High-temperature preventive coating process

A technology of protective coating and process method, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of insufficient ability of the coating to resist gas corrosion, achieve the improvement of process and labor conditions, and extend the overhaul cycle, high temperature oxidation and corrosion resistance superior effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

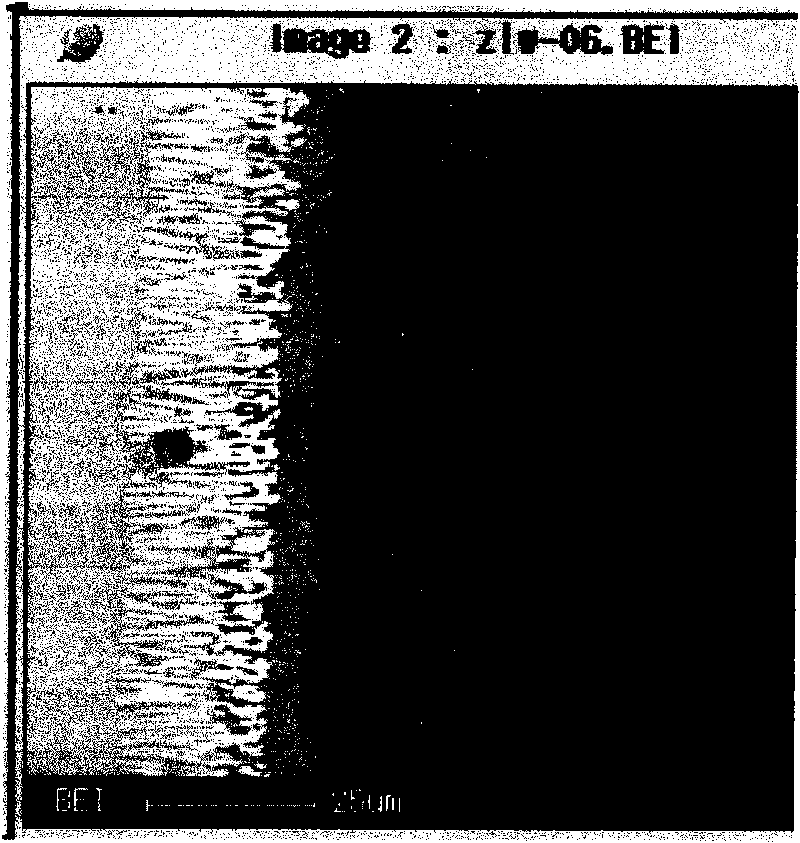

Image

Examples

Embodiment 1

[0016] This embodiment provides a high-temperature protective coating process. The process flow is: preparation of adhesive → batching slurry → spraying → curing → heating in a vacuum furnace; the composition and mass ratio of the adhesive are: water: 800g, three Chromium oxide: 70g, magnesium oxide: 80g, phosphoric acid: 350g; the binder preparation process is: add phosphoric acid in water → add magnesium oxide and fully dissolve → add chromium trioxide; the step of adding magnesium oxide and fully dissolving is to use a small amount of The principle of adding multiple times is to add a small amount first, and then add again after it becomes clear easily.

[0017] The high-temperature protective coating process described in this embodiment, the batching slurry is according to the following ratio and process: take binder: 800g → add aluminum powder: 500g → add zinc powder: 100g → fully stir and mix.

[0018] The high-temperature protective coating process described in this emb...

Embodiment 2

[0021] This embodiment provides a high-temperature protective coating process. The process flow is: preparation of binder → batching slurry → spraying → heating in a vacuum furnace; wherein the binder composition and mass ratio are: water: 700g, chromium trioxide : 60g, magnesia: 70g, phosphoric acid: 270g; the binder preparation process is: add phosphoric acid in water → add magnesia and fully dissolve → add chromium trioxide; the step of adding magnesia and fully dissolving is to use a small amount of multiple times The principle of adding is to add a small amount first, and then add again after the solution becomes clear.

[0022] The high-temperature protective coating process described in this embodiment, the batching slurry is according to the following ratio and process: take binder: 700g → add aluminum powder: 450g → add zinc powder: 110g → fully stir and mix.

[0023] The high-temperature protective coating process described in this embodiment uses 0.2-0.3MP air press...

Embodiment 3

[0026] This embodiment provides a high-temperature protective coating process. The process flow is: preparation of binder → batching slurry → spraying → curing → heating in a vacuum furnace; wherein the binder composition and mass ratio are: water: 900g, three Chromium oxide: 90g, magnesium oxide: 90g, phosphoric acid: 400g; the binder preparation process is: add phosphoric acid in water → add magnesium oxide and fully dissolve → add chromium trioxide; the step of adding magnesium oxide and fully dissolving is to use a small amount of The principle of adding multiple times is to add a small amount first, and then add again after the solution becomes clear.

[0027] The high-temperature protective coating process method described in this embodiment, the proportion and process of the batching slurry are as follows: take binder: 900g → add aluminum powder: 600g → add zinc powder: 120g → fully stir and mix.

[0028] The high-temperature protective coating process described in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com