Patents

Literature

40results about How to "With cleaner production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for modifying natural zeolite powder

InactiveCN101569852AGood modification effectImprove exchange capacityOther chemical processesAluminium silicatesChemistryRaw water

The invention discloses a method for modifying natural zeolite powder, which uses an inorganic alkali and sodium chloride as modification medicaments to modify the natural zeolite powder by a solution soaking method. The method comprises the following steps: firstly, mixing the natural zeolite powder and the sodium chloride, soaking the mixture in sodium hydroxide solution for an adsorption reaction, washing the product of the absorption reaction with water till the pH value of the product is neutral after the reaction is finished; and secondly, drying the product of the absorption reaction to obtain modified zeolite powder. The modification method of the invention avoids the use of organic acids and the production of toxic and harmful substances, effectively prevents low-concentration ammonian pollution of the raw water of drinking water without changing the prior drinking water treatment process, does not change the pH value of the raw water after being used, does not exert influence on the subsequent processes, and improves the ammonian adsorption performance of the modified zeolite powder by 30 to 80 percent.

Owner:JINAN UNIVERSITY

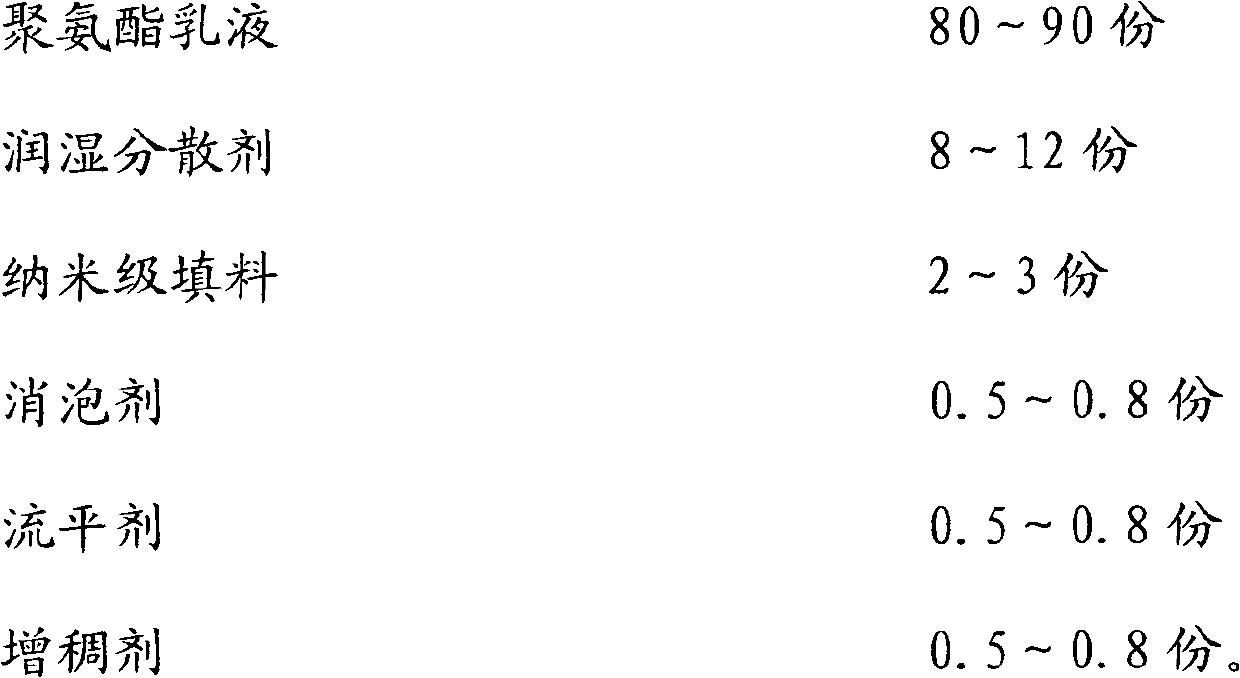

Aqueous normal temperature curing peelable paint and preparation method of paint

ActiveCN102827537AWide variety of sourcesWith cleaner productionPolyurea/polyurethane coatingsEmulsionFilling materials

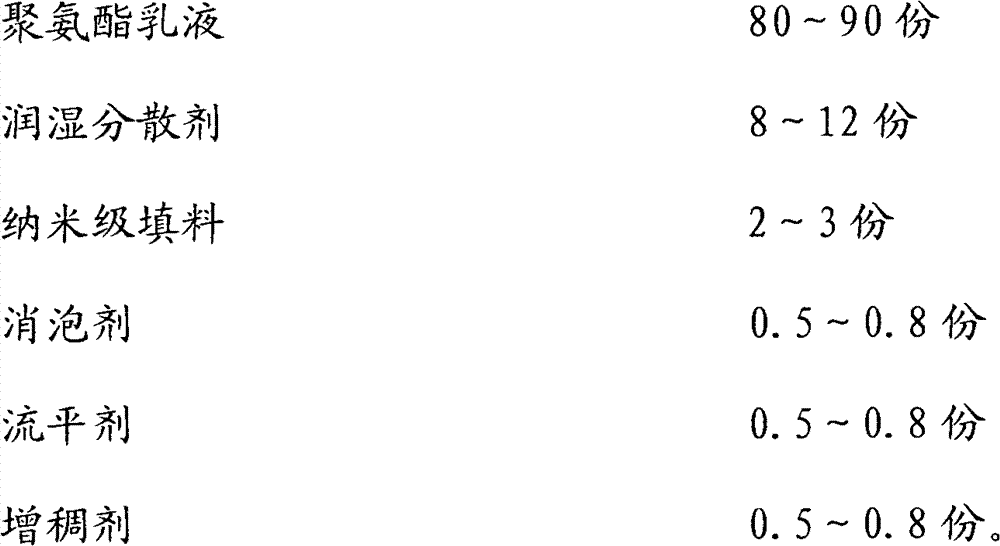

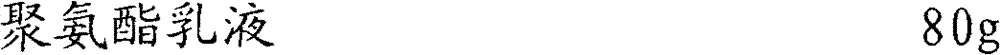

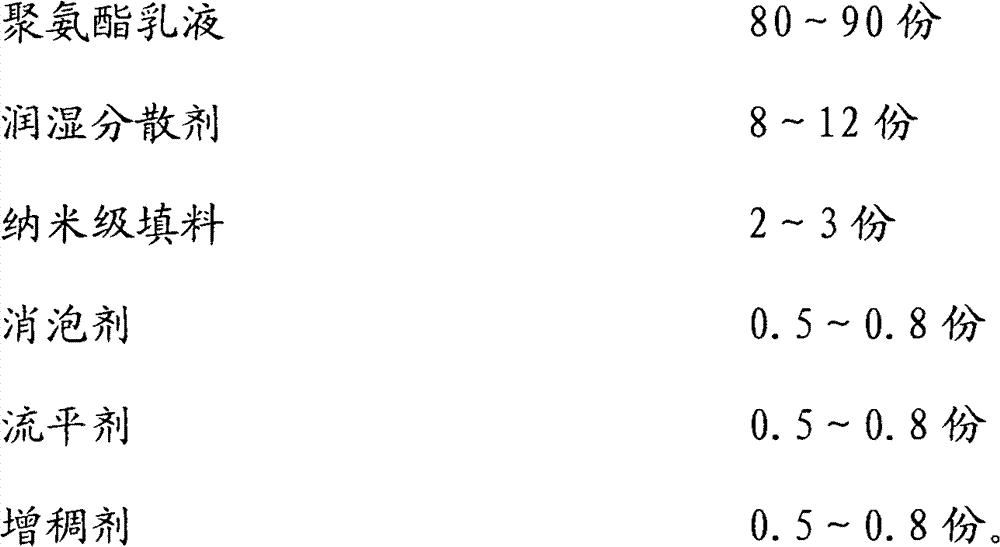

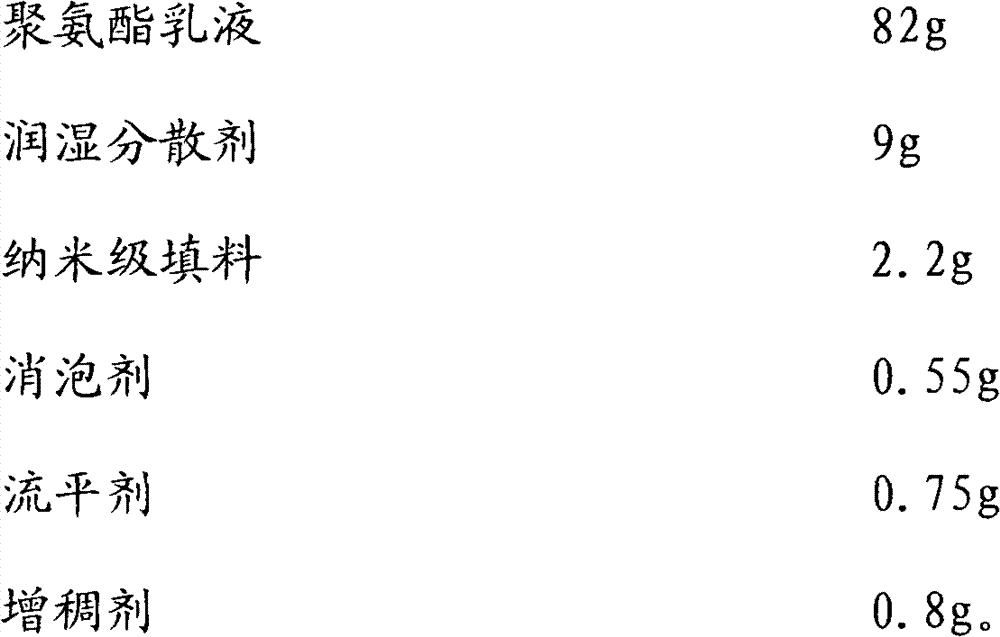

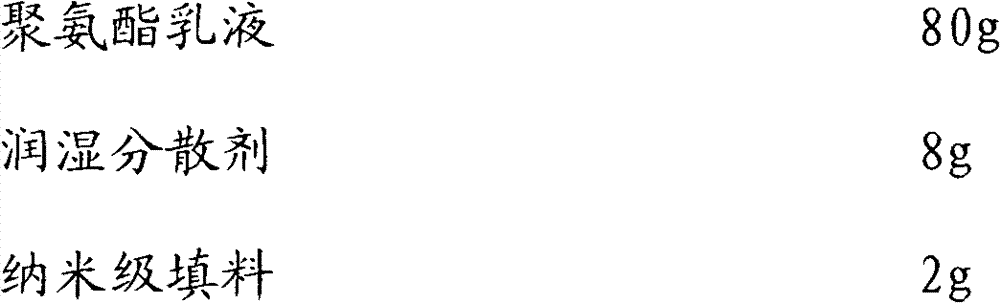

The invention discloses aqueous normal temperature curing peelable paint, which is applicable to the technical field of metal surface treatment and consists of the following ingredients in parts by weight: 80 to 90 parts of polyurethane emulsion, 8 to 12 parts of wetting dispersing agents, 2 to 3 parts of nanometer level filling materials, 0.5 to 0.8 parts of defoaming agents, 0.5 to 0.8 parts of flatting agents and 0.5 to 0.8 parts of thickening agents. The aqueous normal temperature curing peelable paint has the advantages that on the basis of the polyurethane emulsion film forming mechanism, through major ingredient screening and compounding of polyurethane emulsion, other film forming auxiliary agents and the like, the aqueous normal temperature curing peelable paint adopting the polyurethane emulsion as major film forming agents is developed. The product has the characteristics that nontoxicity and harmlessness are realized, the pollution is avoided, the operation is simple, the raw material resources are wide, the price is low, the clean production is realized, and the like.

Owner:合肥华清高科表面技术股份有限公司

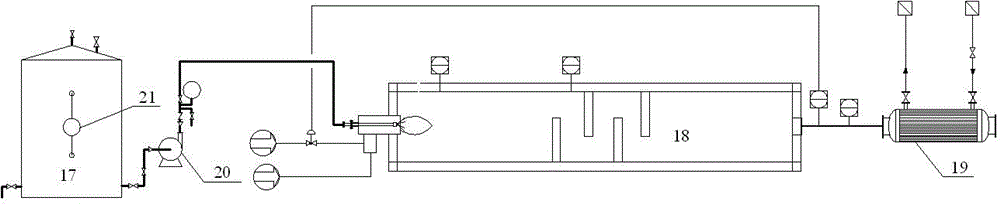

Desulfurization method for fume gas containing low-concentration sulfur dioxide

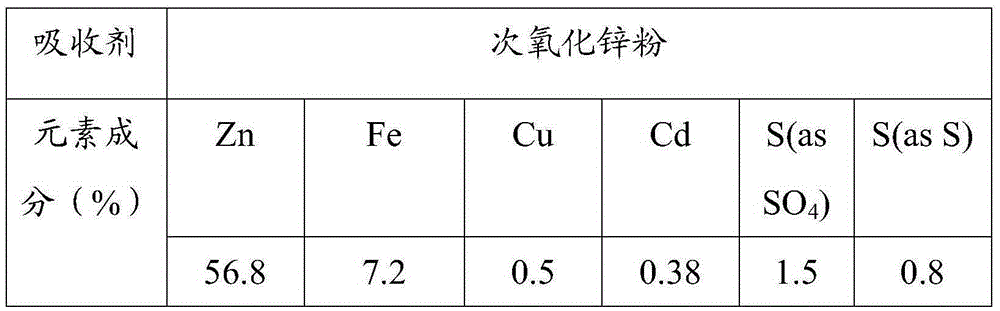

ActiveCN103506001ASolve the blockageRealize pollution control without pollutionZinc sulatesDispersed particle separationLiquid wasteElectrolysis

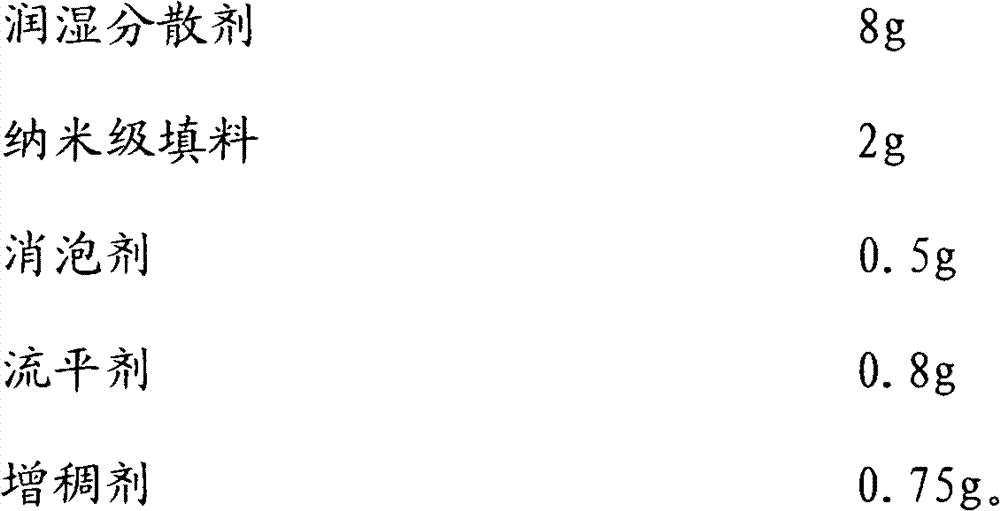

The invention discloses a desulfurization method for fume gas containing low-concentration sulfur dioxide. The desulfurization method comprises the following steps: making zinc hypoxide powder into absorption slurry with a predetermined concentration, making the absorption slurry reversely contact the fume gas containing low-concentration sulfur dioxide in a reverse-injection material feeding pipe of a dynamic wave washing tower, conversing sulfur dioxide into zinc sulfite by utilizing the reactions between zinc oxide and sulfur dioxide, then decomposing zinc sulfite into zinc sulfate through an electrolysis waste liquid, recycling the sulfur dioxide generated by the decomposition into a sulfuric acid producing system, and finally filtering so as to obtain zinc sulfate for leaching.

