Method for producing micro-surface three-dimensional interconnected-nanopore anodic aluminum oxide template

An anodized aluminum, three-dimensional interconnection technology, applied in nanotechnology, surface reaction electrolytic coating, electrolytic coating, etc., can solve the problems that the anodized aluminum template cannot be used as a template, the mechanical strength is difficult to guarantee, and the raw materials are difficult to obtain. Suitable for large-scale production, easy access to raw materials, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing a three-dimensional interconnected nanoporous anodized aluminum template with a micro-curved surface, comprising the following steps:

[0033] (1) Cleaning high-purity aluminum flakes with a mass fraction ≥ 99.99% in absolute ethanol and deionized water to obtain clean aluminum flakes;

[0034] (2) With the clean aluminum flake that step (1) obtains as anode, graphite is cathode, carry out constant voltage electrochemical polishing in the mixed solution that the volume ratio of perchloric acid and dehydrated alcohol is 0.2 under-5 ℃, voltage is 23V, the polishing time is 5min, and the polished aluminum sheet is obtained;

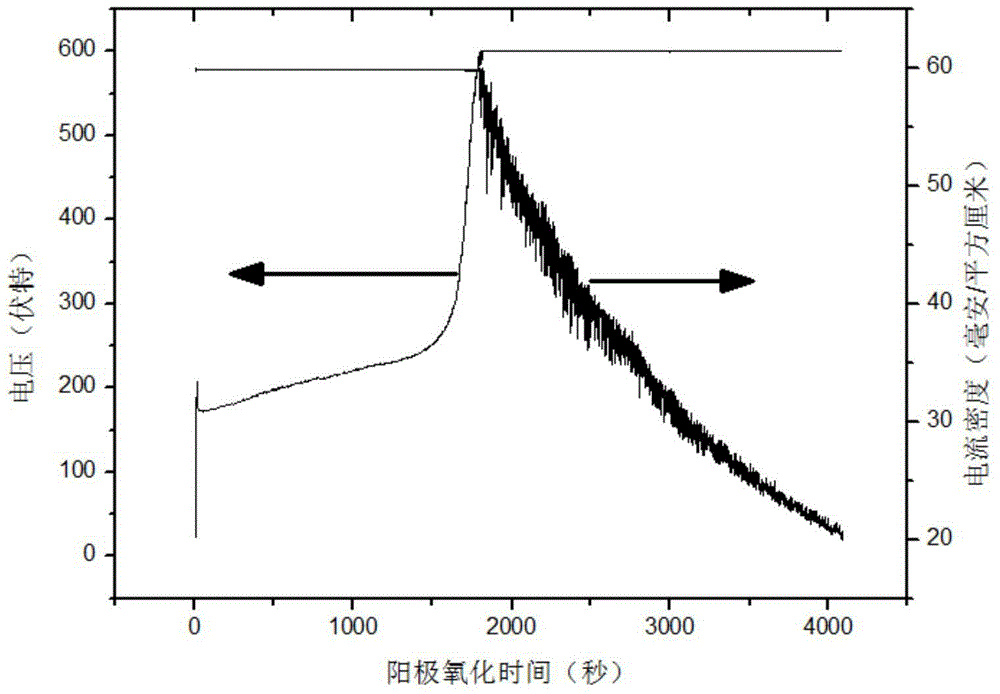

