Patents

Literature

330 results about "Aromatic solvents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An aromatic solvent is a solvent that contains an aromatic hydrocarbon such as naptha, toluene or xylene. Aromatic solvents are primarily used as solvents and diluents in various industrial fields. Aromatic solvents such as toluene are commonly used in paints, varnishes, adhesives and as chemical intermediates.

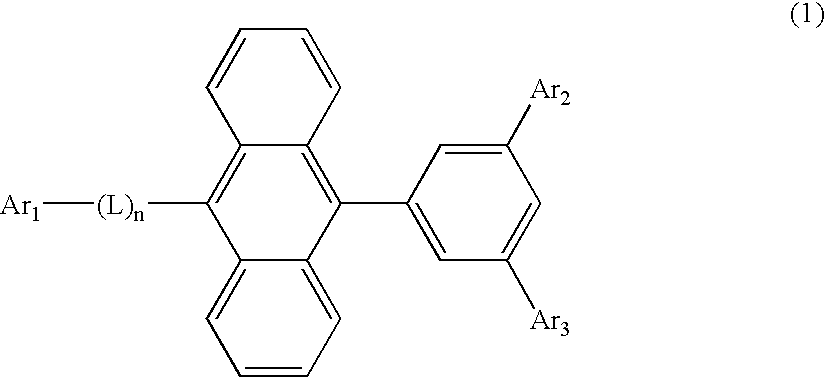

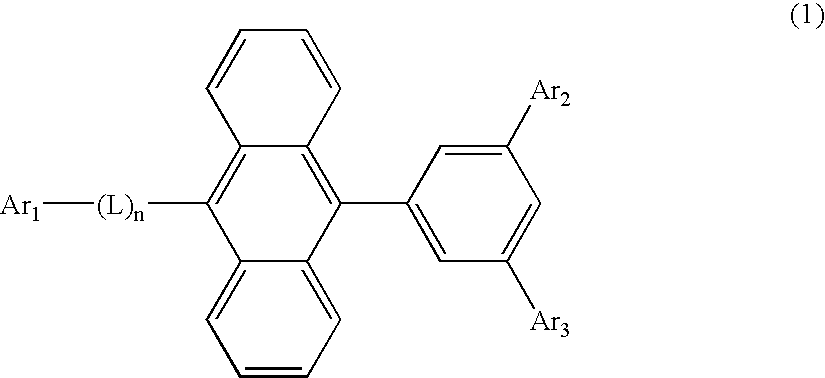

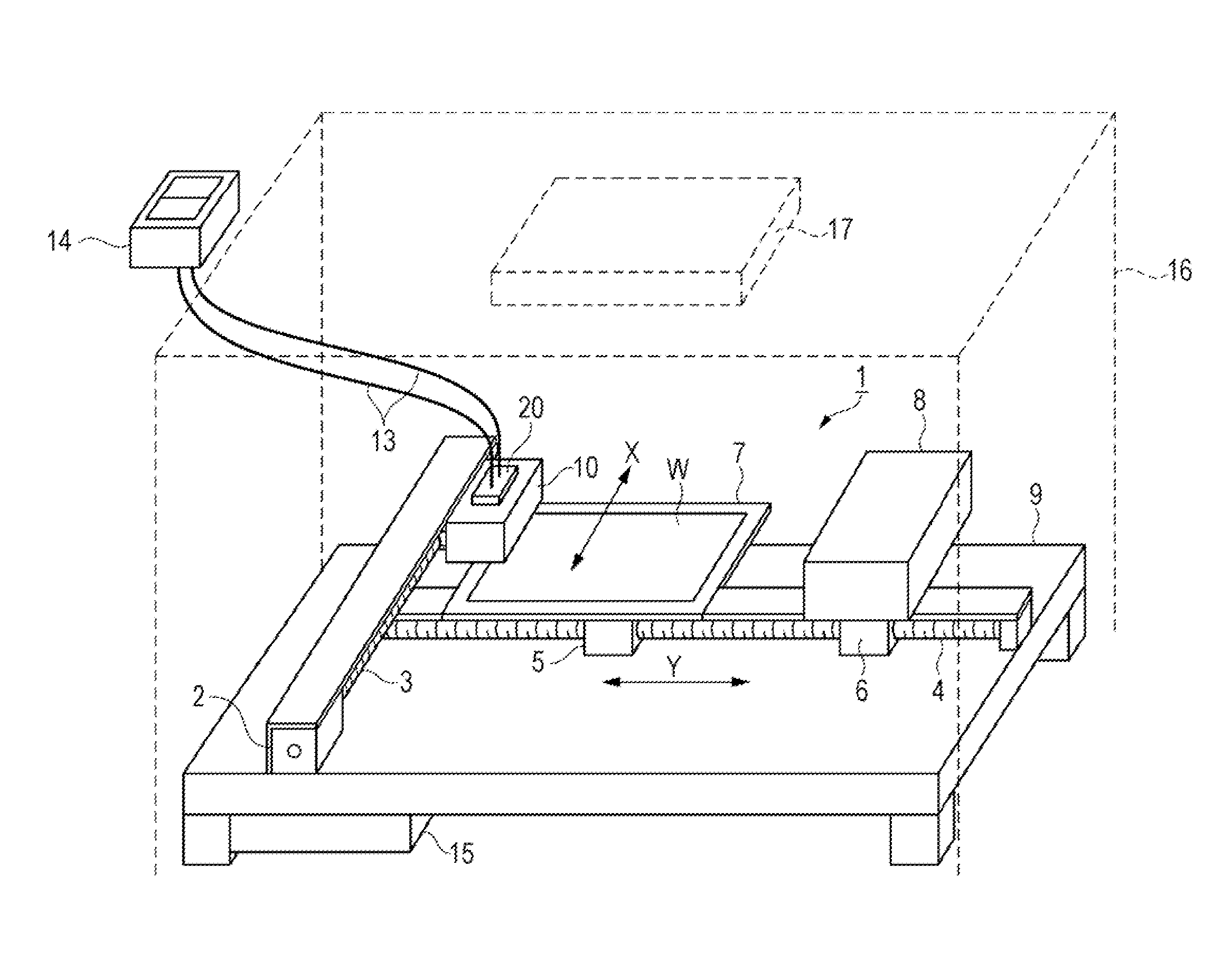

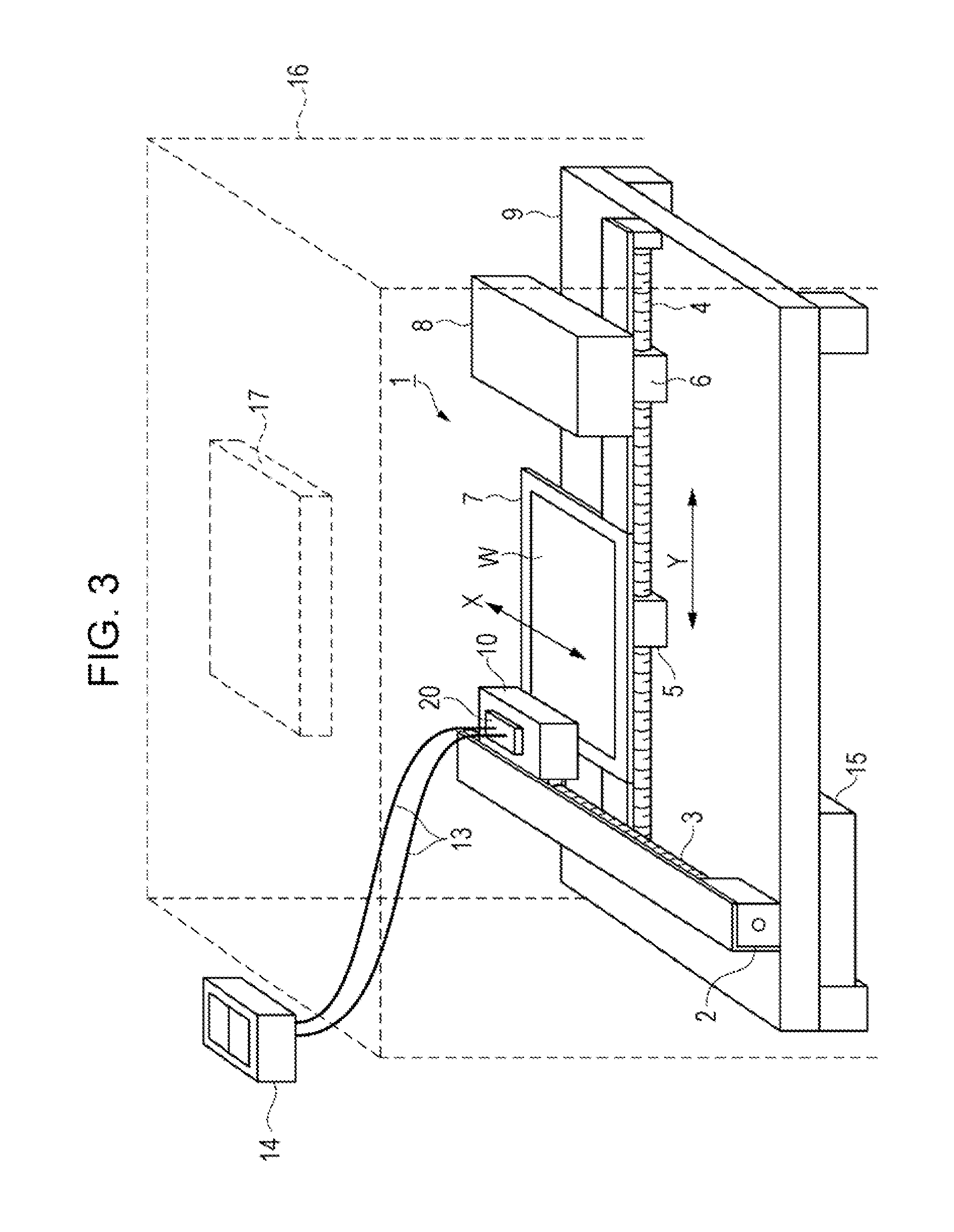

Organic-electroluminescence-material-containing solution, method for forming thin film of organic electroluminescence material, thin film of organic electroluminescence material and organic electroluminescence device

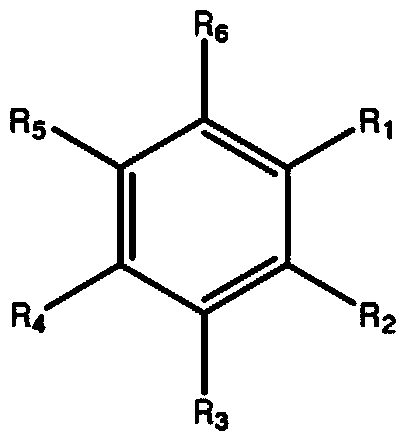

An organic EL material-containing solution contains an organic EL material, a solvent and a viscosity control agent. The organic EL material contains a host and a dopant.The host is a compound shown by Formula (1) below and has a solubility of 2 wt % or higher in the solvent. The solvent is an aromatic solvent, while the viscosity control agent is an alcohol type solution or an alkyl-substituted aromatic solution having 4 or more carbon atoms.

Owner:IDEMITSU KOSAN CO LTD

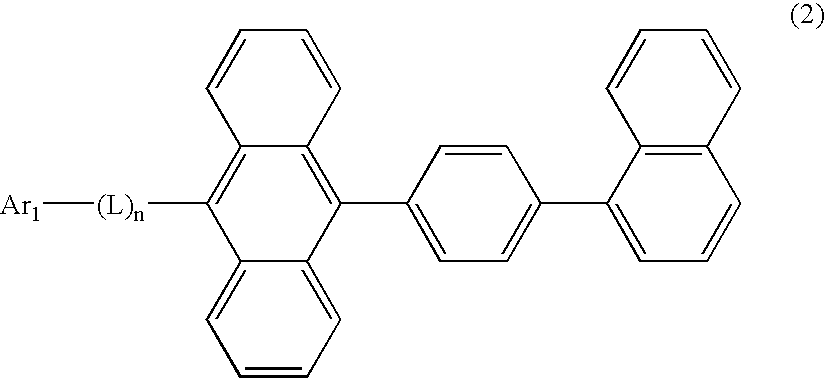

Methods for synthesis of oligonucleotides

Improved methods for synthesis of oligonucleotides and other phosphorus-linked oligomers are disclosed. The methods include the use of aromatic solvents, alkyl aromatic solvents, halogenated aromatic solvents, halogenated alkyl aromatic solvents, or aromatic ether solvents to achieve deprotection of protected hydroxyl groups.

