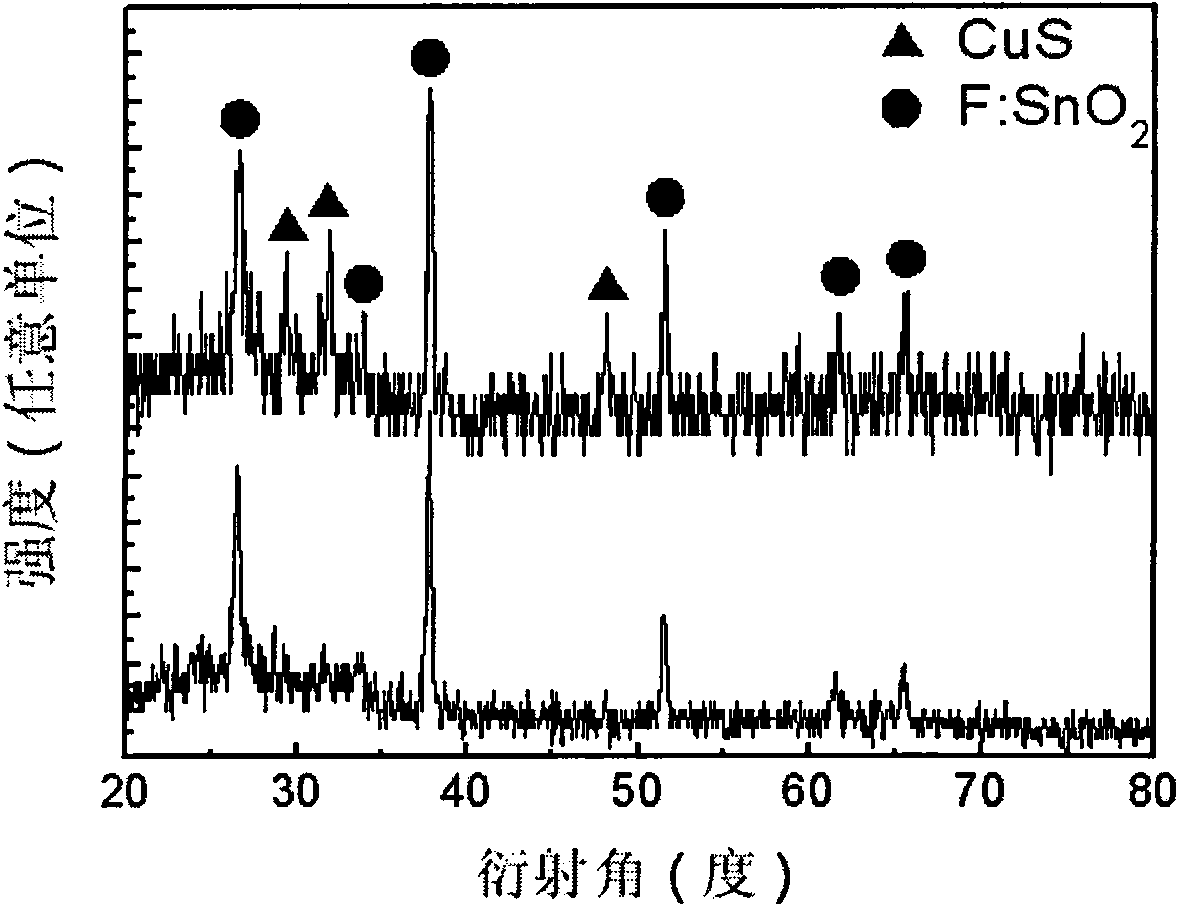

Method for depositing copper sulphide nano film rapidly in low temperature

A nano-film and copper sulfide technology, applied in copper sulfide, liquid chemical plating, metal material coating process, etc., can solve the problems that affect the application of CuS film, unfavorable industrial production, long preparation time, etc., and shorten the film deposition time , uniform heating, lower deposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

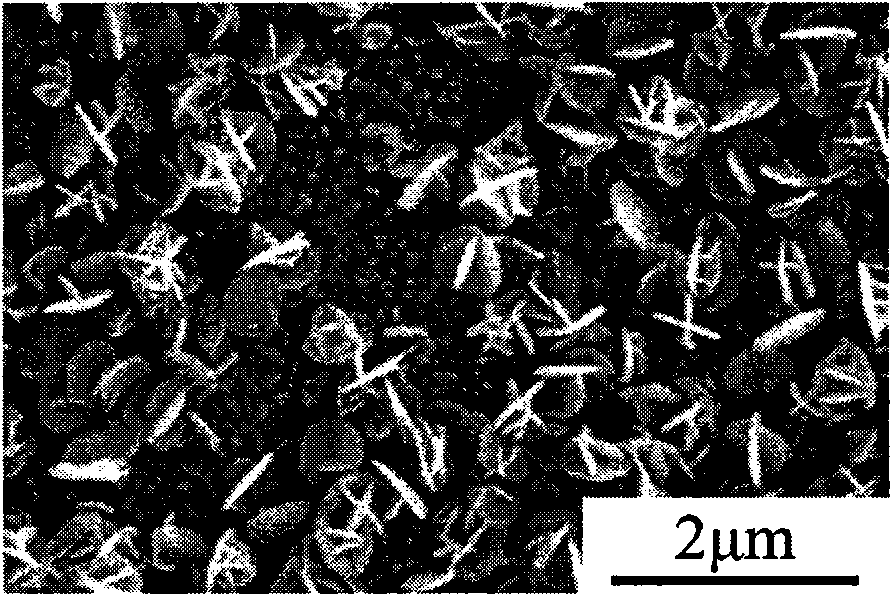

Embodiment 1

[0024] a) Substrate pretreatment: The transparent conductive glass substrate (FTO glass) is fully cleaned in an ultrasonic cleaner with toluene, acetone and ethanol in sequence, rinsed with deionized water, soaked in ethanol and stored for later use.