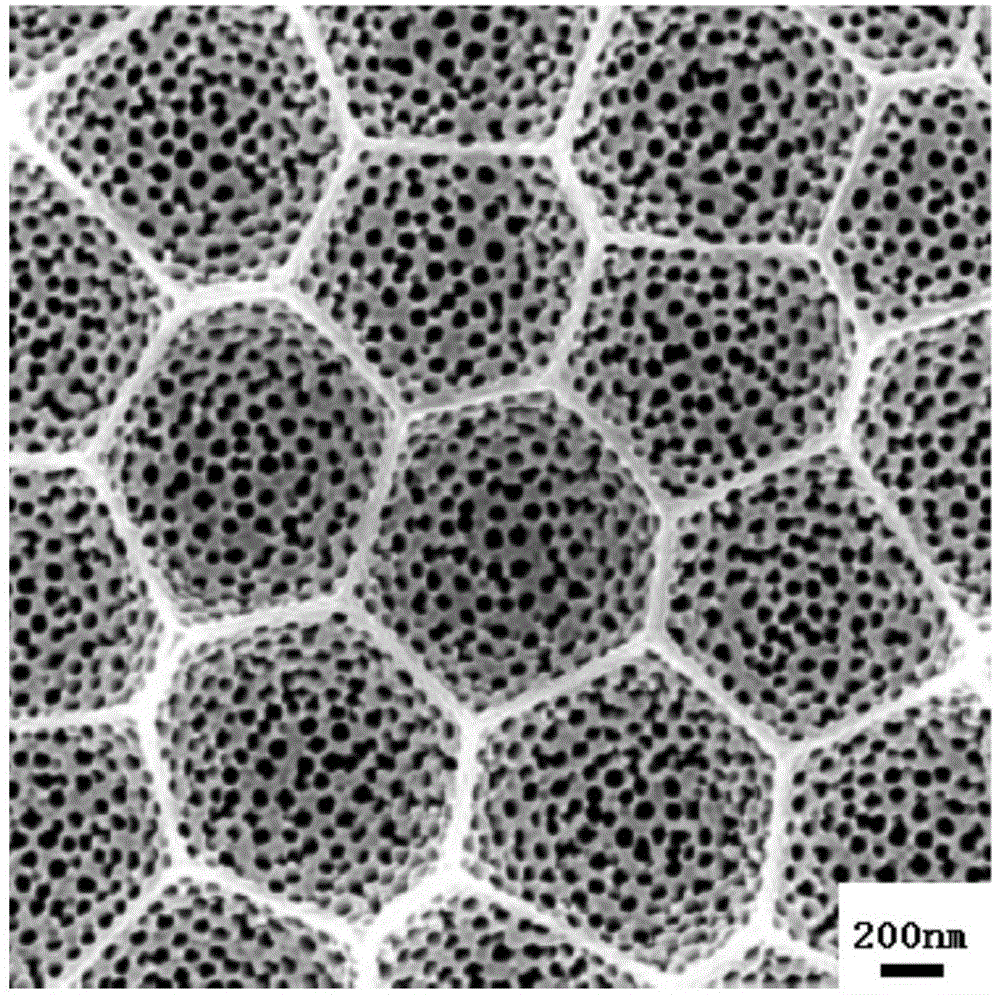

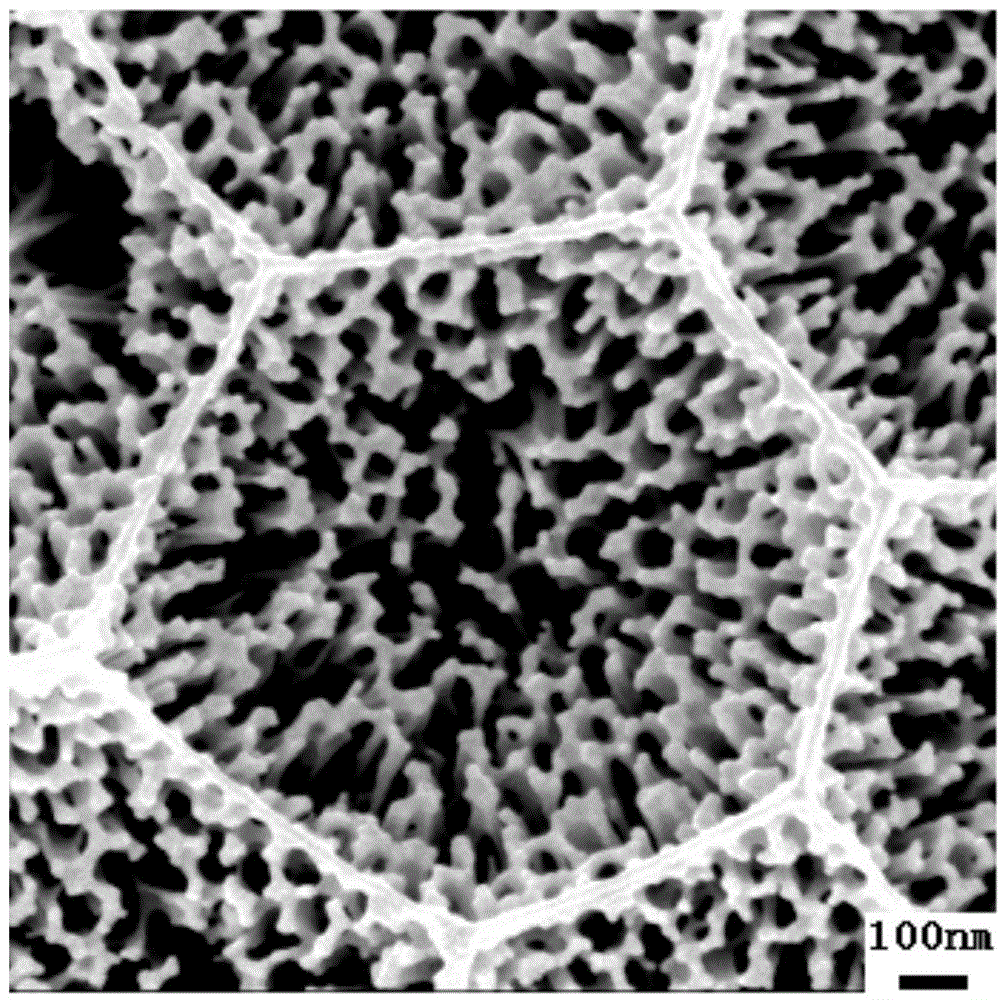

[0035] (3) the aluminum flake of polishing that obtains with step (2) is anode, and graphite is cathode, and the volume ratio of solution A (0.4mol / L oxalic acid aqueous solution) and solution B (dehydrated alcohol) is the mixing of A:B=2.1 solution to carry out the first anodic oxidation process, the temperature is -5 ℃, becau...

Embodiment 2

[0040] A method for preparing a three-dimensional interconnected nanoporous anodized aluminum template with a micro-curved surface, comprising the following steps:

[0041] (1) Cleaning high-purity aluminum flakes with a mass fraction ≥ 99.99% in absolute ethanol and deionized water to obtain clean aluminum flakes;

[0042] (2) With the clean aluminum sheet that step (1) obtains as anode, graphite is cathode, carry out constant voltage electrochemical polishing in the mixed solution that the volume ratio of perchloric acid and dehydrated alcohol is 0.3 under 0 ℃, voltage is 15V , the polishing time is 7min, and a polished aluminum sheet is obtained;

