Patents

Literature

109 results about "Mineral spirit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

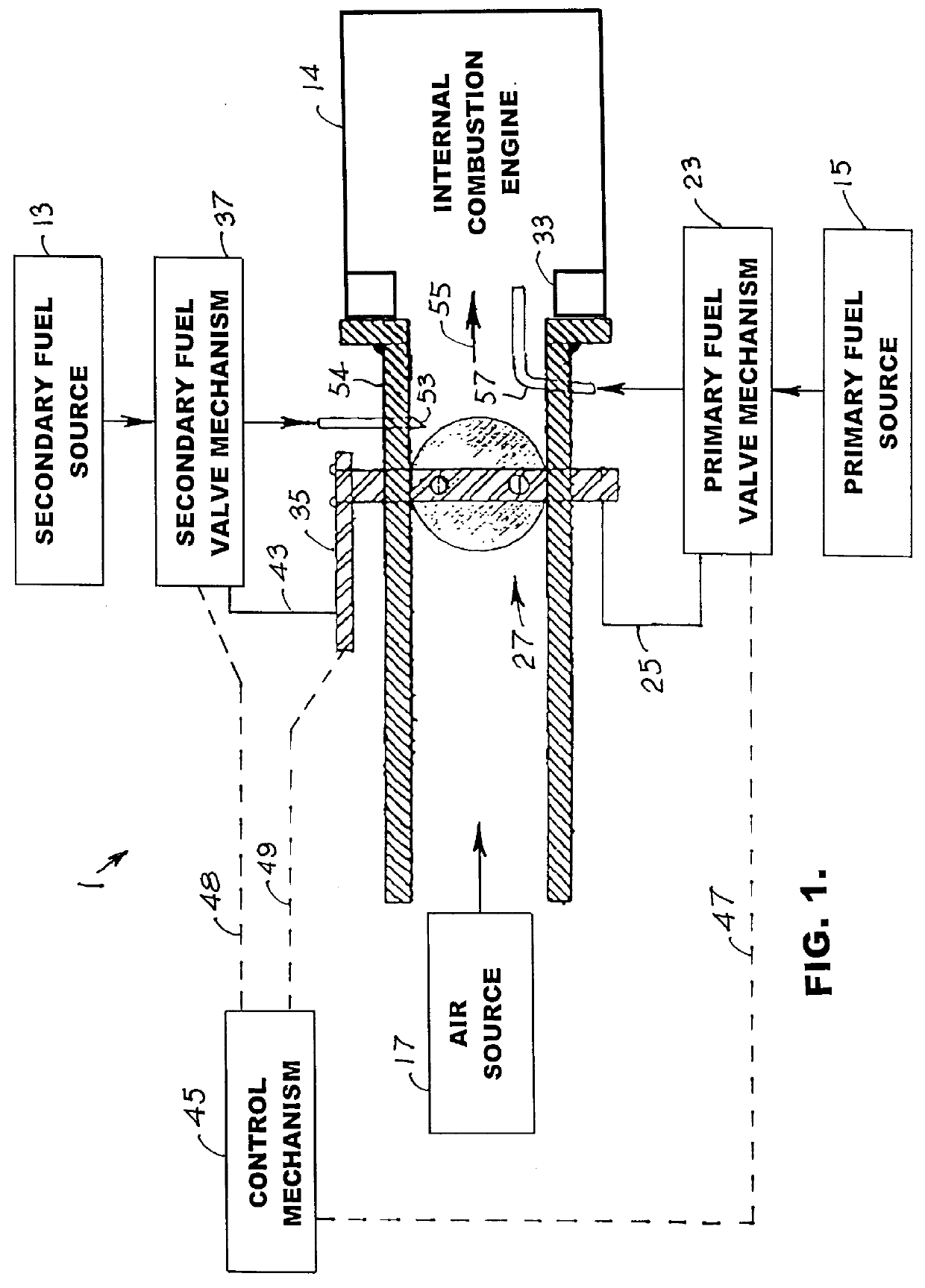

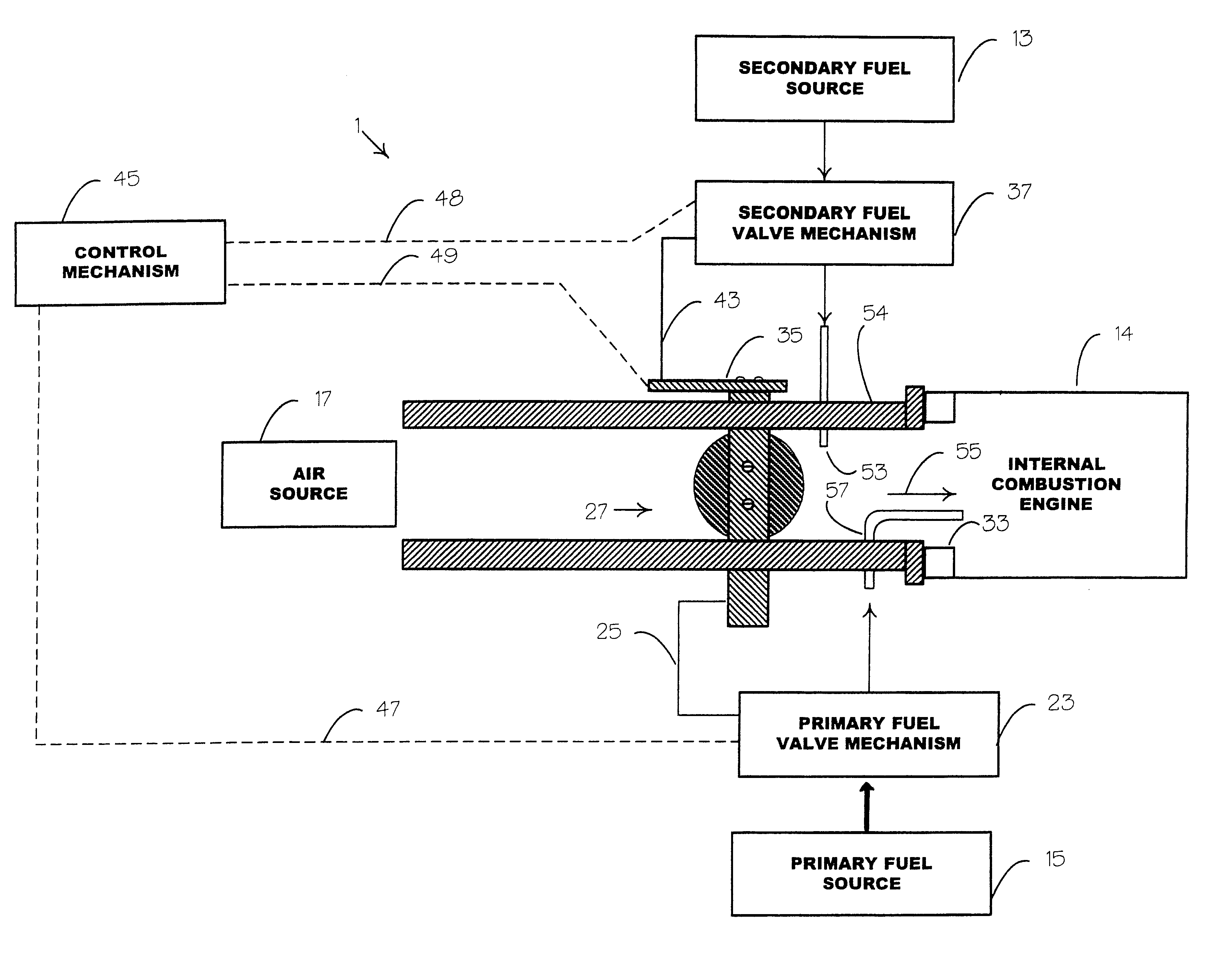

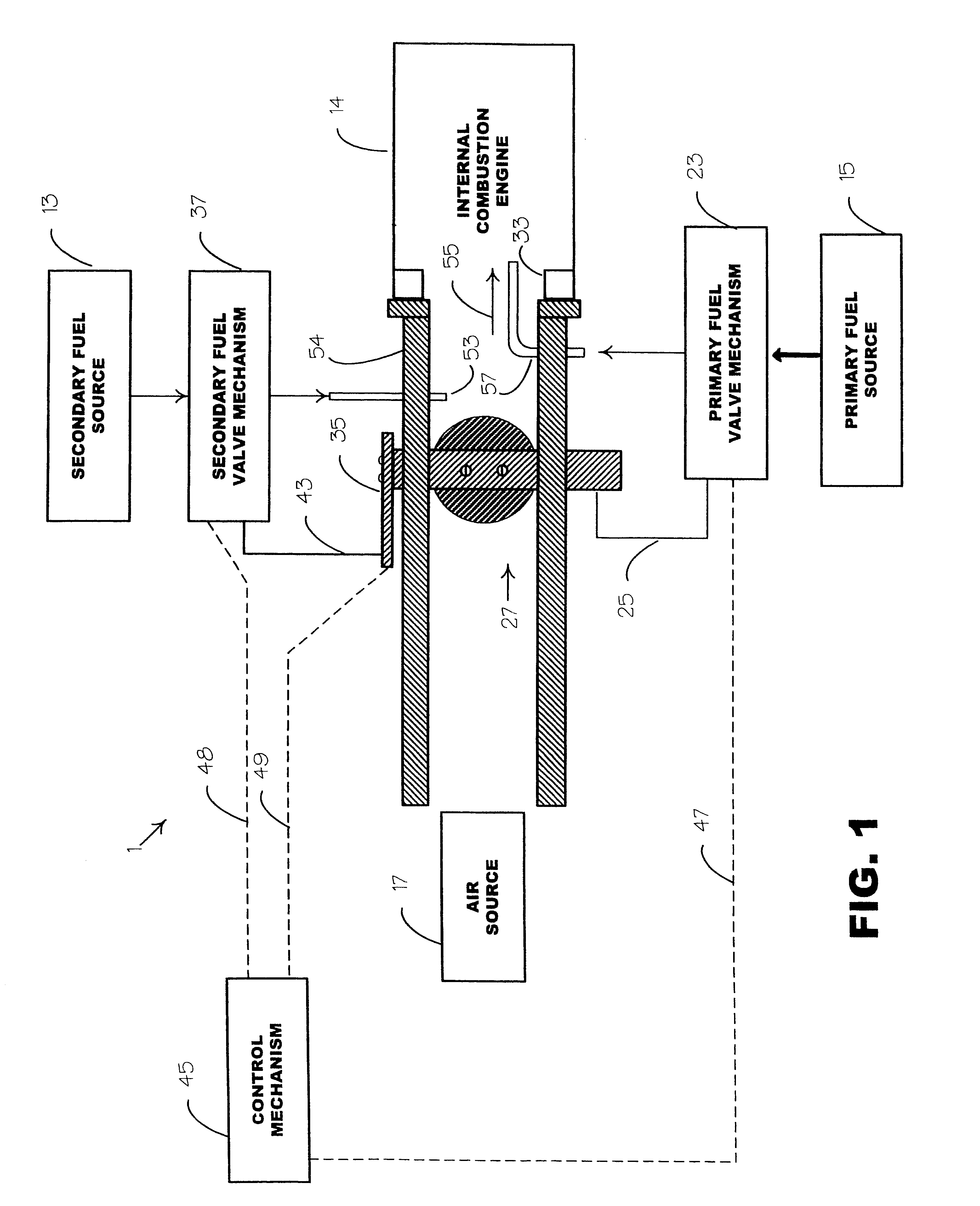

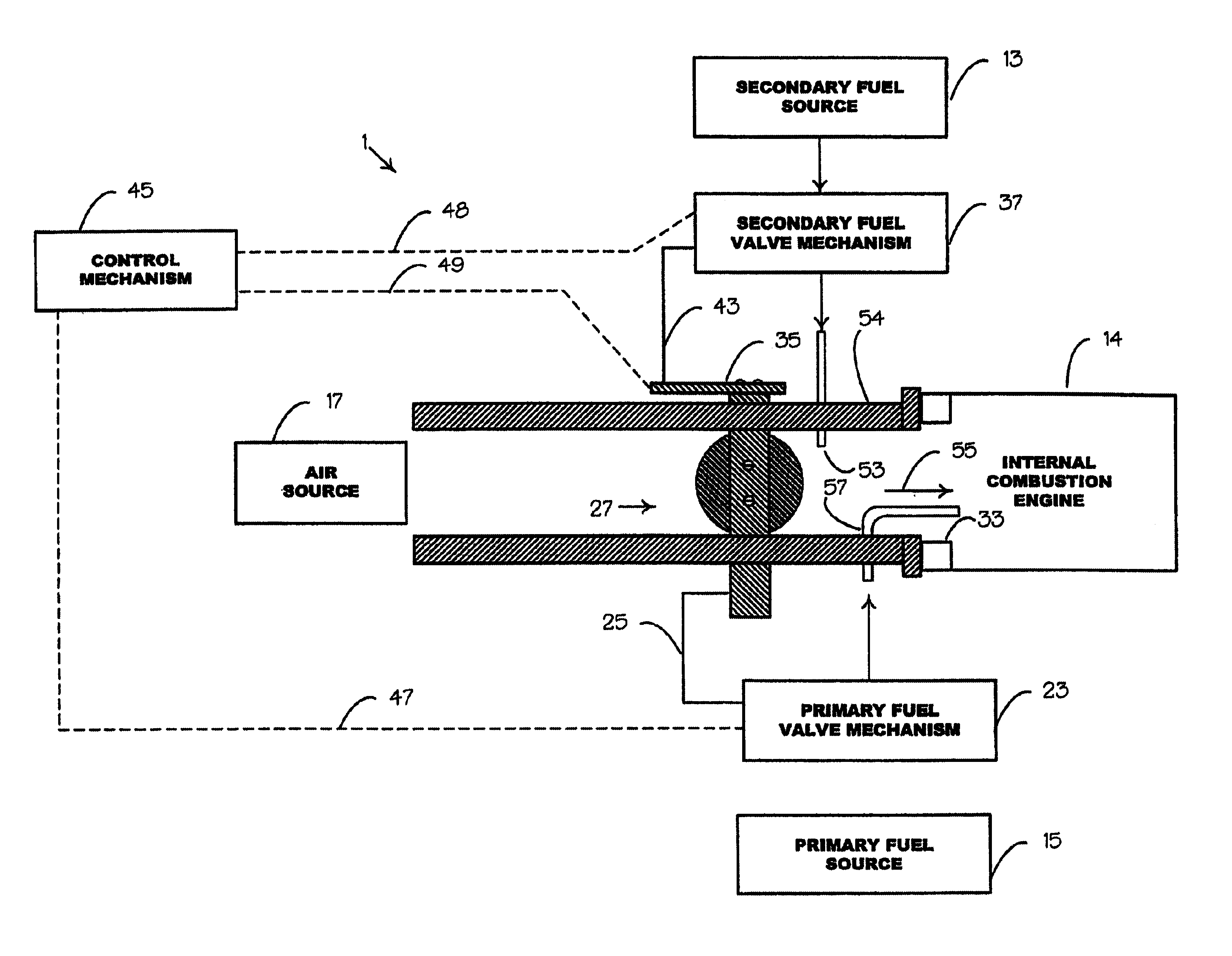

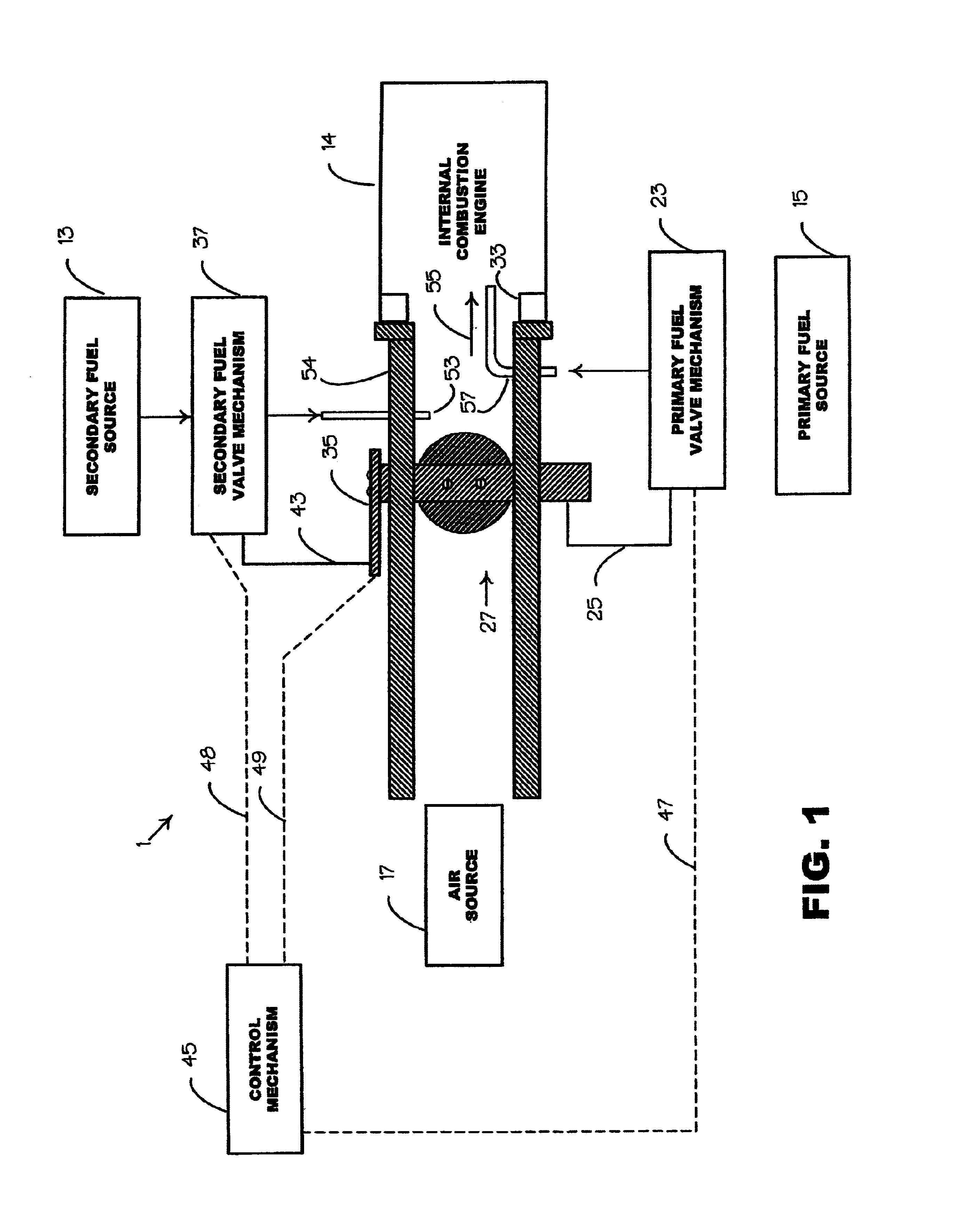

Internal combustion system using acetylene fuel

InactiveUS6076487AInternal combustion piston enginesNon-fuel substance addition to fuelCarbon chainInternal combustion engine

An environmentally clean dual fuel for an internal combustion engine, comprising acetylene as a primary fuel and a combustible fuel, such as one or more fluids selected from an alcohol such as ethanol, methanol or any other alcohol or alcohols from the group comprising C1-C20 carbon chains, ethers such as from the group comprising dimethyl ether, diethyl ether, methyl t-butyl ether, ethyl t-butyl ether, t-amyl methyl ether, di-isopropyl ether and the like, low-molecular-weight esters such as from the group comprising methyl formate, methyl acetate, ethyl acetate, methyl propionate, ethyl propionate and the like, or other suitable combustible fluid such as mineral spirits and the like, as a secondary fuel for operatively preventing early ignition and knock arising from the primary fuel. The dual fuel, internal combustion system, which generally utilizes a two-stage process for start-up and operation and can be operated with air- or liquid-cooling, is environmentally clean with hydrocarbon, CO, NOx, and SOx emissions substantially eliminated.

Owner:GOTEC

Internal combustion system adapted for use of a dual fuel composition including acetylene

InactiveUS6575147B2Easy to operateImprove performanceNon-fuel substance addition to fuelInternal combustion piston enginesCarbon chainMineral spirit

An internal combustion engine adapted to use an environmentally clean multi-fuel composition, comprising acetylene as a primary fuel and a combustible fuel, such as one or more fluids selected from an alcohol such as ethanol, methanol or any other alcohol or alcohols from the group comprising C1-C12 carbon chains, ethers such as from the group comprising dimethyl ether, diethyl ether, methyl t-butyl ether, ethyl t-butyl ether, t-amyl methyl ether, di-isopropyl ether and the like, low-molecular-weight esters such as from the group comprising methyl formate, methyl acetate, ethyl acetate, methyl propionate, ethyl propionate, ethyl malate, butyl malate, and the like, or other suitable combustible fluid such as mineral spirits and the like, as a secondary fuel for operatively preventing early ignition and knock arising from the primary fuel.

Owner:GOTEC INC

Hydrophobic self-cleaning coating composition

InactiveUS20080250978A1Efficient use ofSolve the lack of resistanceSemiconductor/solid-state device manufacturingMixingWater basedMineral spirit

The present invention provides a water based, low VOC super hydrophobic coating composition that can be used to make wet and dry dirt repellent surfaces to keep the surfaces clean for a reasonable period of time. The coating utilizes hydrophobic nanoparticles dispersed in water. This treatment produces a virtually transparent coating releasing very little or no VOC compounds whereas previous coatings of comparable hydrophobicity release up to 99 percent VOC compounds. The coating can be applied by a simple, single application method and the super hydrophobic property can be achieved by drying at room temperature for 5 to 10 minutes. A preferred coating can be easily removed and renewed when desired. The aqueous hydrophobic self cleaning coating composition that can be applied by conventional methods such as by spraying the composition onto a surface creating a wet and dry dirt repellent coating on the surface. The hydrophobic self cleaning coatings are used on exterior automotive and boat surfaces, and in many other applications, to produce a self cleaning surface, reduce adherence of dirt and contaminants to a treated surface, and reduce drag in some applications providing an energy savings. The coating solves the problem of poor resistance to UV light, opaque appearance, and / or abrasion found in previous coatings of similar nature. A preferred coating has good resistance to UV light and some resistance to abrasion. Clear, nearly transparent and translucent coatings are produced as compared to conventional coatings of comparable hydrophobicity which are typically white or opaque. The coating can be applied by a single and easy spraying method and the super hydrophobic