High-strength PVC (Polyvinyl Chloride) awning cloth

A kind of tarpaulin, high-strength technology, applied in the direction of fiber type, textile and papermaking, fiber treatment, etc., can solve the problems of low strength and easy aging of PVC tarpaulin, and achieve the effect of reducing mechanical defects, improving hardness and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

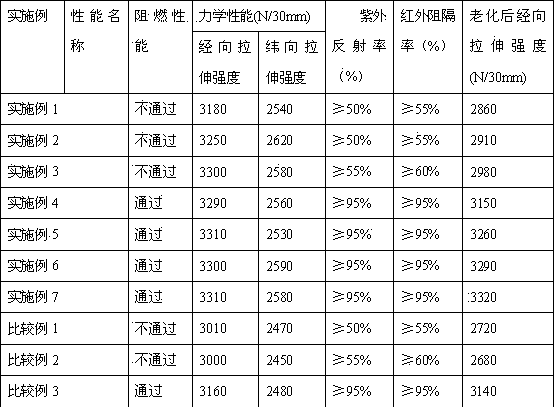

Examples

Embodiment 1

[0024] The present invention is a kind of high-strength PVC tarpaulin, which is composed of PVC coating coated on both sides of mesh cloth. The raw material formula of PVC coating includes the following components according to the weight parts: 80 parts of PVC paste resin, phthalic acid di 70 parts of octyl ester, 55 parts of calcium carbonate, 6 parts of chlorinated paraffin, 3 parts of stabilizer, 3 parts of dearomatized solvent oil, and 1 part of vinylpyridine-based adhesive.

Embodiment 2

[0026] The present invention is a kind of high-strength PVC tarpaulin, which is composed of PVC coating coated on both sides of mesh cloth. The raw material formula of PVC coating includes the following components according to the weight parts: 80 parts of PVC paste resin, phthalic acid di 90 parts of octyl ester, 65 parts of calcium carbonate, 3 parts of chlorinated paraffin, 6 parts of stabilizer, 10 parts of dearomatized solvent oil, and 8 parts of vinylpyridine-based binder.

Embodiment 3

[0028] The present invention is a kind of high-strength PVC tarpaulin, which is composed of PVC coating coated on both sides of mesh cloth. The raw material formula of PVC coating includes the following components according to the weight parts: 80 parts of PVC paste resin, phthalic acid di 80 parts of octyl ester, 59 parts of calcium carbonate, 5 parts of chlorinated paraffin, 4 parts of stabilizer, 5 parts of dearomatized solvent oil, 4 parts of vinylpyridine-based adhesive, and 7 parts of flame-retardant glue. The flame retardant mortar is made by mixing and beating 8 parts by weight of octane diester and 7 parts of antimony trioxide, and the flame retardant is antimony trioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com