A kind of bimetallic petroleum spirit refining adsorbent and its preparation method and application

A petroleum solvent and bimetallic technology, which is applied in the field of bimetallic petroleum solvent oil refining adsorbent and its preparation, can solve the problems of workers' difficulty in operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

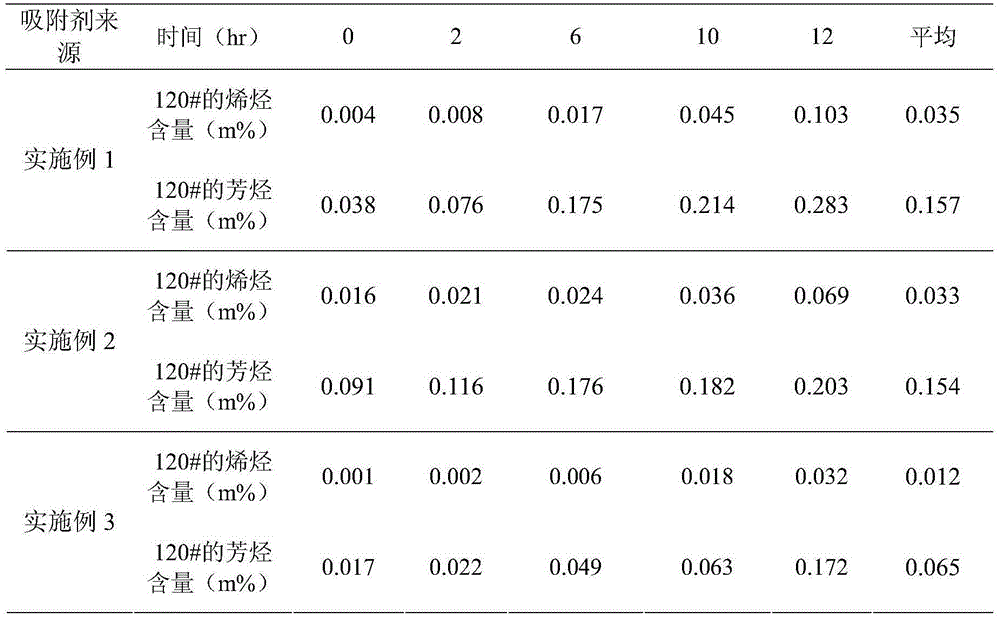

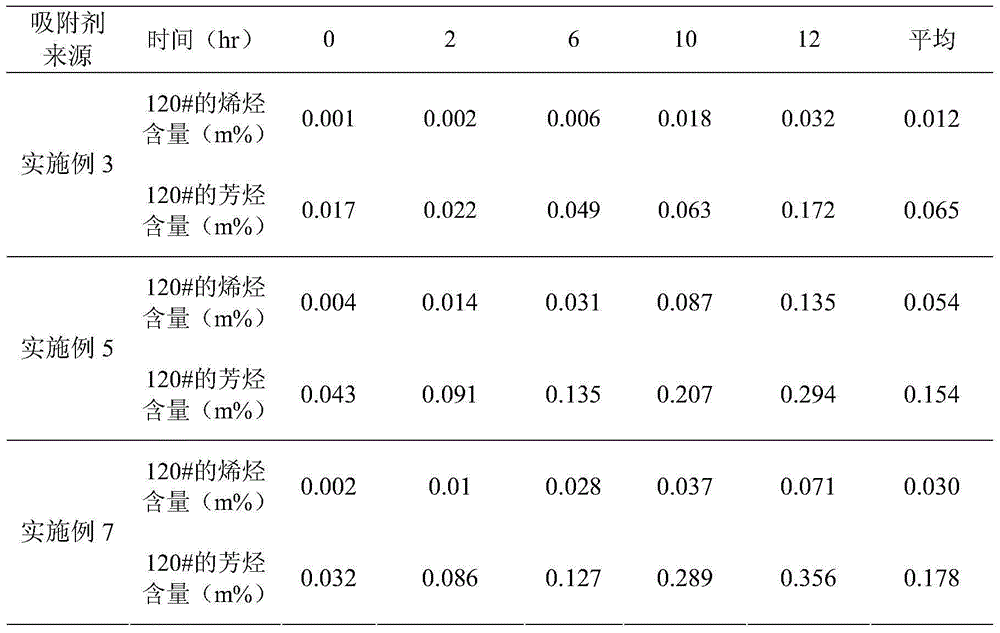

Examples

Embodiment 1

[0074] Use AgNO 3 solution to impregnate 10X molecular sieves, AgNO 3 The mass ratio of solid to molecular sieve is 4:100, and the impregnated molecular sieve is dried at 120°C for 12 hours, and then raised to 550°C at a rate of 6°C / min from room temperature to 400°C and 2°C / min from 400 to 550°C Post bake for 4 hours.

Embodiment 2

[0076] Using Ni(NO 3 ) 2 The solution was ion-exchanged for 10X molecular sieve at 90°C for 100min, and the molecular sieve and Ni(NO 3 ) 2 The mass ratio of the solution is 1:8, Ni(NO 3 ) 2 The solution concentration was 0.251 g / ml, and the mixture obtained after ion exchange was washed with deionized water and dried at 100° C. for 20 hours. Using Cu(NO 3 ) 2 The solution impregnates the dried molecular sieve, Cu(NO 3 ) 2 The mass ratio of solid to molecular sieve is 4:100, and the impregnated molecular sieve is dried at 120°C for 12 hours, and then raised to 550°C at a rate of 6°C / min from room temperature to 400°C and 2°C / min from 400 to 550°C Post bake for 4 hours.

Embodiment 3

[0078] Using Ni(NO 3 ) 2 The solution was ion-exchanged for 10X molecular sieve at 90°C for 100min, and the molecular sieve and Ni(NO 3 ) 2 The mass ratio of the solution is 1:8, Ni(NO 3 ) 2 The solution concentration was 0.251 g / ml, and the mixture obtained after ion exchange was washed with deionized water and dried at 100° C. for 20 hours. Use AgNO 3 The solution impregnates the dried molecular sieve, AgNO 3 The mass ratio of solid to molecular sieve is 4:100, and the impregnated molecular sieve is dried at 120°C for 12 hours, and then raised to 550°C at a rate of 6°C / min from room temperature to 400°C and 2°C / min from 400 to 550°C Post bake for 4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com