Patents

Literature

280results about How to "Short film forming time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

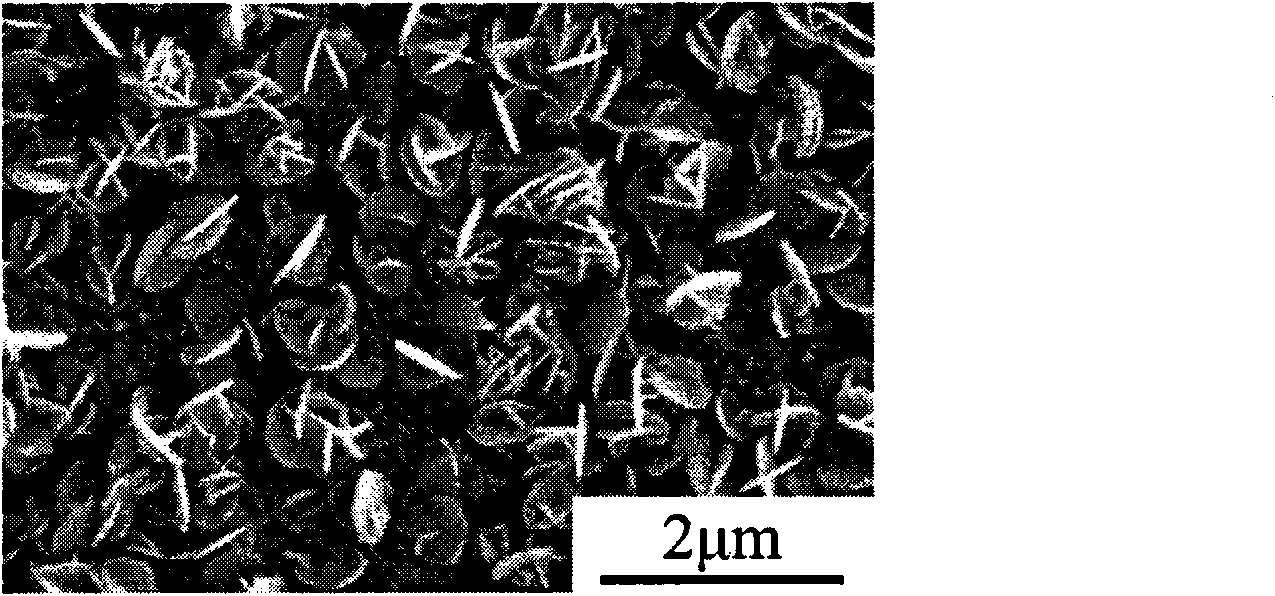

Cellulose nanocrystal/graphene composite colored film and fast preparation method thereof

The invention relates to a cellulose nanocrystal / graphene composite colored film and a fast preparation method thereof. The cellulose nanocrystal / graphene composite colored film can be prepared under the existence of a flow field by adopting a vacuum filtration method, the composite film has a cholesteric liquid crystal phase structure, and the color of the composite film can be regulated by controlling the ultrasonic time during preparation process. The prepared colored film can absorb water, and the color can be changed along with the change of humidity. The cellulose nanocrystal / graphene composite colored film has application values in the photoelectric field and the preparation of anti-counterfeit labels, anti-counterfeit paper and high-grade discoloring anti-counterfeit ink.

Owner:QINGDAO UNIV OF SCI & TECH

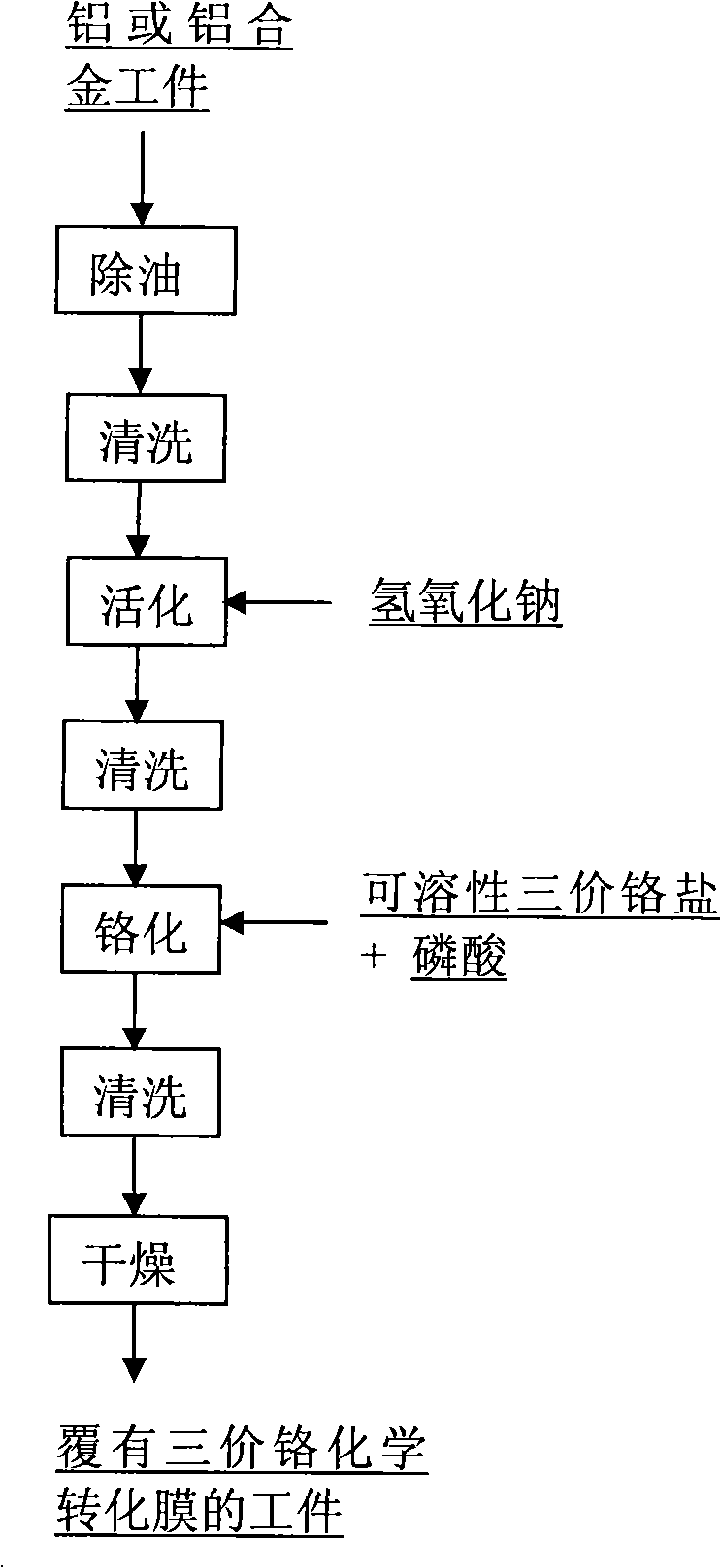

Preparation for aluminum or aluminum alloy trivalent chromium chemical conversion film

InactiveCN101275225ASolve the disadvantages of high toxicityMeet environmental protection requirementsMetallic material coating processesCleaning using liquidsPhosphoric acidReaction temperature

The invention discloses a method of preparing aluminum or aluminum alloy trivalent chromium chemical conversion film, comprising: aluminum or aluminum alloy work pieces are activated for 1 to 2 minutes in sodium hydroxide solution with a concentration of 50g / L to 100g / L and activation reaction temperature is 5 deg C to 30 deg C; using deionized water to wash the work pieces; putting the washed work pieces into mixed aqueous solution of soluble chromic salt and phosphoric acid to make a chromaking for 6 to 10 minutes, wherein, chromium ion has a concentration of 1g / L to 20g / L, and the phosphoric acid has a concentration of 1g / L to 25g / L; using dilute sodium hydroxide or dilute sulfuric acid to adjust reaction system PH value to 1.6 to 4.0 and the chromaking temperature to 10 deg C to 60 deg C. The invention solves a shortcoming that in existing technology hexavalent chromium has great toxicity. Technological process and products of the invention reach environmental requirements. The produced trivalent chromium chemical conversion film has the same quality with hexavalent chromium chemical conversion.

Owner:CENT SOUTH UNIV

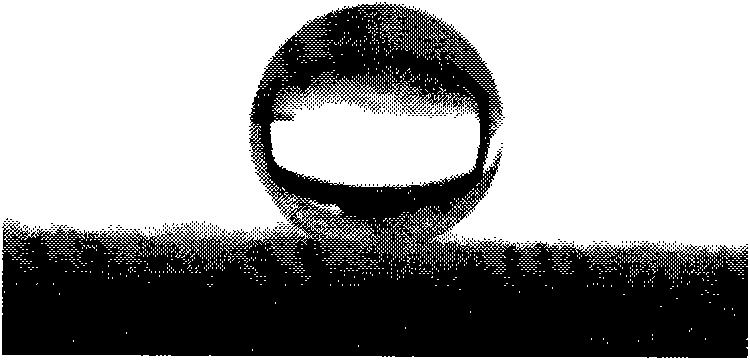

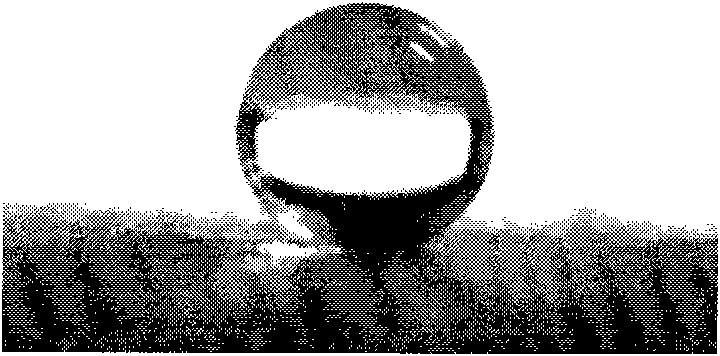

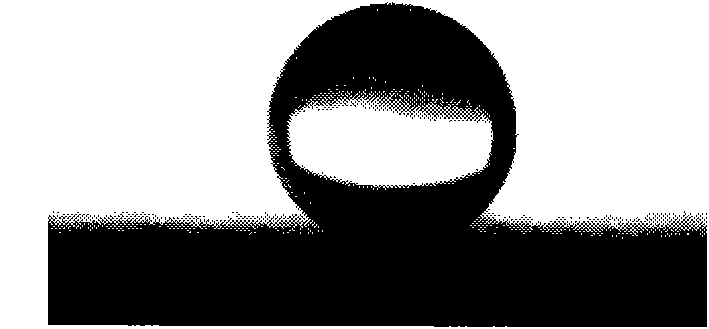

Simple and convenient method for preparing super-hydrophobic film on surface of metal matrix

InactiveCN101935859ASpeed up anodic dissolutionPromote complexationSurface reaction electrolytic coatingElectrochemistryFatty acid

The invention relates to technology for preparing a super-hydrophobic surface, in particular to a simple and convenient method for preparing a super-hydrophobic film on the surface of a metal matrix. The super-hydrophobic film is prepared by the following steps of: cleaning the surface of the metal matrix with ethanol and de-ionized water and drying the surface of the metal matrix for later use; applying current or voltage to the cleaned matrix and a platinum electrode serving as a cathode in 10<-1> to 1mol / L ethanol solution of fatty acid CH3(CH2)nCOOH (n is equal to 10 to 16) by an electrochemical method; and forming a fatty acid-metal complex film on the surface of the anodic metal matrix after processing and drying the film to obtain the super-hydrophobic film. The method has the advantages of simple and easy operation and no need of expensive equipment. The prepared super-hydrophobic surface is expected to be applied to the fields of metal corrosion resistance, water resistance, self-cleaning and the like.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

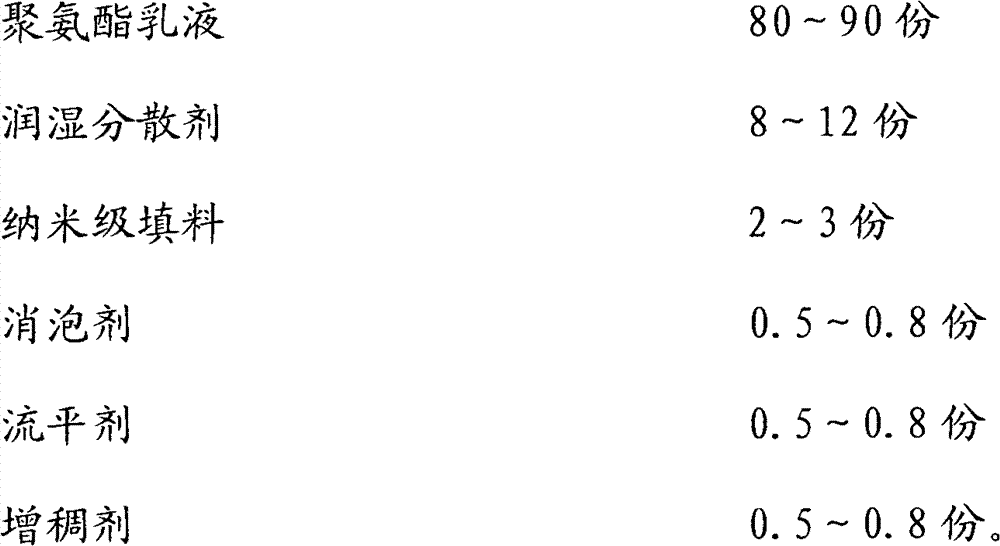

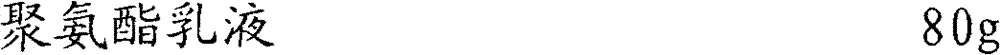

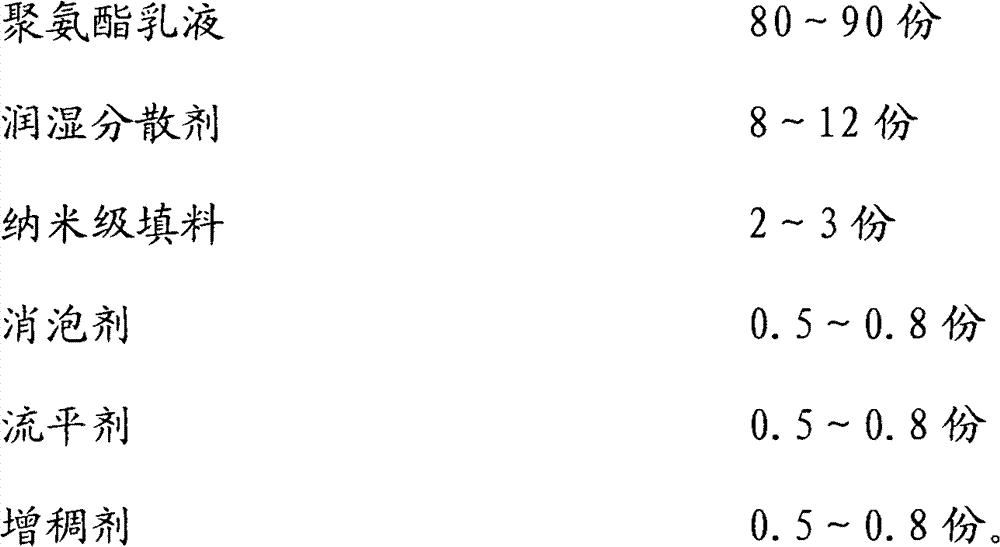

Aqueous normal temperature curing peelable paint and preparation method of paint

ActiveCN102827537AWide variety of sourcesWith cleaner productionPolyurea/polyurethane coatingsEmulsionFilling materials

The invention discloses aqueous normal temperature curing peelable paint, which is applicable to the technical field of metal surface treatment and consists of the following ingredients in parts by weight: 80 to 90 parts of polyurethane emulsion, 8 to 12 parts of wetting dispersing agents, 2 to 3 parts of nanometer level filling materials, 0.5 to 0.8 parts of defoaming agents, 0.5 to 0.8 parts of flatting agents and 0.5 to 0.8 parts of thickening agents. The aqueous normal temperature curing peelable paint has the advantages that on the basis of the polyurethane emulsion film forming mechanism, through major ingredient screening and compounding of polyurethane emulsion, other film forming auxiliary agents and the like, the aqueous normal temperature curing peelable paint adopting the polyurethane emulsion as major film forming agents is developed. The product has the characteristics that nontoxicity and harmlessness are realized, the pollution is avoided, the operation is simple, the raw material resources are wide, the price is low, the clean production is realized, and the like.

Owner:合肥华清高科表面技术股份有限公司

Anticorrosion treatment process for converting/electro-statically spraying environment-friendly zirconium titanate on surfaces of aluminum alloys

ActiveCN105132900AEasy to operateLow film forming temperatureLiquid surface applicatorsMetallic material coating processesCompound (substance)Titanium

The invention belongs to the technical field of chemical materials and discloses an anticorrosion treatment process for converting / electro-statically spraying environment-friendly zirconium titanate on surfaces of aluminum alloys. The anticorrosion treatment process comprises the following steps: (1) carrying out surface pretreatment on the aluminum alloys; (2) converting the surfaces of the aluminum alloys, putting the aluminum alloys subjected to surface pretreatment into a zirconium titanate converting solution, soaking, washing, standing and drying the aluminum alloys to obtain conversion films; (3) suspending the dried aluminum alloys in a powder spraying room and electro-statically spraying organic powder on the aluminum alloys; and (4) standing, preserving heat at 180-200 DEG C, then cooling to obtain anticorrosion coatings. According to the anticorrosion treatment process, the conversion treatment is low in film-forming temperature and short in film-forming time; the zirconium titanate treatment solution is stable, chromium-free and environmentally-friendly; through the treatment process, the surfaces of the aluminum alloys are high in corrosion resistance; the conversion films are excellent in combination with the aluminum alloys and the organic coatings.

Owner:SOUTH CHINA UNIV OF TECH

Self-crosslinking acrylic resin leather finishing agent and preparation method thereof

InactiveCN102199389AAchieve room temperature controllable self-crosslinkingExcellent adhesionProtein coatingsLeather surface finishingCross-linkEmulsion

The invention provides a self-crosslinking acrylic resin leather finishing agent and a preparation method thereof. The preparation method comprises the following steps: firstly, carrying out radical polymerization on acrylate, methacrylic acid and diacetone acrylamide so as to prepare an acrylic resin emulsion; regulating the pH of the emulsion to 5-6; and adding a substance with a water-soluble protide structure as a cross-linking agent, so as to prepare a novel self-crosslinking acrylic resin leather finishing agent. According to the invention, the protide substance is used as the cross-linking agent of the acrylic resin, thereby achieving the room temperature controllable self-crosslinking of the acrylic resin, effectively promoting the physical property of a film and simplifying the production process of the acrylic resin film. The hot adhesive and cold short defects of the acrylic resin finishing agent are improved through crosslinking action; and simultaneously, the protide substance is introduced in the acrylic resin molecular chain, thus the resin film has a property of a protide film-forming agent and good comprehensive property.

