Patents

Literature

300 results about "Chromium trioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chromium trioxide is an inorganic compound with the formula CrO₃. It is the acidic anhydride of chromic acid, and is sometimes marketed under the same name. This compound is a dark-purple solid under anhydrous conditions, bright orange when wet and which dissolves in water concomitant with hydrolysis. Millions of kilograms are produced annually, mainly for electroplating. Chromium trioxide is a powerful oxidiser and a suspected carcinogen.

Pd radicel duplex metal selective hydrogenation catalyzer and method for preparing the same and application thereof

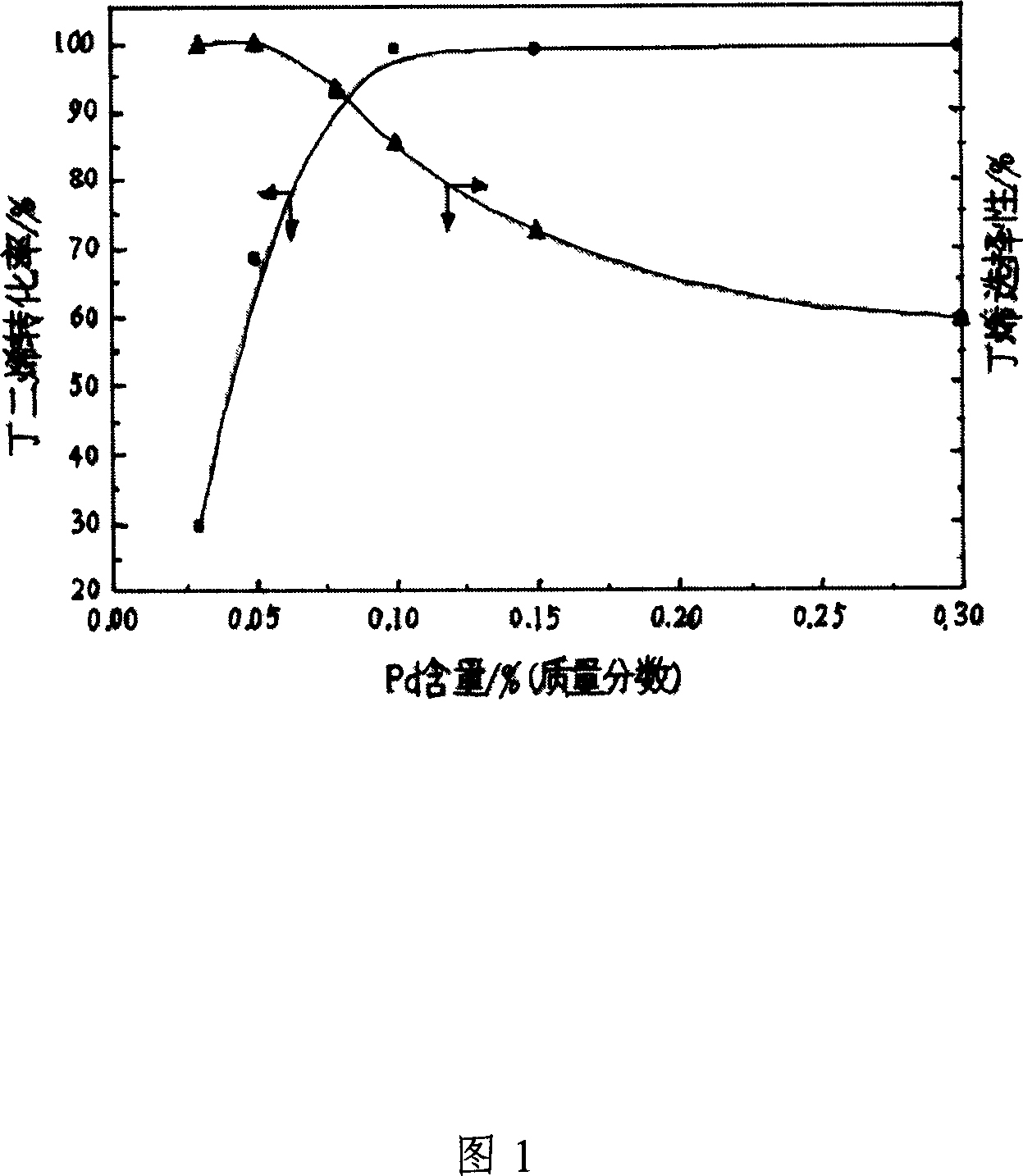

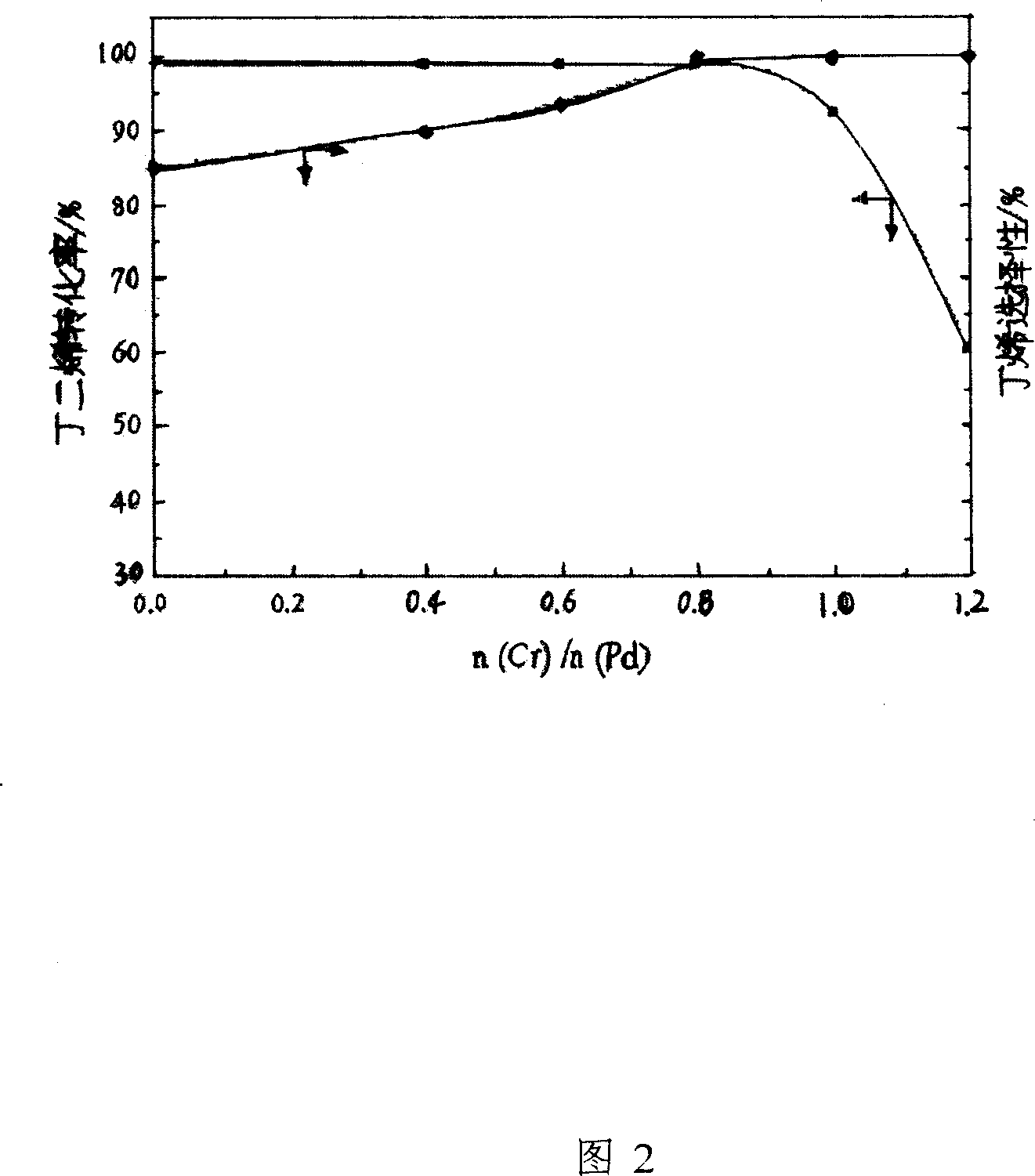

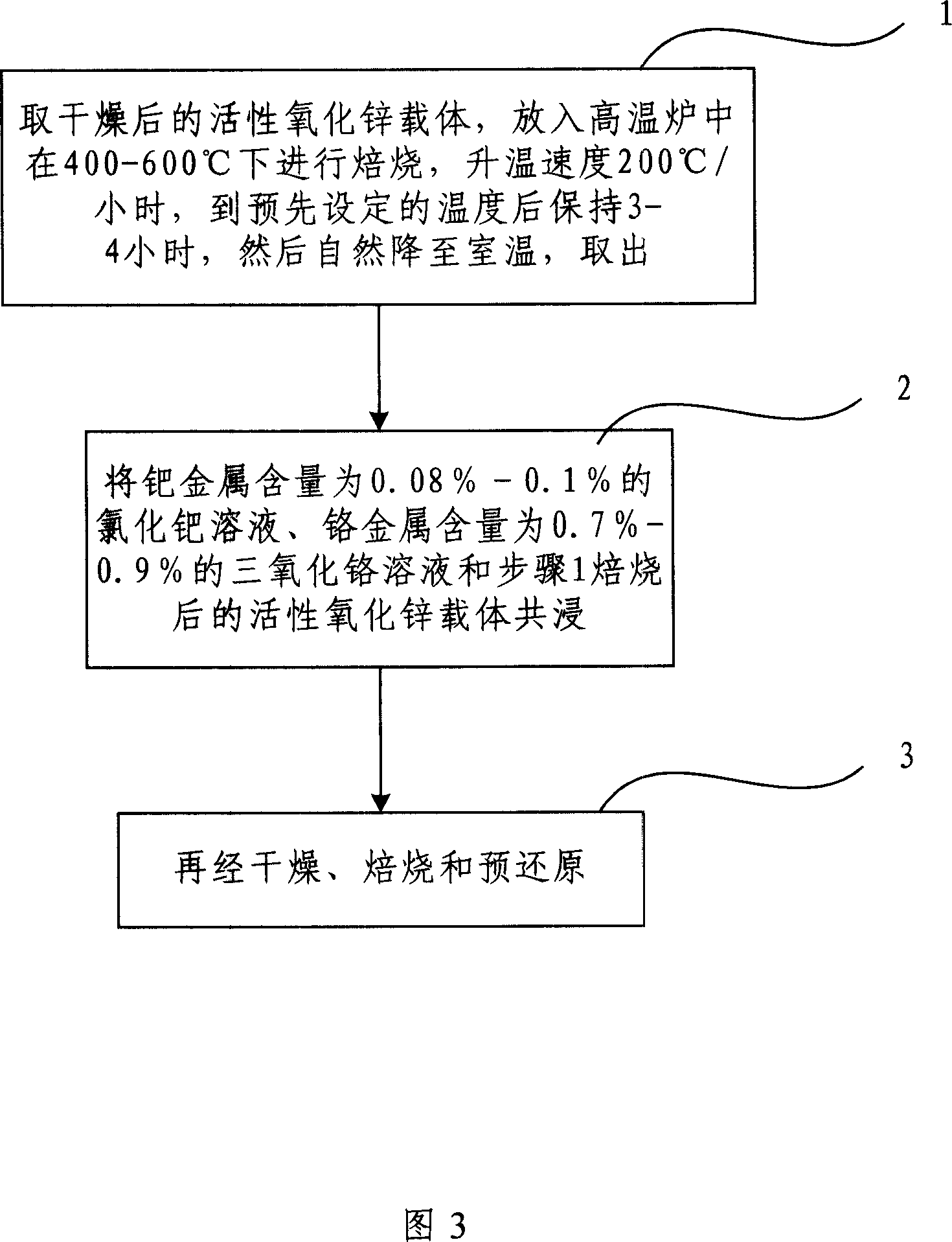

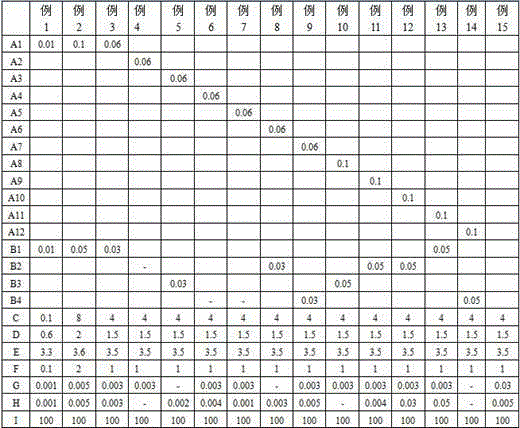

InactiveCN101081366AHigh activityHigh selectivityHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsChromium trioxideActive component

The palladium-base bimetal catalyst for selective hydrogenation includes active zinc oxide as carrier; metal palladium as the active component in 0.03-0.3 wt% of the catalyst; and one of Cr, Ag, Ni, Cs and Pb as cocatalyst in 0.4-1.2 wt%. Its preparation process includes the steps of: roasting dried active zinc oxide carrier, soaking the carrier in palladium chloride solution with palladium content of 0.08-0.1 % and chromium trioxide with chromium content of 0.7-0.9 %, drying, roasting and pre-reducing. The catalyst has high activity, high selectivity, high stability, long service life and high catalytic efficiency.