[0025] b) 0.1mol / L of Cu(Ac) 2 The analytically pure powder was dissolved in 10ml of deionized water, fully stirred in a 100ml beaker with a magnetic stirrer, and then 10ml of 0.1mol / L disodium ethylenediaminetetraacetic acid (EDTA-2Na) solution was added to clear Cu(Ac ) 2 In the solution, the solution was continuously stirred to obtain a completely clear and transparent blue solution A.

[0026] c) Add NaOH solution with a concentration of 6 mol / L to solution A, adjust the pH value to 10, and obtain solution B.

[0027] d) Slowly add 10 ml of 0.1 mol / L thioacetamide solution to solution B, add deionized water to 80 ml, and stir evenly to obtain clear and transparent solution C.

[0028] e) Dry the pretreated substrate with ...

Embodiment 2

[0031] a) Substrate pretreatment: The transparent conductive glass substrate (FTO glass) is fully cleaned in an ultrasonic cleaner with toluene, acetone and ethanol in sequence, rinsed with deionized water, soaked in ethanol and stored for later use.

[0032] b) A certain amount of 0.1mol / L Cu(Ac) 2 The analytically pure powder was dissolved in 10ml of deionized water, fully stirred in a 100ml beaker with a magnetic stirrer, and then 10ml of 0.1mol / L disodium ethylenediaminetetraacetic acid (EDTA-2Na) solution was added to clear Cu(Ac ) 2 In the solution, the solution was continuously stirred to obtain a completely clear and transparent blue solution A.

[0033] c) Add NaOH solution with a concentration of 6 mol / L to solution A, adjust the pH value to 8, and obtain solution B.

[0034] d) Slowly add 10 ml of 0.1 mol / L thioacetamide solution to solution B, add deionized water to 80 ml, and stir evenly to obtain clear and transparent solution C.

[0035] e) Dry the pretreated...

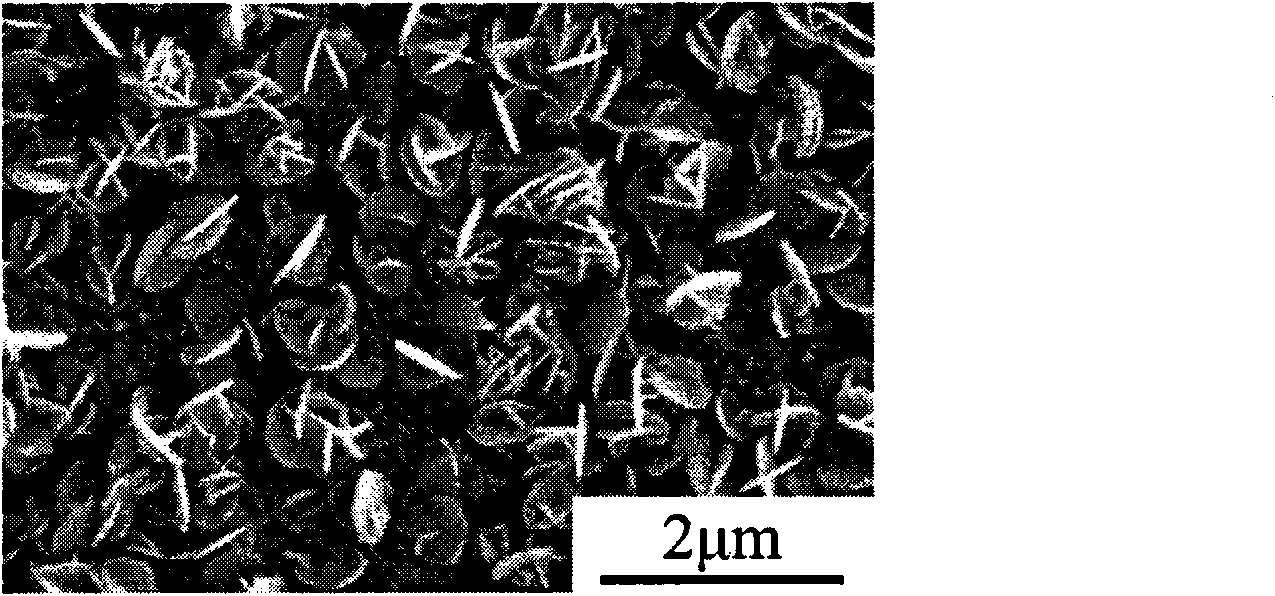

Embodiment 3

[0038] a) Substrate pretreatment: The transparent conductive glass substrate (FTO glass) is fully cleaned in an ultrasonic cleaner with toluene, acetone and ethanol in sequence, rinsed with deionized water, soaked in ethanol and stored for later use.

[0039] b) A certain amount of 0.1mol / L Cu(Ac) 2The analytically pure powder was dissolved in 10ml of deionized water, fully stirred in a 100ml beaker with a magnetic stirrer, and then 10ml of 0.1mol / L disodium ethylenediaminetetraacetic acid (EDTA-2Na) solution was added to clear Cu(Ac ) 2 In the solution, the solution was continuously stirred to obtain a completely clear and transparent blue solution A.

[0040] c) Adding HCl solution with a concentration of 3 mol / L to Solution A to adjust the pH value to 6 to obtain Solution B.

[0041] d) Slowly add 10 ml of 0.1 mol / L thioacetamide solution to solution B, add deionized water to 80 ml, and stir evenly to obtain clear and transparent solution C.

[0042] e) Dry the pretreate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com