Owner:SHAANXI UNIV OF SCI & TECH

Water soluble anti-rust agent

InactiveCN101712817AShort film forming timeImprove quick-drying performanceAnti-corrosive paintsHazardous substanceSebacic acid

The invention relates to a water soluble anti-rust agent on the surface of ferrous metal, which comprises the following components: 2 to 10 weight percent of barium petroleum sulfonate and / or barium dinonyl decyl sulfonate, 1 to 6 weight percent of sodium molybdate and / or amine molybdate, 0 to 10 weight percent of sebacic acid, 2 to 10 weight percent of polyacrylic ester, 3 to 20 weight percent of triethanolamine oleic soap and / or 2 to 6 weight percent of polyoxyethylenesorbitan monooleate, 0 to 15 weight percent of sodium alkylsulfonate, 0 to 8 weight percent of glycerin and the balance of water or machine oil. Compared with the conventional water soluble anti-rust agent, the water soluble anti-rust agent of the invention has the advantages of short film forming time, firm film forming adsorption and good anti-rust effect; the actual anti-rust period can reach 3 to 6 months; the formed film is thin and only 3 to 5 microns; common workpieces do not need film removal and can be directly assembled and coated; the film removal is convenient, and the film is only soaked and rinsed in mild water over 50DEG C and then can be removed quickly; and the anti-rust agent has no component containing toxic and harmful substances, does not contain phosphorus, has the advantages of good environmental protection and no pollution to the environment, and is the environment-friendly water soluble anti-rust agent.

Owner:无锡市弘育化工有限公司

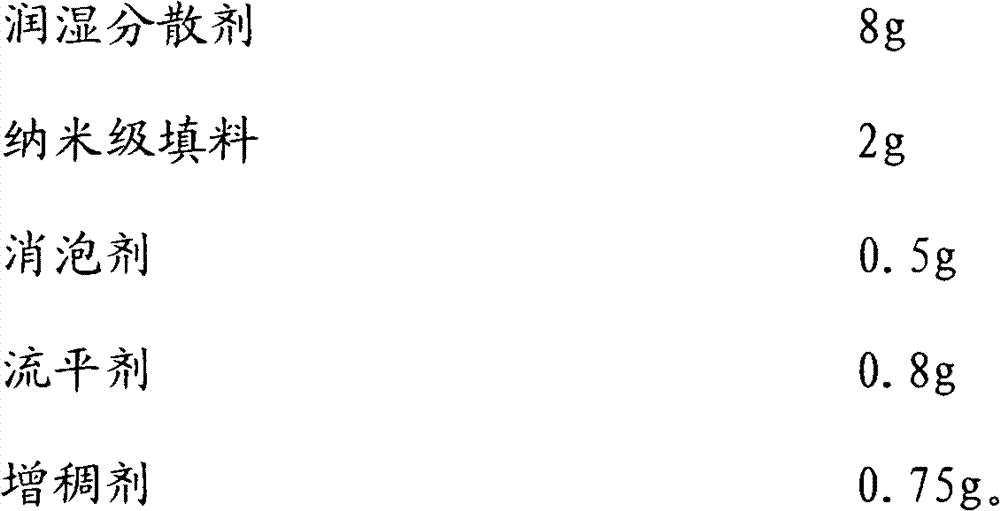

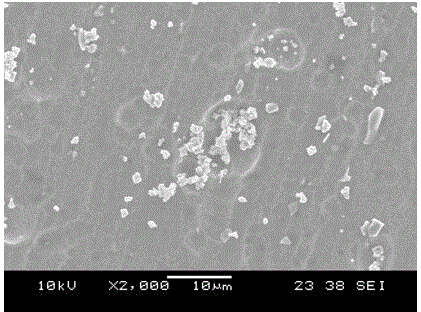

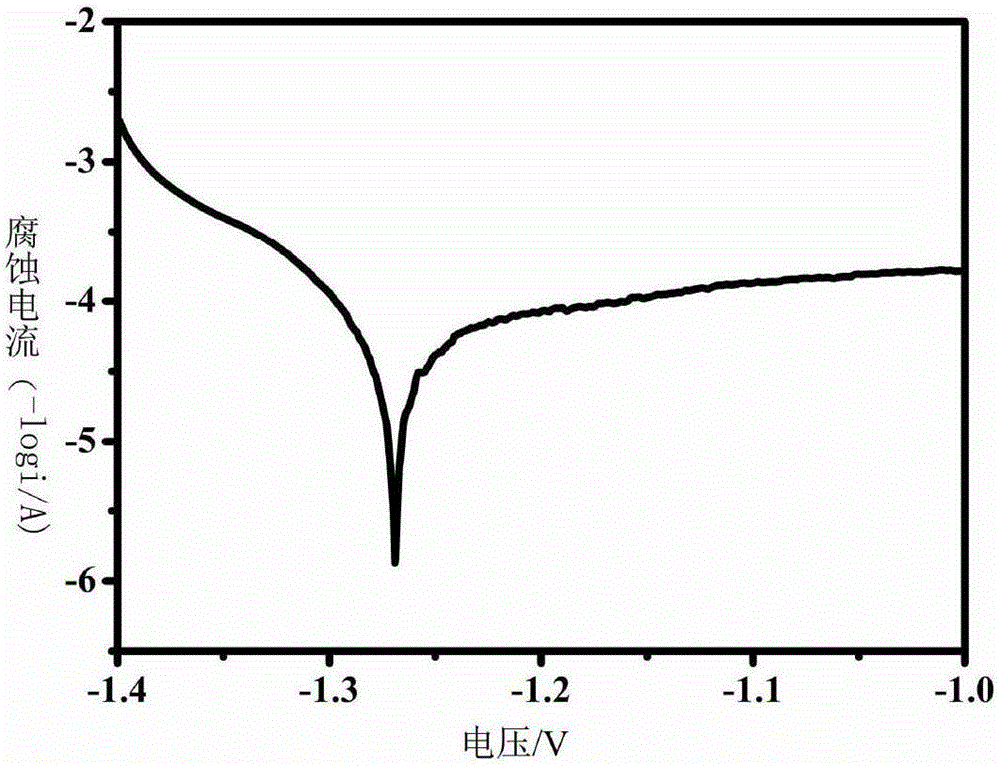

Corrosion-resistant self-assembled doped film layer on aluminum alloy surface and preparation method of corrosion-resistant self-assembled doped film layer

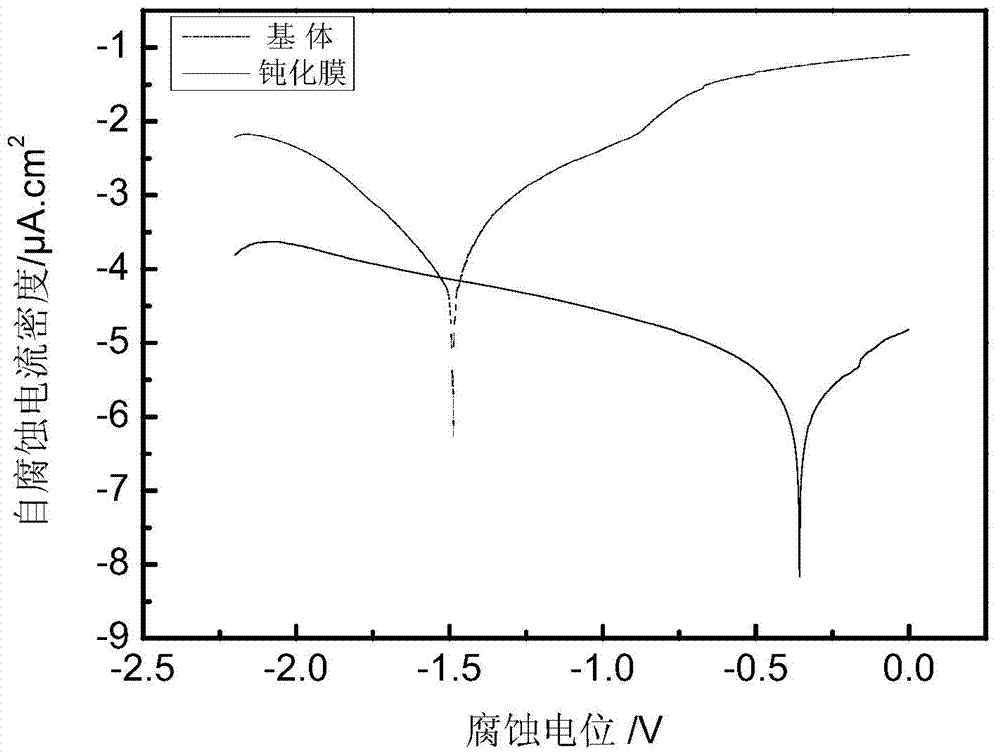

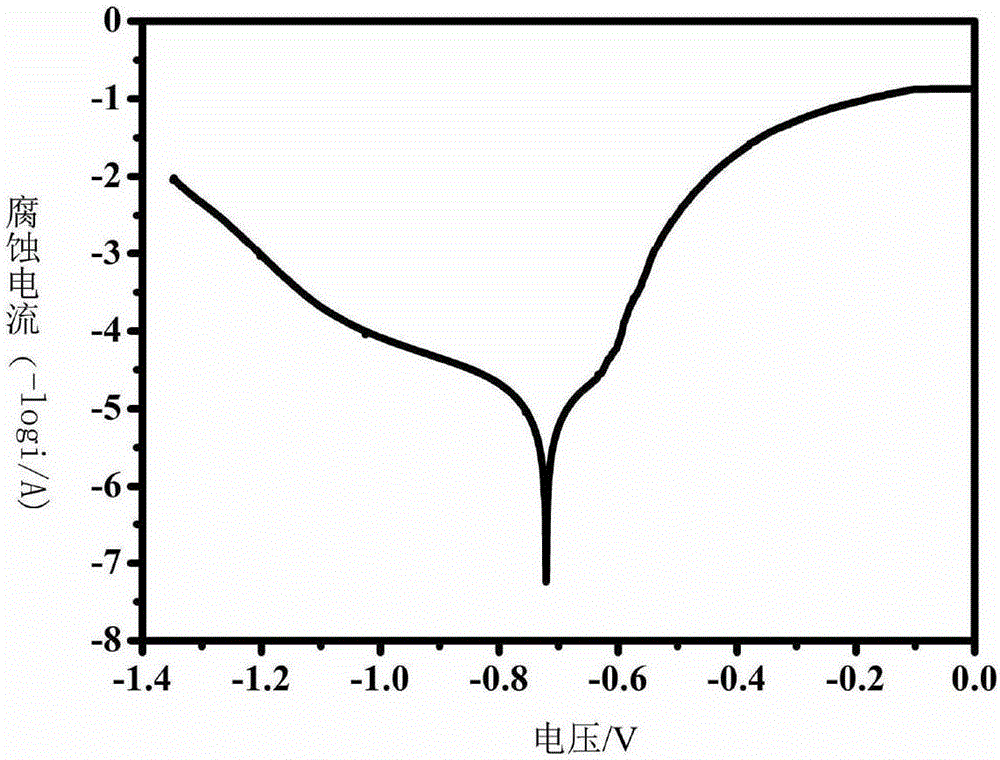

InactiveCN104630749ALow corrosion current densityHigh impedanceLiquid/solution decomposition chemical coatingAlloy substrateCorrosion current density

The invention discloses a corrosion-resistant self-assembled doped film layer on an aluminum alloy surface and a preparation method of the corrosion-resistant self-assembled doped film layer. The corrosion-resistant self-assembled doped film layer is composed of a self-assembled film and particles. The preparation method comprises the steps of firstly, carrying out pretreatment, namely grinding, washing, oil removal and the like on an aluminum alloy substrate; then, preparing a self-assembled doped solution; self-assembling the pretreated aluminum alloy to form a film; and taking out the film, drying and curing to obtain the corrosion-resistant self-assembled doped film layer on the aluminum alloy surface. The preparation method is low in cost, simple in preparation process and short in film formation time; the prepared self-assembled doped film is high in resistance and low in corrosion current density; and the film layer is uniform and level in surface, good in binding force on the aluminum alloy substrate, capable of favorably improving the corrosion resistance of the aluminum alloy surface and incapable of polluting the environment and equipment.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Graphene-based coating agent

ActiveCN106011816AImprove corrosion resistanceImprove performanceMetallic material coating processesGraphiteGraphene

The invention discloses a graphene-based coating agent. The graphene-based coating agent comprises, 0.1-1 part of nano-graphite, 1-3 parts of a graphene dispersing agent, 2-10 parts of fluorine-bearing acid, 2-10 parts of fluorine-bearing acid salt, 1-2 parts of a silane coupling agent, 2-5 parts of a complexing agent, 0-2 parts of a surface wetting agent and 70-95 parts of water. The graphene-based coating agent has the advantages of short film forming time, good film forming property and environment friendliness. An inorganic film formed on the surface of metal through the graphene-based coating agent has excellent lubricity and corrosion resistance and is thin. The formed inorganic nanofilm has excellent conductivity, lubricating property and corrosion resistance and has higher corrosion resistance and longer salt mist time, and therefore corrosion resistance of a metal substrate is better improved, surface impedance of the metal is not influenced after the film is formed, and finish machining of the metal is better facilitated.

Owner:苏州禾川化学技术服务有限公司

Quick-dry solvent-free anti-sagging polyurethane water-proof paint and preparation method thereof

ActiveCN109321122ALow viscosityImprove thixotropyPolyurea/polyurethane coatingsPlasticizerSolvent free

Owner:JIANGSU CANLON BUILDING MATERIALS

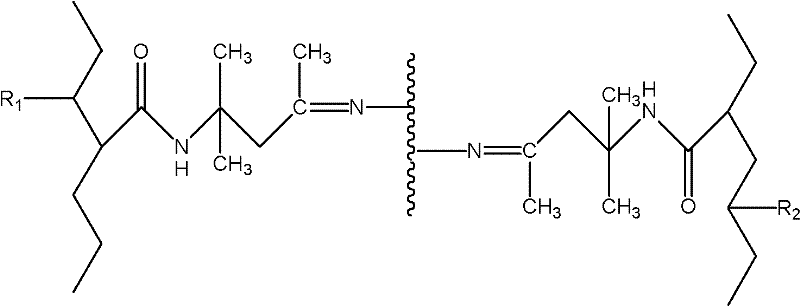

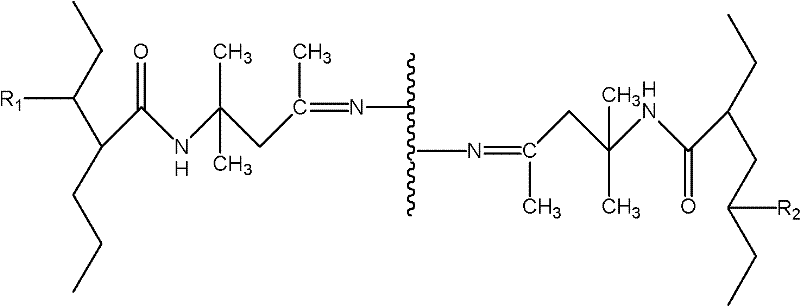

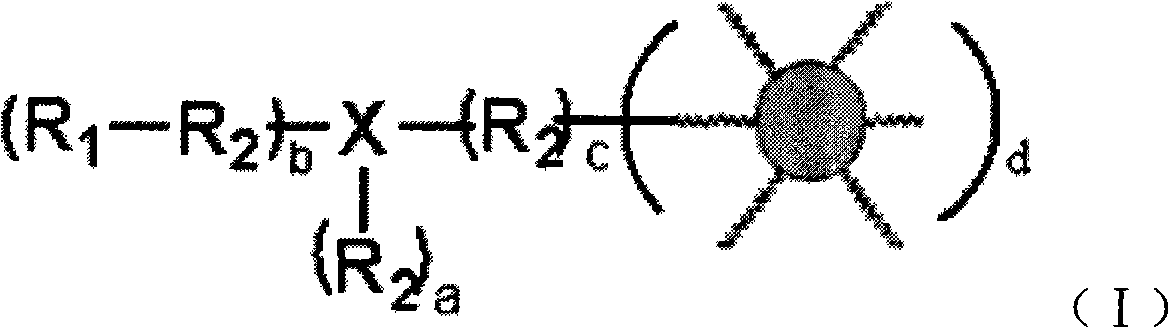

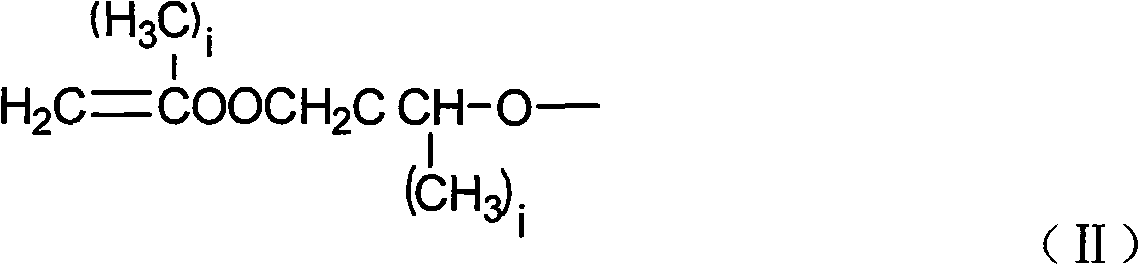

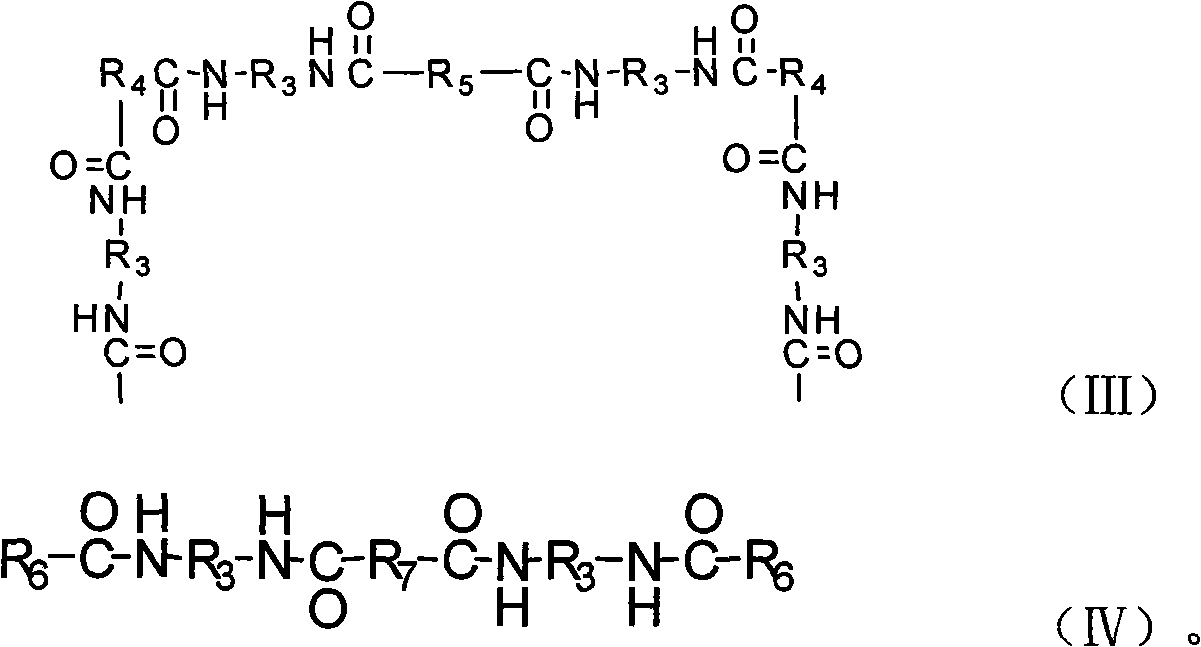

Multiple curable aqueous hyperbranched polyurethane inorganic nanomaterial hybrid coating agent and preparation method thereof

