Preparation method of self-assembled folded rGO composite membrane

A self-assembly, composite membrane technology, applied in the field of membrane separation, can solve the problems of low flux, long diffusion path, large resistance, etc., and achieve the effects of simple preparation process, uniform and dense surface, and short film formation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

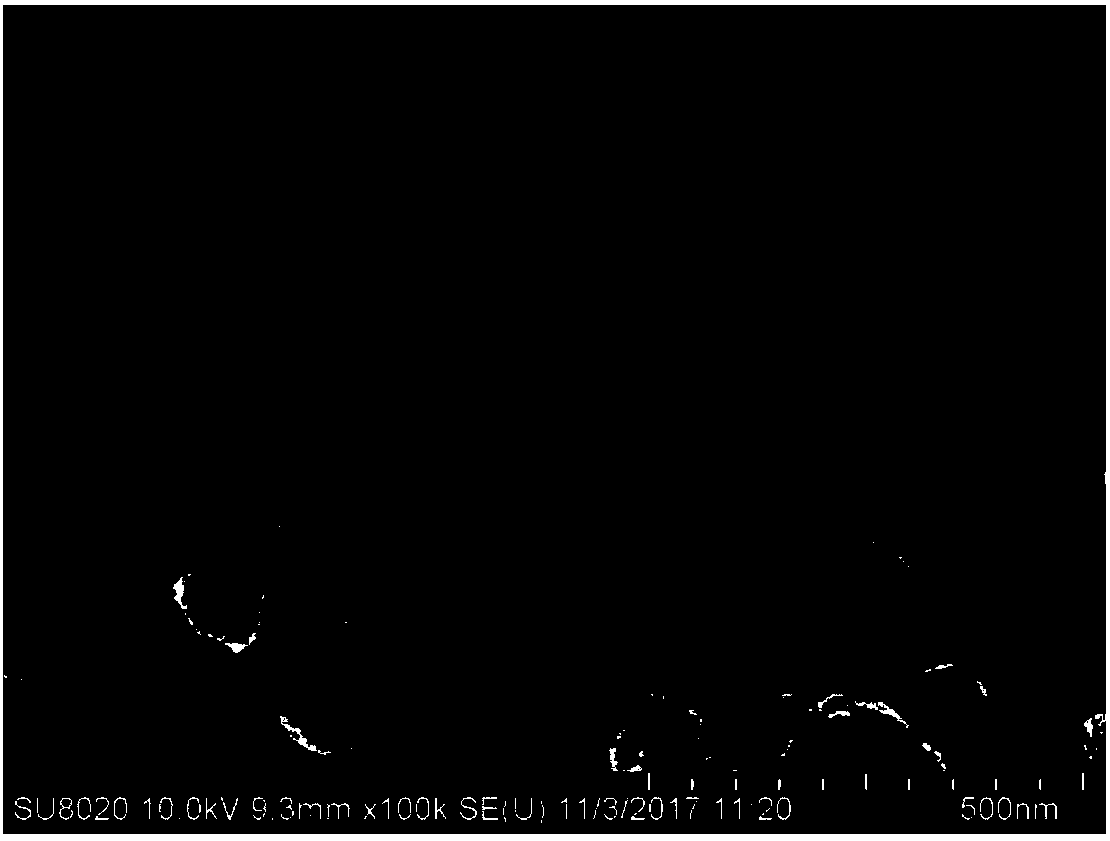

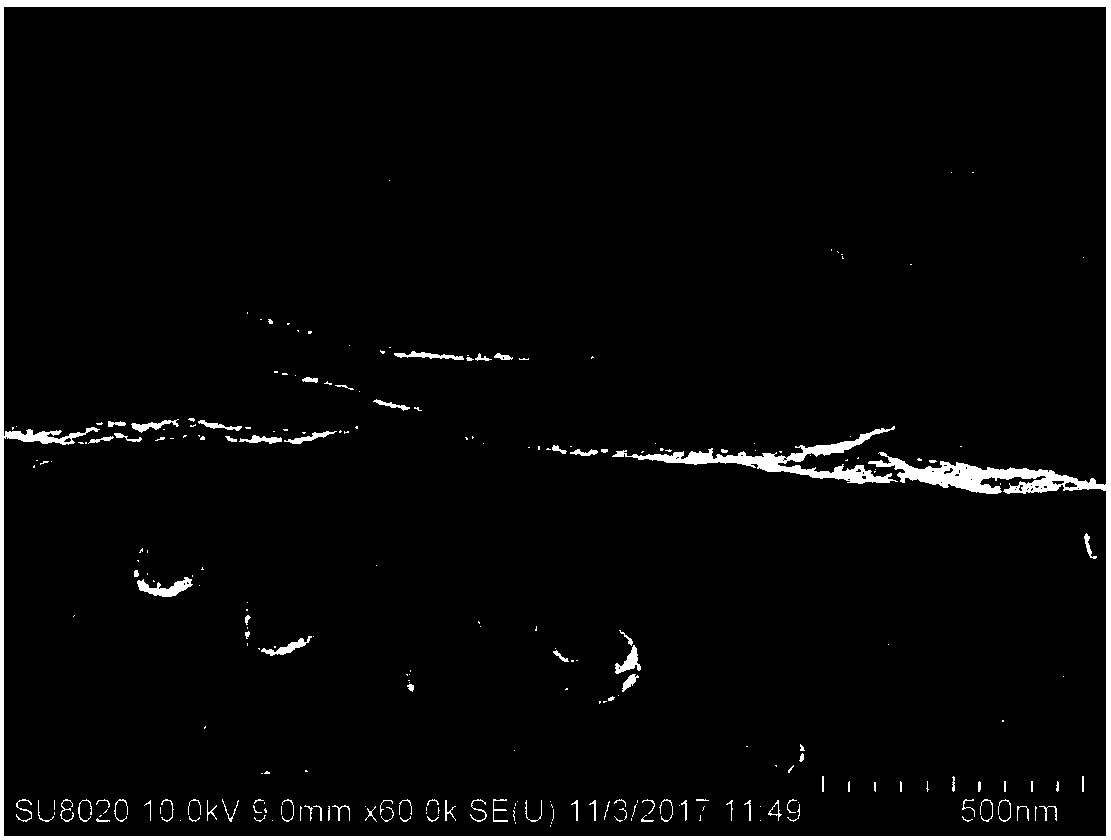

Image

Examples

Embodiment 1

[0045] The commercial porous membrane used is alumina material in the form of a tubular ultrafiltration membrane with a membrane pore size of 0.1-1.0 μm and a membrane area of 10 cm 2 , the selected organic solvent is DMF, and the crosslinking agent A is glutaraldehyde.

[0046] Preparation method of self-assembled wrinkled rGO composite membrane

[0047] (1) Rinse the ceramic substrate four times with deionized water, ultrasonically treat it for 3 minutes, then rinse it four times with deionized water, soak it in a water bath at 90°C for 2 hours, and put it in an oven to dry to remove surface impurities and microorganisms;

[0048] (2) Tris3.025g, dopamine 1.000g, copper sulfate 0.624g and 30%H 2 o 2 1mL was dissolved in 500mL deionized water successively to deposit dopamine on the pretreated porous base film to form a polydopamine-modified layer with rich amine groups, and the deposition time was 3h;

[0049] (3) Suction filter GO onto the porous base membrane with rich...

Embodiment 2

[0056] The commercial porous membrane used is alumina material in the form of a tubular ultrafiltration membrane with a membrane pore size of 0.1-1.0 μm and a membrane area of 10 cm 2 , the selected organic solvent is DMF, the polyelectrolyte is PEI, and the crosslinking agents A and B are glutaraldehyde.

