Patents

Literature

172results about "Chromium trioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

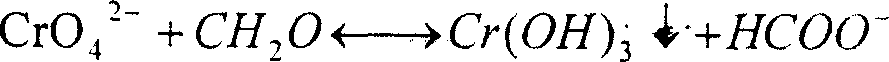

Method of preparing chromium oxide powder using water heat reducing chromate

InactiveCN100999335AControl particle size distributionGood dispersionChromium trioxideSlurrySurface-active agents

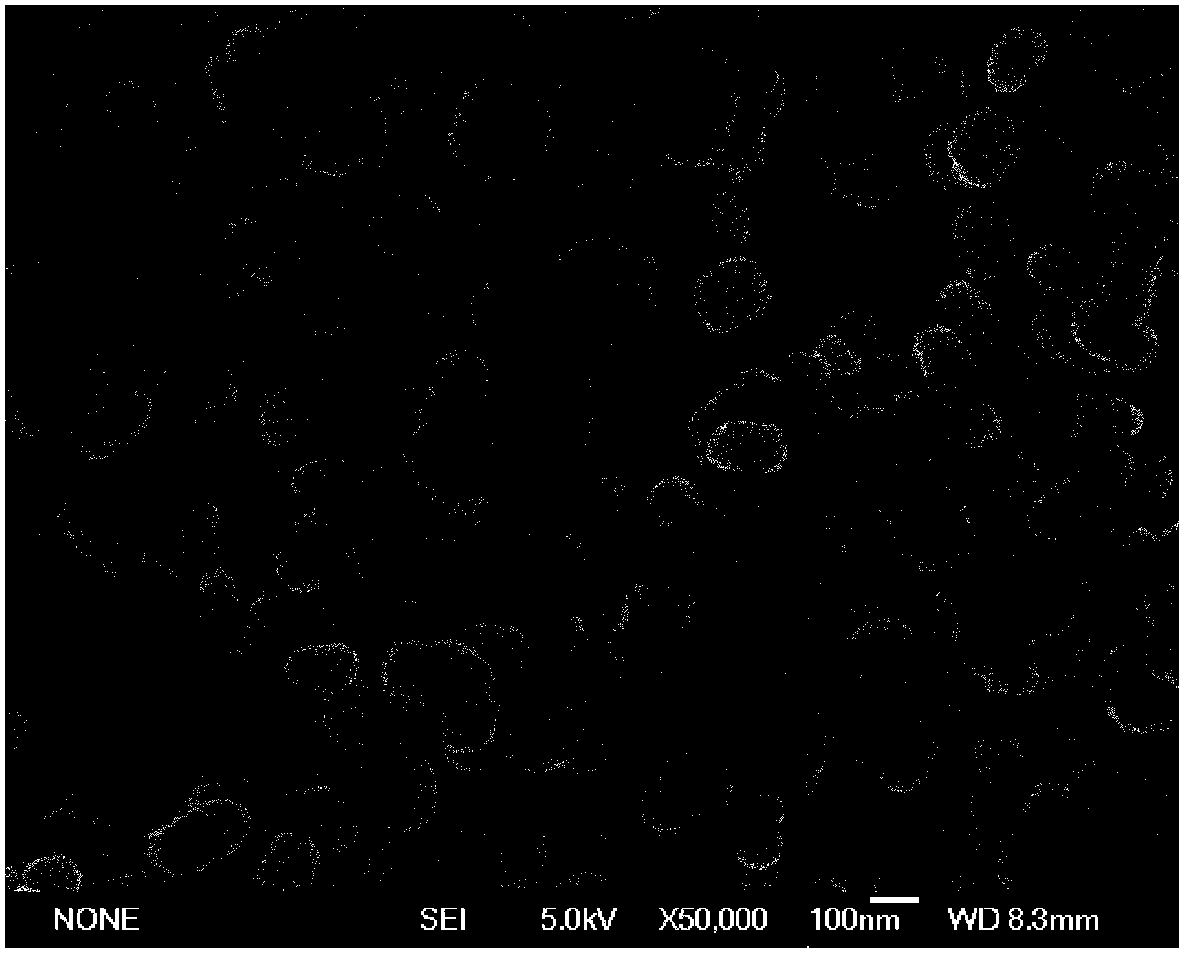

This invention relates to a preparation method that prepares chromic oxide powder by using water heat to deoxidize chromate. Use chromate water solution as raw material, CO2 as acidifying agent, process by surface active agent, directly deoxidize at condition of heat water, get hydrated Cr2O3 slurry, centrifugalize, separate, dry, calcinate hydrated Cr2O3 at different temperature, prepare globular Cr2O3 micropowder. Its grade size is between submicron and nanometer. This invention utilizes surface active agent to control sexavalent chromic salt which can be directly deoxidized to get trivalence chrome crystal. It can control hydrated chromic oxide calcinating temperature to prepare globular Cr2O3 micropowder of which grade size can be controlled.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method of preparing chromium oxide using precarbonation wet reducing potassium chromate or sodium chromate

InactiveCN1410356AIncrease acidityImprove the reduction conversion rateChromium trioxideSucrosePotassium

A process for preparing chromium oxide from potassium (or sodium) chromate by the pre-carbonating and wet reduction method includes such steps as preparing the aqueous solution of potassium (or sodium) chromate, pre-carbonating by CO2 gas, reducing by a reducer to obtain the hydrate of chromium oxide, filtering, drying, high-temp. calcining under protection of inertial gas, washing and drying to obtain the alpha-Cr2O3.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Process for roasting chromite resources in ring kiln through pure oxygen by using low-temperature method and harmlessly and deeply utilizing chromium residue

InactiveCN101824530AImprove resource conversion rateMagnesium carbonatesChromium trioxideSodium bicarbonateSlag

The invention belongs to the field of metallurgy and chemical engineering. The process comprises the following steps of: firstly, crushing chromite, adding sodium hydroxide and a catalyst to be oxidized and roasted by using a low-temperature pure oxygen method; diluting, cooling, extracting and filtering to obtain a sodium chromate crystal and ferrum-magnesium slag; adding an alkali washing solution into a sodium hydroxide solution to back extract to obtain the sodium hydroxide solution for recycling; adding water into the sodium chromate crystal and ferrum-magnesium slag to be dissolved and feeding filtrate into a carbonizer to decompose to extract aluminum; carbonizing, evaporating, condensing and crystallizing the extracted solution to obtain sodium chromate; and carbonizing ferrum-magnesium filter slag to generate sodium bicarbonate, reacting to generate a magnesium hydrogen carbonate solution, heating and cracking to generate a magnesium carbonate product and drying a filter cake to obtain ore refined powder; and secondly, crushing chromium residue, adding sodium bicarbonate in the ration of 1:8, adding a catalyst for calcination, cooling and adding water to soak; adding an aluminum hydroxide crystal into supernatant liquid, carbonizing and decomposing to remove aluminum in a reaction tank; filtering and washing an aluminum hydroxide product; adding a reducing agent into the filtrate to reduce hexavalent chromium to generate anhydrous chromium hydroxide and drying and roasting to obtain chromium sesquioxide; and returning the filtrate to a system for mixing after pyrolyzing and extracting to remove magnesium.

Owner:白向南 +2

Method for producing chromic oxide by using sludge of containing chrome

A process for preparing Cr2O3 from the Cr contained sludge includes water washing, press filtering for dewatering, drying, calcining to obtain coarse Cr2O3 product, removing the water-soluble impurities by use of hot water, centrifugal drying, baking, grinding and sieving.

