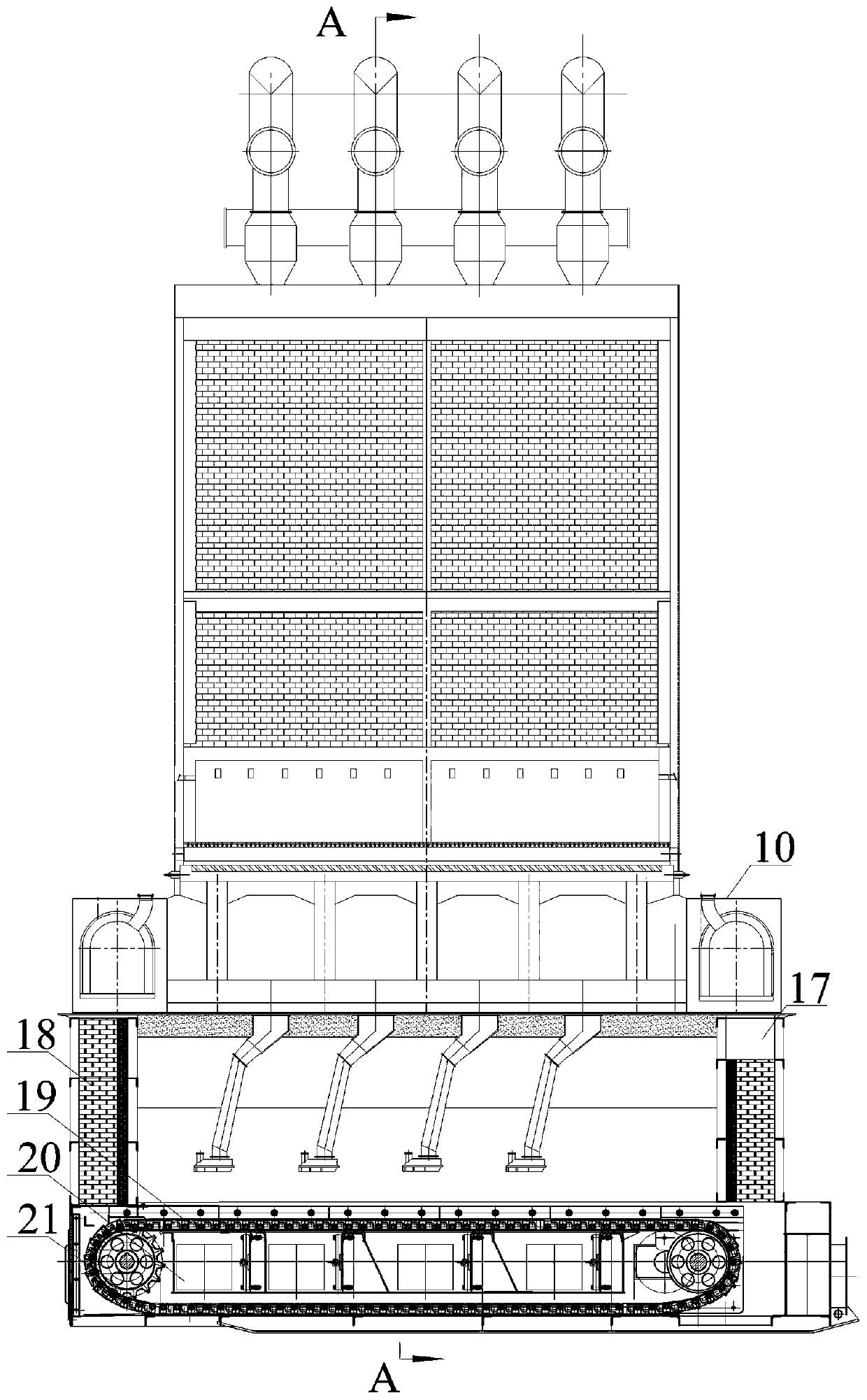

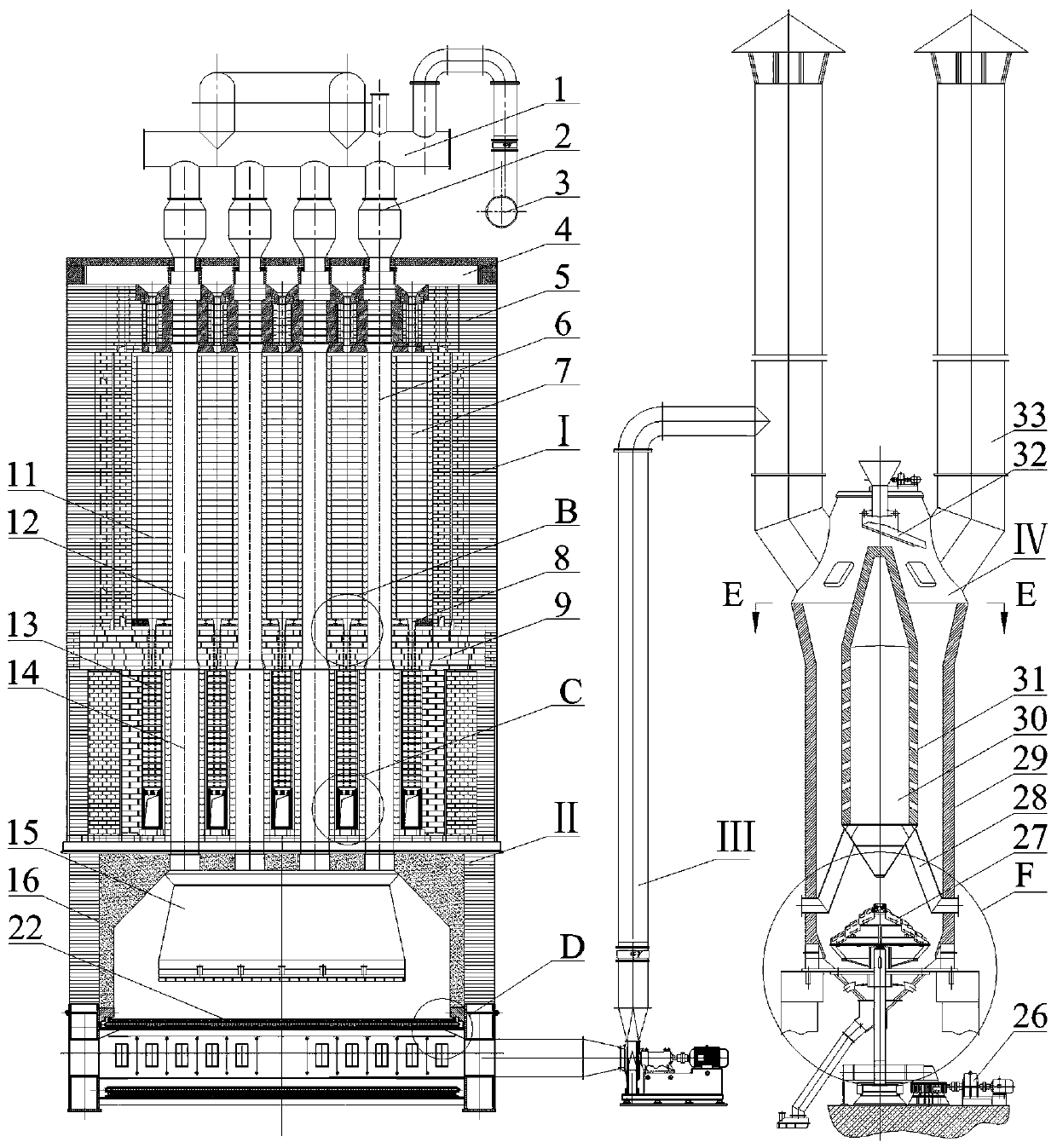

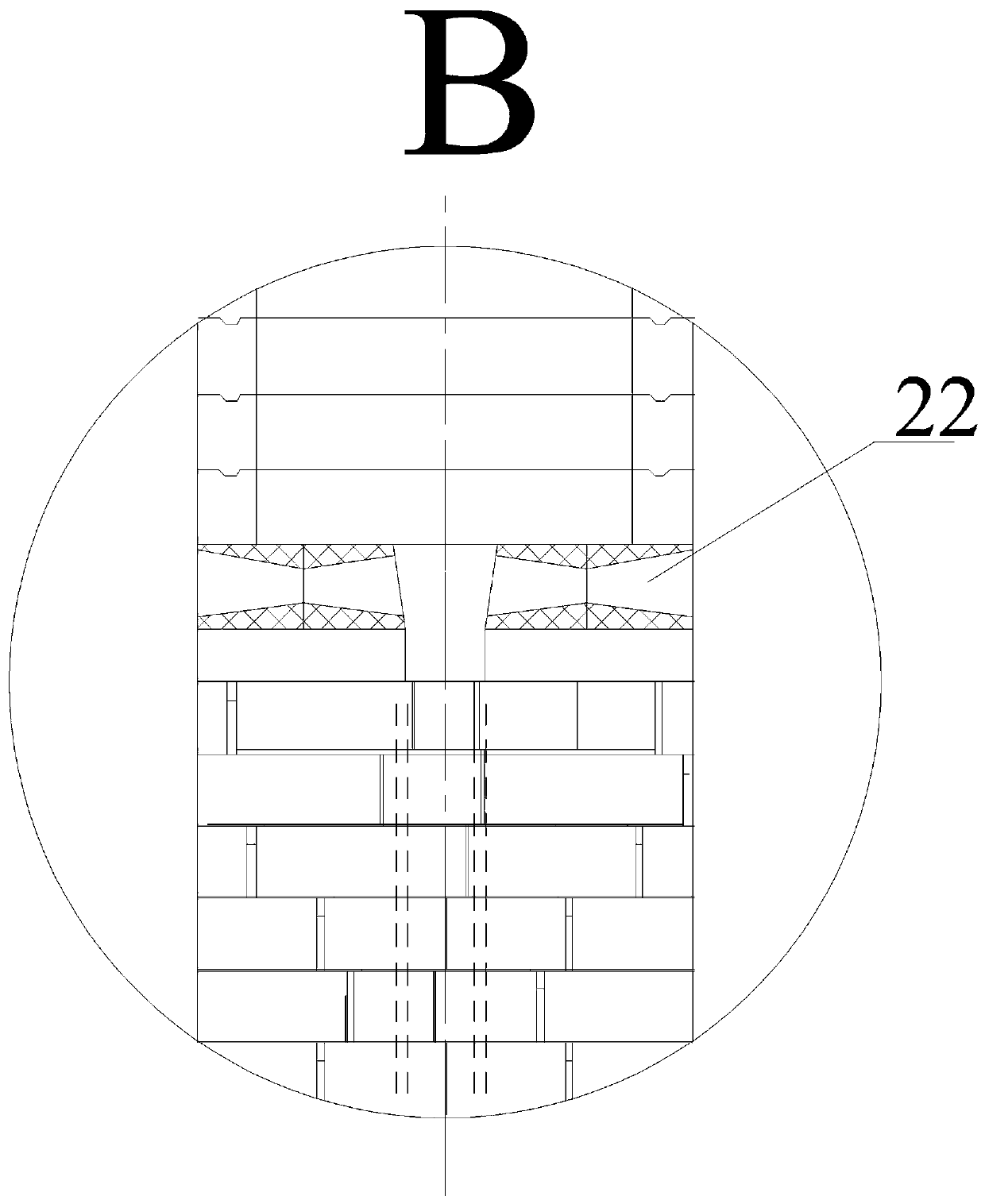

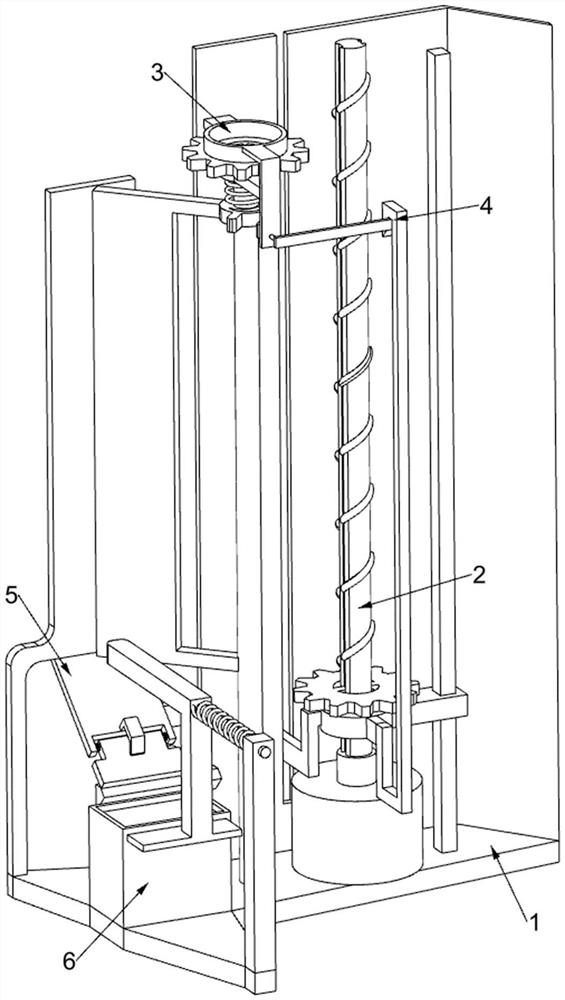

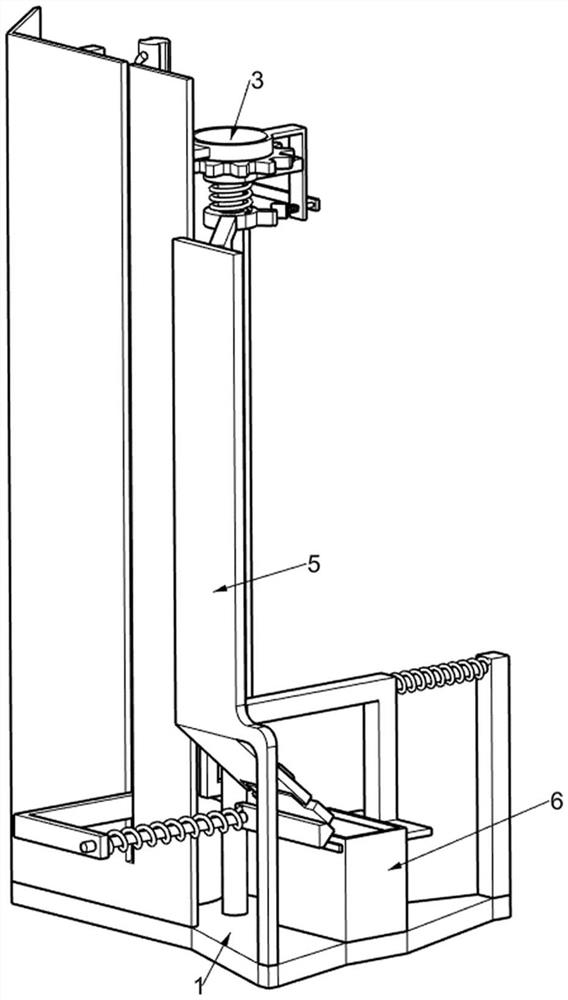

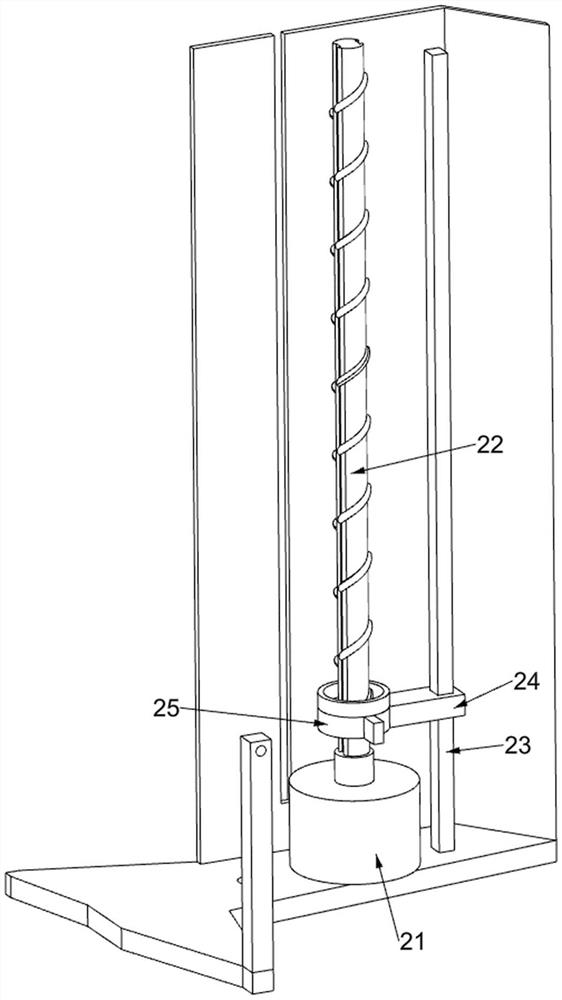

Cyclic regeneration process system for governing VOCs exhaust gas

ActiveCN109745824ALower ignition pointImprove the heating effectOther chemical processesDispersed particle separationProcess systemsBrick

The invention relates to the technical field of environmental protection, in particular to a cyclic regeneration process system for governing VOCs exhaust gas. The system is characterized by comprising a desorption pyrolyzing furnace, a chain transmission grate bed, an induced draught system and an adsorbent moving bed. The desorption pyrolyzing furnace comprises a desorption pyrolyzing furnace body and a material supply system. The desorption pyrolyzing furnace body is provided with a flame path and a vertical path, high-temperature glue gas circulates in the flame path, an adsorbent moves tofall off in the vertical path, and the flame path and the vertical path are built adjacently. The material supply system comprises a storage tank and an air injection container. The air injection container introduces tail gas discharged by the flame path into a purging adsorbent, is then mixed with desorbed VOCs exhaust gas and is then conveyed to a pyrolyzing room to be oxidized and pyrolyzed through a grate brick in the bottom of a desorption room. The chain transmission grate bed comprises material legs and a chain transmission grate bed body. A kiln box and a chain transmission grate bedrow are designed on the chain transmission grate bed, an exhaust port is formed