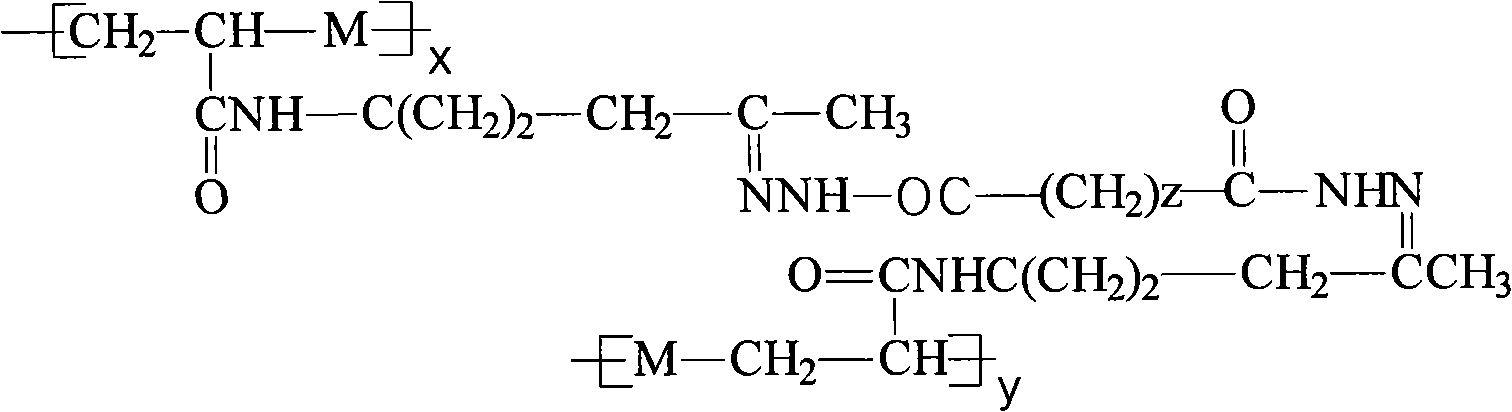

InactiveCN101597461AHigh strengthImprove rigidityPolyurea/polyurethane coatingsLeather surface finishingStructural formulaTemperature resistance

The invention relates to a multiple curable aqueous hyperbranched polyurethane inorganic nanomaterial hybrid coating agent and a preparation method thereof. The coating agent comprises the following compositions in percentage by mass: 20 to 45 percent of polyurethane shown in a structural formula below, and 55 to 80 percent of deionized water. A film coated by the coating agent has the characteristics of flatness, smoothness, temperature resistance, oil resistance and the like, and has excellent low-temperature toughness performance. Leather coated by the coating agent has the characteristics of high gloss, good hand touch, abrasion resistance, difficult cracking, good elasticity, excellent water resistance and deflection resistance, and the like.

Owner:ZHEJIANG DONGHUA IND

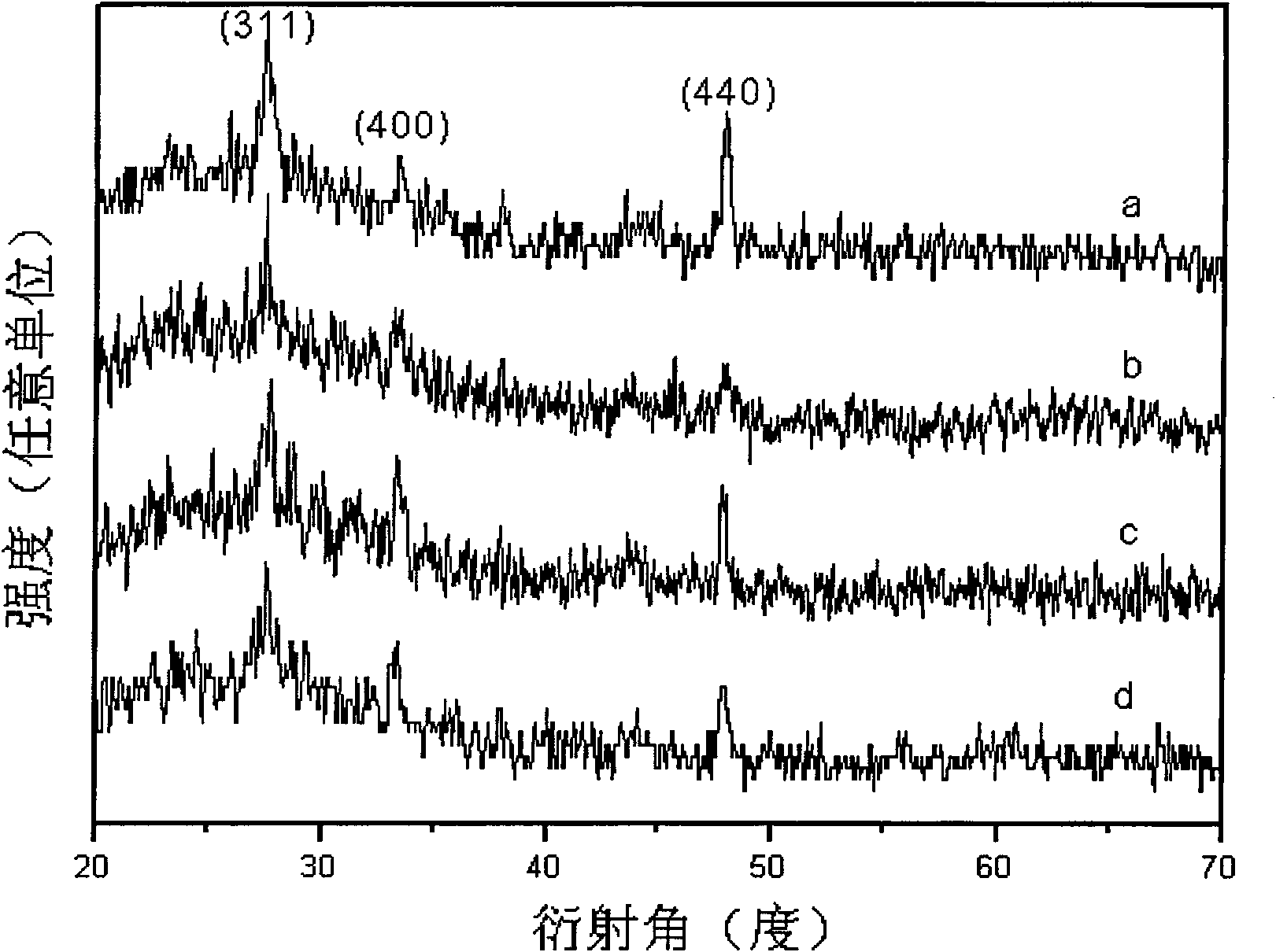

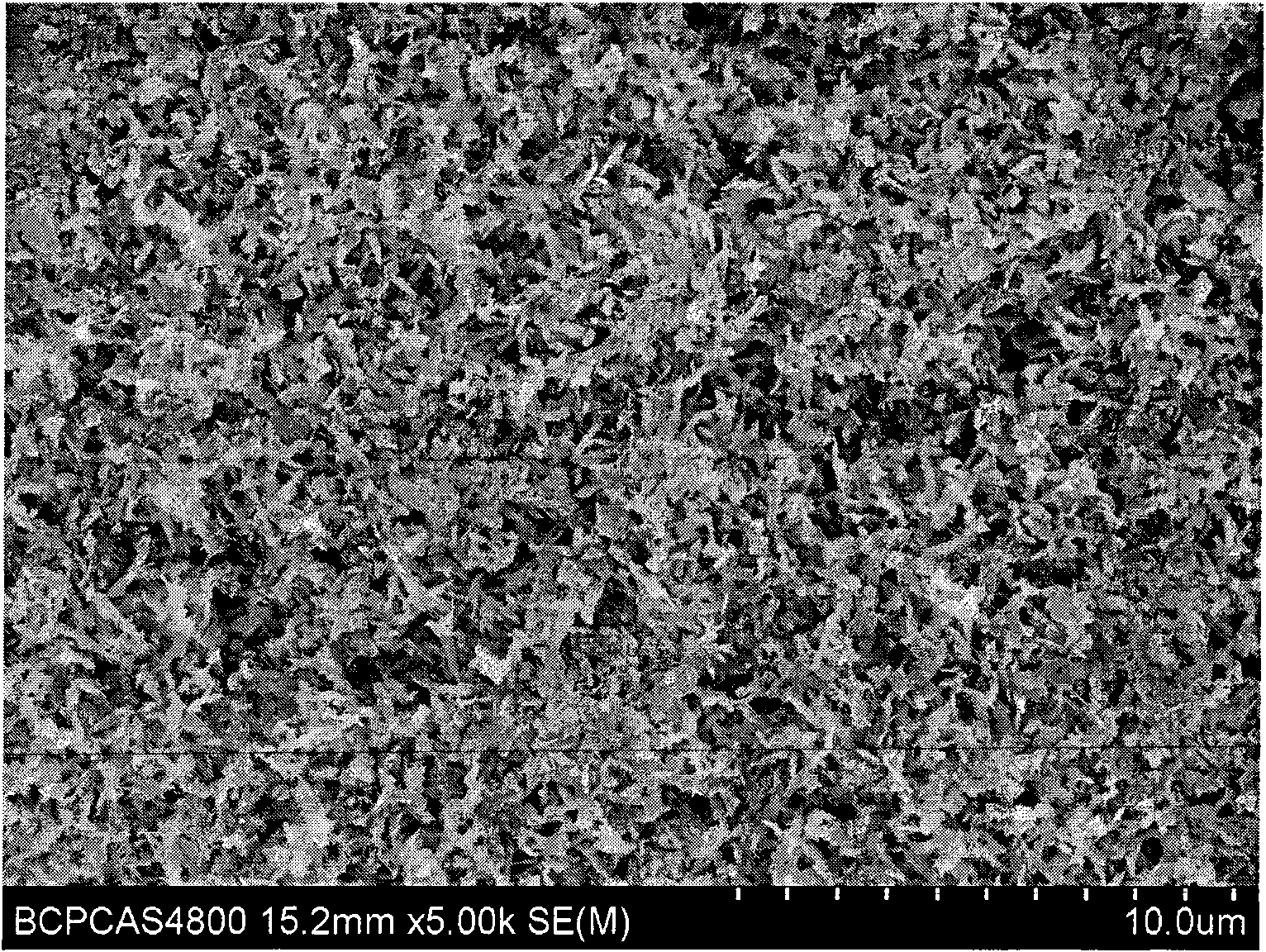

Method for depositing indium sulfide thin film by chemical bath

InactiveCN101608304AHigh crystallinityAvoid adsorptionGallium/indium/thallium compoundsLiquid/solution decomposition chemical coatingWater bathsIndium

The invention relates to a method for depositing an indium sulfide thin film by a chemical bath, which belongs to the technical field of preparation of functional thin film materials. The prior method for preparing indium sulfide has higher requirements on deposition conditions, needs high-temperature heating and has great limitations in substrate deposition. The method for preparing the indium sulfide adopts citric acid or malonic acid as a complexing agent, and the uniform, dense and high crystalline indium sulfide thin film with a cubic structure can be obtained on modified ordinary glass under a water bath environment which is lower than 100 DEG C. The method has no selectivity to a substrate, is synthesized in low temperature solution and has the advantages of good crystallinity, simple process and low cost, thereby being applicable to large-scale production application.

