Recovery method of valuable metal in vanadium chromium slag

A technology of valuable metals and recovery methods, applied in the field of metallurgy, can solve problems such as the inability to achieve economical and efficient separation and extraction of vanadium and chromium, and chromium pollution, and achieve the effects of fast reaction rate, low operating temperature, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

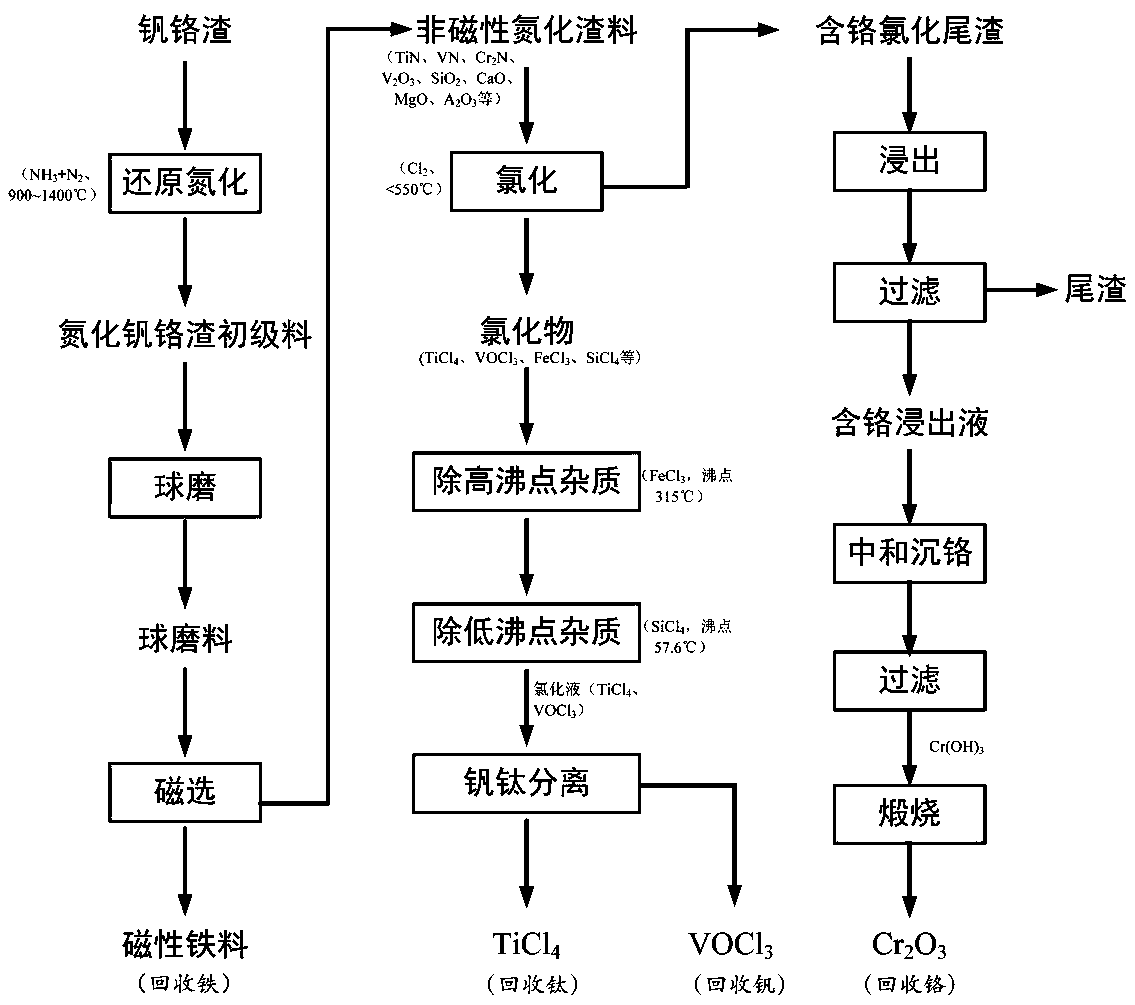

[0030] Example: see figure 1 A method for recovering valuable metals in vanadium-chromium slag, comprising the following steps:

[0031] Using vanadium chromium slag as raw material, the process method of the invention is used to recover valuable metals. The percentages of valuable elements in the vanadium-chromium slag raw materials are as follows: V 7.57%, Cr 4.04%, Fe 28.0%, Ti 8.76%, Si 5.97%, Mn4.26%, Ca 2.14%, Mg 1.62%, Al 1.69%.

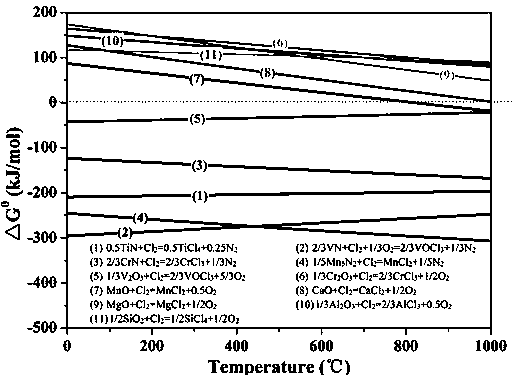

[0032] S1: Mix the fine powder of vanadium with 10% NH in the fluidized bed 3 , 90%N 2 The mixed gas reacts for 4 hours, and the operating temperature is 1200°C. Specifically, 900°C, 950°C, 1300°C or 1400°C can be selected, and the primary material of vanadium chromium nitride slag is obtained by cooling. The slag contains 75% V, 68% Cr, 90% of Ti is nitrided and 99% of Fe is reduced to metallic iron and iron nitride.

[0033] S2: The above-mentioned vanadium chromium nitride slag primary material is fully ball milled in a ball mill, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com