property can be achieved by drying the film by evaporation of the solvent wetting solution and water based carrier at ambient temperature for 5 to 10 minutes. Embodiments of the hydrophobic self-cleaning coating composition can be produced resulting in a clear coating or in some cases a translucent dirt repellant film or coating on painted material, plastic, metal, glass, ceramic, fiberglass or a polymer substrate. The coating typically utilizes hydrophobic nanoparticles of fumed silica and / or titania wetted by a hydrophilic solvent such as acetone for no VOC applications, or with mineral spirits, alcohol or a light distillate if VOC are not a consideration, together with a selected surfactant typically having an HLB value in a range of from 9 to 13.At least one preferred coating composition comprising an effective amount of a treated fumed silica wetted with a solvent and dispersed in water, upon drying, resulted in a coated surface providing a contact angle of at least 165 degrees and a surface energy below 12 dynes / centimeter as compared to water having a contact angle of from 65 to 80 degrees on a noncoated surface. The composition imparts a degree of hydrophobicity to a surface so that the surface will have a tilt angle of sliding of less than 2 degrees as compared to water on a noncoated surface having a tilt angle of sliding of 90 degrees or higher. The coating composition is removed by washing with a detergent or applying pressure to the coating wiping same from the treated surface. Exposure to water in the form of rain or snow does not remove the coating composition.

Owner:ASHLAND LICENSING & INTPROP LLC

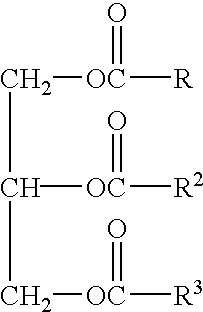

Biodegradable penetrating lubricant

InactiveUS20030040444A1Easy to moveEnhanced inhibitory effectAdditivesBase-materialsOrganic solventAntioxidant

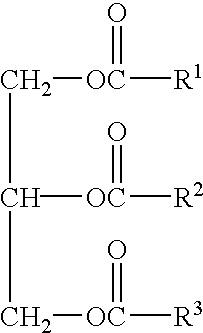

A biodegradable penetrating lubricant, comprised of: (A) at least one triglyceride oil of the formula: wherein R1, R2, and R3 are aliphatic hydrocarbyl groups containing from about 7 to about 23 carbon atoms; (B) an organic solvent selected from the group comprising: (1) ethyl lactate, (2) soy methyl ester, (3) at least one mineral spirit, and (4) combinations of 1, 2, and 3; and, (C) an antioxidant. Optionally, the lubricant may further include an additive selected from the group comprising: (D) an anti-wear inhibitor; (E) a corrosion inhibitor; (F) a pour point depressant; and, (G) a component chosen from the group comprising: (1) a food grade tackifier; (2) molybdenum disulfide; and (3) a combination of 1 and 2.

Owner:RENEWABLE LUBRICANTS INC

Universal Synthetic Penetrating Lubricant, Method and Product-by-Process

ActiveUS20080182769A1Improve protectionOrganic chemistryLiquid carbonaceous fuelsEngineeringMineral spirit

A penetrating lubricant with the capacity to offer a both penetration into rust and corrosion. Further, this lubricant actively penetrates the crystalline surface of the metal while exhibiting extreme pressure lubrication, non-migrating with lasting protection. Further lubricant exhibits dielectric strength of over 8000 volts, at the same time cleaning electrical contacts, thereby reducing resistance and associated heat. The preferred embodiment may contain alpha-olefins, low-odor aromatic solvents, base oils, and high flash mineral spirits.

Owner:BESTLINE INT RESEACRH

Universal Synthetic Gasoline Fuel Conditioner Additive, Method and Product-by-Process

ActiveUS20100269404A1Reduce premature mechanical wearReduce failureLiquid carbonaceous fuelsAdditivesGasoline fuelEngineering

A process of producing a universal synthetic based gasoline fuel additive that cleans the fuel system including valves surface, lubricates the fuel pump, injectors and valves while allowing for a clean and more efficient burn. A major portion will consist of (a) Alfa-Olefins, (b) 2-propanol (c) Hydrolsomerized High VI HT Base Oils, (d) Dimethyl Ketones, (e) Low Flash Mineral Spirits, (f) Low Aromatic Solvent, (g) Isomer Reformate, (h) Solvent Activated Dye. In a preferred embodiment, this universal synthetic gasoline conditioner additive for improving lubrication comprises: alpha-olefins comprising from 5 to 30 percent thereof, by weight; low odor aromatic solvents comprising from 3 to 27 percent thereof, by weight; 2-Propanol comprising of 3 to 30 percent thereof, by weight; and at least one a base oil comprising from 0.50 to 15 percent thereof, by weight; wherein: the percentages by weight are specified in relative proportion to one another.