in the kiln box, the chain transmission grate bed row comprises a chain wheel, a chain, a grate row and an air distributing plate, and the induced draught system is responsible for introducing and conveying tail gas of an exhaust barrel of the adsorbent moving bed into the air distributing plate of the chain transmission grate bed.

Owner:ZIBO PENGDA ENVIRONMENTAL PROTECTION TECH

Incinerator flue gas purification treatment system and purification treatment method

InactiveCN113318568AEasy to cleanEasy to collectGas treatmentDispersed particle filtrationActivated carbonFlue gas

The invention relates to an incinerator flue gas purification treatment system and a purification treatment method.The incinerator flue gas purification treatment system comprises a reaction tower, a working cavity and a purification device, the working cavity is formed in the reaction tower, and the purification device is arranged in the working cavity. The invention can solve the technical problems that when smoke dust in smoke of an incinerator is treated, the smoke dust is usually adsorbed to purification equipment in an adsorption mode, the treatment effect of the purification equipment can be reduced, and the adsorbed smoke dust is difficult to clean and collect due to the fact that smoke purification treatment is usually carried out in a sealed space; besides, when the flue gas of the incinerator is purified by using activated carbon, the flue gas generally directly passes through an activated carbon pile, and the activated carbon is stacked together to reduce the contact area with the flue gas and smoke dust, so that the adsorption efficiency of the activated carbon is reduced, and the purification effect of the flue gas.