Owner:云南云铜锌业股份有限公司

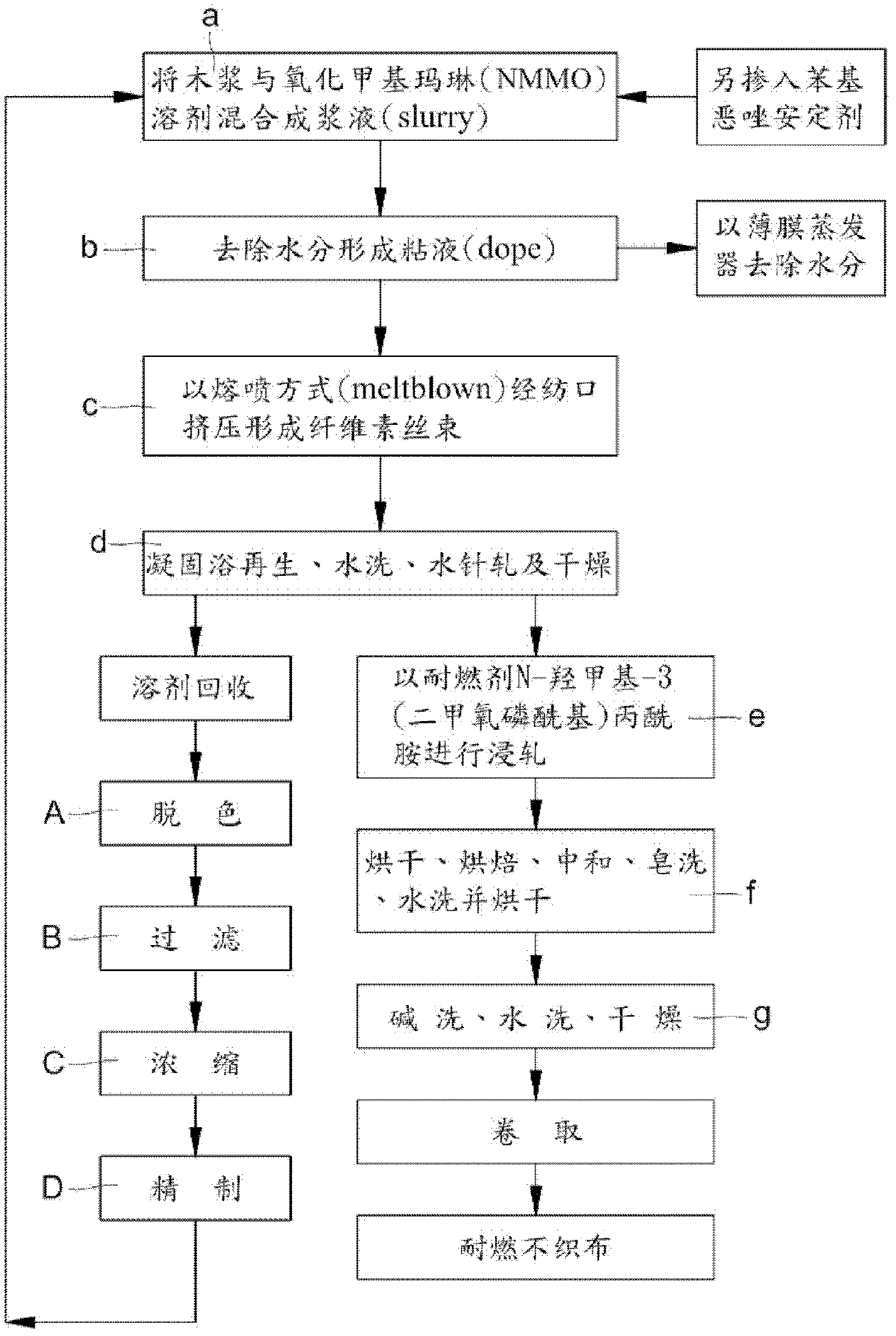

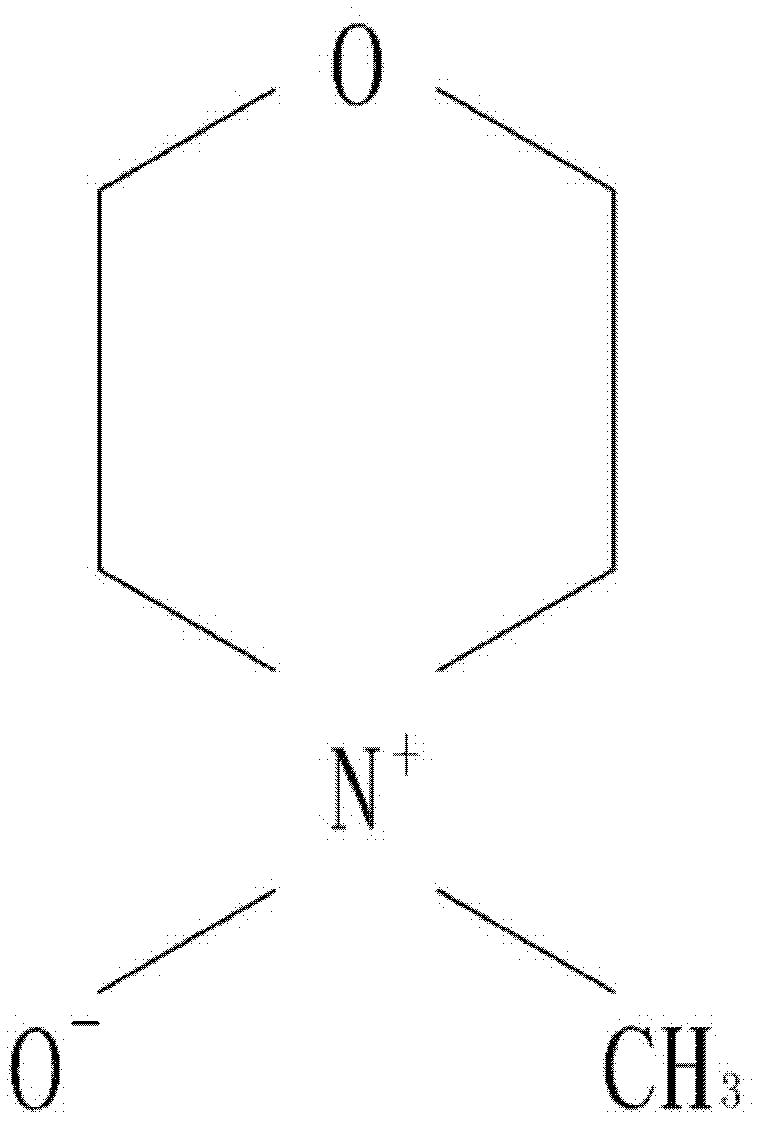

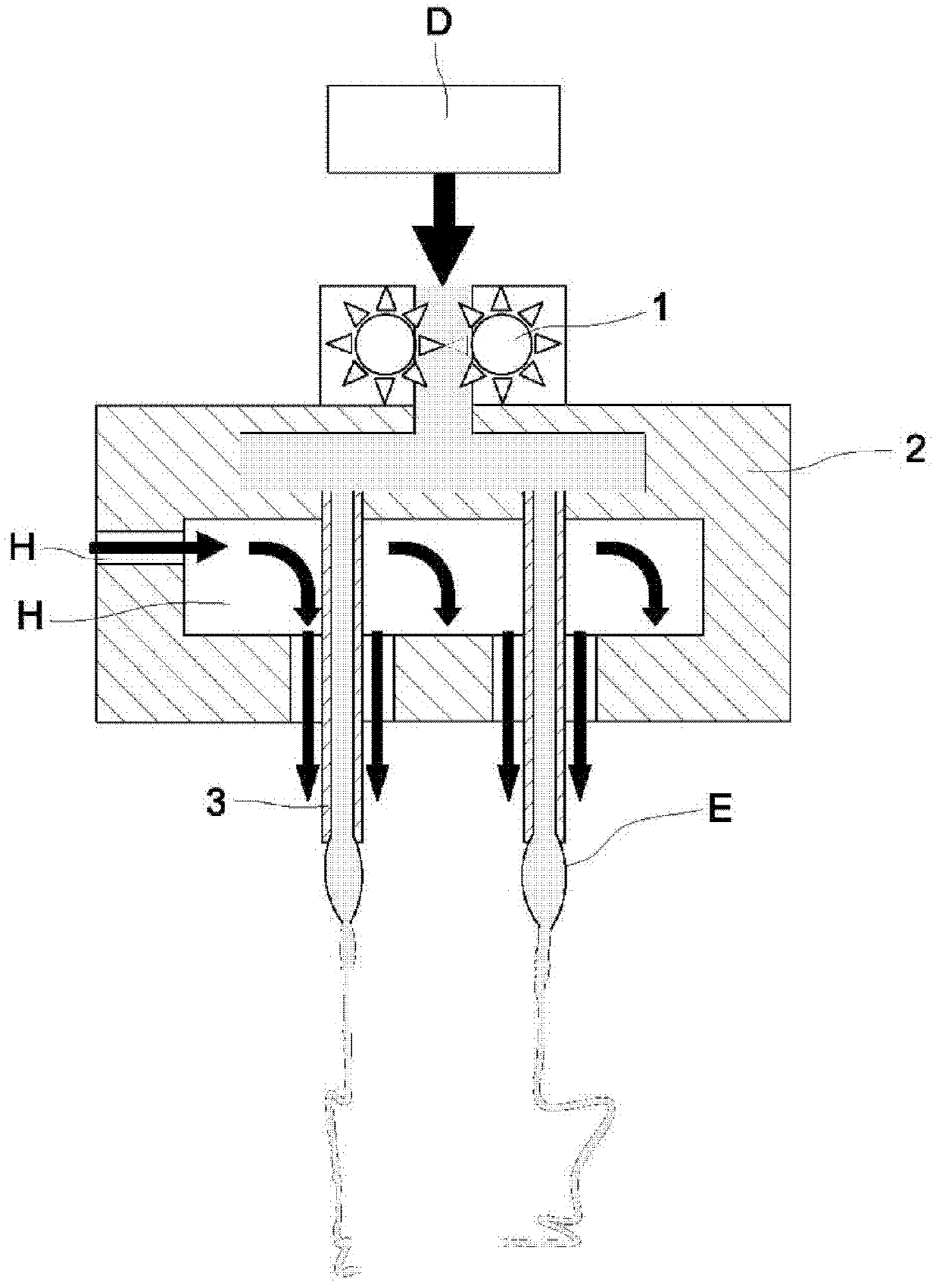

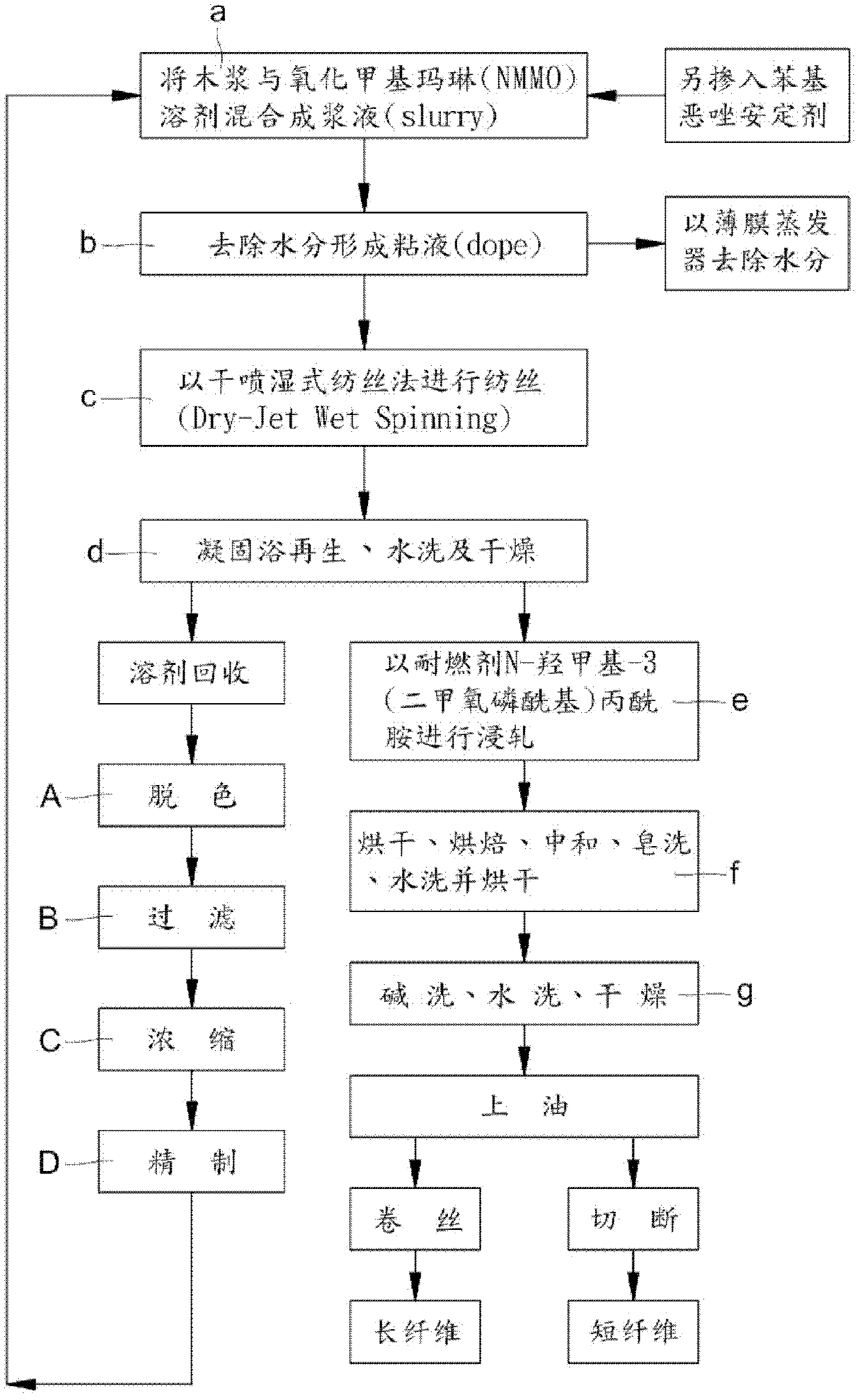

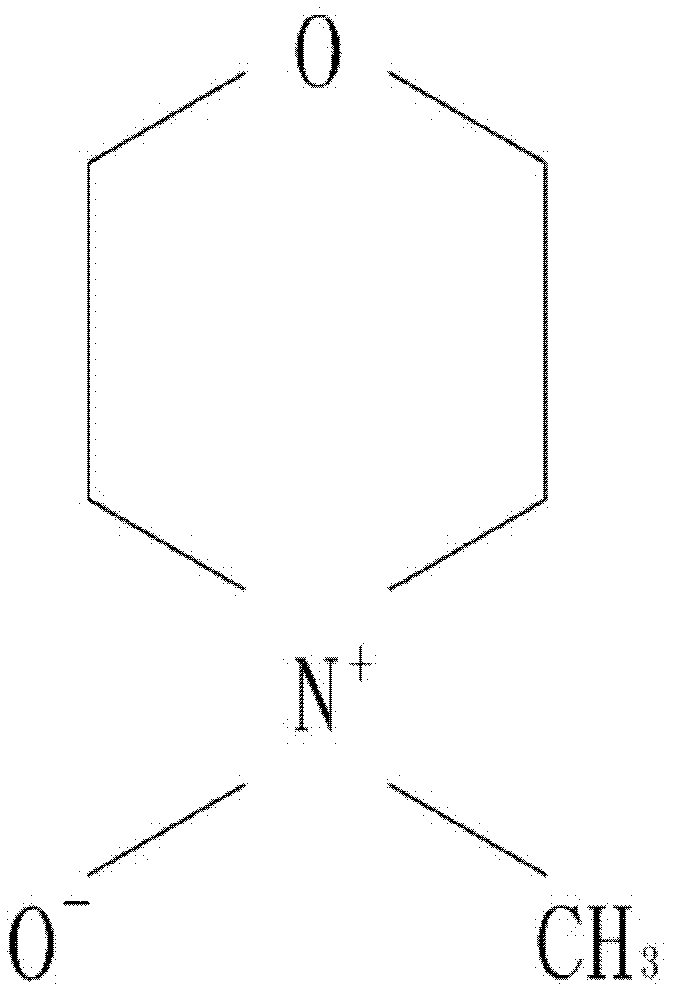

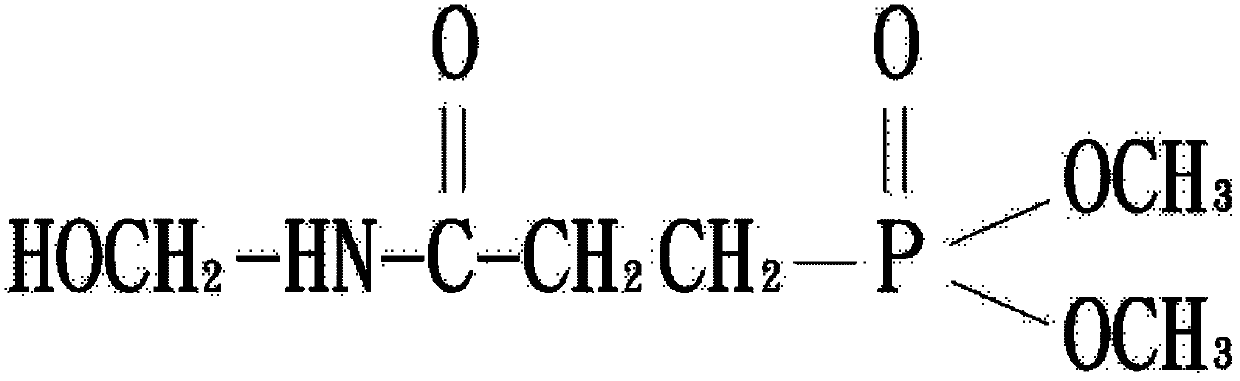

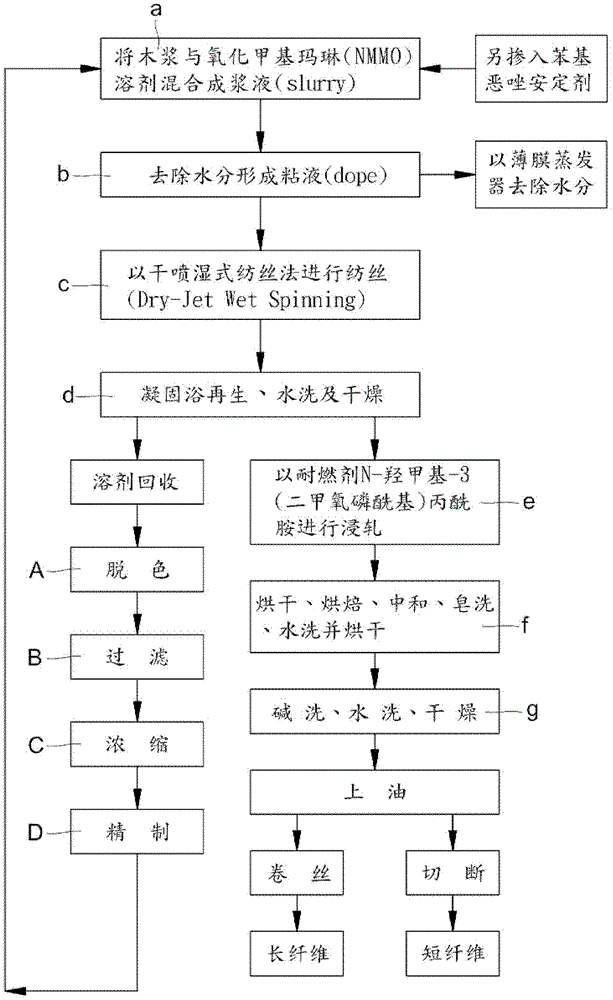

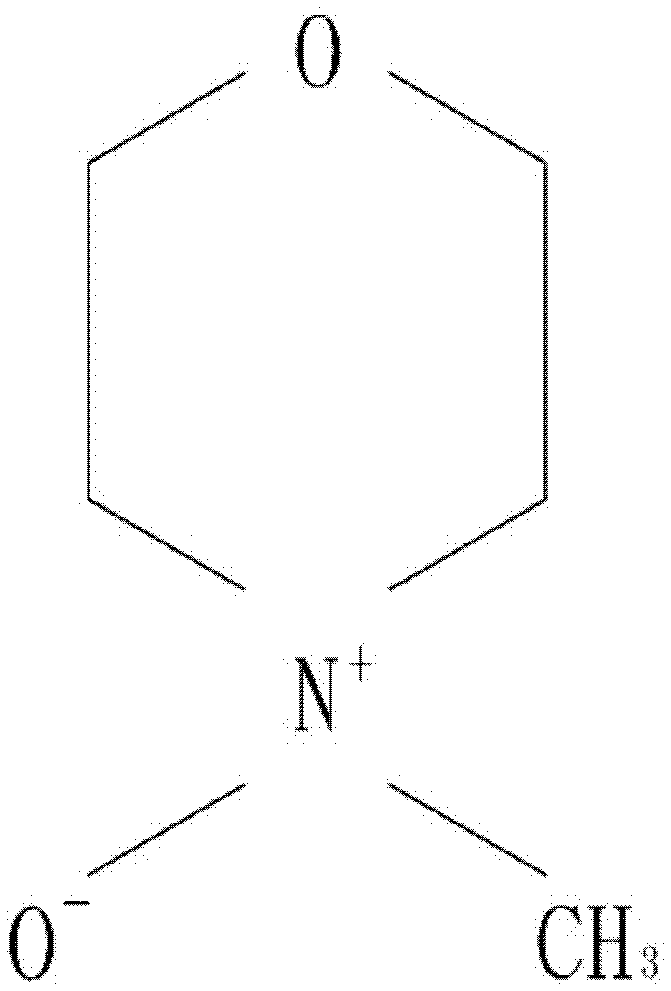

Preparation method for natural cellulose melt-blown non-woven fabric with burning-resistant function

