High-efficiency energy-saving activated carbon fiber organic waste gas recycling system

A technology of activated carbon fiber and organic waste gas, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of poor desorption effect, poor sealing effect of the adsorber valve cover, energy waste, etc., to maintain adsorption efficiency, Improve the effect of adsorption or desorption, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

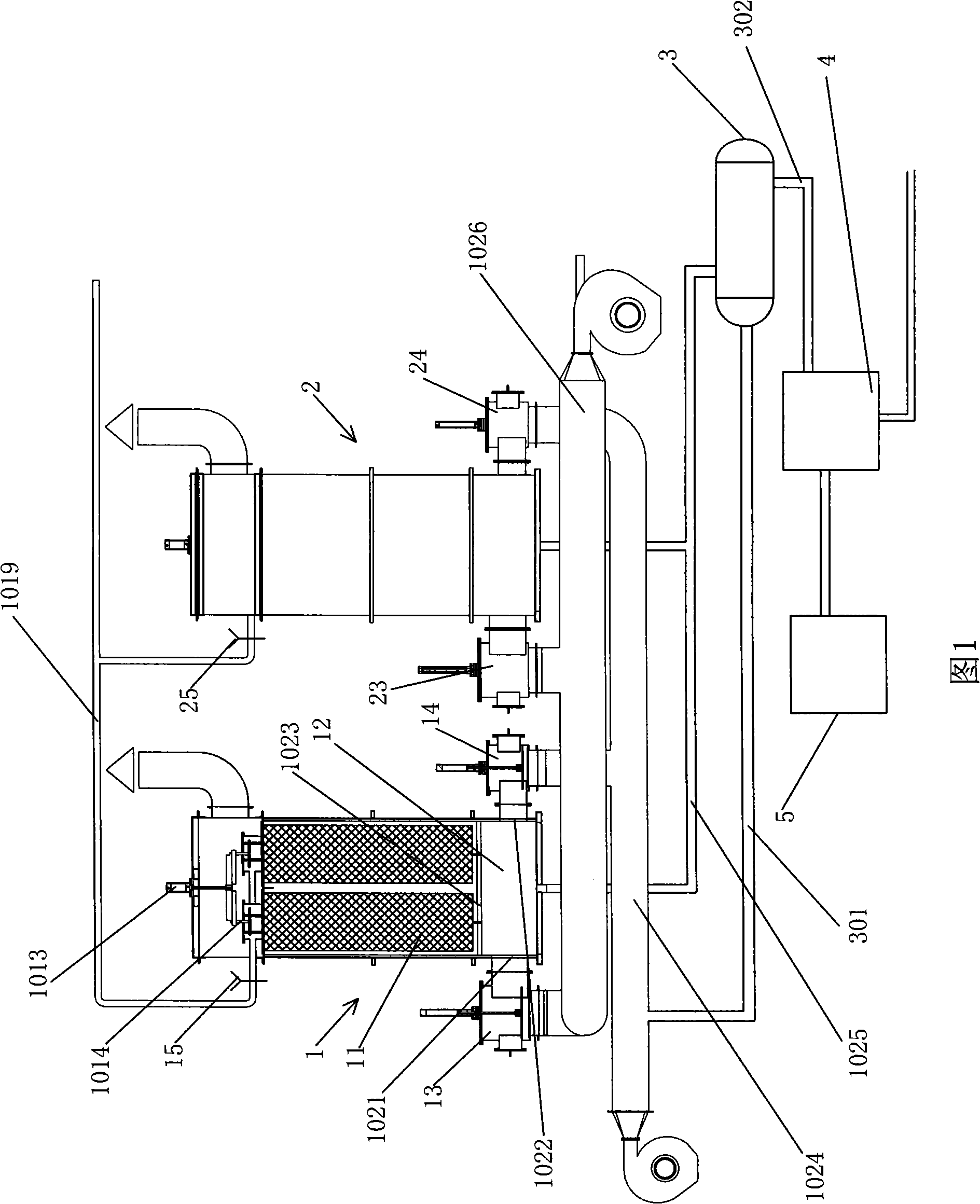

[0025] In this embodiment, two activated carbon adsorbers are installed in a high-efficiency and energy-saving activated carbon fiber organic waste gas recovery system as an example, and the content of the invention is described in detail:

[0026] Combined with Figures 1, 2, 3, and 4, the high-efficiency and energy-saving activated carbon fiber organic waste gas recovery system includes: two activated carbon adsorbers, activated carbon adsorber 1 and activated carbon adsorber 2, taking activated carbon adsorber 1 as an example to analyze the inside of the activated carbon adsorber The structure is explained.