Owner:高志远

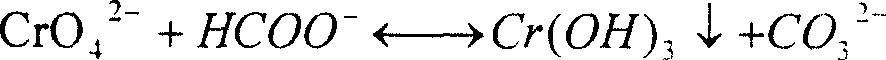

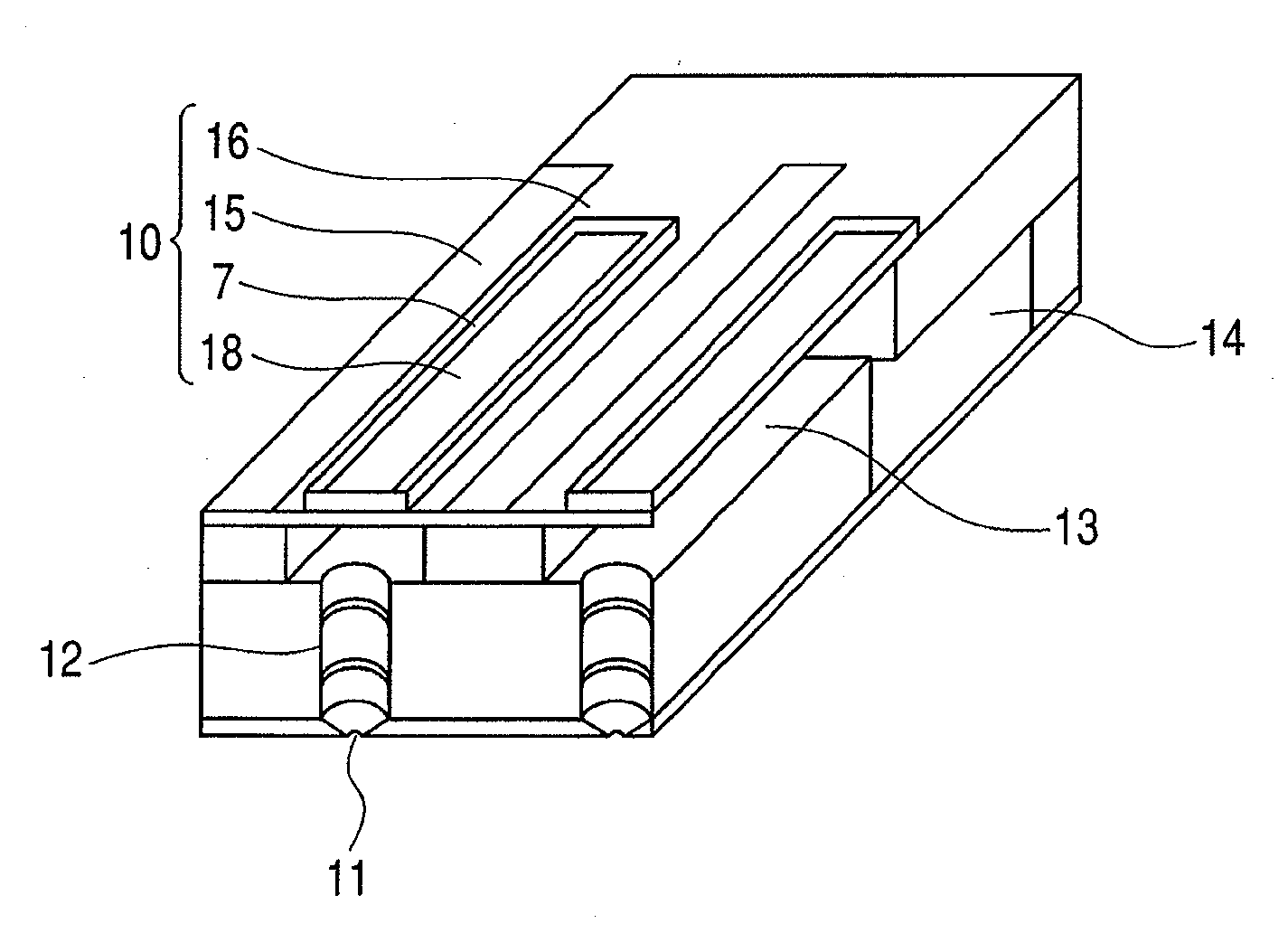

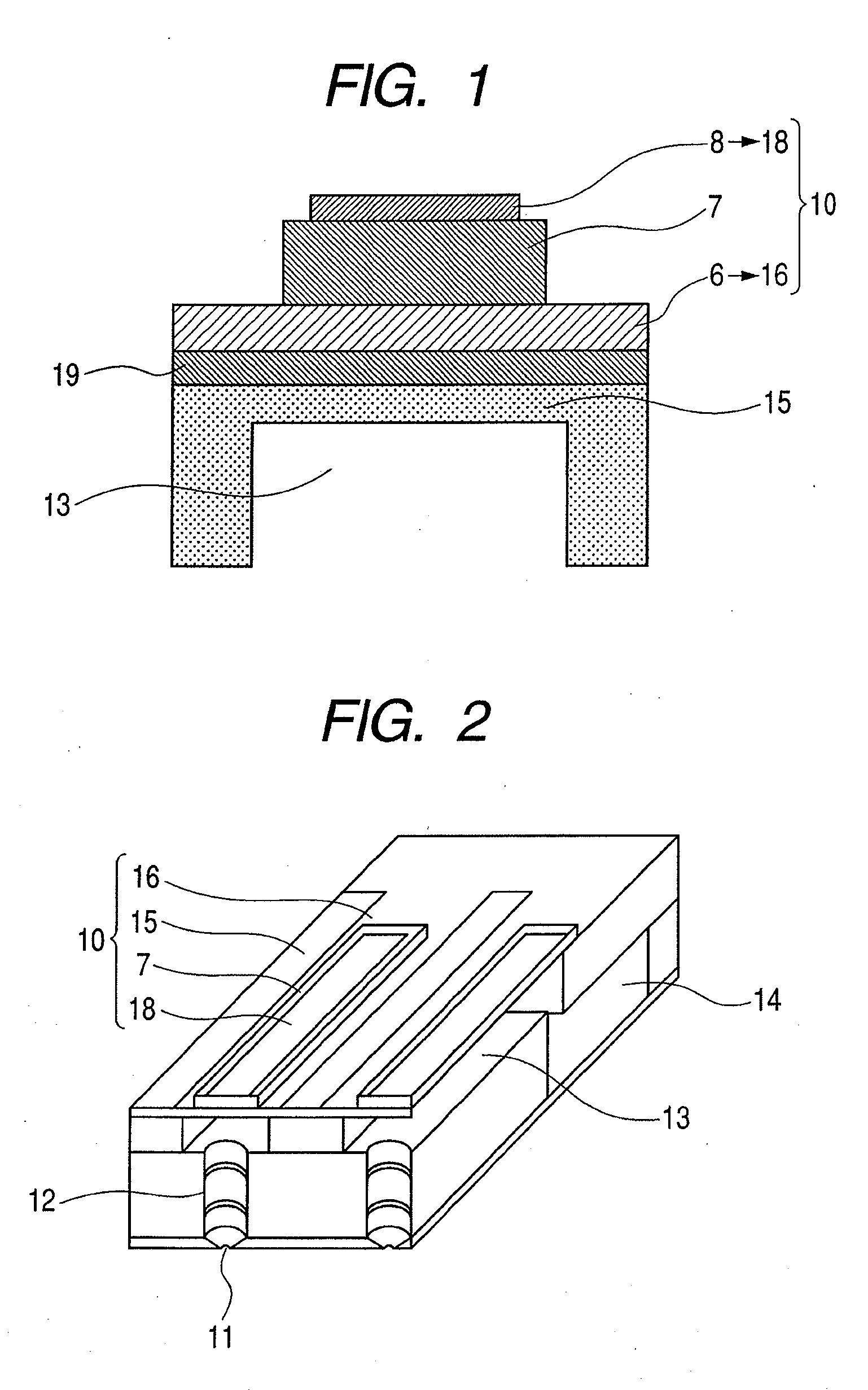

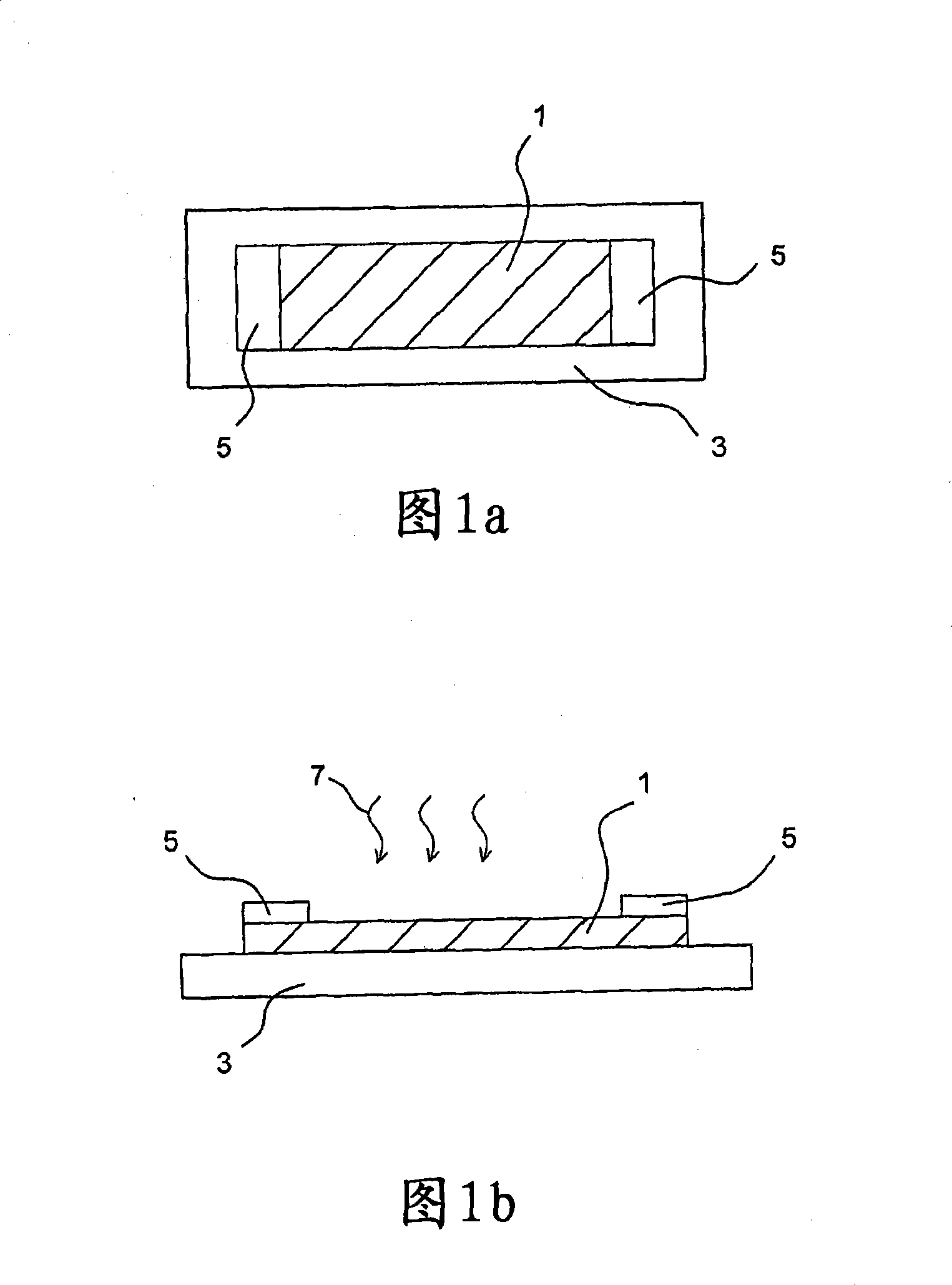

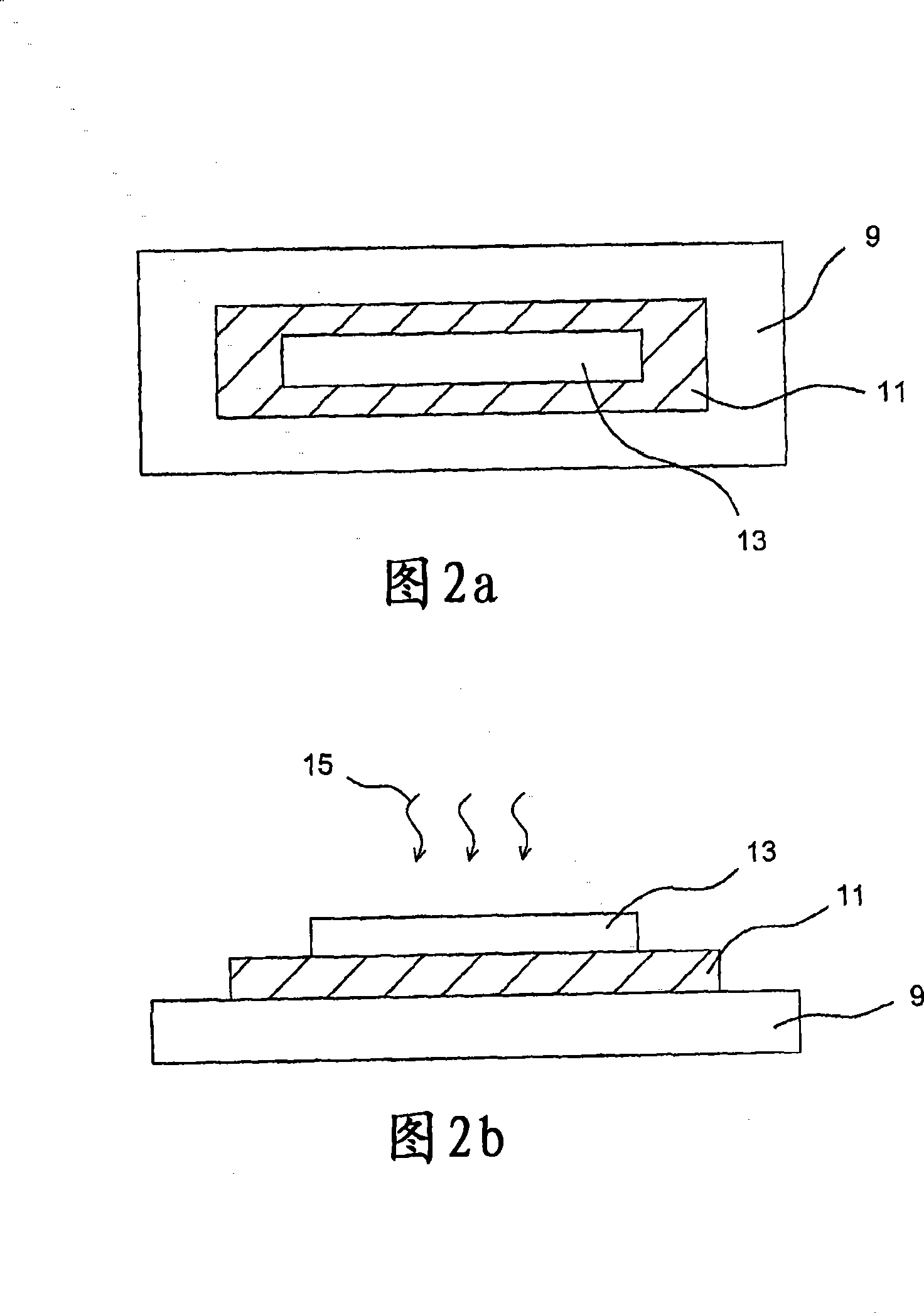

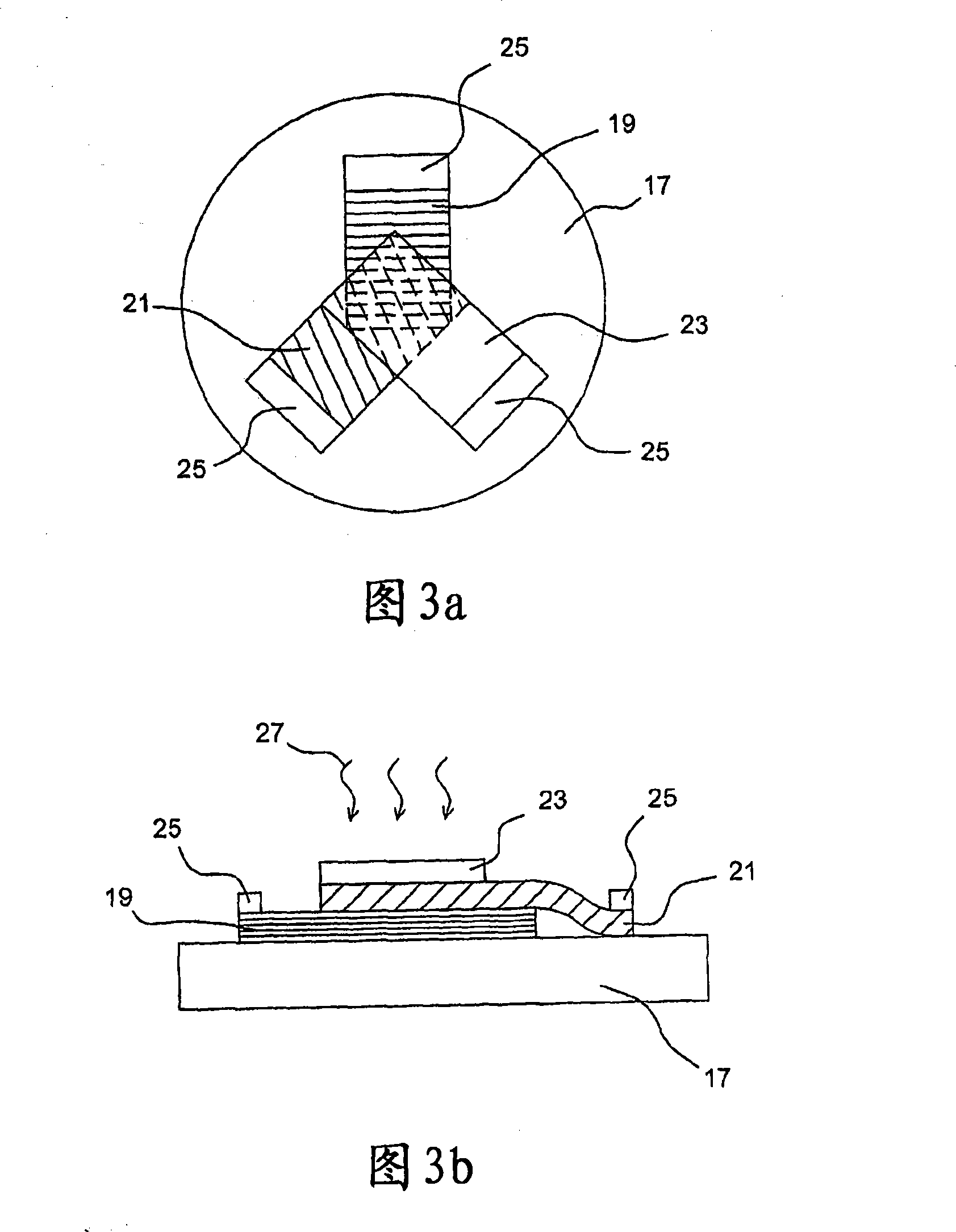

Piezoelectric body and liquid discharge head

InactiveUS20080089832A1Excellent piezoelectric propertiesLarge discharge forceInking apparatusPiezoelectric/electrostriction/magnetostriction machinesEngineeringPerovskite

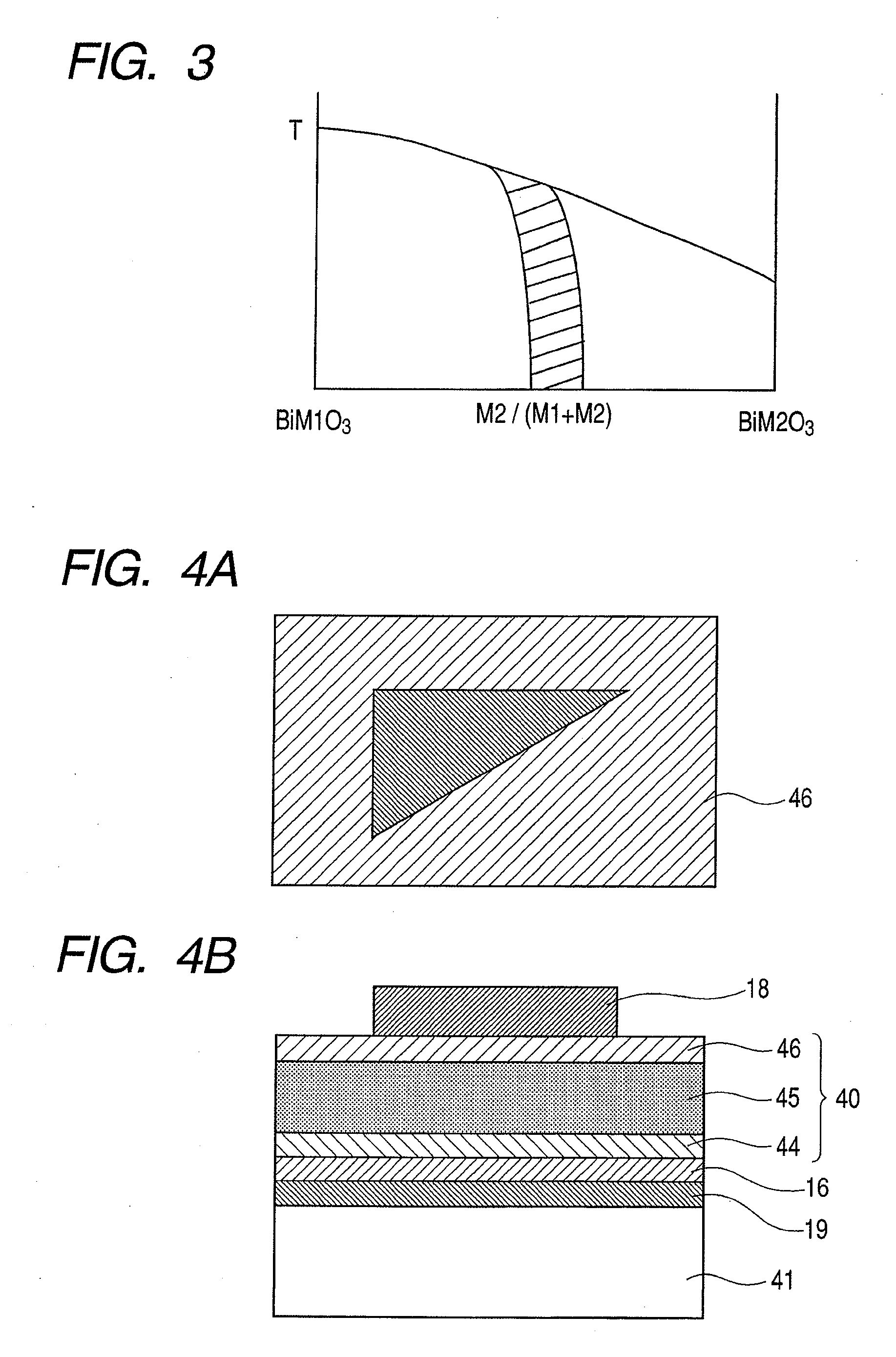

The present invention provides a piezoelectric element and having a piezoelectric body and a pair of electrodes being contact with the piezoelectric body, wherein the piezoelectric body consists of an ABO3 perovskite oxide in which an A-site atom consists of Bi and a B-site atom is composed of an atom of at least two types of elements.

Owner:CANON KK

Method of producing dichromium trioxide using chromic acid thermal decomposition continuous method

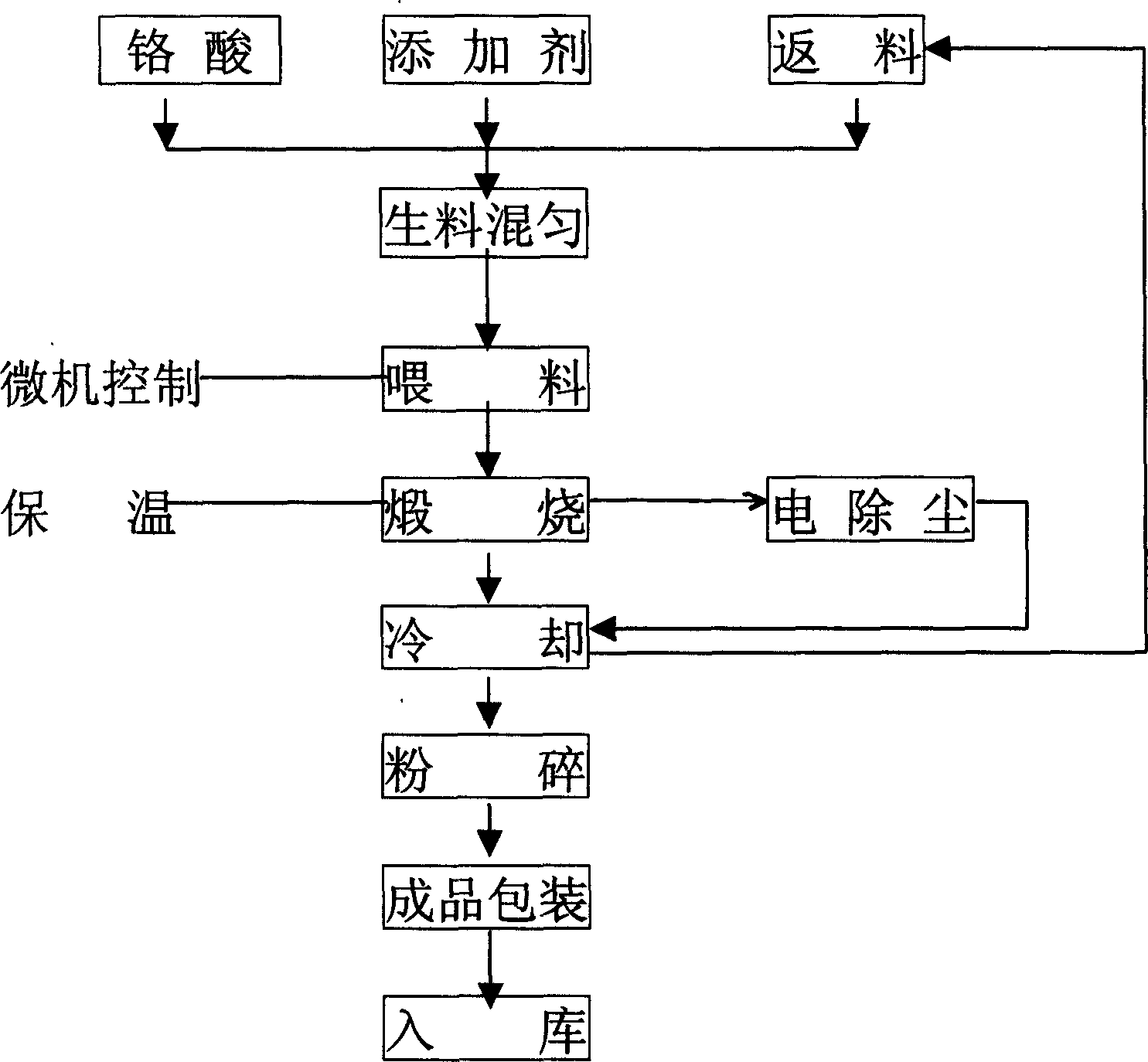

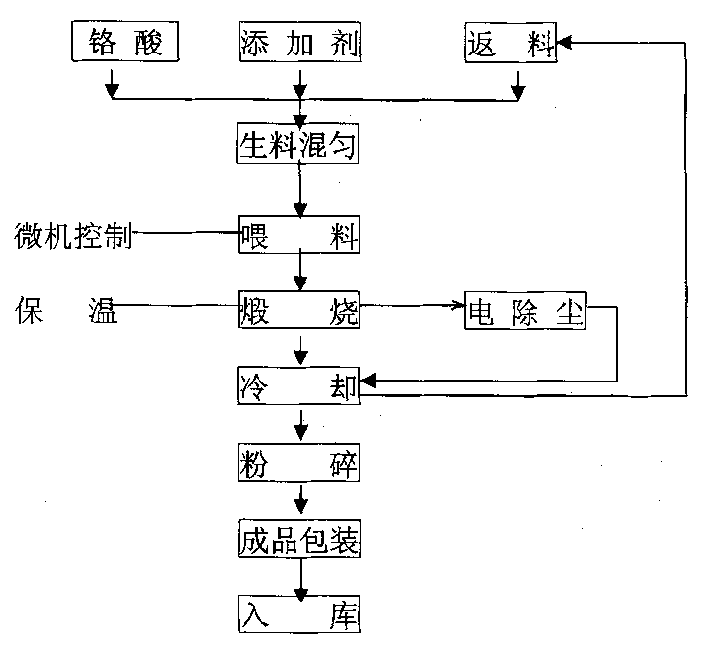

InactiveCN1459419AHigh thermal efficiencyReduce consumptionChromium trioxideLiquid gasComputer control

A process for preparing Cr2O3 by continuous thermodecomposition of chromic acid includes such steps as proportionally mixing chromic acid, coarse Cr2O3 as returning charge and additive chosen from boric acid (preferable), ammonium chloride, starch and saw dust; after uniformly mixing under a computer control, parallel-flow combustion of the said mixture and liquefied gas as fuel in an insulated rotary furnace, thermodecomposition reaction to generate Cr2O3, keeping the temp. for a certain time, cooling and pulverizing to obtain the product. The unpulverized material is used as the said returning charge.