Owner:BESTLINE INT RESEACRH

Universal synthetic gasoline fuel conditioner additive, method and product-by-process

ActiveUS7931704B2Improve the lubrication effectReduce failureLiquid carbonaceous fuelsAdditivesGasoline fuelKetone

A process of producing a universal synthetic based gasoline fuel additive that cleans the fuel system including valves surface, lubricates the fuel pump, injectors and valves while allowing for a clean and more efficient burn. A major portion will consist of (a) Alfa-Olefins, (b) 2-propanol (c) Hydroisomerized High VI HT Base Oils, (d) Dimethyl Ketones, (e) Low Flash Mineral Spirits, (f) Low Aromatic Solvent, (g) Isomer Reformate, (h) Solvent Activated Dye. In a preferred embodiment, this universal synthetic gasoline conditioner additive for improving lubrication comprises: alpha-olefins comprising from 5 to 30 percent thereof, by weight; low odor aromatic solvents comprising from 3 to 27 percent thereof, by weight; 2-Propanol comprising of 3 to 30 percent thereof, by weight; and at least one a base oil comprising from 0.50 to 15 percent thereof, by weight; wherein: the percentages by weight are specified in relative proportion to one another.

Owner:BESTLINE INT RESEACRH

Universal Synthetic Penetrating Lubricant, Method and Product-by-Process

ActiveUS20100273688A1Improve protectionOrganic chemistryLiquid carbonaceous fuelsElectrical resistance and conductanceAlpha-olefin

A penetrating lubricant with the capacity to offer a both penetration into rust and corrosion. Further, this lubricant actively penetrates the crystalline surface of the metal while exhibiting extreme pressure lubrication, non-migrating with lasting protection. Further lubricant exhibits dielectric strength of over 8000 volts, at the same time cleaning electrical contacts, thereby reducing resistance and associated heat. The preferred embodiment contains alpha-olefins, low-odor aromatic solvents, base oils, and high flash mineral spirits.

Owner:BESTLINE INT RESEACRH

Universal Synthetic Gasoline Fuel Conditioner Additive, Method and Product-by-Process

ActiveUS20110197499A1Negative effectImprove the lubrication effectLiquid carbonaceous fuelsFuel additivesGasoline fuelKetone

A process of producing a universal synthetic based gasoline fuel additive that cleans the fuel system including valves surface, lubricates the fuel pump, injectors and valves while allowing for a clean and more efficient burn. A major portion will consist of (a) Alfa-Olefins, (b) 2-propanol (c) Hydroisomerized High VI HT Base Oils, (d) Dimethyl Ketones, (e) Low Flash Mineral Spirits, (f) Low Aromatic Solvent, (g) Isomer Reformate, (h) Solvent Activated Dye. In a preferred embodiment, this universal synthetic gasoline conditioner additive for improving lubrication comprises: alpha-olefins comprising from 5 to 30 percent thereof, by weight; low odor aromatic solvents comprising from 3 to 27 percent thereof, by weight; 2-Propanol comprising of 3 to 30 percent thereof, by weight; and at least one a base oil comprising from 0.50 to 15 percent thereof, by weight; wherein: the percentages by weight are specified in relative proportion to one another.

Owner:BESTLINE INT RESEACRH

Dual fuel composition including acetylene

InactiveUS7288127B1Easy to operateImprove performanceInternal combustion piston enginesNon-fuel substance addition to fuelCarbon chainDiethyl ether

An environmentally clean dual fuel for use in an internal combustion engine, comprising acetylene as a primary fuel and a combustible fuel, such as one or more fluids selected from an alcohol such as ethanol, methanol or any other alcohol or alcohols from the group comprising C1-C20 carbon chains, ethers such as from the group comprising dimethyl ether, diethyl ether, methyl t-butyl ether, ethyl t-butyl ether, t-amyl methyl ether, di-isopropyl ether and the like, low-molecular-weight esters such as from the group comprising methyl formate, methyl acetate, ethyl acetate, methyl propionate, ethyl propionate, ethyl malate, and butyl malate, and the like, or other suitable combustible fluid such as mineral spirits and the like, as a secondary fuel for operatively preventing early ignition and knock arising from the primary fuel.

Owner:GOTEC

Headlight cleaner, restorer, and methods for the manufacture and use thereof

InactiveUS6984612B2Less severe oxidation and damageReduce wearInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsWaxCLARITY

An automotive headlight restorer and cleaner which removes oxidation and yellow haziness and restores optical clarity. The method of manufacture consists of several solutions. Solution A, which is an industrial degreasing compound, diluted to 1:20. Solution B1 is a mixture of 53%–56% mineral spirits, 1%–3% butanol, and gloss spar varnish and / or acrylic urethane. Solution B1 is used on lenses with heavy oxidation and severe damage. It will improve them greatly, but not restore them to like new clarity. Solutions B2 and C are for lenses with less severe oxidation and damage (the majority of lenses fit in this category.) Solution B2 is a fine cut cleaner (a professional quality rubbing compound of low abrasive content with diminishing abrasiveness). Solution C is a combination wax, polish, sealer. This solution protects against future damage to the lenses. Subsequent methods for the manufacture and use of this method for headlight restoration and cleaning for the purpose of removing yellowing and haziness are provided.

