Process for preparing an acryloyloxysilane

一种丙烯酰氧基硅烷、烃基的技术,应用在用于制备丙烯酰氧基硅烷领域,能够解决大量时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

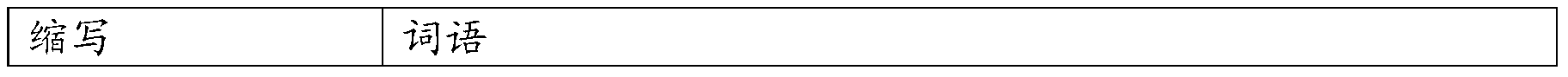

[0082] The following examples are provided to better illustrate the method of the present invention, but the following examples are not to be construed as limiting the invention, which is defined by the appended claims. All parts and percentages reported in the examples are by weight unless otherwise indicated. The following table describes the abbreviations used in the examples:

[0083] Table 1: List of abbreviations used in the examples .

[0084]

[0085]

example 1

[0087]A 500ml three-necked round bottom flask equipped with a mechanical stirrer and thermometer contained 72.5g of a 21% (w / w) NaOEt solution in ethanol. Acrylic acid (16.6 g; 231 mmol) was added dropwise while maintaining the temperature below 25°C. After the acrylic acid addition, the slurry was stirred at ambient temperature for 1 hr. Then the stabilizers PTZ and BHT (each 0.022g), TBAB (2.98g; 9.24mmol), CPTES (55.6g; 231mmol) and mineral spirits (55.6g) (CAS 68551-17-7; C 10-13 isoalkane) into the flask in sequence. The temperature of the reaction mixture was gradually increased up to 140°C while condensing and collecting the low boiling agent (65.5 g) by distillation. The reaction mixture was heated at 140°C for 3 hrs, providing approximately 9% (w / w) sodium chloride in the reaction mixture. GC analysis showed 95% conversion to g-ATE.

[0088] Stirring was stopped and the sodium chloride salt precipitated rapidly and settled completely to give a clear interface betw...

example 2

[0092] Acrylic acid (15.7 kg) was added to 70 kg of a 21 % (w / w) sodium ethoxide solution in ethanol, 61.2 kg of xylene and 30 g of a premix of PTZ, BHT and EDTA-NA. Then 1.2 kg of TBAB and 53 kg of CPTES were added. After distilling ethanol, the reaction mixture was heated at 120° C. for 5 hours to obtain approximately 9% (w / w) sodium chloride in the reaction mixture.

[0093] Water (88.4 g) was poured into 221.0 g of the suspension reaction mixture, resulting in a combined weight percent of sodium chloride in water of about 18%. After brief stirring, the mixture separated into a hazy organic phase and a cloudy salt suspension. A clear solution-solution interface formed within 3 minutes and 191.6 g of organics were decanted, resulting in an 86% organic recovery rate. GC of the organics showed no apparent compositional difference before and after water washing, indicating no measurable hydrolysis of g-ATE. This example shows that metal halides can be removed from g-ATE by w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com