Method for preparing color hydrated chromium oxide by using atmospheric pressure reduction process

A technology of hydrated chromium oxide and reduction method, applied in the directions of chromium trioxide, chromium oxide/hydrate, etc., to achieve the effects of cheap and easy-to-obtain raw materials, simple process operation and equipment, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

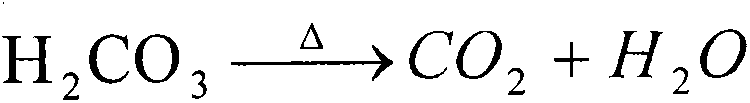

Problems solved by technology

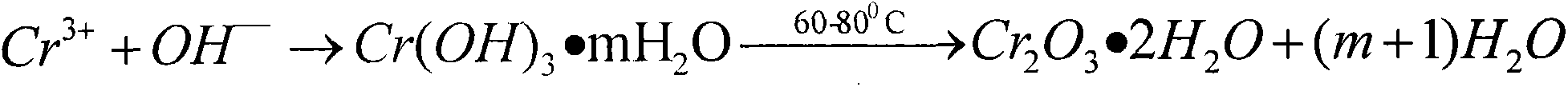

Method used

Image

Examples

Embodiment 1

[0028] In the present embodiment, get 500 milliliters of water, adjust to pH value 3 with the mixed solution of 1mol / L sulfuric acid+1mol / L hydrochloric acid (the consumption of mixed acid is about 2~3 milliliters), add 100 grams of potassium dichromate under stirring and completely dissolved, adding 5 ml of 0.5% dodecyltrimethylammonium chloride aqueous solution; stirring and heating to 80° C., slowly adding 74 grams of glucose, reacting for 1 hour, and insulated at 80° C. for 2 hours; filtering to obtain Chromium hydroxide hydrate filter cake and the filtrate containing a small amount of hexavalent chromium, wash the filter cake twice with 50 ml of water, and return the combined filtrate to the batching process for recycling; N 2 Air protection and drying at a temperature of 60° C. for 1.5 hours, and cooling to room temperature gave 62.5 grams of emerald blue hydrated chromium oxide product (yield 98.3%). After testing, the total chromium in the product (as Cr 2 o 3 Count,...

Embodiment 2

[0031] In this embodiment, take 500 milliliters of water, adjust the pH value to 2 with a mixed solution of 1mol / L sulfuric acid+1mol / L boric acid (the amount of mixed acid is about 3-5 milliliters), and add 100 grams of potassium dichromate under stirring And completely dissolved, add 5 milliliters of 0.5% dodecyltrimethylammonium chloride aqueous solution; stir and heat to 60 ℃ and slowly add 74 grams of glucose, react for 1.5 hours, keep warm at 86 ℃ for 2 hours; filter to obtain chromium hydroxide Hydrate filter cake and filtrate containing a small amount of hexavalent chromium, wash the filter cake twice with 50 ml of water, and return the combined filtrate to the batching process for recycling; N 2 Air protection and drying at 65° C. for 1.6 hours, and cooling to room temperature gave 63.1 g of vivid blue hydrated chromium oxide product (yield: 99.26%). After testing, the mass percentage of total chromium in the product is 61.8%, the mass percentage of water is 34.9%, an...

Embodiment 3

[0034] In this embodiment, take 500 milliliters of water, adjust the pH value to 1 with a mixed solution of 1mol / L hydrochloric acid+1mol / L boric acid (the amount of mixed acid is about 6-10 milliliters), and add 100 grams of potassium dichromate under stirring And dissolve completely, add 5 milliliters of 0.5% dodecyltrimethylammonium chloride aqueous solution; stir and heat to 70 ℃ and slowly add 74 grams of glucose, react for 1.5 hours, keep warm at 90 ℃ for 2 hours; filter to obtain chromium hydroxide Hydrate filter cake and filtrate containing a small amount of hexavalent chromium, wash the filter cake twice with 50 ml of water, and return the combined filtrate to the batching process for recycling; N 2 Air protection and drying at 60° C. for 2 hours, and cooling to room temperature gave 61.9 g of bright yellow-green hydrated chromium oxide product (yield: 97.4%). After testing, the mass percentage of total chromium in the product is 61.3%, the mass percentage of moisture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com