Owner:MAILLIE DAVID FRANCIS

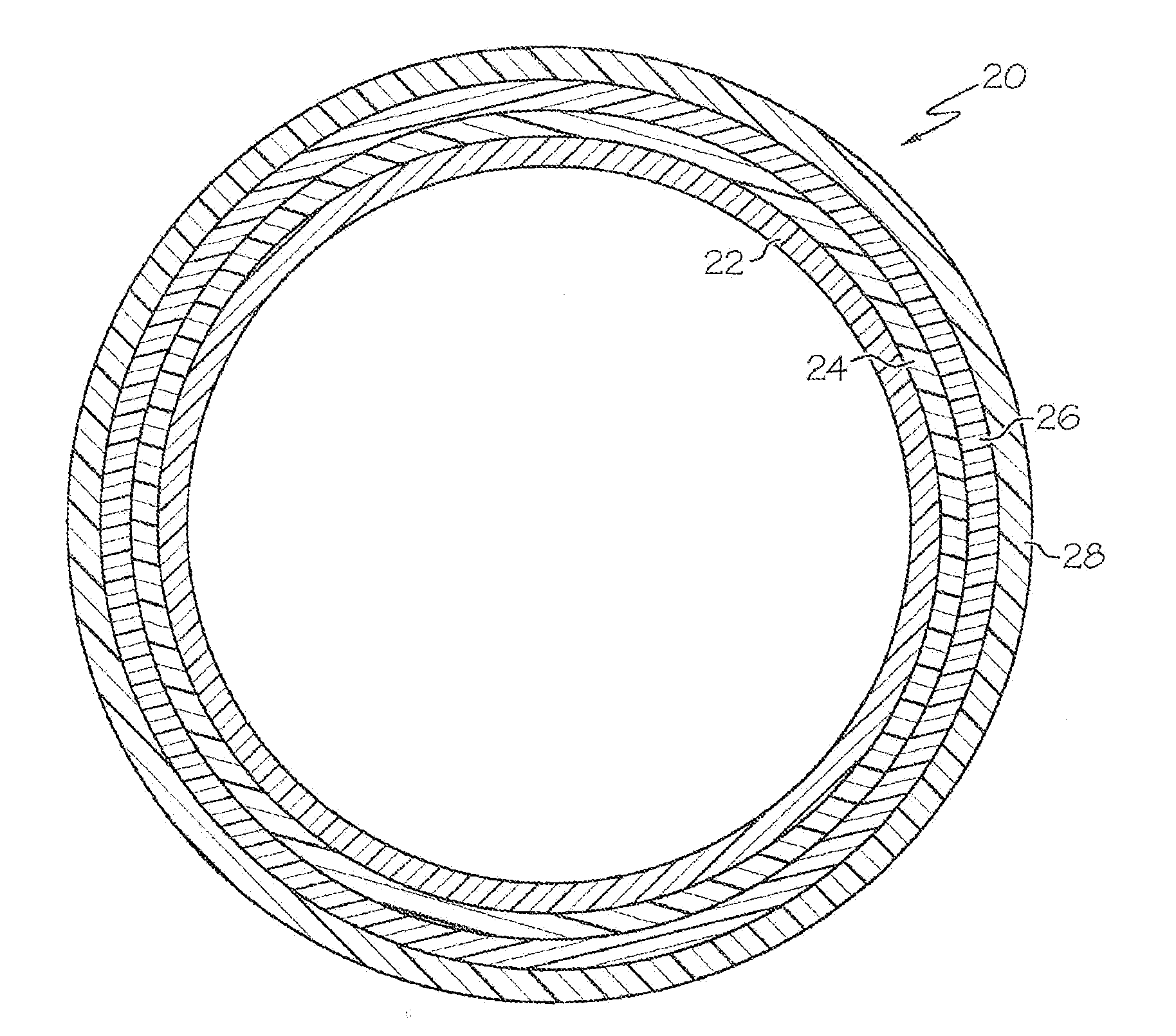

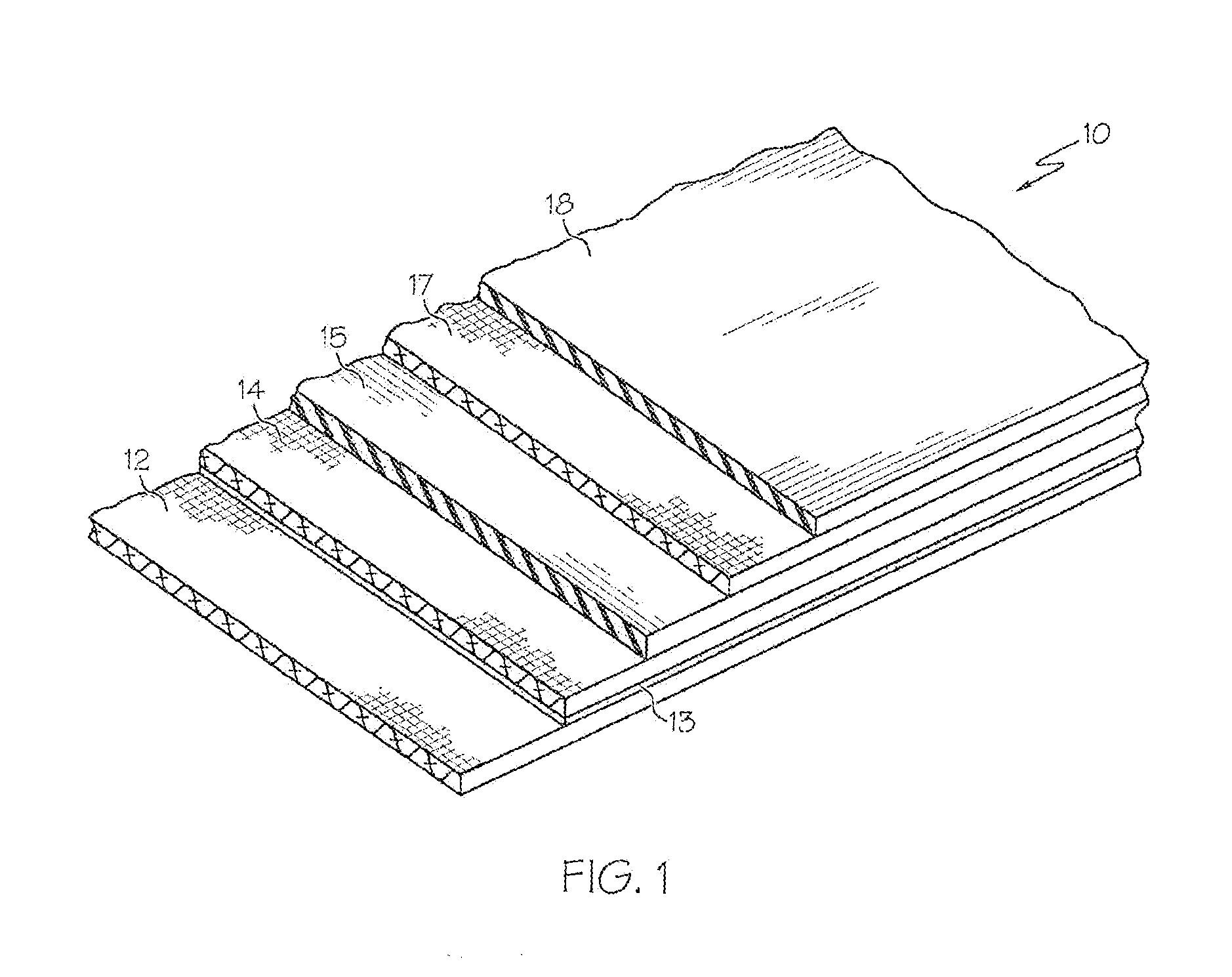

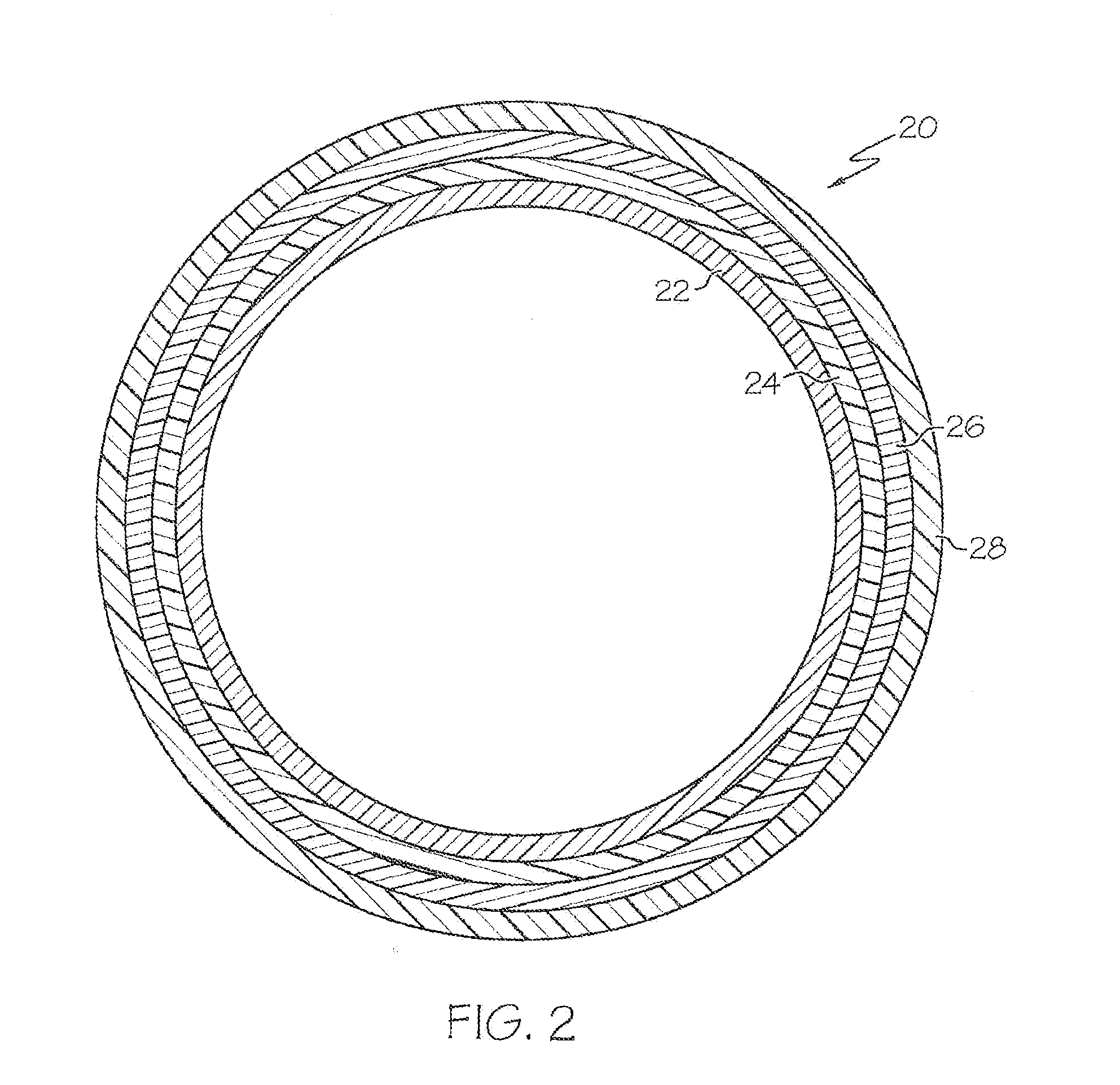

Thermoplastic Polyurethane For Printing Blankets

InactiveUS20110168043A1Improved compression setImprove the immunitySynthetic resin layered productsPlate printingPolyesterCarboxylic acid

The present invention provides an offset printing blanket or sleeve including one or more layers that are made with a soft thermoplastic polyurethane composition that provides excellent compression set and excellent resistance to apolar solvents, such as naphthenic mineral spirits. The subject invention more specifically reveals a printing blanket comprising: a base layer; a compressible layer, and a printing surface layer, wherein the compressible layer and / or the printing surface layer is comprised of a thermoplastic polyurethane composition, wherein the thermoplastic polyurethane composition made by reacting (a) at least one polyester polyol intermediate with (b) at least one diisocyanate and (c) at least one chain extender; wherein the polyester polyol intermediate comprises an intermediate derived from at least one dialkylene glycol and at least one dicarboxylic acid or an ester or anhydride thereof. It is particularly beneficial to utilize the thermoplastic polyurethane composition in the printing surface layer.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Universal Synthetic Penetrating Lubricant, Method and Product-by-Process

ActiveUS20120077720A1Dissolving corrosionDissolving rustOrganic chemistryOrganic compound preparationAromatic solventsMineral spirit

A penetrating lubricant with the capacity to offer a both penetration into rust and corrosion. Further, this lubricant actively penetrates the crystalline surface of the metal while exhibiting extreme pressure lubrication, non-migrating with lasting protection. Further lubricant exhibits dielectric strength of over 8000 volts, at the same time cleaning electrical contacts, thereby reducing resistance and associated heat. The preferred embodiment may contain alpha-olefins, low-odor aromatic solvents, base oils, and high flash mineral spirits.