Owner:BEIJING UNIV OF TECH

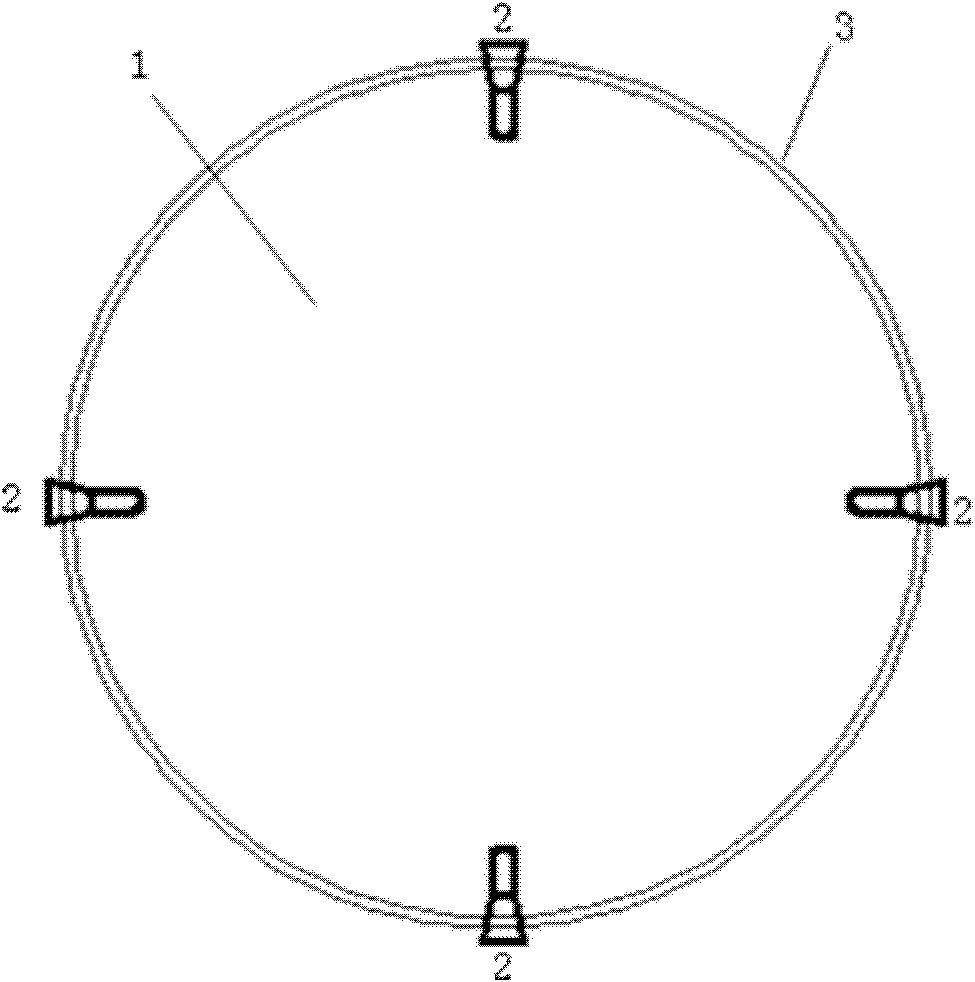

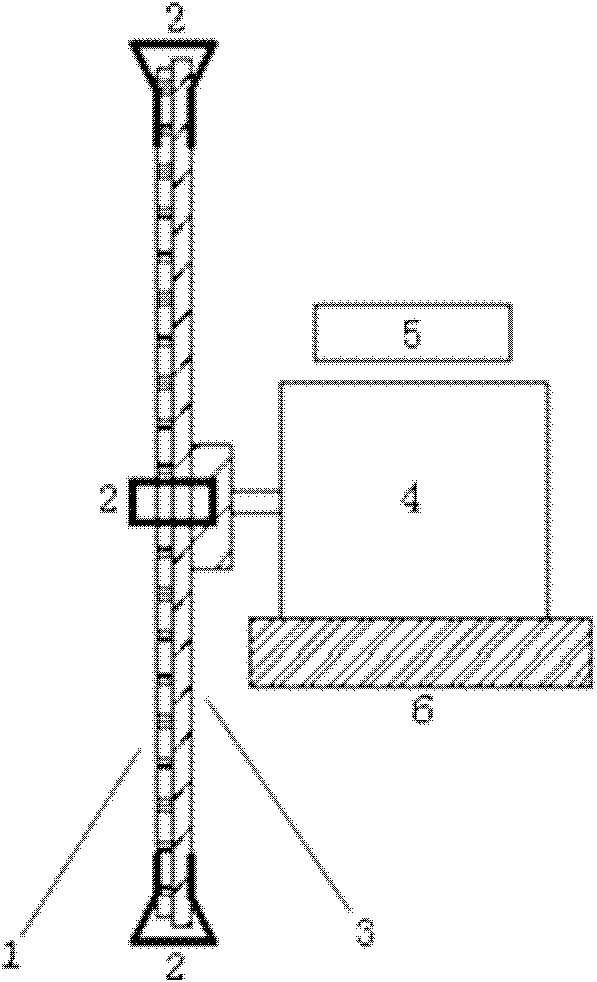

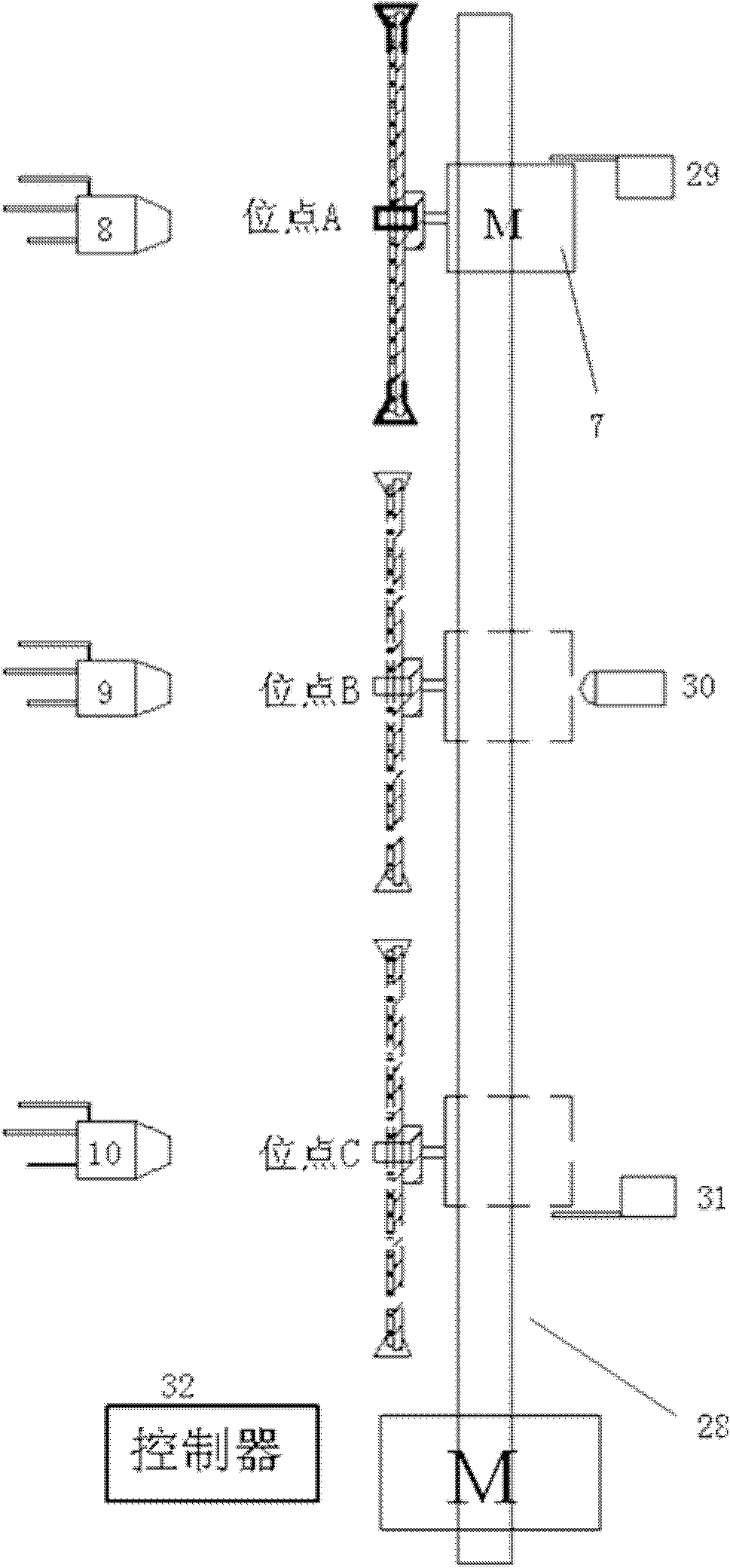

Automatic assembling device and method of multilayer composite separation membrane

InactiveCN102512980AAbundant membrane materialsRich materialSemi-permeable membranesLayer by layer self assemblySelf-assembly

Belonging to the technical field of membrane separation, the invention provides an automatic assembling device and method of a multilayer composite separation membrane. Existing composite membranes prepared by an immersion layer-by-layer self-assembly method has the problems of a lot of composite layers, long film forming cycle, and complex procedures, and is not conducive to industrial production. The automatic assembling device and method of a multilayer composite separation membrane can respectively spray membrane making liquids of different components to the surface of a porous support body in order. And then through layer-by-layer reaction on the surface and assembly, the multilayer composite separation membrane can be formed. The automatic assembling device and method of a multilayer composite separation membrane in the invention can automatically complete spraying and assembly of membrane making liquids with different components, effectively overcome the complicated steps in existing self-assembly membrane forming processes, substantially shorten membrane forming time, and can be adapted to the demands of large scale production.

Owner:BEIJING UNIV OF TECH

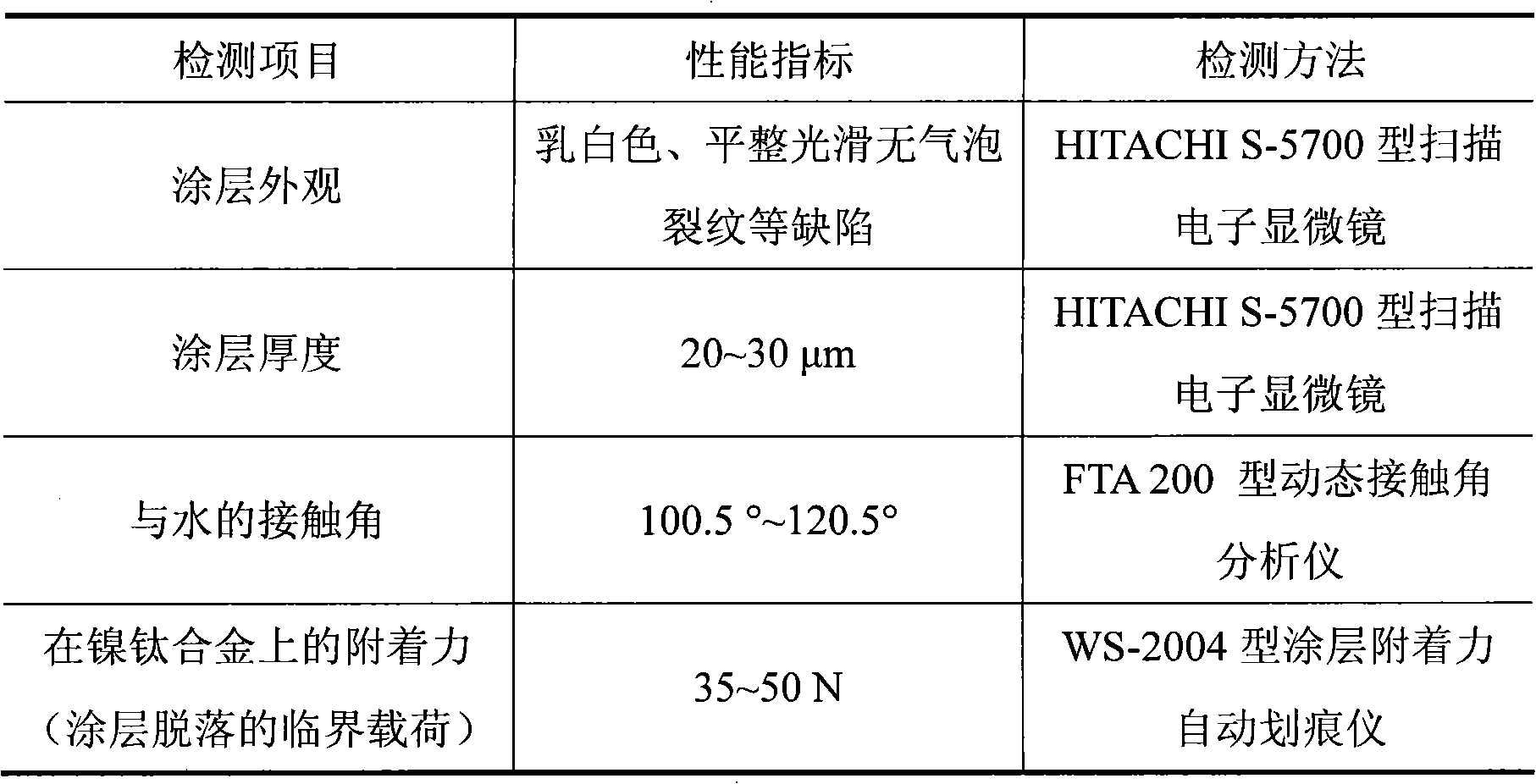

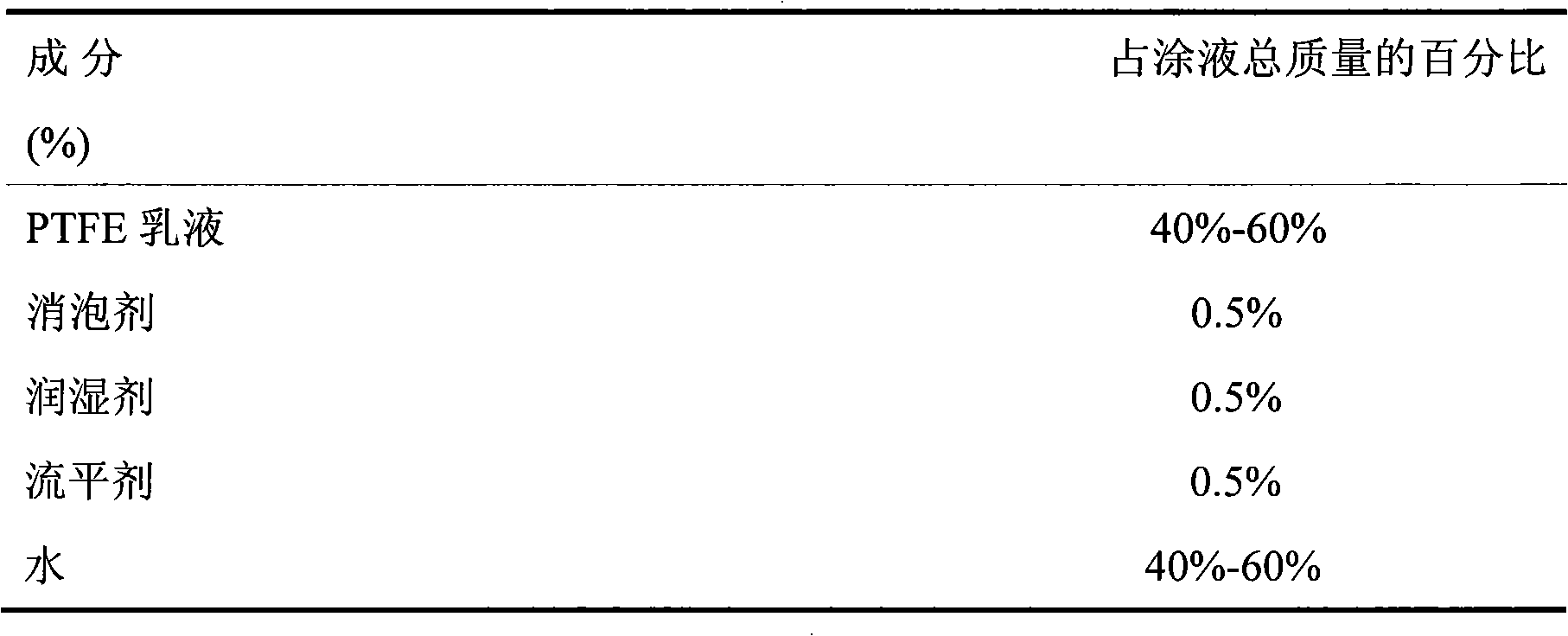

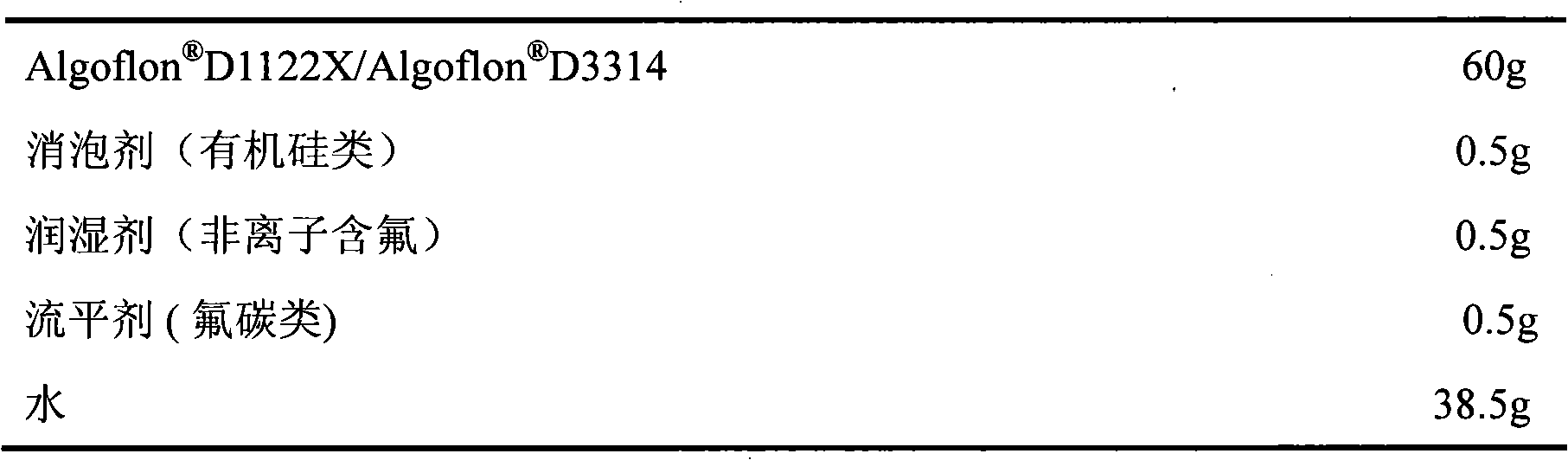

Polytetrafluorethylene coating material for medical apparatus surface and coating method thereof

InactiveCN101353502AShort film forming timeMeet the use requirementsSurgeryPretreated surfacesEmulsionRoom temperature

The invention provides a polytetrafluoroethylene coating material applicable to the surface of medical appliance and a coating method thereof. a. according to the mass percentage, 40-60 percent of PTFE emulsion, 0.5 percent of defoamer, 0.5 percent of wetting agent, 0.5 percent of flow agent and rest water are mixed to crank out PTFE hydrophilic paint applied to medical appliance; b. the PTFE hydrophilic paint applied to medical appliance is coated to positions needing to be coated on the medical appliance; c. under the room temperature, after water content in the PTFE hydrophilic paint waiting for being applied to the medical appliance evaporates, the paint is solidified and sintered under a temperature of 120-350 DEG C, namely, the PTFE lubricating hydrophobic coating is formed on the medical appliance. The invention has the advantages of simple paint system, short confecting and producing period, simple coating technique, and short film-forming time of the paint. The result shows that the coating of the invention not only meets the operation requirement of the medical appliance, but also is provided with simple coating technique and low manufacturing cost, and is good for popularization and application.

Owner:HARBIN ENG UNIV

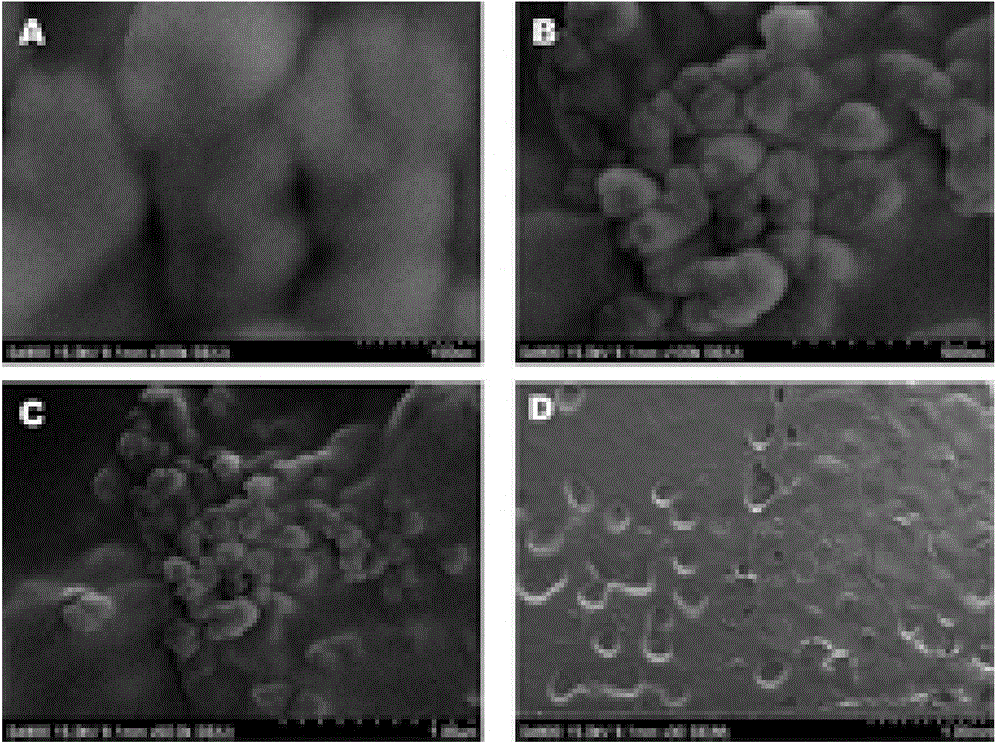

Preparation method of self-assembled folded rGO composite membrane

ActiveCN108295666ASolve the flux is smallResolve separabilityMembranesDistillationSeparation factorWater treatment

The invention discloses a preparation method of a self-assembled folded rGO composite membrane used for dehydration of organic matter and belongs to the field of membrane separation. The method comprises steps as follows: GO (graphene oxide) is sucked to a pretreated porous base membrane with rich amino, then, the base membrane is put in a preheated organic solvent to be modified and put in a glutaraldehyde water solution to be crosslinked, then, a polyelectrolyte is sucked to the surface of the modified GO composite membrane, and finally, the modified GO composite membrane is put in a water solution of a crosslinking agent to be crosslinked. The preparation process is simple, the film forming time is short, the composite membrane is applied to the field of pervaporation, the problems thatthe GO composite membrane has small flux and low separation factor in the pervaporation process are solved, and the composite membrane has uniform and compact surface and can be widely applied to thefield of water treatment.