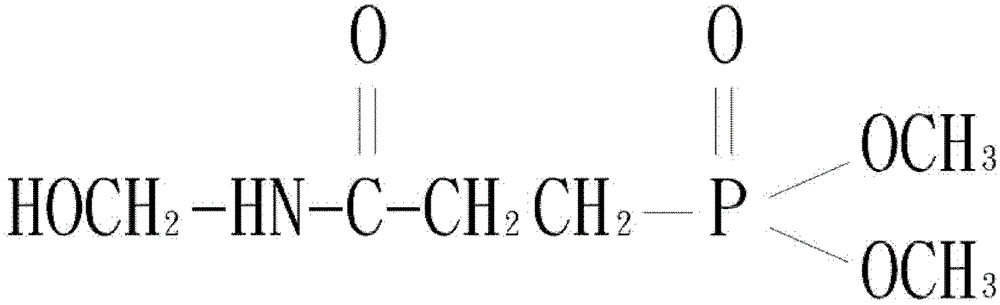

ActiveCN103290682ALow costNo pollutionMonocomponent cellulose artificial filamentDry-cleaning apparatus for textilesCelluloseMorpholine

The invention relates to a preparation method for a natural cellulose melt-blown non-woven fabric with a burning-resistant function. The preparation method comprises the following steps of: mixing wood pulp with a methyl morpholine oxide solvent to form a pulp solution; removing water by a vacuum film evaporator to form a spinning adhesive solution; extruding the adhesive solution from a spinning hole in a melt-blowing way to form a cellulose tow; solidifying, regenerating, washing by water, rolling by a water needle and drying to prepare a natural cellulose non-woven fabric; carrying out pad-rolling on the natural cellulose non-woven fabric and a burning-resistant agent namely N-hydroxymethyl-3-(dimethoxy phosphoryl) propanamide; drying, baking, neutralizing, soaping, washing by the water and drying in sequence; finally washing by alkali, washing by water, drying and rolling to prepare the natural cellulose non-woven fabric with the long-acting burning-resistant function. According to the preparation method, the natural cellulose non-woven fabric and the burning-resistant agent namely N-hydroxymethyl-3-(dimethoxy phosphoryl) propanamide can produce a special crosslinking reaction in the preparation process, the burning-resistant effect of the natural cellulose melt-blown non-woven fabric completely conforms with the test standards of ASTM (American Society for Testing Material) D6413-1999 and ASTM D2863-1995, and the natural cellulose melt-blown non-woven fabric can be naturally decomposed after being used and thrown away, so that the natural cellulose melt-blown non-woven fabric becomes an environment-friendly material harmless to the natural environment.

Owner:张文波

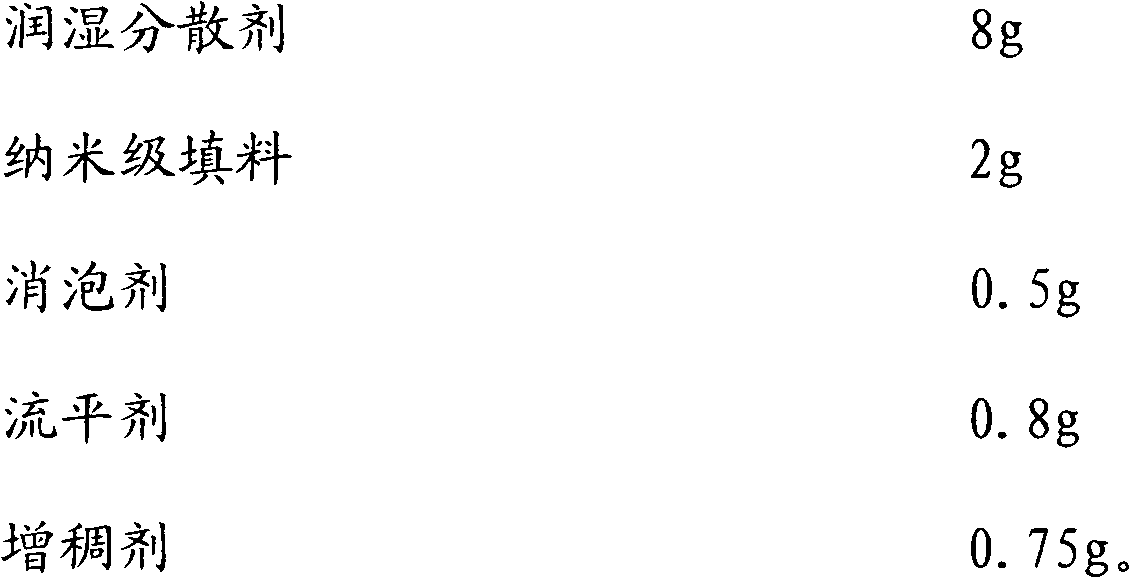

Water-based normal-temperature-curable peelable paint for safekeeping and protection of instrument and equipment

InactiveCN102816508AWide variety of sourcesWith cleaner productionPolyurea/polyurethane coatingsWater basedEngineering

The invention discloses a water-based normal-temperature-curable peelable paint which is applicable to the safekeeping and protection of instrument and equipment. The water-based normal-temperature-curable peelable paint for the safekeeping and protection of instrument and equipment comprises the following raw materials in parts by weight: 80-90 parts of polyurethane emulsion, 8-12 parts of wetting dispersant, 2-3 parts of nano filler, 0.5-0.8 part of defoaming agent, 0.5-0.8 part of leveling agent and 0.5-0.8 part of thickener. The water-based normal-temperature-curable peelable paint product disclosed by the invention fundamentally contains no organic solvent component, is environment-friendly and pollution-free, is short in film-forming time and has good leveling property. The product is convenient to construct, the formed film is uniform, the bonding force exerted on the basal body is moderate, and the paint can be peeled easily. The detection through a test shows that when the coating thickness is 0.13-0.14mm (coated twice), the average tensile strength of the coating is up to 9.51Mpa, the average elongation at break is up to 274.54%, and the peeling property is the best.

Owner:合肥华清高科表面技术股份有限公司

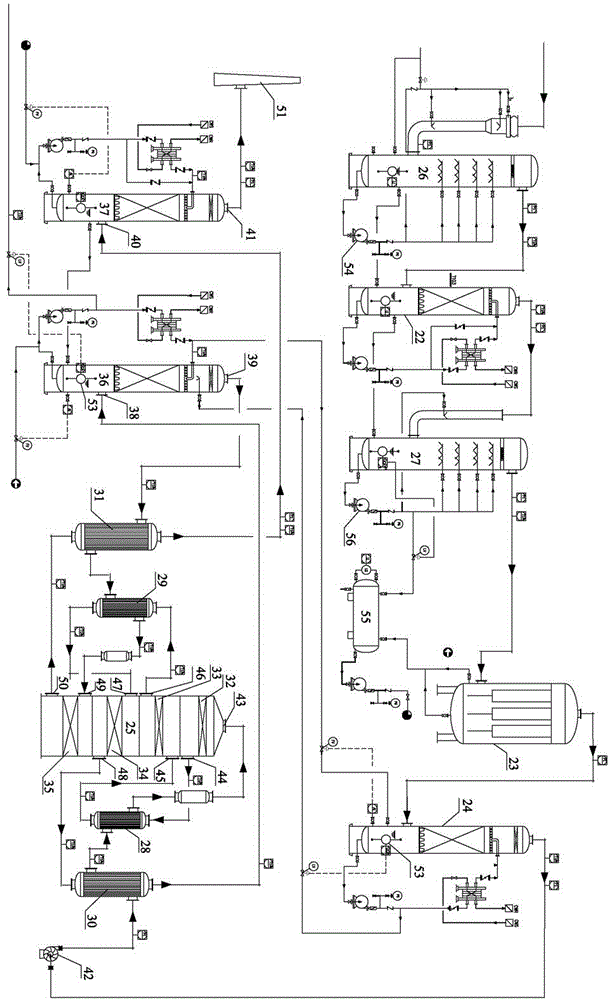

Acetylene gas purification device and process thereof

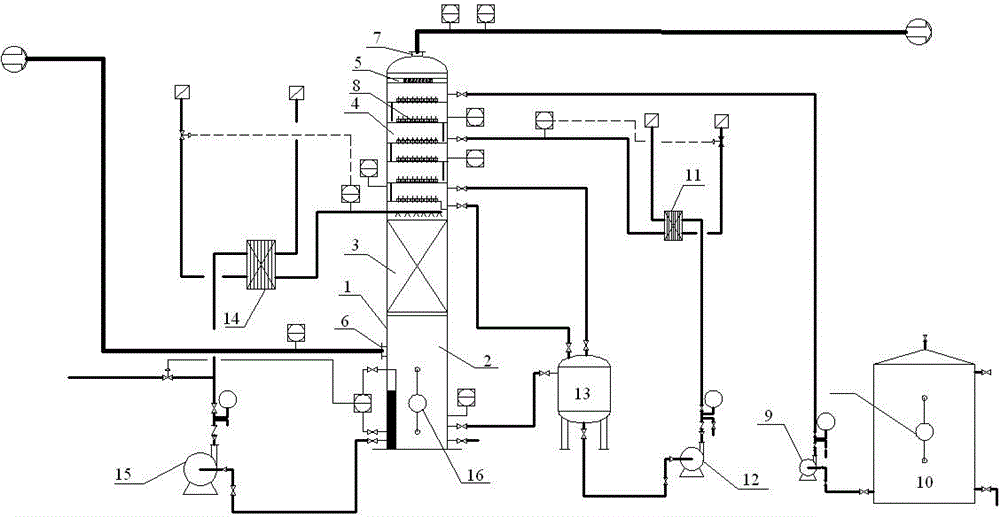

ActiveCN104548902ASolve the shortcomings of low temperature resistance and easy deformationSelf-cleaningSulfur compoundsDispersed particle separationCooling towerFlue gas

The invention relates to an acetylene gas purification device and a process thereof. The device comprises a concentrated sulfuric acid acetylene purification system, a waste sulfuric acid pyrolysis purification system and a flue gas purification acid production system, wherein the concentrated sulfuric acid acetylene purification system comprises a purification tower; an acid storage section, a packing section, a bubble cap section and a demisting section are sequentially arranged in the purification tower from bottom to top; the waste sulfuric acid pyrolysis purification system comprises a waste sulfuric acid storage tank, a pyrolysis furnace and a waste heat boiler which are sequentially communicated with one another; the waste sulfuric acid storage tank is communicated with the acid storage section; and the flue gas purification acid production system comprises a flue gas washing tower, a flue gas cooling tower, a water mist separator, a sulfuric acid drying tower, a heat exchanger, a sulfur dioxide conversion tower and an absorbing tower. According to organic combination of the three systems, the byproduct such as waste sulfuric acid which is difficult to treat is avoided in the system, the sulfuric acid is recycled in the novel system, and the normal operation requirement can be met by supplementing a small amount of the sulfuric acid only. The device disclosed by the invention has typical clean production characteristic and also has the advantages of safety, reliability, environment friendliness, economical efficiency, good acetylene gas purification effect and the like.