Owner:民乐县化工厂

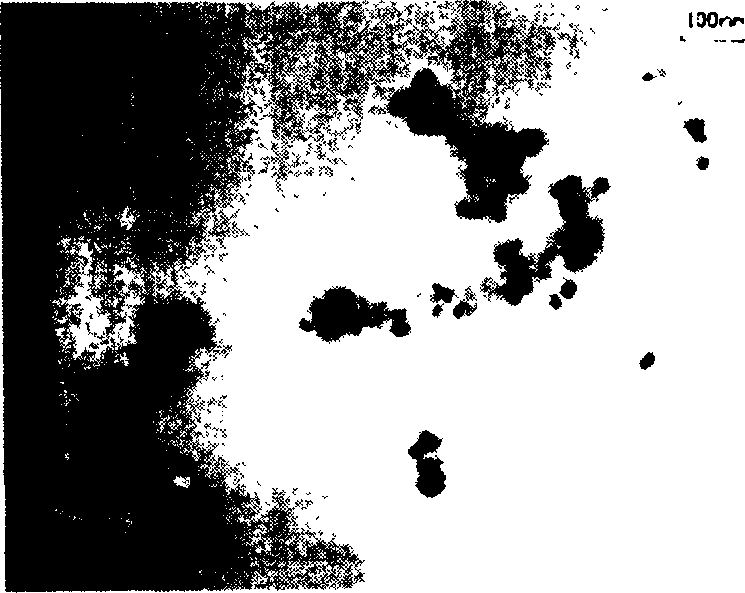

Methods for production of metal oxide nano particles, and nano particles and preparations produced thereby

The invention provides a method for the formation of small-size metal oxide particles, comprising the steps of: a) preparing a starting aqueous solution comprising at least one of metallic ion and complexes thereof, at a concentration of at least 0.1 % w / w of the metal component; b) preparing a modifying aqueous solution having a temperature greater than 5O0C; c) contacting the modifying aqueous solution with the starting aqueous solution in a continuous mode in a mixing chamber to form a modified system; d) removing the modified system from the mixing chamber in a plug-flow mode; wherein the method is characterized in that: i) the residence time in the mixing chamber is less than about 5 minutes; and iii) there are formed particles or aggregates thereof, wherein the majority of the particles formed are between about 2nm and about 500nm in size.

Owner:朱马国际公司

Grain size adjustable spherical chromium oxide superfine powder preparing method

InactiveCN1454850ALess craftLess investment in equipmentOxide/hydroxide preparationChromium trioxideSURFACTANT BLENDLiquid phase

The preparation method of spherical Cr2O3 high-purity ultrafine powder body by using liquid phase method which can control grain size. It uses Na2Cr2O7 as raw material and adopts the processes of acidity reduction, surfactant treatment, pH value regulation, using composite precipitant to control precipitation, solid-liquor separation and roacting to obtain the fresh green spherical Cr2O3 ultrafine powder body with different grain size ranges, and its grain size can be controlled in the range of submicrometer and nanometer range according to the requirements. Said invention also provides a simple method for controlling its granule form and granule size, and said product has extensive application in functional coating material, special product special-purpose additive or special field special-purpose material field.

Owner:DALIAN UNIV OF TECH

Nano dichromium dioxide catalyst for preparing ethylene by using carbon dioxide to oxidate ethane and dehydrogenation

InactiveCN1515354AGood crystal formHigh purityHydrocarbon by hydrogenationChromium trioxideSal ammoniacDehydrogenation

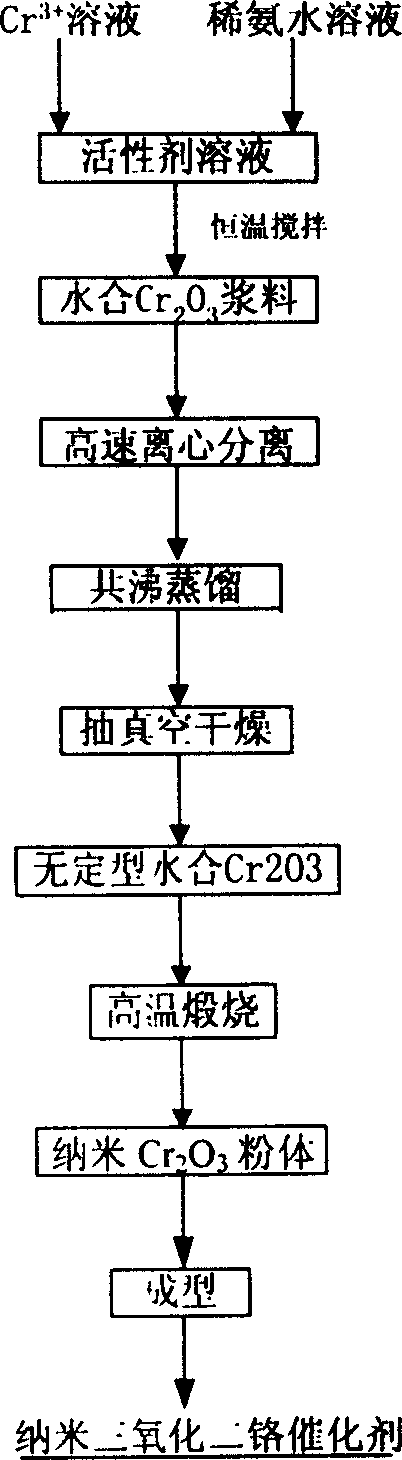

The present invention belongs to the fixed of catalyst for preparing ethylene, in particular, it relates to a nano chromium oxide catalyst for preparing ethylene by using carbon dioxide to oxidate ethane anjd dehydrogenation. The production process of the catalyst includes the following steps: mixing Cr(NO3)3 solution and dilute ammonia water solution, adding them into surfactant solution, making the pH value of the hydrated Cr2O3 nano slurry be retained at 9-11, separating to obtain hydrated Cr2O3 gel whose surface is covered with surfactant, coboiling the obtained hydrated Cr2O3 gel and normal butanol according to volume ratio of 1:6-8, distilling and separating to obtain alcoholic gel, drying and roasting to obtain nano Cr2O3 powder, tableting, grinding and sieving to 20-40 meshes so as to obtain the invented catalyst.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Process for recovering chromium from waste liquid of vitamin K3 production

InactiveCN101289227AEliminate pollutionSimple processChromium trioxideNature of treatment waterLiquid wasteAcetic acid

The invention provides a method for reclaiming chrome from the waste solution used for producing vitamin K3, the steps of which comprises that: firstly, the waste solution is distilled to dry at the temperature of 97 DEG C to 100 DEG C and the solution is reclaimed, so as to obtain the residue containing chrome which is then smashed to 200 to 300 meshes and then calcined or micro-waved in a macro wave oven at the temperature of 400 DEG C to 950 DEG C, so as to obtain chromic oxide with high purity, wherein, the main component of the waste solution is chromic acetate aqueous solution. The method of the invention has the advantages of simple process, easy operation and low reclaiming cost; the rate of recovery can reach 100 percent and the purity of the reclaimed chromic acetate is as high as 98.9 percent to 99.9 percent; the reclaimed chromic acetate aqueous solution can be used in reproduction, thus achieving zero release, thereby greatly reducing the production cost of vitamin K3. The method of the invention is applicable to the reclaiming of the waste solution when adopting 2-methyl naphthalin by oxidation of chromic anhydride / acetic acid to produce the intermediate product of 2-methyl naphthoquinone in the production process of the vitamin K3.

Owner:戴汉松

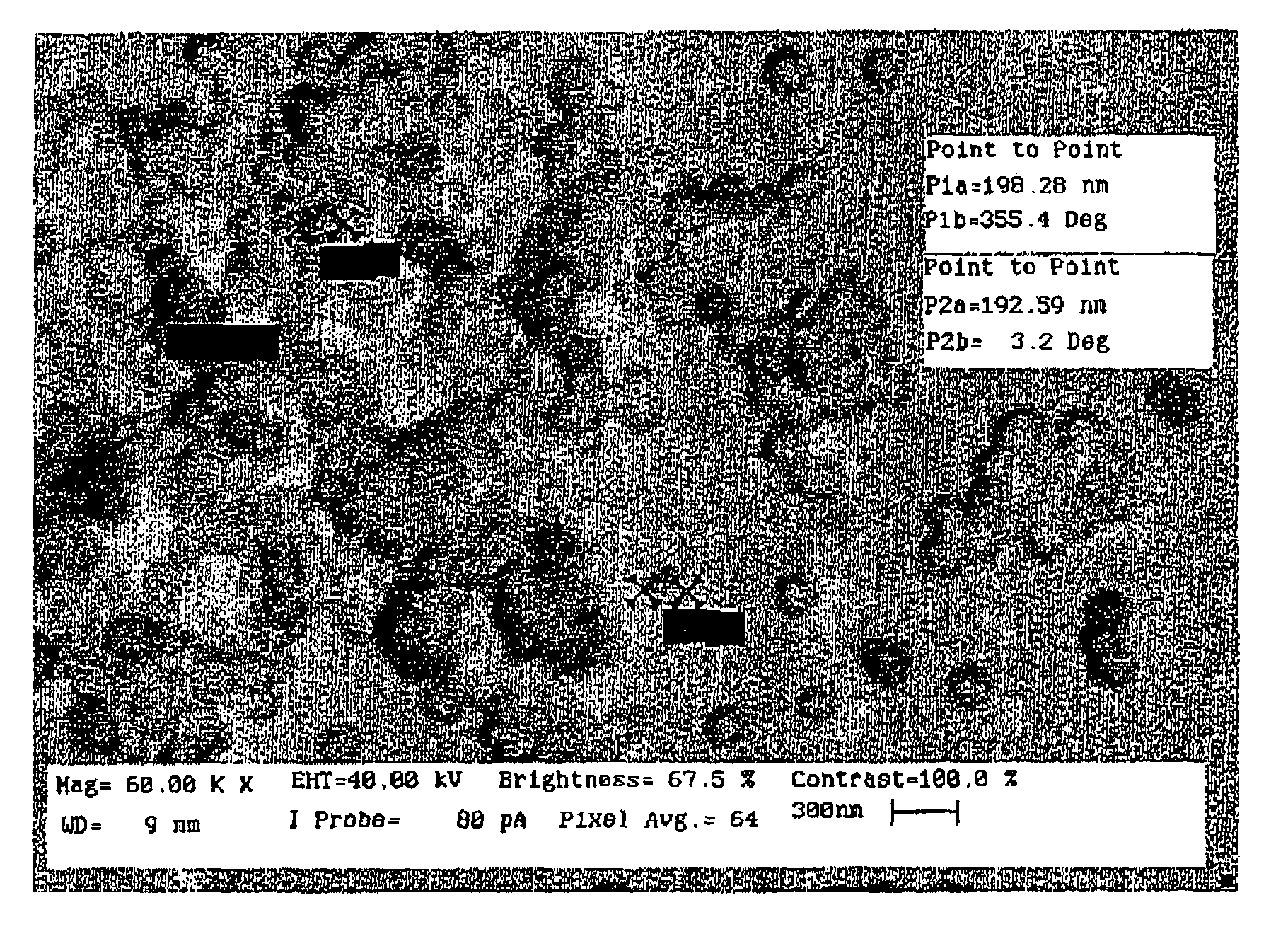

Molecular decomposition processes for the synthesis of nanosize metallic powders

InactiveUS7311754B2Improve solubilitySmall granularityMaterial nanotechnologyOxide/hydroxide preparationMetal alloySolvent

A method for synthesizing nanosize metallic powders can include providing a metallic precursor. The metallic precursor can include a metal alloy formed having a fugitive constituent and a target metal. The fugitive constituent and target metal are chosen such that the fugitive constituent can be selectively dissolved or removed by leaching with an appropriate solvent while leaving the target metal undissolved. The fugitive constituent can be leached from the metallic precursor to leave a metallic residue which is a mass of nanosize metallic particles made substantially of the target metal. The nanosize metallic particles can then be recovered from the metallic residue either merely by removing the solvent and / or breaking up the mass of nanosize metallic particles. The disclosed methods allow for a convenient avenue for production of nanosize particles from readily formed materials for use in a wide variety of potential industrial and commercial applications.