[0043] (3) the polished aluminum sheet that obtains with step (2) is anode, and graphite is cathode, and the volume ratio of solution C (0.3mol / L oxalic acid aqueous solution) and solution B (dehydrated alcohol) is the mixing of C:B=0.5 solution to carry out the first step of anodic oxidation process, the temperature is 5 ℃: fir...

Embodiment 3

[0048] A method for preparing a three-dimensional interconnected nanoporous anodized aluminum template with a micro-curved surface, comprising the following steps:

[0049] (1) Cleaning high-purity aluminum flakes with a mass fraction ≥ 99.99% in absolute ethanol and deionized water to obtain clean aluminum flakes;

[0050] (2) With the clean aluminum sheet that step (1) obtains as anode, graphite is cathode, carry out constant voltage electrochemical polishing in the mixed solution that the volume ratio of perchloric acid and dehydrated alcohol is 0.4 at 5 ℃, voltage is 20V , the polishing time is 8min, and a polished aluminum sheet is obtained;

[0051] (3) the aluminum flake of polishing that obtains with step (2) is anode, and graphite is cathode, and the volume ratio of solution D (0.4mol / L oxalic acid aqueous solution) and solution B (dehydrated alcohol) is the mixing of D:B=3 solution to carry out the first step of anodizing process, the temperature is 0°C: first use c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com