Owner:IONIS PHARMA INC

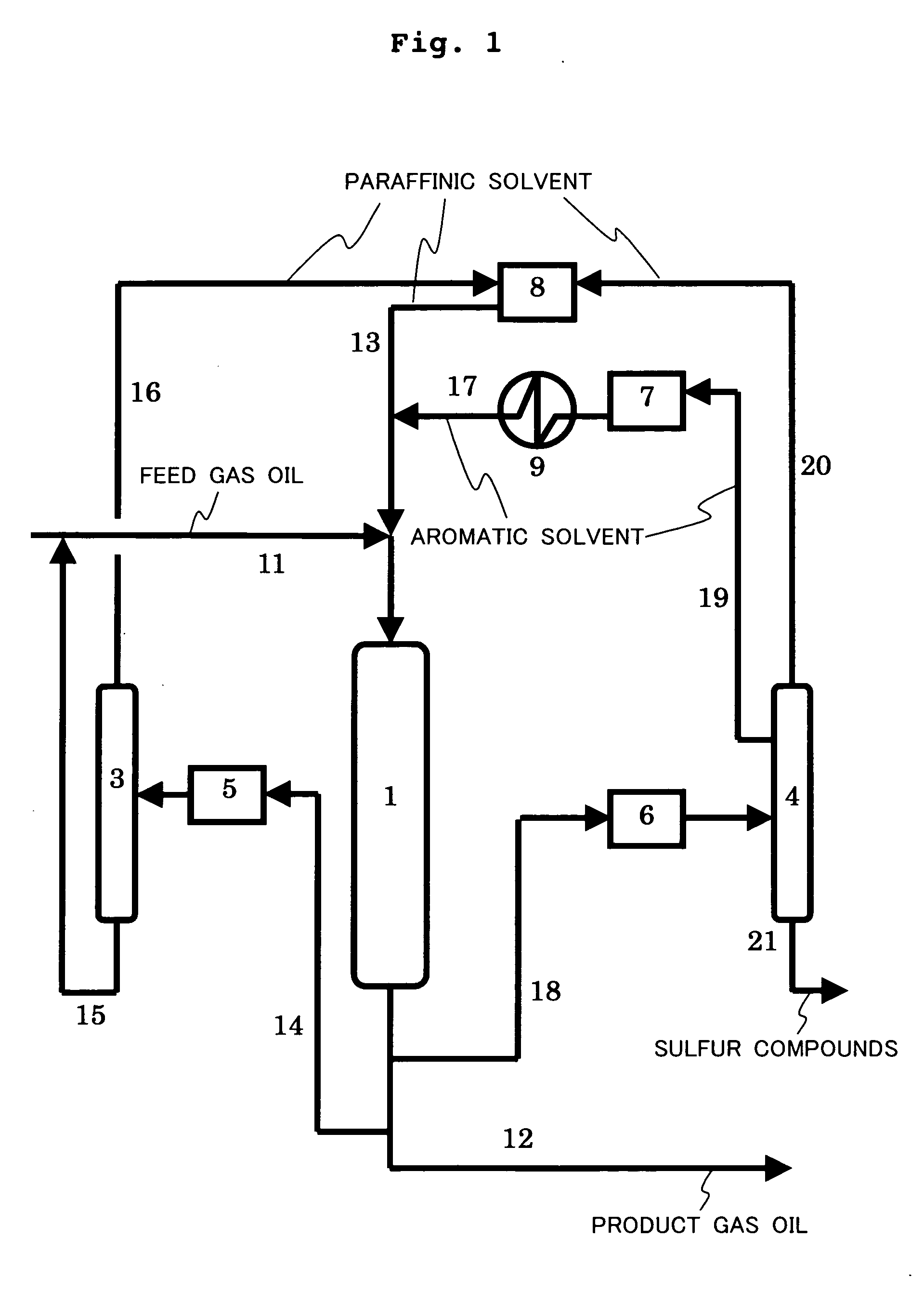

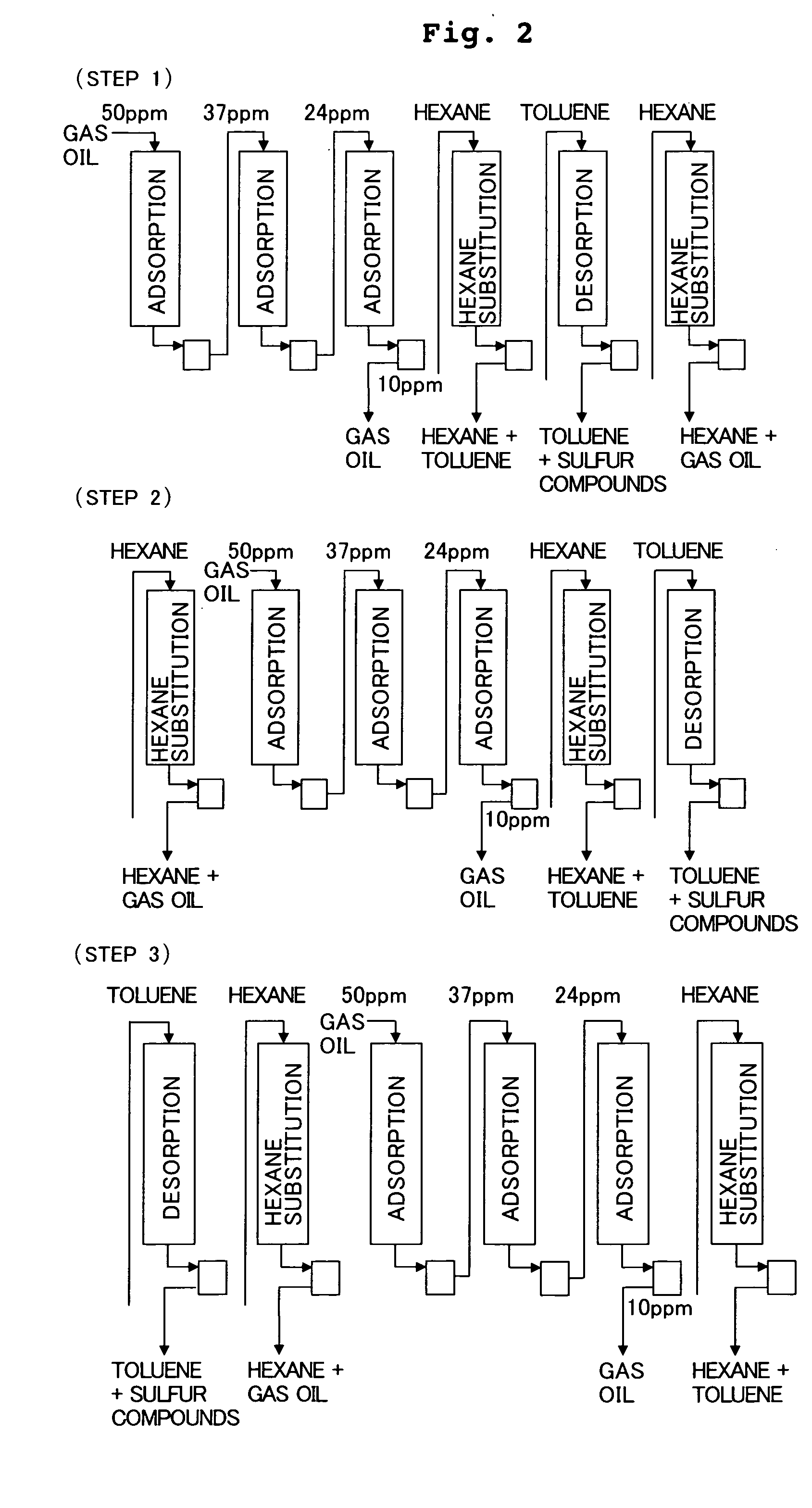

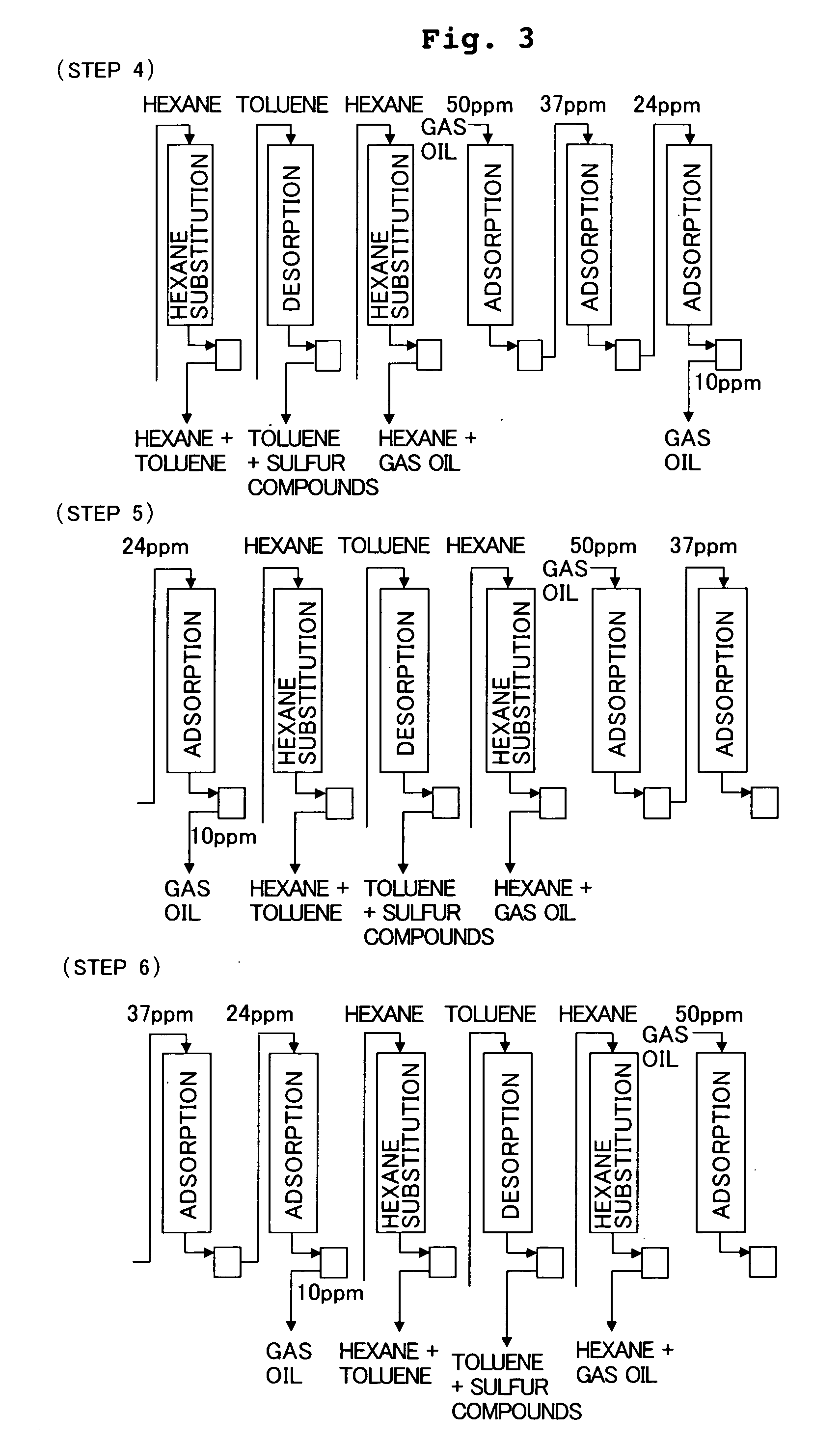

Adsorption desulfurization agent for desulfurizing petroleum fraction and desulfurization method using the same

InactiveUS20050173297A1Reduce equipment costsLow running costOther chemical processesLiquid organic insulatorsDesorptionTower

A desulfurization method for a gas oil which includes a step of removing sulfur compounds contained in a gas oil distillate product by the adsorption with an adsorptive desulfurization agent formed of a fibrous active carbon and provided in an adsorption tower (1), and a desorption regeneration step of washing the used adsorptive desulfurization agent with an aromatic solvent to regenerate the desulfurization agent. The method allows the production of gas oil being satisfactorily freed of sulfur content at relatively low equipment and operation costs over a long period of time, and in the method, difficult-to-remove sulfur compounds, such as 4,6-DMDBT, and polycyclic aromatic compounds having two or more rings are selectively removed.

Owner:JAPAN ENERGY CORP

Alkaline earth metal containing precursor solutions

InactiveUS20090226612A1Anti-corrosive paintsLiquid/solution decomposition chemical coatingAlkaline earth metalBoiling point

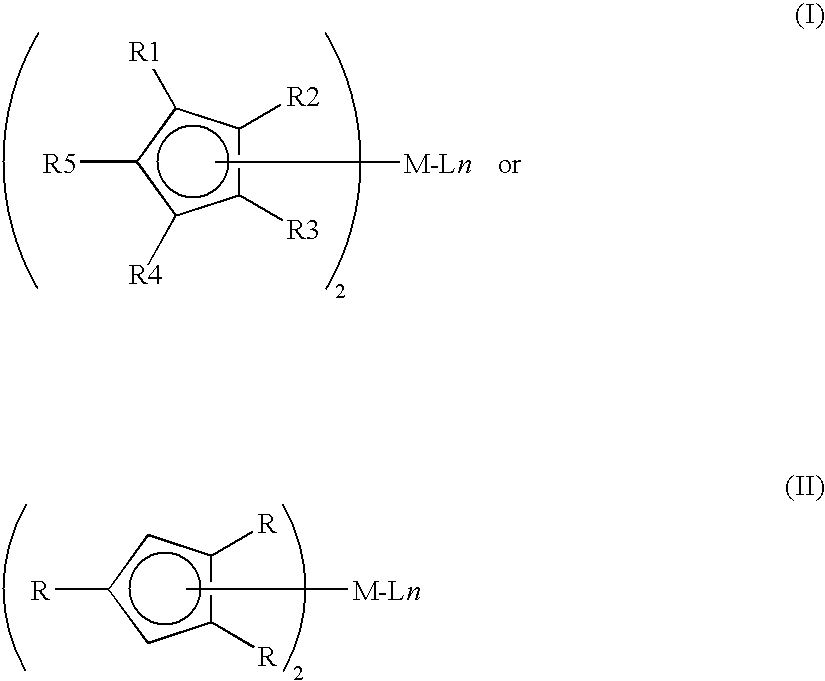

Methods and compositions for depositing a film on one or more substrates include providing a reactor with at least one substrate disposed in the reactor. A liquid precursor solution is provided, where the liquid precursor solution comprises a solid precursor and an aromatic solvent. The solid precursor has the general formula:M(RmCp)2Ln;wherein M is an alkaline earth metal, and each R is independently either H or a C1-C4 linear, branched, or cyclic alkyl group. L is a Lewis base; m is 2, 3, 4, or 5; and n is 0, 1, or 2. The aromatic solvent comprises at least one aromatic ring, and has a greater boiling point than the melting point of the solid precursor. The liquid precursor solution is vaporized to form a precursor solution vapor, and the vapor is introduced into the reactor. At least part of the vapor is deposited onto the substrate to form an alkaline earth metal containing film.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