Owner:PETROCHINA CO LTD +1

Fire coal combustion improver

InactiveCN102191110AImprove operational safetyExtended service lifeSolid fuelsChromium trioxideDolomite

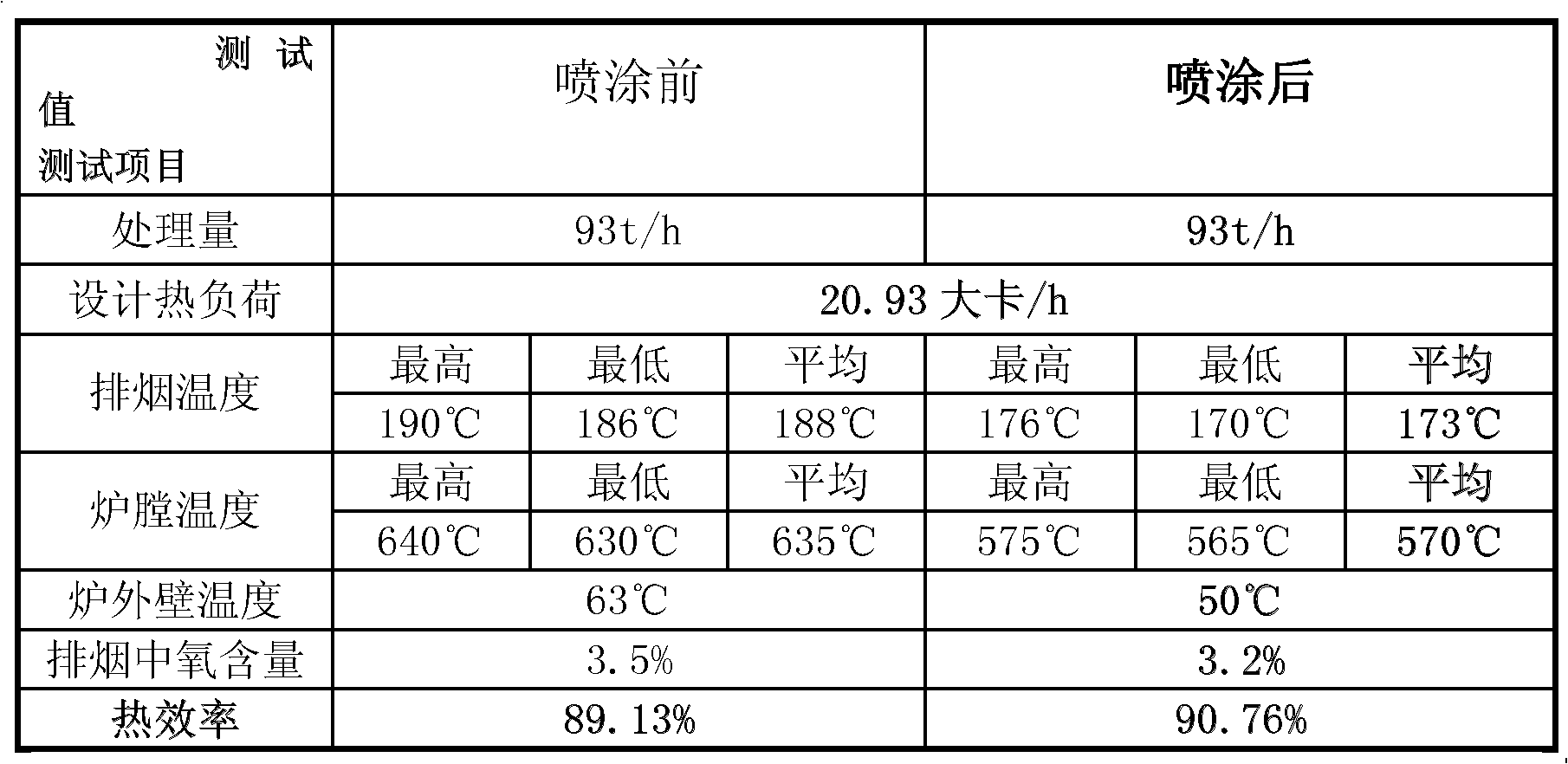

The invention relates to an improvement of a fire coal combustion improver. The improved fire coal combustion improver is characterized by being prepared by compounding and mixing the following components: 20 to 30 weight percent of dolomite powder, 5 to 15 weight percent of dicyclopentadieny iron, 3 to 10 weight percent of chromium trioxide, 3 to 10 weight percent of manganese dioxide, 3 to 15 weight percent of magnesium nitrate, 3 to 15 weight percent of sodium dichromate and / or potassium dichromate, 3 to 18 weight percent of zinc oxide, 15 to 30 weight percent of active clay. The fire coal combustion improver has a plurality of functions of combustion acceleration, sulfur solidification, smoke abatement and the like; the thermal efficiency of a boiler can be improved by 3 to 8 percent; the coal-saving efficiency is up to 5 to 15 percent; the Ringelmann smoke blackness is less than 1; the total removal rate of SO2, NOx and the like is 25 to 60 percent, and the combustion improver has remarkable coal-saving and environmental-protection effect. Since the combustion effect is improved, the inferior coal (such as coal gangue), which is difficult to combust normally, is combusted and comes into play. After the long use, the boiler is not corroded, the scaling of the calcium sulfate in the boiler can be reduced, the operation safety of the boiler can be improved and the service life of the boiler can be prolonged.

Owner:YIXING KEQI CHEM

Pole lug aluminum strip surface treatment passivation solution

The invention discloses a pole lug aluminum strip surface treatment passivation solution. The pole lug aluminum strip surface treatment passivation solution comprises chromium trioxide, nickel nitrate hexahydrate, a pickling agent, a film formation accelerant and water. By means of the pole lug aluminum strip surface treatment passivation solution, the passivation film compactness and the salt mist can be improved, and the bonding performance between a film and pole lug glue can be improved.

Owner:MAIKAIMEN ELECTRONICS TECH SHANGHAI

Polishing solution for ultra-precise low-damage polish of large size diamond wafer and preparation thereof

InactiveCN101302403AImprove surface accuracyQuality improvementPolishing machinesAqueous dispersionsChromium trioxideSuperhard material

The invention belongs to the superhard material polishing technical field and discloses polishing solution used for ultraprecise and low-damage polishing of a large-scale diamond wafer and a method for preparing the same. The method is characterized in that: oxidants with strong oxidbillity including chromium trioxide, ammonium persulphate, potassium permanganate, potassium dichromate, oxydol, potassium ferrate, potassium perchlorate and so on are adopted as main compositions; a proper amount of abrasive material is added for preparing the polishing solution; and micro-removal of surface material of the diamond wafer can be realized by means of chemical and mechanical composite action at normal temperature or low temperature. Moreover, the polishing effect of the polishing solution can be improved by addition of proper amount of catalyst, stabilizer, dispersant and so on as well. The polishing solution and the method have the advantages that: the polishing solution prepared has the advantages of high polishing efficiency, good polishing quality, good stability and so on; and the ultraprecise and low-damage polishing of the large-scale diamond wafer can be realized at the normal temperature or the low temperature.

Owner:DALIAN UNIV OF TECH

Ventilated brick and preparation method thereof

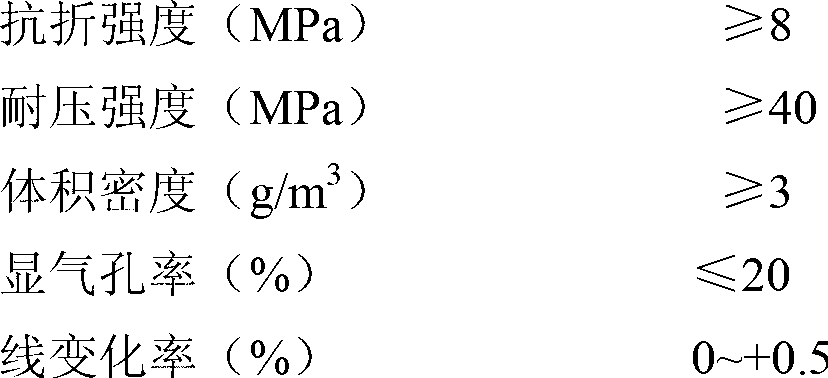

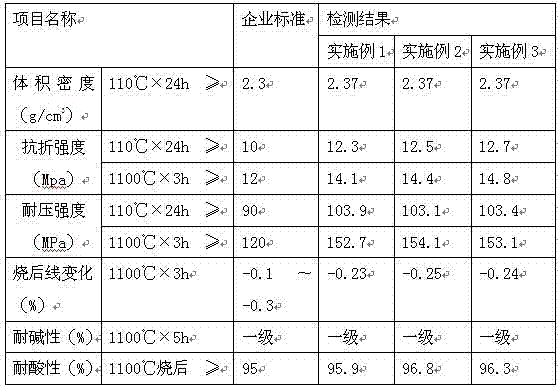

The invention relates to a ventilated brick and a preparation method thereof. The ventilated brick is composed of the following raw materials: compact fused corundum, sintered tabular corundum, sintered spinel, fused magnesite, active alumina micro powder, industrial chromium trioxide, aluminium-enriched spinel micro powder, pure calcium aluminate cement, SM water reducing agent, SN-2 water reducing agent, sprayed aluminium powder and polypropylene fibre. The invention further relates to the preparation method of the ventilated brick. The ventilated brick prepared by the invention has the advantages of being strong in anti-pressure ability, long in service life, high in high-temperature resistant strength, good in anti-residue permeability and melting loss resistant peeling property, low in sintering temperature, low in energy consumption, clean, free from pollution, and simple and environment-friendly in preparation process; one ventilated brick can be used for above 90 times; and the sintering temperature is only 1200-1550 DEG C.

Owner:山东华强环保科技有限公司

Decoating liquid

The invention relates to a de-coating liquid that includes vitriol and oxidant that includes at least from hydrogen peroxide, potassium permanganate, potassium dichromate and chromic anhydride. It also includes reserve salt inter-nitrobenzene sodium xanthate, and accelerating agent copper sulphate. It could effectively decrease the adverse effect of the plastic itself and could decrease environment pollution and decrease harm to human, etc.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

Preparation method of compound 19-desmethyl-4-androstene-3,17 diketone

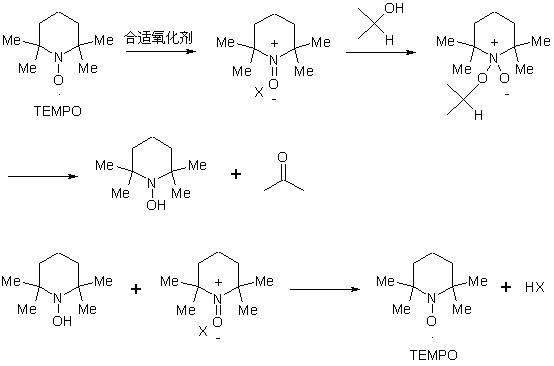

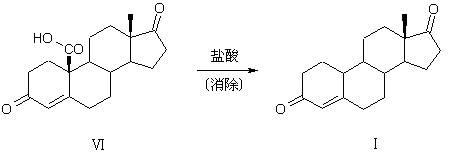

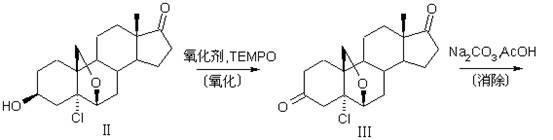

The invention discloses a preparation method of a compound 19-desmethyl-4-androstene-3,17 diketone, comprises the following step of by taking compounds of 5alpha-chloro-3beta-hydroxy-6beta and 19beta-epoxy-androstane-17-ketone as raw materials, and carrying out oxidation reaction on the compounds of 5alpha-chloro-3beta-hydroxy-6beta and 19beta-epoxy-androstane-17-ketone as well as an intermediate compound 19-hydroxy-4-androstene-3,17-diketone with N-halogenated amide oxidant in a mixed solution of an organic solvent and an alkaline buffer solution in the presence of a catalytic amount of 2,2,6,6-tetramethylpiperidine-N-oxide (TENPO) in the mild condition. In the two steps of oxidation reaction, the catalytic amount of 2,2,6,6-tetramethylpiperidine-N-oxide and the N-halogenated amide oxidant are both adopted to replace a mixed solution of chromium trioxide, sulfuric acid and water. In the oxidation method, without using the chromium trioxide, the use of carcinogenic substances are avoided being used, limitation by environmental protection is avoided and a great amount of wastes containing heavy metals in preparation are avoided being generated and accumulated, thereby no money and labor is consumed for removing the wastes.

Owner:ZHEJIANG XIANJU PHARMA

High-temperature resistant absorption enhancement nano coating and preparation method thereof

ActiveCN102675933AGuaranteed long-term stabilityImprove thermal shock resistanceRadiation-absorbing paintsChromium trioxidePhosphate

The invention provides a high-temperature resistant absorption enhancement nano coating and a preparation method and application thereof. The coating comprises metallic stuffing, metal oxides, nano ceramic, oxidant and adhesive. The coating is characterized in that the metallic stuffing comprises metallic silver, tungsten powder, barium powder and potassium; the metal oxides comprise titanium dioxide, ferric oxide, zinc oxide, manganese dioxide, chromium trioxide, cesium oxide and magnesium oxide; the adhesive comprises phosphate and silicate; and the oxidant is aluminum oxide. The preparation method comprises the following steps of: proportioning according to the proportion of the coating components, polishing, soaking, heating, reacting, stirring, mixing and filtering.

Owner:上海乐恒石油化工集团有限公司

Preparation method of glass glaze surface winebottle

The invention relates to a preparation method of a glass glaze surface winebottle. The preparation method is characterized in that a glaze material is prepared from the following raw materials in parts by weight: 12-14 parts of talcum, 4-5 parts of limestone, 3-4 parts of calcium phosphate, 4-5 parts of B2O3, 1-2 parts of potassium chloride, 3-4 parts of tin chloride, 1-2 parts of boracic acid, 1-2 parts of chromium trioxide, 1-2 parts of Nb2O5, 13-14 parts of adhesives and a right amount of water. The glass winebottle prepared through the method disclosed by the invention is smooth and lustrous in glaze surface without cracks and can be used for achieving the sintering finished product ratio of 99% without damage.

Owner:安徽鑫民玻璃股份有限公司

HTEE series special infrared radiation coating for high temperature kiln

InactiveCN101481551APerformance impactReduce the temperatureChemical industryCoatingsChromium trioxideSodium phosphates

The invention relates to an HTEE series nocturnal radiation paint which is a special energy-saving material for a high temperature furnace and is applicable to petrochemical engineering furnaces and furnaces in the metallurgic, electric power, ceramic, architectural and aviatic industries and other industries, as well as civil furnaces. The invention utilizes a Y2O3 rare-earth nanophase material for enhancing the strength and the aging resistance performance of nocturnal radiation paint and provides a high temperature nocturnal radiation paint which is directly coated on the lining of a metal heating device or on a heater or a fire-resistant ceramic material of the high temperature furnace. The high temperature radiation paint has the advantages of high thermal efficiency, high temperature resistance, stable adhesive property, capability of effectively saving energy, furnace-body service life prolonging, and the like. The invention adopts the hydro-thermal method to synthesize the Y2O3 rare-earth nanophase material, the solid material of the high temperature paint is selected to comprise 50% of zirconia, 20% of monox, 8-15% of aluminum oxide, 3-6% of ferric oxide, 10-14% of chromium trioxide, 3-9% of sodium sodium phosphate and 1-3% of calcium carbonate. A corresponding liquid material (adhesive agent) is a special high temperature adhesive agent and mainly comprises 0.5-3% of Y2O3, 2-6% of aluminum oxide, 1-3% of ferric oxide, 0.4-2% of manganese oxide, 1-3% of calcium carbonate, and the balance of tap water. The ratio of the solid material and the liquid material is maintained to be 3:2. The solid material and the liquid material are proportionally mixed and then evenly stirred at the normal temperature, and then the special nocturnal radiation paint for the high temperature furnace can be obtained. The use temperature of the nocturnal radiation paint ranges from 1,200 DEG C to 1,800 DEG C.