Owner:BEIJING UNIV OF CHEM TECH

Concrete release paint

InactiveCN110079214AImprove stabilityAvoid condensationAnti-corrosive paintsUltimate tensile strengthDefoaming Agents

The invention discloses concrete release paint. The concrete release paint is prepared from raw materials in parts by weight as follows: 20-40 parts of vegetable oil, 25-35 parts of dilute water, 25-35 parts of an emulsifier, 5-15 parts of a stabilizer, 2-5 parts of a thickening agent, 2-5 parts of a defoaming agent and 2-5 parts of an antirust agent. According to the concrete release paint, the vegetable oil is adopted as the environment-friendly release paint, so that the concrete release paint has the advantages of being reproducible, biodegradable and harmless to a human body; with addition of a coalescing agent and the stabilizer, the coalescing agent can guarantee excellent film-forming property and higher film-forming strength of the concrete release paint, the film-forming time isshort, a formwork is easy to clean after form stripping, construction progress and efficiency can be guaranteed, and the concrete release paint has higher stability and longer storage time by means ofthe stabilizer.

Owner:湖南加美乐素新材料股份有限公司

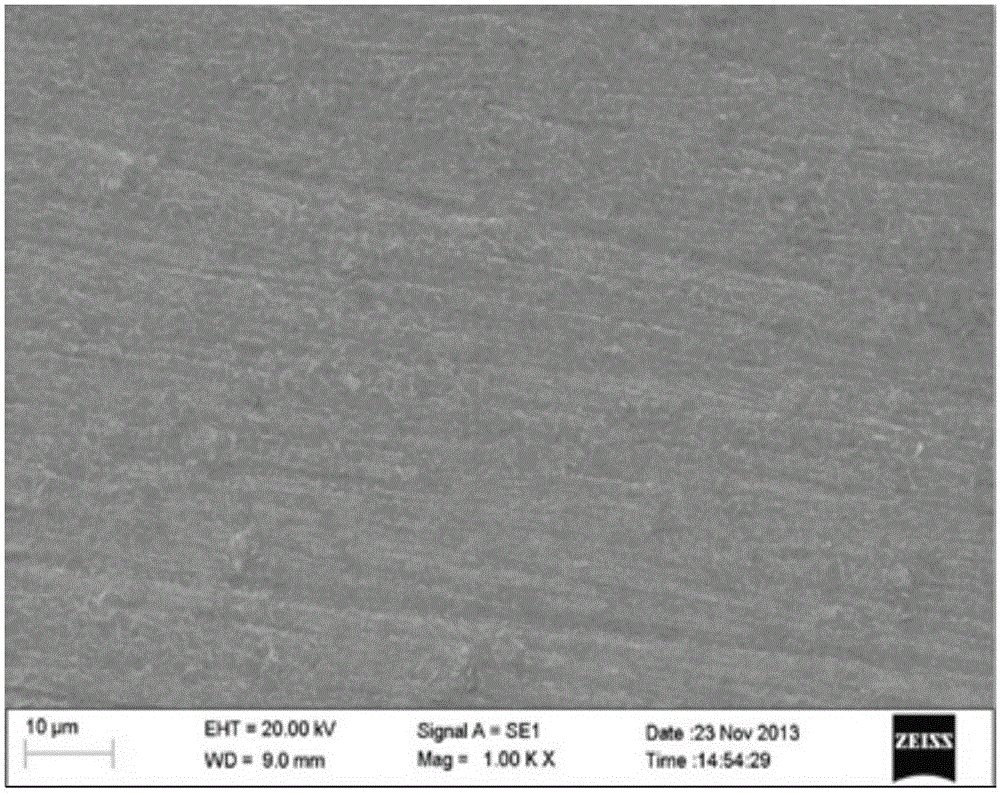

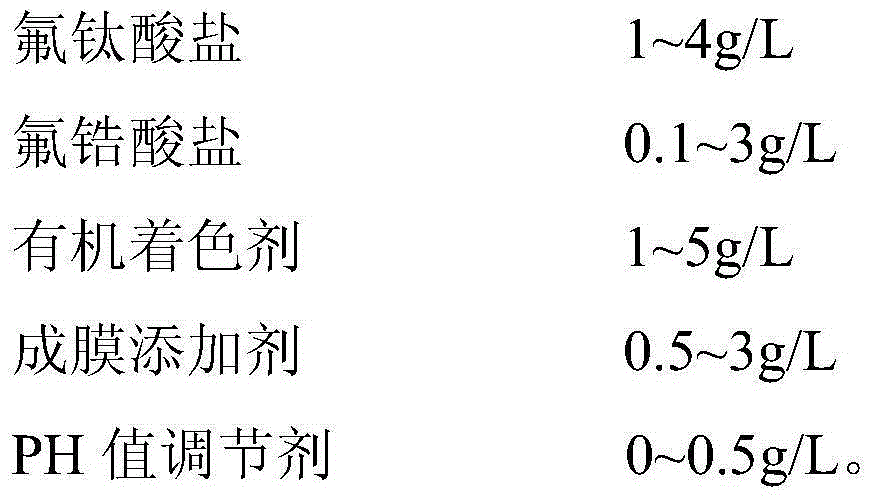

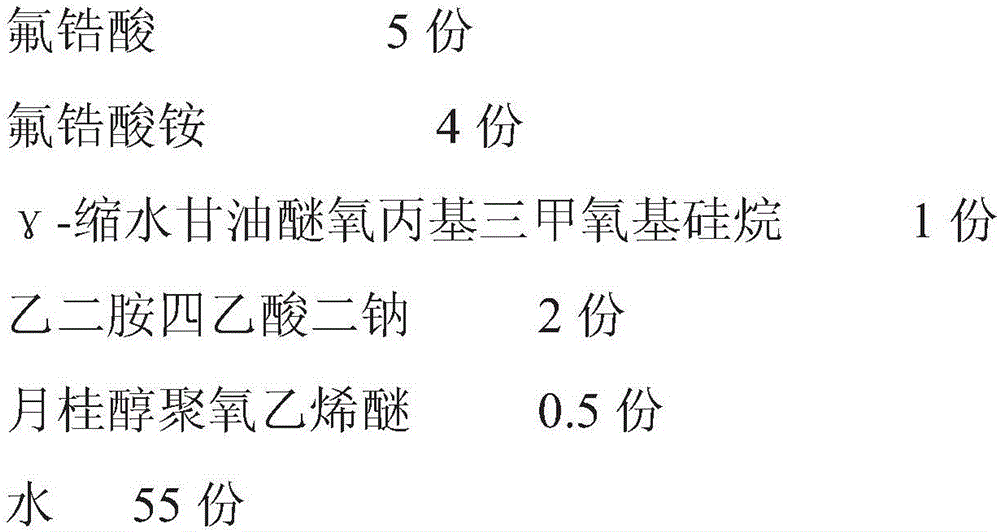

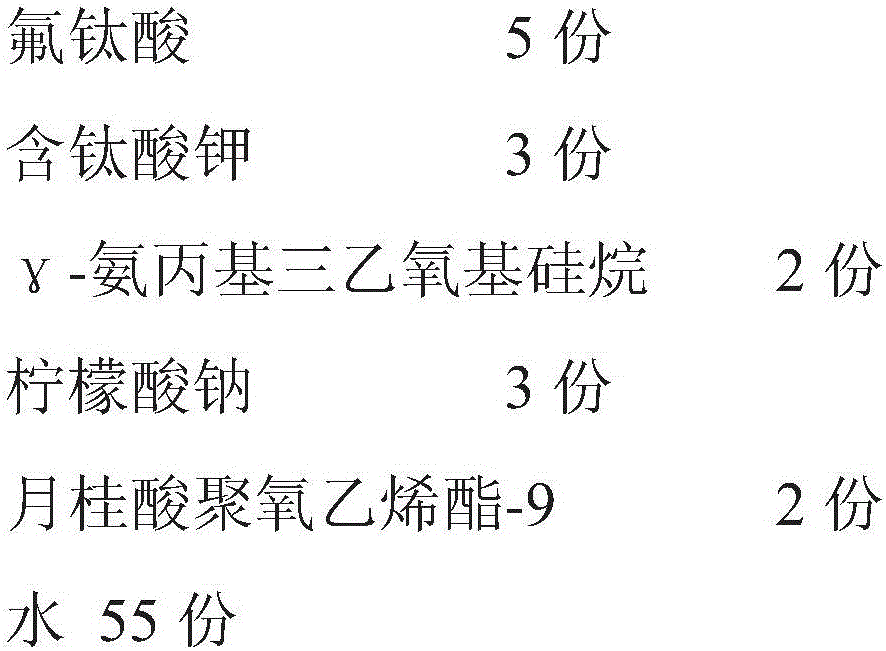

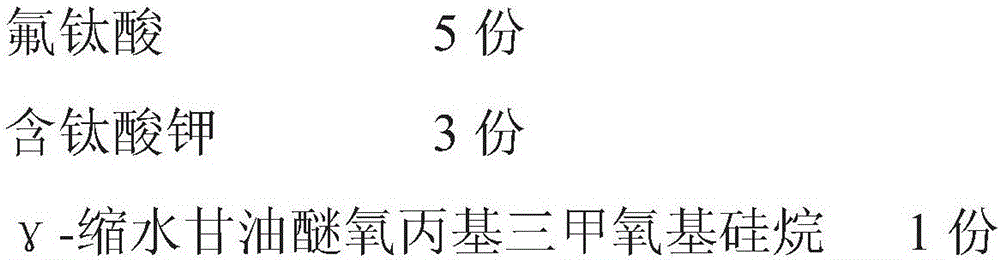

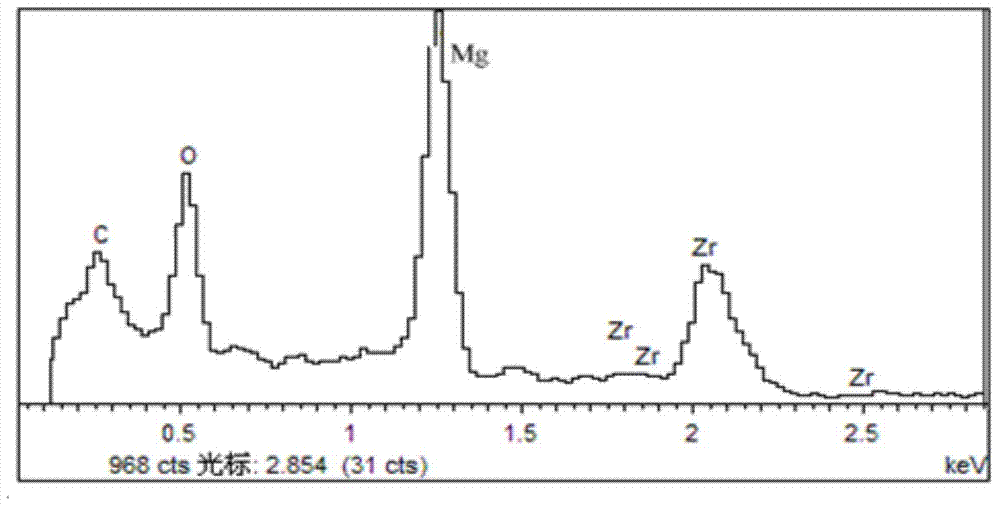

Treatment liquid and treatment method for preparing zirconium-based colored conversion film on magnesium alloy surface

The invention discloses treatment liquid for preparing a zirconium-based colored conversion film on a magnesium alloy surface, wherein each liter of treatment liquid contains 0.2-2.5 g of zirconium-containing main film forming agent, 0.2-1.5 g of zirconium-containing film forming oxidant, 0.5-1.5 g of film forming aid, 0.5-3.0 g of complexation colorant, 0.5-2.0 g of solution pH buffer agent and 0.01-0.05 g of solution pH regulator; the zirconium-containing main film forming agent is composed of fluorozirconic acid and fluorozirconate, which are mixed in any proportion; the zirconium-containing film forming oxidant is zirconium oxychloride; the film forming aid is any one of fluorotitanic acid, potassium fluotitanate, ammonium fluorotitanate or sodium fluorotitanate; the complexation colorant is tannic acid or citric acid. The invention further discloses a treatment method for preparing zirconium-based colored conversion film on the magnesium alloy surface by utilizing the treatment liquid. The conversion film generated by using the treatment liquid and the treatment method disclosed by the invention is good in corrosion resistance, colored, high in film forming speed and environmental-friendly.

Owner:东莞市镁皓镁合金科技有限公司

Electroluminescence device and manufacturing method thereof

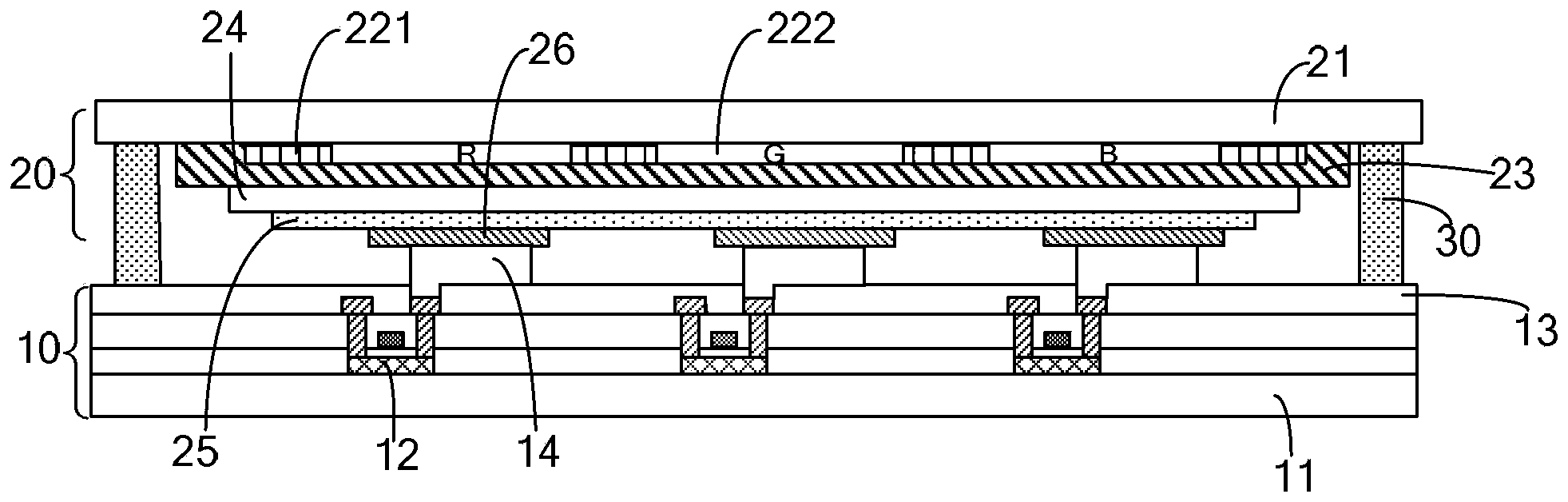

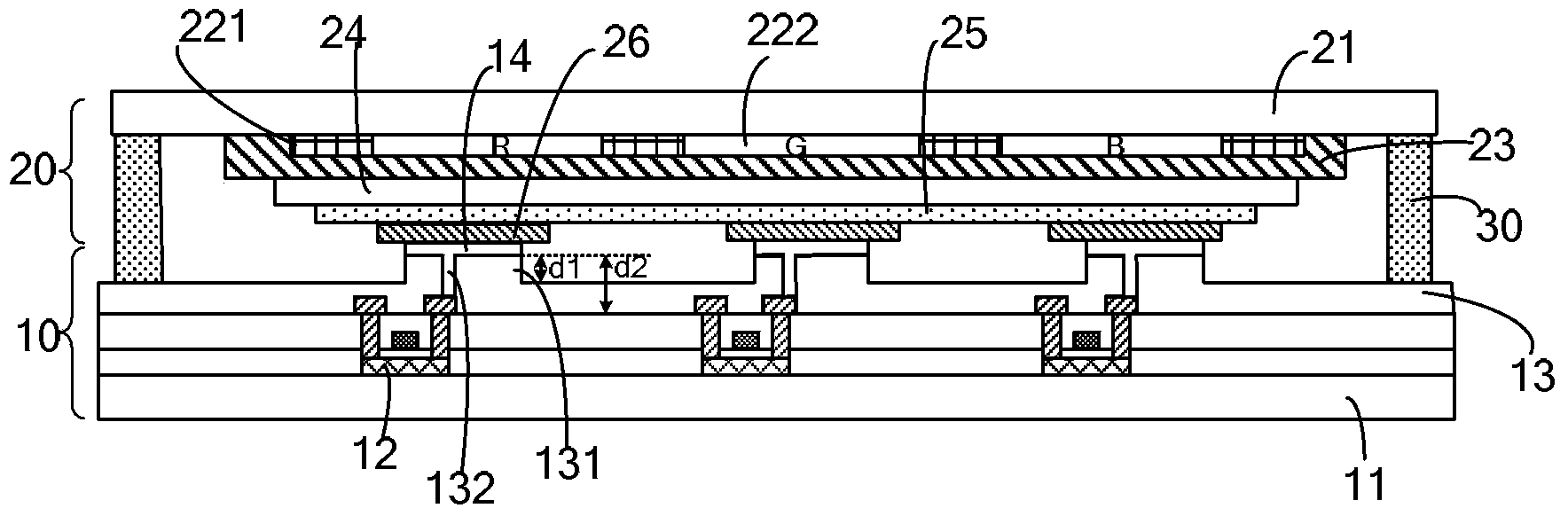

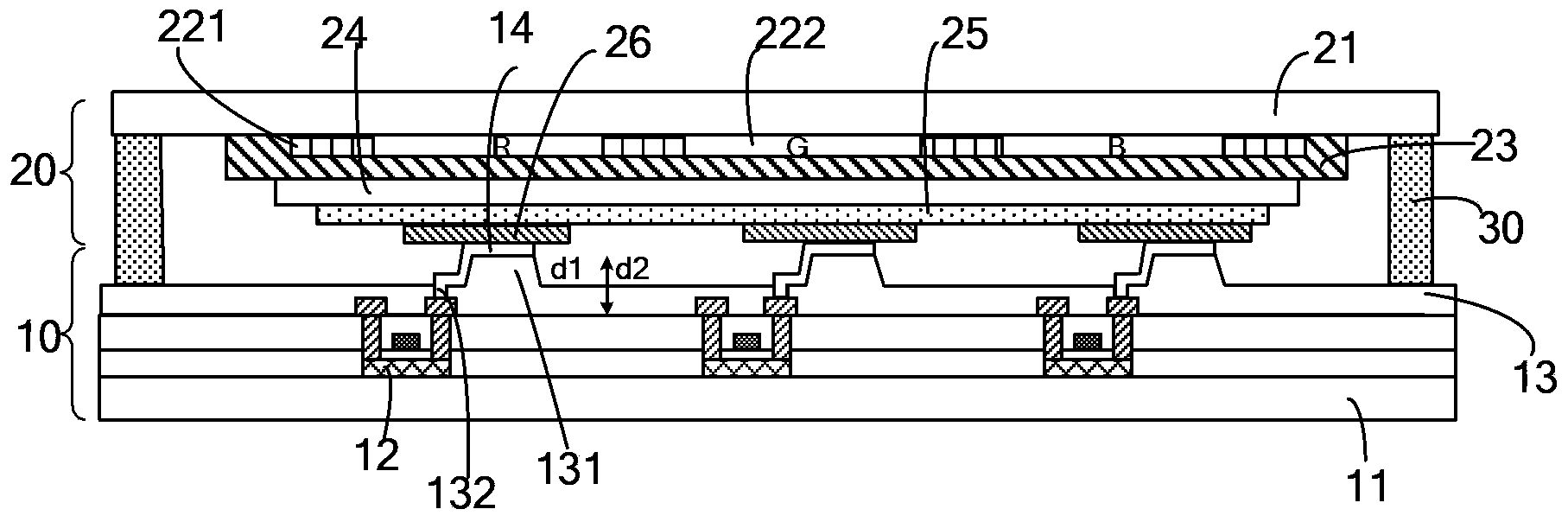

ActiveCN103474453AReduce thicknessShort film forming timeSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringTransistor

An embodiment of the invention discloses an electroluminescence device and a manufacturing method thereof, and relates to the display field. The reliability of electric connection of a thin film transistor and a second electrode is ensured, and in the meanwhile, film forming time can be shortened, the etching difficulty can be reduced and accordingly the production efficiency can be improved in the connecting electrode manufacturing process. The electroluminescence device comprises an array substrate, wherein the array substrate comprises a substrate body, thin film transistors sequentially arranged on the substrate body, protective layers covering the thin film transistors and connecting electrodes arranged on the protective layers. The protective layers under the connecting electrodes protrude towards one side away from the substrate body to form bosses. Protective layer through holes are formed in the positions, corresponding to drain electrodes of the thin film transistors, of the protective layers, and the connecting electrodes are connected with the drain electrodes of the thin film transistors through the protective layer through holes.