Owner:UNIV OF UTAH RES FOUND

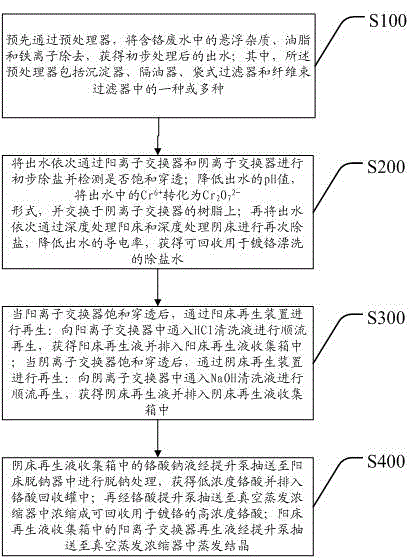

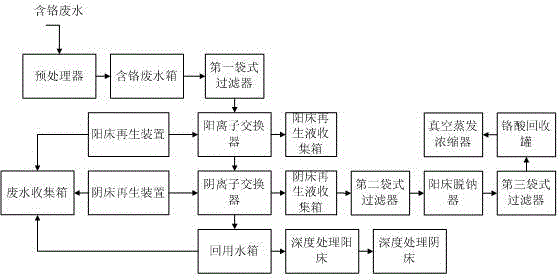

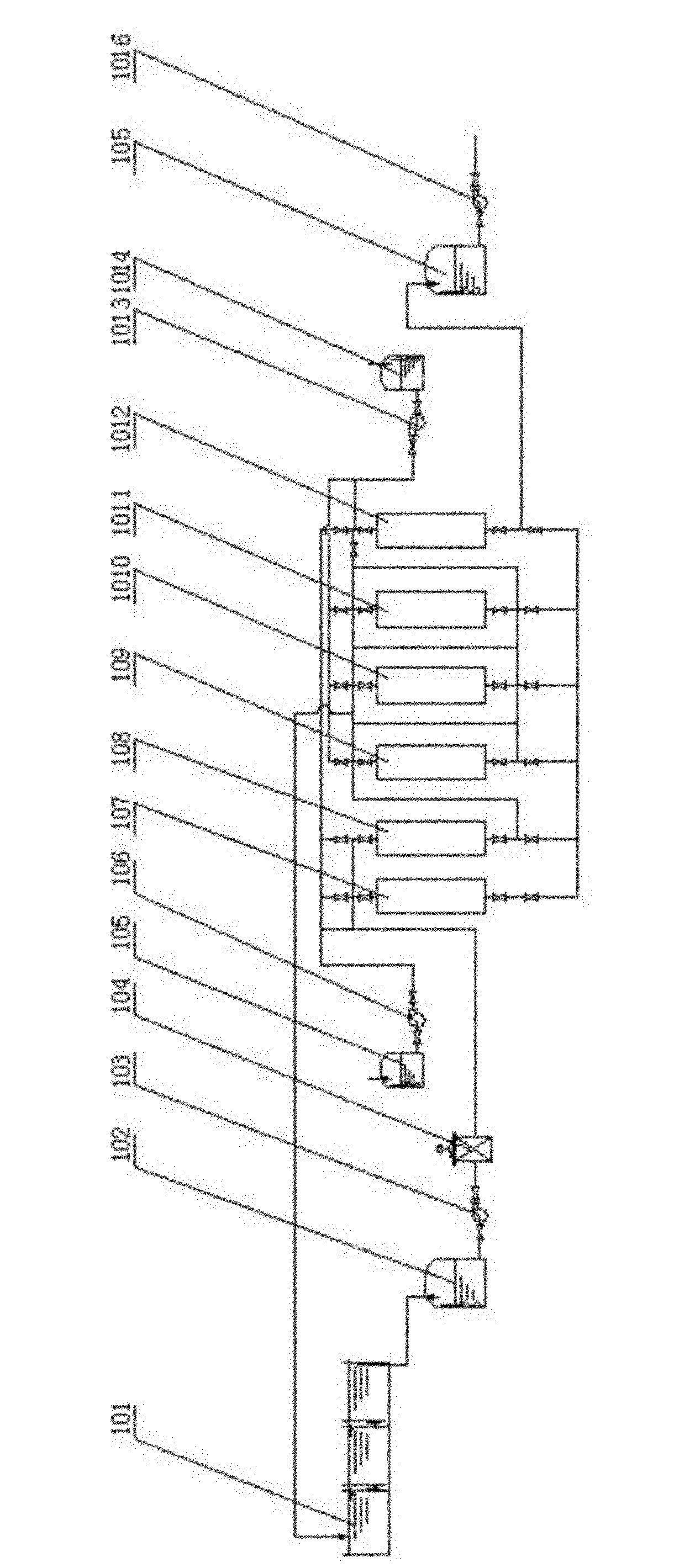

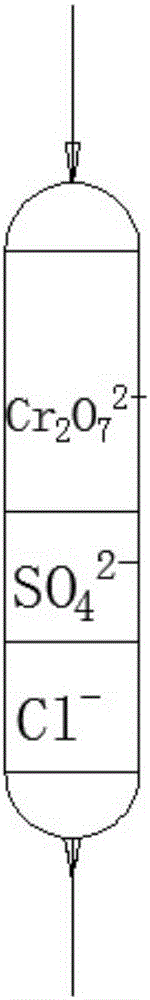

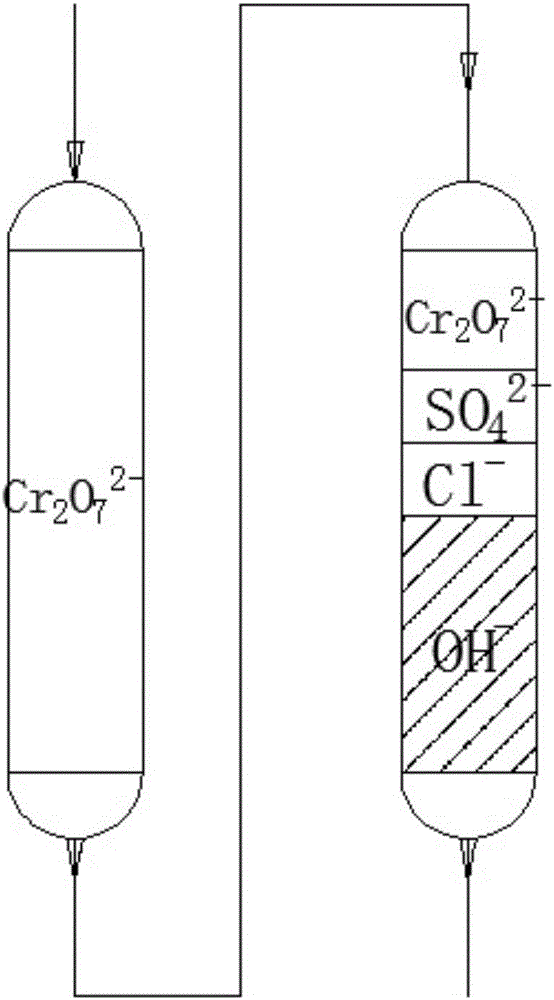

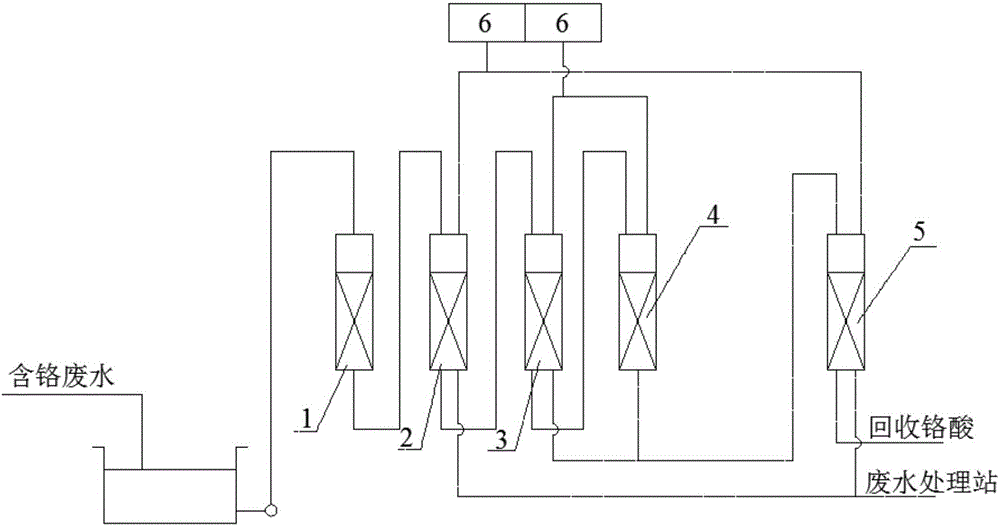

Electroplating chromium-containing wastewater treatment method and device

ActiveCN104909508ARealize closed loop recyclingReduce dosageGeneral water supply conservationWater contaminantsHigh concentrationImpurity

The invention discloses an electroplating chromium-containing wastewater treatment method and device. The treatment method comprises the following steps: (A) pre-removing impurities in chromium-containing wastewater by virtue of a pretreatment device, so as to acquire primarily treated effluent; (B) sequentially carrying out primary desalination on effluent by virtue of a cation exchanger and an anion exchanger, carrying out secondary desalination on effluent by virtue of an advanced treatment cation bed and an advanced treatment anion bed again, so as to obtain desalted water which can be recycled for chromium plating rinsing; (C) regenerating by virtue of a cation bed regeneration device when the cation exchanger is saturated and penetrated, and regenerating by virtue of an anion bed regeneration device when the anion exchanger is saturated and penetrated; and (D) carrying out sodium removal on anion bed regenerated liquid, and concentrating to form recyclable high-concentration chromic acid or carrying out evaporative crystallization. According to the electroplating chromium-containing wastewater treatment method, by virtue of a two-stage cation-anion bed system, the environmental pollution of hexavalent chromium is eliminated, and meanwhile, high-quality desalted water can be obtained and can be applied to production, so that the consumption of tap water and desalted water is saved, and the good economic benefit is achieved.

Owner:GUANGDONG XINTAILONG ENVIRONMENTAL PROTECTION GRP CO LTD

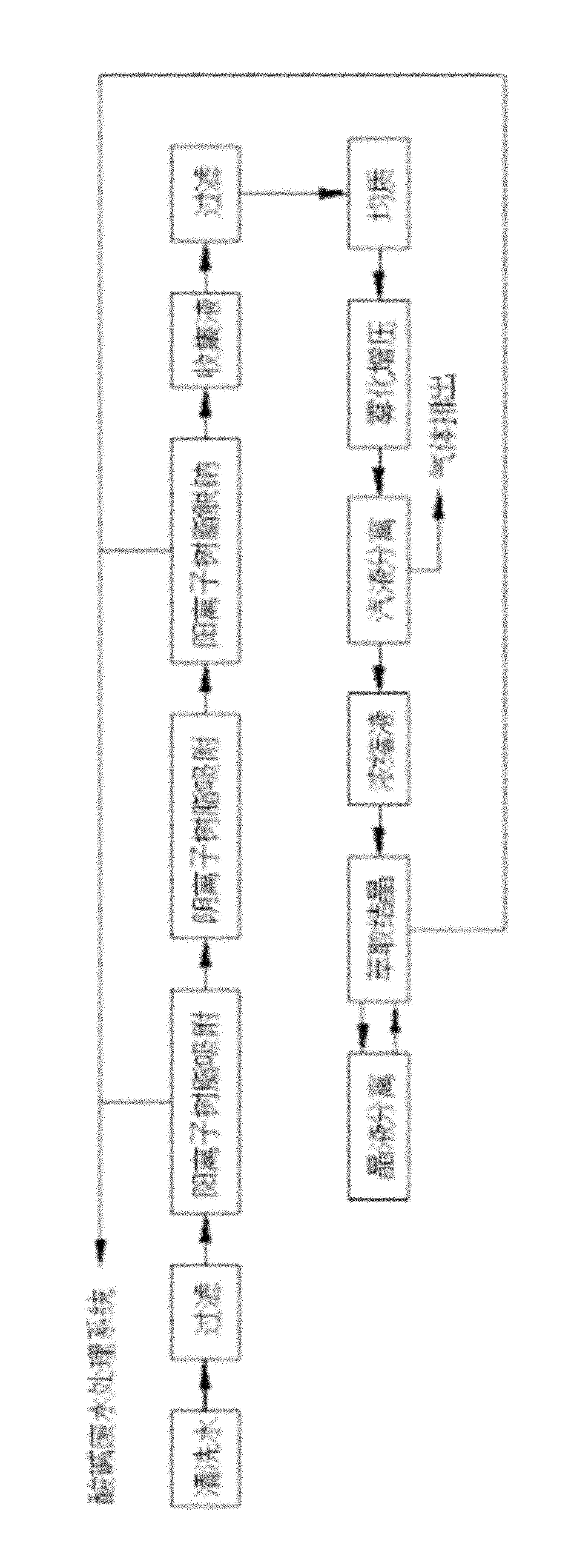

Method for recycling chromic acid in electroplating waste water

ActiveCN102001707AOvercoming the problems existing in the technical method of recyclingEasy to implementChromium trioxideResource utilizationEvaporation

The invention discloses a method for recycling chromic acid in electroplating waste water. A complete set of method which can be used for directly and efficiently recycling chromic acid from electroplating cleaning solution and obtaining chromic acid crystals is designed by making use of technical means such as ion exchange, atomization, evaporation, extraction, crystallization, separation and the like and comprehensively utilizing experiences obtained in practice and a method obtained by researches and experiments. Problems existing in the conventional recycling treatment technical method are solved by the method and chromic acid in electroplating waste water is recycled directly by the complete set of method so as to obtain a chromic anhydride raw material. Chromic acid in electroplating chromium-containing waste water is recycled fully by a complete set of device and is taken as an industrial raw material, so that a waste material is recycled, the environment is protected, resources are saved and remarkable economic, social and environmental benefits are achieved. The method is an important innovation for clean production, environmental protection and resource utilization technology.

Owner:NANJING YUANQUAN TECH CO LTD

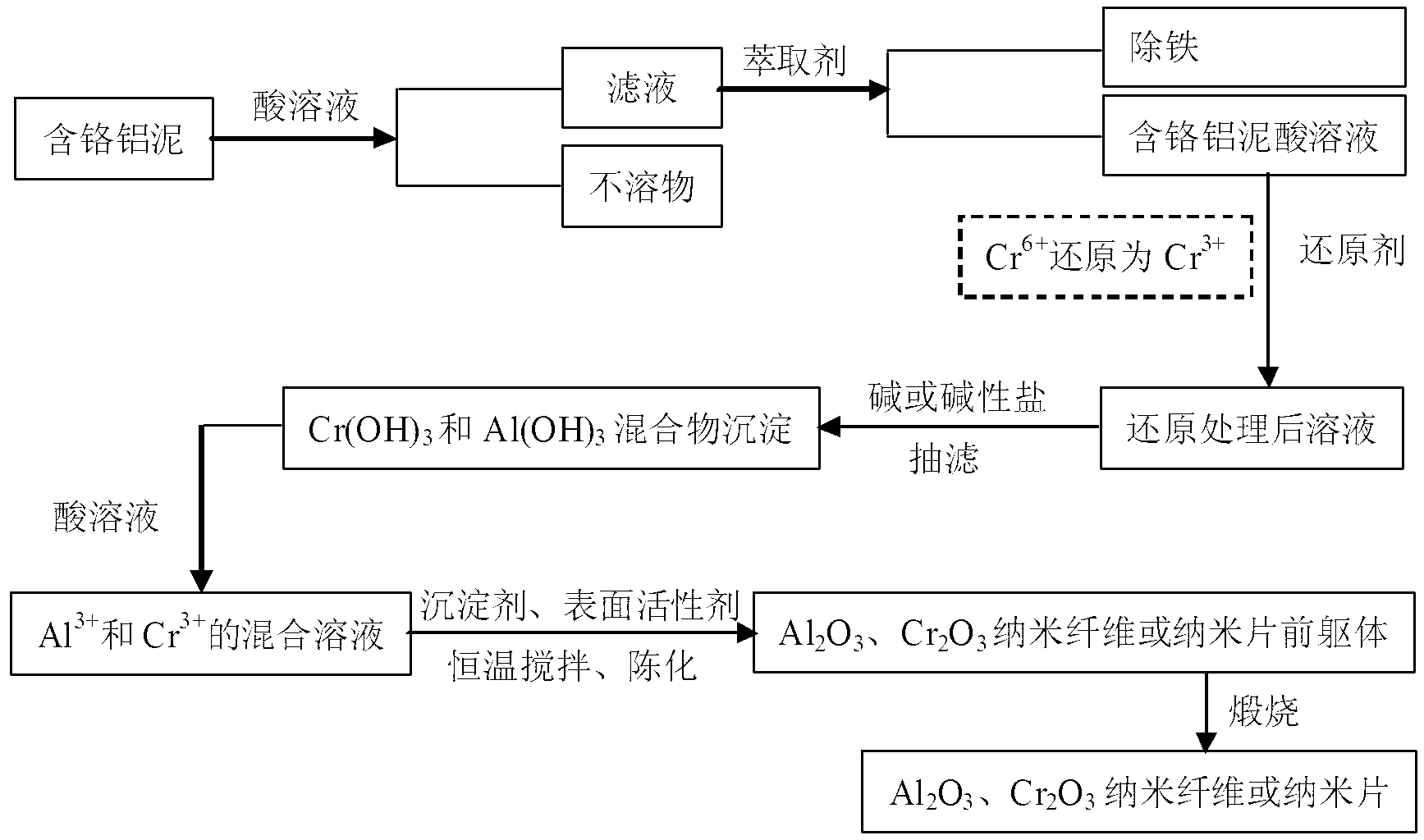

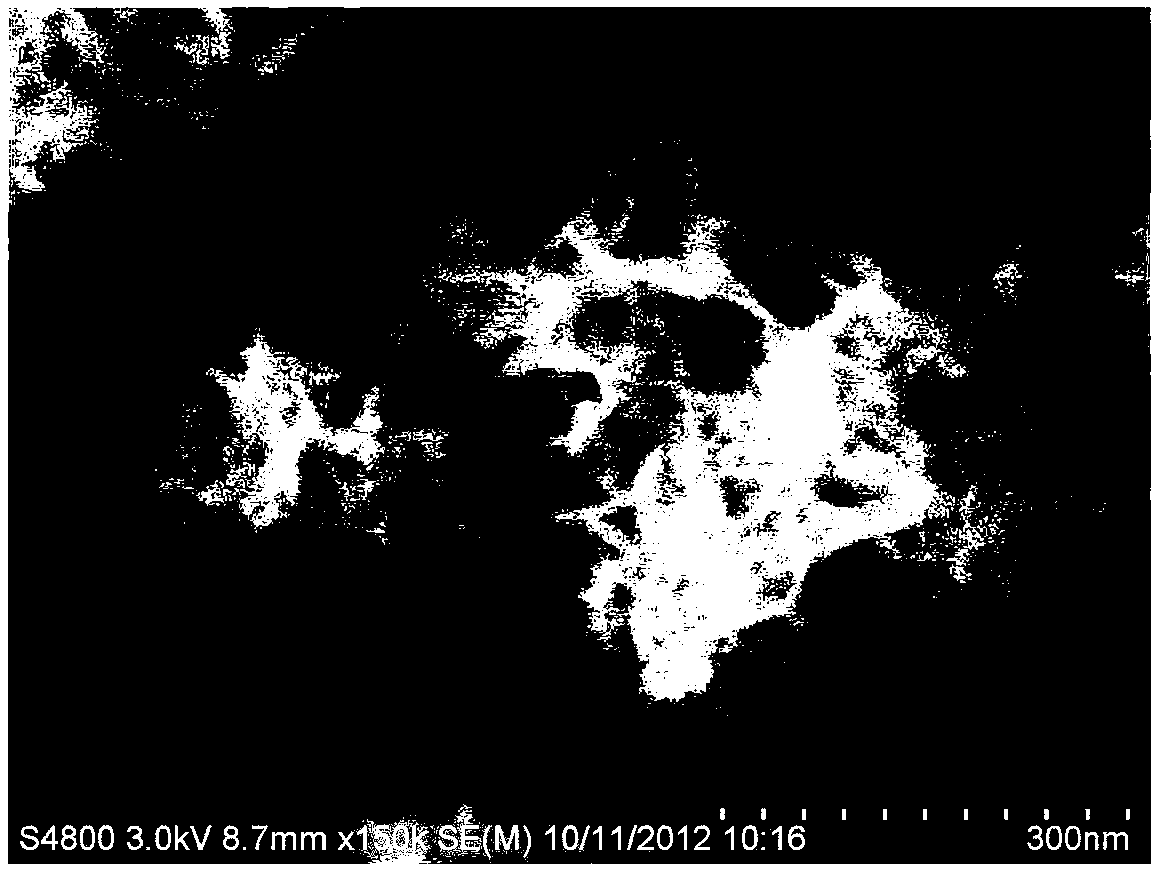

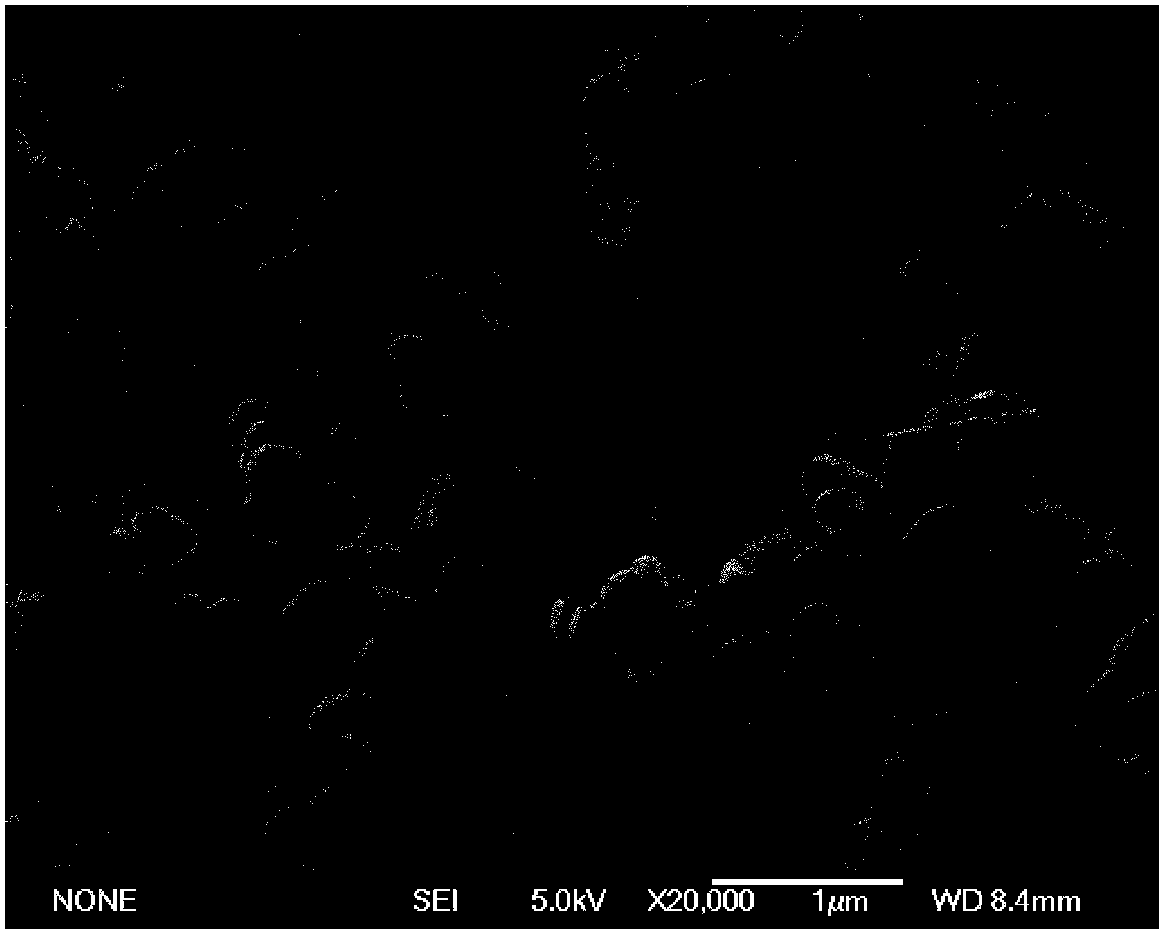

Al2O3, Cr2O3 composite nanofiber or nanosheet prepared from chromium-bearing aluminium sludge and preparation method thereof

InactiveCN103225131AQuick responseMild reaction conditionsMaterial nanotechnologyInorganic material artificial filamentsComposite nanofibersSludge

The invention mainly relates to an Al2O3, Cr2O3 composite nanofiber or nanosheet prepared from chromium-bearing aluminium sludge and a preparation method thereof. The method is performed according to the following steps: dissolving aluminium sludge with acid, removing iron, reducing, preparing a mixture of Al(OH)3 and Cr(OH)3, preparing an Al2O3, Cr2O3 composite nanofiber or nanosheet precursor, and finally preparing the Al2O3, Cr2O3 composite nanofiber or nanosheet. The preparation method provided by the invention has advantages of rapid reaction speed, mild and safe condition, controllable morphology and size of the product and low cost, and is suitable for popularization and application.