Owner:HANGZHOU ZHONGHAO TECH

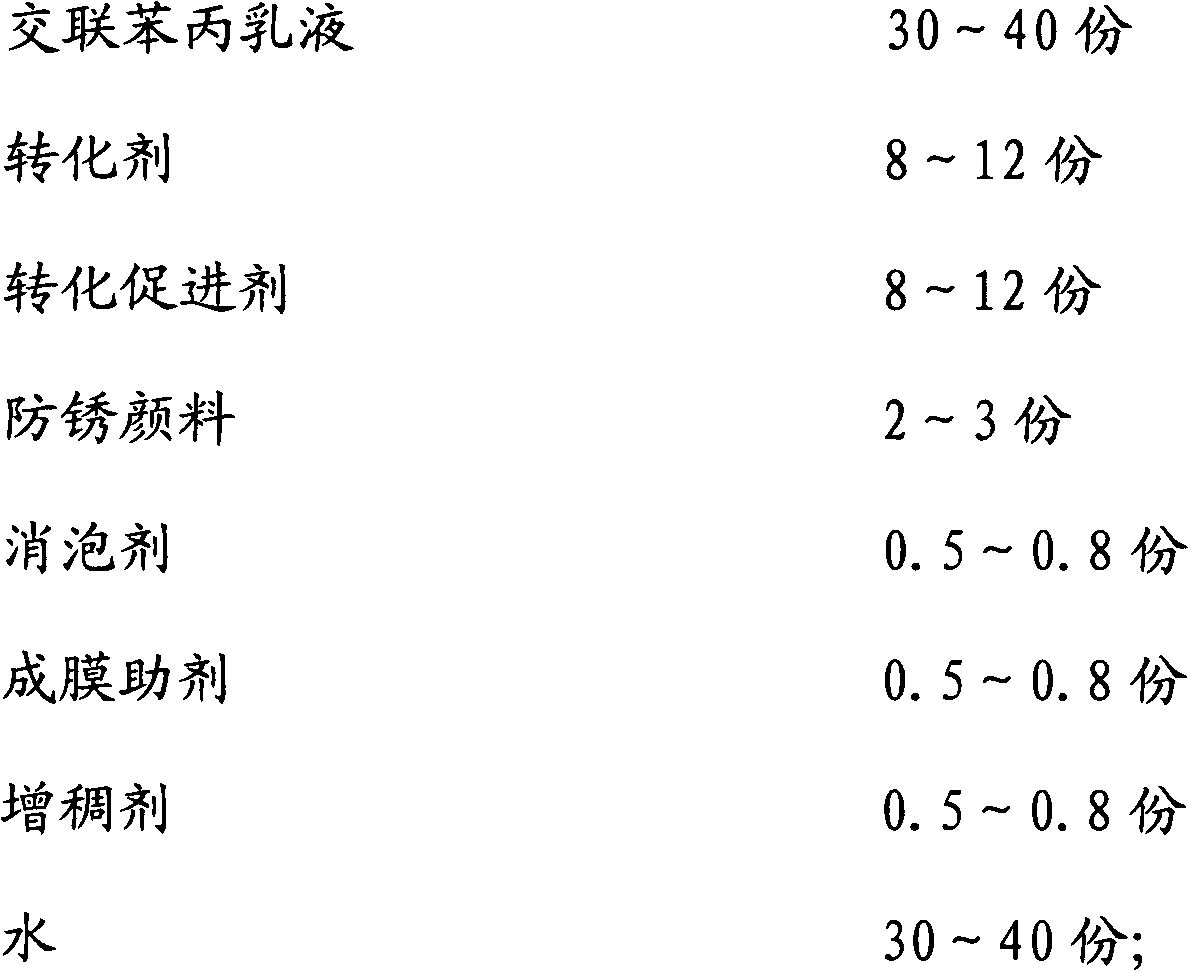

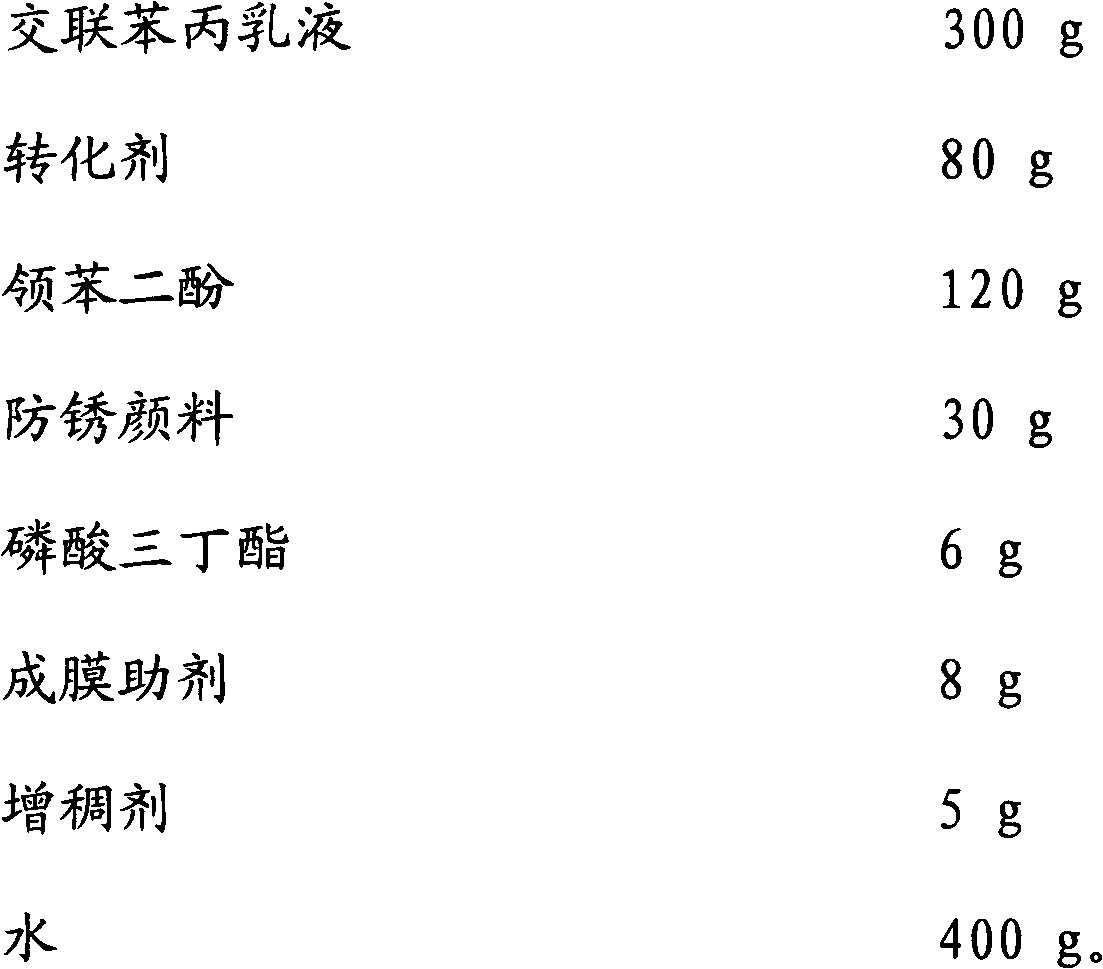

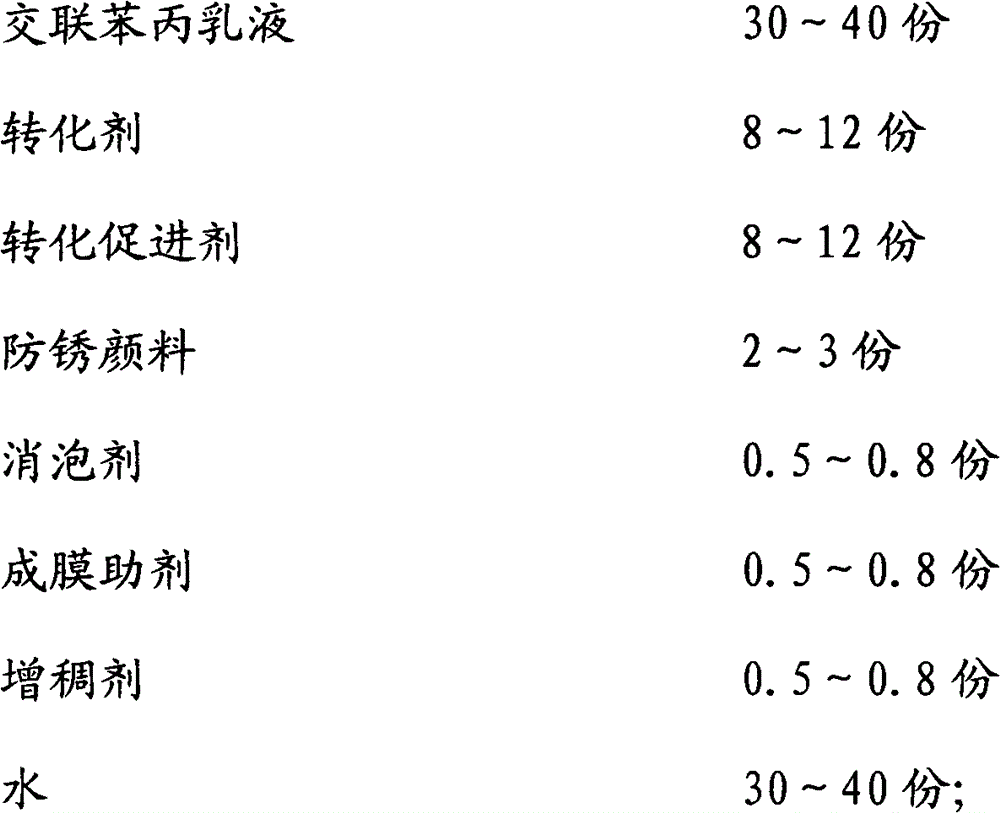

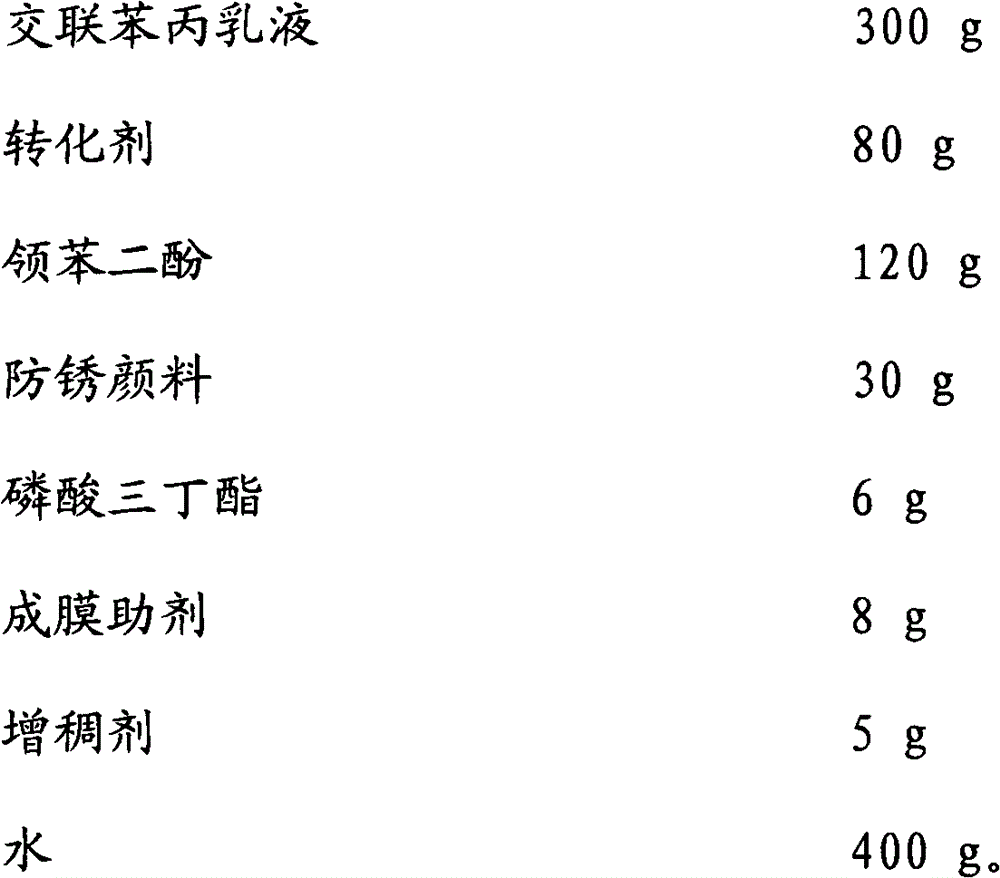

Waterborne rusty coating for protecting coating of steel-structure work pieces and preparation method thereof

ActiveCN102911565AEasy to operateExtensive sources of raw materialsAnti-corrosive paintsEmulsionMicrometer

The invention belongs to the field of anticorrosive protection of coatings of steel structures, and particularly relates to a waterborne rusty coating for protecting the coating of steel-structure work pieces and a preparation method thereof. Antirust pigment is mixed with 8 to 12 parts of water, and ground and dispersed to fineness of 20 to 60 micrometers; and then a cross-linked styrene-acrylate emulsion, a converting agent, a conversion accelerating agent, a defoaming agent, film forming additives, a thickening agent and the balance amount of water are added to the antirust pigment, evenly stirred therewith and packaged. According to the preparation method, the waterborne rusty coating for protecting the coating of the steel-structure of work pieces, which uses the cross-linked styrene-acrylate emulsion as the main film forming agent, is developed on the basis of a film forming mechanism of the cross-linked styrene-acrylate emulsion through screening and compounding main components such as the cross-linked styrene-acrylate emulsion and other film forming additives. A product has the characteristics of no toxicity, harmlessness, no pollution, wide raw material source, low cost, clean production, and the like, and is simple to operate.

Owner:合肥华清方兴表面技术有限公司

Manufacture method of native cellulose fiber with flameproof function

ActiveCN103290502ALow costNo pollutionArtificial filament recoveryFibre treatmentPulp and paper industrySlurry

The invention relates to a manufacture method of a native cellulose fiber with a flameproof function. The manufacture method comprises the following steps of: mixing wood pulp with an N-methylmorpholine-N-oxide monohydrate (NMMO) solvent into slurry, removing water by using a vacuum film evaporator to form a spinning viscous solution, extruding the spinning viscous solution from a spinning nozzle by adopting a dry spraying wet type spinning method, regenerating, washing and drying by using a coagulating bath, padding the spinning viscous solution and an N-hydroxymethyl-3-(dimethoxyphosphoryl) propanamide flameproof compound, sequentially carrying out drying, roasting, neutralizing, soaping, washing and drying, and finally, carrying out alkali washing, washing and drying and oiling to manufacture the native cellulose fiber with a long-effect type flameproof function. The native cellulose fiber and the N-hydroxymethyl-3-(dimethoxyphosphoryl) propanamide flameproof compound can generate a special crosslinking reaction in a manufacture process, and the flameproof effect of the native cellulose fiber has the flameproof effect completely according with the testing standards of ASTM (American Society for Testing Material) D6413-1999 and ASTM D2863-1995; meanwhile the native cellulose fiber can be naturally degraded after being discarded, and becomes an environment-friendly material which is harmless to the nature environment.

Owner:ACELON CHEM & FIBER

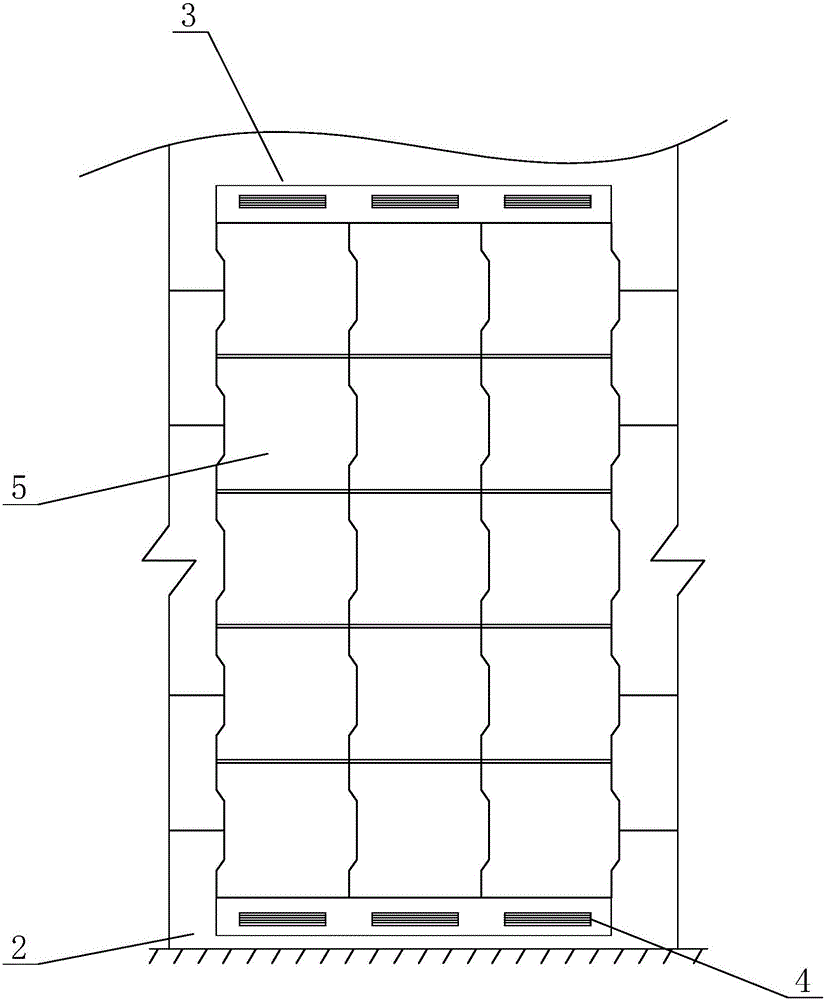

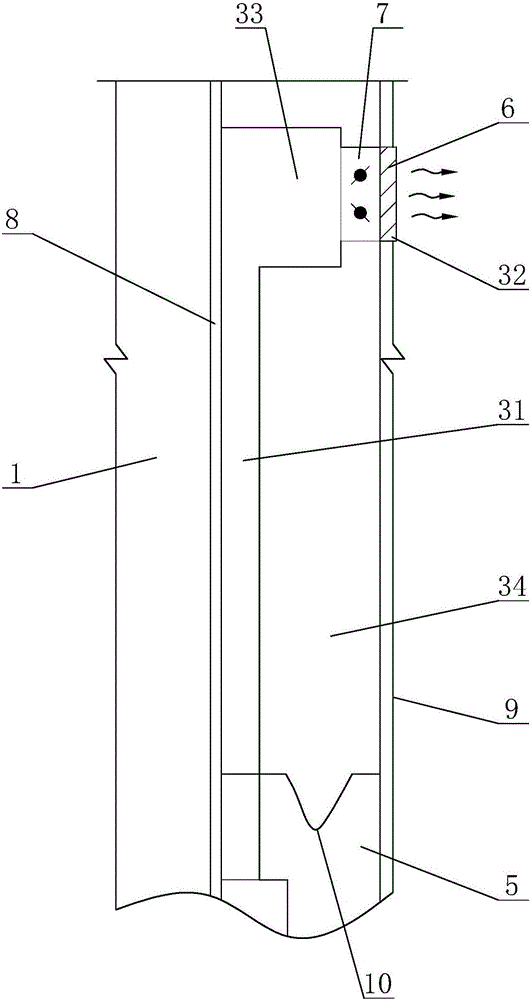

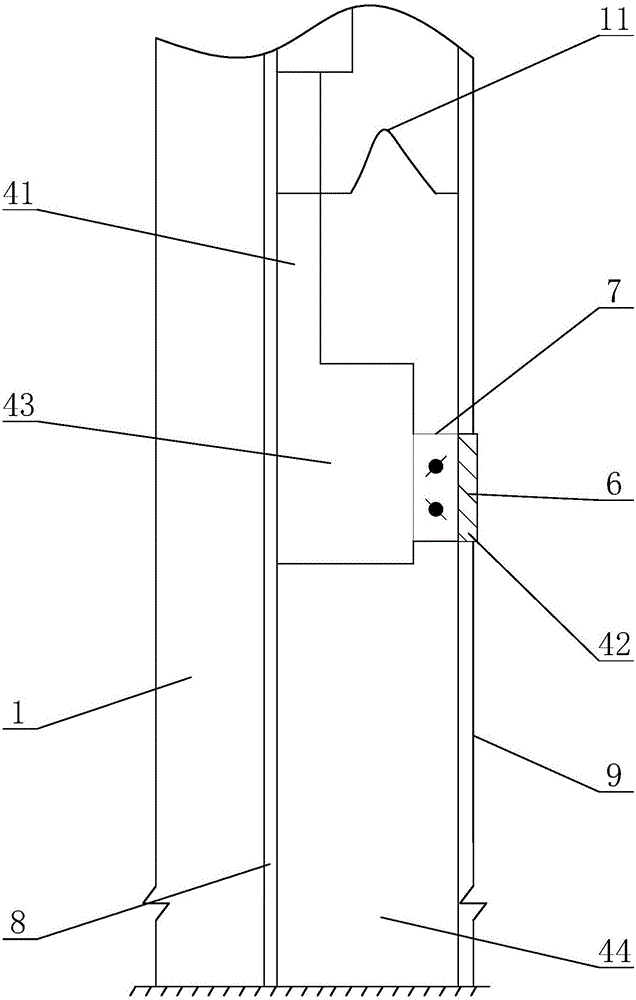

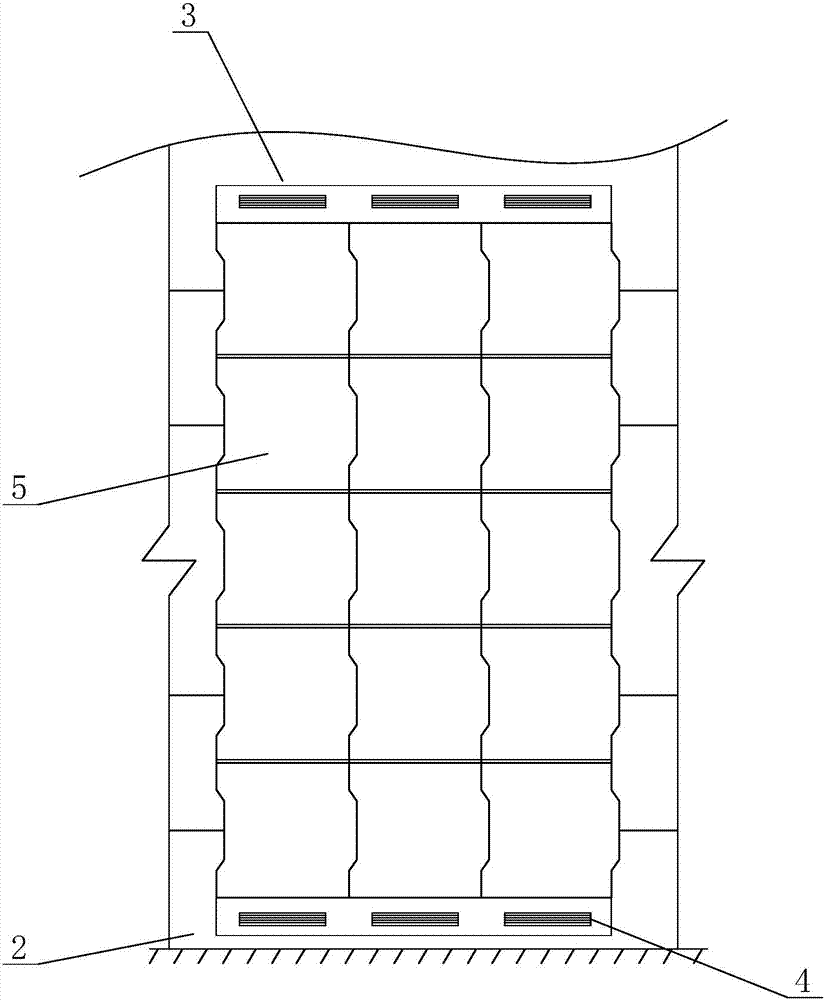

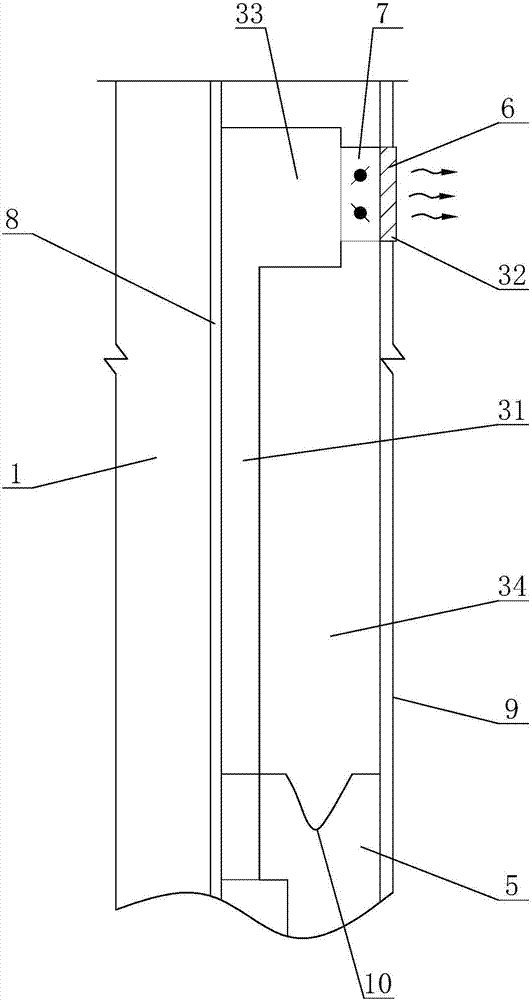

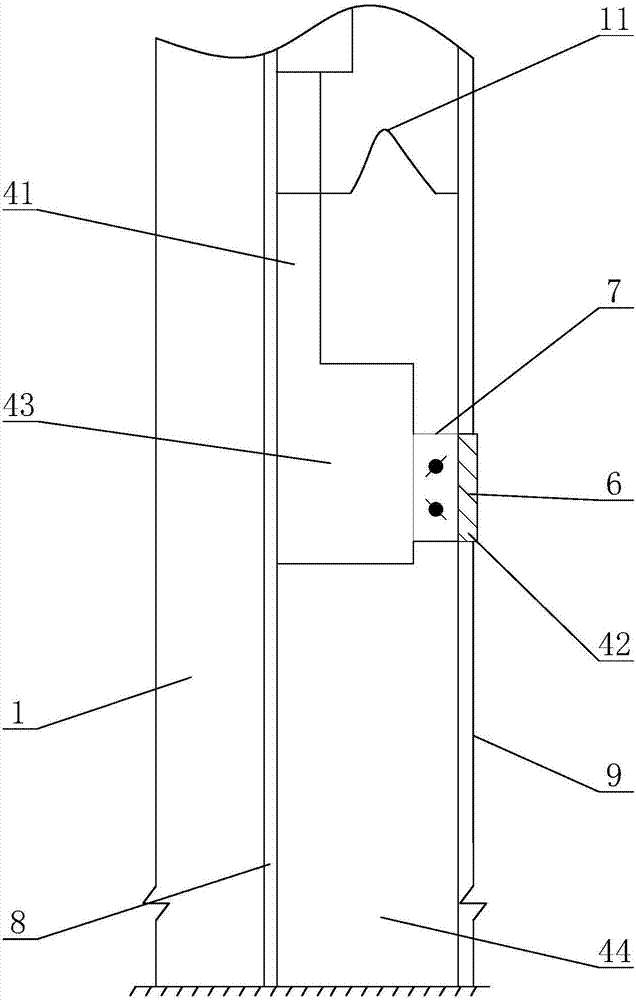

Cellular convection ventilation exterior wall heat insulation device

ActiveCN105821987AImprove insulation effectImprove bearing capacityWallsLighting and heating apparatusThermal insulationEngineering