Owner:湖北森态香精香料有限公司

Ammonia gas adsorbent and preparation method thereof

InactiveCN109692662AIncrease forceImprove adsorption capacityGas treatmentOther chemical processesActivated carbonSorbent

The present invention discloses an ammonia gas adsorbent, which comprises 6-20 wt% of an active component and 80-94 wt% of a carrier, wherein the active component is a transition metal chloride, and the carrier is active carbon. The preparation method of the ammonia gas adsorbent comprises: immersing active carbon in a NaOH solution, filtering out the immersion liquid, and drying so as to be spare; preparing an ethanol solution with a certain concentration from at least one of the transition metal chlorides; adding the dried active carbon into the ethanol solution, completely immersing, and filtering out the immersing liquid; and roasting under an air-isolating condition to prepare the ammonia gas adsorbent. According to the present invention, the prepared ammonia gas adsorbent can adsorba large amount of ammonia gas under normal temperature and low temperature conditions, wherein the adsorption capacity can be up to 0.52 g / g; and the desorption is easy after the ammonia gas adsorbentadsorbs ammonia gas, such that the ammonia gas adsorbent can be recycled so as to achieve the environmental protection.

Owner:SINOPEC YANGZI PETROCHEM +1

Electrostatic dust collector with high cleaning efficiency for coal cleaning

PendingCN113769894AEfficient scrapingGuaranteed adsorption efficiencyElectrodes cleaningThermodynamicsMechanical engineering

The invention relates to the field of coal, in particular to an electrostatic dust collector with high cleaning efficiency for coal cleaning. The electrostatic dust collector comprises a first fixing frame, a lifting mechanism, a rotating mechanism, a clamping mechanism and the like, wherein the lifting mechanism is arranged on the first fixing frame, the rotating mechanism is arranged on the first fixing frame, and the clamping mechanism is arranged on the second fixing frame. Through cooperation of a sliding cover and the fixing frame, the sliding cover can be opened and closed in time, when the sliding cover is opened, the scraped smoke dust can fall into the fixing frame, then the sliding cover is closed, the smoke dust collected in the fixing frame can be prevented from flying out again, and the effect that the scraped smoke dust can be effectively collected and prevented from flying out again is achieved.

Owner:周隆奎

Combined type soybean impurity removal and air-drying device

InactiveCN109092682AEasy to cleanIncreased quick drying efficiencyGas current separationDrying gas arrangementsEngineeringGuide tube

The invention provides a combined type soybean impurity removal and air-drying device. The combined type soybean impurity removal and air-drying device comprises a push rod with a rubber sleeve, a concentric-square-shaped impurity removal and air-drying box, a base, universal wheels with brake pads, soybean anti-jump boards, a center seat, a small grain funnel, a medium grain funnel, a large grainfunnel, a super large grain funnel, a draggable mobile collection barrel structure, a soybean adjustable selection type picking rod structure, a soybean iron impurity inclination adjustable adsorption rod structure, a rapid air intake air-drying tube structure, a detachable dust and fine impurity collection tube structure, a soybean flow guiding tube and a soybean feed hopper. The push rod with the rubber sleeve is installed on the lower right side of the concentric-square-shaped impurity removal and air-drying box in a bolt mode. The concentric-square-shaped impurity removal and air-drying box is mounted on the upper surface of the base in a bolt mode. The combined type soybean impurity removal and air-drying device increases a soybean selection function, realizes the combination function of integrating the removal of iron impurities in soybeans with air drying, and can collect the impurities removed and increases a storage classification function after the soybean sorting.

Owner:郑制强 +4

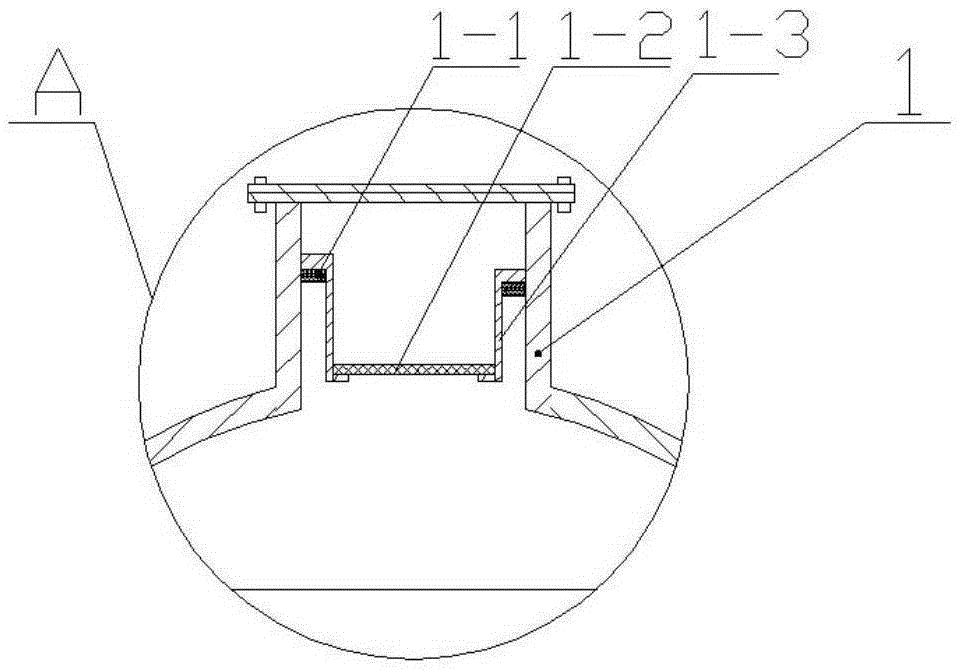

Adsorption column with high sealing performance and high filtering performance

InactiveCN106630212AGuaranteed adsorption efficiencyEasy to installMultistage water/sewage treatmentFiltrationEngineering

The invention relates to an adsorption column with high sealing performance and high filtering performance. The upper part of an upper sealing cover and a column body are coaxially and integrally upward to form a cylindrical extension opening; a clamping ring is arranged at coaxial integral radial inward part of the inner wall of the extension opening; a circular support frame is coaxially embedded on the clamping ring; an outer overlapping ring is coaxially, integrally and outwardly arranged at the upper end of the support frame; the outer overlapping ring is directly overlapped on the clamping ring; an inner overlapping ring is coaxially and integrally arranged at the lower end of the support frame; a filtering screen is coaxially, integrally and fixedly mounted on the inner overlapping ring; an embedding ring is coaxially, radially and integrally arranged at the inner edge of the lower end of an upper column body; an annular embedding groove is coaxially and integrally arranged at the inner edge of the upper end of a lower column body; when the upper column body and the lower column body are jointed with each other, the embedding ring is mounted in the embedding groove. The adsorption column with a primary filtration clamping disc, the filter screen can be replaced in real time according to the filtered sewage; the filtering diameter can be adjusted in time; the adsorption column is suitable for sewage with different impurities in different places, and is extremely high in practicability.

Owner:TIANJIN BINHUAN CHEM ENG TECH RES INST

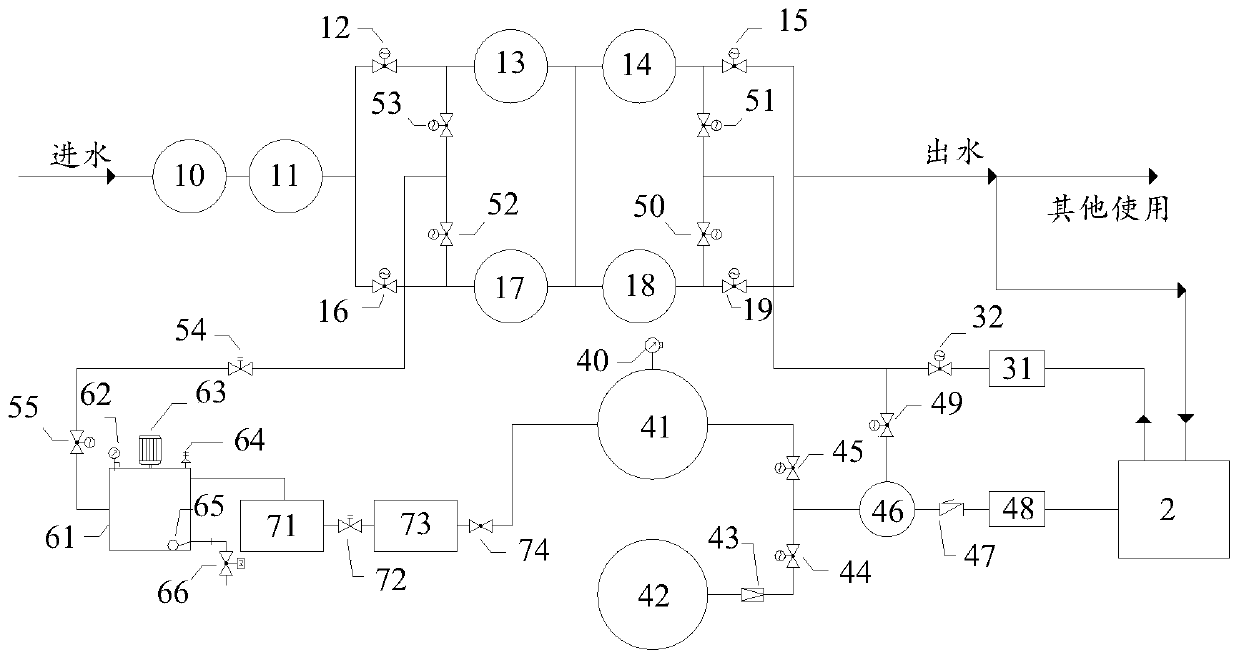

Efficient deionization system for sewage treatment

InactiveCN110386638AImprove purification efficiencyQuality improvementTreatment involving filtrationWater/sewage treatment by ion-exchangeSewageSeparation system

The invention relates to the technical field of water treatment, in particular to an efficient deionization system for sewage treatment. The efficient deionization system includes a deionization system and a regeneration cleaning system, and the regeneration cleaning system is composed of a cleaning system, a carbon dioxide mixing system, a back washing system, a gas-liquid separation system and apressurization system; and the structure of the efficient deionization system is simple, in the whole system, the efficiency of sewage purification and the quality of ion adsorption are improved, thewhole system internally forms an internal circulation regeneration system, and the continuous and high-quality purification of sewage can be realized.