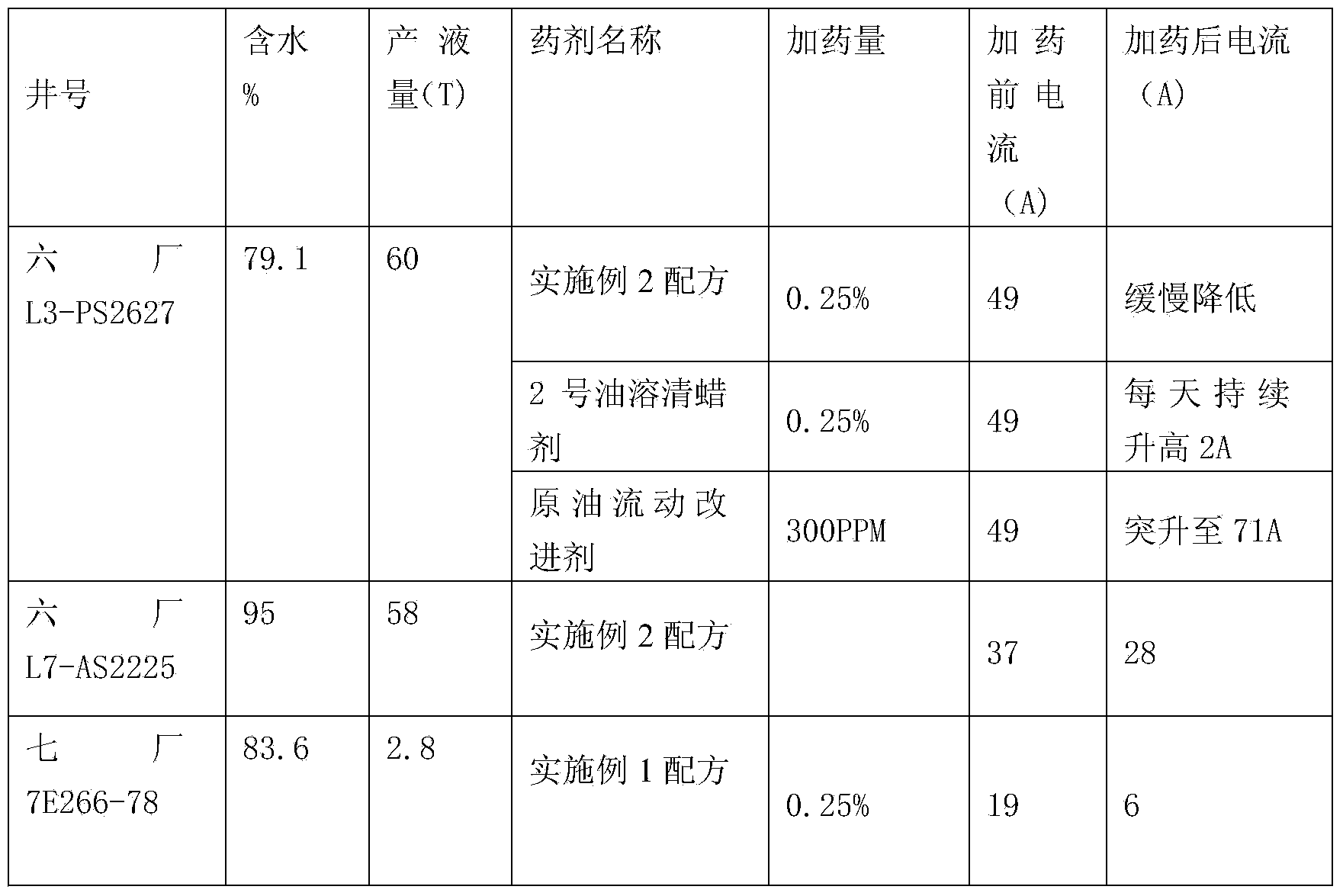

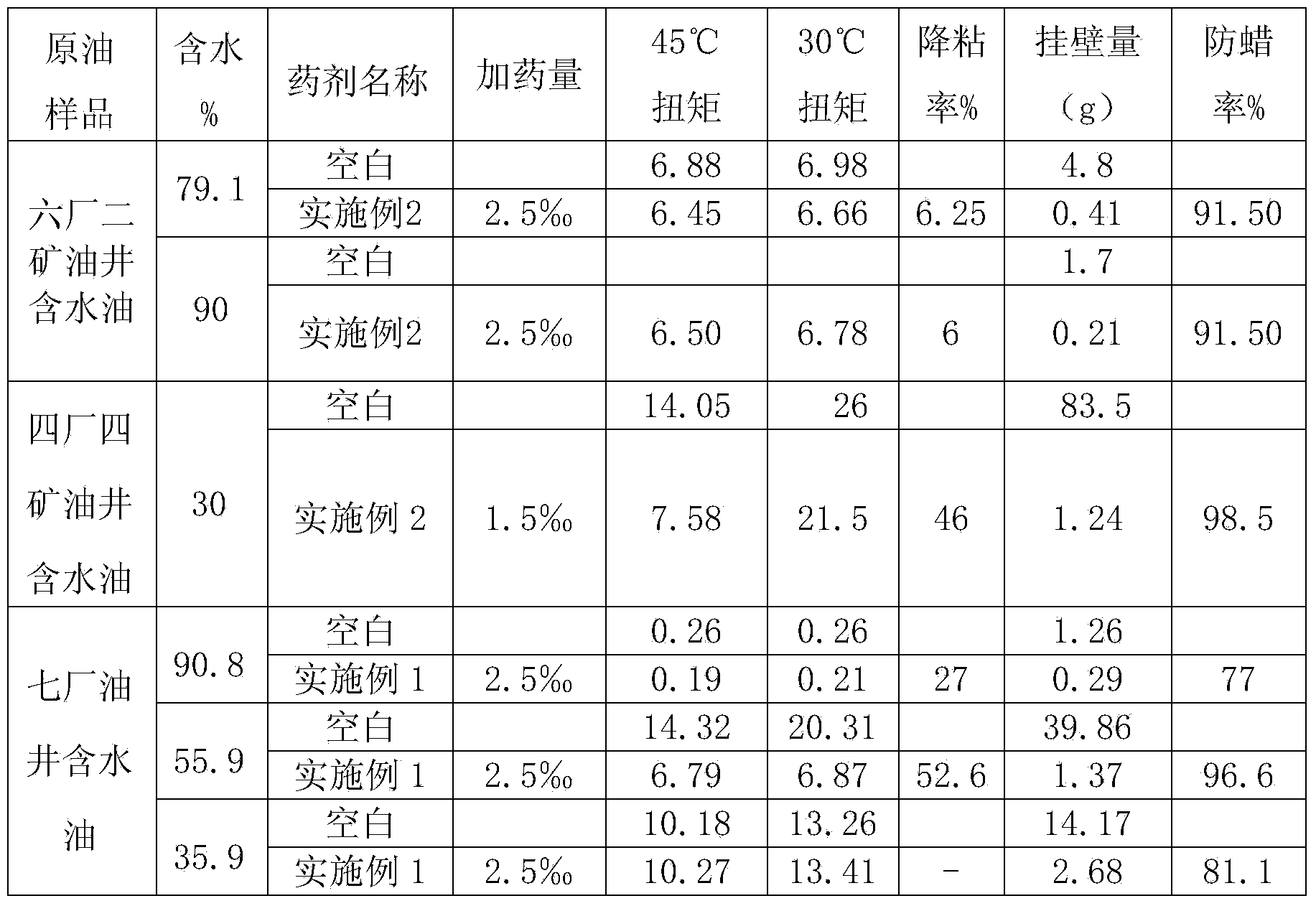

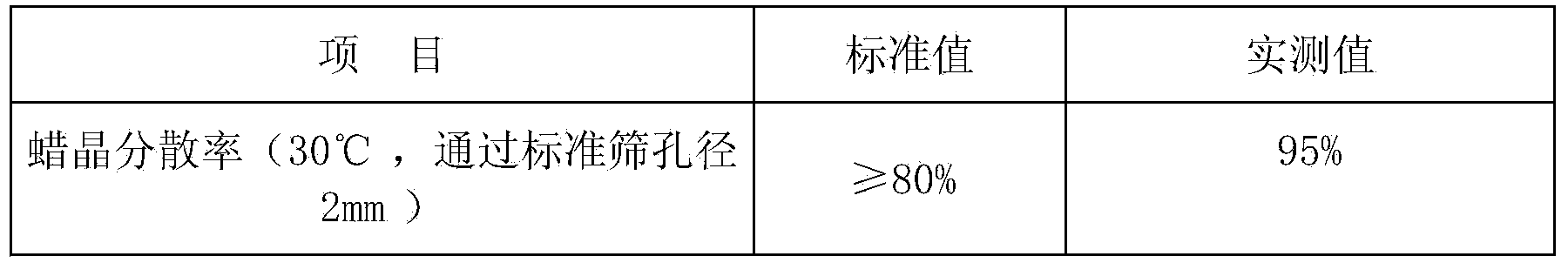

Microemulsion heavy wax crystal emulsifying dispersant applied to oil well for tertiary oil recovery

InactiveCN103614128AUnique penetrationImprove permeabilityDrilling compositionHigh carbonAromatic solvents

The invention relates to a microemulsion heavy wax crystal emulsifying dispersant applied to an oil well for tertiary oil recovery, and is mainly used for solving the problem that the oil production rate is influenced due to the high return pressure and the short thermal washing period of the oil recovery well caused by that serious wax precipitations are generated by the oil well which contains thickened oil and is high in polymer flooding and viscosity. The emulsifying dispersant is prepared from the following components by weight percent: 1% to 3% of high-molecular polymer wax inhibitor, 13% to 25% of organic aromatic solvent, 1% to 3.5% of emulsifying agent, 8% to 12% of sulfonate, 10% to 12.5% of alcohol, 10% to 20% of demulsifier and 25% to 35% of water. The emulsifying dispersant has the dual effects of eliminating and preventing the waxy bitumen colloid precipitations with long molecular chains or high carbon number in crude oil from being precipitated, so that the wall sticking quantity of condensate oil is greatly decreased; the running load of the oil well is reduced; and the well washing period is prolonged. Thus, the oil production rate is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