The invention discloses a cellular convection ventilation exterior wall heat insulation device, and relates to the technical field of heat insulation. The cellular convection ventilation exterior wall heat insulation device comprises a prefabricated heat insulation body, a cellular convection ventilation heat insulation module, an upper ventilation assembly and a lower ventilation assembly, wherein the prefabricated ventilation airflow channel is arranged in the prefabricated heat insulation body; the upper ventilation assembly is located at the upper end of the cellular convection ventilation heat insulation module and is communicated with the cellular convection ventilation heat insulation module; and the lower ventilation assembly is located at the lower end of the cellular convection ventilation heat insulation module and is communicated with the cellular convection ventilation heat insulation module. The cellular convection ventilation exterior wall heat insulation device has the beneficial effects that a cavity-type cellular convection heat preservation and insulation wall body penetrating up and down is achieved; through the arranged automatically controlled heat insulation airtight valve, the cellular convection ventilation exterior wall heat insulation device has ventilating and cooling performance in summer and heat preservation and insulation performance in winter; by a cellular bionic design, the structure is firm; and the cellular convection ventilation exterior wall heat insulation device and a prefabricated standard component are subjected to integral construction.

Owner:INNER MONGOLIA UNIV OF TECH

Environment friendly room temperature non-slag colorful chemical conversion solution and process

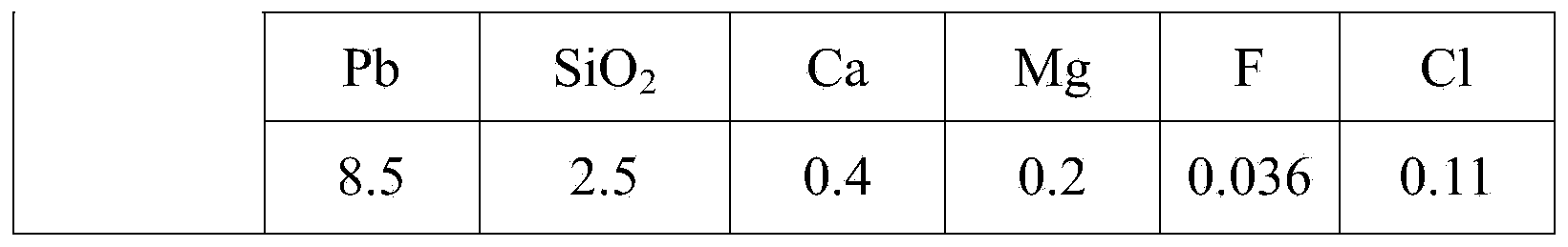

InactiveCN101457354ACrystal fineUniform colorMetallic material coating processesSlagSodium phosphates

The invention relates to an environment-friendly room temperature no-slag colorful chemical conversion solution and a process thereof; the process is characterized in that the carbon steel is arranged and treated in bath solution with the temperature of 10-31 DEG C which contains 3.8-10.3g / L of zinc phosphate, 4.0-15.0mL / L of phosphoric acid, 0.6-2.8g / L of manganese salt, 1.8-6.0g / L of sodium phosphate, 4.1-8.4g / L of organic acid salt and 0.6-4.6g / L of accelerator and has the pH value of 2.5-3.2 for 8-30 minutes, washed by tap water and dried, thus forming a uniform and compact colorful chemical conversion film on the surface of the carbon steel; the conversion film has excellent decoration performance, anti-corrosion performance and subsequent manufacturability. The conversion solution and the process excellently solve the problem of heavy pollution and large energy dissipation during phosphating at high and intermediate temperature and bluing at high temperature, and also solve the problems of environment pollution, harm on the health of operators, bad anti-corrosion performance of the blued film, bad adhesion of the substrate and the blued film, and the like due to selenious acid and copper ions in blued solution at normal temperature and hexavalent chromium ions in oxidation passivation solution.

Owner:BEIJING UNIV OF CHEM TECH

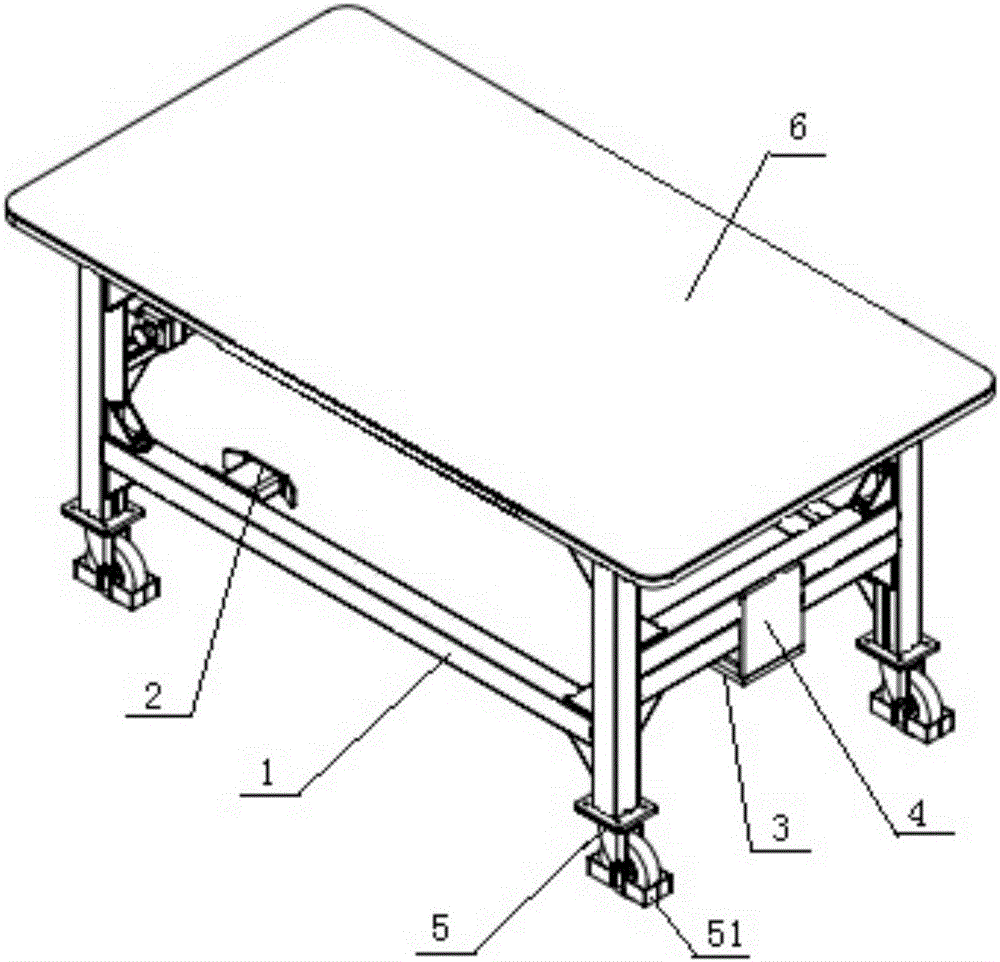

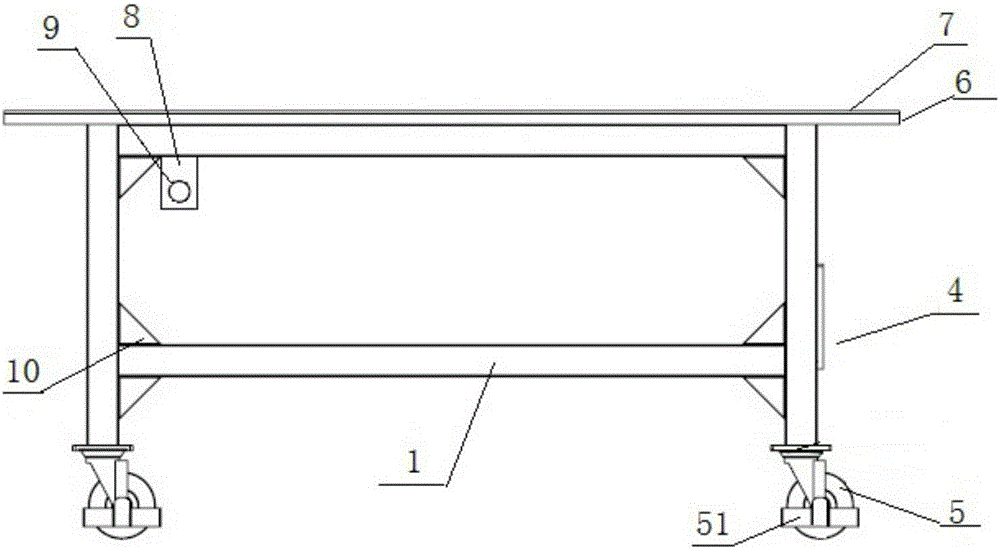

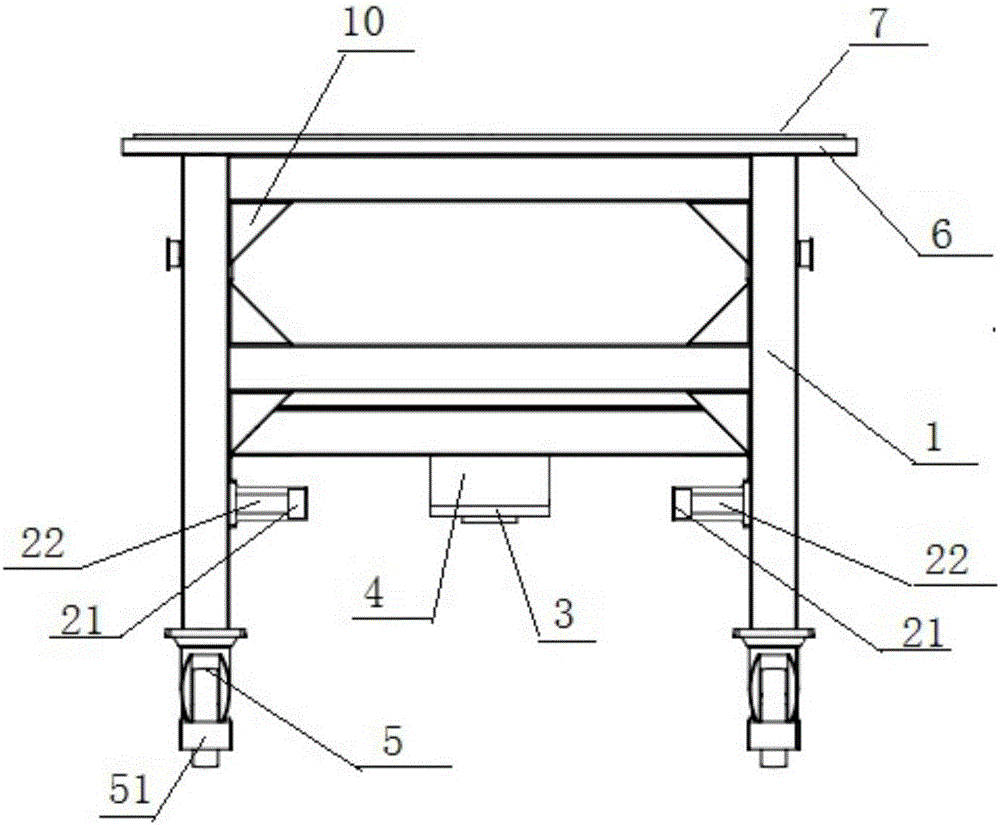

Submerged AGV trailing device

The invention relates to a submerged AGV trailing device. The device comprises a mechanism rack (1), a submerged guiding positioning component, a connecting guiding component (3) and a connecting component (4) which are arranged on the mechanism rack (1), wherein a travelling mechanism is arranged at the bottom of the mechanism rack (1); the submerged guiding positioning component comprises two elastic mechanisms (2) which are arranged on two opposite inner faces of the mechanism rack (1) and act on two sides of an AGV body when AGV is submerged; the connecting guiding component (2) and the connecting component (4) are sequentially arranged along the AGV submerging direction; the connecting guiding component (3) is used for guiding the AGV in the mechanism rack (1) to the connecting component (4), so that the AGV is connected with the trailing device. Compared with the prior art, the submerged AGV trailing device has the advantages of high work efficiency, simple structure, strong controllability, good safety and the like, can realize automatic logistic transportation, and can be used for delivering materials efficiently, economically and flexibly.

Owner:SHANGHAI UNIV OF ENG SCI

Aqueous normal temperature curing peelable paint and preparation method of paint

ActiveCN102827537BWide variety of sourcesWith cleaner productionPolyurea/polyurethane coatingsEmulsionFilling materials

The invention discloses aqueous normal temperature curing peelable paint, which is applicable to the technical field of metal surface treatment and consists of the following ingredients in parts by weight: 80 to 90 parts of polyurethane emulsion, 8 to 12 parts of wetting dispersing agents, 2 to 3 parts of nanometer level filling materials, 0.5 to 0.8 parts of defoaming agents, 0.5 to 0.8 parts of flatting agents and 0.5 to 0.8 parts of thickening agents. The aqueous normal temperature curing peelable paint has the advantages that on the basis of the polyurethane emulsion film forming mechanism, through major ingredient screening and compounding of polyurethane emulsion, other film forming auxiliary agents and the like, the aqueous normal temperature curing peelable paint adopting the polyurethane emulsion as major film forming agents is developed. The product has the characteristics that nontoxicity and harmlessness are realized, the pollution is avoided, the operation is simple, the raw material resources are wide, the price is low, the clean production is realized, and the like.

Owner:合肥华清高科表面技术股份有限公司

Water washing technology of denim fabric

InactiveCN107675380ASoft touchFeel goodFabric breaking/softeningPattern makingEngineeringPre treatment

The invention discloses a water washing technology of denim fabric, and relates to the field of fabric water washing. The water washing technology comprises the following steps of 1, pretreatment of the denim fabric; 2, steaming, wherein the denim fabric treated in the step 1 is placed in a steam cylinder to be preheated for 30 s, then the denim fabric is taken out to be cooled for 30 s, and the following steps are repeated for 3 times; 3, enzyme wash, wherein the denim fabric treated in the step 2 is put into washing liquid of 45 DEG C to be subjected to enzyme wash for 35-40 min, and then the liquid is drained; 4, water washing, wherein the denim fabric is repeatedly washed with clear water 3-5 times; 5, dehydration for the first time; 6, drying for the first time; 7, passing through silicone oil, wherein the denim fabric treated in the step 6 passes through the silicone oil according to the proportion of 50 g of the silicone oil and 1.6 L of water; 8, softening, wherein after softening agent and the water are mixed, the fabric obtained after the step 7 is softened, the treating time is 15-25 min, and the temperature is 25-35 DEG C; 9, dehydration for the second time; 10, dryingfor the second time. By means of the water washing technology, the denim fabric good in breathability and soft in hand feeling can be obtained.