Owner:曾宏图 +1

Hydrogen-generating material and method for generating hydrogen

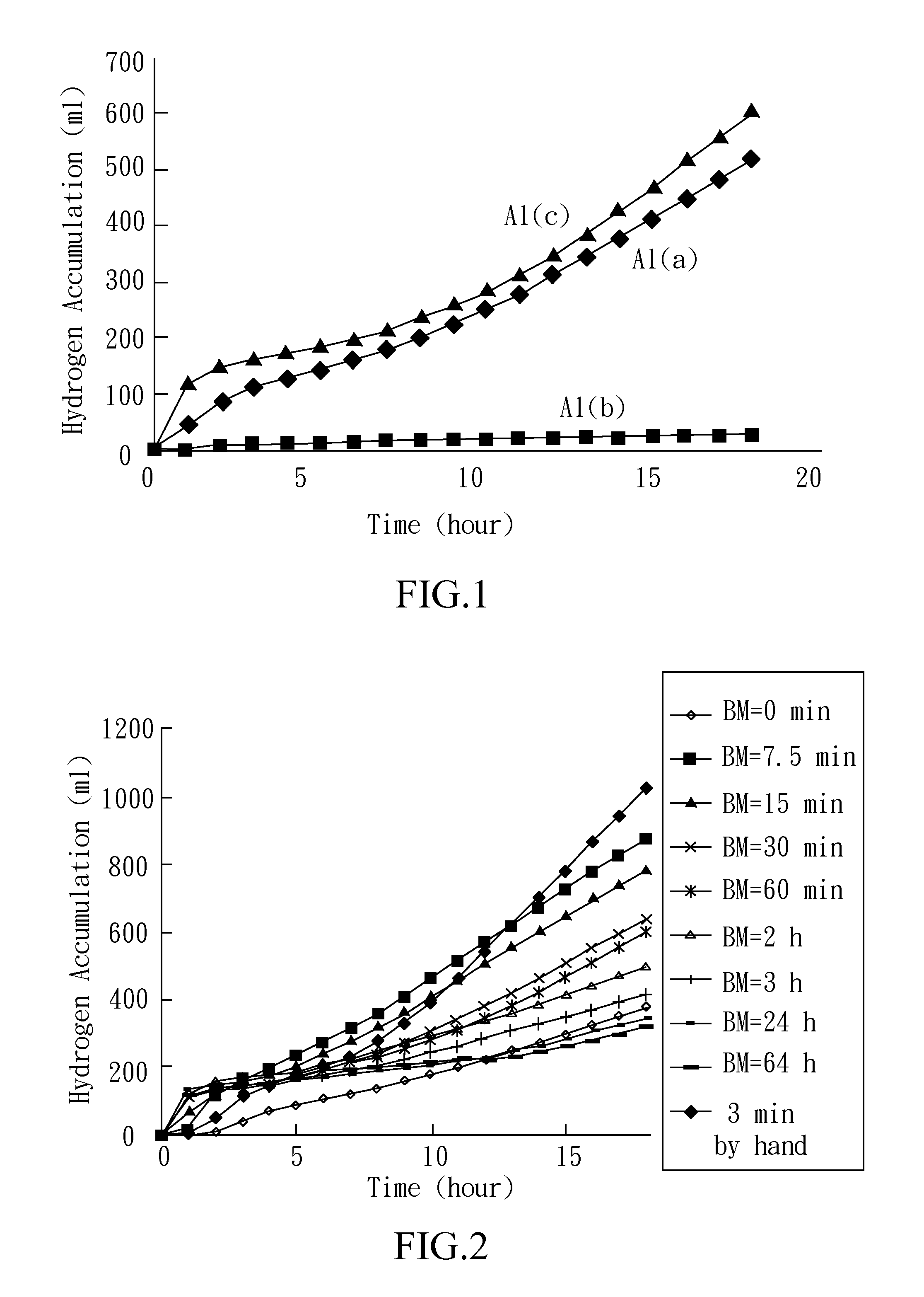

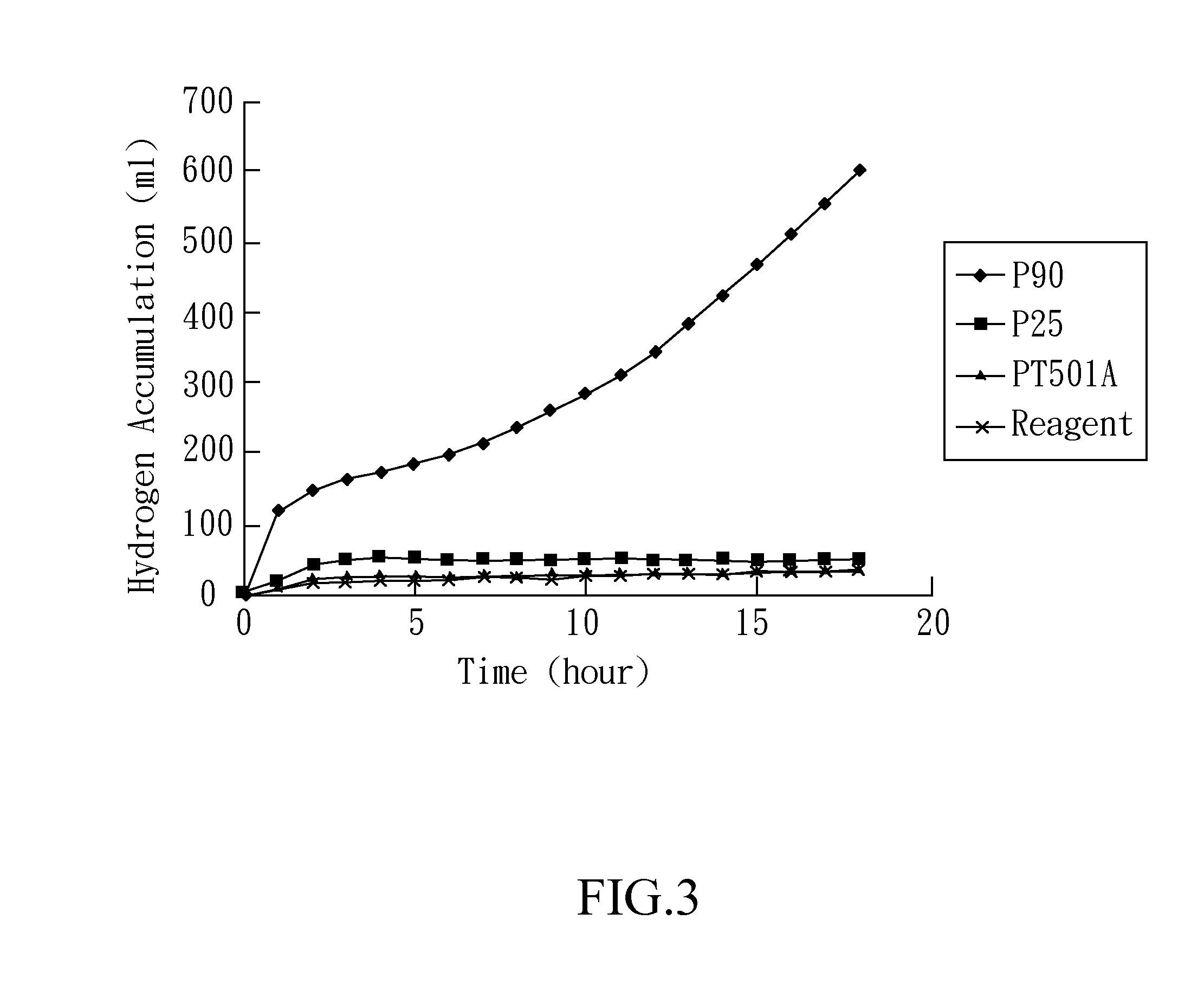

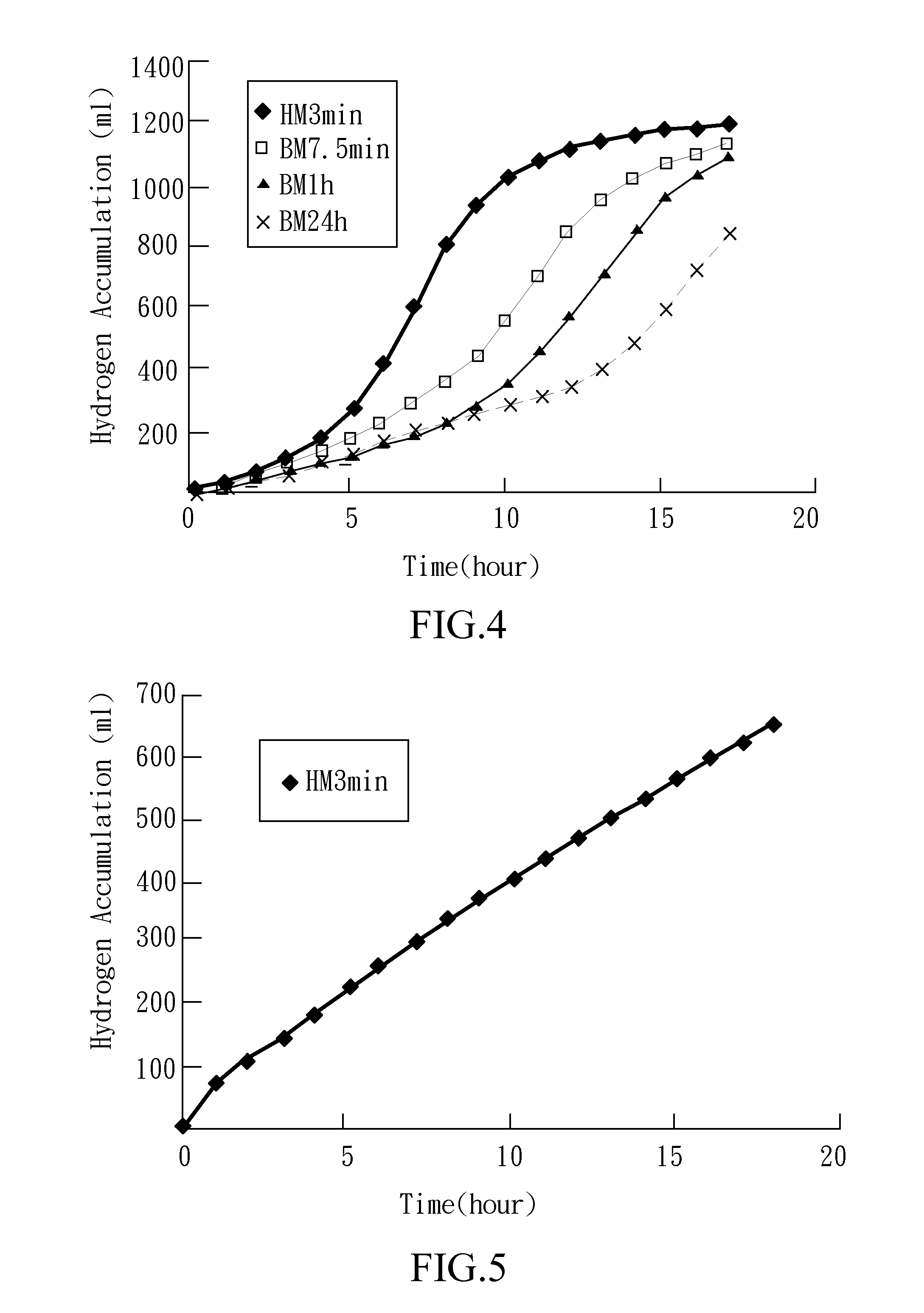

A hydrogen-generating material and method for generating hydrogen are provided. A plurality of metal particles and a plurality of modifier particles are mixed and than reacted with water to generate hydrogen. The metal particles are made of material including aluminum or aluminum alloy or combination thereof. The modifier particles preferably comprise titanium dioxide (TiO2), chromium trioxide (Cr2O3), cobalt tetroxide (CO3O4), nickel oxide (NiO), iron oxide (Fe2O3), and / or iron tetroxide (Fe3O4) particles, and the average particle size of the modifier particles is preferably between about 10 nm to about 50 nm.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

High-temperature preventive coating process

InactiveCN101724809AAchieve local preparationImprovement of working conditions in coating processSolid state diffusion coatingChromium trioxidePhosphoric acid

The invention relates to a high-temperature preventive coating process which is characterized by comprising the process flows of: preparing a caking agent, preparing slurry, spraying, solidifying and heating in a vacuum furnace, wherein the caking agent comprises the following ingredients in mass ratio: 700 to 900g of water, 60 to 90g of chromium trioxide, 70 to 90g of magnesium oxide and 270 to 400g of phosphoric acid; a preparation process of the caking agent comprises the following steps of: adding the phosphoric acid in water, adding the magnesium oxide and fully dissolving, and adding the chromium trioxide, wherein the step of adding the magnesium oxide and fully dissolving adopts a principle of adding in small amount and a plurality of times, that is to say, adding in small amount and then adding again after the solution become clear. The invention changes the traditional process flow, improves the coating performance, can be applied to components and parts that work for a long time in severe environment, and is particularly suitable for a gas turbine.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

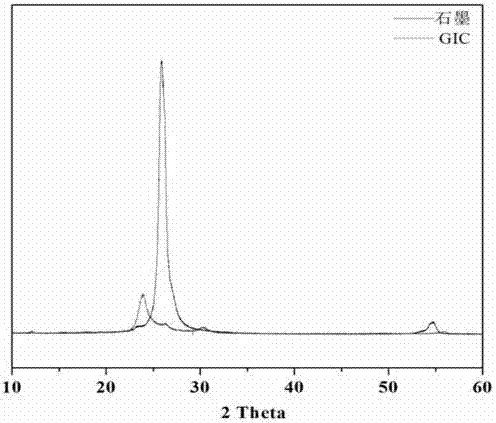

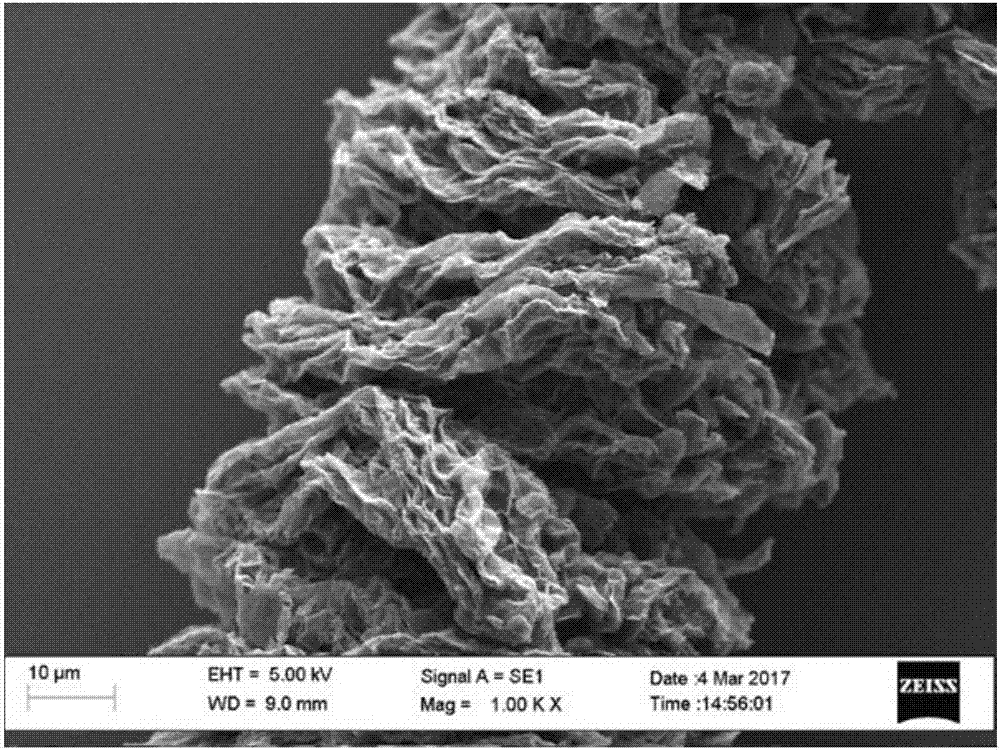

Preparation method of high conductivity graphene

InactiveCN107416811AIncrease dispersion speedAvoid pollutionGrapheneChromium trioxideOrganic solvent