Owner:BESTLINE INT RESEACRH

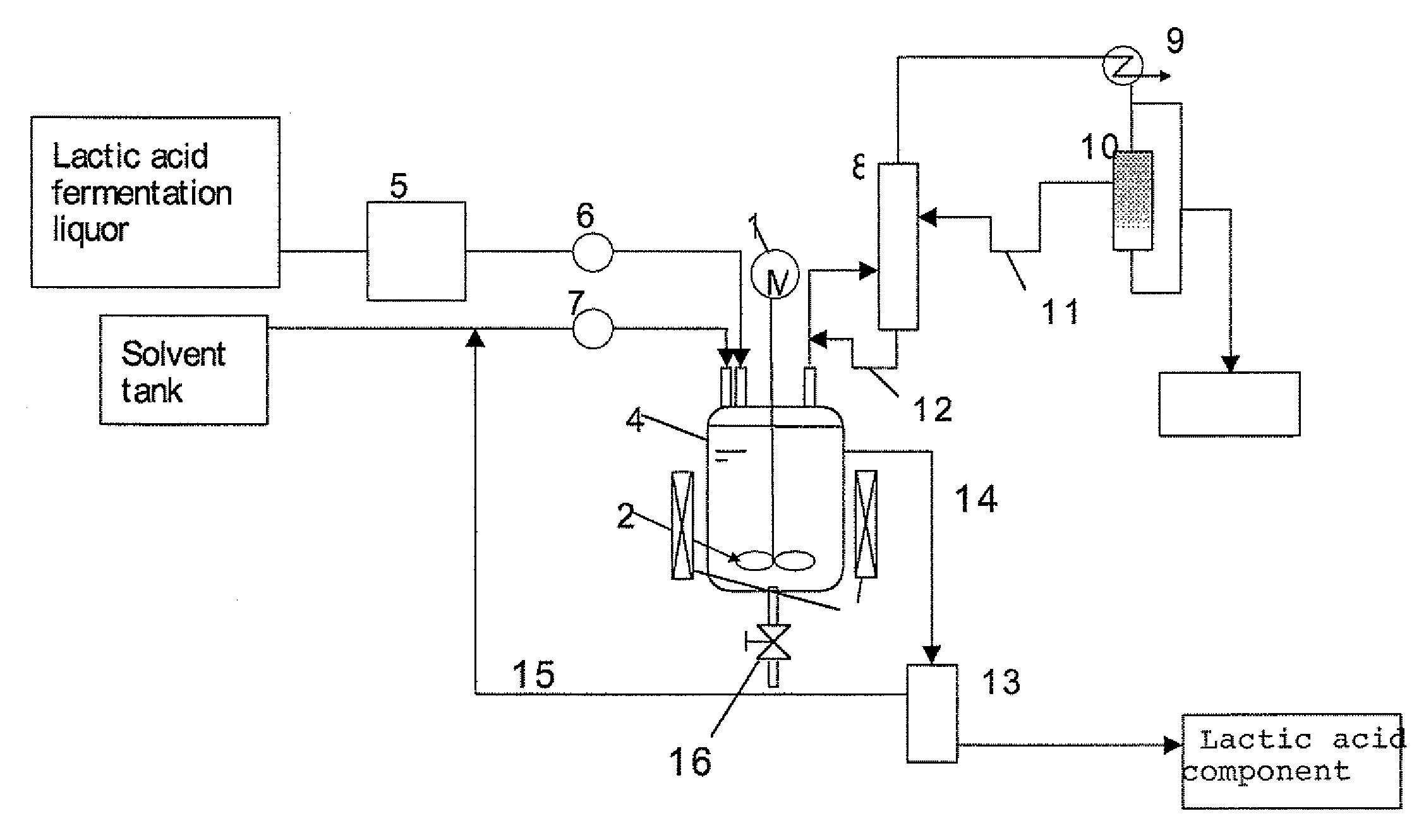

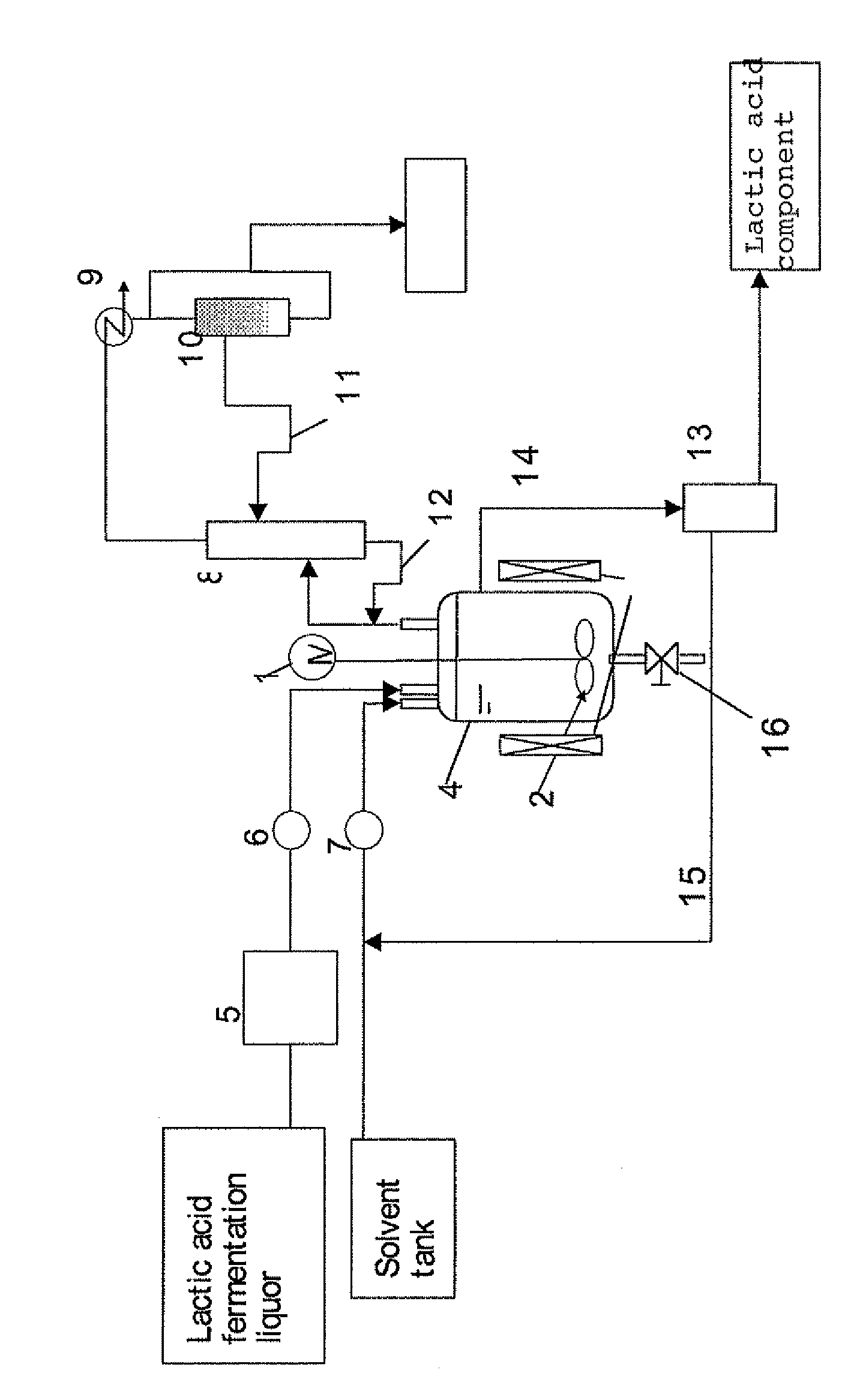

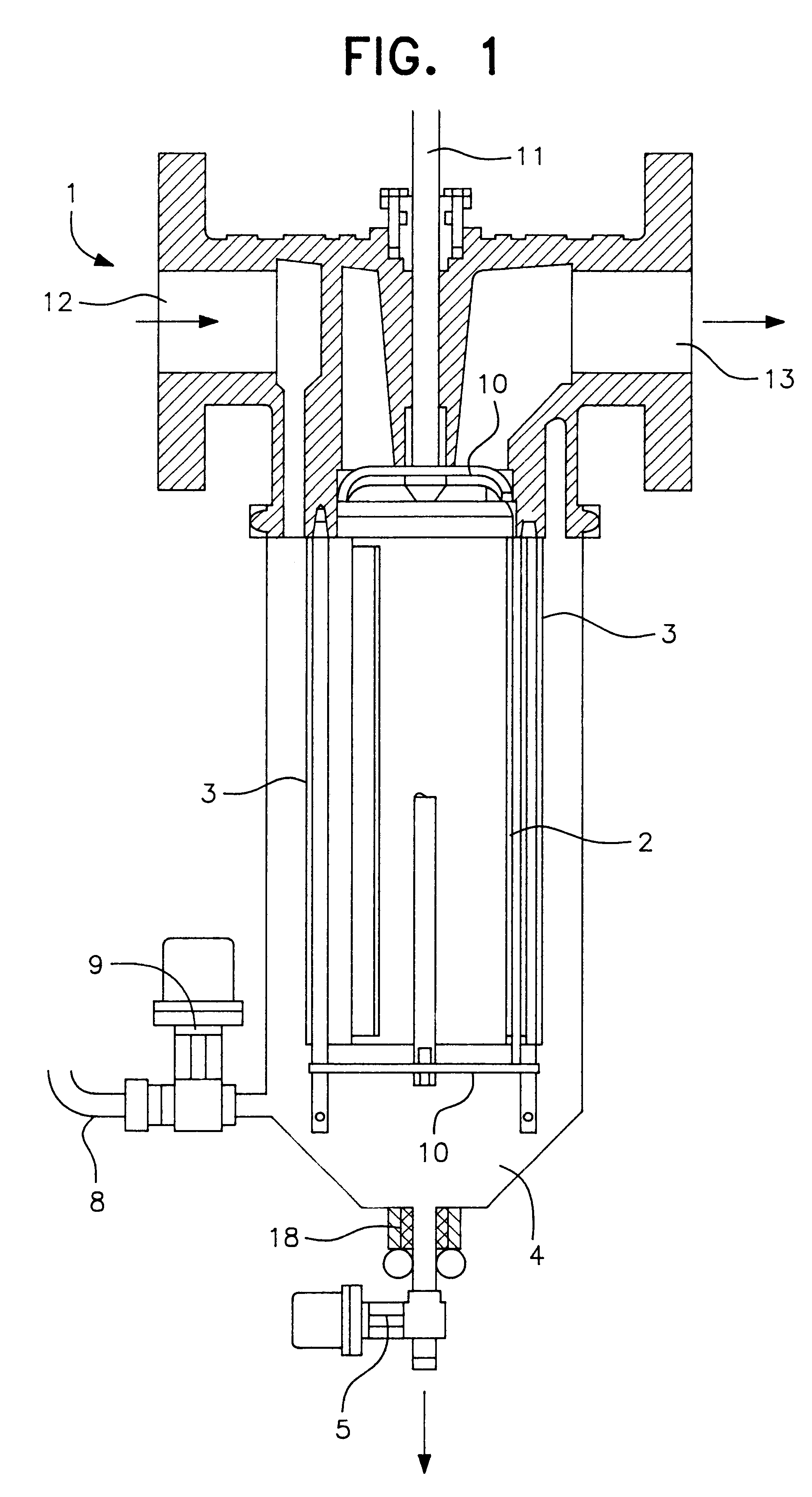

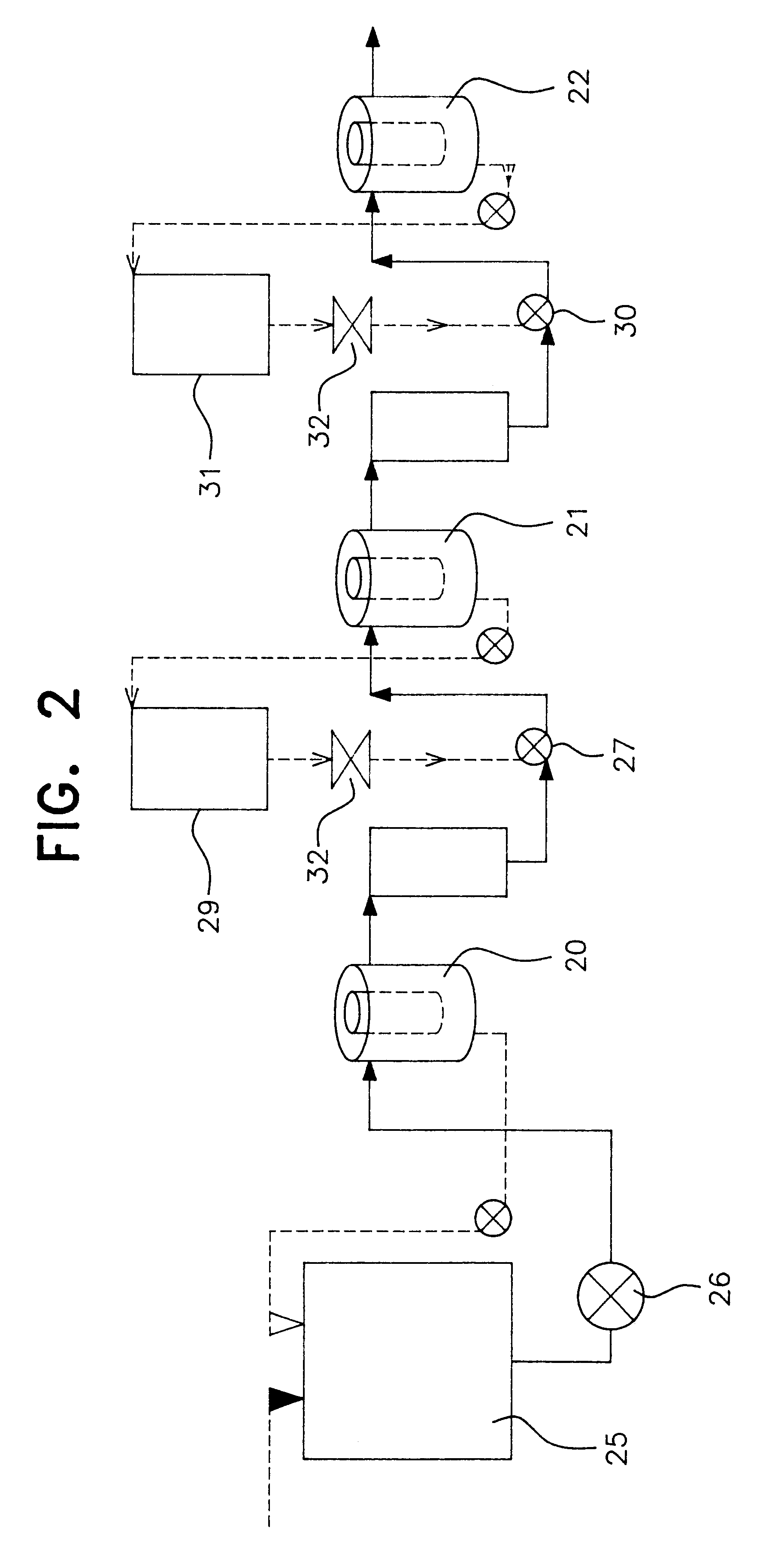

Method for Separation of Lactic Acid Component from Lactic Acid Fermentation Liquor, and Separation Apparatus

InactiveUS20090093034A1Simple processLow costBioreactor/fermenter combinationsBiological substance pretreatmentsPropanolLactic acid fermentation

A lactic acid component (e.g., lactic acid or oligo (lactic acid)) can be obtained by extraction from a lactic acid fermentation liquor with a pH of 4.8 or less, using at least one solvent selected from the group consisting of toluene, xylene, mesitylene, ethylbenzene, methanol, ethanol, propanol, butanol, and mineral spirit. Furthermore, oligo (lactic acid) can be obtained, by heating a lactic acid fermentation liquor with a pH of 4.8 or less under reduced pressure, and washing, with water, the fermentation liquor containing a produced oligo (lactic acid). Hence, a method is provided for separating a lactic acid component from a lactic acid fermentation liquor, which is free from incorporation of impurities and which includes simple steps.

Owner:KANSAI CHEM ENG CO LTD +1

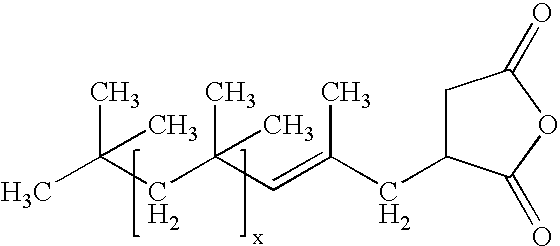

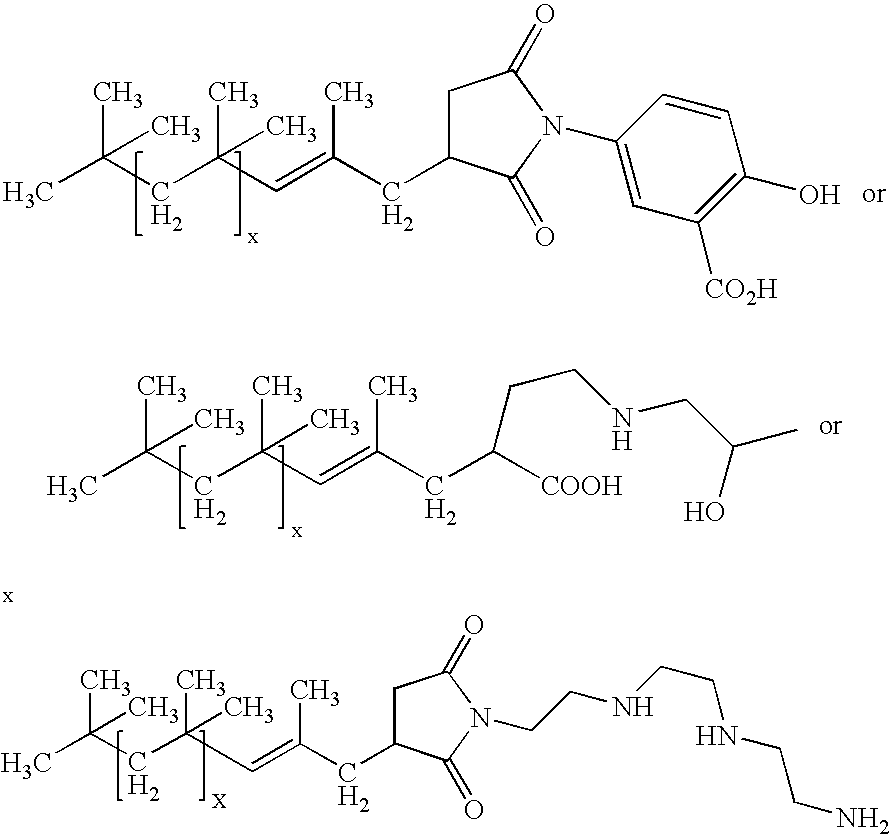

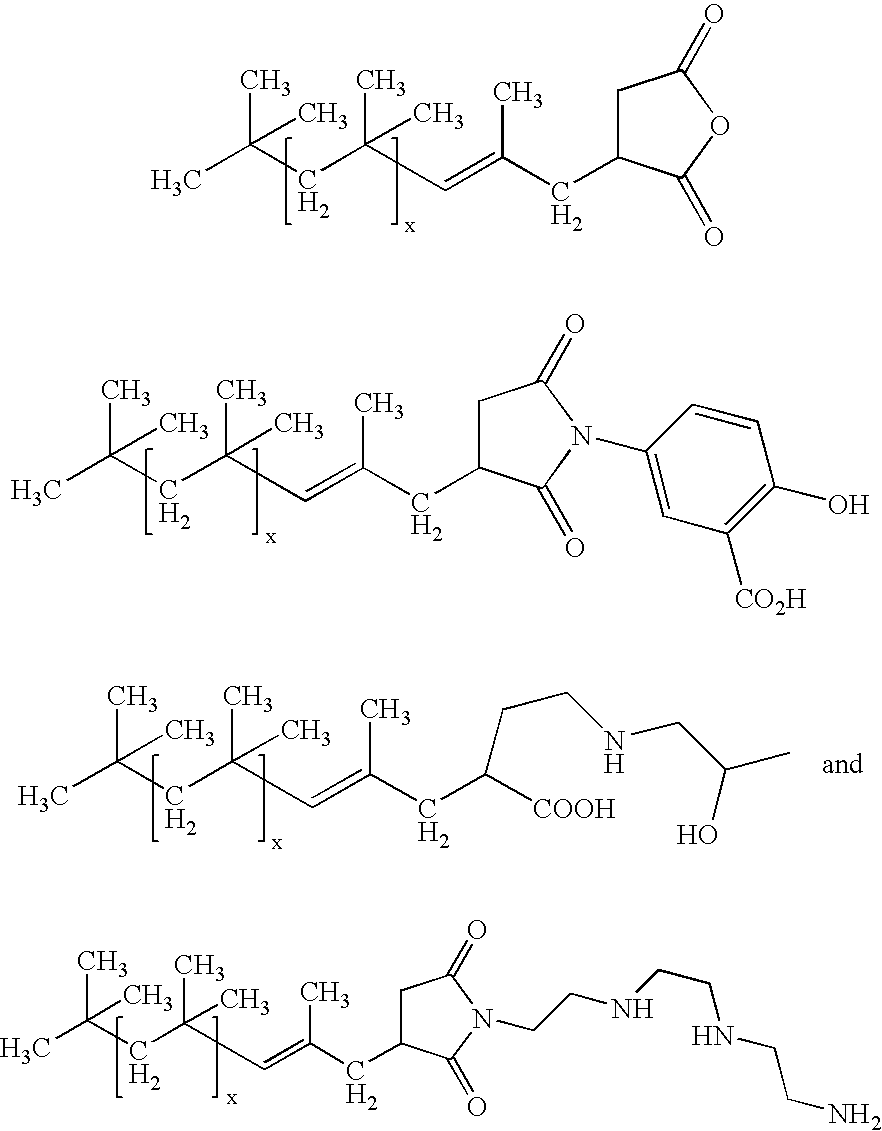

Polyisobutenyl containing dispersions and uses thereof

InactiveUS20080182927A1Reduce overall dispersant loadingReduce loadMaterial nanotechnologySilicaMetal oxide nanoparticlesMineral spirit

Owner:AIR PROD & CHEM INC

Water soluble printing ink and production thereof

A water soluble printing ink and its production are disclosed. The ink consists of pine resin 5-20 proportion, polystyrene 1-20 proportion, acrylate 2-8 proportion, pigment 4-20 proportion, emulsifier 1-10 proportion, mineral spirits 10-30 proportion, assistants 1-10 proportion and water 20-70 proportion. The process is carried out by adding solvent, emulsifier, pigment and filler into waste polystyrene. Its advantages include stable performance, good color fixing ability, fast dry speed, low cost and no environmental pollution.