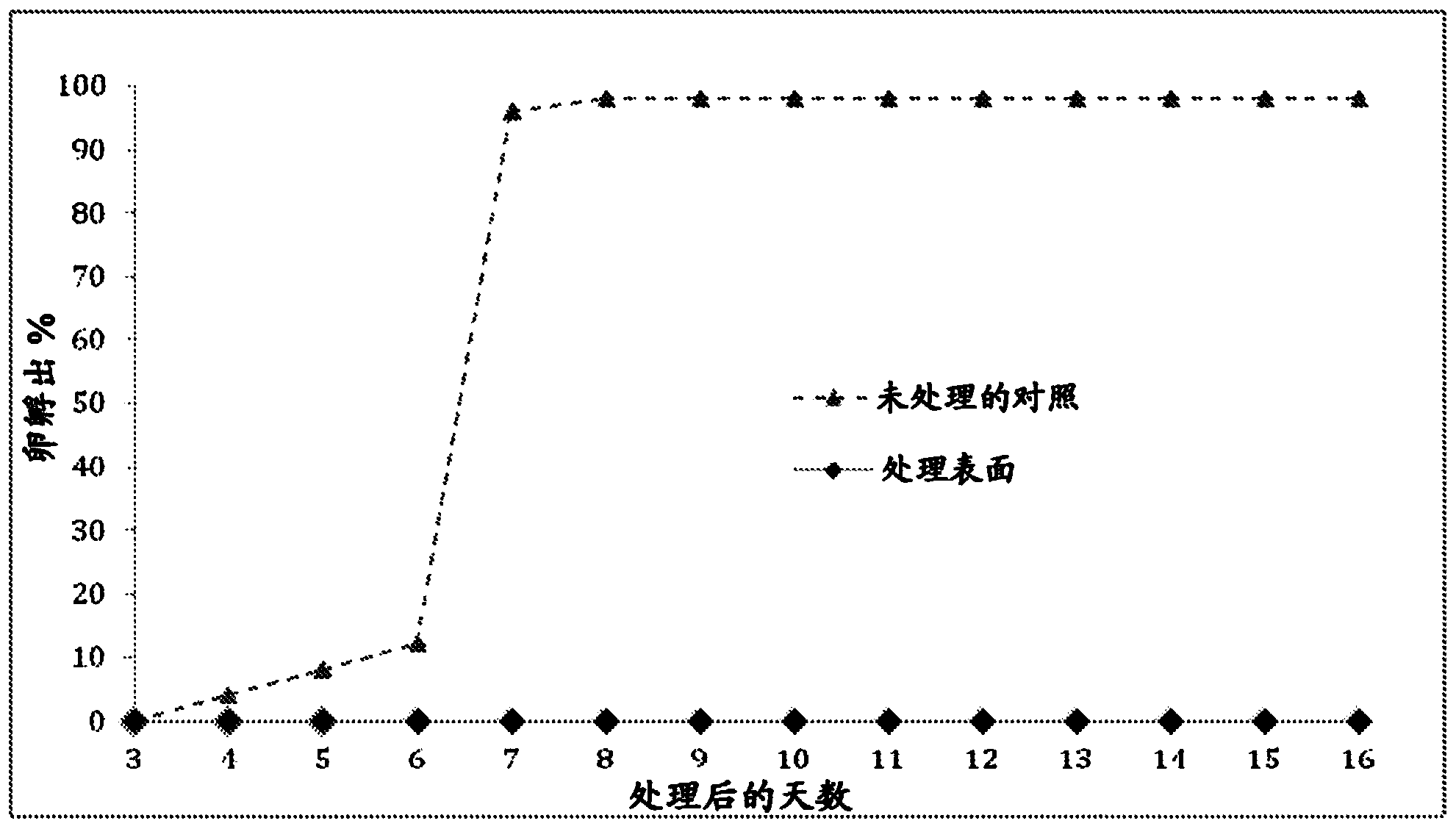

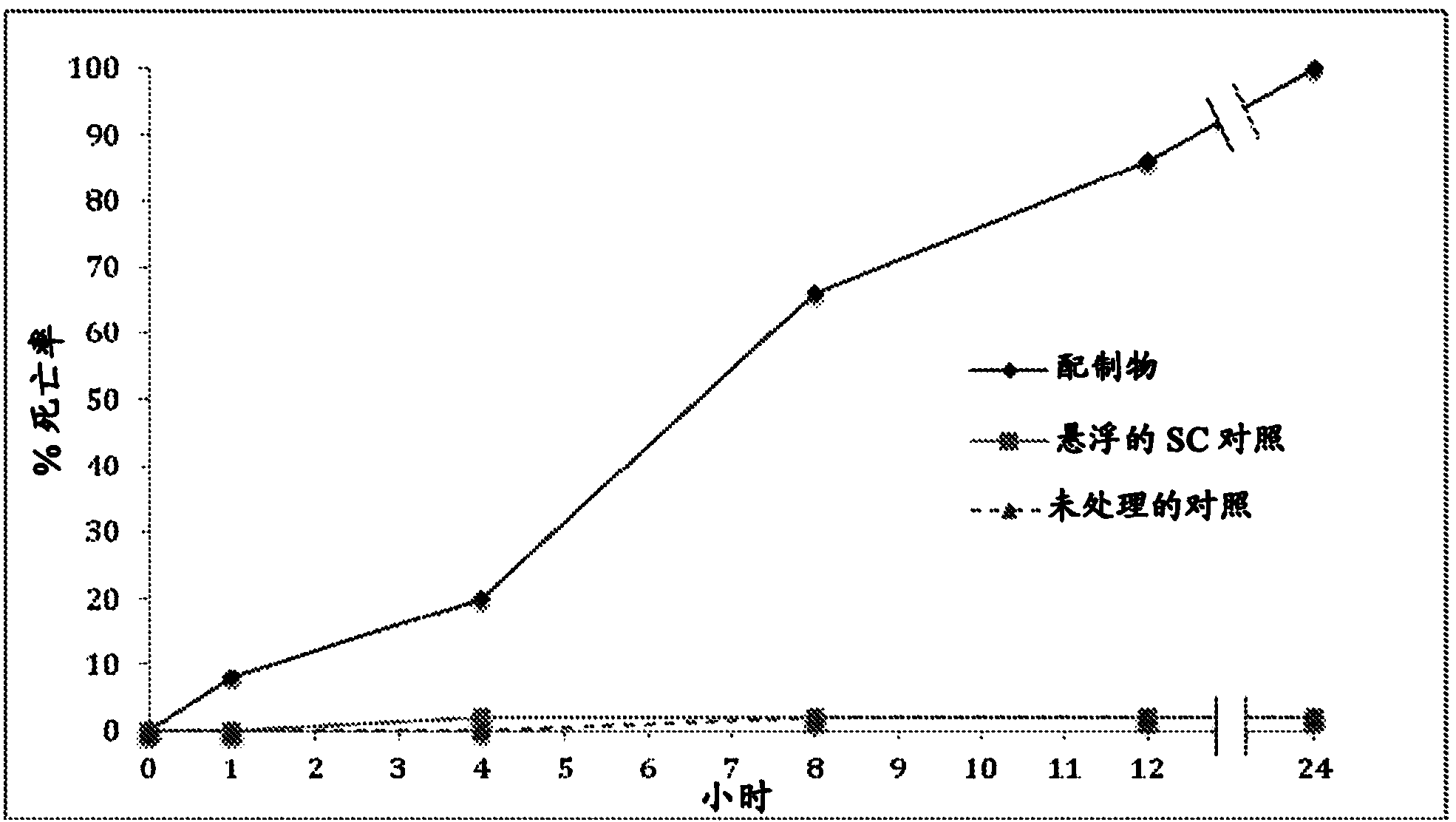

Pest control formulations and methods of making and using same

Compositions useful for controlling pests are disclosed. In some embodiments, the composition includes a pesticidal natural oil and a polar aromatic solvent. Methods of making and using the compositions are disclosed.

Owner:0903608 B C

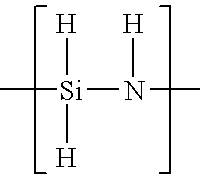

Anti-staining coating solution comprising inorganic polysilazane

By applying the solution comprising 0.5 to 10 % by weight of an inorganic polysilazane having repeating units represented by the general formula below and soluble in a solvent and a catalyst such as 4,4'-trimethylenebis (1-methylpiperidine) etc. onto the surfaces of the bodies and wheels of automobiles, dentures, tombstones, the interior and exterior of a house, products used with water in toilets, kitchens, washrooms, bathtubs, etc., signboards, signs, plastic products, glass products, etc., a rigid and dense silica coating is formed to confer a long-durable hydrophilic effect and anti-fouling effect on the surfaces. The solvent is properly selected from mineral spirit, paraffin type solvents, aromatic solvents, alicyclic solvents and mixture thereof depending on the article being coated.

Owner:CLARIANT FIANCE (BVI) LTD

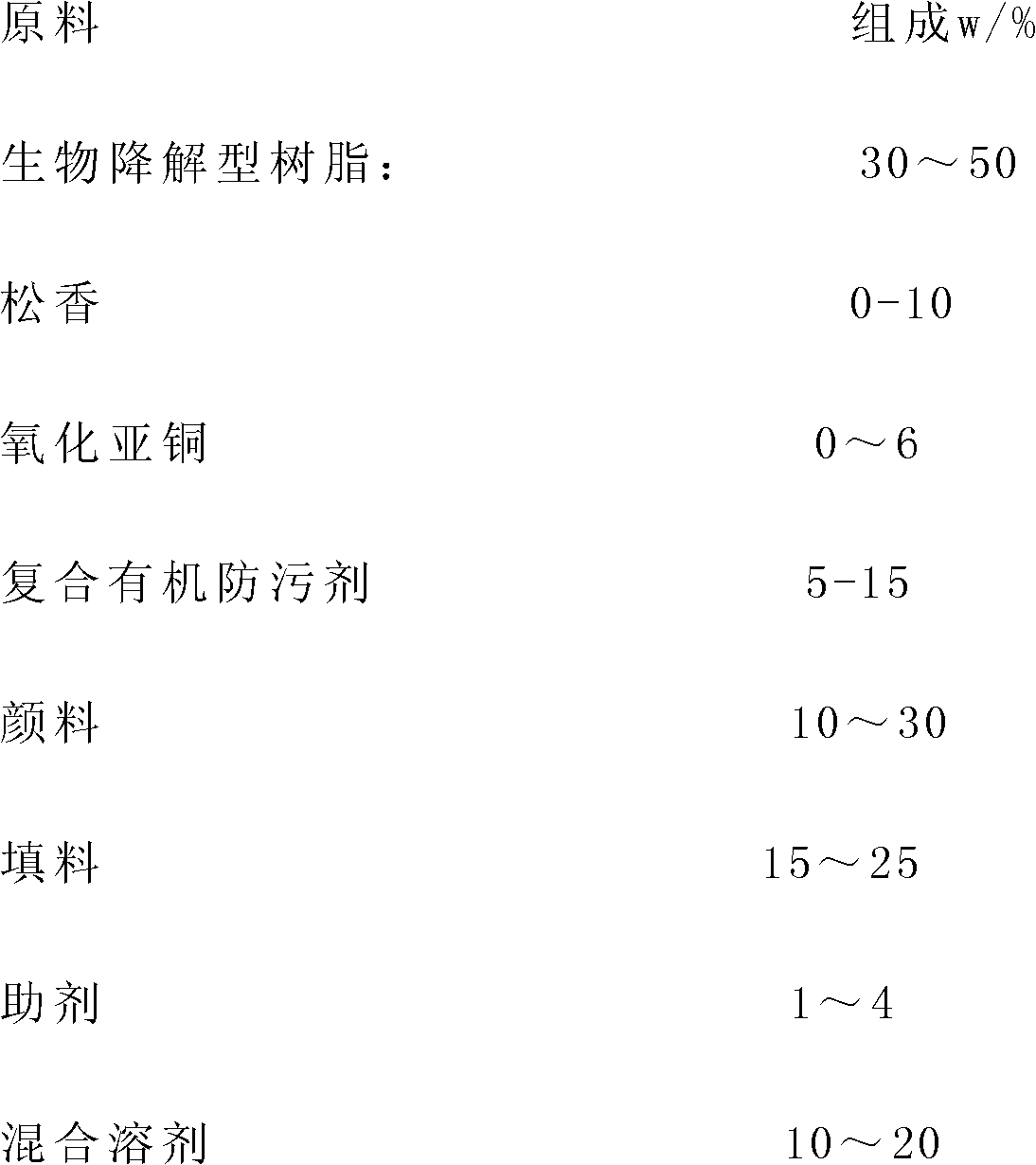

Resin for biodegradable anti-fouling paint, synthetic method of the same, and anti-fouling paint composition containing the same

ActiveCN102432802AReduce dosageHigh requirements for reaction conditionsAntifouling/underwater paintsPaints with biocidesCompound organicEnvironmental resistance

The invention provides a resin for a biodegradable anti-fouling paint. The resin for the biodegradable anti-fouling paint is a polymer containing a multi-block structure, characterized in that: the resin is prepared by polymerizing by polylactic acid oligomer, flexible segments, polyisocyanates under the effect of catalysts, wherein, the polylactic acid oligomer is prepared by carrying out reflux reaction on lactic acid having a monomer content of 80-85 % and aromatic solvents under negative pressure or normal pressure until no water generates; the flexible segments comprises polyols or / and polyester polyols; and the amount of the flexible segments accounts for 5-30 % of the weight percentage of the lactic acid raw material; and the amount of polyisocyanates accounts for 10-30 % of the weight percentage of the lactic acid raw material. The invention further provides a biodegradable anti-fouling paint composition containing the resin as a matrix resin. The anti-fouling paint contains composite organic antifouling agent and contains no or little cuprous oxide, and has the advantages of low toxicity, environmental protection, and good anti-fouling effect.

Owner:MARINE CHEM RES INST CO LTD

Methods and compositions for on-line gas turbine cleaning

InactiveUS20040016445A1Inorganic/elemental detergent compounding agentsDetergent mixture composition preparationCombustion chamberAromatic solvents

Methods and compositions for on-line cleaning of internal surfaces of selected sections of a hydrocarbon fuel burning gas turbine and associated heat recovery equipment, during operation. Cleaning solutions containing graphite and / or molybdenum-based particles and oil soluble corrosion inhibitors, aromatic solvents, and surfactants are selectively introduced directly into the combustion chamber (combustor) of the gas turbine, into the fuel stream, water washing system, or the combustion air system (hot gas path). The cleaning process dislodges unwanted ash deposit buildup and, thereby restores the gas turbine to rated power. When introduced into the compressor section, the particles impinge on the metal surfaces, cleaning them prior to entering the hot gas section where the process may be repeated. They may also be carried through the exhaust to additionally clean attendant heat recovery equipment, if present.

Owner:LIQUID MINERALS GRP LTD

Method for removing asphaltene deposits

InactiveUS20080020949A1Reduce and prevent formationPreventing and reducing precipitationWorking-up pitch/asphalt/bitumen by chemical meansFlushingKeroseneFuel oil

Compositions comprising at least one C4-C30 olefin or oxidation product thereof and kerosene or an aromatic solvent are particularly effective for use in removing asphaltene and asphaltene-containing organic deposits and in preventing or reducing the precipitation and deposition of asphaltenes from hydrocarbon fluids. When added to heavy oils comprising asphaltenes, alone or in combination with dispersants and further inhibitors, the invented compositions lower viscosity and pour point, and aid in preventing asphaltene precipitation during transport and in combustion.

Owner:INEOS USA LLC

Continuous sedimentation process for production of needle coke

InactiveCN101531909AGood for long-term operationEasy to operateWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionTarQuinoline

The invention relates to a continuous sedimentation process for production of needle coke. Under the continuous condition of in-out materials, the process carries out settling separation on an insoluble substance of quinoline to obtain a qualified light phase of the insoluble substance of the quinoline. The mixed ratio of an aliphatic solvent to an aromatic solvent is (0.6-1.2) to 1; the mixed ratio of a mixed solvent to soft coal-tar asphalt is (0.6-1.2) to 1; the mixed oil is pumped into settling separation equipment by a pump for the settling separation; light liquid slowly rises; and after the insoluble substance of the quinoline reaches the requirement, the light liquid is continuously discharged from the upper part and distilled to obtain refined asphalt. The continuous sedimentation process has the advantages that the prior intermittent sedimentation process is improved into the continuous sedimentation process, namely the in-out materials are processed under the continuous operating condition. The continuous operation can simplify operation, reduce equipment, the floor space and the blocking of the equipment, and is favorable for long-period operation of the process.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

Universal Synthetic Penetrating Lubricant, Method and Product-by-Process

ActiveUS20080182769A1Improve protectionOrganic chemistryLiquid carbonaceous fuelsEngineeringMineral spirit

A penetrating lubricant with the capacity to offer a both penetration into rust and corrosion. Further, this lubricant actively penetrates the crystalline surface of the metal while exhibiting extreme pressure lubrication, non-migrating with lasting protection. Further lubricant exhibits dielectric strength of over 8000 volts, at the same time cleaning electrical contacts, thereby reducing resistance and associated heat. The preferred embodiment may contain alpha-olefins, low-odor aromatic solvents, base oils, and high flash mineral spirits.