Owner:BOE TECH GRP CO LTD

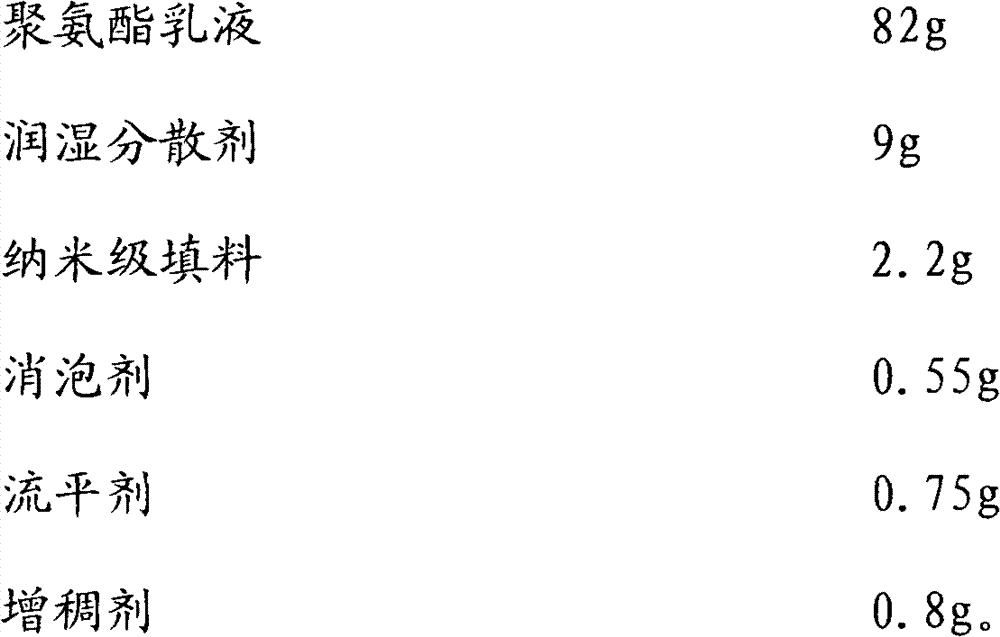

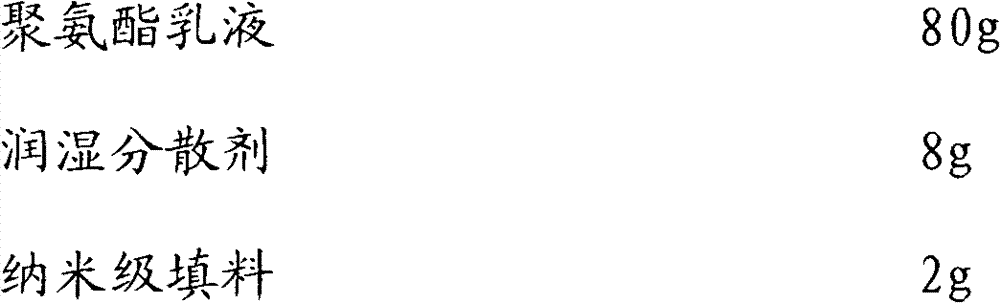

Water-based normal-temperature-curable peelable paint for safekeeping and protection of instrument and equipment

InactiveCN102816508AWide variety of sourcesWith cleaner productionPolyurea/polyurethane coatingsWater basedEngineering

The invention discloses a water-based normal-temperature-curable peelable paint which is applicable to the safekeeping and protection of instrument and equipment. The water-based normal-temperature-curable peelable paint for the safekeeping and protection of instrument and equipment comprises the following raw materials in parts by weight: 80-90 parts of polyurethane emulsion, 8-12 parts of wetting dispersant, 2-3 parts of nano filler, 0.5-0.8 part of defoaming agent, 0.5-0.8 part of leveling agent and 0.5-0.8 part of thickener. The water-based normal-temperature-curable peelable paint product disclosed by the invention fundamentally contains no organic solvent component, is environment-friendly and pollution-free, is short in film-forming time and has good leveling property. The product is convenient to construct, the formed film is uniform, the bonding force exerted on the basal body is moderate, and the paint can be peeled easily. The detection through a test shows that when the coating thickness is 0.13-0.14mm (coated twice), the average tensile strength of the coating is up to 9.51Mpa, the average elongation at break is up to 274.54%, and the peeling property is the best.

Owner:合肥华清高科表面技术股份有限公司

Aluminum or aluminum alloy protection chromium-free passivation solution, preparation method and aluminum or aluminum alloy surface protection method thereof

InactiveCN105177561AImprove corrosion resistanceAvoid harmMetallic material coating processesToxic materialHydrolysis

The invention relates to an aluminum or aluminum alloy protection chromium-free passivation solution, a preparation method and an aluminum or aluminum alloy surface protection method thereof. According to the passivation solution, a silane coupling agent serves as a silicon source; an inorganic salt aqueous solution of rare earth ions serves as a hydrolysis accelerant. The organic-inorganic hybridized passivation solution free of chromium or fluorine or other toxic substances is prepared by adding an organic inhibitor. A hybrid film on the treated surface of aluminum alloy has the characteristics of being compact, uniform and high in corrosion resistance. The chromate process can be replaced. In addition, the adhesive force between the surface of the aluminum alloy and a coating can be improved.

Owner:SHANDONG UNIV

Anti-rust spraying fluid for metals

ActiveCN104294274AShort film forming timeImprove quick-drying performanceSodium molybdateIsobutyl alcohol

The invention provides anti-rust spraying fluid for metals, which is composed of the following components in parts by mass: 12-15 parts of triethanolamine, 4-5 parts of borax, 1-2 parts of sodium molybdate, 3-5 parts of sodium bisulfate, 1-2 parts of diethanolamine, 2-3 parts of isobutanol, 0.5-1 parts of isopropyl alcohol, 0.5-1 parts of sodium chloride, 8-12 parts of ethanol, and 85-95 parts of water. When the anti-rust spraying fluid for metals disclosed by the invention is splayed on a metal workpiece, an anti-oxidation protection film can be formed on the surface of the metal workpiece, and the film is compact in tissue structure and fine in particles, so that a rust protection effect is achieved; the anti-rust spraying fluid for metals disclosed by the invention is short in film-forming time and good in fast drying property, and can form a film in 2-3 minutes; and in a normal environment, metals can be prevented from rusting in 5-6 months.

Owner:武汉腾耀新材料工程有限公司

Method for producing transparent high-temperature electric heating membrane pipe with self-constant temperature

ActiveCN101355831AUniform thicknessShort film forming timePretreated surfacesHeating element shapesSilver pasteRoom temperature

The invention relates to a method for producing a self constant-temperature transparent high-temperature electric heating membrane tube. The method is characterized in that a tubular metallic-membrane plating workpiece is cleaned and dried, a magnesia sizing agent is coated on the non-metallic-membrane plating area and is dried as well as is fixed on a clamp of a metallic-membrane plating device and is put inside a furnace cavity of the metallic-membrane plating device, the workpiece is coated by a spraying device and the surface of the workpiece is plated with a transparent high-temperature electric heating membrane and is cooled to the normal temperature, the workpiece is cleaned by ultrasound to remove the magnesia coating of the non-metallic-membrane plating area and is dried, the silver paste is printed on the workpiece by a screen printer to manufacture the electrode, the drying process is performed, and the workpiece is dried naturally to the normal temperature to manufacture the finished product of the self constant-temperature transparent high-temperature electric heating membrane tube. The method has the advantages that the thickness of the metallic-membrane plating is even, the plating time is short, the positive temperature coefficient is formed, the self constant temperature function is realized, the service life is long, the stability is good and the security and the effect are good.

Owner:佛山康疆电器科技有限公司

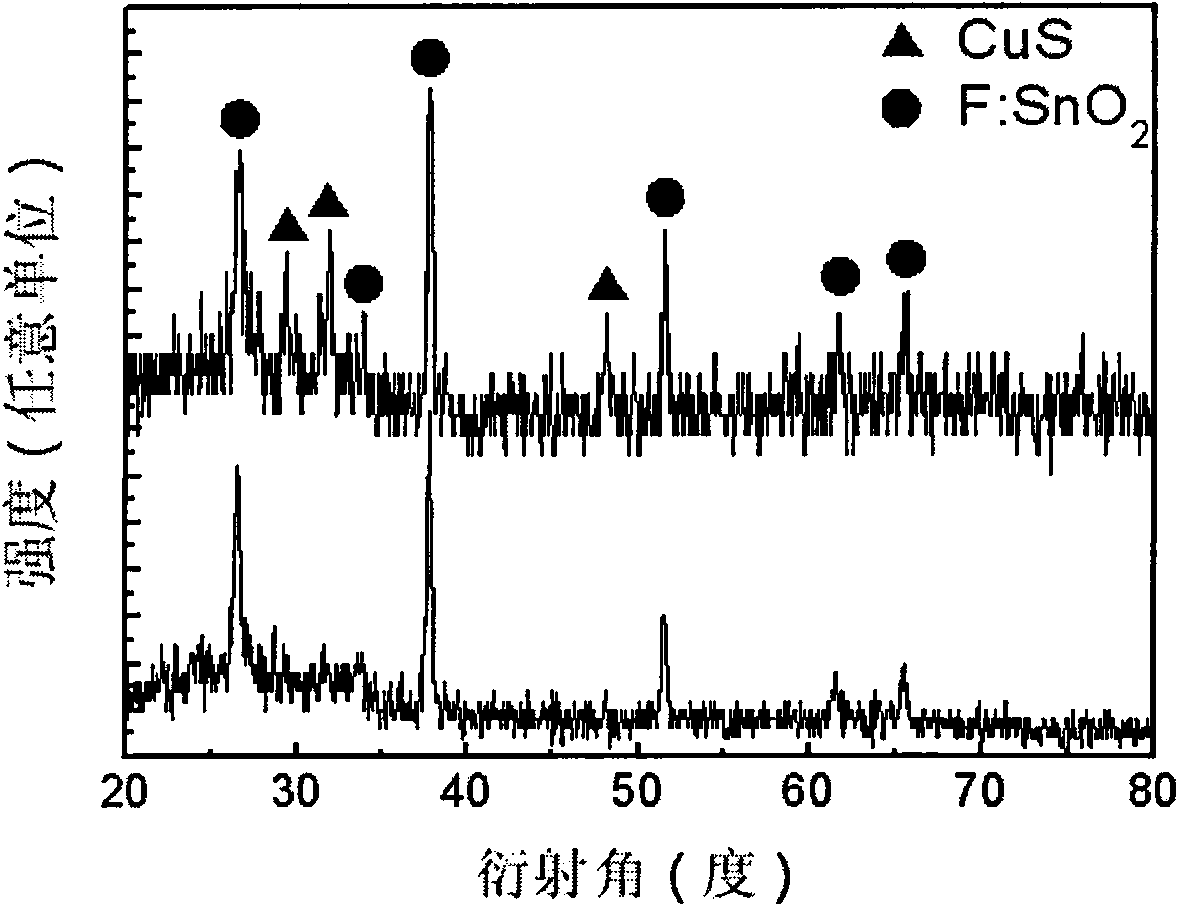

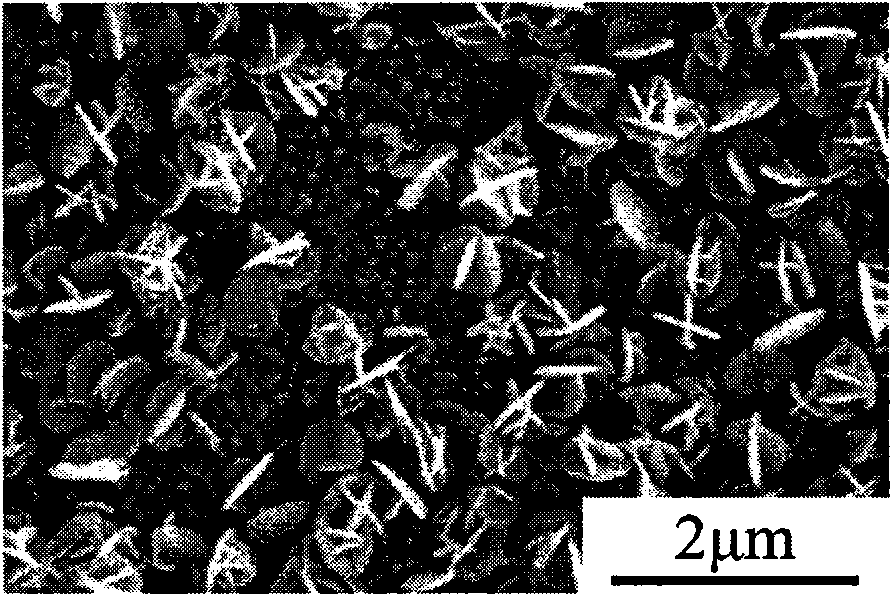

Method for depositing copper sulphide nano film rapidly in low temperature

InactiveCN101638777AHigh crystallinityAvoid nucleation and precipitationLiquid/solution decomposition chemical coatingCopper sulfidesWater bathsEthylene diamine

The invention relates to a method for depositing copper sulphide nano film rapidly in low temperature, belonging to the technical field of the preparation of functional film materials. The preparationmethod of copper sulphide film in the prior art has high requirement on the deposition conditions, needs high temperature heating, has great limitations for the deposition of substrate, and has longer preparation time and low efficiency, thus being not benefical to the industrial production. In the preparation method of copper sulphide nano film of the invention, the ethylene diamine tetraaceticacid disodium (EDTA-2Na) is used as complexing agent, nano copper sulphide film with an indigo copper ore structure can be obtained on semiconductor substrate and conducting substrate within 40 minutes and in the microwave water-bath environment at the temperature of lower than 100 DEG C, and the crystal particles of the nano copper sulphide film are tiny, uniform, compact and have specific microstructure. The invention has simple technology and low cost, and is suitable for large-scale production and application.

