Hyperbranched curing agent for two-component polyurethane waterproof coating and preparation method thereof

A two-component polyurethane and waterproof coating technology, used in polyurea/polyurethane coatings, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of carcinogenic price and high cost, and achieve low production cost and low dosage. , the effect of a simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

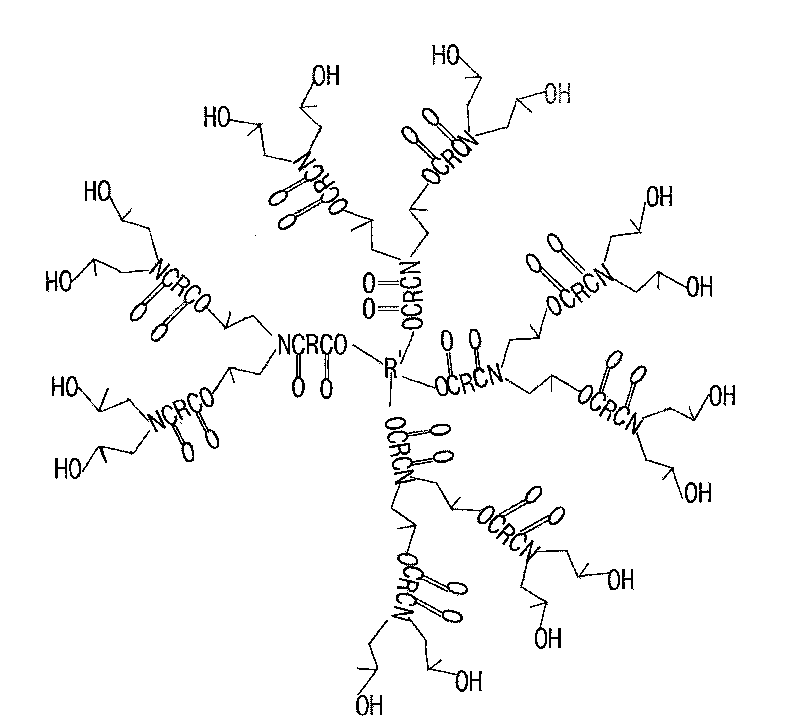

[0032] Weigh 10.01g of succinic anhydride and 13.32g of diisopropanolamine (refluxing and dehydrating before use), first dissolve diisopropanolamine in 40mL of carbon tetrachloride, and pour it into a three-port container equipped with a thermometer and a water separator after dissolving. In the flask, dissolve succinic anhydride with 40ml of carbon tetrachloride, then slowly drop it into the three-necked flask, use a magnetic stirrer to react at 10°C for 2h, and distill off the solvent under reduced pressure to obtain AB 2 type monomer.