Owner:BESTLINE INT RESEACRH

Universal Synthetic Gasoline Fuel Conditioner Additive, Method and Product-by-Process

ActiveUS20100269404A1Reduce premature mechanical wearReduce failureLiquid carbonaceous fuelsAdditivesGasoline fuelEngineering

A process of producing a universal synthetic based gasoline fuel additive that cleans the fuel system including valves surface, lubricates the fuel pump, injectors and valves while allowing for a clean and more efficient burn. A major portion will consist of (a) Alfa-Olefins, (b) 2-propanol (c) Hydrolsomerized High VI HT Base Oils, (d) Dimethyl Ketones, (e) Low Flash Mineral Spirits, (f) Low Aromatic Solvent, (g) Isomer Reformate, (h) Solvent Activated Dye. In a preferred embodiment, this universal synthetic gasoline conditioner additive for improving lubrication comprises: alpha-olefins comprising from 5 to 30 percent thereof, by weight; low odor aromatic solvents comprising from 3 to 27 percent thereof, by weight; 2-Propanol comprising of 3 to 30 percent thereof, by weight; and at least one a base oil comprising from 0.50 to 15 percent thereof, by weight; wherein: the percentages by weight are specified in relative proportion to one another.

Owner:BESTLINE INT RESEACRH

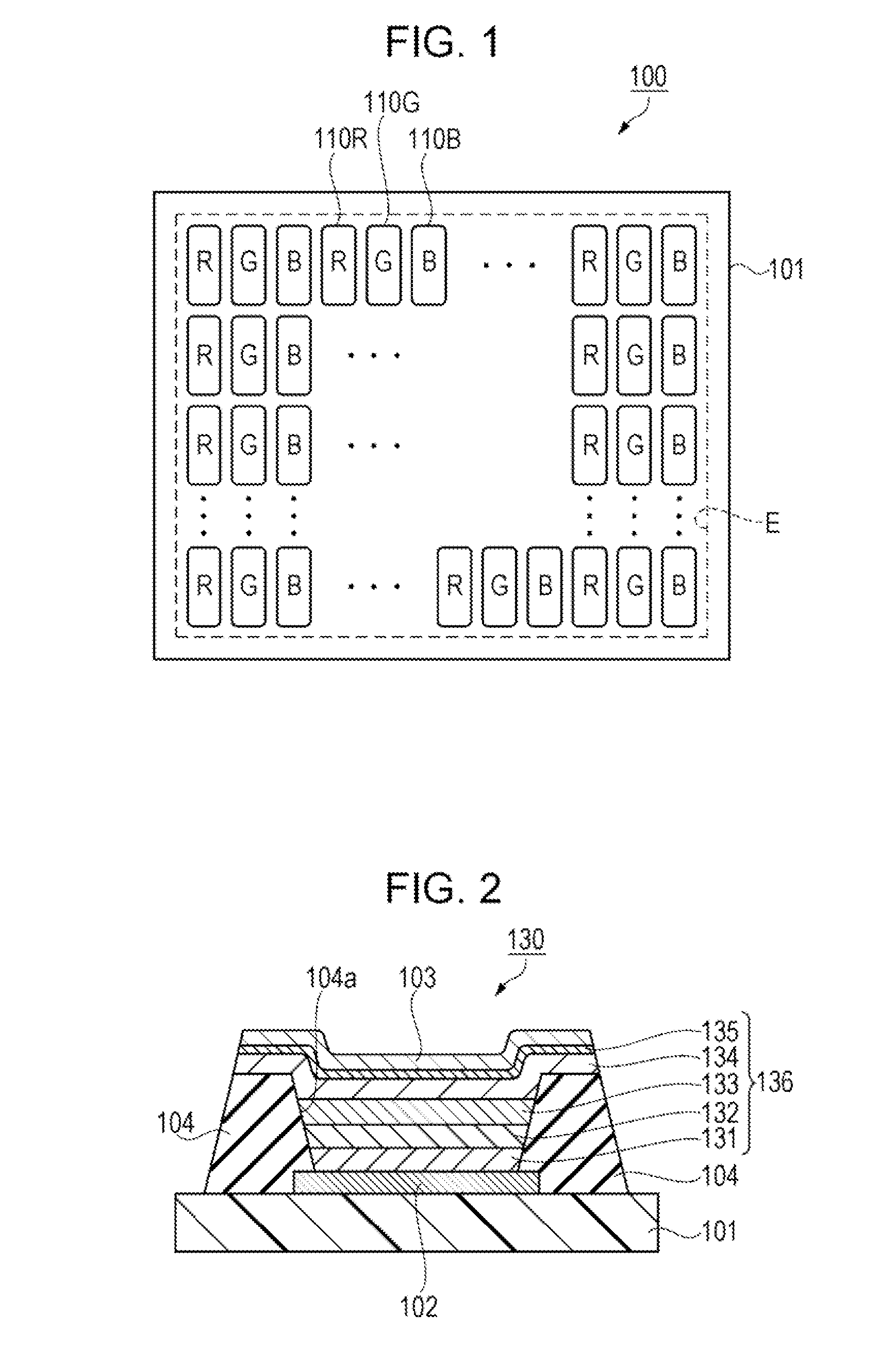

Ink for forming functional layer, ink container, discharging apparatus, method for forming functional layer, method for manufacturing organic el element, light emitting device, and electronic apparatus

ActiveUS20140138655A1Improve display qualityConductive materialSolid-state devicesSolubilityHole injection layer

An ink for forming a functional layer includes a first component that contains at least one kind of aromatic solvent of which a boiling point is higher than or equal to 250° C. and lower than or equal to 350° C., a second component that contains at least one kind of aliphatic solvent of which a boiling point is higher than or equal to 200° C., and a third component that is a positive hole injection material (m-MTDATA) for forming a positive hole injection layer, in which a solubility of the third component in the first component is higher than the solubility of the third component in the second component, a mixing ratio of the second component is 30 vol %, the boiling point of the first component is higher than the boiling point of the second component, and a difference between the boiling points thereof is higher than or equal to 30° C.

Owner:SEIKO EPSON CORP

Universal synthetic gasoline fuel conditioner additive, method and product-by-process

ActiveUS7931704B2Improve the lubrication effectReduce failureLiquid carbonaceous fuelsAdditivesGasoline fuelKetone

A process of producing a universal synthetic based gasoline fuel additive that cleans the fuel system including valves surface, lubricates the fuel pump, injectors and valves while allowing for a clean and more efficient burn. A major portion will consist of (a) Alfa-Olefins, (b) 2-propanol (c) Hydroisomerized High VI HT Base Oils, (d) Dimethyl Ketones, (e) Low Flash Mineral Spirits, (f) Low Aromatic Solvent, (g) Isomer Reformate, (h) Solvent Activated Dye. In a preferred embodiment, this universal synthetic gasoline conditioner additive for improving lubrication comprises: alpha-olefins comprising from 5 to 30 percent thereof, by weight; low odor aromatic solvents comprising from 3 to 27 percent thereof, by weight; 2-Propanol comprising of 3 to 30 percent thereof, by weight; and at least one a base oil comprising from 0.50 to 15 percent thereof, by weight; wherein: the percentages by weight are specified in relative proportion to one another.

Owner:BESTLINE INT RESEACRH

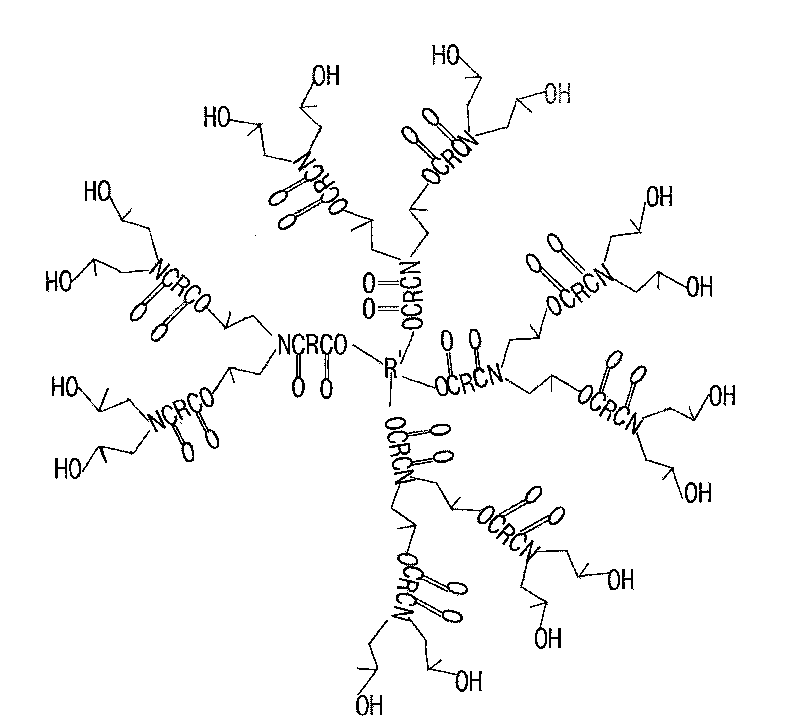

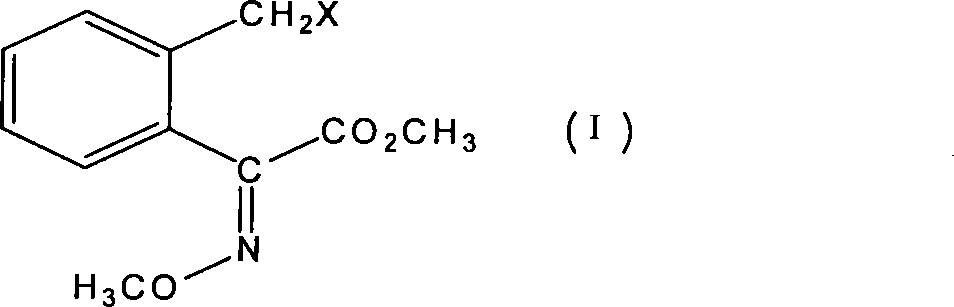

Hyperbranched curing agent for two-component polyurethane waterproof coating and preparation method thereof

ActiveCN101709039AReduce manufacturing costLow costOrganic compound preparationCarboxylic acid amides preparationSolubilityDissolution

The invention relates to a hyperbranched curing agent for two-component polyurethane waterproof coating and a preparation method thereof. The preparation method comprises the following steps: (1) reacting equimolar anhydride with equimolar diisopropanolamine in the equal molar weight in an aprotic solvent at a temperature of between 0 and 40 DEG C for 1 to 6 hours, and removing the solvent through vacuum distillation to prepare an AB2-type monomer having a carboxyl redical and two hydroxyl redicals; and (2) dissolving the prepared AB2-type monomer into an aromatic solvent, adding nuclear molecules and a catalyst into the solvent for heating reflux, dehydrating reaction water, performing heat preservation to react for 4 to 10 hours, and stopping the reaction to prepare a target product through dissolution, sedimentation and drying. The structure of the hyperbranched curing agent is shown in the figure 1. The hyperbranched curing agent has the advantages of simple preparation process, lower production cost, and suitability for large-scale industrial production. The prepared hyperbranched curing agent has a large number of active end functional groups, has low viscosity, high solubility and less adulterating amount, has excellent intermiscibility with polyurethane prepolymer, can improve the crosslinking density of a polyurethane system greatly and integrally improve the tensile strength and tenacity of the polyurethane waterproof coating and the bond strength of the polyurethane waterproof coating with substrates.