The invention provides a preparation method of graphene. The preparation method comprises the following steps: firstly, performing a reaction on graphite, chromium trioxide and concentrated hydrochloric acid to obtain an intercalated graphite compound; then mixing the intercalated graphite compound obtained in the previous step with hydrogen peroxide to obtain expanded graphite; and finally, peeling the expanded graphite obtained in the previous step in an aqueous phase to obtain the graphene. In order to overcome the defect of high temperature and high pressure of an existing conventional graphene liquid phase peeling method, a graphene preparation method of low-temperature intercalation, low temperature expansion and aqueous phase peeling is creatively achieved by optimizing and combining raw materials and refining the reaction steps by means of a low-temperature constant-pressure liquid phase peeling method. Therefore, the production cost is lowered, the environmental pollution caused by an organic solvent is also avoided, and the dispersing speed of graphene is also increased.

Owner:SHANDONG OBO NEW MATERIAL CO LTD

Acid-resisting alkali-resisting refractory castable for garbage incinerator

InactiveCN103496994AGood chemical resistanceImproved thermal shock stabilityChromium trioxideMullite

The invention relates to a refractory castable, and particularly relates to an acid-resisting alkali-resisting refractory castable for a garbage incinerator. The acid-resisting alkali-resisting refractory castable comprises the following raw materials: low-iron sintered mullite, boron carbide powder, silicon carbide, pure calcium aluminate cement, chromium trioxide powder, alpha-Al2O3 fine powder, uf-SiO2, zirconium oxide, magnesium oxide, a water reducing agent, a retarder, an explosion-proof agent and the like. The acid-resisting alkali-resisting refractory castable for the garbage incinerator, provided by the invention, has the advantages of good chemical corrosion resistance, good thermal shock stability, high operating temperature and long service life.

Owner:宜兴市张泽浇注耐火材料有限公司

Galvanized layer chromium-free passivant and use method thereof

ActiveCN101717932AEliminate hazardsMetallic material coating processesChromium trioxideChromium free

The invention relates to a galvanized layer chromium-free passivant and a use method thereof, wherein the passivant comprises a passivation film-forming agent, an adhesion promoter, an emulsifying agent, acetone and an aqueous solution, when using, the chromium-free passivant and water are diluted according to the proportion of 1: 4 and then put in a passivation tank, a galvanized part is bright-dipped through diluted acid at a plating bath outlet of a continuous electrogalvanizing production line, then enters into the passivation tank under the normal temperature for passivating 5-20 seconds, taken out, flushed with water and dried by hot air. The galvanized layer chromium-free passivant forms a passivation film on the metal surface by reasonably utilizing certain chromium-free organic acids, and the like, has corrosion inhibition property, adopts resin as the promoter as well as the acetone and water as solvents, is prepared by adopting a compound method, free of chromium and used for carrying out passivating treatment instead of chromate and chromium trioxide and eliminates hazards to the environment and the human body from chromium pollution.