Owner:黎烔光

Fire resisting paint

The invention discloses a fire resistant paint, comprising a mixture additive and an anion ecological paint, wherein, the mixture additive comprises 30-55 wt% of asphalt, 15-30 wt% of mineral spirit, 5-15 wt% of vermiculite, 5-15 wt% of fine asbestos, 2-3 wt% of borax, and 5-10 wt% of mica powder. The fire resistant paint is mainly applied on utensils and furniture, and can resist flame when a fire starts.

Owner:NANTONG XIYUN TRADE

Polishing compound

ActiveUS20060283094A1Extended durationClean appearancePigmenting treatmentSoap detergents with inorganic compounding agentsCompound aStearic acid

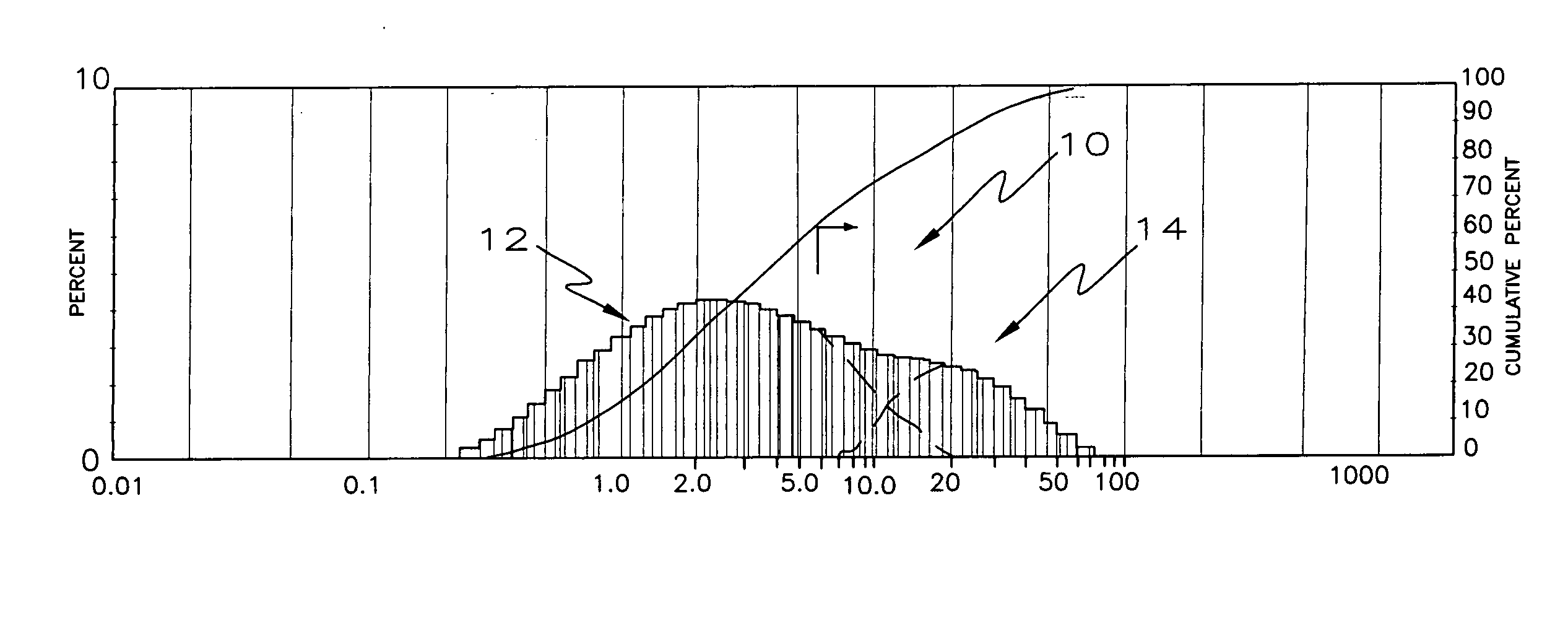

A cleaning and polishing composition contains mineral spirits, a first abrasive component of particles having a median size in a range of 1-4 microns, a second abrasive component of particles having a median size in a range of 15-30 microns and a fatty acid. The composition is a free flowing liquid having the viscosity of mineral spirits and has the ability to provide a long lasting finish. After cleaning and polishing an aluminum surface and after several weeks of rough use, the surface may be washed and looks like a newly polished surface. A preferred composition is 85-90% mineral spirits, balance stearic acid and aluminum oxide. The median particle size of the abrasive is less than about six microns and a sizeable fraction is below one micron.