Owner:江苏超力建材科技有限公司

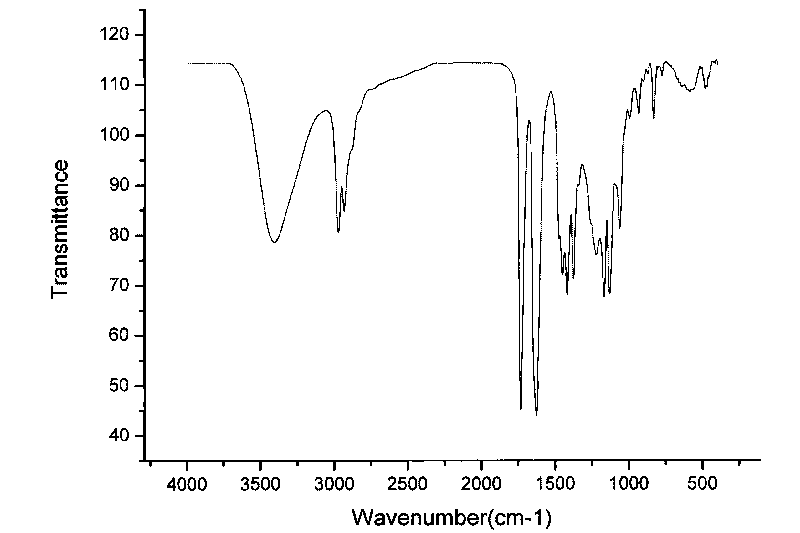

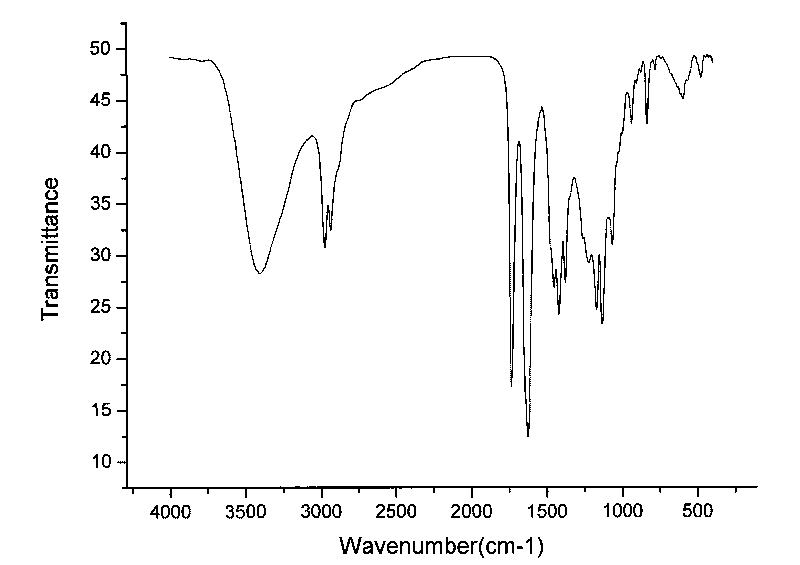

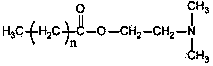

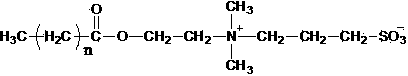

Surface active agent and oil-soluble viscosity reducer for crude oil as well as preparation method of surface active agent

InactiveCN103468228AEasy to operateLow costSulfonic acids salts preparationDrilling compositionLong chain fatty acidReduction rate

The invention provides a surface active agent and an oil-soluble viscosity reducer for crude oil as well as a preparation method of the surface active agent. The surface active agent is fatty acid ester ethyl sulphobetaine; and the oil-soluble viscosity reducer for crude oil comprises the following components in percentage by mass: (1) 40%-70% of mixed aromatics solvent, (2) 20%-55% of mutual solvent and (3) 2%-10% of surface active agent. The oil-soluble viscosity reducer for crude oil has the advantages that the fatty acid ester ethyl sulphobetaine type surface active agent obtained by the reaction of propane sultone and long-chain fatty acid-2-(dimethylamino) ethyl ester is firstly adopted in the oil-soluble viscosity reducer for the crude oil, the viscosity reducing effect is obvious, the using amount of the oil-soluble viscosity reducer does not exceed 5%, and the viscosity reduction rate of the oil-soluble viscosity reducer is above 90%.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

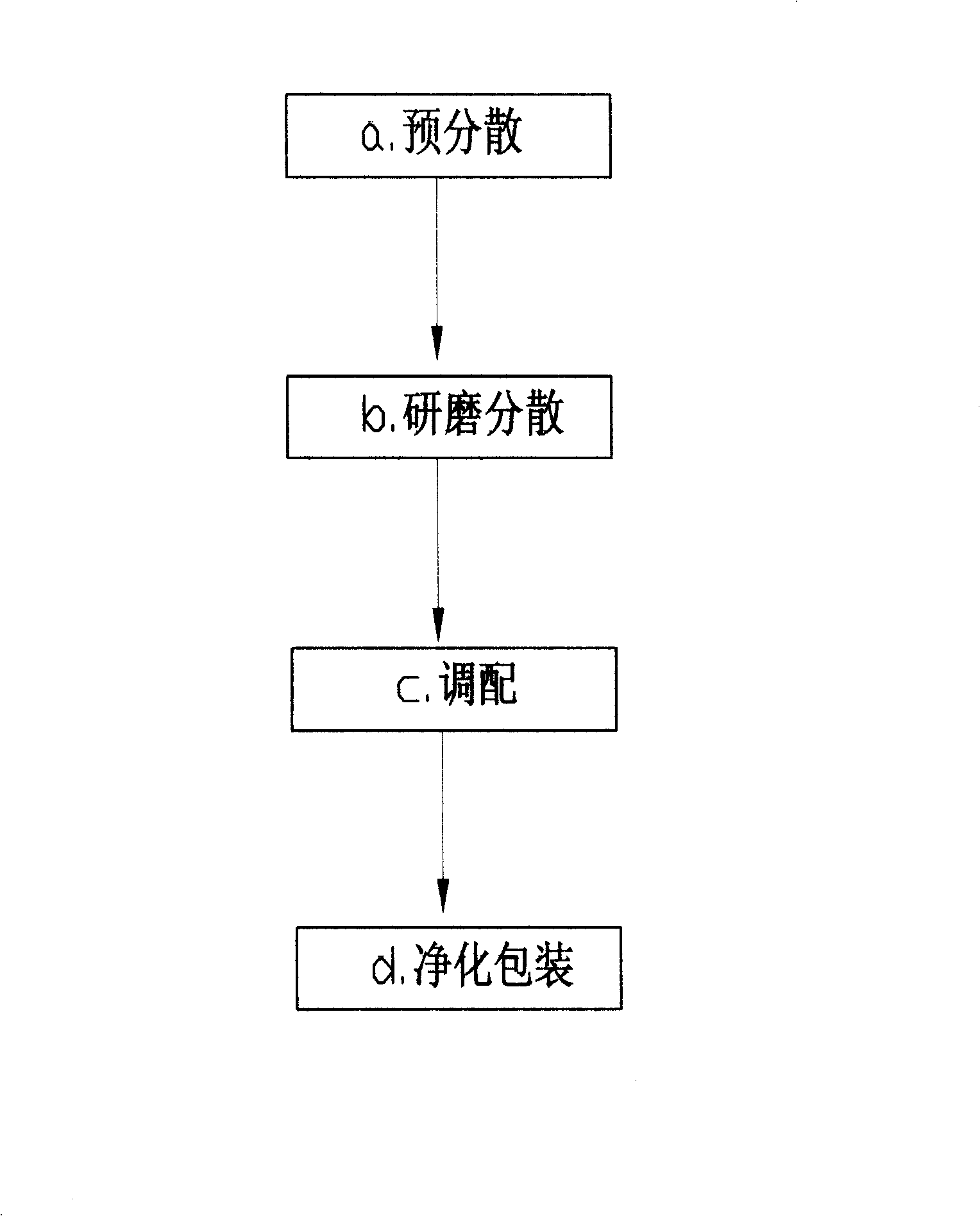

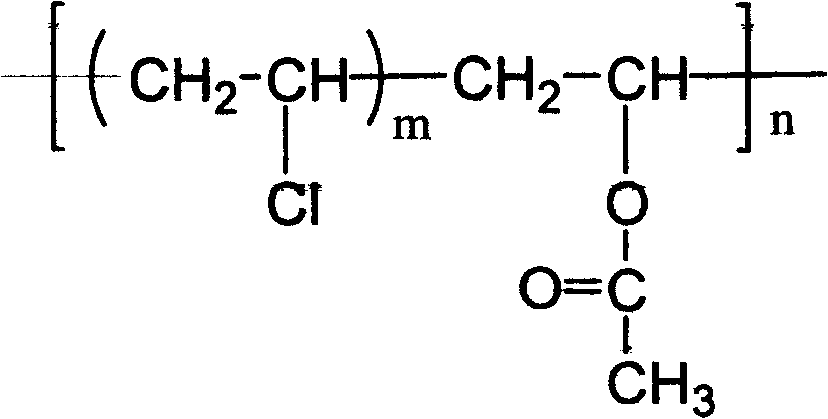

Polyurethane resin compound oil ink and method for manufacturing same

The invention discloses a polyurethane resin compound ink and preparation method thereof, comprising polyurethane resin, chloride-vinyl acetate resin, solvent, dye and dispersing auxiliary, wherein the solvent comprises methyl benzene, butanone, isopropyl alcohol. The composition of the polyurethane resin compound ink is: polyurethane resin liquor (30% solid content) 25-40%, chloride-vinyl acetate resin 0-4%, dye 5-25%, dispersing auxiliary 0.2-0.5%, methyl benzene 0-20%, butanone 25-35%, isopropyl alcohol 5-15%. The invention provides polyurethane resin compound ink with wide application range, good thermal stability, good adhesion and no aromatics solvent, in order to conquer the lacks such as not environment protection, narrow application range and bad thermal stability.

Owner:BAUHINIA VARIEGATA INK ZHEJIANG

Universal Synthetic Lubricant, Method and Product-by-Process to Replace the Lost Sulfur Lubrication when Using Low-Sulfur Diesel Fuels

A diesel fuel lubricant as a replacement for sulfur lubrication in Ultra-Low and Low Sulfur Diesel fuels, the process for producing said lubricant, and the method of using said lubricant. This lubricant comprises alpha-olefins; low odor aromatic solvents; and at least one a base oil selected from the base oil group consisting of hydrolsomerized high base oils and HT Severe Hydro-cracked Base Oils; as well as other ingredients. Also disclosed is a method for producing this lubricant.

Owner:BESTLINE INT RESEACRH

Universal Synthetic Penetrating Lubricant, Method and Product-by-Process

ActiveUS20100273688A1Improve protectionOrganic chemistryLiquid carbonaceous fuelsElectrical resistance and conductanceAlpha-olefin

A penetrating lubricant with the capacity to offer a both penetration into rust and corrosion. Further, this lubricant actively penetrates the crystalline surface of the metal while exhibiting extreme pressure lubrication, non-migrating with lasting protection. Further lubricant exhibits dielectric strength of over 8000 volts, at the same time cleaning electrical contacts, thereby reducing resistance and associated heat. The preferred embodiment contains alpha-olefins, low-odor aromatic solvents, base oils, and high flash mineral spirits.

Owner:BESTLINE INT RESEACRH

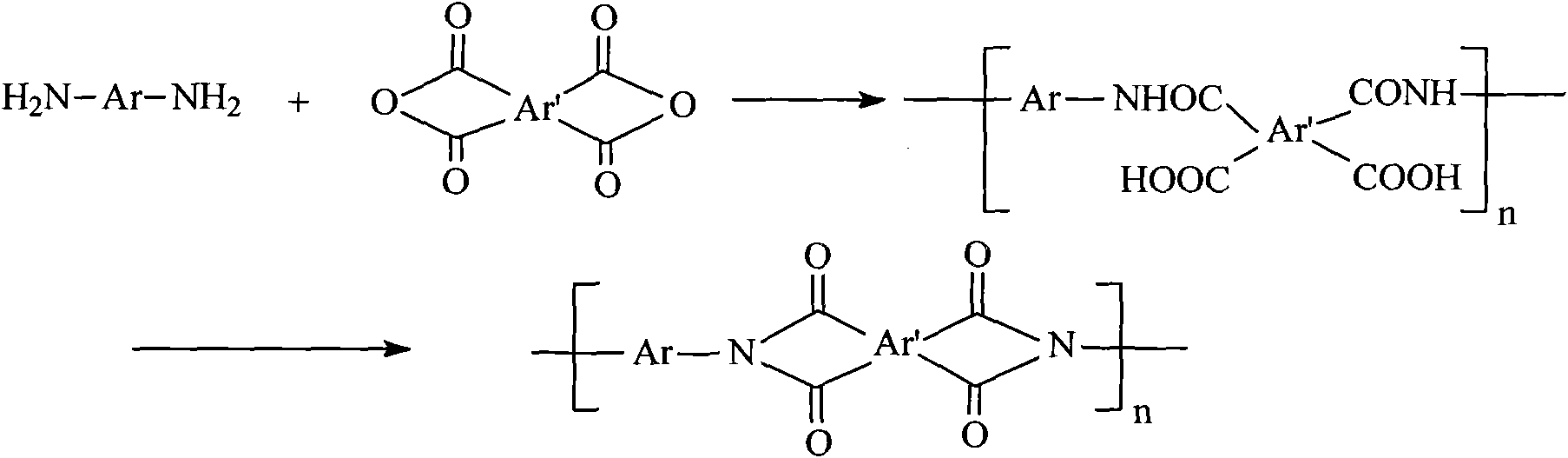

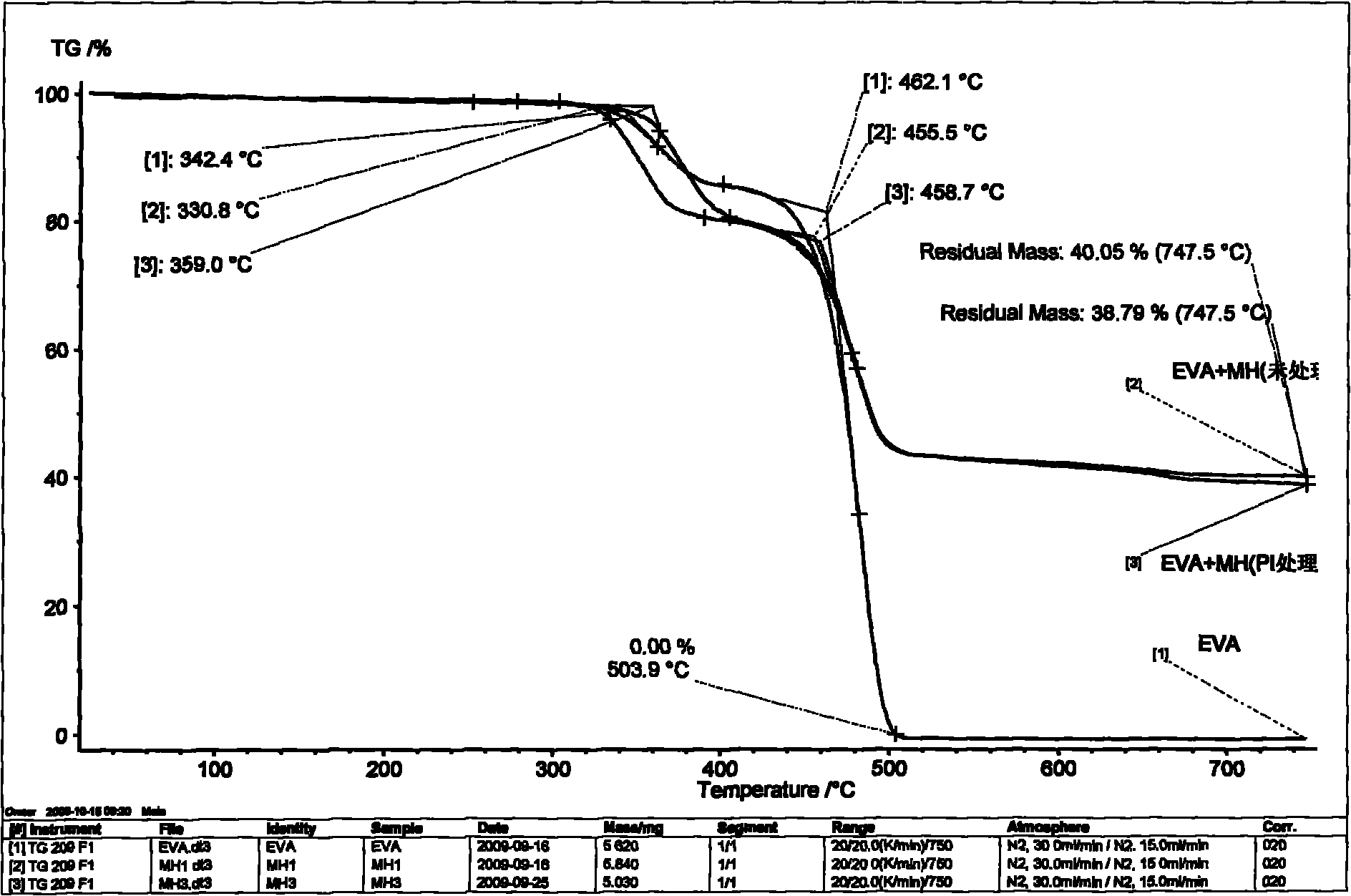

Method for preparing polyimide intercalated grafted magnesium hydroxide flame retardant