Owner:FANCHANG QINGXIN WASHING CO LTD

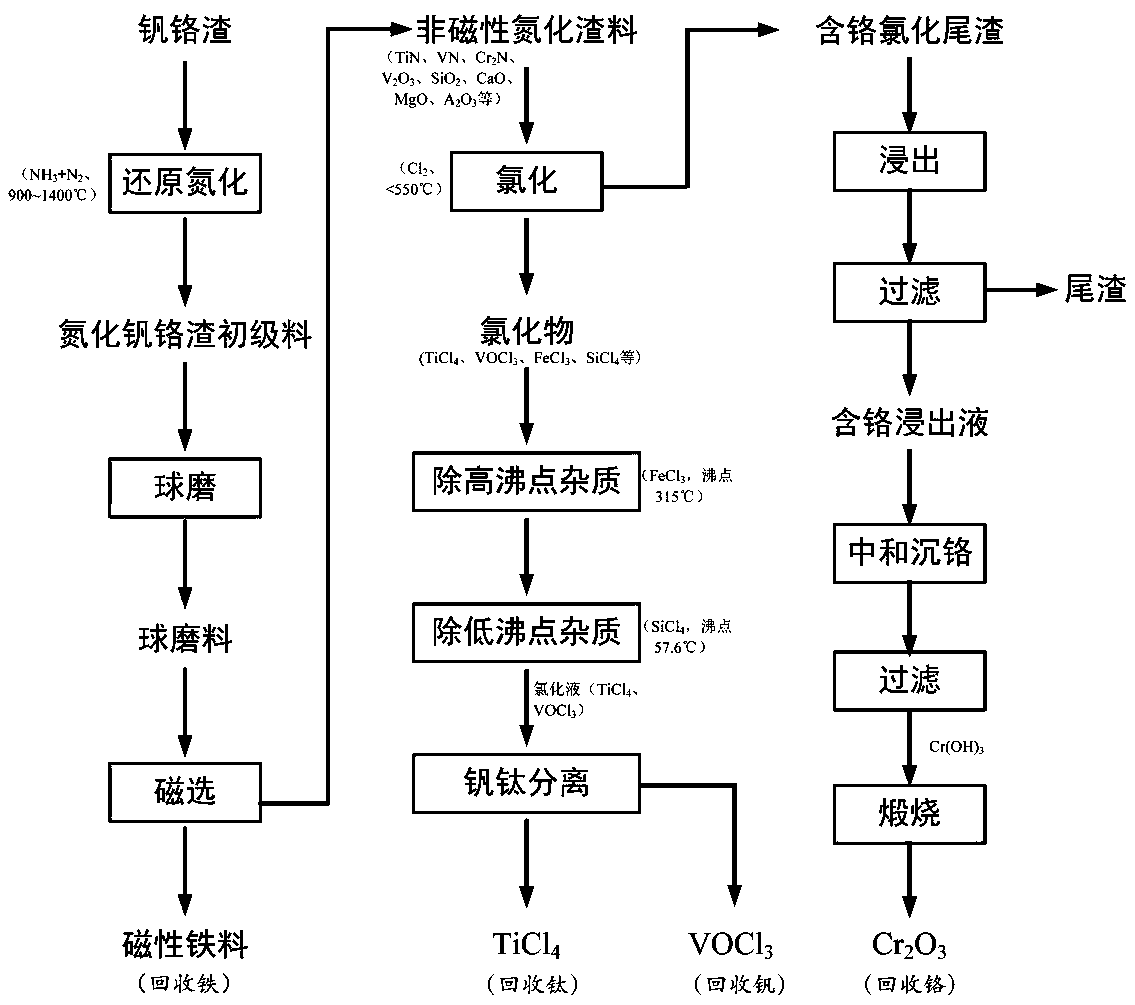

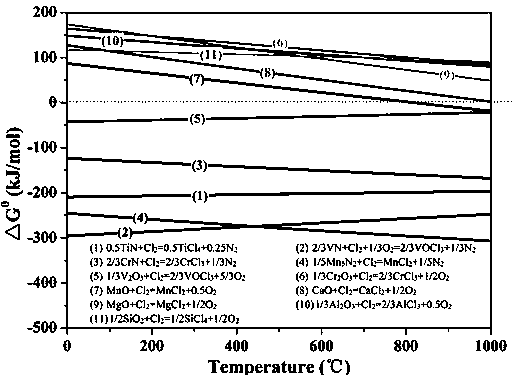

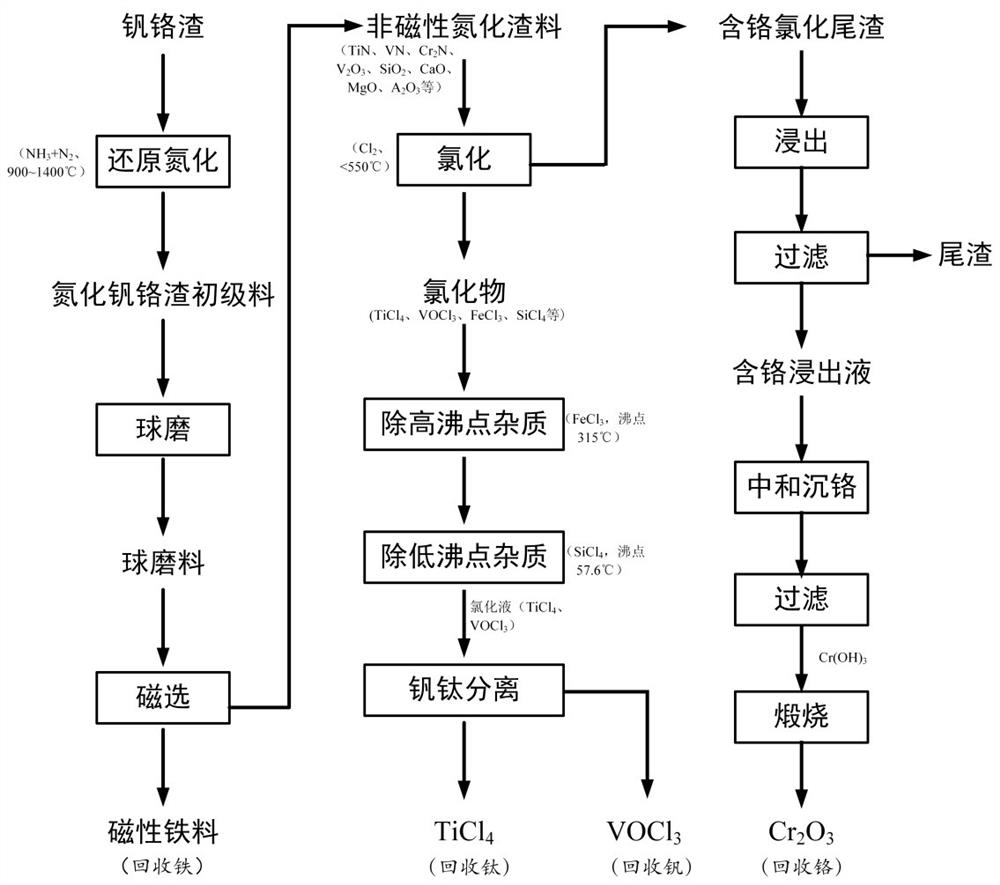

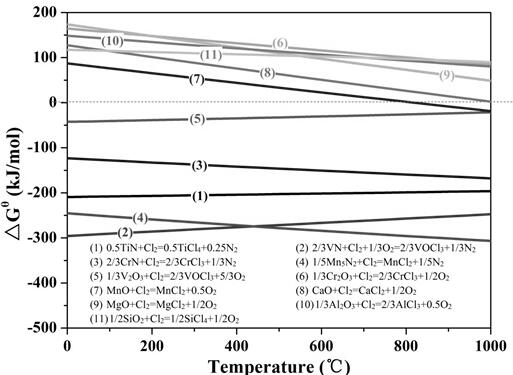

Recovery method of valuable metal in vanadium chromium slag

InactiveCN109868370ALower operating temperatureIncrease reaction rateChromium trioxideVanadium oxidesRecovery methodSlag

The invention relates to a recovery method of valuable metal in vanadium chromium slag. According to the method, vanadium chromium slag fine powder and mixed gas mainly dominated by NH3+N2 are subjected to reduction and nitridation to obtain a vanadium chromium nitride slag primary material; then metal iron is removed through ball milling magnetic separation, so that non-magnetic nitridation slagis obtained; then the non-magnetic nitridation slag and chlorine react in a fluidized bed at a low temperature, thus TiN, VN, V2O3 and the like and chlorine react to generate chloride, and chromium chloride is left in the chlorination tailings to obtain chromium-contained chlorination tailings; then after high-boiling-point and low-boiling-point impurities in the chloride are removed, separation is carried out so that pure VOC13 and TiC14 products are obtained; and finally, the chromium-contained chlorination tailings are subjected to the working procedures of leaching out, neutralizing chromium depositing, calcining and the like, so that a Cr2O3 product is obtained. The method achieves comprehensive recovery and utilization of valuable metal iron, chromium, vanadium and titanium in the vanadium chromium slag, and has the characteristics of being high in comprehensive recovery rate, clean and environmentally friendly.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

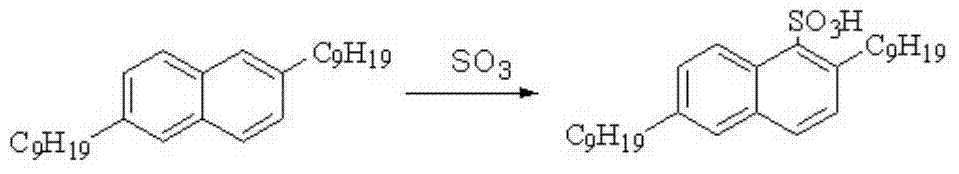

Method for continuously preparing 2,6-dinonyl naphthalene sulfonic acid

InactiveCN104262212AShort reaction timeIncrease productivitySulfonic acid preparationSulfur trioxideSolvent

The invention discloses a method for continuously preparing a 2,6-dinonyl naphthalene sulfonic acid. The 2,6-dinonyl naphthalene sulfonic acid is continuously produced through a falling film sulfonation reactor, and the method comprises the specific steps: 2,6-dinonyl naphthalene and a sulfur trioxide gas are continuously introduced into the falling film sulfonation reactor to be subjected to a falling film sulfonation reaction, a sulfonation reaction product is aged, settled to separate out acid residues, extraction and separation are carried out, the separated product is concentrated, acidized, washed with water, evaporated to remove a solvent to obtain the 2,6-dinonyl naphthalene sulfonic acid. According to the method, the efficient production of the high-purity 2,6-dinonyl naphthalene sulfonic acid is realized based on the fact that the 2,6-dinonyl naphthalene is continuously sulfonated in the falling film sulfonation reactor, the process flow is short, the reaction time is short, the facility request is low, the purification of the product is easy, the cost is low, and the industrial production requirements are completely met.

Owner:湖南立新环保科技发展有限公司

Continuous preparation method for 2,6-dinonylnaphthalenesulfonic acid

InactiveCN104262212BShort reaction timeIncrease productivitySulfonic acid preparationSulfur trioxideSolvent

Owner:湖南立新环保科技发展有限公司

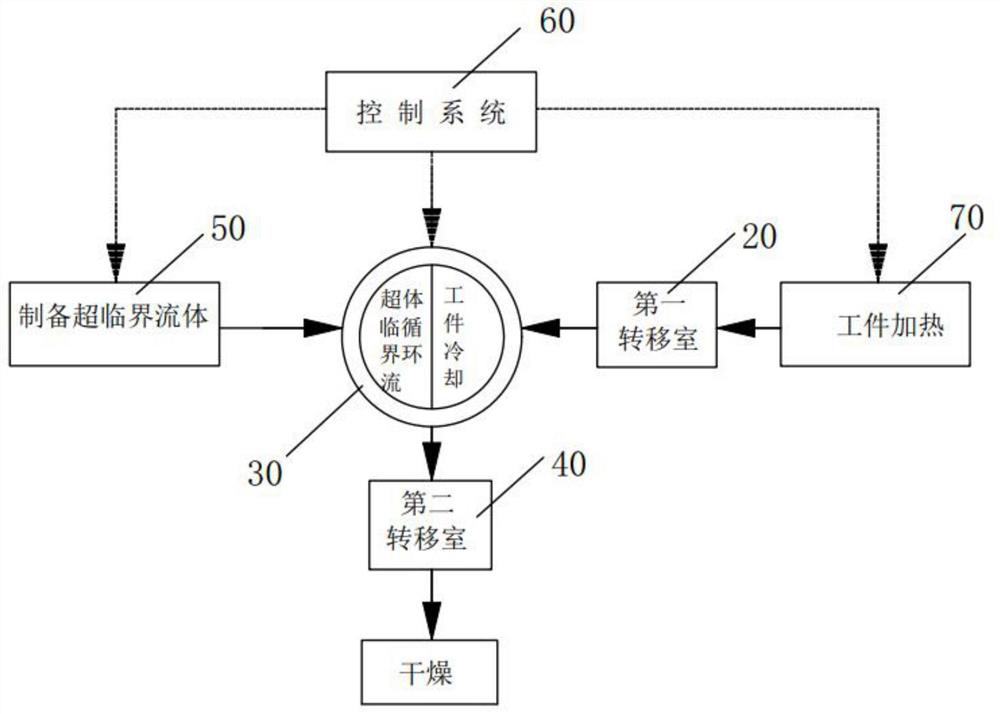

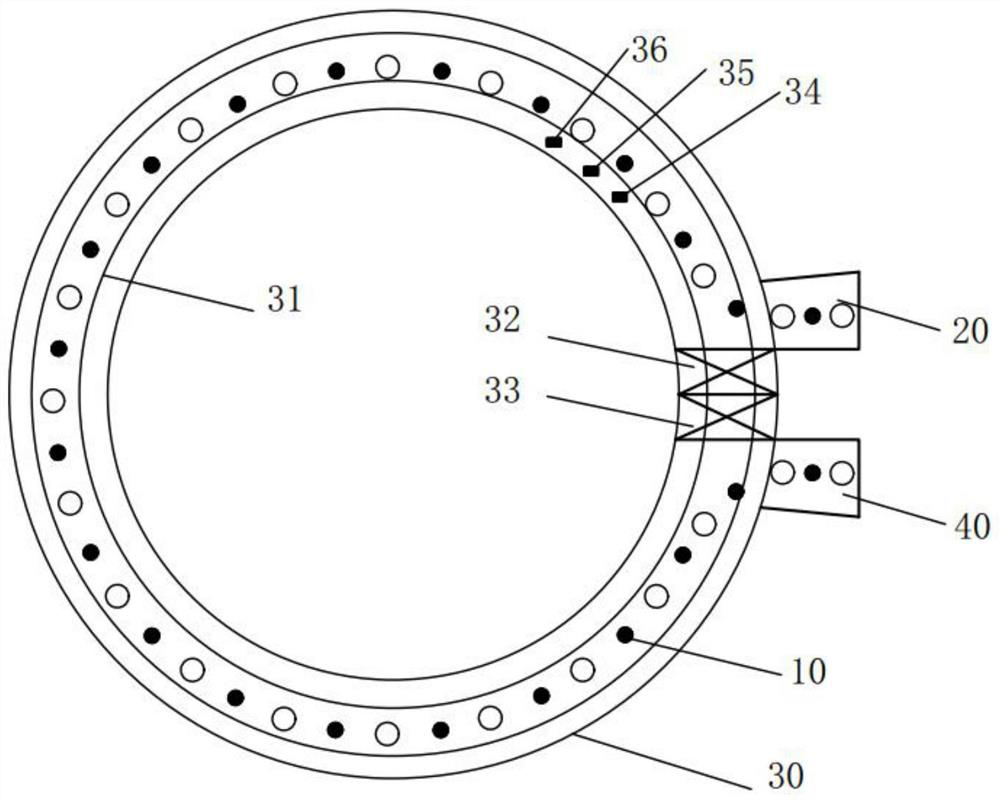

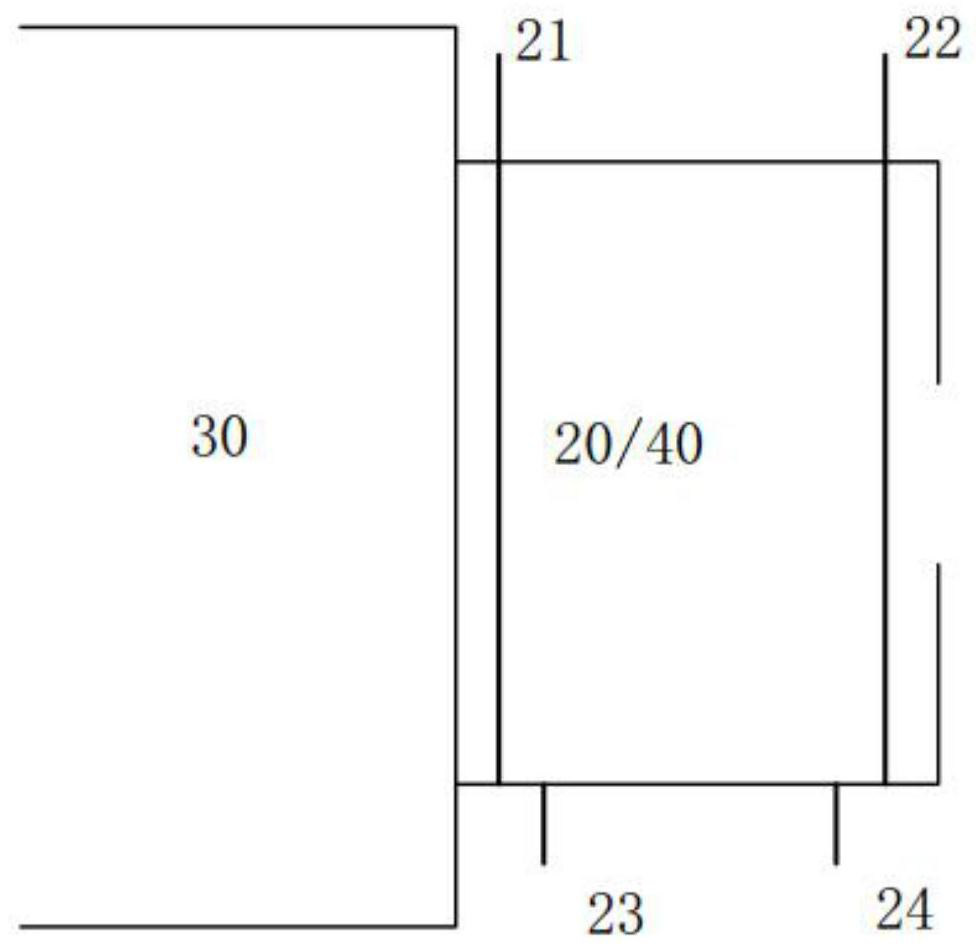

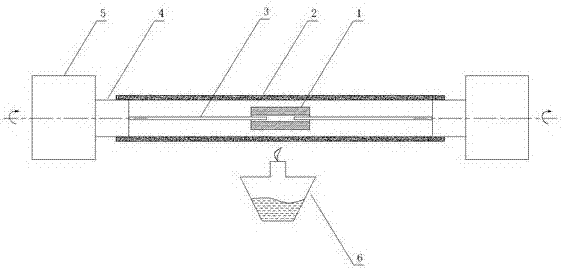

Supercritical fluid circulating cooling method and device

PendingCN111912157AGood economic benefitsGood environmental benefitsLighting and heating apparatusCooling fluid circulationAssembly lineCooling methods

The invention discloses a supercritical fluid circulating cooling method and device. The cooling method includes the steps: providing an annular closed cavity, introducing supercritical fluid into theclosed cavity, and enabling the supercritical fluid to flow in the closed cavity in a circulating manner; feeding a workpiece into the closed cavity, moving the workpiece in the closed cavity along an annular cavity way to carry out convection heat exchange with the supercritical fluid flowing in the circulating manner, and cooling the workpiece; and transferring the cooled workpiece out of the closed cavity. The circulating cooling device comprises the annular closed cavity, and an annular conveying belt for conveying the workpiece is arranged in the annular closed cavity; and a supercritical fluid supply system communicates with the closed cavity in order to supply the supercritical fluid into the closed cavity. The supercritical fluid circulating cooling method and device are stable and controllable in cooling process and good in cooling treatment effect; and the supercritical fluid circulating cooling method and device are novel in structural design and easy and convenient to operate, the production manner of assembly line cooling is achieved, the production efficiency is high, and the production cost is low.