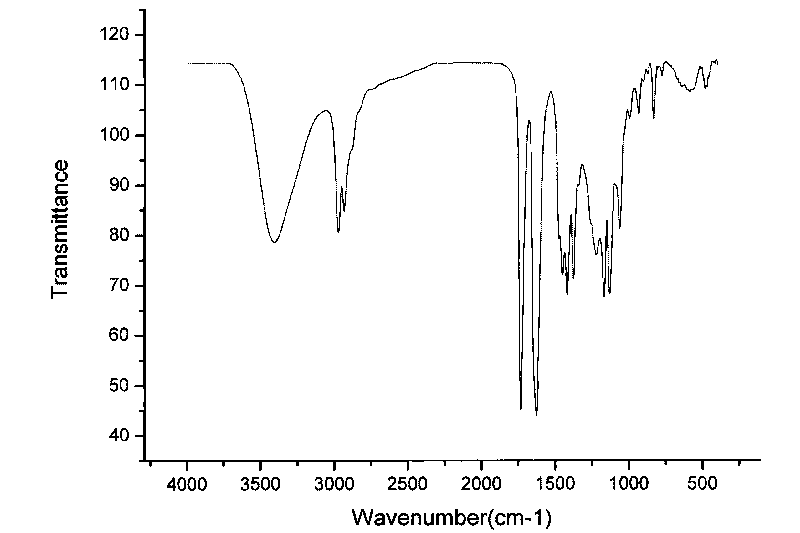

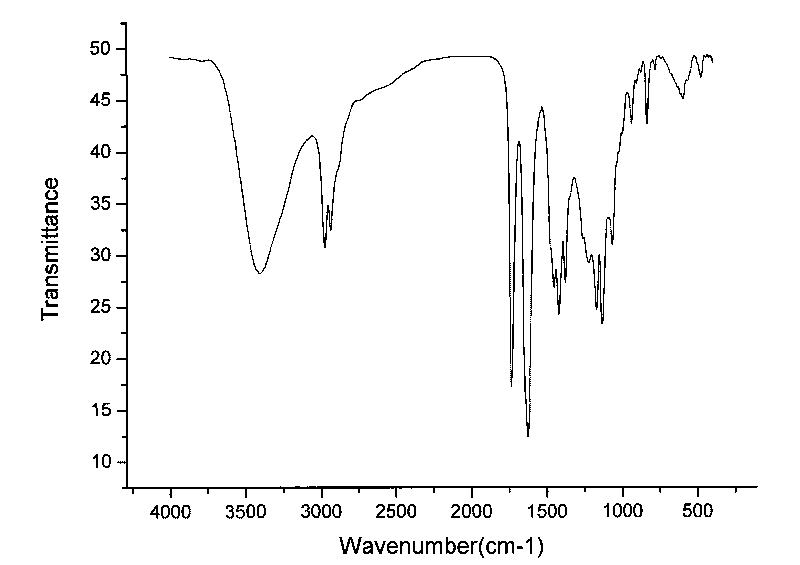

[0033] Then add 50mL toluene to the above-mentioned three-necked flask, then add 1.49g trimethylolpropane as the nuclear molecule, wait until the trimethylolpropane is completely dissolved, then add 0.15g sulfamic acid, stir and heat until reflux occurs, Separate the generated water with a water separator, finish the reaction after 6 hours of heat preservation, cool down and discharge the material, and obtain the target product after dissolu...

Embodiment 2

[0035] Take by weighing 15.01g succinic anhydride, 19.98g diisopropanolamine (reflux dehydration before use), first diisopropanolamine is dissolved in 50mL pyridine, after dissolving, pour into a three-necked flask equipped with a thermometer and a water separator, Dissolve succinic anhydride with 50ml of pyridine, then slowly drop it into a three-necked flask, use a magnetic stirrer to react at 25°C for 3h, and distill off the solvent under reduced pressure to obtain AB 2 type monomer.

[0036] Then add 60mL toluene to the above-mentioned three-necked flask, then add 0.96g trimethylolpropane as the nuclear molecule, wait until the trimethylolpropane is completely dissolved, then add 0.20g sulfamic acid, stir and heat until reflux occurs, Separate the generated water with a water separator, finish the reaction after 7 hours of heat preservation, cool down and discharge the material, and obtain the target product after dissolution, precipitation and drying. This product is the ...

Embodiment 3

[0038] Take by weighing 20.01g succinic anhydride, 26.64g diisopropanolamine (refluxing dehydration before use), at first diisopropanolamine is dissolved in 60mL chloroform, after dissolving, pour in the there-necked flask that thermometer and water separator are housed, Dissolve succinic anhydride in 60ml of chloroform, then slowly drop it into a three-necked flask, use a magnetic stirrer to react at 30°C for 4h, and distill off the solvent under reduced pressure to obtain AB 2 type monomer.

[0039] Then add 60mL xylene to the above-mentioned three-necked flask first, then add 0.60g trimethylolpropane as the nuclear molecule, wait until the trimethylolpropane is completely dissolved, then add 0.25g sulfamic acid, stir and heat until reflux occurs , use a water separator to separate the generated water, finish the reaction after 9 hours of heat preservation, cool down and discharge the material, and obtain the target product after dissolution, precipitation and drying. This p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com