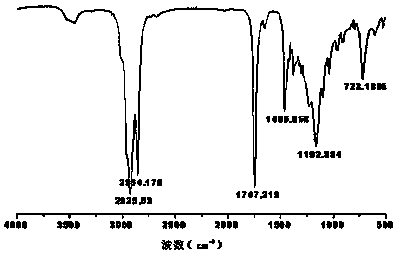

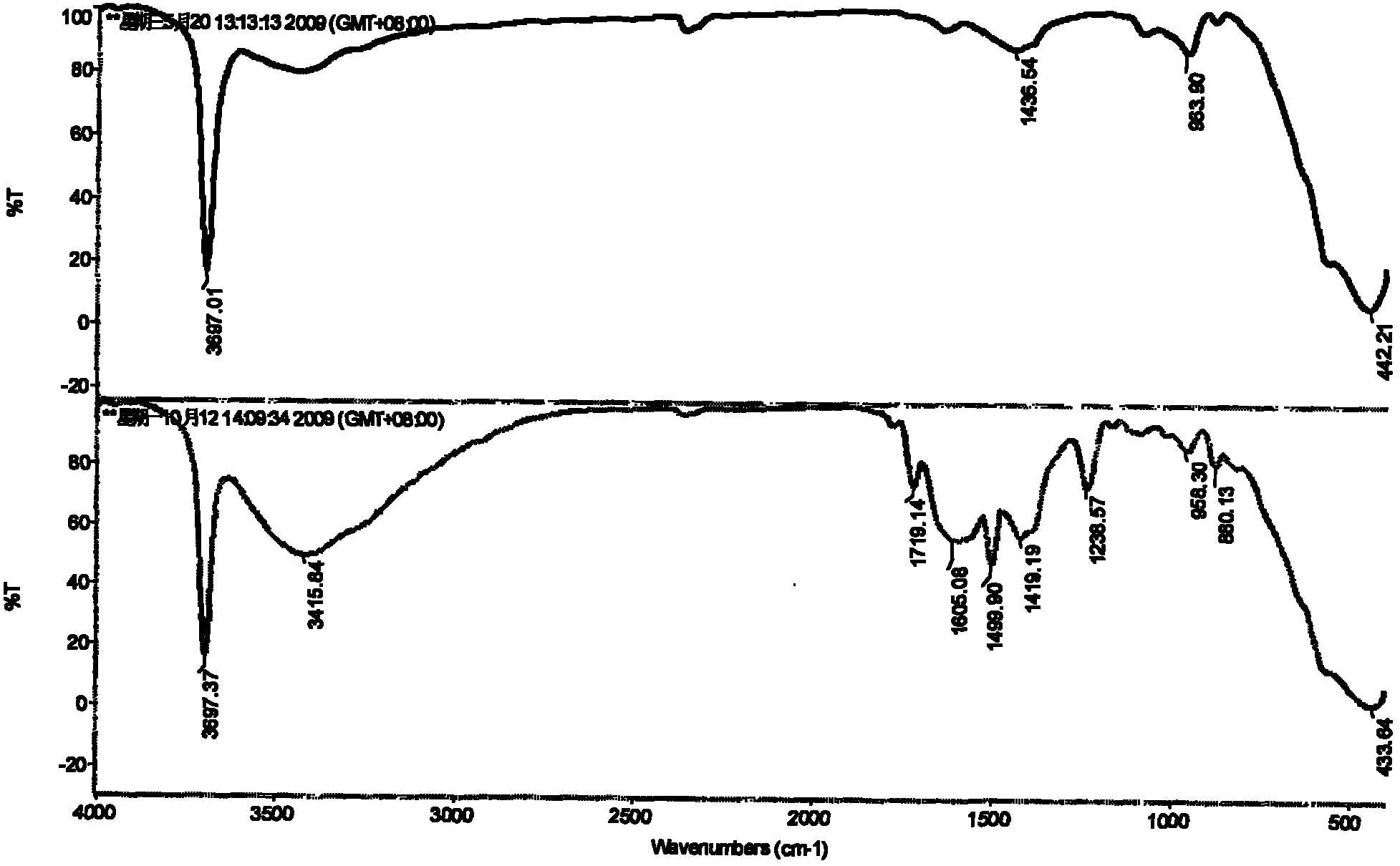

InactiveCN101787290AHigh limiting oxygen indexImprove flame retardant performanceFireproof paintsEnd-groupAromatic solvents

The invention relates to a method for preparing polyimide intercalated grafted magnesium hydroxide flame retardant. The method comprises: mixing binary primary amine, amino end-group coupling agent and strong polar non-proton organic solvent; uniformly stirring the mixture at room temperature; adding magnesium hydroxide powder; performing high-speed shearing dispersion for 20 to 30 minutes; adding aromatic dianhydride powder, catalysts and aromatic hydrocarbon solvent; performing water-separating reaction for 6 to 8 hours; and separating out aromatic solvent and part of strong polar non-proton organic solvent to obtain the polyimide intercalated grafted magnesium hydroxide flame retardant. The polyimide intercalated grafted magnesium hydroxide flame retardant has the vertical combustion level at V-0, limiting oxygen index up to 32, tensile strength up to over 13.6 MPa, significant flame retardant effect and good application prospects. In addition, the method has the advantages of simple preparation process, low cost, convenient operation, friendliness to environment, capability of completing preparation in general equipment and help to industrial production.

Owner:DONGHUA UNIV +1

LED gallium arsenide substrate dewaxing cleaning agent

InactiveCN101974377AImprove solubilityAvoid the disadvantage of low flash pointSurface-active non-soap compounds and soap mixture detergentsAlkaneHalohydrocarbon

Owner:JIANGSU TIANHENG NANO SCI & TECH

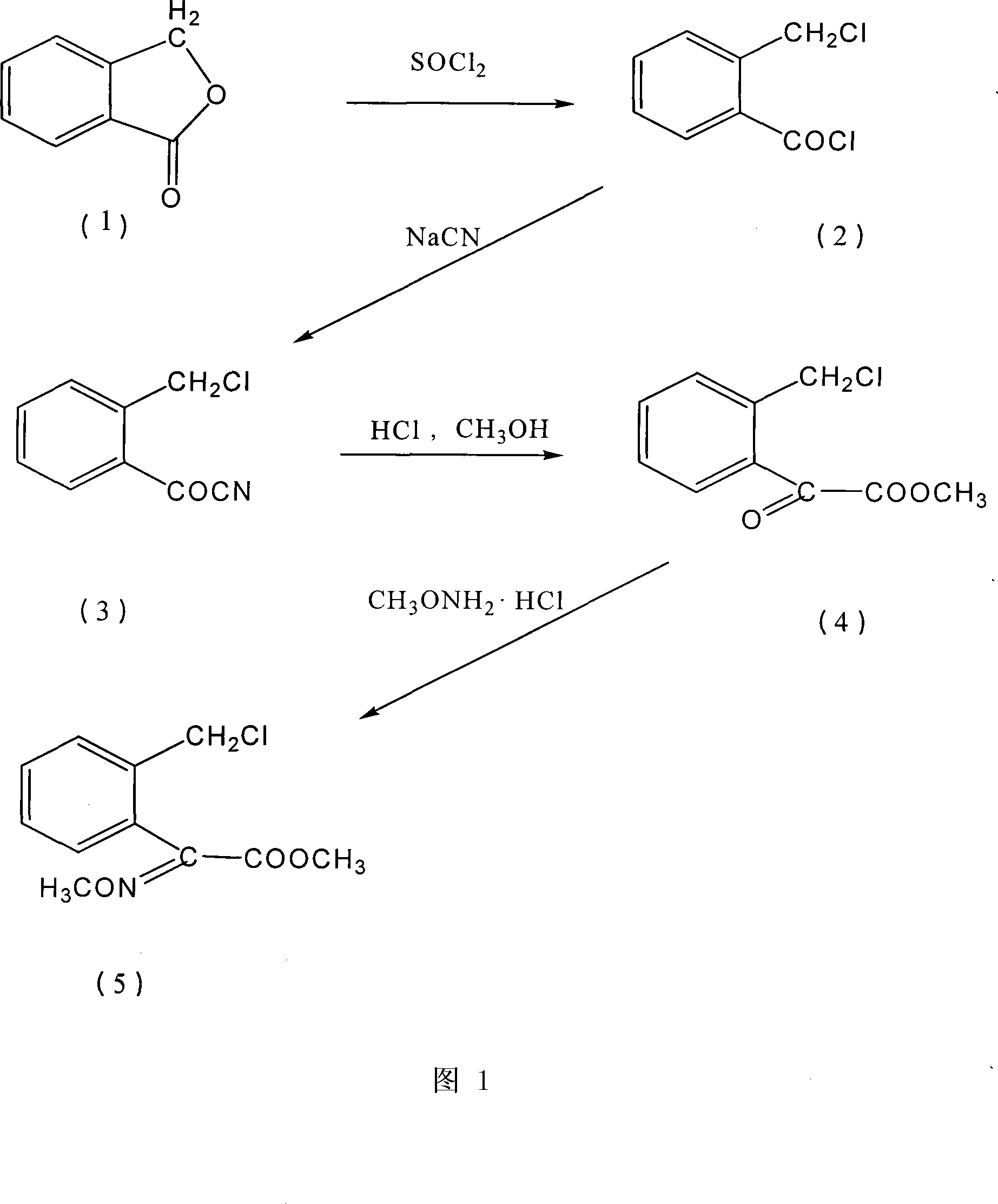

Method for preparing bactericidal agent intermediate (E)-2-(2'-chloromethyl)phenyl-2-methoxy imino methyl acetate

ActiveCN101139308AReduce energy consumptionReduce riskBiocideFungicidesPotassium cyanideProduction risk

The preparation method of the fungicide intermediate (E)-2-(2'-chloromethyl)-2-methicillin imino acetic methyl ester is: 1) the phenyl phthalate and the thionyl dihalide react with the influence of a catalyst; the catalyst is the Louis acid and phosphonic derivative; 2) the product of the first step and the alkali metal cyanide react with the influence of the organic solvent and phase transfer catalyst; the organic solvent is selected from the non-polar aromatic solvent or the halogen hydrocarbon; the phase transfer catalyst is selected from the halide of the four-level nitride or the ammonium salt; the alkali metal cyanide is selected from the sodium cyanide and potassium cyanide; 3) the products of the second step and the methanol react under the condition with the organic solvent and the chlorinated hydrogen; 4) the products of the third step and the methicillin amine hydrochloride under the condition with the organic solvent; thus, the target product can be got. The energy consumption and production risk of the present invention are obviously lowered; the relative collection rate is high; the safety in the production process is improved; and the present invention has no drawbacks such as the obstruction.

Owner:JIANGSU GENGYUN CHEM CO LTD

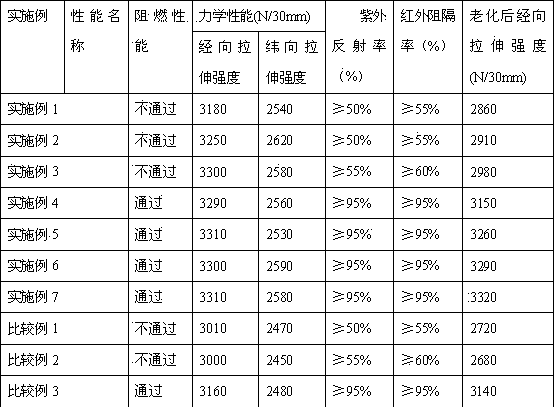

High-strength PVC (Polyvinyl Chloride) awning cloth

InactiveCN103741474AHigh tensile strengthHigh hardnessFibre typesPolyvinyl chlorideCarvacryl acetate

The invention discloses high-strength PVC (Polyvinyl Chloride) awning cloth which is formed by coating both sides of gridding cloth with PVC coatings. According to a raw material formula, each PVC coating comprises the following components in parts by weight: 80 parts of PVC paste resin, 70-90 parts of dioctyl phthalate, 55-65 parts of calcium carbonate, 3-6 parts of chlorinated paraffin, 3-6 parts of a stabilizer, 3-10 parts of de-aromatic solvent oil, 1-8 parts of a vinylpyridine bonding agent, 7-20 parts of flame retardant mortar, 3-8 parts of titanium dioxide, 0.1-0.8 part of an anti-UV (Ultraviolet) agent and 2-30 parts of heat insulation powder. The heat insulation powder is a mixture prepared from hollow glass beads and polyvinyl acetate according to the weight part ratio of 100: (1-5). Compared with the prior art, the awning cloth has the advantages that the tensile strength is up to 3,300N / 30mm, the ultraviolet reflectivity and infrared ray blocking rate are up to 95%, and the favorable mechanical property stability is kept after an ageing test is ended.