Owner:GUIZHOU WIRE ROPE

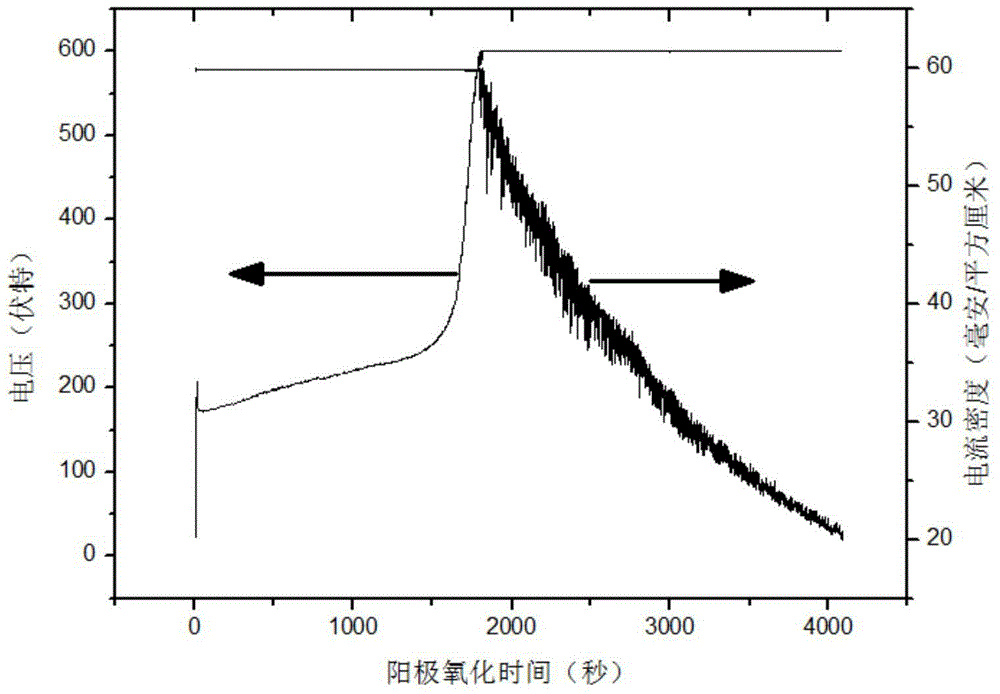

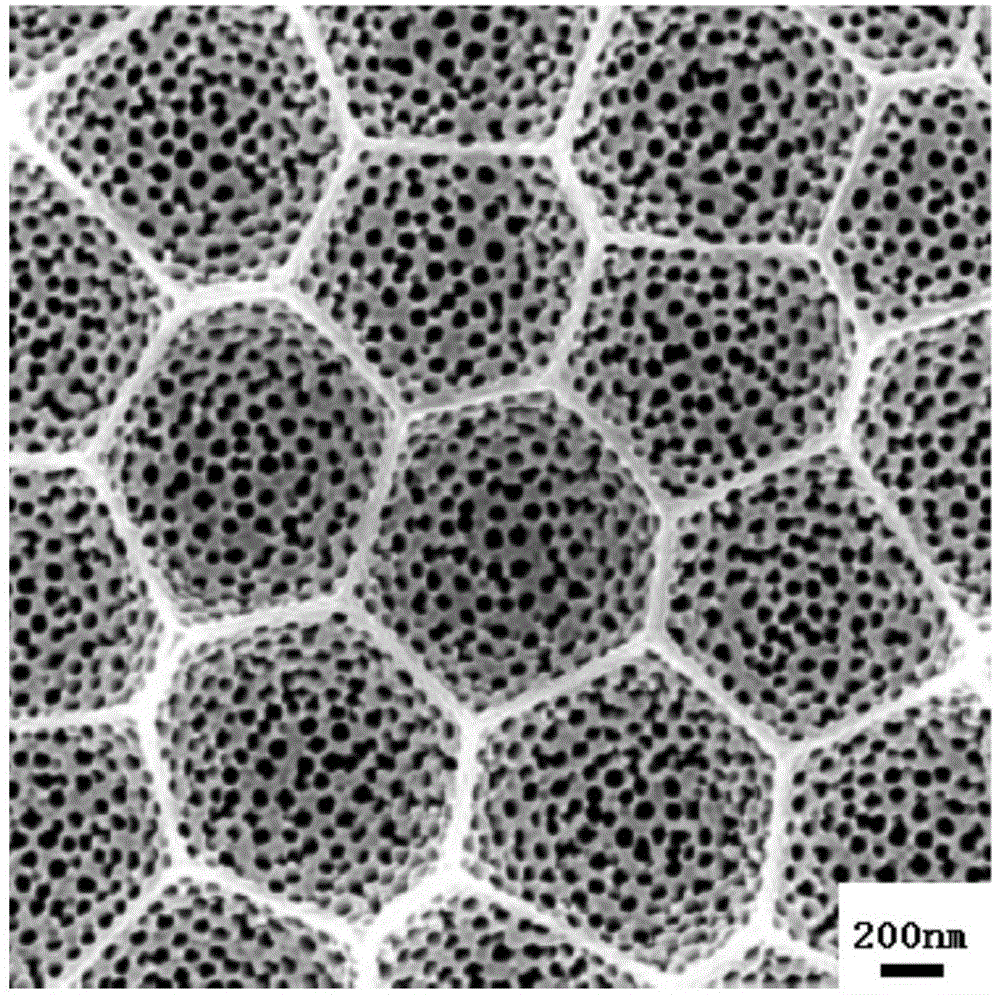

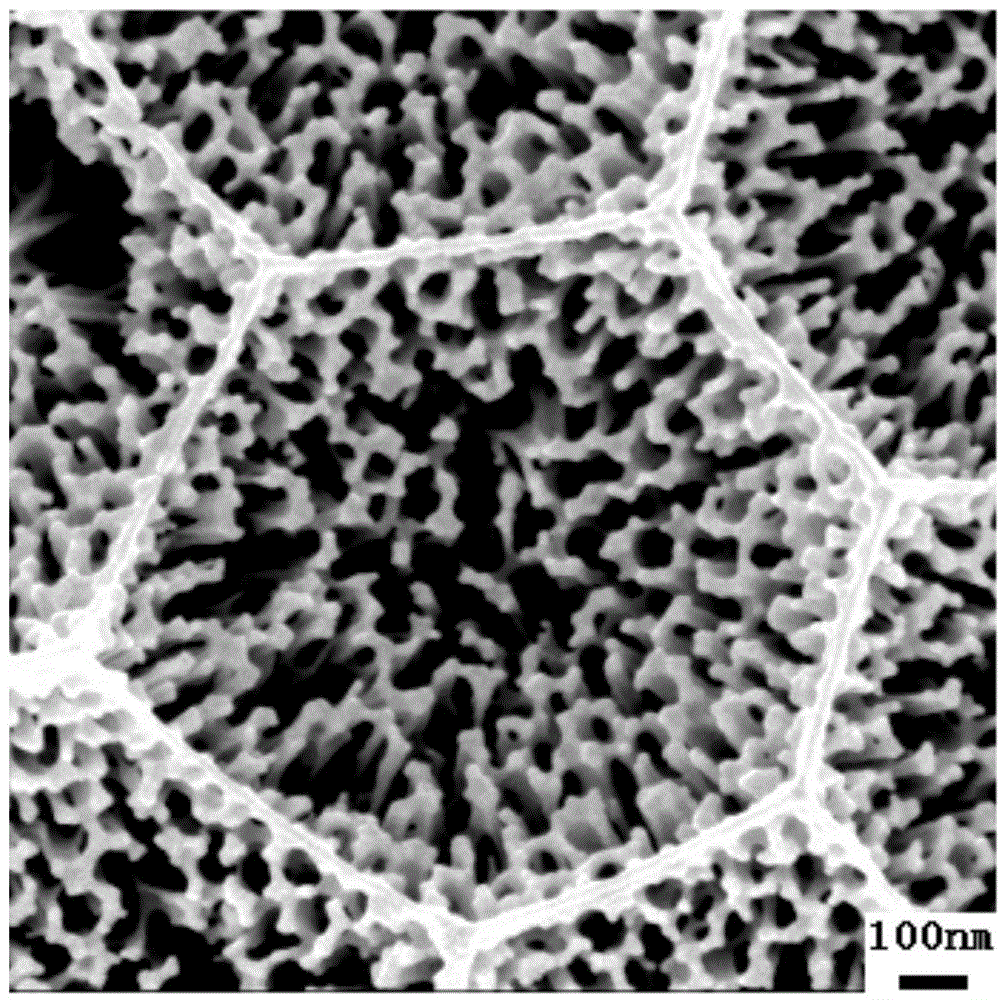

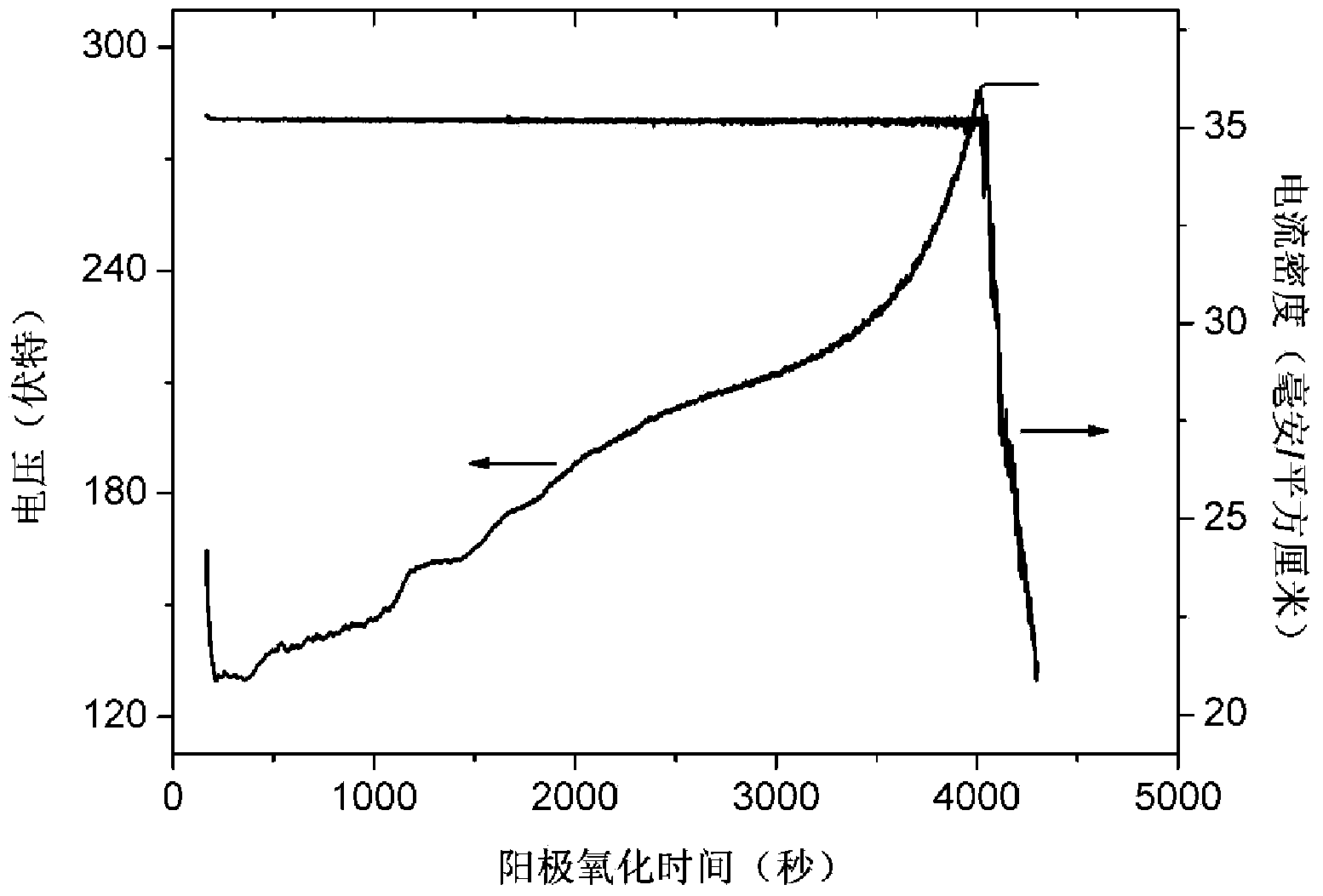

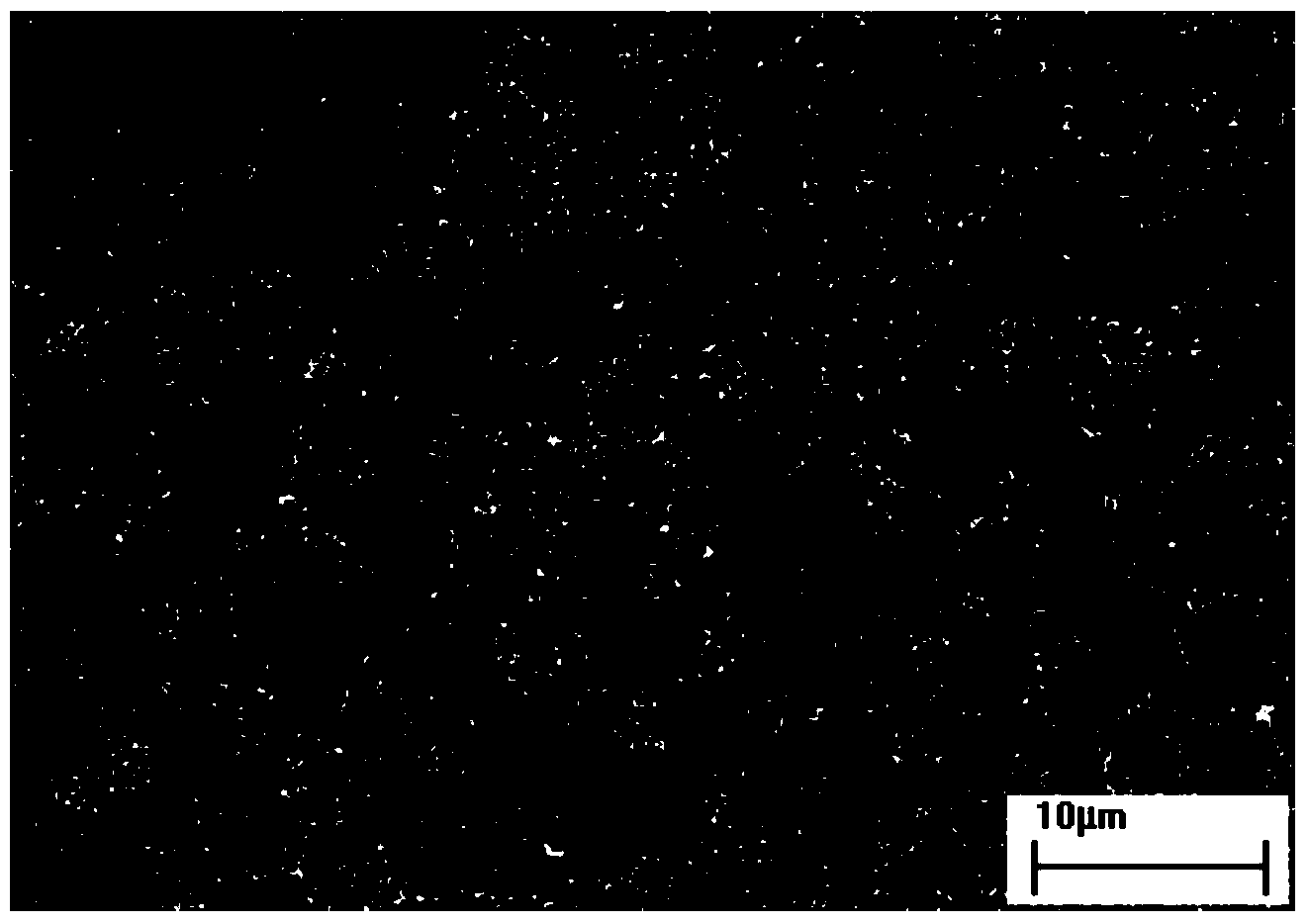

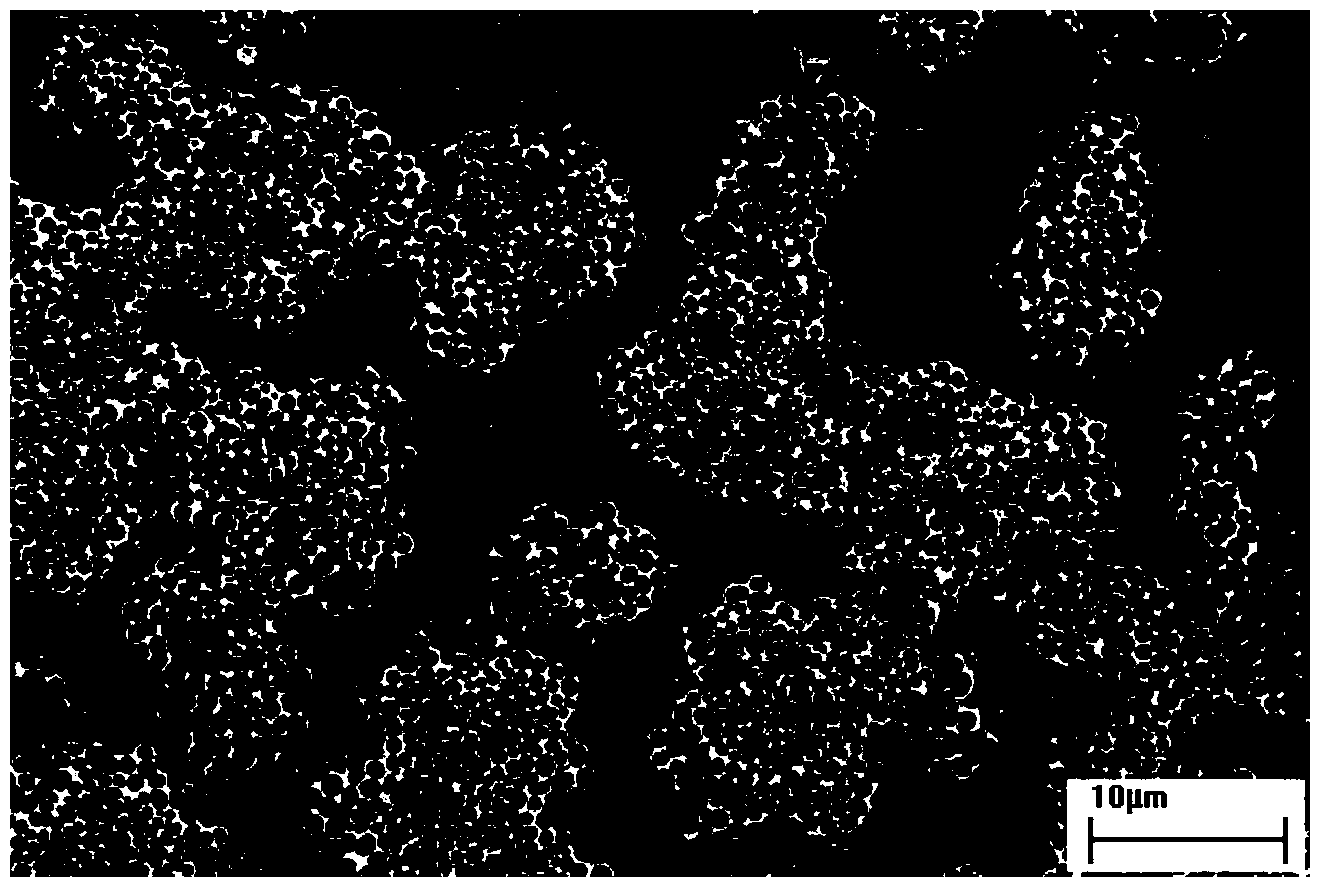

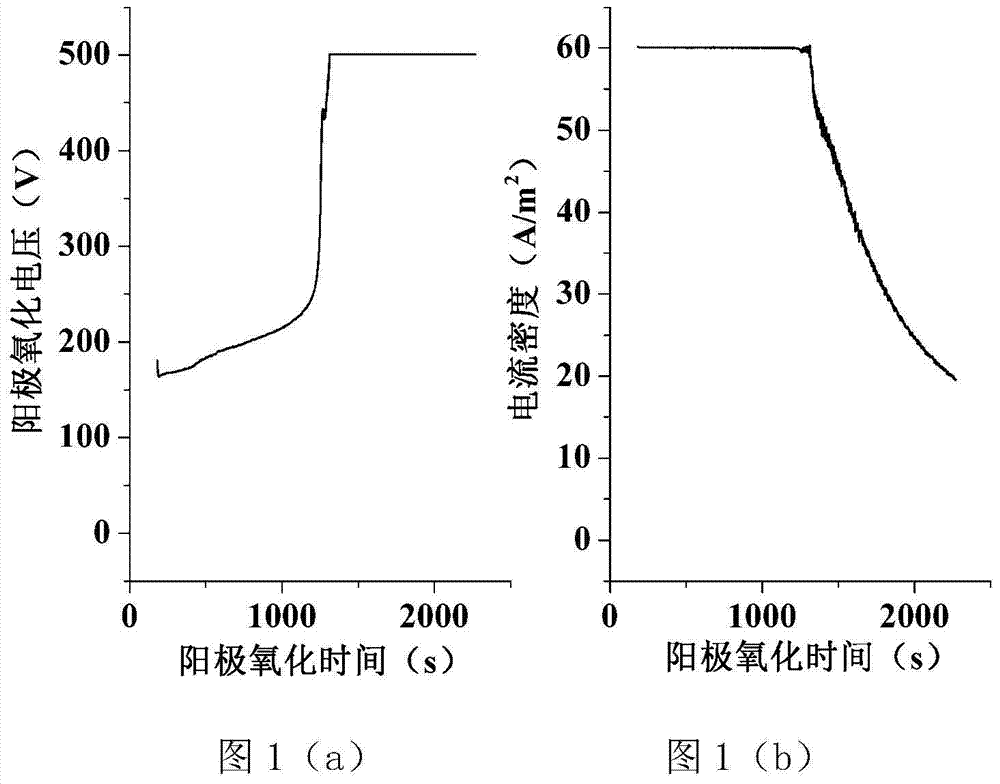

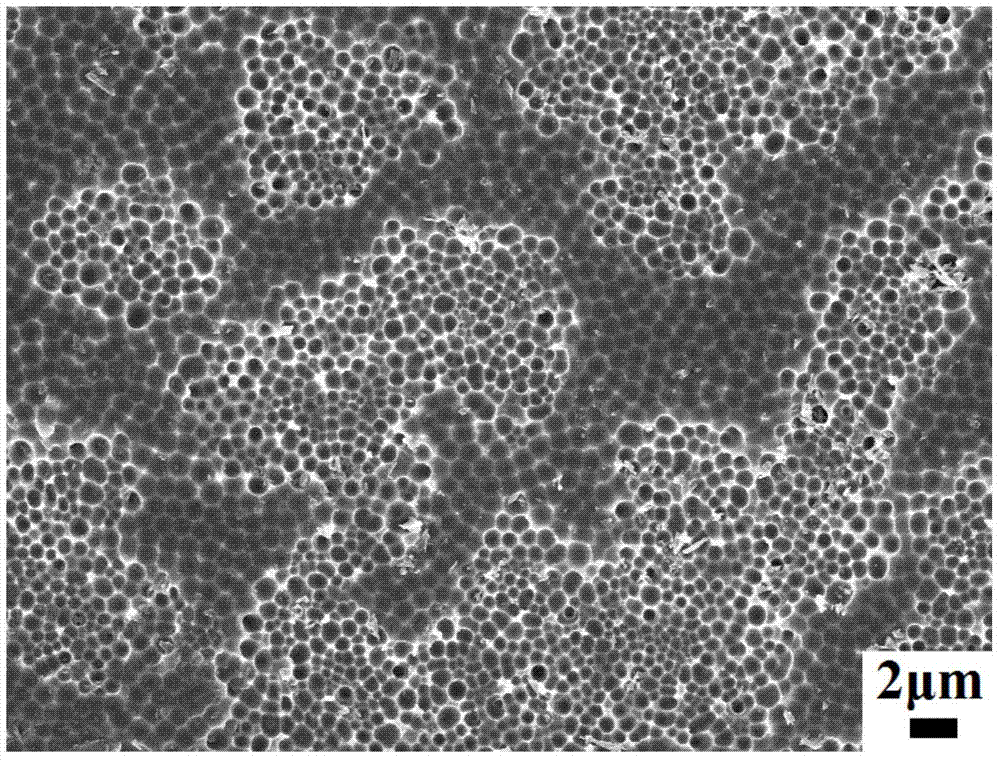

Method for producing micro-surface three-dimensional interconnected-nanopore anodic aluminum oxide template