Owner:BOHAI UNIV

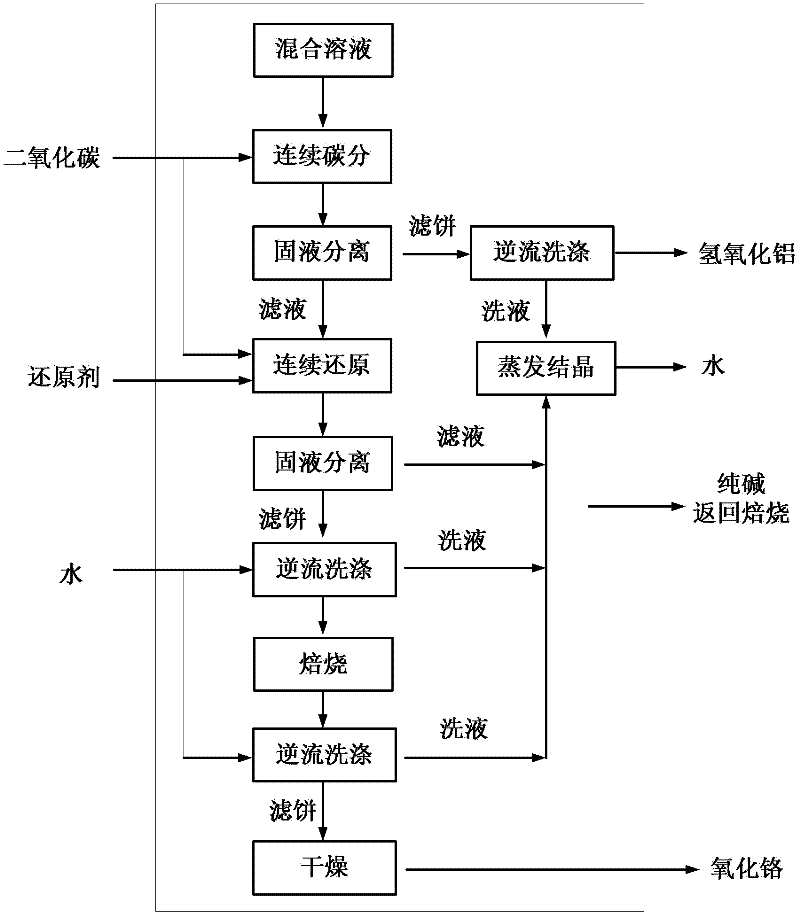

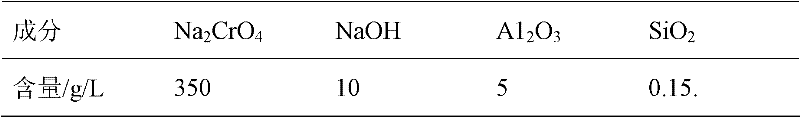

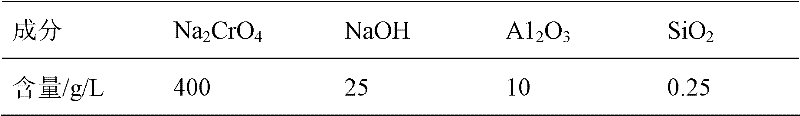

Sodium chromate alkali solution impurity removal method and preparation method of chromic oxide

ActiveCN102583541ARich sourcesLow priceChromium trioxideChromates/bichromatesDecompositionCalcination

The invention discloses a sodium chromate alkali solution impurity removal method and a preparation method of chromic oxide. According to sodium chromate alkali solution impurity removal, CO2 with rich resources and low cost serves as acidulant, aluminium and silicon are removed by continuous carbonating decomposition, and the removal rates of the aluminium and the silicon are high; new impurities are not introduced; and aluminium mud after sedimentation has thick and large particles, is low in chromium belt loss, and can be used in alumina industries after being filtered and washed, thus having a high added value. Impurities and sodium chromate solution are separated to obtain solution, cheap and rich starch and derivatives of the starch serve as reductants, and hydrated chromium hemitrioxide is prepared under a hydrothermal reducing condition, and then pigment-level chromium hemitrioxide is generated after dehydration and calcination. The reducing condition is mild, the conversion rate is higher than 90%, slurry easy to filter and wash, and final filtrate and alkaline rinse in production process can be returned to mix with chromite to enter a calcination process, thereby recycling sodium carbonate. According to the invention, the process adopted for generating the chromium hemitrioxide is simple and environment-friendly, the cost is low, and industrialization is easy to realize.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Molecular decomposition process for the synthesis of nanosize ceramic and metallic powders

InactiveUS6803027B1Easy to implementImprove scalabilityMaterial nanotechnologyTantalum compoundsSolventMetal powder

A process is disclosed for forming a nanosize ceramic powder. A precursor ceramic material is formed of a fugitive constituent and a non-soluble constituent in a single phase. The precursor is contacted with a selective solvent (water, acid, etc.) to form a solution of the fugitive constituent in the solvent and a residue of the non-soluble constituent. The precursor is sufficiently reactive with the solvent to form the solution of the fugitive constituent in the solvent and form the nondissolved residue of the non-soluble constituent. The precursor material and the non-soluble residue are sufficiently insoluble in the solvent such that there is insufficient precursor material and non-soluble residue in solution to deposit and precipitate upon the residue of the non-soluble-constituent. The fugitive constituent is sufficiently soluble in the solvent such that the precursor reacts with the solvent to form the solution of the fugitive constituent without precipitation and deposition of fugitive constituent upon the residue of the non-soluble constituent in the form of nanosize particles. After the fugitive constituent is dissolved the selective solvent containing the fugitive constituent is removed from the residue. The residue remains in the form of a nanosize powder of the non-soluble constituent.

Owner:UNIV OF UTAH RES FOUND

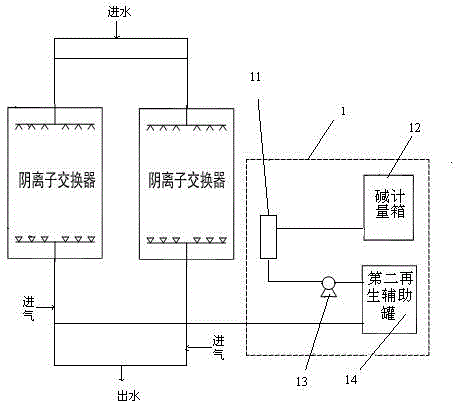

Chromium-containing waste water treatment system adopting double anion exchange columns and treatment method of system

ActiveCN106587433AHigh degree of automationEasy to handleWater contaminantsTreatment involving filtrationWater treatment systemWastewater

The invention provides a chromium-containing waste water treatment system adopting double anion exchange columns and a treatment method of the system. The system comprises a filtering device, a cation exchange column, a first anion exchange column, a second anion exchange column and a sodium removing column, wherein, solution inlets and outlets of the filtering device, the cation exchange column, the first anion exchange column and the second anion exchange column are sequentially connected; and saturated liquid outlets of the first anion exchange column and the second anion exchange column are connected with a liquid inlet of the sodium removing column. According to the system, by means of the difference of the adsorbing appetency of resin on different ions and the selective adsorptivity of the resin, the purpose of removing, separating and recycling chromic acid is achieved. Meanwhile, by performing the coating treatment on ion exchange resin, the appetency of the ion exchange resin on corresponding ions is further improved, and therefore the recycling efficiency of hexavalent chromium is improved, and the service life of the ion exchange resin is prolonged.

Owner:无锡出新环保设备有限公司

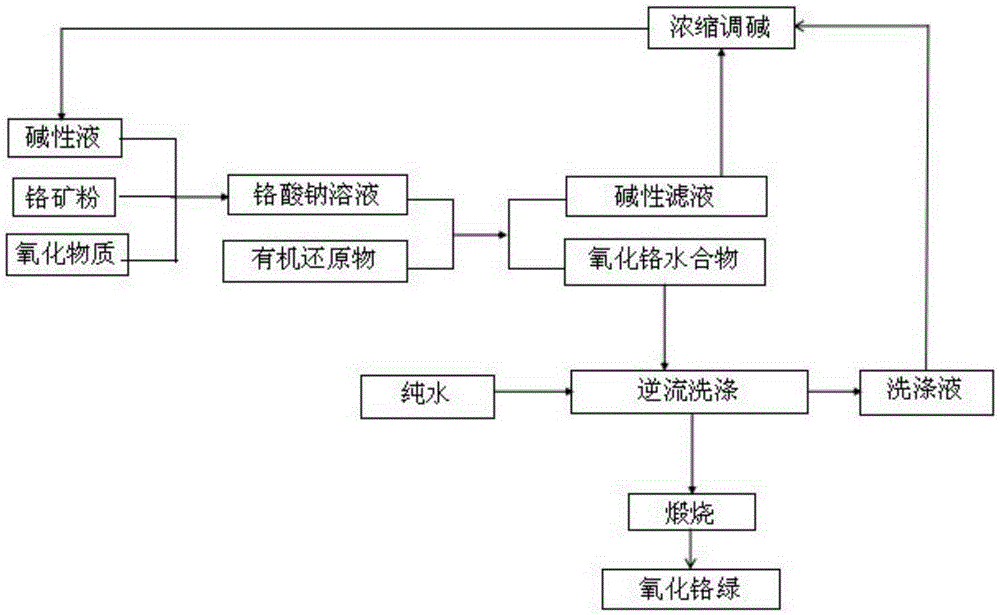

Method for producing chromium oxide green through sodium circulation

ActiveCN105366724ASimple processLow costChromium trioxideEnvironmental resistanceReducing substances

The invention discloses a method for producing chromium oxide green through sodium circulation. The method comprises the following steps: adding powdery chromite ores or ferrochromium powder into an alkali solution and introducing oxidation materials for reaction, and separating to obtain a sodium chromate alkali solution after full reaction; adding organic reducing substances into the sodium chromate alkali solution, after hydrothermal reaction, filtering and separating to obtain chromic oxide hydrate and alkali filter liquor; performing countercurrent washing on the chromic oxide hydrate and recycling the washing liquid; calcining the chromic oxide hydrate after washing in a high temperature furnace to obtain chromium oxide green; concentrating and performing alkali modulation on the alkali filter liquor and the washing liquid, and further returning the alkali filter liquor and the washing liquid after concentration and alkali modulation, so as to serve as the alkali solution to realize cyclic utilization of sodium resource in the technological process. Compared with the conventional preparation process of chromium oxide green, the method for producing chromium oxide green, provided by the invention, has the advantages that the production technical process is short, the operation is simple, and the prepared chromium oxide green is high in quality; besides, cyclic utilization of sodium resources in the production technology process is realized, and zero emission of the three wastes is also realized, so that the method is an environment-friendly and clean novel method for producing chromium oxide green.

Owner:绵阳市安剑皮革化工有限公司

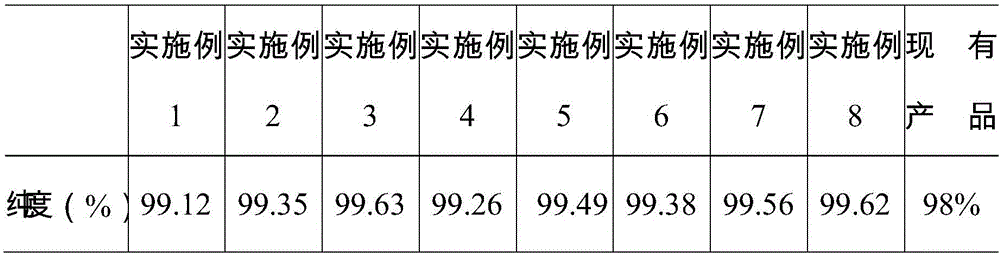

Method for preparing chromium oxide green pigment through hydrated chromium oxide

The invention discloses a method for preparing chromium oxide green pigment through hydrated chromium oxide. The method comprises the following steps of: calcining hydrated chromium oxide used as an active ingredient at 700-1,500 DEG C for more than 0.3 hour to obtain pigment-level chromium oxide green. The hydrated chromium oxide can be prepared by adopting a solid phase method (such as a method of reducing chromium salt gas), or a liquid phase method (such as precipitation, hydrothermal and the like). The content of chromium oxide in the obtained product is greater than 99%, and different trademarks of pigment-level chromium oxide green can be prepared simply by regulating the preparation technique and calcining conditions (temperature, time, atmosphere and feeding modes) of the hydrated chromium oxide. Compared with the prior art, the method for preparing the chromium oxide green pigment through hydrated chromium oxide has the advantage that additives are not needed for activating and sintering, the regulation and preparation of different trademarks of pigment-level chromium oxide green can be realized simply by regulating the preparation technique and calcining conditions of the hydrated chromium oxide.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

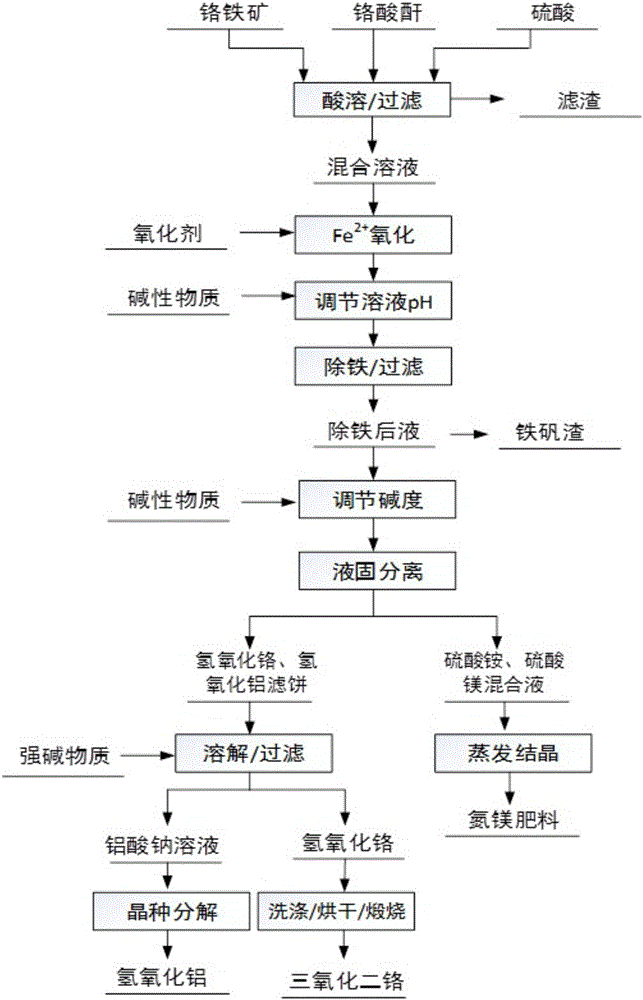

Method for clean production of chromium sesquioxide by using chromite as raw material

ActiveCN106186067AAchieve separationEasy to cleanChromium trioxideChromium(III) hydroxideFerrochrome

The invention discloses a method for clean production of chromium sesquioxide by using chromite as a raw material. The method comprises the following steps of by using the chromite as the raw material and chromic anhydride as an oxidizer, enabling the chromite and the chromic anhydride to be dissolved in sulphuric acid so as to obtain a mixed solution of elements of chromium sulfate, ferric sulfate and the like; by using an ammonium salt deferrization technique, realizing chromium-iron separation in the solution; adjusting the acidity of the mixed solution after separation so as to obtain precipitation of chromium hydroxide and aluminum hydroxide; performing evaporative crystallization on a mixed solution of ammonium sulphate and magnesium sulphate after chromium and aluminum are precipitated so that a nitrogen and magnesium fertilizer is prepared; performing liquid-solid separation on obtained liquid of chromium hydroxide and aluminum hydroxide after alkali dissolution so as to obtain and chromium hydroxide solids; performing washing and calcining on the chromium hydroxide solids so as to obtain chromium oxide products; and preparing aluminum hydroxide products by a Bayer method from a solution obtained through separation. The method disclosed by the invention is simple in preparation technology, by-products are mixtures of the aluminum hydroxide, the ammonium sulphate and the magnesium sulphate, waste and pollution are not generated, the synthesizing cost is low, and the energy consumption is low. The method has great popularization and application potentials in the field of green production of the chromium sesquioxide.

Owner:于佳湲 +3

Molecular decomposition processes for the synthesis of nanosize metallic powders

InactiveUS20050115362A1Improve solubilityImprove microstructureMaterial nanotechnologyOxide/hydroxide preparationMetal alloySolvent

A method for synthesizing nanosize metallic powders can include providing a metallic precursor. The metallic precursor can include a metal alloy formed having a fugitive constituent and a target metal. The fugitive constituent and target metal are chosen such that the fugitive constituent can be selectively dissolved or removed by leaching with an appropriate solvent while leaving the target metal undissolved. The fugitive constituent can be leached from the metallic precursor to leave a metallic residue which is a mass of nanosize metallic particles made substantially of the target metal. The nanosize metallic particles can then be recovered from the metallic residue either merely by removing the solvent and / or breaking up the mass of nanosize metallic particles. The disclosed methods allow for a convenient avenue for production of nanosize particles from readily formed materials for use in a wide variety of potential industrial and commercial applications.