Owner:芜湖沃泰环保科技有限公司

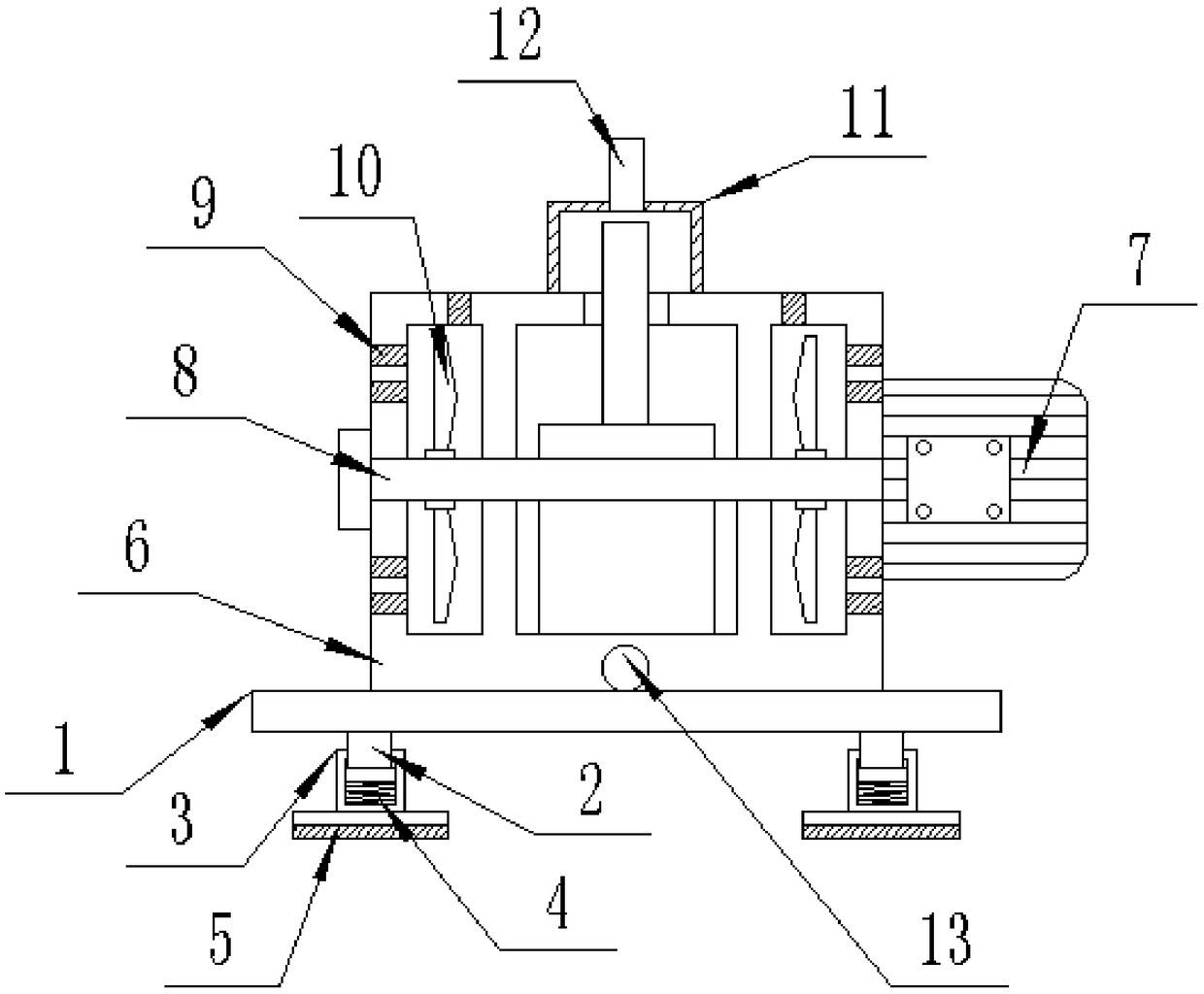

Oil-gas separating type vacuum pump

InactiveCN108730186AGuaranteed adsorption efficiencyPumpsRotary/oscillating piston pump componentsEngineeringFan blade

The invention discloses an oil-gas separating type vacuum pump. The oil-gas separating type vacuum pump comprises a bottom plate, a pump body and an oil-gas separator; thin rods are vertically downward and fixedly connected to the two ends of the bottom plate; hollow rods are connected to the lower ends of the thin rods in a sleeving mode; a damping spring is fixedly connected to the bottom end ofthe interior of each hollow rod; the upper ends of the damping springs are fixedly connected to the positions under the thin rods; the pump body is fixedly connected to the upper end of the bottom plate; a motor is fixedly connected to the center position of the right end of the pump body; a rotary shaft is vertically and fixedly connected to the center position of the left end of the motor; therotary shaft horizontally penetrates through the center position of the pump body; fan blades are symmetrically and fixedly connected to the upper side and the lower side of the left end of the rotaryshaft as well as the upper side and the lower side of the right end of the rotary shaft; a buffer cavity is fixedly connected to the upper end of the pump body; an air intake pipe is vertically and fixedly connected to the center position of the upper end of the buffer cavity; and a rotor is arranged inside the pump body and fixedly connected to the rotary shaft. According to the oil-gas separating type vacuum pump, a screw rod can be conveniently taken down regularly, a movable cover plate is opened, a long filter plate and a short filter plate are taken out by holding a handle, then cleaning can be carried out, the suction efficiency of a filter device is ensured, and the filter device can be recycled.

Owner:XIAN TECHNOLOGICAL UNIV

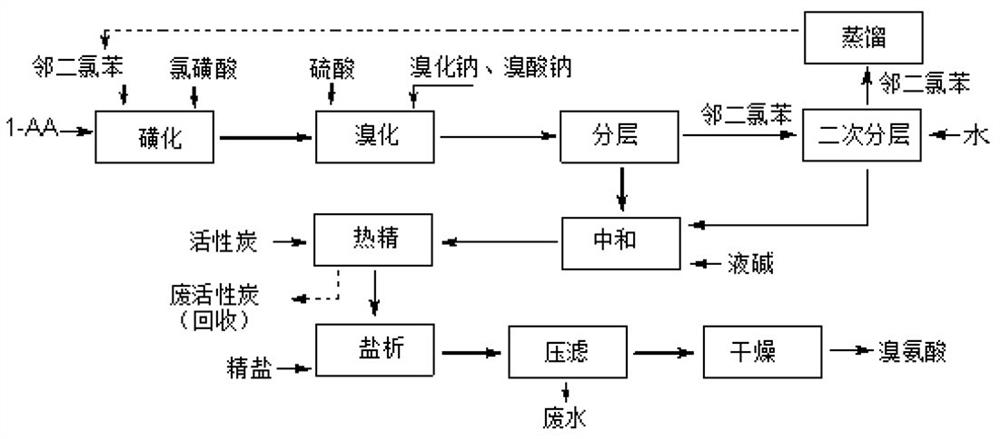

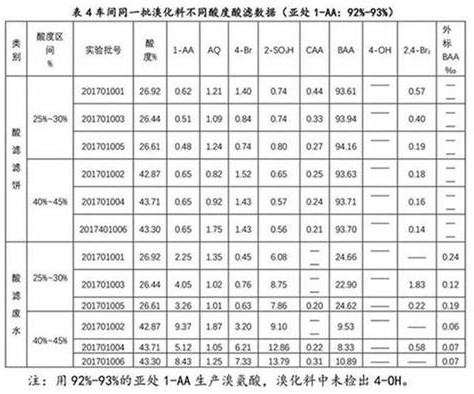

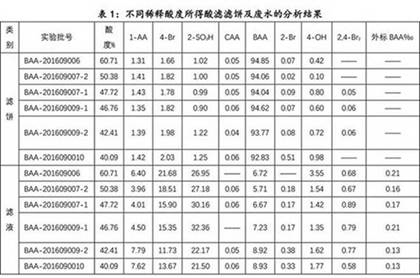

Clean production method of bromamine acid

InactiveCN112645851AImprove production efficiencyLess quantityOrganic compound preparationWater contaminantsAnthraquinonesActivated carbon

The invention relates to a clean production method of bromamine acid. The method comprises the following steps: preparing 1-amino anthraquinone-2-sulfonic acid; preparing a sulfuric acid solution of 1-amino anthraquinone-2-sulfonic acid; adjusting the acidity of a sulfuric acid solution of 1-amino anthraquinone-2-sulfonic acid to a preset value, and adding a brominated material to prepare a bromamine acid crude product; standing a bromamine acid crude product to remove redundant o-dichlorobenzene solution; carrying out thermal refining on the bromamine acid solution, and adsorbing organic matters in the solution by using activated carbon after thermal refining; salting out the solution to obtain a solution containing bromamine acid crystals, compressing the solution, and drying the filter cake to obtain bromamine acid. By adjusting the acidity of the sulfuric acid solution of 1-amino anthraquinone-2-sulfonic acid in the BAA preparation process, the isomer 1-amino-4-hydroxy anthraquinone which is difficult to remove can be effectively reduced, the amount of acid chloride wastewater generated in the subsequent process is effectively reduced, and the content of BAA in the prepared BAA filter cake is effectively increased; therefore, the preparation efficiency of the BAA prepared by the method provided by the invention is effectively improved.