ActiveCN104928746ALow costSuitable for mass productionSurface reaction electrolytic coatingNanotechnologyChromium trioxideLow voltage

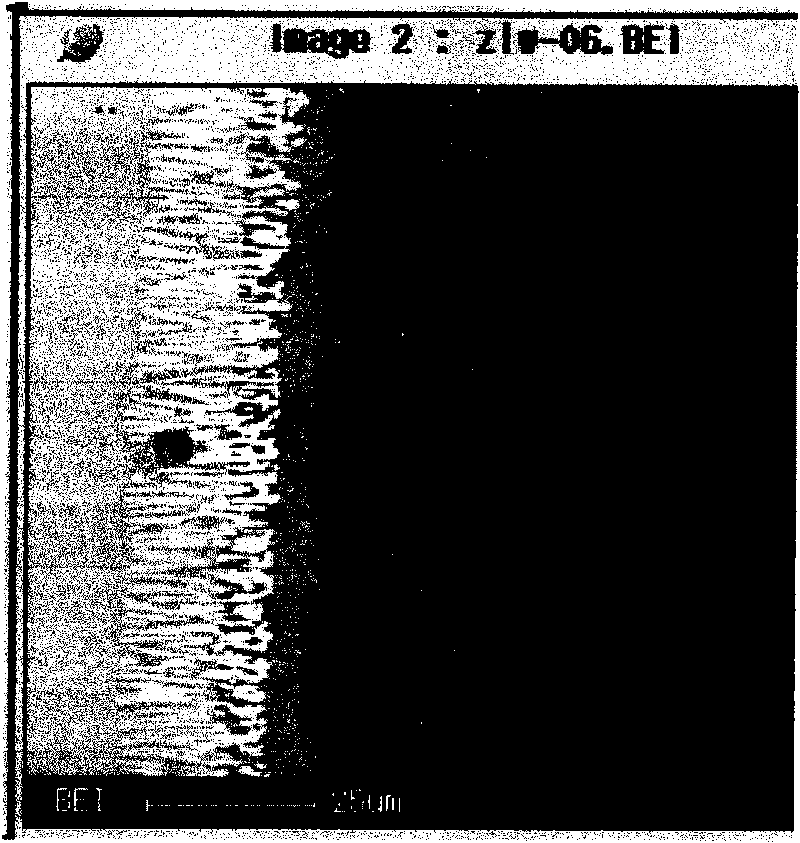

The invention discloses a method for producing a micro-surface three-dimensional interconnected-nanopore anodic aluminum oxide template. The method includes: placing a high-purity aluminum sheet in absolute ethyl alcohol and ionized water sequentially for washing, and then performing electrochemical polishing; performing a first-step anodic oxidation process by taking the polished aluminum sheet as an anode and graphite as a cathode to obtain a porous anodic aluminum membrane with an aluminum base, and enabling the porous anodic aluminum membrane to be adjustable from sub-micron grade to micron grade in structural unit size by adjusting anodic oxidation conditions such as voltage and current density; placing the porous anodic aluminum membrane with the aluminum base in chromium trioxide and phosphate mixed aqueous solution for membrane removing to obtain the aluminum base with the surface provided with sub-micron grade and micro grade pits; subjecting the aluminum base obtained from the previous step to secondary anodic oxidation under low voltage, and finally performing chambering and corrosion in a phosphoric acid solution to obtain the micro-surface three-dimensional interconnected-nanopore anodic aluminum oxide template by controlling time for chambering.

Owner:SOUTH CHINA UNIV OF TECH

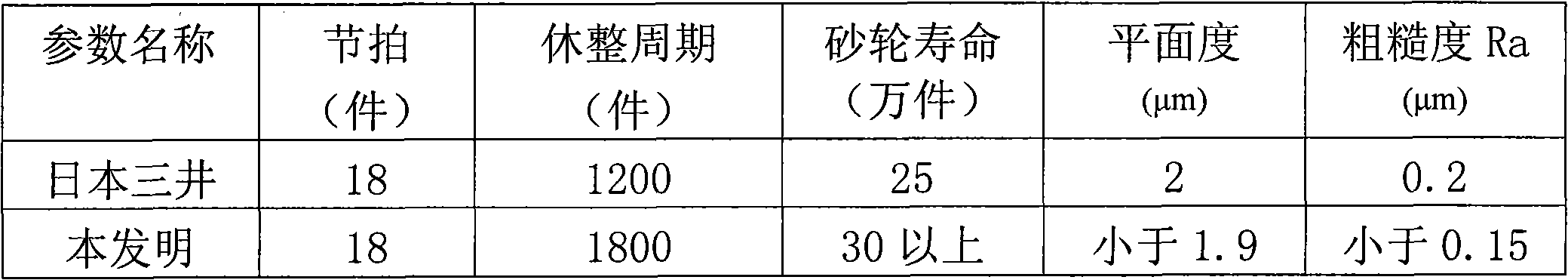

Formula system for abrasive layer of resin cubic boron nitride (CBN) end face grinding wheel

The invention relates to a formula system for the abrasive layer of a resin cubic boron nitride (CBN) end face grinding wheel, belonging to the preparation technique of an accurate grinding wheel. The formula system in the invention special for the abrasive layer is designed aiming at the grinding wheel for the grinding processing of an air condition compressor piston. In the invention, graphite, cryolite and silicon dioxide are added in the formula of the abrasive layer of the known resin CBN grinding wheel and chromium trioxide is eliminated, and a bonding agent is still the common phenolic resin. The formula system provided by the invention has the advantages of cheap raw materials and no pollution, and the end face of the manufactured grinding wheel has the combination properties of high tenacity, high strength, high holding force and the like.

Owner:沈阳中科超硬磨具磨削研究所

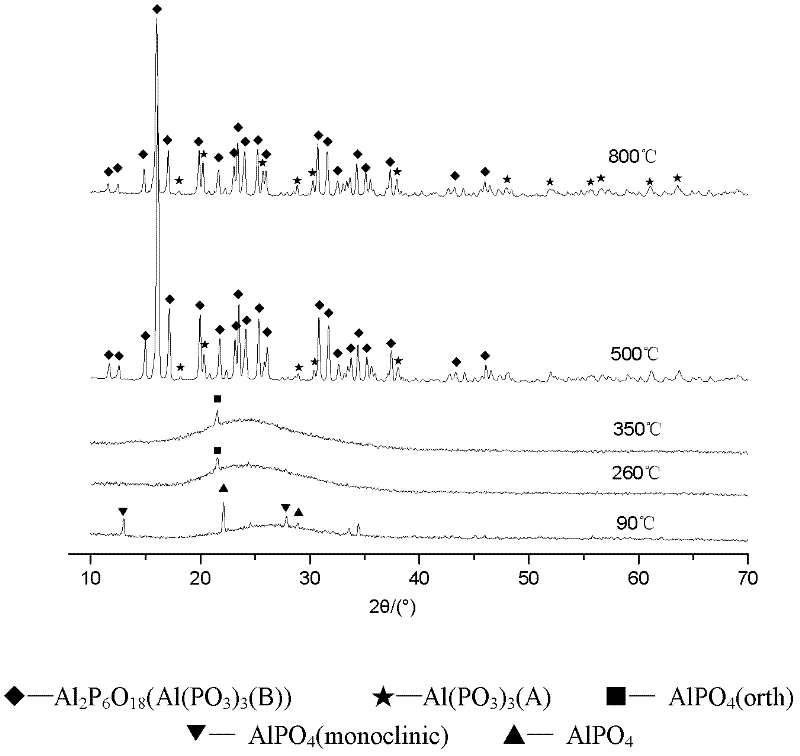

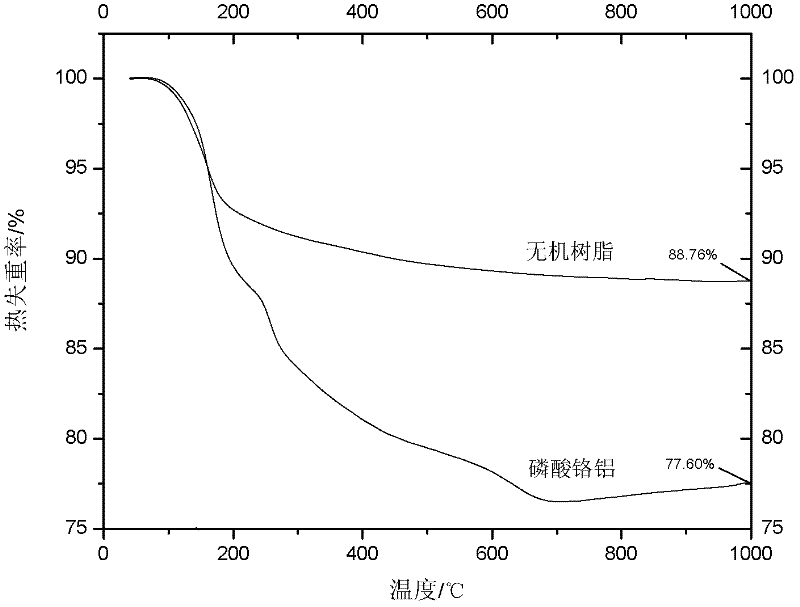

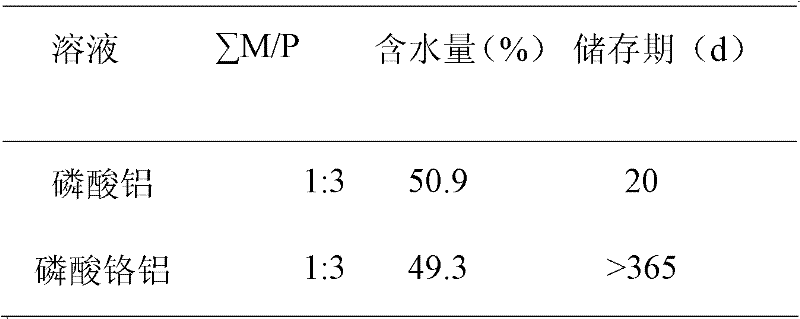

High-temperature resistant low dielectric phosphorus-containing inorganic resin capable of compositing with fiber, preparation and application

The invention discloses a high-temperature resistant low dielectric phosphorus-containing inorganic resin capable of compositing with fiber, and a preparation method and application of the inorganic resin, which belongs to the technical field of inorganic resin. The high-temperature resistant low dielectric phosphorus-containing inorganic resin capable of compositing with fiber comprises a chrome-alumina phosphate solution, melted quartz powder, alumina powder and aluminium nitride. The preparation method comprises the following steps: adding chromium trioxide and selecting different reductants to reduce Cr6+ to Cr3+ based on preparation of an aluminium phosphate solution to prepare the chrome-alumina phosphate solution; and adding oxide and nitride with high- temperature resistance and low dielectric constant to obtain the high-temperature resistant low dielectric phosphorus-containing inorganic resin. The high-temperature resistant low dielectric phosphorus-containing inorganic resin capable of compositing with fiber has a simple preparation technology and a universal device, is easy to achieve industrial production, can be completely cured at 150 DEG C, and has better high-temperature mechanical property, excellent dielectric property and moisture absorption resistant property. A wave-transmitting material used for making an antenna housing can be obtained by soaking quartzfibers or quartz fiber fabrics with surfaces being specially treated in the inorganic resin, airing in room temperature and hot-pressing.

Owner:BEIJING UNIV OF CHEM TECH

Chemical etching agent for displaying metallurgical structure of INVAR steel and soldered joints thereof and preparation method thereof

The invention relates to a chemical etching agent for displaying the metallurgical structure of INVAR steel and soldered joints thereof and a preparation method thereof. One part of the chemical etching agent comprises the following components: 3-10g of chromium trioxide CrO3, 30-100ml of hydrochloric acid HCL (analytically pure) and 30-100ml of water H2O. The method comprises the following steps: (1) weighing required raw materials based on the prescription of each part of etching agent; and (2) firstly adding the chromium trioxide to water, stirring until the chromium trioxide is completely dissolved to form a mixed solution, then slowly adding the analytically pure hydrochloric acid to the mixed solution, and uniformly stirring to obtain the required chemical etching agent. The chemical etching agent for displaying the metallurgical structure of the INVAR steel and the soldered joints thereof has the advantages of good etching effect, high etching speed and high efficiency, can be stored for long, and has extremely high popularization and application value for the metallographic examination of the INVAR steel and the soldered joints thereof.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

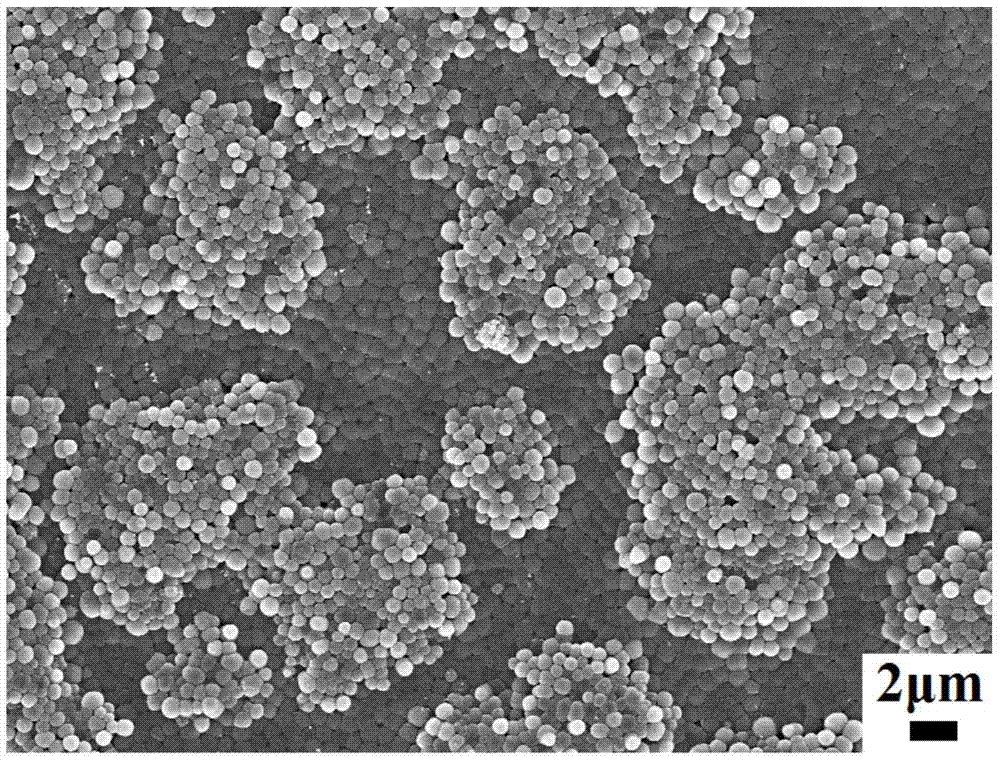

Method for manufacturing submicron/micron aluminum mold plate

The invention discloses a method for preparing a submicron / micron aluminum mold plate. The method comprises the following steps: sequentially putting a high-purity aluminum piece into absolute ethyl alcohol and deionized water for washing, subsequently polishing in an electrochemical mode, performing anode oxidation by taking the polished aluminum piece as an anode, graphite as a cathode and an oxalic acid-ethanol-water mixture solution as electrolyte, so as to obtain a porous aluminum oxide film with an aluminum substrate, regulating anode oxidation conditions such as the voltage and the current density to enter a submicron-order structure unit into a competitive growth mode, so as to form a micron-order structural unit cluster, and putting the porous aluminum oxide film with the aluminum substrate into a mixture solution of chromium trioxide and phosphoric acid for removing the film, thereby obtaining the aluminum mold plate with submicron / micron composite pits in the surface. The method has the advantages that the raw materials are easily available, the cost is low, the equipment is simple, the operation is convenient, the controllability is good and the like, and the feasibility that the method is applied to production is greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