Owner:SHANGHAI FULUDI FLUID TECH CO LTD

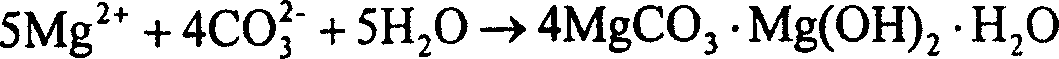

Cleaning type preparation method for medicinal basic magnesium carbonate

InactiveCN100333999CHigh yieldReduce manufacturing costMagnesium carbonatesReaction temperatureChloride

Owner:SHANDONG UNIV

Normal-pressure boiling dyeable biomass polyester fiber and preparation method thereof

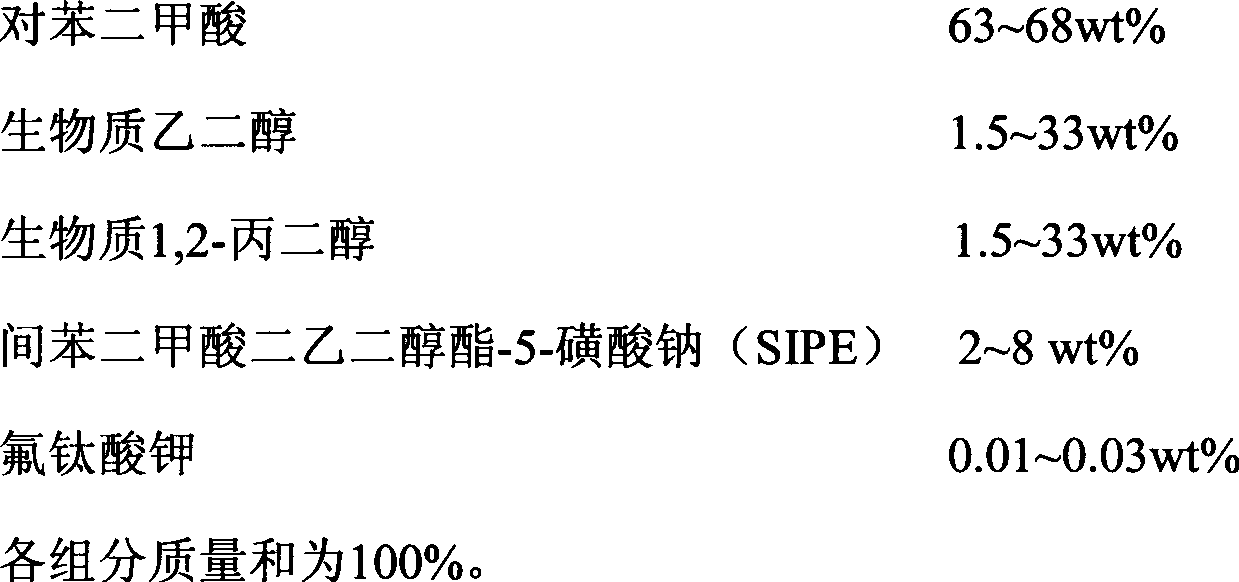

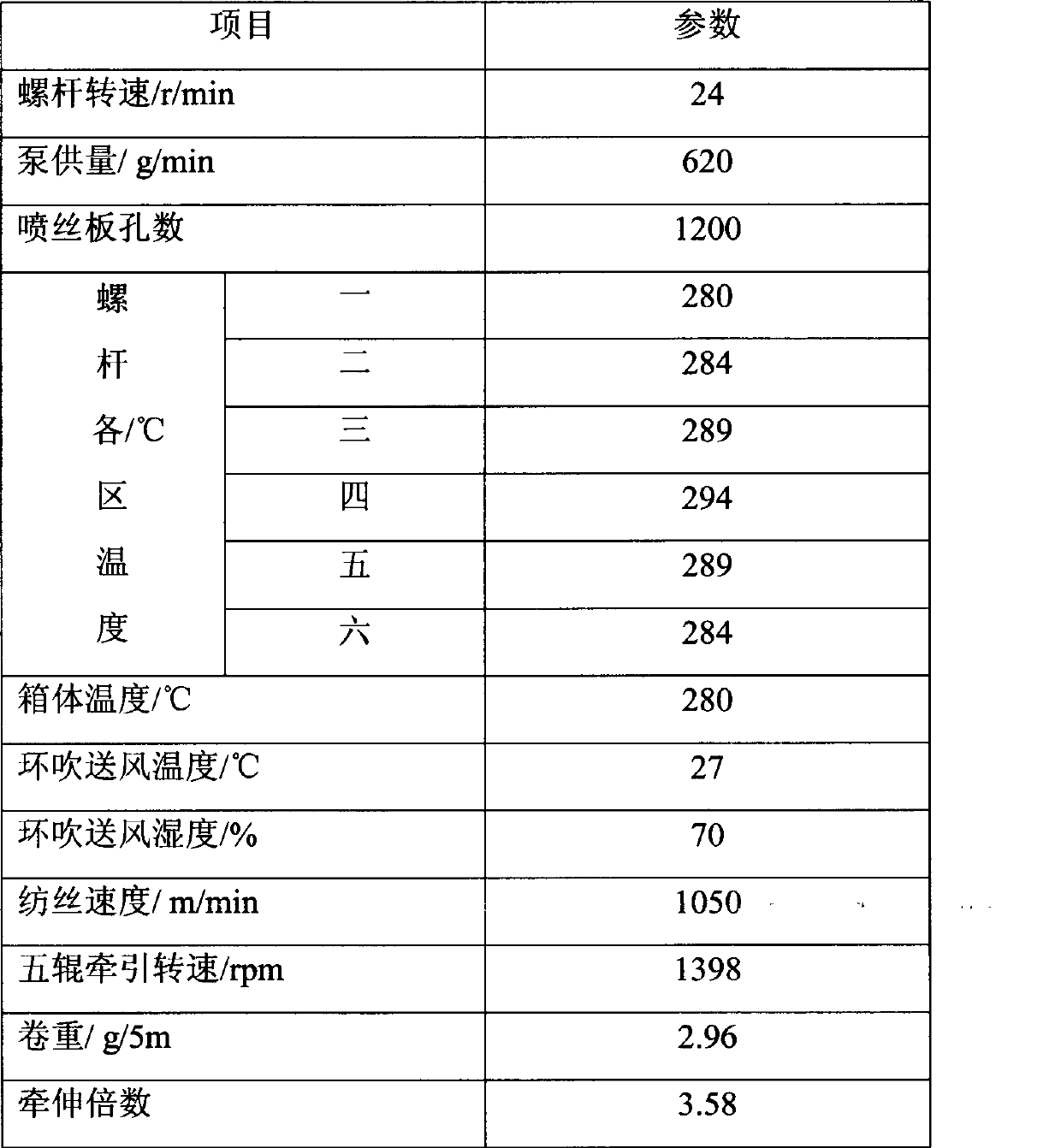

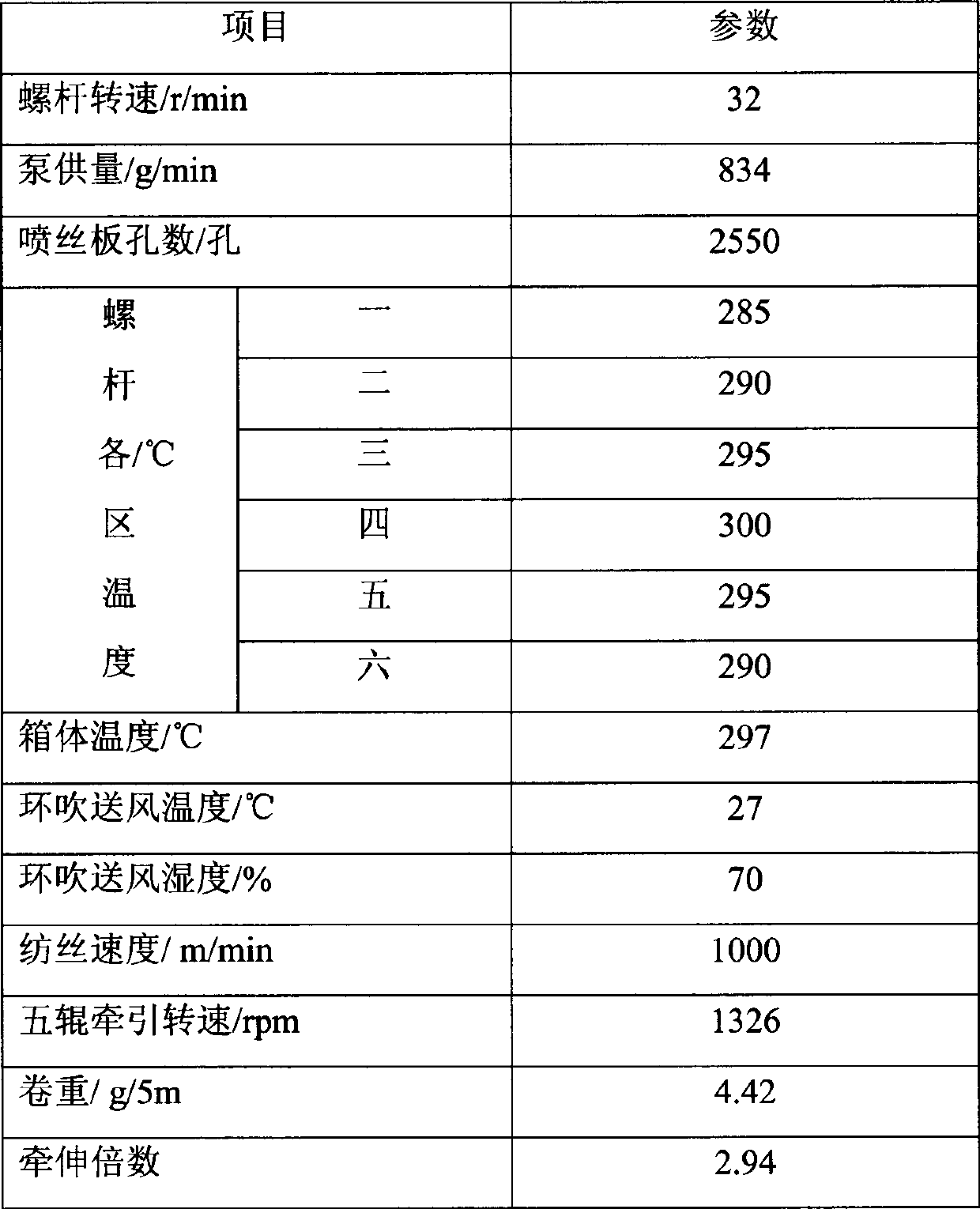

ActiveCN102965757BReduce dependencePromote sustainable developmentFilament forming substance formingMonocomponent copolyesters artificial filamentPotassiumNatural fiber

The invention discloses a novel normal-pressure boiling dyeable biomass polyester fiber which comprises the following raw materials: 63-68wt% of terephthalic acid, 1.5-33wt% of biomass ethylene glycol, 1.5-33wt% of biomass 1,2-propanediol, 2-8wt% of monomer 5-sodiumsulfa bis-isophthalate (SIPE) and 0.01-0.03wt% of catalyst potassium fluotitanate. A preparation method of the polyester fiber comprises the following steps: performing esterification and polycondensation reaction on the raw materials to obtain a biomass polyester chip; and based on optimal fiber-spinning process parameters, producing to obtain the biomass polyester fiber having a normal-pressure boiling dyeable function. The fiber has the characteristics of natural softness, low static, favorable resilience and low-temperature dyeing, is boiling dyeable under normal pressure, has high dye-uptake rate and dye exhaustion rate, can be blended with a natural fiber such as wool and the like, has the advantages of cost saving, energy consumption reduction and clean production, can reduce the dependence of the chemical fiber industry on petroleum and can greatly relieve resource restriction and environment pressure.

Owner:SHANGHAI DEFULUN CHEM FIBER

Scented kudzuvine root tea and preparation method thereof

InactiveCN108378175ASignificant blood pressure lowering effectNourishingTea substituesFlavorCodonopsis

The invention provides scented kudzuvine root tea and a preparation method thereof, and relates to the technical field of health-caring tea. The scented kudzuvine root tea provided by the invention comprises the following raw materials: kudzuvine roots, honeysuckle flowers, pseudo-ginseng, tendrilleaf fritillary bulbs, radix codonopsis, rose flowers, fructo-oligosaccharides, and honey. The scentedkudzuvine root tea provided by the invention contains relatively much flavone compound, and thus, the scented kudzuvine root tea has multiple health-caring effects, including dilating coronary arteries and cerebral vessels, reducing myocardial oxygen consumption, improving myocardial contractile functions, promoting blood circulation, enhancing body immunity and so on; moreover, the honeysuckle flowers, the pseudo-ginseng, the tendrilleaf fritillary bulbs, the radix codonopsis, the rose flowers, the fructo-oligosaccharides and the honey are added into the kudzuvine roots so that the scented kudzuvine root tea also has the functions of nourishing, moistening dryness, detoxifying, whitening, beautifying, lubricating the intestines and relaxing the bowels. The scented kudzuvine root tea canbe simply and conveniently brewed; moreover, flavor and nutrients of the other raw materials can be very easily dissolved into tea water when the kudzuvine roots are brewed. The brewed tea water is aromatic and strong in taste, as well as mellow in flavor.

Owner:安徽金龙山葛业有限公司

Jean fabric washing process

InactiveCN107780227ASoft touchFeel goodPattern makingDry-cleaning apparatus for textilesProcess engineeringPre treatment

The invention discloses a jean fabric washing process and relates to the field of fabric washing. The jean fabric washing process comprises the following steps of 1) preprocessing jean fabric, 2) after the jean fabric is processed in the step 1), heating primary desizing liquid to 80 DEG C, putting in and washing the jean fabric for 20 min, 3) performing first washing in clean water for 3-5 times,4) performing first dewatering, 5) performing first drying, 6) enzyme-washing the processed jean fabric of the step 5) in washing liquid of 45 DEG C for 35-40 min, discharging the liquid, and controlling the bath ratio to be 1:4-1:9, 7) performing silicone oil treatment on the processed jean fabric of the step 6) through 50 g of silicone oil and 1.6 L of water, 8) softening the processed jean fabric of the step 7) for 15-25 min and at 25-35 min by mixing softening agent with water, 9) performing second dewatering, and 10) performing second drying. The jean washing process can produce jean fabric good in breathability and soft in hand feeling.

Owner:FANCHANG QINGXIN WASHING CO LTD

A method for desulfurization of flue gas containing low concentration sulfur dioxide

ActiveCN103506001BSolve the blockageRealize pollution control without pollutionZinc sulatesDispersed particle separationElectrolysisDecomposition

The invention discloses a desulfurization method for fume gas containing low-concentration sulfur dioxide. The desulfurization method comprises the following steps: making zinc hypoxide powder into absorption slurry with a predetermined concentration, making the absorption slurry reversely contact the fume gas containing low-concentration sulfur dioxide in a reverse-injection material feeding pipe of a dynamic wave washing tower, conversing sulfur dioxide into zinc sulfite by utilizing the reactions between zinc oxide and sulfur dioxide, then decomposing zinc sulfite into zinc sulfate through an electrolysis waste liquid, recycling the sulfur dioxide generated by the decomposition into a sulfuric acid producing system, and finally filtering so as to obtain zinc sulfate for leaching.