Owner:YANCHENG OUHUA CHEM IND

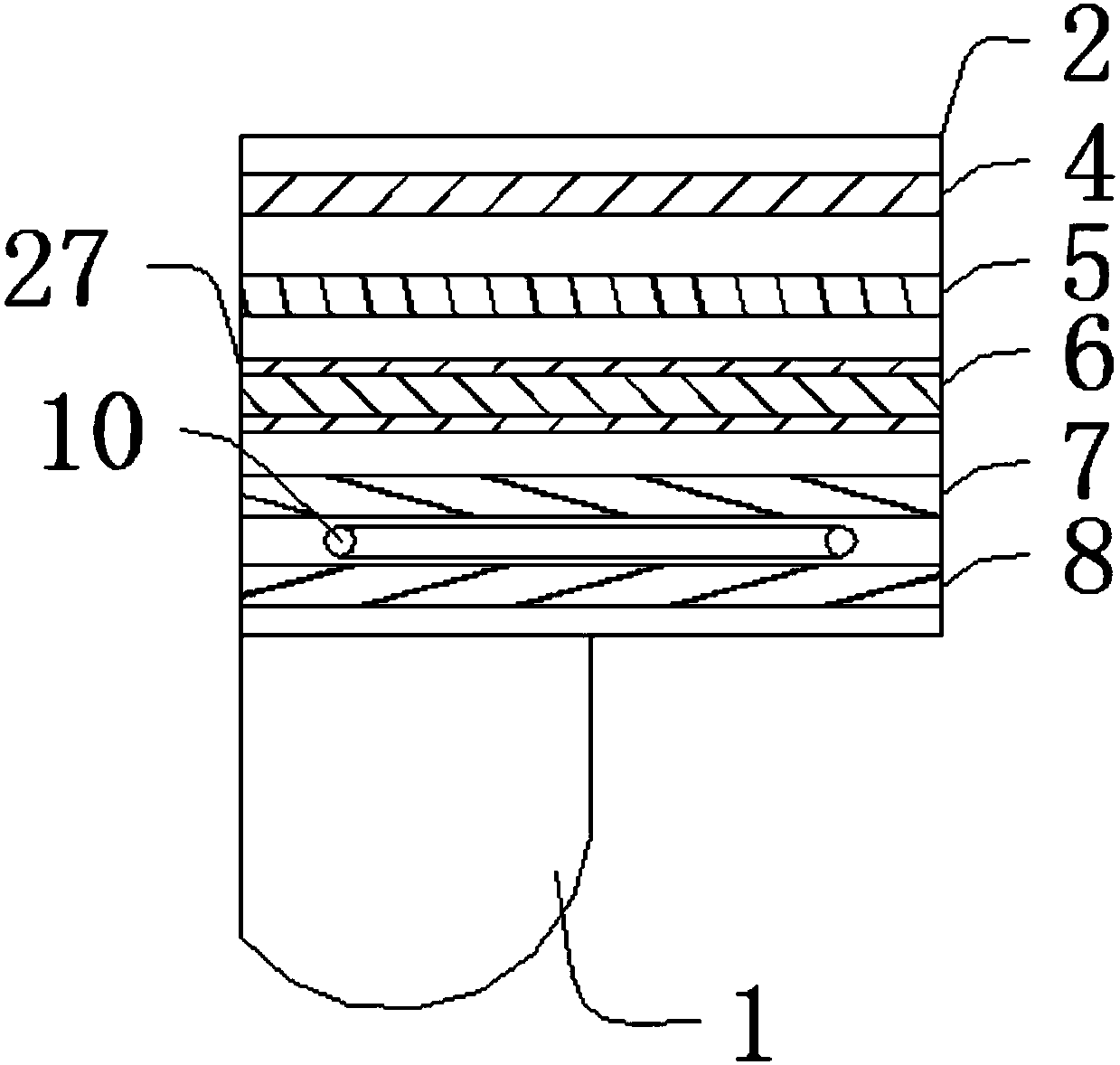

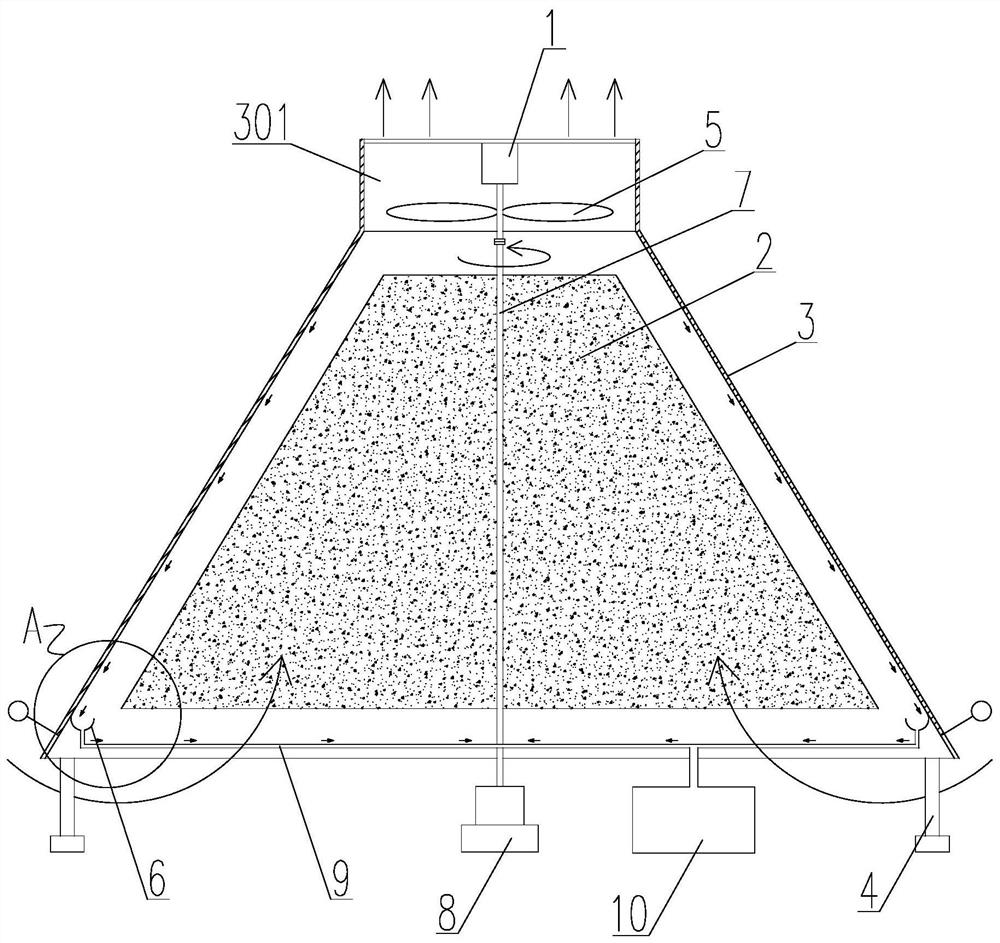

Centrifugal desorption type air water production tower

PendingCN113175029AEasy accessReduce contact areaDrinking water installationHigh humidityElectric machine

The invention relates to the technical field of air water production towers, in particular to a centrifugal desorption type air water production tower. The tower comprises a motor, a hydrophilic adsorption inner core and a tower cylinder with openings in the upper end and the lower end, a support is fixed to the opening in the lower end of the tower cylinder, an air outlet is fixed to the opening in the upper end of the tower cylinder, the motor is fixed to the air outlet, the hydrophilic adsorption inner core is rotationally arranged in the tower cylinder, the output end of the motor is in transmission connection with the hydrophilic adsorption inner core, fan blades are fixed on the hydrophilic adsorption inner core, and the hydrophilic adsorption inner core is in a conical shape with a small upper end and a large lower end. According to the tower, air with high humidity can conveniently enter the tower cylinder; through the design of the fan blades on the hydrophilic adsorption inner core, when the hydrophilic adsorption inner core performs dehydration, flow guide can be conducted through the fan blades, so that more air enters the tower cylinder from the air inlet in the bottom of the tower cylinder, and the water production efficiency is improved; and the structure is compact, the adsorption efficiency is guaranteed, meanwhile, the size of the hydrophilic adsorption inner core can be effectively reduced, material waste cannot be caused, and the cost is reduced.

Owner:CHANGZHOU UNIV

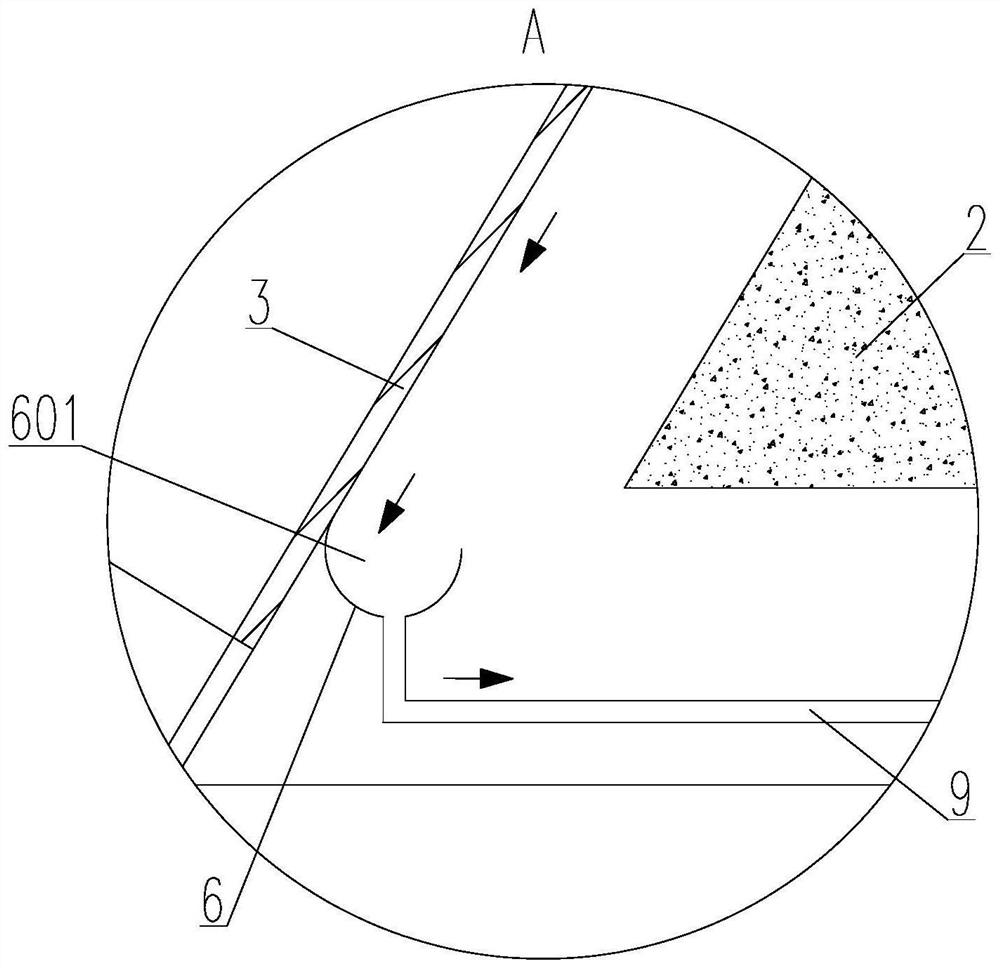

Rolled steel pipe manufacturing process

PendingCN113426580AAvoid high temperature effectsAffect healthEdge grinding machinesGrinding work supportsEngineeringPipe