Owner:UNIV OF UTAH RES FOUND

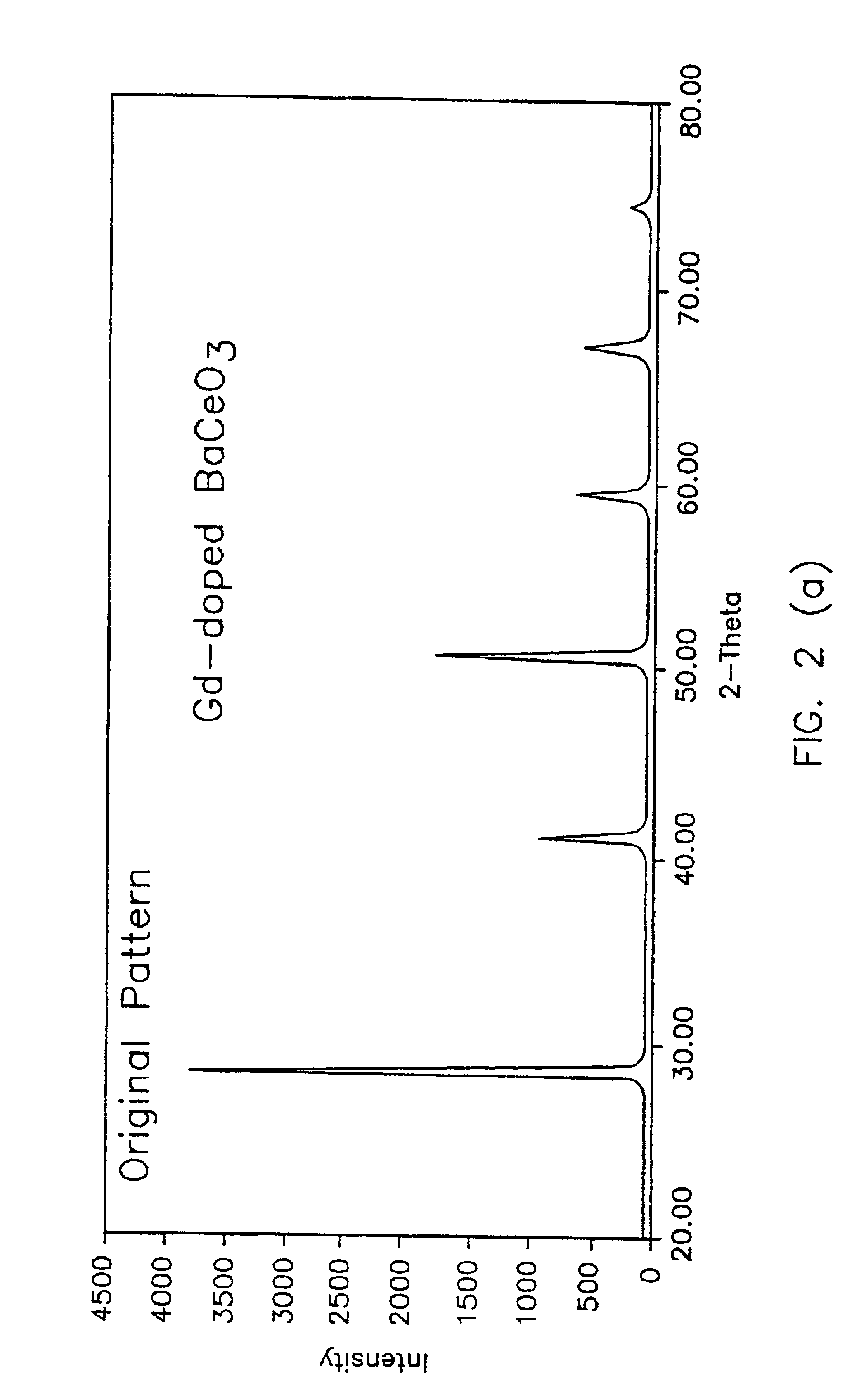

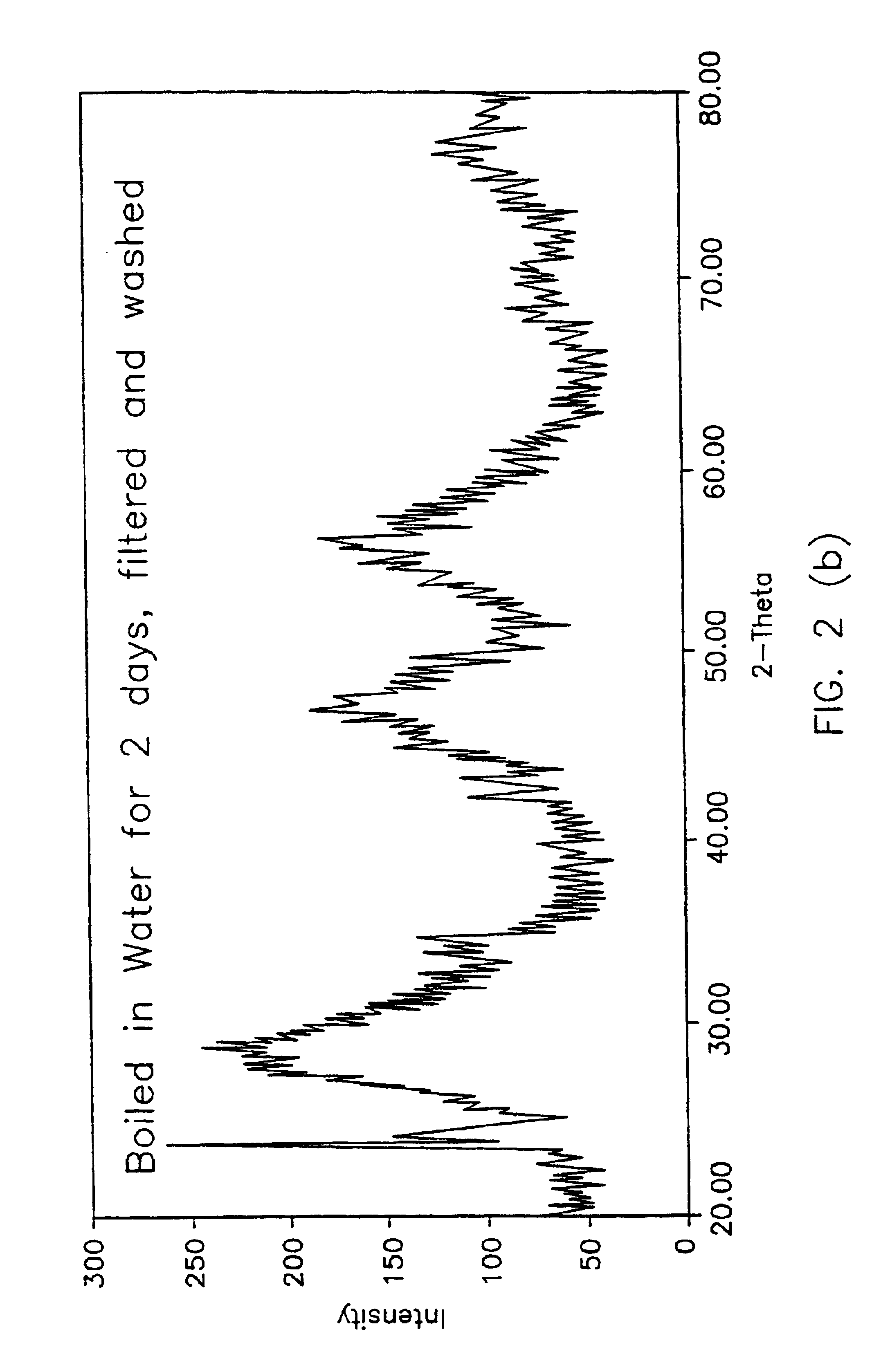

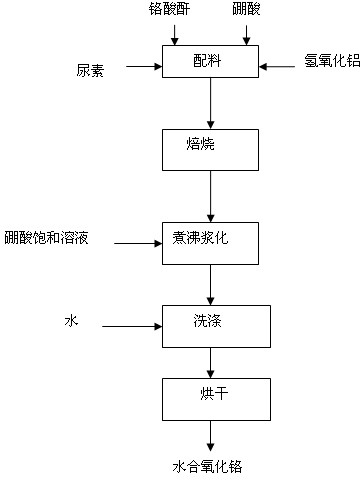

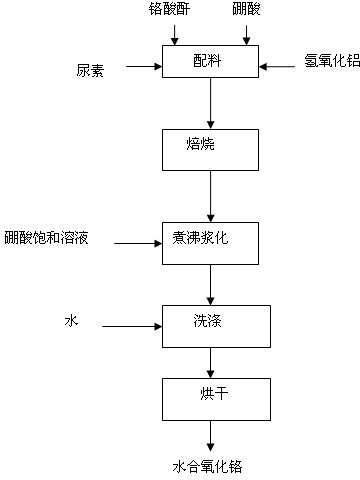

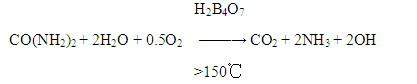

Preparation method of hydrated chromium oxide green

The invention discloses a preparation method of hydrated chromium oxide green. The method comprises the steps of: mixing the raw materials of chromic anhydride and boric acid with the leavening agent urea uniformly, conducting roasting within a certain temperature range, boiling the obtained clinker in a boric acid solution for slurrying, carrying out filtration and subjecting the obtained substance to slurrying in boiling water, then performing filtration, washing and drying so as to obtain hydrated chromium oxide green. The hydrated chromium oxide green prepared by the method of the invention can be widely used in pigments, and also can be used as an adsorbent of sodium vanadate.

Owner:GANSU JINSHI CHEM

Method for improving color of chromium oxide green

ActiveCN102557136AReduce dosageWill not be affected by chromium oxide green contentChromium trioxidePotassium fluoridePhysical chemistry

The invention discloses a method for improving the color of chromium oxide green, and aims to solve the problem that the tone of the traditional chromium oxide green prepared by thermally decomposing chromic anhydride is dark. The method comprises the following steps of: A, adding an additive in an amount which is 2 to 5 percent of the mass of the chromic anhydride, uniformly mixing the additive and the chromic anhydride, putting into a rotary kiln, and performing thermal decomposition reaction, wherein the additive is one of ammonium chloride, potassium fluoride and sodium fluoride; B, controlling the temperature of a high-temperature zone of the rotary kiln to 1,050-1,100 DEG C, feeding into the rotary kiln, and roasting for 3 to 4 hours; and C, grinding the chromium oxide green obtained by roasting into 600-mesh powder with the passing rate of over 90 percent, packaging and delivering after the product is qualified through detection. In order to improve the color brightness and coloring power of the chromic anhydride chromium green, the additive is added in the process of preparing the chromium oxide green by thermally decomposing the chromic anhydride to promote pigment synthesis reaction, and reducing atmosphere when the chromic anhydride is subjected to thermal decomposition is enhanced, so the chromium oxide green obtained by thermal decomposition has bright color, and the brightness and coloring power of the chromium oxide green are increased.