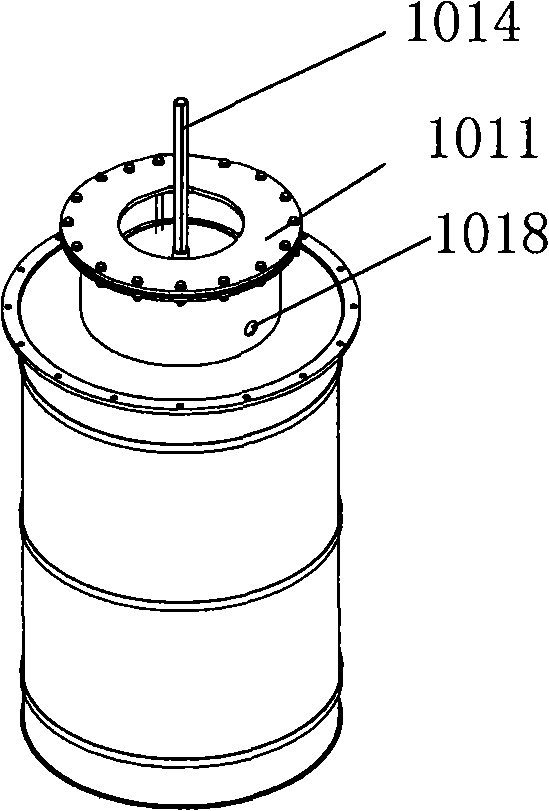

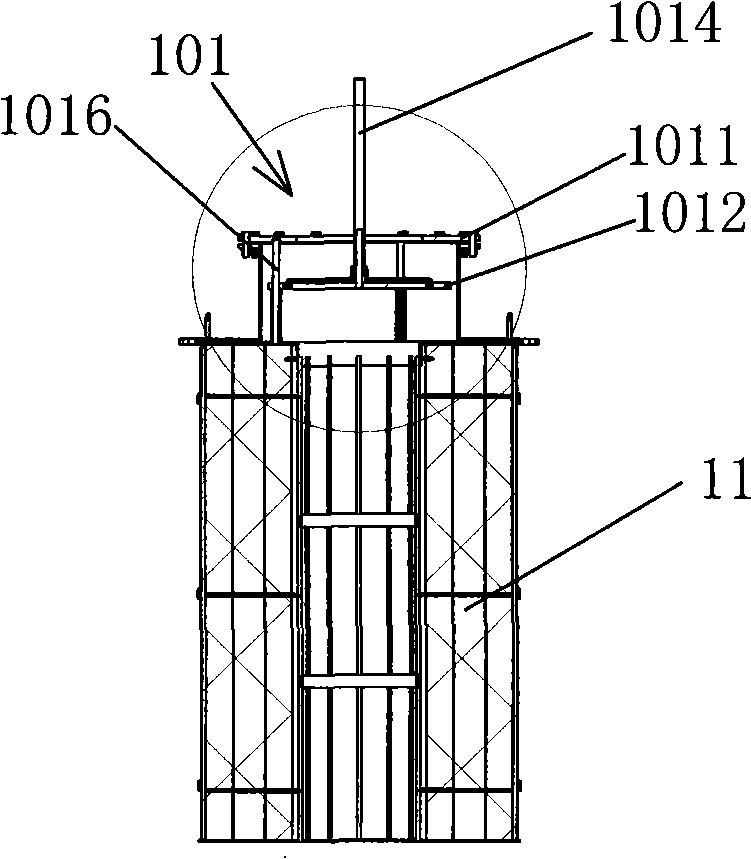

[0027] The activated carbon adsorber 1 is equipped with an adsorption filter element. The valve 101 configured by the adsorption filter element 11 is a built-in valve core. The valve 101 includes a flange 1011, a sealing disc 1012 and an opening cylinder 1013. The flange 1011 is fixed above the adsorption filter element 11, and the sealing disc 1012 is set as a valve co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com