Owner:JIANGYIN DONGHENG NEW MATERIAL SCI TECH

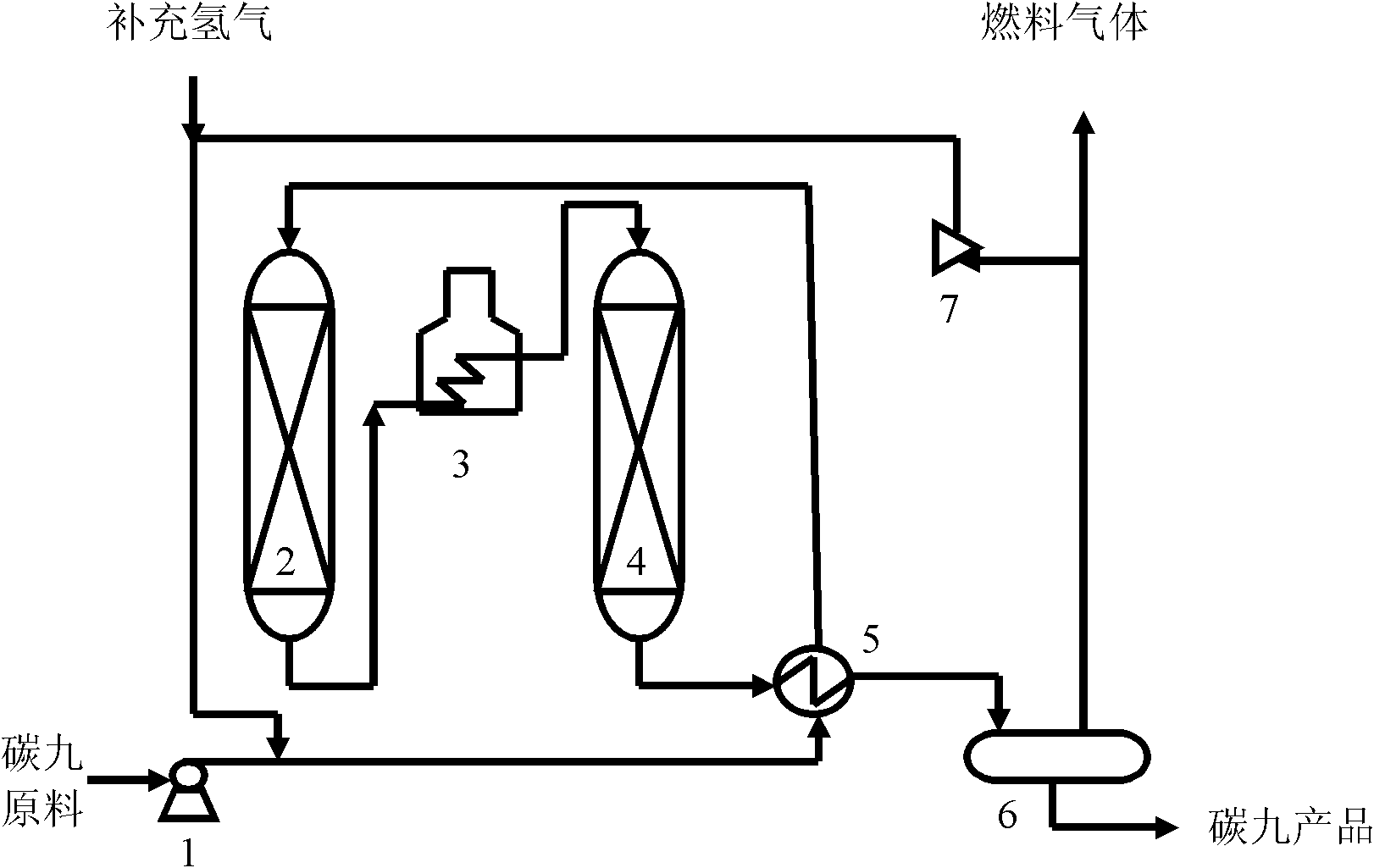

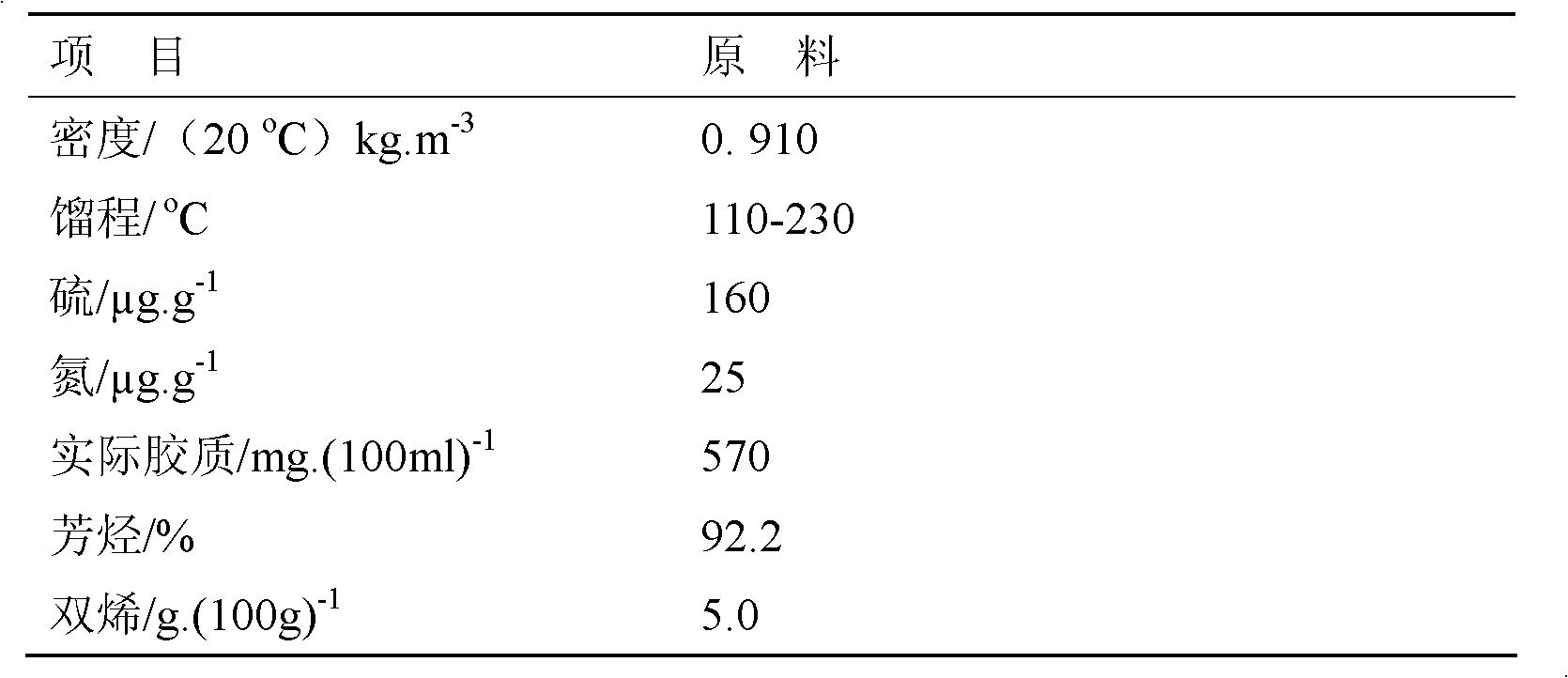

Catalysis upgrading method for cracking ethylene by-product carbon-9

ActiveCN101914387AExtend your lifeMild reaction conditionsTreatment with hydrotreatment processesGas phaseSulfide

The invention discloses a catalysis upgrading method for cracking ethylene by-product carbon-9, belonging to the field of heterogeneous catalysis. The catalysis upgrading method is characterized by comprising the following steps of: firstly, carrying out selective hydrogenation reaction on a metal (noble metal or non-noble metal) catalyst under the mild condition and eliminating dialkene and styrene derivatives, carrying out hydrogenation refining reaction on a sulfide catalyst, and eliminating monoene, nitrogen-containing compounds and sulfur-containing compounds through monoolefine hydrogenation saturation, hydrogen desulfurization and hydrogenation denitrogenation reaction to obtain a water-white and odorless carbon-9 product with favorable stability. The carbon-9 product can be used as a high-octane gasoline ingredient and higher aromatics solvent oil. The metal catalyst and the sulfide catalyst used in the invention are prepared by selecting a proper carrier according to the component and the performance of the cracking ethylene by-product carbon-9 through liquid phase and gaseous phase deposition methods. The invention has the advantages of simple process, high catalyst activity and selectivity, and favorable economic benefit and industrial application potentials.

Owner:DALIAN UNIV OF TECH

Universal Synthetic Gasoline Fuel Conditioner Additive, Method and Product-by-Process

ActiveUS20110197499A1Negative effectImprove the lubrication effectLiquid carbonaceous fuelsFuel additivesGasoline fuelKetone

A process of producing a universal synthetic based gasoline fuel additive that cleans the fuel system including valves surface, lubricates the fuel pump, injectors and valves while allowing for a clean and more efficient burn. A major portion will consist of (a) Alfa-Olefins, (b) 2-propanol (c) Hydroisomerized High VI HT Base Oils, (d) Dimethyl Ketones, (e) Low Flash Mineral Spirits, (f) Low Aromatic Solvent, (g) Isomer Reformate, (h) Solvent Activated Dye. In a preferred embodiment, this universal synthetic gasoline conditioner additive for improving lubrication comprises: alpha-olefins comprising from 5 to 30 percent thereof, by weight; low odor aromatic solvents comprising from 3 to 27 percent thereof, by weight; 2-Propanol comprising of 3 to 30 percent thereof, by weight; and at least one a base oil comprising from 0.50 to 15 percent thereof, by weight; wherein: the percentages by weight are specified in relative proportion to one another.

Owner:BESTLINE INT RESEACRH

Process for preparing N-(hydrocarbyl) phosphoric or thiophosphoric triamides

The invention provides a process for preparing N-(hydrocarbyl)phosphoric or thiophosphoric triamides with substantially improved yields and purity. Two equivalents of hydrocarbylamine are used in the reaction with phosphoryl or thiophosphoryl chloride and then with ammonia in an aromatic solvent. The invention further relates to N-(hydrocarbyl)phosphopric or thiophosphoric triamides having the purity of at least 98% wherein R is a hydrocarbyl group and X is O or S.(RNH)(NH2)2P=X (I).

Owner:AGRA GROUP AS

Flexible electroconductive foam, and method of preparation thereof

InactiveUS20040089849A1Swelling of the matrixReduce swellingConductive materialSynthetic resin layered productsDopantLiquid medium

A method of preparing an electroconductive foam, and the foam so prepared. An electroconductive polymer such as polyaniline is dispersed in a liquid medium that includes an aromatic solvent such as xylene and an organic dopant / dispersant such as an aromatic sulfonic acid. The electroconductive polymer together with the organic dopant / dispersant constitute between 10% and 25% of the resulting dispersion. The dispersion is introduced to the pores of an electrically insulating foam matrix such as polyurethane. Excess dispersion is expelled and the foam is dried actively, to line the pores with an electroconductive lining.

Owner:MORE ENERGY

Method for removing asphaltene deposits

InactiveUS7754657B2Reduce and prevent formationPreventing and reducing and depositionWorking-up pitch/asphalt/bitumen by chemical meansFlushingKeroseneFuel oil

Compositions comprising at least one C4-C30 olefin or oxidation product thereof and kerosene or an aromatic solvent are particularly effective for use in removing asphaltene and asphaltene-containing organic deposits and in preventing or reducing the precipitation and deposition of asphaltenes from hydrocarbon fluids. When added to heavy oils comprising asphaltenes, alone or in combination with dispersants and further inhibitors, the invented compositions lower viscosity and pour point, and aid in preventing asphaltene precipitation during transport and in combustion.

Owner:INEOS USA LLC

Fuel Additive and Fuel Treatment Process

InactiveUS20070015656A1Improve solubilityHighly effectiveNon-fuel substance addition to fuelOrganic-compounds/hydrides/coordination-complexes catalystsCentistokesOn board

Disclosed is a fuel additive concentrate having a high flash point which is characterized by a viscosity controlled for dosing in a Bernoulli feed device. The concentrate is high temperature stable and is in a form suitable for on-board dosing of fuel which can provide predictable feed rates from a feed device. It comprises a fuel soluble platinum group metal composition and / or a fuel soluble or dispersible cerium composition and / or a fuel soluble or dispersible iron compound and a high flash aromatic solvent. The solvent and the metal composition or compositions are present in relative amounts to provide a FBC concentrate having a flash point (ASTM D93-85) of greater than 140° F. and, a preferred kinematic viscosity within the range of from 7 to 25 centistokes, as measured by ASTM D445 at 105° F.

Owner:CLEAN DIESEL TECHNOLOGIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com