Owner:CRISSEY GORDON K

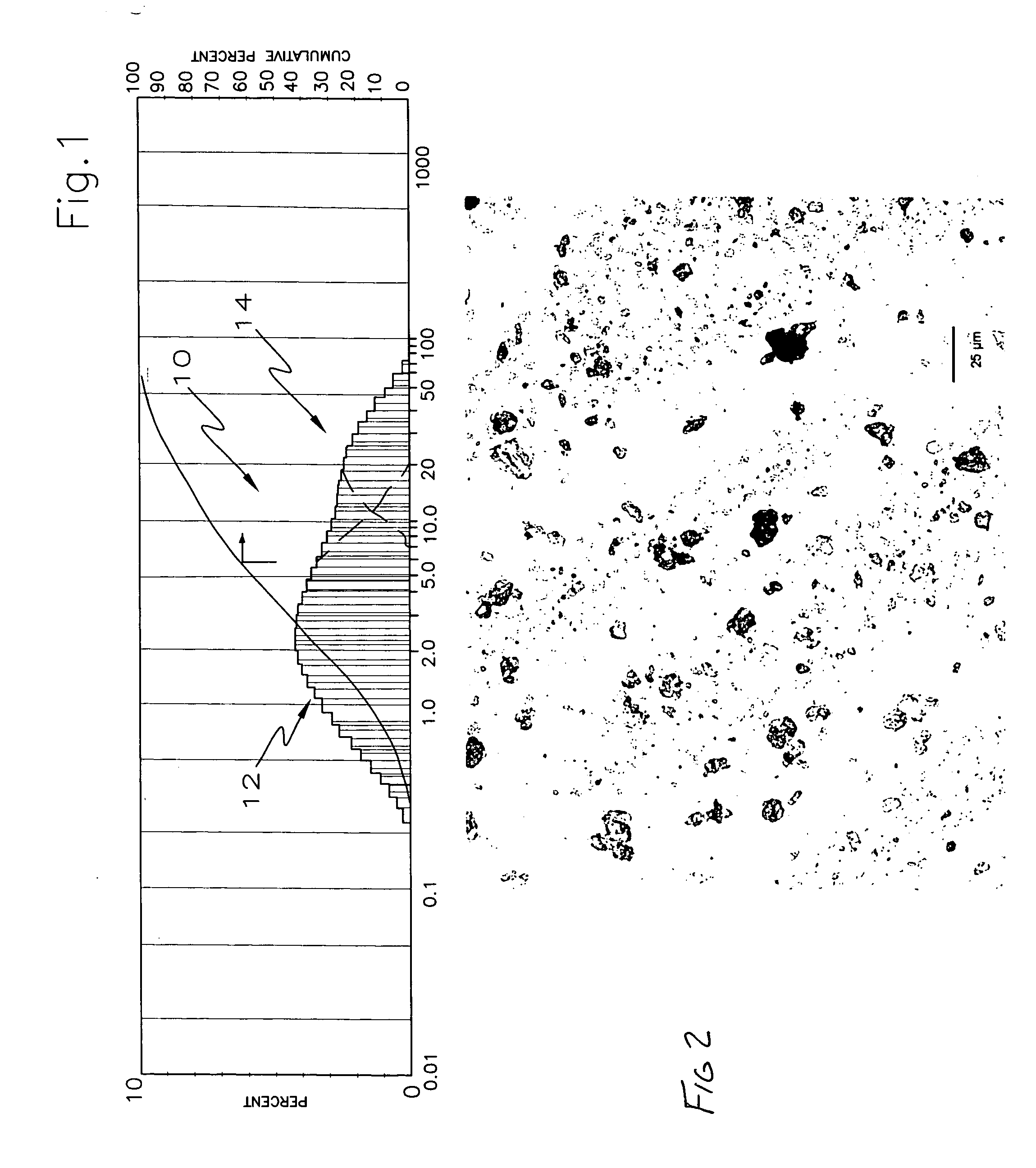

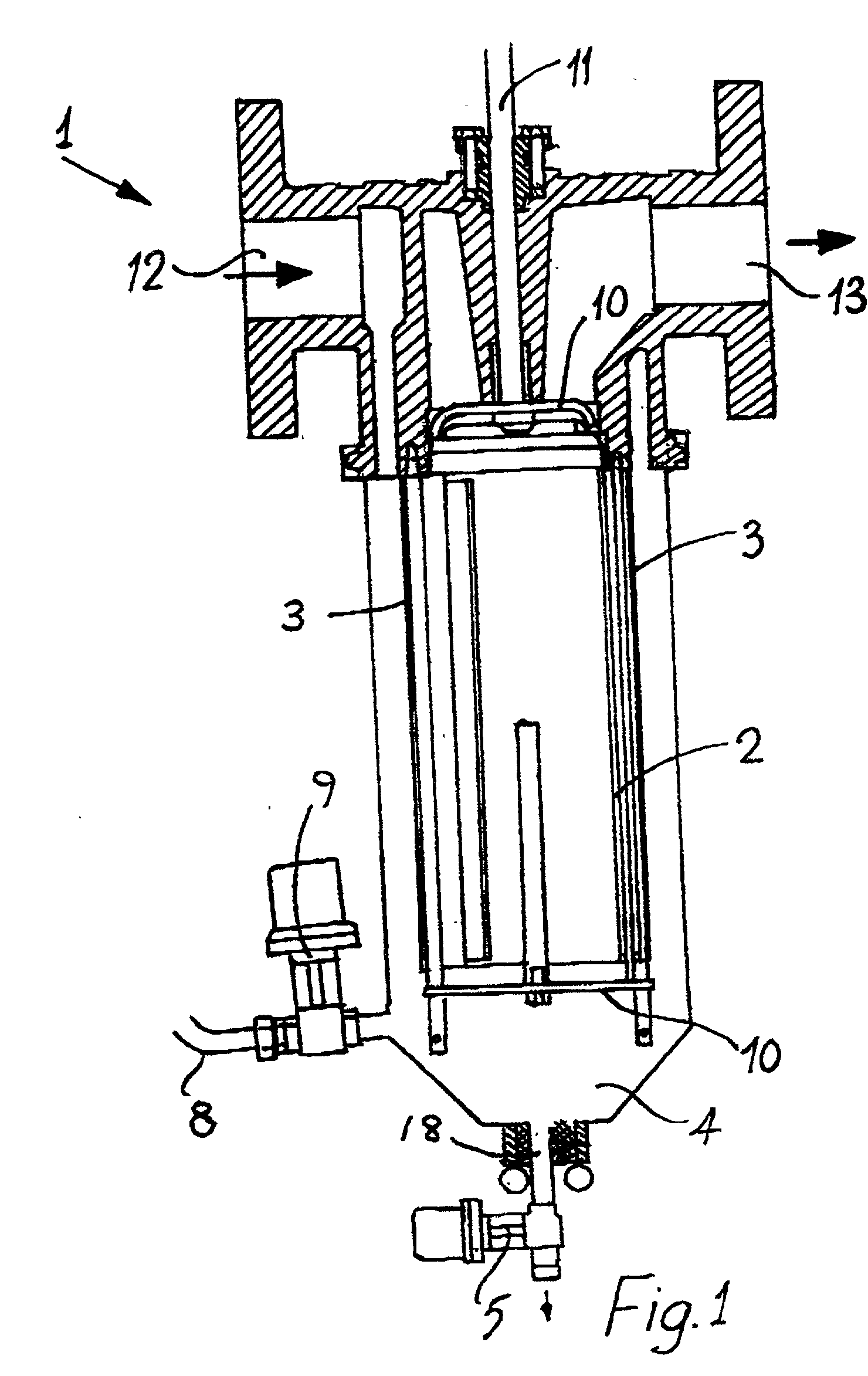

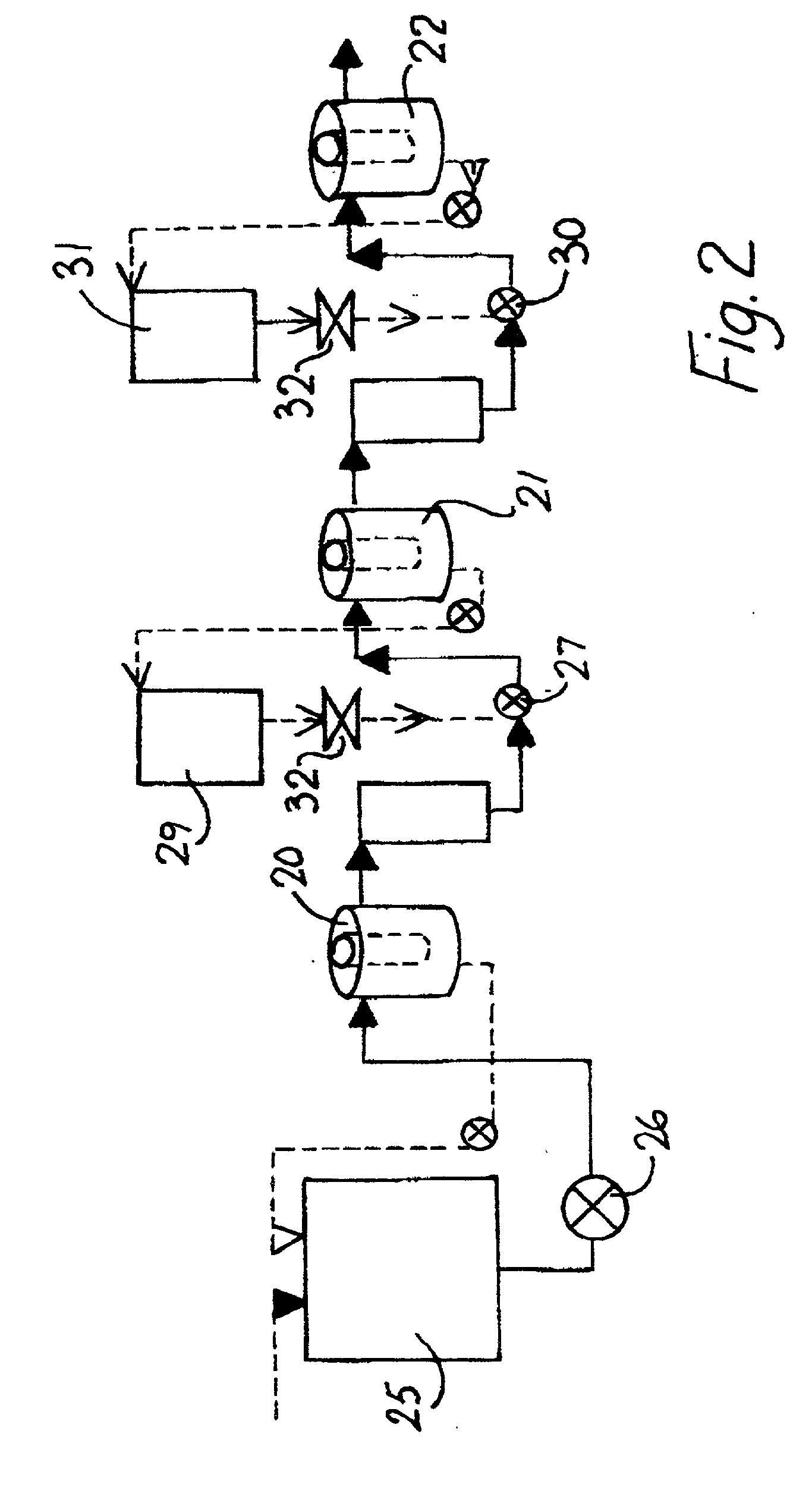

Method for the production of metallic flake pigments

InactiveUS20020005144A1Effective classificationEfficient preparationPigmenting treatmentSlurryMineral spirit

A method of manufacturing metallic, especially aluminum flake pigments comprises comminuting metallic flake particles in an inert solvent such as mineral spirit and in-line screening of the slurry thus formed in at least two in-line cylindrical rotary screens with different mesh size. The screening system is fully enclosed to avoid solvent emissions. The finished product has consistent flake particle size distribution with brighter metallic finishes than conventionally produced products.

Owner:US ALUMINUM +2

Fireproof paint

Disclosed fireproof paint is prepared from the following raw materials in parts by weight: 100-120 parts of linseed oil, 50-60 parts of organosilicon resin, 10-12 parts of xylene, 1-2 parts of asbestos, 2-4 parts of magnesium hydroxide, 6-10 parts of water glass, 2-4 parts of acrylic resin, 5-10 parts of mineral spirit, 10-18 parts of vermiculite, 8-15 parts of titanium dioxide, 1-9 parts of toluene, 9-18 parts of silicone, 3-9 parts of xylene, 9-14 parts of heptane and 6-15 parts of butanol. The provided fireproof paint is capable of making up disadvantages of conventional paint and enriching functions and compositions of paint, and has extremely strong fireproof performance.

Owner:QINGDAO CHENQING INFORMATION TECH

Universal synthetic gasoline fuel conditioner additive, method and product-by-process

ActiveUS8268022B2Improve the lubrication effectReduce failureLiquid carbonaceous fuelsFuel additivesGasoline fuelKetone

A process of producing a universal synthetic based gasoline fuel additive that cleans the fuel system including valves surface, lubricates the fuel pump, injectors and valves while allowing for a clean and more efficient burn. A major portion will consist of (a) Alfa-Olefins, (b) 2-propanol (c) Hydroisomerized High VI HT Base Oils, (d) Dimethyl Ketones, (e) Low Flash Mineral Spirits, (f) Low Aromatic Solvent, (g) Isomer Reformate, (h) Solvent Activated Dye. In a preferred embodiment, this universal synthetic gasoline conditioner additive for improving lubrication comprises: alpha-olefins comprising from 5 to 30 percent thereof, by weight; low odor aromatic solvents comprising from 3 to 27 percent thereof, by weight; 2-Propanol comprising of 3 to 30 percent thereof, by weight; and at least one a base oil comprising from 0.50 to 15 percent thereof, by weight; wherein: the percentages by weight are specified in relative proportion to one another.

Owner:BESTLINE INT RESEACRH

Method for the production of metallic flake pigments

InactiveUS6464769B2Considerable operational advantageBrighter metallic finishesPigmenting treatmentSlurryMineral spirit

A method of manufacturing metallic, especially aluminum flake pigments comprises comminuting metallic flake particles in an inert solvent such as mineral spirit and in-line screening of the slurry thus formed in at least two in-line cylindrical rotary screens with different mesh size. The screening system is fully enclosed to avoid solvent emissions. The finished product has consistent flake particle size distribution with brighter metallic finishes than conventionally produced products.

Owner:US ALUMINUM +2

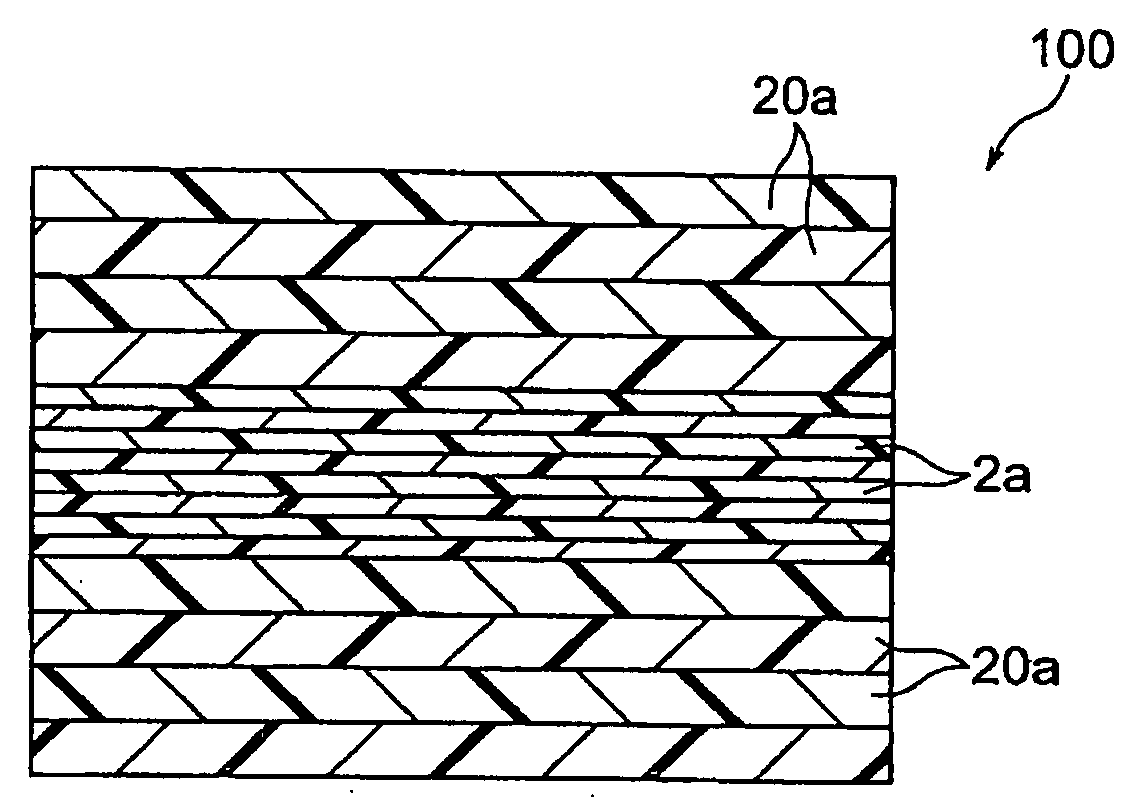

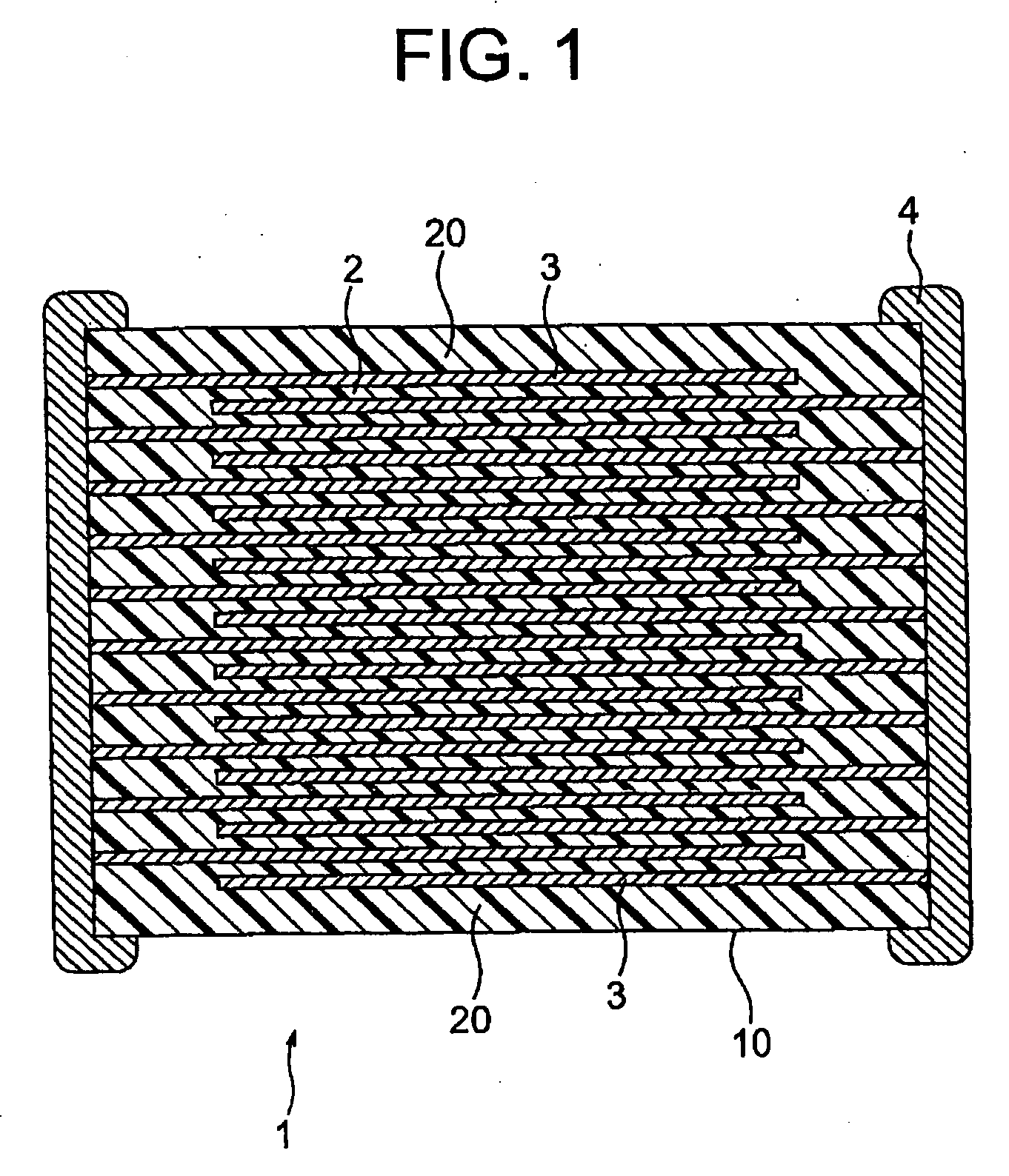

Thick film green sheet slurry, production method of thick film green sheet slurry, production method of thick film green sheet and production methods of thick film green sheet and electronic device

InactiveUS20090078358A1Strict managementCutting adhesivenessStacked capacitorsCeramic layered productsSolubilityAlcohol

A thick film green sheet slurry, a production method of thick film green sheet slurry, a production method of a thick film green sheet, a thick film green sheet and a production method of an electronic device are provided; by which coating of a relatively thick film becomes possible, a sheet formed after coating has excellent cutting property (strength capable of being cut), and a sheet having high air permeability, excellent handleability and a high adhesive force can be formed. In the present invention, a thick film green sheet slurry comprises a ceramic powder, a binder resin including a butyral based resin as the main component, and a solvent: wherein the solvent includes a good solvent for letting the binder resin dissolved well therein and a poor solvent having lower solubility to the binder resin comparing with that of the good solvent; and the poor solvent is included in a range of 30 to 60 wt % with respect to the entire solvent. The good solvent is alcohol, and the poor solvent may be toluene, xylene, mineral spirit, benzyl acetate, solvent naphtha, etc.

Owner:TDK CORPARATION

Universal synthetic penetrating lubricant, method and product-by-process

ActiveUS8415280B2Improve protectionOrganic chemistryOrganic compound preparationElectrical resistance and conductanceMineral spirit

A penetrating lubricant with the capacity to offer a both penetration into rust and corrosion. Further, this lubricant actively penetrates the crystalline surface of the metal while exhibiting extreme pressure lubrication, non-migrating with lasting protection. Further lubricant exhibits dielectric strength of over 8000 volts, at the same time cleaning electrical contacts, thereby reducing resistance and associated heat. The preferred embodiment may contain alpha-olefins, low-odor aromatic solvents, base oils, and high flash mineral spirits.