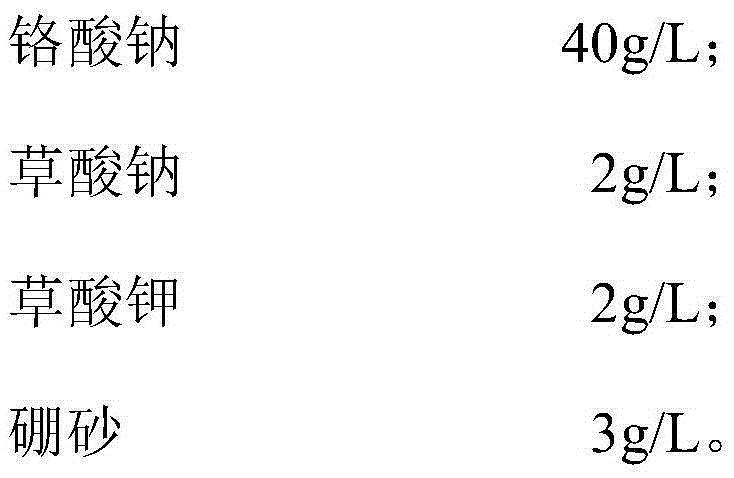

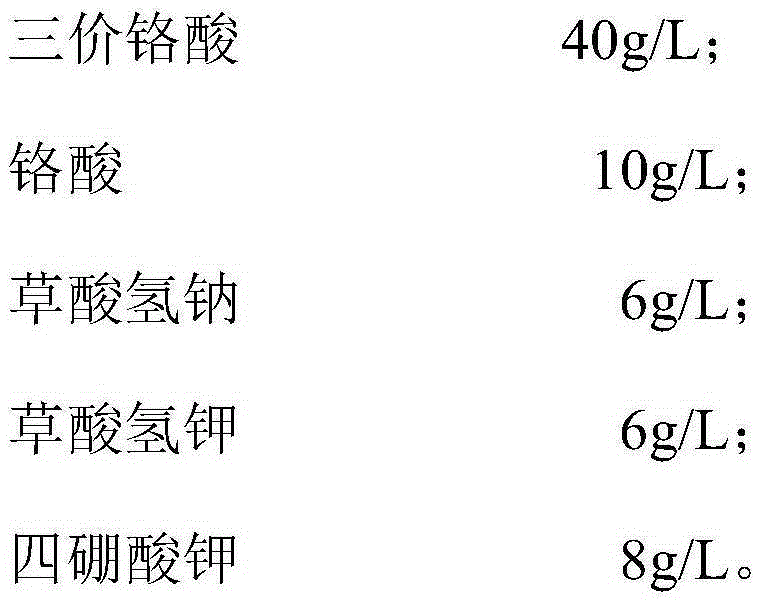

Technique for preparing trivalent chromium white deactivation liquid

InactiveCN101191216ANo irritating smellOperational securityMetallic material coating processesChromium trioxideDissolution

The invention relates to a trivalent chromium white passivating liquid, wherein, under normal temperature and pressure, water is added into chromium trioxide for mixture and dissolution; seignette salt is added into mixture for stirring, dissolution and reaction; the mixture is kept for a plurality of hours and then stirred; when PH value is between 4 and 5, sulphuric acids are added into the mixture for even stirring; the mixture is kept for a plurality of hours; galvanized parts with over half brightness are immersed into the passivating liquid; the trivalent chromium white passivating liquid is obtained after washing by clear water and drying. The invention has the advantages of capability of directly exhausting cleaning water after passivation, stable nonirritant odor, safe operation and strong corrosion resistance.

Owner:TIANJIN HANLONG ZINC PLATING

Thin-wall honeycomb type low-temperature sulfur-resistant SCR denitration catalyst and preparation method thereof

ActiveCN110354843ALarge specific surface areaImprove denitrification activityGas treatmentHeterogenous catalyst chemical elementsChromium trioxideSilicon dioxide

The embodiment provides a thin-wall honeycomb type low-temperature sulfur-resistant SCR denitration catalyst. A catalyst carrier is a titanium dioxide-coated silicon dioxide composite nanotube, an active component is vanadium pentoxide, and a catalytic assistant is molybdenum trioxide and chromium trioxide. The thin-wall honeycomb SCR denitration catalyst with low-temperature sulfur resistance performance is prepared by adopting an extrusion molding process. The catalyst has good low-temperature activity and sulfur poisoning resistance, can solve the problems of low activity and sulfur poisoning of the catalyst in low-temperature flue gas, and is suitable for low-temperature sulfur-containing flue gas; by adding various inorganic and organic forming additives and optimizing the drying androasting processes, the wall thickness of the catalyst is reduced on the basis of maintaining the mechanical strength of the catalyst, the sulfur poisoning resistance of the catalyst is improved, theproduction cost is reduced, and the thin-wall honeycomb type low-temperature sulfur-resistant SCR denitration catalyst has good economic benefits. The embodiment also provides a preparation method ofthe thin-wall honeycomb type low-temperature sulfur-resistant SCR denitration catalyst.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for preparing nano/submicron/micron multi-stage anode alumina template

InactiveCN104294344ALow costSuitable for mass productionAnodisationNanotechnologyChromium trioxideLow voltage

The invention discloses a method for preparing a nano / submicron / micron multi-stage anode alumina template. The method comprises the following steps: firstly, washing a high-purity aluminum sheet, and subsequently performing electrochemical polishing; performing anodic oxidation by using an oxalic acid-water-ethanol mixed solution as electrolyte, thereby obtaining a porous anode alumina membrane with an aluminum substrate; enabling a submicron structural unit to enter into a competitive growth mode by adjusting the conditions of voltage and the current density, thereby forming island-shaped and strip-shaped micro-grade structure unit clusters of different shapes; putting the alumina membrane with the aluminum substrate into a chromium trioxide and phosphoric acid mixing solution so as to remove the membrane, subsequently performing low-voltage anode oxidation in an oxalic acid solution, and performing hole expansion treatment by using a phosphoric acid solution, thereby obtaining the anode alumina template of a nano / submicron / micron multi-stage pore pipeline structure. The method has the advantages that the raw materials are easily available, the cost is low, the equipment is simple, the controllability is good, and the like, and the feasibility of industrial production is greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

Method for synthesizing 3-methyl-4-nitrobenzoic acid by using stepped heating method and indirect electrosynthesis method

The invention discloses a method for synthesizing 3-methyl-4-nitrobenzoic acid by using a stepped heating method and an indirect electrosynthesis method. The method is implemented by taking 2,4-dimethylnitrobenzene and chromium sulfate as main raw materials through the following steps of: firstly, carrying out electrolytic oxidation on chromium sulfate by using an electrolytic process so as to obtain chromium trioxide; then, selectively oxidizing 2,4-dimethylnitrobenzene into a 3-methyl-4-nitrobenzoic acid by using chromium trioxide through using the stepped heating method. According to the invention, through adopting the stepped heating method, the oxidation reaction rate of 2,4-dimethylnitrobenzene is controlled, and the selectivity and conversion rate of reaction are remarkably improved. The conversion rate of chromium trioxide obtained by using an electrolytic oxidation method is 85-95%, and the conversion rate of 3-methyl-4-nitrobenzoic acid obtained by using the stepped heating method can reach 65-86%. According to the invention, the problem that in the process of reaction, the reaction rate declines due to the consumption of acids is solved; through carrying out electrolytic oxidation on chromium sulfate produced after reaction, chromium trioxide is circularly produced, thereby not only avoiding the environment pollution, but also greatly saving the cost.

Owner:HUNAN UNIV OF SCI & TECH

Ceramic anodizing solution and ceramic anodizing process

InactiveCN105297103AExpand the range of surface decoration colorsBeautiful surface enamelAnodisationChromium trioxideAnodizing

The invention relates to the technical field of anodizing solution formulas and anodizing processes, in particular to a ceramic anodizing solution and a ceramic anodizing process. The ceramic anodizing solution comprises, by mass concentration, 30-80 g / L of one or combination of chromic acid, chromium trioxide, origanum vulgare, chromate and trivalent chromic acid, 1-30 g / L of an additive A, and 1-30 g / L of an additive B. Firstly, an aluminum alloy material to be subjected to ceramic anodizing is placed in a reaction tank containing the ceramic anodizing solution, then the ceramic anodizing solution is heated to 25-60 DEG C, voltage of 20-90 V is introduced, anodizing is carried out for 30-80 min, and the ceramic anodizing step is completed. A film generated on a ceramic anode is in a tree root shape, and has the incomparable advantage compared with a common anode in hardness, a beautiful surface porcelain glaze feel is maintained, and meanwhile, the firm luster appearance meeting different decoration requirements is achieved; in the using process, good abrasion resistance, corrosion resistance and weather resistance functions are achieved, the process conditions are simple, and implementation is convenient.