Owner:云南云铜锌业股份有限公司

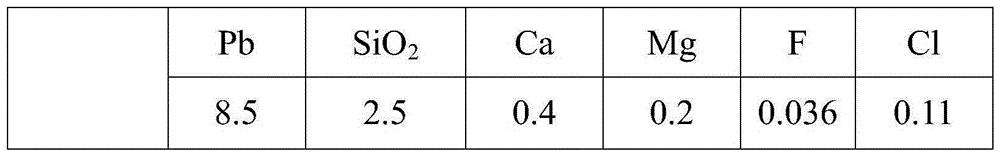

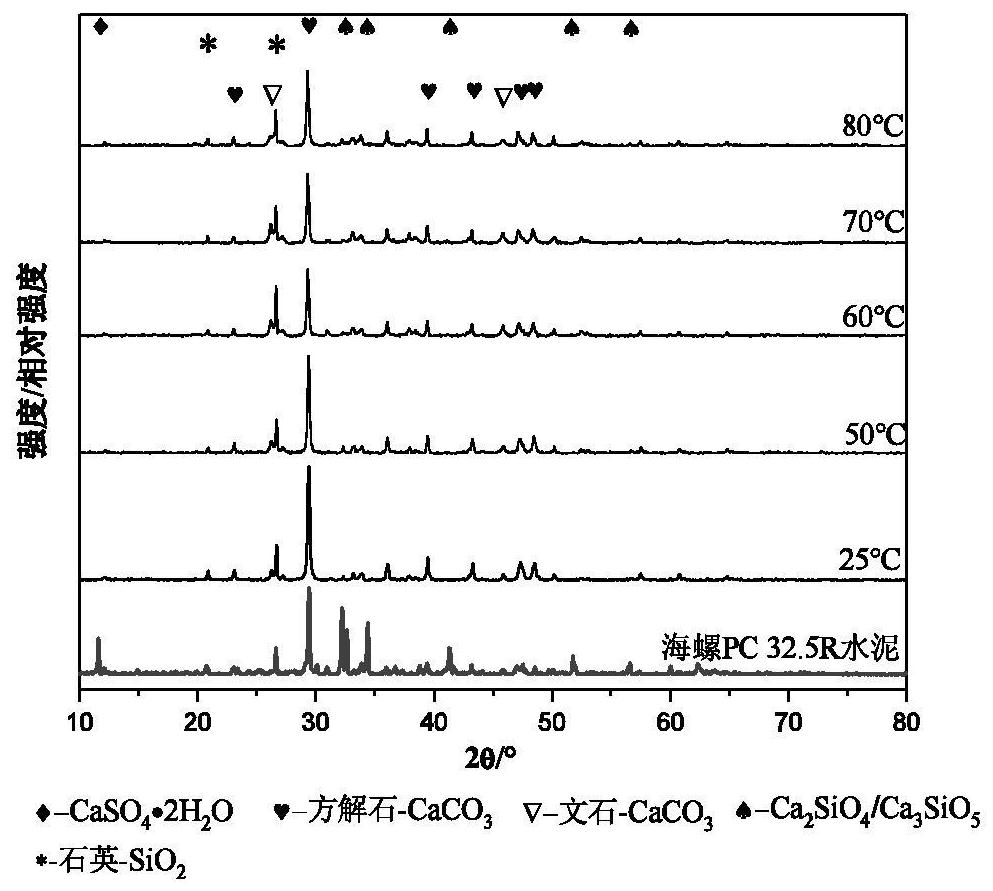

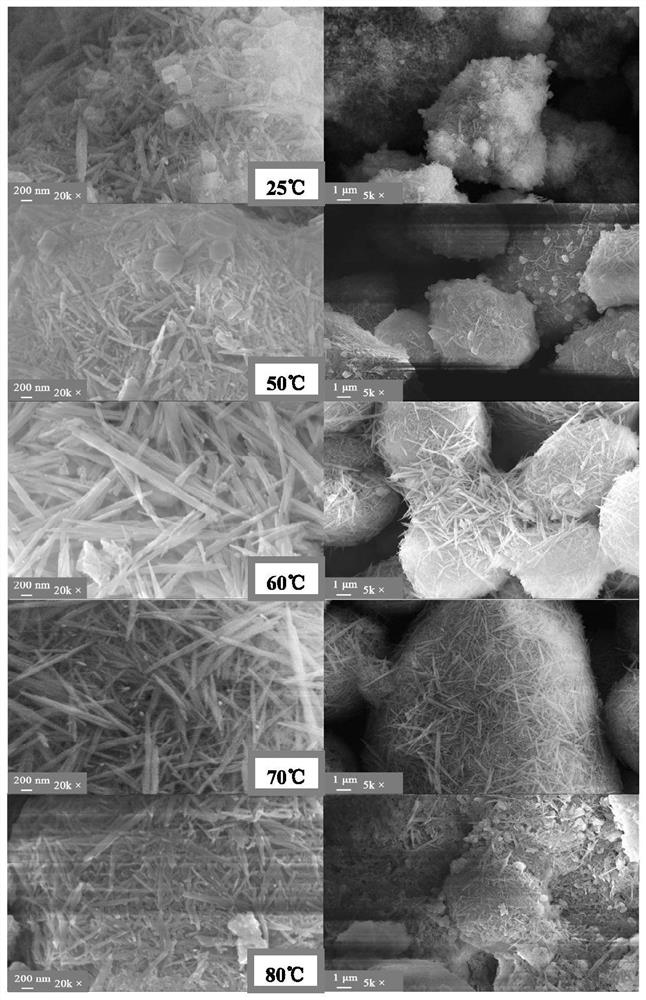

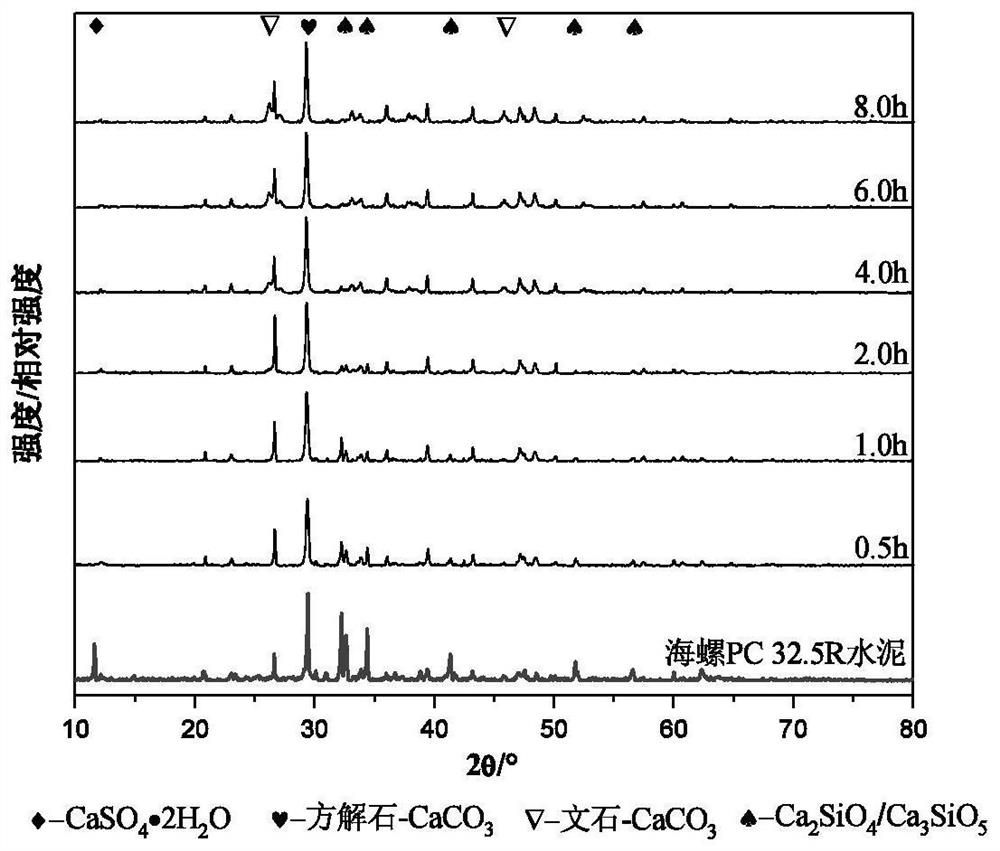

Zero-dimensional and one-dimensional calcium carbonate micro-nano composite product taking cement and 'three wastes' as raw materials, composite material and synthesis process

ActiveCN113511665ARaw materials are cheap and easy to getSimple production processCalcium/strontium/barium carbonatesSilicaMicro nanoNanowire

The invention provides a novel process for producing an aragonite type calcium carbonate whisker / nano white carbon black compound or a calcite type nano calcium carbonate / nano white carbon black compound on a large scale at low cost. The invention develops a new way for producing a micro-nano wire or nano powder compound product with one-dimensional or zero-dimensional structural characteristics by taking a large amount of cheap Portland cement or cement clinker and flue gas as raw materials, mixing and suspending the raw materials in a water-containing system, introducing the flue gas or carbon dioxide for hydration, double decomposition for neutralization and precipitation, and dehydration and condensation, and an inorganic micro-nano product library is enriched. Application results show that the calcium carbonate-based micro-nano composite product can greatly improve the tensile strength and impact toughness of materials such as plastic and rubber, enhance the adhesive strength of an adhesive, has remarkable cost performance advantages in quality improvement and cost reduction, and has a huge application potential. The invention develops a new way for producing high-performance calcium carbonate-based micro-nano composite products and novel composite materials on a large scale at low cost by taking cheap and large-amount cement as a basic raw material and simultaneously utilizing and reducing emission of carbon dioxide.

Owner:XIAMEN UNIV +2

A kind of recovery method of valuable metal in vanadium-chromium slag

InactiveCN109868370BLower operating temperatureIncrease reaction rateChromium trioxideVanadium oxidesSlagWater chlorination

The invention relates to a recovery method of valuable metal in vanadium chromium slag. According to the method, vanadium chromium slag fine powder and mixed gas mainly dominated by NH3+N2 are subjected to reduction and nitridation to obtain a vanadium chromium nitride slag primary material; then metal iron is removed through ball milling magnetic separation, so that non-magnetic nitridation slagis obtained; then the non-magnetic nitridation slag and chlorine react in a fluidized bed at a low temperature, thus TiN, VN, V2O3 and the like and chlorine react to generate chloride, and chromium chloride is left in the chlorination tailings to obtain chromium-contained chlorination tailings; then after high-boiling-point and low-boiling-point impurities in the chloride are removed, separation is carried out so that pure VOC13 and TiC14 products are obtained; and finally, the chromium-contained chlorination tailings are subjected to the working procedures of leaching out, neutralizing chromium depositing, calcining and the like, so that a Cr2O3 product is obtained. The method achieves comprehensive recovery and utilization of valuable metal iron, chromium, vanadium and titanium in the vanadium chromium slag, and has the characteristics of being high in comprehensive recovery rate, clean and environmentally friendly.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Preparation method of waterproof material of water supply equipment

InactiveCN108485272ACold-resistantHeat resistantBuilding insulationsPowder mixtureUltrasonic dispersion

The invention provides a preparation method of a waterproof material of water supply equipment. The method comprises the following steps that a, modified calcium carbonate, filler, lightweight calciumcarbonate and quartz sand are mixed and crushed; then, ultrasonic dispersion is performed to obtain a powder mixture; b, organic rubber, a polyurethane material, a composite material and asphalt aremixed and smelted; then, a compound emulsifying agent is added; stirring reaction is performed to obtain a first mixture; c, a low-temperature-resistant modifying agent is added into the first mixture; stirring and heating are performed; then, the powder mixture is added; stirring is performed to obtain a second mixture; d, a thickening agent, water and a defoaming agent are added into the secondmixture; heating and stirring are performed into a sticky state; the waterproof material is obtained. The prepared waterproof material has excellent characteristics of cold resistance, heat resistance, aging resistance, antibiosis, environment-friendly effect, long service life and the like.

Owner:合肥博之泰电子科技有限公司

Preparation method of natural cellulose fiber with flame-resistant function

ActiveCN103290502BLow costNo pollutionArtificial filament recoveryFibre treatmentSlurryCellulose fiber

Owner:ACELON CHEM & FIBER

A honeycomb type convection ventilation external wall thermal insulation device

ActiveCN105821987BImprove insulation effectImprove bearing capacityWallsLighting and heating apparatusThermal insulationHoneycomb

The invention discloses a cellular convection ventilation exterior wall heat insulation device, and relates to the technical field of heat insulation. The cellular convection ventilation exterior wall heat insulation device comprises a prefabricated heat insulation body, a cellular convection ventilation heat insulation module, an upper ventilation assembly and a lower ventilation assembly, wherein the prefabricated ventilation airflow channel is arranged in the prefabricated heat insulation body; the upper ventilation assembly is located at the upper end of the cellular convection ventilation heat insulation module and is communicated with the cellular convection ventilation heat insulation module; and the lower ventilation assembly is located at the lower end of the cellular convection ventilation heat insulation module and is communicated with the cellular convection ventilation heat insulation module. The cellular convection ventilation exterior wall heat insulation device has the beneficial effects that a cavity-type cellular convection heat preservation and insulation wall body penetrating up and down is achieved; through the arranged automatically controlled heat insulation airtight valve, the cellular convection ventilation exterior wall heat insulation device has ventilating and cooling performance in summer and heat preservation and insulation performance in winter; by a cellular bionic design, the structure is firm; and the cellular convection ventilation exterior wall heat insulation device and a prefabricated standard component are subjected to integral construction.

Owner:INNER MONGOLIA UNIV OF TECH

Waterborne rusty coating for protecting coating of steel-structure work pieces and preparation method thereof

ActiveCN102911565BWide variety of sourcesWith cleaner productionAnti-corrosive paintsCross-linkPolymer chemistry

The invention belongs to the field of anticorrosive protection of coatings of steel structures, and particularly relates to a waterborne rusty coating for protecting the coating of steel-structure work pieces and a preparation method thereof. Antirust pigment is mixed with 8 to 12 parts of water, and ground and dispersed to fineness of 20 to 60 micrometers; and then a cross-linked styrene-acrylate emulsion, a converting agent, a conversion accelerating agent, a defoaming agent, film forming additives, a thickening agent and the balance amount of water are added to the antirust pigment, evenly stirred therewith and packaged. According to the preparation method, the waterborne rusty coating for protecting the coating of the steel-structure of work pieces, which uses the cross-linked styrene-acrylate emulsion as the main film forming agent, is developed on the basis of a film forming mechanism of the cross-linked styrene-acrylate emulsion through screening and compounding main components such as the cross-linked styrene-acrylate emulsion and other film forming additives. A product has the characteristics of no toxicity, harmlessness, no pollution, wide raw material source, low cost, clean production, and the like, and is simple to operate.

Owner:合肥华清高科表面技术股份有限公司

A heating method for assembly and molding of middle-connected terminals

ActiveCN105048251BResolve distortionImprove production rateContact member assembly/disassemblyConnection insulationEngineeringCopper

The invention discloses a heating method for assembling and molding intermediate terminals. The method is to fix both ends of a heat-shrinkable tube covered with a copper sleeve and then rotate synchronously, and introduce a clean heat source such as an alcohol lamp under the heat-shrinkable tube where the copper sleeve is located. heating. Adopting the technical solution provided by the present invention, compared with the traditional heating method, the present invention has the advantage of cleaner production, and more importantly, through the synchronous rotation and heating at both ends of the heat shrinkable tube, both sides of the heat shrinkable tube shrink uniformly, which solves the problem of assembly shrinkage heat. The problem of twisting the shrink tube improves the production rate of the intermediate connection terminal.

Owner:深圳市智豪特材科技有限公司

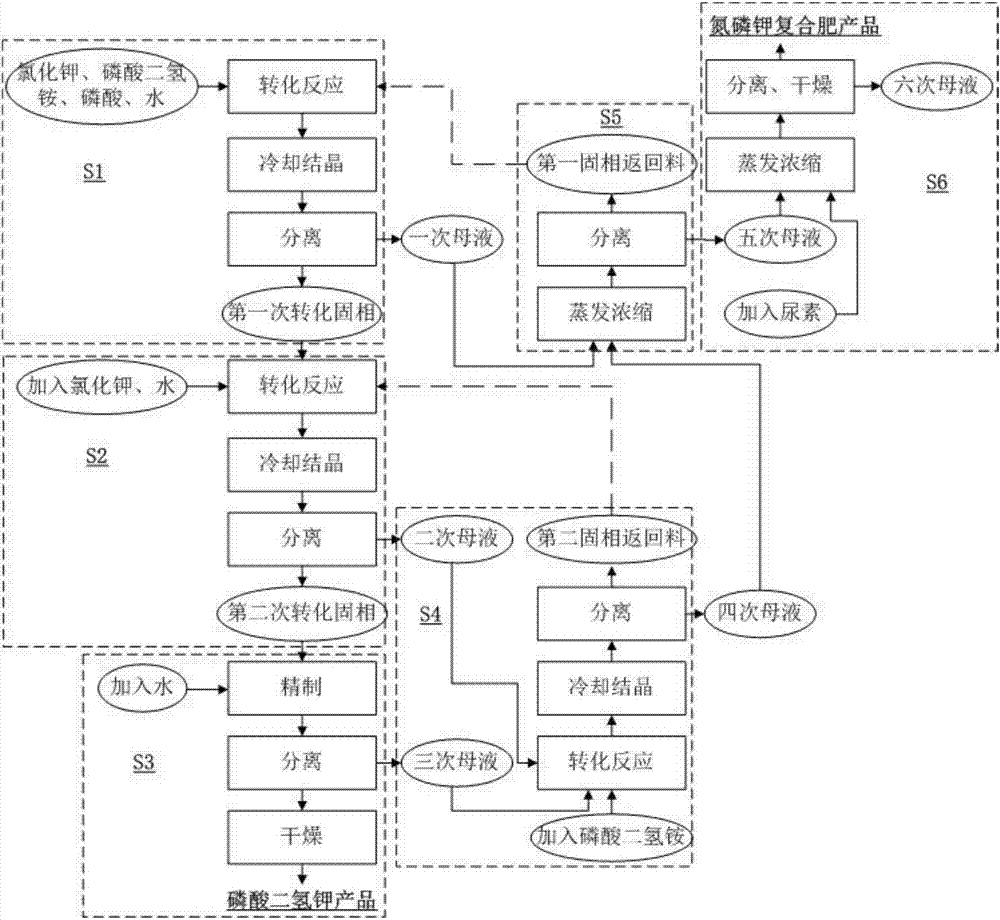

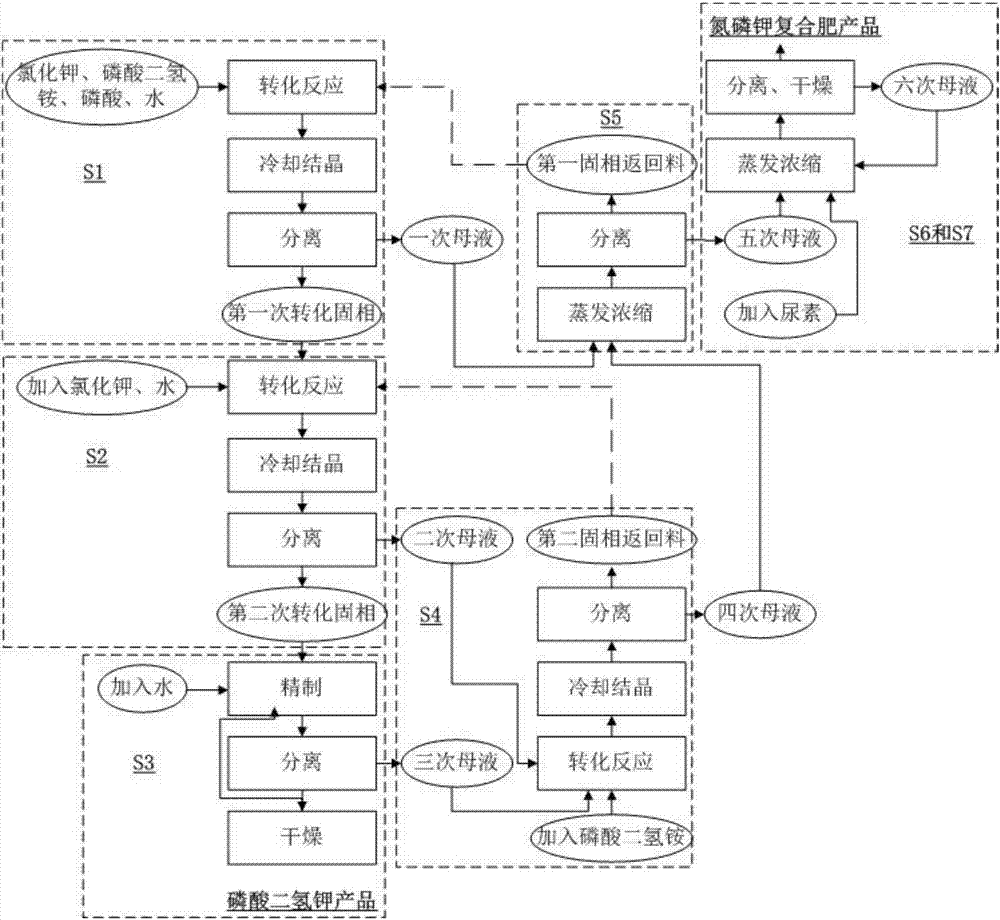

Method for co-producing monopotassium phosphate and nitrogen phosphorus and potassium compound fertilizer

InactiveCN107500828ARealize joint productionImprove qualityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphoric acidMonopotassium phosphate

The invention relates to the technical field of fertilizer production, and in particular to a method for coproducing monopotassium phosphate and nitrogen phosphorus and potassium compound fertilizer. The method comprises the following steps: S1, carrying out hybrid reaction on potassium salt, ammonium dihydrogen phosphate, phosphoric acid and water, and separating to obtain a first-time conversion solid phase and a primary mother solution; S2, carrying out hybrid reaction on the first-time conversion solid phase, sylivine and the water, and separating to obtain a second-time conversion solid phase and a secondary mother solution; S3, mixing the second-time conversion solid phase with the water, stirring, and separating to obtain a monopotassium phosphate product and a tertiary mother solution; S4, carrying out hybrid reaction on the tertiary mother solution, the secondary mother solution and the ammonium dihydrogen phosphate, and separating to obtain a second solid phase return scrap and a quartic mother solution, and returning the second solid phase return scrap to the step S2 for participating in the reaction; S5, mixing the quartic mother solution with the primary mother solution, and separating to obtain a first solid phase return scrap and a quintic mother solution, and returning the first solid phase return scrap to the step S1 for participating in the reaction; S6, mixing the quintic mother solution with urea, and separating to obtain a nitrogen phosphorus and potassium compound fertilizer product and a sextic mother solution. The method has the advantages of reasonable cost and low pollution emission.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com