Owner:BESTLINE INT RESEACRH

Process For Preparing An Acryloyloxysilane

ActiveUS20130184482A1Easy to separateLess time to filterSilicon organic compoundsAlkaline earth metalCarboxylic acid

A process for preparing an acryloyloxysilane, the process comprising reacting a metal salt of a carboxylic acid having the formula [CR22═CR1COO−]aMa+ (I), with a haloorganoalkoxysilane having the formula XR3Si(OR4)nR53<sub2>—< / sub2>n (II) in the presence of mineral spirits and a phase transfer catalyst at a temperature of from 50 to 160° C. to form a mixture comprising an acryloyloxysilane and a metal halide having the formula Ma+X−a (III), wherein R1 is H or C1-C6 hydrocarbyl, each R2 is independently R1 or [COO−]aMa+, Ma+ is an alkali metal cation or alkaline earth metal cation, a is 1 or 2, X is halo, R3 is C1-C6 hydrocarbylene, each R4 is independently C1-C10 Q hydrocarbyl, each R5 is independently R1 and n is an integer from 1 to 3.

Owner:DOW SILICONES CORP

Composition of matter and method for removing plant resins from skin

InactiveUS6113929AEfficient removalInorganic/elemental detergent compounding agentsCosmetic preparationsPoison IviesCleansers skin

Plant resin exuded by poison ivy, poison oak, poison sumac and other plant resins are removed from the skin by successive applications of an alkaline cleanser and acidic stripper. The skin is first thoroughly washed with the alkaline cleanser. After rinsing the cleanser from the skin, the skin is daubed with the acidic stripper. The alkaline cleanser is a mixture of water, soap, turpentine, a mild abrasive, and mineral spirits. The acidic stripper is a mixture of an acid, and astringents such as tannin and witch hazel extract.

Owner:KARL A ROBERT

Process for preparing an acryloyloxysilane

The invention provides a process for preparing an acryloyloxysilane, comprising reacting a metal salt of a carboxylic acid having the formula [CR2 2=CR1COO-]aMa+ (I), with a haloorganoalkoxysilane having the formula XR3Si(OR4)nR5 3_n (II) in the presence of mineral spirits and a phase transfer catalyst at a temperature of from 50 to 160 DEG C to form a mixture comprising an acryloyloxysilane and a metal halide having the formula Ma+X- a (III), wherein R1 is H or C1 -C6 hydrocarbyl, each R2 is independently R1 or [COO-]aMa+, Ma+ is an alkali metal cation or alkaline earth metal cation, a is 1 or 2, X is halo, R3 is C1 -C6 hydrocarbylene, each R4 is independently C1 -C10 Q hydrocarbyl, each R5 is independently R1 and n is an integer from 1 to 3.

Owner:DOW SILICONES CORP

Metal antirust compound containing oil-soluble polyaniline and application thereof

InactiveCN103305317AGood solubility and dispersibilityStrong anti-rustAdditivesSolubilityFilm-forming agent

The invention relates to a metal antirust compound containing oil-soluble polyaniline and application thereof. The invention is characterized in that the antirust compound comprises, expressed in mass percentages, 5 to 30% of oil-soluble polyaniline, 10 to 40% of dodecenylsuccinic acid and 40 to 80% of barium petroleum sulfonate. When the antirust compound provided by the invention is added into a lubricant base oil or / and mineral spirit, the antirust compound has good dissolvability and realizes phase-free separation, a solution system is uniform and stable, a lubricant anti-rust oil, or a solvent dilution type anti-rust oil not containing a film forming agent or a hard-film anti-rust oil can be prepared, and the formed anti-rust oils have the advantages of a small total addition amount, low viscosity and a good antirust effect, in particular, protruding salt mist prevention performance; when the total addition amount of the antirust compound is within 9%, antirust periods of the prepared lubricant anti-rust oil, the solvent dilution type anti-rust oil not containing a film forming agent and the hard-film anti-rust oil under a salt mist condition are greater than 6 d, greater than 11 d and greater than 31 d, respectively, and antirust periods the above-mentioned anti-rust oils under damp and hot conditions are all greater than 60 d.

Owner:PETROCHINA CO LTD

Biodegradable wipe utilizing bio-based lubricant comprising refined soybean oil

The present invention generally relates to a biodegradable lubricating wipe, such as wet wipes. The wet wipes typically being fibrous sheet materials, pre-moistened with a solution for improved lubrication and / or protection of an area. In one embodiment the solution is comprised of a bio-based lubricant, a bio-based solvent and water. In one embodiment, the solution is comprised of mineral spirits and refined soybean oil. In another embodiment the solution is comprised of soy methyl ester and refined soybean oil. In yet another embodiment, the fibrous sheet material of the invention is biodegradable and the solution portion breaks down into a vaporizing component and a biodegradable carrier portion.

Owner:HOOVER LIMITED

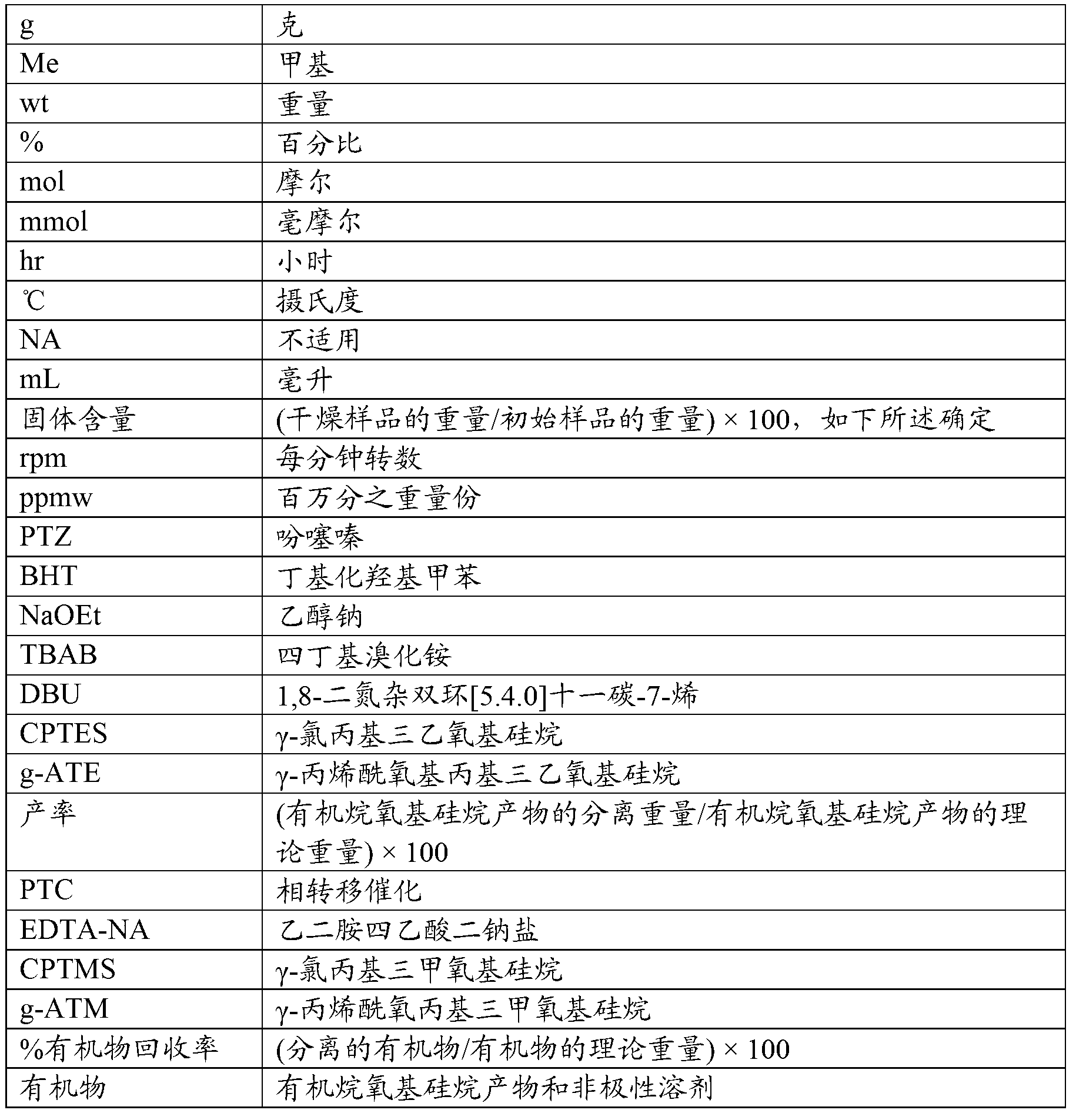

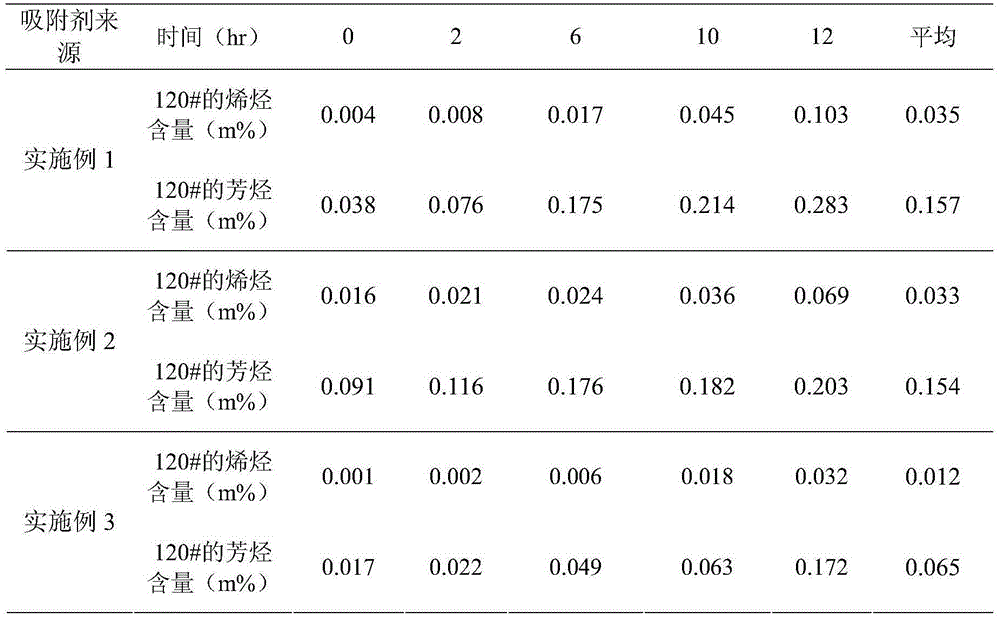

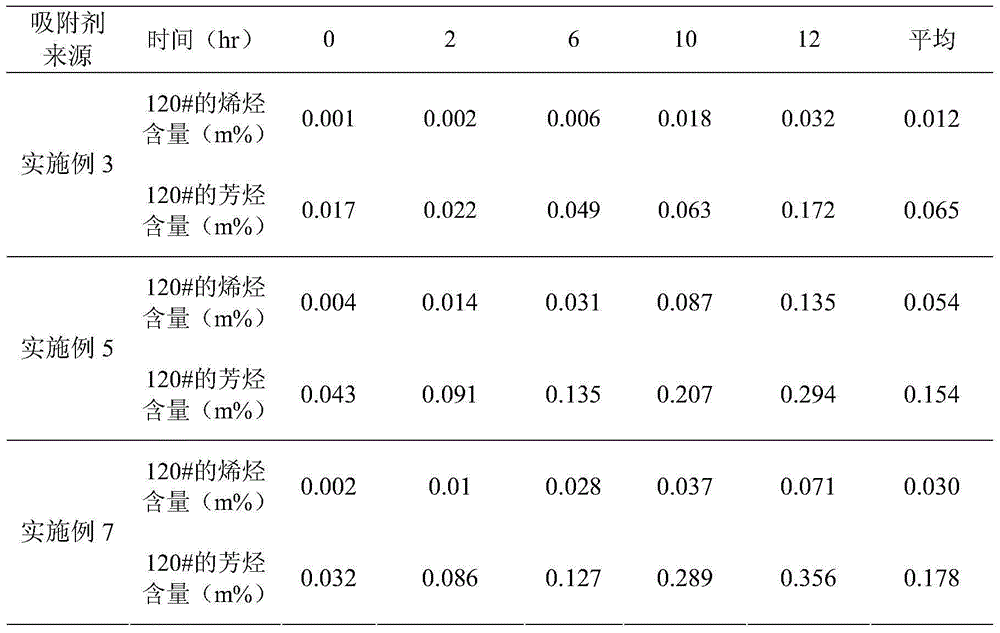

A kind of bimetallic petroleum spirit refining adsorbent and its preparation method and application

ActiveCN103752266BSimple processOther chemical processesHydrocarbon oils refiningMolecular sieveMetal nitrate

The invention provides a preparation method for a bimetallic mineral spirit refining adsorbent. The method comprises the following steps: (1) pretreatment: drying and activating a molecular sieve; (2) ion exchange: mixing the molecular sieve activated in the step (1) with a metal nitrate solution for ion exchange, and drying the exchanged molecular sieve; (3) impregnation: isovolumetrically impregnating the molecular sieve dried in the step (2) by using another metal nitrite solution, and drying the impregnated molecular sieve; (4) calcination: calcining the molecular sieve dried in the step (3) to obtain the bimetallic mineral spirit refining adsorbent. The bimetallic mineral spirit refining adsorbent is applied to the removal of impurities such as olefin and arene from 6#, 120# and 200# mineral spirits for refining at normal temperature, the treatment process is simple, and remarkable olefin and arene removal effects are achieved.

Owner:HEBEI REFINING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com