The invention discloses a rolled steel pipe manufacturing process, and belongs to the technical field of steel pipe processes. According to the rolled steel pipe manufacturing process, metal powder generated in the polishing process can be adsorbed by static electricity generated by friction between a filter screen and a polishing shell through expansion of the filter screen; and therefore, metal powder is prevented from being dispersed in the air to affect the health of operators in the polishing process; the adhesive force of the metal powder on the surface of the filter screen is obviously reduced after the filter screen returns to the original shape, and an air bag rebounds after the filter screen returns to drive the whole filter screen to shake, so that the falling rate of the metal powder on the surface of the filter screen is increased; the automatic dust removing function of the filter screen is achieved, fallen metal powder can fall into a recycling tank to be recycled, workers can recycle the metal powder conveniently, meanwhile, cold water is arranged in a polishing shell and can absorb heat generated in the polishing process, the polishing shell and the surface of a steel plate are prevented from being affected by high temperature, and the manufacturing efficiency of coil steel is improved.

Owner:广西天正钢结构有限公司

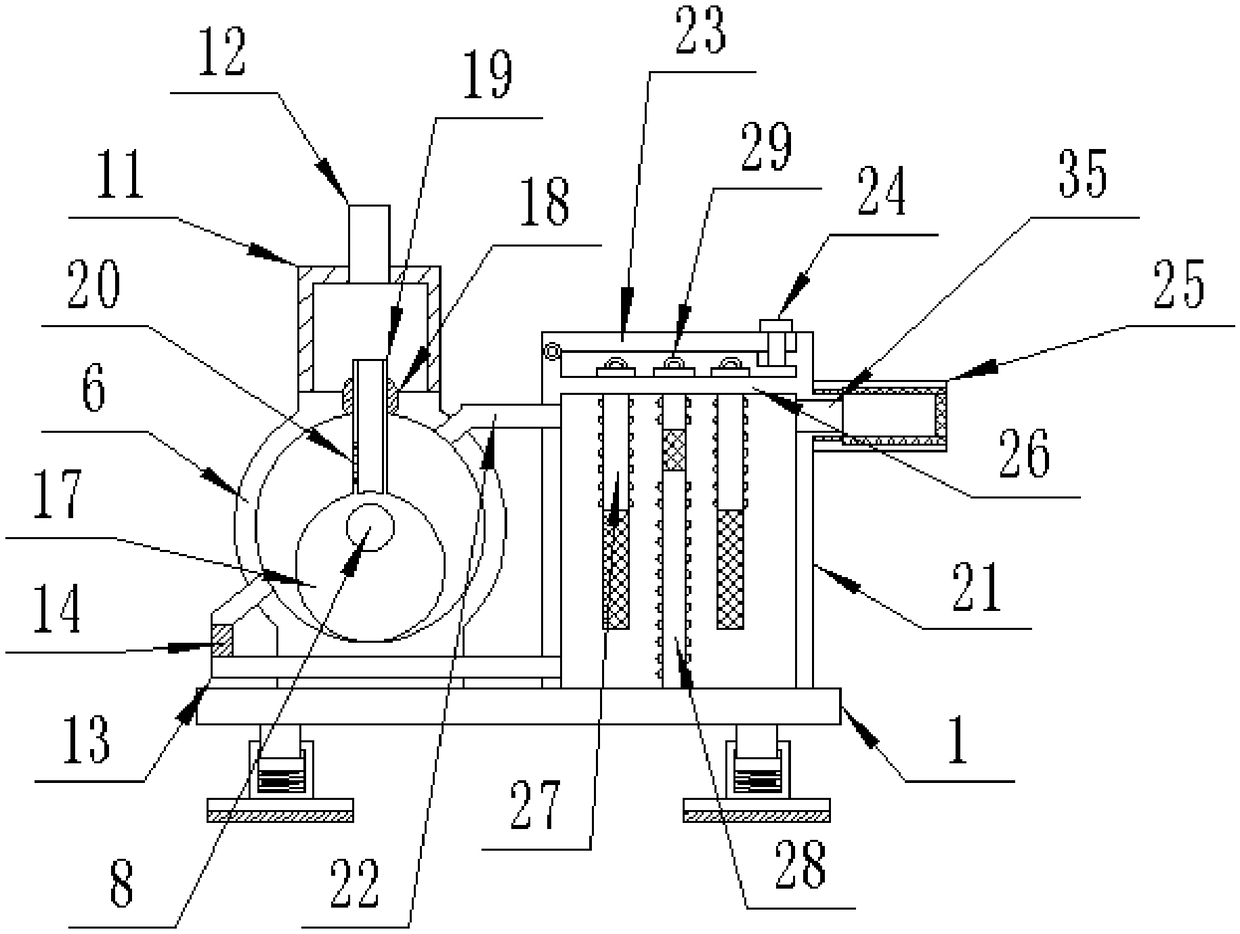

Processing equipment of perlite

InactiveCN107913552AImplement automatic cleanupGuaranteed adsorption efficiencyDispersed particle filtrationTransportation and packagingProcess equipmentEngineering

The invention relates to processing equipment of perlite. The processing equipment comprises a cleaning device, wherein the cleaning device is provided with an upper filter element and a lower filterelement; two rotary rods are arranged in the upper filter element, and the middle parts of the two rotary rods are rotationally connected; each side of the upper filter element is provided with a first opening, and the bottom part of the upper filter element is provided with a second opening; the top end of each rotary rod is connected with a first transverse rod; each first transverse rod penetrates through the corresponding first opening and extends outwards; a tension spring is connected between the top ends of the rotary rods; the bottom end of each rotary rod is connected with a second transverse rod; the top part of the lower filter element is connected with an ejection rod; the ejection rod penetrates through the second opening and extends inwards, the top end of the ejection rod isin a circular truncated cone shape, the small-diameter end of the ejection rod is kept away from the bottom end of the ejection rod, the top end of the ejection rod is abutted against the second transverse rod, and a spring is connected between the top end of the ejection rod and the top part of the upper filter element; two cleaning plates are arranged between the inner wall of the cleaning device and the filter elements; a pressure spring is connected between the inner wall of the cleaning device and each cleaning plate; each cleaning plate is abutted against the first transverse rod; the upper filter element is connected with a motor. By adopting the scheme, the processing equipment has the advantage that the filter elements can be automatically cleaned.