Owner:BEIJING UNIV OF TECH

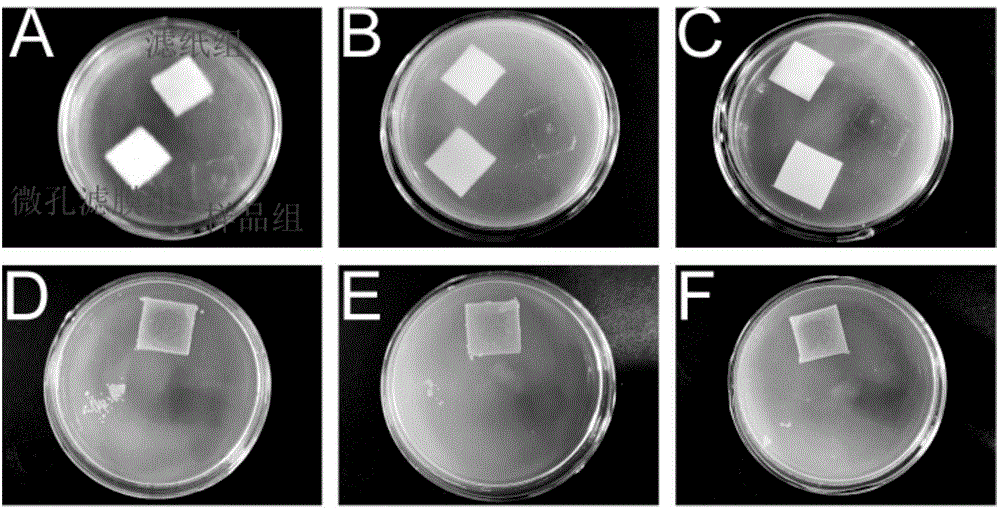

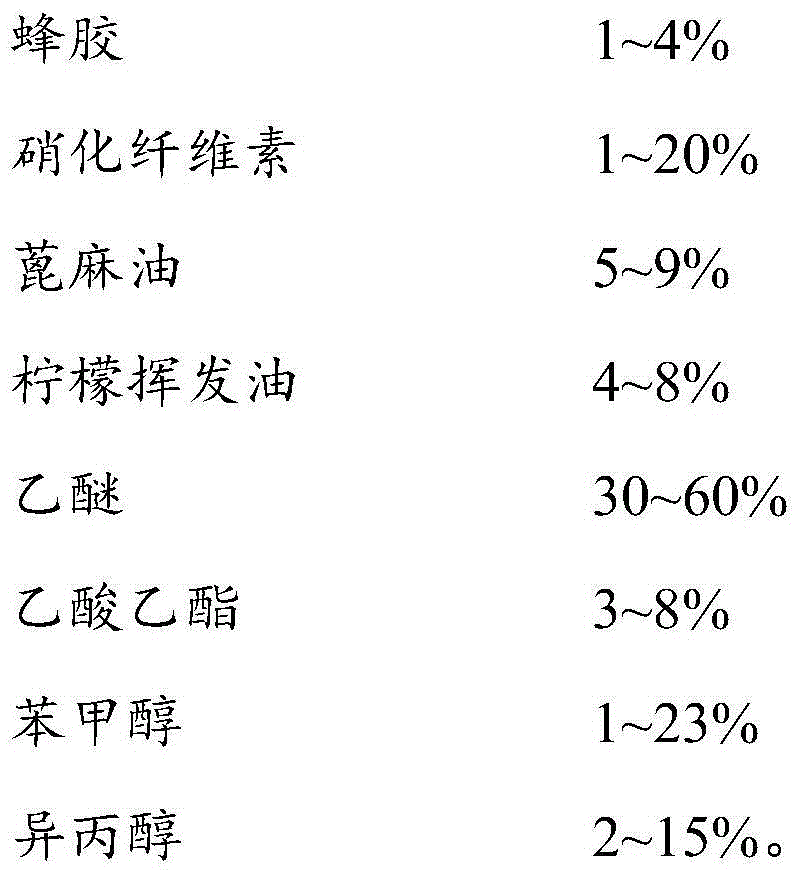

Traditional Chinese medicine liquid adhesive bandage and preparation method

ActiveCN104814982AGood antibacterialEnhance anti-inflammatoryAntibacterial agentsAntiviralsWound healingPropolis

The invention provides a traditional Chinese medicine liquid adhesive bandage. The traditional Chinese medicine liquid adhesive bandage comprises 1-4% of traditional Chinese medicine propolis, 1-20% of film-forming material nitrocellulose, 5-9% of plasticizer plasticizer, 4-8% of flavouring agent lenmon volatile oil, 30-60% of diethyl ether, 3-8% of ethyl acetate, 1-23% of phenylcarbinol and 2-15% of isopropanol. The traditional Chinese medicine liquid adhesive bandage provided by the invention has the following characteristics of being ventilate and waterproof due to a nano-aperture structure; the film-forming time is fast because 30s is needed; furthermore, the odour is faint scent, the traditional Chinese medicine liquid adhesive bandage is antibacterial and antiseptic, regenerated tissues can be protected, the wound healing can be promoted, and the wound infection can be effectively prevented; meanwhile, the traditional Chinese medicine liquid adhesive bandage does not pollute clothes and is good in comfort, and cannot be limited by the wound shape and location, thereby being applicable to the wounds of various sizes.

Owner:HUAQIAO UNIVERSITY

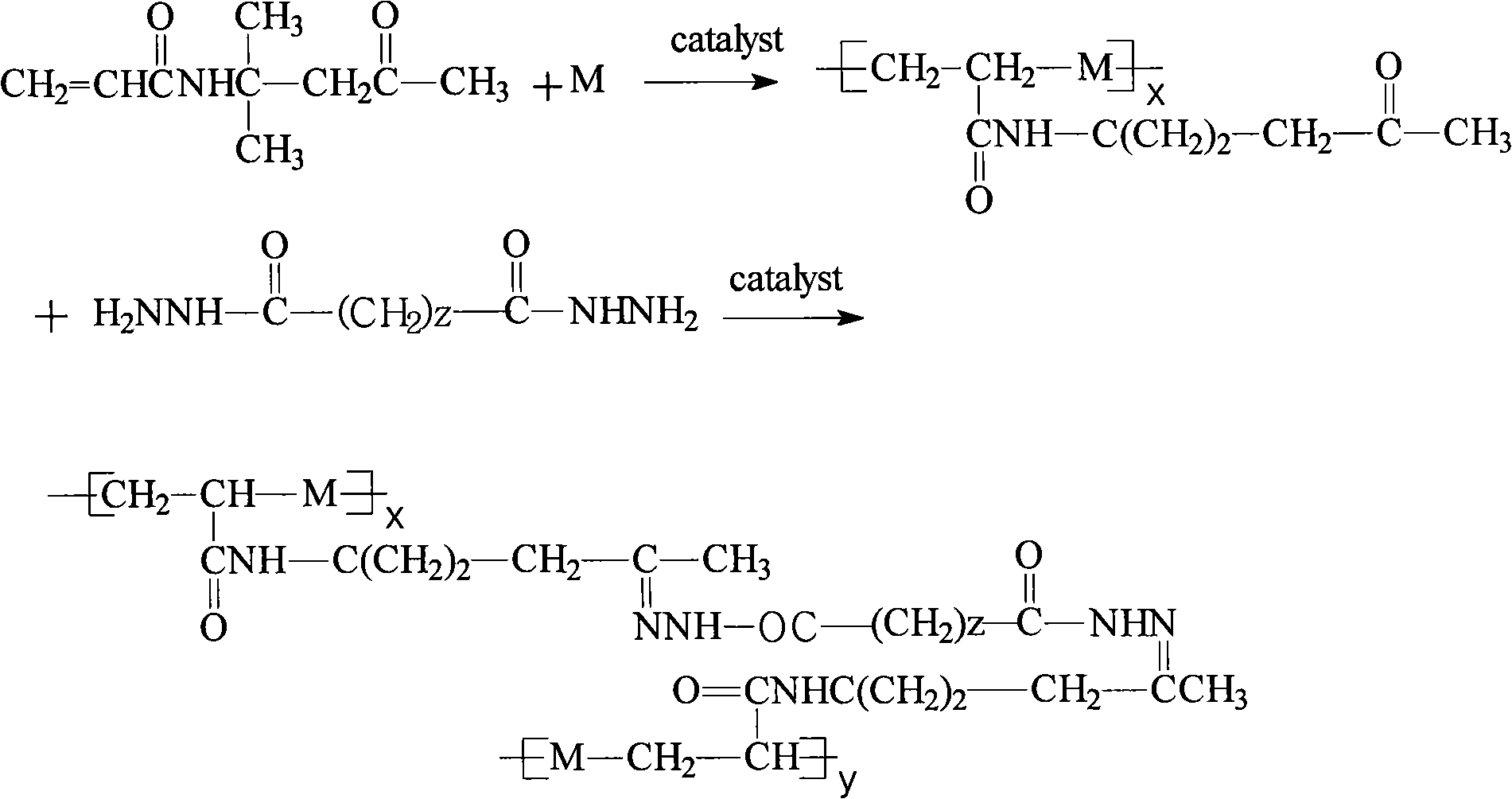

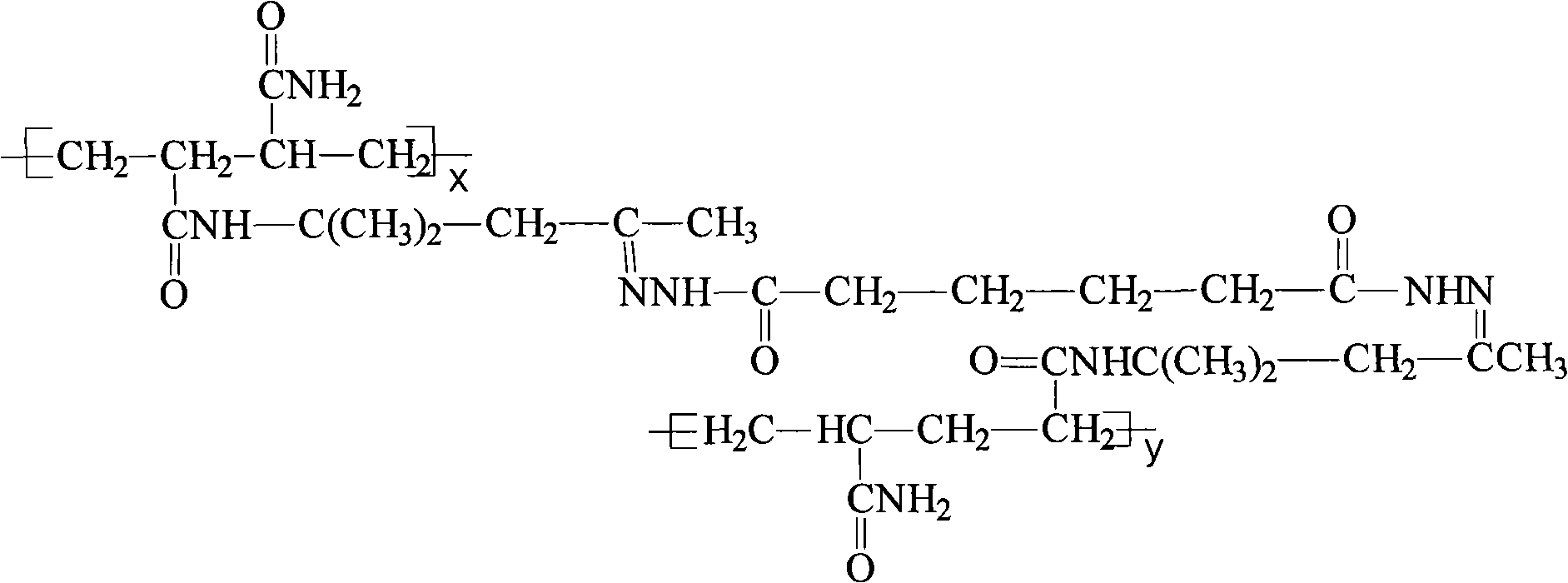

Film-forming agent for seed clothing sheet and preparation method thereof

InactiveCN101314627AShort film forming timeCoating shedding rate is lowSeed coating/dressingMethylvinyl ketoneVinyl carbazole

The invention discloses a film former for seed coating and the preparation method thereof. The preparation method comprises the steps as follows: subjecting diacetone acrylamide and unsaturated monomer to copolymerization reaction to obtain polymer, and reacting with dihydrazide compound to obtain film-forming material for seed-coating. The unsaturated monomer compound can be one or more selected from methyl methacrylate, styrene, vinyl acetate, vinyl chloride, maleic anhydride, N-vinyl pyrrolidone, vinylidene chloride, acrylonitrile, methyl vinyl ketone, methacrylic acid, acrylamide, methyl acrylate, ethyl acrylate, butyl acrylate, dihydrazide, N-vinylcarbazole and butadiene. The film former prepared by the method has good film physical chemical properties such as forming property, water resistance, air permeability, water permeability, etc., and drug slow release function to prolong drug effect and protect healthy growth of crops.

Owner:CHINA AGRI UNIV

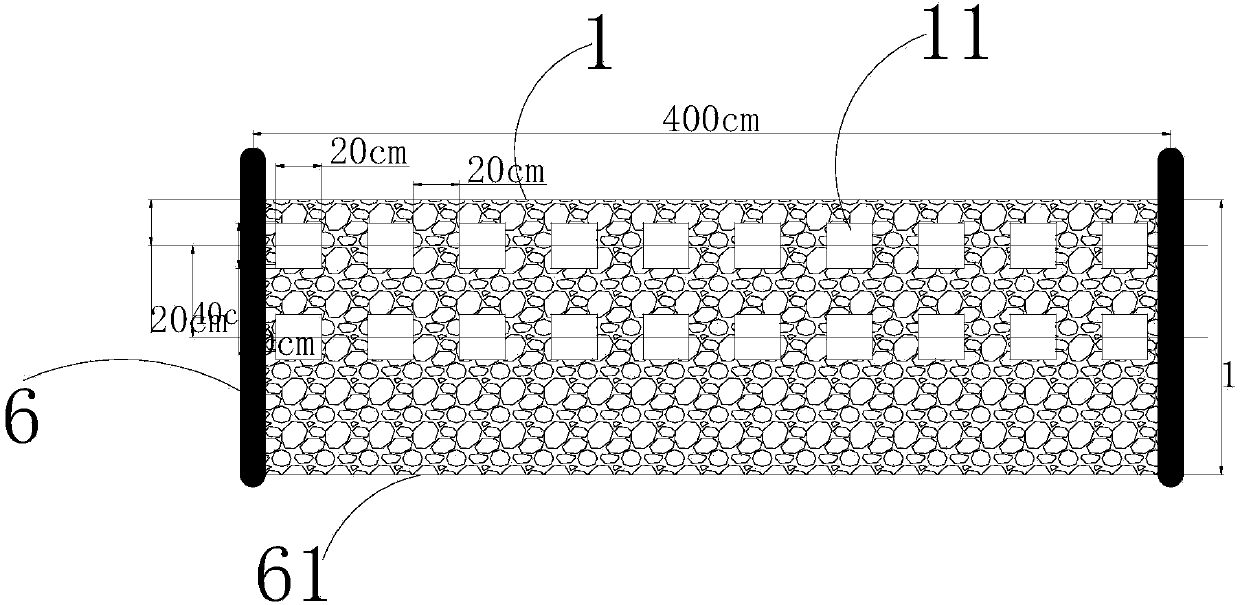

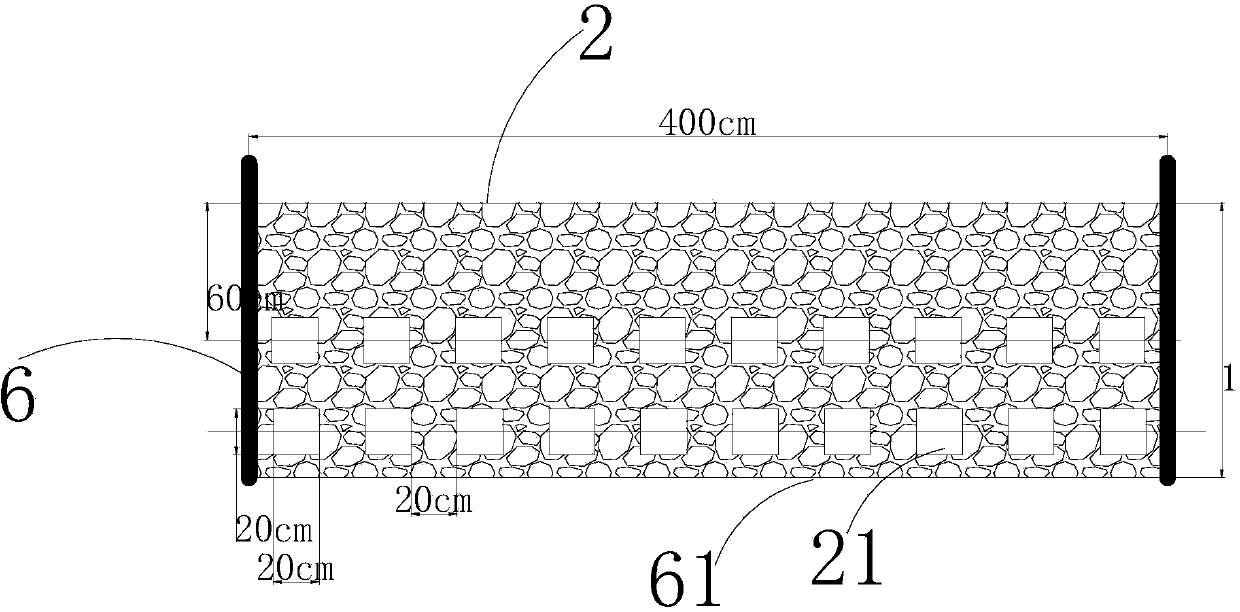

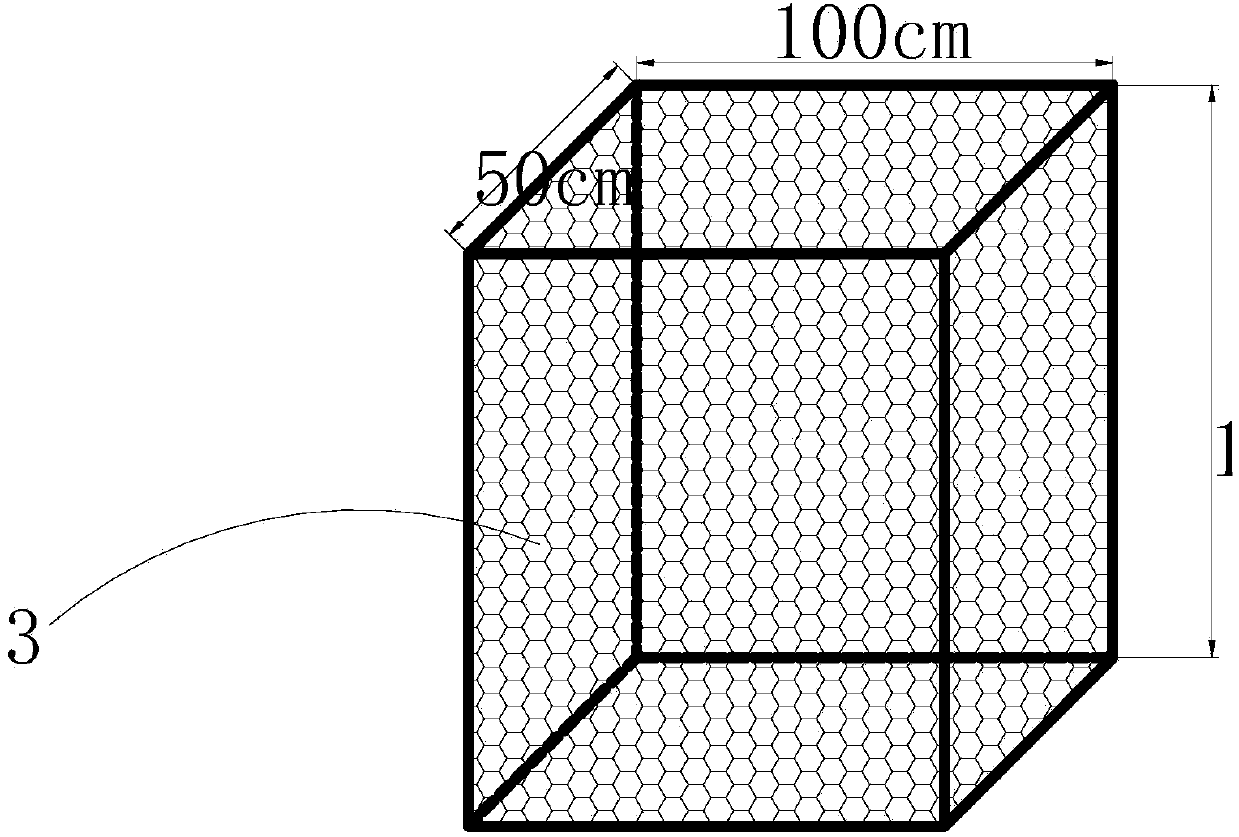

Water purifying device for plate and frame biological filtering dam

InactiveCN104229975AOvercome the cycleOvercoming easy cloggingTreatment with aerobic and anaerobic processesBiological filterEnvironmental engineering

The invention provides a water purifying device for a plate and frame biological filtering dam. The water purifying device for the plate and frame biological filtering dam comprises an upstream filtering dam, a downstream filtering dam and at least one filter material filling frame, wherein the upstream filtering dam is fixed at the upstream base of a riverway, and the downstream filtering dam is fixed at the downstream base, a preset distance far away from the upstream filtering dam, of the riverway; a water inlet hole is formed in the upstream filtering dam; a water draining hole is formed in the downstream filtering dam; a containing slot used for containing the filler material filling frame is formed between the upstream filtering dam and the downstream filtering dam; the filler material filling frame is movably contained in the containing slot; and a filling matrix which can roll in the filter material filling frame and has filtering and adsorption effects is filled in the filter material filling frame. The water purifying device for the plate and frame biological filtering dam is high in water purifying efficiency and easy to maintain, can be easily attached by a biological membrane and is resistant to water impact.