[0057] Preparation method of self-assembled wrinkled rGO composite membrane

[0058] (1) Rinse the ceramic substrate four times with deionized water, ultrasonically treat it for 3 minutes, then rinse it four times with deionized water, soak it in a water bath at 90°C for 2 hours, and put it in an oven to dry to remove surface impurities and microorganisms;

[0059] (2) Tris3.025g, dopamine 1.000g, copper sulfate 0.624g and 30%H 2 o 2 1mL was dissolved in 500mL deionized water successively to deposit dopamine on the pretreated porous base film to form a polydopamine-modified layer with rich amine groups, and the deposition time was 3h;

[0060] (3) Suction filter GO ont...

Embodiment 3

[0068] The commercial porous membrane used is alumina material in the form of a tubular ultrafiltration membrane with a membrane pore size of 0.1-1.0 μm and a membrane area of 10 cm 2 .

[0069] Preparation method of self-assembled wrinkled rGO composite membrane

[0070] (1) Rinse the ceramic substrate four times with deionized water, ultrasonically treat it for 3 minutes, then rinse it four times with deionized water, soak it in a water bath at 90°C for 2 hours, and put it in an oven to dry to remove surface impurities and microorganisms;

[0071] (2) Tris3.025g, dopamine 1.000g, copper sulfate 0.624g and 30%H 2 o 2 1mL was dissolved in 500mL deionized water successively to deposit dopamine on the pretreated porous base film to form a polydopamine-modified layer with rich amine groups, and the deposition time was 3h;

[0072] (3) Suction filter GO onto the porous base membrane with rich amine groups, the concentration of graphene oxide is 0.01g / L, and the assembly time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com