Owner:GANSU JINSHI CHEM

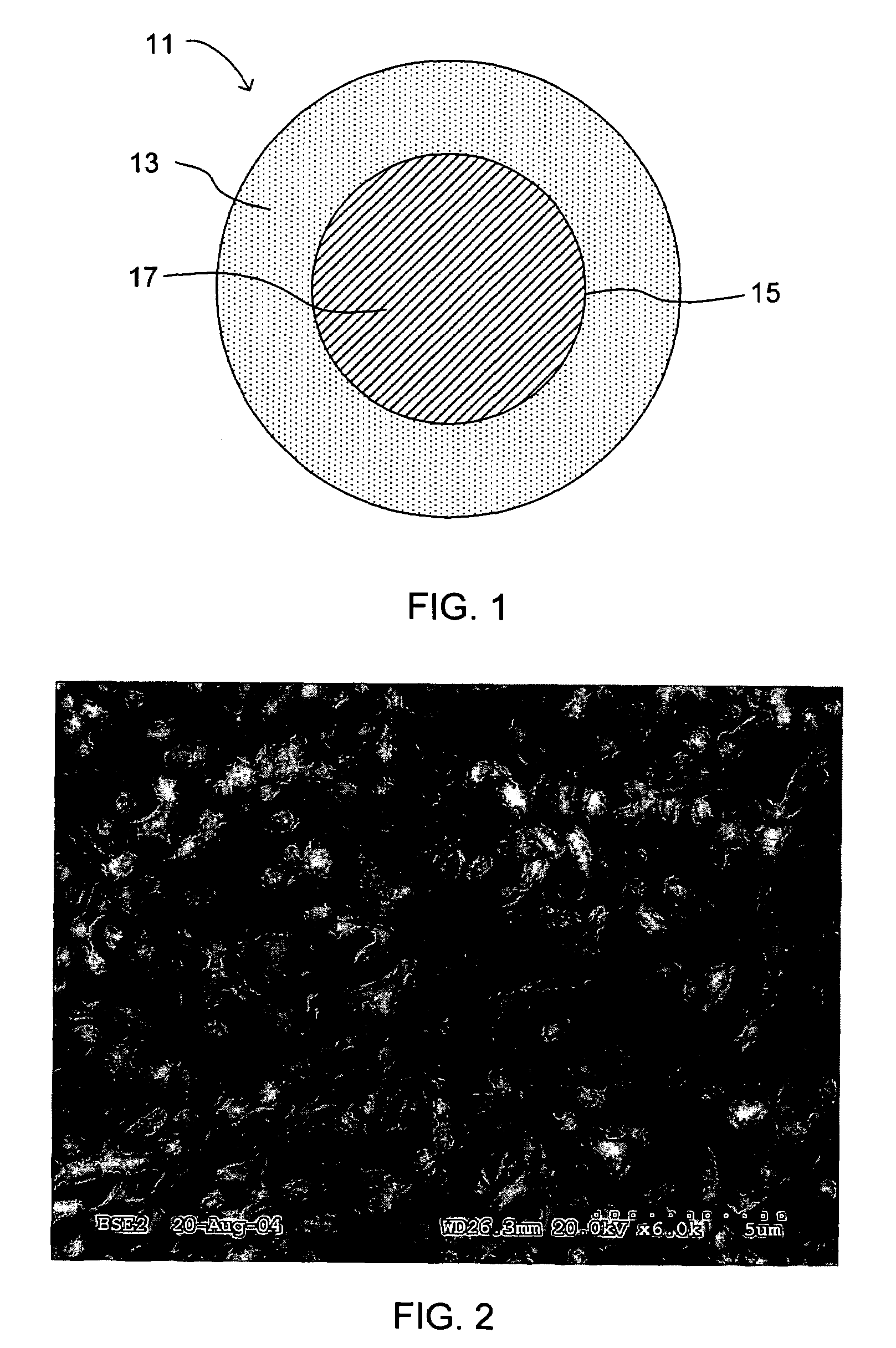

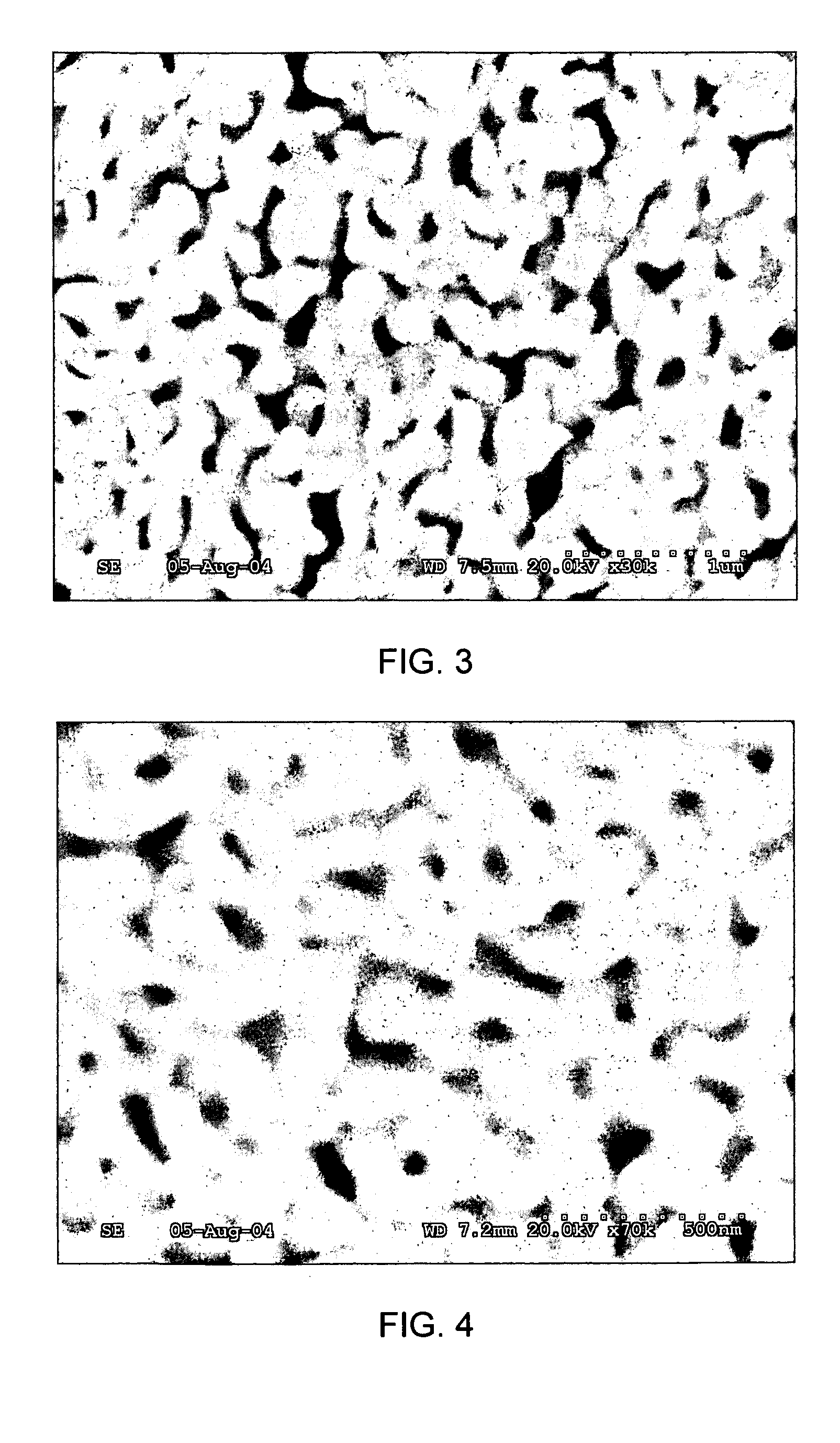

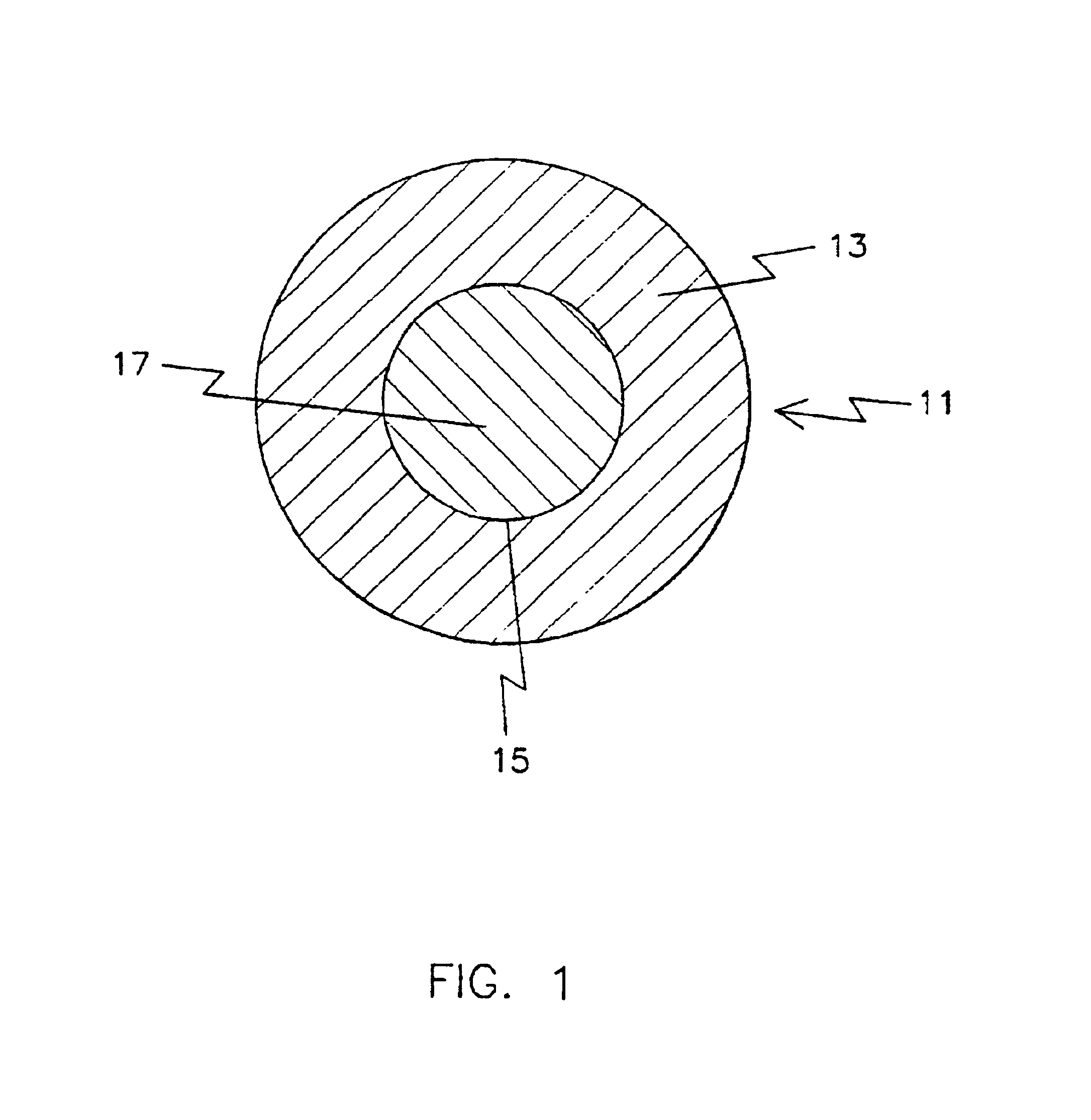

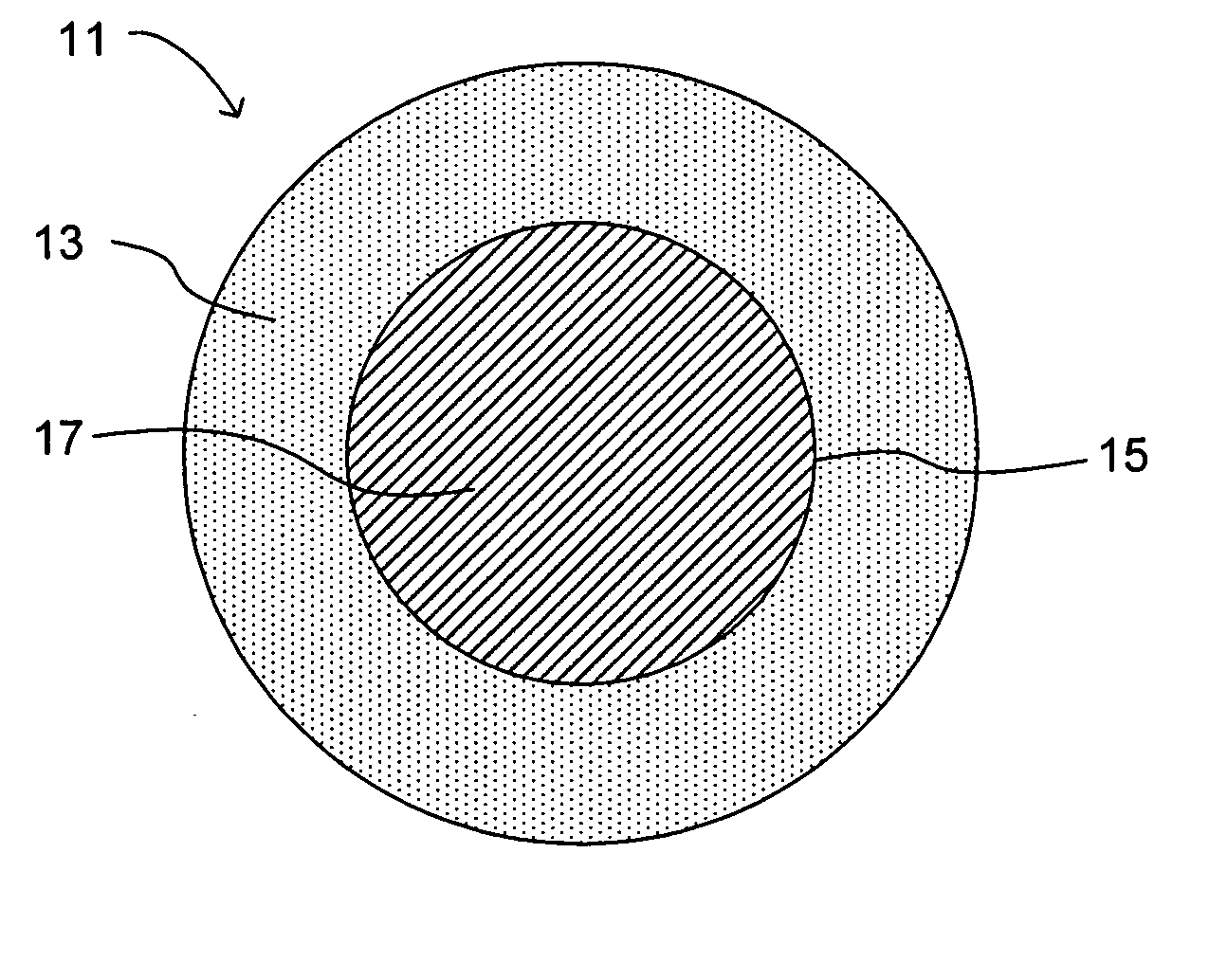

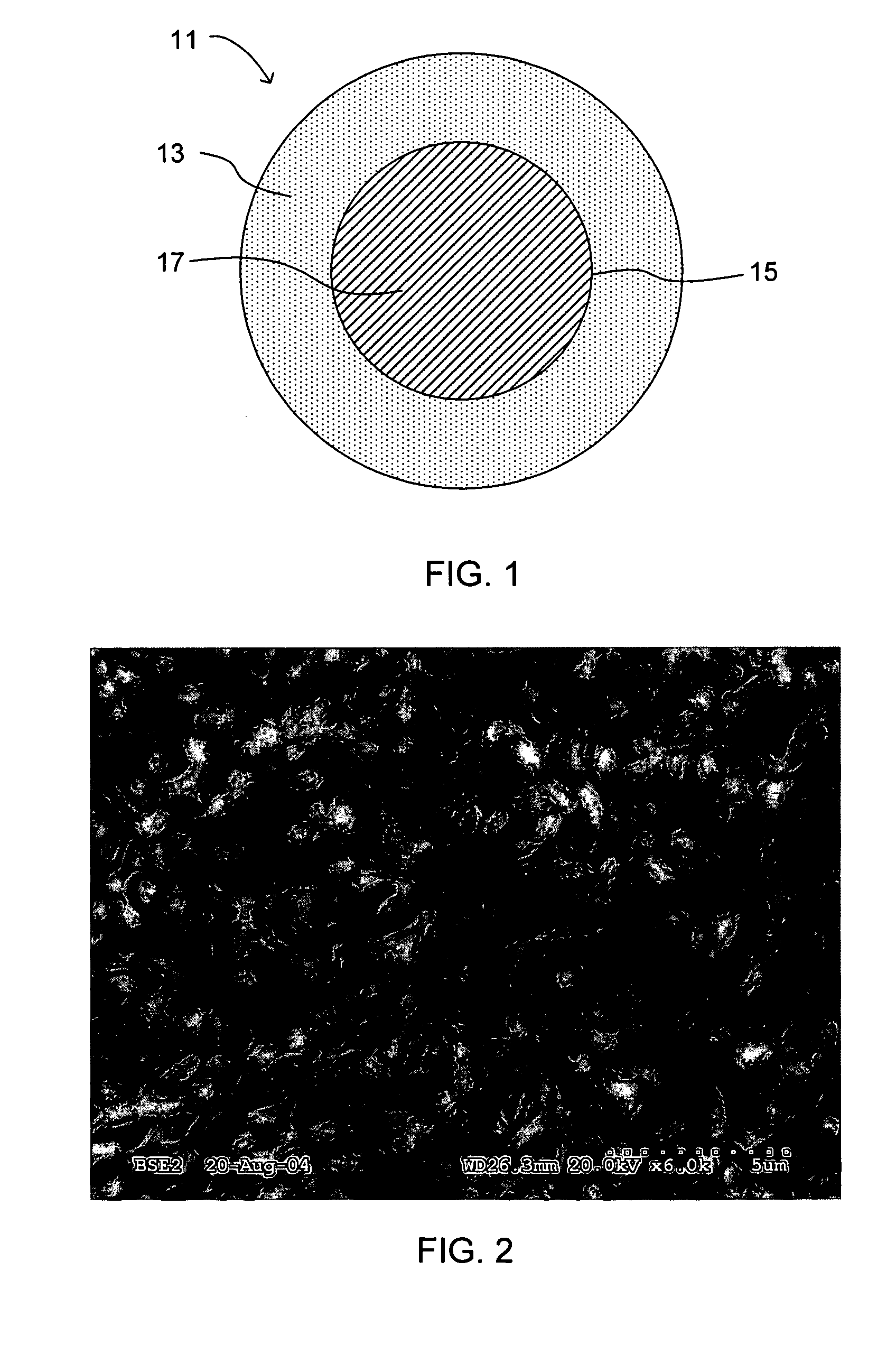

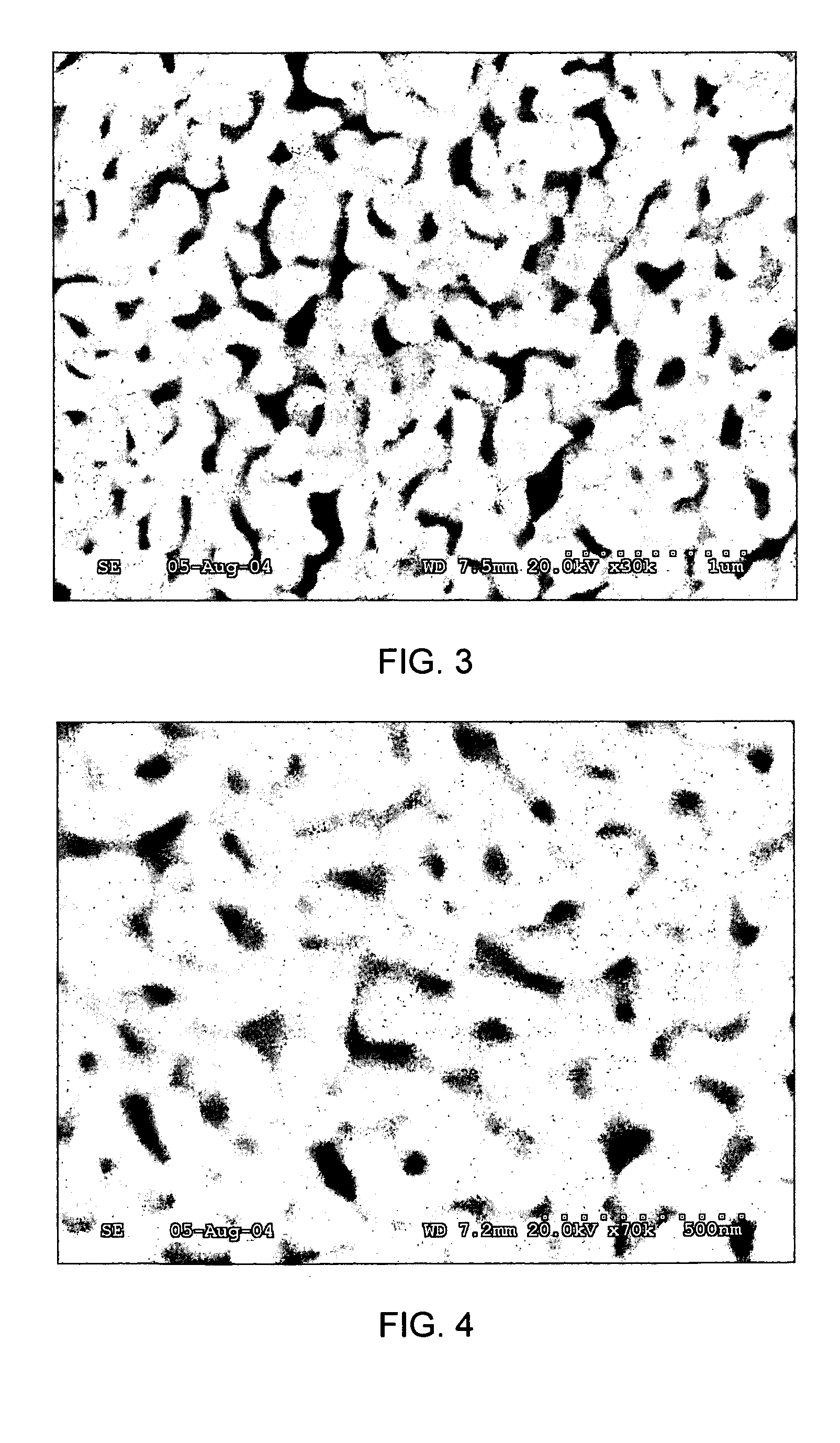

Semiconductor materials and methods of producing them

InactiveCN101208450ALow costLow running costMolten spray coatingMetal-working apparatusMolten stateSemiconductor materials

A method of producing particles containing metal oxide for use in semiconductor devices includes the steps of heating metal-containing particles in a flame produced by a mixture of oxygen and a fuel component comprising at least one combustible gas selected from hydrogen and hydrocarbons, the oxygen being present in the mixture in a proportion of not less than 10 mole% below, and not more than 60 mole% above, a stoichiometric amount relative to the fuel component, so as to oxidize metal in at least an outer shell of the particles; cooling the oxidized particles by feeding them into a liquid or sublimable solid medium; collecting the cooled oxidized particles; and providing a distance between entry of the particles into the flame and collection of the particles of at least 300mm. In this manner, such particles may be oxidized so as to provide a shell of metal oxide material which leaving unoxidized a core of metal. A semiconductive layer of such particles on a substrate may be formed by feeding, to a hot zone, such preoxidized metal-containing particles; heating the metal-containing particles in the hot zone to render the particles at least partially molten; and depositing the particles in the at least partially molten state onto the substrate. The above oxidation process may be employed to provide metal oxide particles in which different respective metals having different respective valencies are present in different respective molar proportions. The valencies and molar proportions may be selected so as to provide n- or p-type semiconductor layers.

Owner:ATMOS (1998) LTD

Process for preparing chromic anhydride and dichromate by carbon ferrochrome liquid phase method

The invention relates to a process for preparing chromic anhydride and dichromate by a carbon ferrochrome liquid phase method and belongs to the technical field of preparation of chromic compounds, ferrum-series pigments, silicone new materials, photovoltaic new materials and new-energy chemical-industry new materials from industrial metallurgical products. The process disclosed by the invention is advanced, energy-saving and environment-friendly and is free of emission of waste residues, waste gases and waste water. Products such as the chromic compounds, the pigments, new energy sources and new-energy-source silicon-carbon battery materials are produced from ferrochrome by a liquid phase method in one time without high pressure and high temperature, so that a series of novel high-end industry chains are formed, and the original situation that the ferrochrome is single in use and pure in production is thoroughly changed; the out-of-date production process that heavy pollution generated by the original chromate compound roasting production heavily harms environment is changed, and the production of chromic anhydride, dichromate and the chromic compounds can be in a energy-saving, environment-friendly and high-benefit development path; and the field of diversified development and application of ferrochrome industry is extremely extended, the international competitiveness of enterprises is greatly enhanced, and the optimized upgrading and developing of national industries are promoted, so that the process is of far reaching importance. The process meets the modern requirements on environment-friendly development of economy and has very good enterprise economic benefit, perfection benefit and social benefit.