Owner:ZUNYI CITY GUI KE TECH

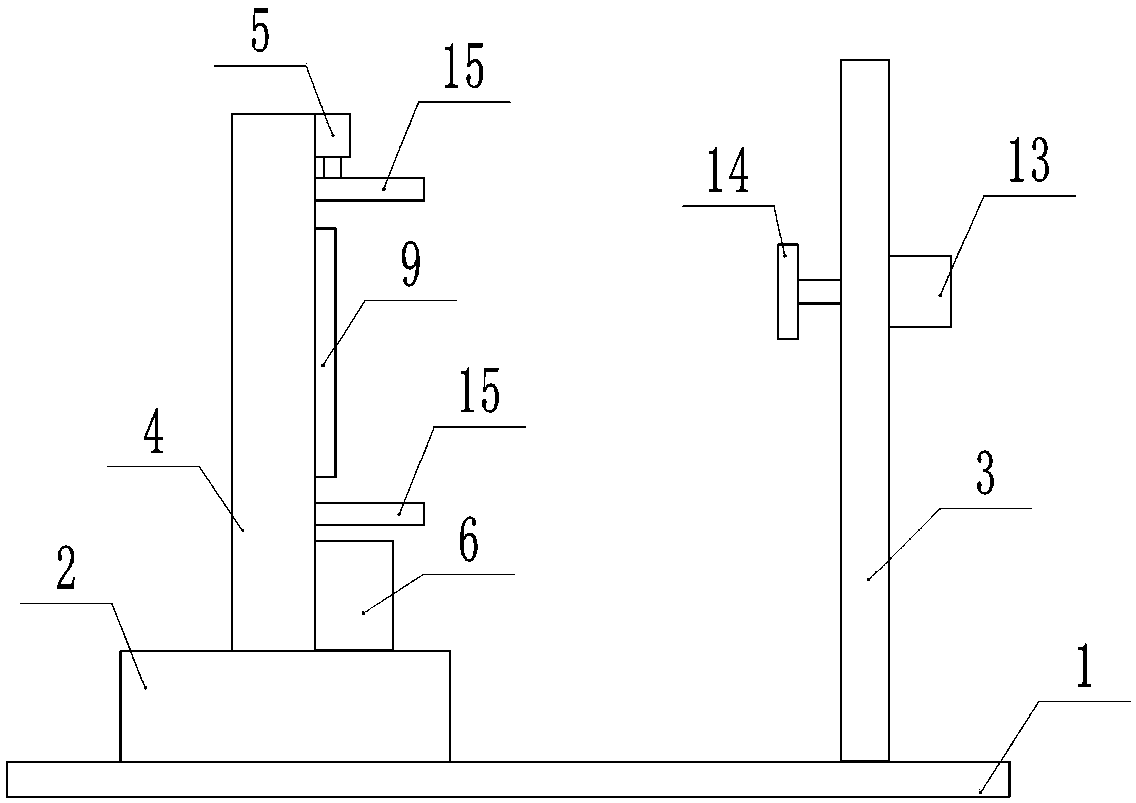

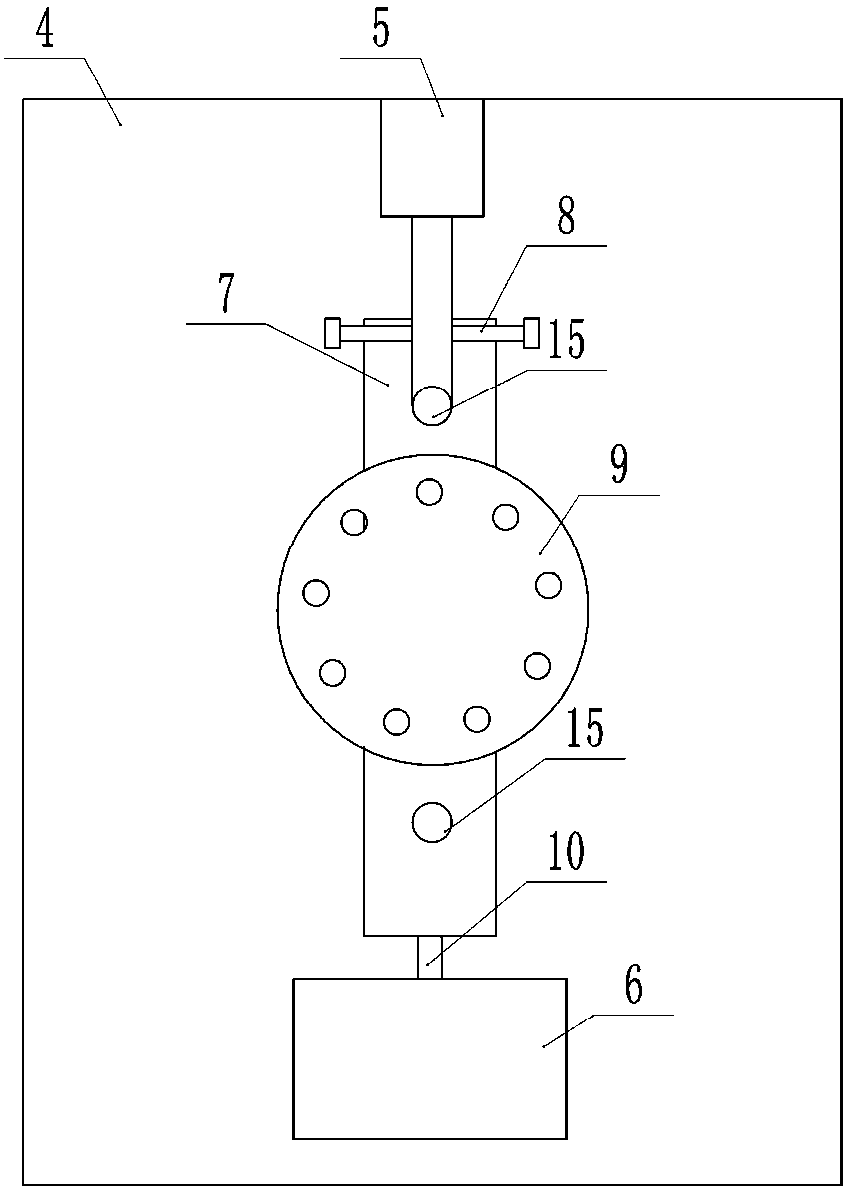

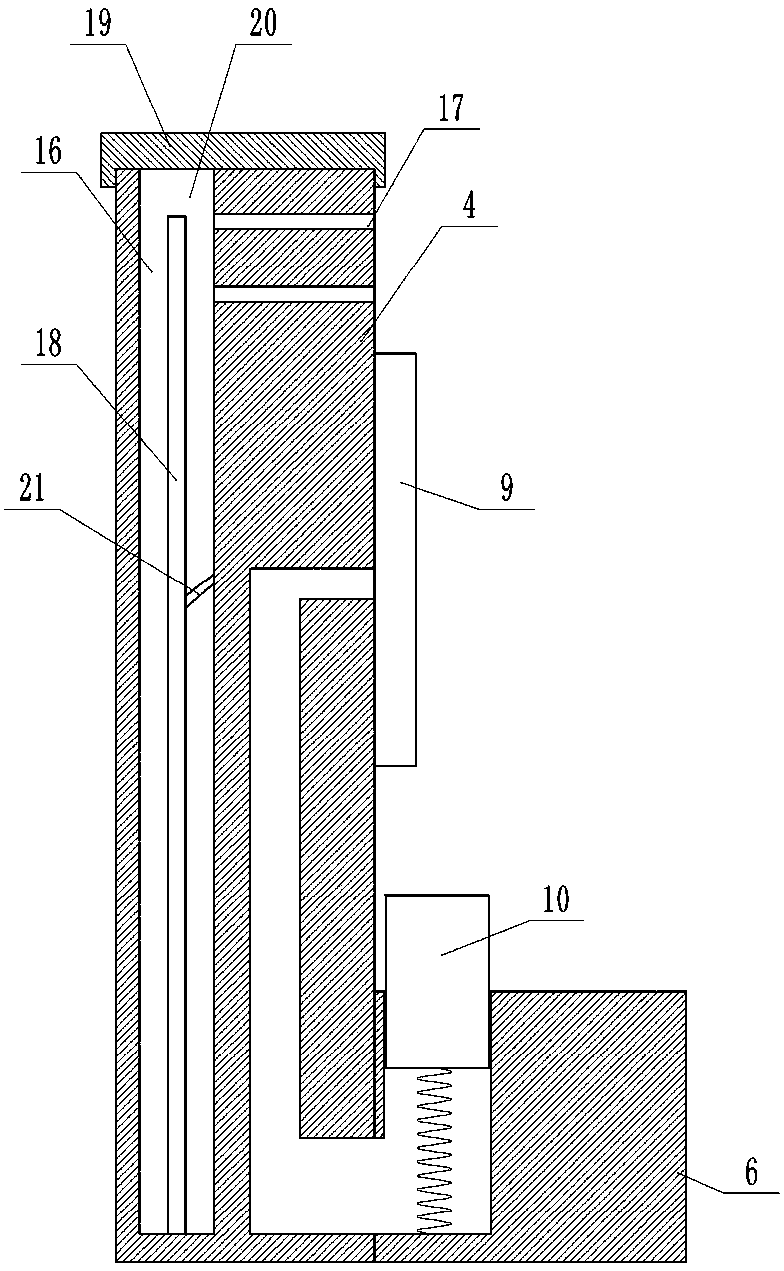

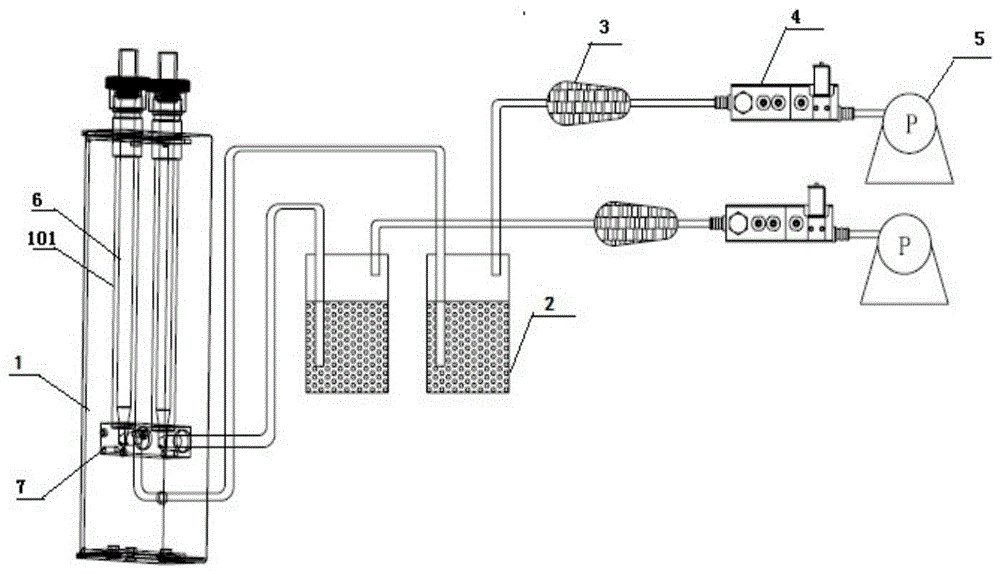

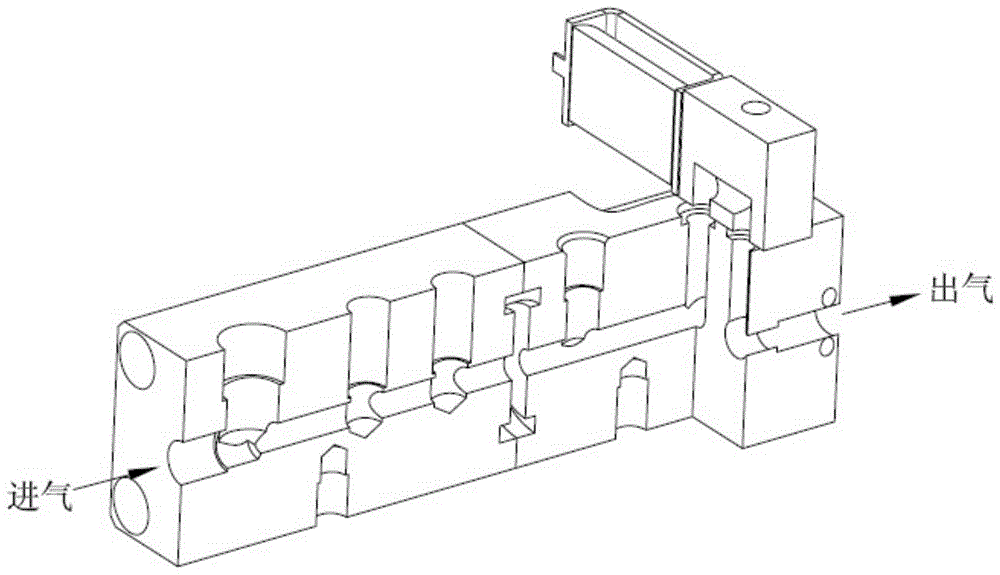

An Atmospheric Gas Mercury Sampling Device

ActiveCN104181014BGuaranteed adsorption efficiencyGuaranteed PenetrationWithdrawing sample devicesGaseous mercuryStreamflow

