Method for separating and purifying functional protein in plasma

A technology for separation and purification of plasma proteins, applied in the field of bioengineering, which can solve the problems of huge differences in protein types and contents, failure to overcome the Cohn method, high cost of affinity media, etc., and achieve easy industrial scale-up, low cost, and convenient solvent recovery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1 Purification of Human Plasma Functional Proteins

[0052] (1) Two-phase solid-liquid separation treatment

[0053] Prepare 40%K 2 HPO 4 solution, adjusted to pH 7.0 with phosphoric acid, at room temperature (24°C), weigh 2.5 g of 40% K with pH 7.0 2 HPO 4 Solution, 0.8g water, 1.0g human plasma, 0.7g ethanol, stir and mix well, stand at 4°C for 2 hours to form a two-phase aqueous phase, collect the upper phase extract, protein concentration analysis shows that the upper phase extract is rich in IgG and albumin, the yields were 81.18% and 87.61%.

[0054] (2) Hydrophobic chromatography purification

[0055] After adjusting the pH of the upper layer extract in step (1) to 6.0, carry out vacuum distillation to recover ethanol, the distillation temperature is 37°C, the distillation time is 30min, and the ethanol content in the upper layer extract is less than 10%.

[0056] Phenyl Sepharose 6FF TM Pack the hydrophobic medium into the XK16 / 20 column, the colu...

Embodiment 2

[0066] Example 2 Separation and Purification of Porcine Plasma Functional Proteins

[0067] (1) Two-phase solid-liquid separation treatment

[0068] At room temperature (24°C), take 1,000ml of fresh pig blood, centrifuge twice at 3000r / min for 15min, remove blood cells, take the supernatant, and dilute it with 0.9% normal saline to obtain a pig plasma solution. Weigh 20gK 2 HPO 4Dissolve in 46g of water, slowly add 20g of plasma and 14g of ethanol, stir well, and measure the pH of the system to be 9.6. After standing at room temperature for 2 hours, an aqueous two-phase phase was formed, and the upper phase extract was collected. Protein concentration analysis showed that the upper phase extract was rich in IgG and albumin, and the yields were 95.7% and 93.0%, respectively.

[0069] (2) Hydrophobic chromatography purification

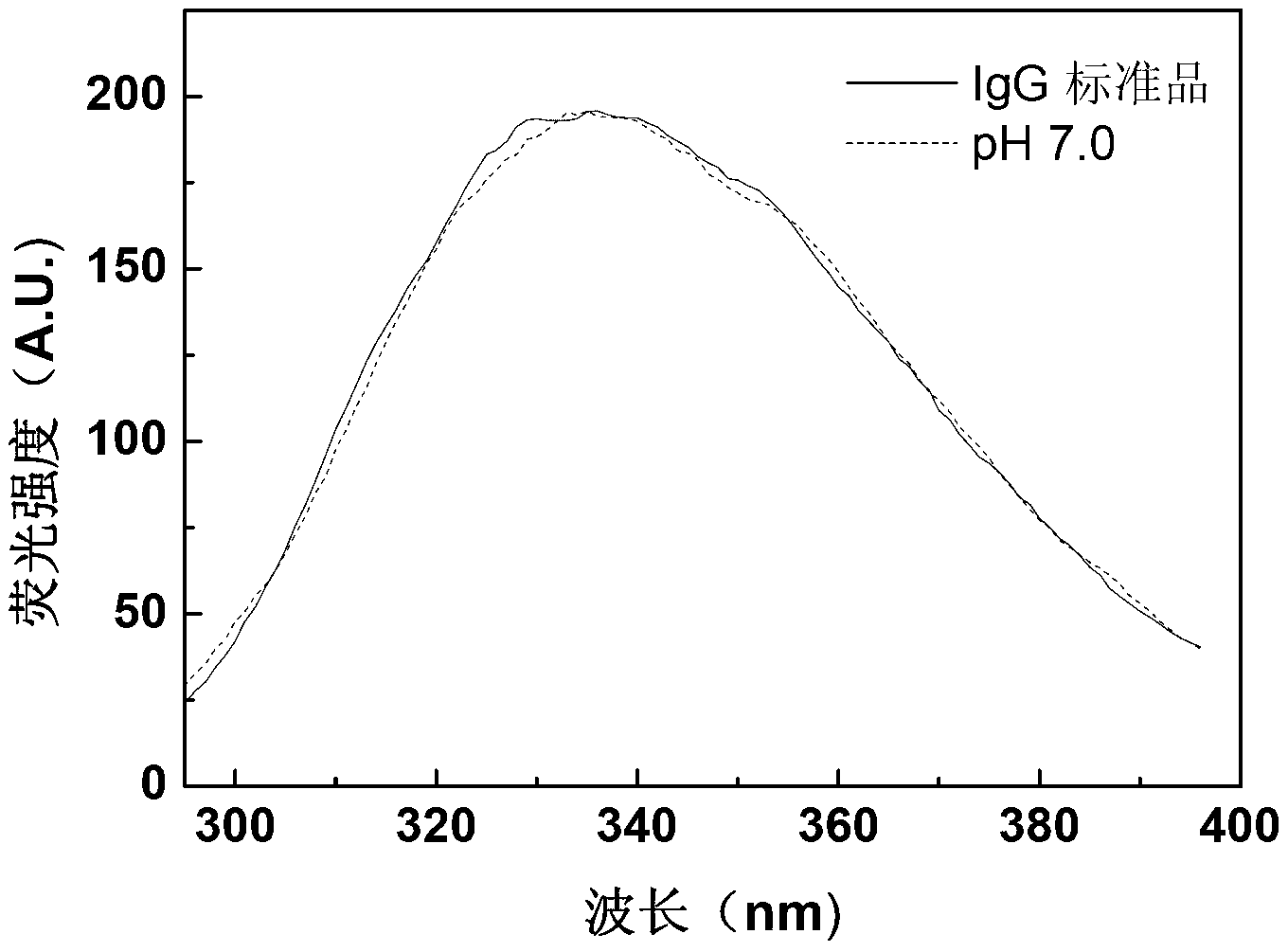

[0070] Adjust the pH of the upper layer extract in step (1) to 7.0, then carry out vacuum distillation to recover ethanol, the distillation tempera...

