Resin for biodegradable anti-fouling paint, synthetic method of the same, and anti-fouling paint composition containing the same

A biological and resin technology, applied in antifouling/underwater coatings, biocide-containing paints, polyurea/polyurethane coatings, etc., can solve the problems of short antifouling period, high raw material price of polymer materials, and seawater immersion resistance No defects and other problems, achieve the effect of low catalyst dosage, low reaction temperature and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

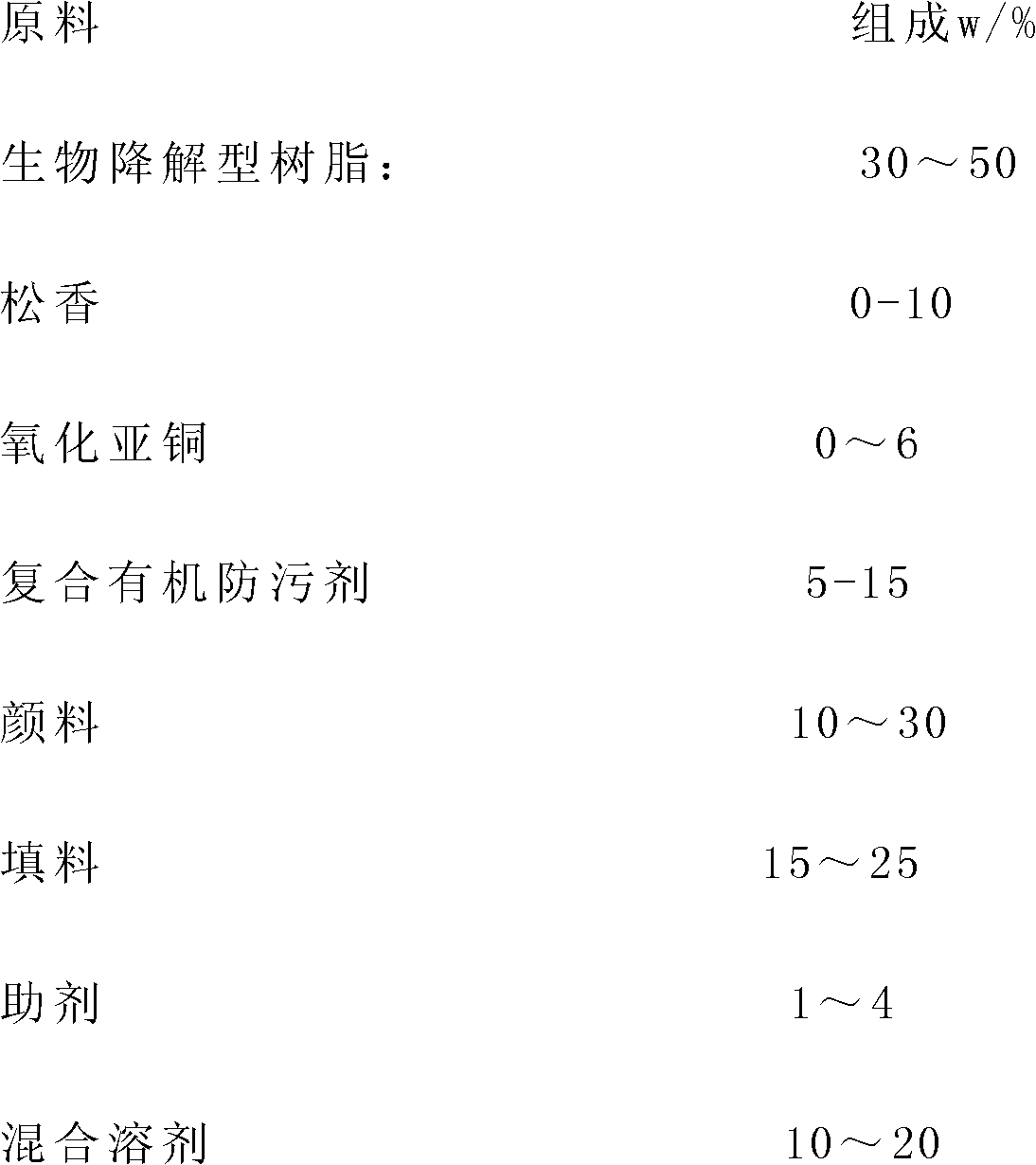

Method used

Image

Examples

Embodiment 1

[0063] Add 200g lactic acid (containing 85% of the monomer) successively in a 500ml four-necked bottle equipped with a stirring device, a thermometer, a water separator, a condenser tube and a vacuum pump, and 100g toluene and xylene are mixed solvents at a ratio of 1:1. Reflux reaction at 130-140°C, remove water from the water separator until anhydrous is formed, and obtain a yellow polylactic acid prepolymer. Add flexible segment: butanediol 15g and 15g PEG-200, dihydrate stannous dichloride (SnCl2.2H2O) and p-toluenesulfonic acid (TSA) of esterification catalyst 0.2g1: 1, under negative pressure at Reflux reaction at 130-140°C for 10 hours until no water is formed, and a light brown resin is obtained, which is a polylactic acid-based multi-block prepolymer. After cooling, add 80g mixed solvent: xylene and butyl acetate of 1: 1, 45g polyisocyanate is 2: 1 toluene diisocyanate and 1,6-hexamethylene diisocyanate, catalyst dibutyltin dilaurate 0.1g, Heating, stirring and react...

Embodiment 2

[0065]Add 200g lactic acid (content 85%), 100g toluene and xylene 1: 1 mixed solvents successively in the 500ml four-necked bottle that is installed with stirring device, thermometer, water separator, condensing tube and connect vacuum pump, under negative pressure at 130 Reflux reaction at -140°C, remove water from the water separator until no water is formed, and obtain a yellow polylactic acid prepolymer. Add a flexible segment such as 3g propylene glycol, 5g butanediol, 25g PEG-400, a catalyst such as 0.2g of stannous octoate, reflux reaction under the same conditions as in Example 1 for 8 hours until anhydrous is generated, and a light brown resin is obtained, which is poly Lactic acid based multi-block prepolymer. After cooling, add 100g of mixed solvent such as 1:1 butyl acetate and methyl isobutyl ketone, 47g of polyisocyanate such as 1,6-hexamethylene diisoate, 0.1g of dibutyltin dilaurate, heat and stir at 80°C for 4 hours , to obtain the final multi-block biodegrad...

Embodiment 3

[0067] Add 200g of lactic acid (containing 85% of the monomer) and 100g of aromatic solvents such as xylene in a 500ml four-necked bottle equipped with a stirring device, a thermometer, a water separator, and a condenser, and return to the reaction under normal pressure, and the water separator is dewatered. When anhydrous is formed, a light yellow polylactic acid oligomer is obtained. Add a flexible segment such as 10g pentylene glycol, 10g PEG-200, 15g polycaprolactone polyol with a molecular weight of 1000, add a catalyst such as 0.2g tetrabutyl titanate, and reflux at normal pressure for several hours until anhydrous is formed to obtain The light brown resin is polylactic acid-based multi-block prepolymer. After cooling, add 100g of a mixed solvent such as 1:1 xylene and butyl acetate, 50g of polyisocyanate such as toluene diisocyanate, 0.1g of dibutyltin dilaurate into the system, heat and stir at 80°C for 4 hours to obtain the final polyisocyanate. Block biodegradable r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com