Owner:HUIZHOU ZEHONG TECH CO LTD

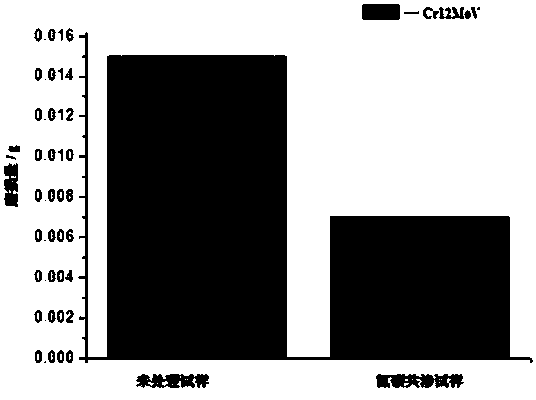

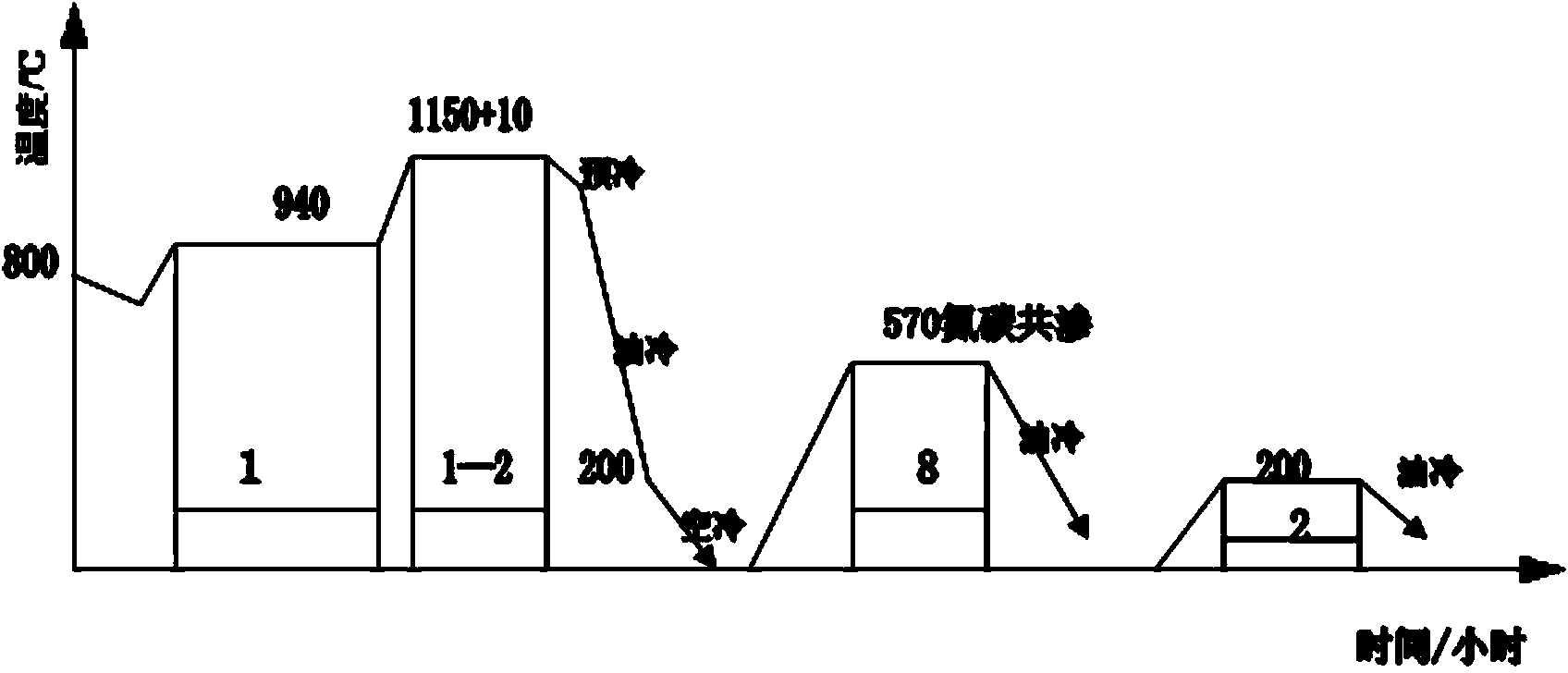

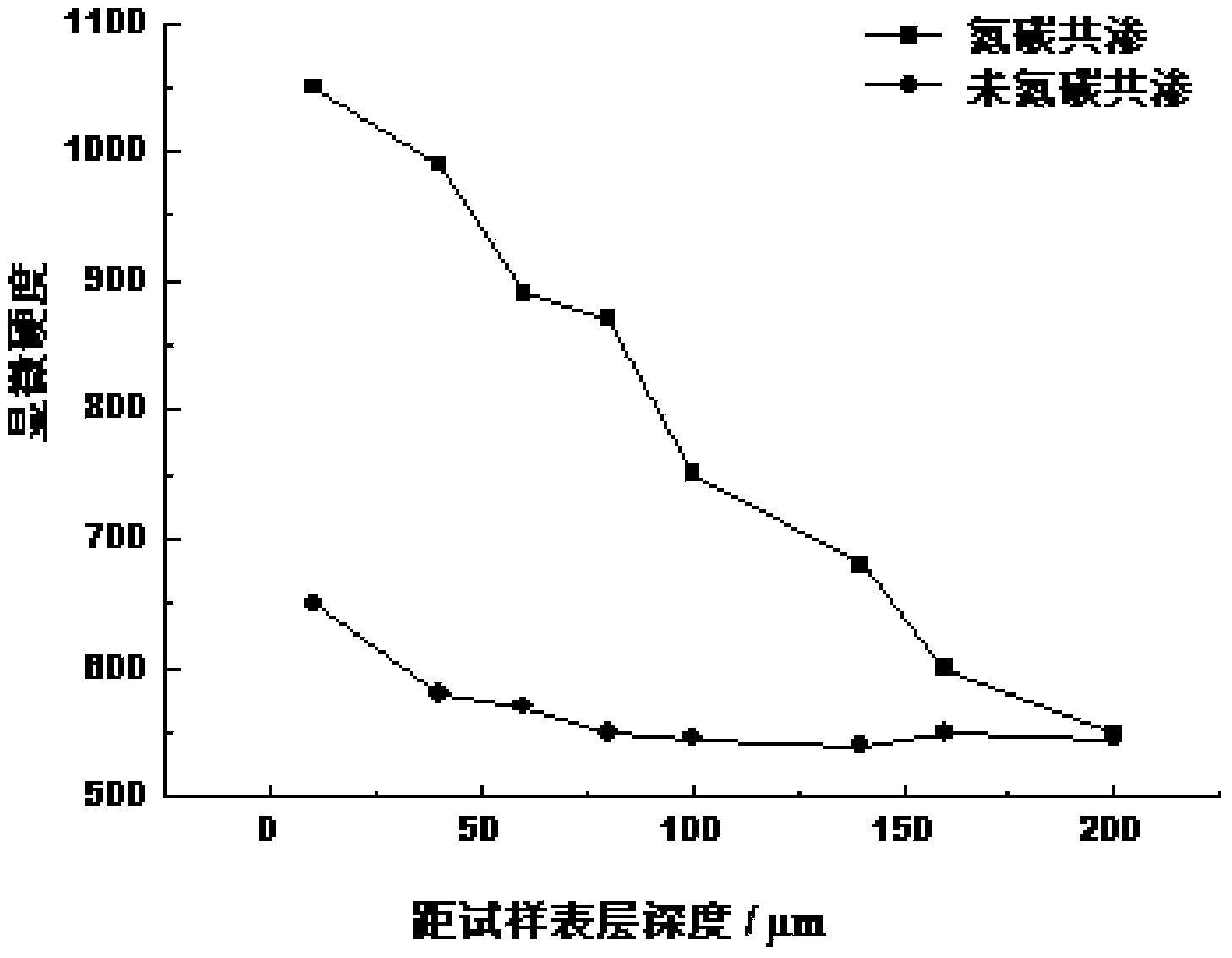

Nitrocarburizing process of Cr12MoV steel

InactiveCN103866333AIncrease temperatureShorten the processing flowSolid state diffusion coatingChromium trioxideNitrogen

The invention relates to a nitrocarburizing process of Cr12MoV steel. The nitrocarburizing process comprises the following steps: carrying out high-temperature quenching on a mold of the Cr12MoV steel, putting the mold into a box, putting the box into an electric furnace, carrying out nitrocarburizing, maintaining the temperature for 4-8 hours, and adding a small amount of catalyst, namely chromium trioxide to carry out catalysis nitriding, wherein the process temperature of the nitrocarburizing is 560-580 DEG C, nitriding agents are charcoal and urea, and the proportion of the charcoal to the urea is 3:2; and putting the mold into the electric furnace at 200 DEG C, tempering for 2 hours while maintaining the temperature, discharging the mold out of the electric furnace, adding the mold into cold oil, and taking out the mold after the mold is cooled to the room temperature. According to the nitrocarburizing process, the service life of the mold of the Cr12MoV steel is effectively prolonged.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

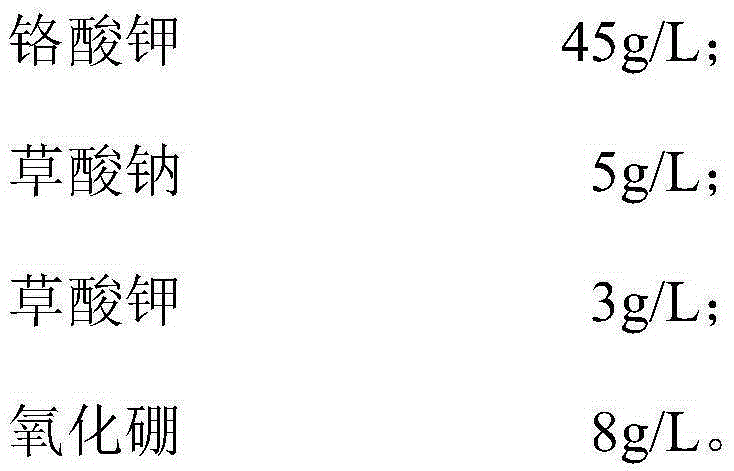

Pole lug nickel strap surface treatment passivation solution

ActiveCN105331959AImprove adhesionImprove compactnessMetallic material coating processesChromium trioxideAccelerant

The invention discloses a pole lug nickel strap surface treatment passivation solution and a preparing method thereof. A composition comprises water, chromium trioxide, mineral acid and a film formation accelerant. By means of the pole lug nickel strap surface treatment passivation solution, the problems that the passivation film compactness is low, and the bonding performance between a film and pole lug glue is poor are solved.

Owner:MAIKAIMEN ELECTRONICS TECH SHANGHAI

Technology for manufacturing black chromium coating for rotating anode X-ray tube

InactiveCN101768764AImprove high temperature resistanceNon-foamingChromium trioxideMetallic materials

The invention belongs to the field of plating of metal materials, in particular to technology for manufacturing a black chromium coating on a rotating anode X-ray tube. The plating solution is prepared, and the black chromium coating is directly deposited on a rotor matrix of the rotating anode X-ray tube through plating, without a middle transition plating layer. The plating solution is prepared from the following components by weight: 200 to 400 grams of chromium trioxide, 2 to 4 grams of barium carbonate, 15 to 25 grams of boric acid, 5 to 15 grams of sodium nitrate, 0.05 to 0.15 milliliters of fluosilicic acid and 1,000 milliliters of ionized water. The technology has the advantages that: compared with the prior art, the black chromium coating needs no middle transition plating layer and can be directly deposited on the rotor matrix; and the black chromium coating is applied to a vacuum state and has excellent high temperature resistance, can resist the temperature of between 600 and 700 DEG C, does not foam or wrinkle, has high bonding strength and does not fall off.

Owner:科罗诺司医疗器械(上海)有限公司

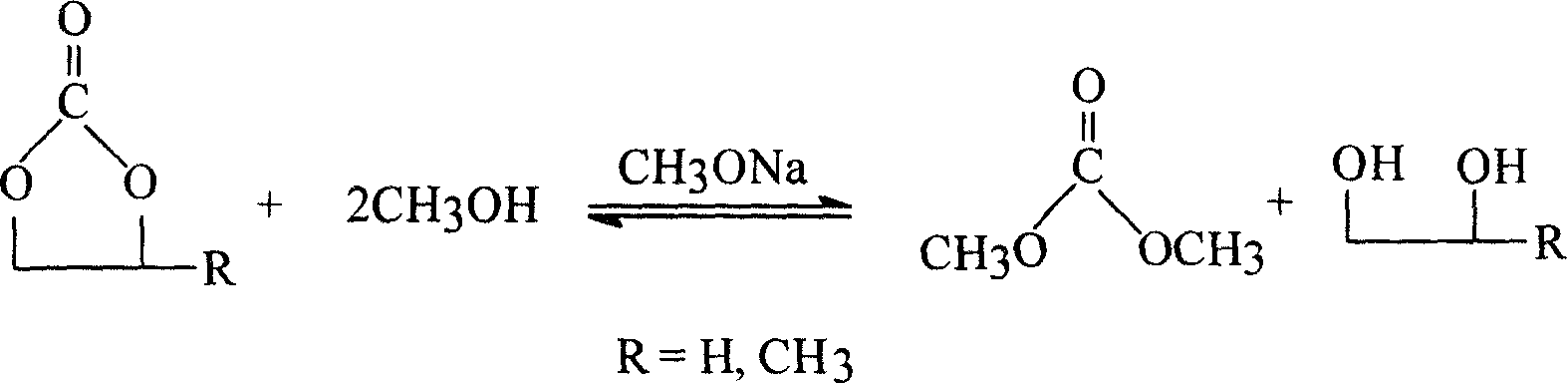

Process for improving product quality and yield of propanediol and glycol

InactiveCN101157598AHigh yieldQuality improvementHydroxy compound separation/purificationPreparation from organic carbonatesChromium trioxideSolvent

A method of preparing pyruvaldehyde by propylene glycol in low temperature liquid phase oxidation highly selectively is characterized in that below 50 to 55 DEG C and in the acidic solvent, taking chromium trioxide as the oxidant and highly selectively oxidizing 1, 2-propylene glycol to pyruvaldehyde. The conversion of the 1, 2-propylene glycol is 100 percent, and the selection of preparing pyruvaldehyde is from 95.6 percent to 99.6 percent.

Owner:北京格瑞华阳科技发展有限公司

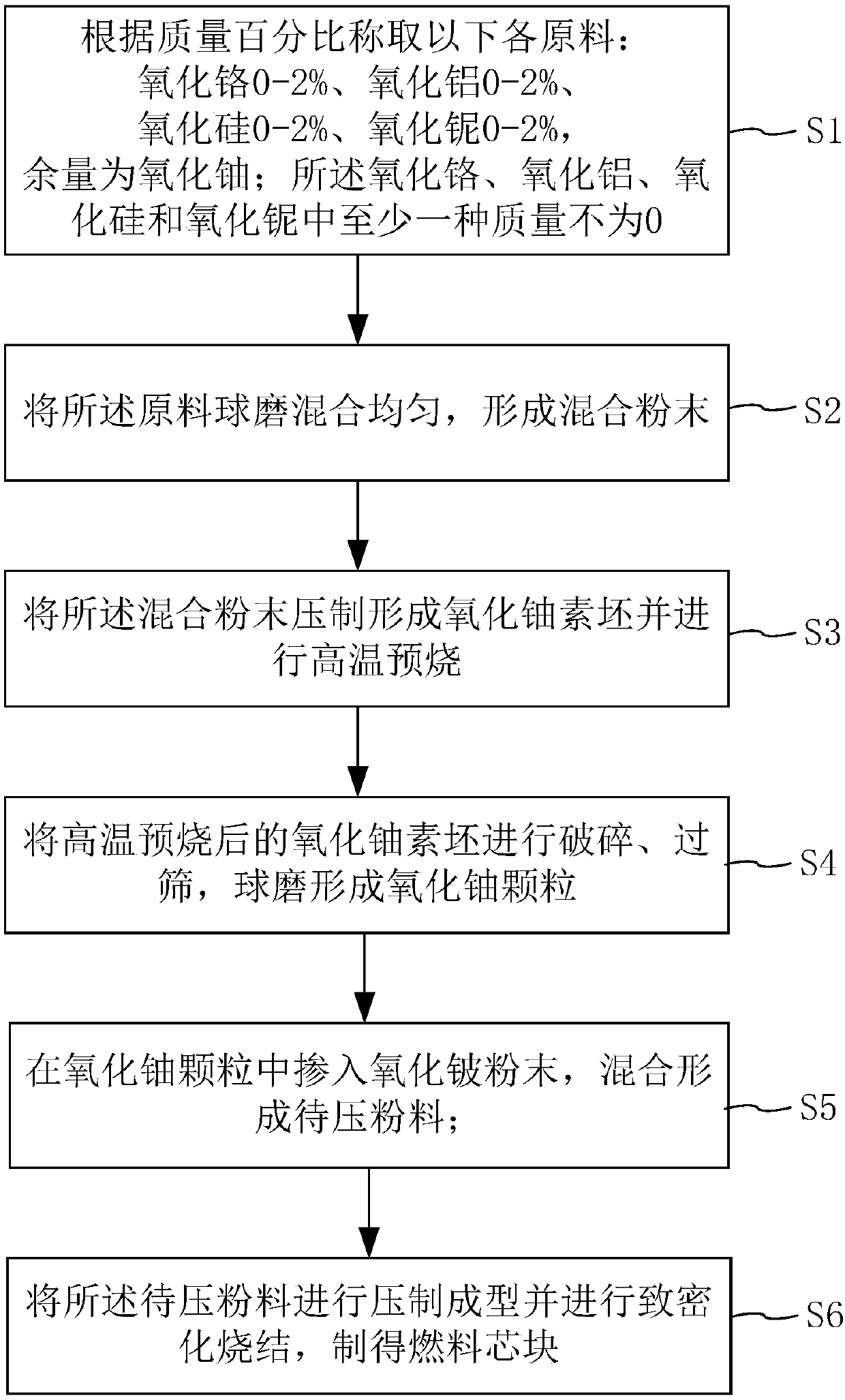

A fuel pellet and a manufacturing method thereof

InactiveCN108039210AReduce spreadDoes not affect thermal conductivityNuclear energy generationReactors manufactureChromium trioxideCompression molding

A fuel pellet and a manufacturing method thereof are disclosed. The method includes S1) weighing raw materials including 0-2% of chromium trioxide, 0-2% of alumina, 0-2% of silicon oxide and 0-2% of niobium pentoxide, with the balance being uranium dioxide; S2) ball milling and fully mixing the raw materials to form a powder mixture; S3) compressing the powder mixture to form a uranium dioxide blank, and subjecting the blank to high-temperature pre-sintering; S4) crushing the blank, sieving the crushed blank, and grinding the crushed blank into uranium dioxide particles; S5) adding beryllium oxide powder into the uranium dioxide particles, mixing the mixture to form powder to be compressed, with each uranium dioxide particle being covered with a cover layer formed from the beryllium oxidepowder; and S6) subjecting the powder to be compressed to compression molding and densification sintering to obtain the fuel pellet. A manner of two times of compound addition and two times of sintering is adopted, and therefore sintering aids form solid solution or are distributed in the uranium dioxide matrix, diffusion or solid solution formation of the sintering aids into the beryllium oxide is reduced, and on the premise that the sintering aids do not influence heat conductivity of the BeO phase, the pellet crystal grain size is effectively increased, and sintering activity is improved.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com