Embodiment 3

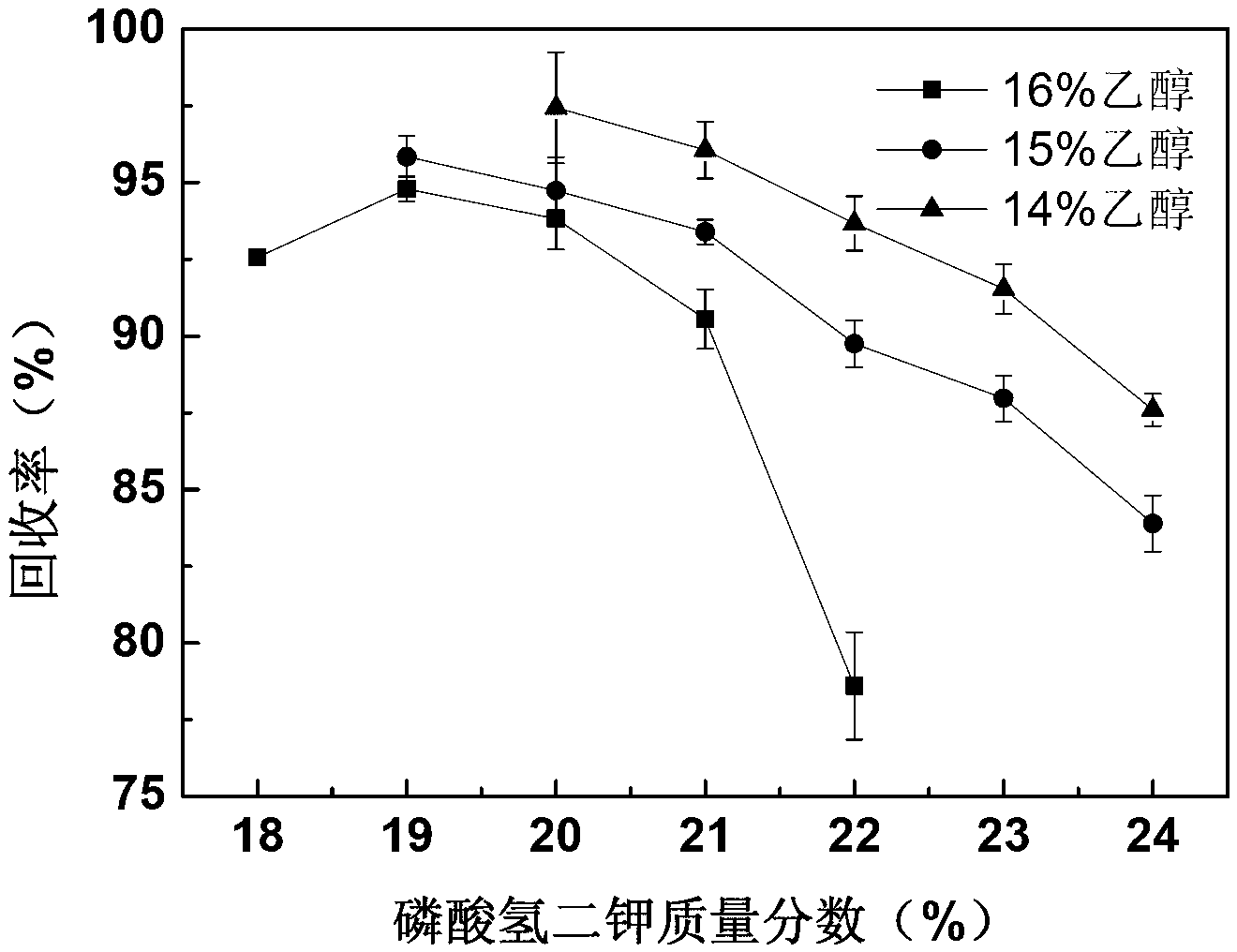

[0078] Example 3 Effect of Organic Solvent and Salt Concentration on the Yield of IgG in Two-phase Extraction

[0079] Select different concentrations of dipotassium hydrogen phosphate, sodium citrate and sodium carbonate with different concentrations of ethanol and appropriate amount of water to form a two-phase system, the pH of the system is 7.0, and investigate the organic solvent in different two-phase systems. , The effect of salt concentration on the extraction yield of human IgG. In all systems, the amount of IgG added was 1 mg, and the standing time was 8 hours. The upper phase extract was collected, and the protein content in it was determined by Bradford method, and the IgG recovery (%) was calculated.

[0080] In the dipotassium hydrogen phosphate-ethanol system, the final concentration of ethanol is 14-16% (w / w), the concentration of dipotassium hydrogen phosphate is 18-24% (w / w), and the temperature is 15°C; IgG recovery rate results such as image 3 shown.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com