The invention relates to a gas sampling device, belongs to the field of environment monitoring, and in particular relates to an atmospheric gaseous mercury sampling device. The atmospheric gaseous mercury sampling device comprises a constant-temperature box, dryers, filters, flow controllers and gas pumps which are connected with one other in sequence, and adsorption gas pipes partially positioned in the constant-temperature box, wherein a gas suction opening of each adsorption gas pipe is fixed outside the constant-temperature box; a gas outlet of each adsorption gas pipe is connected with the corresponding dryer through a gas nozzle. Therefore, the atmospheric gaseous mercury sampling device has the advantages that atmospheric gaseous mercury sampling can be carried out, and the national condition requirement in China can be met; the sampling effect is good, and the constant-temperature heating box guarantees the adsorption efficiency and the penetrating rate of the adsorption pipes, and the special volume flow controllers enable the sampling flow range to be wide and the gas flow to be stable; the precision of the sampling device is high, and by virtue of a stainless steel structure, the reliability of the sampling device is also improved.

Owner:WUHAN TIANHONG INSTR

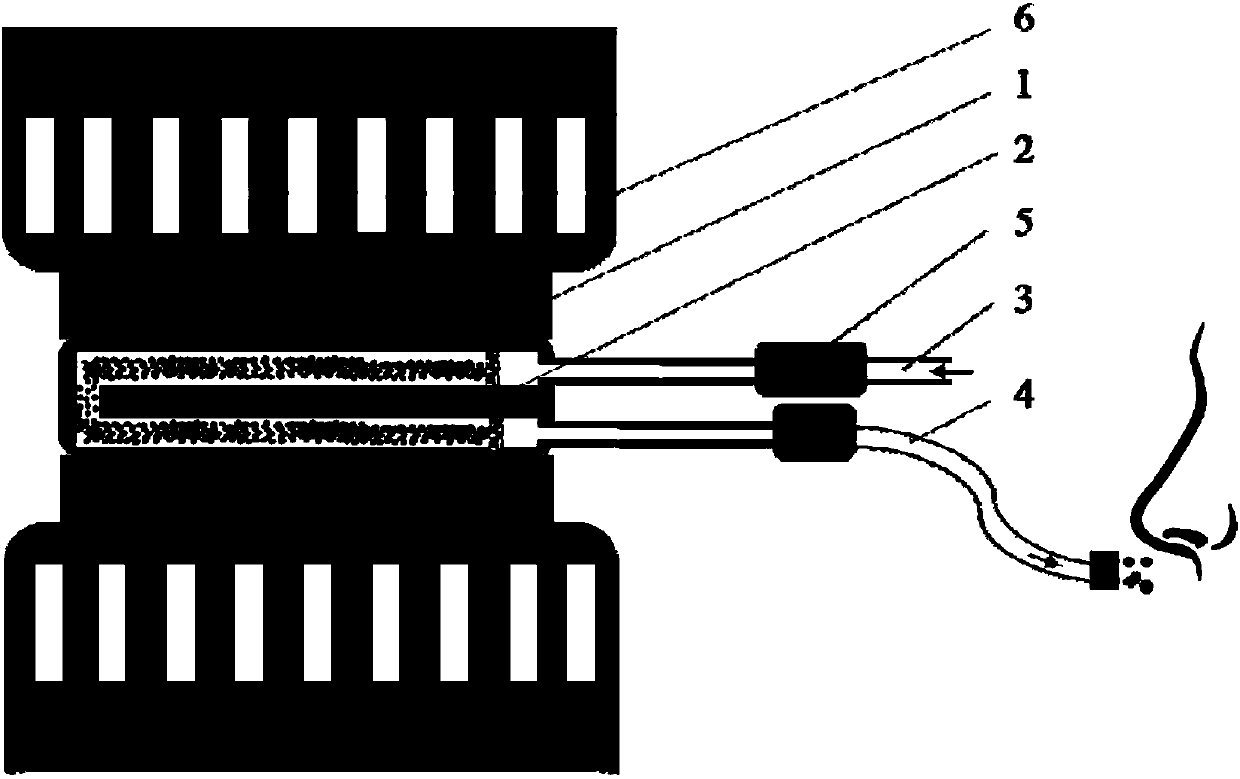

Smell enhancer based on pre-concentration principle

PendingCN108036995ARealize the collection and concentrationGuaranteed adsorption efficiencyPreparing sample for investigationHigh concentrationRefrigerated temperature

The invention provides a smell enhancer based on a pre-concentration principle. The smell enhancer comprises two semiconductor refrigerators and an adsorption material between two semiconductor refrigerators, wherein the semiconductor refrigerators are connected with a power supply; the adsorption material is cooled through the Peltier effect, so that smell is adsorbed, and a power supply is reversely connected for cooling the adsorption material, and therefore, adsorbed high-concentration smell can be released. The device can be utilized for concentrating low-concentration smell, and releasing the smell, so that the smell is directly judged by the sense of smell of a user.

Owner:NANJING UNIV

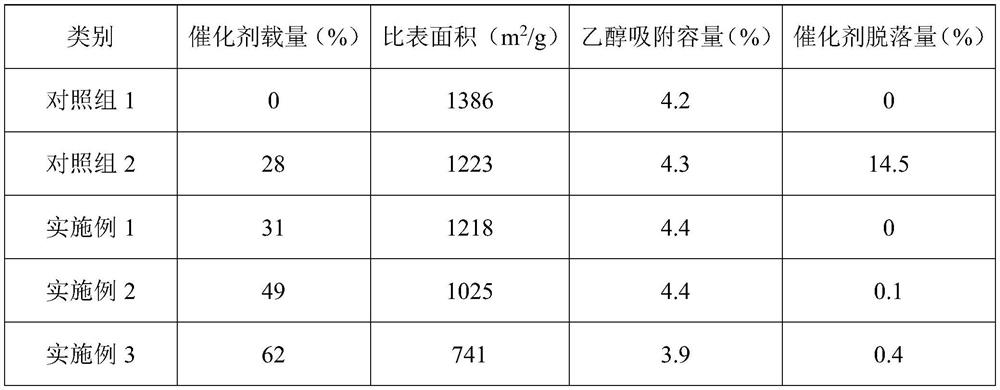

Efficient carbon fiber supported catalyst and preparation method thereof

ActiveCN113663729AMake full use of the effect of adsorption and concentrationIncrease loadOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationFiberCarbon fibers

The invention discloses an efficient carbon fiber supported catalyst and a preparation method thereof. The preparation method comprises the following steps: step 1, dissolving manganese nitrate, copper nitrate and nickel nitrate in deionized water and alcohol, and forming a precursor alcohol solution of nitrate; heating and stirring the precursor alcohol solution until viscous thick gel is formed; and drying and calcining to obtain catalyst powder, wherein the catalyst mainly comprises a mixture of manganese oxide, copper oxide and nickel oxide; step 2, carrying out ball milling on the catalyst powder, and then mixing and stirring the catalyst powder with a prepolymer, a photoinitiator and silica sol for 10-60 minutes to form a mixed dipping solution; and step 3, completely immersing carbon fibers in the mixed dipping solution, carrying out ultrasonic treatment for 0.5-2 h, and then standing for 0.5-2 h; taking out the wet carbon fibers and placing the wet carbon fibers under a high-pressure mercury lamp or a xenon lamp for irradiation until drying; and dipping and loading the carbon fibers once or for multiple times. The catalyst has the advantages of high catalyst loading rate, difficult falling of the catalyst and the like.

Owner:南大恩洁优环境技术江苏股份公司

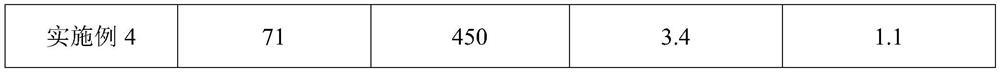

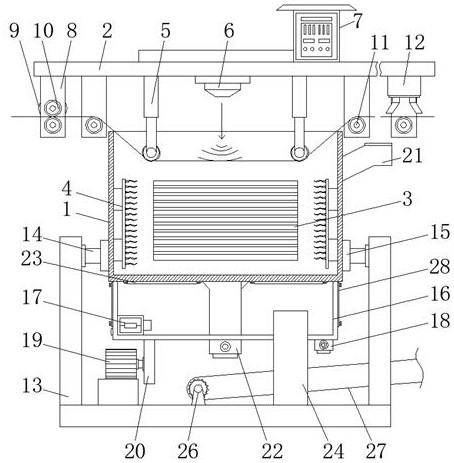

Filtering device for dehydrating gypsum generated by desulfurization

The invention belongs to the technical field of dehydration filtering devices, and particularly relates to a filtering device for dehydrating gypsum generated by desulfurization. The filtering device comprises a filtering cavity and an external fixed base plate, wavy sheets are arranged on both sides of the inner cavity of the filtering cavity, and a control box is mounted above the external fixed base plate; and a distance measuring instrument positioned right above the filtering cavity is fixedly mounted at the bottom of the external fixed base plate. A vibrating device is arranged in the filtering cavity, a sealing box is used as power to shake a fluff sheet plate, gypsum in the filtering cavity is precipitated, water is floated at the upper part of the inner cavity of the filtering cavity, then the distance measuring instrument is used for detection, and a controller in the control box is used for controlling the lifting height of a lifting device and adjusting the lifting height of the lifting device. Thus a water absorption device below the lifting device continuously adsorbs water in the upper-layer inner cavity of the filtering cavity.

Owner:烟台核一过滤设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com