Owner:唐翔

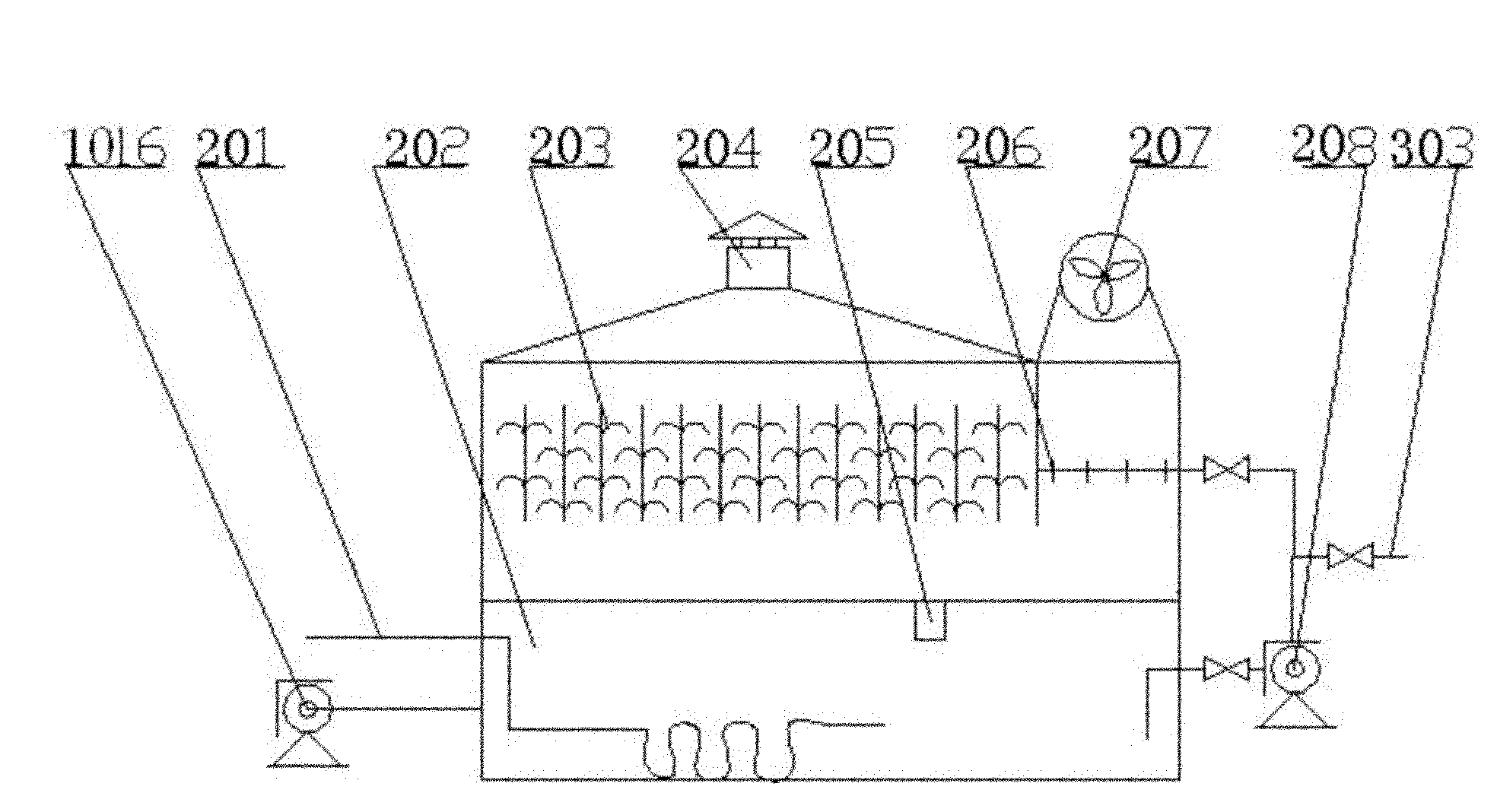

Method for recovering chromic acid and water from chromeplating rinse water

ActiveCN101575119AAchieve enrichmentRealize closed loopWaste water treatment from metallurgical processChromium trioxideWater vaporLiquid water

The invention relates to the technical field of chromate waste water treatment, and in particular discloses a method for reclaiming chromic acid and water from chromeplating rinse water. The method comprises the following steps: rinsing chromium-plated parts from a coating bath in a first-level washing reclaiming tank, a second-level washing reclaiming tank until the last-level washing reclaiming tank in turn; refluxing the rinse water in the last-level washing reclaiming tank to the previous level reclaiming tank in turn and finally to the first-level washing reclaiming tank; overflowing the chromium-containing rinse water in the first-level washing reclaiming tank to a circulating reclaiming tank, and heating the rinse water to a temperature of 50 DEG C by a heating device; pumping the rinse water into a vacuum evaporator by a circulating pump so that the water content is evaporated and chromic acid concentrated solution is left at the bottom of the evaporator; refluxing the chromic acid concentrated solution to the circulating recovery tank, and performing circulating evaporation in the vacuum evaporator again; and pumping finally concentrated chromic acid into a chrome-plating bath for reclaiming by a chromic acid reclaiming pump. The top of the vacuum evaporator is connected with a condensate water reclaiming tank through an ejector vacuum pump, and a cooling device in the condensate water reclaiming tank condensates water vapor into liquid water which is overflowed to the last-level washing reclaiming tank from the condensate water reclaiming tank for recycling. The method can recycle the chromic acid and the water in the chromeplating rinse water on line, save the significant cost required by a chemical method control, and reclaim resources.

Owner:WUXI XINGYI INTELLIGENT ENVIRONMENT EQUIP CO LTD

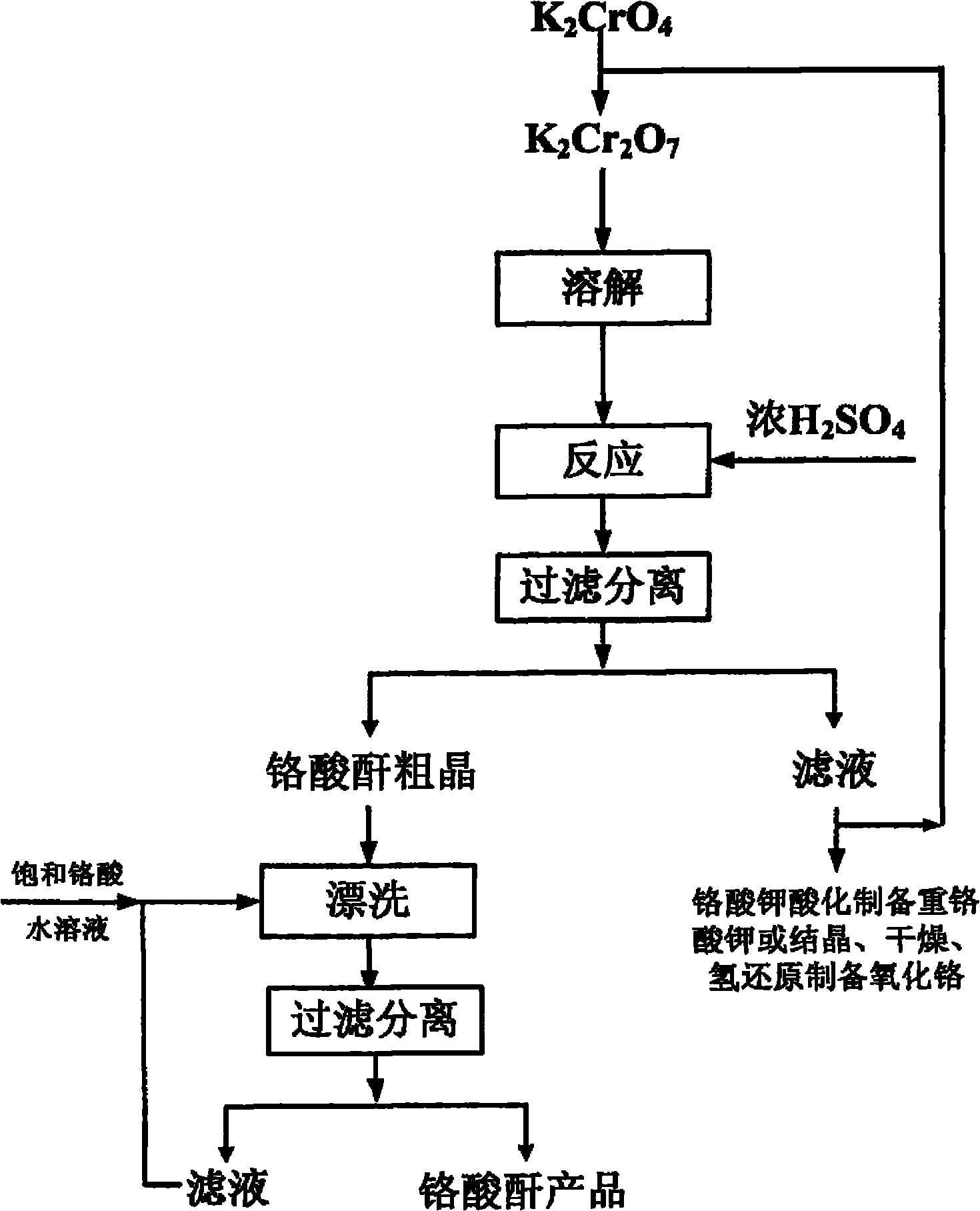

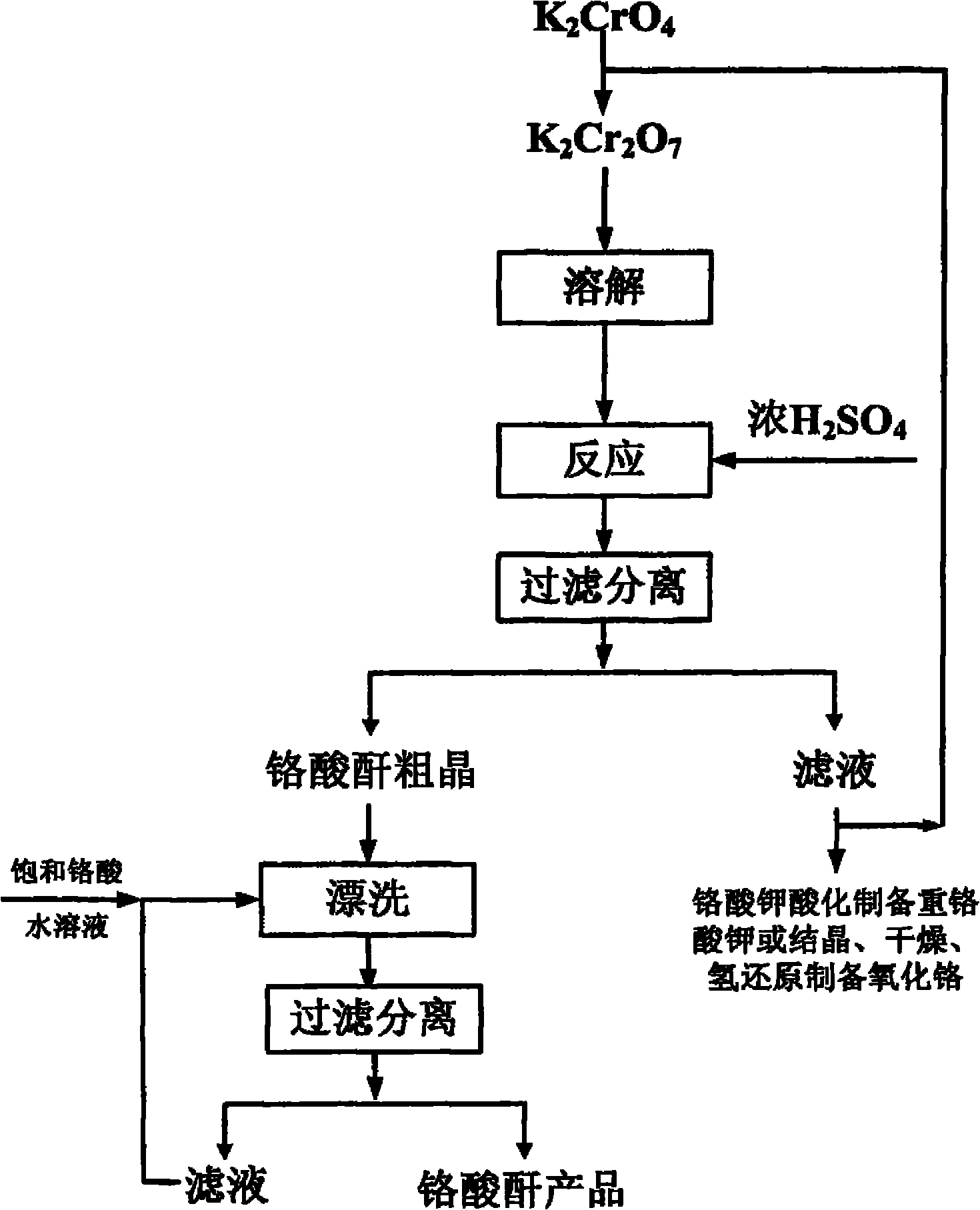

Method for preparing chromic anhydride from potassium chromate

InactiveCN102020316AAchieve regenerationRealize closed loopChromium trioxideDecompositionPotassium dichromate

The invention relates to a method for preparing chromic anhydride from potassium chromate. The method comprises the following steps: 1) dissolving and acidizing the potassium chromate to obtain saturated potassium dichromate solution; 2) adding concentrated sulfuric acid in the potassium dichromate solution in the step 1 so that the mole ratio of the dichromate solution to the concentrated sulfuric acid is 1:1-7, stirring, reacting for 0.5-2 hours at the temperature of 20-150 DEG C, precipitating chromic anhydride crystals, filtering to obtain chromic anhydride macro crystals and mother liquor; 3) feeding 40%-60% of mother liquor in the step 2) back to the step 1) for the acidification of the potassium chromate, and carrying out crystallization and reduction on the residual parts to prepare chromic oxide; and 4) rinsing and filtering the chromic anhydride macro crystals in the step 2) with saturated chromic anhydride solution to obtain the chromic anhydride crystals and filtrate, recycling the filtrate to rinse the chromic anhydride macro crystals, and drying the chromic anhydride macro crystals to obtain the chromic anhydride. The invention has the advantages that the method is operated at the temperature lower than the decomposition temperature of the chromic anhydride and under normal pressure, and the obtained product has the advantages of high quality, high yield and low energy consumption.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Method for preparing color hydrated chromium oxide by using atmospheric pressure reduction process

The invention discloses a method for preparing color hydrated chromium oxide by using an atmospheric pressure reduction process. The method comprises the following steps: dissolving bichromate in an aqueous solution, wherein the pH value of the aqueous solution is adjusted to 1 to 3 by using a proper amount of combined inorganic acid, slowly adding polyhydroxy carbohydrates or alcohols with stirring under normal pressure, wherein a mol ratio of the polyhydroxy carbohydrates or alcohols to bichromate is 1.2 to 1.3, carrying out a reaction with stirring for 1 to 2 h and maintaining a resultant at a temperature in a range of 80 to 100 DEG C for 2 h so as to obtain chrome oxide hydrate slurry; filtering the slurry to obtain a hydrated chromium oxide filter cake and a filtrate containing a small amount of hexavalent chromium, rinsing the filter cake a plurality of times, combining obtained filtrates together and allowing a combined filtrate to be returned to a batching procedure for cycle use; and drying the filter cake at a temperature of 60 to 80 DEG C under the protection of N2 for 1.5 to 2 h and cooling to room temperature so as to obtain a color hydrated chromium oxide product. The method has the characteristics of simple process, short flow, low production cost, high purity and yield, etc.

Owner:HUBEI ZHENHUA CHEMICAL CO LTD

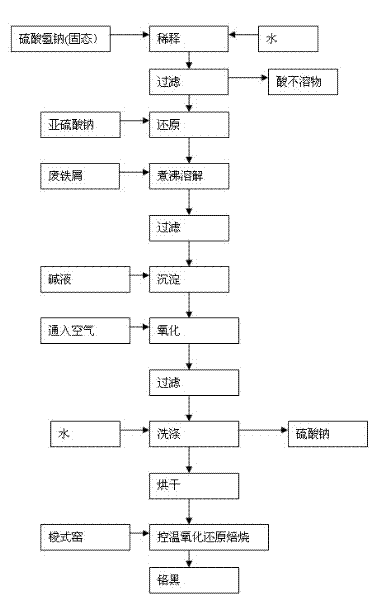

Method of producing eriochrome black with sodium bisulfate, byproduct of chromic trioxide

The invention discloses a method of producing eriochrome black with sodium bisulfate, a byproduct of chromic trioxide, and the method has the advantages of low cost and a simple process. The method is as follows: sodium bisulfate, the byproduct of chromic trioxide, and waste scrap iron are used as raw materials; solid sodium bisulfate is diluted with water and dissolved with stirring, sodium hydrosulphite is added into a sodium bisulfate solution which has been filtered and contains sodium bichromate for a reduction reaction, then waste scrap iron is added and dissolved through heating, and filtration is carried out to remove residues; the pH value of obtained filtrate is adjusted by a sodium hydroxide solution, air is blown in for stirring an obtained mixture, the mixture is then subjected to filtration and separation, obtained deposition is dried after rinsing and is then roasted at a high temperature so as to obtain an eriochrome black pigment with good dispersibility and powerful tinting strength. The beneficial effects of the invention are as follows: (1) raw materials used in the method are mainly the solid byproduct of sodium bisulfate generated in production of chromic trioxide and waste scrap iron, which enables environmental protection and energy saving to be realized, industrial waste materials to be effectively utilized and low cost to be achieved; (2) process flow is simple, the raw materials are easily available, and the method is applicable to industrial production.

Owner:GANSU JINSHI CHEM

Method for manufacturing refractory grains containing chromium(III) oxide

ActiveUS20140011031A1Limited amountSynthetic resin layered productsCellulosic plastic layered productsLiquid mediumRefractory

A method for manufacturing sintered refractory grains containing Cr2CO3 from an initial refractory product including one or more chromium that includes: A) optionally, \crushing the starting refractory material; B) grinding a filler, comprising said starting refractory material in a liquid medium to obtain a suspension of particles of said starting refractory material; C) preparing a starting mixture including at least 1 wt % of particles of the suspension obtained during the preceding step; D) shaping the starting mixture into the shape of a preform; E) optionally drying the preform obtained in step D); F) sintering the preform so as to obtain a sintered body; G) optionally grinding the sintered body; and H) the optional selection by particle size.

Owner:SAINT GOBAIN CENT DE RES & DEVS & DETUD EUROEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com