Owner:HUBEI UNIV

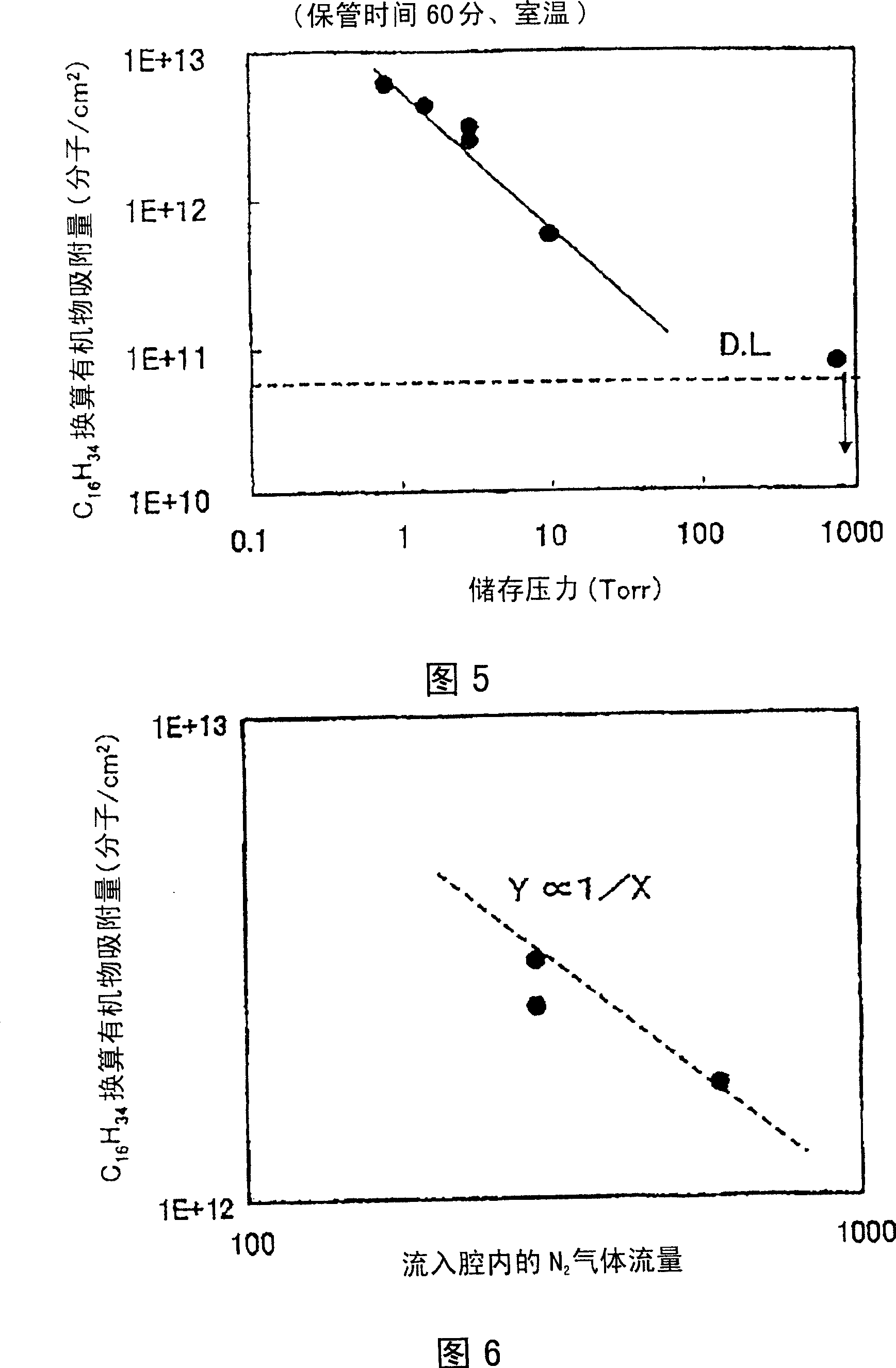

Film-forming apparatus and film-forming method

InactiveCN1938447AImprove economyAvoid wastingElectrical apparatusElectroluminescent light sourcesEngineeringRaw material

For increasing the film-forming rate and enabling uniform film formation and waste elimination of raw material, a film-forming method and a film-forming apparatus can reach an evaporated film-forming material to a surface of a substrate by the flow of a transport gas so as to control the film-forming conditions by the flow of the gas. Thereby a uniform thin film can be deposited on the large-area substrate. That is, by directing the evaporated raw material toward the substrate, it is possible to increase the film-forming rate and achieve uniform film formation.

Owner:大见忠弘 +1

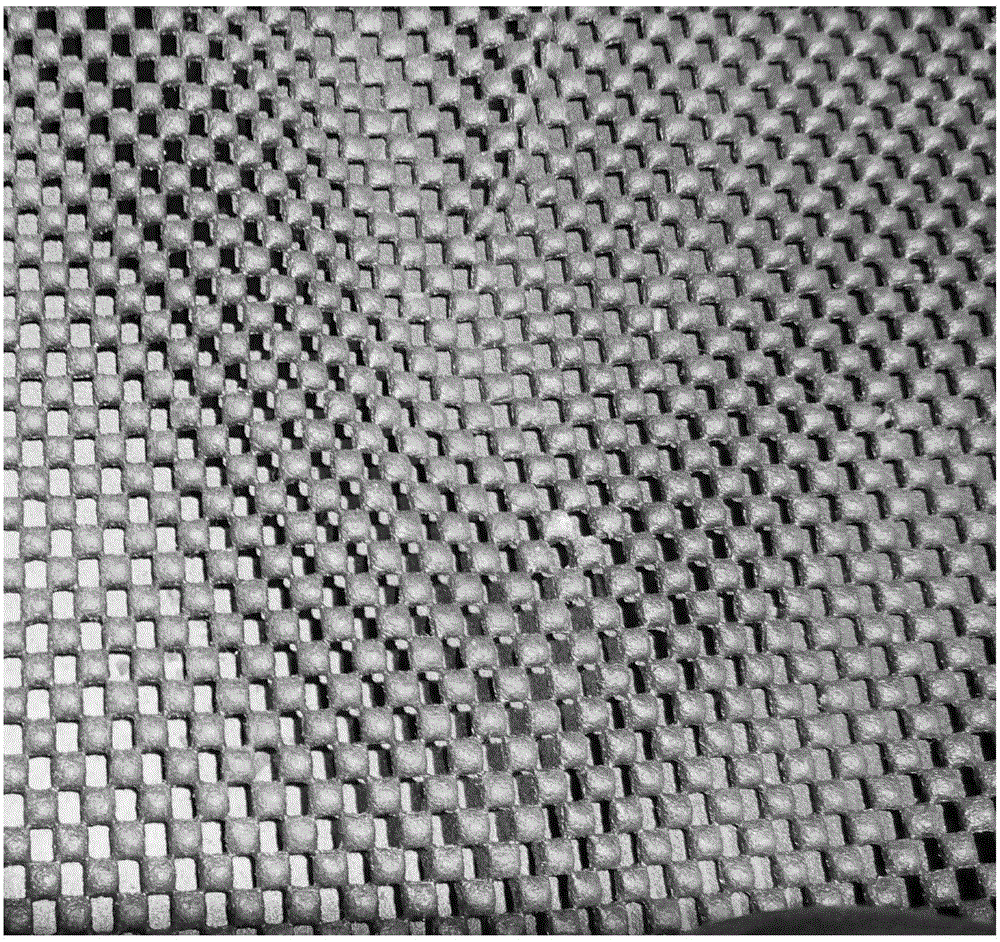

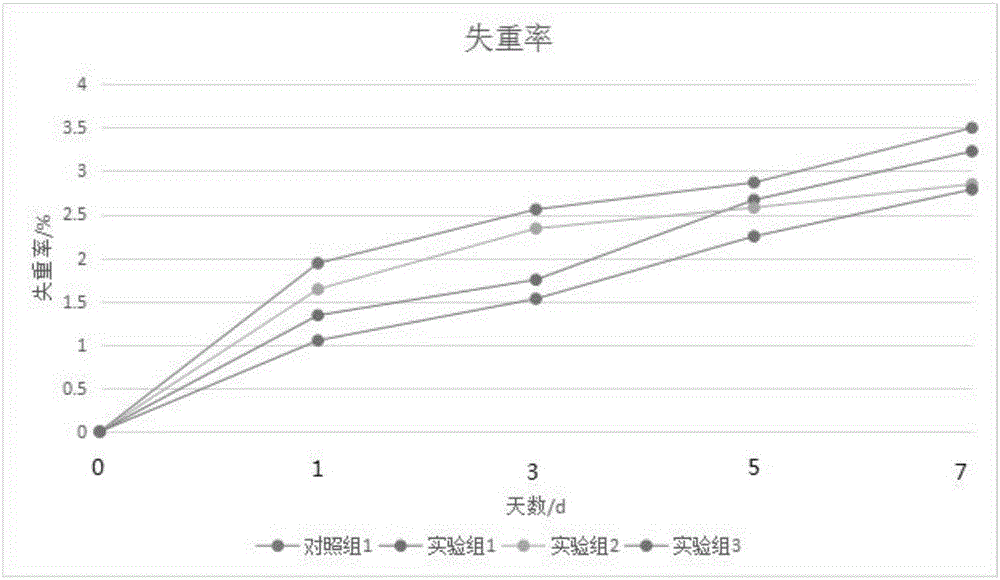

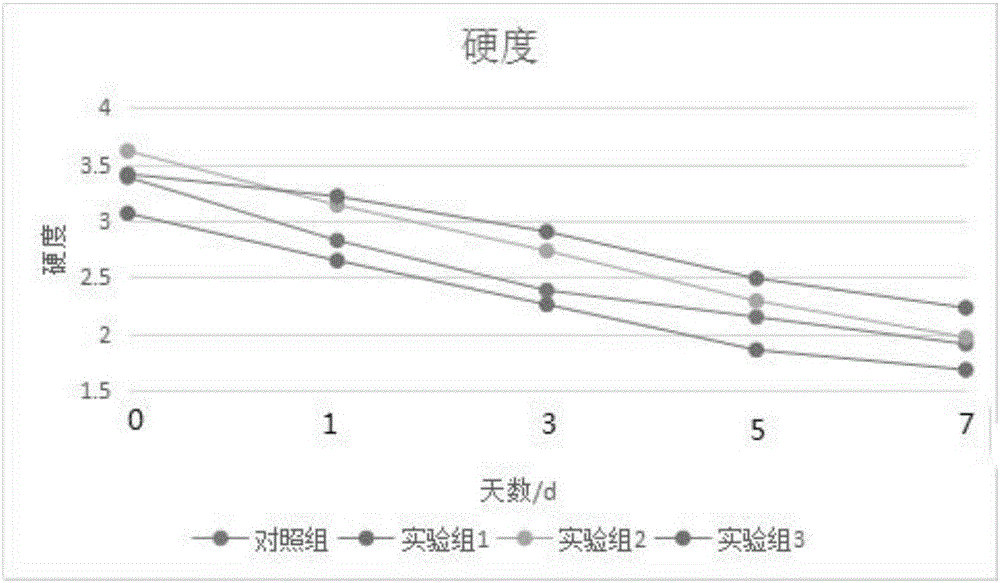

Strawberry preserving composite packaging film and preparation method thereof

ActiveCN106172734AShort film forming timeEasy to operateFruits/vegetable preservation by coatingComposite filmElectrospinning

The invention provides a preparation method of a strawberry preserving composite packaging film. The method mainly comprises the following steps: carrying out film casting on a film-forming liquid with chitosan, corn starch and cinnamyl aldehyde as raw materials and then carrying out hot press molding on the film and an electrostatic spinning film with chitosan, corn starch and cinnamyl aldehyde as raw materials. The invention also provides the packaging film prepared by the method. The packaging film and the preparation method have the beneficial effects that the preparation method is simple to operate, the raw materials widely exit in nature, and the composite film is formed fast; the adopted three main raw materials, namely chitosan, corn starch and cinnamyl aldehyde, are all natural substances and are food grade, so compared with many existing food packaging materials, the raw materials are lower in environmental pollution, have better biocompatibility and are safer to food; the obtained composite packaging film has excellent preservation effects on strawberries, can conduce to increasing the length for preservation of the strawberries and lengthening the strawberry selling time to 15 days or over and brings greater economic benefits to the markets.

Owner:SICHUAN AGRI UNIV

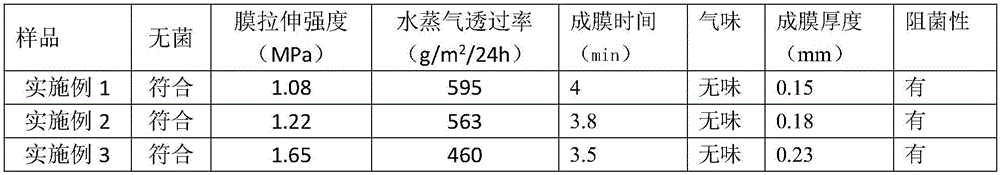

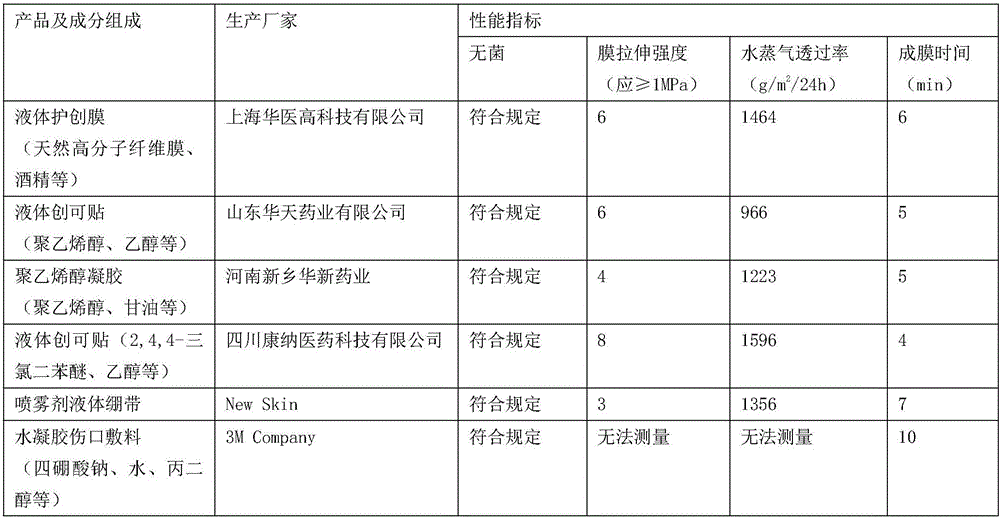

Liquid band-aid and preparing method thereof

The invention belongs to the technical field of medical instruments and particularly discloses a liquid band-aid. The liquid band-aid is prepared from a film forming ingredient, a plasticizer and a solvent, wherein polyacrylic resin serves as the film forming ingredient. With polyacrylic resin serving as the main ingredient, the liquid band-aid can be volatized immediately when smeared to a wound and form a semi-transparent adhesive film which is very soft, good in air permeability, rich in elasticity and very thin, the effects of wound contamination prevention and protection can be performed, and the water-proof feature is achieved; the liquid band-aid is convenient to use and capable of providing the best moist environment needed by wound healing to the maximum and being applied to sensitive skin. The liquid band-aid has the functions of wound infection prevention, protection and water proofing, can be used for bruising, protection of a sutured part generated after a surgical operation, skin allergies, barb scratching, cracks, rhagades, tiny knife cut, mosquito bite prevention, quick blood crust, scar and mosquito mark removal and the like.

Owner:GUANGZHOU RHFAY BIOTECH CO LTD

Metal anti-rust phosphating solution

InactiveCN103397318AImprove corrosion resistanceShort film forming timeMetallic material coating processesIron sulfateO-Phosphoric Acid

The invention provides a metal anti-rust phosphating solution, comprising the following raw materials by concentration: 2 g / L of octylphenol polyoxyethylene ether, 2 g / L of sodium polyoxyethylenelauryl ether sulfate, 2 g / L of diethyl thiourea, 10 g / L of phosphoric acid, 5 g / L of citric acid, 15 g / L of nickel sulfate (NiSO4.6H2O), 10 g / L of ferric sulfate, 10 g / L of zinc dihydrogen phosphate, 5 g / L of ferrocene, 5.0 g / L of sodium perborate, 2 g / L of hydroxyethyl cellulose, 5 g / L of gelatin, 40 g / L of aluminium hydroxide and 5 g / L of graphite. Harmful substances such as nitrate, nitrite, chromate and the like are not adopted, so that the metal anti-rust phosphating solution is environment-friendly. Meanwhile, an anti-rust object of the metal surface can be achieved; and a phosphating film formed by the phosphating solution has good corrosion resistance, thereby completely reaching relevant standards.

Owner:石欣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com